Patents

Literature

569 results about "Nanostructured materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

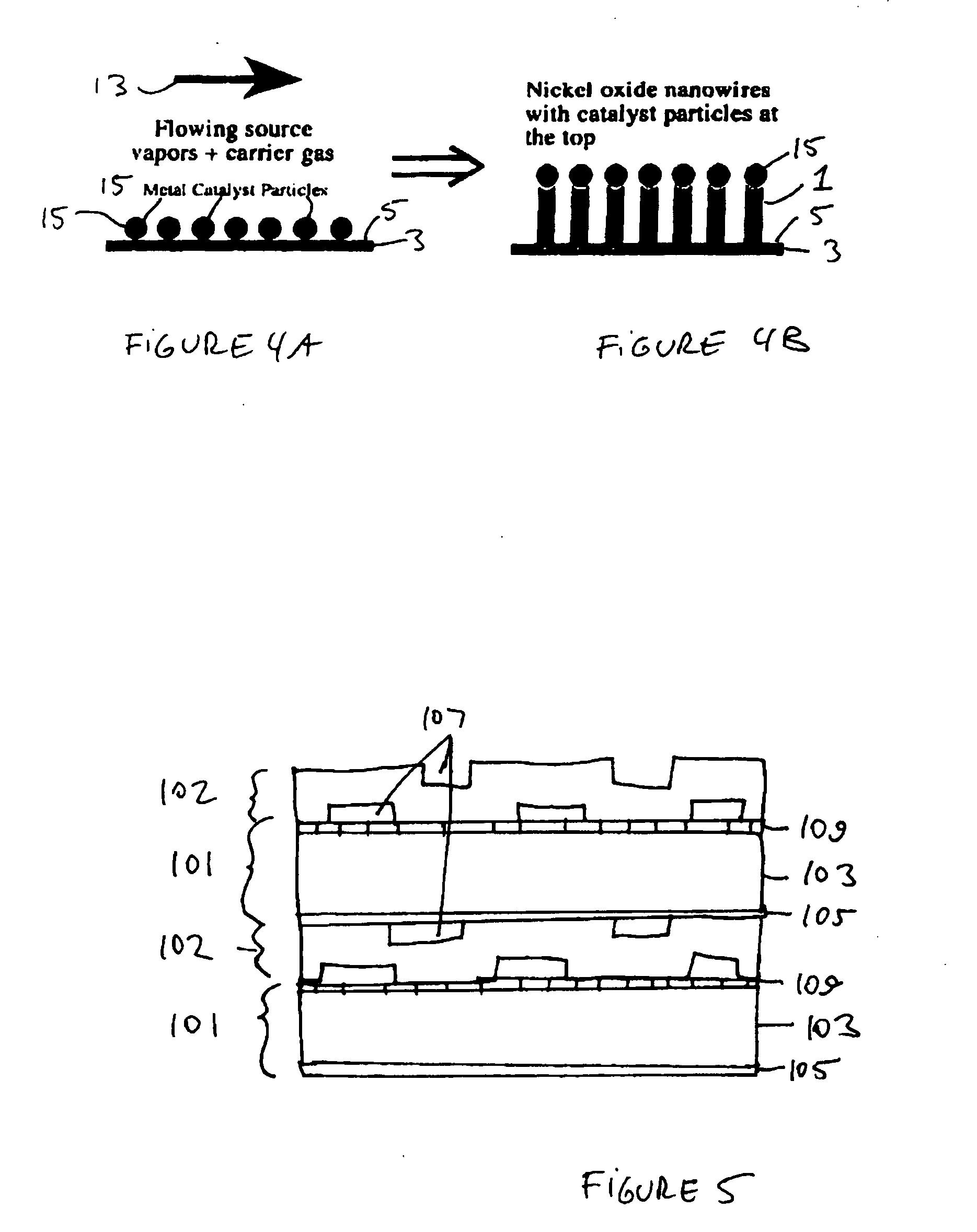

High efficiency inorganic nanorod-enhanced photovoltaic devices

InactiveUS20060207647A1Reduce weight and sizeImprove reliabilityNanoopticsSemiconductor devicesSolar cellNanostructured materials

The present invention is directed to photovoltaic devices comprising nanostructured materials, wherein such photovoltaic devices are comprised exclusively of inorganic components. Depending on the embodiment, such nanostructured materials are either 1-dimensional nanostructures or branched nanostructures, wherein such nanostructures are used to enhance the efficiency of the photovoltaic device, particularly for solar cell applications. Additionally, the present invention is also directed at methods of making and using such devices.

Owner:GENERAL ELECTRIC CO

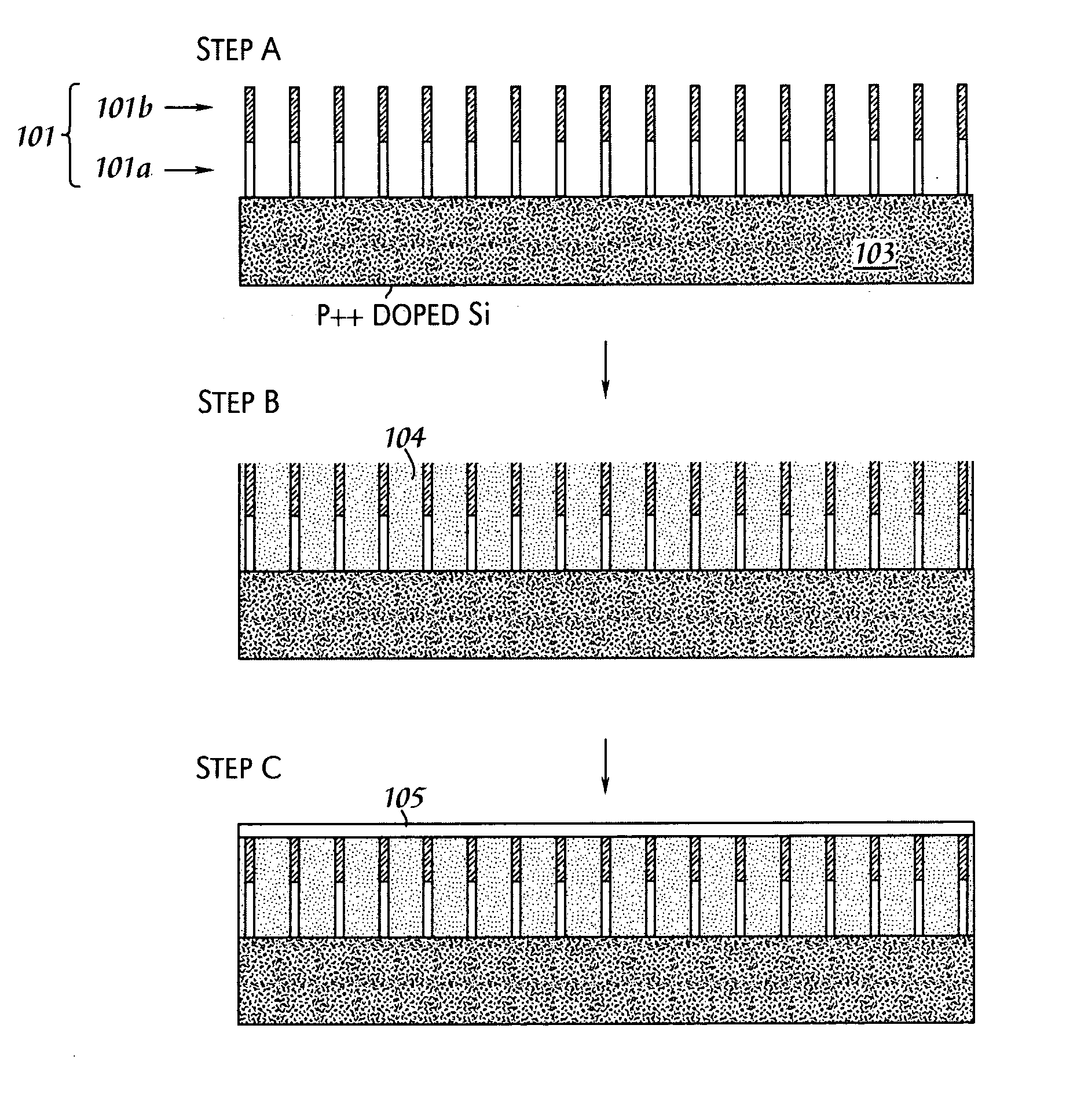

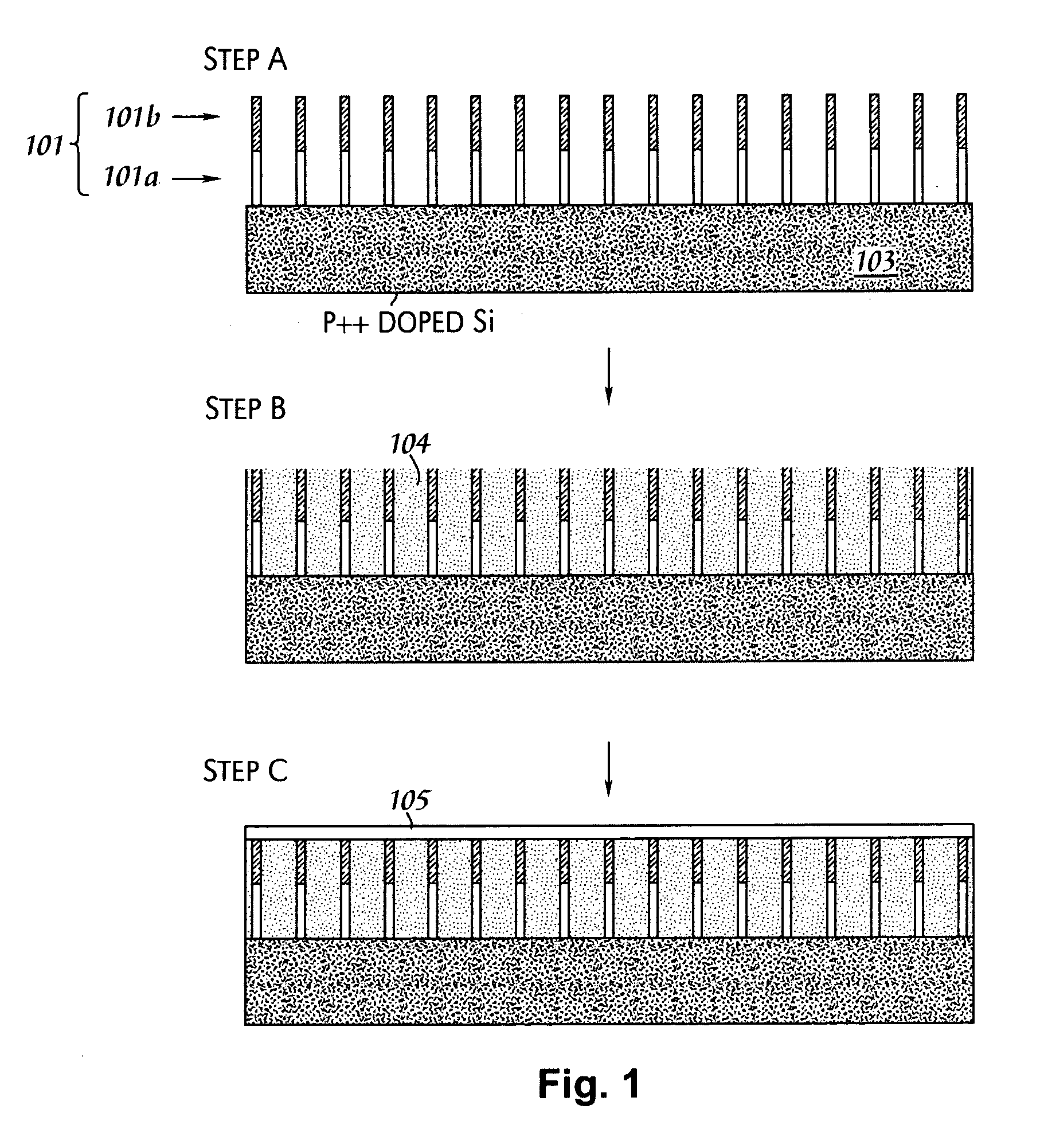

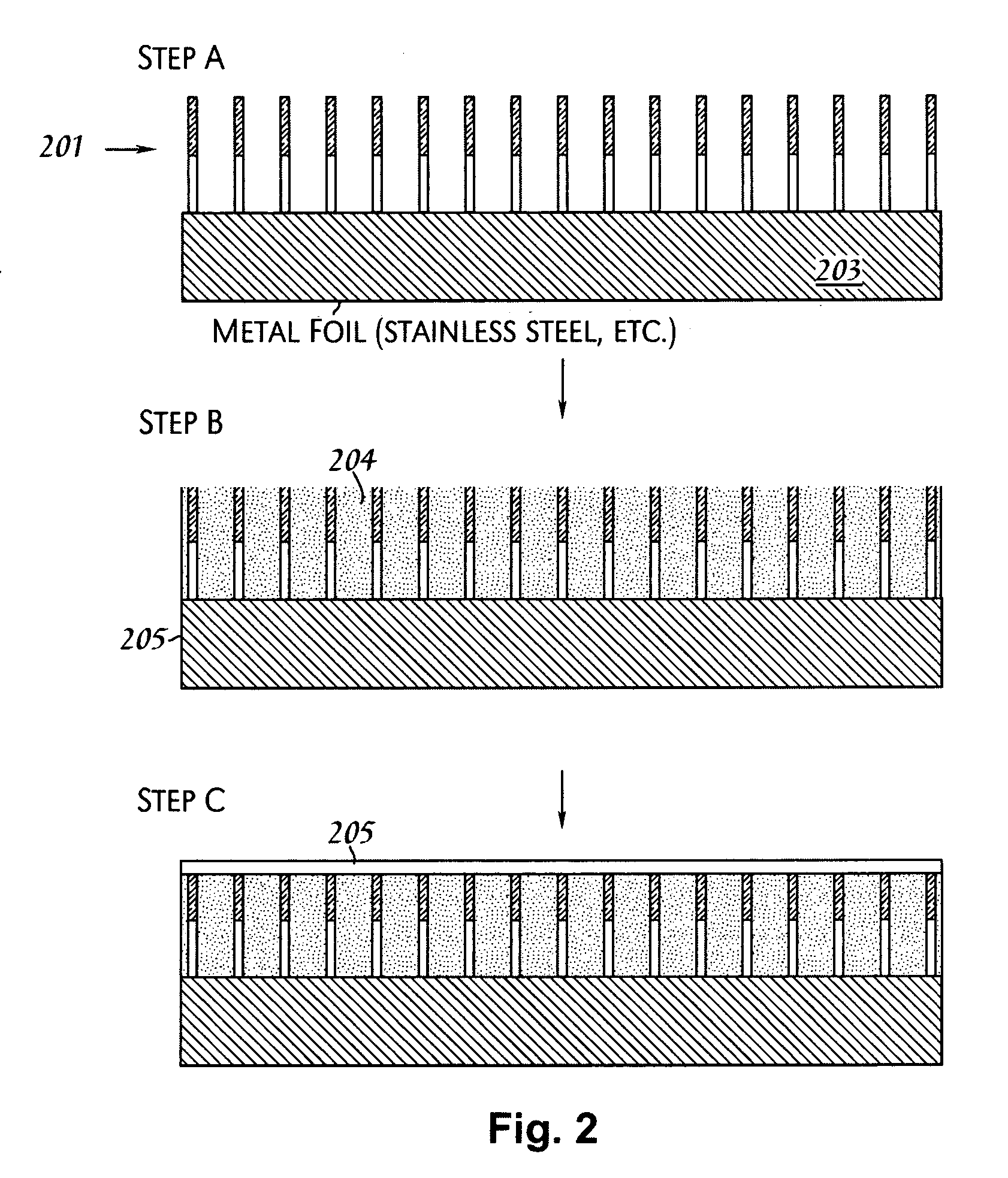

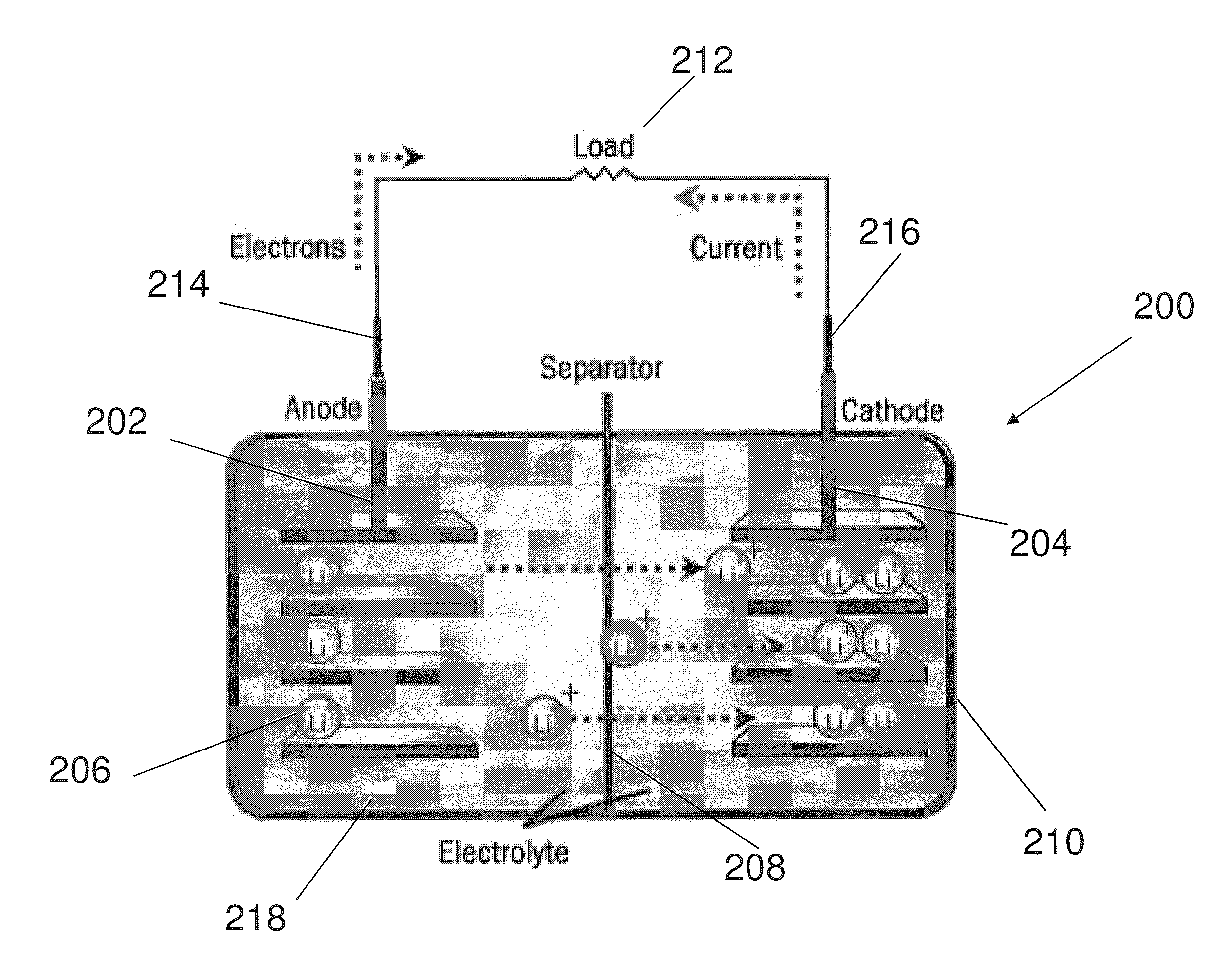

Nanostructured Materials for Battery Applications

The present invention relates to nanostructured materials (including nanowires) for use in batteries. Exemplary materials include carbon-comprising, Si-based nanostructures, nanostructured materials disposed on carbon-based substrates, and nanostructures comprising nanoscale scaffolds. The present invention also provides methods of preparing battery electrodes, and batteries, using the nanostructured materials.

Owner:ONED MATERIAL INC

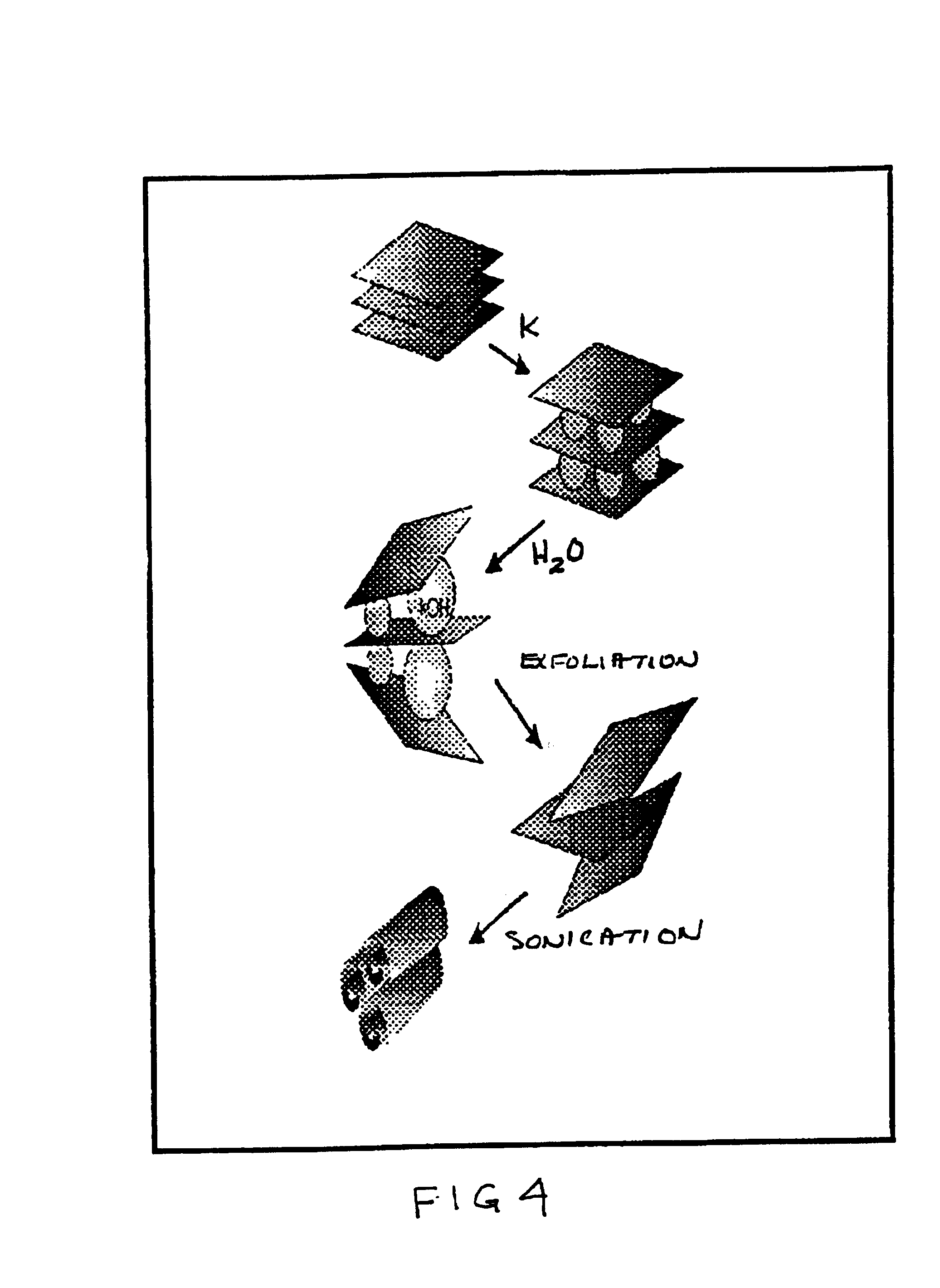

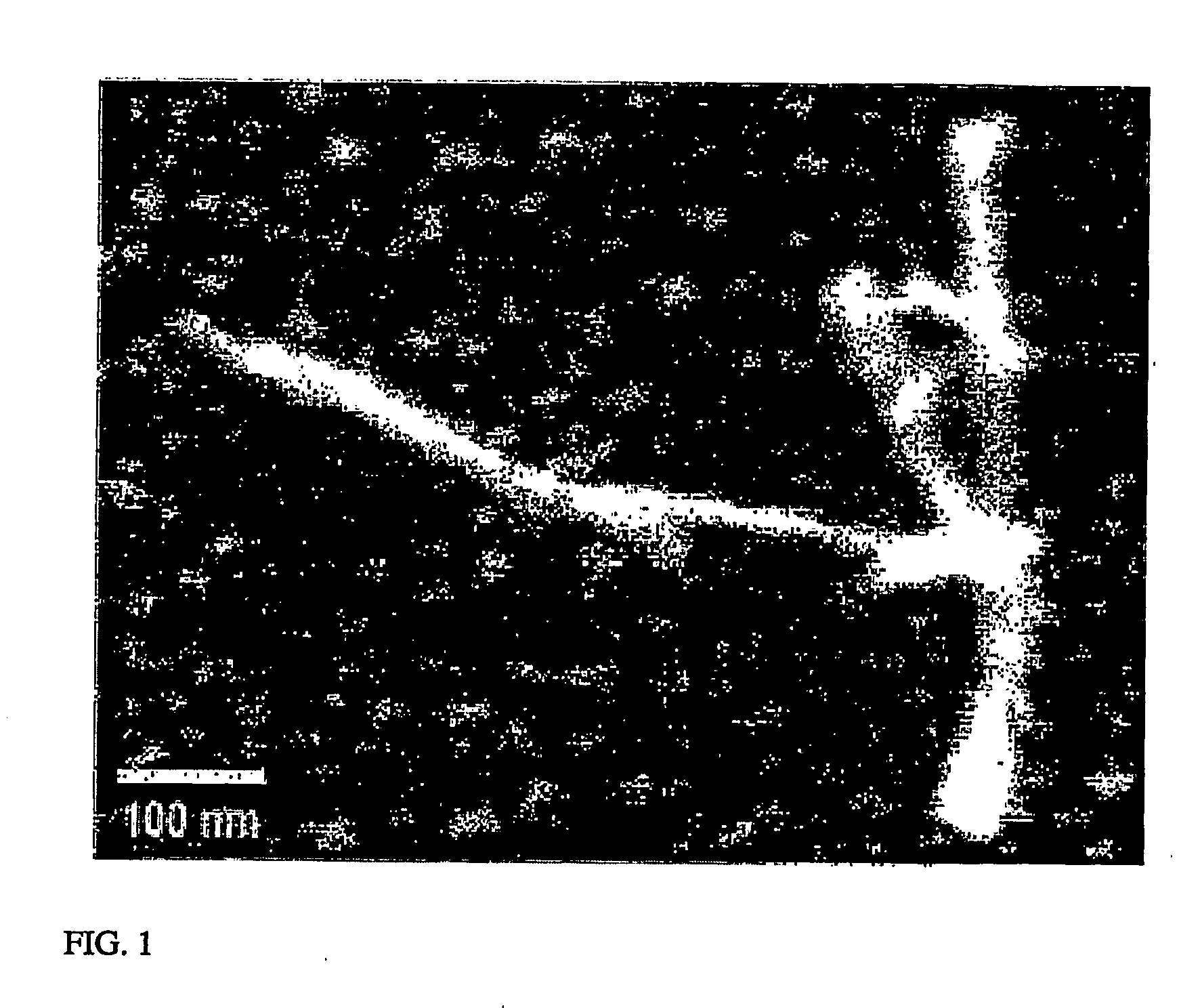

Chemical manufacture of nanostructured materials

InactiveUS6872330B2High strengthIncrease volumeMaterial nanotechnologyOxide/hydroxide preparationInorganic compoundTe element

A low temperature chemical route to efficiently produce nanomaterials is described. The nanomaterials are synthesized by intercalating ions into layered compounds, exfoliating to create individual layers and then sonicating to produce nanotubes, nanorods, nanoscrolls and / or nanosheets. It is applicable to various different layered inorganic compounds (for example, bismuth selenides / tellurides, graphite, and other metal complexes, particularly transition metal dichalcogenides compounds including oxygen, sulfur, tellurium or selenium).

Owner:RGT UNIV OF CALIFORNIA

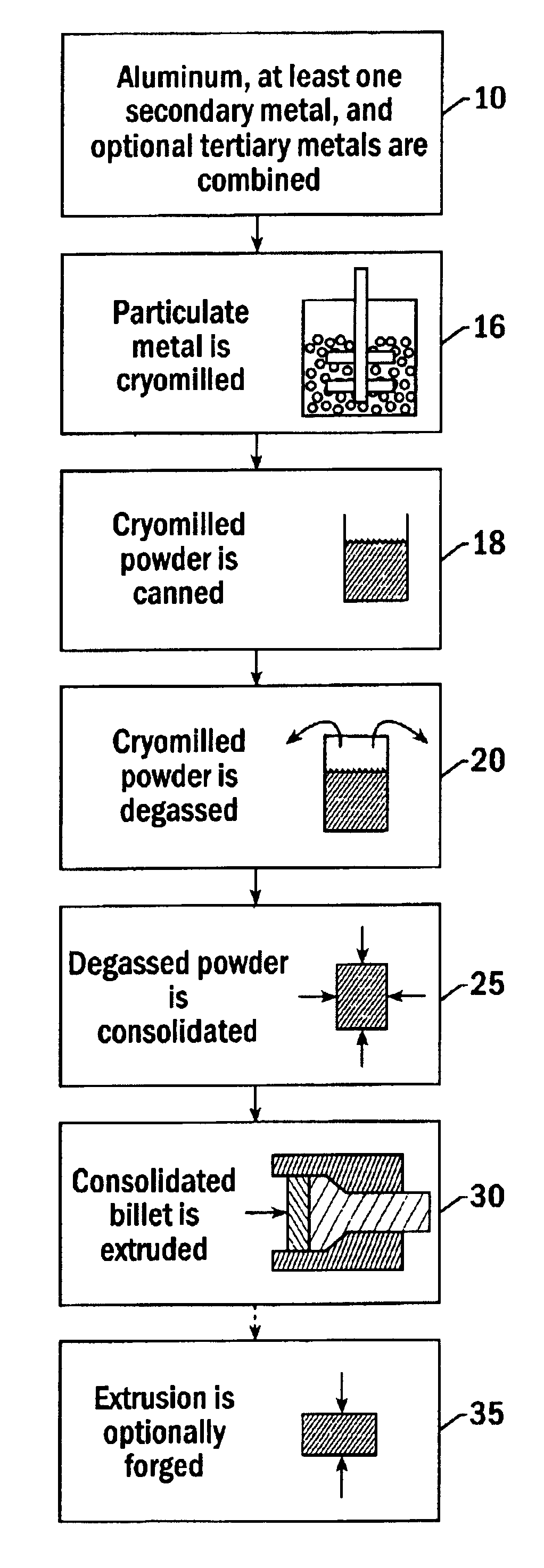

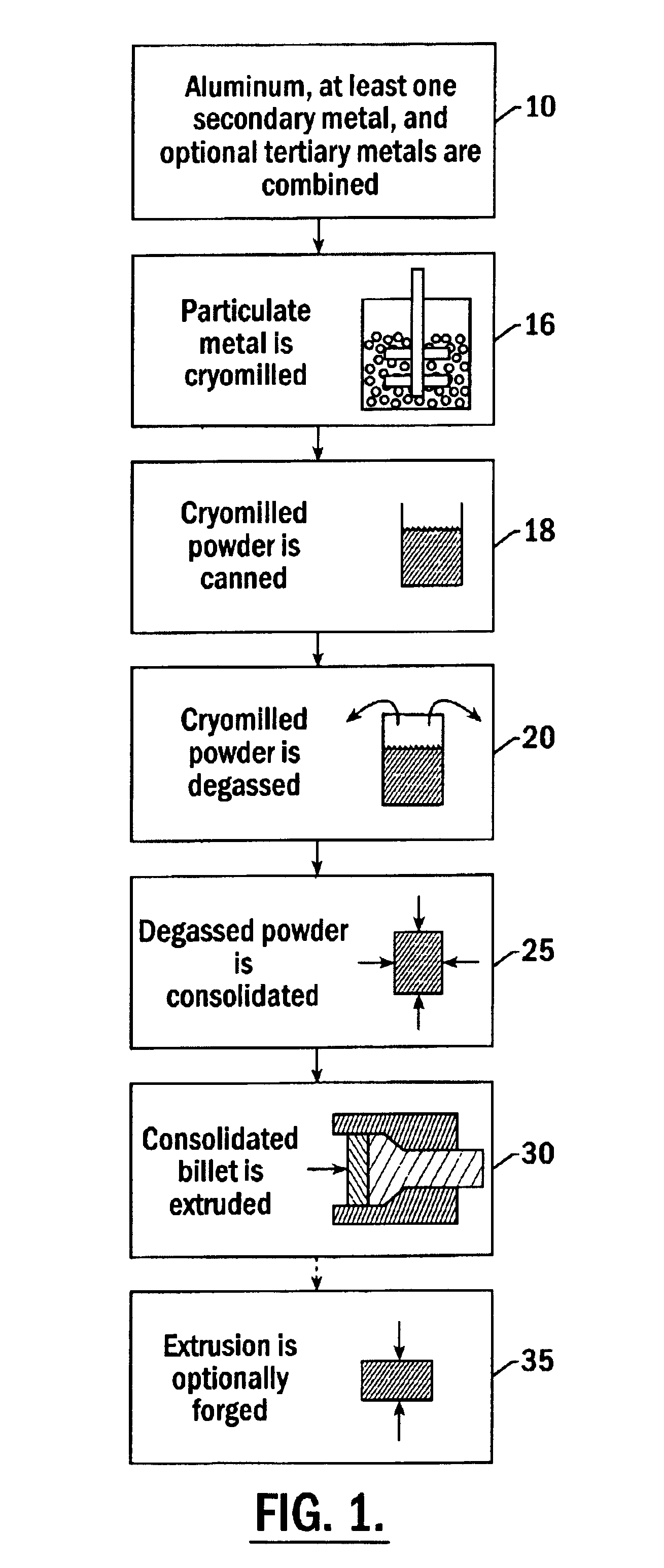

Method for preparing cryomilled aluminum alloys and components extruded and forged therefrom

InactiveUS6902699B2Stable structureHigh strengthTransportation and packagingMetal-working apparatusNanostructureAluminium alloy

High strength aluminum alloy powders, extrusions, and forgings are provided in which the aluminum alloys exhibit high strength at atmospheric temperatures and maintain high strength and ductility at extremely low temperatures. The alloy is produced by blending about 89 atomic % to 99 atomic % aluminum, 1 atomic % to 11 atomic % of a secondary metal selected from the group consisting of magnesium, lithium, silicon, titanium, zirconium, and combinations thereof, and up to about 10 atomic % of a tertiary metal selected from the group consisting of Be, Ca, Sr, Ba, Ra, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Nb, Mo, Tc, Ru, Rh, Pd, Ag, Cd, W, and combinations thereof. The alloy is produced by nanostructure material synthesis, such as cryomilling, in the absence of refractory dispersoids. The synthesized alloy is then canned, degassed, consolidated, extruded, and optionally forged into a solid metallic component. Grain size within the alloy is less than 0.5 μm, and alloys with grain size less than 0.1 μm may be produced.

