Patents

Literature

199results about How to "Inhibition of nucleation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

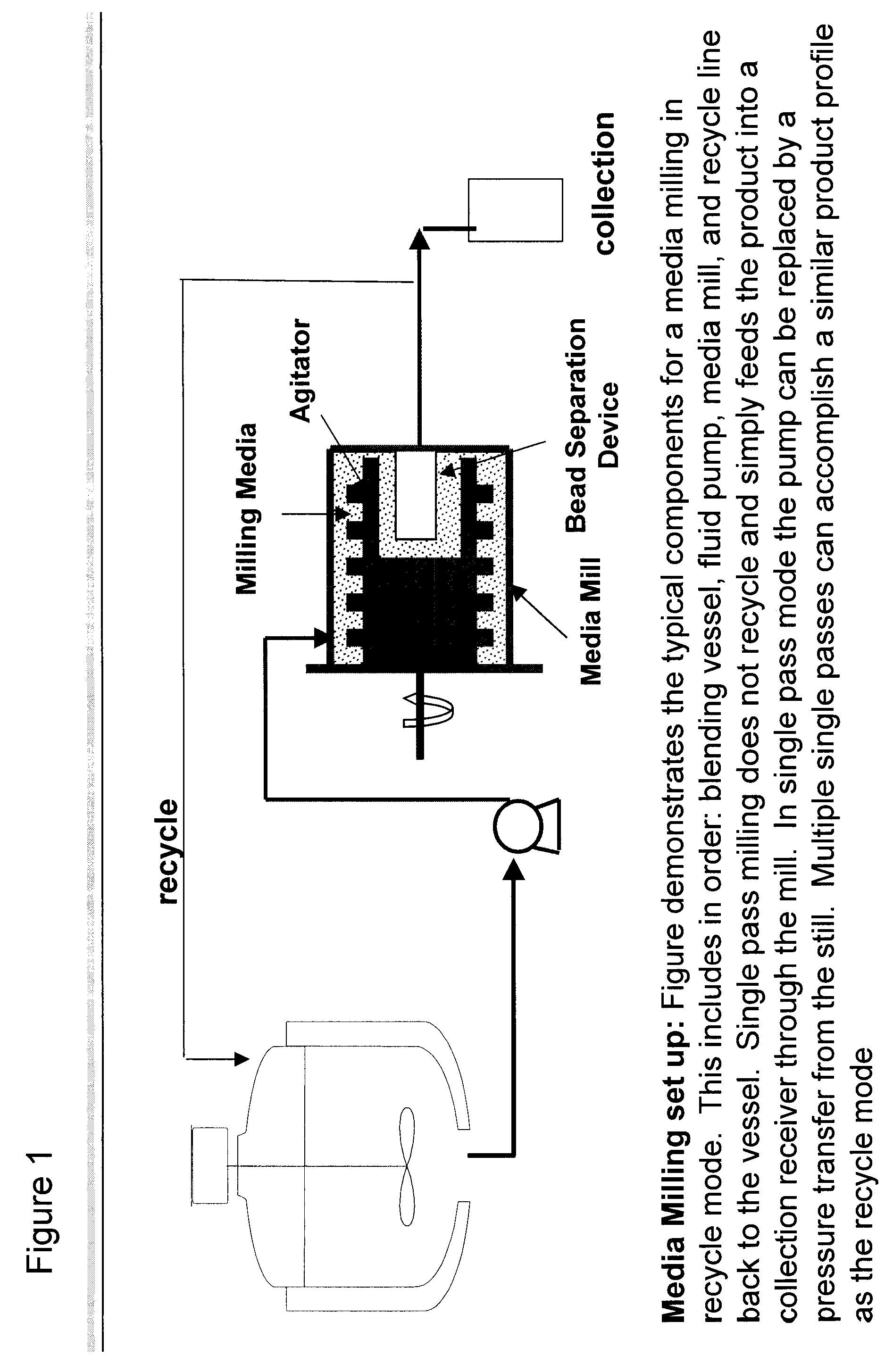

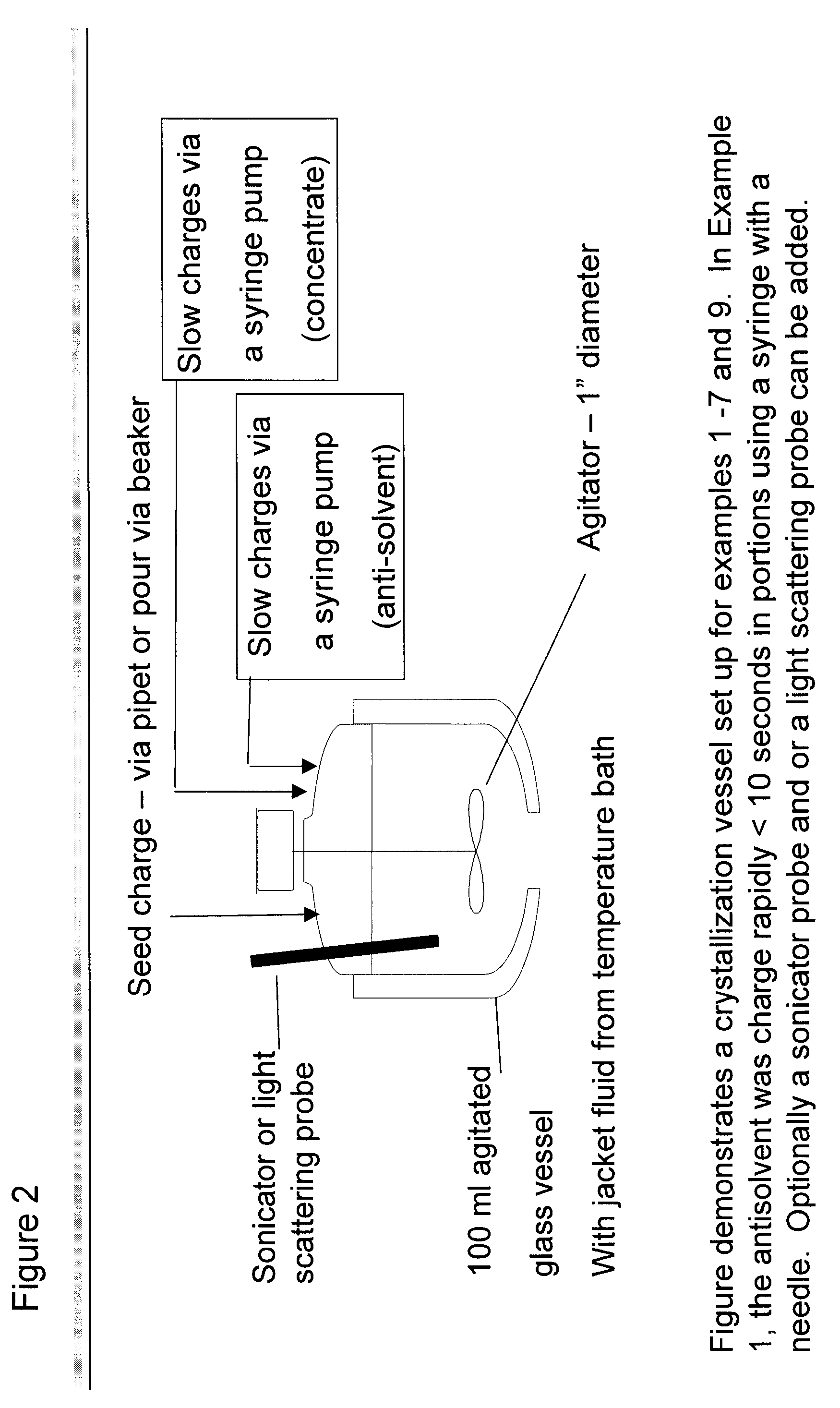

Processes and Apparatuses for the Production of Crystalline Organic Microparticle Compositions by Micro-Milling and Crystallization on Micro-Seed and Their Use

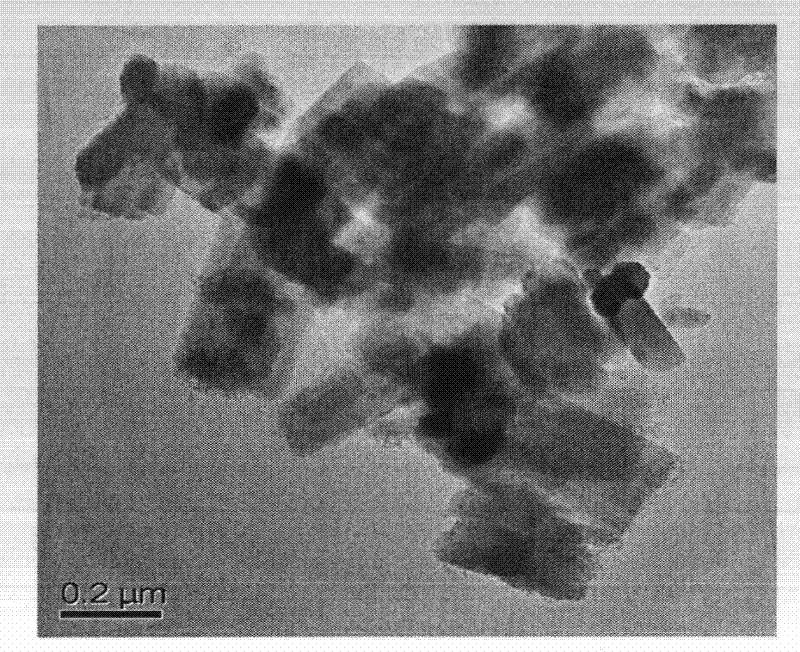

InactiveUS20090087492A1Large specific surface areaIncrease ratingsBiocideNervous disorderMicroparticleOrganic compound

The present invention relates to a process, for the production of crystalline particles of an active organic compound The process includes the steps of generating a micro-seed by a wet-milling process and subjecting the micro-seed to a crystallization process. The resulting crystalline particles have a mean particle size of less than about 100 μm. The present invention also provides for a pharmaceutical composition which includes the crystalline particles produced by the method described herein and a pharmaceutically acceptable carrier.

Owner:MERCK SHARP & DOHME CORP

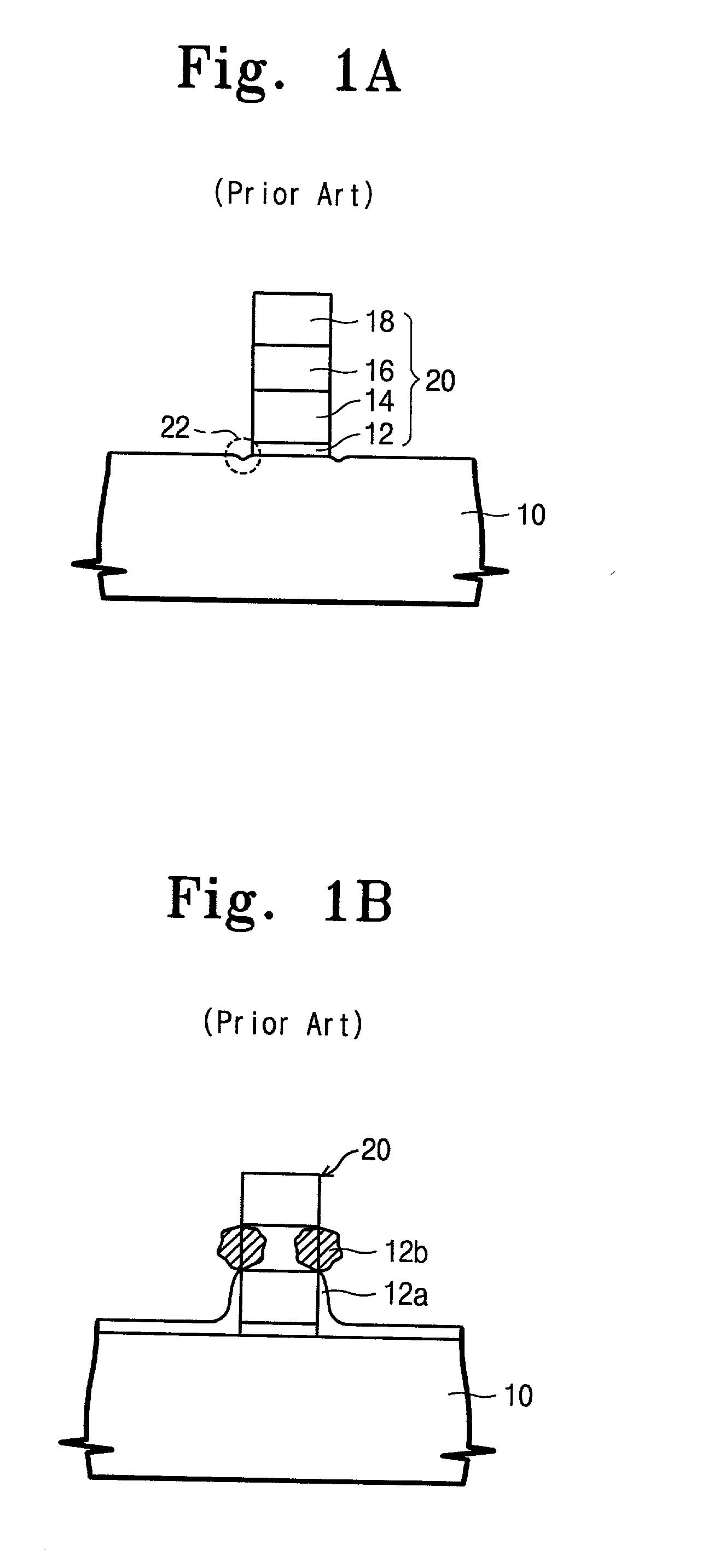

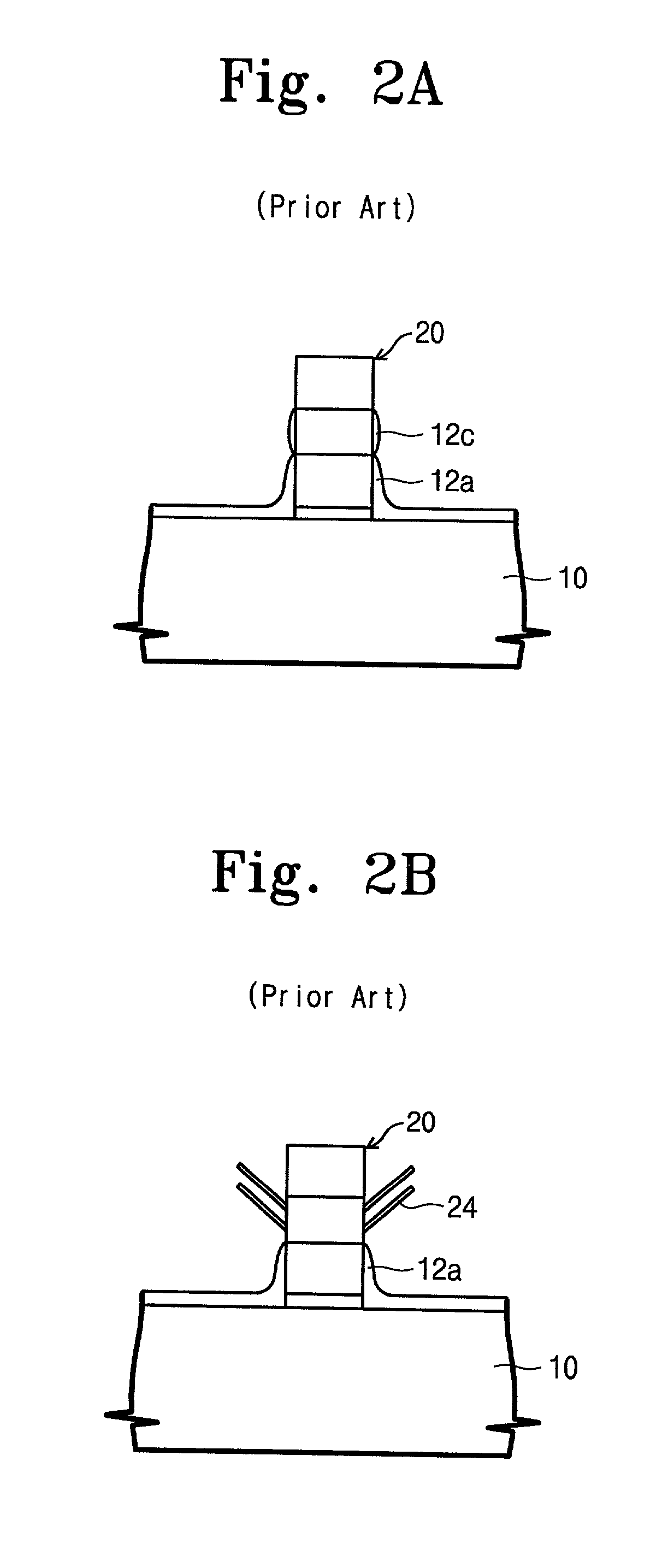

Method of forming a metal gate

InactiveUS20020127888A1Enhance uniformitySuppresses surface mobilitySemiconductor/solid-state device manufacturingBulk negative resistance effect devicesOxideWhiskers

In a method of forming a metal gate electrode, an annealing process is performed in a hydrogen-containing gas ambient following a selective oxidation process. During the annealing process, a metal oxide layer formed by the selective oxidation process is removed by a reduction reaction or hydrogen atoms are contained in the metal oxide layer to suppress whisker nucleation and surface mobility.

Owner:SAMSUNG ELECTRONICS CO LTD

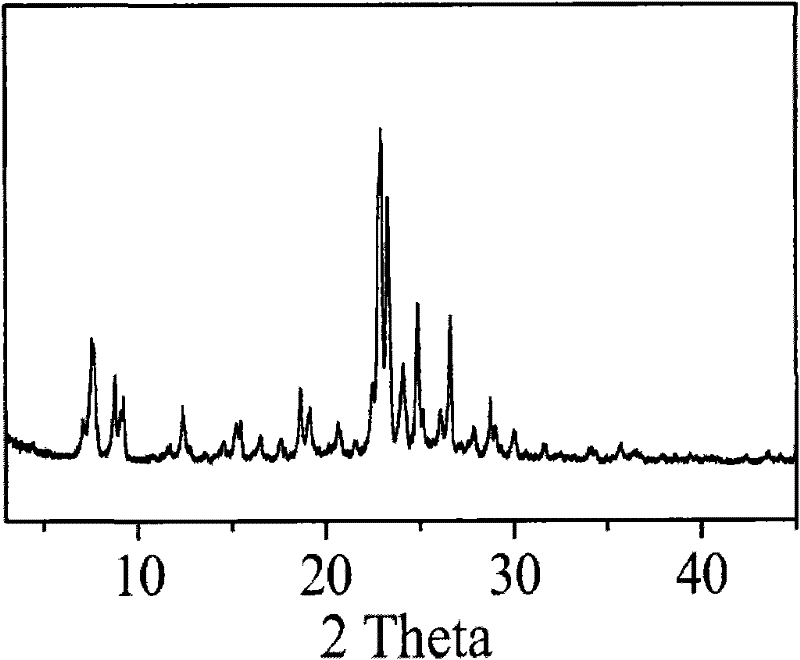

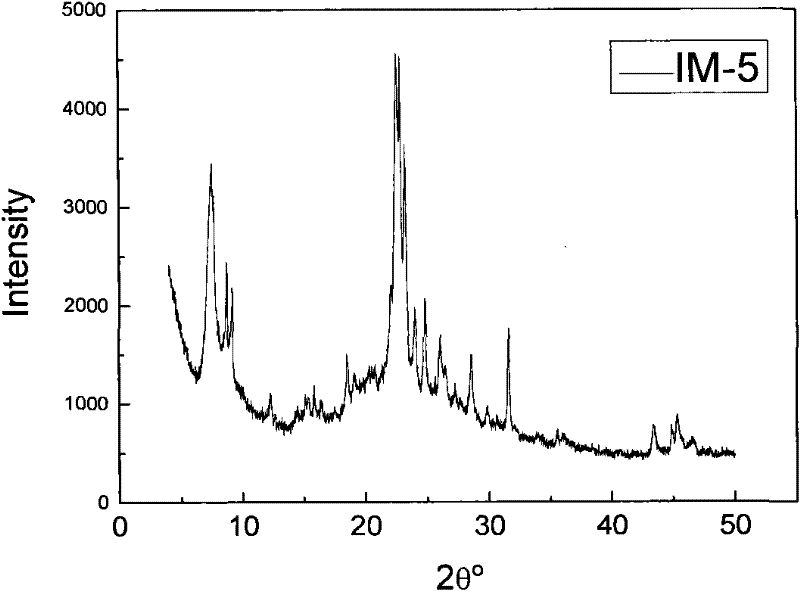

Method of synthesizing IM-5 molecular sieve by using composite template

ActiveCN102452667AReduced nucleation timeShorten crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveAlkali metal oxide

The invention provides a method of synthesizing IM-5 molecular sieve by using a composite template. The method comprises the following steps: (1) dissolving an inorganic base, an aluminum source and two templates in deionized water and carrying out uniform mixing so as to prepare a mixed solution; (2) adding a silicon source into the mixed solution obtained in step (1), optionally adding an additive and carrying out uniform mixing so as to prepare colloid or a solid-liquid mixture; (3) transferring the colloid or the solid-liquid mixture obtained in step (2) to a crystallization kettle, carrying out hydrothermal crystallization at a temperature of 120 to 200 DEG C for 1 to 10 d, carrying out cooling after crystallization and rinsing, filtering and drying the obtained mixed liquor so as to obtain raw powder of the IM-5 molecular sieve. A mole ratio of reactants satisfies the equation of SiO2: Al2O3: M2O: R1: R2: H2O = 60: 0.4-6: 6-21: 0.6-18: 0.6-12: 300-1800, wherein M2O is an alkali metal oxide, R1 is a first template, and R2 is a second template. The method provided in the invention widens the range of mixing ratios of raw materials, improves yield of a single kettle and enables time for crystallization to be further shortened and enlarged production to be easier.

