Patents

Literature

760results about How to "Increase feed rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

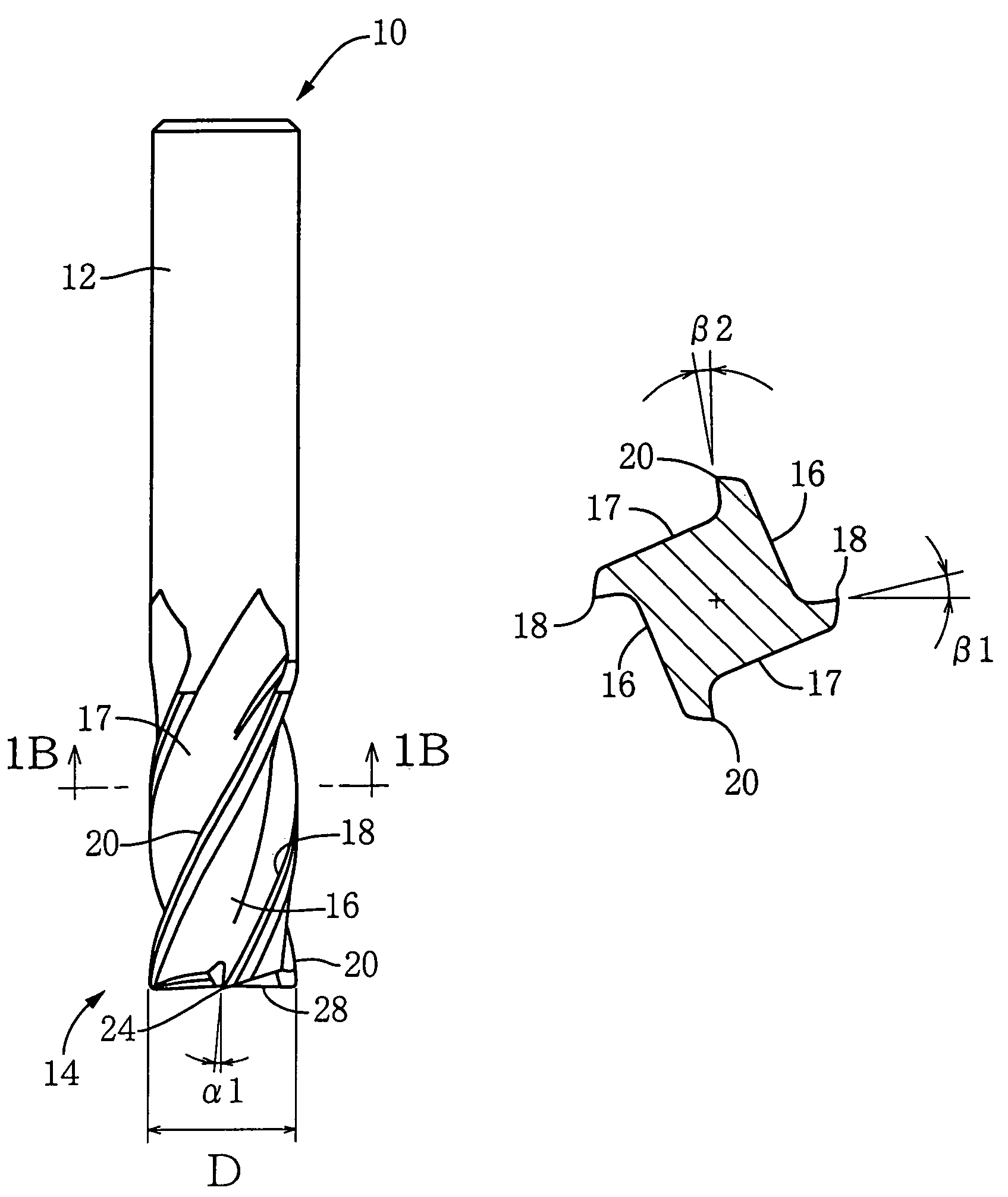

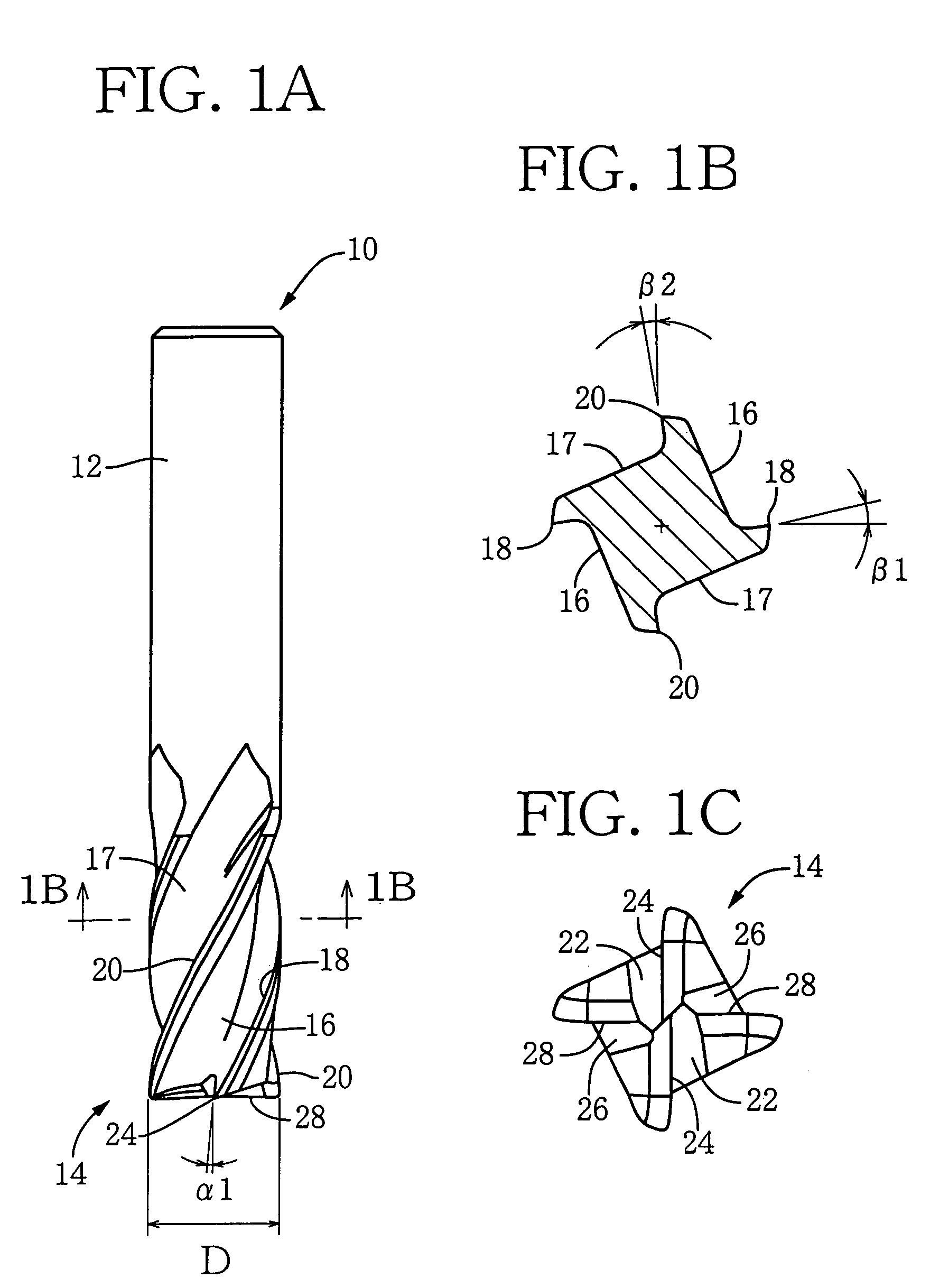

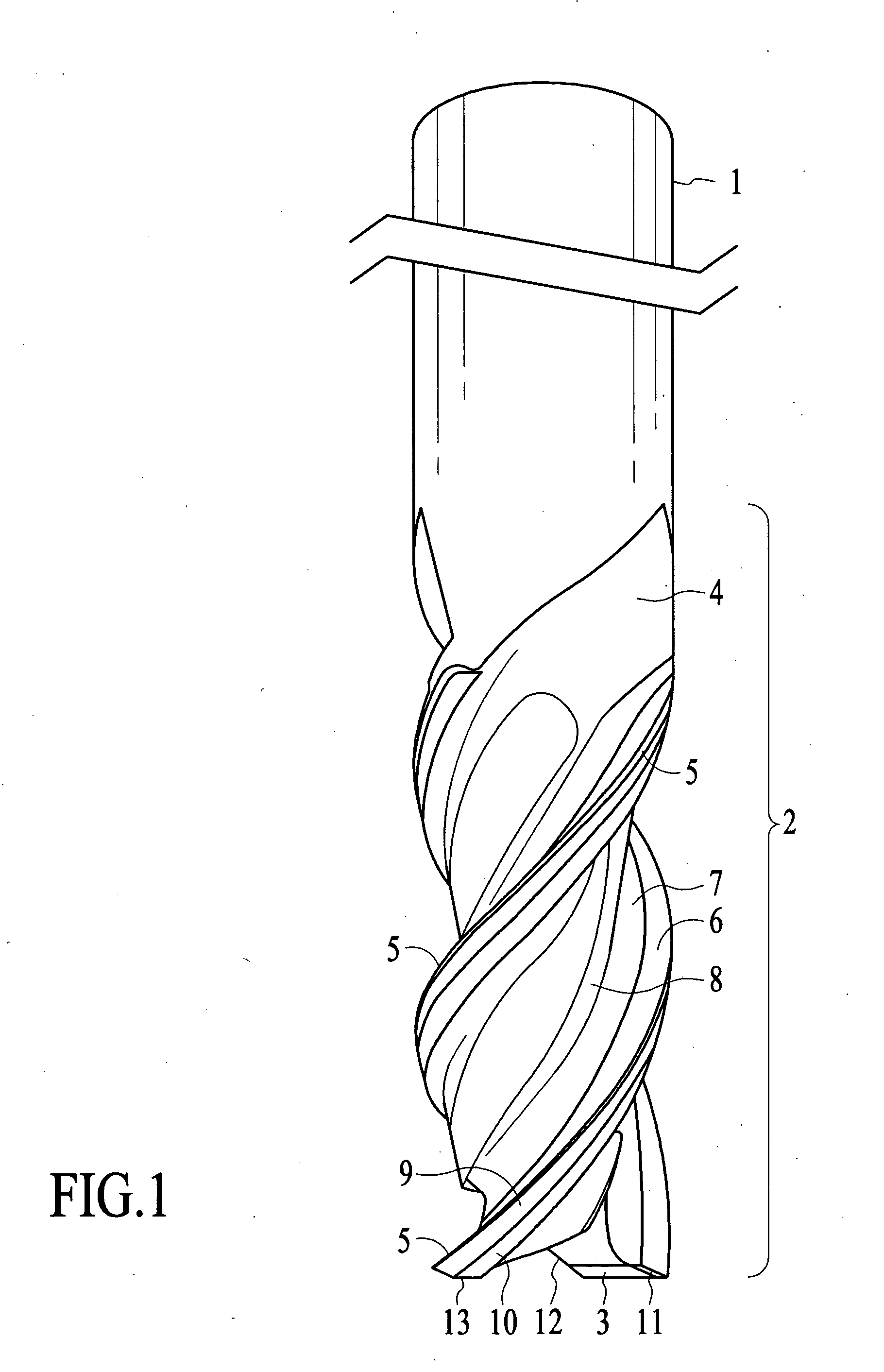

End mill having different axial rake angles and different radial rake angles

ActiveUS6997651B2High degree of durabilityPrevent chatterMilling cuttersShaping cuttersFluteEngineering

An end mill including a cylindrical body having (a) flutes each formed in the cylindrical body and each extending from an axially distal end of the cylindrical body toward an axially proximal end of the cylindrical body, (b) peripheral cutting edges each provided by one of widthwise opposite edges of a corresponding one of the flutes, and (c) end cutting edges each located at the axially distal end of the cylindrical body and contiguous to a corresponding one of the peripheral cutting edges. The end cutting edges include first and second end cutting edges, while the peripheral cutting edges include first and second peripheral cutting edges which are contiguous to the first and second end cutting edges, respectively. A first axial rake angle of the first end cutting edge is smaller than a second axial rake angle of the second end cutting edge, while a first radial rake angle of the first peripheral cutting edge is larger than a second radial rake angle of the second peripheral cutting edge.