Owner:THE BOEING CO

Process for preparing nanostructured materials of controlled surface chemistry

InactiveUS6669823B1Good dispersionReduce hydrolysis rateMaterial nanotechnologyMolten spray coatingCharge carrierNanostructured materials

A process to prepare stoichiometric-nanostructured materials comprising generating a plasma, forming an "active volume" through introduction of an oxidizing gas into the plasma, before the plasma is expanded into a field-free zone, either (1) in a region in close proximity to a zone of charge carrier generation, or (2) in a region of current conduction between field generating elements, including the surface of the field generation elements, and transferring energy from the plasma to a precursor material to form in the "active volume" at least one stoichiometric-nanostructured material and a vapor that may be condensed to form a stoichiometric-nanostructured material. The surface chemistry of the resulting nanostructured materials is substantially enhanced to yield dispersion stable materials with large zeta-potentials.

Owner:NANOPHASE TECH CORP

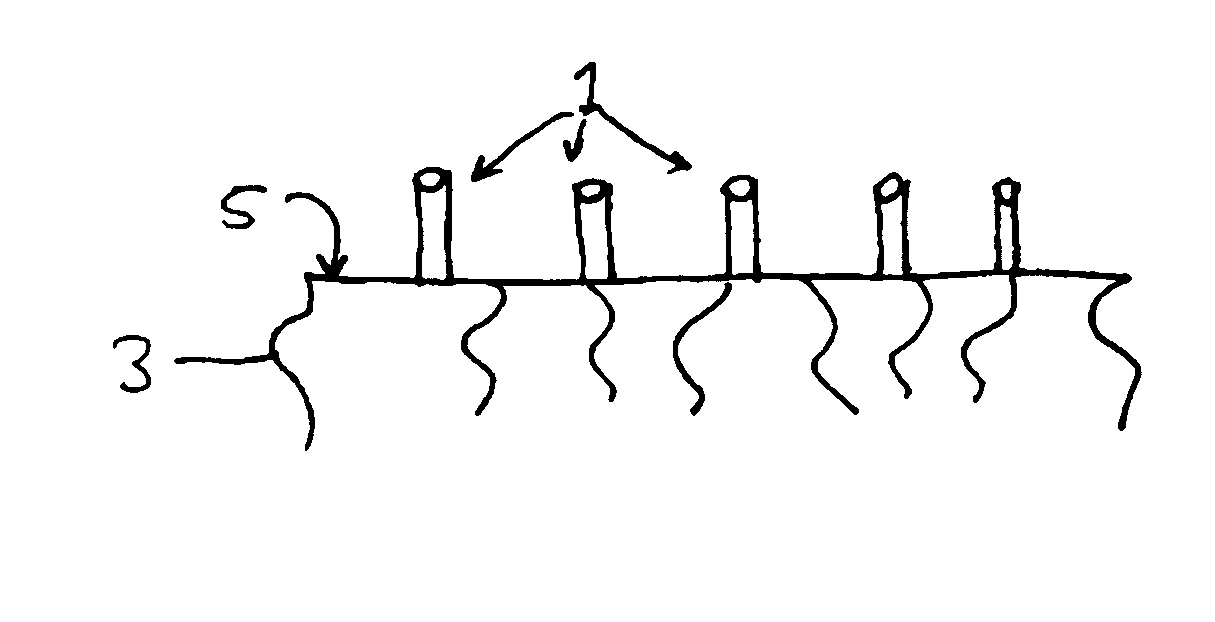

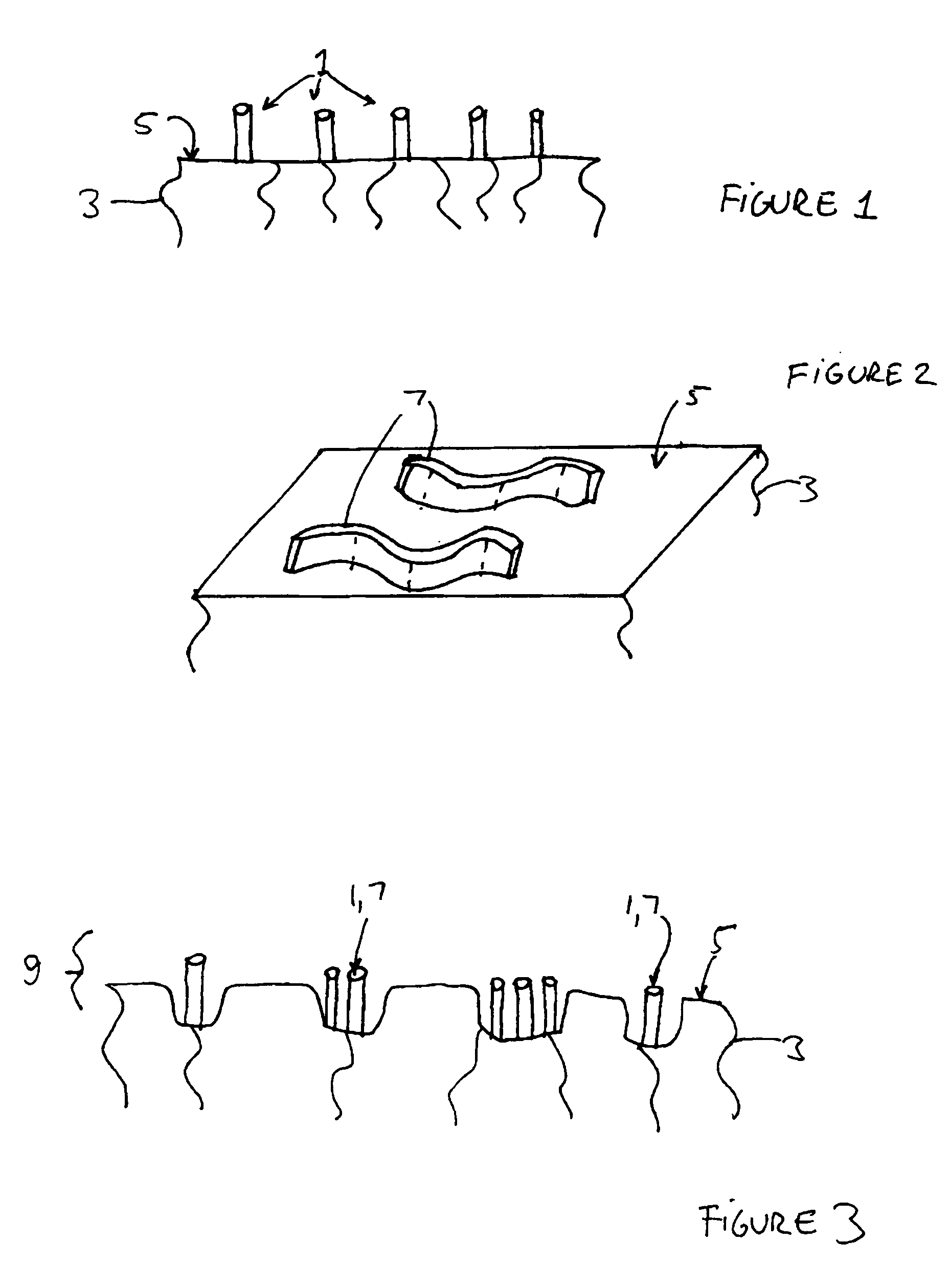

Surface treatments and modifications using nanostructure materials

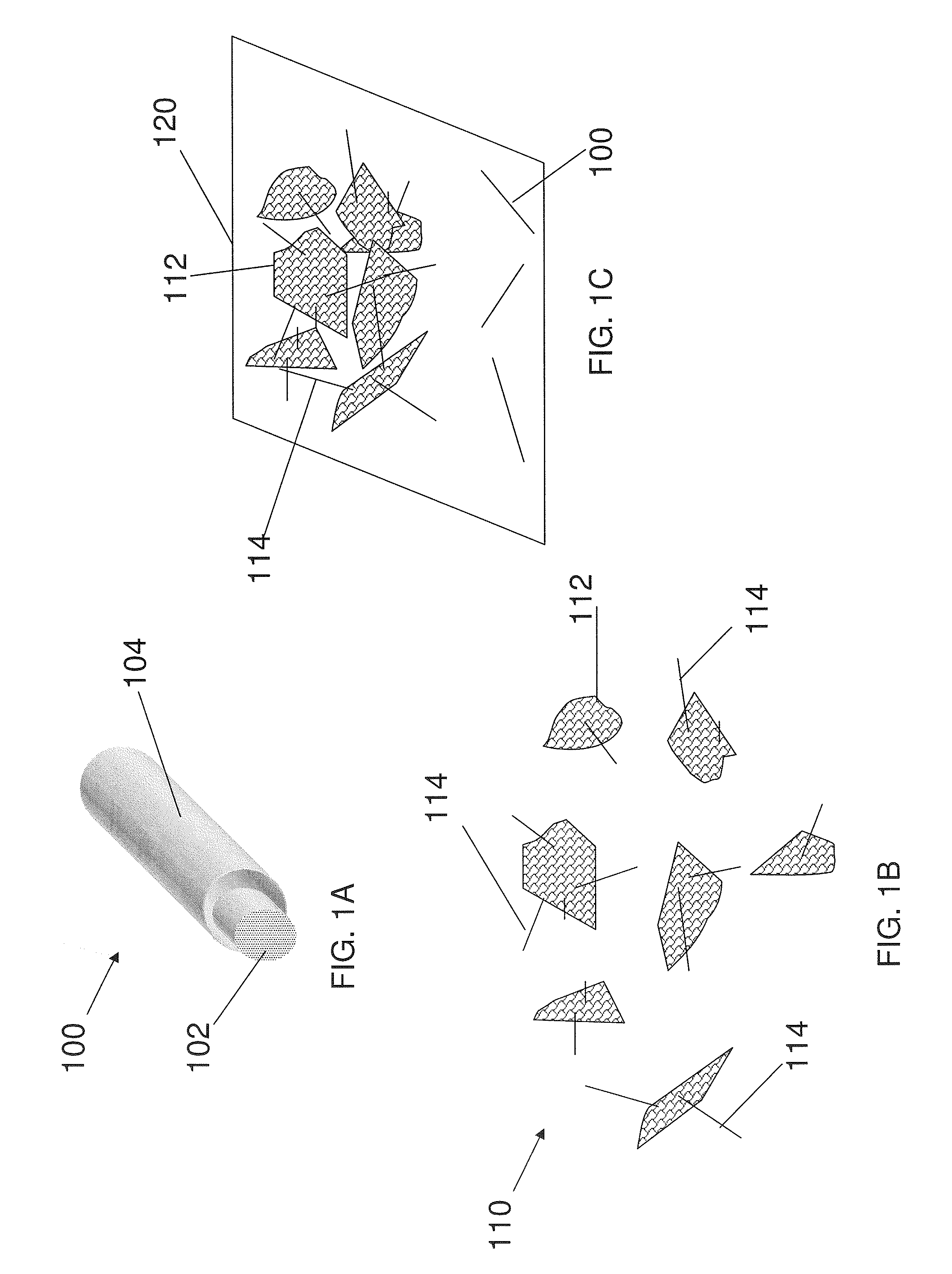

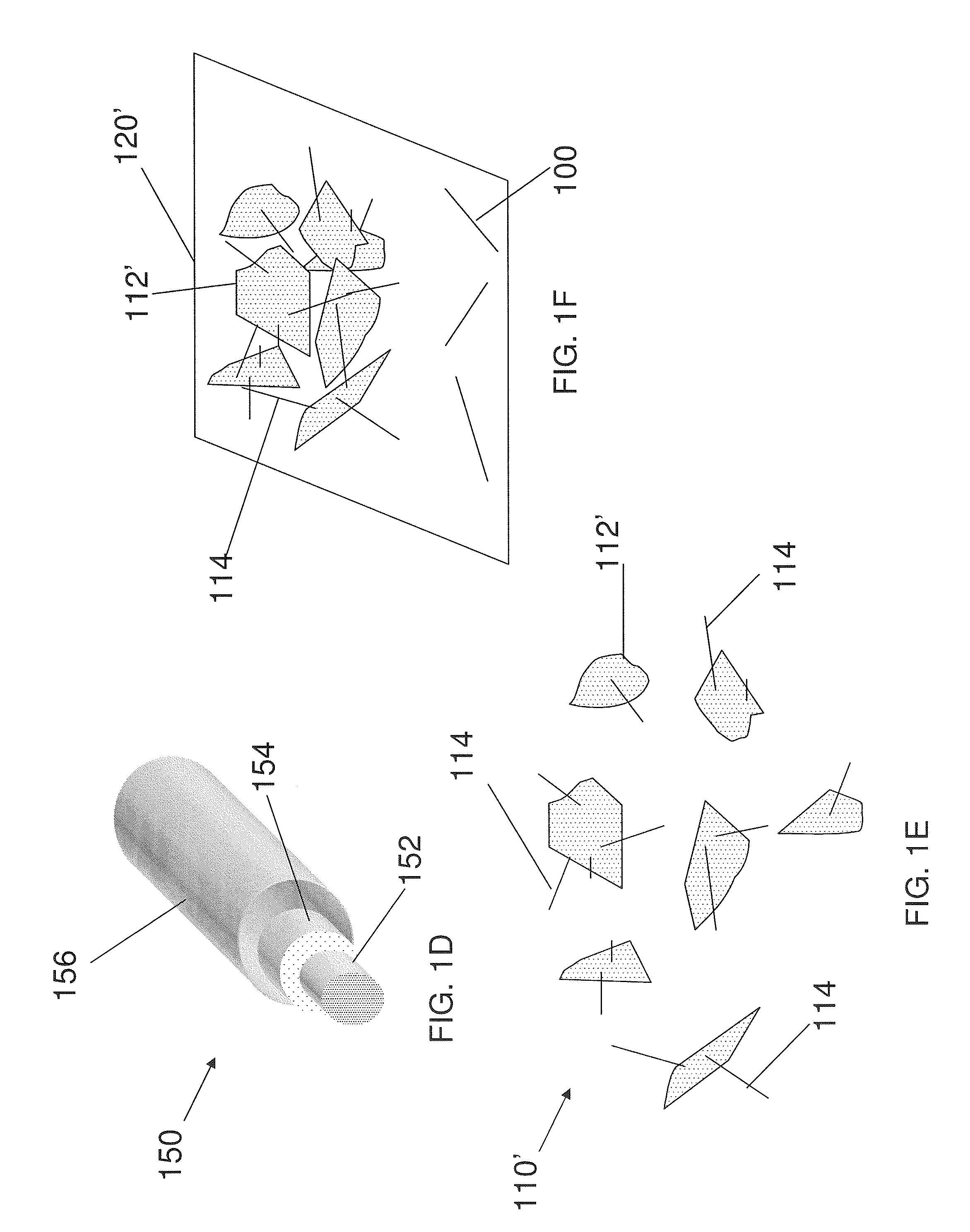

InactiveUS20050113936A1Reduce surface tensionPromote and inhibit ingrowthSuture equipmentsHeart valvesGas phaseNanostructure

The invention is directed to nanostructure surface treatments, coatings or modifications formed from nanoscale building blocks. The nanostructure surface treatments, modifications or coatings have hydrophobic, hydrophilic and surface adherence properties. The nanoscale building blocks have orientation, geometry, packing density and composition that may be adjusted to control the unique surface characteristics of the desired treatment, coating or modification. Applications of this nanostructure technology include surgical clips, staples, retractors, sutures and manipulators where an improvement in traction, retention or occlusion is desired without excessive material or tissue deformation or where high compressive forces would be undesirable, dangerous or ineffective. In one aspect, a nanostructure surface treatment for a medical device having an external surface is disclosed, wherein the treatment is applied on the external surface to provide a hydrophobic or a hydrophilic surface. With this aspect, the treatment comprises titanium dioxide and provides nanoscopic structures having nearly vertical sidewalls. The treated surface of the device has contact angles greater than or equal to 150 degrees. The vertical sidewalls provide a negative capillary effect and have a width of about 200 nm. The vertical sidewalls attach to a wet surface by the negative capillary effect. The van der Waals forces of the vertical sidewalls enable the treated surface to attach to a dry surface. The treatment may be vapor deposited and cured on the device, or the treatment may be laser blasted on the device.

Owner:APPL MEDICAL RESOURCES CORP

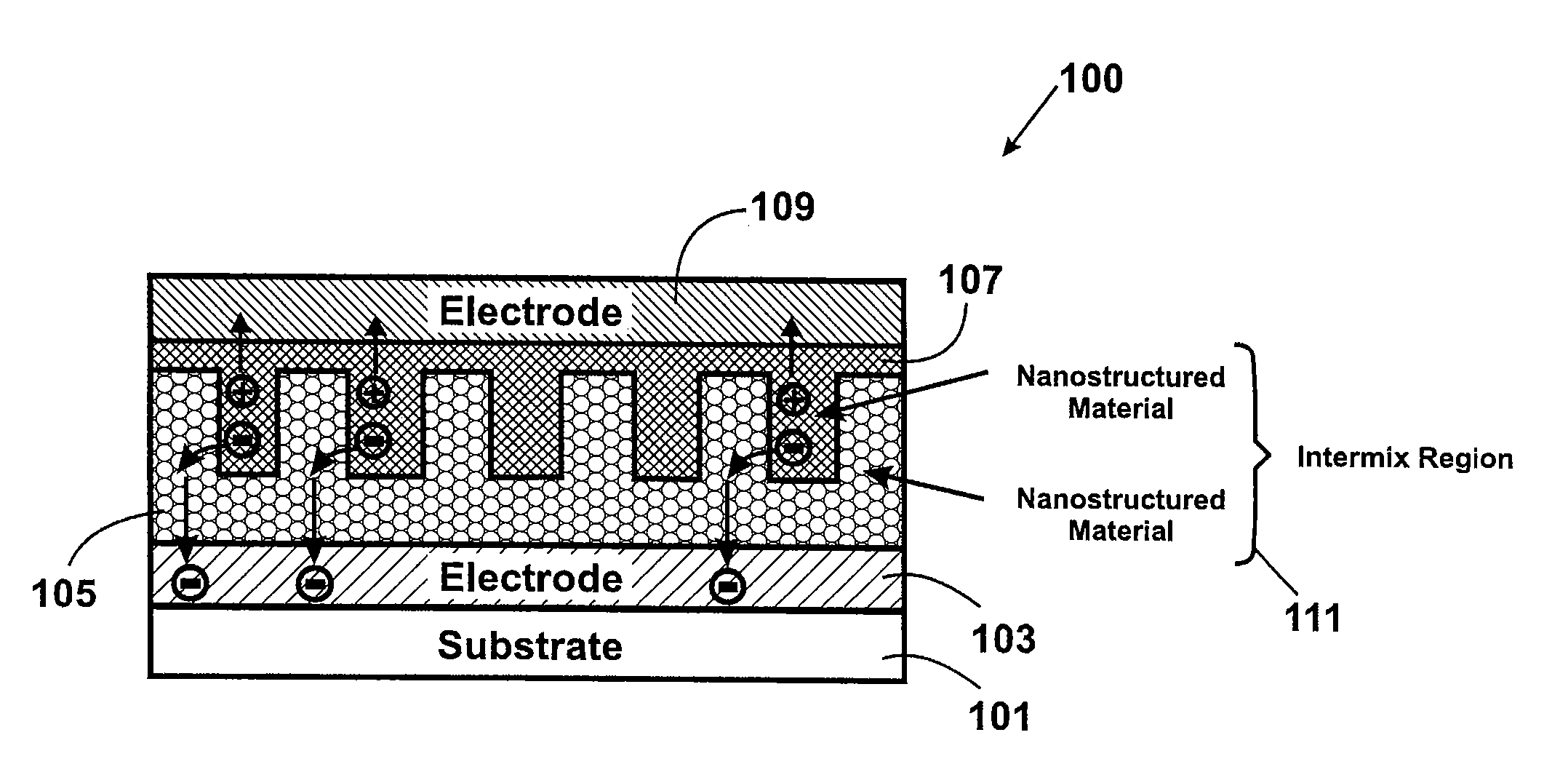

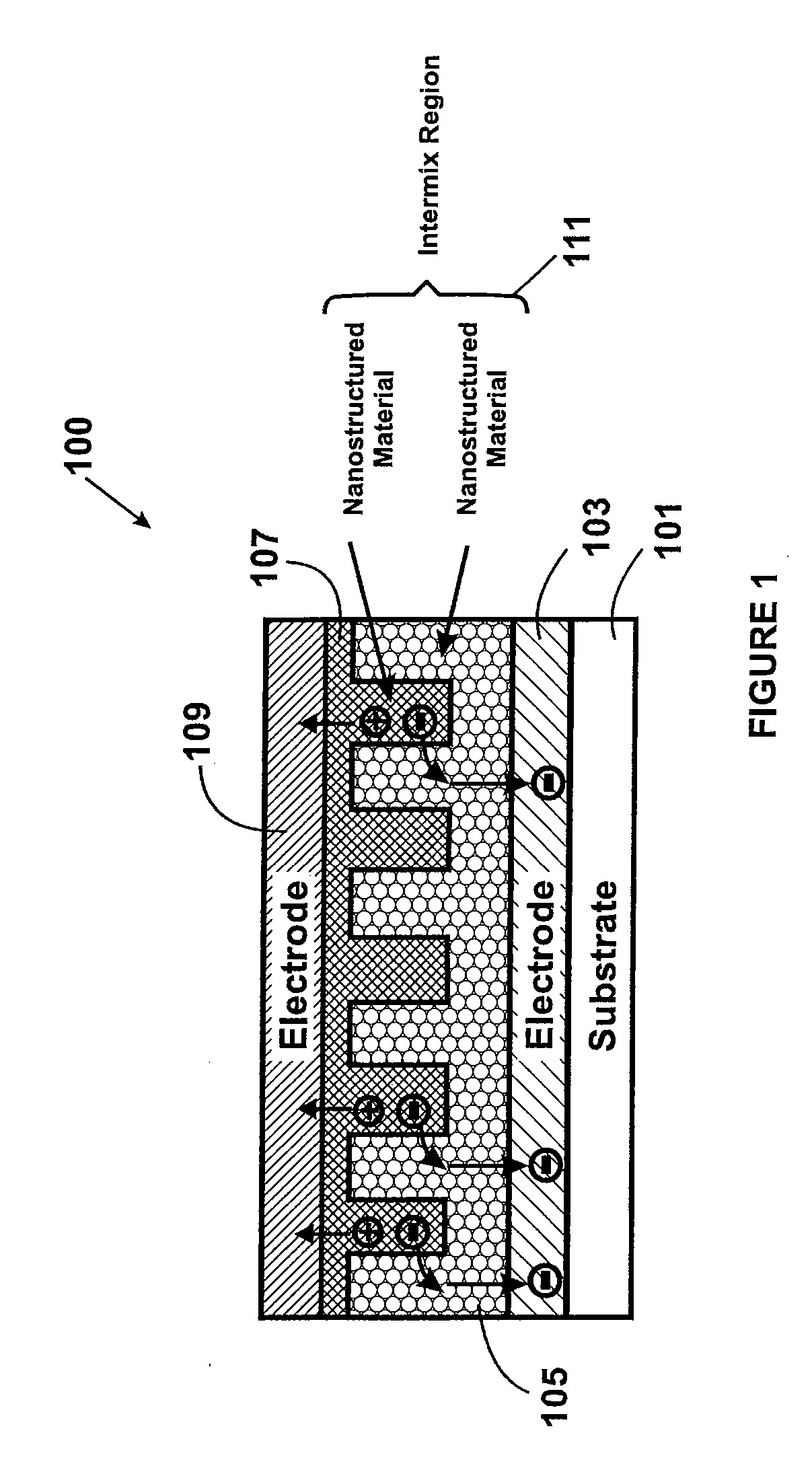

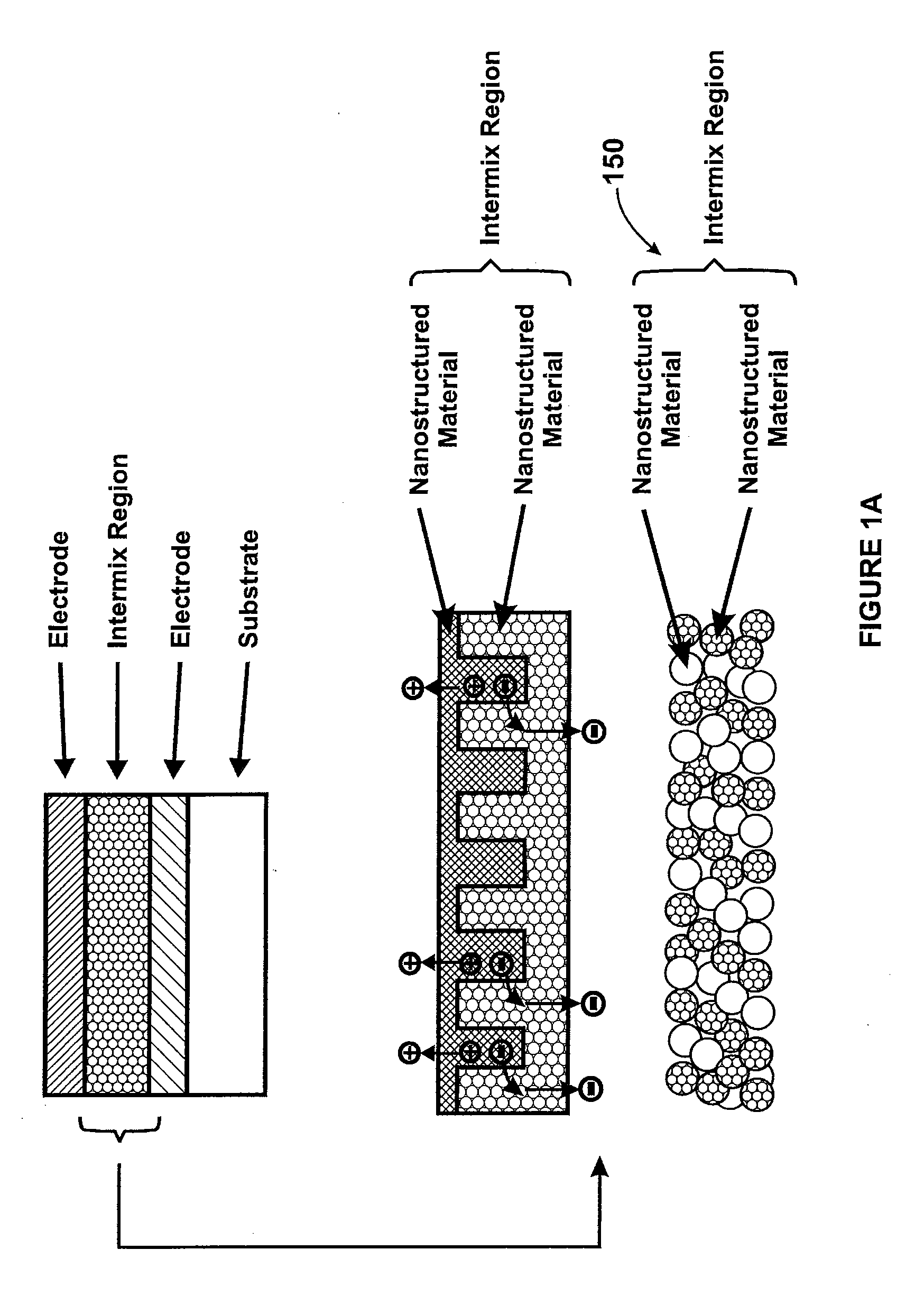

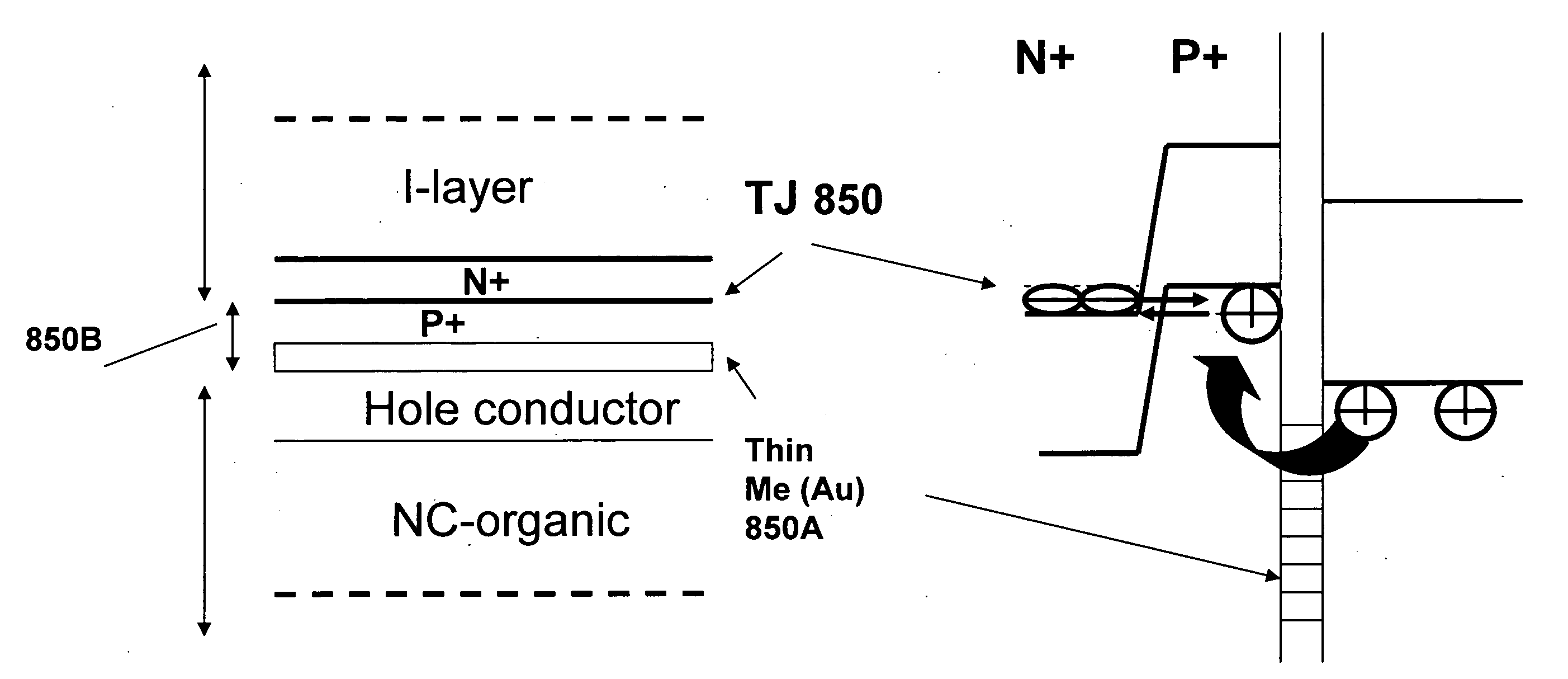

Method and structure for thin film photovoltaic materials using semiconductor materials

ActiveUS20070264488A1Easy to useImprove conversion efficiencyLayered productsConductive materialSemiconductor materialsCharge carrier

A photovoltaic device and related methods. The device has a nanostructured material positioned between an electron collecting electrode and a hole collecting electrode. An electron transporting / hole blocking material is positioned between the electron collecting electrode and the nanostructured material. In a specific embodiment, negatively charged carriers generated by optical absorption by the nanostructured material are preferentially separated into the electron transporting / hole blocking material. In a specific embodiment, the nanostructured material has an optical absorption coefficient of at least 103 cm−1 for light comprised of wavelengths within the range of about 400 nm to about 700 nm.

