Synthetic method of load type floriform silver nanostructured material

A structural material, silver nanotechnology, applied in the field of synthesis of nanostructured materials, can solve problems affecting product performance, complex synthesis steps, and restrictions on the synthesis of nanostructured materials in large quantities, to achieve convenient application, simple equipment, and good industrial application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

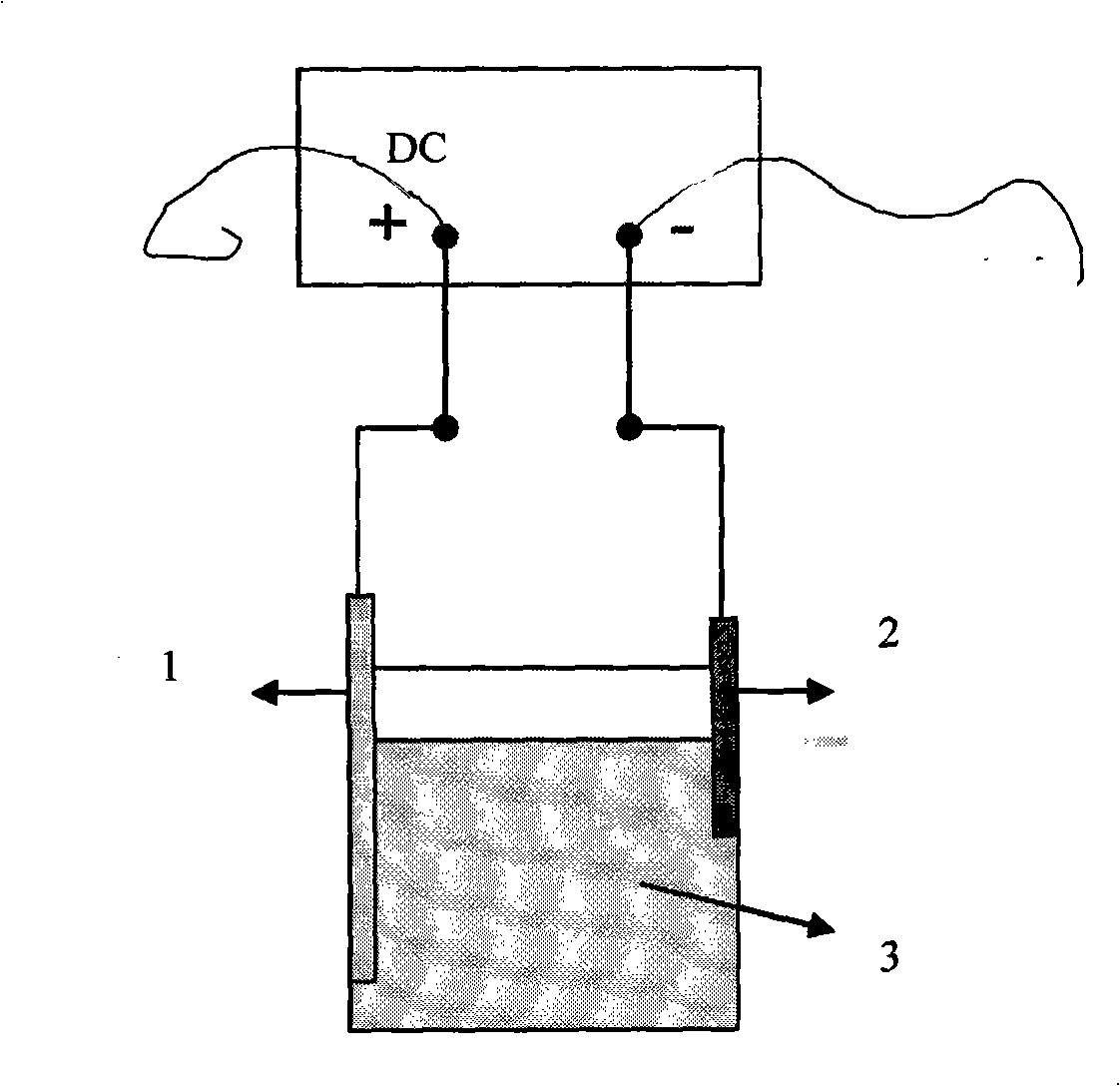

[0022] The preparation device of the loaded flower-shaped silver nanostructure material: including a precision DC power supply with stable voltage and current, an iron stand for fixing two electrodes, and a rectangular plastic tank with a size of 5cm (length) × 3cm (width) × 0.5cm (thickness), two electrodes are fixed on both sides of the electrolytic cell, so the distance between them is 30-40mm, and the whole circuit is connected by copper wire.