Owner:CHINA PETROLEUM & CHEM CORP +1

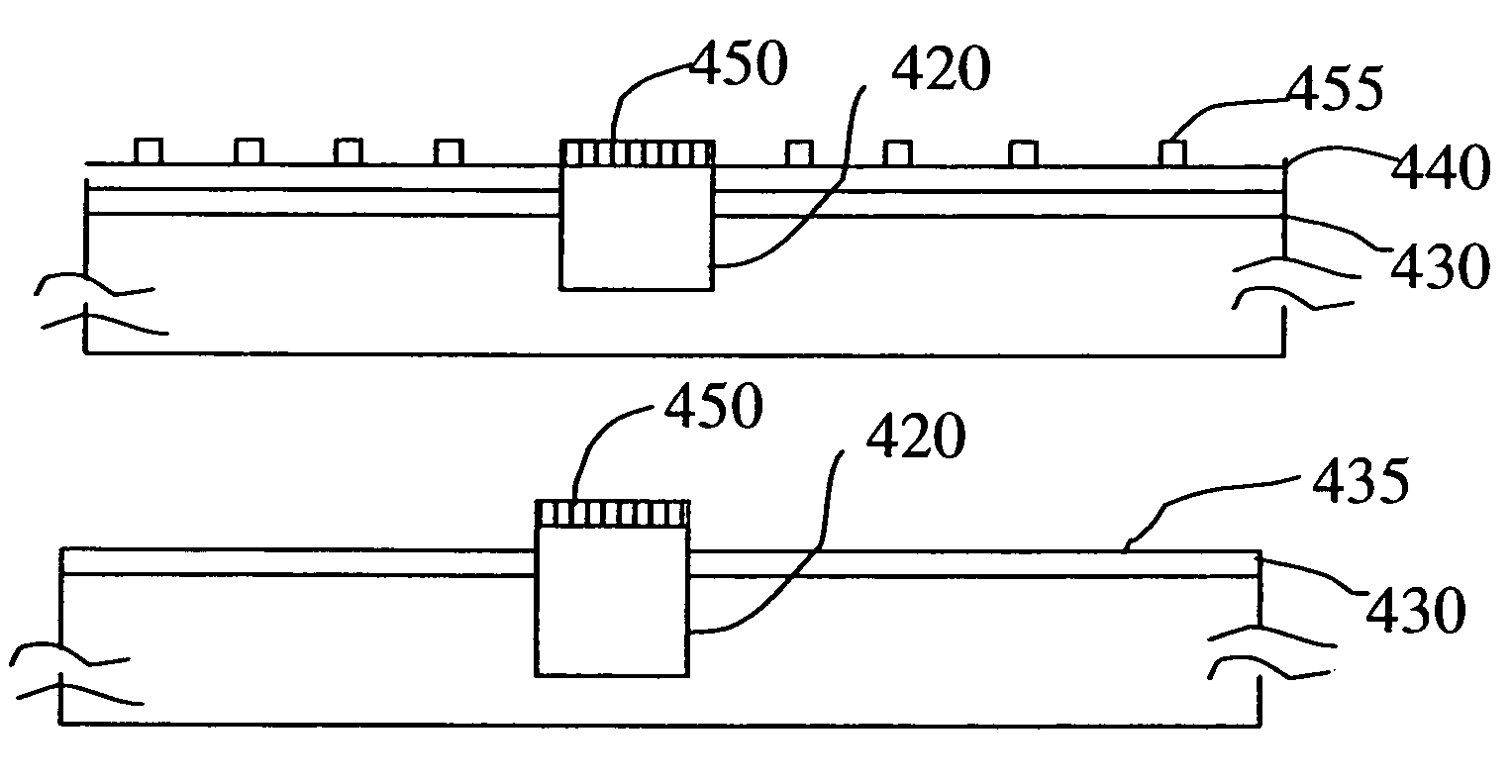

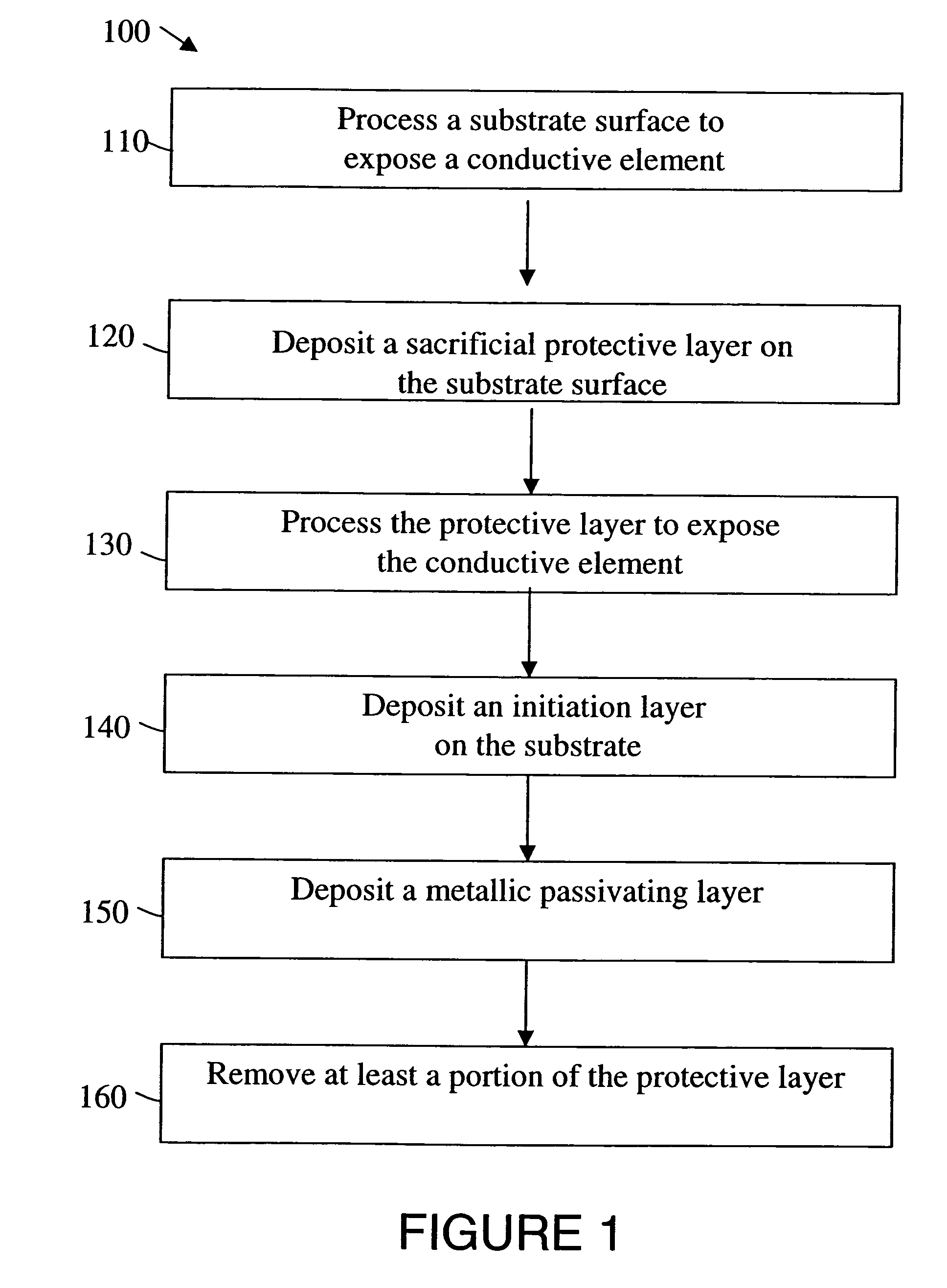

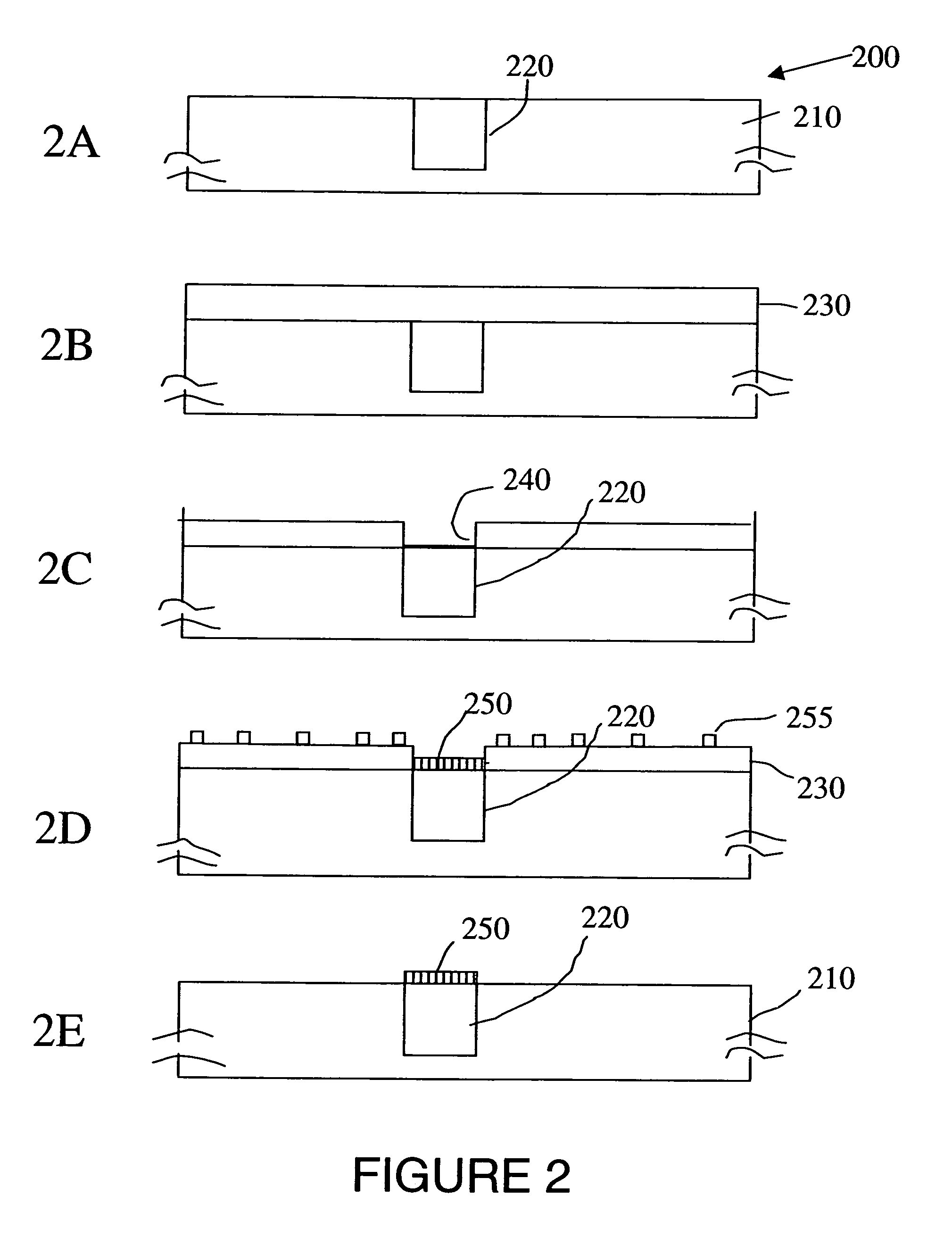

Selective metal encapsulation schemes

InactiveUS7205228B2Low capacitanceReduce incidenceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSubstrate surfaceSemiconductor

A method and system of processing a semiconductor substrate includes, in one or more embodiments, depositing a protective layer on the substrate surface comprising a conductive element disposed in a dielectric material; processing the protective layer to expose the conductive element; electrolessly depositing a metallic passivating layer onto the conductive element; and removing at least a portion of the protective layer from the substrate after electroless deposition. In another aspect, a method and system of processing a semiconductor includes depositing a metallic passivating layer onto a substrate surface comprising a conductive element, masking the passivating layer to protect the underlying conductive element of the substrate surface, removing the unmasked passivating layer, and removing the mask from the passivating layer.

Owner:APPLIED MATERIALS INC

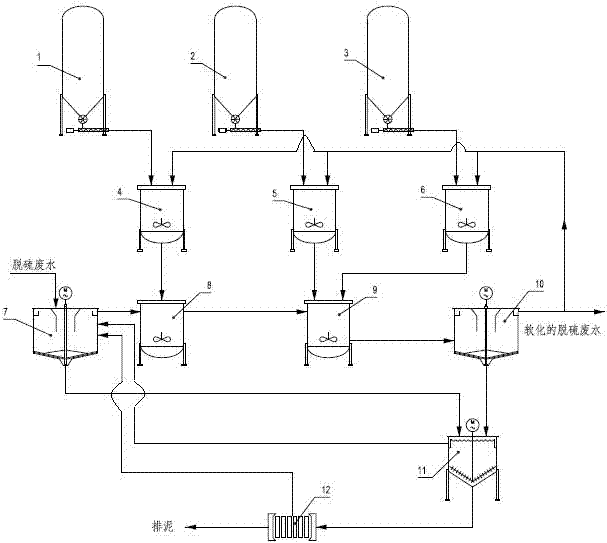

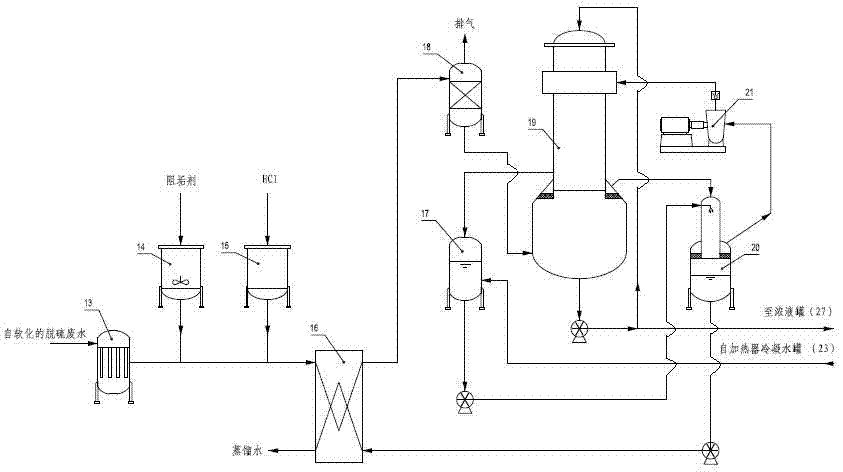

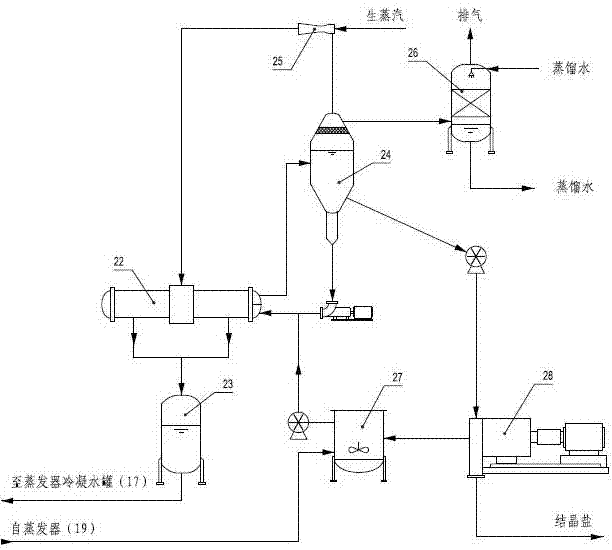

Power plant wastewater zero-discharge treatment technique

ActiveCN104276708AImprove flushing effectRemove supersaturationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationProcess equipmentDegasser

The invention discloses a power plant wastewater zero-discharge treatment technique which comprises a pretreatment process, an evaporative concentration process and an evaporative crystallization process, wherein the pretreatment process equipment comprises a precipitation and concentration tank, a sludge dewatering machine, and a raw water precipitation tank, a primary softening reactor, a secondary softening reactor and a softening precipitation tank which are sequentially connected; the evaporative concentration process equipment comprises an automatic back flush filter, a plate-type preheater, a degasser and a falling film evaporator which are sequentially communicated; and the evaporative crystallization process equipment comprises a concentrated solution tank, a crystallizing heater and a crystallizer which are sequentially communicated. The desulfurization water treatment technique is reasonable in step design and performs the pretreatment, evaporative concentration and evaporative crystallization on the desulfurization wastewater, and the end products are only distilled water and crystalline salt, thereby reducing the discharge of the harmful substances, lowering the energy consumption and implementing the goal of zero discharge of desulfurization wastewater.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

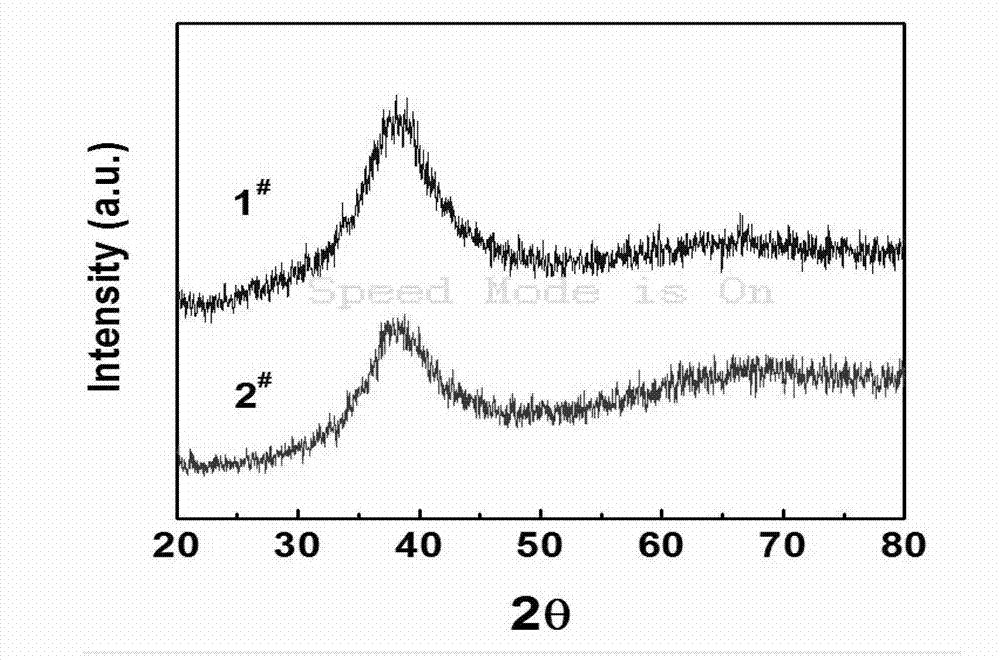

Zirconium-based amorphous alloy

The invention relates to a zirconium-based amorphous alloy. Composition of the zirconium-based amorphous alloy is (Zr, Hf, Nb)aCubNicAldRee, wherein a, b, c, d and e are corresponding contents in atomic percent of each element in the zirconium-based amorphous alloy, a is more than or equal to 45 and less than or equal to 65, b is more than or equal to 15 and less than or equal to 40, c is more than or equal to 0.1 and less than or equal to 15, d is more than or equal to 5 and less than or equal to 15, e is more than or equal to 0.05 and less than or equal to 5, the sum of a, b, c, d and e is less than or equal to 100, Re is one or combination of more than one of La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu elements, or Re is one or combination of Y with more than one of La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu elements.