Owner:CM MFG

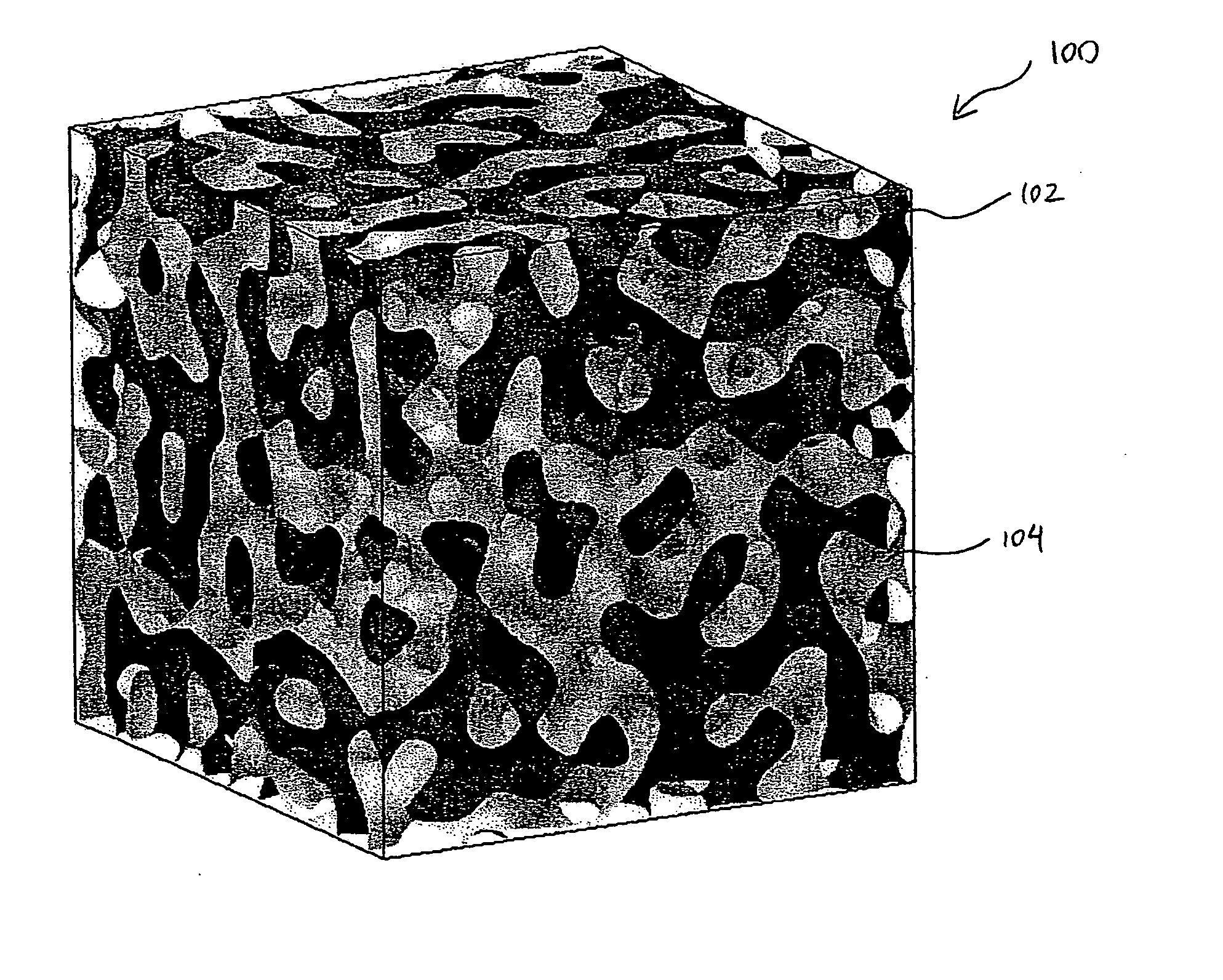

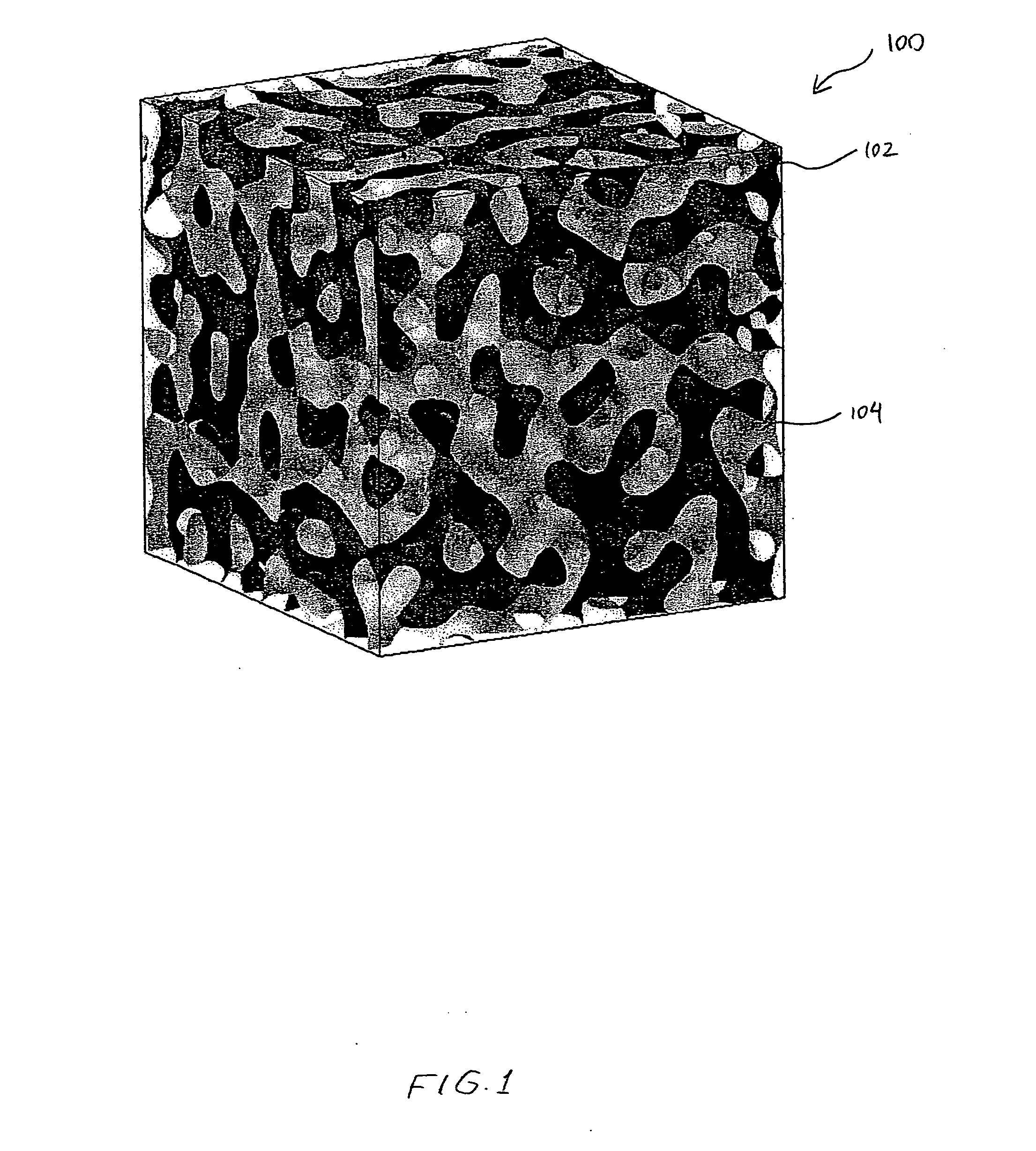

Nanostructured materials and photovoltaic devices including nanostructured materials

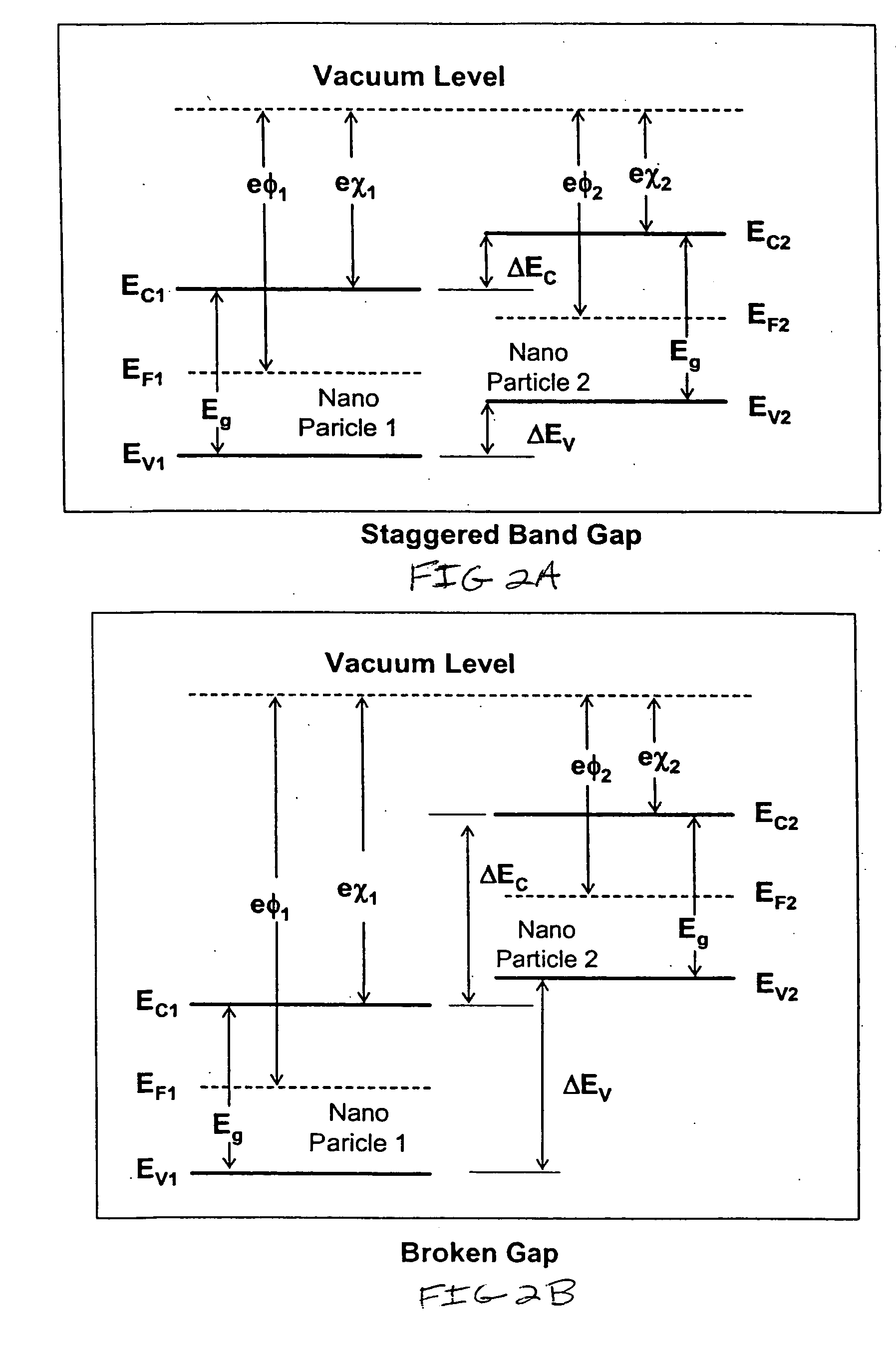

Nanostructured materials and photovoltaic devices including nanostructured materials are described. In one embodiment, a nanostructured material includes: (a) a first nano-network formed from a first set of nanoparticles; and (b) a second nano-network coupled to the first nano-network and formed from a second set of nanoparticles. At least one of the first set of nanoparticles and the second set of nanoparticles are formed from an indirect bandgap material. The nanostructured material is configured to absorb light to produce a first type of charge carrier that is transported in the first nano-network and a second type of charge carrier that is transported in the second nano-network. The nanostructured material has an absorption coefficient that is at least 103 cm−1 within a range of wavelengths from about 400 nm to about 700 nm.

Owner:SAMSUNG ELECTRONICS CO LTD

Purification of fluids with nanomaterials

ActiveUS7211320B1Low costSimple processMaterial nanotechnologyRecord information storageNanostructured materialsNanometre

Disclosed herein is a nanostructured material comprising defective carbon nanotubes chosen from impregnated, functionalized, doped, charged, coated, and irradiated nanotubes, and combinations thereof. The defective carbon nanotubes contain a defect which is a lattice distortion in at least one carbon ring. Also disclosed is a method of purifying fluids, such as liquids, including water, as well as gases, including the air using, this nanostructured material.

