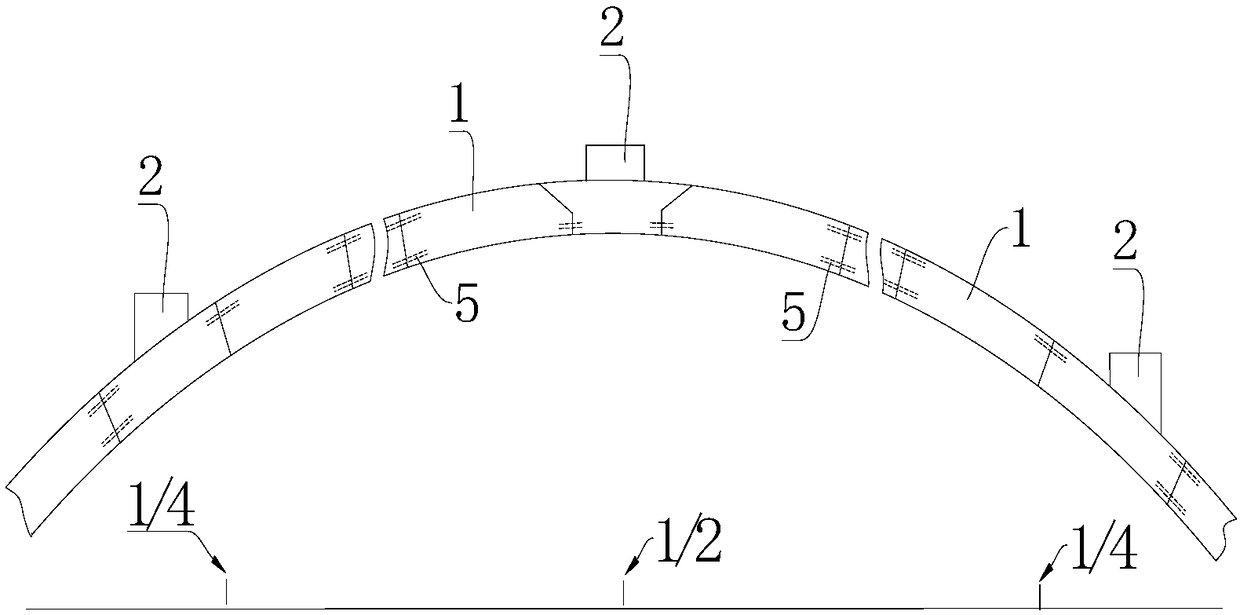

Pre-casting and mounting method for super-high performance concrete deck type slab arch bridge segments

An ultra-high-performance, prefabricated installation technology, applied in bridges, bridge materials, bridge construction, etc., to achieve convenient transportation and installation, reduce steel consumption, and improve earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