Owner:HUAWEI TECH CO LTD

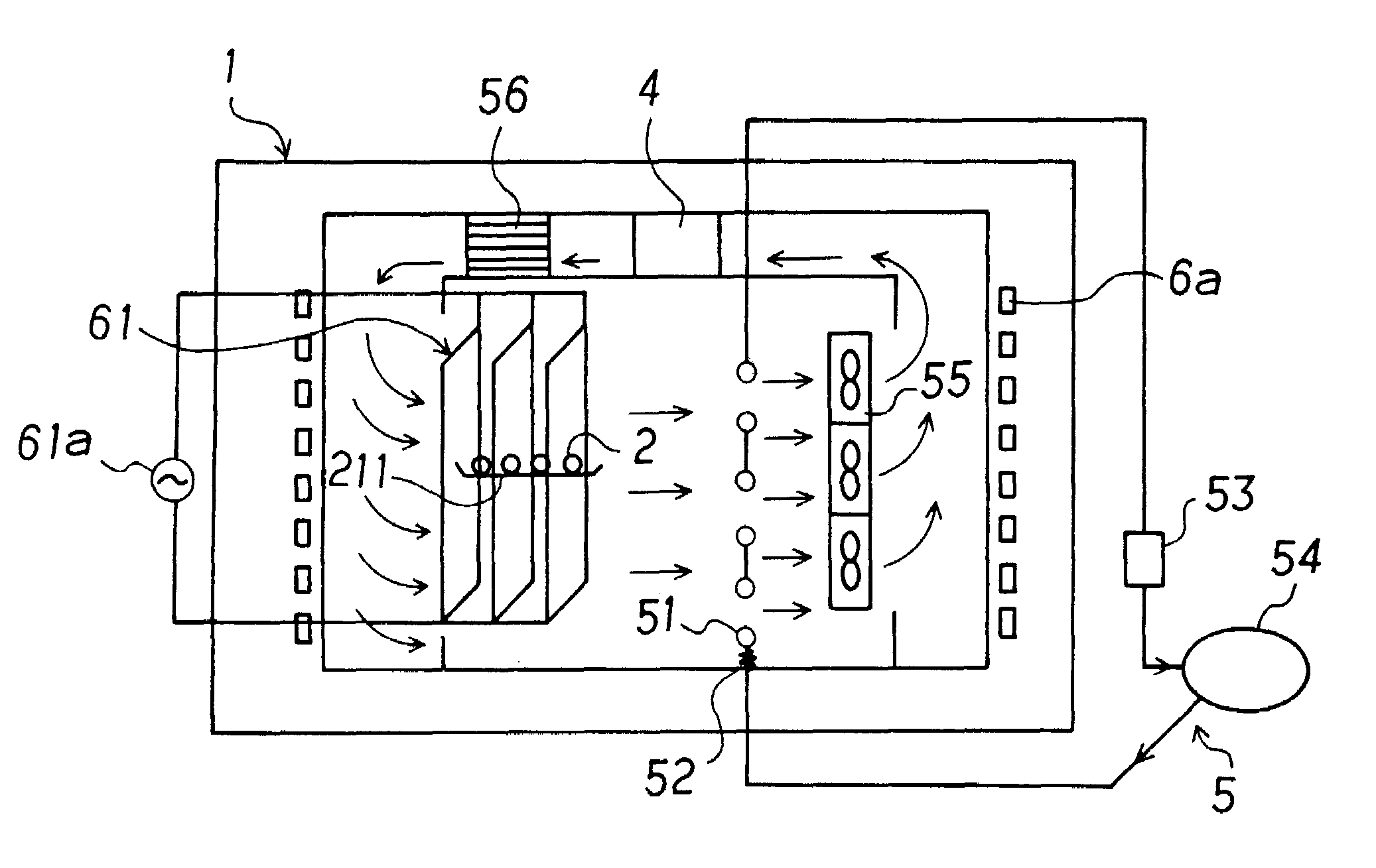

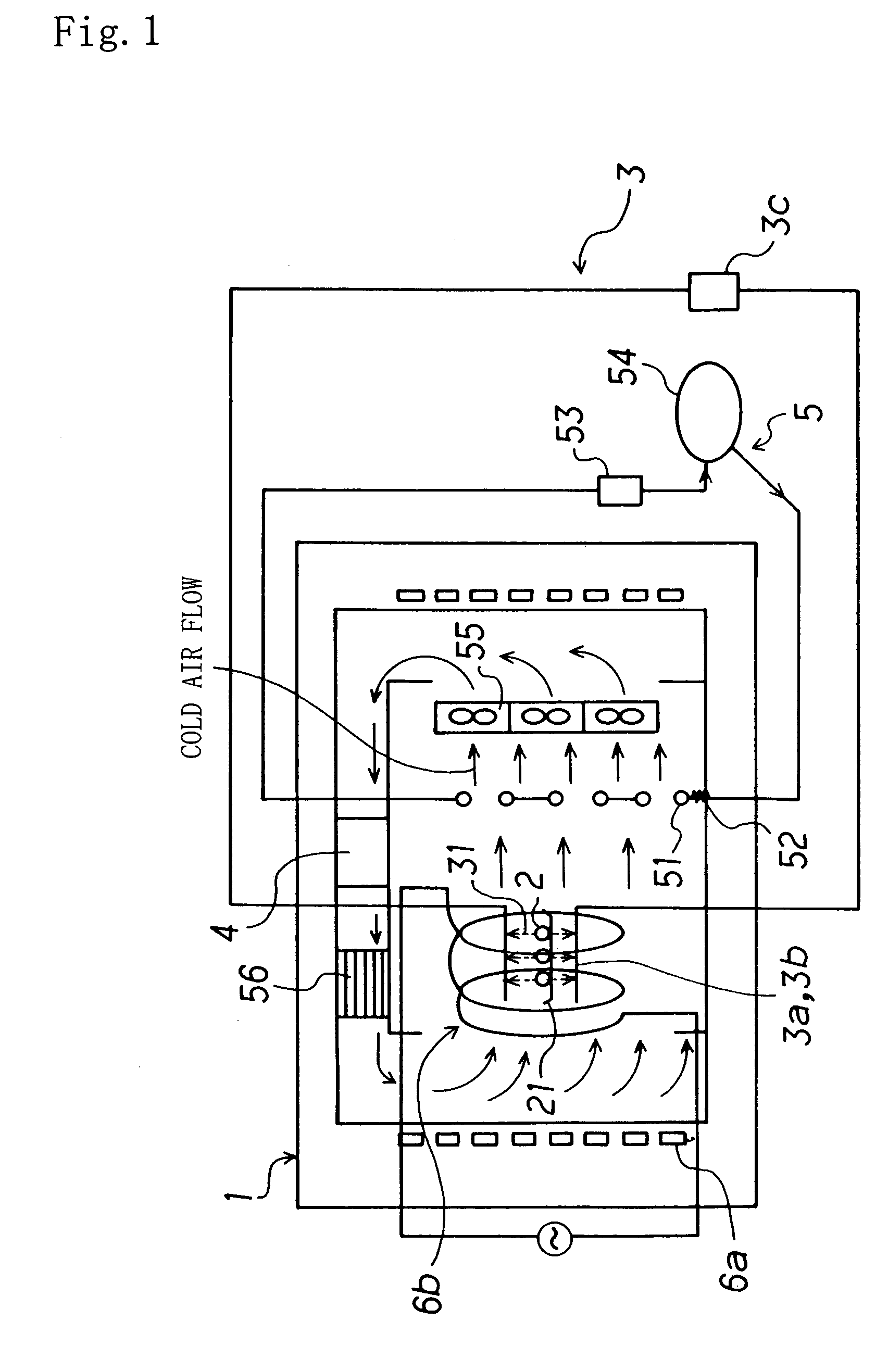

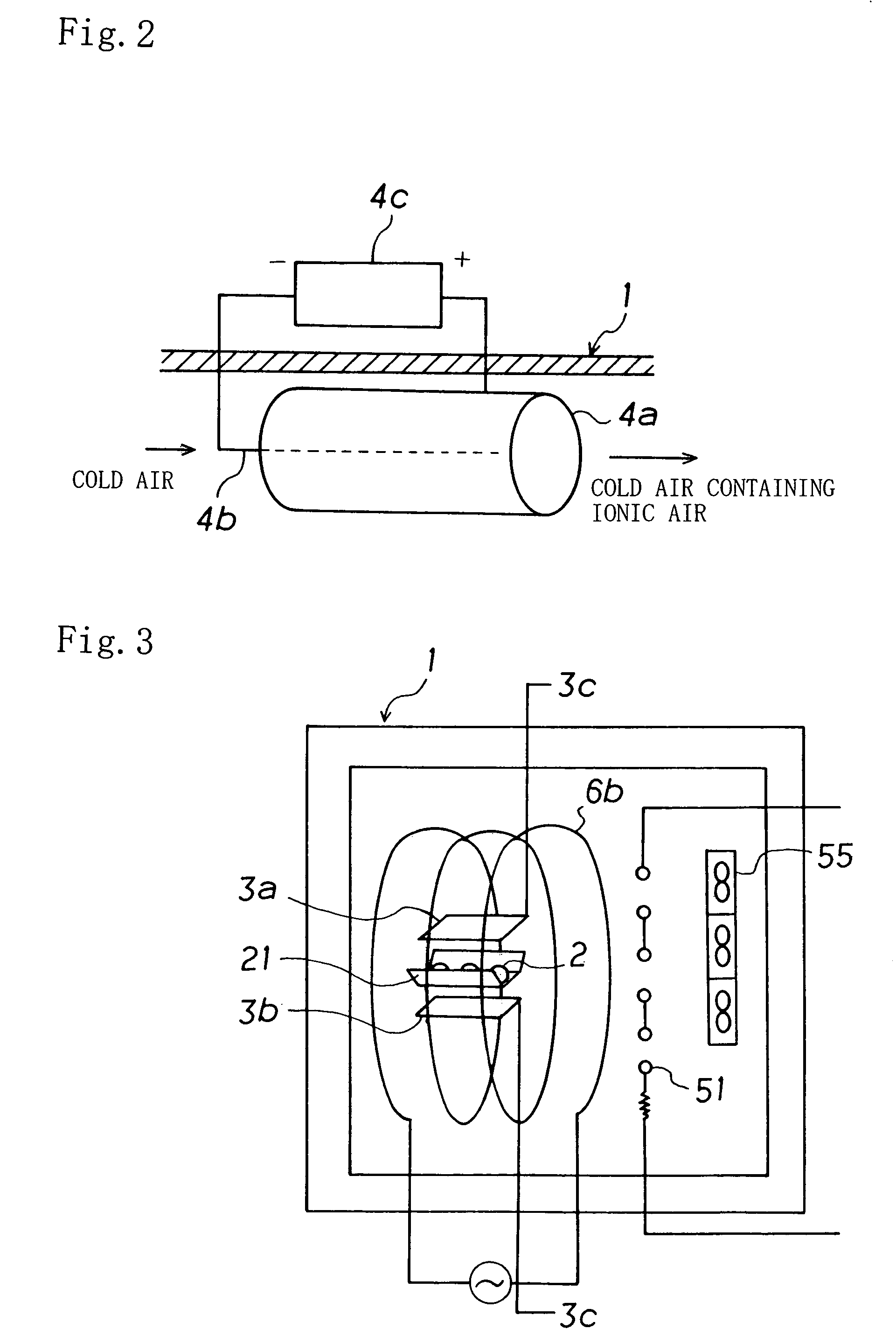

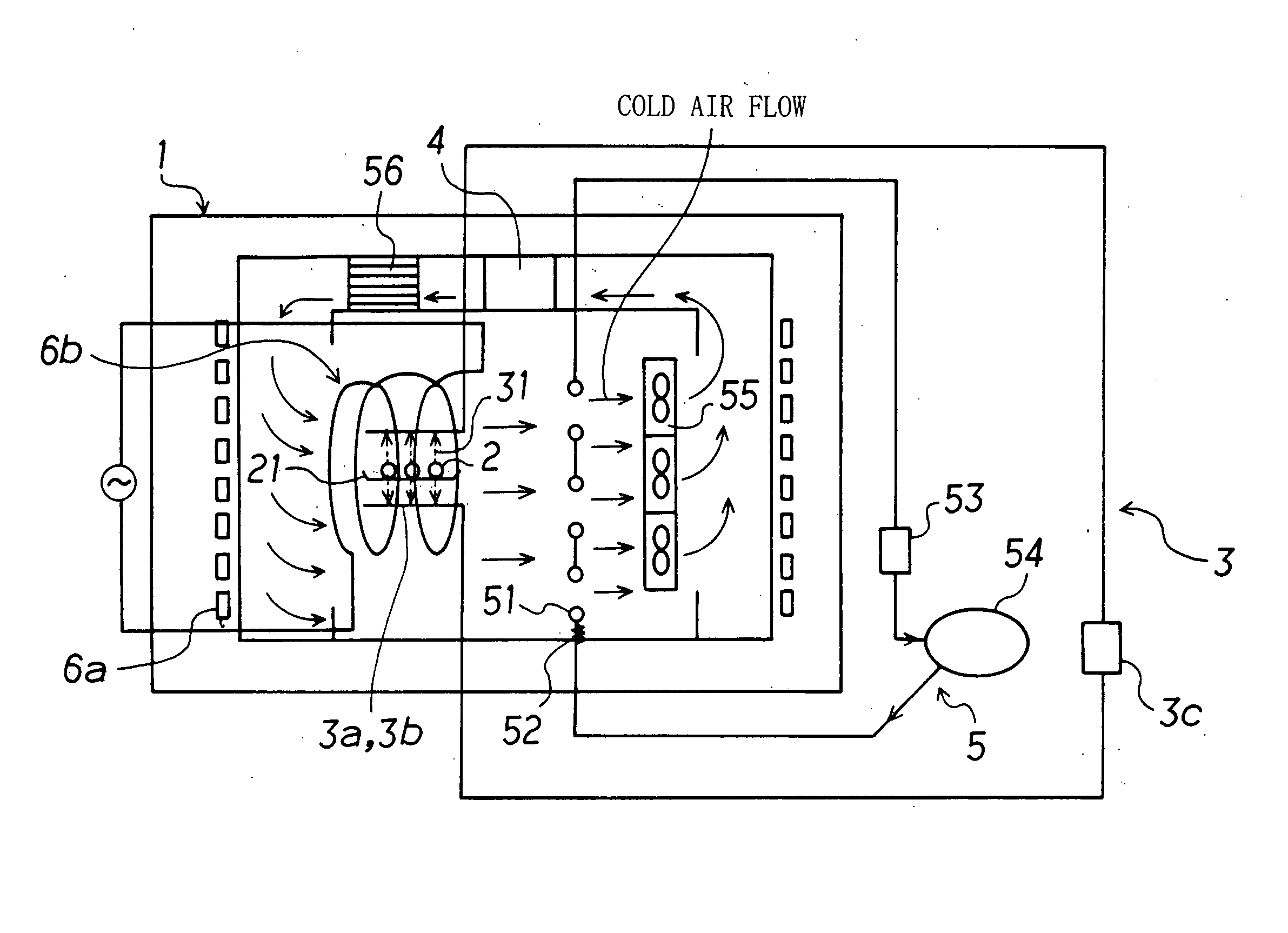

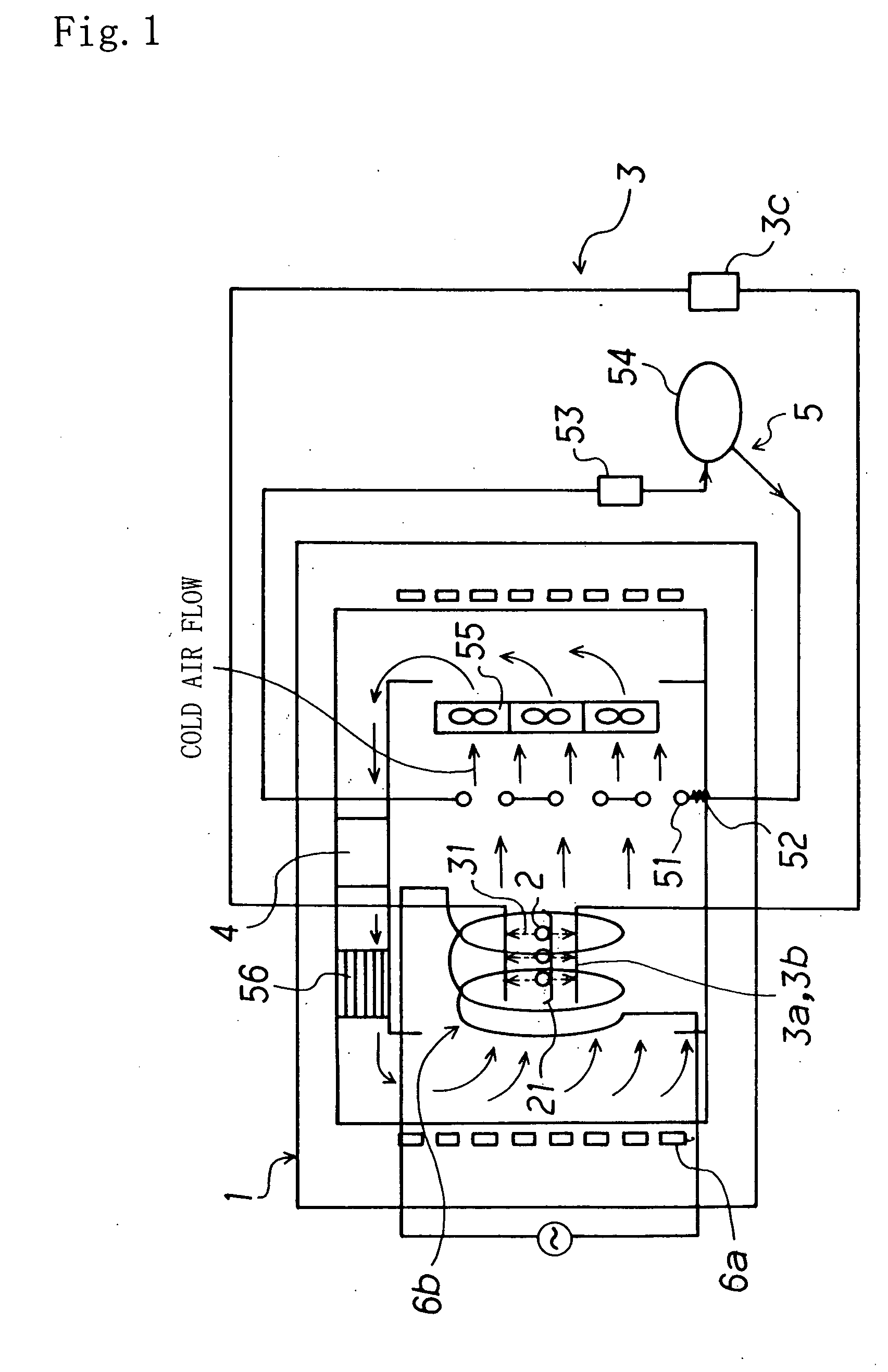

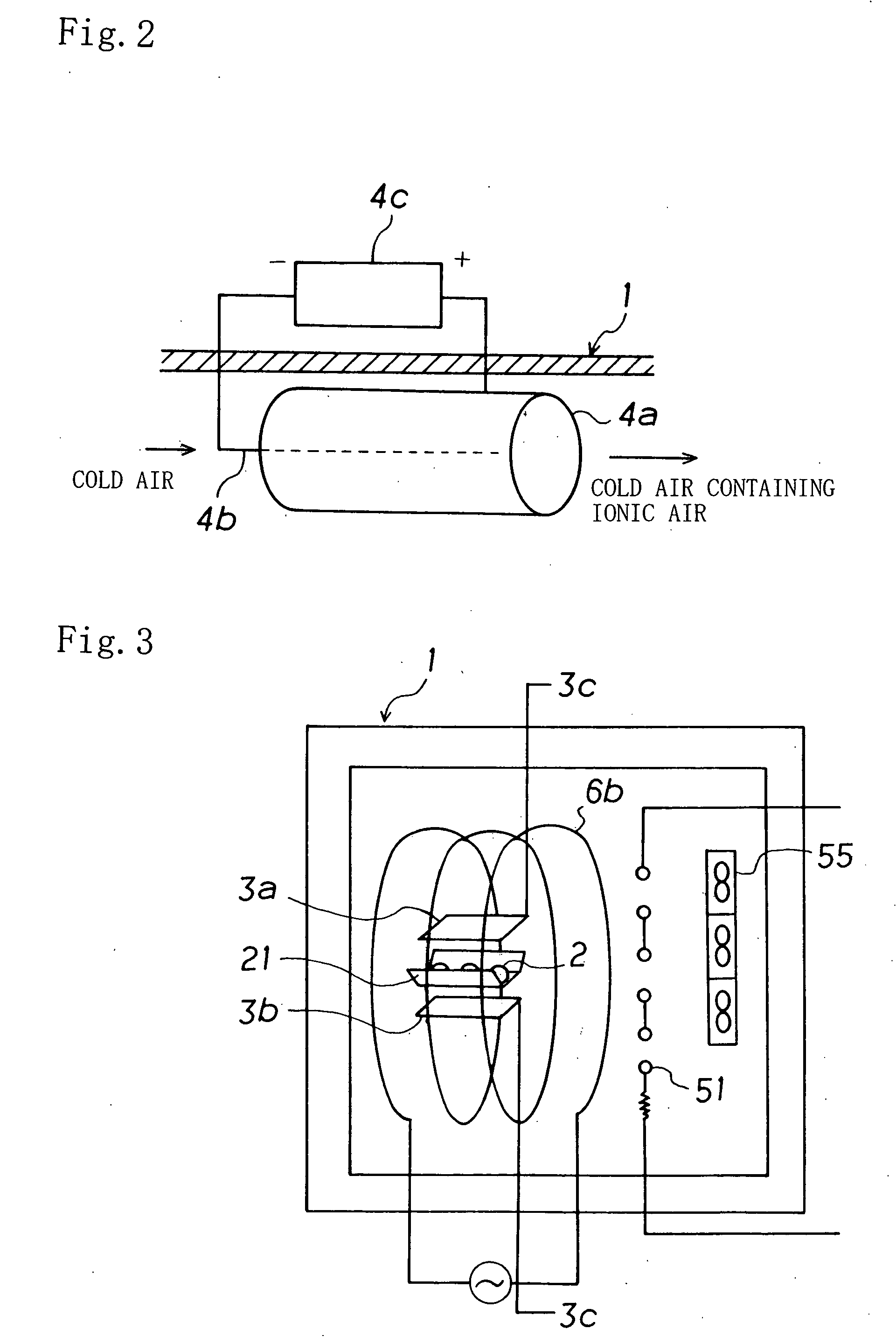

Highly-efficient freezing apparatus and highly-efficient freezing method

InactiveUS7237400B2Avoid destructionRapid coolingDomestic refrigeratorsFood preservationOscillating electric fieldMagnetic field

An object accommodated in an internal space of a freezer is quickly cooled to a predetermined temperature with preventing water from freezing while an oscillating electric field of, preferably, a variable frequency in the range of 50 Hz to 5 MHz and / or a magnetic field are applied to the object, or further ionic air is added to clod air, and subsequently the object is instantaneously frozen at the predetermined temperature. Preferably, the magnetic field is a static magnetic field and / or a variable magnetic field.

Owner:ABI

Highly-efficient freezing apparatus and highly-efficient freezing method

InactiveUS20050005611A1Avoid destructionRapid coolingDomestic refrigeratorsFood preservationOscillating electric fieldMagnetic field

An object accommodated in an internal space of a freezer is quickly cooled to a predetermined temperature with preventing water from freezing while an oscillating electric field of, preferably, a variable frequency in the range of 50 Hz to 5 MHz and / or a magnetic field are applied to the object, or further ionic air is added to clod air, and subsequently the object is instantaneously frozen at the predetermined temperature. Preferably, the magnetic field is a static magnetic field and / or a variable magnetic field.

Owner:ABI

Silica sols with controlled minimum particle size and preparation thereof

InactiveUS20070034116A1Increase feed rateInhibition of nucleationPigmenting treatmentSilicaColloidal silicaSilica particle

Colloidal silica having an increased particle size and narrow particle size distribution is disclosed. A method for continuously producing the desired colloidal composition is disclosed comprising the steps of providing preformed silica particles having a surface area which controls the particle size of the colloidal silica product, adding a feed silica comprising an alkaline solution and silicate at a feed rate which is less than a nucleation rate, and increasing the feed rate as the feed silica is added wherein the feed rate is less than the nucleation rate.

Owner:NALCO CO

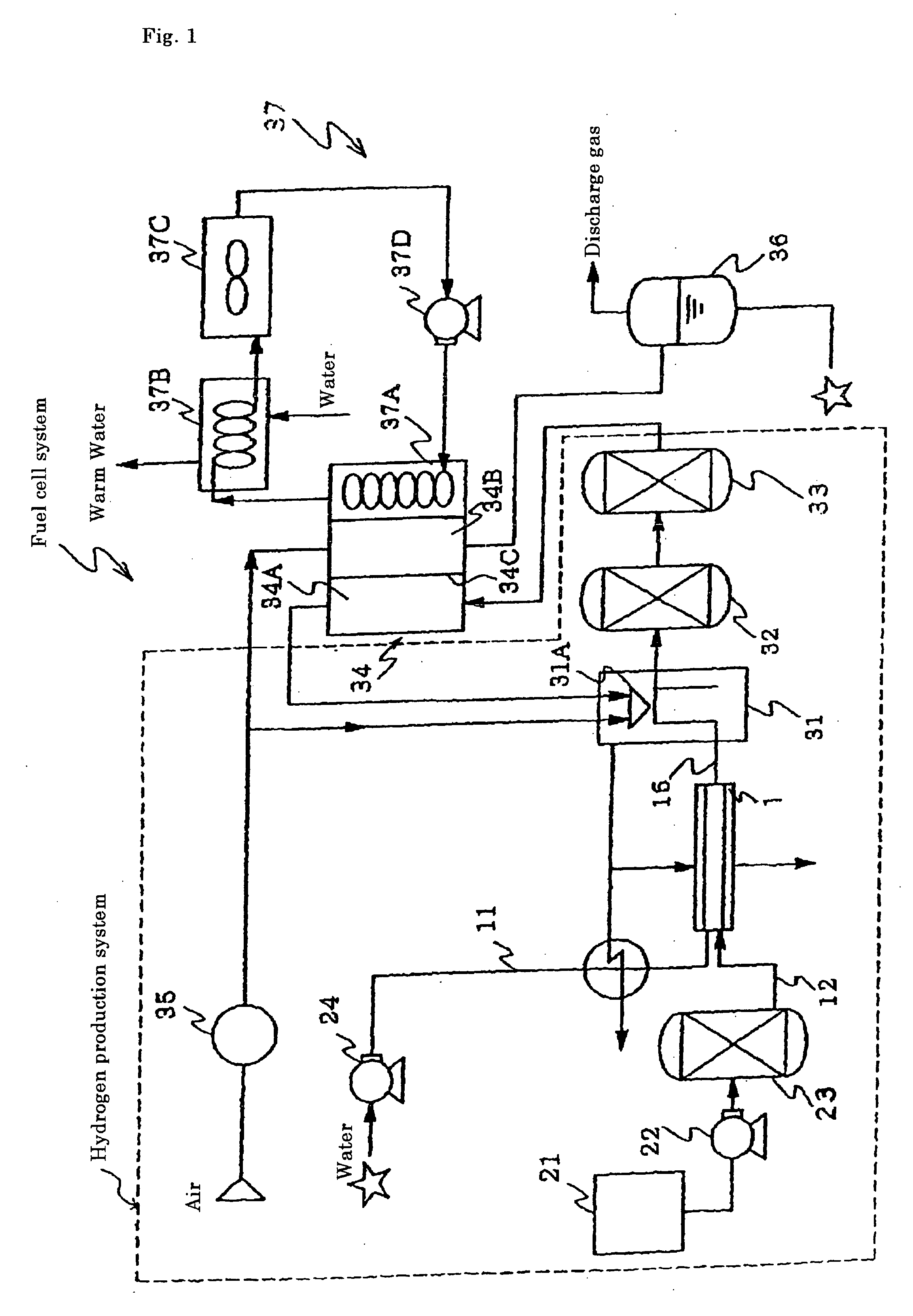

Reforming catalyst for hydrocarbon, method for producing hydrogen using such reforming catalyst, and fuel cell system

InactiveUS20070172416A1High catalytic activityImprove heat resistanceCatalyst activation/preparationHydrogen productionSteam reformingIridium

A hydrocarbon reforming catalyst which maintains carrier strength even after a long-term thermal history and which exhibits high catalytic activity is prepared by causing at least one noble metal component selected from among a ruthenium component, a platinum component, a rhodium component, a palladium component, and an iridium component to be supported on a carrier containing manganese oxide, alumina, and at least one compound selected from among lanthanum oxide, cerium oxide, and zirconium oxide, or a carrier containing silicon oxide, manganese oxide, and alumina. By use of the reforming catalyst, hydrogen is produced through steam reforming (1), autothermal reforming (2), partial-oxidation reforming (3), or carbon dioxide reforming (4). A fuel cell system is constituted from a reformer employing the reforming catalyst, and a fuel cell employing, as a fuel, hydrogen produced by the reformer.

Owner:IDEMITSU KOSAN CO LTD

Ultrahigh strength 6000 series aluminium alloy and preparation method thereof

Ultrahigh strength 6000 series aluminium alloy and a preparation method thereof belong to the technical field of metallurgy. The ultrahigh strength 6000 series aluminium alloy comprises the following components by weight: 0.9-1.4% of Si, 1.4-1.8% of Mg, 0.9-1.3% of Cu, 0.05-0.25% of Cr, 0.05-0.25% of Zr, 0.3-0.7% of Fe, no more than 0.04% of Ti, the balance of Al and impurities, has tensile strength of 500-520 MPa, yield strength of 465-503 MPa and elongation percentage no less than 10%. The preparation method is as below: (1) preparing raw materials; (2) melting and uniformly stirring the raw materials and heating to 745-755 DEG C; (3) carrying out degassing treatment, allowing standing and removing scum; (4) carrying out semi continuous casting to obtain ingot casting; (5) carrying out homogenization treatment; (6) insulating at 400-500 DEG C for 1-2 h, and then carrying out hot extrusion deformation, mold stripping and on-line water passing to obtain a extruded bar; and (7) carrying out solid solution treatment, water quenching and artificial aging treatment in order, carrying out air cooling to room temperature to obtain an ultrahigh strength 6000 series aluminium alloy bar. According to the invention, trace elements of Zr, Cr and a proper amount of Fe are added to the aluminium alloy to gain excellent strength and toughness performance, maintain the characteristics of easy formability, good welding performance and corrosion resistance; and the ultrahigh strength 6000 series aluminium alloy is suitable for production of high-strength lightweight structural members with complex sections.