Owner:MULTIPURE INT

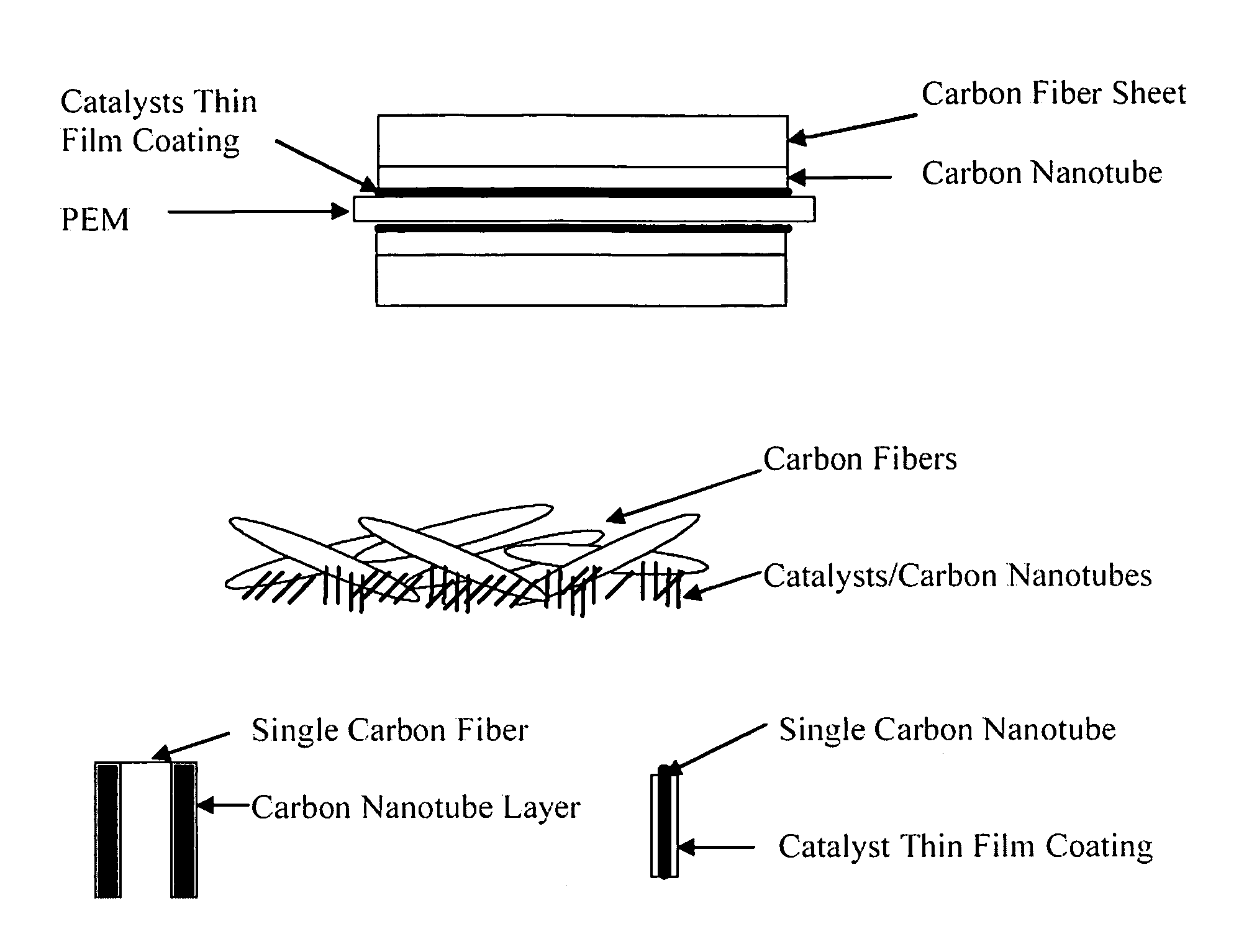

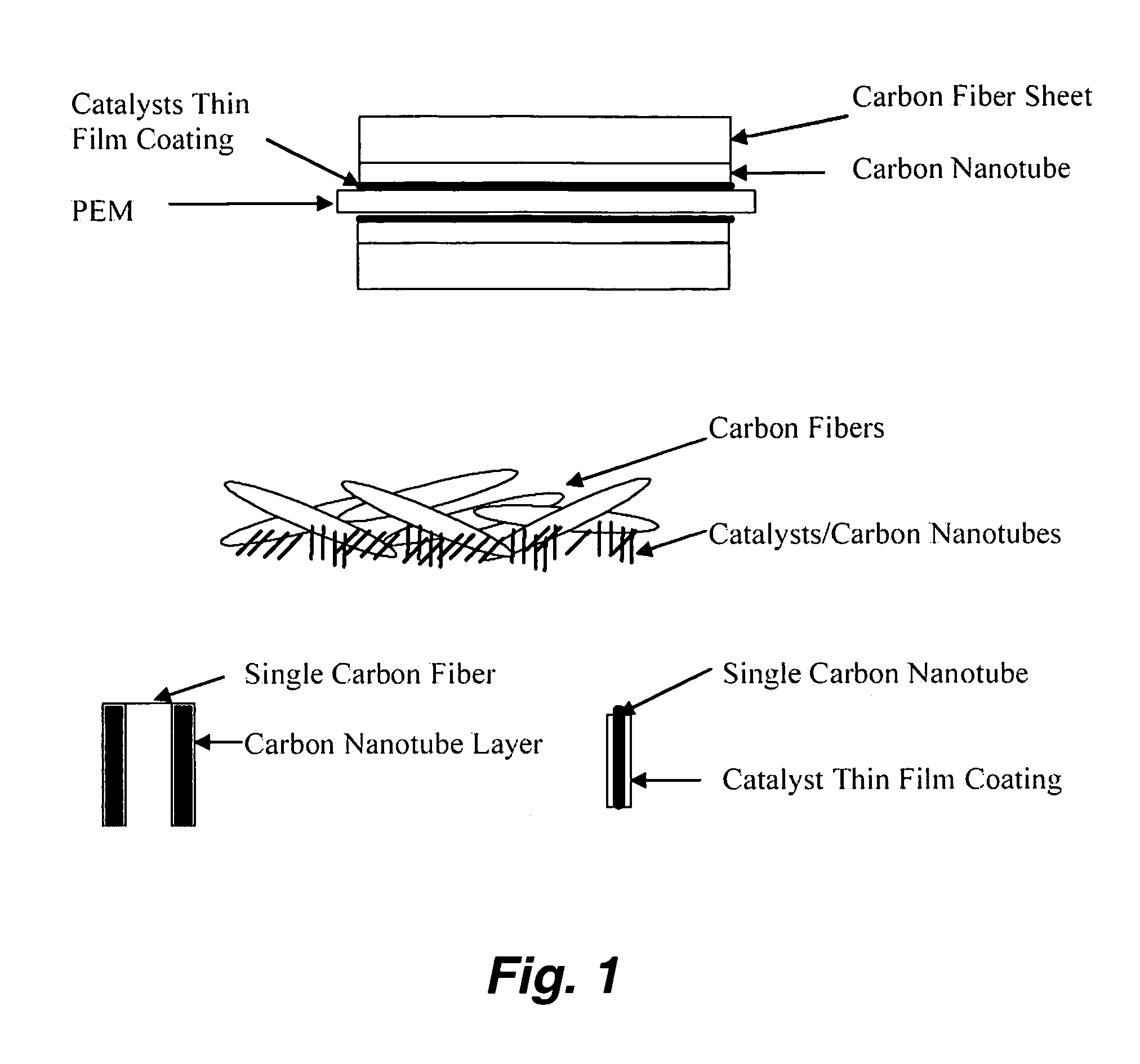

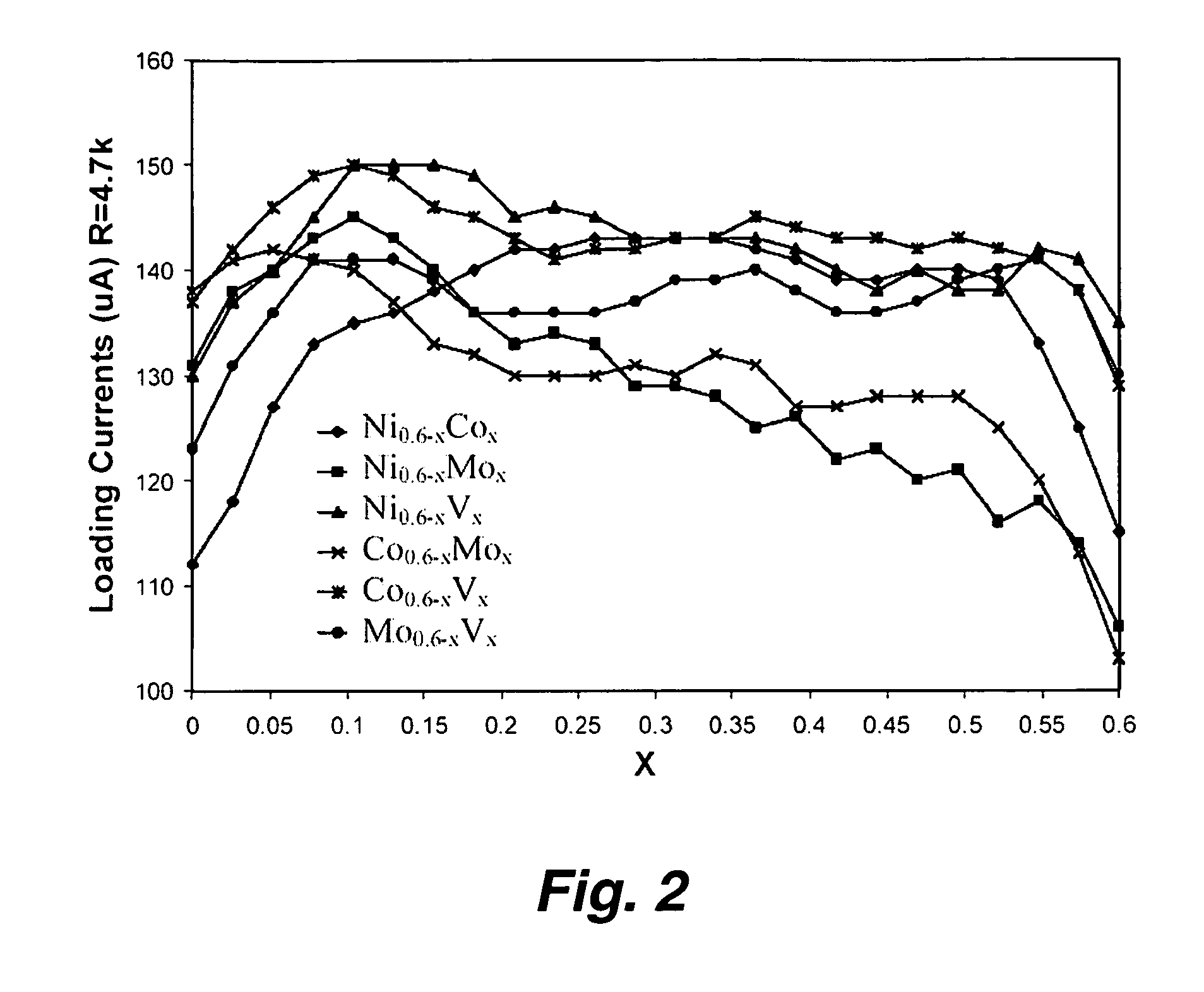

Low platinum fuel cell catalysts and method for preparing the same

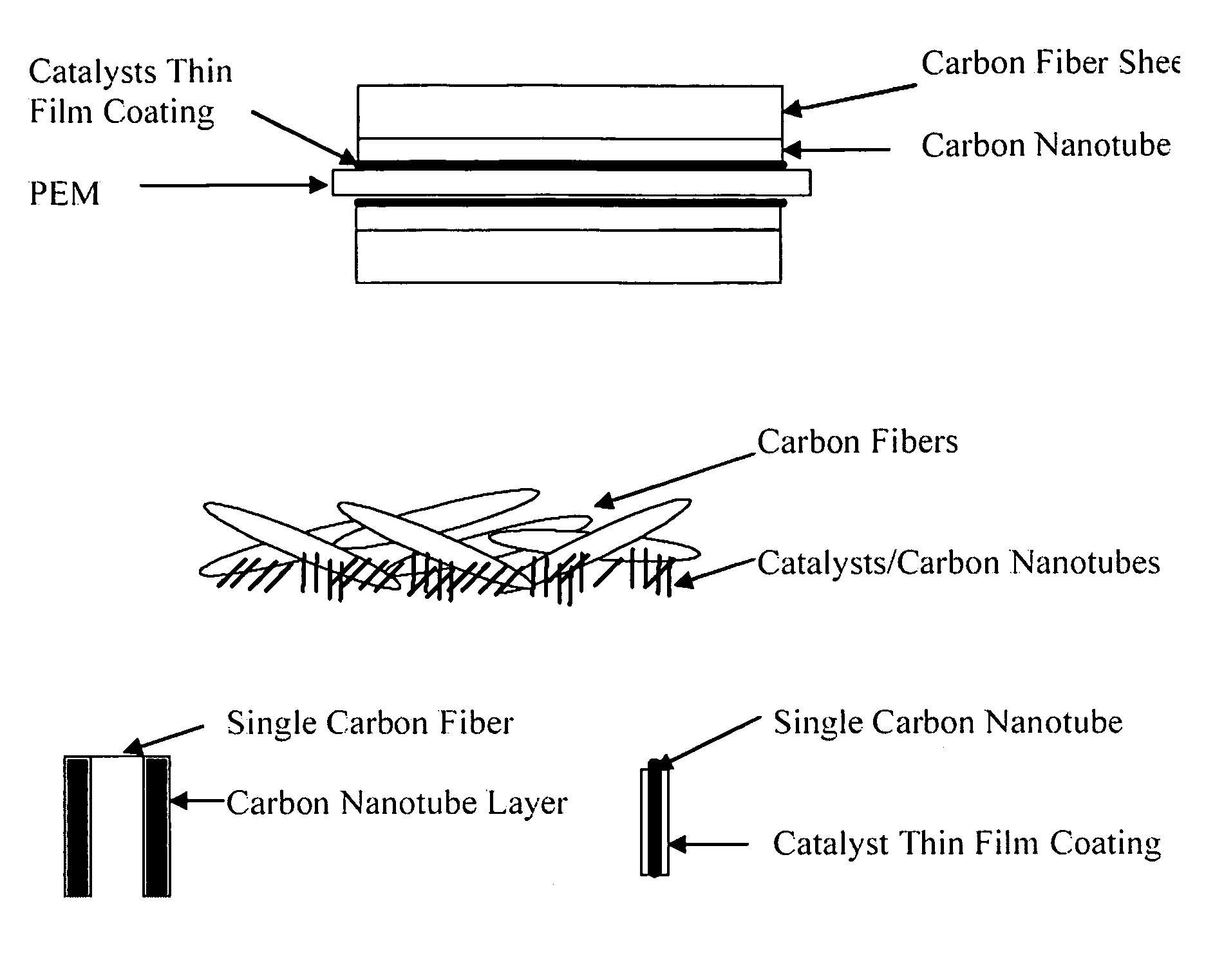

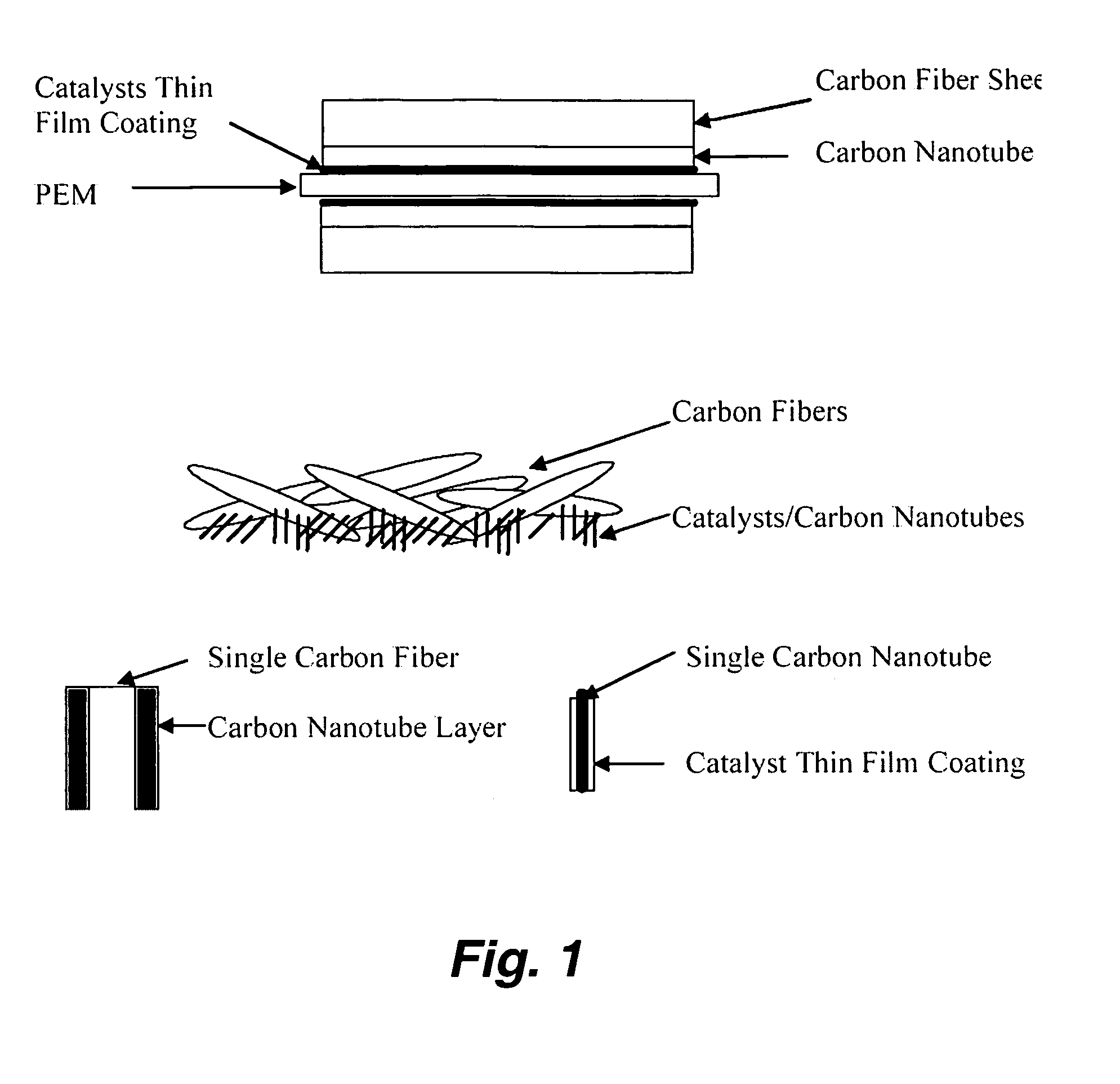

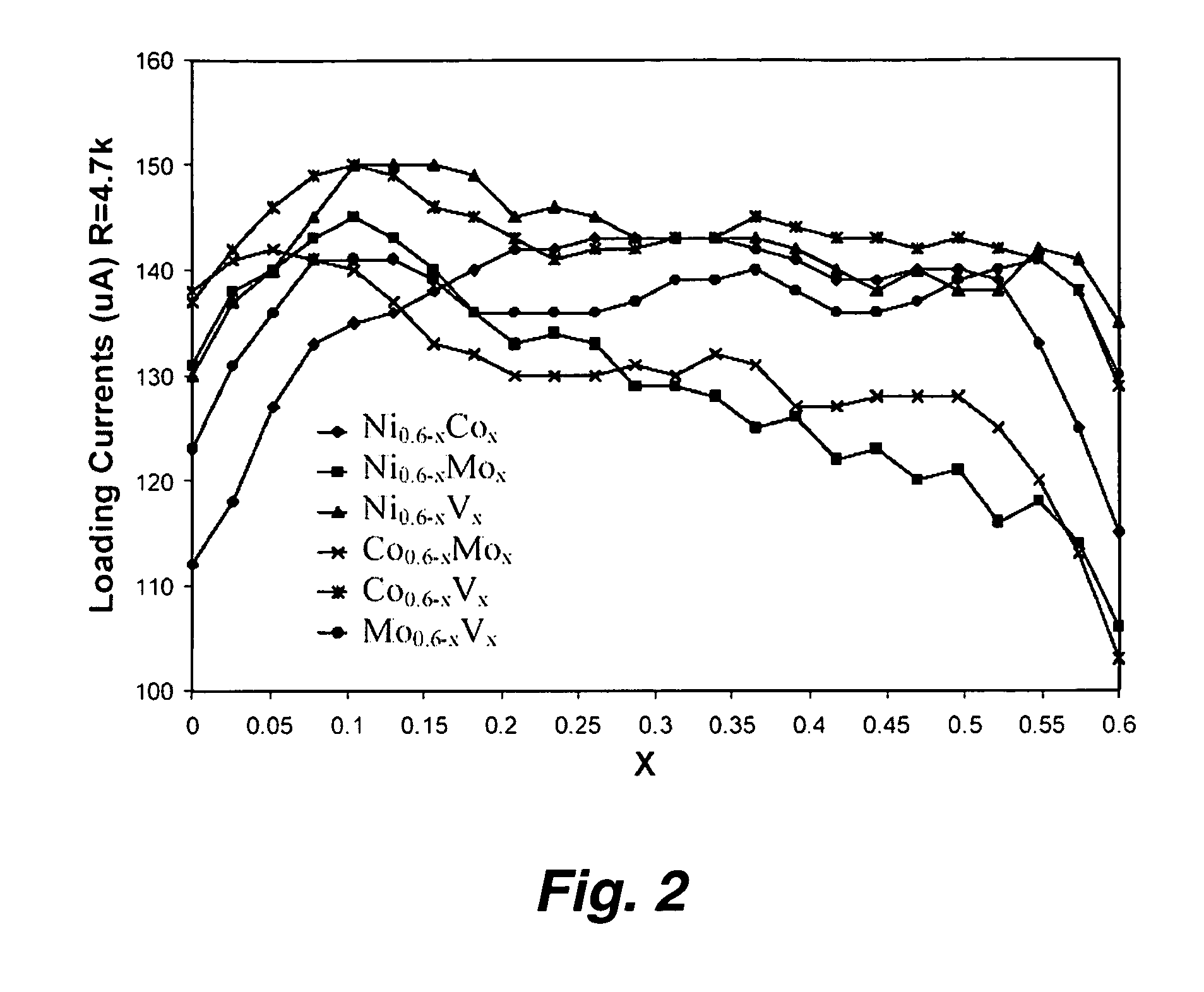

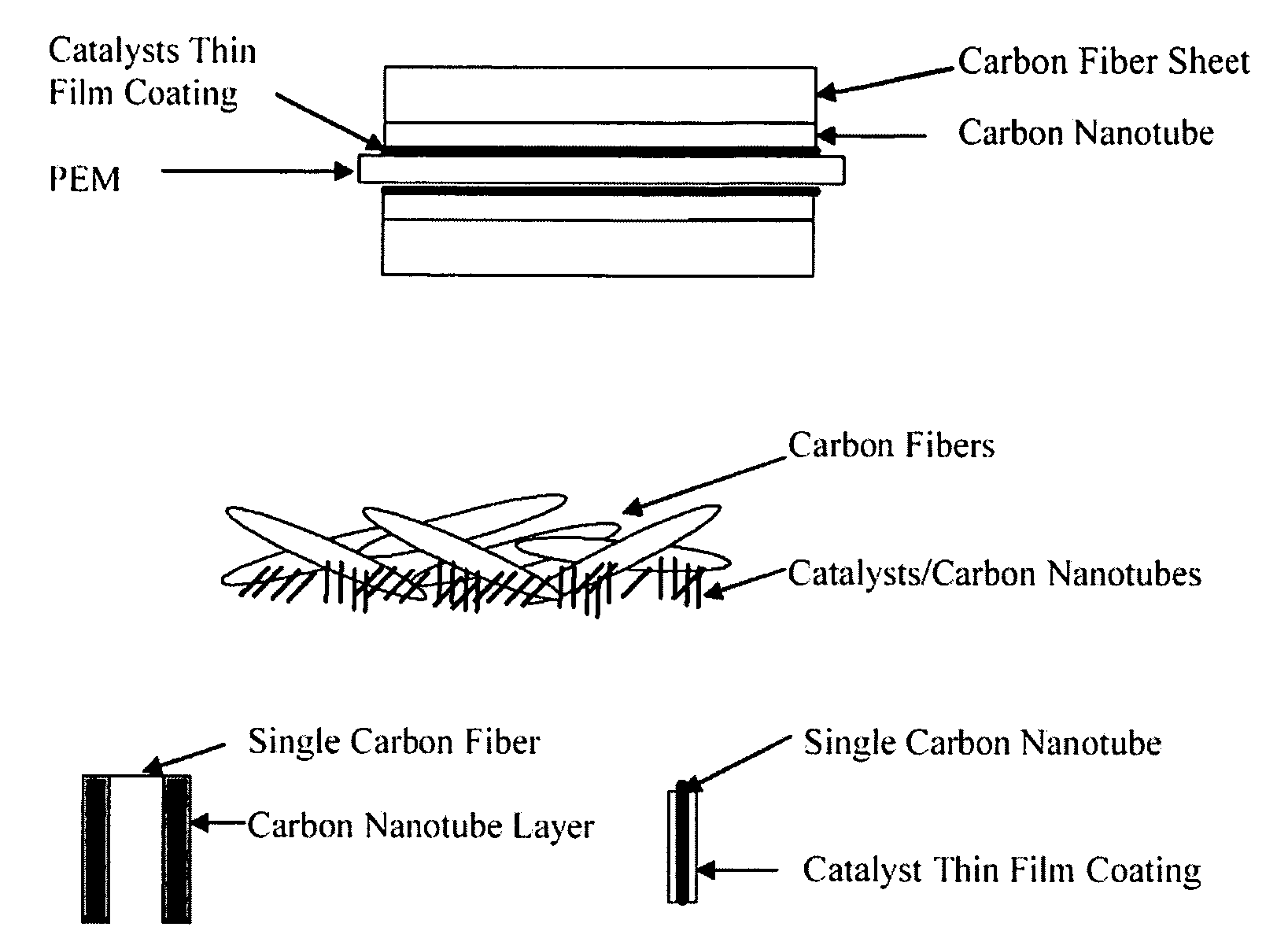

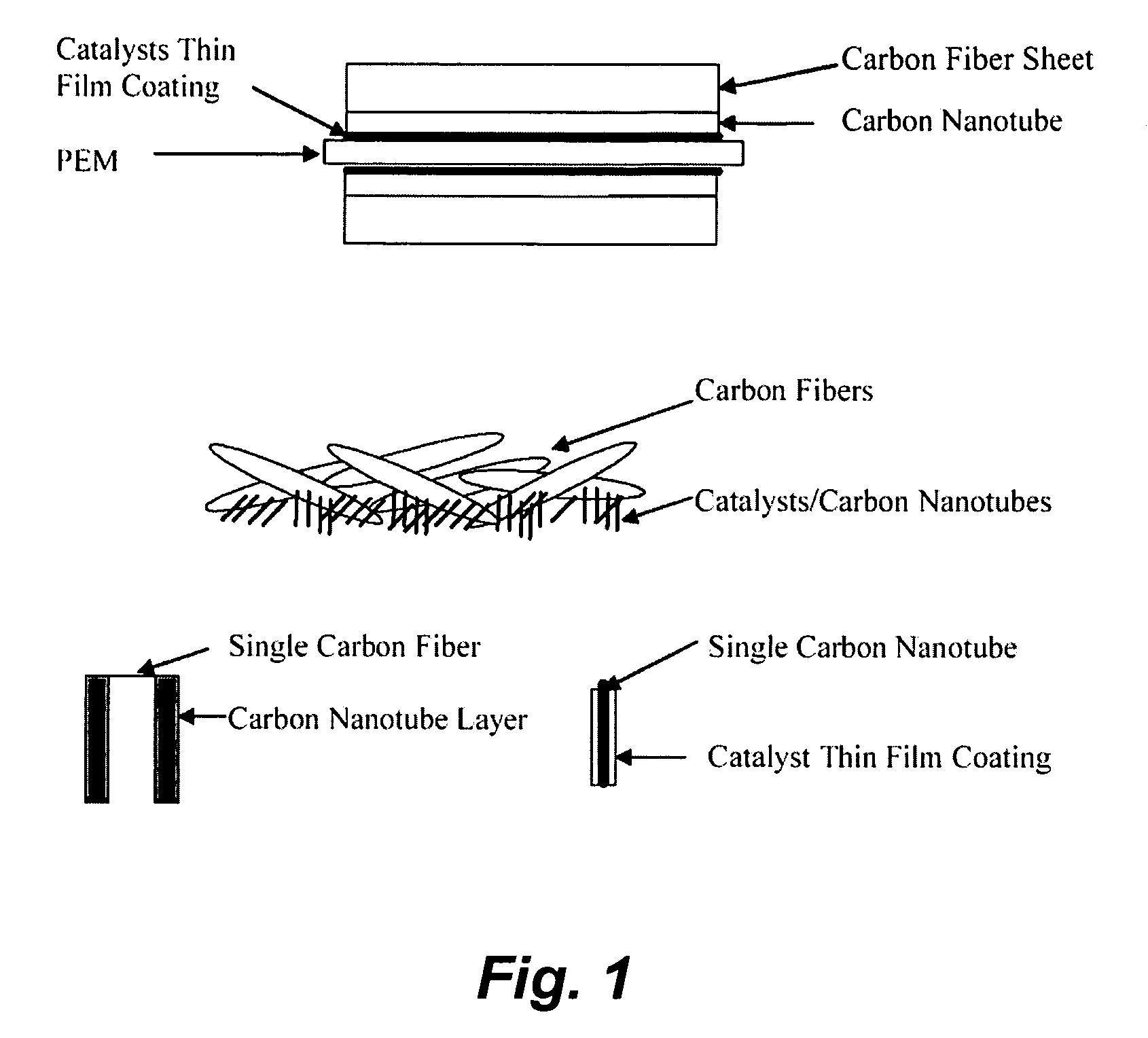

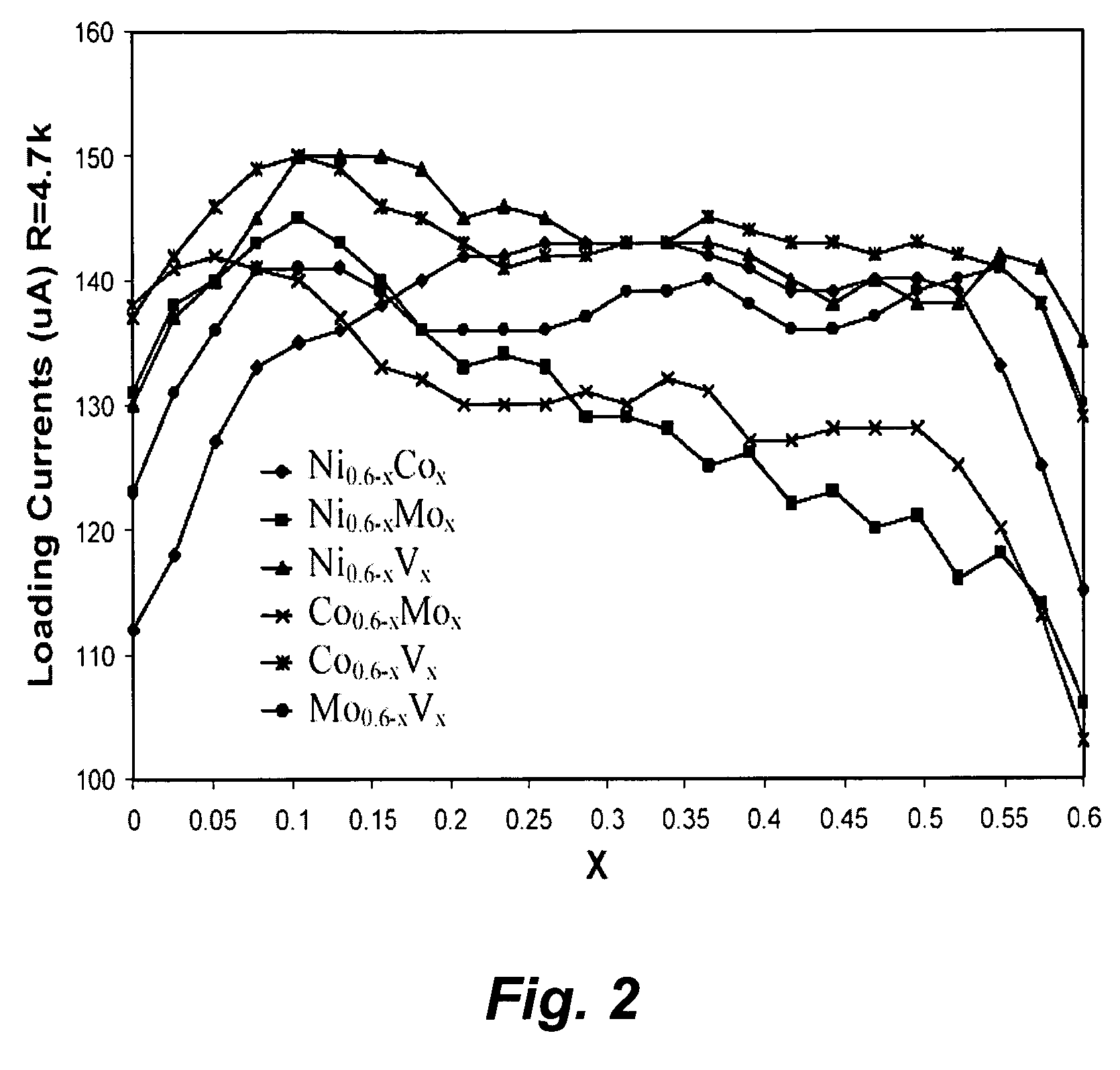

InactiveUS20050053826A1Good dispersionEfficient CatalysisMaterial nanotechnologyConductive materialFiberCarbon fibers

This invention provides novel fuel cell catalysts comprising new series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticales into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