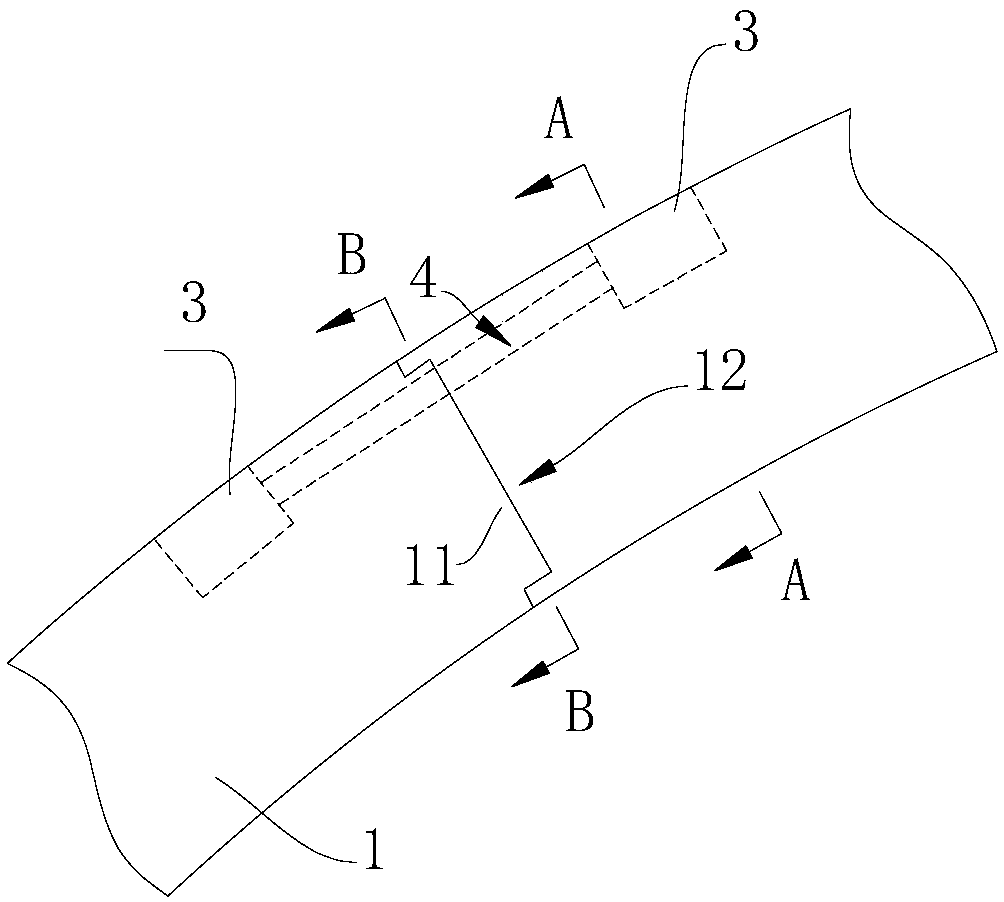

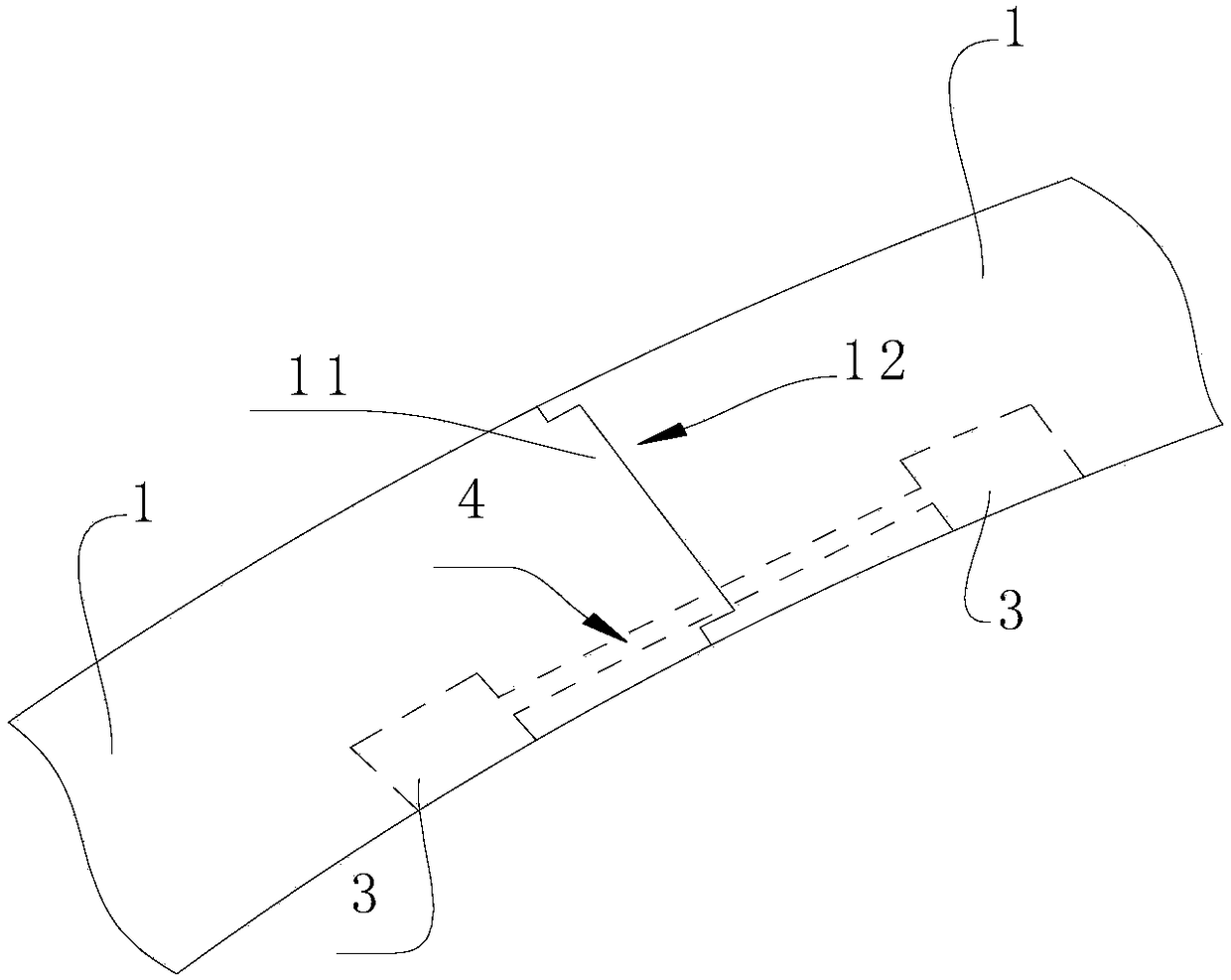

[0037] The invention discloses a method for prefabricating and installing sections of an ultra-high-performance concrete slab-arch bridge, which comprises the following steps:

[0038] (1) The sections of the top-supported slab-arch bridge are made of ultra-high-performance concrete. The ultra-high-performance concrete can be made of quartz sand, quartz powder, or natural sand as fine aggregate, and machine-made sand can also be used. If machine-made sand is used to prepare ultra-high performance concrete, special attention must be paid. The raw materials for preparation can be machine-made sand, steel fiber, cement, water, silica fume, and water reducing agent. The fresh parent rock mechanism of widely distributed limestone is selected, the mass ratio of mud block content of machine-made sand is ≤ 0.5%, the MB value of the methylene blue test of machine-made sand is <1.4 and the mass percentage of stone powder content is ≤7.0%, and the single-stage machine-made sand is the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com