Owner:NORTHEASTERN UNIV

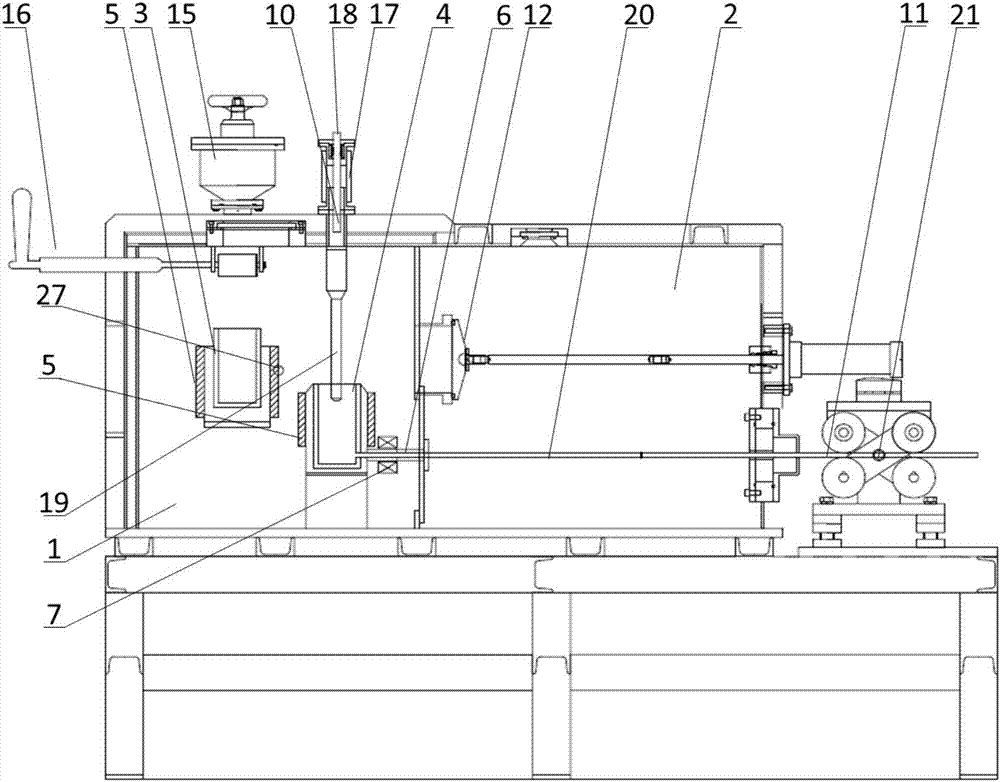

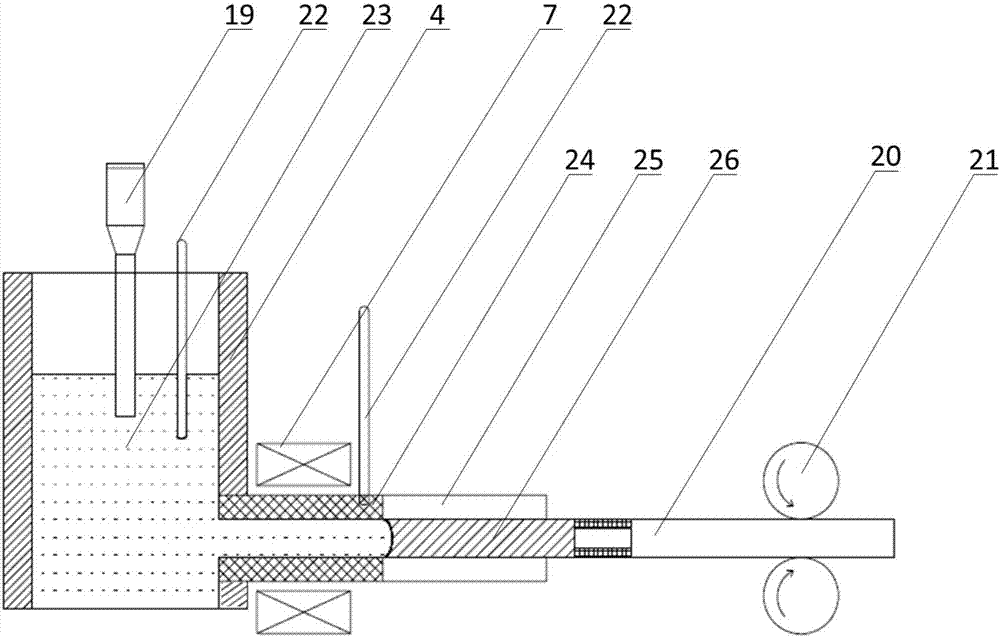

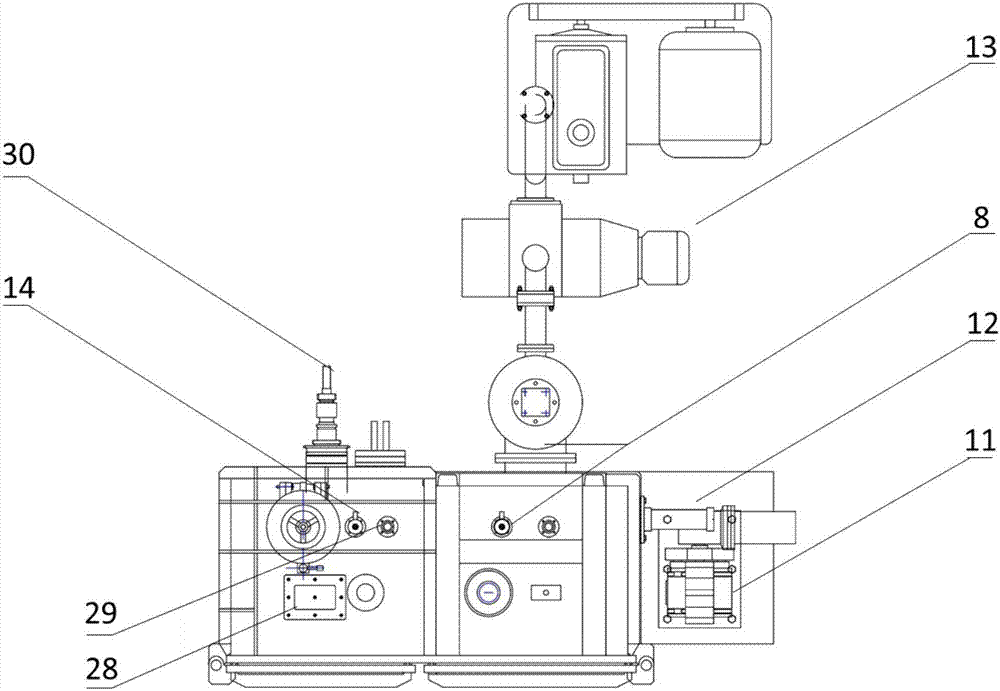

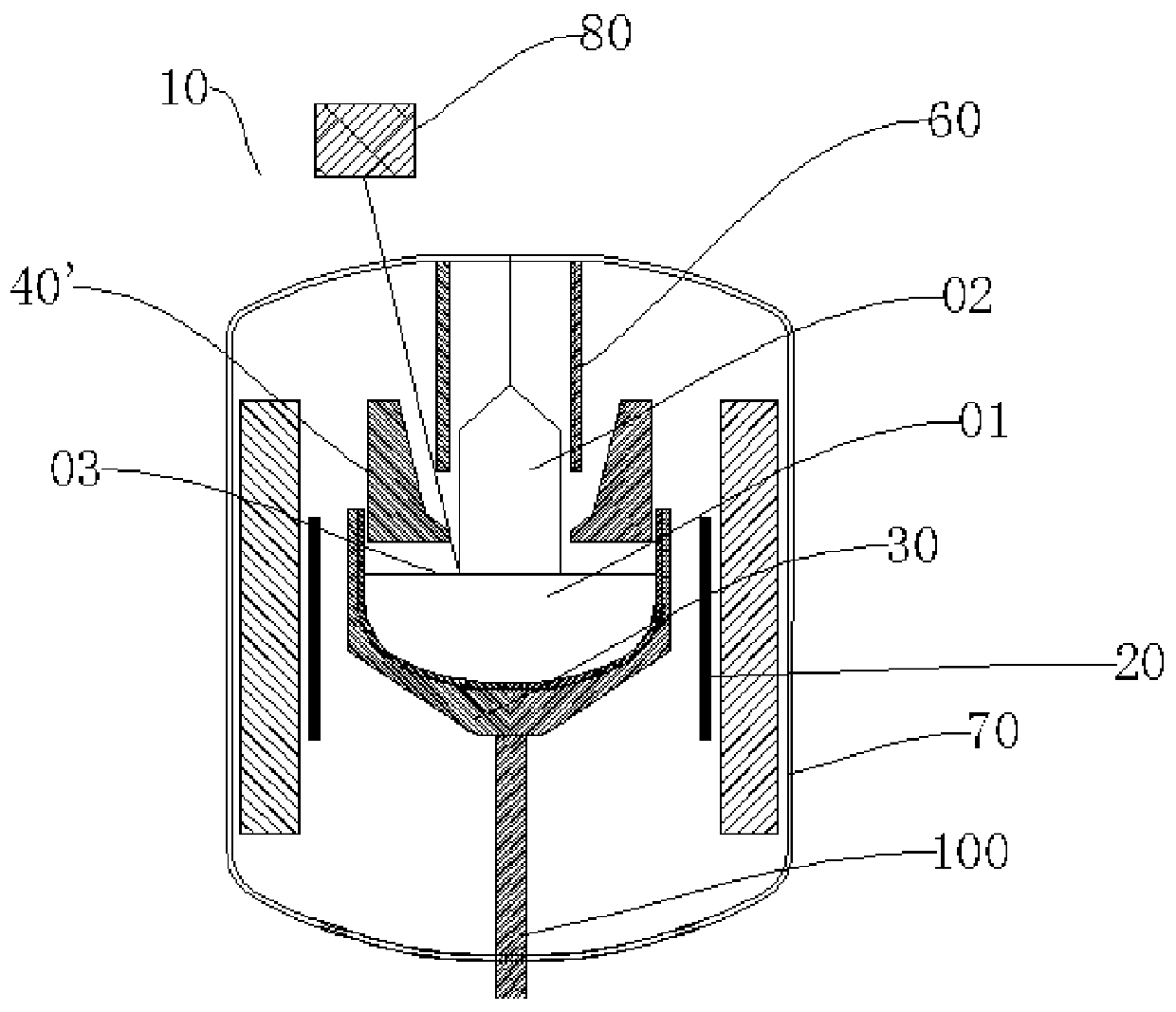

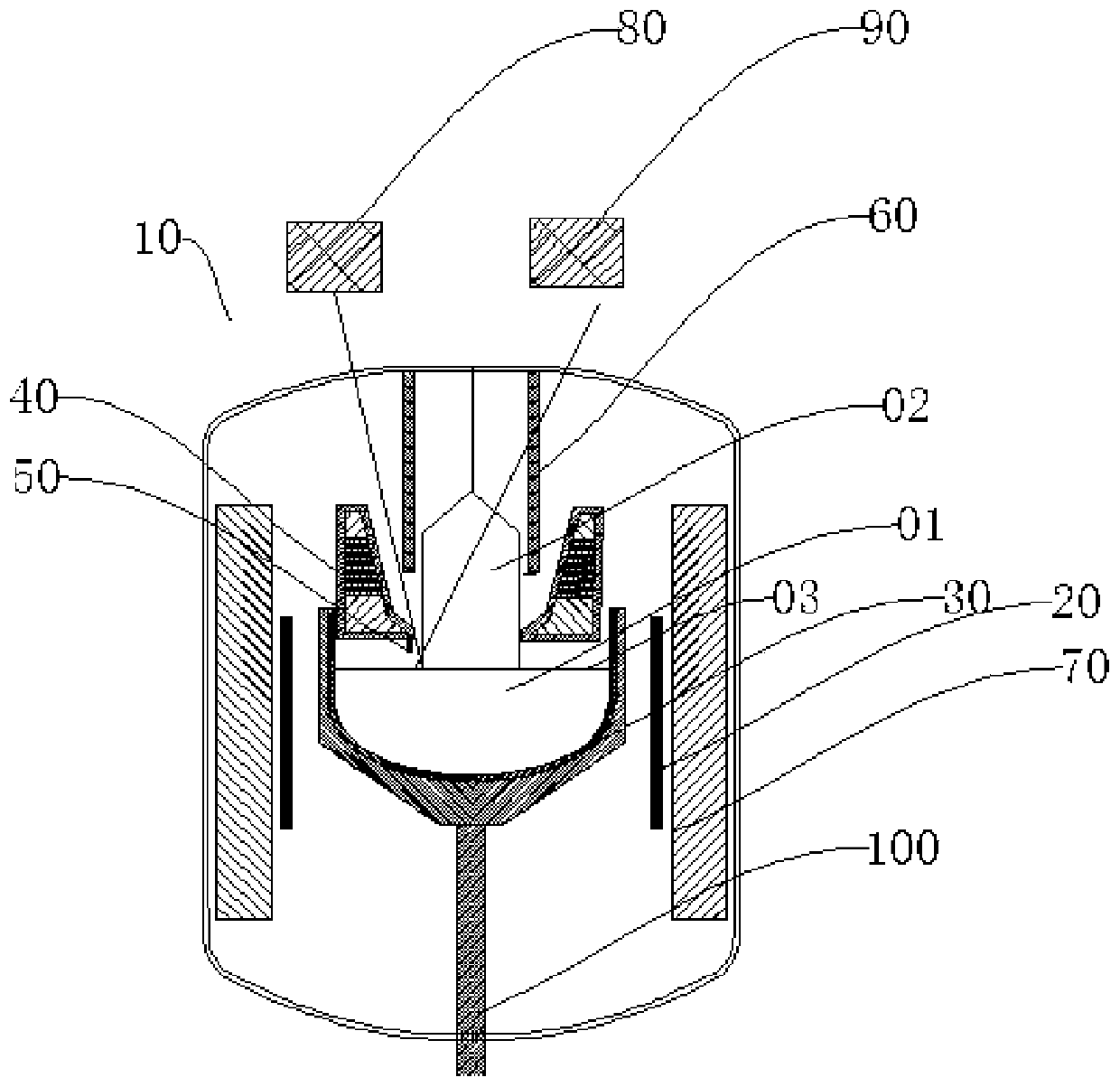

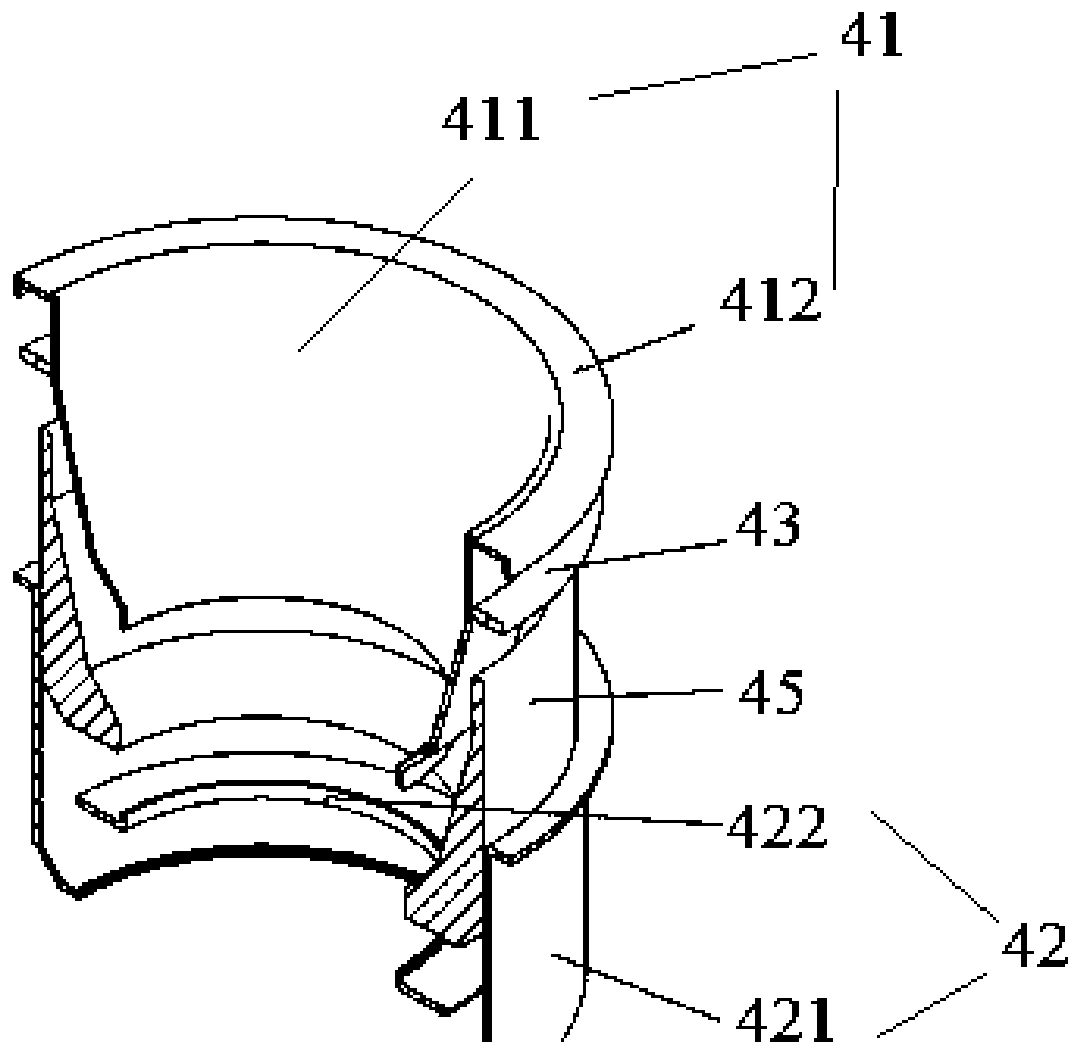

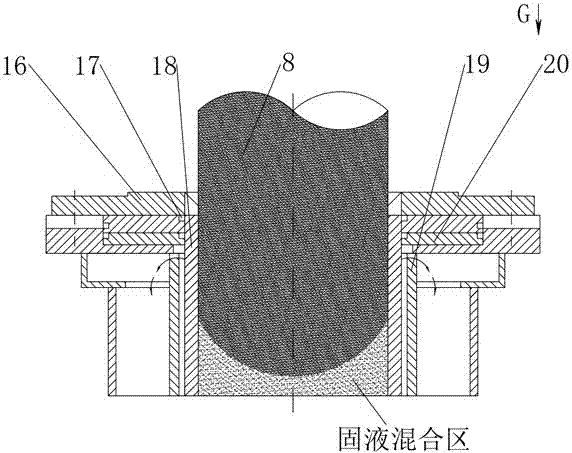

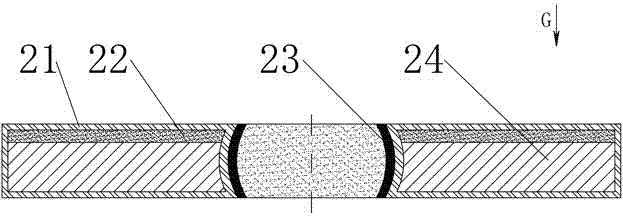

Integrated device and method for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on vacuum condition

The invention provides an integrated device and method for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on the vacuum condition and belongs to the field of metal casting. The integrated device comprises a first vacuum chamber, a second vacuum chamber, a vacuum control system, a material supplementing device, an ultrasonic treatment device and a throwing device. According to the integrated device and technology for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on the vacuum condition, the device can be widely applied to horizontal continuous casting of a high-temperature alloy, a titanium alloy, a magnesium alloy, a rare earth metal, multi-component amorphous alloy, high-entropy alloy and other active alloys, smelting, pouring and continuous forming under electromagnetic and ultrasonic coupled fields of the alloys can be all completed in the vacuum state, and the obtained horizontal continuous casting alloy workpiece has the effects of being smooth and clean in surface, uniform in component and dense in structure.

Owner:DALIAN UNIV OF TECH

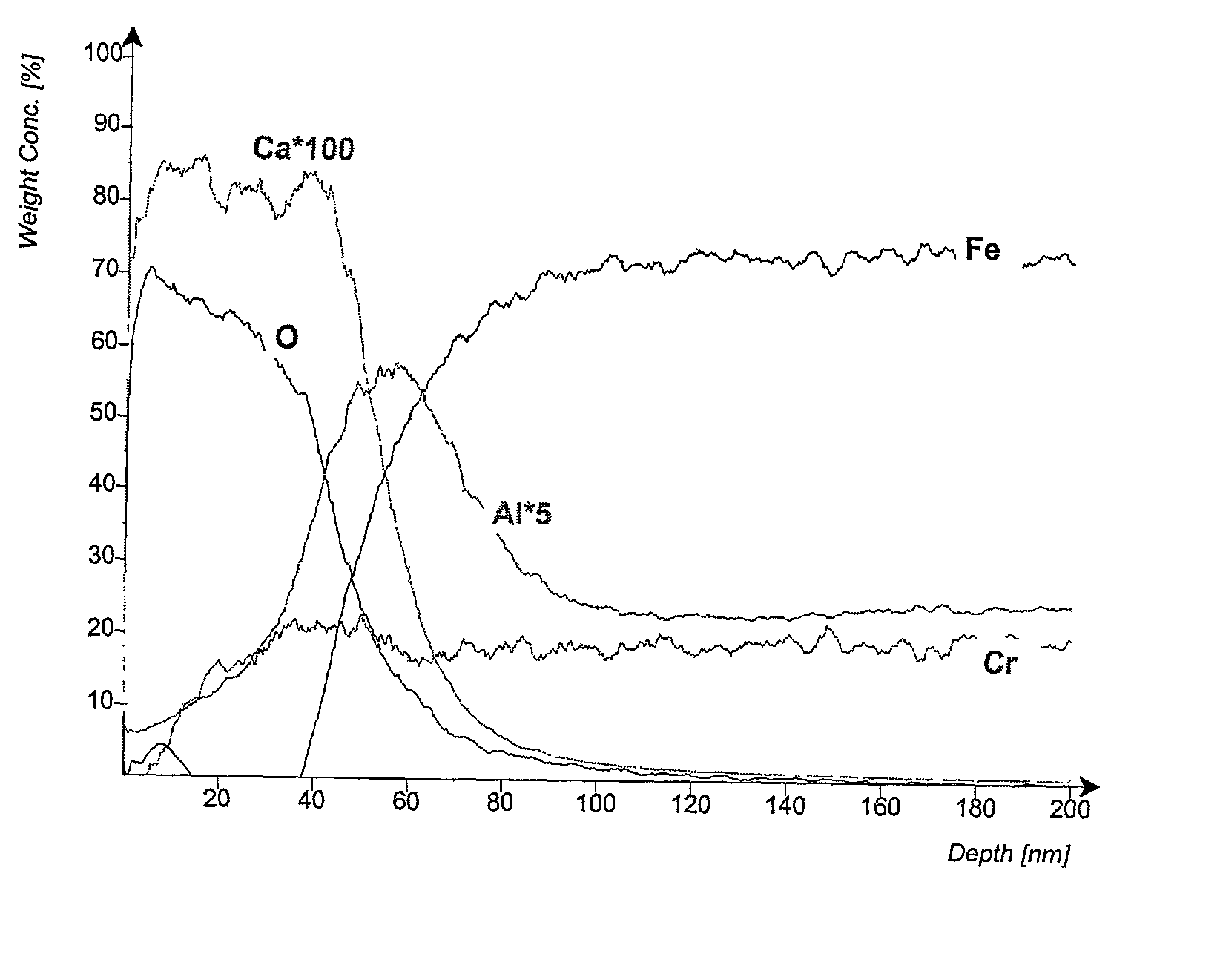

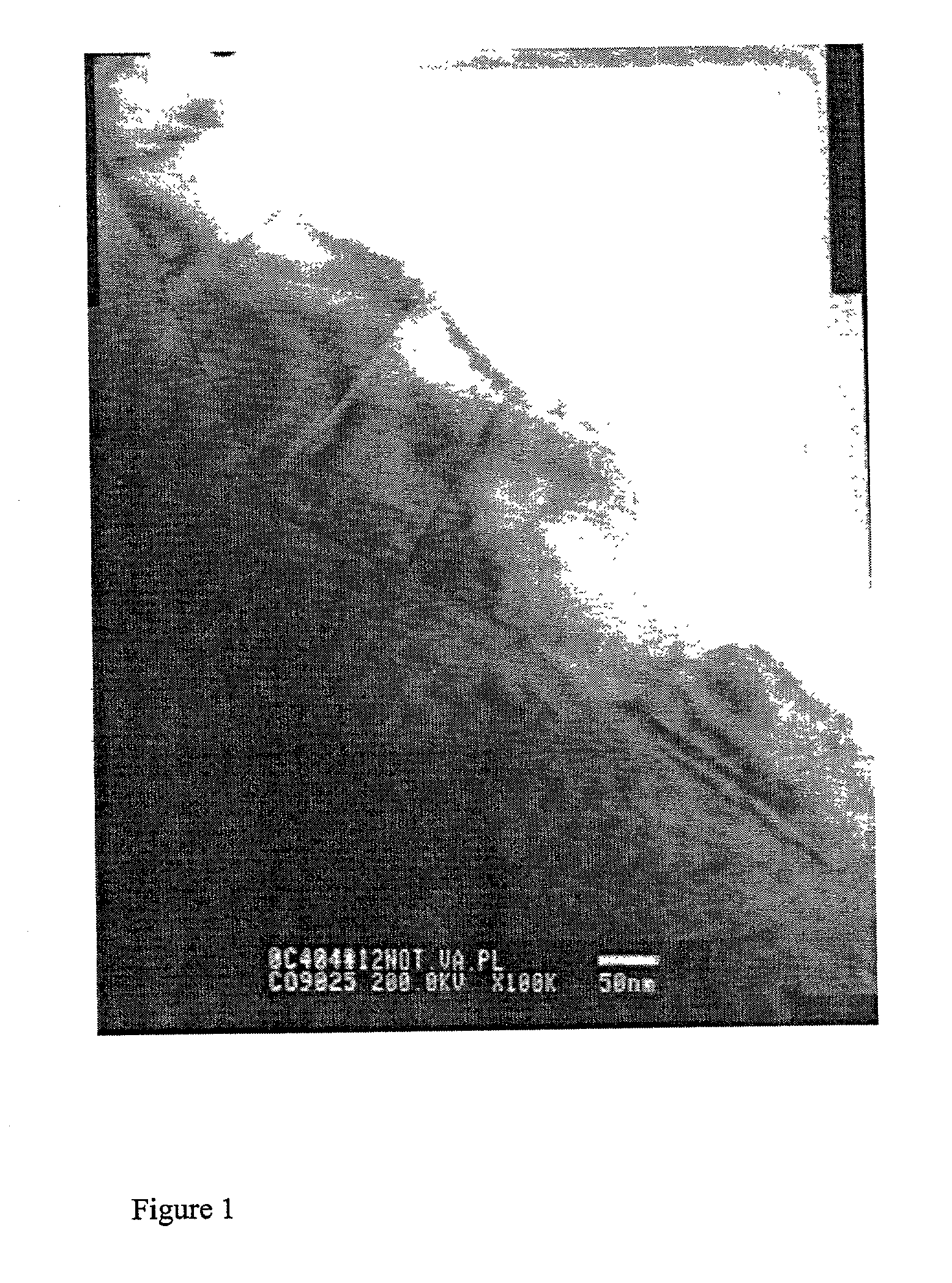

Surface modified stainless steel

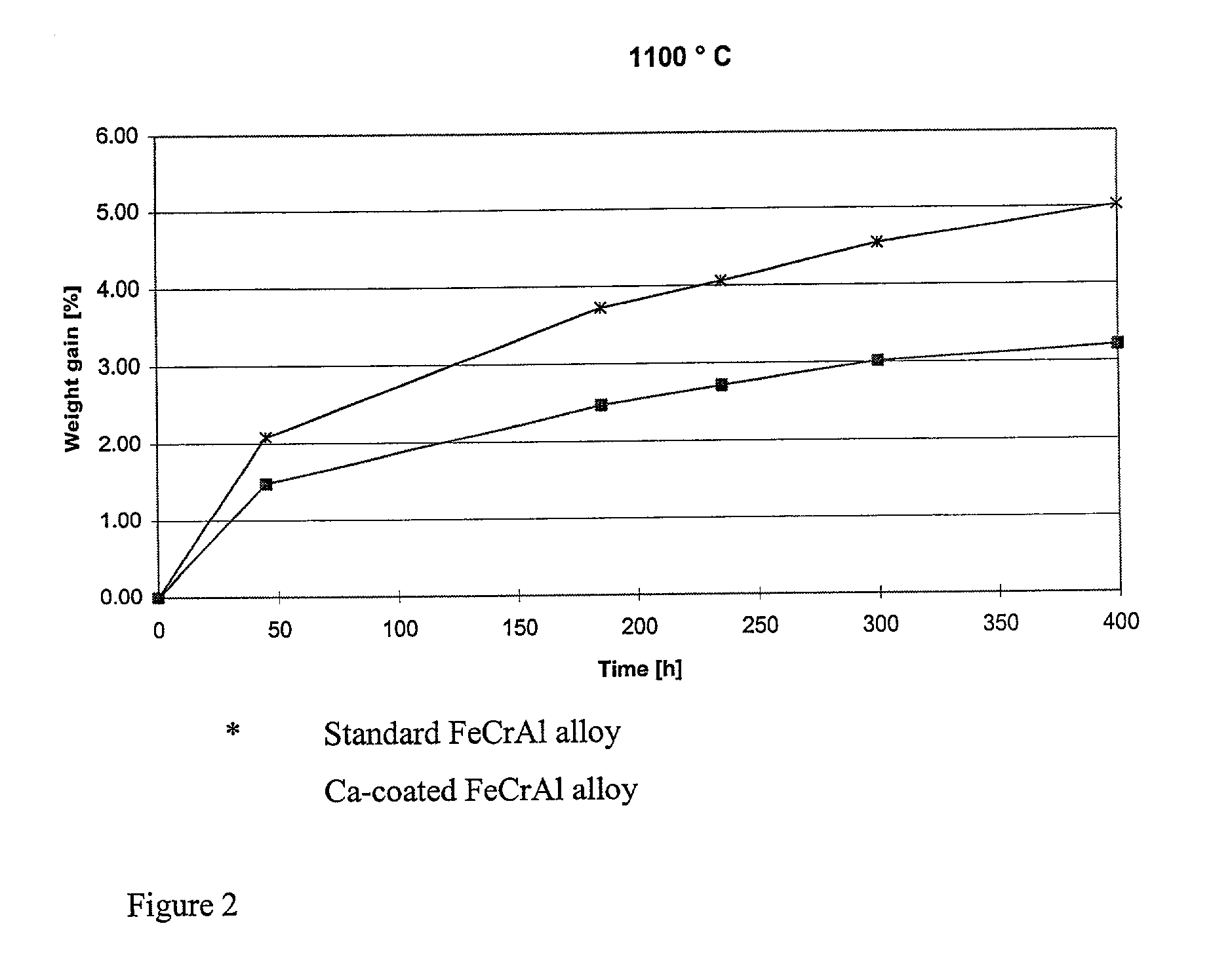

InactiveUS20020014282A1Inhibition formationInhibition of nucleationCatalyst carriersVacuum evaporation coatingSuperalloyHigh-temperature corrosion

A method has been developed for surface modifications of high temperature resistant alloys, such as FeCrAl alloys, in order to increase their resistance to corrosion at high temperatures. Coating it with a Ca-containing compound before heat-treating builds a continuos uniform and adherent layer on the surface of the alloy, that the aluminum depletion of the FeCrAl alloy is reduced under cyclic thermal stress. By this surface modification the resistance to high temperature corrosion of the FeCrAl alloy and its lifetime are significantly increased.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

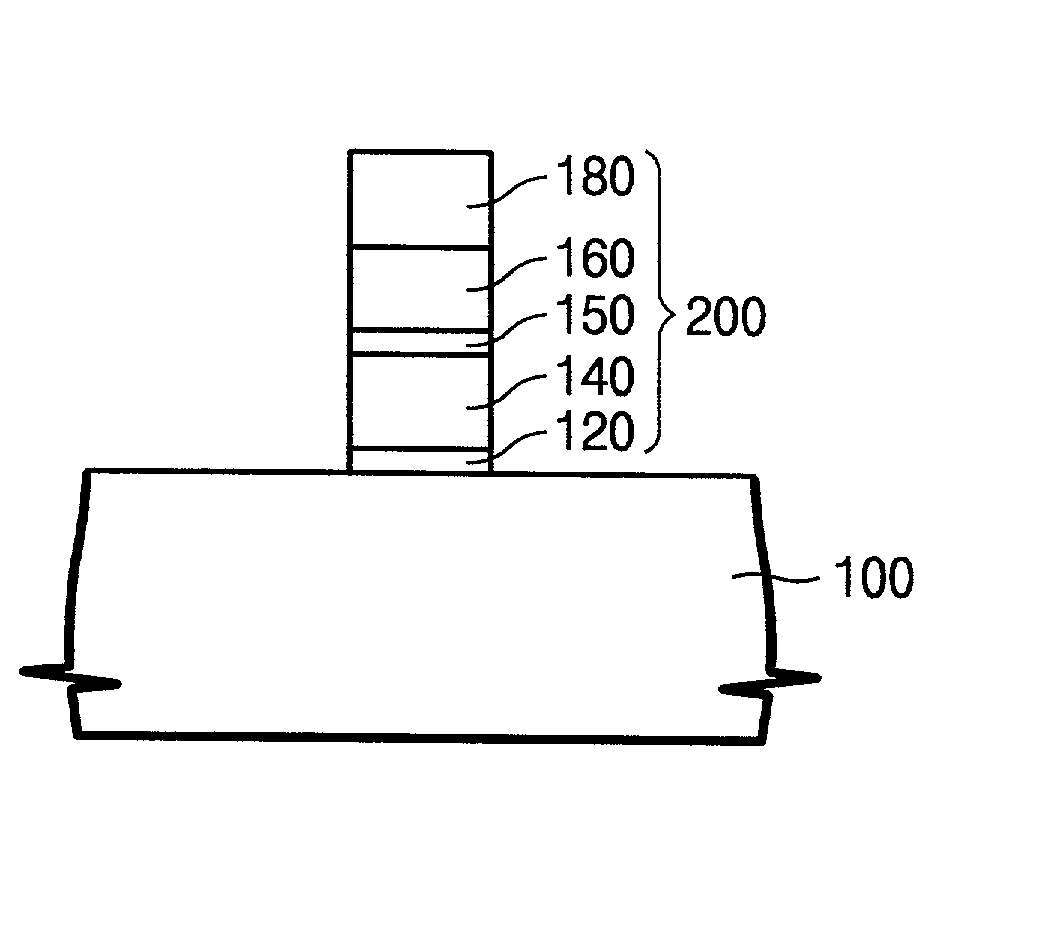

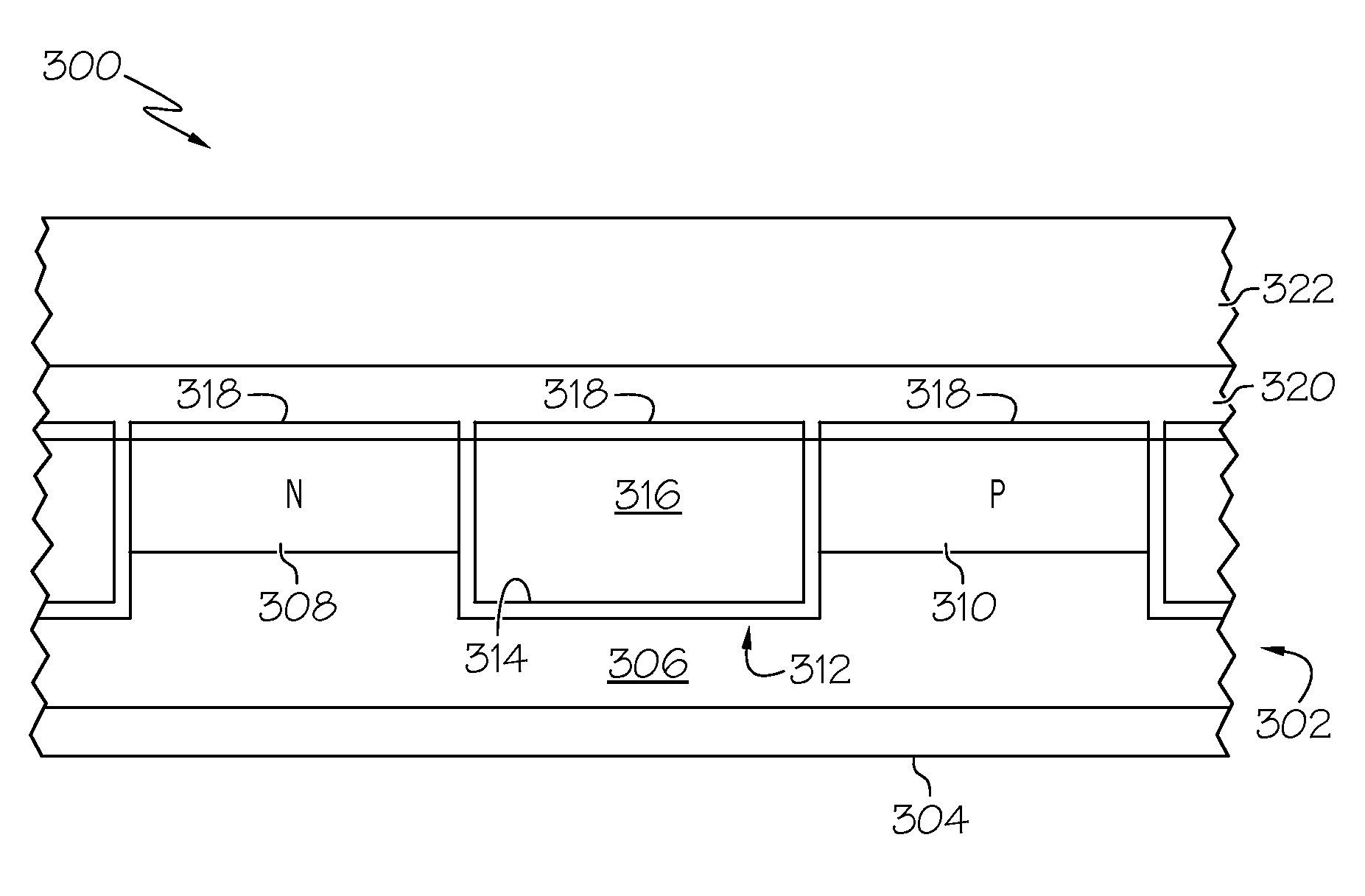

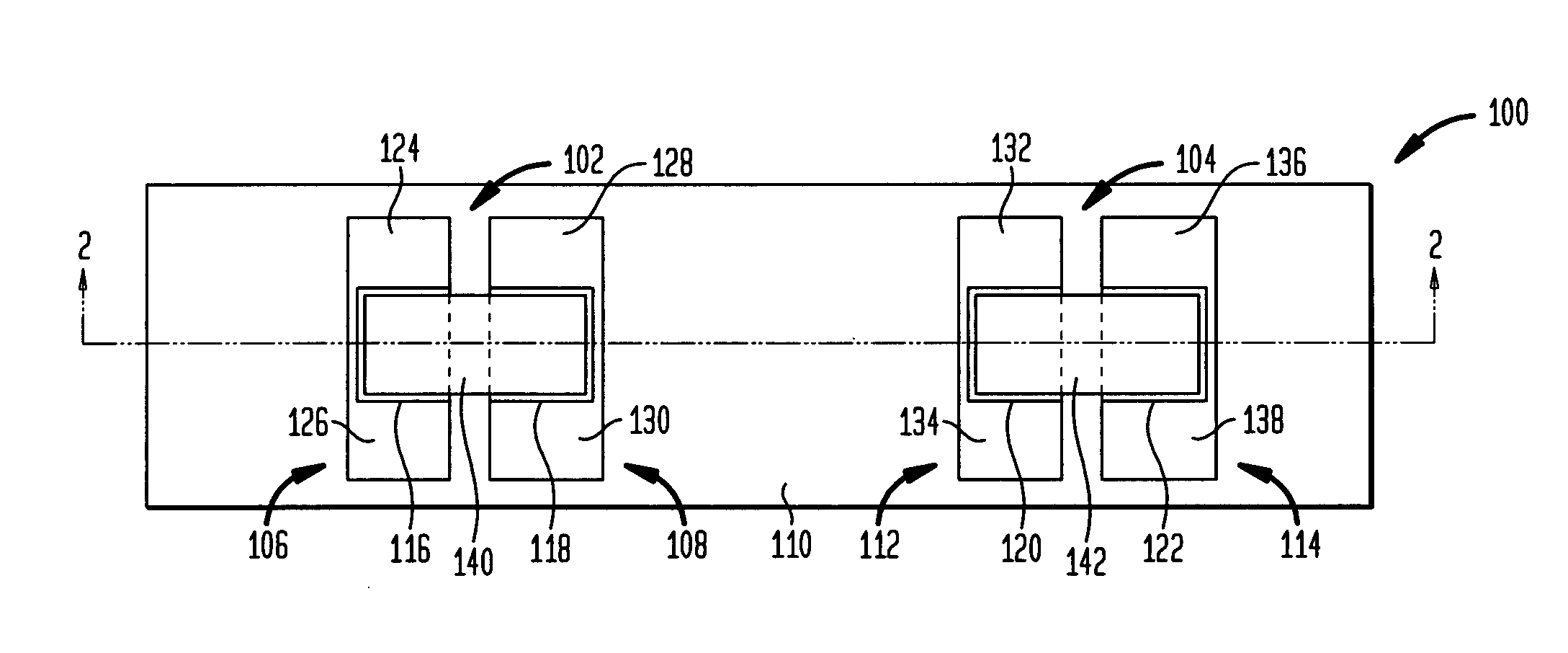

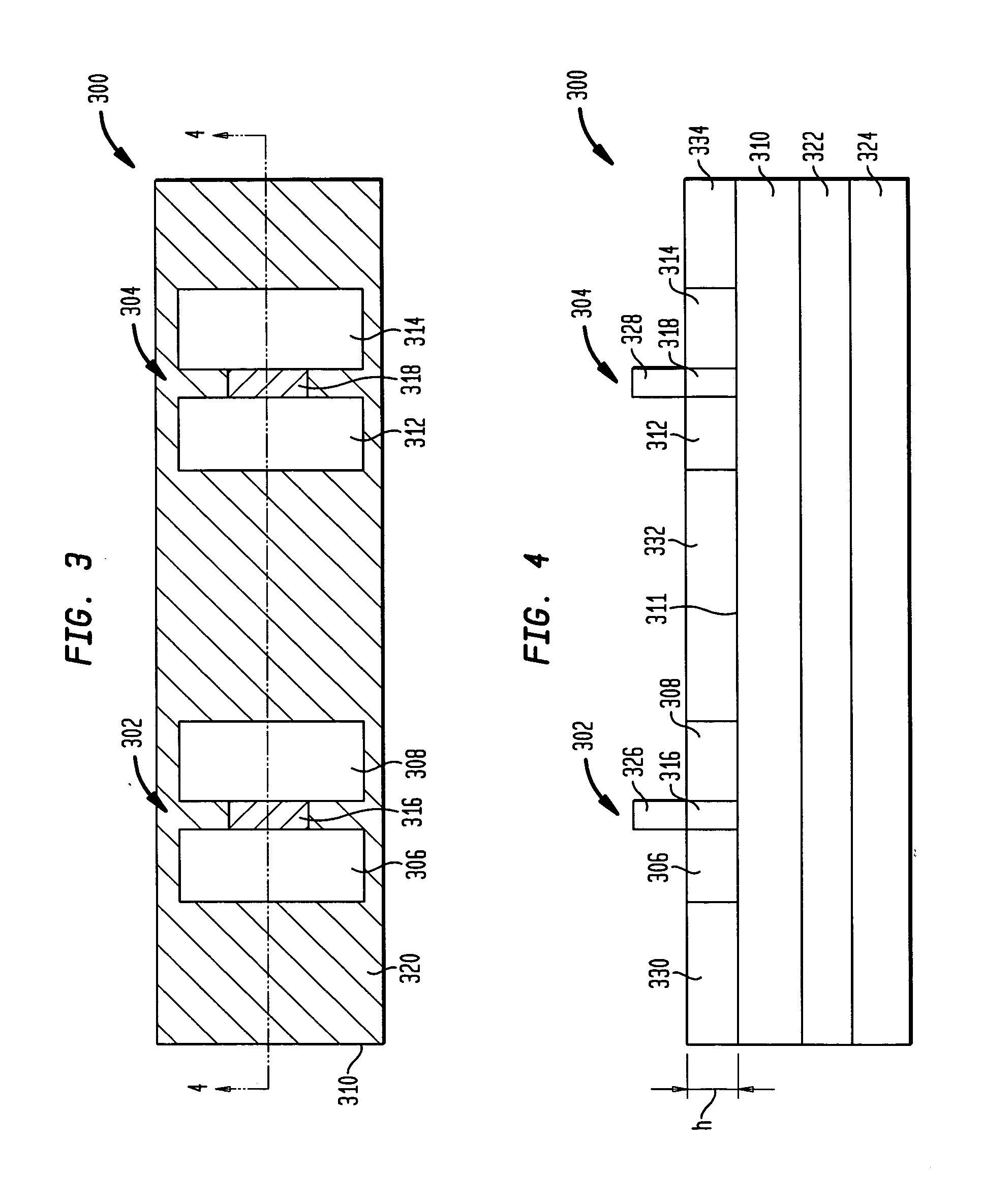

Semiconductor device with isolation trench liner, and related fabrication methods

ActiveUS20100052094A1Inhibition formationInhibition of nucleationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsDevice material

A method of manufacturing a semiconductor device is provided herein, where the width effect is reduced in the resulting semiconductor device. The method involves providing a substrate having semiconductor material, forming an isolation trench in the semiconductor material, and lining the isolation trench with a liner material that substantially inhibits formation of high-k material thereon. The lined trench is then filled with an insulating material. Thereafter, a layer of high-k gate material is formed over at least a portion of the insulating material and over at least a portion of the semiconductor material. The liner material divides the layer of high-k gate material, which prevents the migration of oxygen over the active region of the semiconductor material.