Owner:OSG

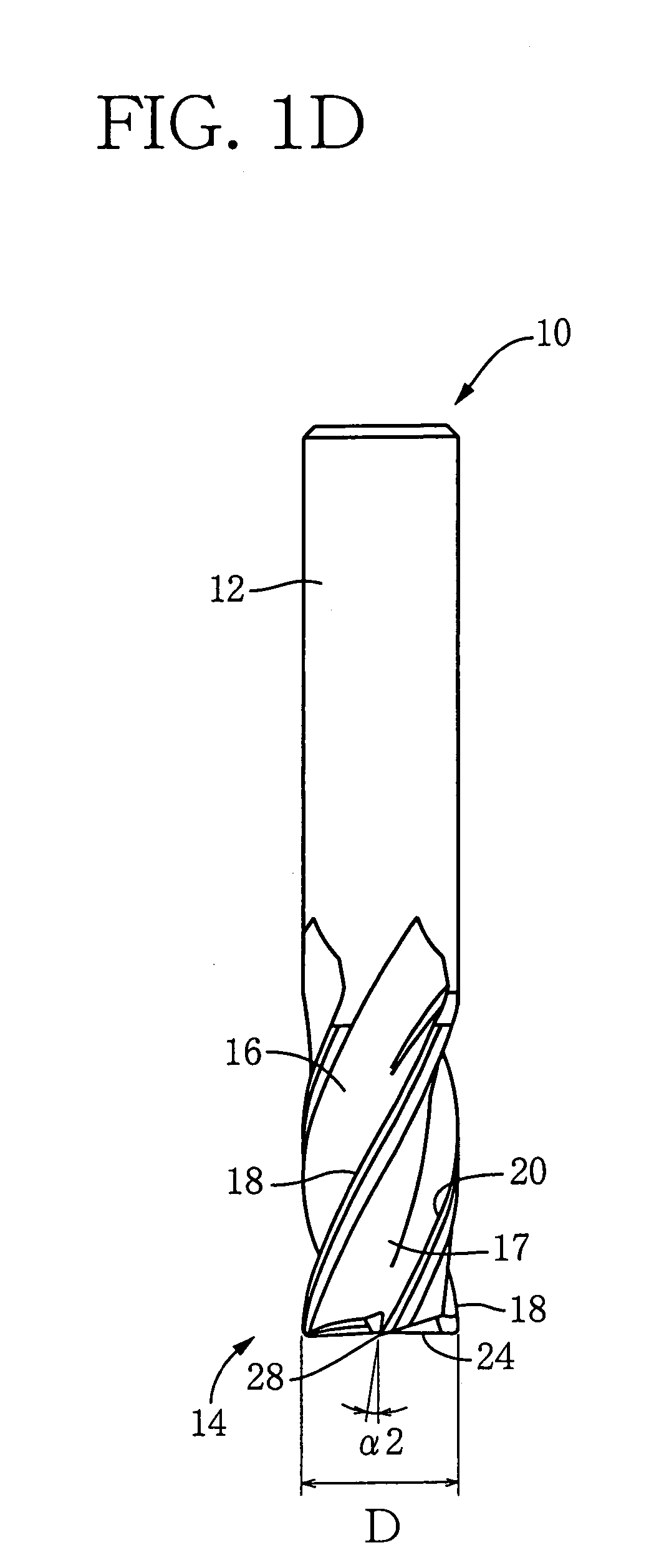

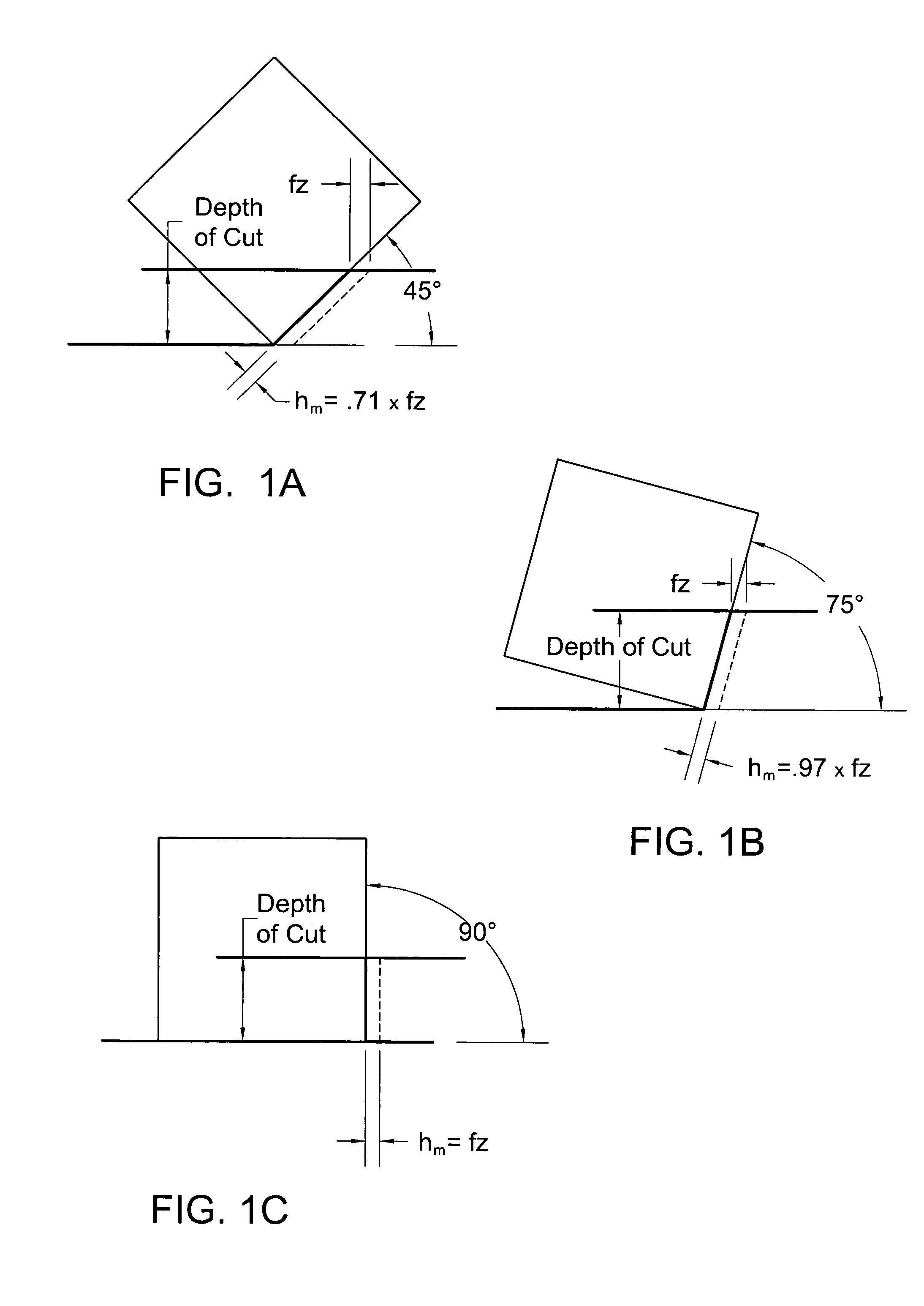

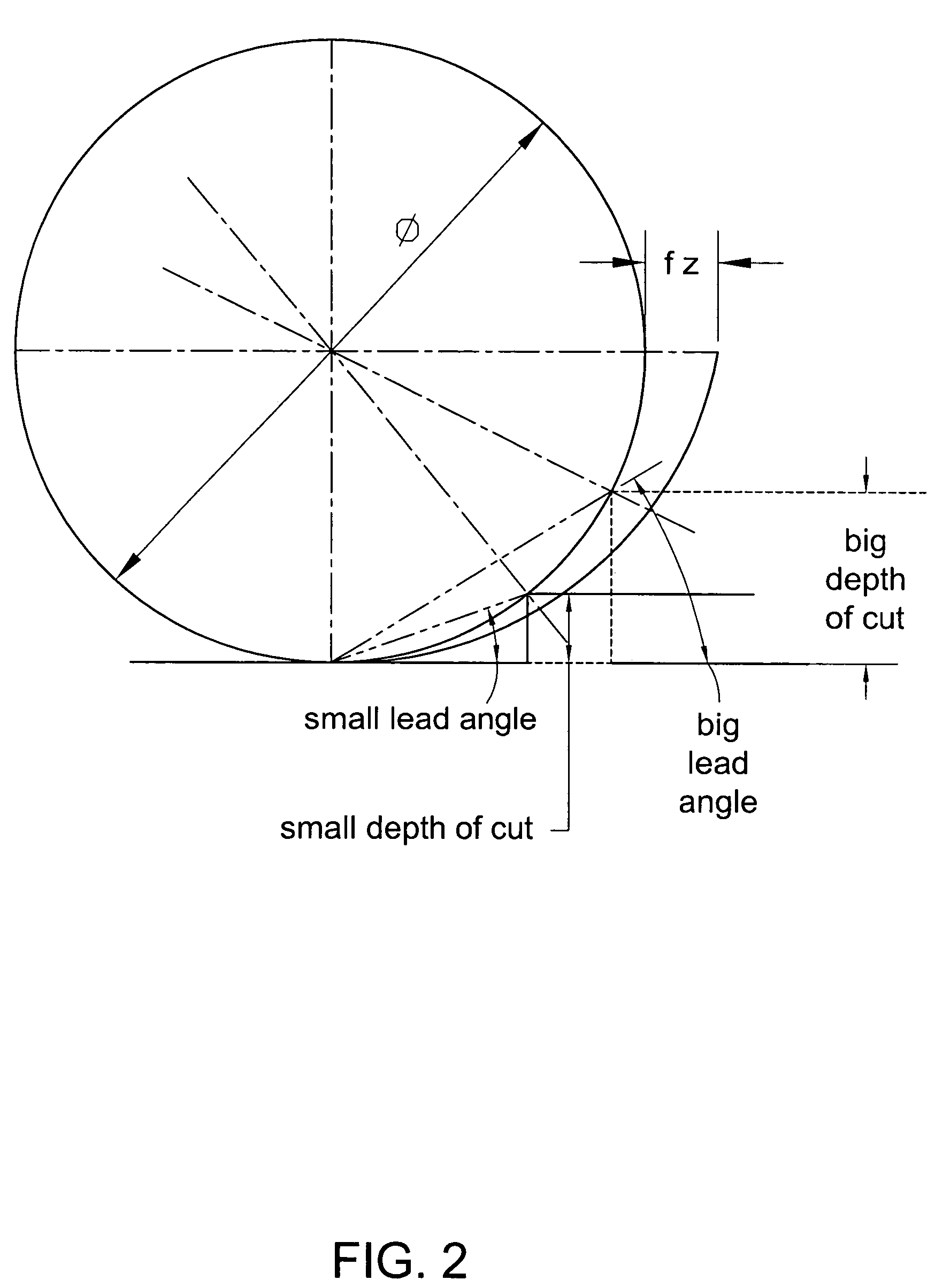

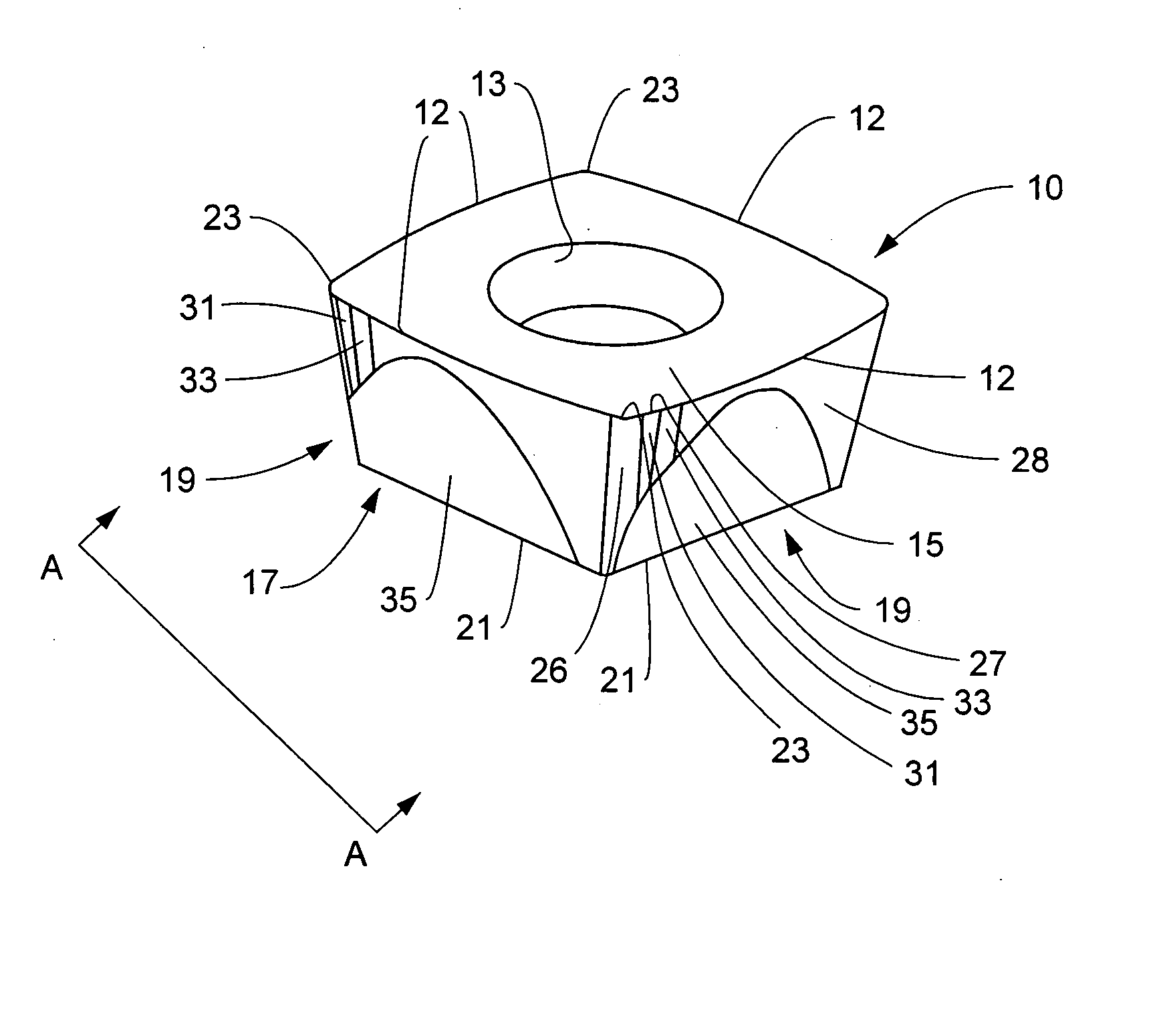

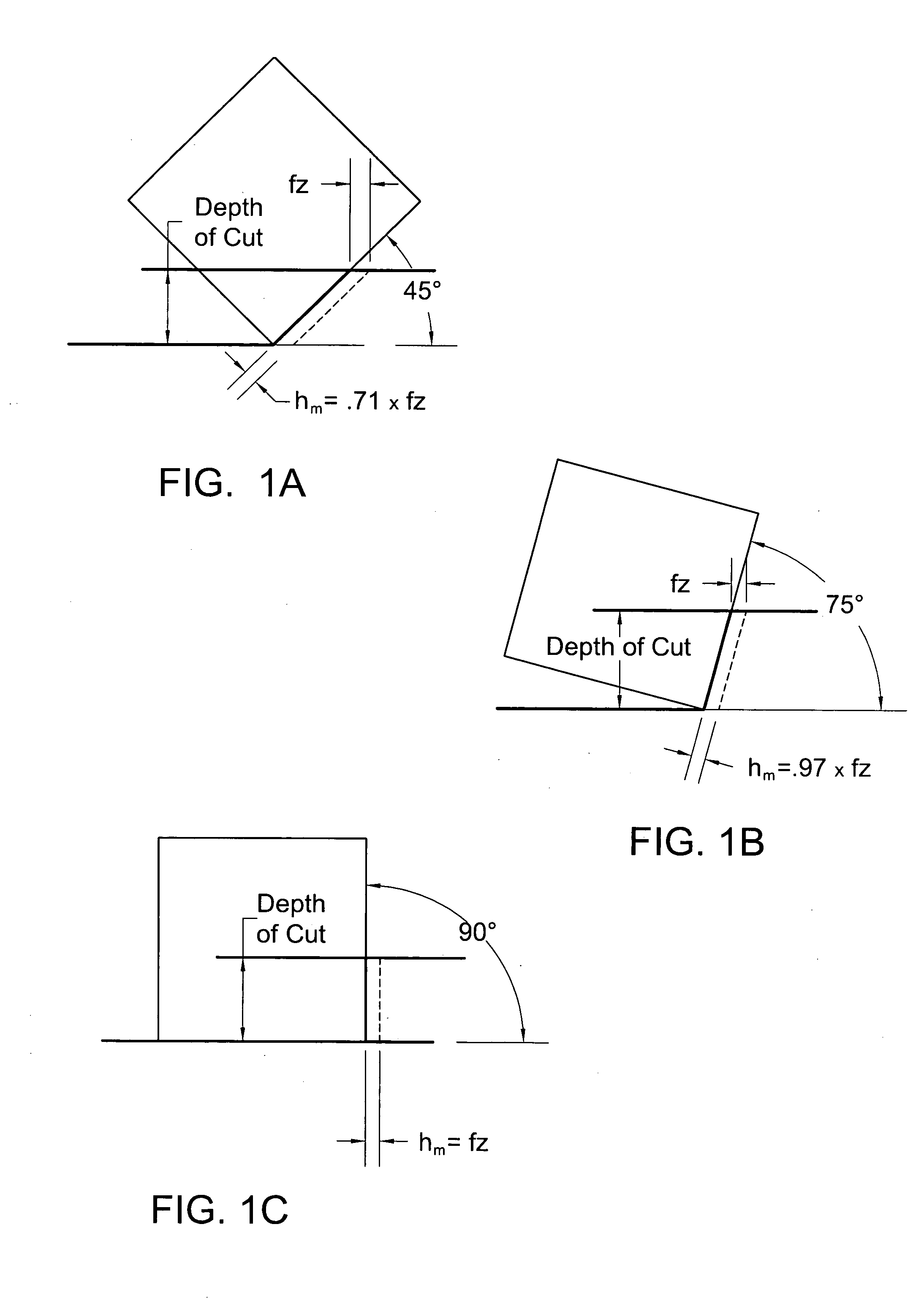

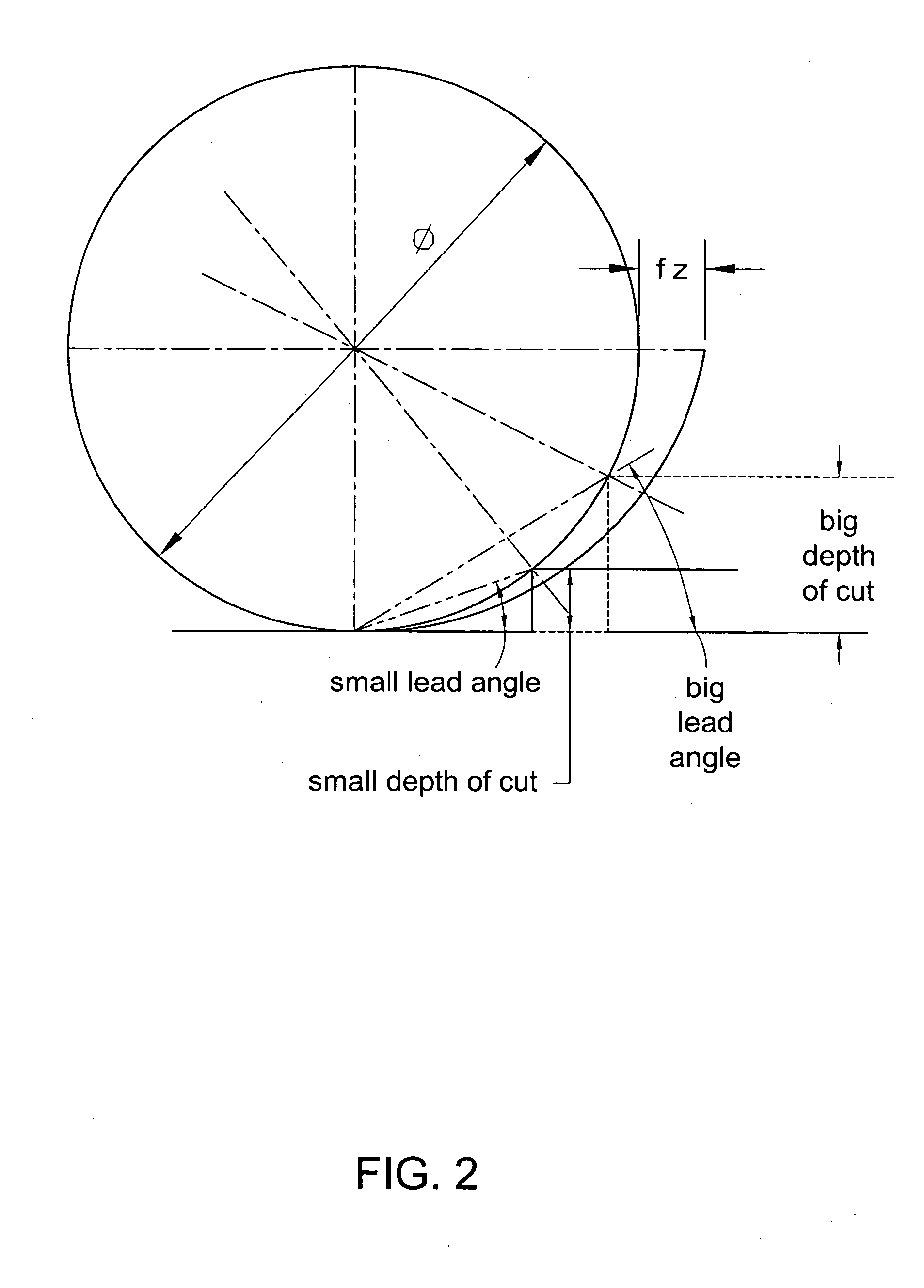

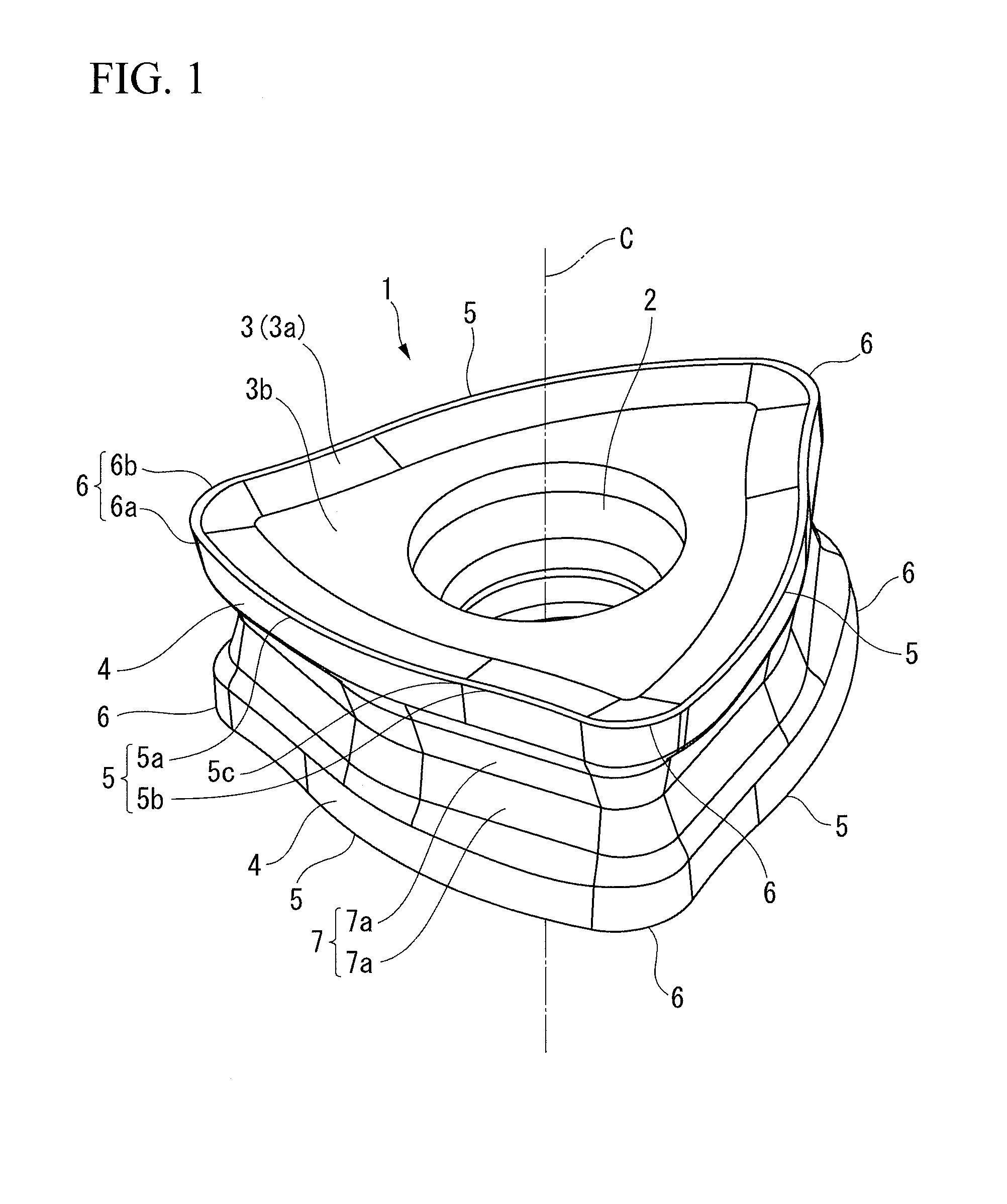

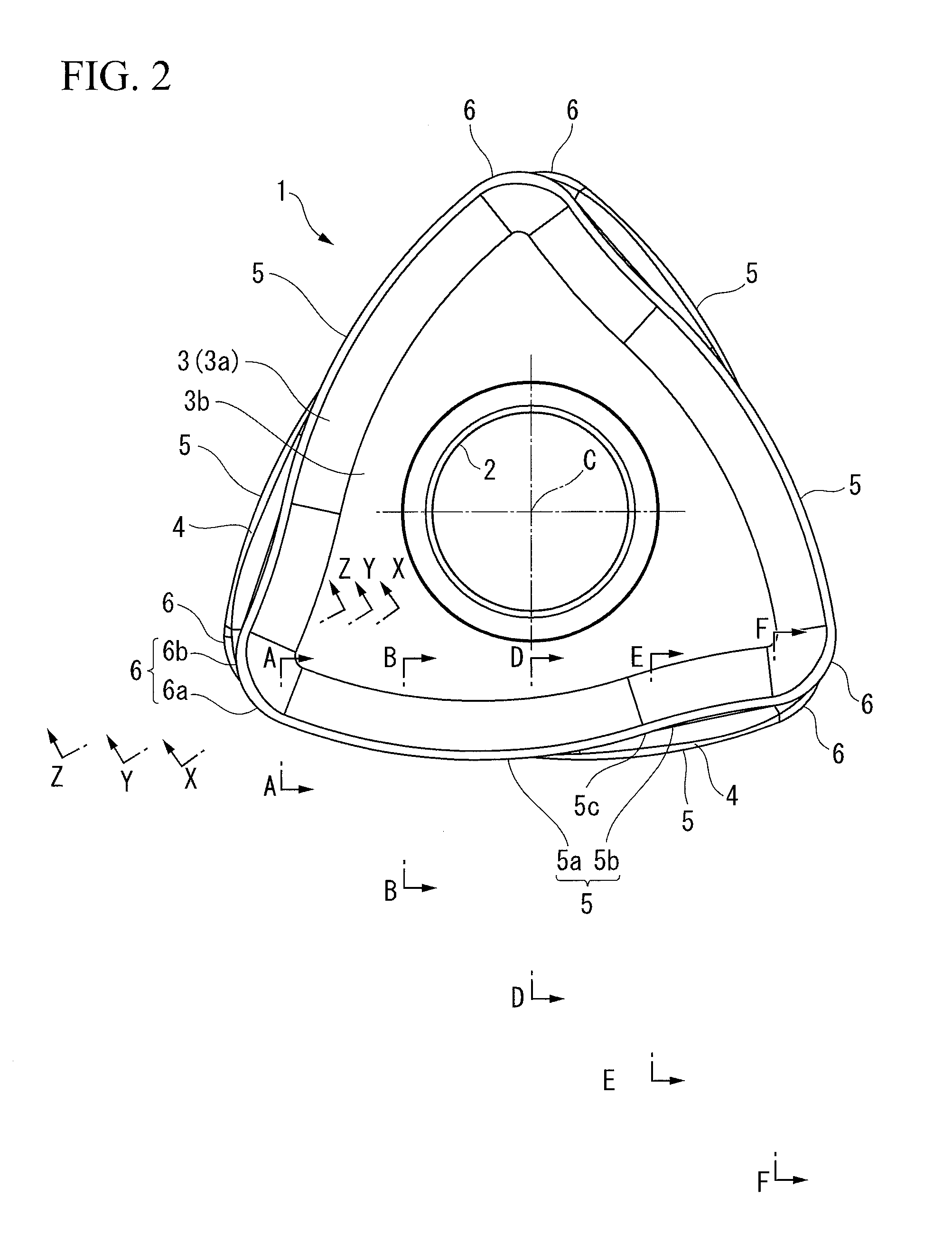

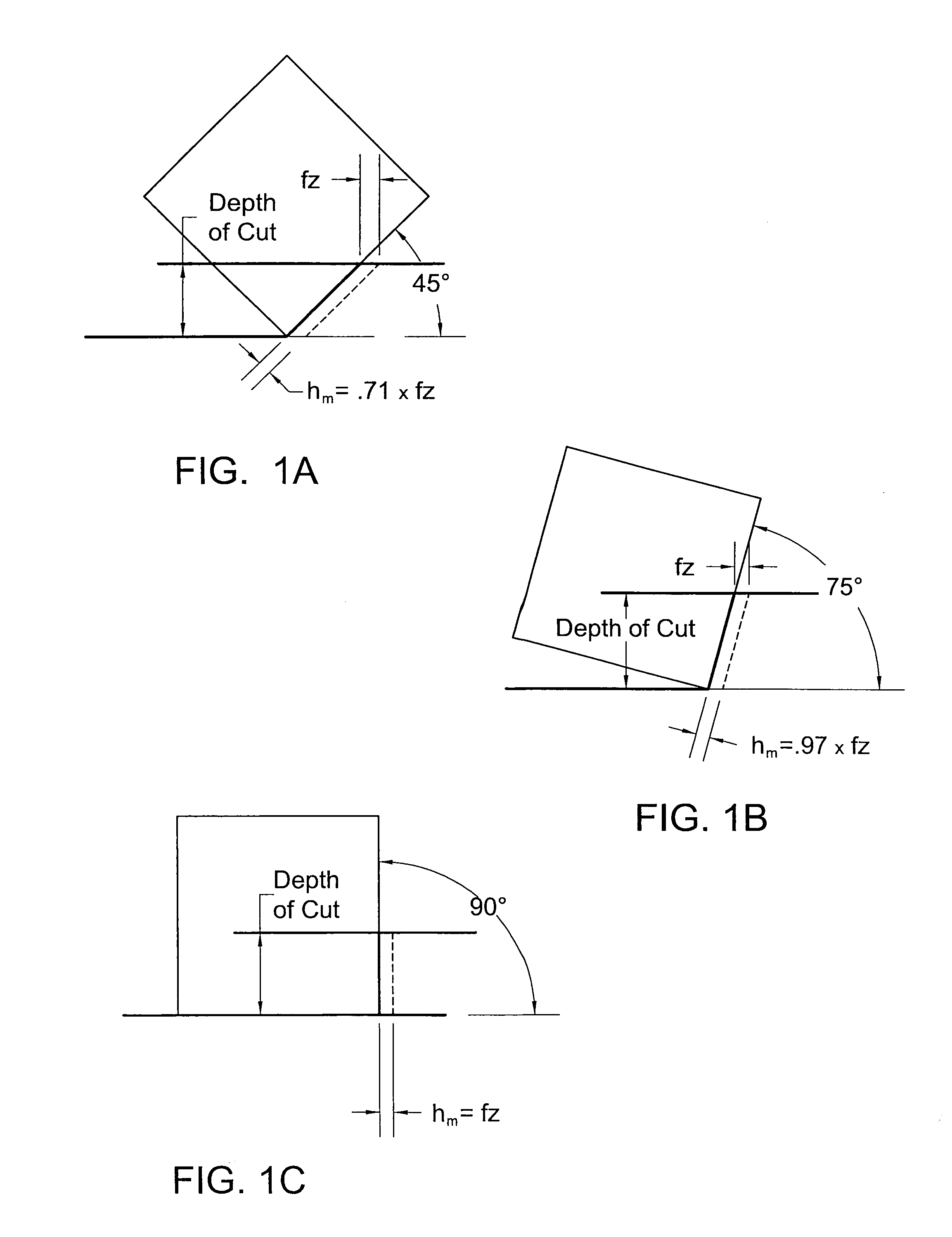

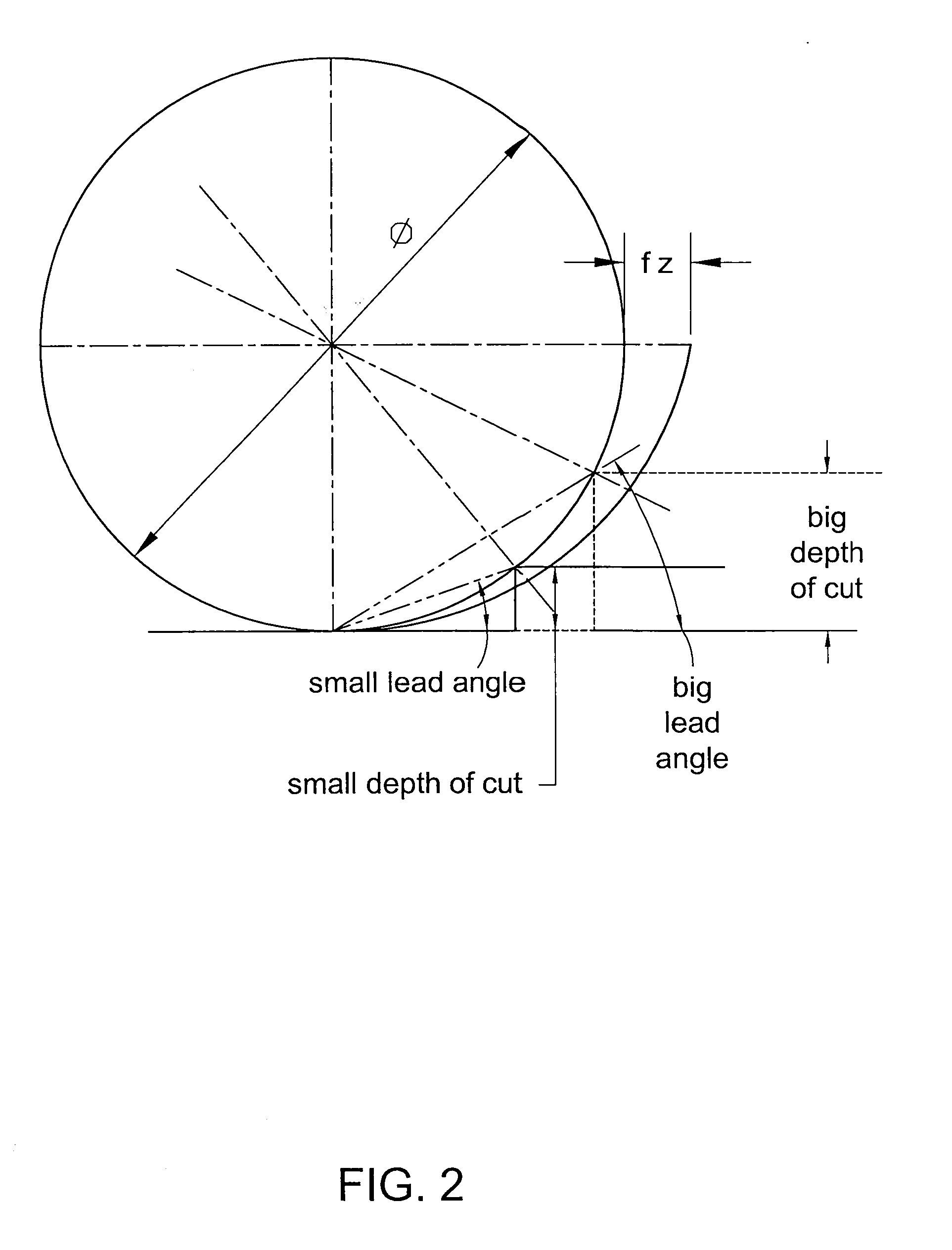

Cutting insert for high feed face milling

InactiveUS7220083B2Increase feed rateReduce forceTransportation and packagingMilling cuttersEllipseEdge strength

A cutting insert for milling operations, such as, face milling, slot milling, plunge milling, and ramping operations. The cutting insert exhibits a combination of favorable cutting edge strength, and unique cutting edge geometry, thus, allowing milling operations at relatively high feed rates. The cutting insert includes at least four cutting edges, wherein at least one of the cutting edges is a convex cutting edge. Certain embodiments of square cutting inserts will have four convex cutting edges which may be connected by nose corners. The convex cutting edge may comprise at least one of a circular arc, a portion of an ellipse, a portion of a parabola, a multi-segment spline curve, a straight line, or combinations of these. Wherein the convex cutting edge comprises a circular arc, the circular arc may have a radius greater than or equal to two times a radius of the largest circle that may be inscribed on the top surface.

Owner:KENNAMETAL INC

End mill

InactiveUS20060067797A1Aggressive and deep cutLess forceMilling cuttersWorkpiecesUltra fineEngineering

An end mill with a peripheral margin which increases in width from the terminal end of the tool to the shank portion of the tool. The end mill also has a tooth face made up of three tooth-face walls The depth of the tool face gradually decreases from the terminal end to the shank portion of the tool. The end mill also has an end cutting face which includes a flat, narrow land at the outmost region of the end cutting end. The end mill has chip breakers with rounded peripheral corners. The end mill can be made up of ultra-fine micro grain tungsten carbide with a cobalt content which varies throughout the length of the tool.

Owner:CALAMIA GUY ALLEN

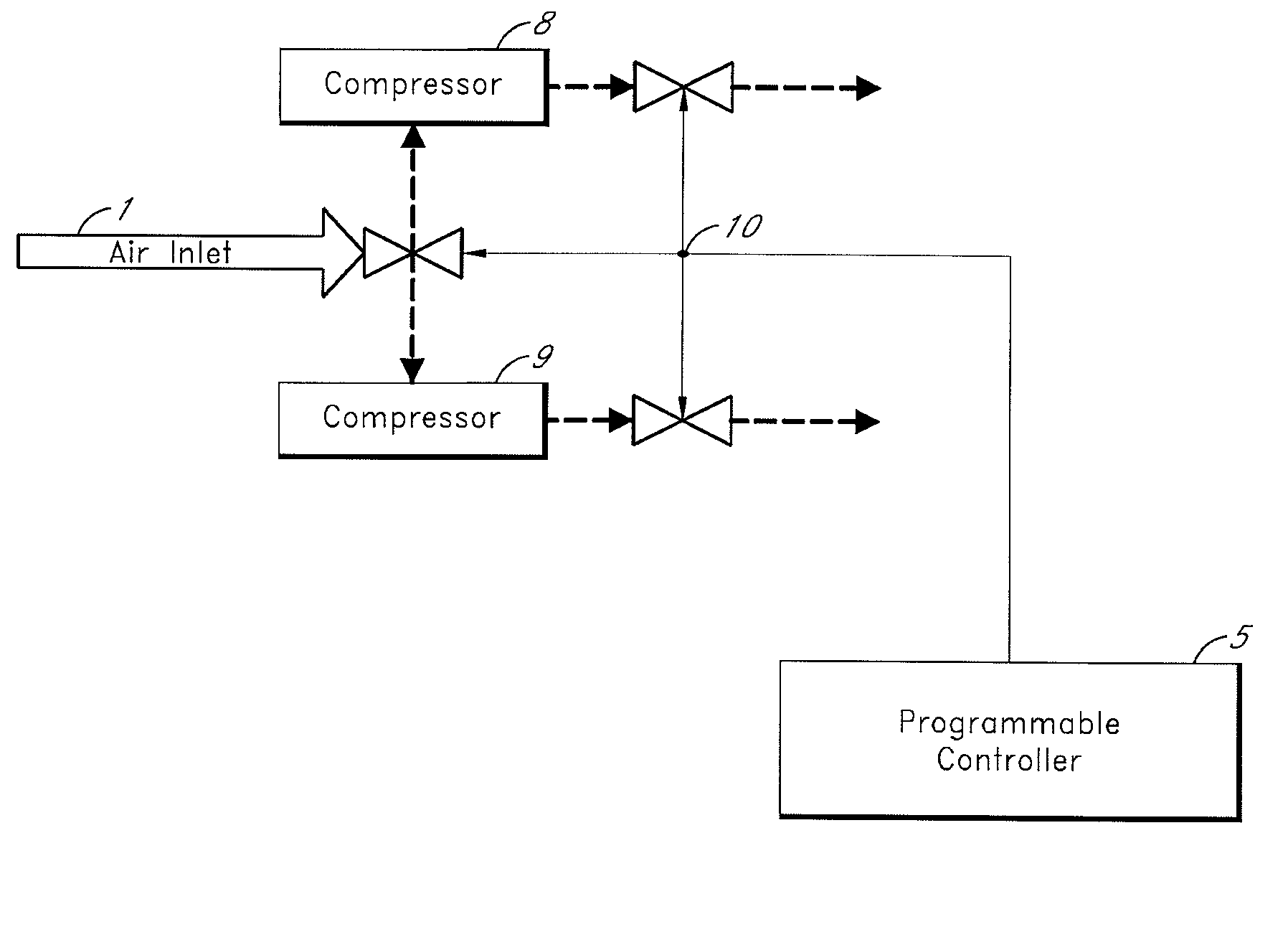

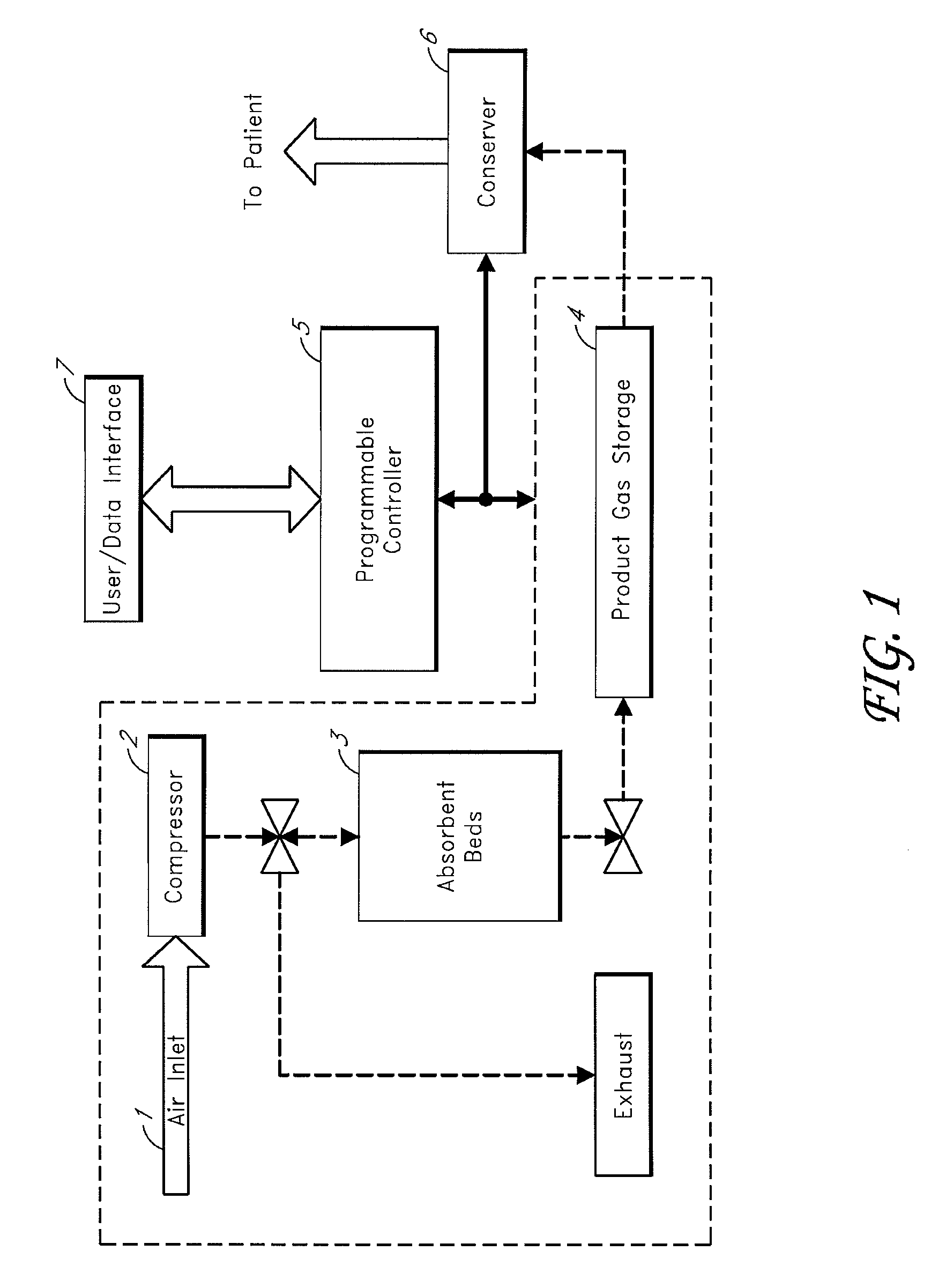

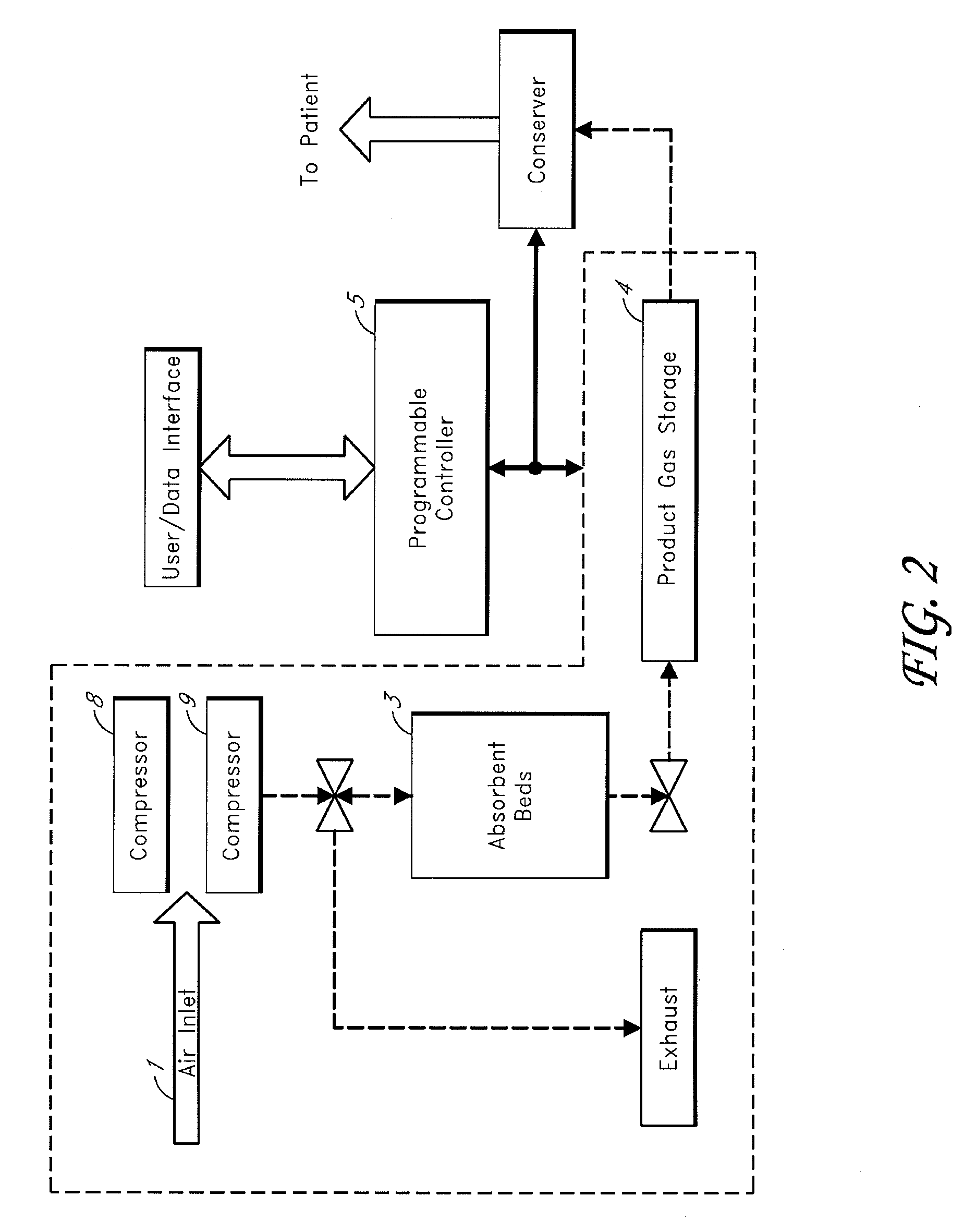

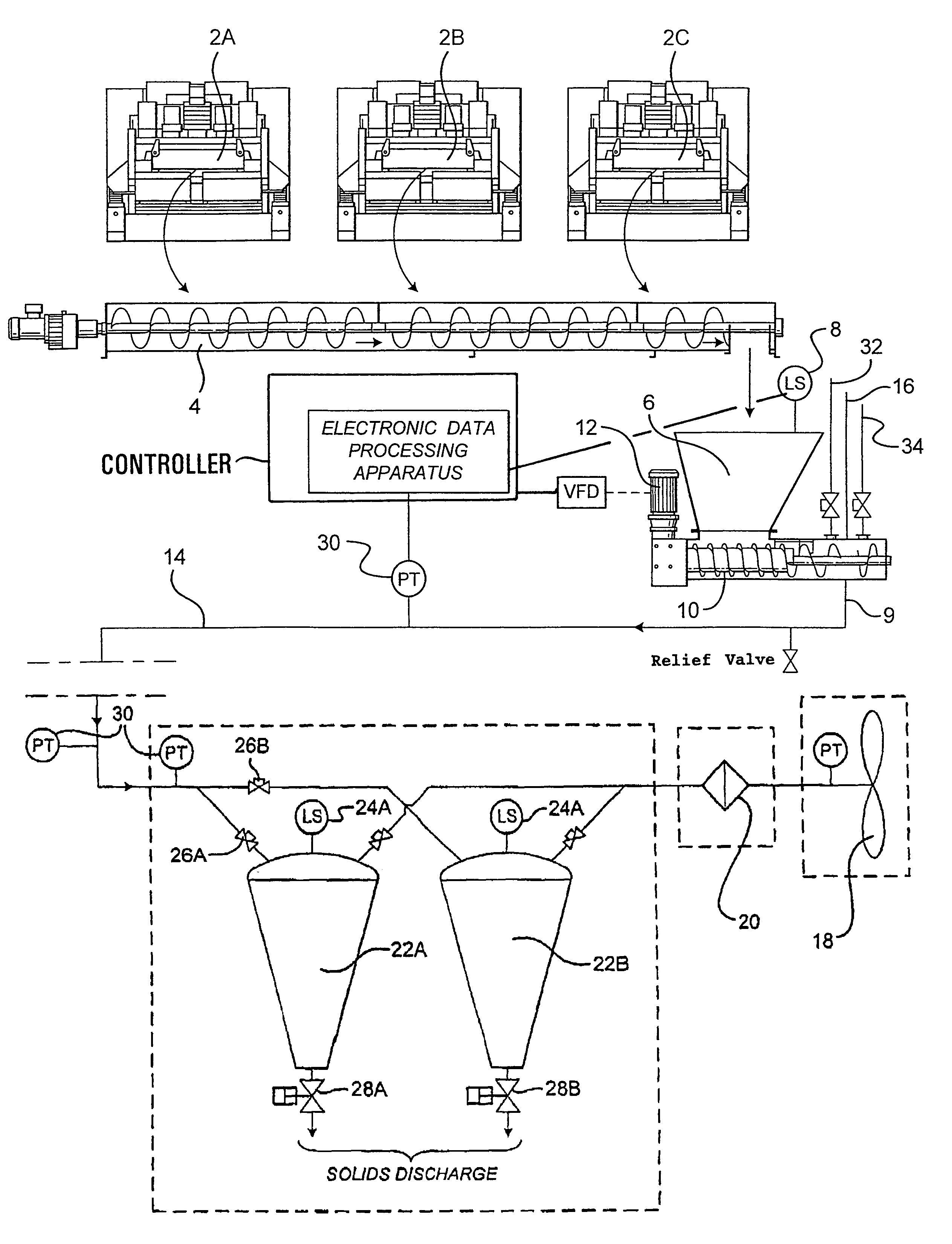

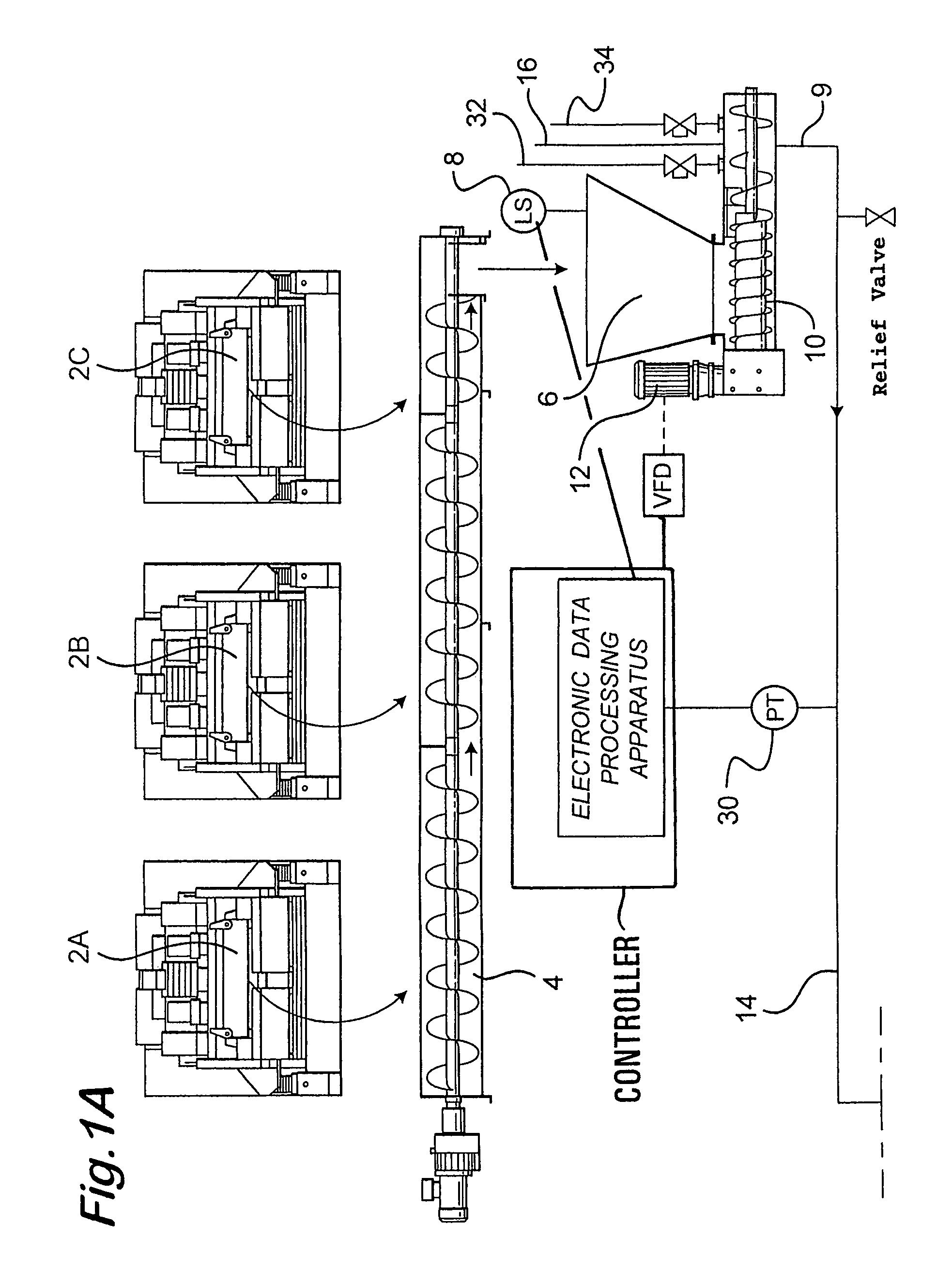

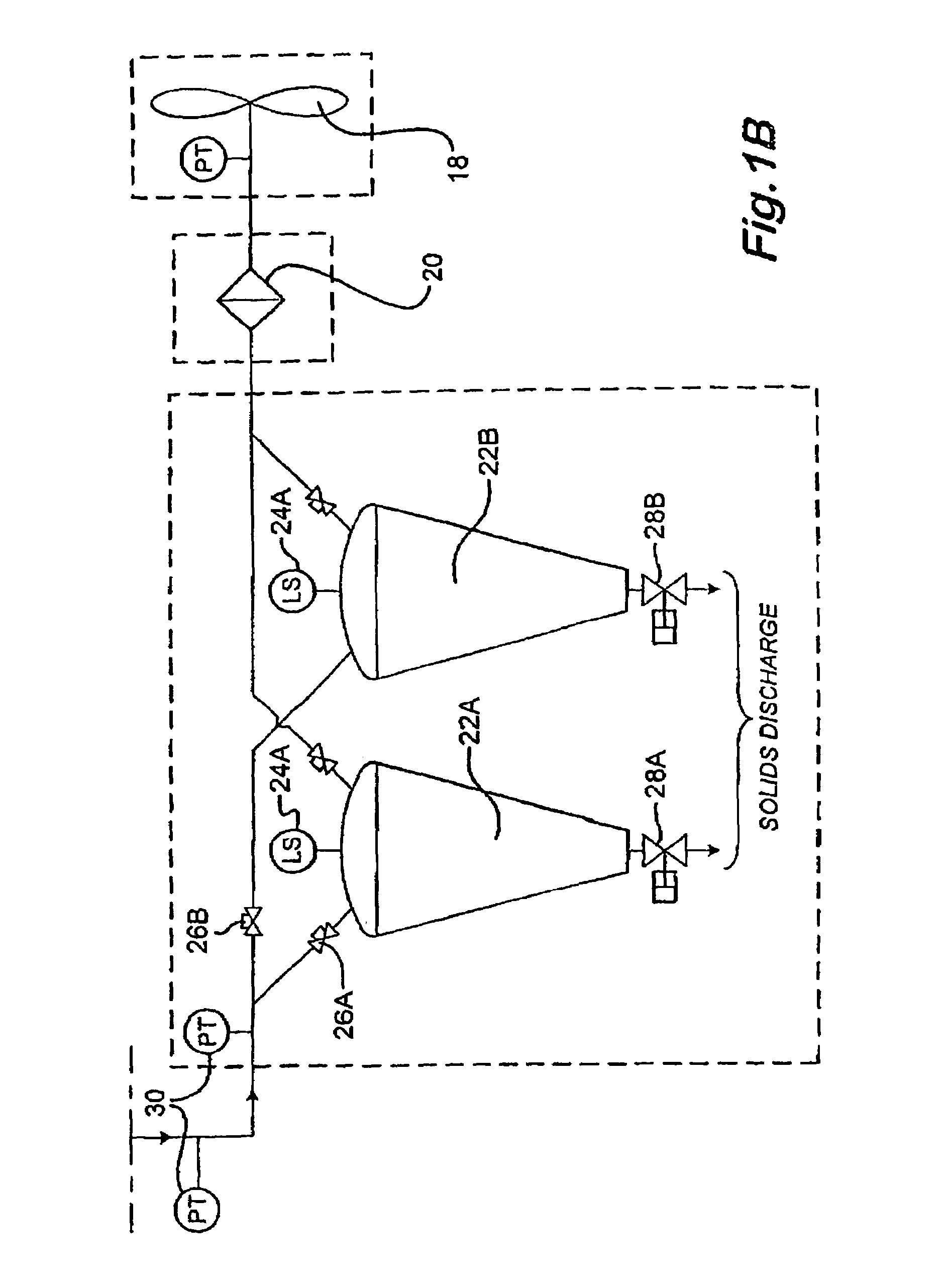

Expandable product rate portable gas fractionalization system

ActiveUS7686870B1Improve pressure resistancePromote recoveryRespiratorsGas treatmentProduct gasEngineering

An oxygen concentrator system that includes or can be expanded to include more than one compressor is provided. The system utilizes a controller that is adapted to selectively activate or deactivate one or more of the compressors to optimize system performance and efficiency. Multiple compressors can be selected to operate at the same time, thereby enabling the system to operate at a higher peak pressure, increase the recovery of the PSA cycle, and expand the product rate. The additional compressors can also be removed when not in use so as to reduce weight of the system. In some implementations, the system housing reserves a certain amount of space for accommodating additional compressors and related components, which can be added to the system as after market parts. In other implementations, the additional compressor can be located external to the system.