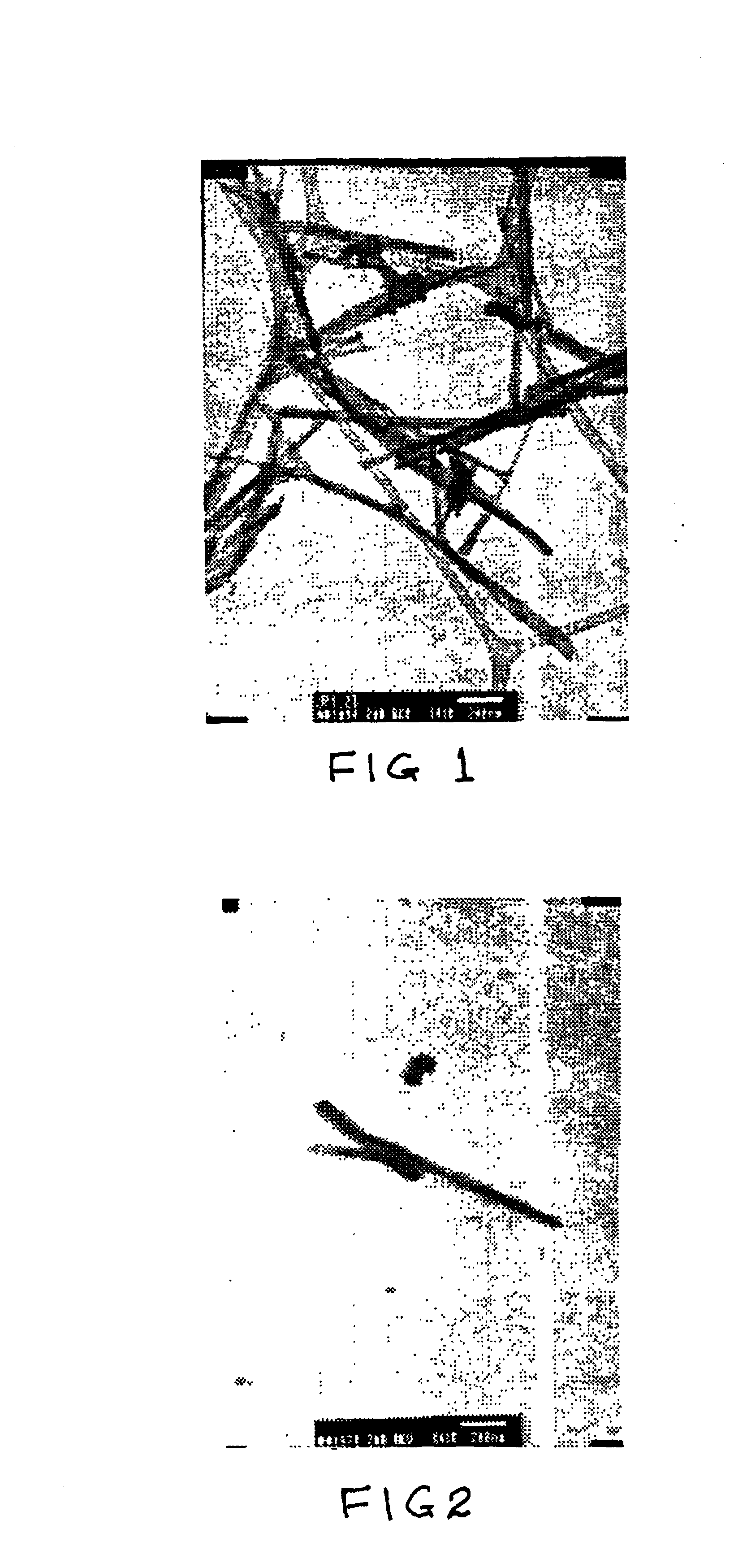

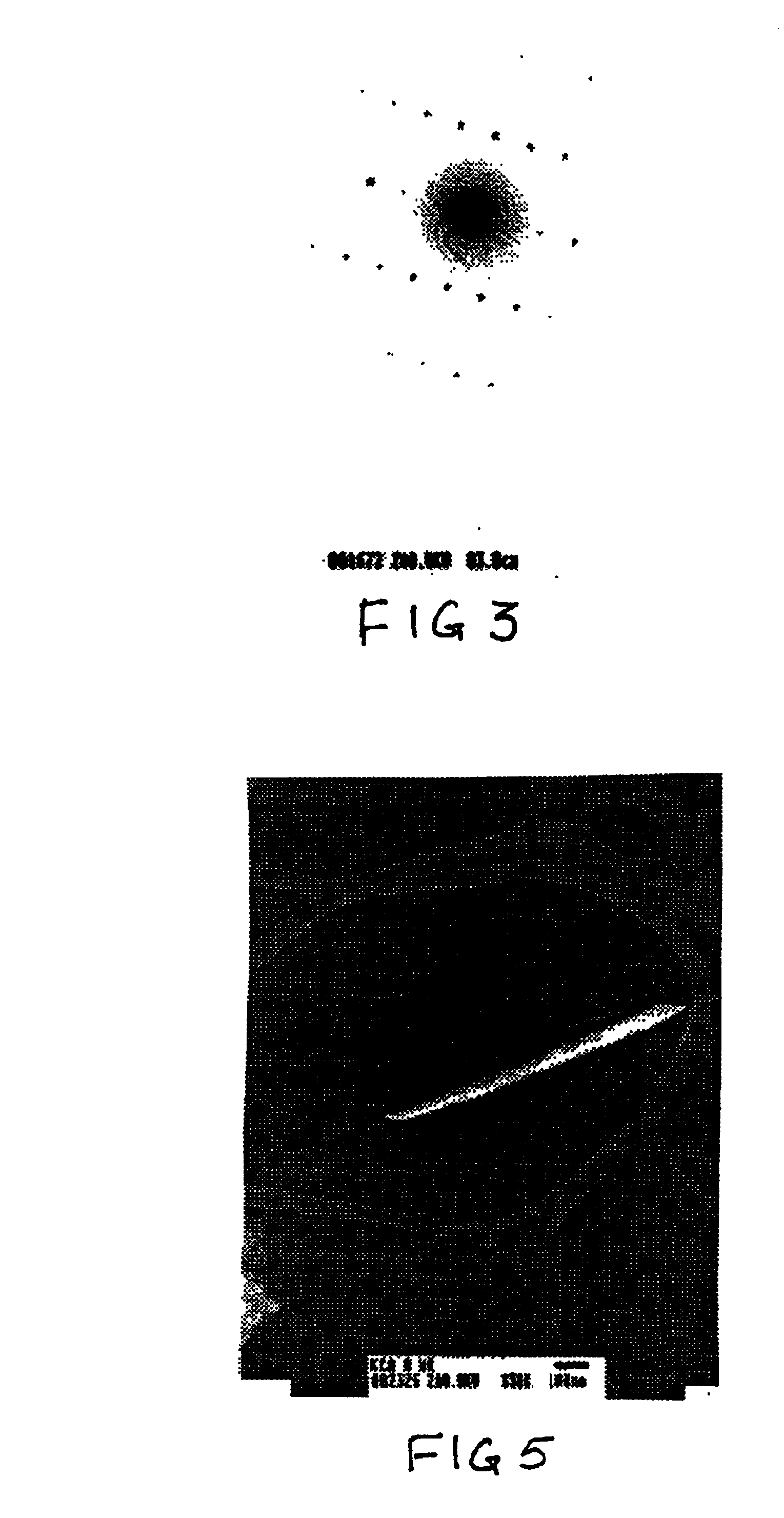

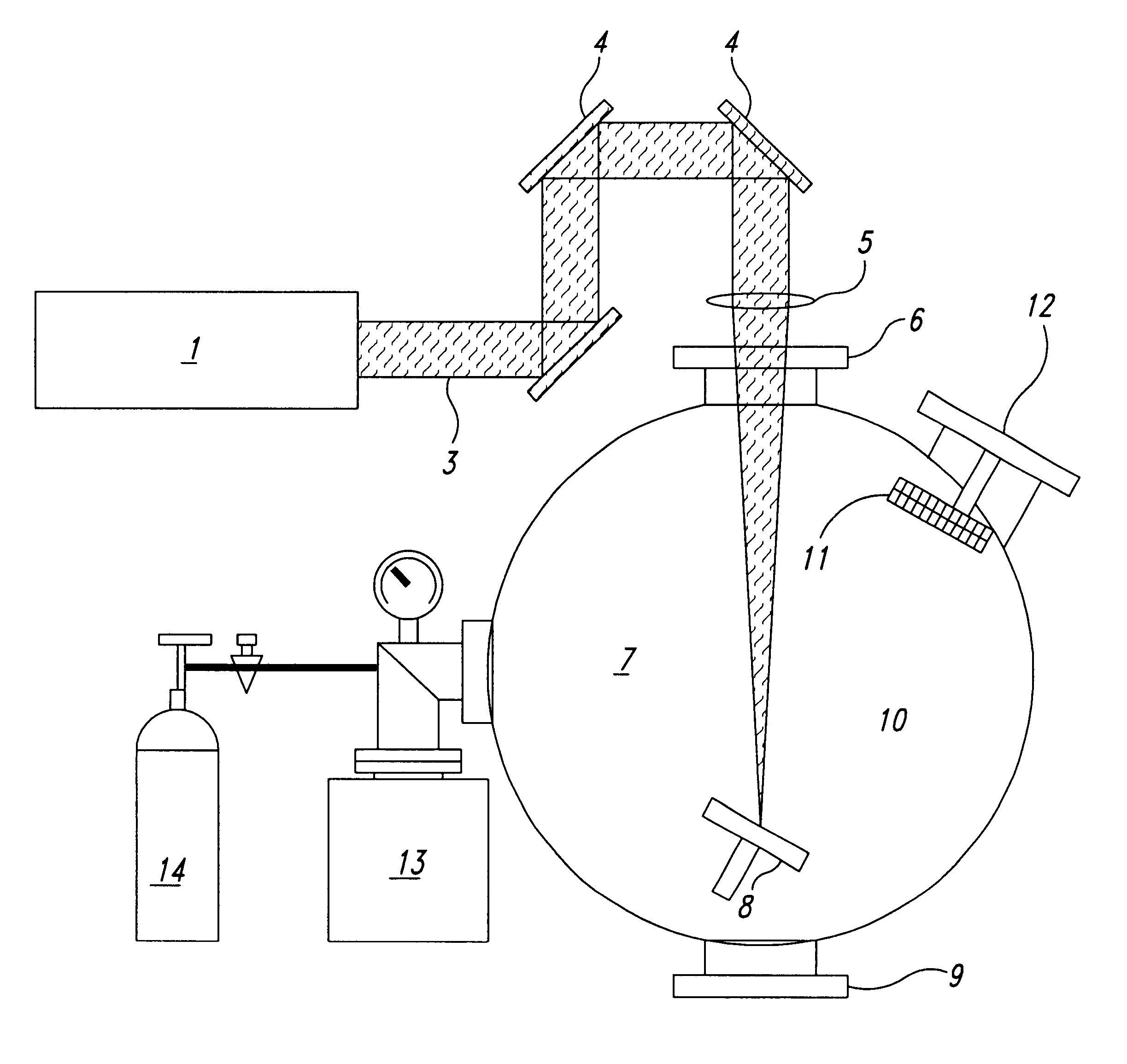

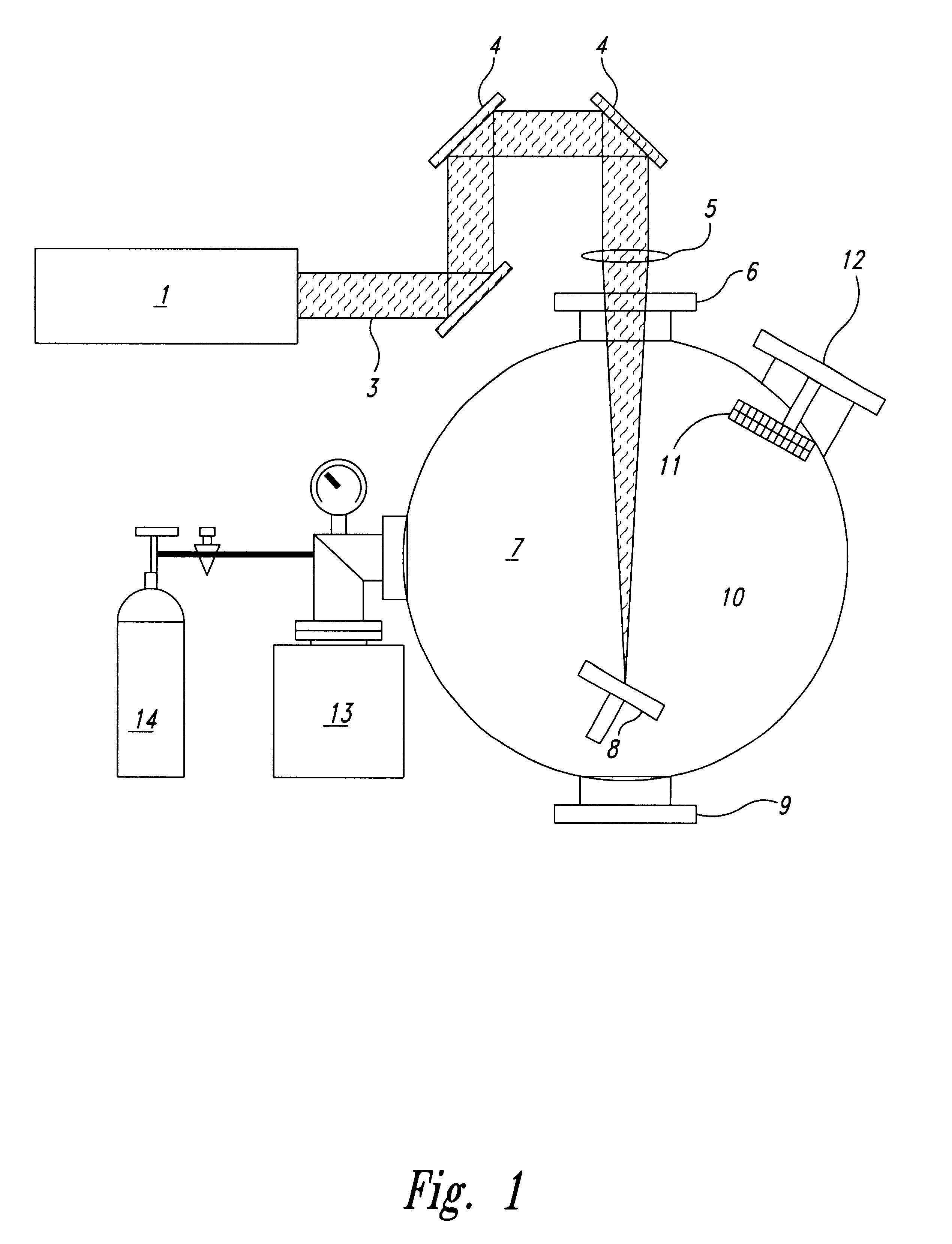

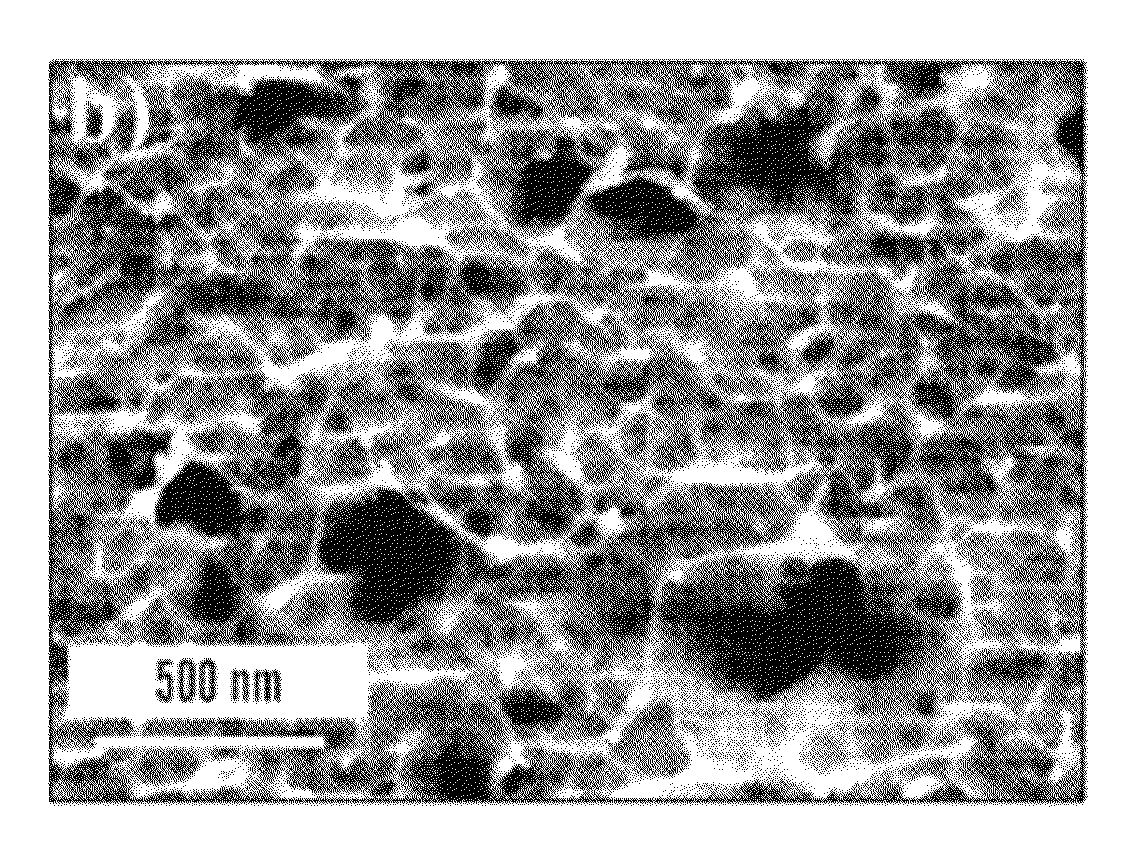

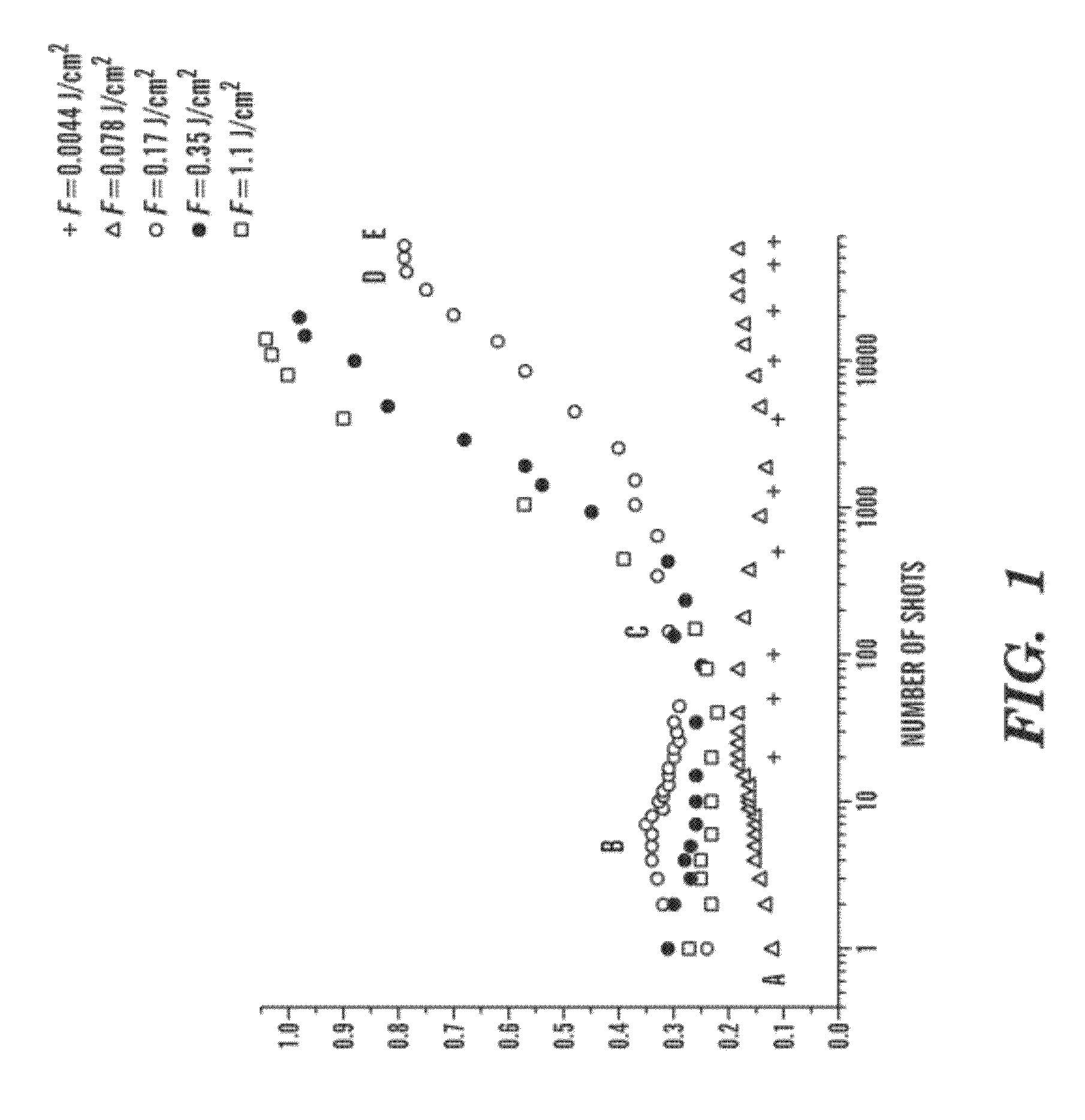

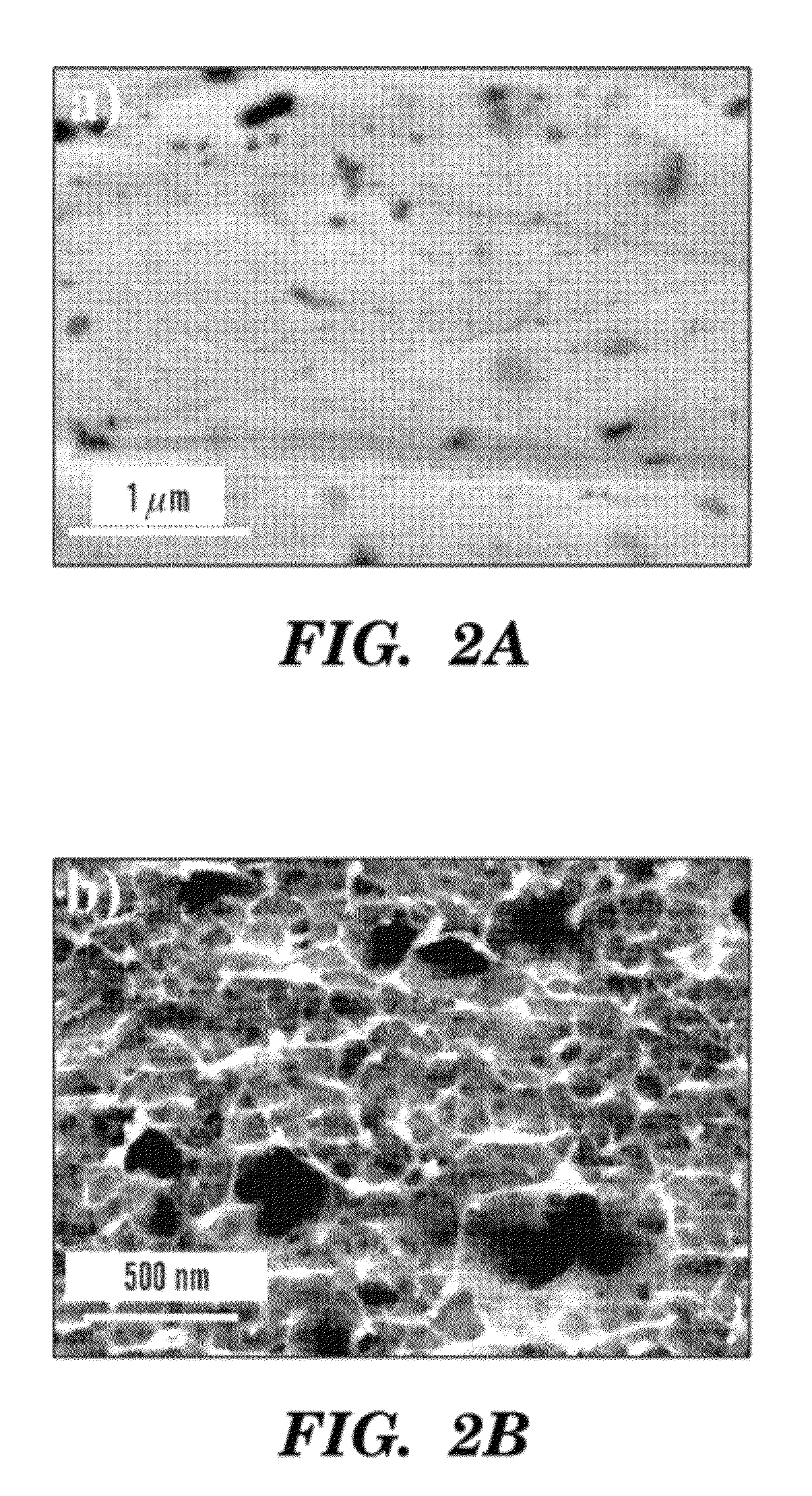

Method of deposition of thin films of amorphous and crystalline microstructures based on ultrafast pulsed laser deposition

InactiveUS6312768B1Improve surface qualityImprove efficiencyMaterial nanotechnologyElectric discharge heatingMacroscopic scaleCarbon nanotube

Powerful nanosecond-range lasers using low repetition rate pulsed laser deposition produce numerous macroscopic size particles and droplets, which embed in thin film coatings. This problem has been addressed by lowering the pulse energy, keeping the laser intensity optional for evaporation, so that significant numbers of the macroscopic particles and droplets are no longer present in the evaporated plume. The result is deposition of evaporated plume on a substrate to form thin film of very high surface quality. Preferably, the laser pulses have a repetition rate to produce a continuous flow of evaporated material at the substrate. Pulse-range is typically picosecond and femtosecond and repetition rate kilohertz to hundreds of megahertz. The process may be carried out in the presence of a buffer gas, which may be inert or reactive, and the increased vapour density and therefore the collision frequency between evaporated atoms leads to the formation of nanostructured materials of increasing interest, because of their peculiar structural, electronic and mechanical properties. One of these is carbon nanotubes, which is a new form of carbon belonging to the fullerene (C60) family. Carbon nanotubes are seamless, single or multishell co-axial cylindrical tubules with or without dome caps at the extremities. Typically diameters range from 1 nm to 50 nm with a length >1 mum. The electronic structure may be either metallic or semiconducting without any change in the chemical bonding or adding of dopant. In addition, the materials have application to a wide range of established thin film applications.

Owner:AUSTRALIEN NAT UNIV

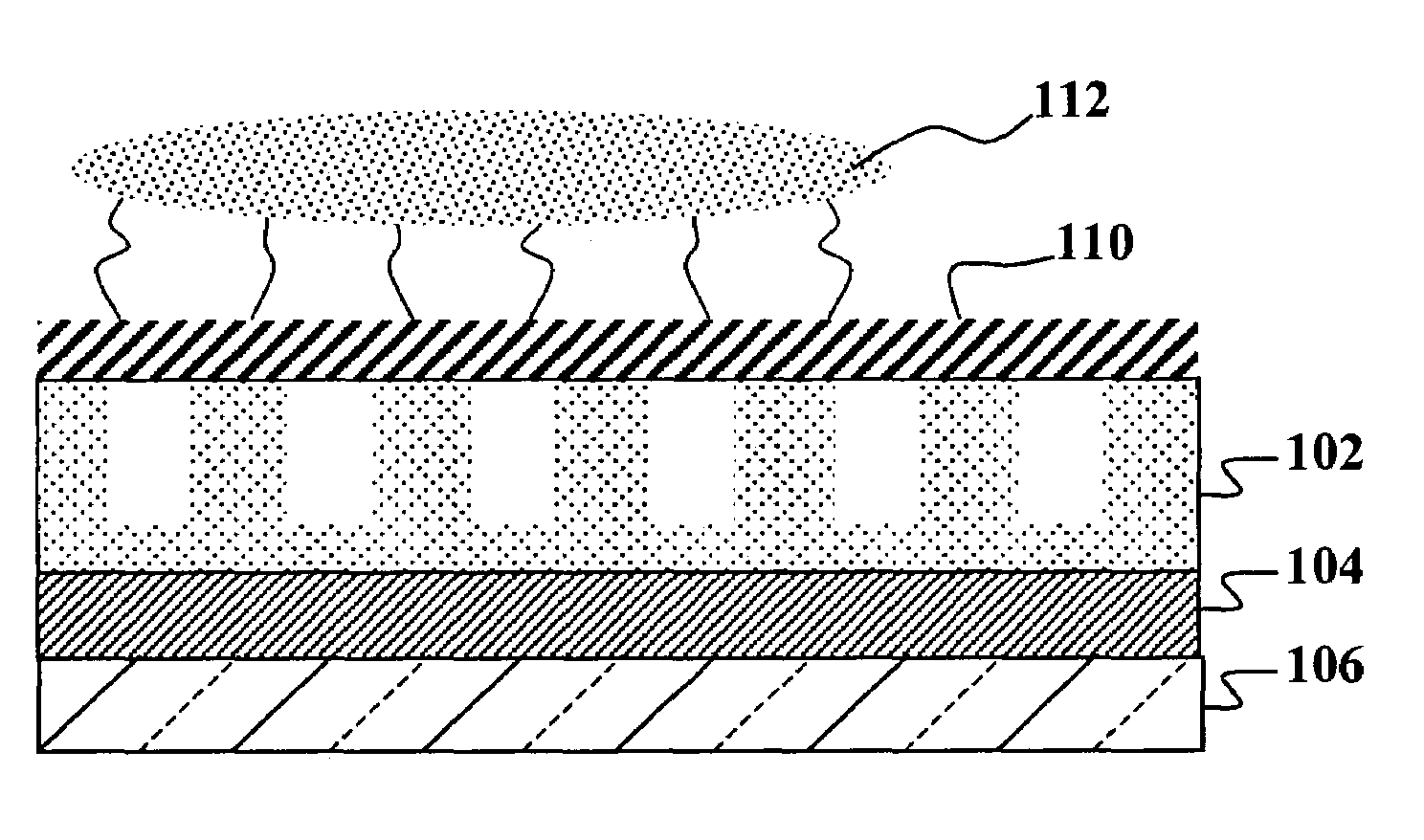

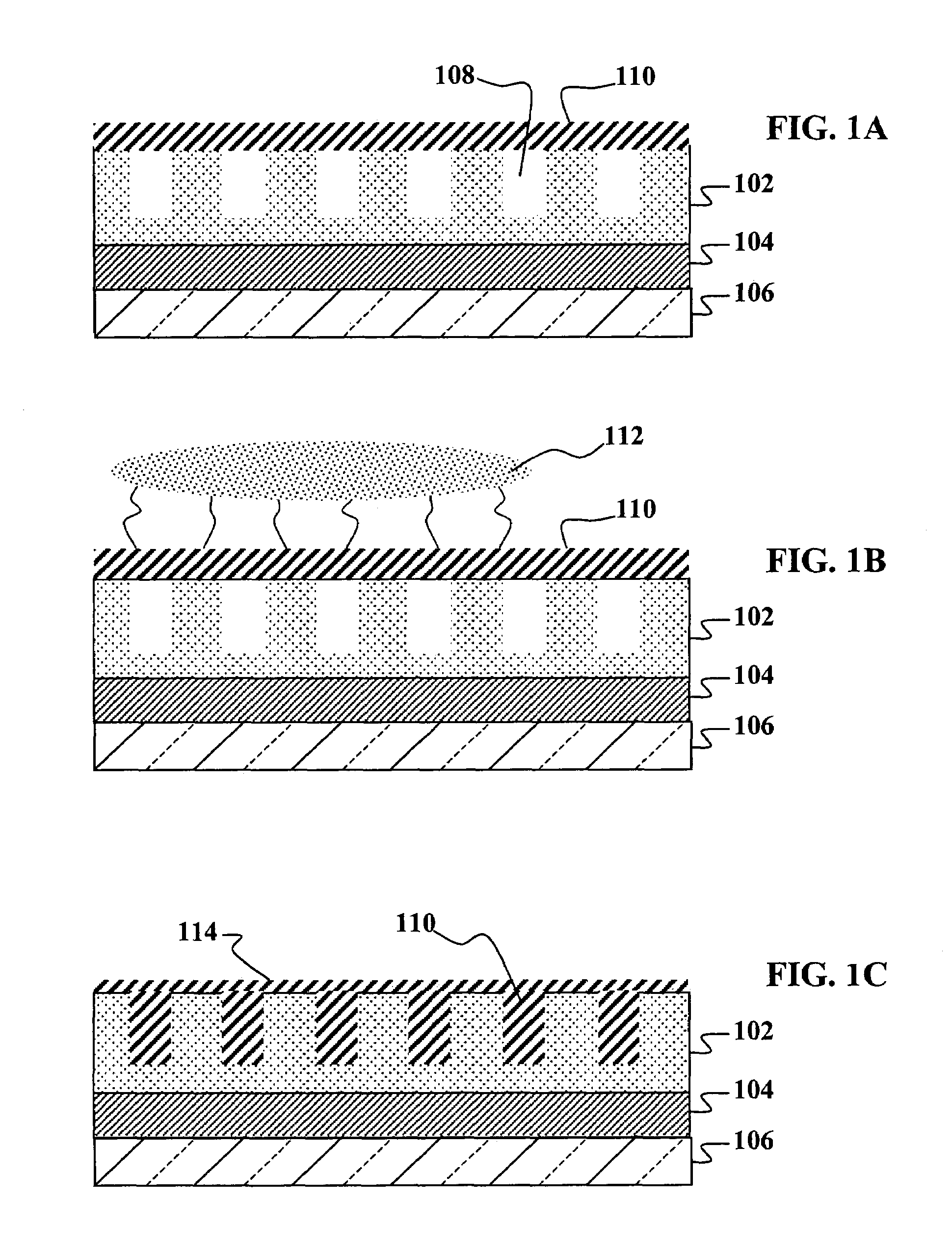

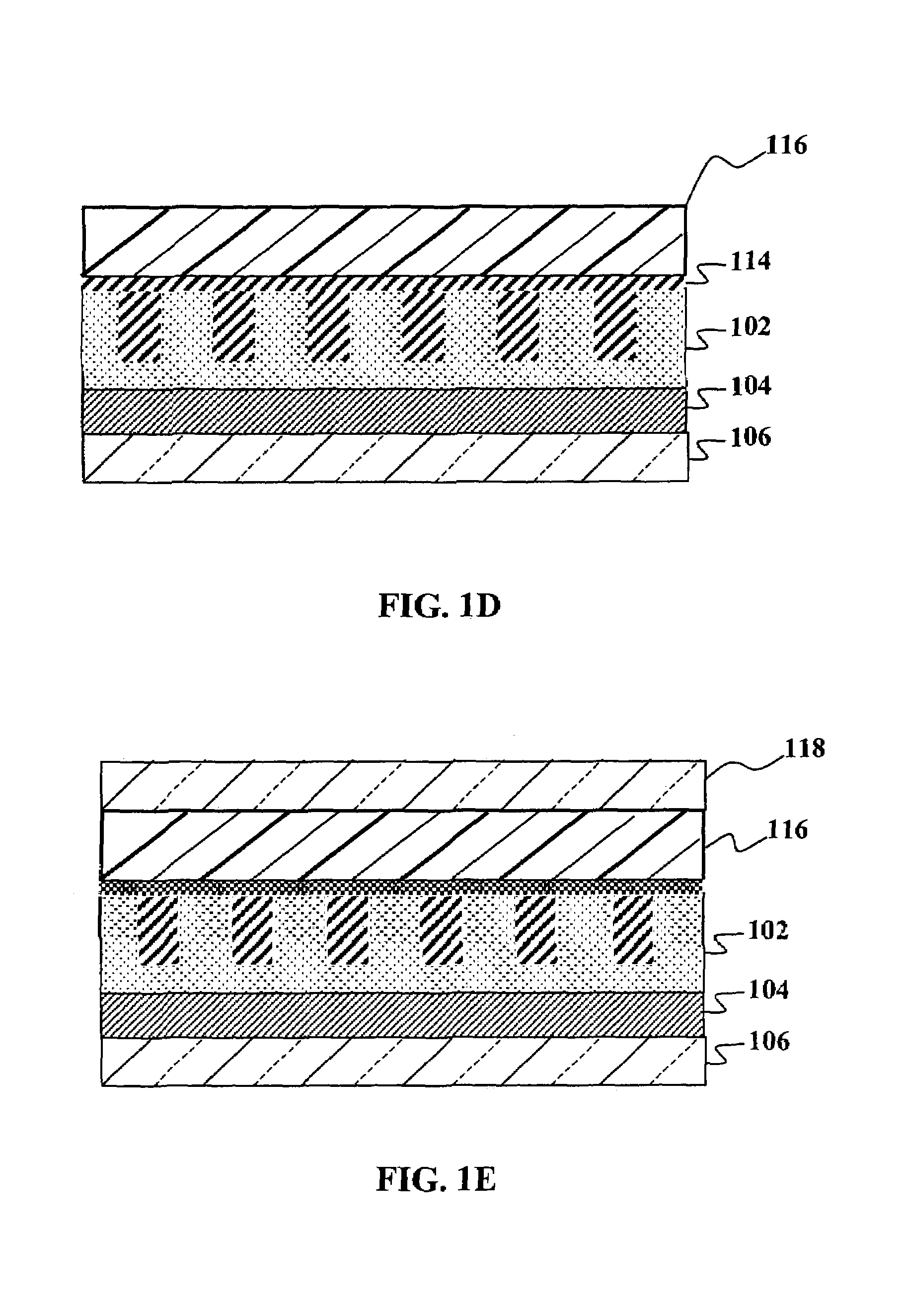

Solvent vapor infiltration of organic materials into nanostructures

Spaces in a nanostructure can be filled with an organic material while in the solid state below Tm (without heating) by exposing the organic material to solvent vapor while on or mixed with the nanostructured material. The exposure to solvent vapor results in intimate contact between the organic material and the nanostructured material without having to expose them to possibly detrimental heat to melt in the organic material. Solution processing methods need only to be employed to create bulk films while organic material infiltration can take place in the solid state after depositing the film.

Owner:AERIS CAPITAL SUSTAINABLE IP

Low platinum fuel cells, catalysts, and method for preparing the same

InactiveUS20060172179A1Efficient processingImprove throughputMaterial nanotechnologyConductive materialFiberCarbon fibers

This invention provides novel fuel cell electrodes and catalysts comprising a series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). Processing of the electrodes and catalysts can include electrodeposition methods, and high-pressure coating techniques. In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticles into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

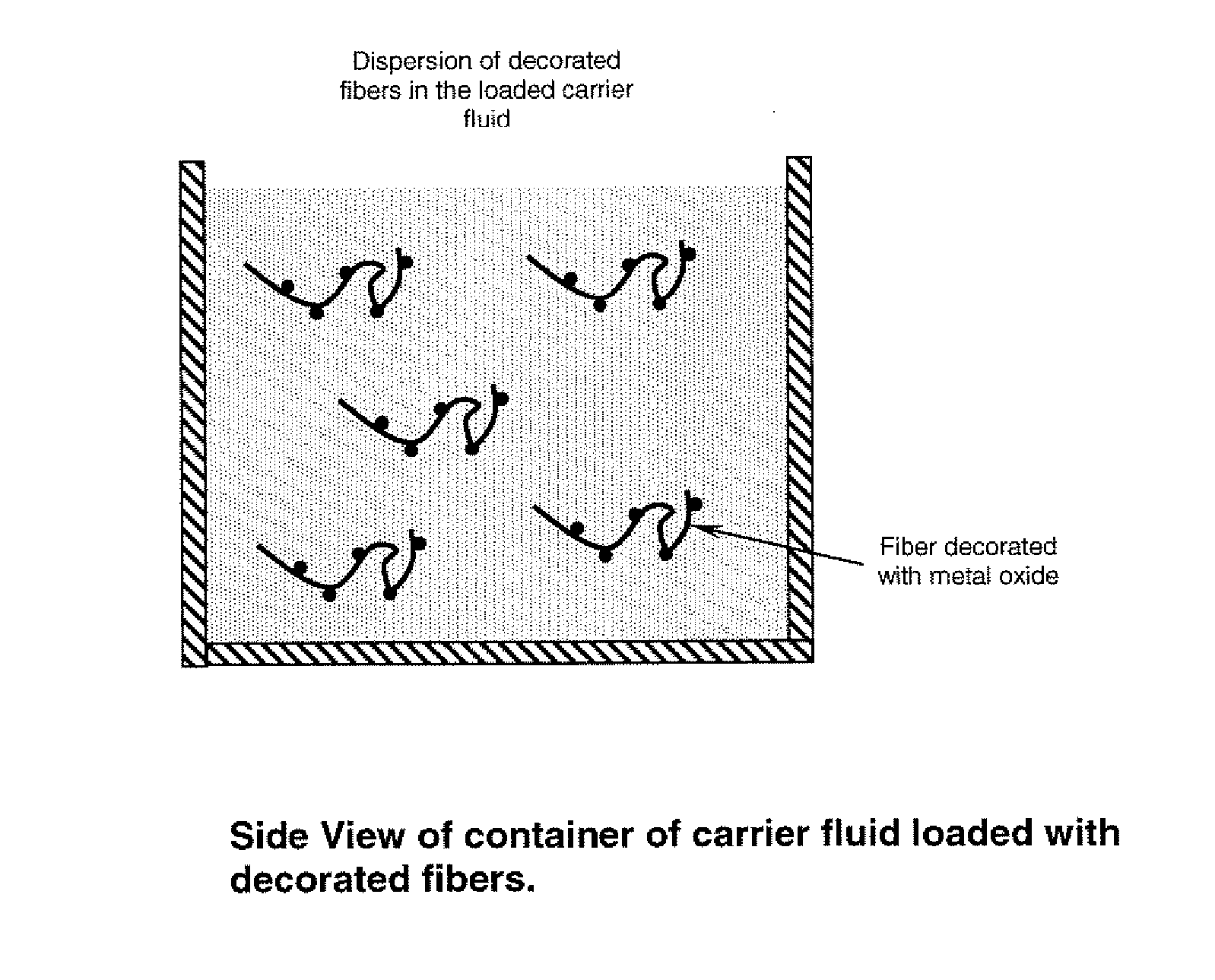

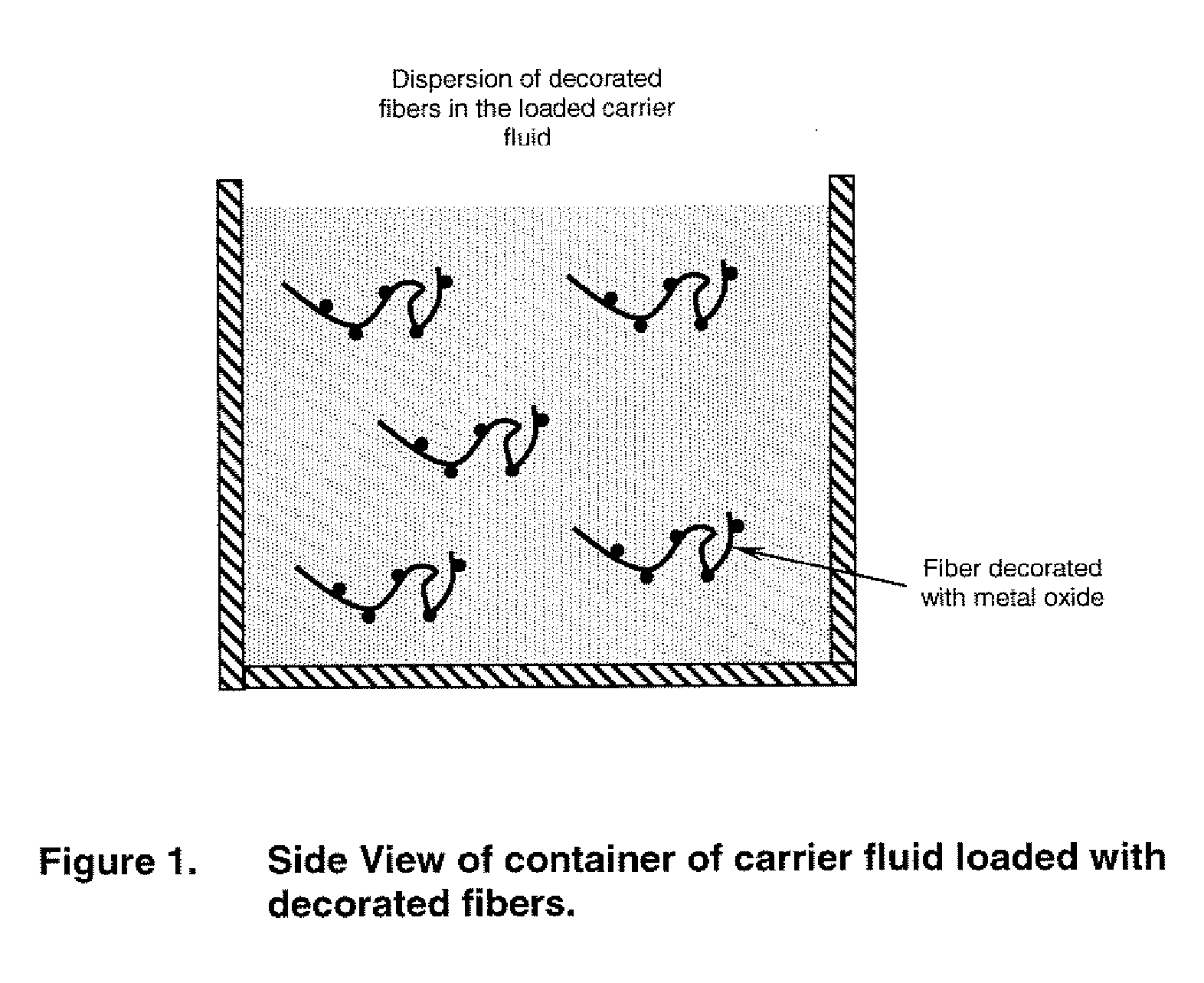

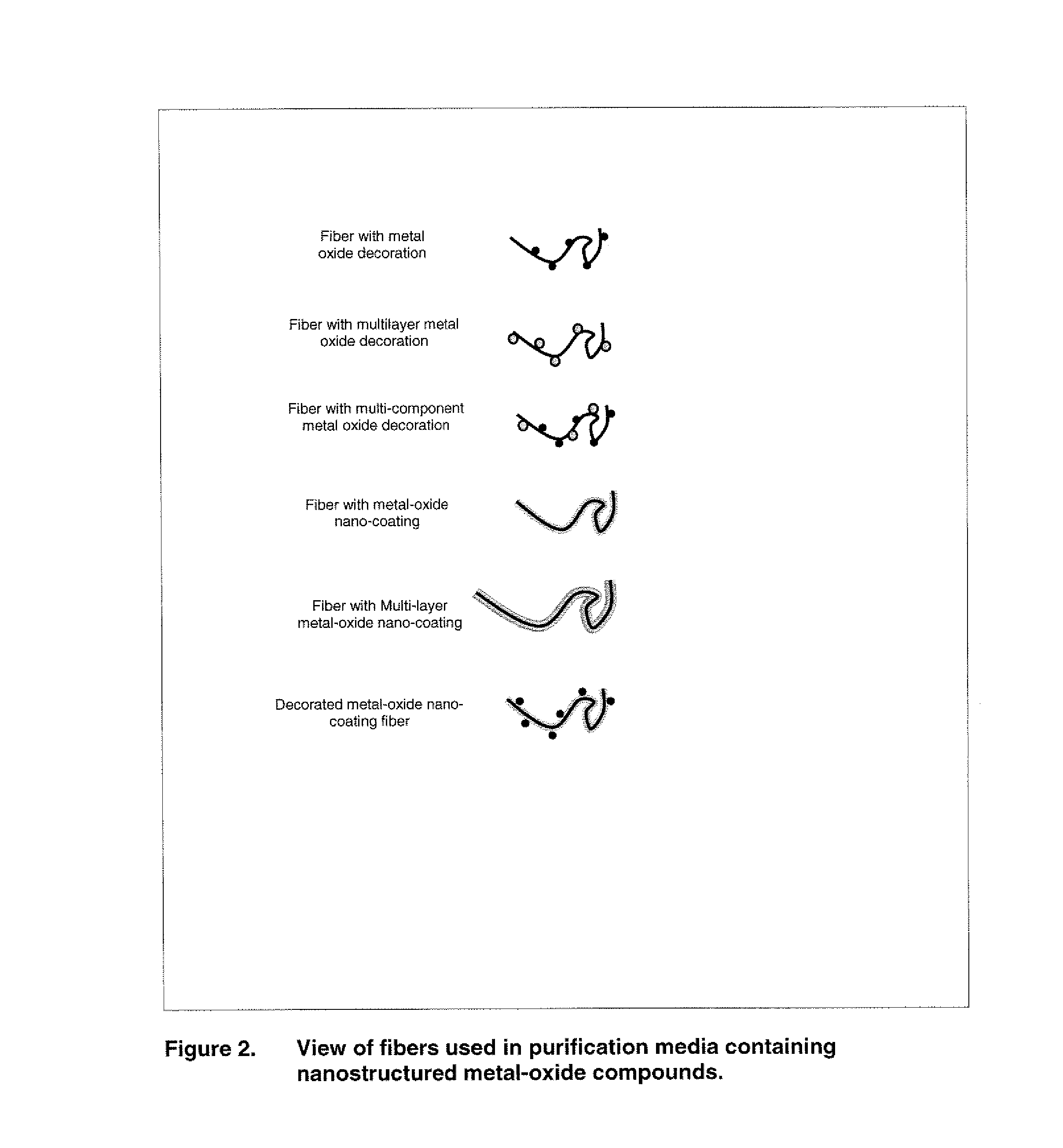

Nanostructured materials comprising support fibers coated with metal containing compounds and methods of using the same

InactiveUS20080053922A1Maintaining and improving rate of fluid flowReduce weightMaterial nanotechnologyLiquid surface applicatorsFiberFilter media

Disclosed herein are fibers comprising an active material that assists in removing contaminants from fluid. The active material, which forms a coating on the fiber, typically comprises a non-fibrous: nanostructured, metal-containing compound, such as a metal-oxygen compound. A filter media made of such fibers, as well as methods of making the fiber and the filter media are also disclosed. Methods of purifying fluids, such as air, water, and fuels, are further disclosed.

