Method for testing adaptability of polycarboxylic water reducer and cement

A technology of water reducing agent and polycarboxylic acid, applied in the field of concrete, can solve the problems of unclear what the slump fluidity reflects, the direction of concrete workability is different, and it is difficult to meet the needs of practical applications, etc. Simple rheological properties, labor saving, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

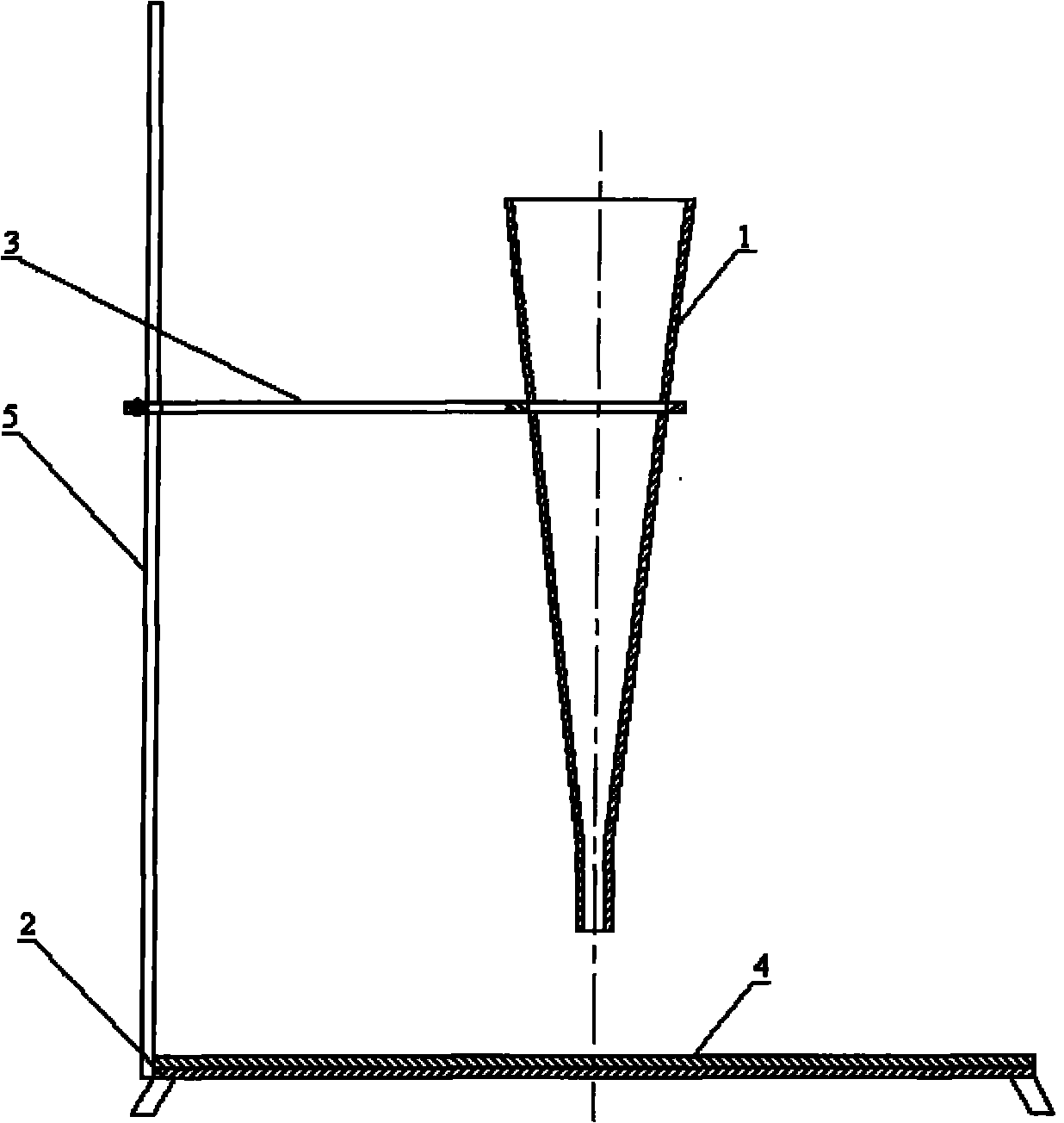

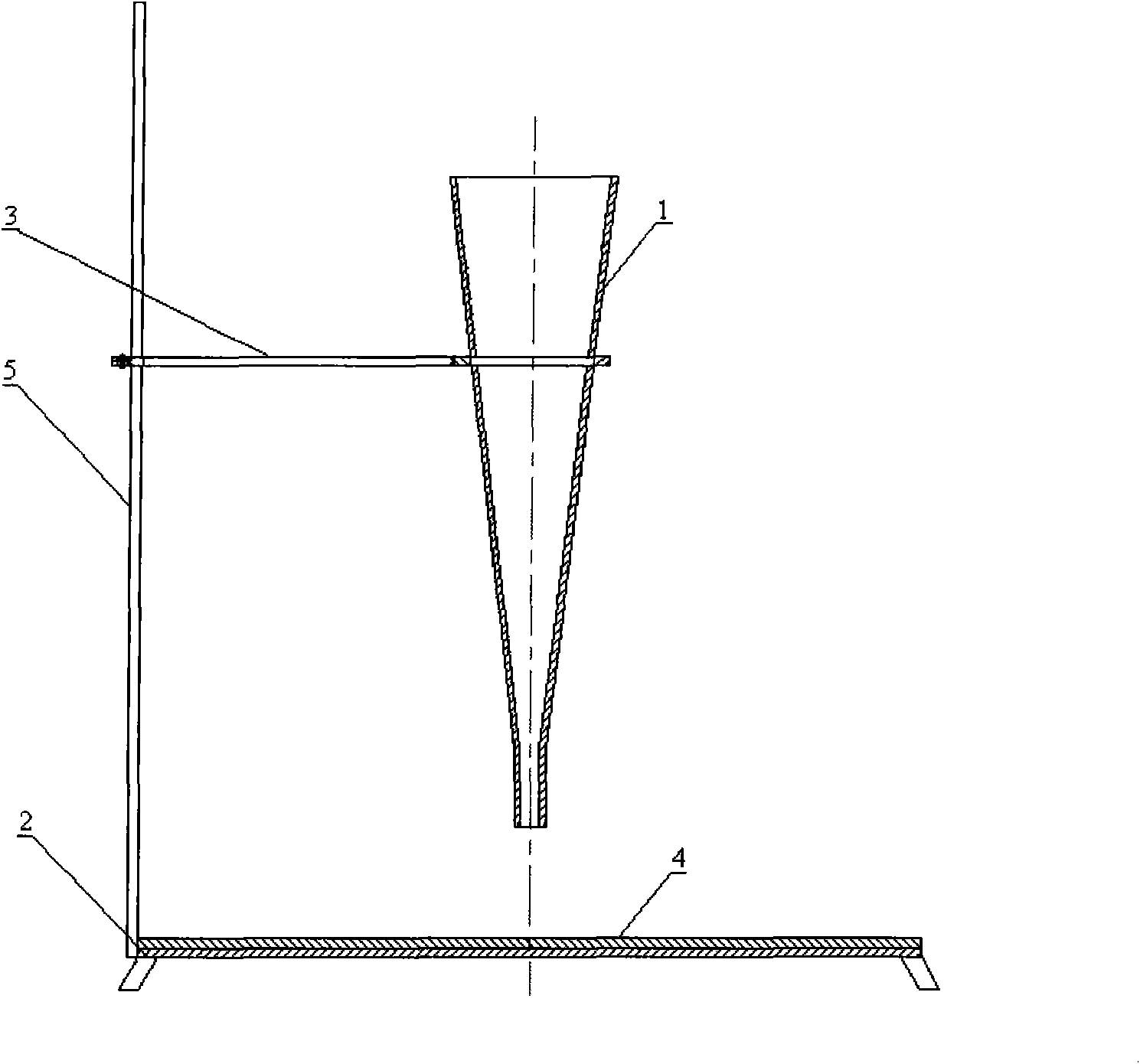

Image

Examples

Embodiment Construction

[0034] (1) Determine the mortar mix ratio according to the amount of cementitious material, sand, water and polycarboxylate superplasticizer in the concrete mix ratio in actual construction, and use the cementitious material used in actual construction and the actual construction that has been sieved through a 5mm sieve Use sand to prepare polycarboxylate water reducer; see Table 1 for specific implementation ratios

[0035] Table 1 Concrete Implementation Mortar Mixing Ratio

[0036] Material

cement

sand

water

Polycarboxylate superplasticizer

[0037] Dosage / g

461

155

1080

228

6.2

[0038](2) Use cement mortar mixer to mix mortar, mixing process: add 6.2g polycarboxylate water reducer to 228g water, then pour water into the mixing pot, then pour 616g cementitious material and 1080g sand into In the stirring pot, first stir slowly for 60s, then stir rapidly for 30s, intermittently for 90s, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com