Owner:INOGEN INC

Apparatus and method for transporting waste materials

InactiveUS7080960B2Reduce feed rateHigh speedControl devices for conveyorsFlushingDrill cuttingsWaste material

Owner:VARCO I P INC

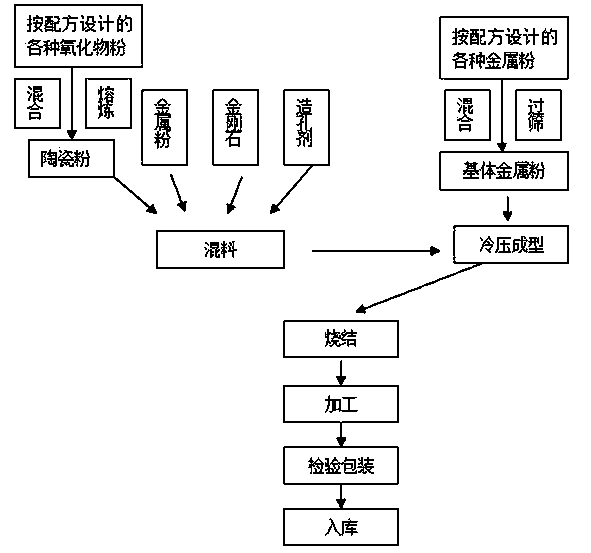

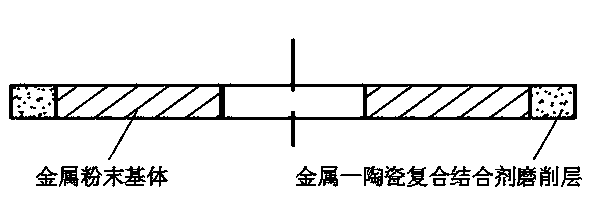

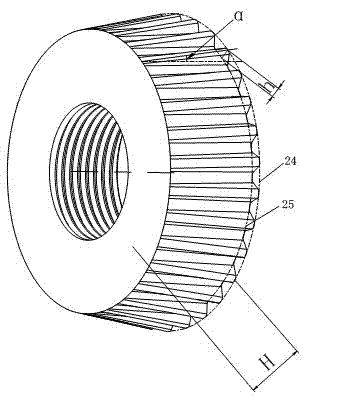

Metal ceramic combination binding agent and combination binding agent diamond wheel

ActiveCN103831740AGood self-sharpeningImprove sharpnessAbrasion apparatusGrinding devicesNumerical controlSilicon dioxide

The invention belongs to the field of diamond wheels and particularly relates to a metal ceramic combination binding agent and a combination binding agent diamond wheel. The metal ceramic combination binding agent is composed of, by weight, 60%-80% of 663 bronze powder and 20%-40% of ceramic powder. The ceramic powder is homemade and composed of, by weight, 45%-60% of silicon dioxide, 20%-30% of boric oxide, 10%-15% of potassium oxide, 5%-10% of magnesium oxide and 2%-5% of calcium oxide. The combination binding agent diamond wheel is composed of, by volume, 25%-40%of diamond abrasive, 55%-75% of combination binding agent and 2%-3% of pore forming agent. When the diamond wheel made of the metal ceramic combination binding agent is applied to a five-axis cnc machine tool, the good sharpness and the good self-sharpening performance of a ceramic binding agent are kept and the advantages of high rigidity and the good shape-maintaining performance of a metal binding agene are obtained. The comprehensive processing efficiency is improved by 100% to 150%.

Owner:江苏赛扬精工科技有限责任公司

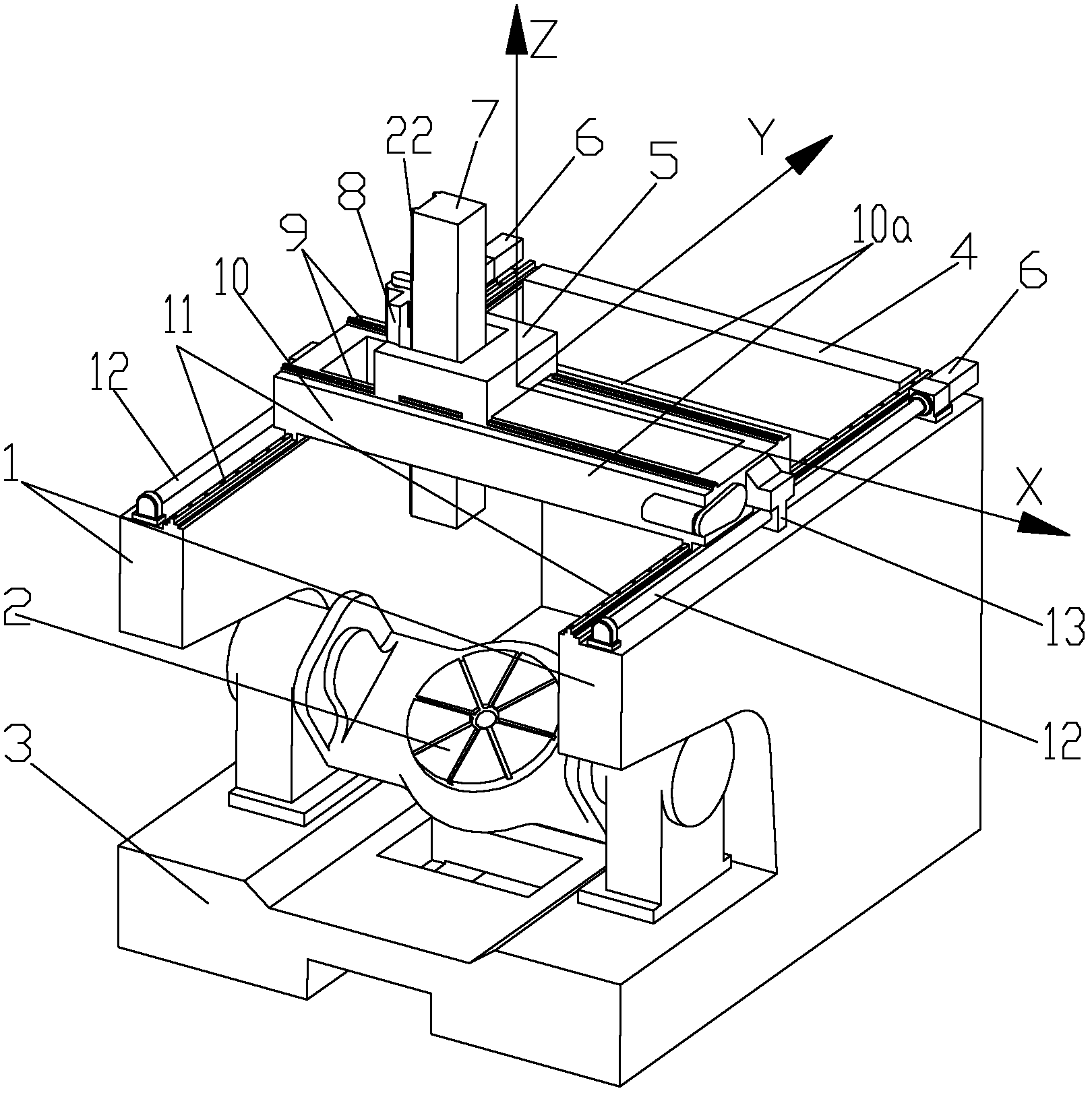

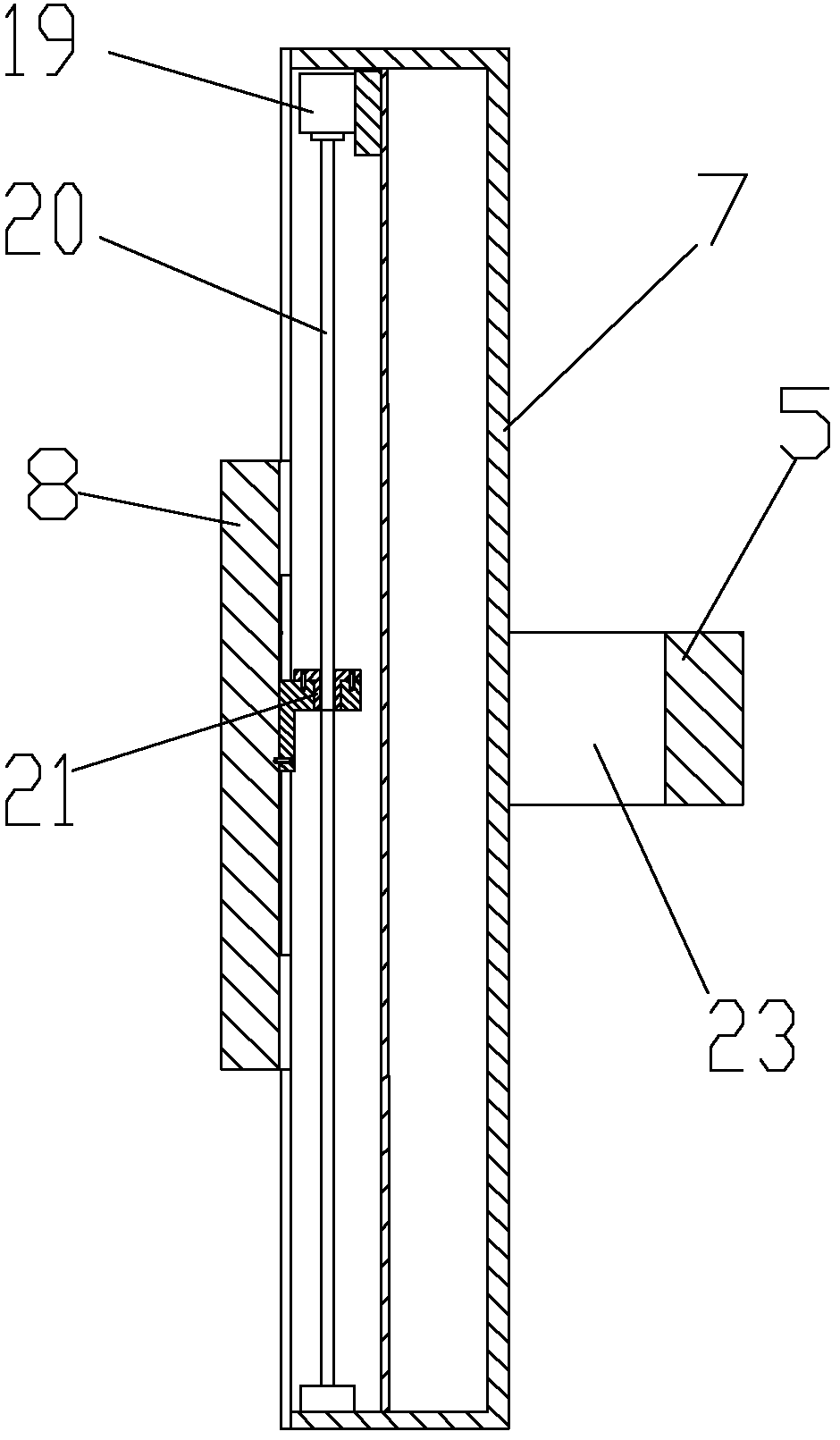

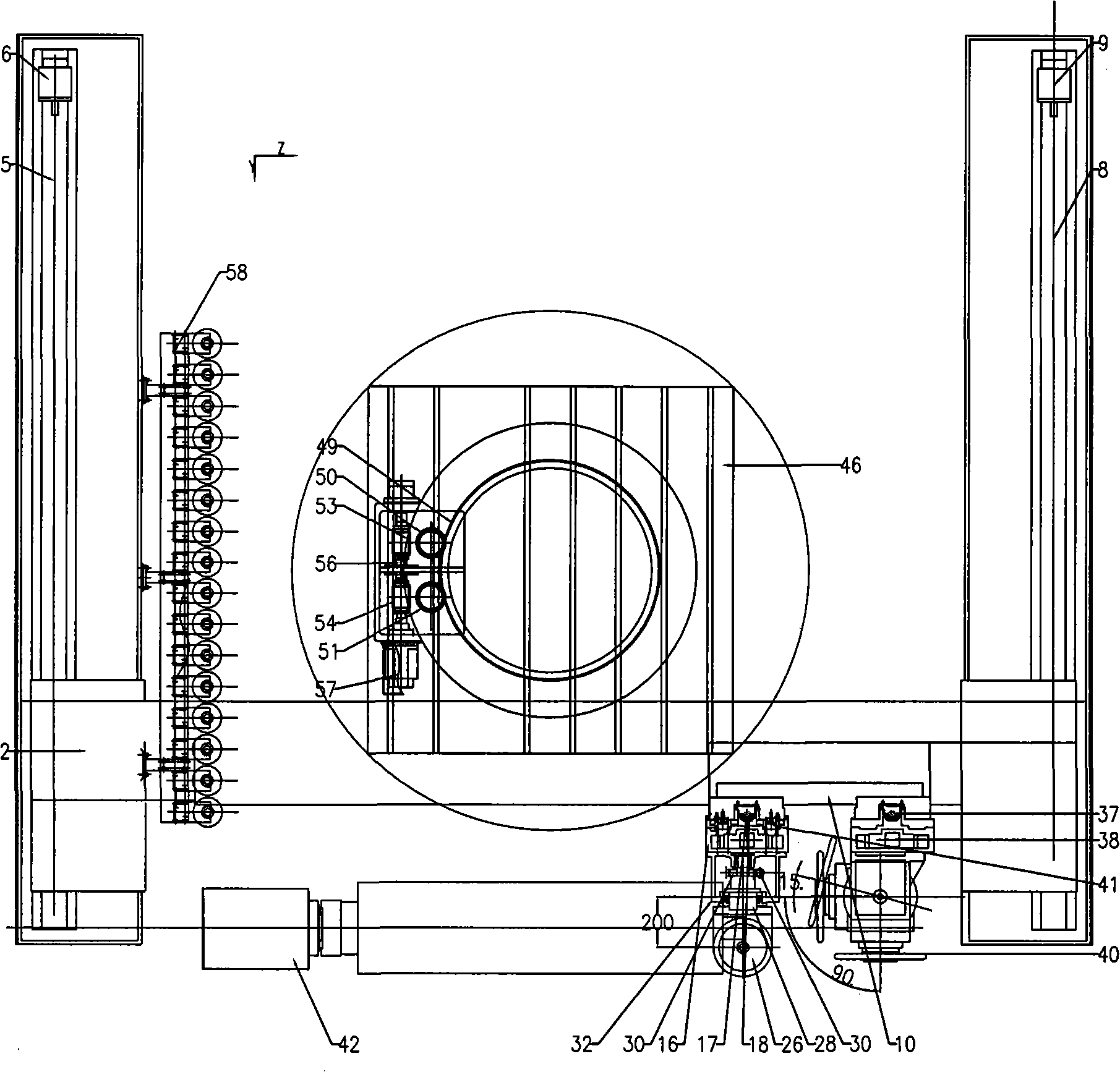

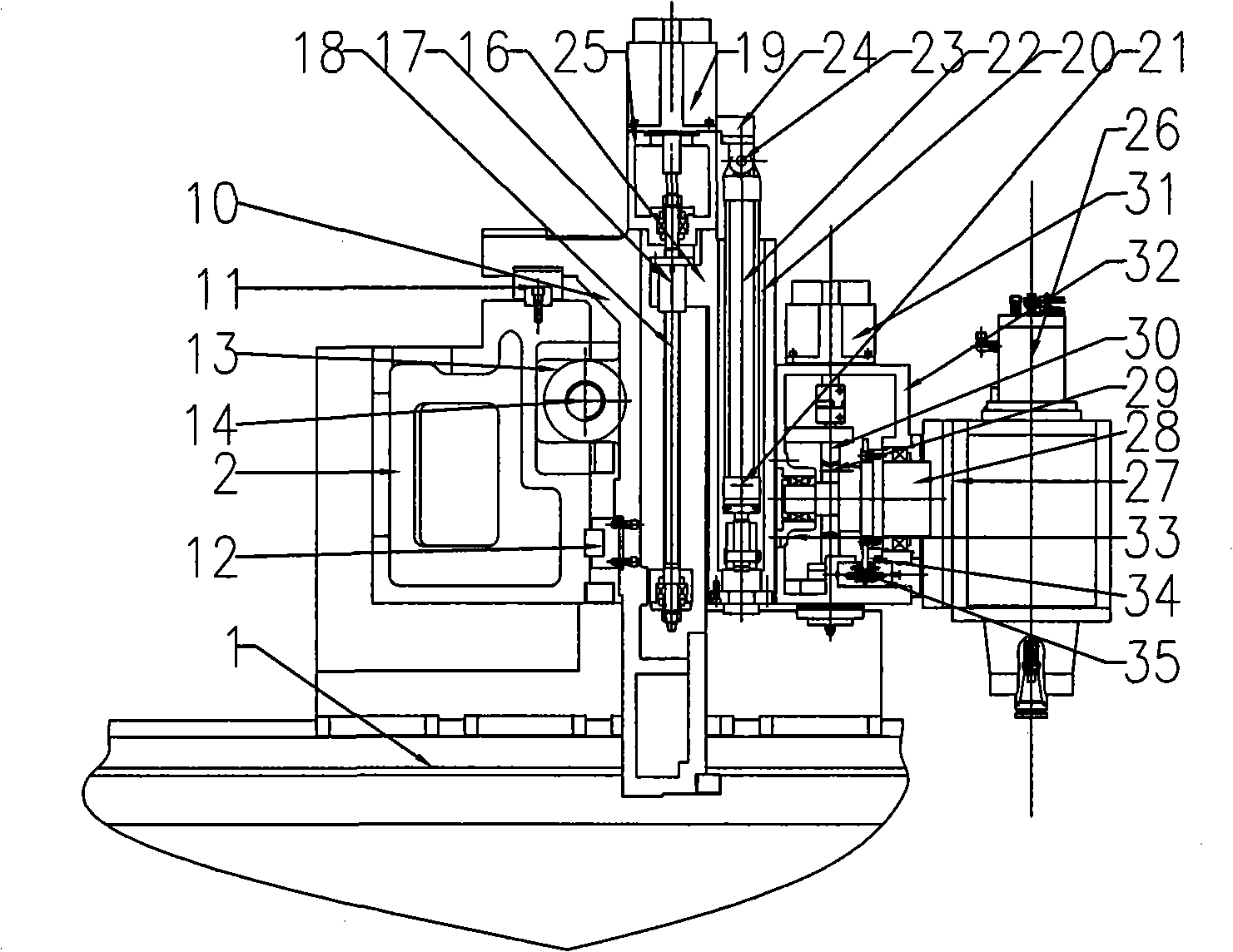

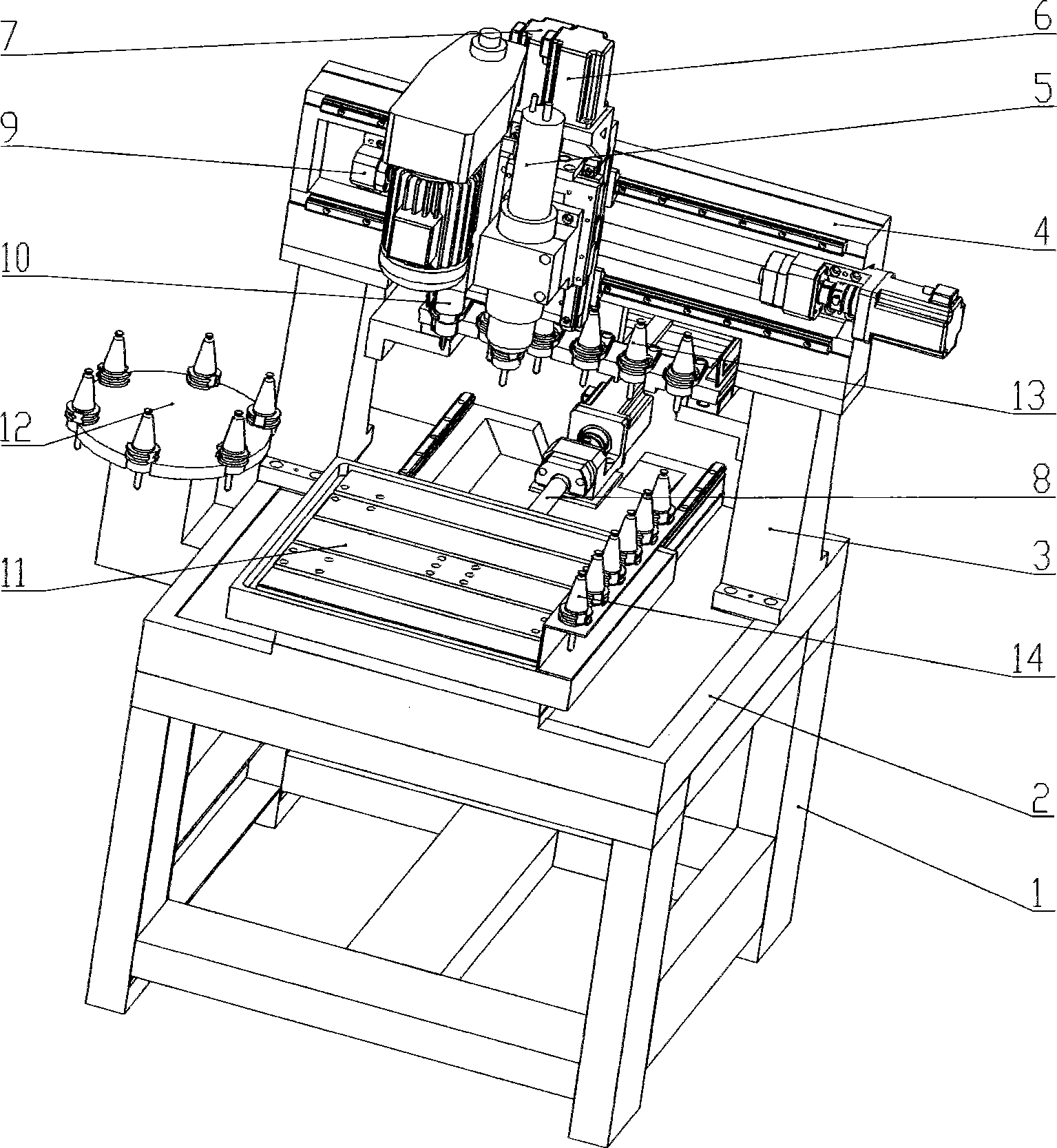

Small high-speed five-axis linkage machine tool

InactiveCN102632422AGuaranteed stabilitySmall sizeMachine tool componentsFeeding apparatusBridge typeEngineering

The invention discloses a small high-speed five-axis linkage machine tool, which comprises a foundation structure, a spindle box component and a cradle type worktable. The spindle box component is supported on the foundation structure, and a crossbeam with a frame-shaped structure is arranged on two upright columns to form a bridge-type portal structure. The torque bearing capacity of the crossbeam is improved, the small high-speed five-axis linkage machine tool has all advantages of a five-axis linkage machine tool in the prior art, and carries identical machining reacting force, the volume of a structural part is reduced, and the weight of the structural part is greatly lightened; a spindle box is positioned between two transverse rods of the frame-shaped crossbeam, overturning moment is eliminated, and the stability of the machine tool can be guaranteed; in addition, sizes of various components are greatly reduced on the premise of identical machining capacity, and the stroke of the machine tool can be large in the design; and by the aid of the structure, the machining precision is greatly improved, the machining range is greatly expanded, better dynamic characteristics and higher feeding speed and higher cutting speed can be realized, cutting and machining time is greatly shortened, better surface machining quality is obtained, and machining efficiency is enhanced.

Owner:CHONGQING UNIV

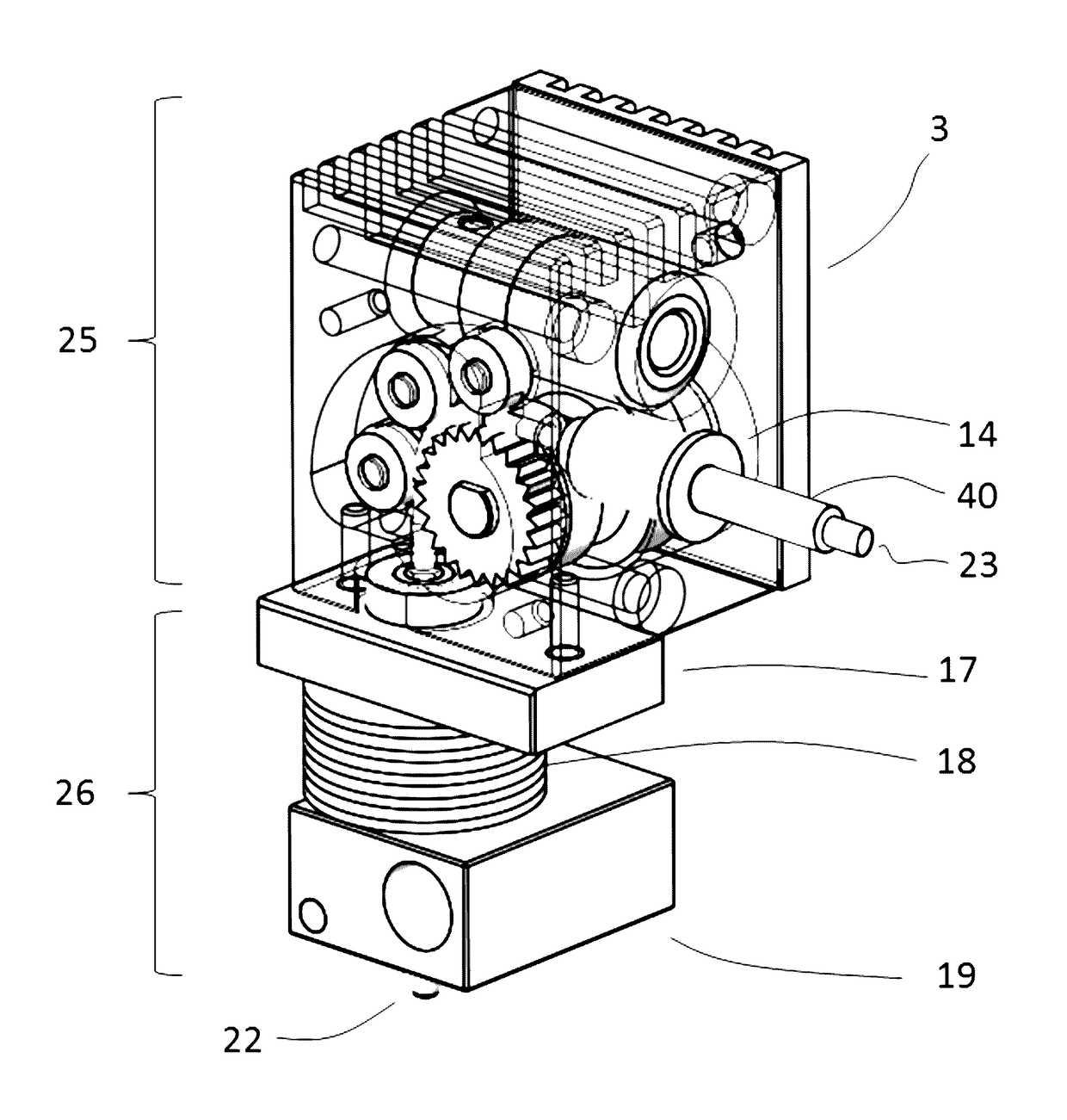

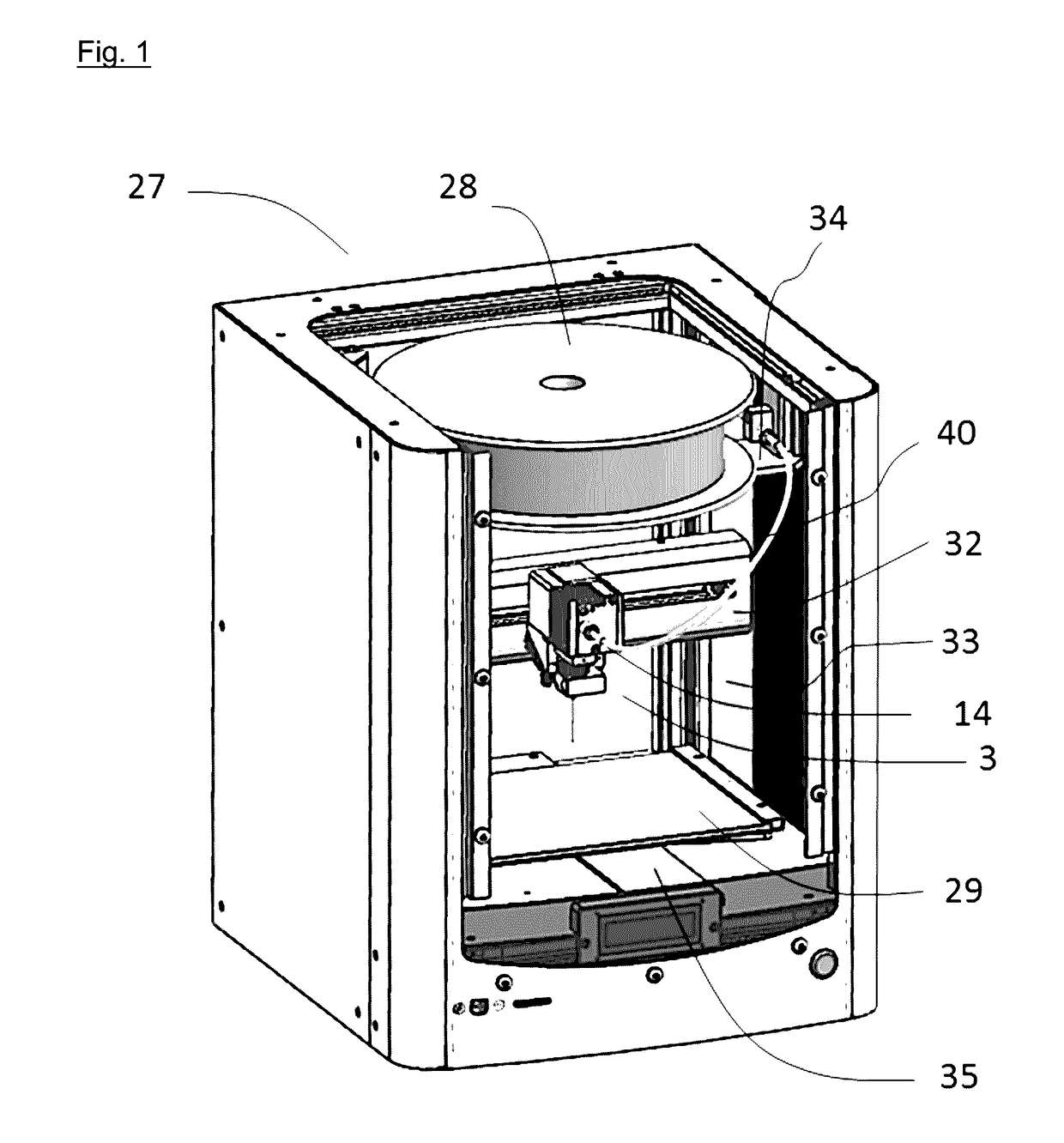

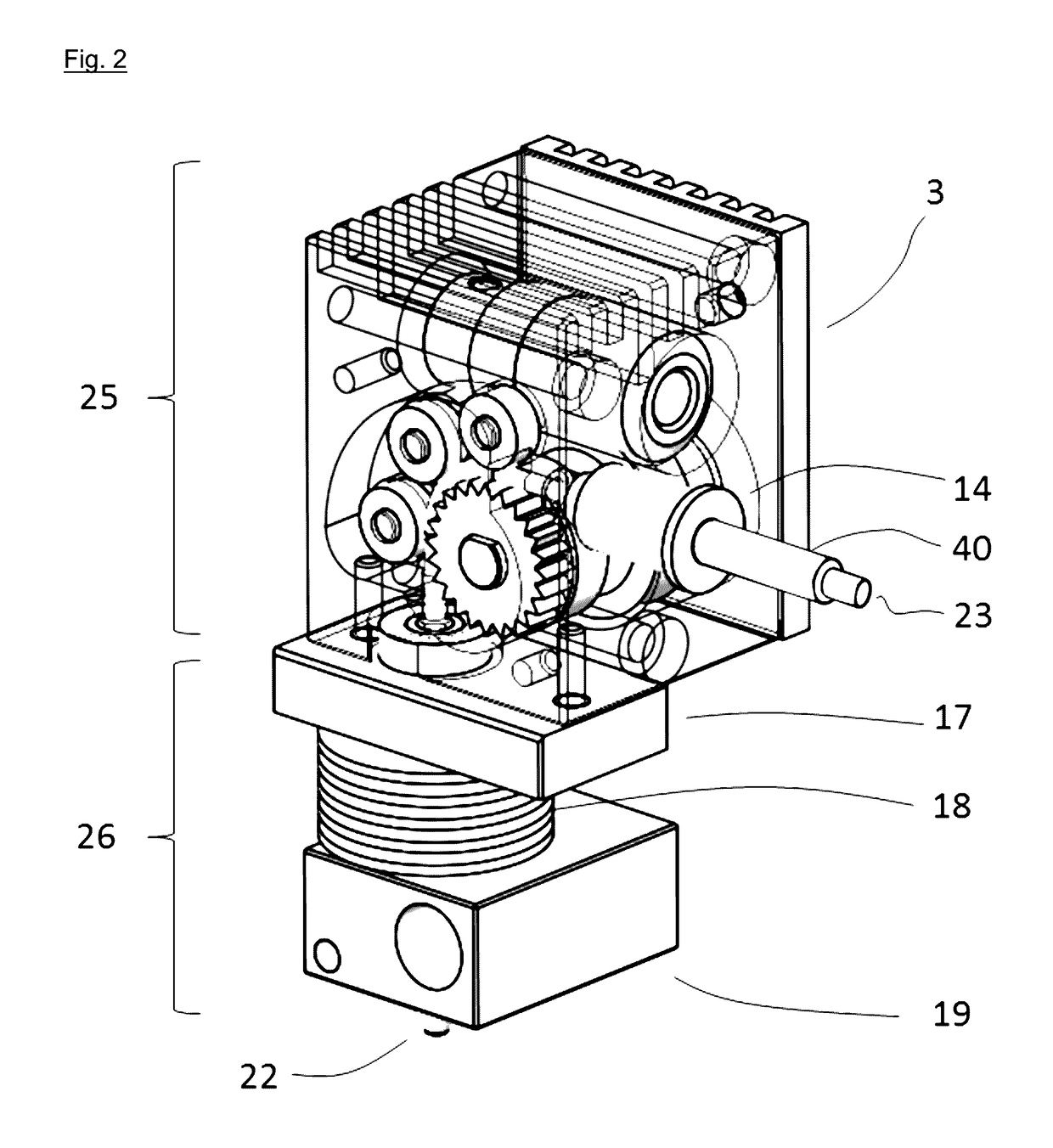

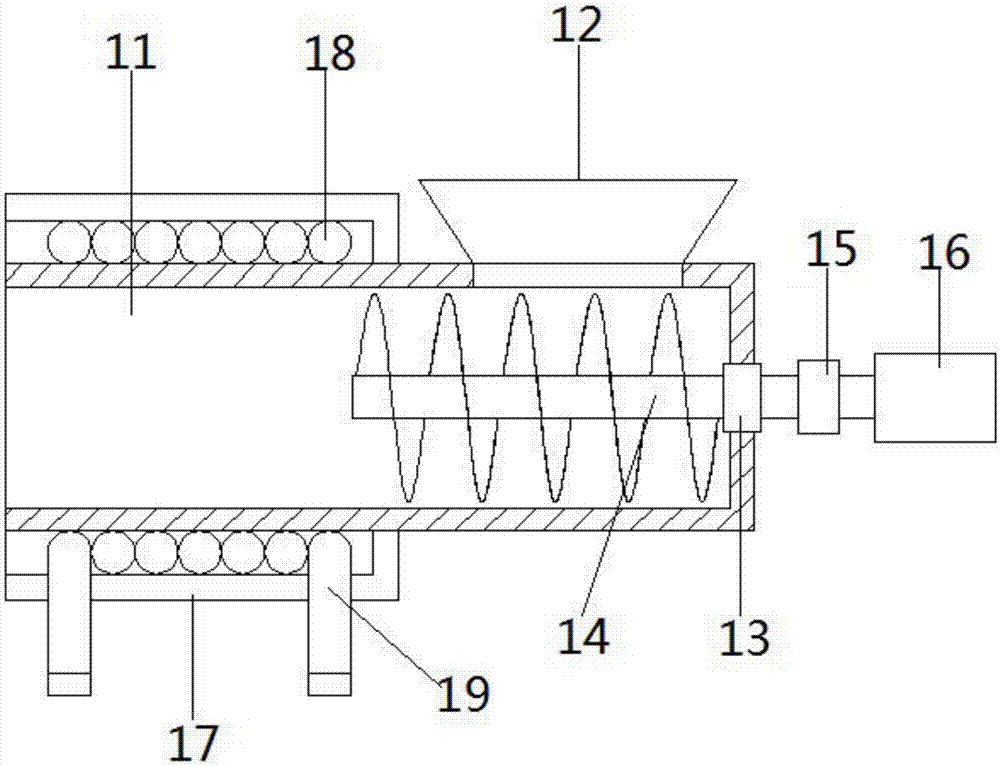

Extruder for fused filament fabrication 3D printer

InactiveUS20170157826A1Increase extrusion speedIncrease feed rateAdditive manufacturing with liquids3D object support structuresFused filament fabricationHigh acceleration