Owner:SELDON TECH INC

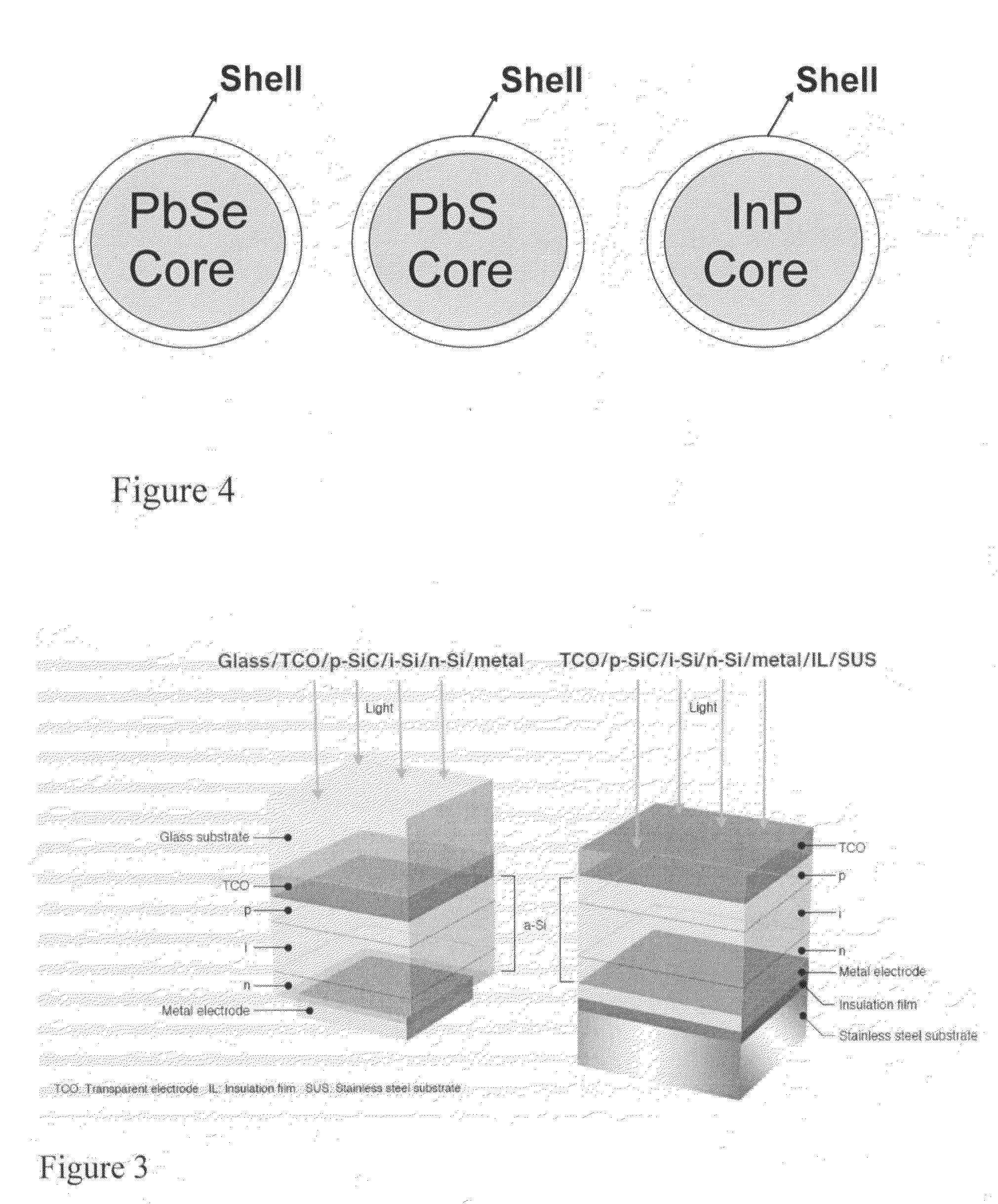

Nanostructured material comprising semiconductor nanocrystal complexes for use in solar cell and method of making a solar cell comprising nanostructured material

InactiveUS20070012355A1Improve performanceLow costNanoopticsPhotovoltaic energy generationNanostructured materialsSolar cell

A solar cell includes a semiconductor base layer, a semiconductor nanocrystal complex over the semiconductor base layer, and a semiconductor emitter layer formed over the semiconductor nanocrystal complex. The semiconductor nanocrystal complex includes nanocrystal cores dispersed in an inorganic matrix material. A corresponding method is also disclosed.

Owner:EVIDENT TECH

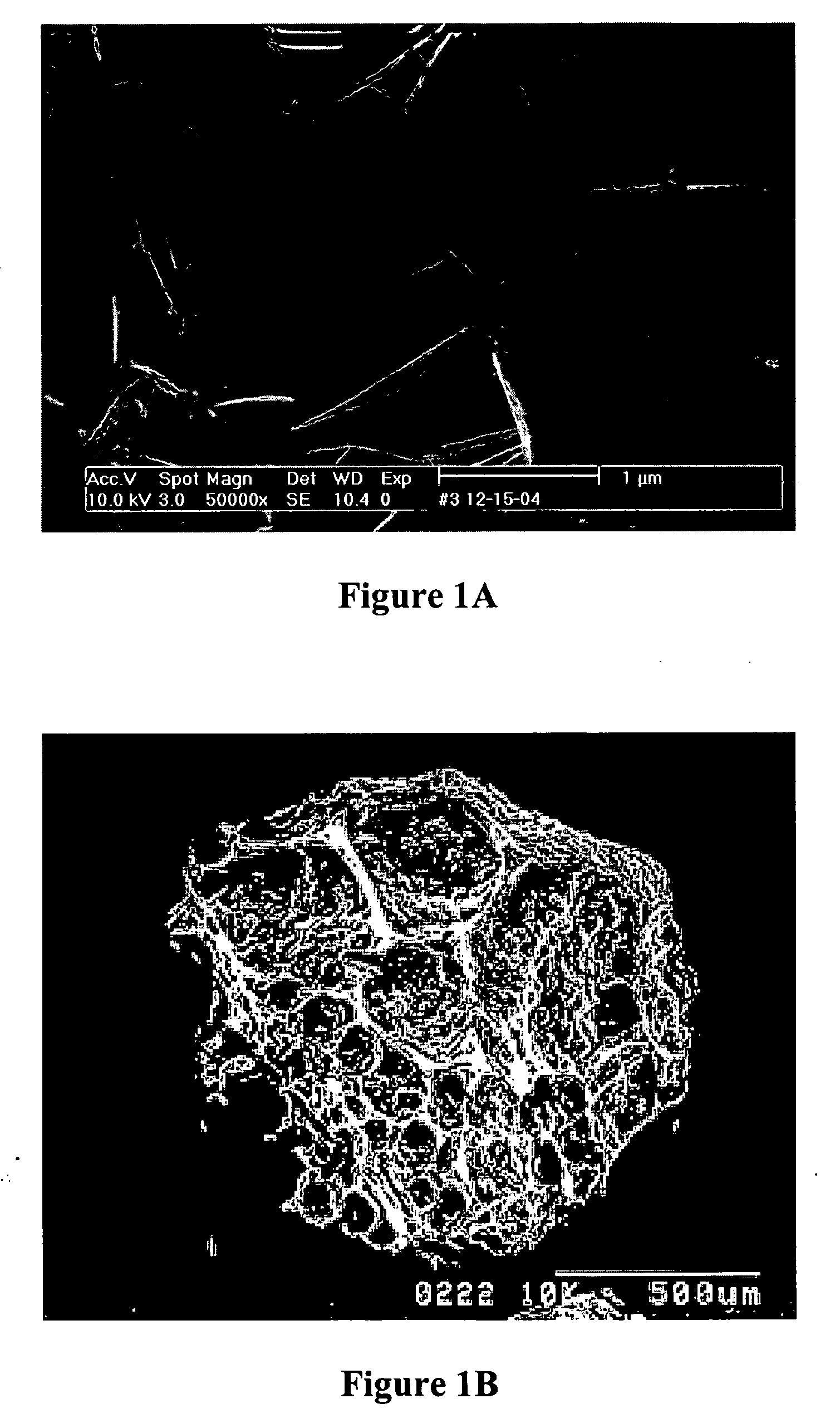

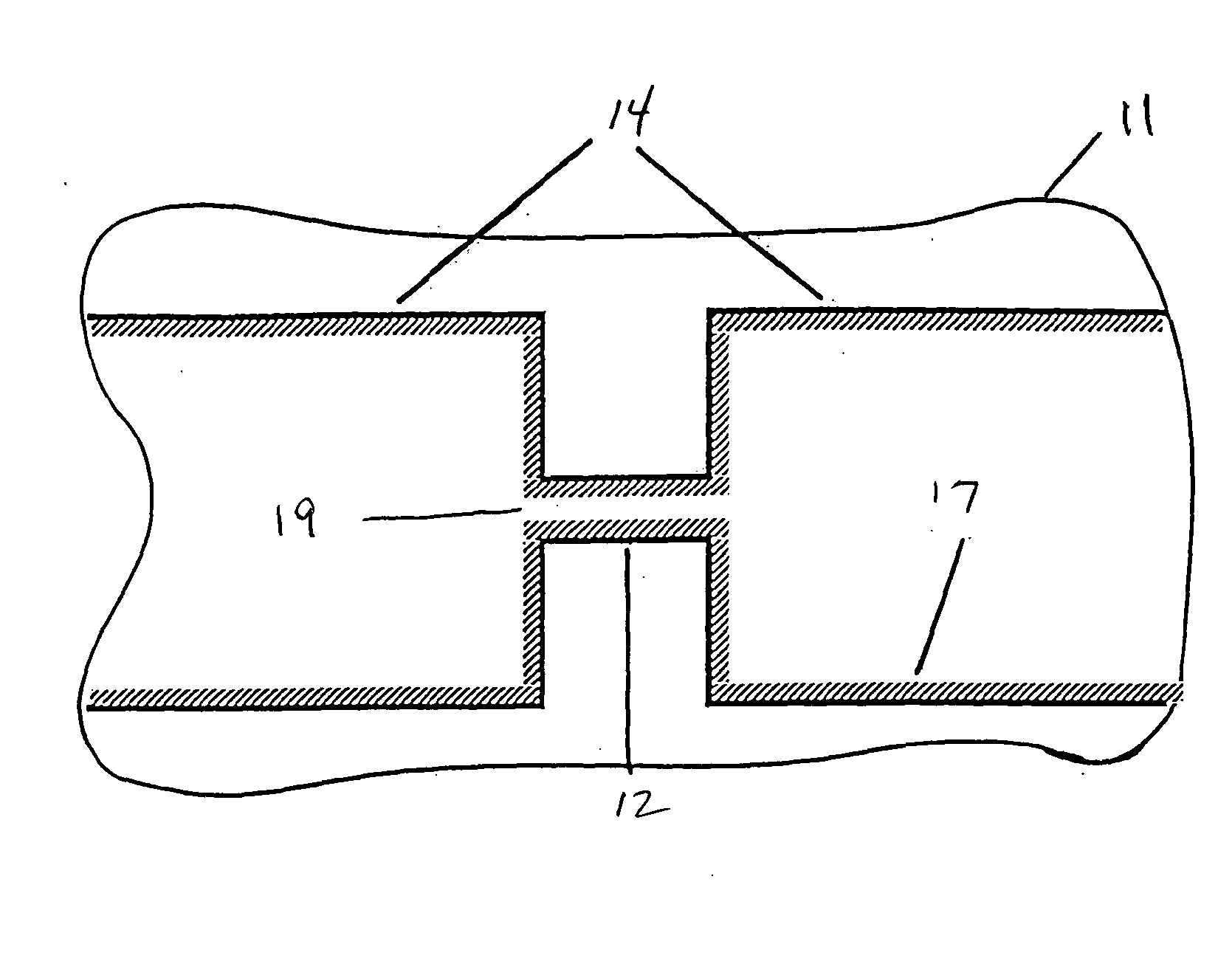

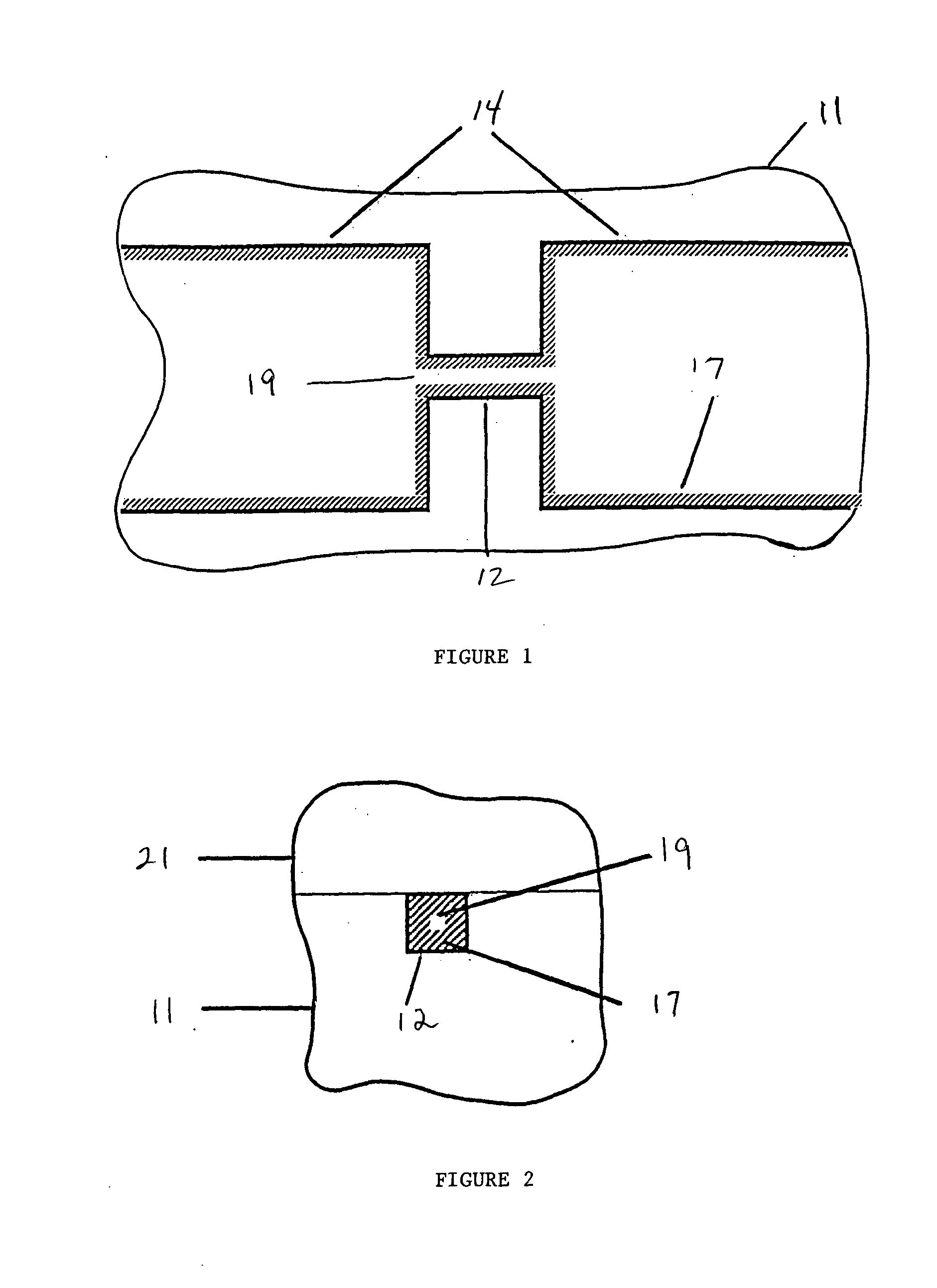

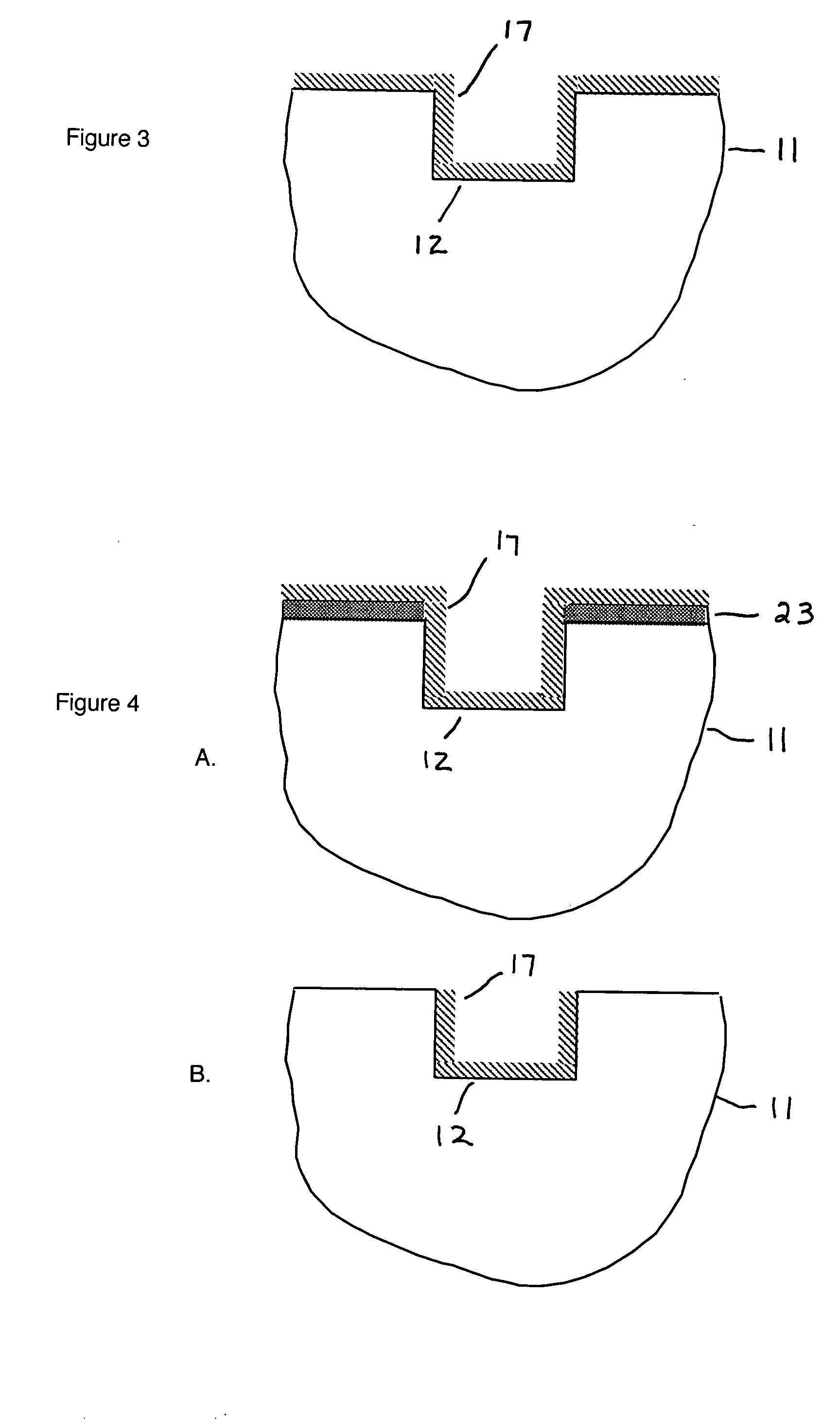

Nanostructured materials, methods, and applications

ActiveUS20120328905A1Simple materialAltered material and material propertyMaterial nanotechnologyRecord information storageRough surfaceNanostructured materials

Methods for making a material superwicking and / or superwetting (superhydrophyllic) involving creating one or more indentations in the surface of the material that have a micro-rough surface of protrusions, cavities, spheres, rods, or other irregularly shaped features having heights and / or widths on the order of 0.5 to 100 microns and the micro-rough surface having a nano-rough surface of protrusions, cavities, spheres, rods, and other irregularly shaped features having heights and / or widths on the order of 1 to 500 nanometers. Superwicking and / or superwetting materials having micro-rough and nano-rough surface indentations, including metals, glass, enamel, polymers, semiconductors, and others.

Owner:UNIVERSITY OF ROCHESTER

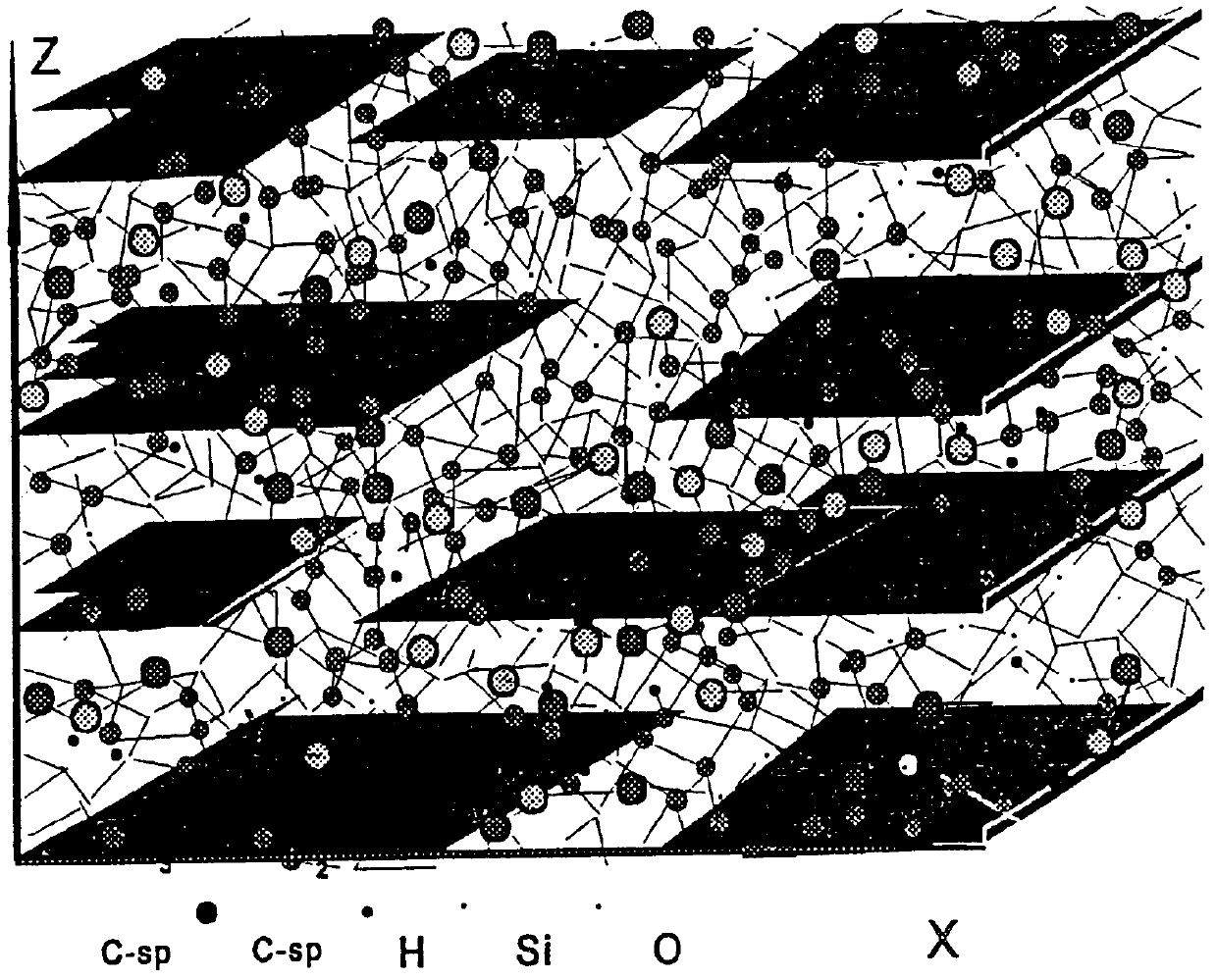

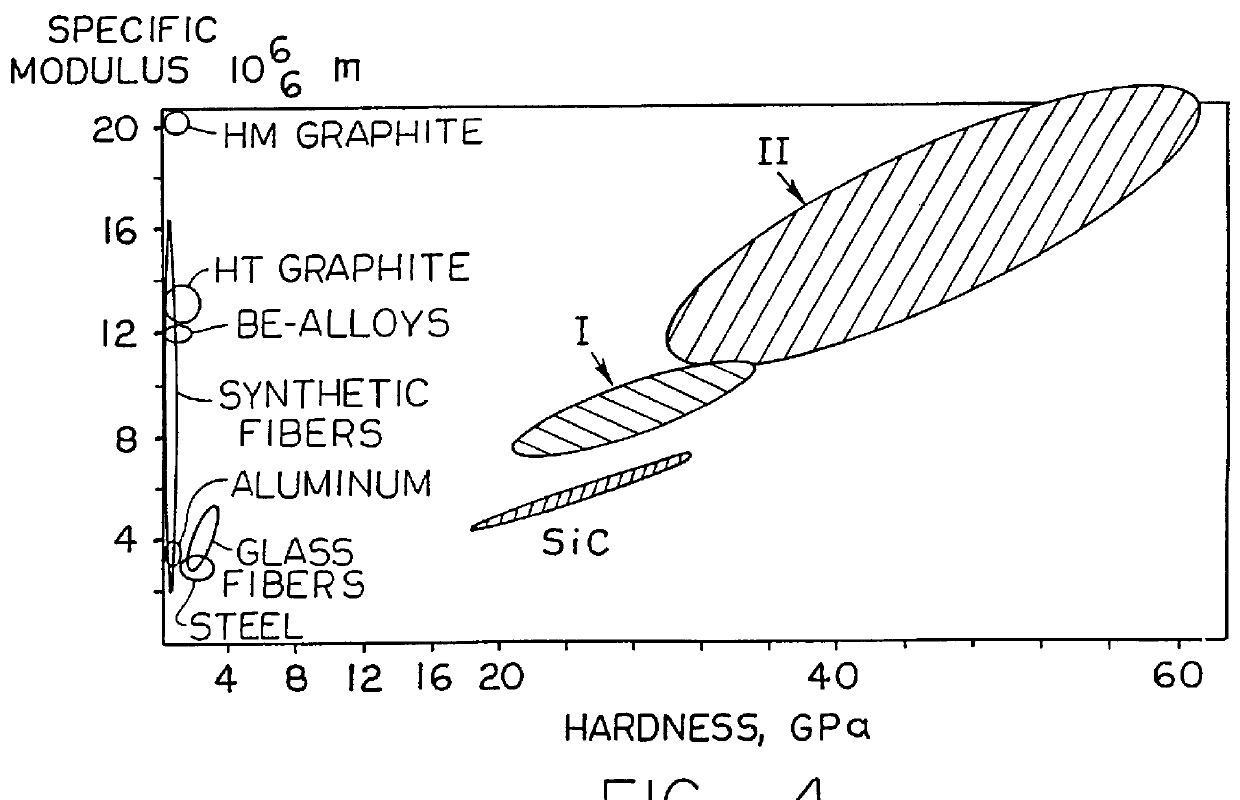

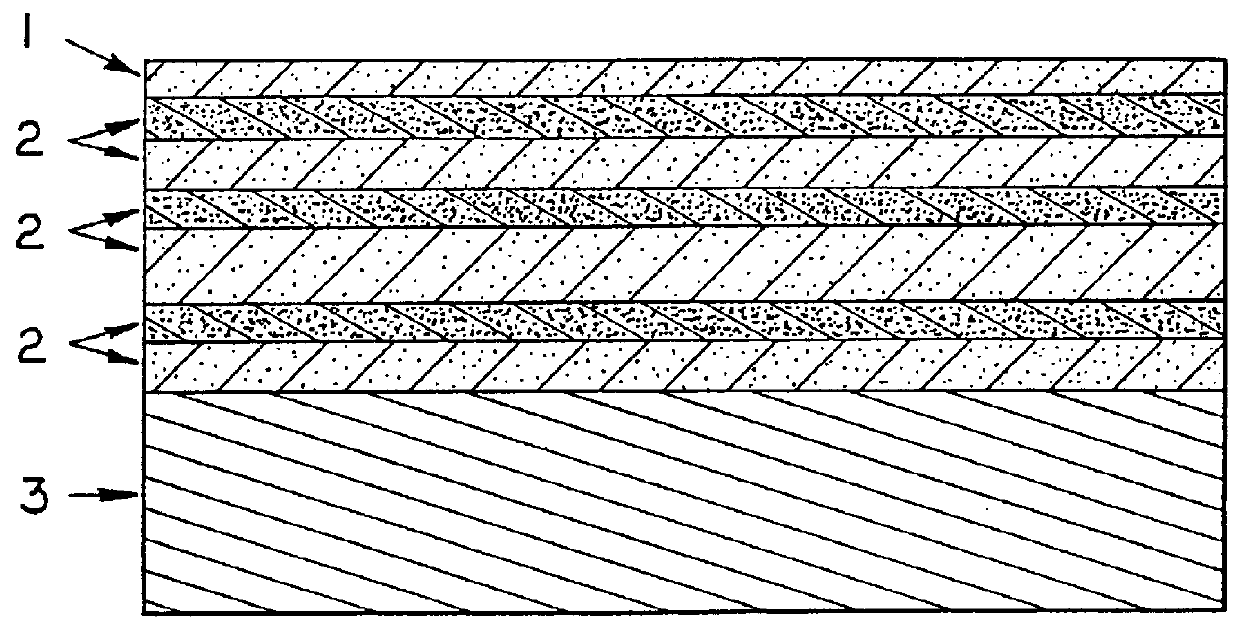

Hard graphite-like material bonded by diamond-like framework

InactiveUS6080470AImprove mechanical propertiesReduce weightMolten spray coatingLayered productsNano structuringGraphite

The present invention provides a novel class of hard nano-structured materials comprising sp2 bonded graphite-like layers bonded together by sp3 three-dimensional diamond-like frameworks, wherein the whole carbon structure is stabilized with at least two alloying elements: the first alloying element selected from the group consisting of O, H, N, and a combination thereof; and the second alloying element selected from the group consisting of Si, B, Zr, Ti, V, Cr, Be, Hf, Al, Nb, Ta, Mo, W, Mn, Re, Fe, Co, Ni, Mn, Re, Fe, Co, Ni and a combination thereof. Also disclosed, are methods of manufacture of the novel class of materials.

