Plastering gypsum and preparation method thereof

A technology of plastering gypsum and anti-cracking agent, which is applied in the field of building materials and can solve problems such as hollowing, cracking and cracking of gypsum-based plastering screeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The application also provides a preparation method for plastering gypsum, comprising the following steps:

[0051] Mix 80wt%-95wt% of heavy calcium powder with the rest of aramid fibers to obtain an anti-cracking agent;

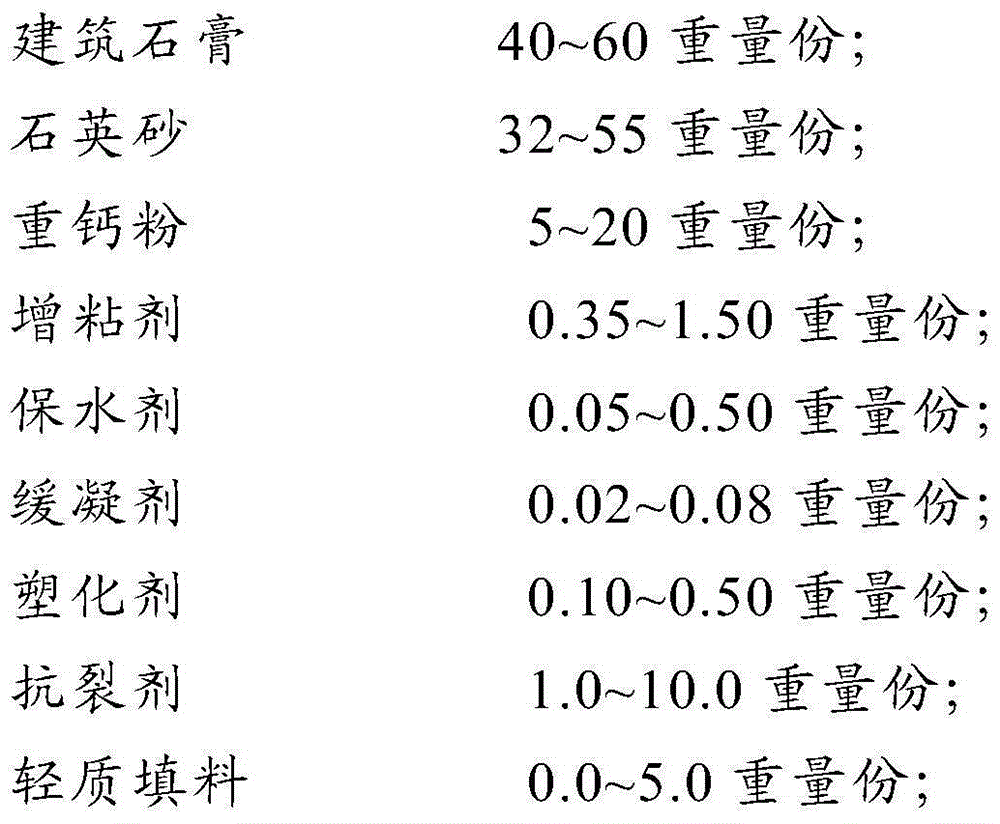

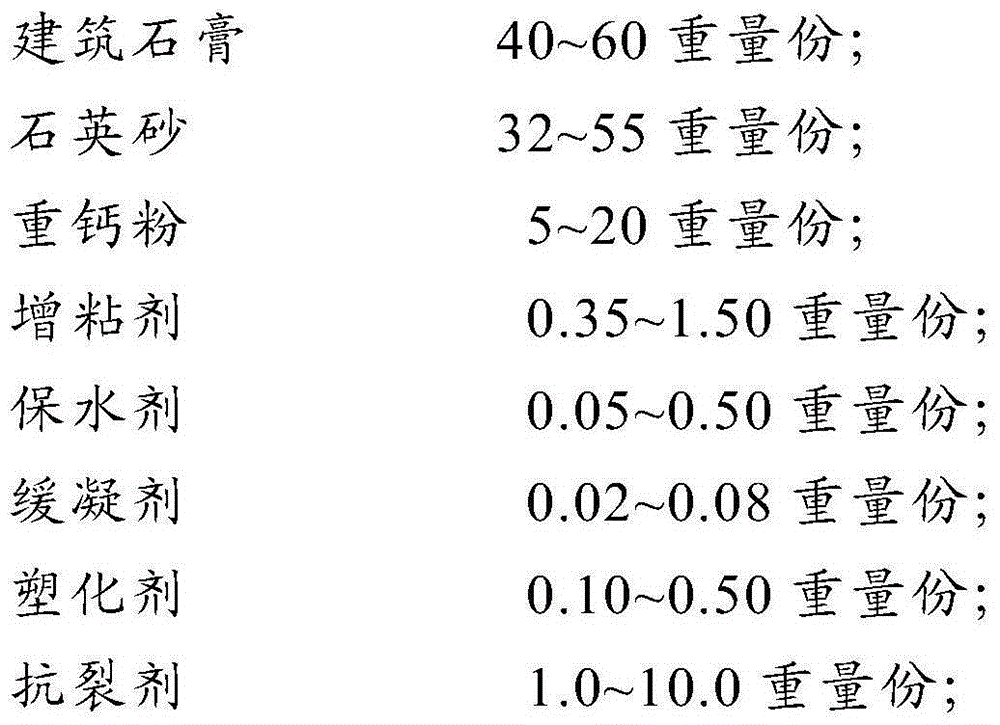

[0052] 40-60 parts by weight of construction gypsum, 32-55 parts by weight of quartz sand, 5-20 parts by weight of heavy calcium powder, 0.35-1.50 parts by weight of tackifier, 0.05-0.50 parts by weight of water-retaining agent, 0.02- 0.08 parts by weight of retarder, 0.10-0.50 parts by weight of plasticizer, 1.0-10.0 parts by weight of anti-cracking agent and 0.0-5.0 parts by weight of light filler are mixed to obtain plastering gypsum.

[0053] The applicant first prepared the anti-cracking agent. In order to obtain a uniform mixture, the applicant preferably puts the heavy calcium powder, wood fiber and aramid fiber into a high-speed high-efficiency mixer, and the high-speed stirring speed is 2000rpm. This application firstly prepares an anti-crack...

Embodiment 1

[0058] In the following examples, the water consumption, setting time, compressive strength, flexural strength, bond strength and water retention rate of the standard diffusion degree of plastering gypsum are tested according to the provisions of the national standard GB / T28627-2012 "Plastering Gypsum" .