Disclosed is an improved extruder head for a fused filament fabrication 3D printer. It would be beneficial with a thinner nozzle diameter and higher extrusion speed without slippage in the feeding mechanism. The proposed improved extruder head enables extrusion of thinner extruded material at a higher extrusion speed without any slippage in filament feeding mechanism, thereby allowing higher overall building speed of the 3D printer with high quality build. Higher feed-rate of the filament material is achieved by increased usable friction between pinch wheel and filament by increasing the grippable area of the filament. This is done by feeding the filament into the feeding mechanism at an angle different to the outlet angle and routing it around the pinch wheel, back supported by a plurality of support rollers, so that the filament is in frictional contact with the pinch wheel along a greater part of its circumference, thereby increasing the surface contact area between the pinch wheel and the filament. Owing to non-slippage of the filament feeder, nominal volume of extruded material is exactly the same as desired volume with high filament feeding rate. Due to compact feeding mechanism, total mass of extruder kept small enough to enable higher acceleration of the printing nozzle resulting higher printing speed. Owing to horizontal loading of the filament material, feed roll can be mounted just above the extruder for smooth filament supply and compact size of 3D printer.

Owner:RHOMBUS INT TECH

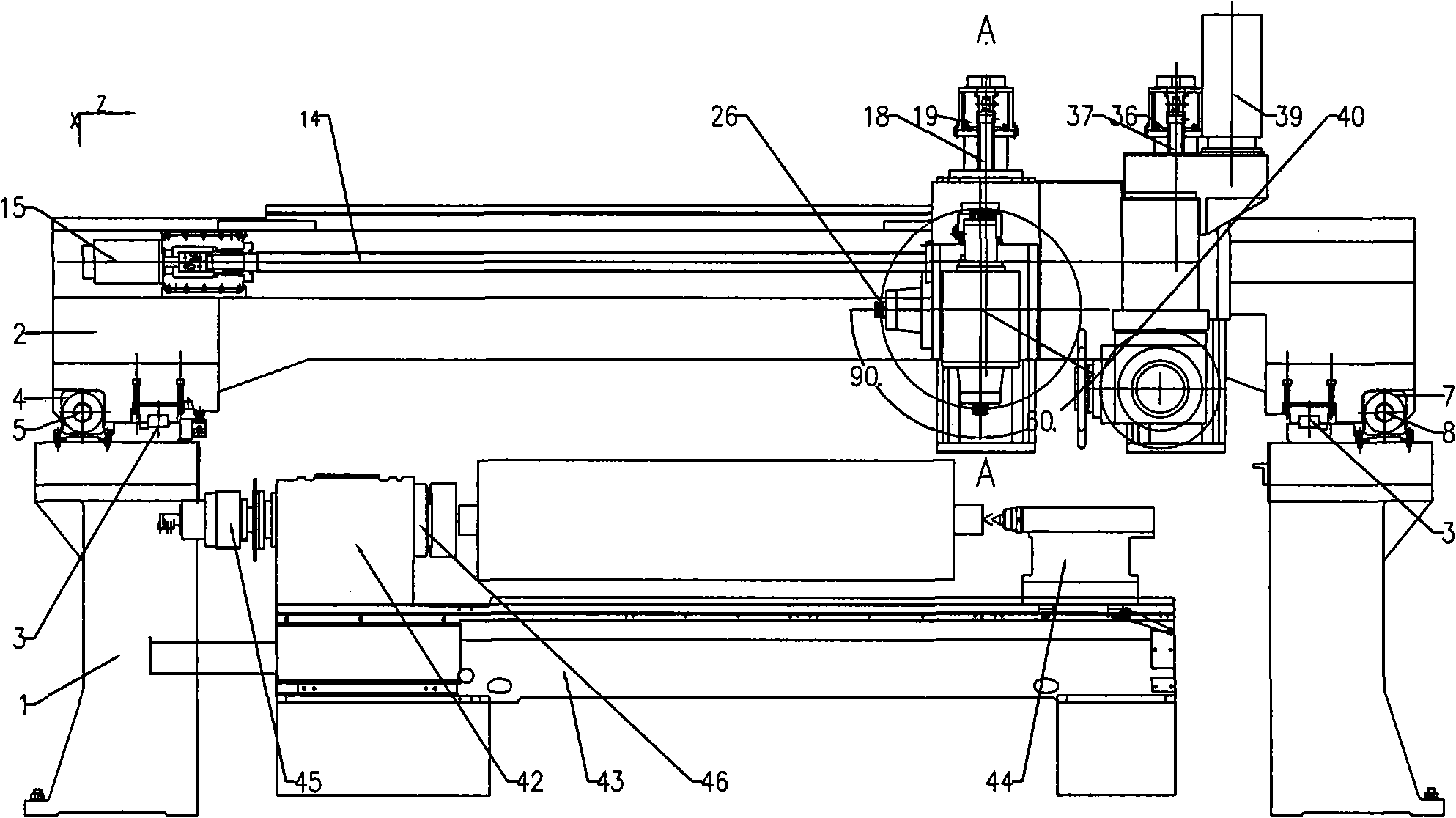

Irregular stone multifunctional composite processing center with double five-axle linkage system

ActiveCN101357490AEngraving and milling realizationAchieve turningGrinding machinesStone-like material working toolsEngineeringMechanical engineering

The invention relates to a special shaped stone high-speed high-efficiency combined machining center with the functions of double five-axis linkage and synchronous cutting by double working heads, and relates to a device for processing stones. Active gantry structure is adopted in the machining center, the double-motor synchronous driving technology is adopted on the gantry beam, and synchronous high-speed driving is realized by the screw bar pair at the two sides; a milling working head component and a turning working head component are respectively arranged on the saddle of the beam, the vertical feeding mechanism thereof is formed by a suit of screw bar pair and a hydraulic pressure auxiliary mechanism; wherein, the milling working head can carry out rotation and scales division around the axis B, and the turning working head facilitates the same servo motor to realize rotation and scale division of axis A and cutting movement; the turning working head and the milling working head are arranged alternately, and both the turning process and the grinding processing can be carried out on stone articles at the same time. The machining center is provided with a numerical control system with the function of double five-axis linkage, and horizontal five-axis linkage machining and vertical five-axis linkage machining can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

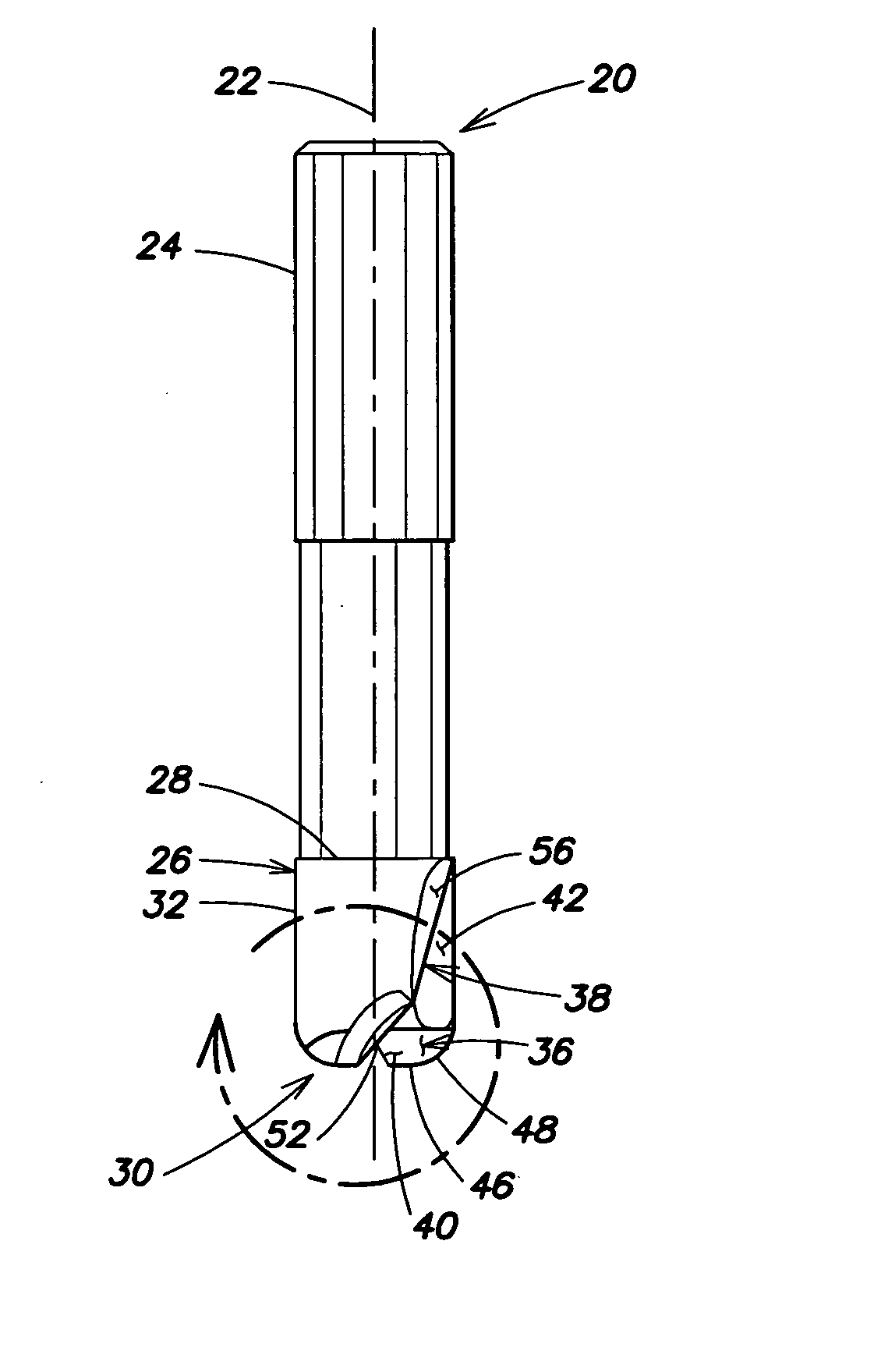

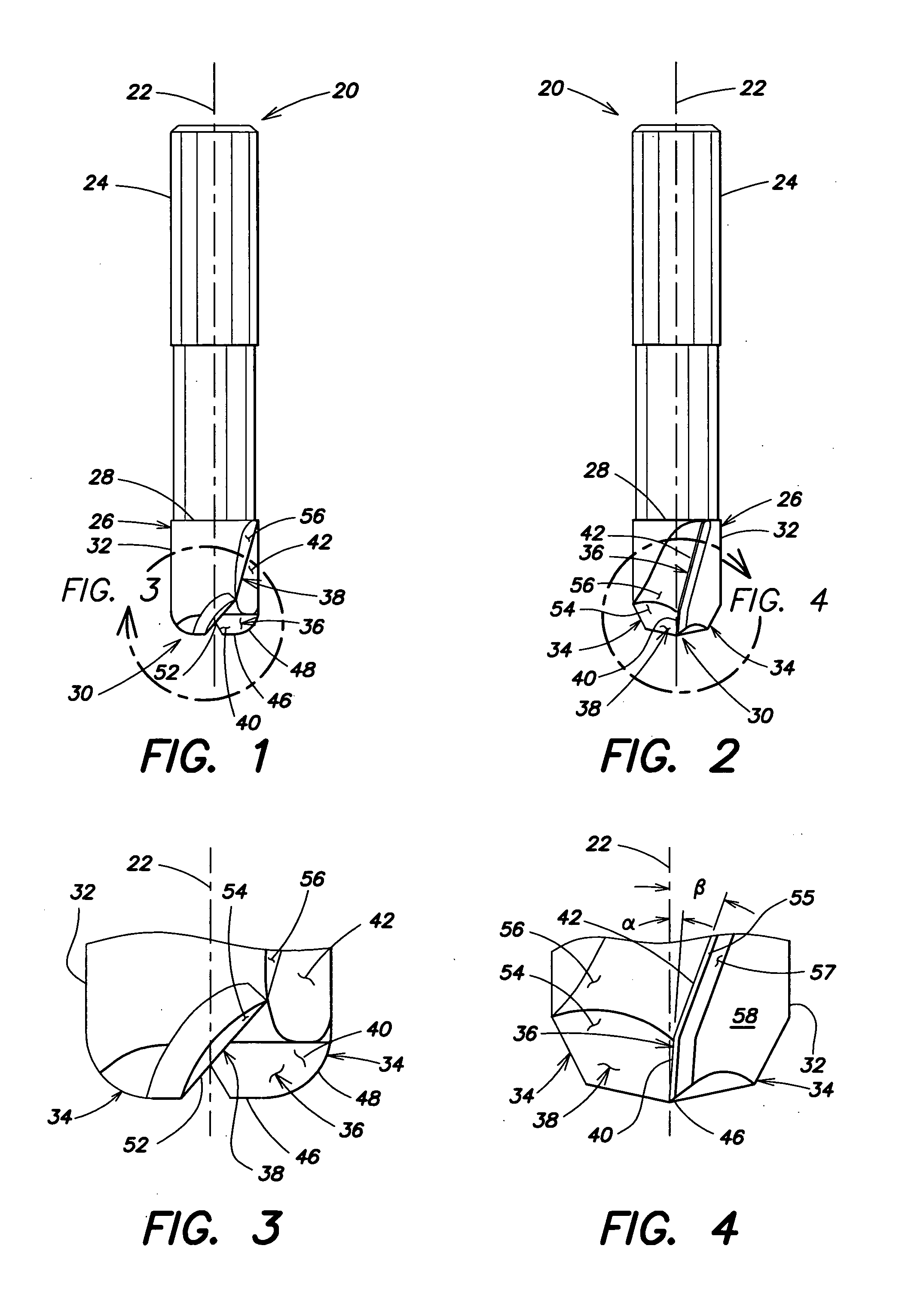

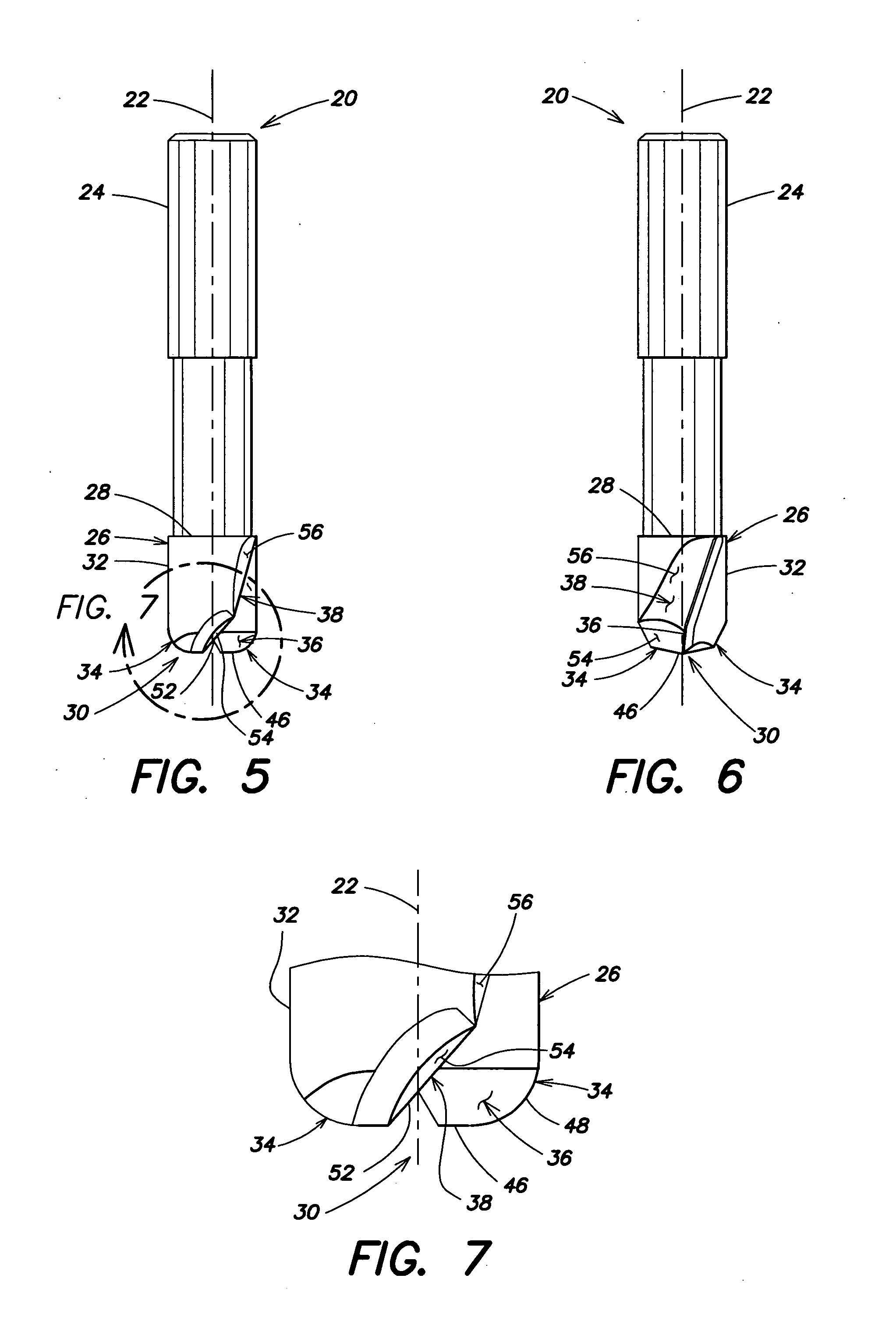

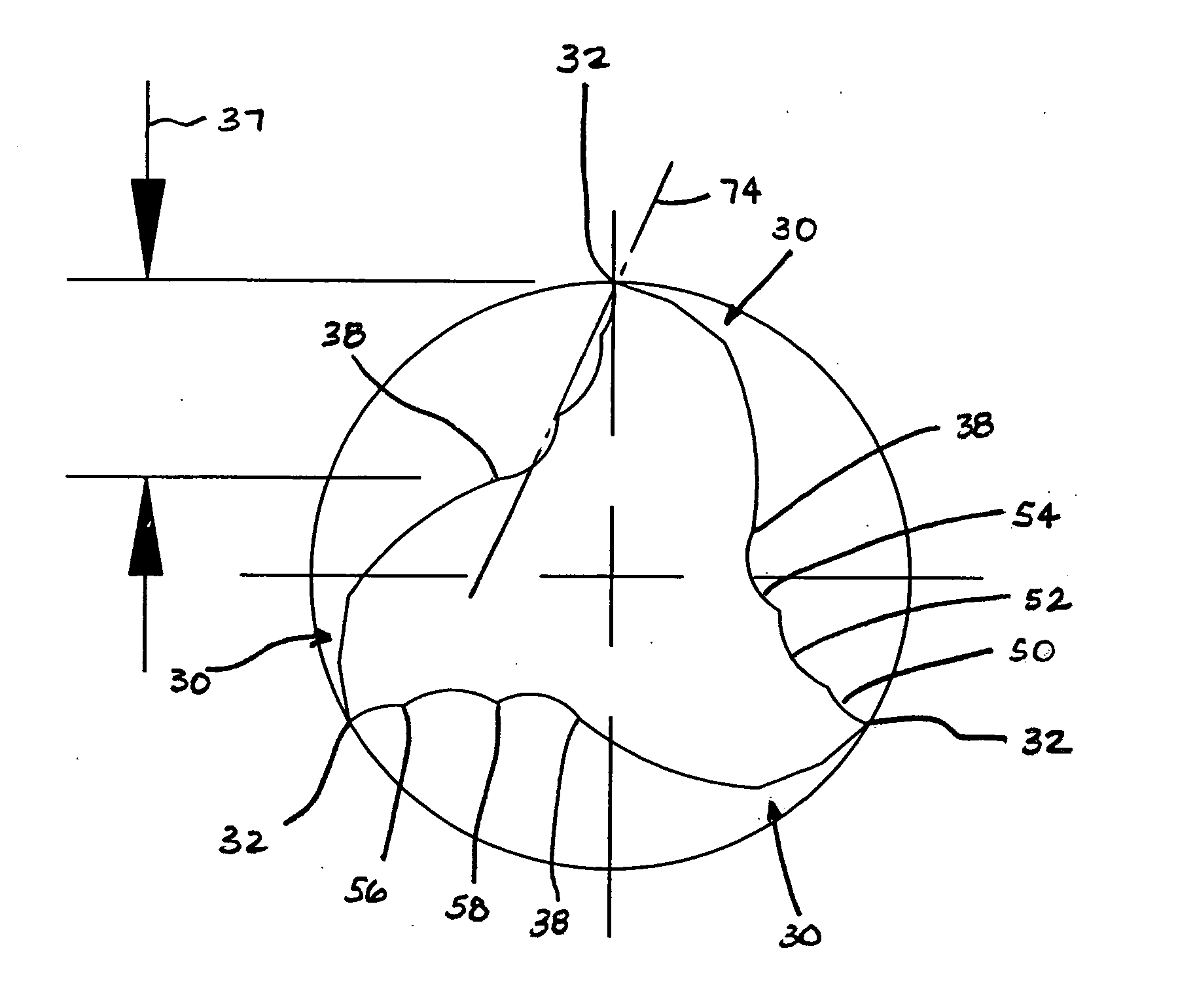

Multiple-axis cutting toroidal end mill

InactiveUS20060045639A1Increases effective machining of machineLower capability requirementsMilling cuttersShaping cuttersRotational axisMilling cutter

A one-piece toroidal end mill having an axis of rotation is provided. The end mill includes a shank section and a fluted section. The shank section extends along the axis of rotation. The fluted section extends along the axis of rotation, and has a first end, an outer surface, and a plurality of teeth. The first end is integrally attached to the shank section. Each of the plurality of teeth has a cutting surface and a shoulder surface. The cutting surface includes a cutting edge. The shoulder surfaces intersect with one another to form a center void disposed between the cutting surfaces.

Owner:BERKSHIRE PRECISION TOOL

Cutting insert for high feed face milling

ActiveUS20050084342A1Increase feed rateReduced radial cutting forceTransportation and packagingMilling cuttersEllipseEdge strength

A cutting insert for milling operations, such as, face milling, slot milling, plunge milling, and ramping operations. The cutting insert exhibits a combination of favorable cutting edge strength, and unique cutting edge geometry, thus, allowing milling operations at relatively high feed rates. The cutting insert includes at least four cutting edges, wherein at least one of the cutting edges is a convex cutting edge. Certain embodiments of square cutting inserts will have four convex cutting edges which may be connected by nose corners. The convex cutting edge may comprise at least one of a circular arc, a portion of an ellipse, a portion of a parabola, a multi-segment spline curve, a straight line, or combinations of these. Wherein the convex cutting edge comprises a circular arc, the circular arc may have a radius greater than or equal to two times a radius of the largest circle that may be inscribed on the top surface.

Owner:KENNAMETAL INC

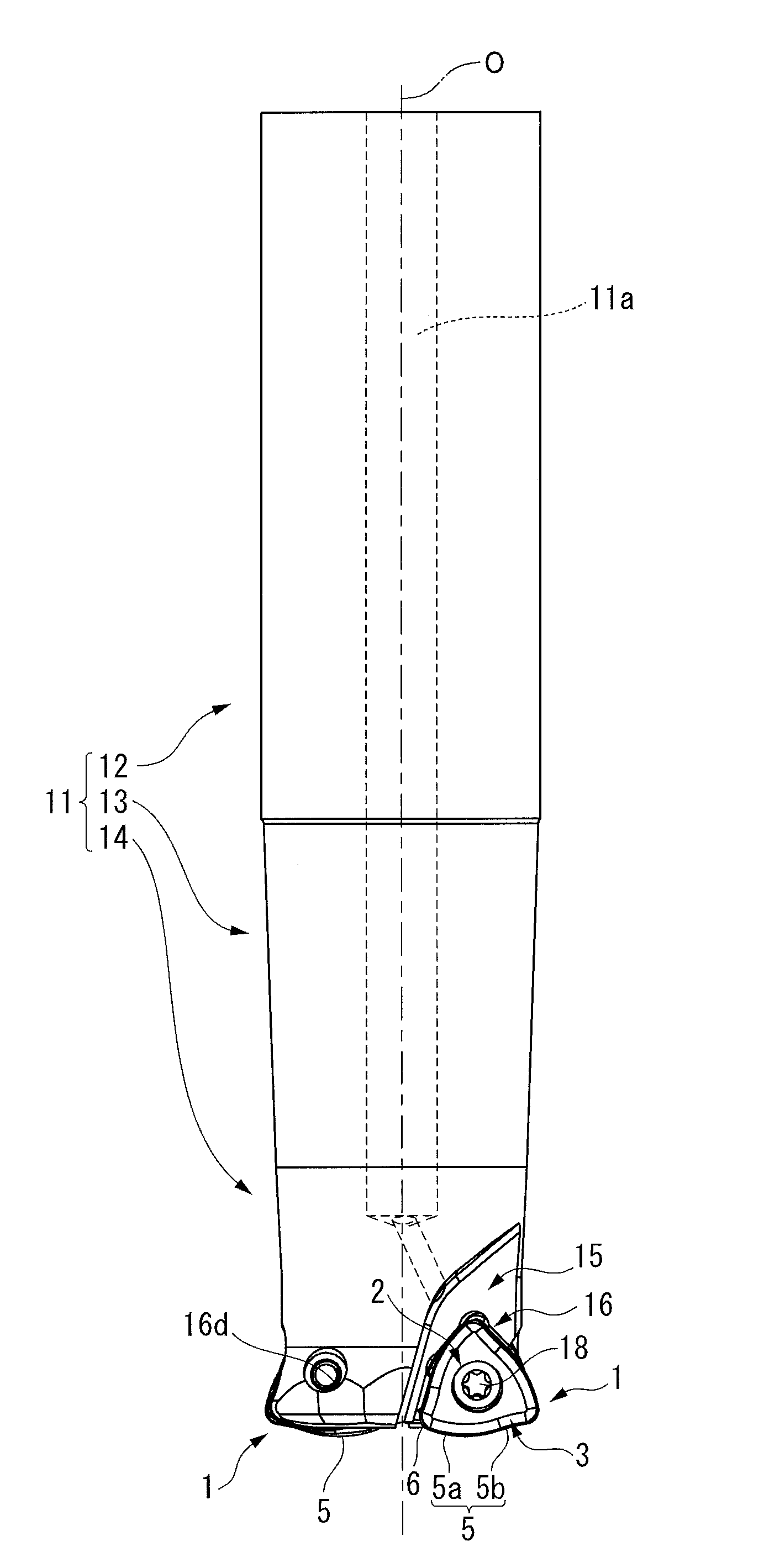

Cutting insert and indexable cutting tool

ActiveUS20140334890A1Abnormal damage can be preventedIncrease feed rateTransportation and packagingMilling cuttersCurve shapeEngineering

A cutting insert includes an insert body having a polygonal plate shape. Rake faces are formed on polygonal surfaces of the insert body, and flank faces are formed on lateral faces of the insert body arranged around the polygonal surfaces. Main cutting edges are formed on side ridges of the polygonal surfaces at intersecting ridgelines between the rake faces and the flank faces. Each main cutting edge extends between two corners adjacent to each other in a circumferential direction of the polygonal surface among corners of the polygonal surface. When seen from a direction opposing the rake face, one end portion of the main cutting edge that stretches to one corner of the two corners has a convexly curved shape, and the other end portion of the main cutting edge that stretches to the other corner of the two corners has a concavely curved shape.