Owner:CHENGDU HAIGUANG INTEGRATED CIRCUIT DESIGN CO LTD

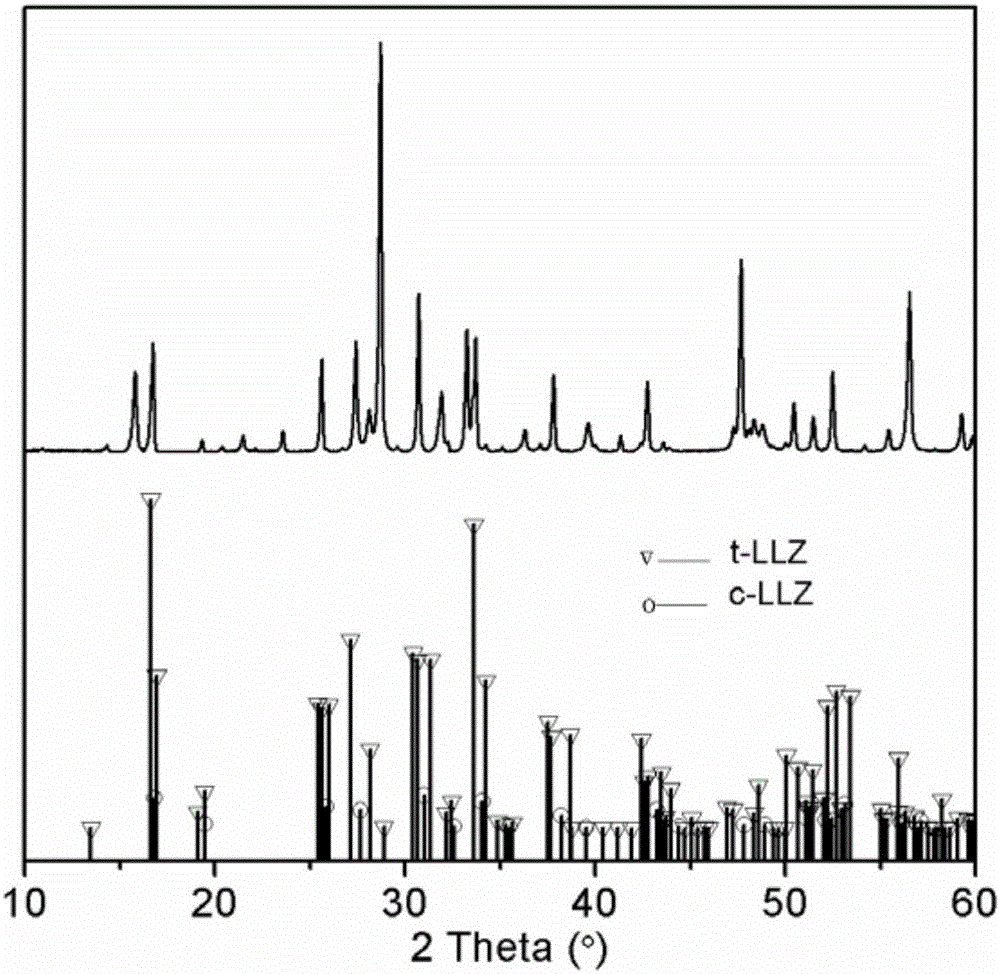

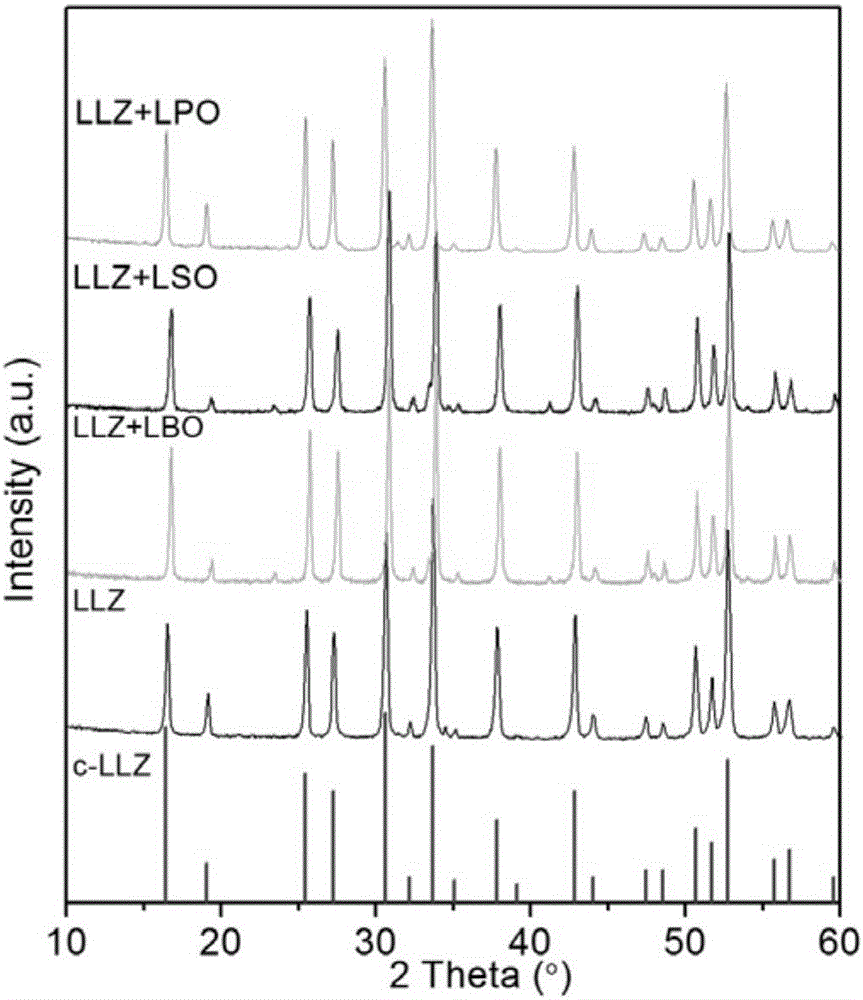

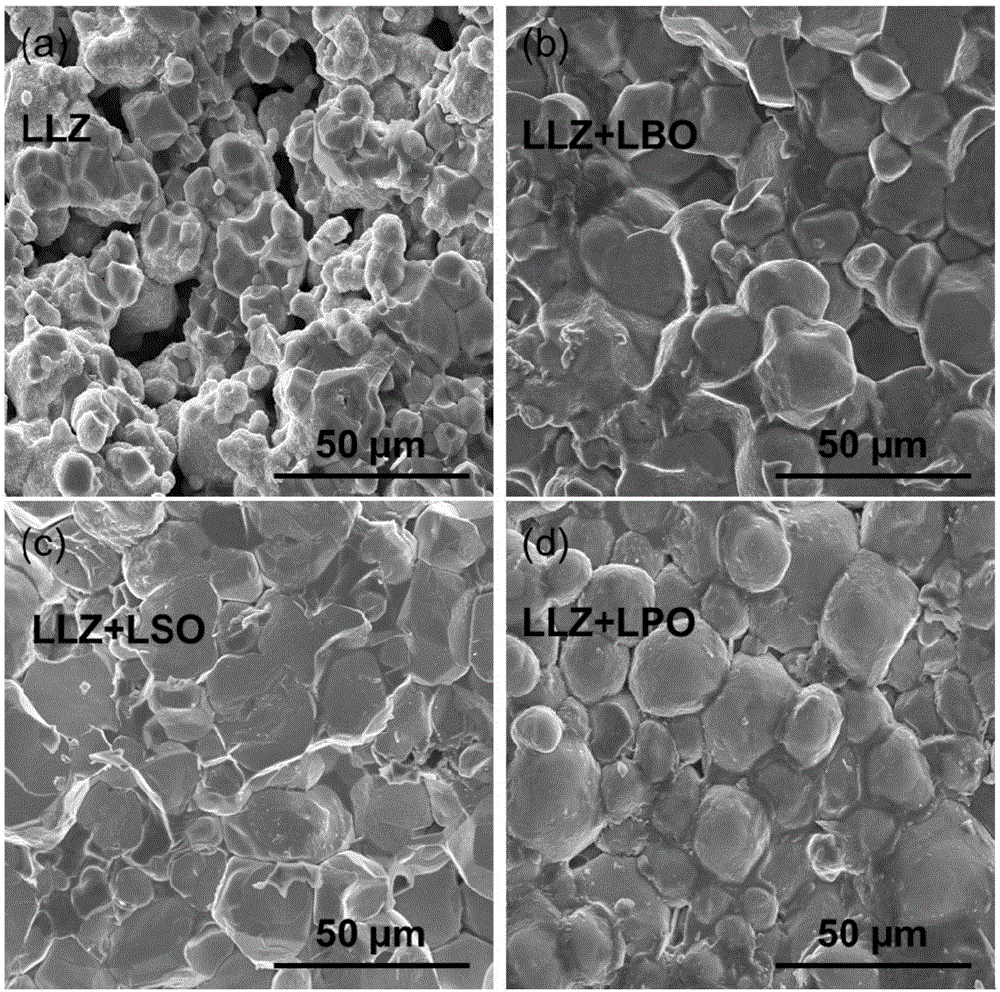

Solid electrolyte for inhibiting lithium dendrites growth in full-solid-state battery, and preparation method thereof

InactiveCN106848392AImprove microstructureImprove sintering performanceSecondary cellsSolid state electrolyteIonic conductance

The invention relates to a solid electrolyte for inhibiting lithium dendrites growth in a full-solid-state battery, and a preparation method thereof. The solid electrolyte is prepared from lithium-lanthanum-zirconium oxide ceramic and 0.1 to 10 weight percent of low-melting-point sintering aid. The preparation method comprises the following steps of dry grinding and uniformly mixing stoichiometric lithium carbonate, lanthanum oxide and zirconium oxide, and then presintering in a muffle furnace at the temperature of 900 DEG C to form a phase; adding the low-melting-point sintering aid into presintering powder, and dry grinding and mixing to obtain a manual pressed sheet sample; densifying during a further high-temperature sintering process to form the solid electrolyte with high ionic conductance, stable performance and high repeatability. Compared with the prior art, without influencing a conductive property of a lithium-contained garnet lithium ion, a low-cost second phase is used so that the conductive property of the lithium ion at a crystal boundary part is improved, the solid electrolyte can better realize lithium ion transmission and plays a role in inhibiting the lithium dendrites growth in the full-solid-state battery, and the safety of the lithium battery is improved.

