Preparation method of ester early-strength polycarboxylic acid water reducing agent

An early-strength, polycarboxylic acid technology, applied in the field of building materials, can solve problems such as reducing 28d strength, achieve superior early-strength performance, promote hydration, and accelerate the formation of results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

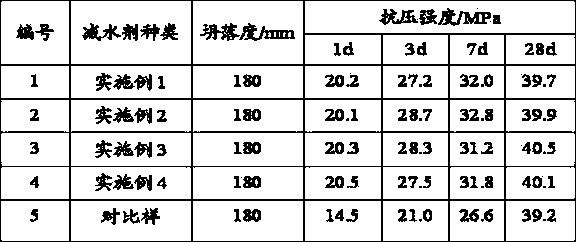

Examples

Embodiment 1

[0021] (1) Amidation reaction: In parts by mass, 86.09 parts of methyl acrylate, 105.14 parts of diglycolamine and 0.96 parts of sodium hydroxide were placed in reactor A, and kept at 70°C for 3 hours to obtain amide small Alcoholamine monomer NP. The molar ratio of methyl acrylate and diglycolamine is 1:1, and the amount of sodium hydroxide is 0.5% of the total mass of methyl acrylate and diglycolamine.

[0022] (2) Esterification reaction: in parts by mass, 100.00 parts of polyethylene glycol monomethyl ether with a molecular weight of 1000, 51.65 parts of methacrylic acid, 2.27 parts of concentrated sulfuric acid and 0.76 parts of hydroquinone were placed in reaction kettle B , at 130° C. for 3 hours to obtain the esterified macromonomer MP. The molar ratio of polyethylene glycol monomethyl ether and methacrylic acid is 1:6, and the consumption of concentrated sulfuric acid and hydroquinone are 1.5% and 0.5% of the total mass of polyethylene glycol monomethyl ether and met...

Embodiment 2

[0025] (1) Amidation reaction: In parts by mass, 128.17 parts of butyl acrylate, 49.67 parts of triethanolamine and 1.78 parts of sodium hydroxide were placed in reaction kettle A, and kept at 80°C for 4 hours to obtain amide small alcohol amine mono Body NP. The molar ratio of butyl acrylate and triethanolamine is 3:1, and the amount of sodium hydroxide is 1% of the total mass of butyl acrylate and triethanolamine.

[0026] (2) Esterification reaction: in parts by mass, 120.00 parts of polyethylene glycol monomethyl ether with a molecular weight of 1200, 43.05 parts of methacrylic acid, 4.08 parts of concentrated sulfuric acid and 1.63 parts of diphenylamine were placed in reaction kettle B, and The temperature was kept at 120° C. for 5 hours to obtain the esterified macromonomer MP. The molar ratio of polyethylene glycol monomethyl ether and methacrylic acid is 1:5, and the dosages of concentrated sulfuric acid and diphenylamine are 2.5% and 1% of the total mass of polyethy...

Embodiment 3

[0029] (1) Amidation reaction: In parts by mass, 116.12 parts of hydroxyethyl acrylate, 40.80 parts of diethanol monoisopropanolamine and 3.14 parts of sodium hydroxide were placed in reactor A, and kept at 90°C for 2 hours, The amide small alcohol amine monomer NP is obtained. The molar ratio of hydroxyethyl acrylate and diethanol monoisopropanolamine is 4:1, and the amount of sodium hydroxide is 2% of the total mass of hydroxyethyl acrylate and diethanol monoisopropanolamine.

[0030] (2) Esterification reaction: in parts by mass, 200.00 parts of polyethylene glycol monomethyl ether with a molecular weight of 2000, 34.44 parts of methacrylic acid, 8.21 parts of concentrated sulfuric acid and 3.52 parts of phenothiazine were placed in reactor B, Keep the temperature at 110° C. for 4 hours to obtain the esterified macromonomer MP. The molar ratio of polyethylene glycol monomethyl ether and methacrylic acid is 1:4, and the consumption of concentrated sulfuric acid and phenothi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com