Owner:MITSUBISHI MATERIALS CORP

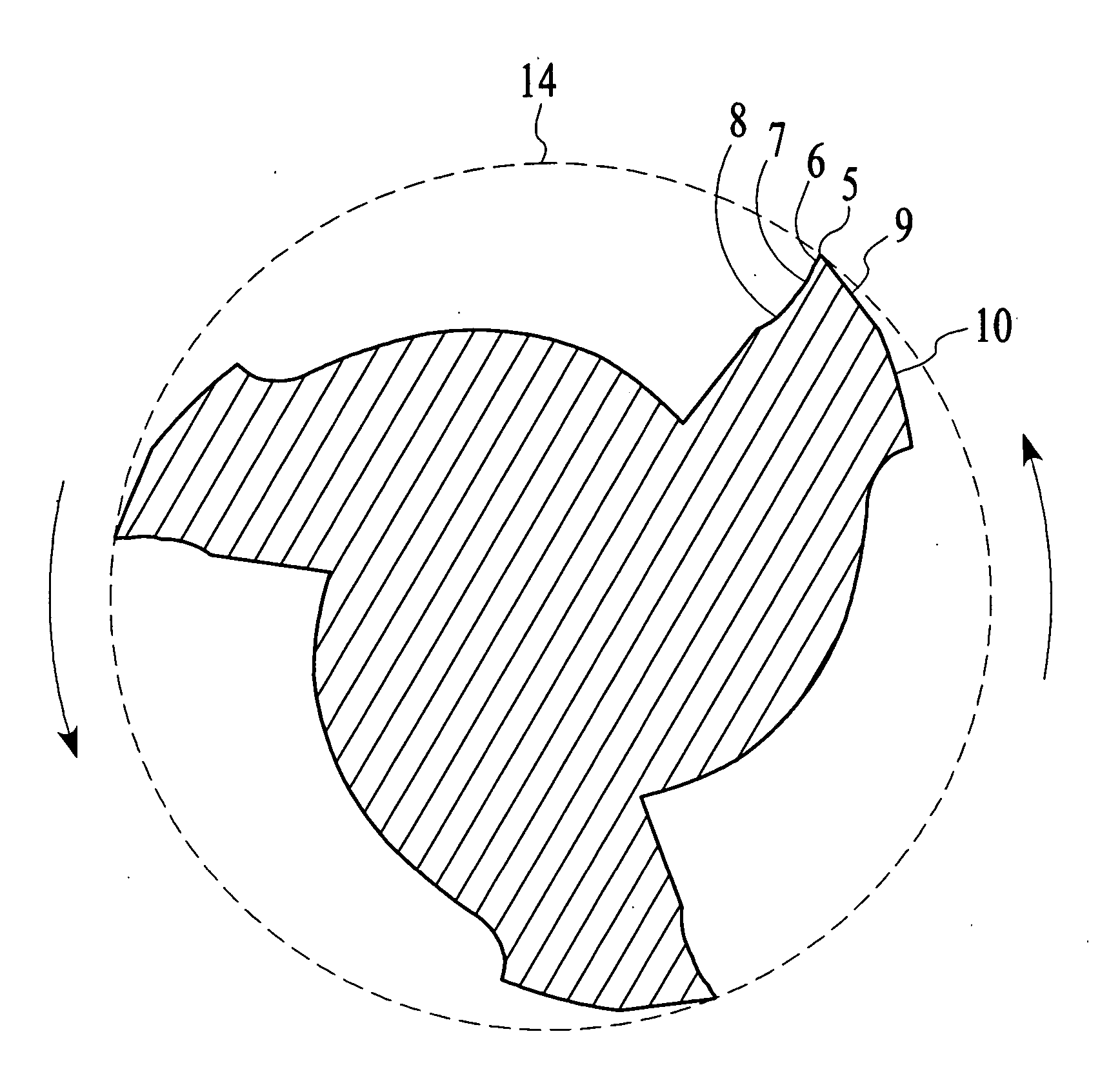

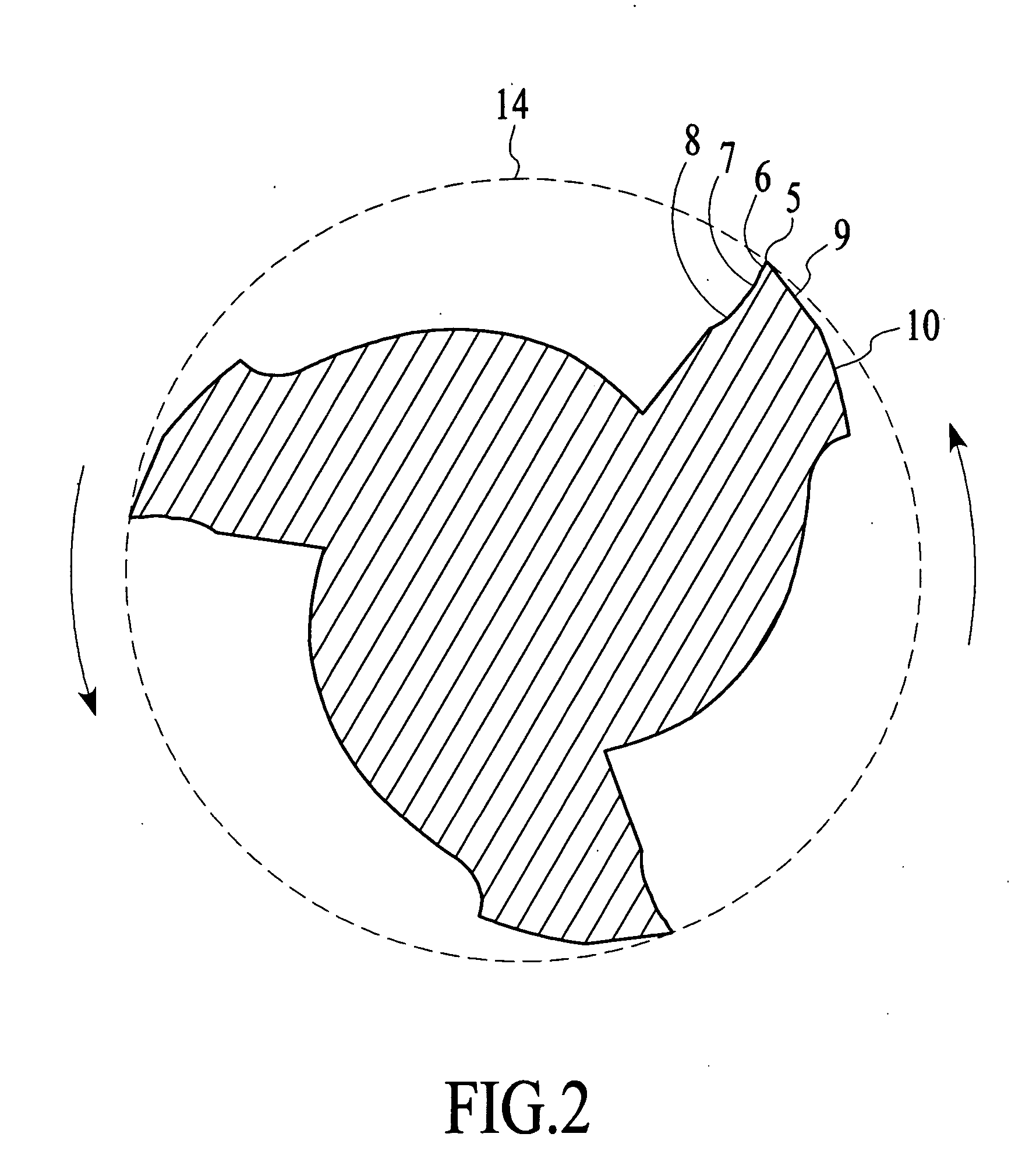

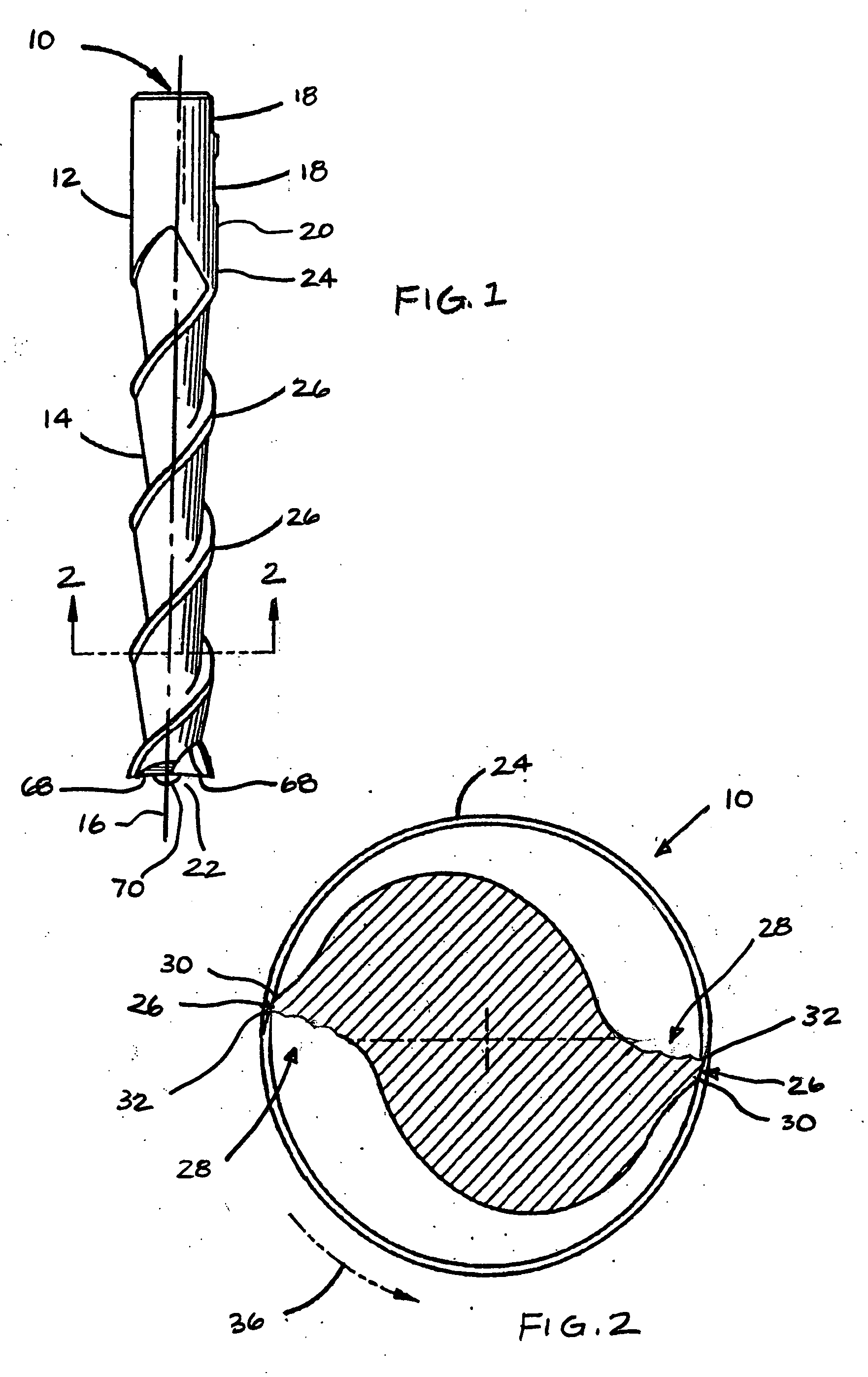

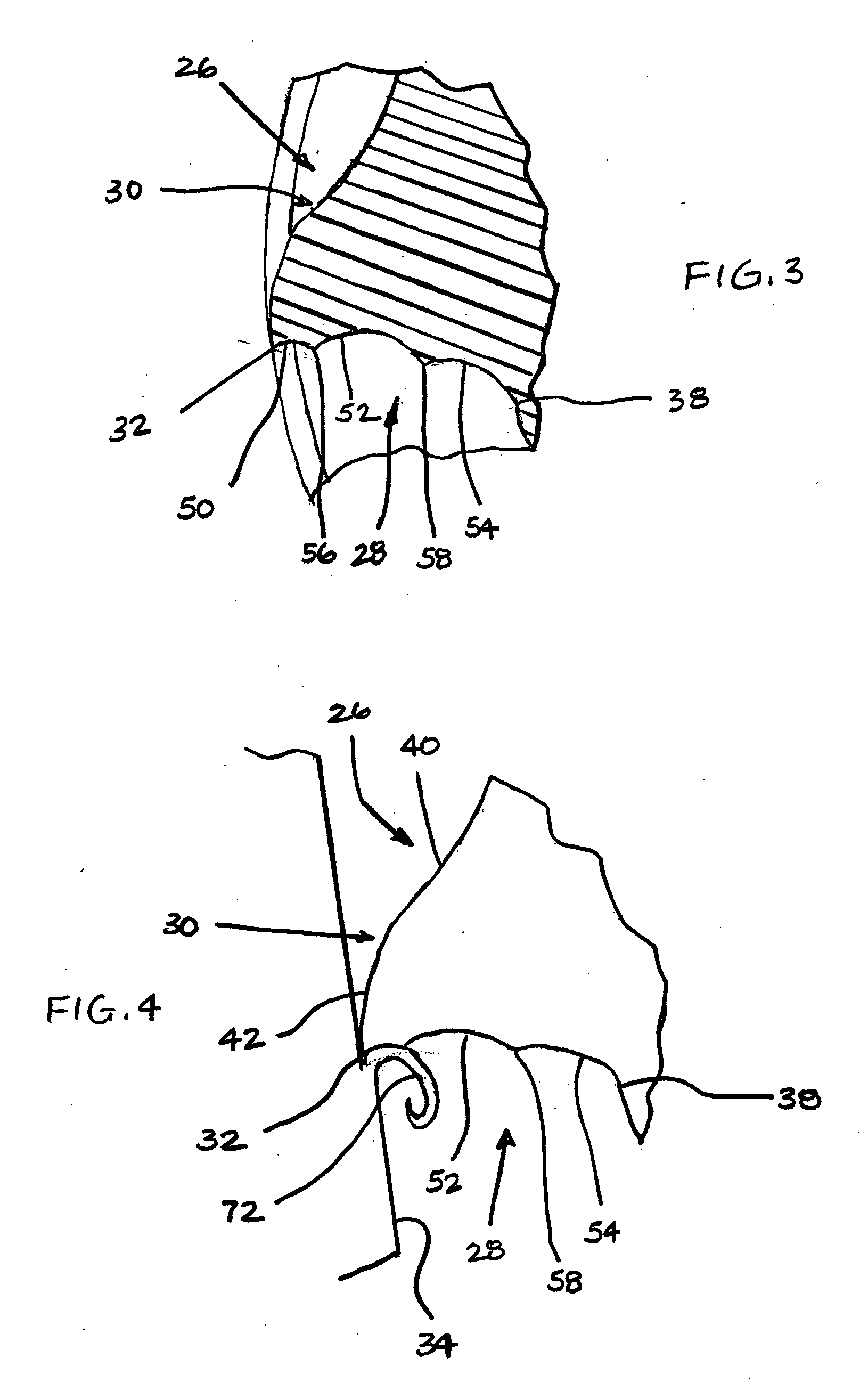

Helical flute end mill with multi-section cutting surface

A rotary cutting end mill is provided. The end mill includes a shank section and a fluted section. The fluted section has a first end integrally attached to the shank section, a second end, and an outer surface. One or more helical teeth are disposed along the outer surface of the fluted section. Each helical tooth has a cutting surface and a relief wall that intersect to form an angle defining a helical cutting edge. The helical cutting edge defines an outer circumferential cutting path. The cutting surface includes first, second, and third sections, and first and second take-off peaks. The first take-off peak is disposed between the first section and second section. The second take-off peak is disposed between the second section and the third section.

Owner:DAUPHIN PRECISION TOOL

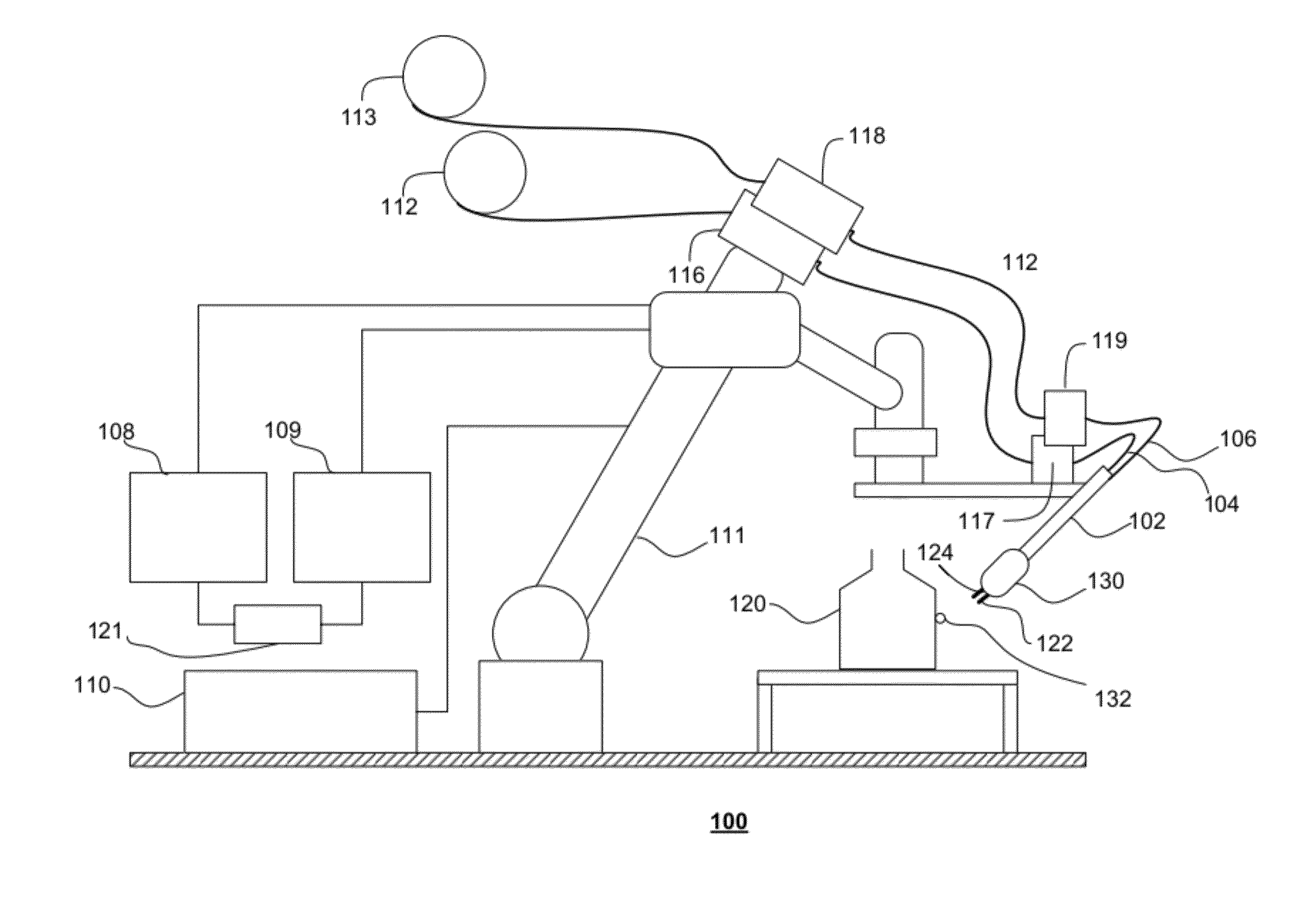

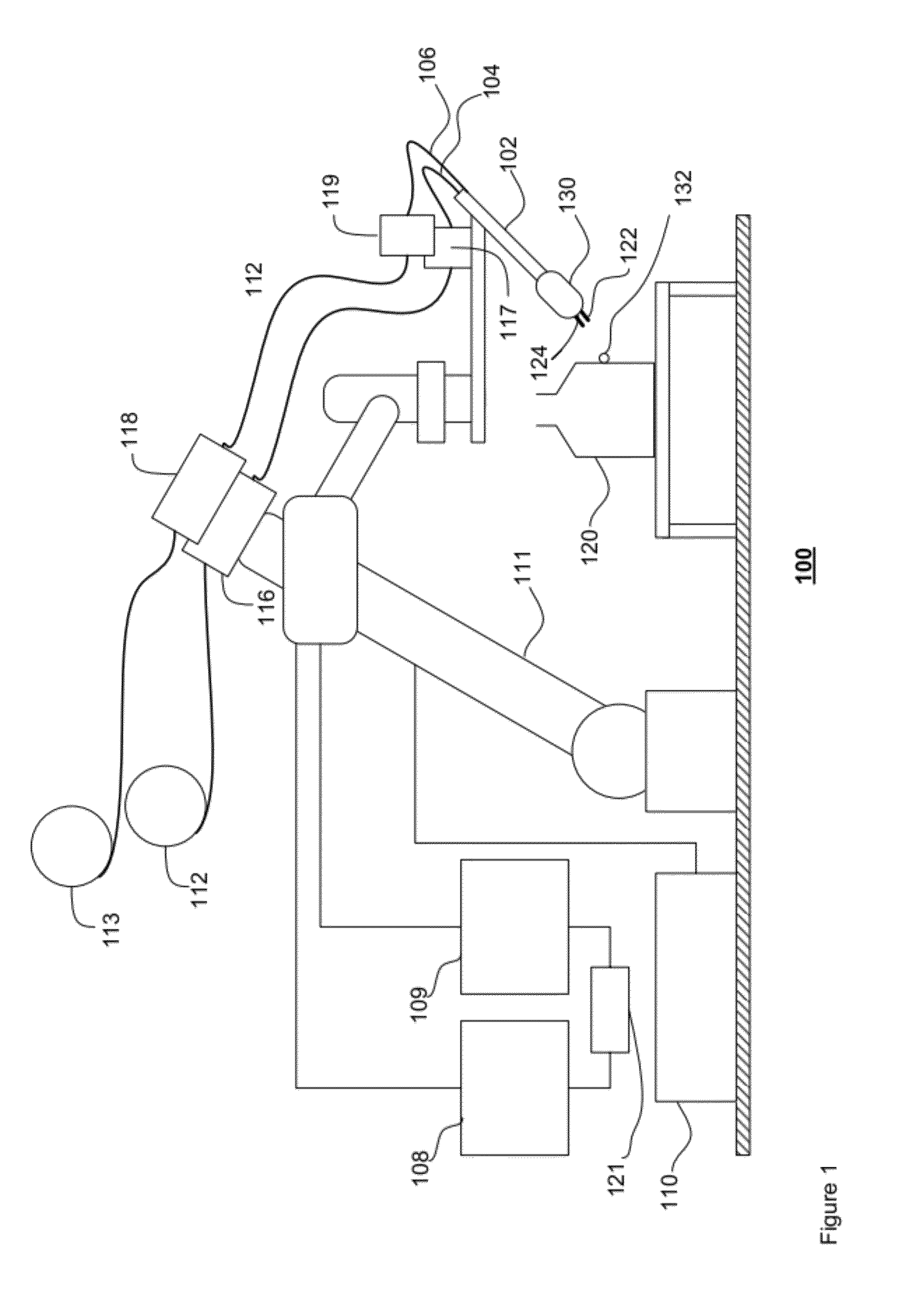

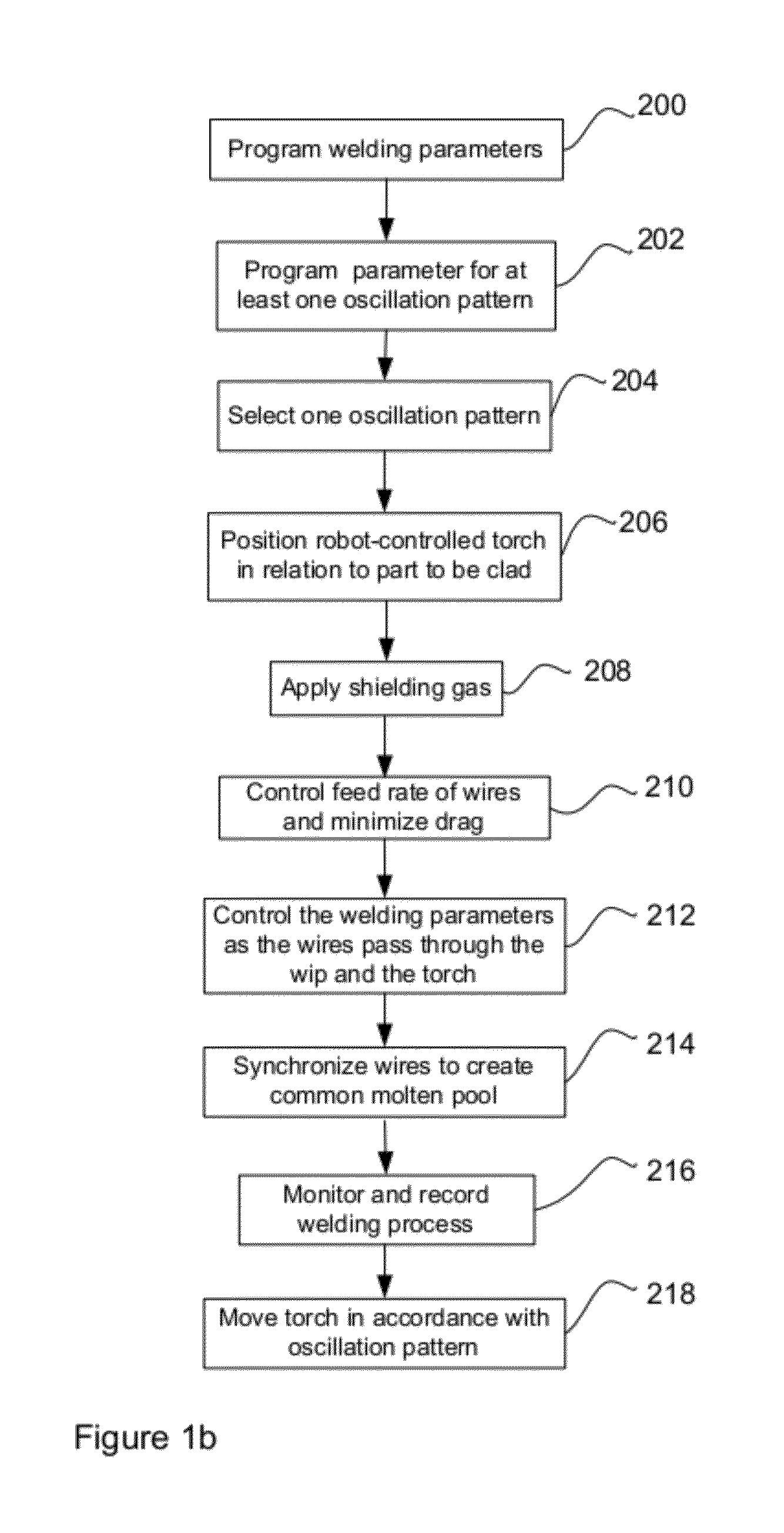

System and Method for High-Speed Robotic Cladding of Metals

A metal cladding process using an automated welding tool, the tool comprising at least one torch for receiving two weld wires to produce a molten pool on the metal, the process having the steps of providing a set of instructions in a non-transitory computer readable medium, the instructions executable by a processor to control the travel speed of the at least one torch; and control the oscillation pattern and frequency of the at least one torch, the oscillation pattern comprising a pause at each of a center position, a lateral left position and a lateral right position relative to a weld reference line.