[0023] First, configure a certain concentration of silver salt electrolyte (the present invention adopts AgNO 3 , analytically pure), and measure a certain volume of solution and pour it into the electrolytic cell; insert the two prepared electrodes into the electrolytic cell and fix them; in the constant voltage (set a certain voltage) mode, pass through the direct current to react for a certain period of time At this time, electrodeposition products will be formed on the surface of the negative electrode; the negative electrode i...

Synthetic example

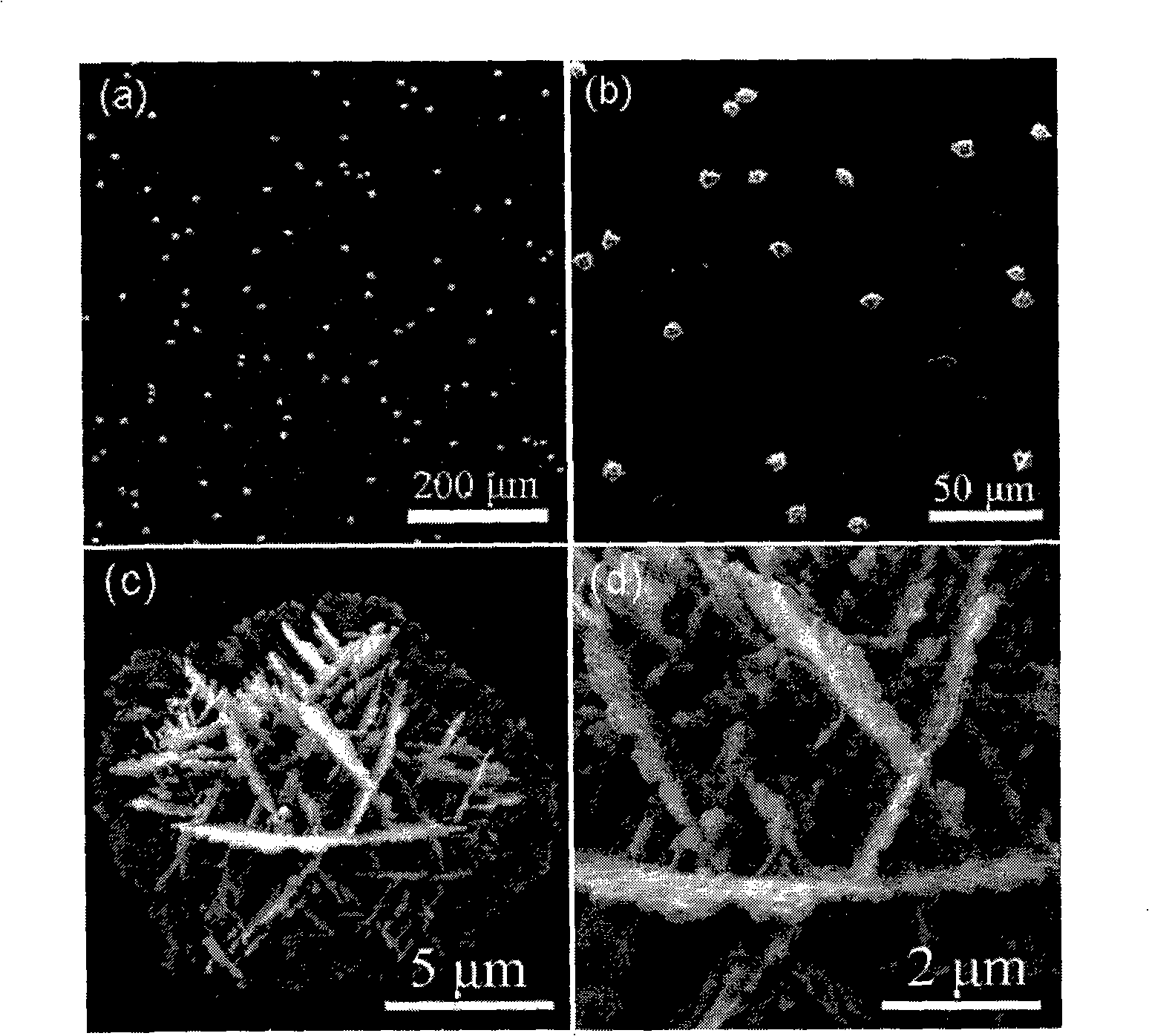

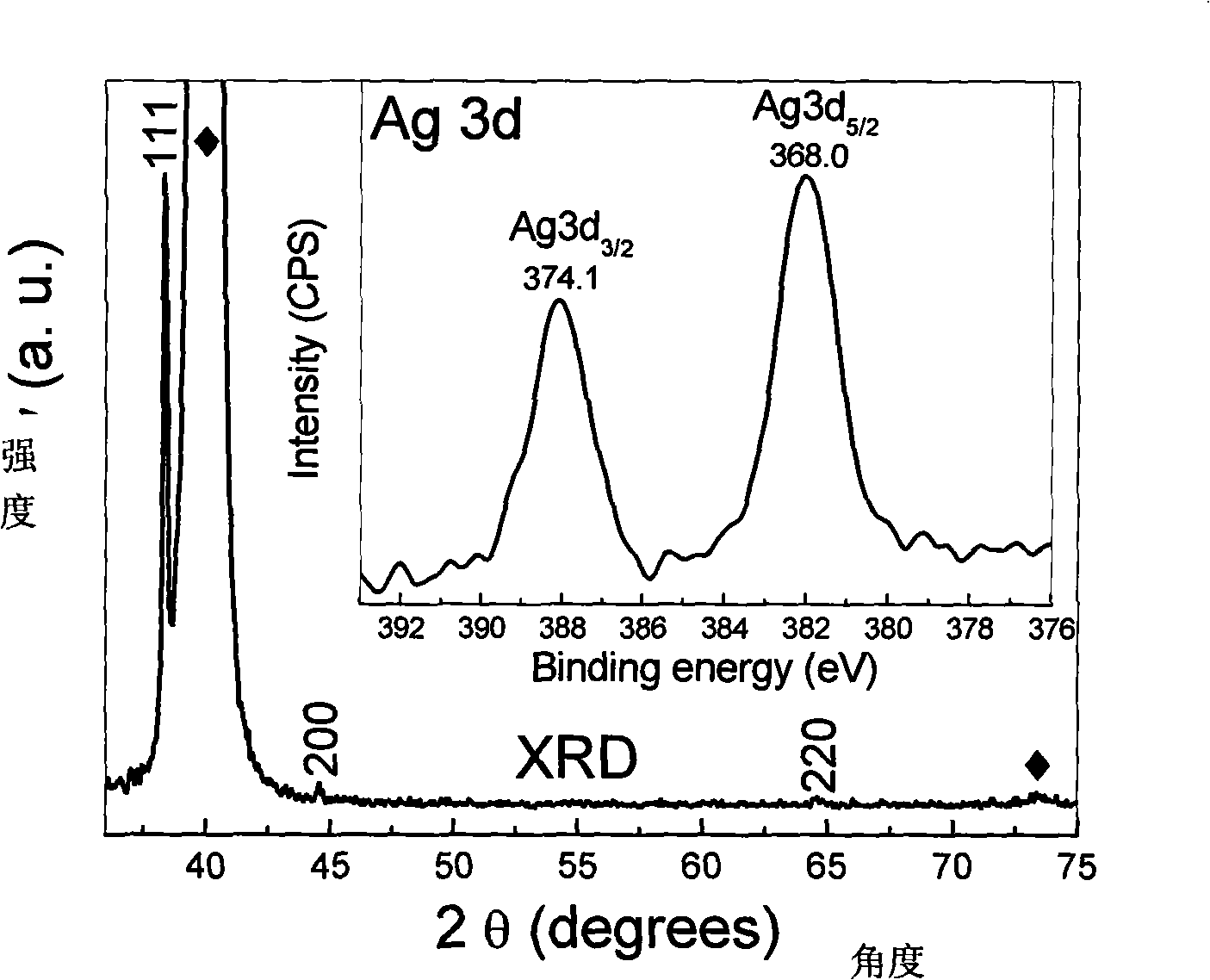

[0043] An example is as follows: under appropriate conditions (total voltage (V), silver ion concentration (C) and deposition time (t) are 3mM, 80mV and 10min, respectively), silver nanostructure materials were prepared on the surface of cathode PFE. Scanning electron microscope analysis (SEM) was used to observe the product directly (no need to spray gold), and the results are as follows: figure 2 shown. Low magnification SEM images ( figure 2 a) shows that a large number of particles are evenly distributed on the surface of the platinum film substrate, and the product achieves a large-area distribution. figure 2 b shows that the particles have a flower-like morphology with a diameter between 9–11 μm. SEM pictures with higher magnification ( figure 2 c) The detailed morphology of the flower-like nanostructure is revealed. It can be seen that the flower-like nanostructure is constructed by two-dimensional nanosheets, and the nanosheets cross each other. This flower-lik...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com