Owner:NANODYNAMICS INC

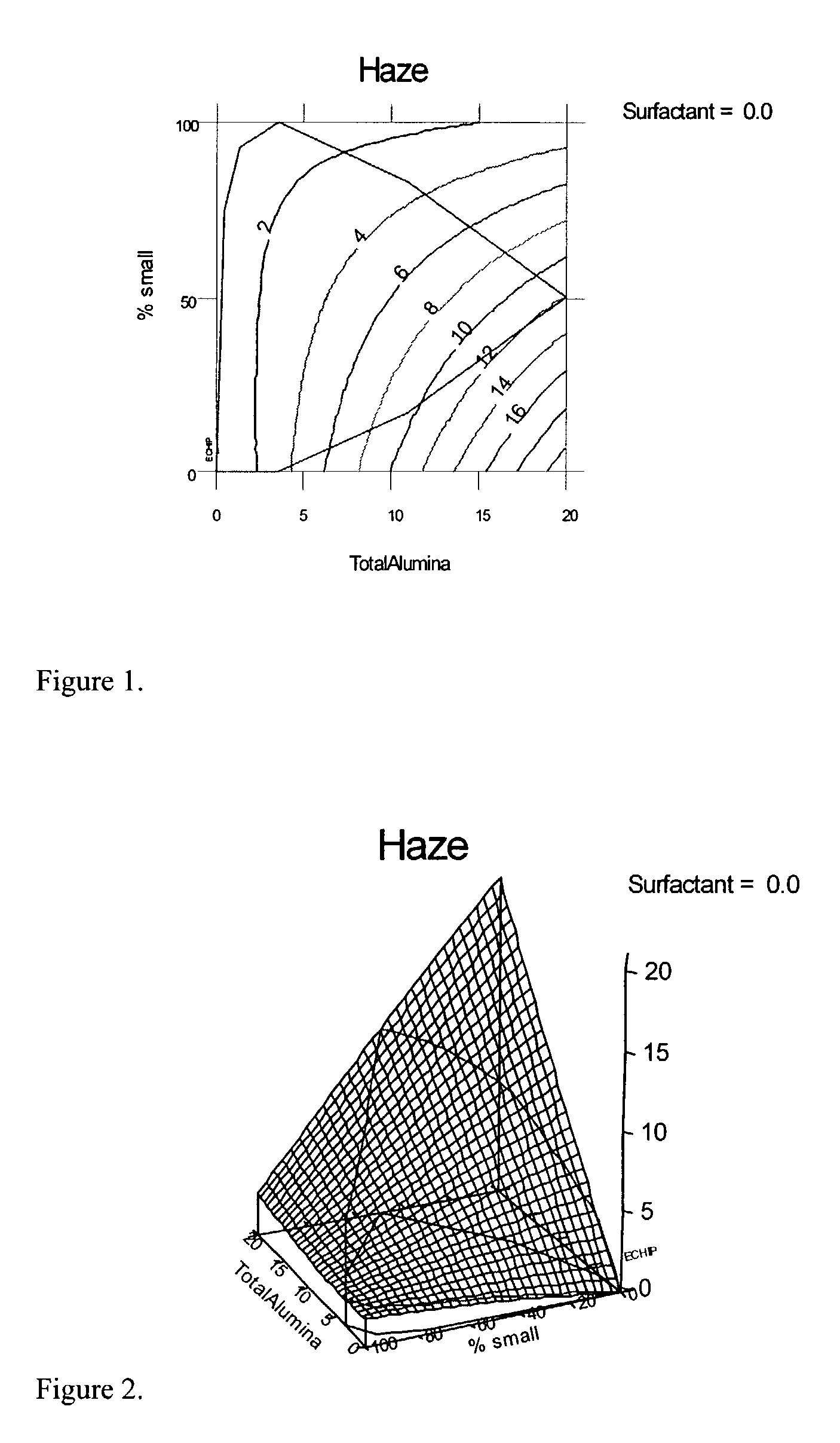

Nanostructured compositions

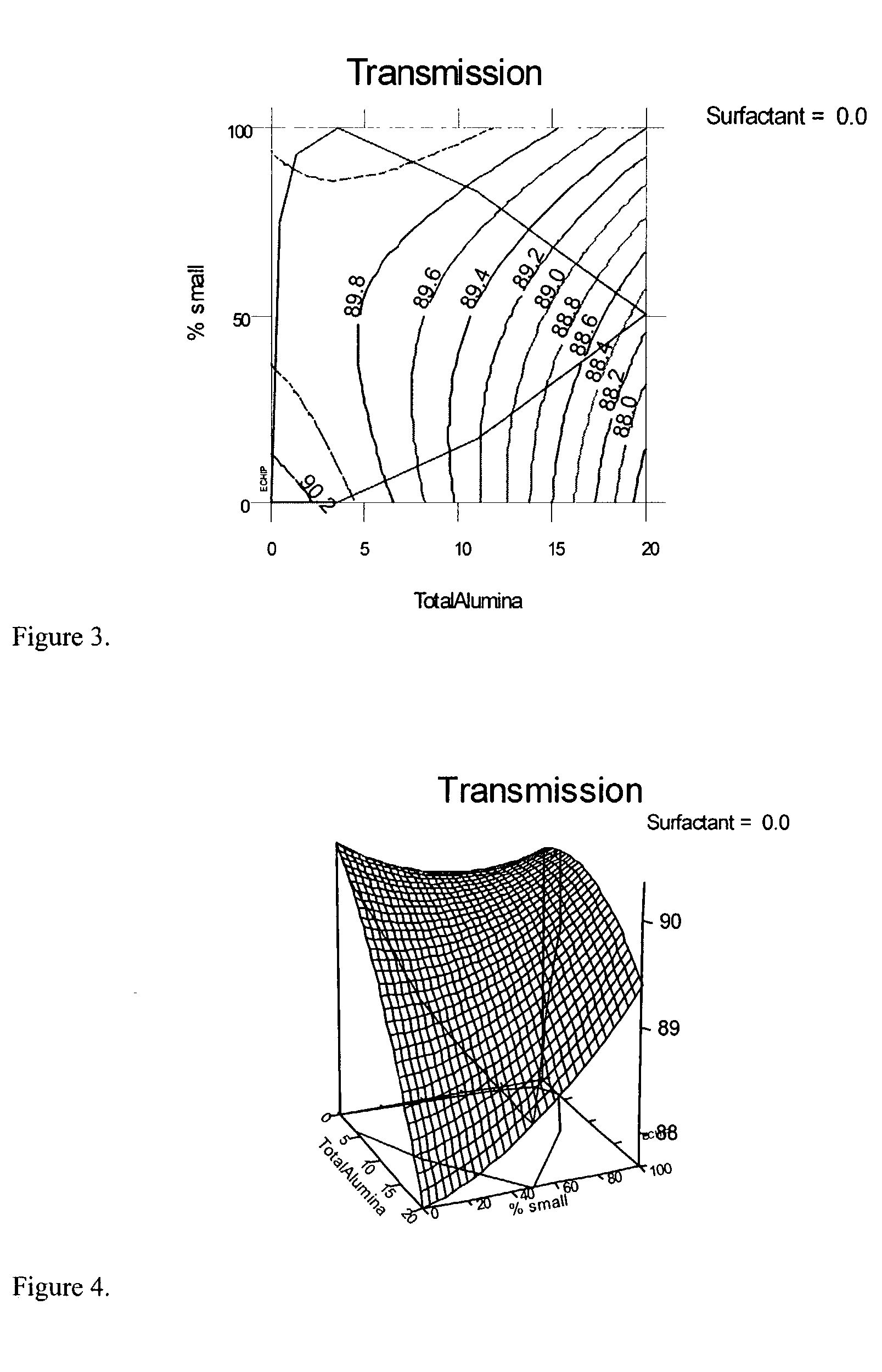

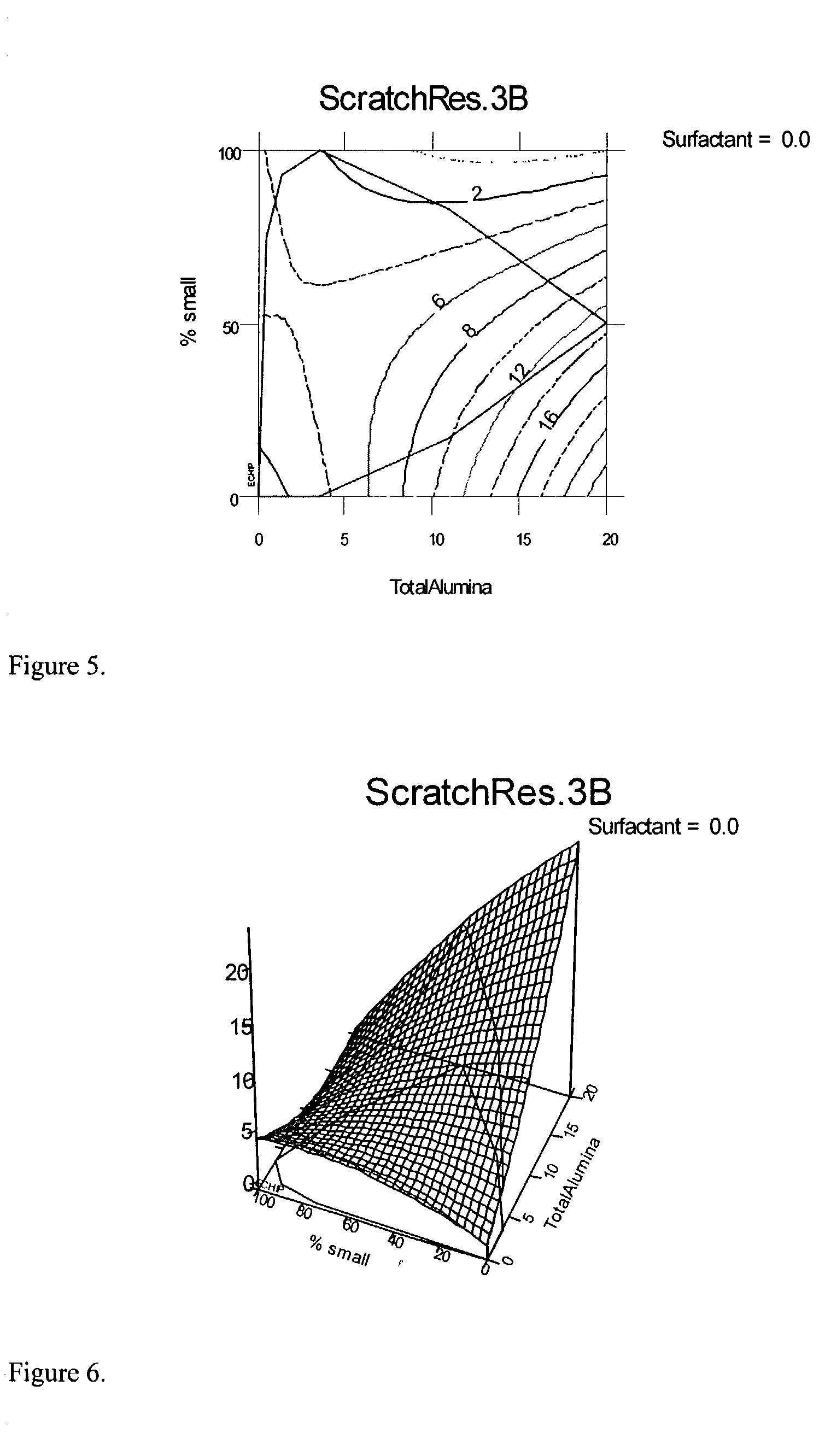

InactiveUS7166663B2Reduce light transmittanceMaterial nanotechnologySpecial tyresParticulatesNanostructured materials

A material composition made of a matrix material, a nano-sized particulate fraction and a micron-sized particulate fraction. A process of making a nano-structured composition. A nano-structured material is provided to initiate a mixture. A micron-sized particulate material is added to the mixture. A matrix material is added to the mixture. Finally, the mixture is utilized to fabricate a nano-structured structure.

Owner:NANOPHASE TECH CORP

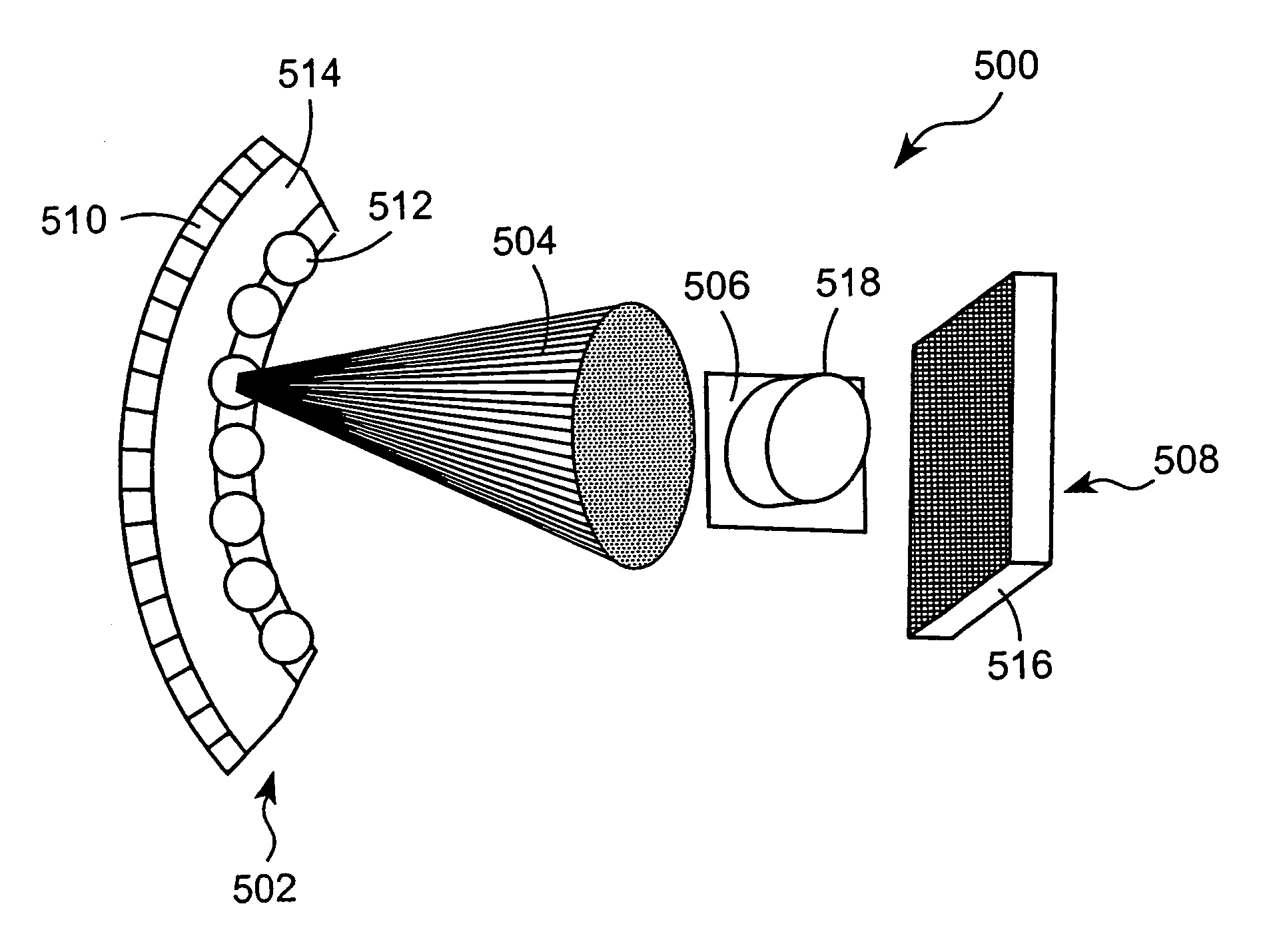

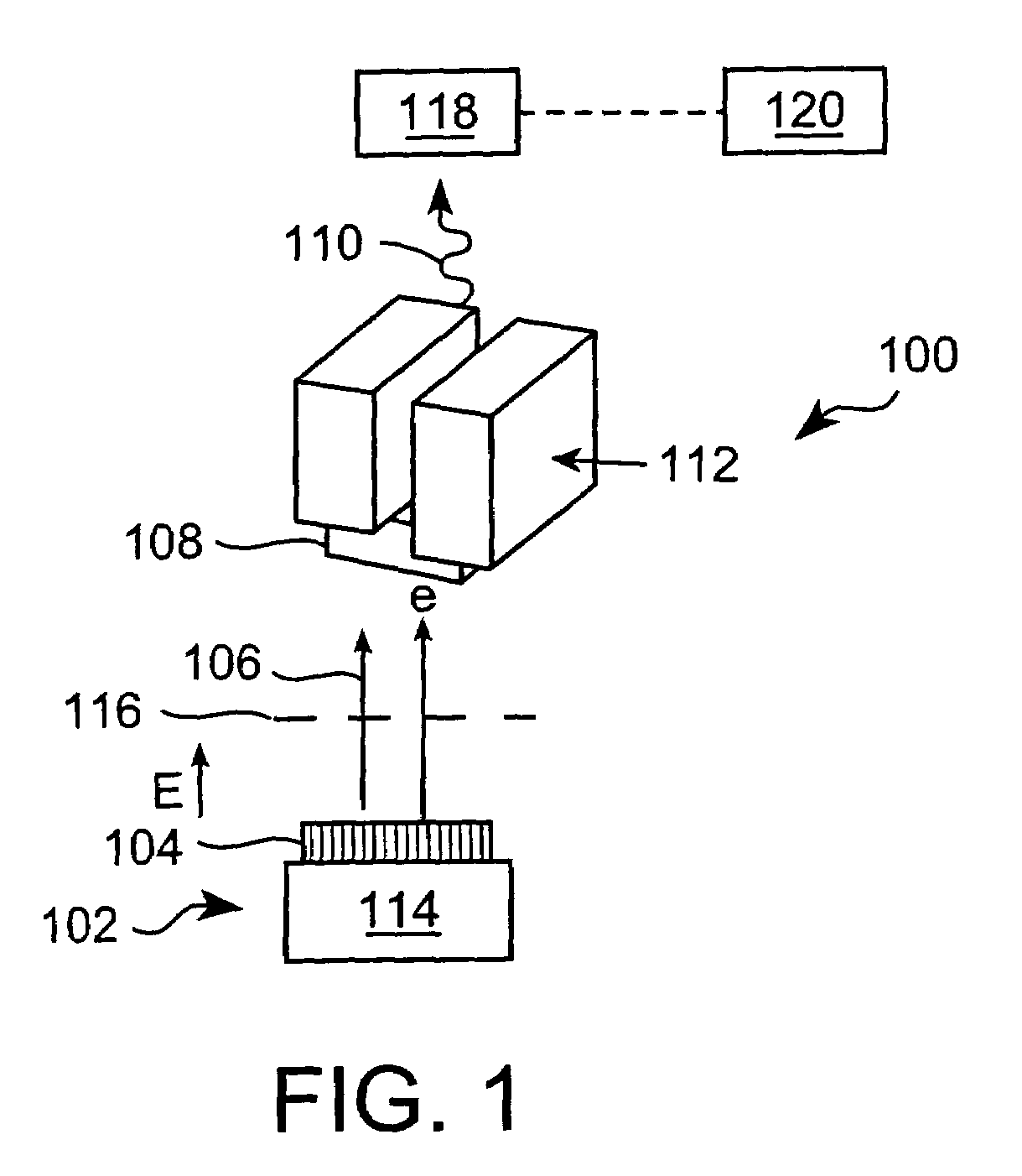

Computed tomography system for imaging of human and small animal

InactiveUS7082182B2Material analysis using wave/particle radiationRadiation/particle handlingSmall animalNanowire

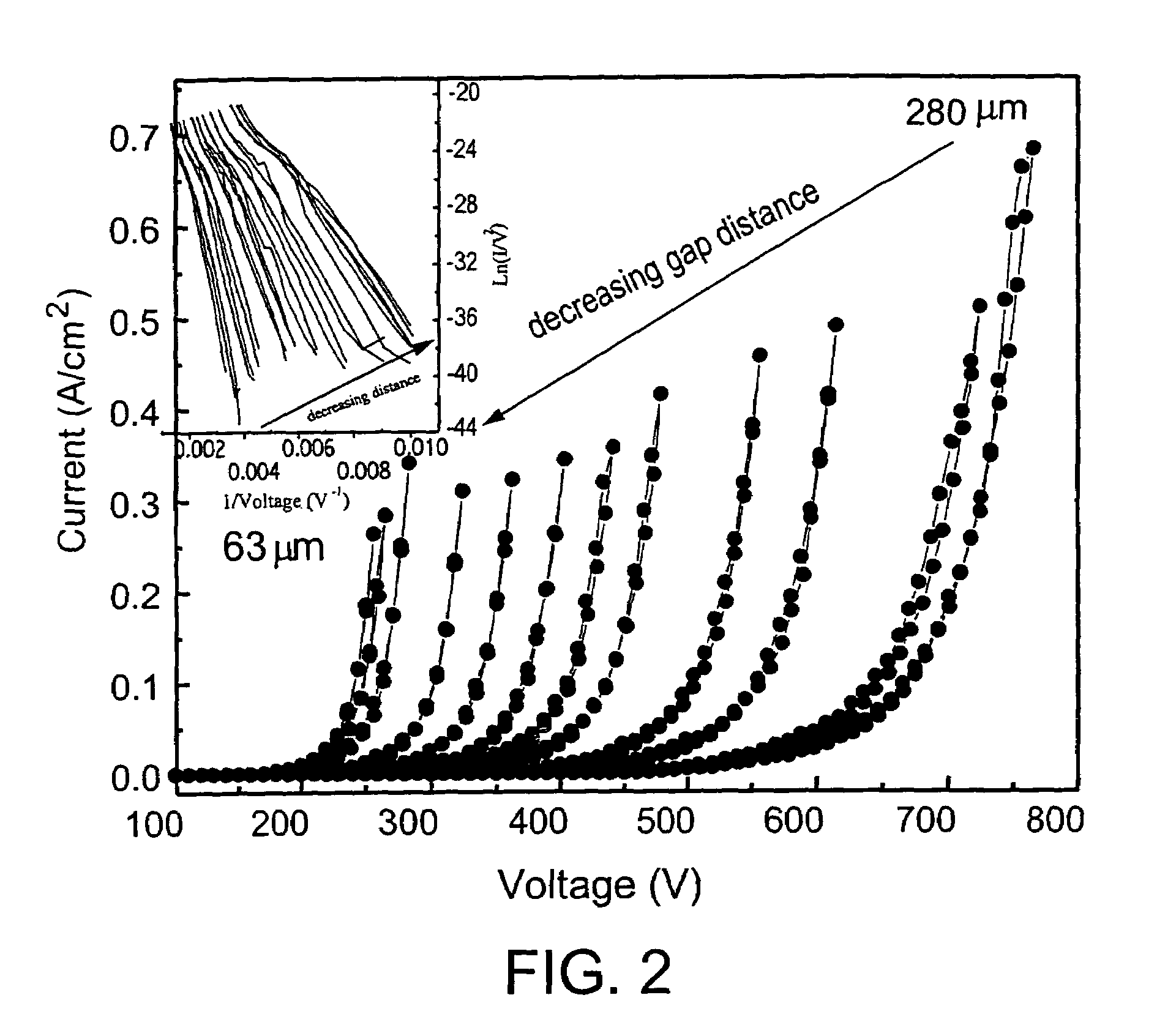

Computed tomography device comprising an x-ray source and an x-ray detecting unit. The x-ray source comprises a cathode with a plurality of individually programmable electron emitting units that each emit an electron upon an application of an electric field, an anode target that emits an x-ray upon impact by the emitted electron, and a collimator. Each electron emitting unit includes an electron field emitting material. The electron field emitting material includes a nanostructured material or a plurality of nanotubes or a plurality of nanowires. Computed tomography methods are also provided.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

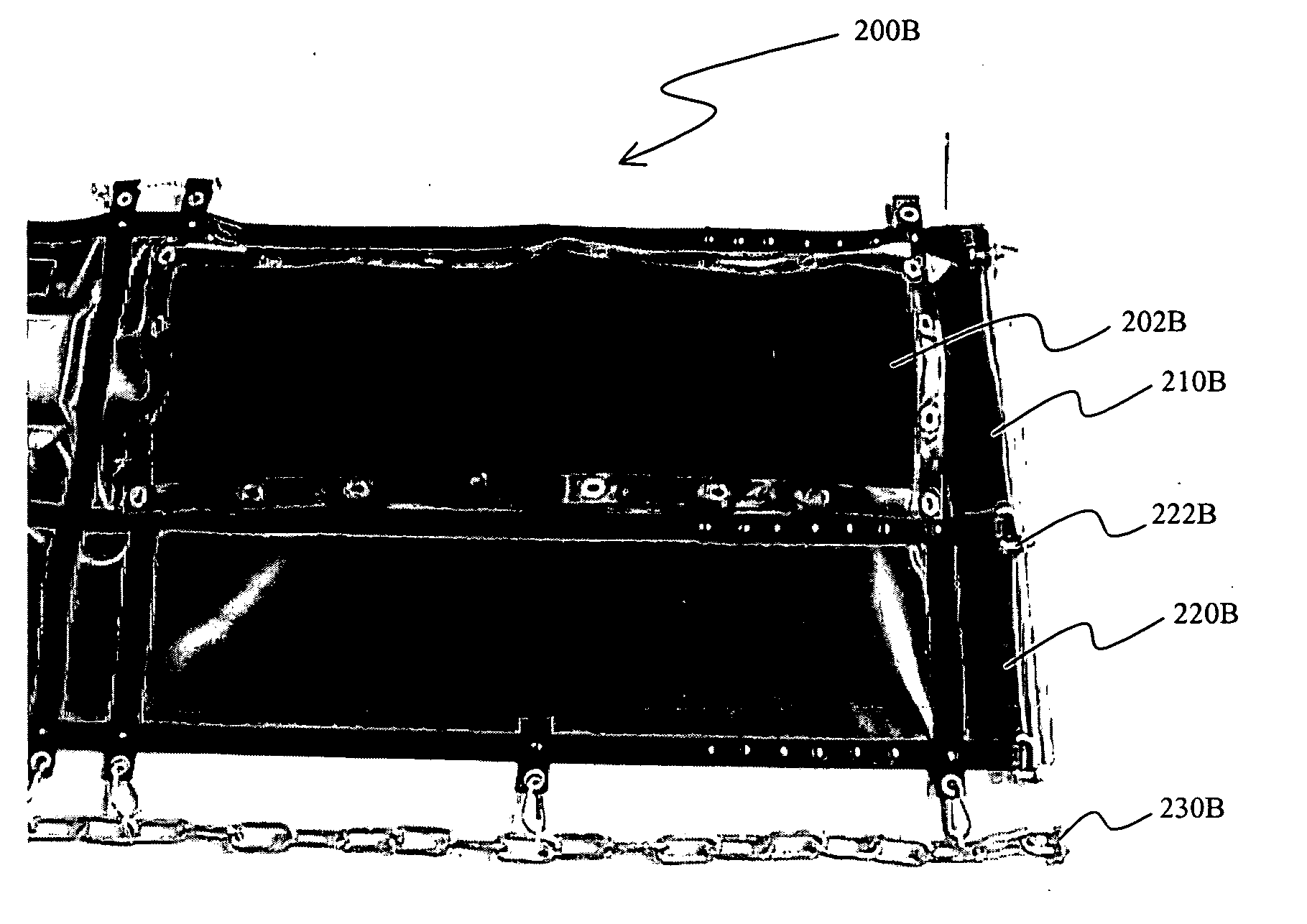

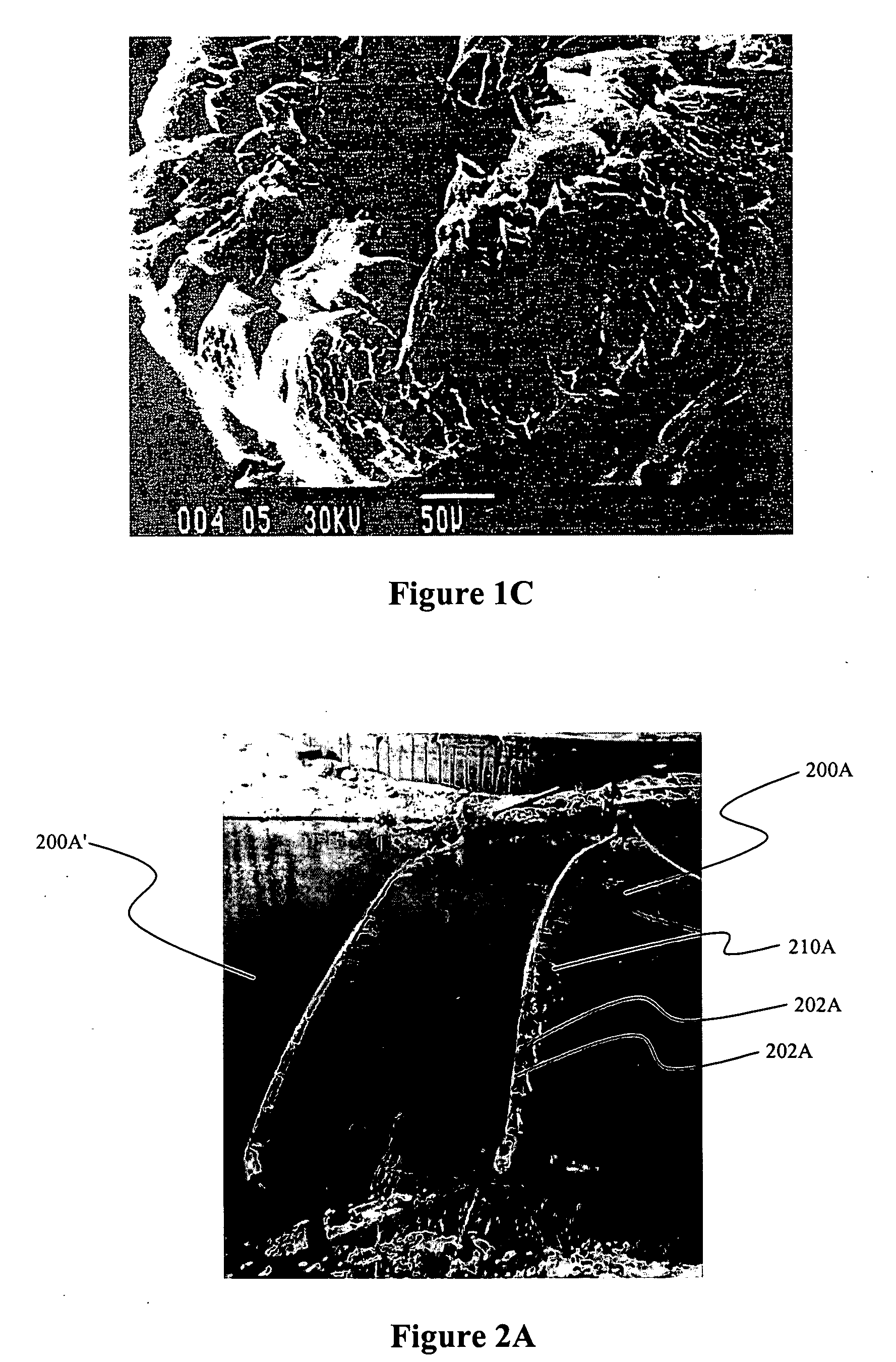

Compositions and methods of remediation devices with nanostructured sorbent

Contemplated remediation devices include a substantially completely hydrophobic, non-porous, and carbonaceous, and most preferably nanostructured material enclosed in a retaining structure. In further preferred aspects, the material inside the retaining structure adsorbs a contaminant from a medium located outside the retaining structure. Especially preferred nanostructured materials comprise graphene, while preferred contaminants include optionally substituted hydrocarbons, organic solvents, and acids.

