System and control method for drawing crystal bar

A control method and a technology for crystal rods, which are applied in chemical instruments and methods, self-melting liquid pulling method, crystal growth and other directions, which can solve the problems of easy disconnection and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

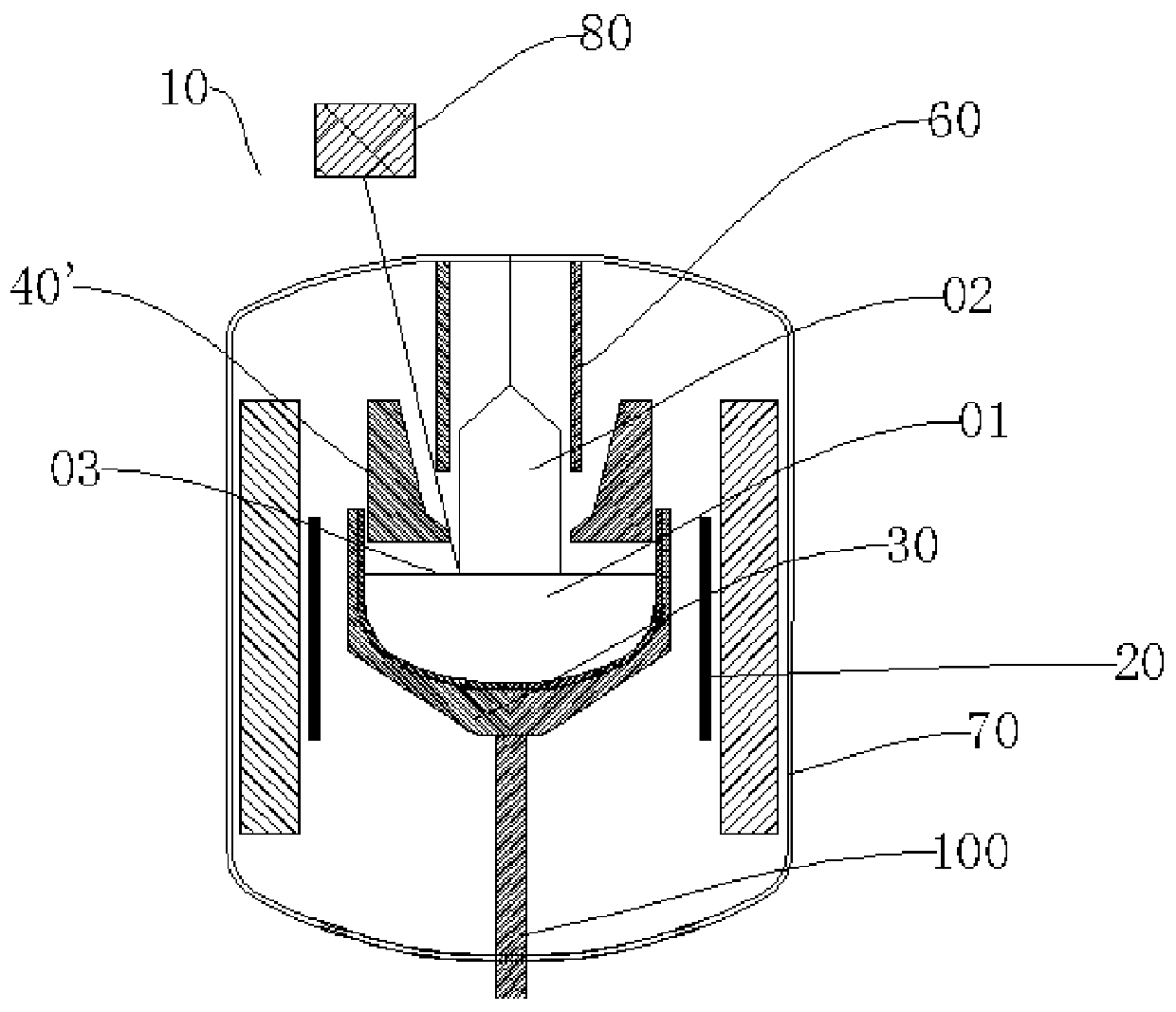

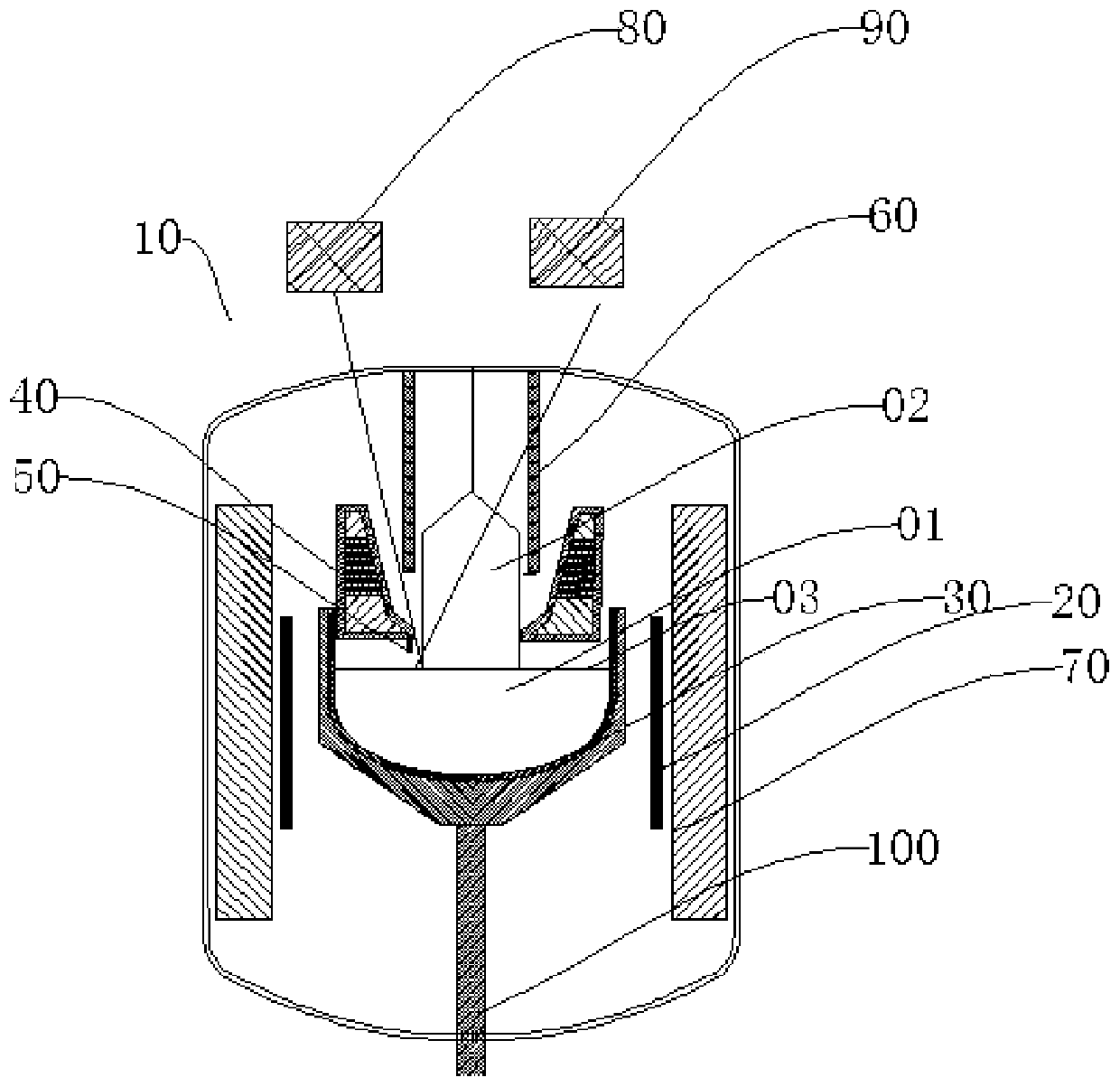

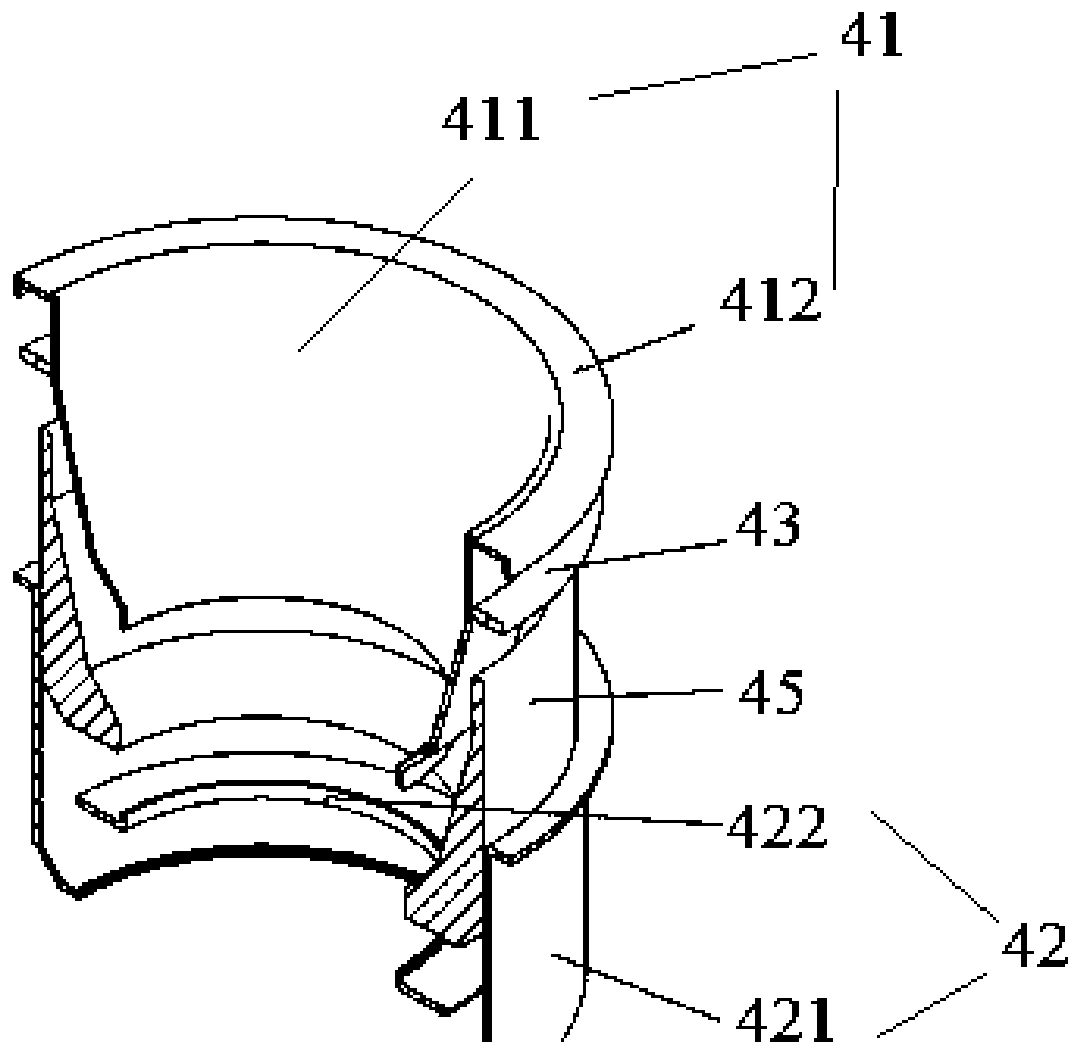

[0107] use figure 2 The system shown includes a single crystal furnace 10 , a heating device 20 , a crucible 30 , a draft tube 40 , a measuring object 50 , a cooling water ring 60 , a second image acquisition device 80 and a first image acquisition device 90 . Wherein, the heating equipment 20 , the crucible 30 , the draft tube 40 , the measuring object 50 and the cooling water ring 60 are all arranged in the single crystal furnace 10 . Assuming that the heating device 20 heats the crucible 30, the crucible 30 holds the crystal liquid 01, the second image acquisition device 80 collects the diameter data of the ingot, and the first image acquisition device 90 measures the reflection of the object 50 on the solid-liquid interface 03 The distance between the solid-liquid interface 03 and the guide tube 40 . The guide tube 40 includes three cooling chambers 44, wherein the lowermost cooling chamber is filled with two layers of soft felt; the second intermediate cooling chamber i...

Embodiment 2

[0111] use figure 2 In the system shown, the second control unit is not used to adjust the crucible ratio in real time, and the other control methods are the same as those in Embodiment 1. Set the predetermined distance to 40-60mm, and set the crucible ratio in advance.

Embodiment 3

[0113] use figure 2In the system shown, the third control unit is not used to control the heating power of the heating equipment for heating crystal liquid, and the rest of the control method is the same as that of Example 1, and a 200mm ingot is drawn, and the crystal pulling speed is 0.45mm / min~0.55mm / minmm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com