Owner:SHANGHAI JIAO TONG UNIV

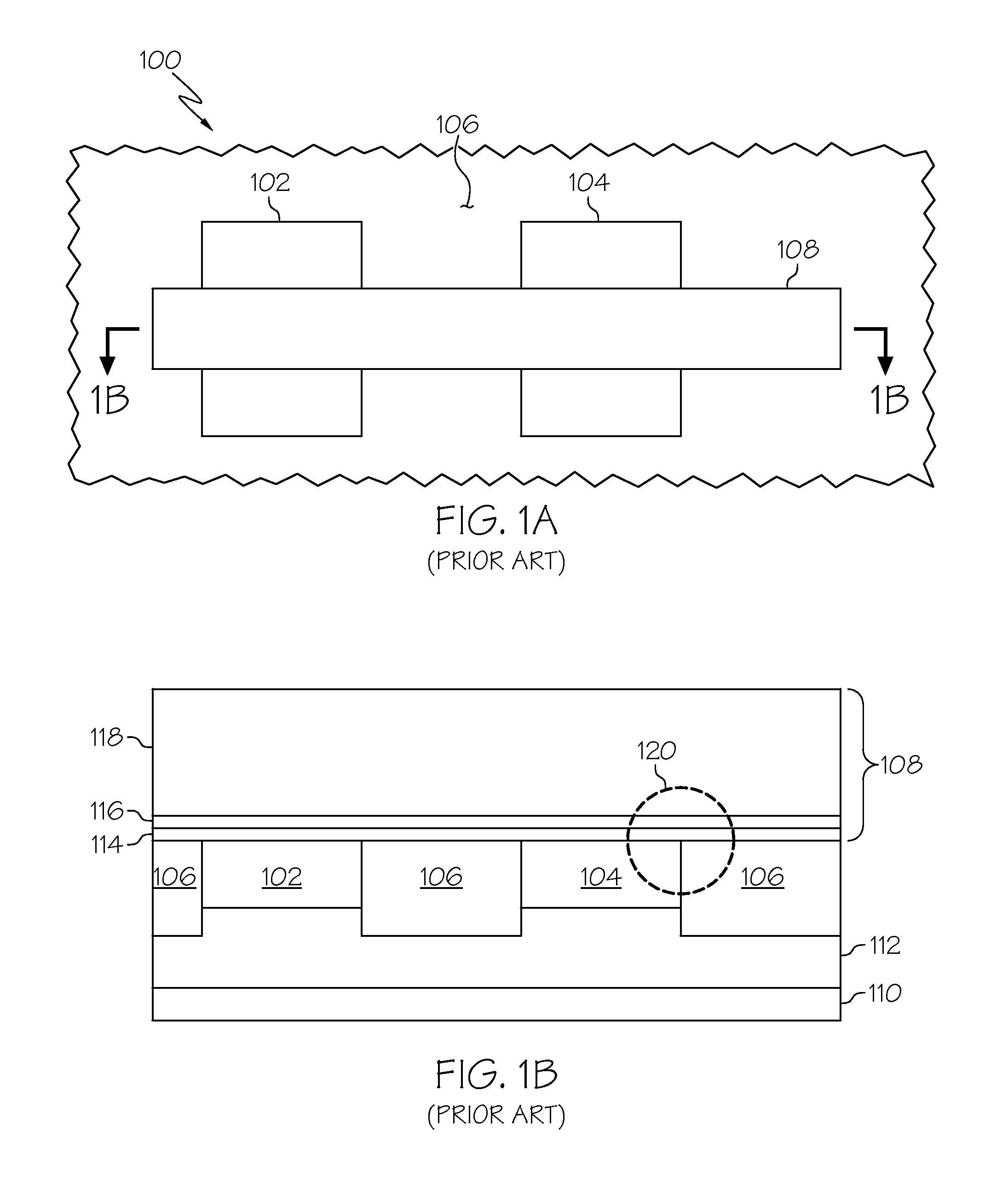

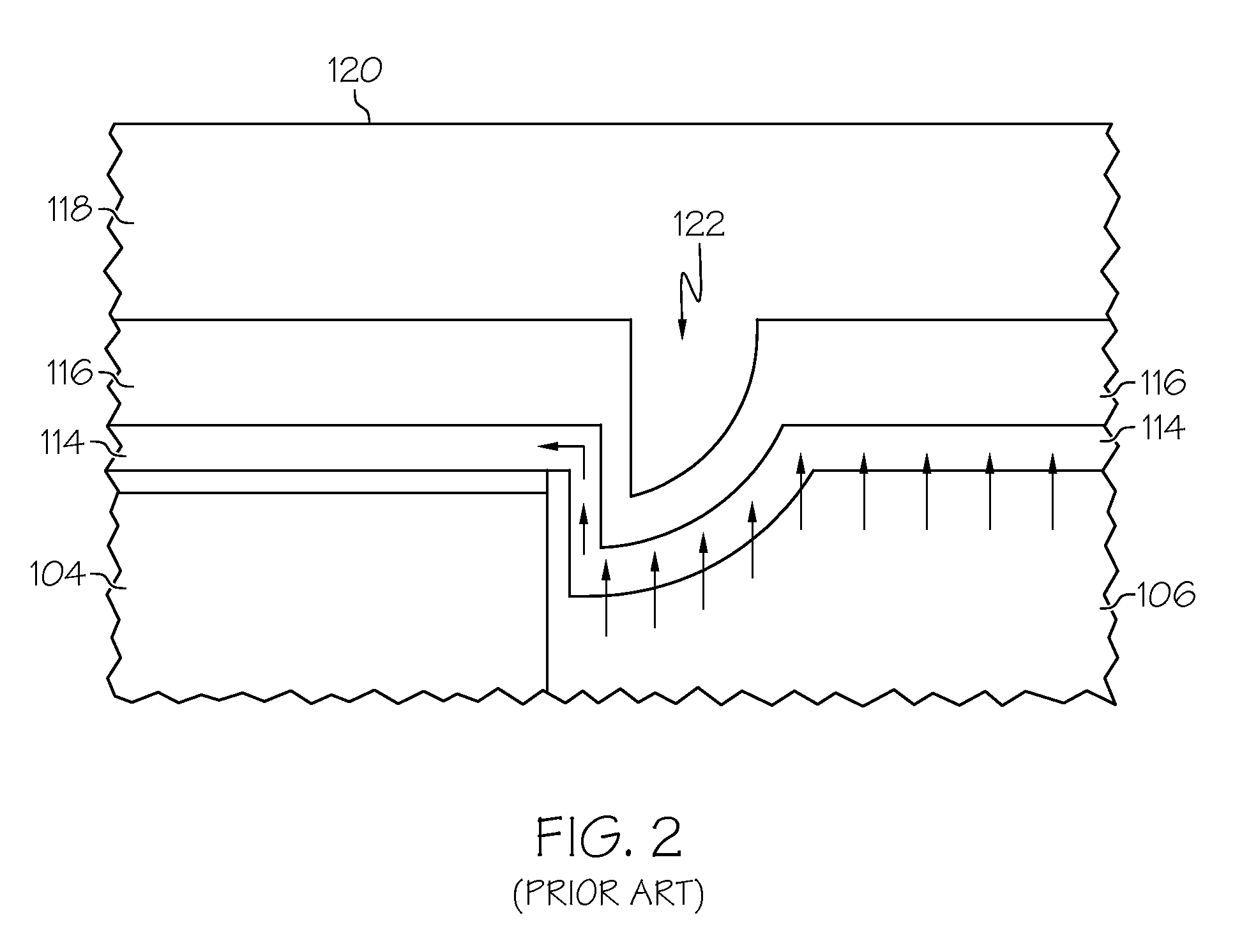

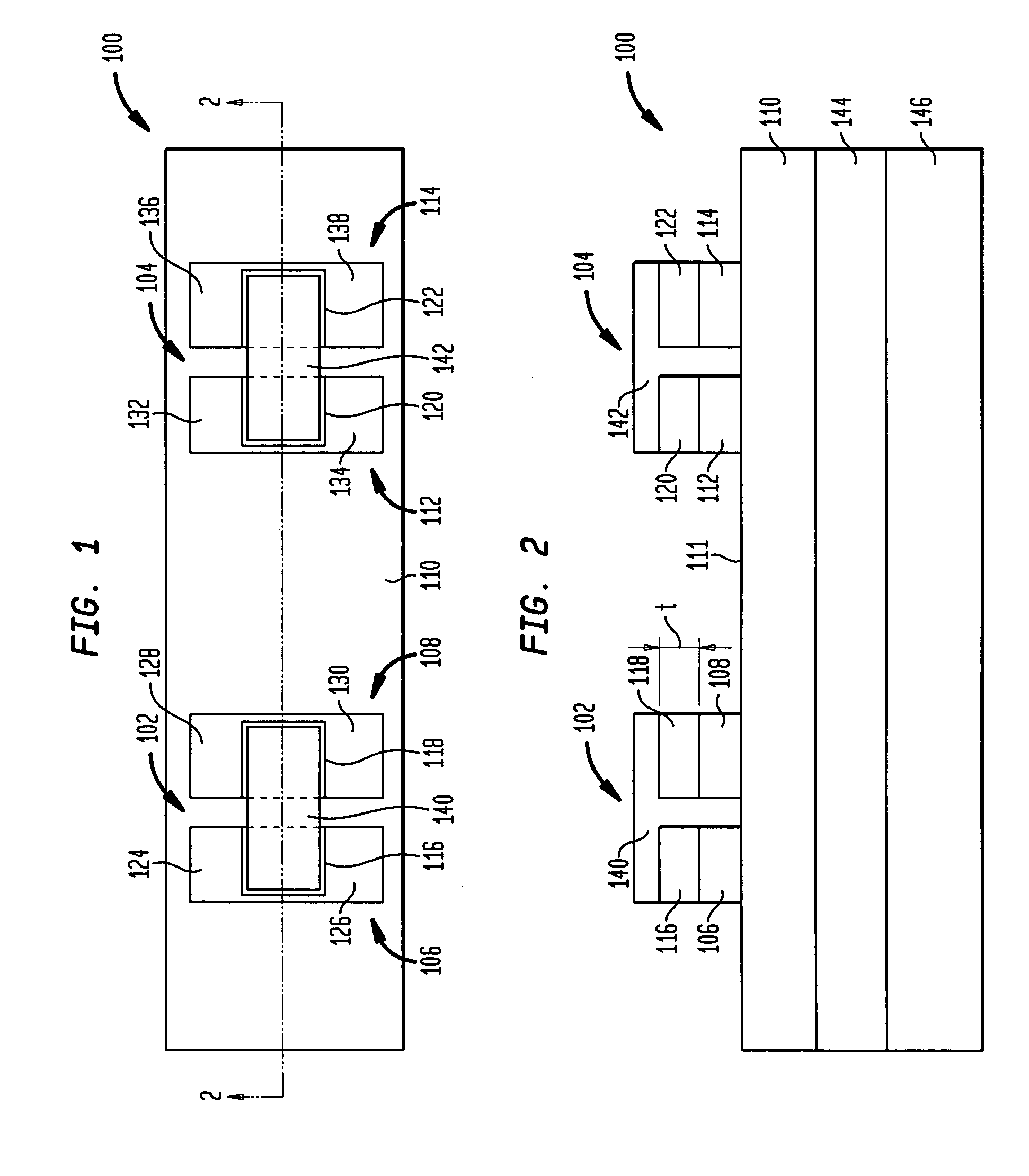

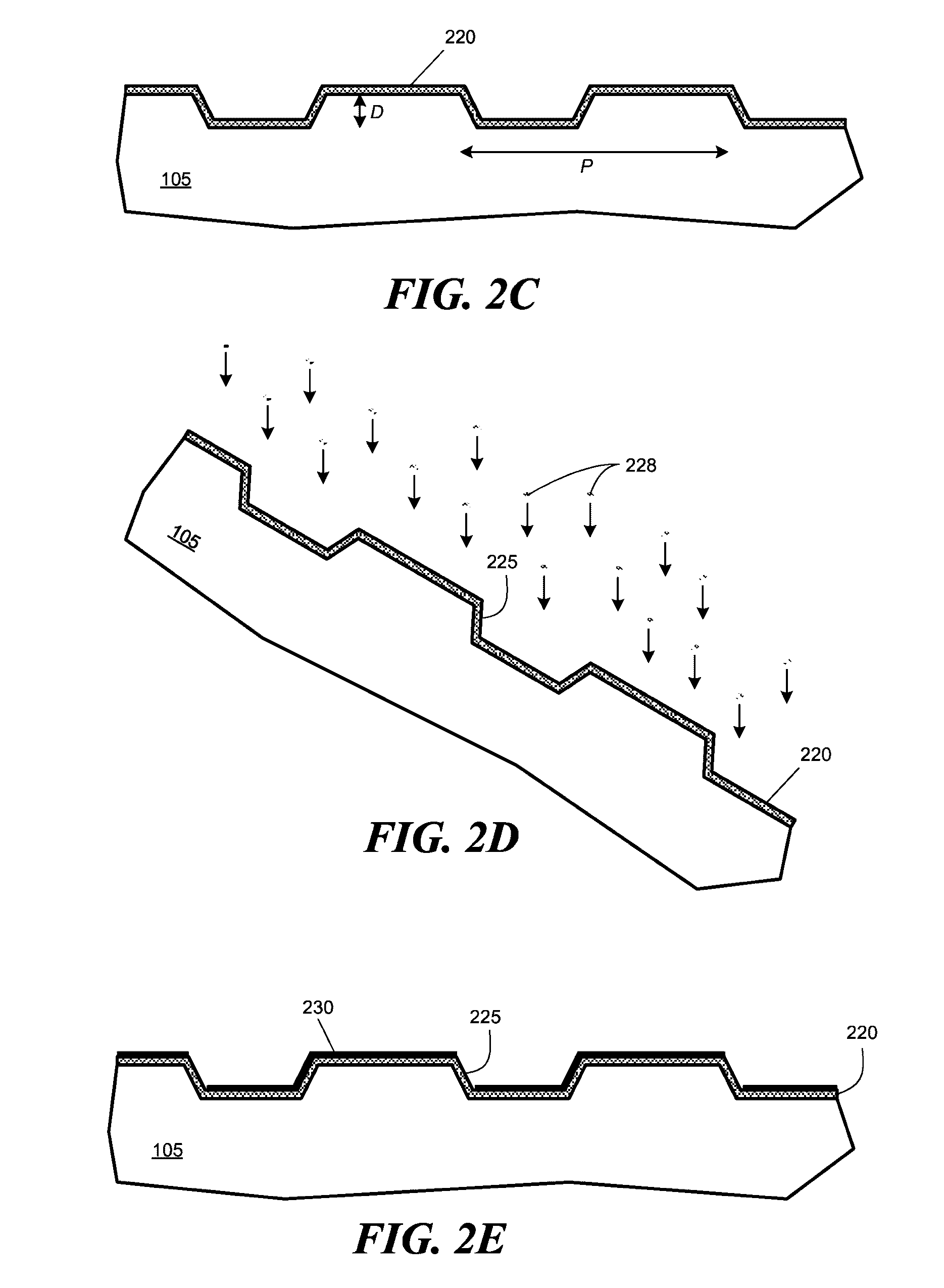

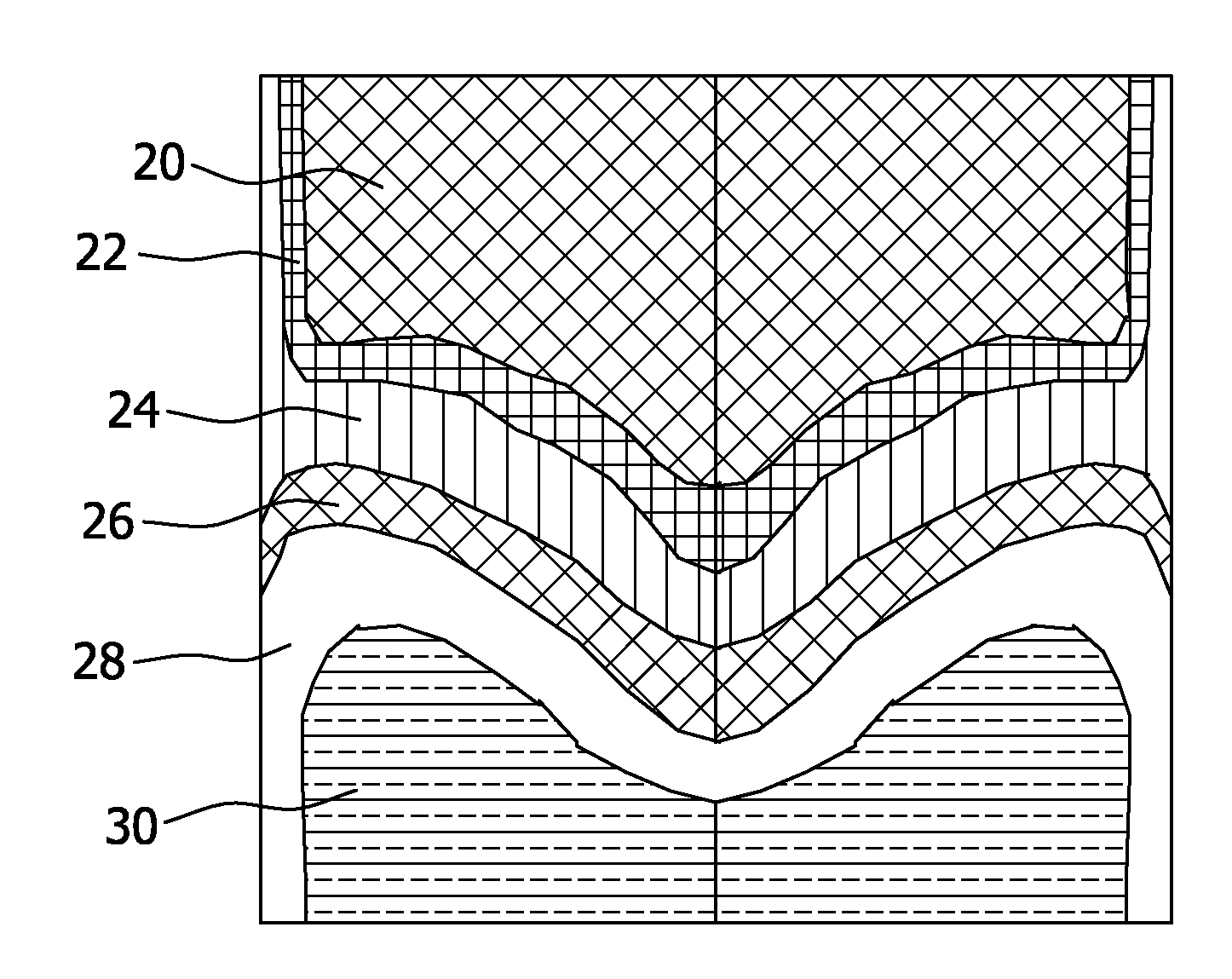

Devices having patterned regions of polycrystalline organic semiconductors, and methods of making the same

InactiveUS20050110006A1Promote and inhibit nucleationInhibition of nucleationTransistorMaterial nanotechnologyCompound (substance)Organic semiconductor

Semiconductor apparatus comprising a substrate having a substrate surface; a first dielectric layer comprising molecules of a first compound, the molecules of the first compound having first ends and second ends, the first ends being covalently bonded to a first region of the substrate surface, the second ends having aromatic regions; and a polycrystalline semiconductor layer comprising organic semiconductor molecules with aromatic portions, the polycrystalline semiconductor layer being on the first region of the substrate. Integrated circuits comprising apparatus, and methods for making apparatus and integrated circuits.

Owner:LUCENT TECH INC

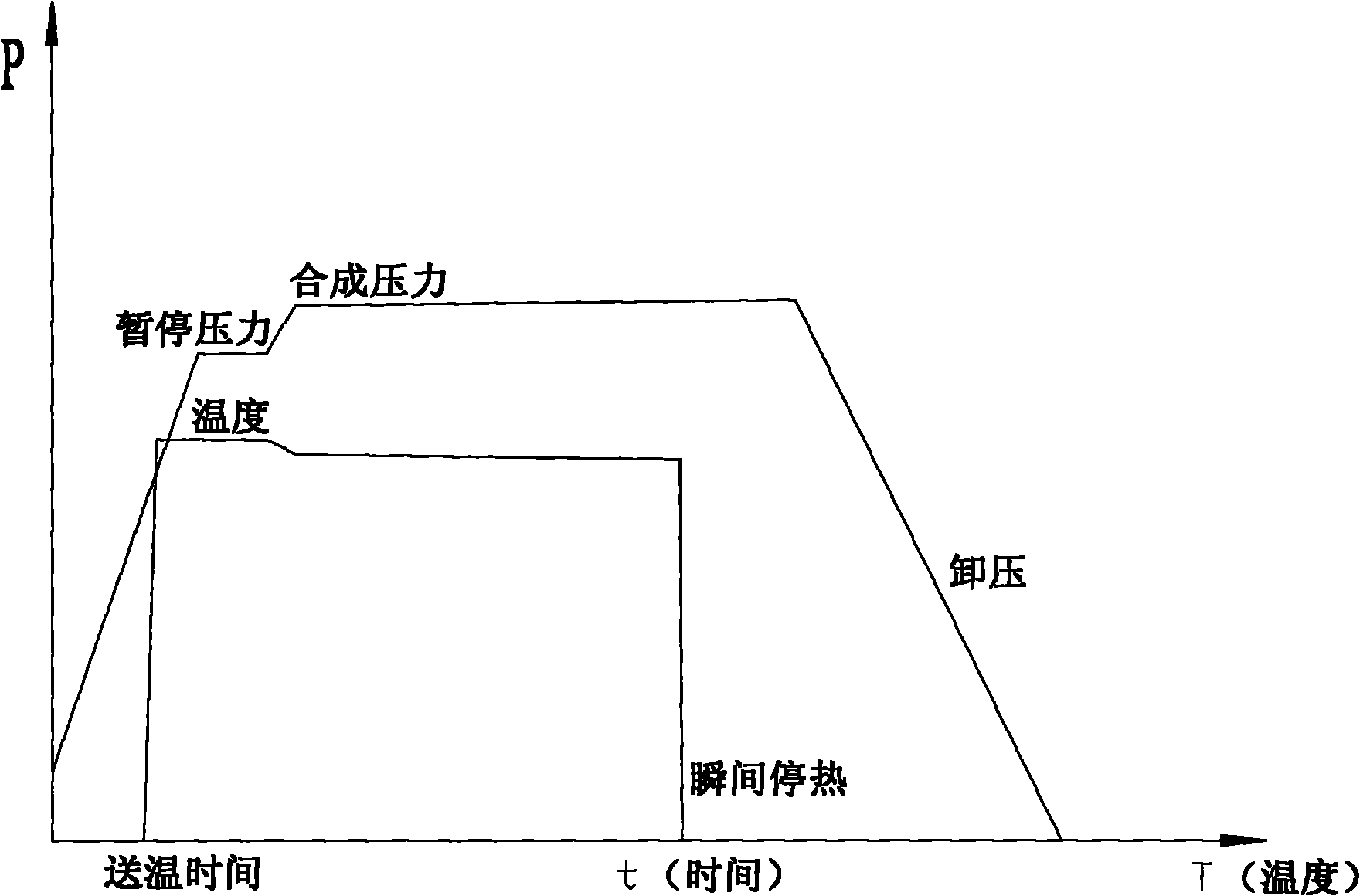

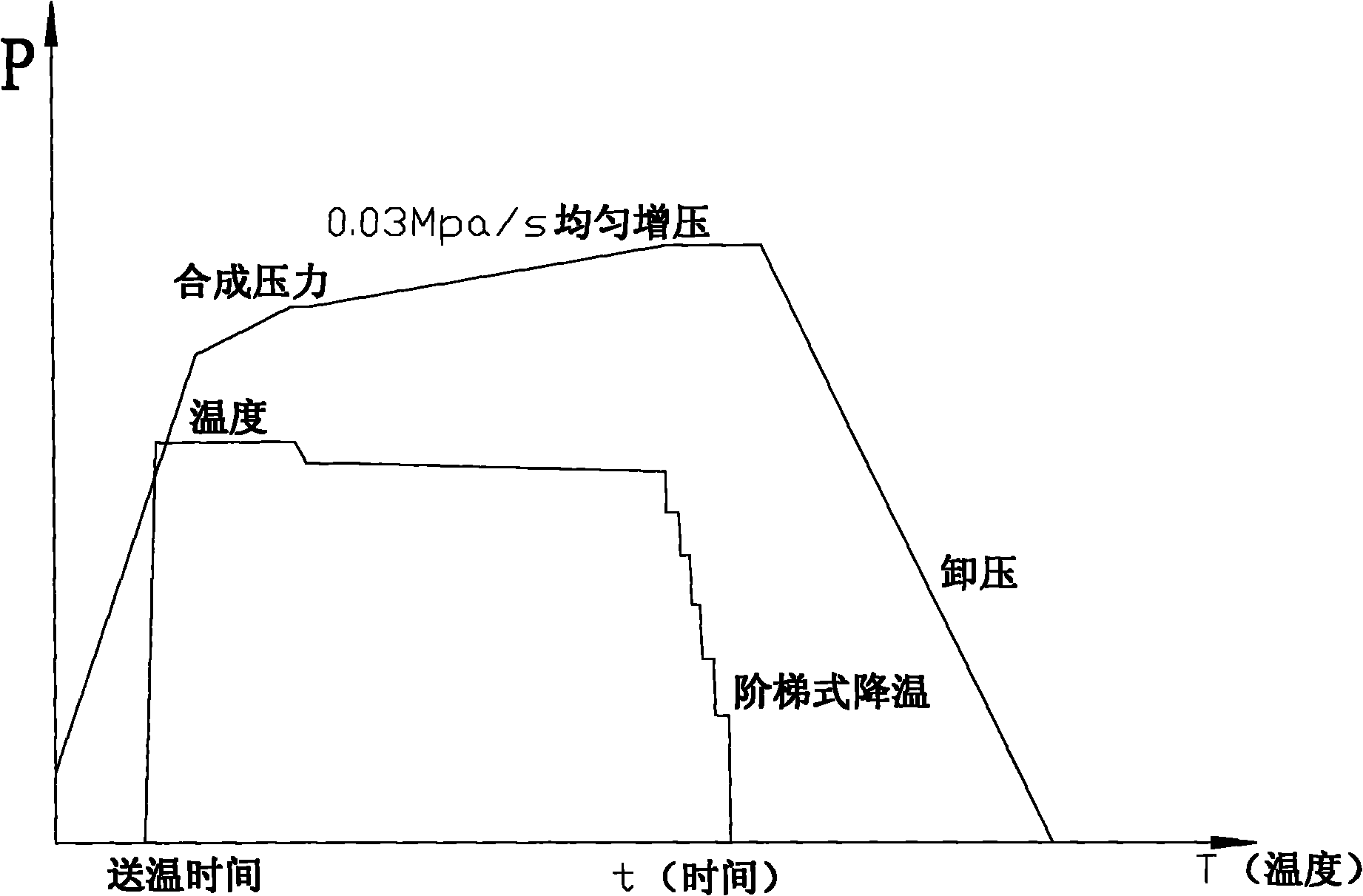

Process for synthesizing diamond

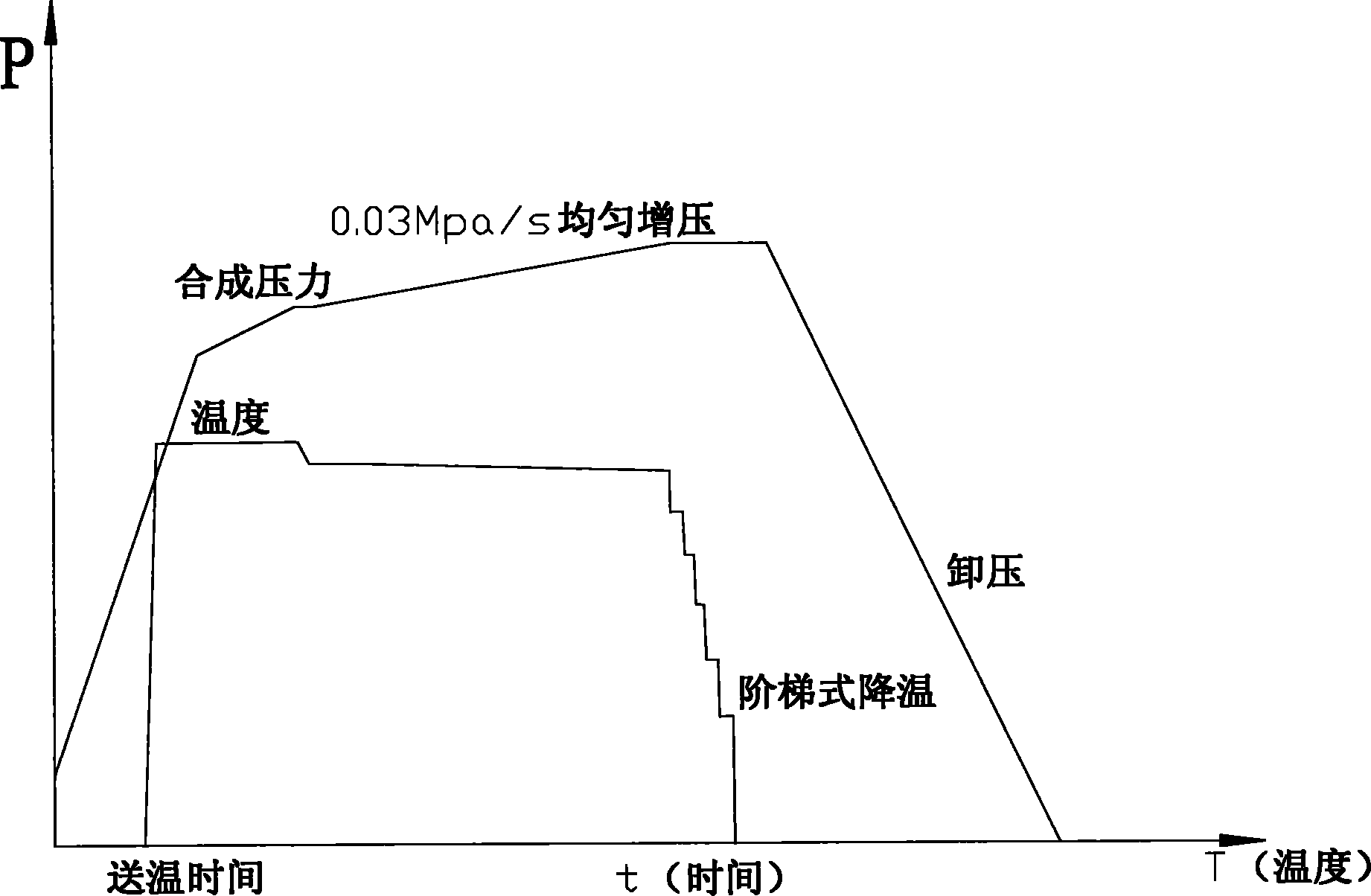

ActiveCN101862622AAvoid nucleationCrystals are complete and regularUltra-high pressure processesOverpressureHigh pressure

The invention belongs to the technical field of diamond synthesis and relates to a process for synthesizing diamond by adopting a special hexahedron press. The process has the steps as follows: (1) placing synthesized blocks in a high pressure cavity of the hexahedron press, pressurizing, connecting with overpressure to 55-65MPa after the pressure reaches 4-6MPa, preserving the pressure for 4-8min, and increasing the pressure to 70-80MPa after 15-20s; (2) preserving the pressure for 1-3min; (3) continuously increasing the pressure at the speed of 0.01-0.03MPa / s; and (4) preserving the pressure and cooling when the pressure is increased to 85-95MPa, and releasing the pressure to normal temperature when the temperature is reduced to the room temperature. The diamond product manufactured by the process for synthesizing the diamond has complete and regular crystals and golden color, and the process with short synthesis time and high extraction ratio can be used for grow the diamond products with the same particle size.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

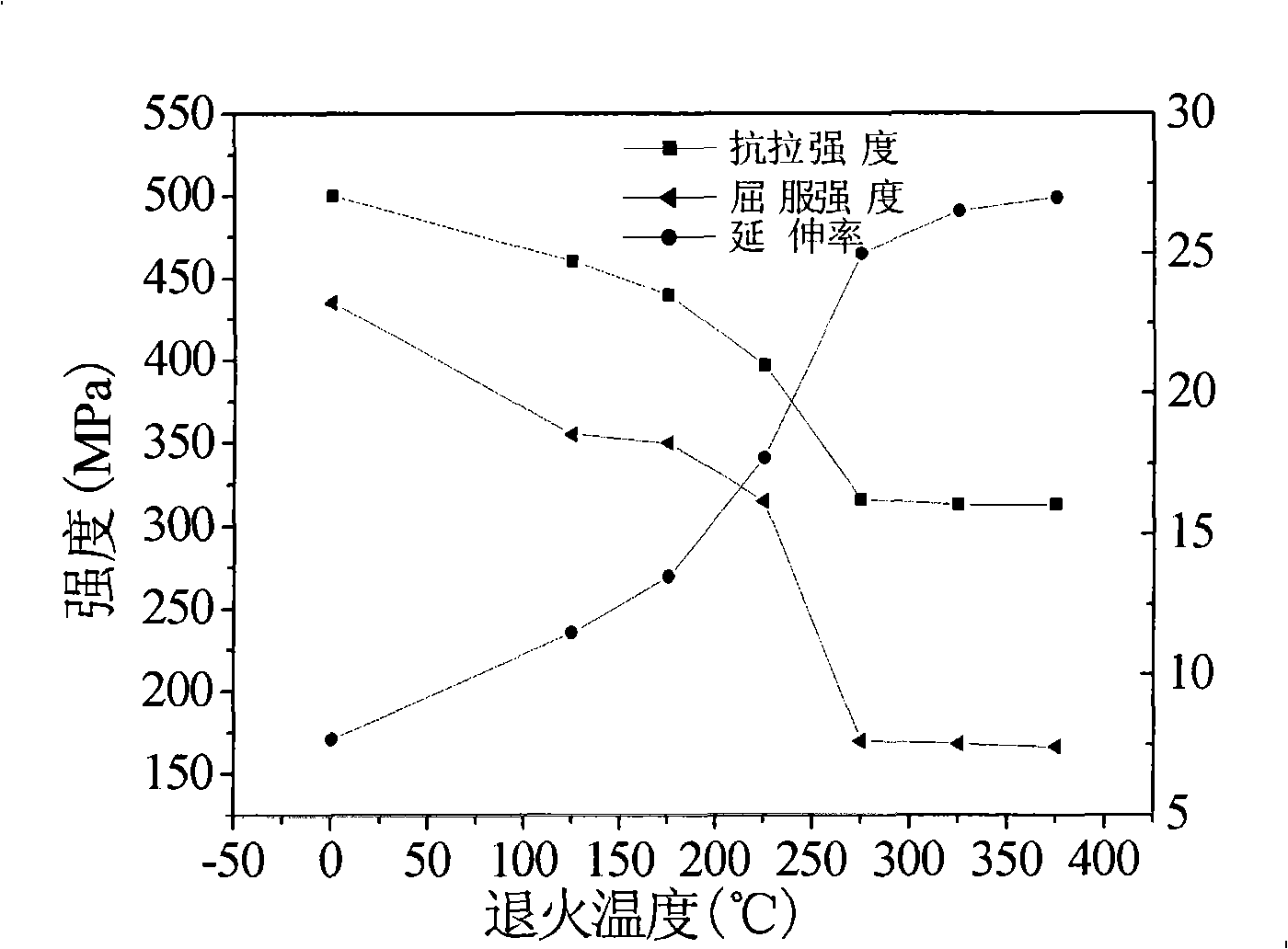

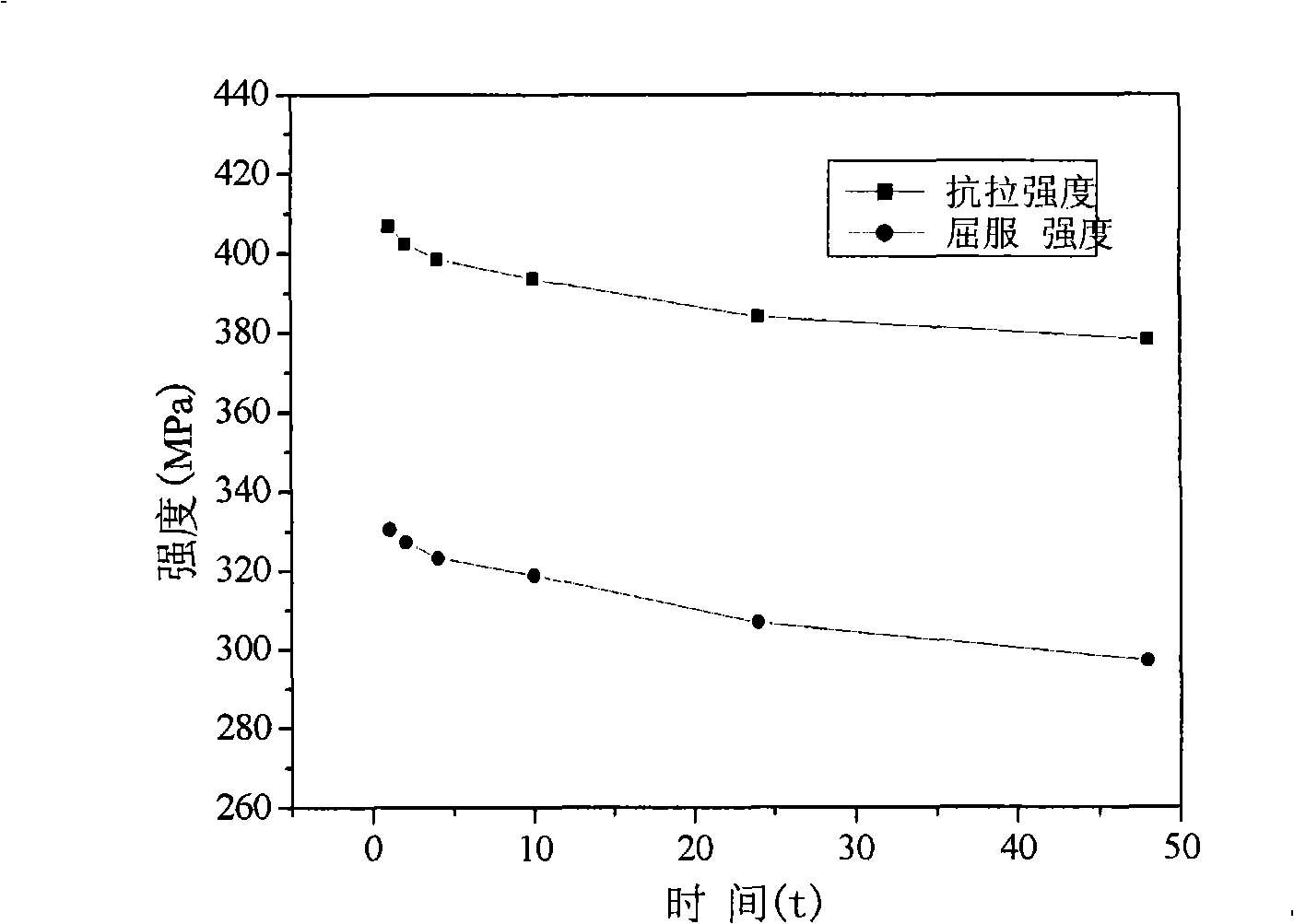

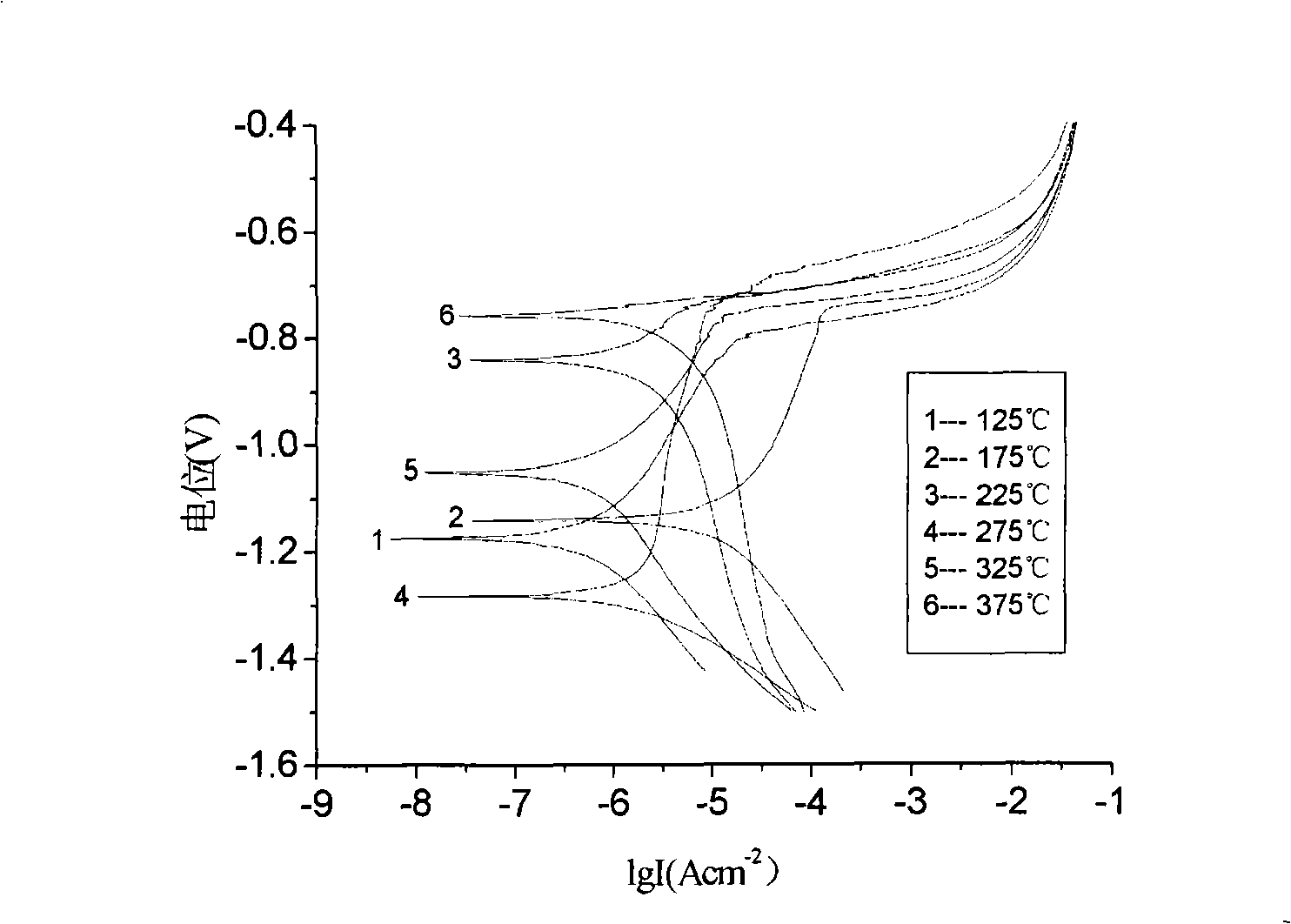

Thermal treatment process for erbium-containing aluminum-magnesium-manganese wrought aluminium alloy

The thermal treatment process for an aluminum-magnesium-manganese wrought aluminum alloy containing erbium belongs to the filed of metal alloys. The existing aluminum alloy thermal treatment process has the problems of strength reducing, corrosion resisting performance reducing after long term use, etc. The invention aims at providing the thermal treatment process for an aluminum-magnesium-manganese cold-rolled sheet containing erbium, which is realized by homogenizing annealing, hot rolling, cold rolling, stabilizing annealing and other process steps, wherein the stabilizing annealing process comprises the steps that, a cold-rolled sheet is annealed at the temperature of 100-400 DEG C and insulated for 1-48h; the annealing temperature and the insulating time are preferably 125-250 DEG C and 1-8h respectively. The thermal treatment process of the invention ensures the alloy to acquire excellent corrosion resisting performance under the condition that the high plasticity of the aluminum-magnesium-manganese cold-rolled sheet containing erbium is kept at a higher level; the treated alloy can be used for a long time with basically constant performance, and the service range of the alloy is wide.