Owner:TECHN & AUTOMATION HELP CORP

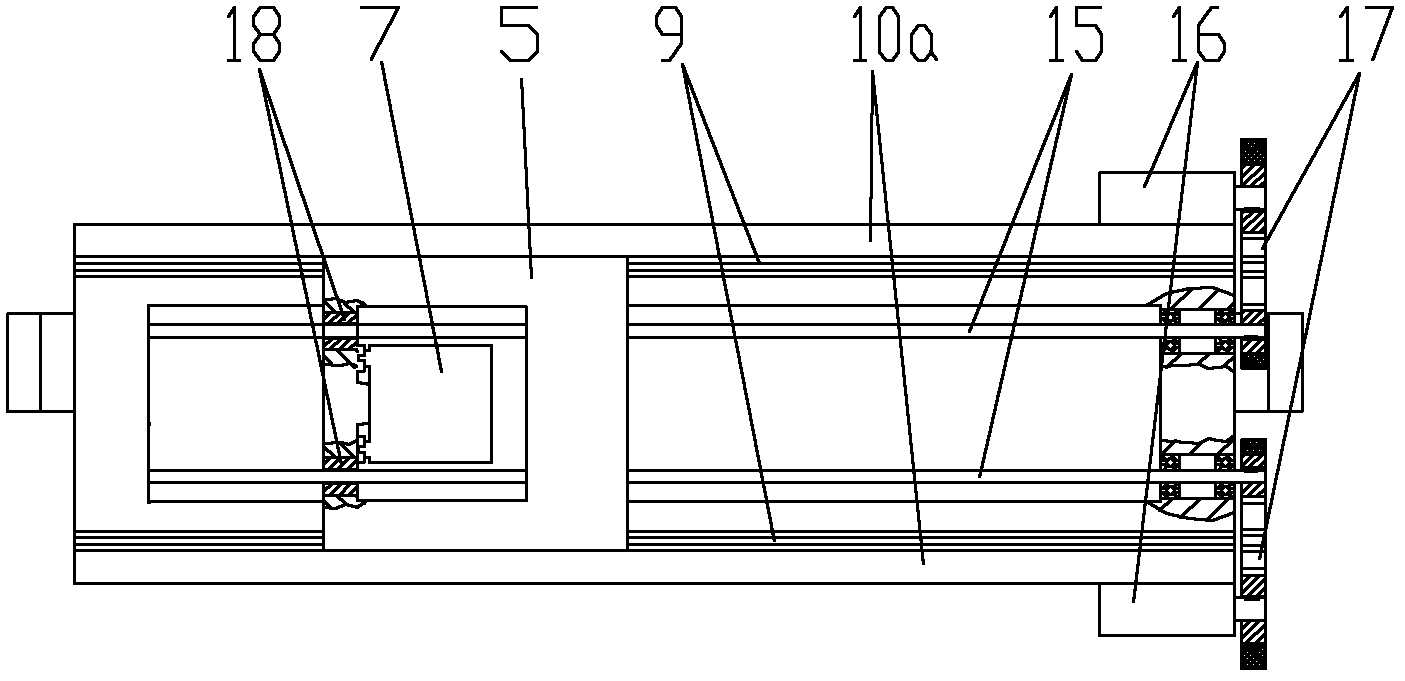

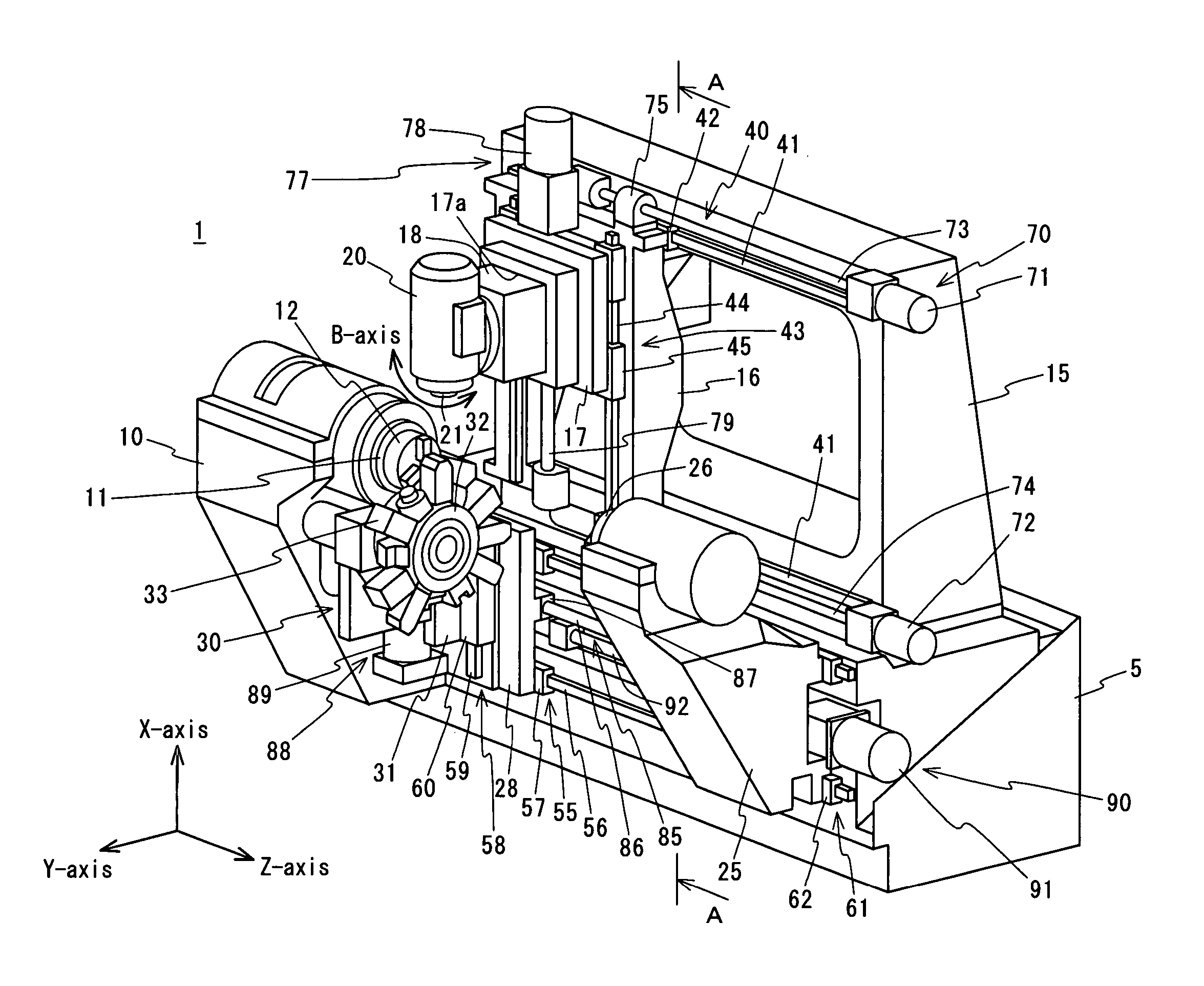

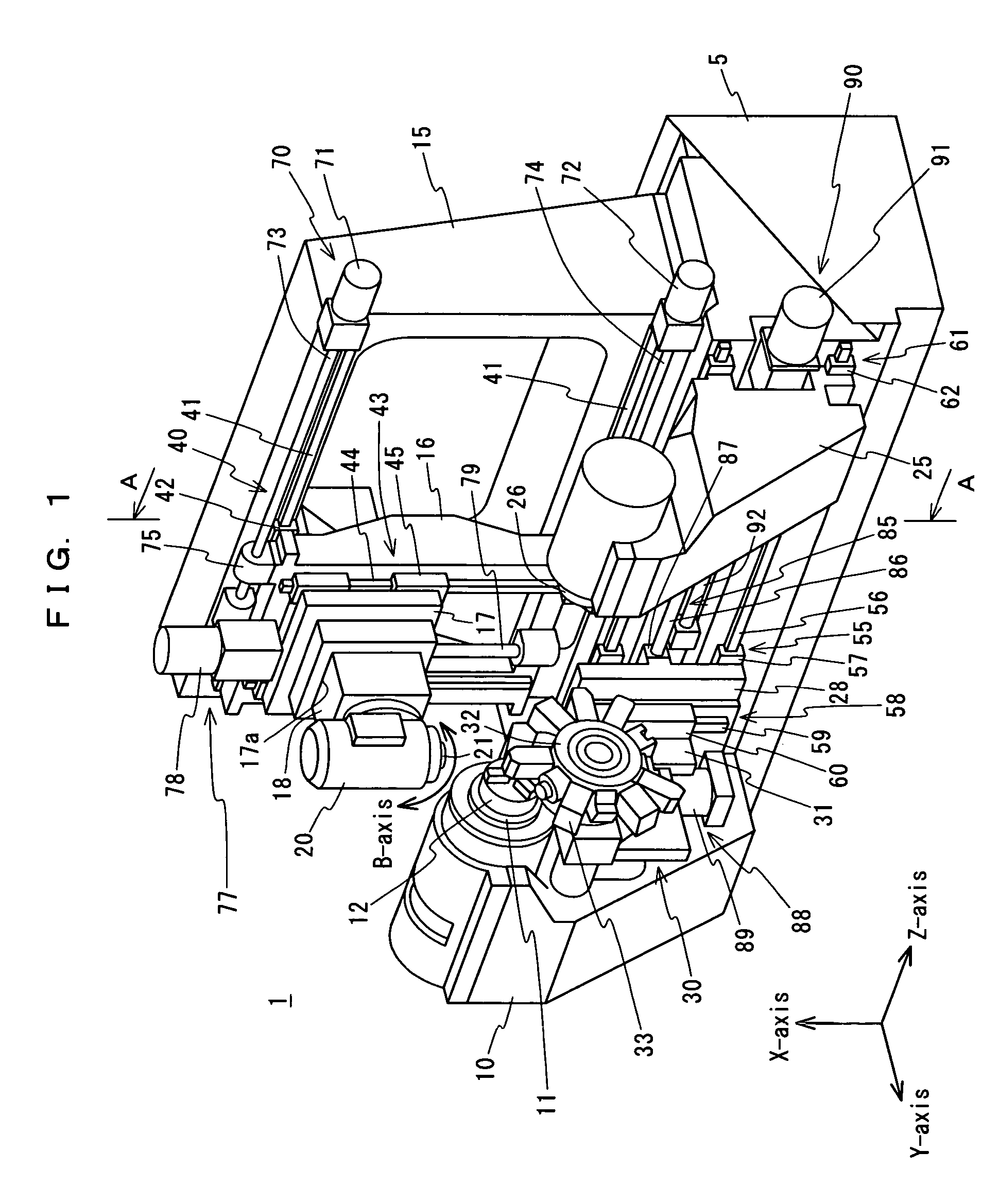

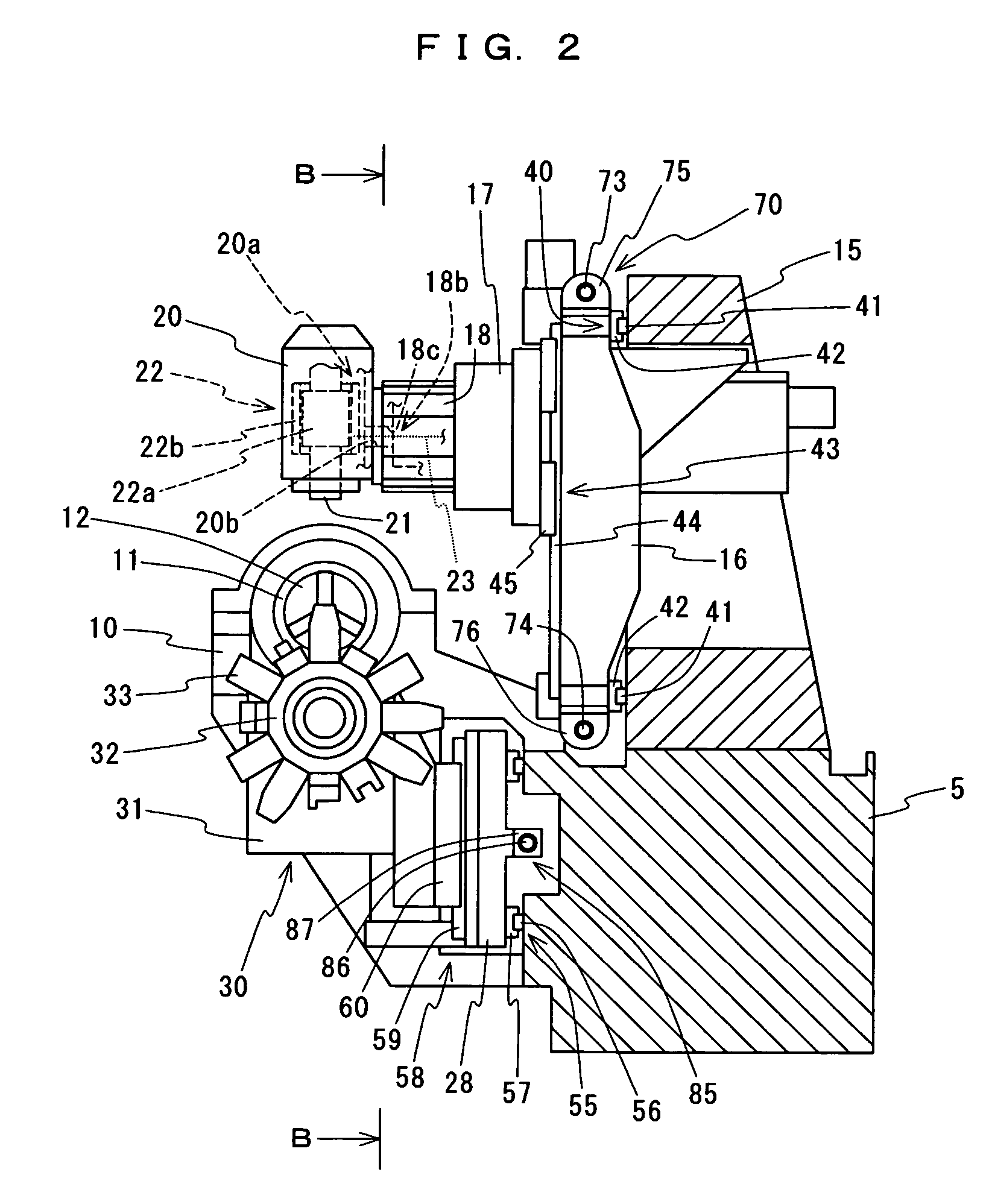

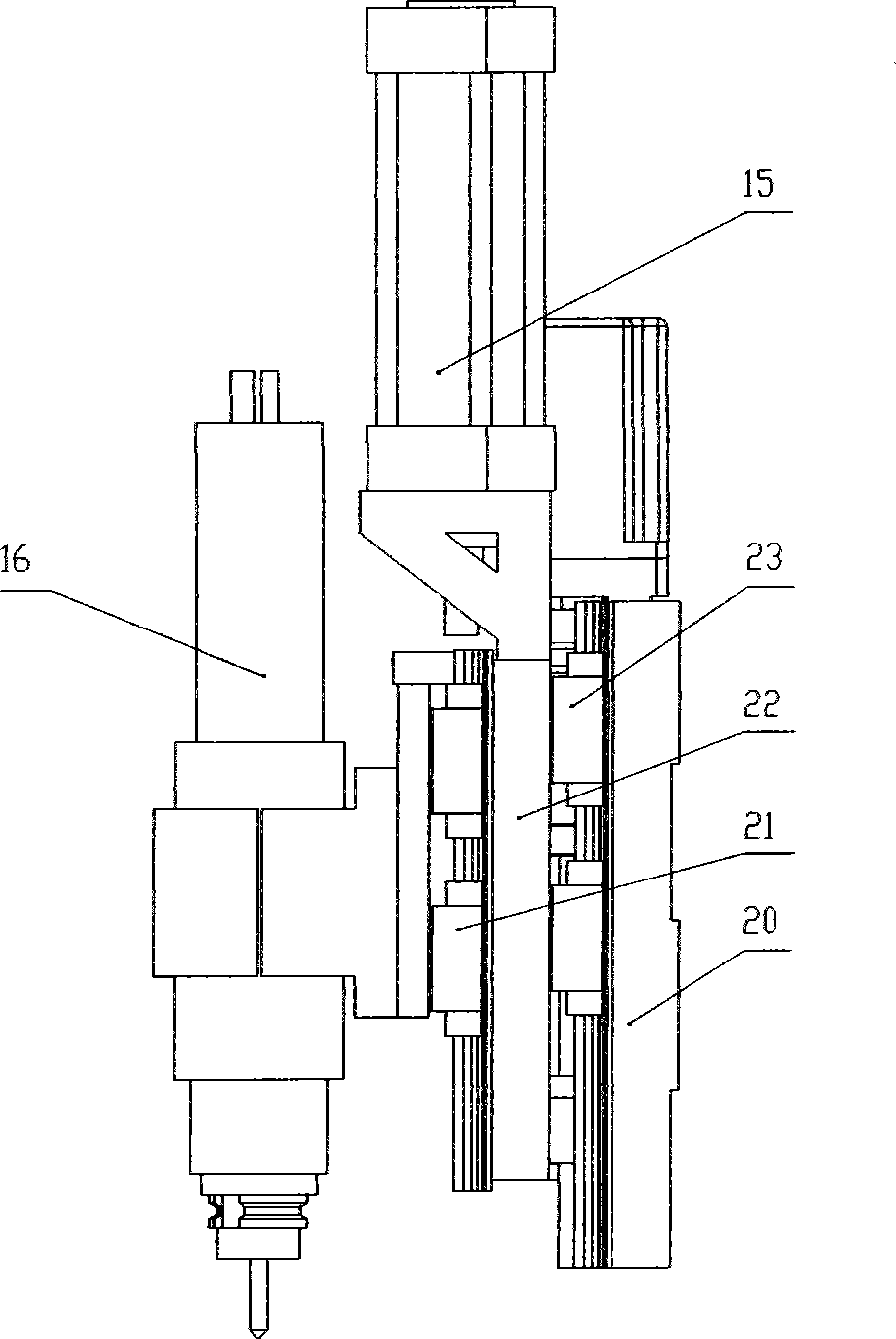

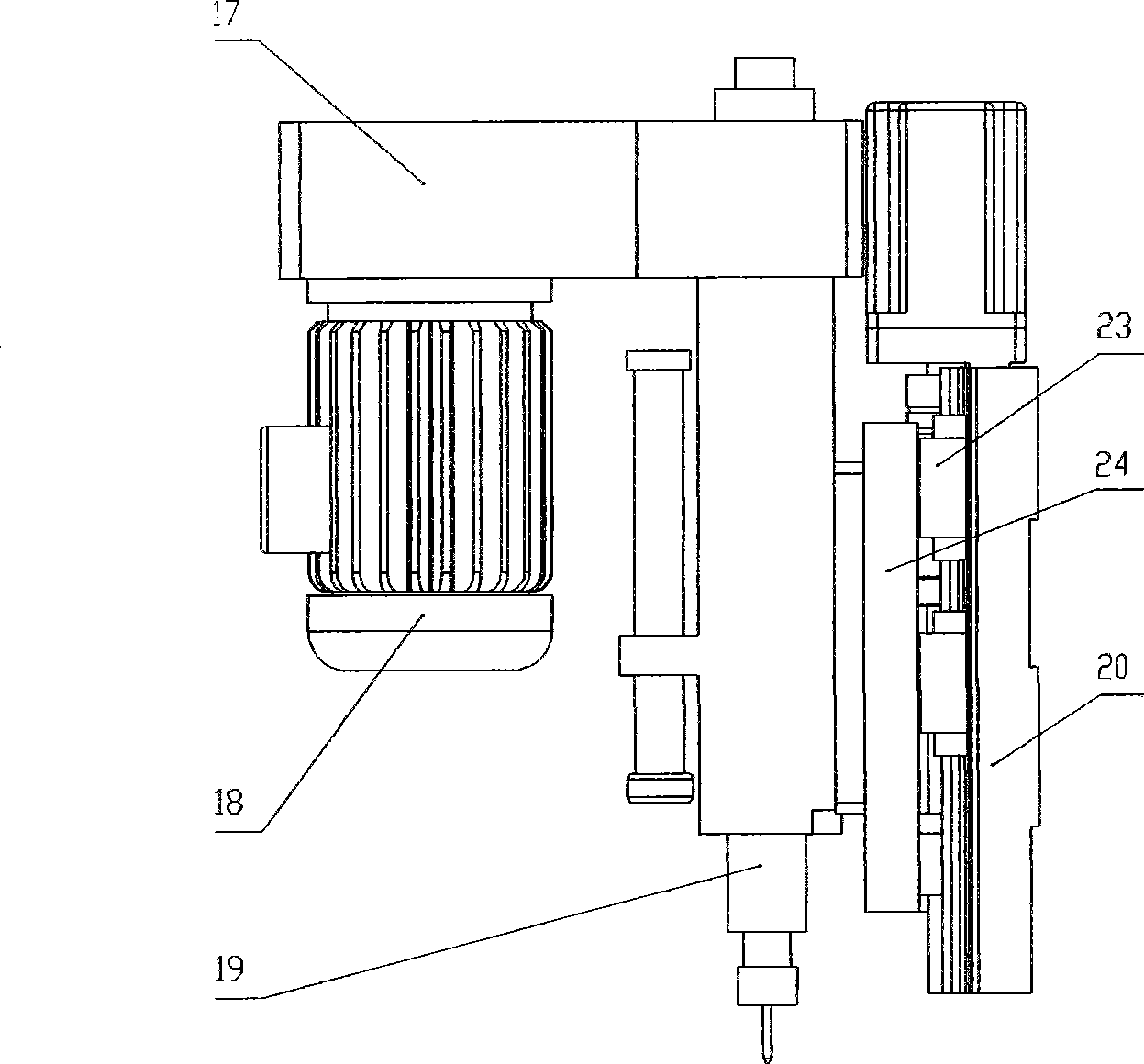

NC lathe

ActiveUS7043805B2Increase feed rateReduce impactAutomatic/semiautomatic turning machinesTurning toolsEngineering

An NC lathe 1 comprises a bed 5, a headstock 10 provided on the bed 5, a main spindle 11 supported on the headstock 10 so as to be rotatable around the axis thereof, a rotation drive device for rotating the main spindle 11, a stationary frame 15 formed in a rectangular frame shape and fixed to the upper face of the bed 5, a movable frame 16 formed in a rectangular frame shape and provided so as to be movable in the Z-axis direction with respect to the stationary frame 15, a saddle 17 provided so as to be movable in the X-axis direction with respect to the movable frame 16, a quill 18 accommodated inside the accommodation hole 17a in the saddle 17 and provided so as to be movable in the Y-axis direction, and a tool rest 20 supported on the quill 18.

Owner:DMG MORI CO LTD

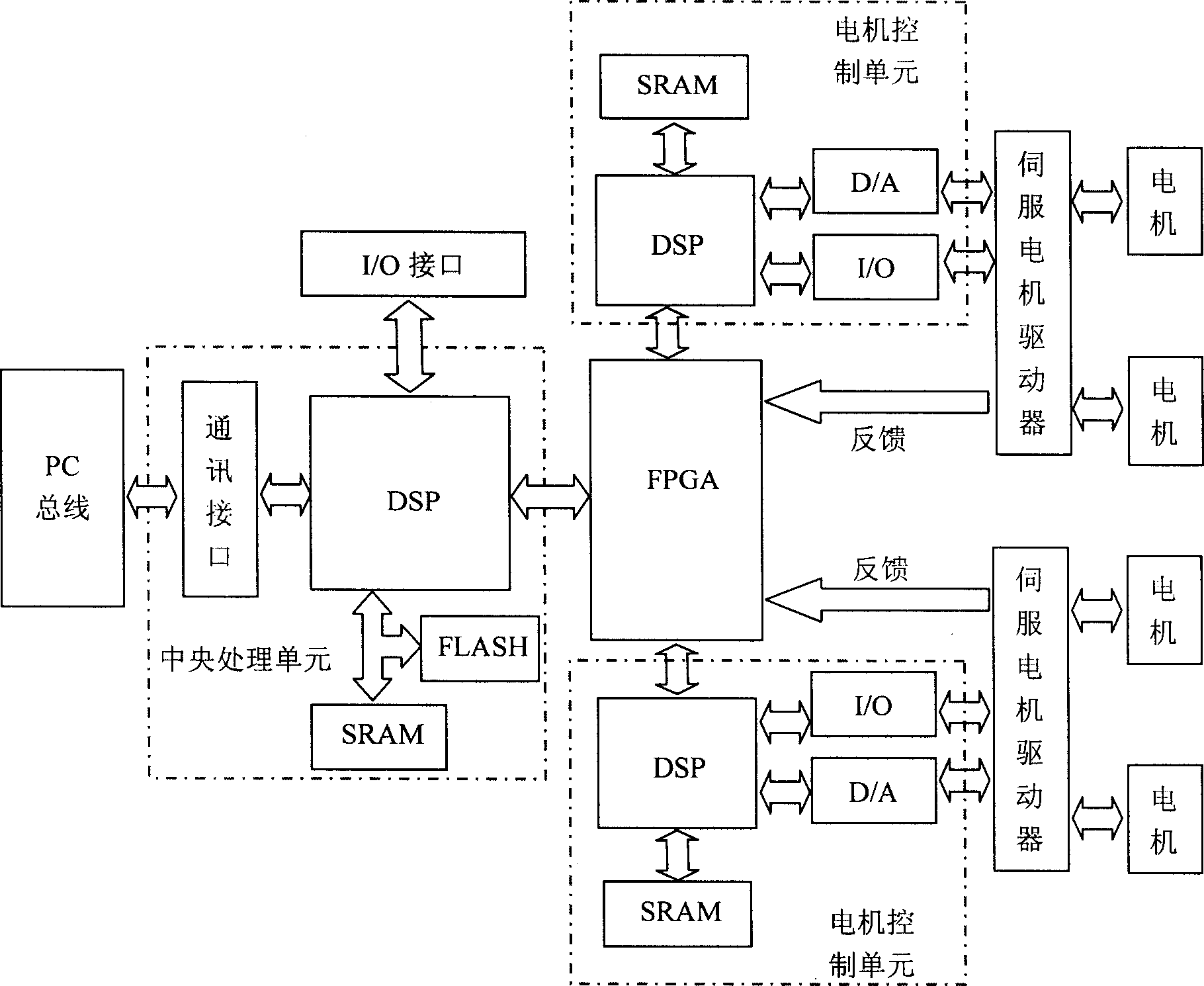

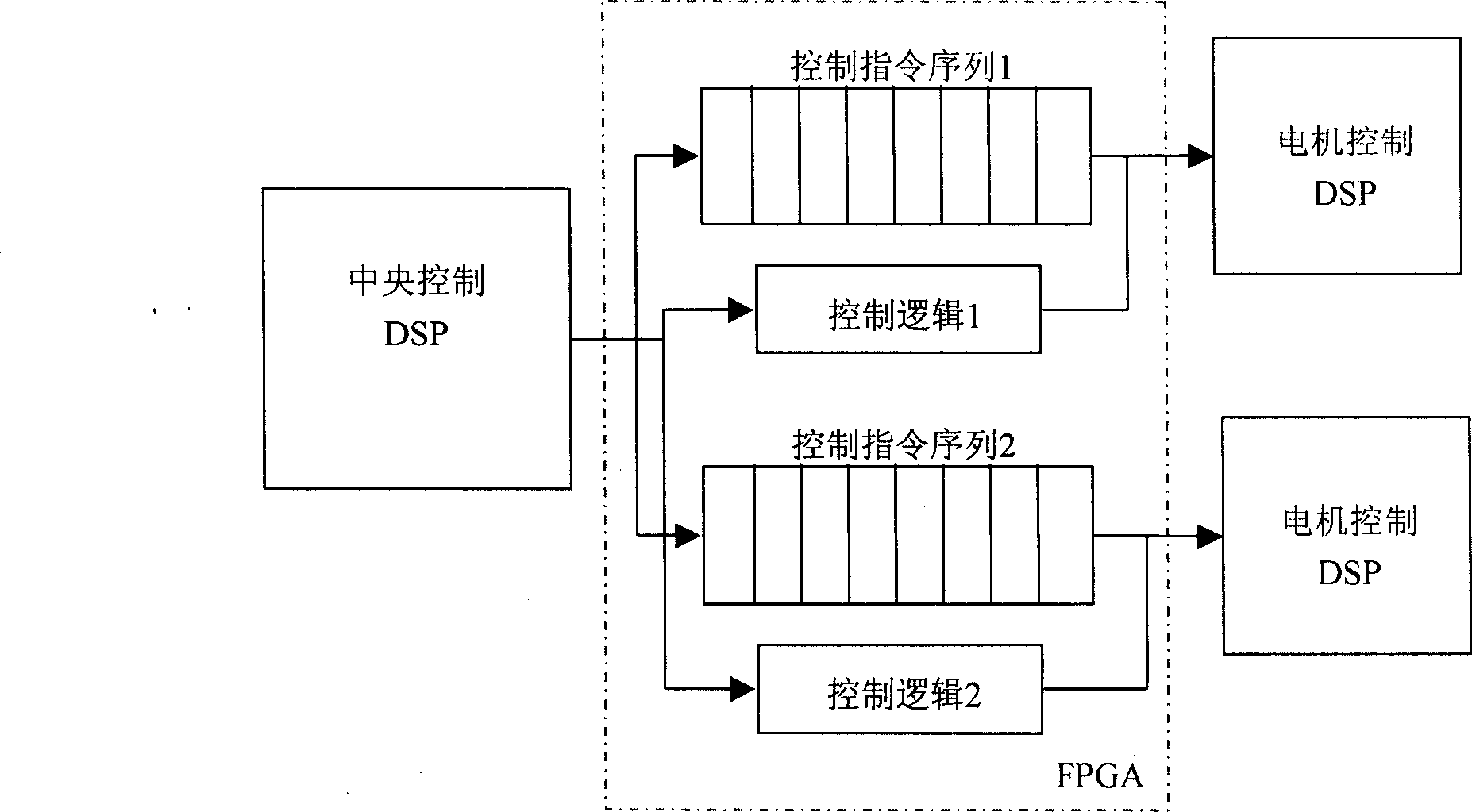

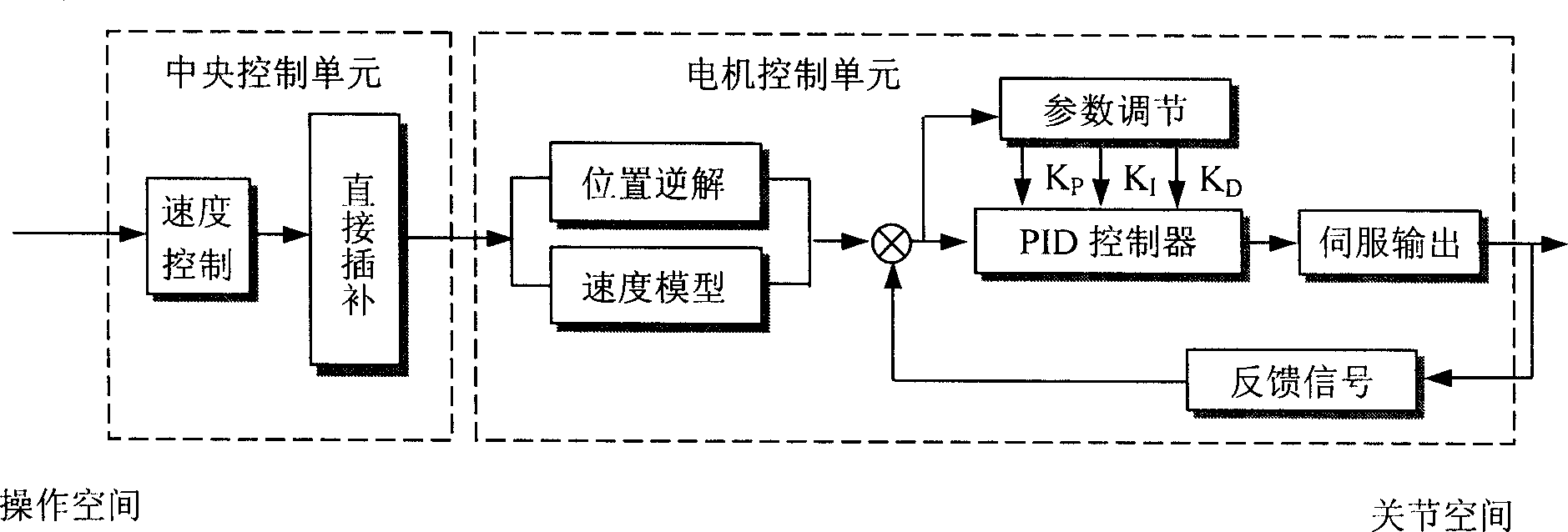

Parallel connection equipment opening type motion control card based on two-stage DSP and control method thereof

InactiveCN1808319ACalculation speedReduce data communication pressureProgramme-controlled manipulatorComputer controlEmbedded systemControl function

The invention discloses an open type movement control card based on two-stage DSP parallel device and the control method. The system employs the two-stage control structure with plural CPU parallel processing for separating the general control function and the specific control function of the motor; the control-class CPU as the core of the control card, controls and coordinates the entire system operation; employing programmable logic gate array FPGA to construct communication interface, connecting the control central-class processing unit and execute-class motor control unit with the FPGA chip, realizing high-speed transmission of data and synchronizing control of motor vial FPGA controlling FIFO and the synchronizing status signal. The control method includes central processing discrete control trace, resetting and taking velocity inversion with execute-class CPU, and PID controlling servo motor via changing parameter position.

Owner:TIANJIN UNIV

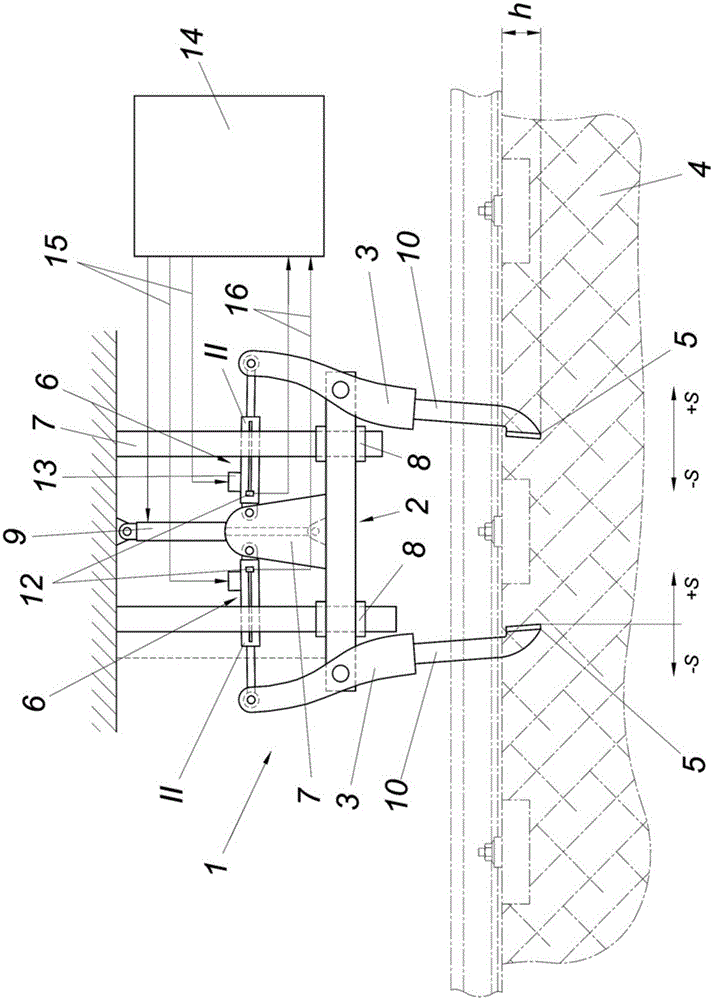

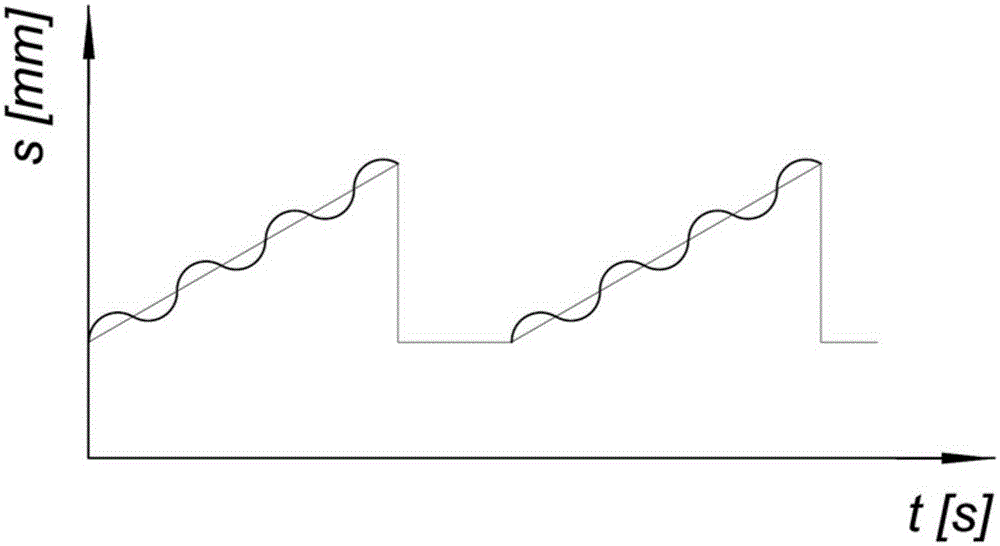

Tamping unit for a track tamping machine

InactiveCN105189868ASimple structureIncrease feed rateBallastwayHydraulic cylinderMechanical engineering

The invention relates to a tamping unit (1) for a track tamping machine, comprising tamping tool pairs, which are arranged on a support (2) that is guided in a tamping unit frame in a height-adjustable manner and which are designed as rocking levers. The lower tamping pick ends (5) of the tamping tool pairs, which lower tamping pick ends are intended to be plunged into a ballast bed (4), can be driven in opposite directions by means of an oscillating drive (6) and can be brought next to each other hydraulically. According to the invention a hydraulic cylinder (11) and a travel sensor (12) for determining the hydraulic cylinder position are associated with each of the tamping tools (3) of a tamping tool pair in order to increase the stability of the tamping unit, wherein the hydraulic cylinders (11) form the drive for bringing the lower tamping pick ends next to each other and the oscillating drive (6) of the tamping tools (3) and the hydraulic cylinders (11) are controlled in dependence on the travel sensor signals.

Owner:HP3 REAL GMBH

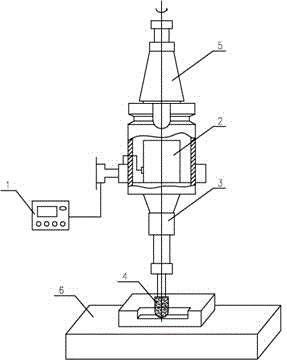

Carbon fiber composite rotary ultrasonic milling and grinding device and method

InactiveCN104647147AGuaranteed machining accuracyImprove surface qualityUltrasonic machiningGrinding

The invention discloses a carbon fiber composite rotary ultrasonic milling and grinding device and a carbon fiber composite rotary ultrasonic milling and grinding method. The carbon fiber composite rotary ultrasonic milling and grinding device comprises an ultrasonic generator, an ultrasonic transducer, an amplitude transformation pole, a tool, a tool handle and a machine tool body. The carbon fiber composite rotary ultrasonic milling and grinding method is achieved by using ultrasound to assist in milling and grinding so as to process non-ablating carbon / carbon composite materials. According to the carbon fiber composite rotary ultrasonic milling and grinding device and the carbon fiber composite rotary ultrasonic milling and grinding method, frequency of an ultrasonic power source used in the carbon fiber composite rotary ultrasonic milling and grinding method is consistent with inherent frequency of the amplitude transformation pole, and therefore the effect that vibration applied onto the amplitude transformation pole can cause resonance of the amplitude transformation pole is guaranteed; ultrasonic milling and grinding is adopted, and therefore surface quality of a carbon fiber composite work piece is obviously improved, and roughness of the carbon fiber composite work piece is reduced by about 16%-36%; ultrasonic machining is adopted, and therefore stress in the feed direction of a grinding head is reduced by about 44%, and stress in the downward pressing direction of the grinding head is reduced by about 46%; ultrasonic processing temperature rise is reduced by 29% from comparison between ultrasonic milling and grinding temperature and traditional milling and grinding cutting temperature of a carbon fiber composite.

Owner:DALIAN KANGSAIPU TECH DEV

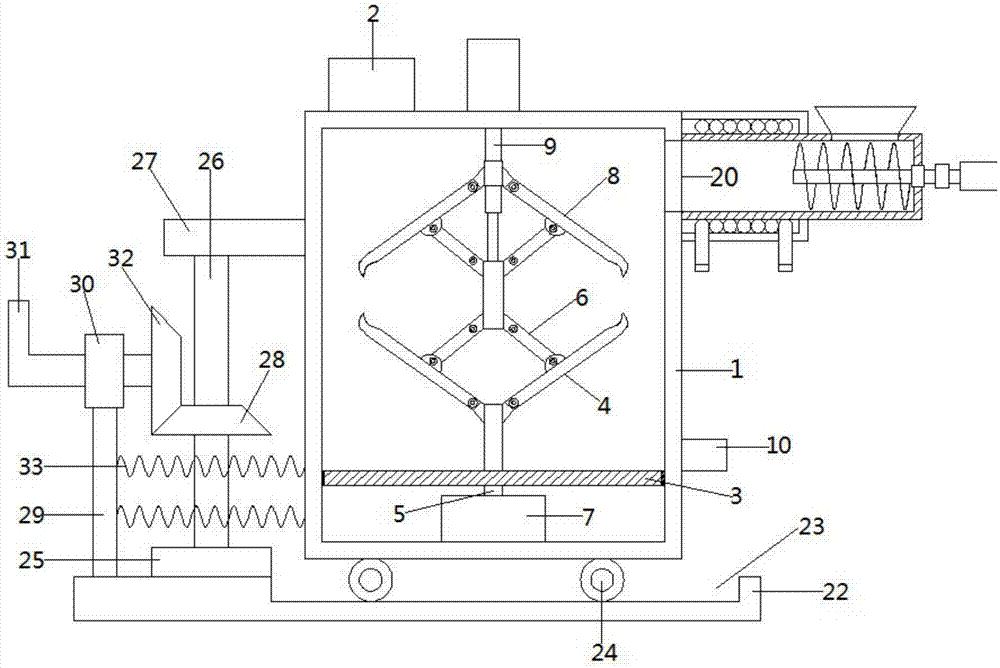

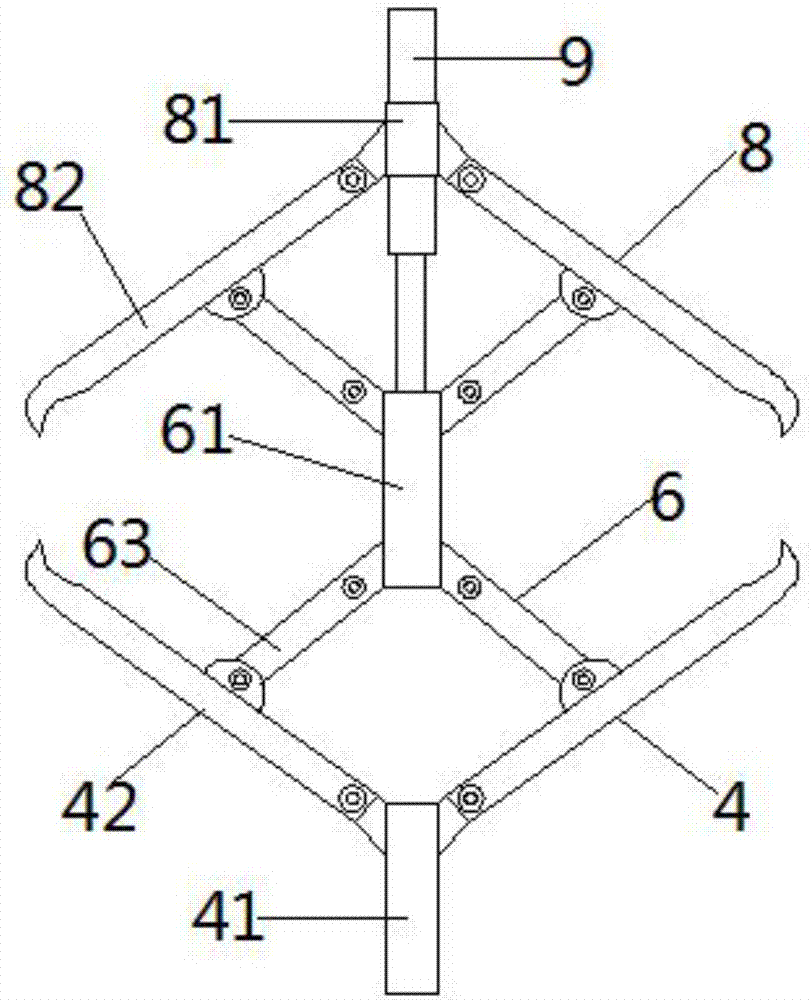

Liquid mixing device capable of rapidly mixing materials

InactiveCN107349852AExtended range of mixingChange fixed mixShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringDrive motor