[0059] The test method of the anti-crack performance of anti-crack plaster plaster of the present invention is:

[0060] Prepare the slurry of plastering gypsum according to the standard diffusion degree of water. Scrape and scrape a slope with a length of 300mm, a width of 50mm, and a slope of 1 / 15 on the cotton-free fiber cement board, and place it in the test environment with wind speeds of 0m / s, 0.5m / s, and 2.5m / s respectively, and last for 6 hours , Observe the cracks on the surface of the plastering plaster: the thickness and range of the cracks, and the shape of the cracks.

[0061] Add 90.0Kg of heavy calcium powder, 5.0kg of wood fiber, and 5.0kg of 0.8mm aramid f...

Embodiment 2

[0073] Add 90.0Kg of heavy calcium powder, 5.0kg of wood fiber, and 5.0kg of 0.8mm aramid fiber into the high-speed mixer, and stir at a high speed (2000rpm) until a uniform mixture is obtained, which is the anti-cracking agent. Put it in a plastic bag and seal it for later use.

[0074] 470.0Kg of building gypsum, 429.6Kg of quartz sand, 50kg of heavy calcium powder, 2.0kg of plasticizer SD601P, 2.0kg of water retaining agent CCA3282.0kg, 0.4kg of retarder P powder, 6.0kg of tackifier 60W, 20.0kg of anti-cracking agent, Add 20kg of light filler into the powder mixer one by one, stir for 15 minutes, mix evenly, and it becomes powder. Pack airtightly in a plastic bag. The standard expansion degree water consumption of the crack-resistant plastering gypsum in this embodiment is 32%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com