Owner:BEIJING UNIV OF TECH

System and control method for drawing crystal bar

PendingCN111020691AAchieve growthPrecise control of temperature gradientPolycrystalline material growthBy pulling from meltThermodynamicsCrucible

The invention provides a system and a control method for drawing a crystal bar. The system comprises: a first control unit which is used for controlling the drawing speed of the drawn crystal bar to be constant; an obtaining unit which is used for obtaining a distance between a solid-liquid interface and a reference surface, wherein the solid-liquid interface is an interface between a crystal liquid and the current crystal bar; a crucible used for containing the crystal liquid; a heating device used for heating the crucible; a second control unit used for adjusting the crucible lifting ratio under the condition that the distance is different from the preset distance in order to make the distance reach the preset distance, wherein the crucible lifting ratio is the ratio of the crystal growth rate to the crucible lifting rate; and a third control unit connected with the heating device and used for controlling the heating power of the heating device to make the diameter of the crystal barat each position is within a preset range. The system makes the ratio v / G of the drawing speed of the drawn crystal bar to the temperature gradient of the solid-liquid interface kept unchanged, so that the defect concentration of the drawn crystal bar is reduced.

Owner:XUZHOU XINJING SEMICON TECH CO LTD +1

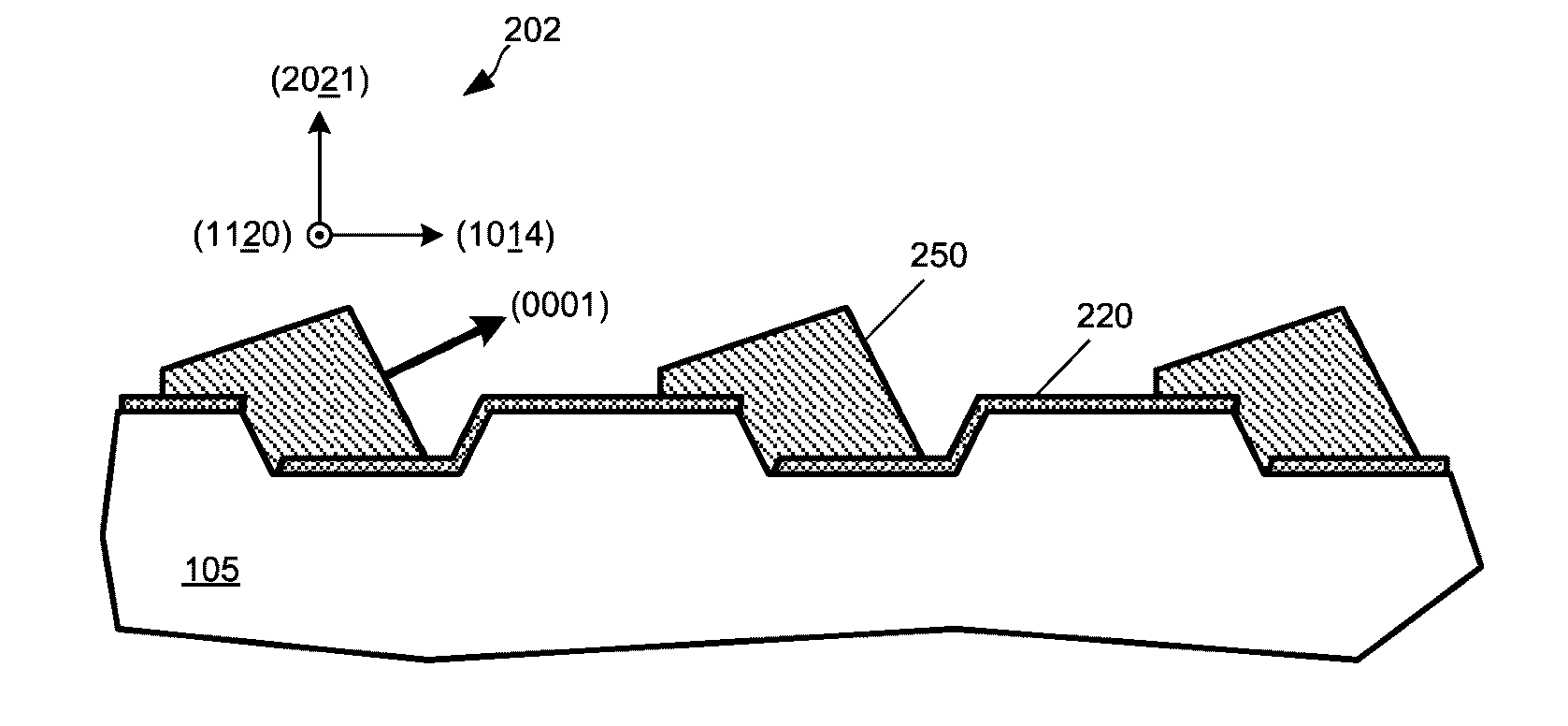

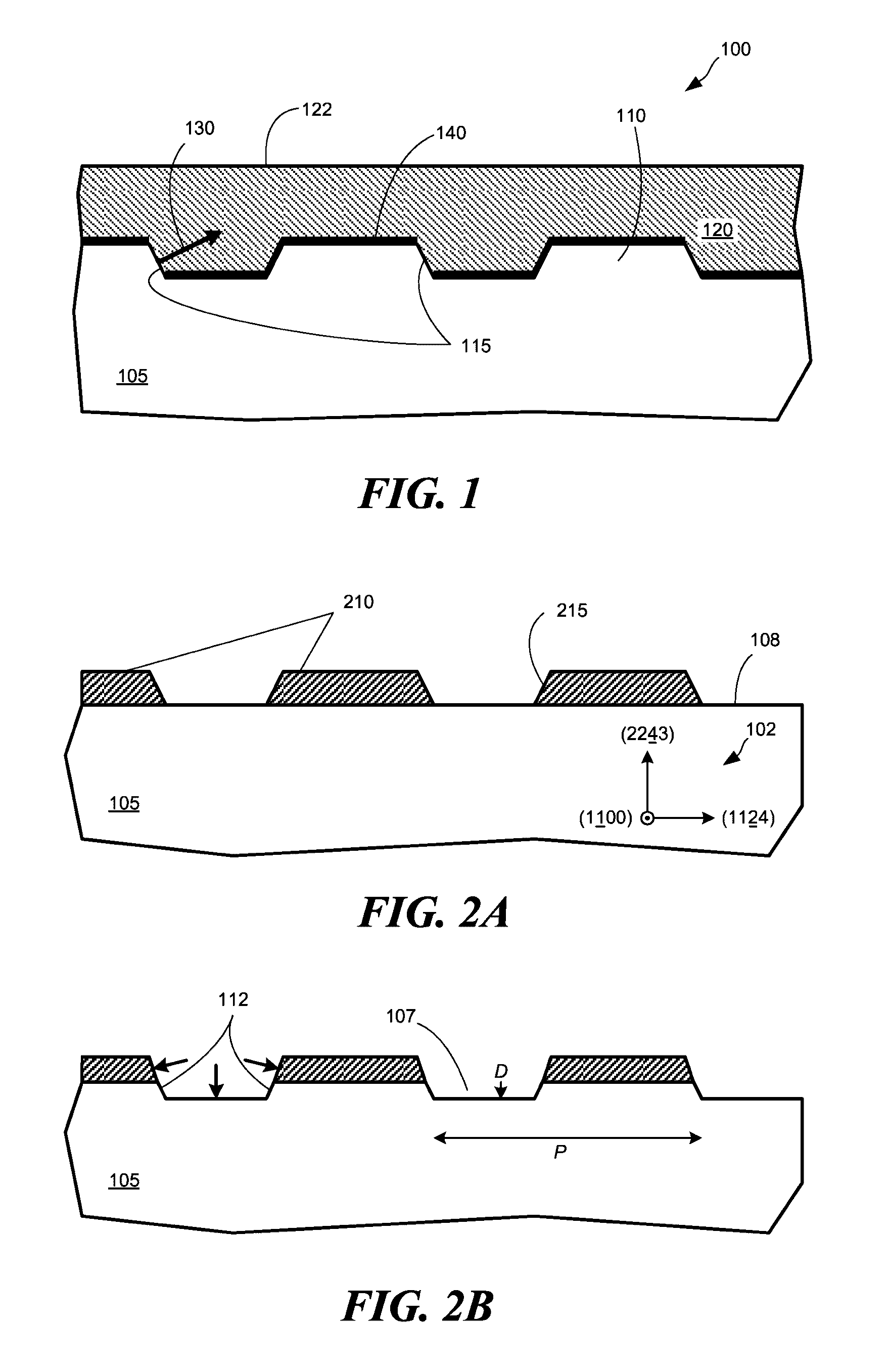

Method of obtaining planar semipolar gallium nitride surfaces

ActiveUS20170033186A1Inhibit growthInhibition of nucleationSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogenGallium nitride

Methods and structures for forming flat, continuous, planar, epitaxial layers of semipolar III-nitride materials on patterned sapphire substrates are described. Semipolar GaN may be grown from inclined c-plane facets on a patterned sapphire substrate, and coalesced to form a continuous layer of semipolar III-nitride semiconductor over the sapphire substrate. Planarization of the layer is followed by crystal regrowth using a nitrogen carrier gas to produce a flat, microfabrication-grade, process surface of semipolar III-nitride semiconductor across the substrate. Quality multiple quantum wells can be fabricated in the regrown semipolar material.

Owner:YALE UNIV

Monatomic noble metal catalyst, preparation method thereof and application thereof in room-temperature catalytic oxidation of formaldehyde

InactiveCN109939712AGood dispersionRaise atomic concentrationDispersed particle separationCatalyst activation/preparationActivated carbonCatalytic oxidation

The invention relates to a monatomic noble metal catalyst, a preparation method thereof and application thereof in the room-temperature catalytic oxidation of formaldehyde. The catalyst is prepared bythe following steps: (1) modifying activate carbon, dipping activate carbon into a noble metal salt solution, so as to obtain dipping liquid; (2) mixing a reducing agent solution with the dipping liquid in the step (1) in an ultralow temperature environment, and reacting; and (3) filtering the reactant in the step (2), washing, and drying, so as to obtain a loaded monatomic noble metal catalyst.The method is simple and environment-friendly, the noble metal in the prepared catalyst is dispersed to the surface of metal oxide, the content of noble metal is 0.01wt%-0.3wt%, the catalyst is applied to the room-temperature catalytic oxidation reaction of formaldehyde, and the removal rate of formaldehyde reaches up to over 93%.

Owner:北京氦舶科技有限责任公司

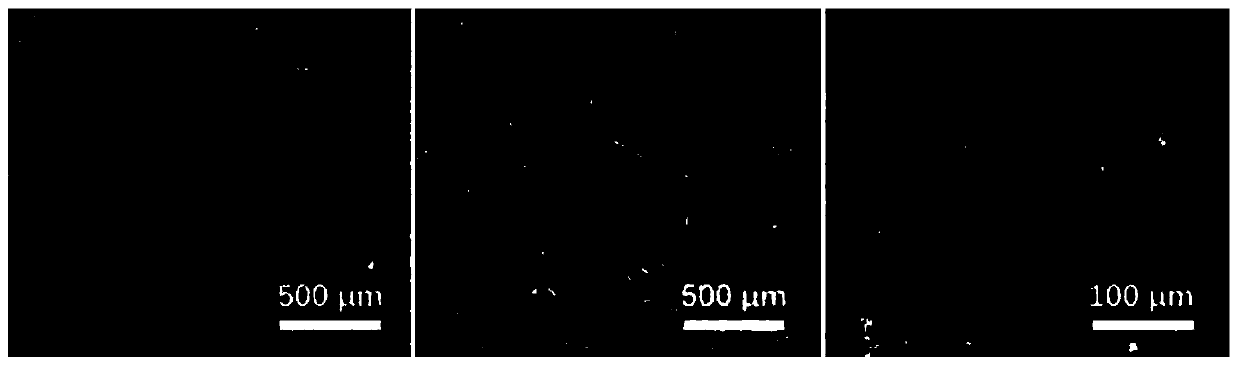

Qualitative crystal defect evaluation method

InactiveUS20130192303A1Inhibition of nucleationPolycrystalline material growthAfter-treatment detailsOxygen precipitatesCrystallographic defect

A process is provided for evaluating oxygen precipitates in a single crystal silicon sample. The process comprises (a) annealing the single crystal silicon sample at a temperature sufficient to selectively grow as-grown oxygen precipitates having a size of about 25 nm or more and selectively dissolve as-grown oxygen precipitates having a size of about 25 nm or less; (b) cooling the single crystal silicon sample at a cooling rate sufficient to inhibit the nucleation of oxygen precipitates having a size of about 25 nm or less; (c) coating a surface of the single crystal silicon sample with a composition containing a metal capable of decorating oxygen precipitates; and (d) annealing the coated single crystal silicon sample at a temperature, for a duration, and in an atmosphere sufficient to decorate the oxygen precipitates in the single crystal silicon sample.

Owner:MEMC ELECTRONIC MATERIALS SPA (IT)

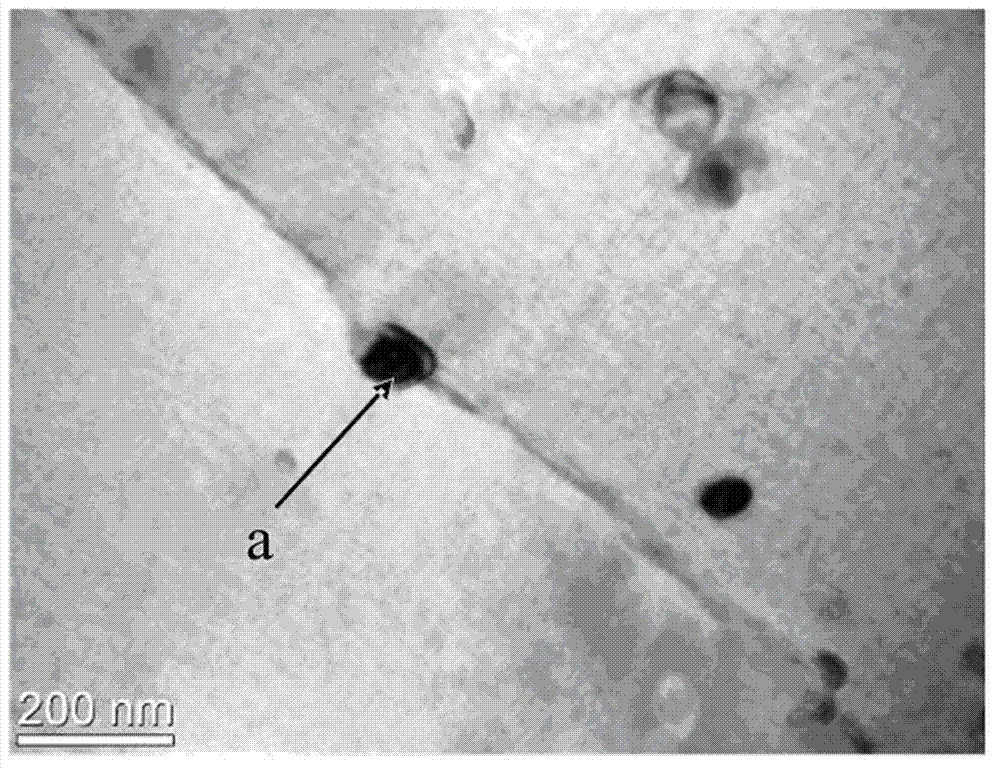

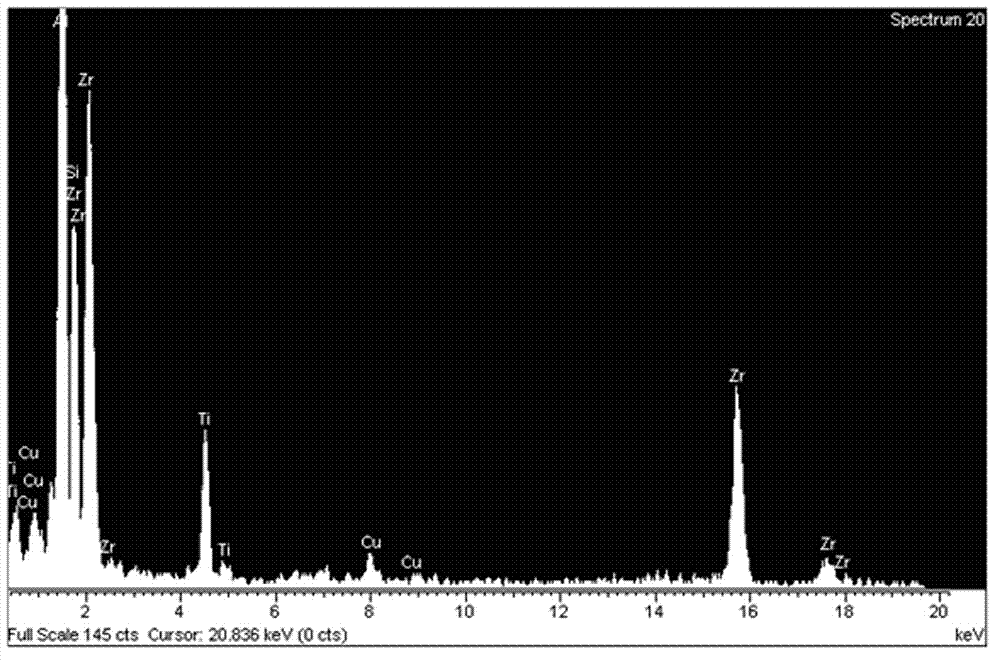

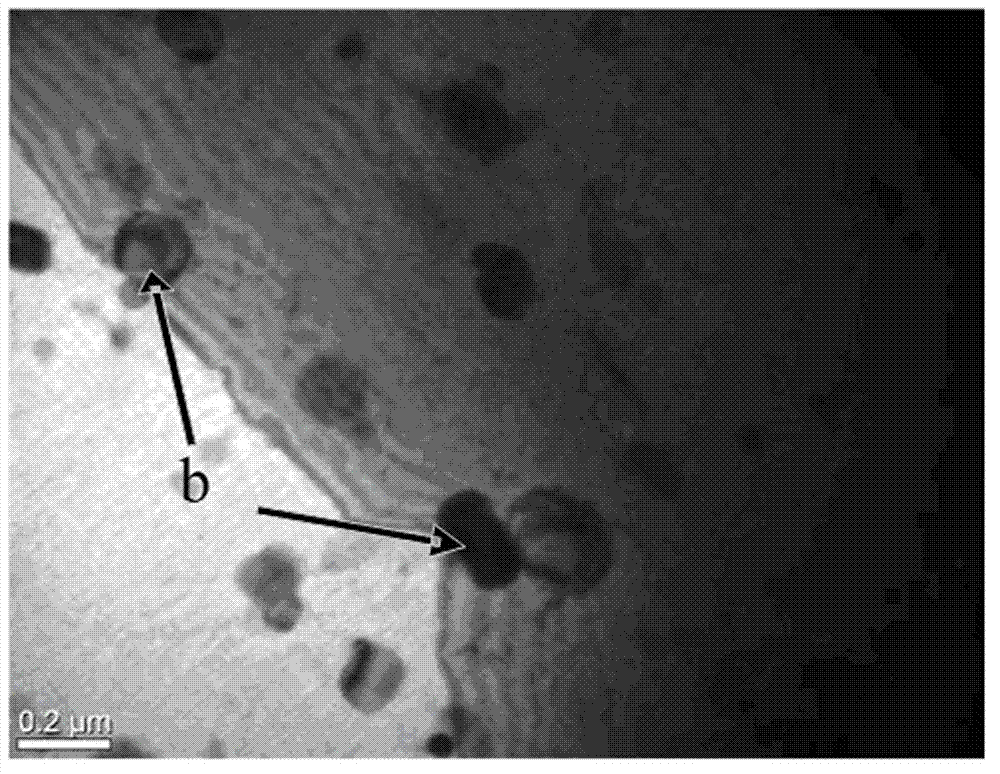

Quasicrystal-strengthened Mg-6Zn-3Y alloy with ultrafine solidification texture and preparation method thereof

The invention discloses a quasicrystal-strengthened Mg-6Zn-3Y alloy with an ultrafine solidification texture and a preparation method thereof. The quasicrystal-strengthened Mg-6Zn-3Y alloy consists of the following chemical components in percentage by weight: 87.0 to 93.0 percent of Mg, 3.0 to 10.0 percent of Zn and 0.5 to 3.0 percent of Y. The Mg-6Zn-3Y alloy with the ultrafine solidification texture, which contains nanoscale granular quasicrystals, is prepared from normal-pressure as-cast Mg-Zn-Y alloy material under GPa-level ultrahigh pressure as solidification pressure, temperature and solidification cooling rate are controlled. The as-cast texture is characterized in that: the granular quasicrystals are evenly and dispersely distributed on the ultrafine Alpha-Mg matrix, wherein the secondary dendrite arm spacing between Alpha-Mg dendrites is 7Mu m to 10Mu m, the diameter of the granular quasicrystal is 50nm to 100nm, and the volume of the granular quasicrystals accounts for 25 to 35 percent of the total volume of the alloy. The invention adopts a cubic press, solidification process parameters are controlled, i.e., the solidification pressure is 6GPa, the solidification temperature is 1300DEG C, and the solidification rate is 300K / S. Theultrafin quasicrystal-strengthened Mg-6Zn-3Y alloy has high mechanical properties and good thermal stability.

Owner:东北大学秦皇岛分校

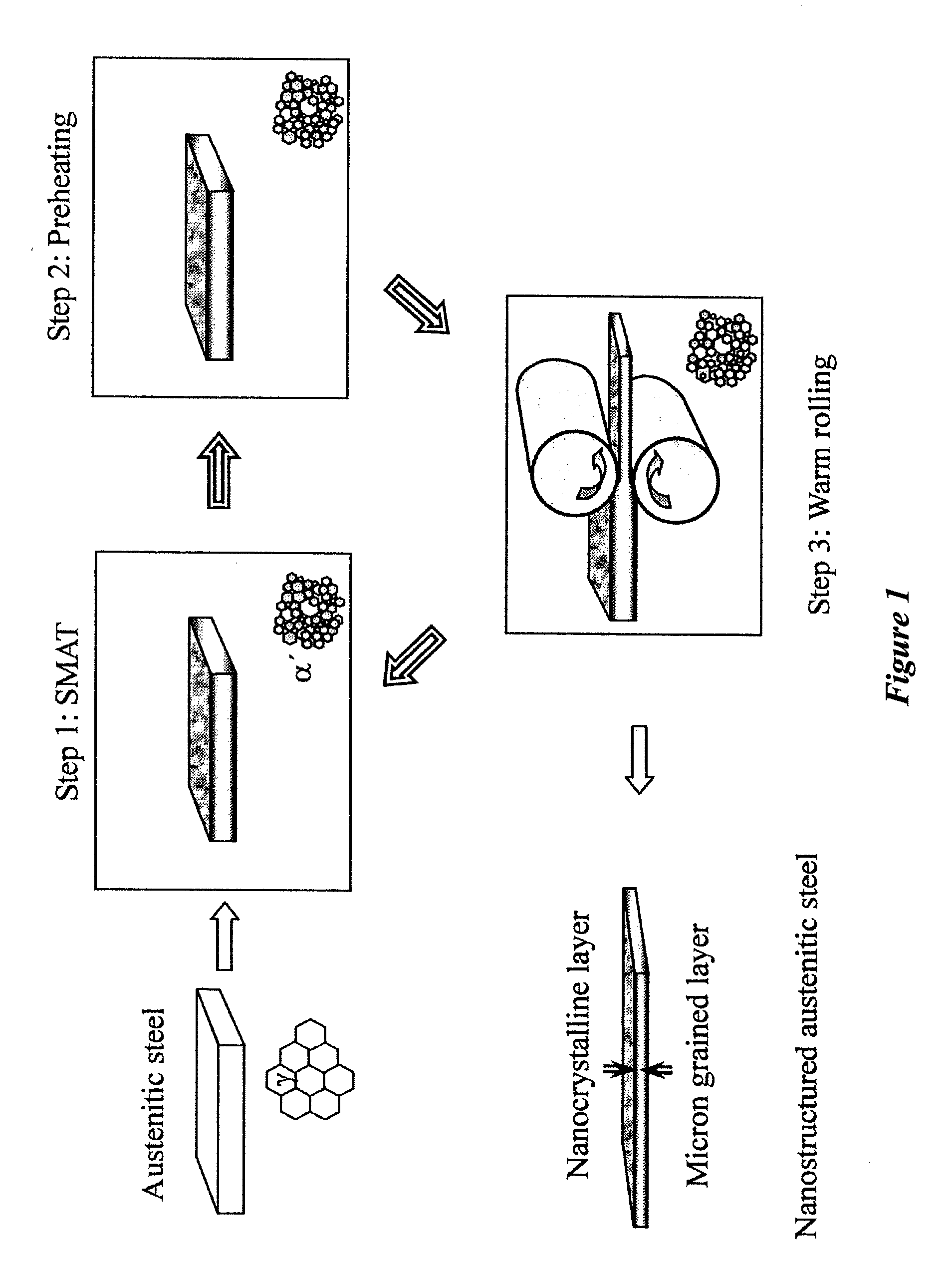

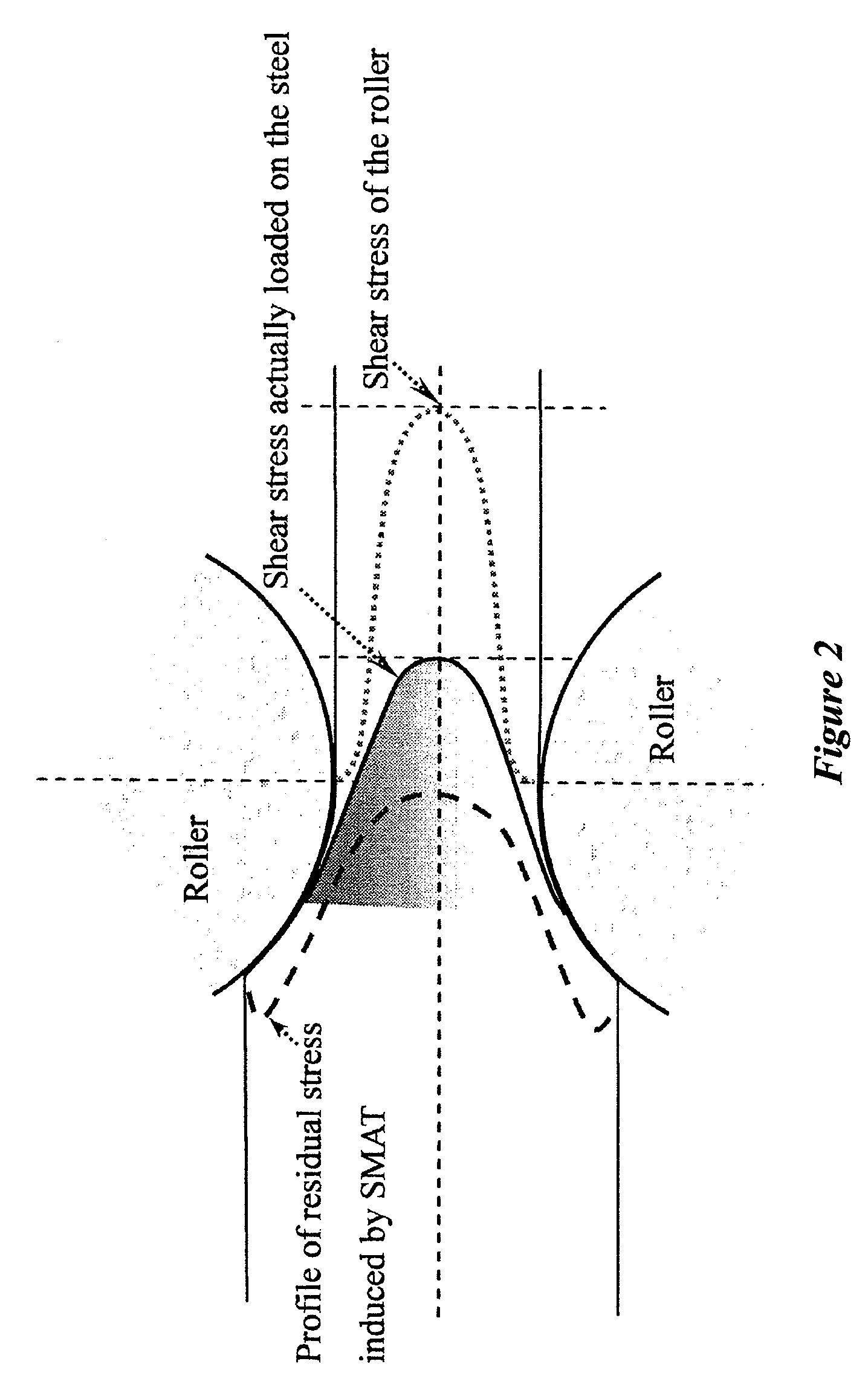

Nanostructured austenitic steel and method of making nanostructured austenitic steel

ActiveUS20100101686A1High strengthSignificant ductilityMaterial nanotechnologyFurnace typesMetallurgyNanostructure

A method for producing a nanostructured austenitic sheet by consecutive martensite and austenite phase (γ / α′) transformations, in which the coarse grained austenite sheet transforms to nanocrystalline martensite by strain-induced transformation, and then generates reverse transformation to nanostructured austenite by warm rolling due to dynamic recrystallization.