Owner:林红英

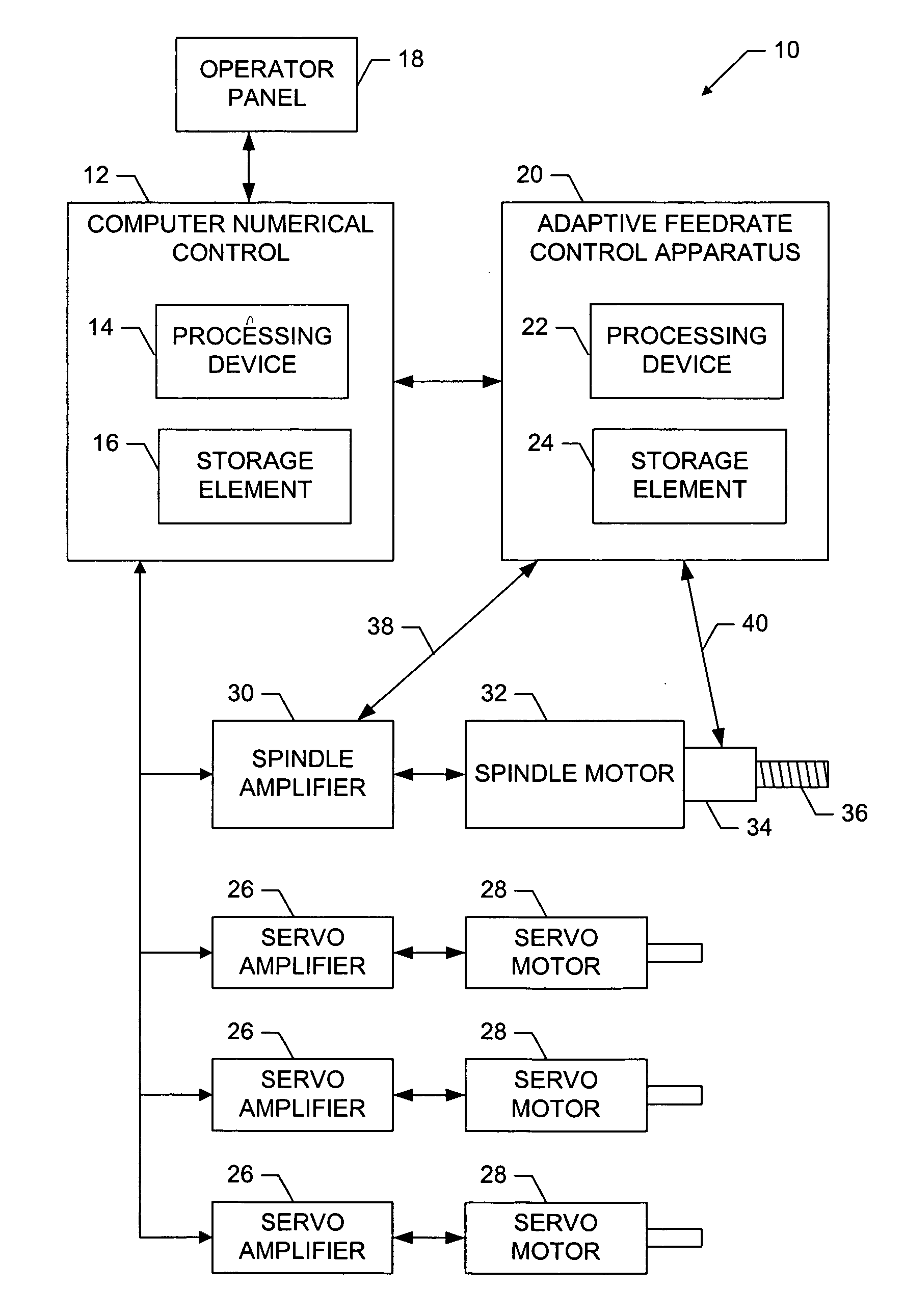

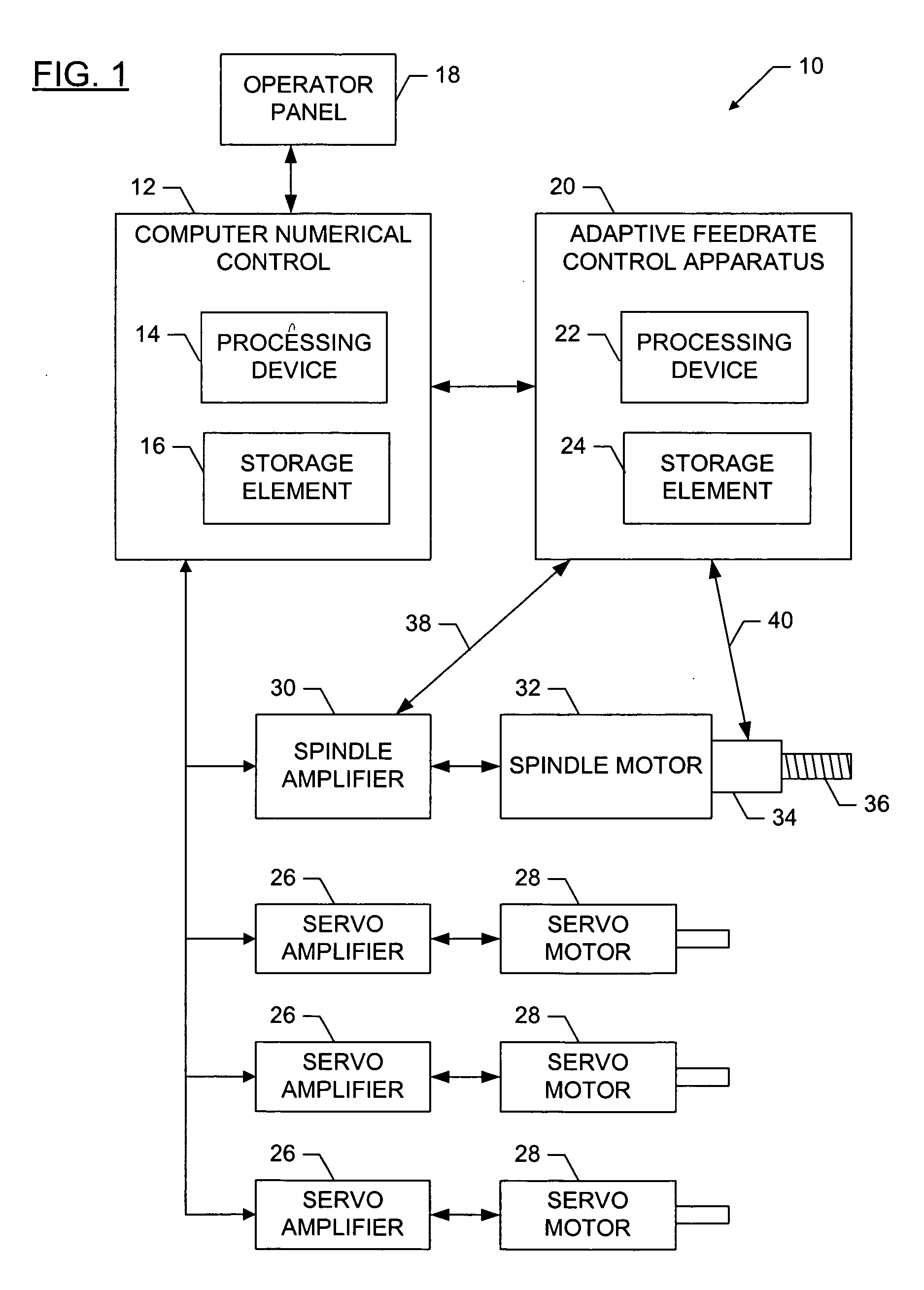

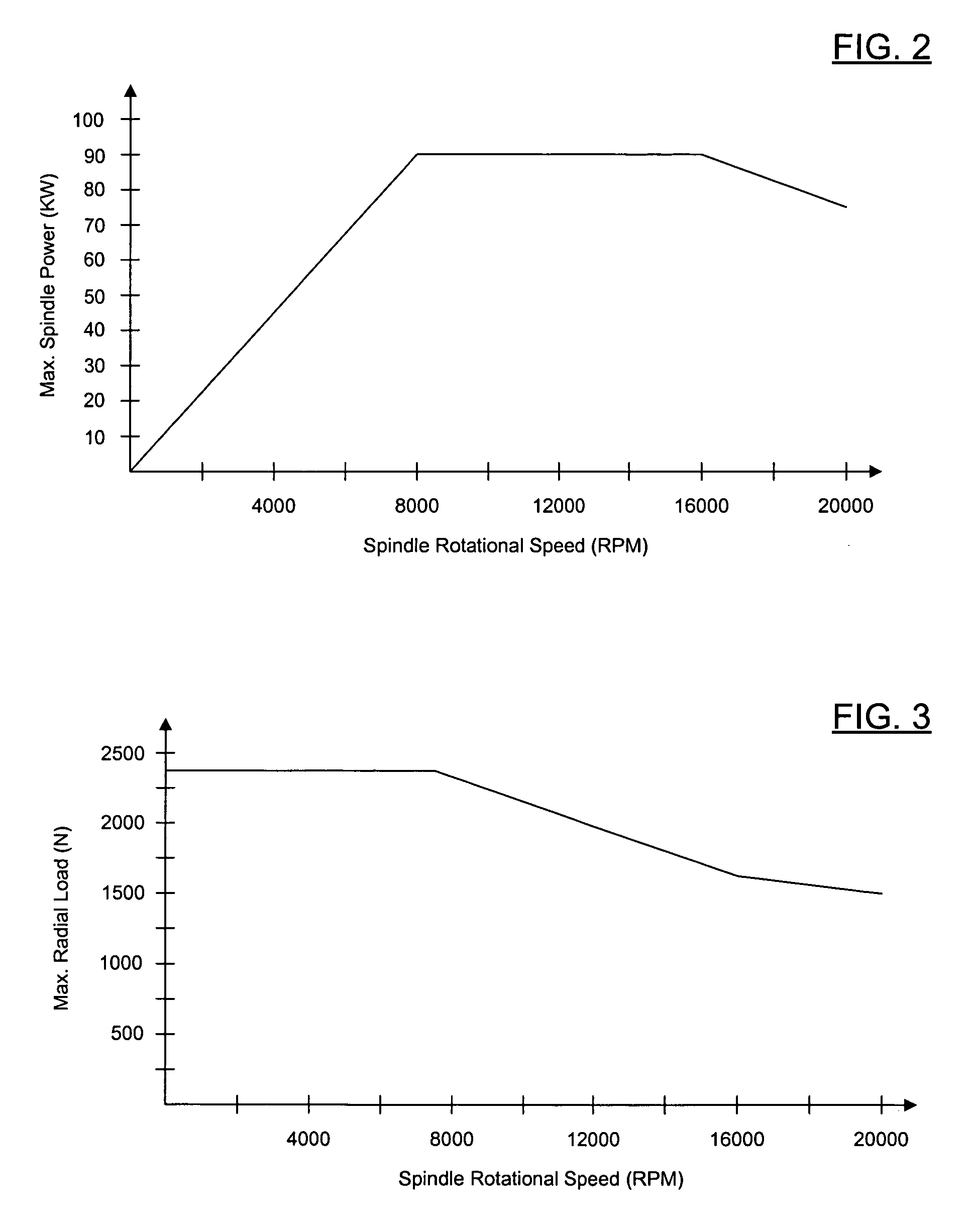

Apparatus for machine tool feedrate override using limiting parameters corresponding to actual spindle speed

ActiveUS20070046238A1Reduce feedrateIncrease feedrateComputer controlSimulator controlSelf adaptiveElectrical and Electronics engineering

An apparatus, machine tool, and method for adaptively controlling a feedrate of a machine tool are provided in which a plurality of maximum spindle power and / or radial load values, each corresponding to a spindle rotational speed, are received, stored and applied. Additionally, the current spindle power and / or the current radial load, along with the current spindle rotational speed may be received. The current spindle power and / or the current radial load may be compared to the maximum spindle power and / or radial load corresponding to the current spindle rotational speed, such that the feedrate may be reduced if the current spindle power and / or the current radial load exceed the corresponding maximum spindle power and / or radial load for the current spindle rotational speed or increased if the current spindle power and the current radial load are below the corresponding maximum spindle power and / or radial load for the current spindle rotational speed.

Owner:THE BOEING CO

Composite cermet and its preparing process

A composite cermet contains Ti (25-30), C (6-8.5), Ni (25-40), Mo (12-20), N (2-3), W (5-10) and Cr (0.4-1), and it prepared through mixing powdered Ti, C, Ni and Mo, Mechanically alloying under protection of argon to prepare nano TiCx and NiMo sosoloid mixture, mixing with TiN, WC, CR2C2 and C powder, adding shaping agent, die pressing, high-vacuum degreasing, high-vacuum sintering and isostatic pressing at 100-150 MPa and 1350-1400 deg.C. It has high hardness and bending strength, and can be used for cutting tools and dies.

Owner:HUAZHONG UNIV OF SCI & TECH

Silica sols with controlled minimum particle size and preparation thereof

InactiveUS20070034116A1Increase feed rateInhibition of nucleationPigmenting treatmentSilicaColloidal silicaSilica particle

Colloidal silica having an increased particle size and narrow particle size distribution is disclosed. A method for continuously producing the desired colloidal composition is disclosed comprising the steps of providing preformed silica particles having a surface area which controls the particle size of the colloidal silica product, adding a feed silica comprising an alkaline solution and silicate at a feed rate which is less than a nucleation rate, and increasing the feed rate as the feed silica is added wherein the feed rate is less than the nucleation rate.

Owner:NALCO CO

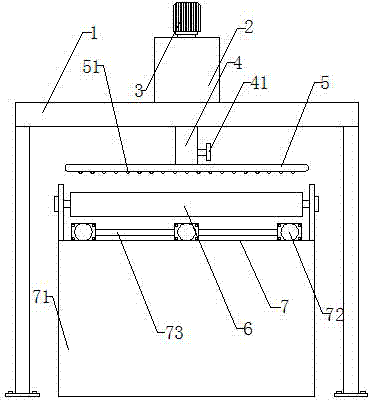

Small-sized gantry double-main shaft numerical control machine for drilling, milling and tapping

InactiveCN101502932AIncrease feed rateHigh positioning accuracyOther manufacturing equipments/toolsPositioning apparatusElectricityNumerical control

The invention relates to a small gantry dual-spindle drilling milling tapping numerical control machine. The small two-axis gantry drilling tapping digital control machine essentially solves the technical problem of providing a drilling milling tapping machine with low cost and high efficiency for the light metal hardware processing of the communication and the consumption electronic industry, and the machine has the advantages of simple structure and stable and reliable operation. The technical proposals for solving this problem is as follows: a frame structure support welded with channel steel, a diamond-shaped rib square structure soleplate and a gantry beam are adopted; a sliding plate of the beam is equipped with dual spindles, and the dual spindles are respectively a high-speed drilling milling head spindle and a high-speed tapping head spindle. The drilling milling head spindle uses a high-speed knife replaceable electric spindle; the tapping head spindle uses a self-invented mechanical tapping spindle able to carry out the screw distance selection automatically. The drilling milling head spindle can install the tool magazine on the rear, left and right positions of the machine; the tool magazine uses row-type tool magazine, inverted bamboo hat style tool magazine or row-type tool magazine and the arbitrary combination methods of inverted bamboo hat tool magazine.

Owner:深圳市康铖机械设备有限公司

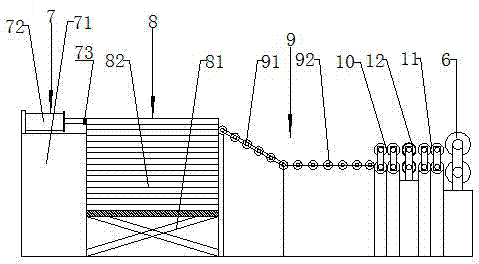

Layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials

ActiveCN104708689AFast processingSpread evenlyOther plywood/veneer working apparatusAdhesive application devicesProduction lineEngineering

The invention discloses layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials. The layer-by-layer automatic feeding, marking and gluing integrated equipment for the sheet materials comprises a marking device and a gluing device; the gluing device is arranged on one side of the marking device and a layer-by-layer automatic feeding device is arranged on the other side of the marking device; the layer-by-layer automatic feeding device comprises a pushing mechanism, a hoisting mechanism and a sliding mechanism in sequence; and the gluing device comprises a supporting framework, a stirring mechanism arranged at the upper end of the supporting framework, a material scattering mechanism arranged at the bottom of a transverse beam of the supporting framework, and a compression roller gluing mechanism arranged under the supporting framework. According to the layer-by-layer automatic feeding, marking and gluing integrated equipment, marking and gluing are integrated, transmission and interruption of machines are reduced in the process and the consistency of a production line is improved; and the machining time of the whole sheet material is shortened, materials can be automatically fed layer by layer, the transmission is buffered, the gluing can be automatically realized and the gluing is uniform.

