Tamping unit for a track tamping machine

A technology of tamping machines and equipment, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of reducing the degree of ballast entering, reducing the elasticity of hydraulic hoses, and reducing the compaction effect, and achieves simple structure and simple Structural conditions, the effect of not being prone to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

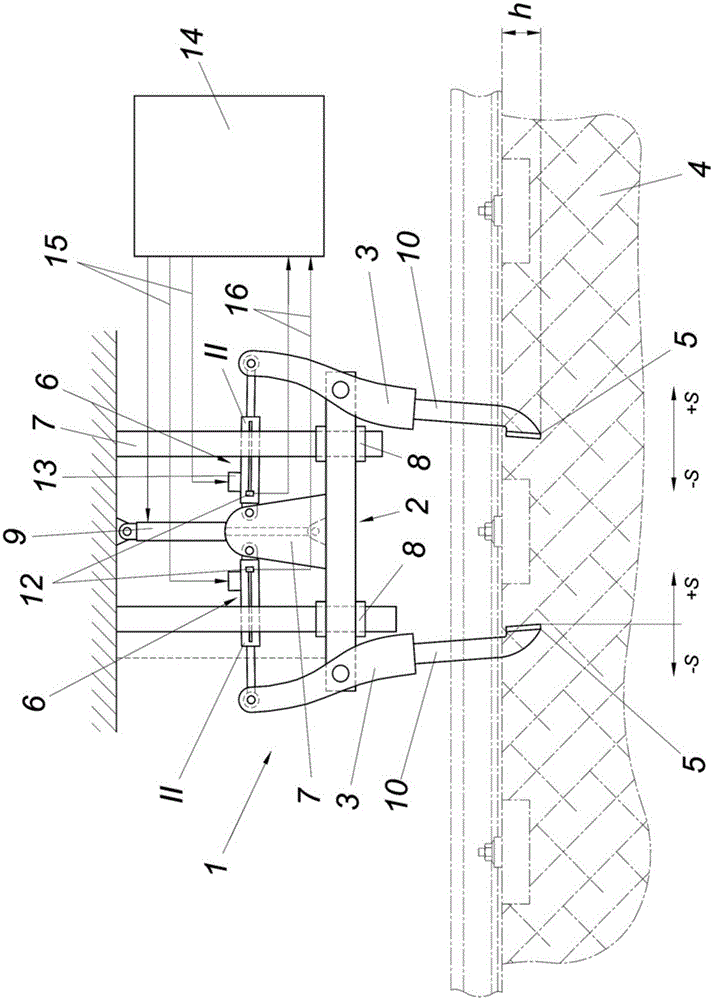

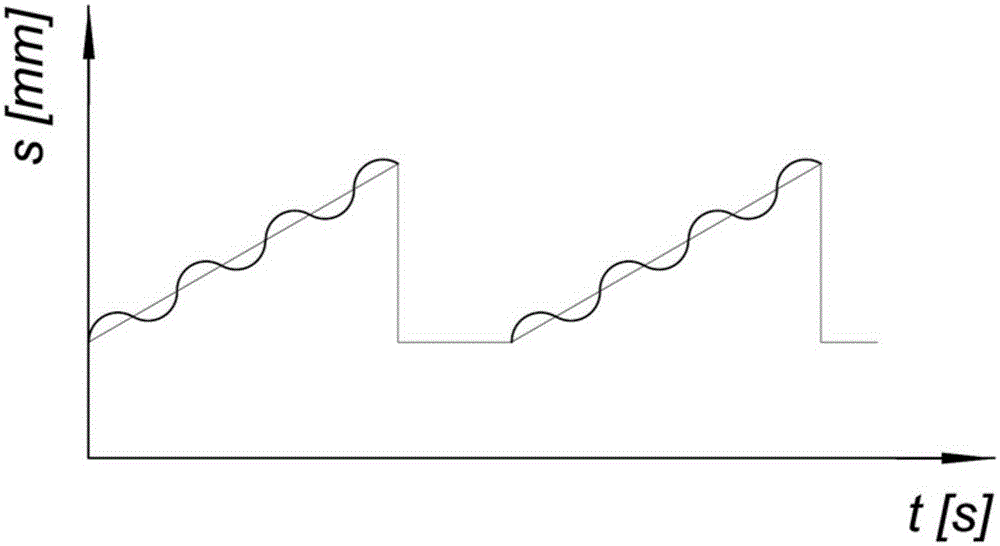

[0019] The tamping device 1 for a track tamping machine also comprises a tamping tool pair with a tamping tool 3 arranged on a support 2 and designed as a pendulum, the pair of tamping tools is defined for insertion into the lower tamping of the ballast bed 4 The pick ends 5 are drivable in opposite directions by means of the vibration drive 6 and can be advanced hydraulically against each other by an advance displacement s. The carriage 2 is guided in a height-adjustable manner in a tamping device frame 7 with a guide 8 and can be moved into a desired height position by means of an adjusting cylinder 9 . The tamping tool 3 is designed as a double arm, which is pivotably mounted on the support 2 . One arm of each tamping tool 3 is formed by a tamping pick 10 , and a hydraulic cylinder 11 acts on the other arm of each tamping tool 3 , the other end of which is in turn supported on the support 2 .

[0020] Each tamping tool 3 of the tamping tool pair is equipped with a hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com