Owner:THE HONG KONG POLYTECHNIC UNIV

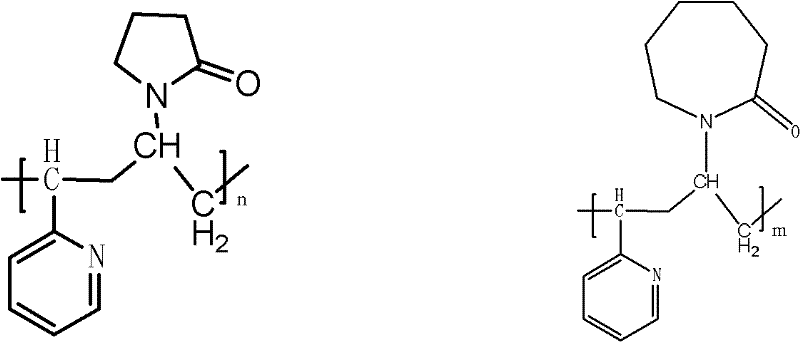

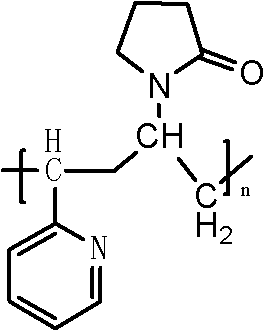

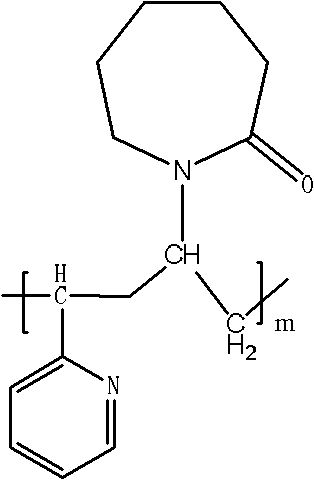

Composite hydrate inhibitor and application thereof

ActiveCN102181275ANon-volatileGood chemical stabilityPipeline systemsDrilling compositionSuper cooling2-Vinylpyridine

The invention discloses a composite hydrate inhibitor and application thereof. The provided composite hydrate inhibitor comprises a copolymer and an anti-aggregation agent; the copolymer is selected from at least one of the following substances: poly (N-vinyl pyrrolidone-2-vinyl pyridine) and poly (N-vinyl caprolactam-2-vinyl pyridine); and the anti-aggregation agent is a quaternary ammonium saltcompound. When the series of copolymer and the anti-aggregation agent are interacted, the composite hydrate inhibitor has good hydrate generation inhibiting performance. The hydrate inhibitor is in aliquid state, and can be used in the range that the water content is 10 to 80 weight percent, the pressure is 1.5 to 70MPa and the temperature is 20 DEG C below zero to 25 DEG C. The hydrate inhibitor cannot be limited by super-cooling degree, and is suitable for oil and water coexistence or oil-gas field and crude oil recovery; and particularly under the condition of high water content, the hydrate nucleation and aggregation inhibiting effects of the inhibitor can be fully exerted. The inhibitor has the advantages of high efficiency, economical efficiency, low dose and good biodegradability,and has good application prospect.

Owner:CHINA NAT OFFSHORE OIL CORP +1

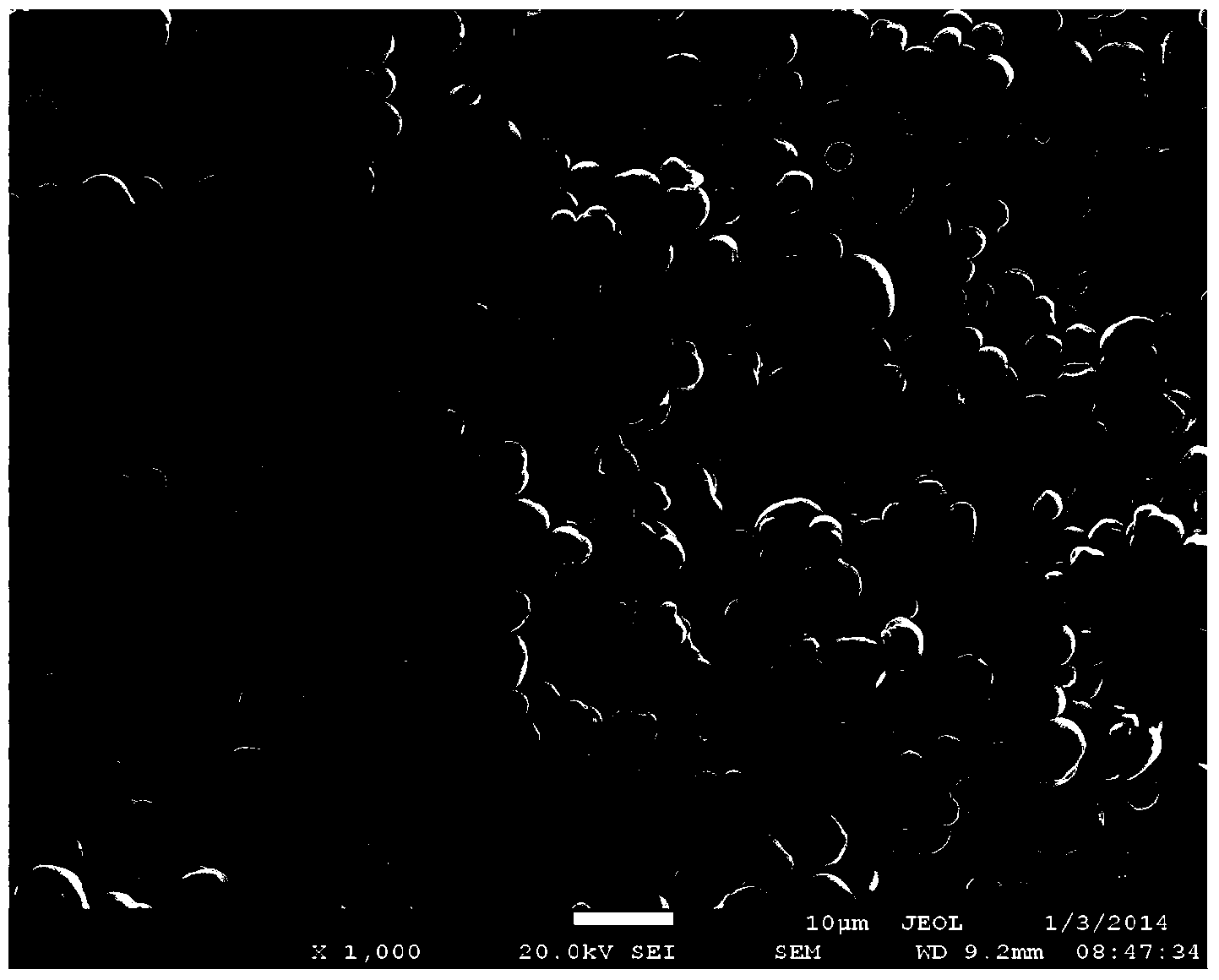

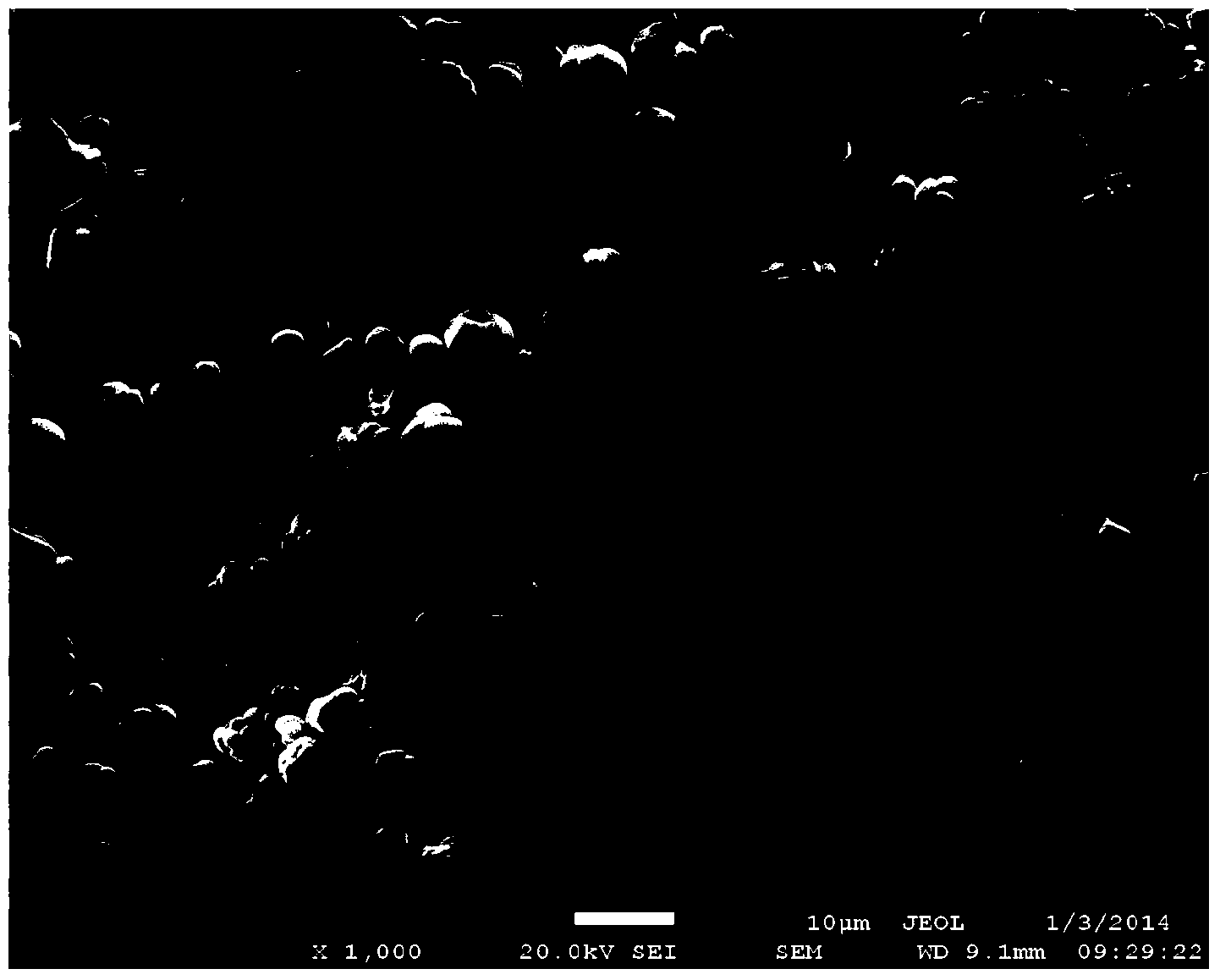

Method for preparing spherical aluminum nitride powder under assistance of high atmospheric pressure and fluoride additive

InactiveCN103979507AAccurate control of holding timeLarge particle sizeNitrogen compoundsReaction temperatureNitrogen gas

The invention discloses a method for preparing spherical aluminum nitride powder under the assistance of high atmospheric pressure and a fluoride additive, belonging to the technical field of preparation of non-oxide ceramic powder materials. The method concretely comprises the following steps: evenly mixing aluminum oxide, a carbon source and fluoride additive through a ball-milling technology, drying and then putting in a graphite crucible, transferring into an atmospheric-pressure sintering furnace, performing carbon thermal reduction reaction for 1-6 hours in the nitrogen atmosphere, and maintaining the pressure of nitrogen to be 0.2-2MPa, and the reaction temperature to be 1650-1900DEG C; and after the reaction is completed, putting the obtained product into a muffle furnace, carrying carbon emission for 1-5 hours under the condition of 500-750DEG C, thus obtaining the spherical aluminum nitride powder. The prepared aluminum nitride powder has the characteristics of being high in spherical degree, smooth in the surface, even for particle size distribution and the like, the intermediate particle size is 3-10mu m, and the spherical degree achieves more than 80%; the spherical aluminum nitride powder is very suitable as high-heat-conducting aluminum nitride filler; in addition, the technological method is simple, the raw material cost is relatively low, and large-scale industrial production can be realized.

Owner:天津纳德科技有限公司

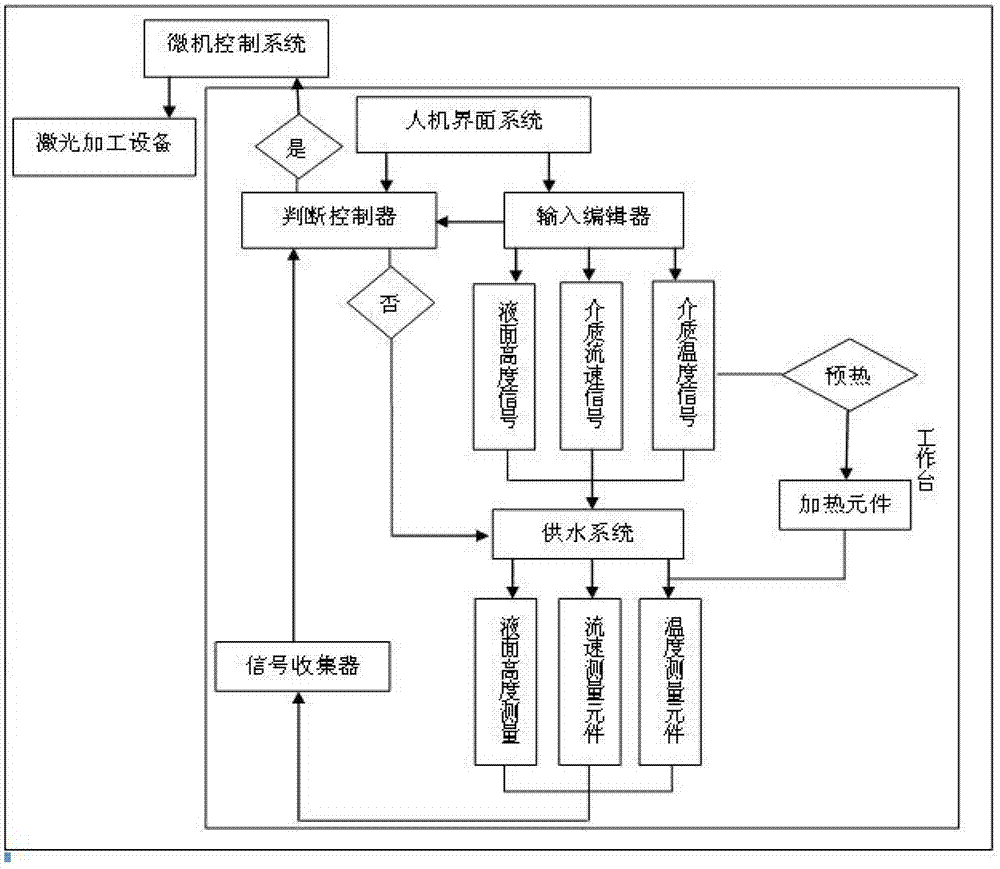

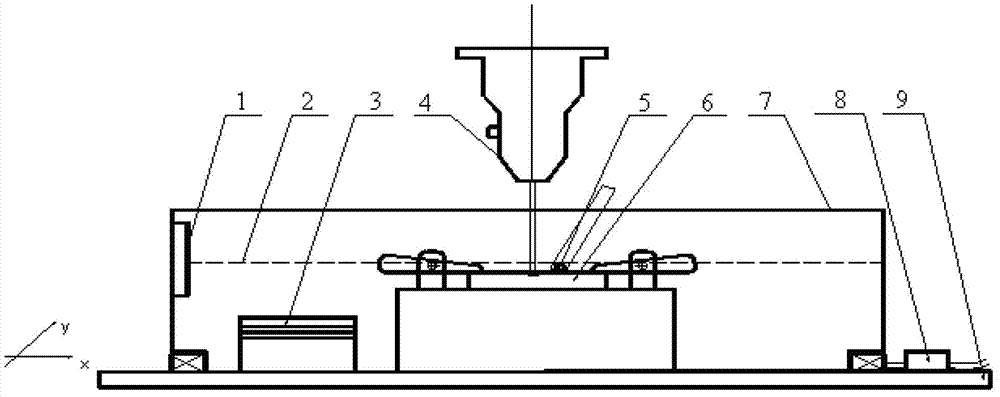

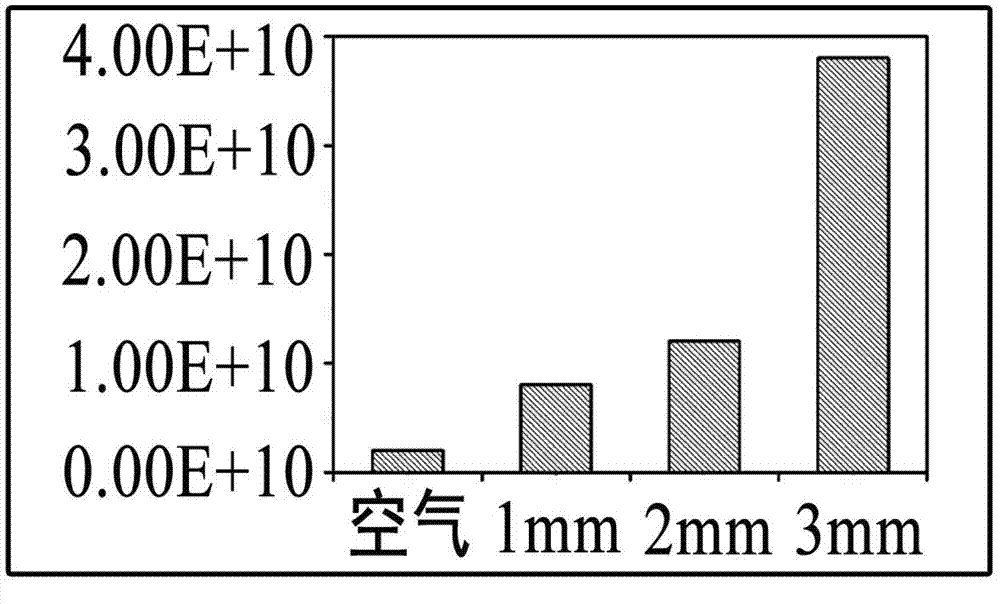

Metal surface laser processing method in liquid medium

The invention relates to a laser surface processing method of a part and a test piece in a liquid medium, especially to a metal surface laser processing method in a liquid medium with excellent treatment structure and special surface performance by the utilization of a laser preparation means. The concrete implementation process is as follows: the part or test piece is immersed in a container filled with some liquid, and a laser terminal permeates through a liquid water film on the surface of the part or test piece and irradiates on the surface of the test piece or part to be processed. Different requirements for processing the part or test piece can be realized through adjusting height of liquid level, speed of liquid flow and temperature. The method can be used as a method for optimizing laser processing structures and also can be used to preheat the part or test piece to be processed, so as to obtain ideal surface mechanical properties and special functions.

Owner:JILIN UNIV

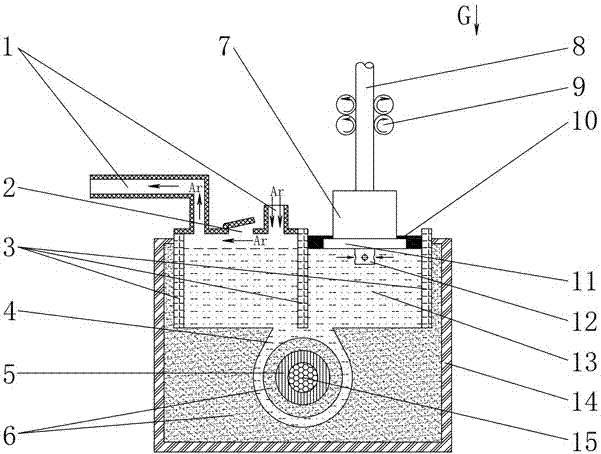

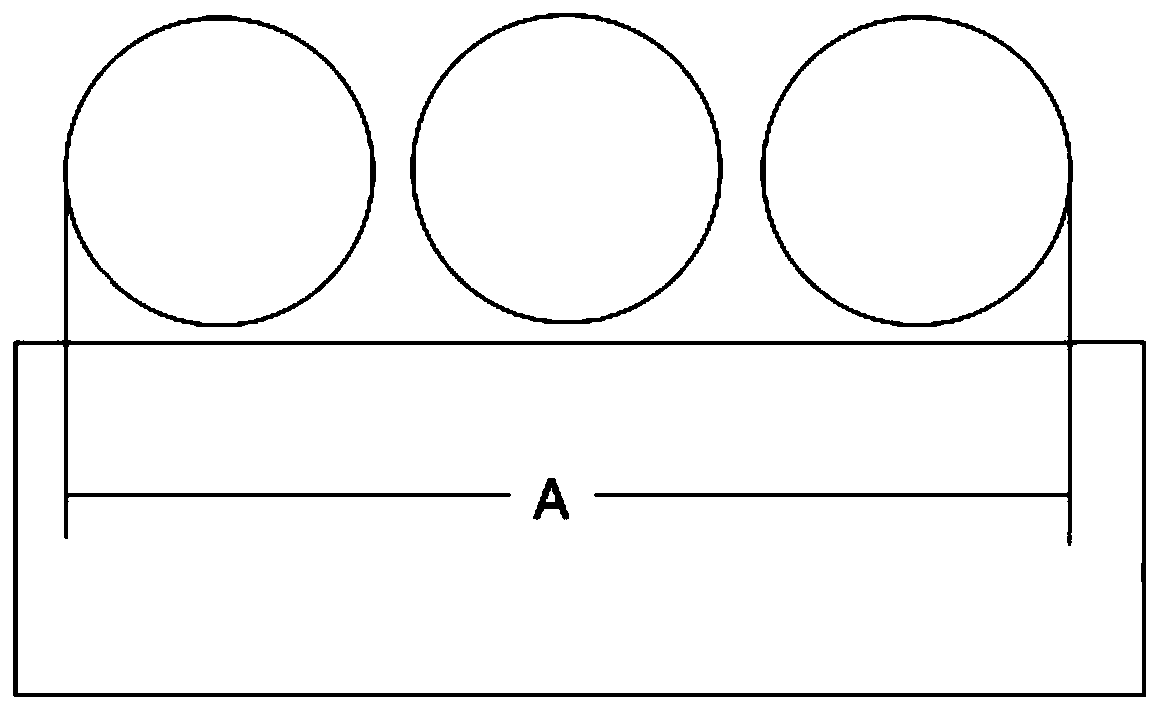

Production process and device for large-length copper-based amorphous alloy contact line for high speed railway

ActiveCN107988567AEnable cooling and continuous productionStrong maneuverabilityConductive materialMetal/alloy conductorsCookerContact line

The invention relates to a production process for a large-length copper-based amorphous alloy contact line for a high speed railway. The production process comprises the following steps of (1) smelting through an Ar atmosphere protected non-vacuum semi-closed single channeling dual-body induction cooker; (2) carrying out semisolid treatment on an on-line melt; (3) carrying out continuous up casting on a T2 red copper mould; and (4) carrying out plastic working and forming on a copper-based amorphous alloy continuous up casting rod blank. According to the production process provided by the invention, the manufacturing difficulty of copper-based amorphous alloy is greatly reduced, and the manufacturing and the producing of the large-length copper-based amorphous alloy contact line for the high speed railway are realized, and the development demand on applying a casting process of a copper-based amorphous alloy to the high-strength high-conductive contact line for the high speed railway in a modern industry and in the further is met.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP KANG YUAN NEW MATERIALS CO LTD

Manufacturing method of flexible three-dimensional metal lithium negative electrode material

The invention provides a manufacturing method of a flexible three-dimensional metal lithium negative electrode material. A three-dimensional carbon cloth material is used as a substrate of a flexibleelectrode, a layer of silicon nanowire grows on a surface of three-dimensional carbon cloth, wettability of a carbon cloth three-dimensional substrate to molten metal lithium is effectively improved by means of an alloying reaction between the silicon nanowire and the molten metal lithium, and a problem of ' 'lithium dredging' ' of a conventional three-dimensional skeleton is solved. Besides, a contact area of the three-dimensional skeleton with molten lithium is increased through a nano-sized silicon wire interlaced structure, a loading capacity of metal lithium in the skeleton is improved, and nucleation and growth of lithium dendrites are avoided.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

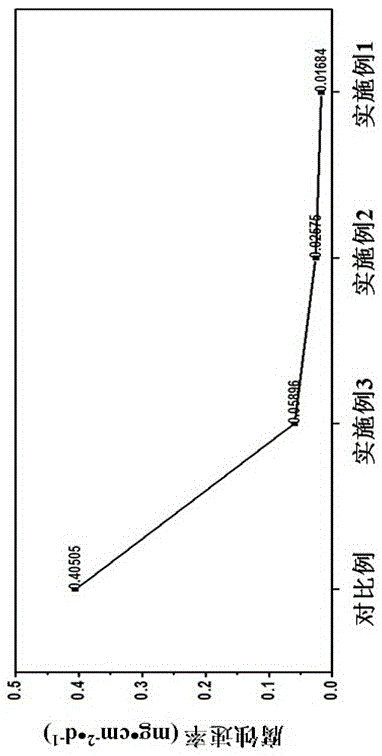

Anti-corrosion wrought magnesium alloy containing rare earth elements and manufacturing method of anti-corrosion wrought magnesium alloy

The invention discloses anti-corrosion wrought magnesium alloy containing rare earth elements and a manufacturing method of the anti-corrosion wrought magnesium alloy and relates to the technical field of magnesium alloy production. The anti-corrosion wrought magnesium alloy includes, by mass percentage, 8.3%-9.2% of Al, 0.5%-0.8% of Zn, 0.1-%-0.3% of Mn, 0.8%-1.5% of LRE, 0.2%-0.6% of HRE and the balance Mg and inevitable impurity elements, wherein the LRE represents the light rare earth elements, and the HRE represents the heavy rare earth elements. A magnesium alloy ingot is manufactured through a semi-continuous casting method, the ingot is turned into a round ingot after being subjected to solution treatment, and then the round ingot is subjected to hot extrusion. The manufactured magnesium alloy is subjected to a 5% NaCl neutral salt spray test at the temperature of 35 DEG C for 100 hours, the corrosion rate is 0.01684 mg / cm<2> / d, and the anti-corrosion wrought magnesium alloy is high-anti-corrosion wrought magnesium alloy with the low rare earth content.

Owner:扬州宏福铝业有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com