Owner:JIANGSU KENTIER WOOD

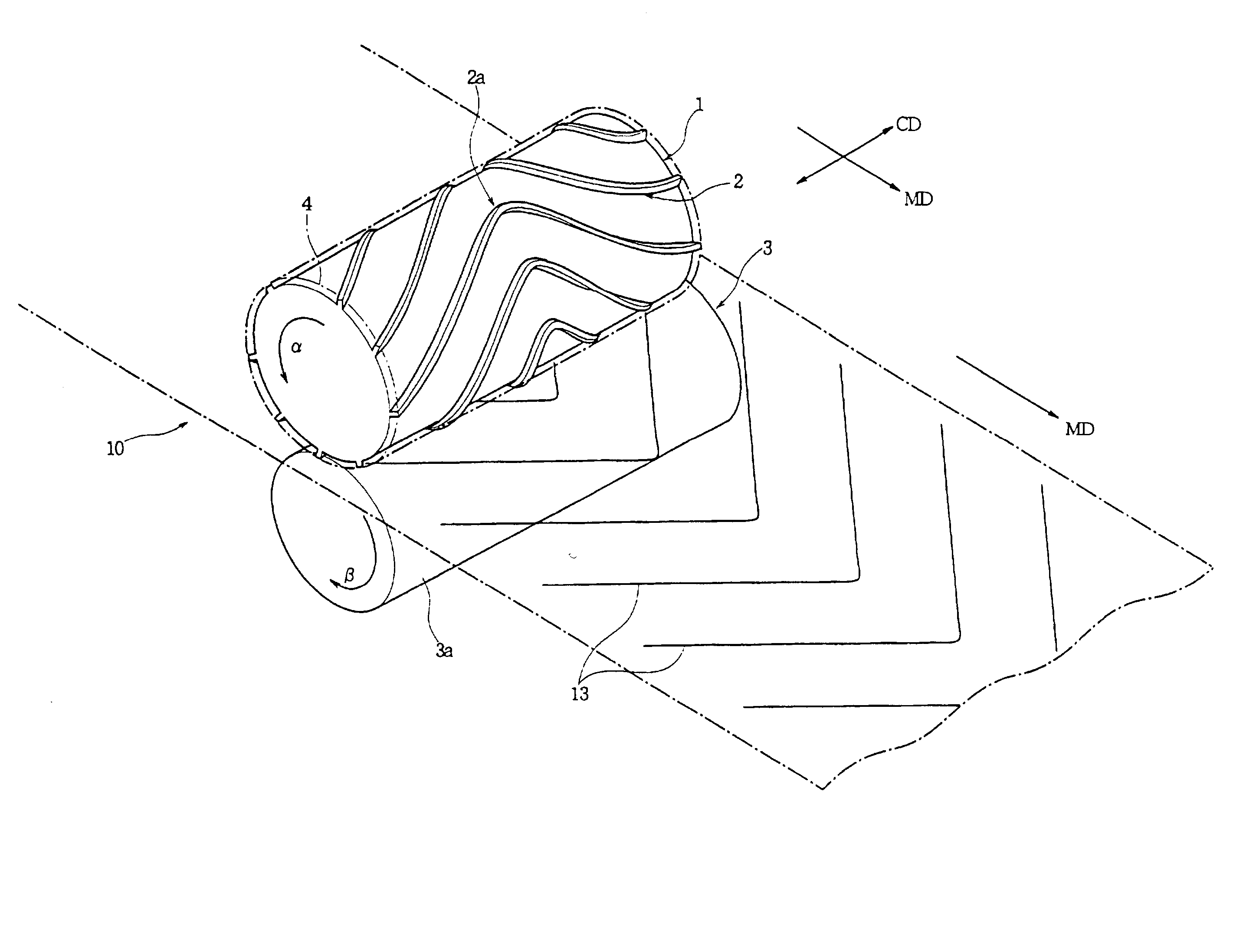

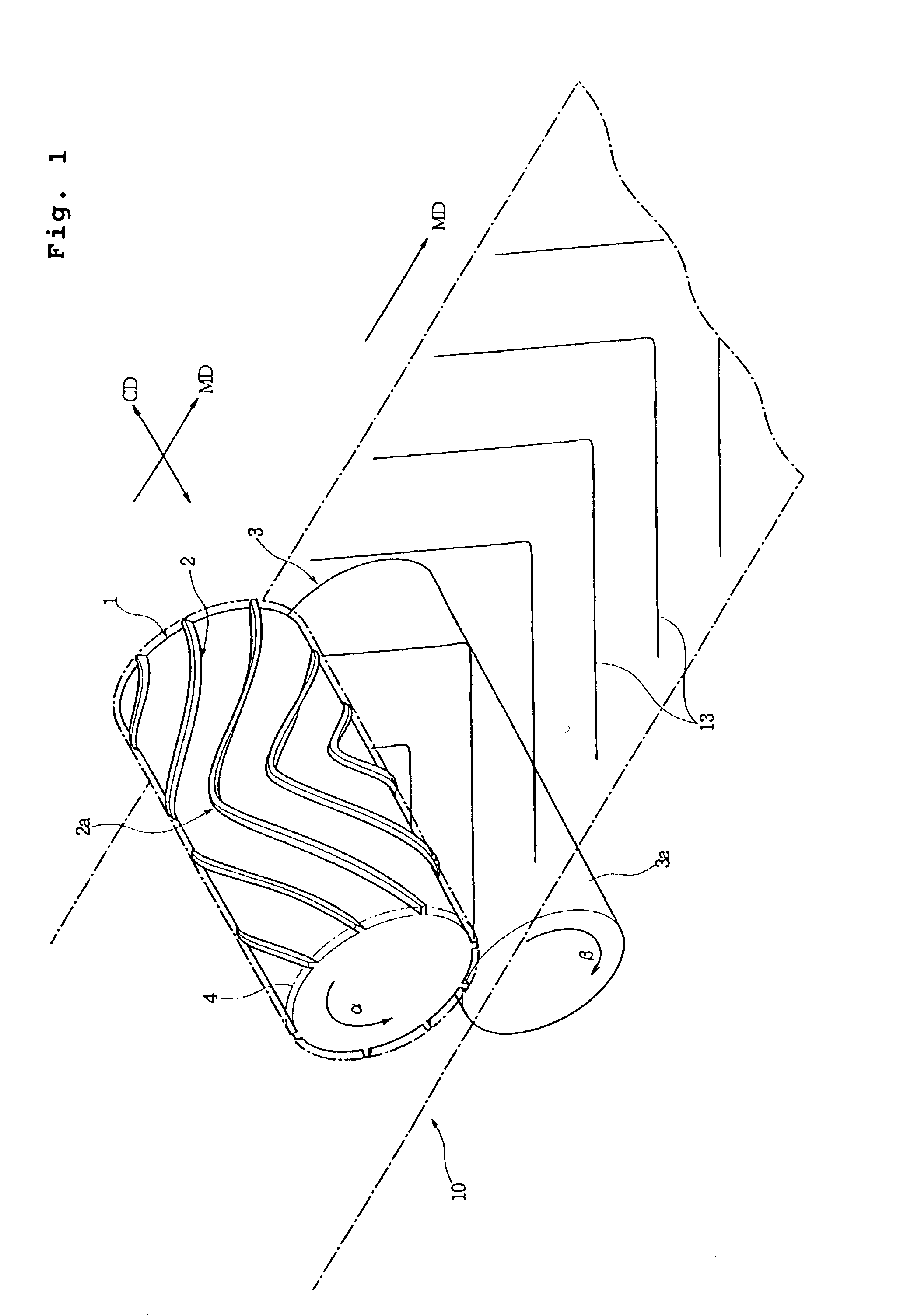

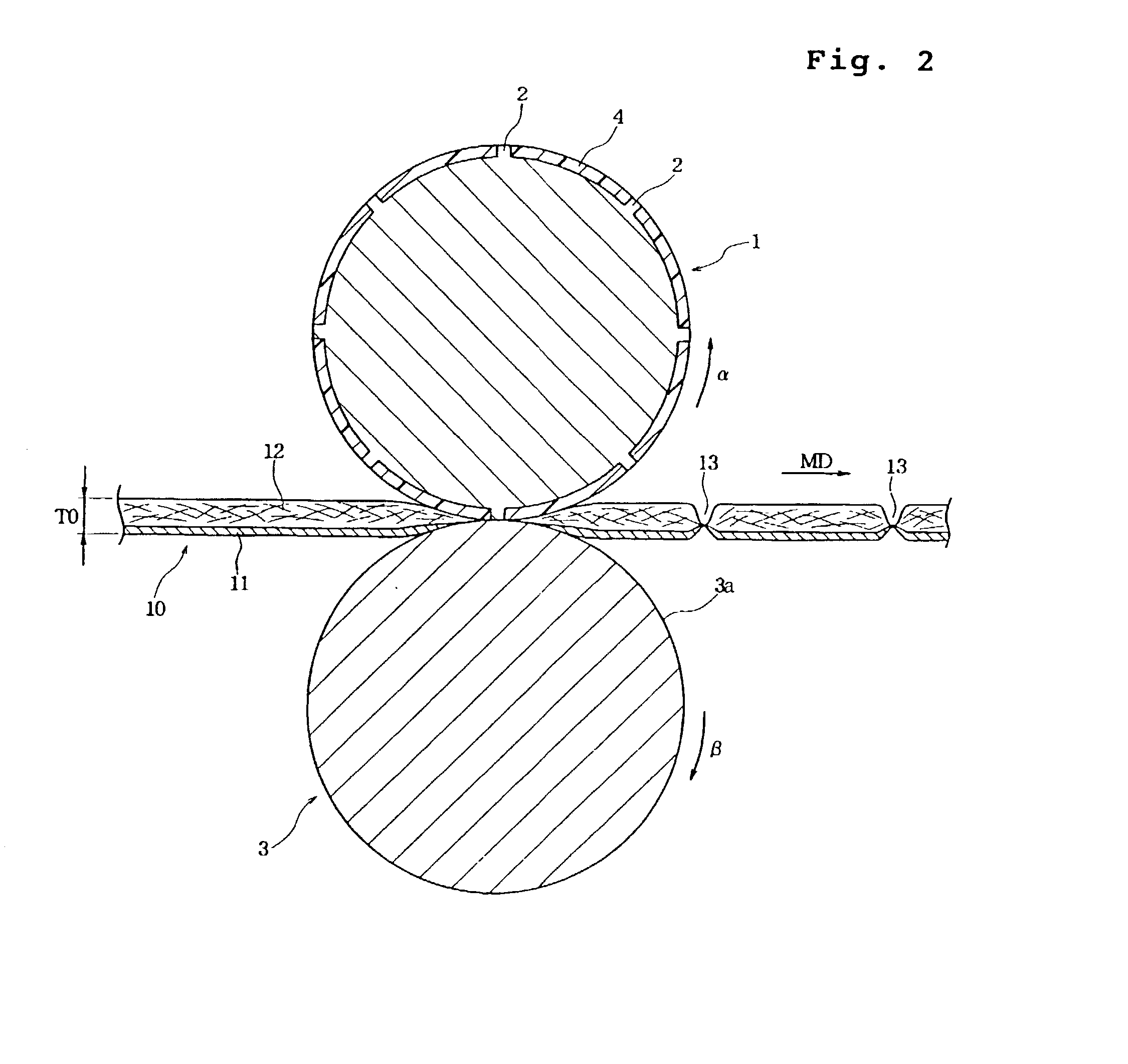

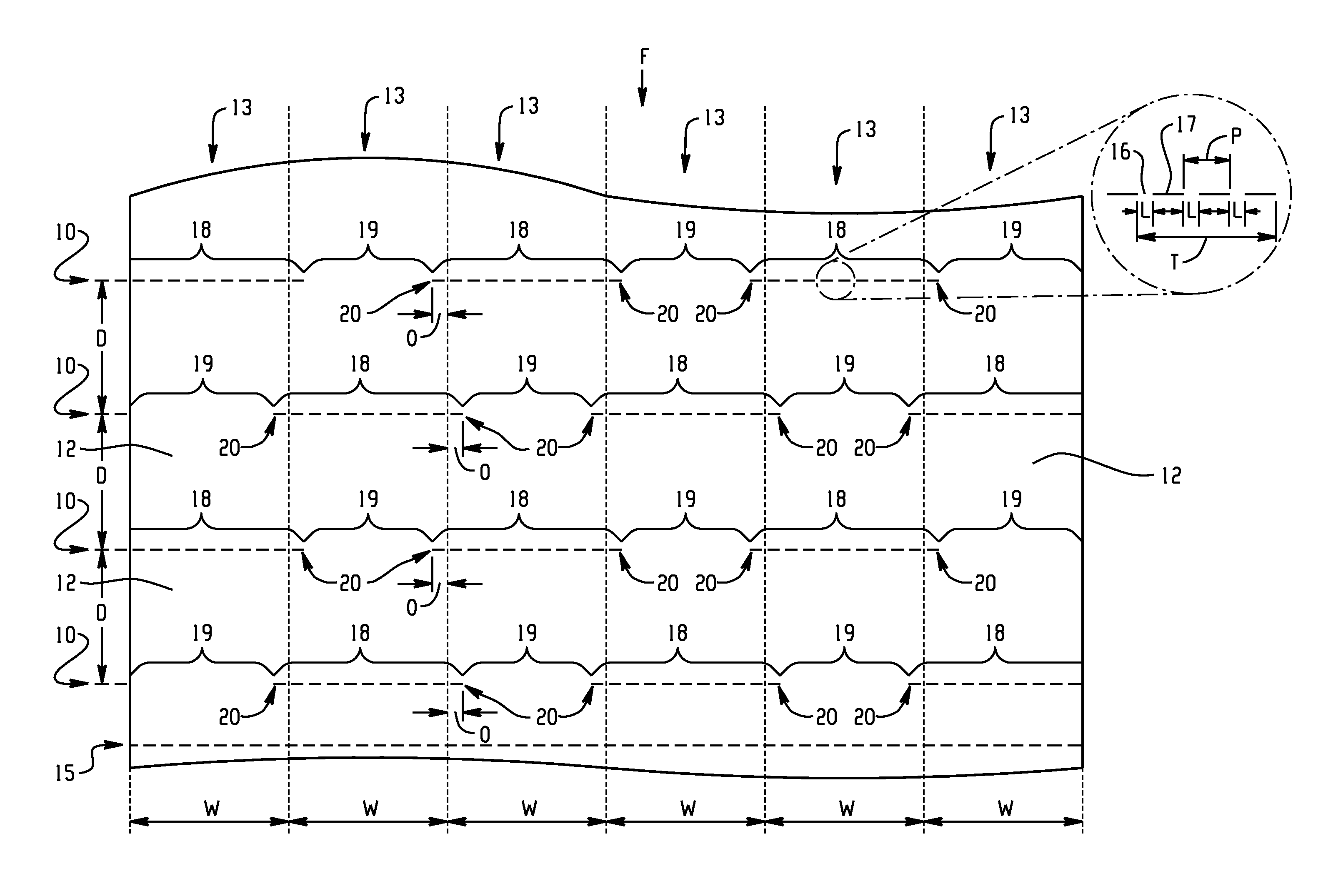

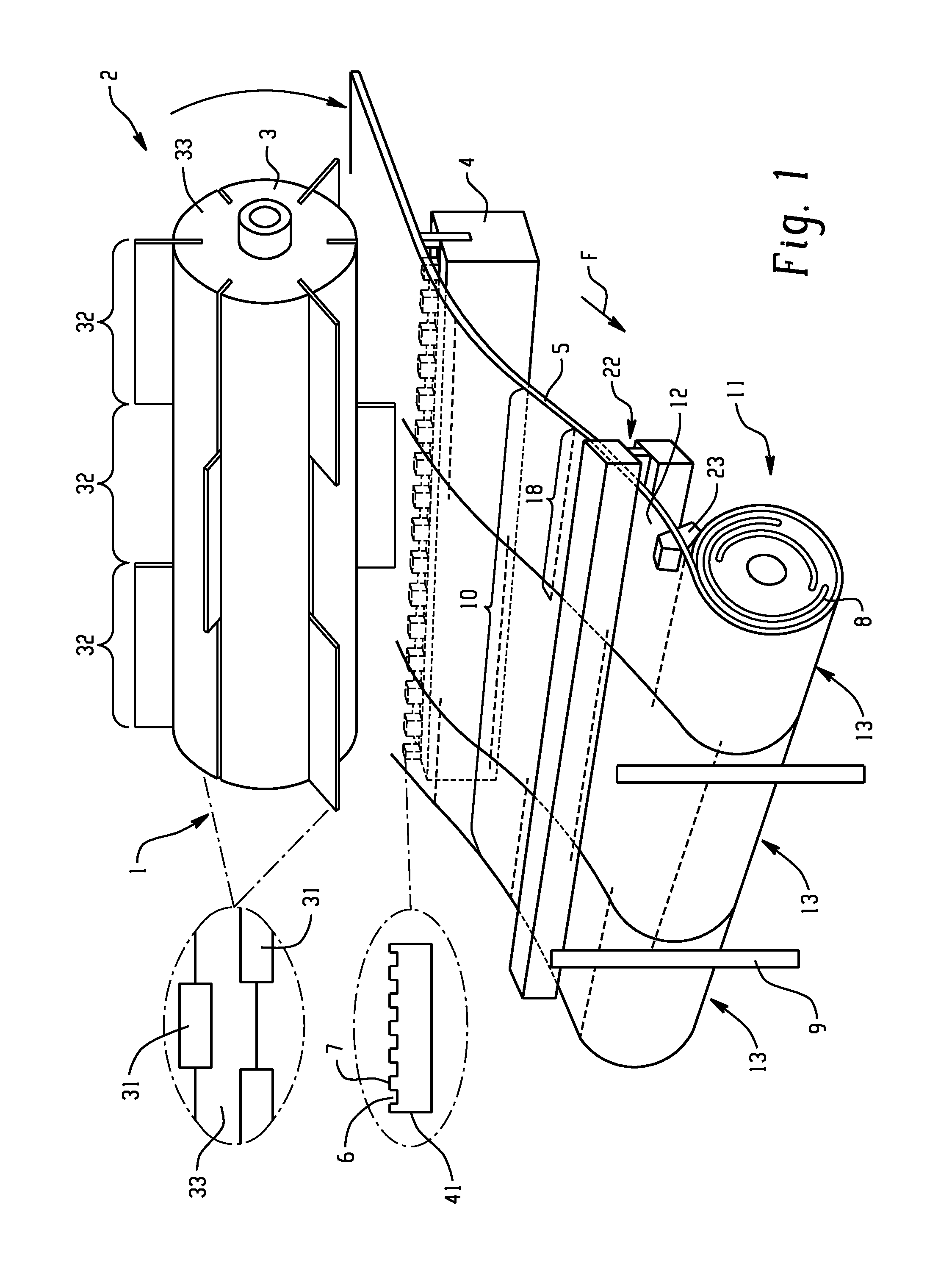

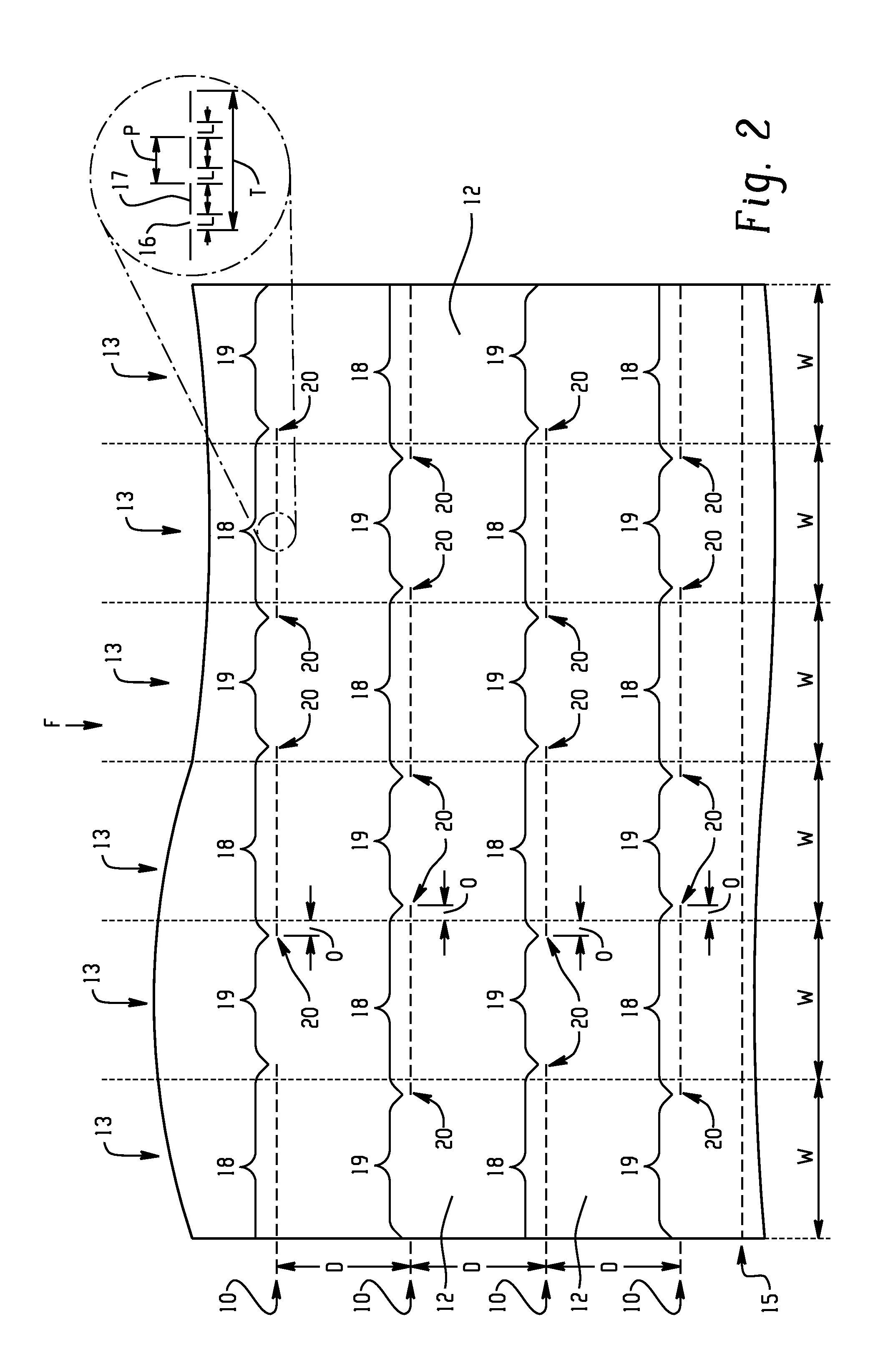

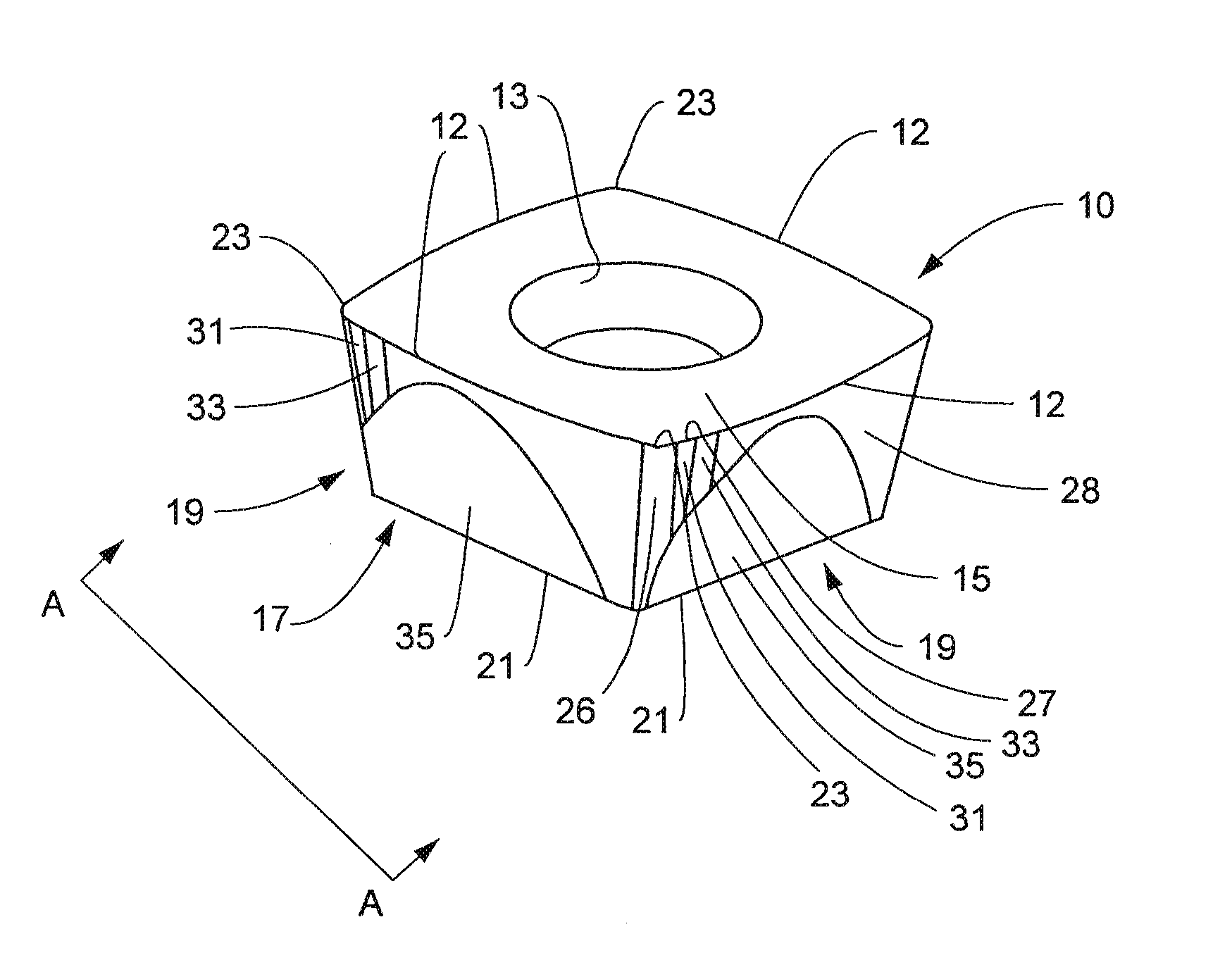

Heat-sealing method and apparatus for fiber sheets

InactiveUS20030000934A1Reduce void volumeReliable heat sealingMechanical working/deformationLaminationFiberMechanical engineering

There is disclosed a heat-sealing method including: feeding a fusible fiber sheet (12) into the clearance between a pair of rolls (1, 5), at least one of which has sealing ridges (2, 6) of a predetermined pattern on its outer circumference; and heating and pressing the fiber sheet (12) with the sealing ridges (2, 6), to form fused portions corresponding to the pattern of the sealing ridges (2, 6), in the fiber sheet (12). An insulator (4) is disposed to cover the outer circumference of the rolls (1, 5), as lacking the sealing ridges. The insulator (4) is made of a material which has a lower thermal conductivity than that of the sealing ridges and which can be elastically contracted by the pressure of the rolls (1, 5). The fiber sheet (12) to be fed into the clearance between the rolls (1, 5) rotating is compressed by the insulator (4) to discharge its internal air and is then heated and pressed by the sealing ridges (2, 6) so that it is heat-sealed.

Owner:UNI CHARM CORP

Method for Manufacturing a Sheet Product for Use in a Dispenser and Strip of Sheet Product

ActiveUS20120237711A1Reduction in perforation breaking strength of stripNot adversely affectingStampsMechanical working/deformationBreaking strengthUltimate tensile strength

The invention relates to a method of manufacturing a web of sheet product, with a discontinuous perforation arrangement such that manufacture of a web of sheet product provides for an increase in the breaking strength of the web of sheet product while feeding the web in a machine direction, thereby reducing the risk of breaking and maintaining the yield and throughput of the production of the perforated web as an intermediate product, yet providing a low breaking force for individual strips produced from the web.

Owner:GPCP IP HLDG LLC

Cutting Insert for High Feed Face Milling

InactiveUS20070189864A1Increase feed rateReduce forceTransportation and packagingMilling cuttersEllipseEdge strength

A cutting insert for milling operations, such as, face milling, slot milling, plunge milling, and ramping operations. The cutting insert exhibits a combination of favorable cutting edge strength, and unique cutting edge geometry, thus, allowing milling operations at relatively high feed rates. The cutting insert includes at least four cutting edges, wherein at least one of the cutting edges is a convex cutting edge. Certain embodiments of square cutting inserts will have four convex cutting edges which may be connected by nose corners. The convex cutting edge may comprise at least one of a circular arc, a portion of an ellipse, a portion of a parabola, a multi-segment spline curve, a straight line, or combinations of these. Wherein the convex cutting edge comprises a circular arc, the circular arc may have a radius greater than or equal to two times a radius of the largest circle that may be inscribed on the top surface.

Owner:KENNAMETAL INC

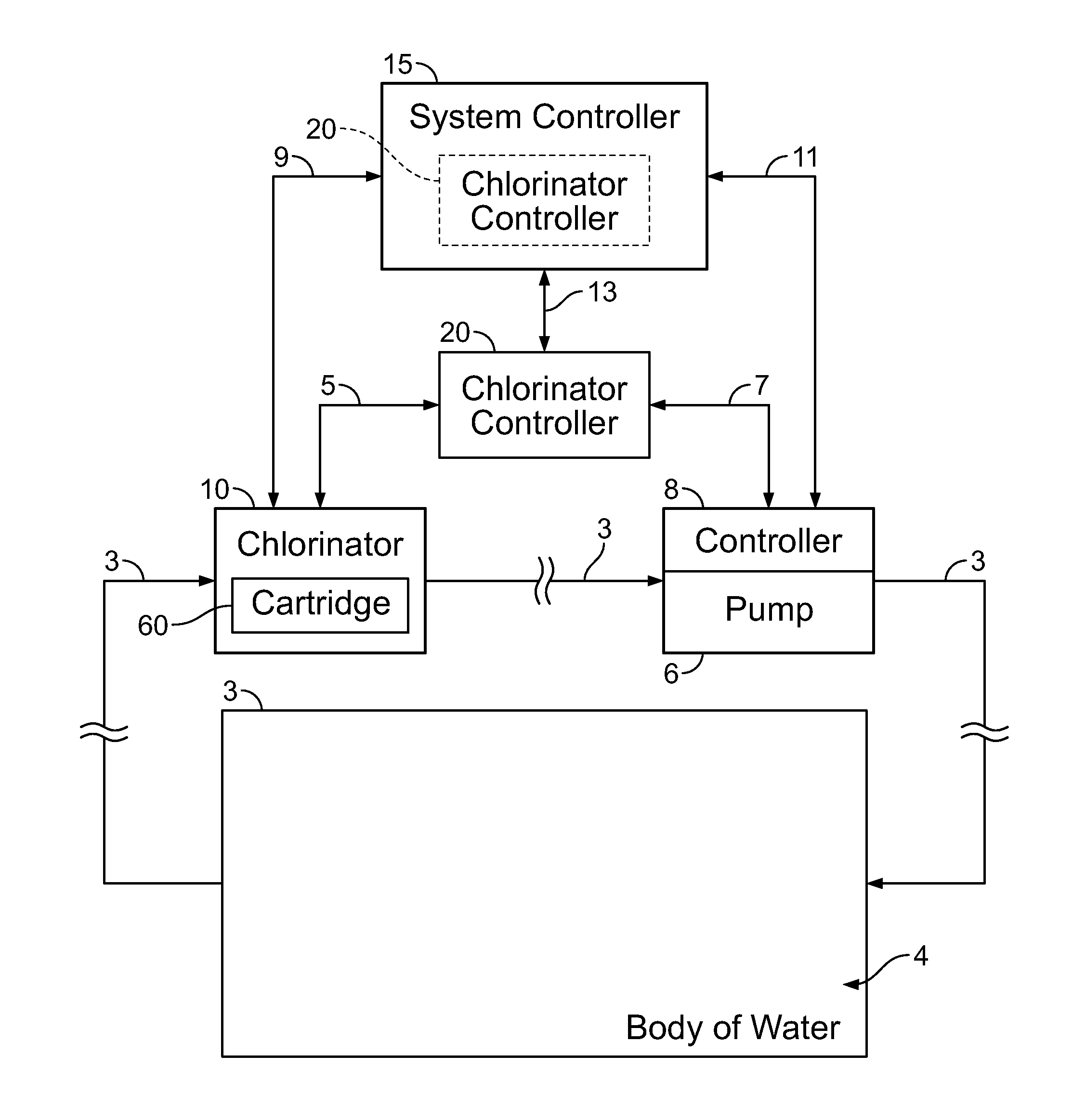

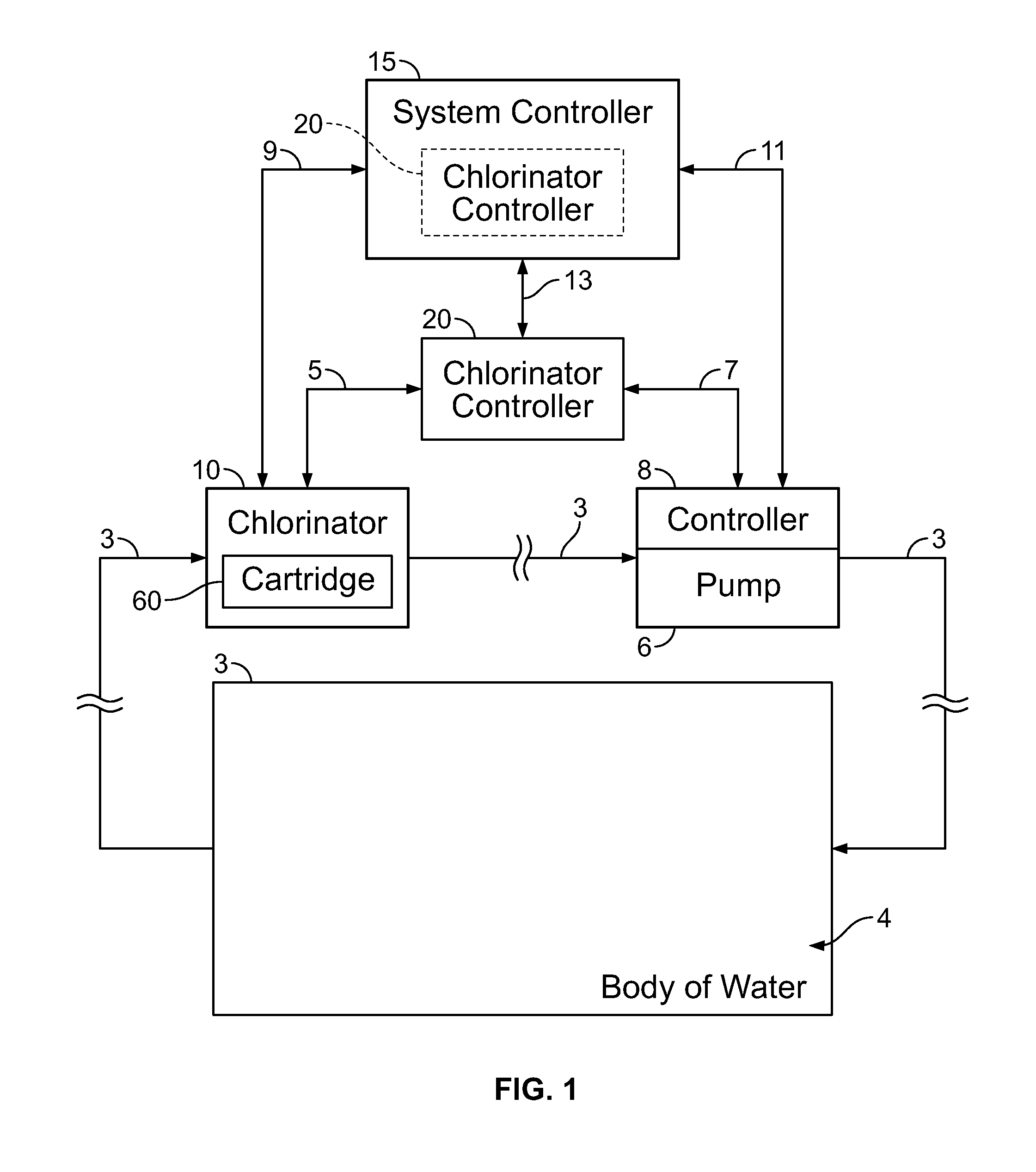

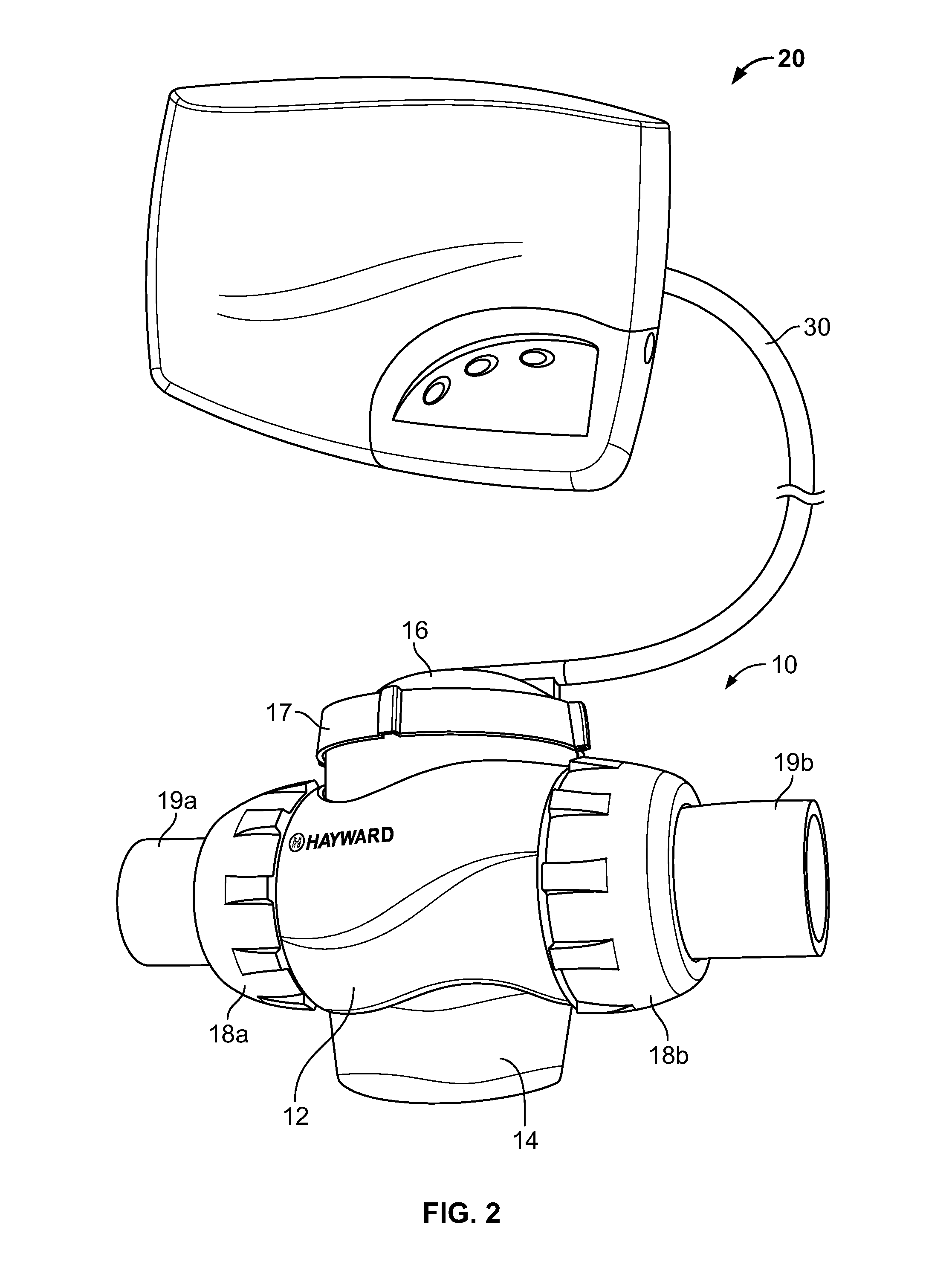

Systems and Methods for Interrelated Control of Chlorinators and Pumps

ActiveUS20160340205A1Accurately reflectConfigurable chlorine feed rateWater treatment parameter controlSpecific water treatment objectivesProcess engineeringChlorine

Systems and methods for combined controlling chlorinators and pumps for pools and spas are provided. Exemplary embodiments can include a pump operable to circulate a fluid for a specified time period according to a pump operation time setting and a chlorinator operatively coupled to the pump. The chlorinator can be configured to generate chlorine based on a chlorine output setting, a chlorine generation capacity of the chlorinator, and the pump operation time. A controller can be operatively coupled to the chlorinator and the pump and can be programmed to control the chlorinator and the pump based on a relationship between the chlorine output setting, a chlorine generation capacity of the chlorinator, and the pump operation time.

Owner:HAYWARD IND INC

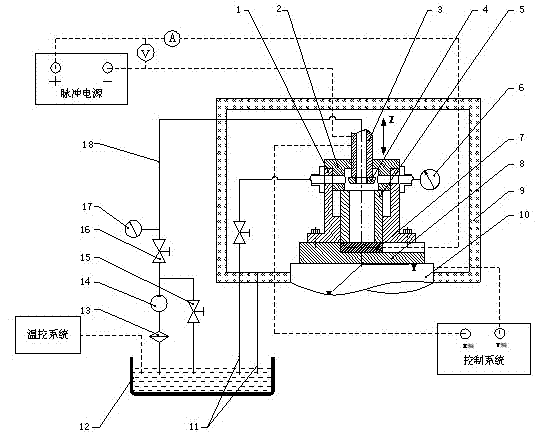

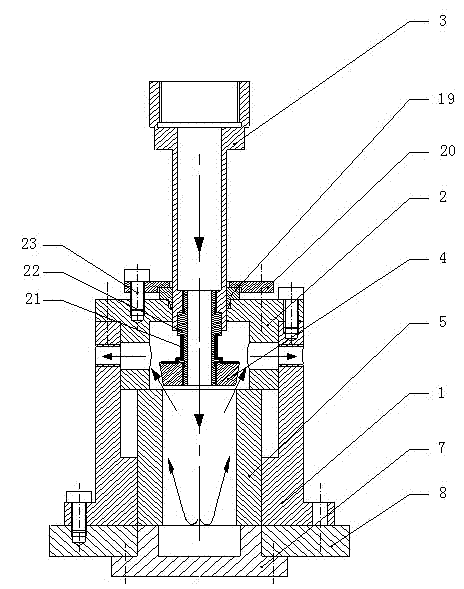

Electrolytic machining method of difficult-to-cut material, fine-module internal gear and device

InactiveCN102896383AIncrease feed rateImprove processing efficiencyMachining electrodesElectrical-based machining electrodesElectrolytic agentEngineering

The invention discloses an electrolytic machining method of a difficult-to-cut material, a fine-module internal gear and a device. The method comprises the following steps that a tool cathode with a top-bottom different shape structure is adopted; the surface of the small end of the tool cathode is circular, and a gap between the tool cathode and a work piece pre-hole is served as an initial machining gap which can ensure that a flow field is stable; the large end of the tool cathode is served as a cathode tooth; a part from the small end to the large end of the tool cathode is smoothly transited to a cathode tooth shape from a circular; a forward flow and backpressure electrolyte flowing mode is adopted; and electrolyte flows into a hollow channel of a cathode system, further an organic glass cavity with organic pieces is filled with the electrolyte, and then the electrolyte flows out off the gap between the tool cathode and the work piece. The tool cathode adopts a top-bottom different shape structure, can realize three-dimensional feeding, a pre-hole is arranged in a work piece blank, so that a feeding speed of the tool cathode is improved by 5 to 10 times relative to the feeding speed of an end surface during electrolytic machining, a machining process is stable, and the method is beneficial to improvement of machining efficiency and forming accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

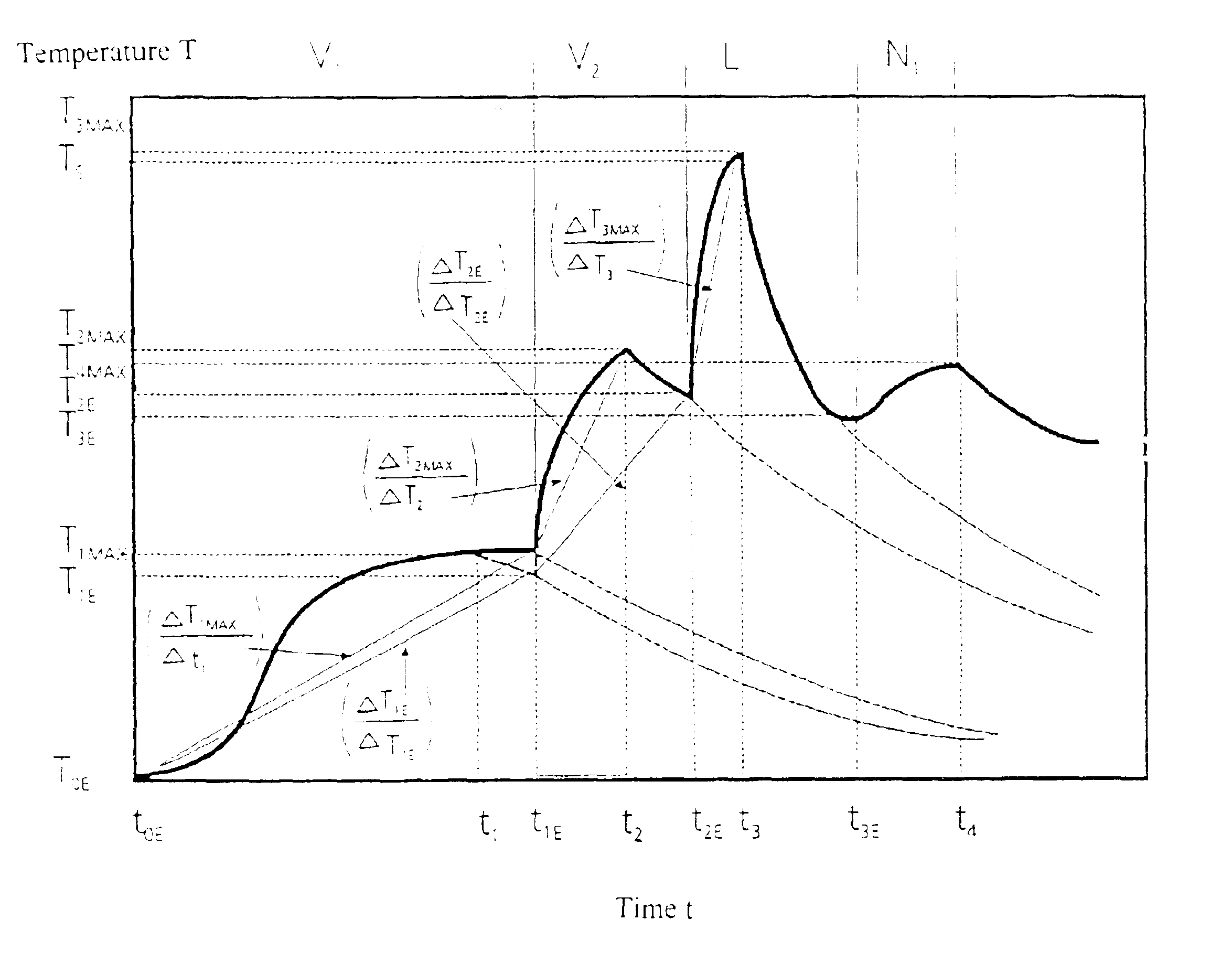

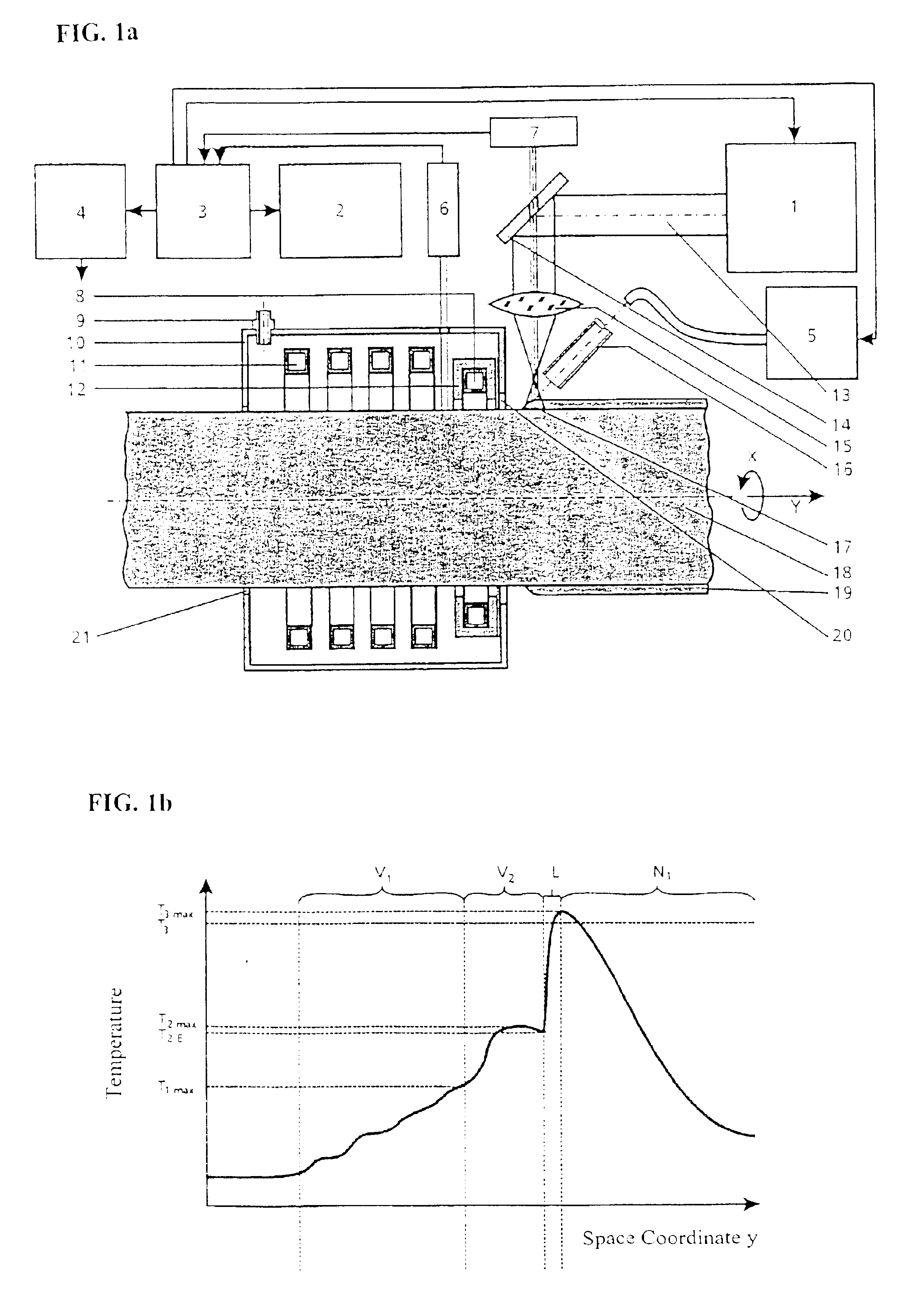

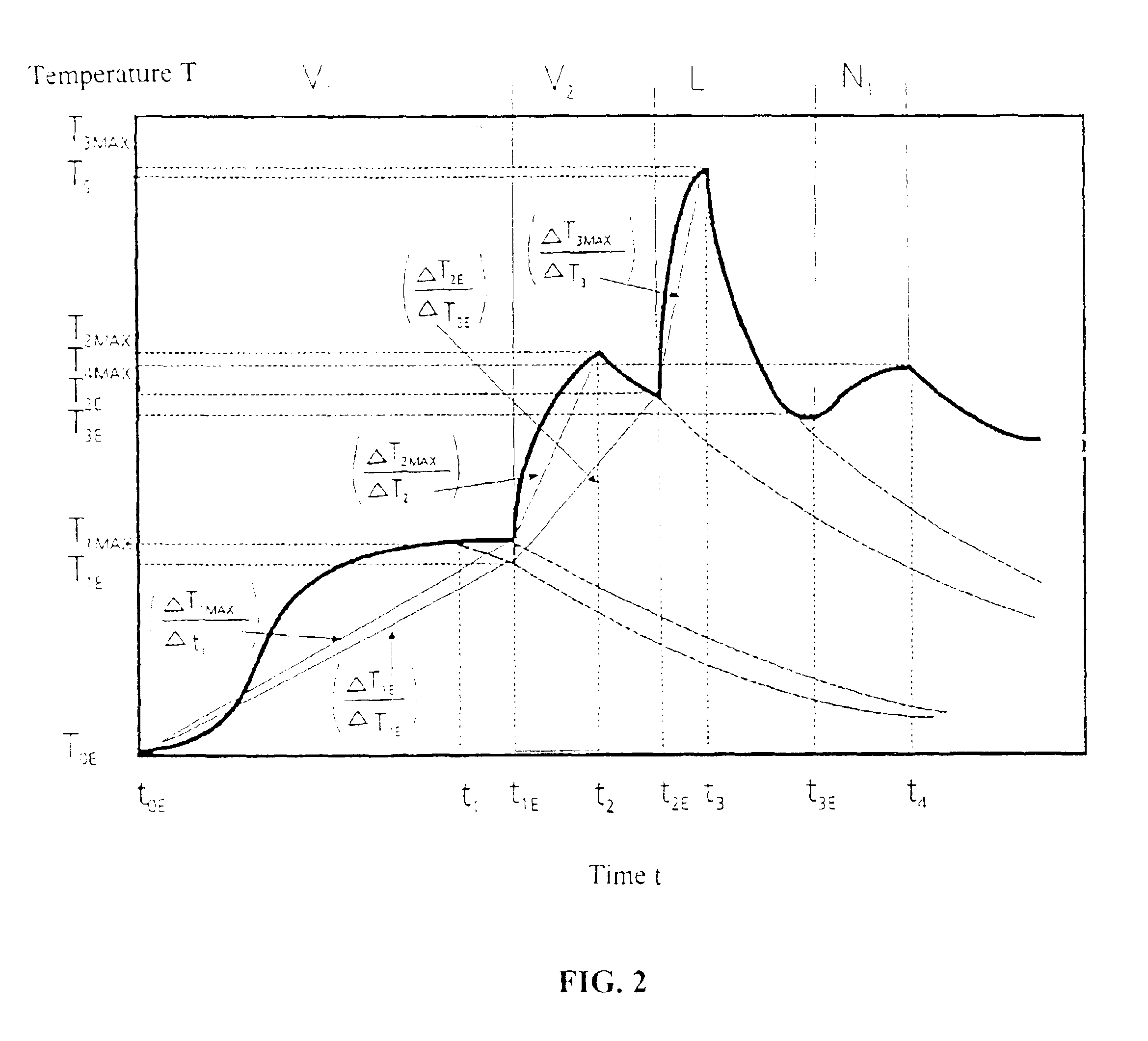

Process for producing wear-resistant surface layers

InactiveUS6843866B2Increase feed rateReduce power densityFurnace typesPlasma welding apparatusSurface layerWear resistant

Process for the effective production of very wear-resistant layers in the thickness range of 0.2 to approx. 3 mm by way of inductively supported surface layer modification. It can be used particularly advantageously for the protection of components of hardenable steels and cast iron with abrasive, corrosive, high-temperature corrosive or mineral sliding wear loading. With the process according to the invention a local two-stage inductive short-time preheating takes place directly before the surface layer coating. Due to the invention it is possible to coat even hardenable steels or other materials difficult to coat without cracking. Furthermore, even harder coating materials susceptible to cracking which provide better wear-resistances can be used. In addition, process speeds and surface coating performances can be achieved that are higher by a factor of 10 compared with conventional laser build-up welding. This abstract is neither intended to define the invention disclosed in this specification nor intended to limit, in any manner, the scope of the invention.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com