Owner:PETRIK VIKTOR I +1

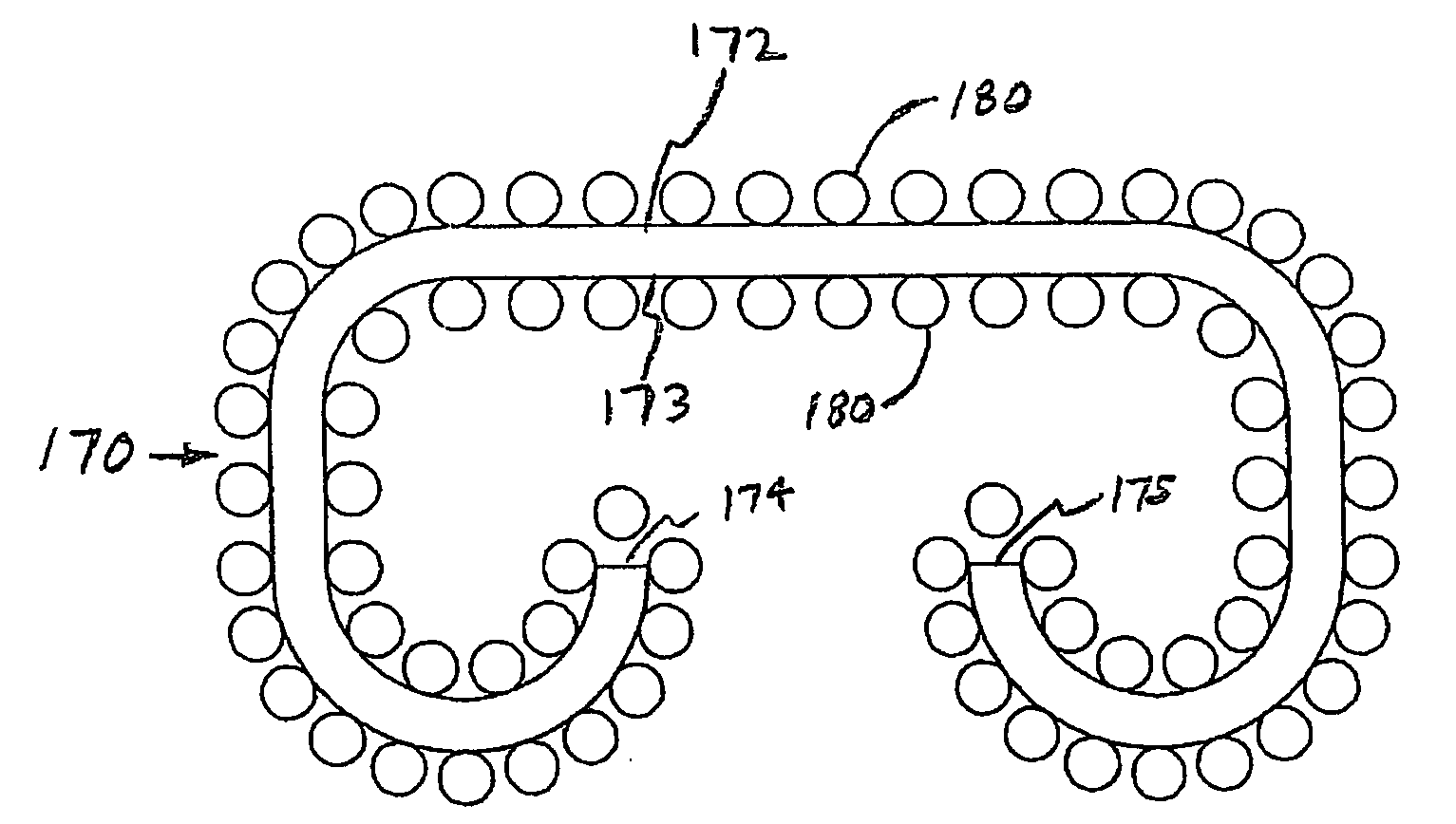

Nanostructured material transport devices and their fabrication by application of molecular coatings to nanoscale channels

InactiveUS20050023156A1Reduced cross-sectional dimensionReduce the cross-sectional areaMaterial nanotechnologyFixed microstructural devicesEngineeringNanostructured materials

Owner:RAMSEY J MICHAEL +3

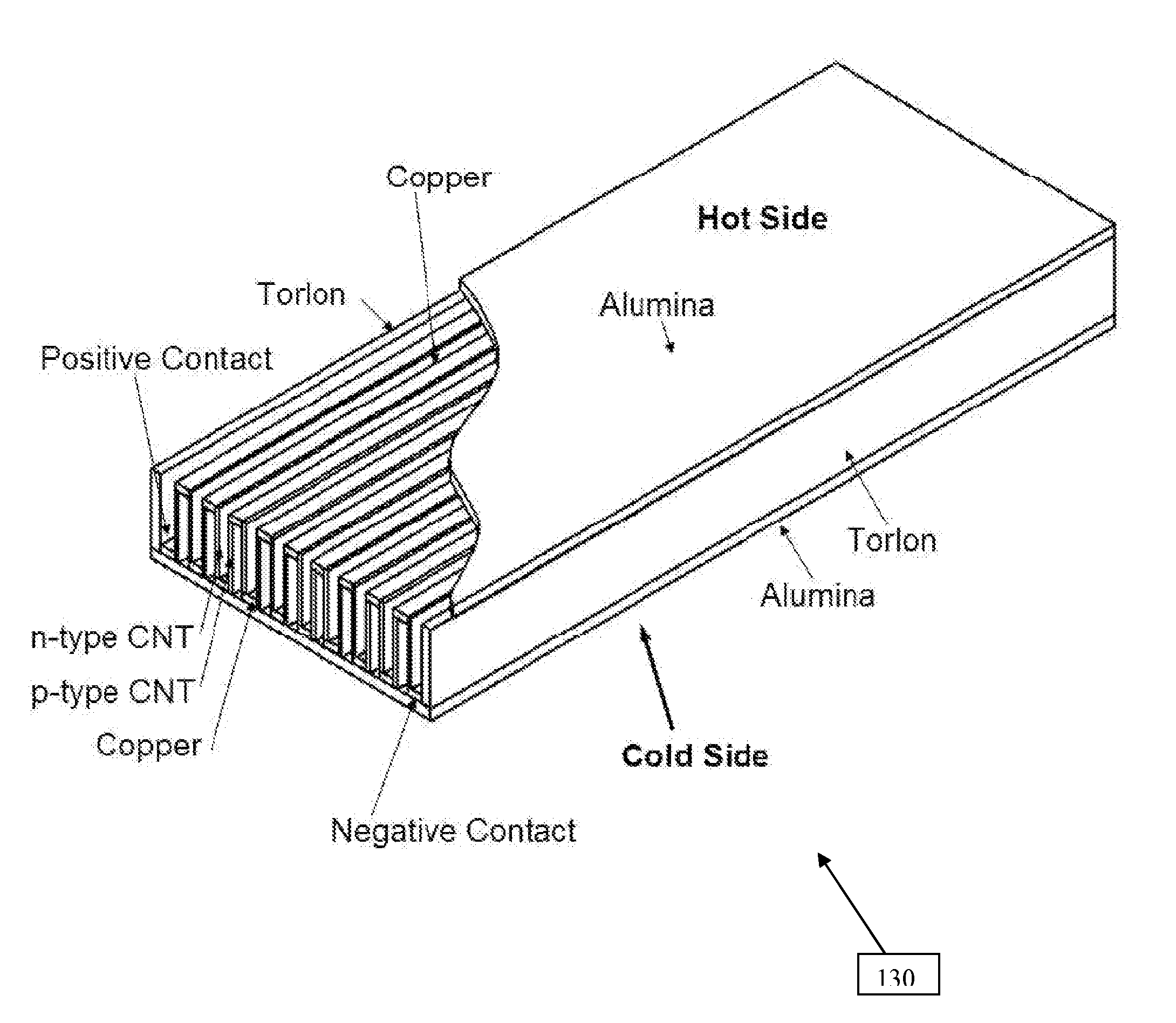

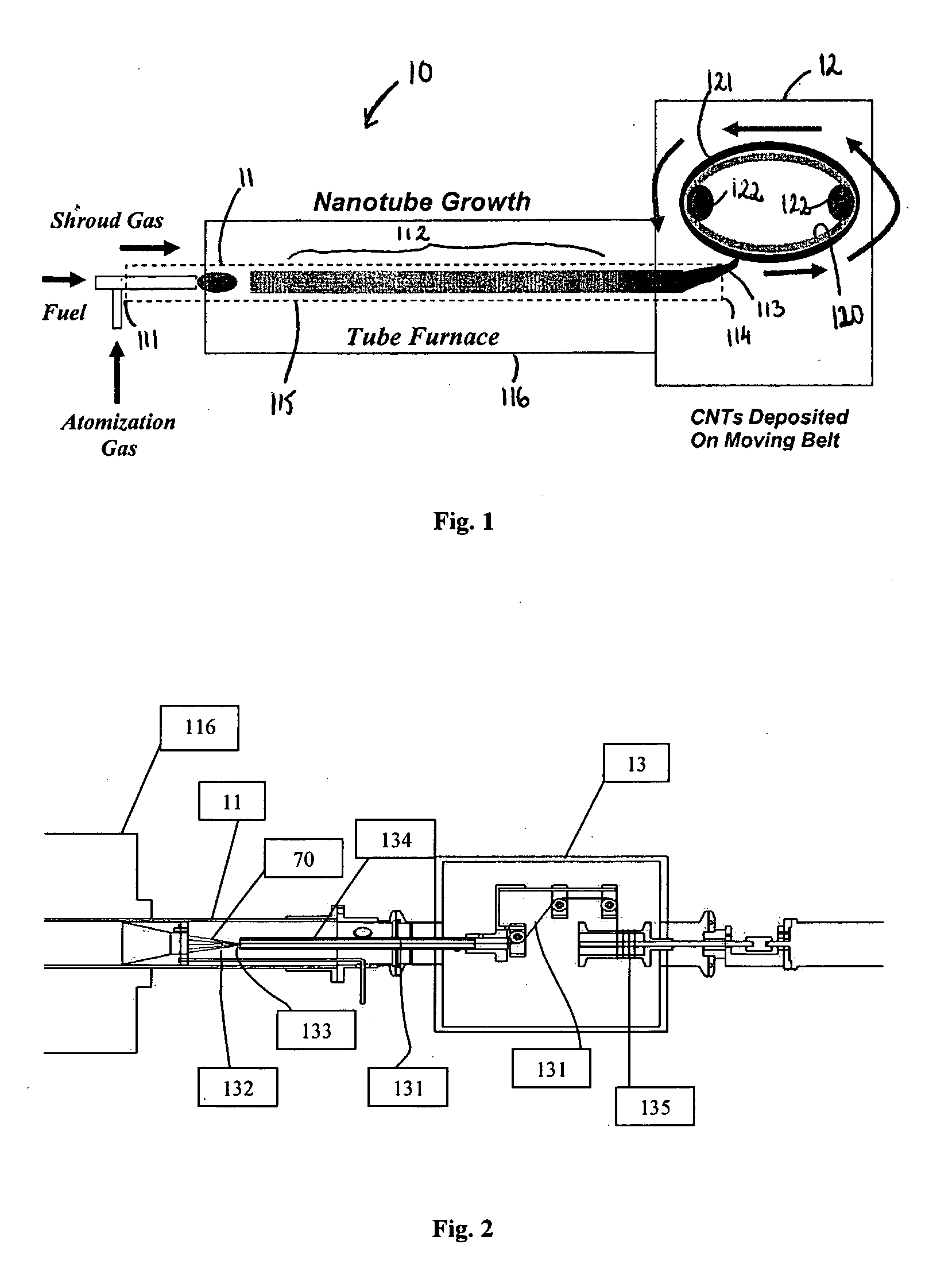

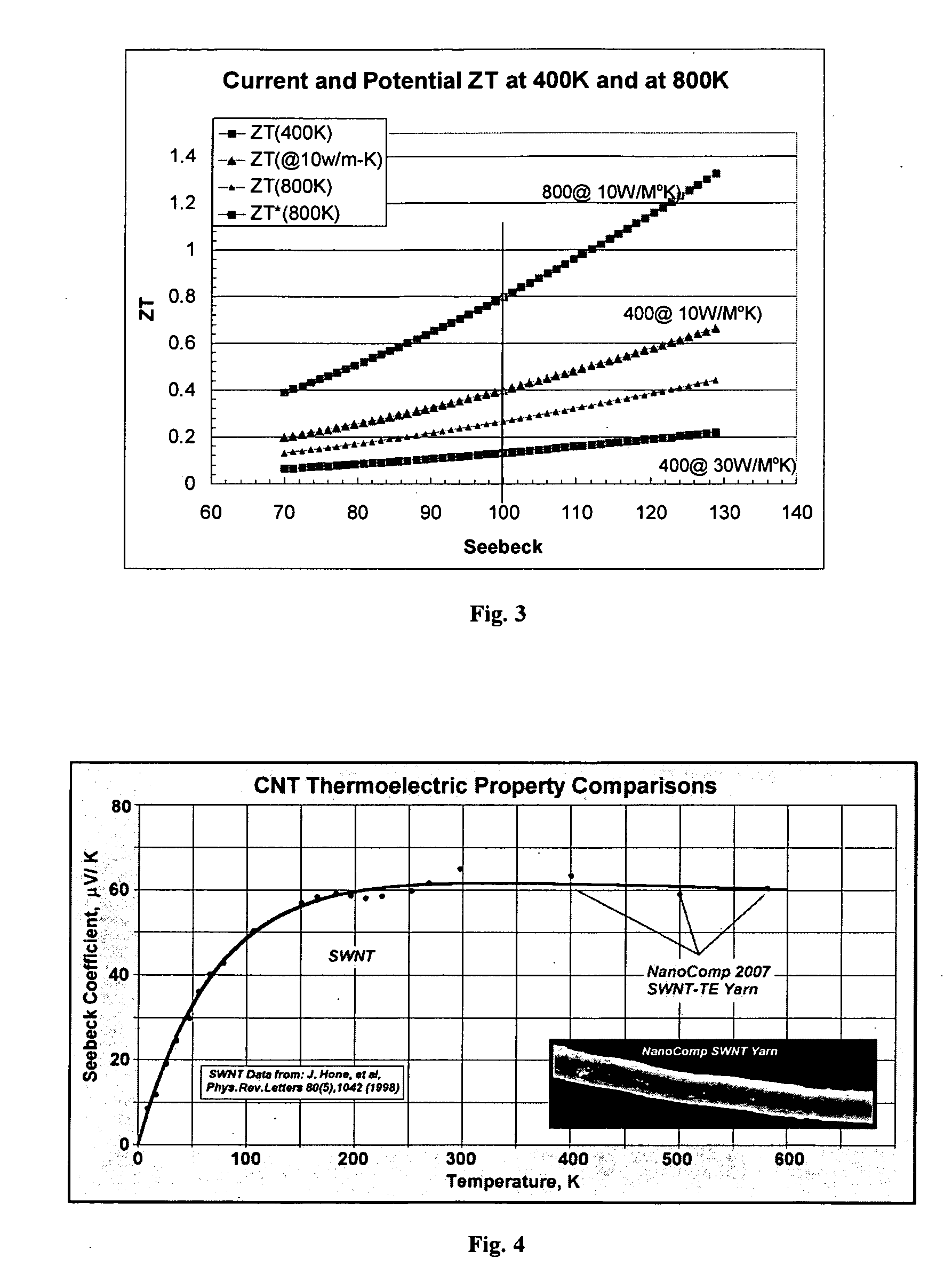

Nanostructured Material-Based Thermoelectric Generators

InactiveUS20090044848A1Improvement factorRaise the transition temperatureAuxillary drivesFrom solar energyCarbon nanotubeEngineering

A thermoelectric device that can exhibit substantially high specific power density is provided. The device includes core having a p-type element made from carbon nanotube and an n-type element. The device also includes a heat plate in and a cool plate, between which the core can be positioned. The design of the thermoelectric device allows the device to operate at substantially high temperature and to generate substantially high power output, despite being light weight. A method for making the thermoelectric device is also provided.

Owner:NANCOMP TECHNOLOGIES INC

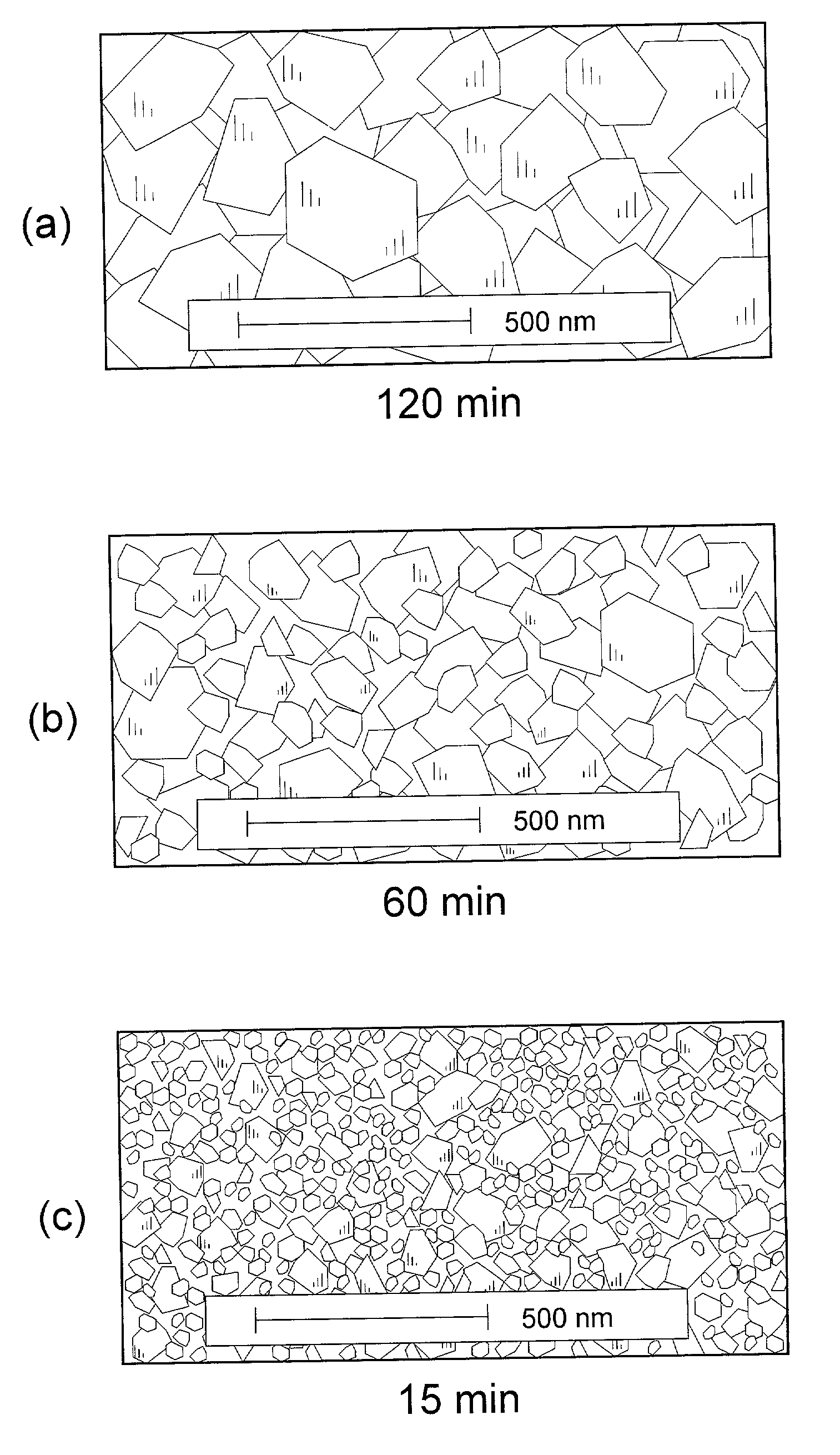

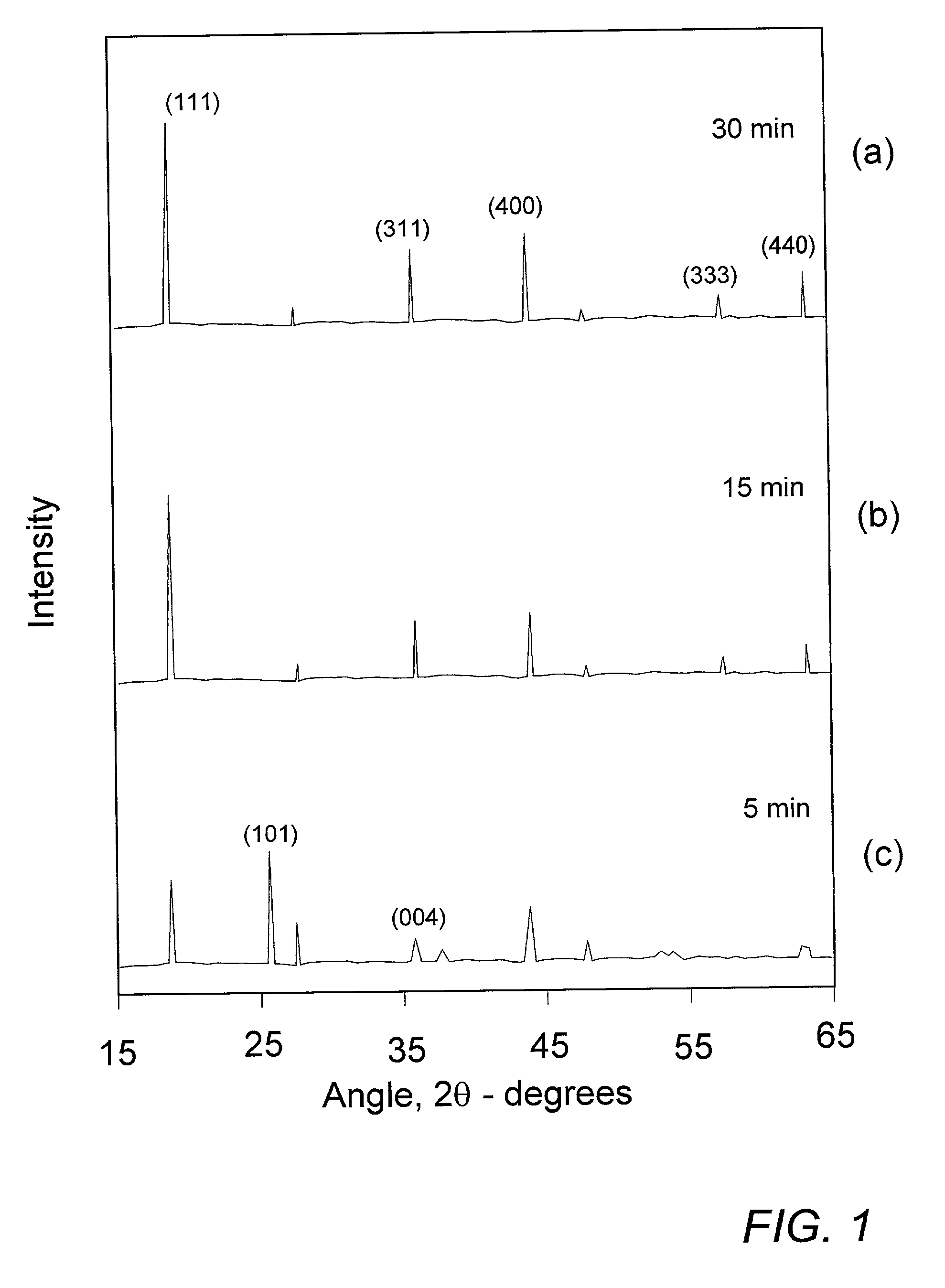

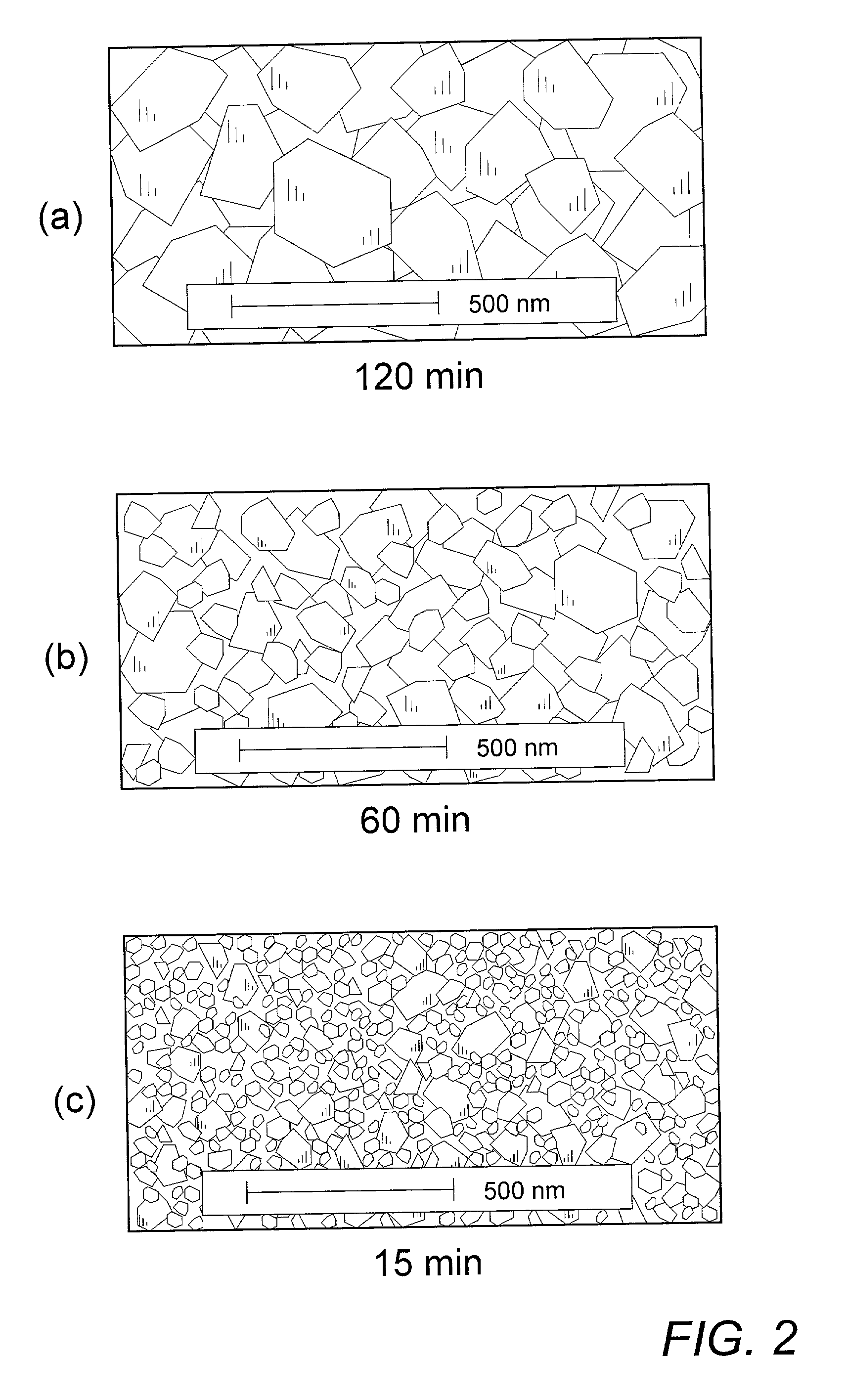

Nanostructure lithium titanate electrode for high cycle rate rechargeable electrochemical cell

Rechargeable electrochemical cells, such as lithium batteries and asymmetric hybrid battery / supercapacitor systems, exhibiting exceptional specific capacity levels and stability over extended high-rate recharge cycling comprise nanostructure zero strain Li4Ti5O12 intercalation electrode material synthesized in a short duration process of annealing mixed TiO2 and Li-source precursor compounds at about 800° C. for a time of about 15–30 min which is not substantially longer than that required to effect maximum available reaction between the precursors, thereby substantially eliminating the growth of synthesized Li4Ti5O12 particles beyond nanostructure size. The process reduces by order of magnitude the time and energy required for synthesis of the active electrode material and fabrication of utilizing cell devices, and provides such nanostructure material which enables repeated, high-rate recharge cycling without loss of cell capacity or efficiency.

Owner:RUTGERS THE STATE UNIV

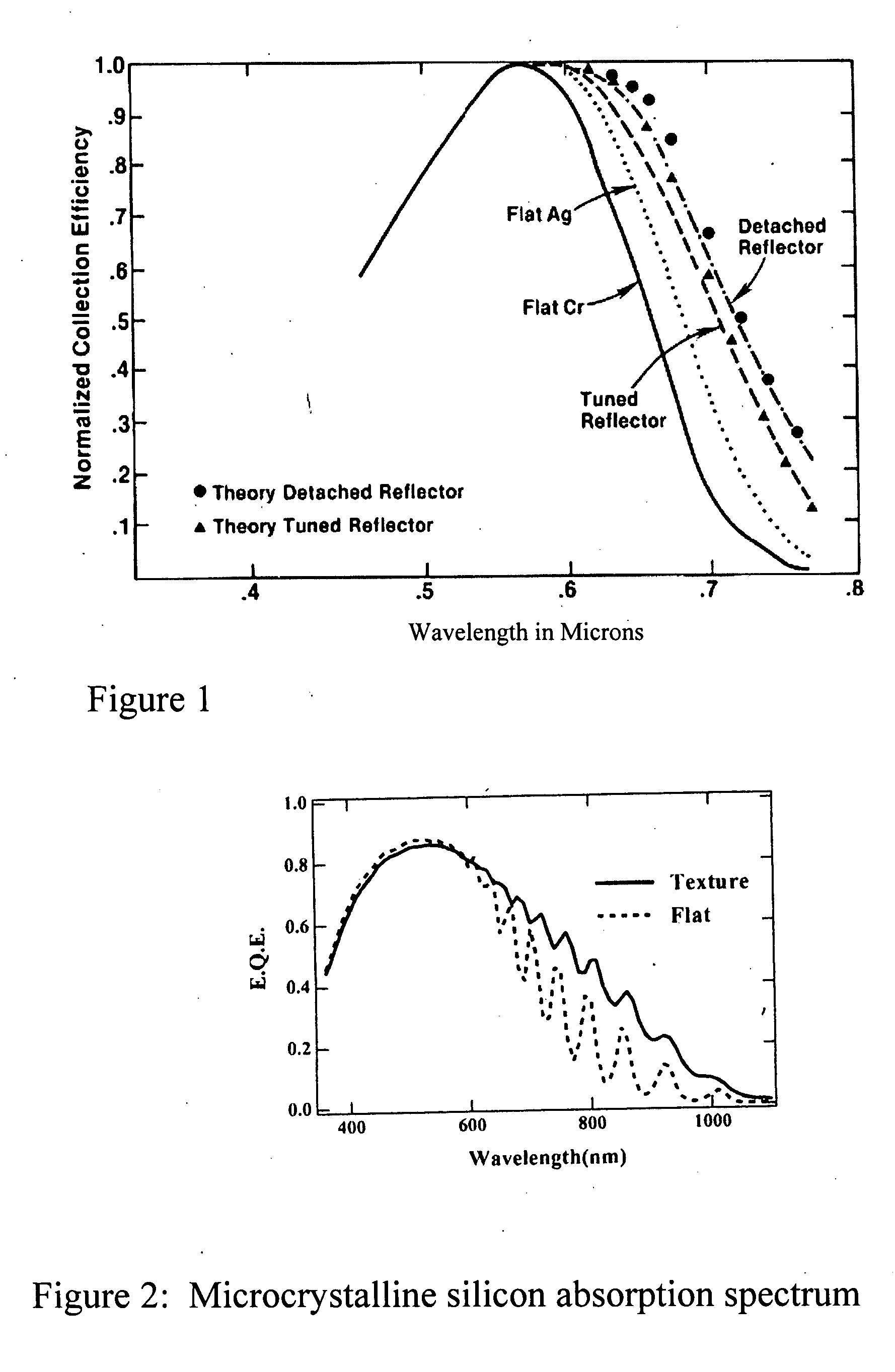

Photovoltaic device with nanostructured layers

InactiveUS20080230120A1Improve absorption efficiencyFinal product manufactureSolid-state devicesNanoparticleQuantum dot

Photovoltaic devices or solar cells are provided. More particularly, the present invention provides photovoltaic devices having IR and / or UV absorbing nanostructured layers that increase efficiency of solar cells. In some embodiments the nanostructured materials are integrated with one or more of: crystalline silicon (single crystal or polycrystalline) solar cells and thin film (amorphous silicon, microcrystalline silicon, CdTe, CIGS and III-V materials) solar cells whose absorption is primarily in the visible region. In some embodiments the nanoparticle materials are comprised of quantum dots, rods or multipods of various sizes.

Owner:SOLEXANT

Nanostructured fuel cell electrode

A fuel cell includes an electrolyte, a first electrode, and a second electrode. At least the first electrode comprises a nanostructured material.

Owner:BLOOM ENERGY CORP

Contact devices with nanostructured materials

InactiveUS20060151382A1Small dimensionCombination devicesMaterial nanotechnologyCarbon nanotubeProduct gas

A device includes a non-porous carbonaceous and nanostructured material other than a carbon nanotube, wherein the smallest dimension of the material is less than 100 nm. In most preferred devices, the carbonaceous material comprises graphene that is retained by a second material, wherein the device is configured as a filter for a gas and / or a liquid.

Owner:PETRIK VIKTOR I

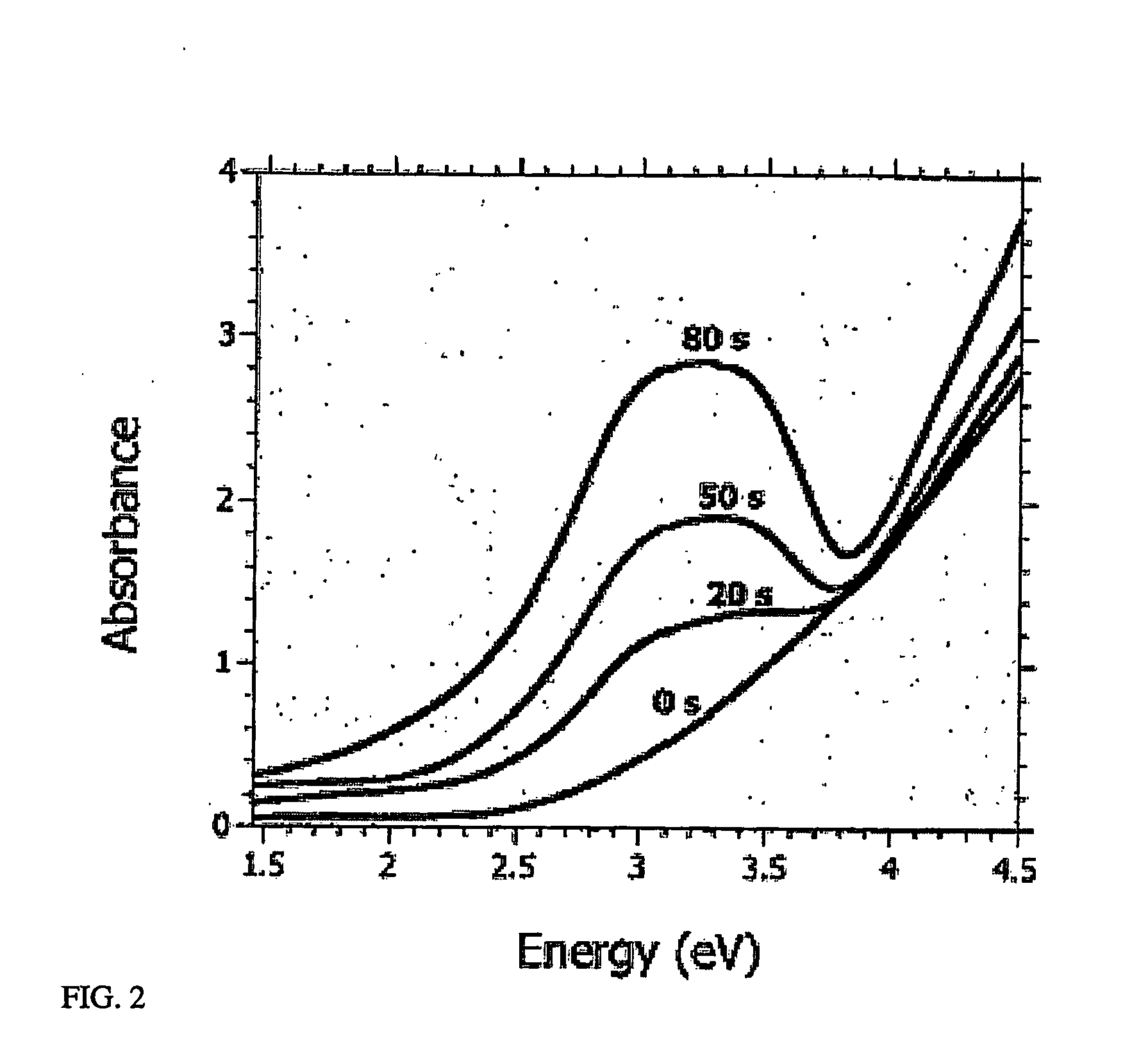

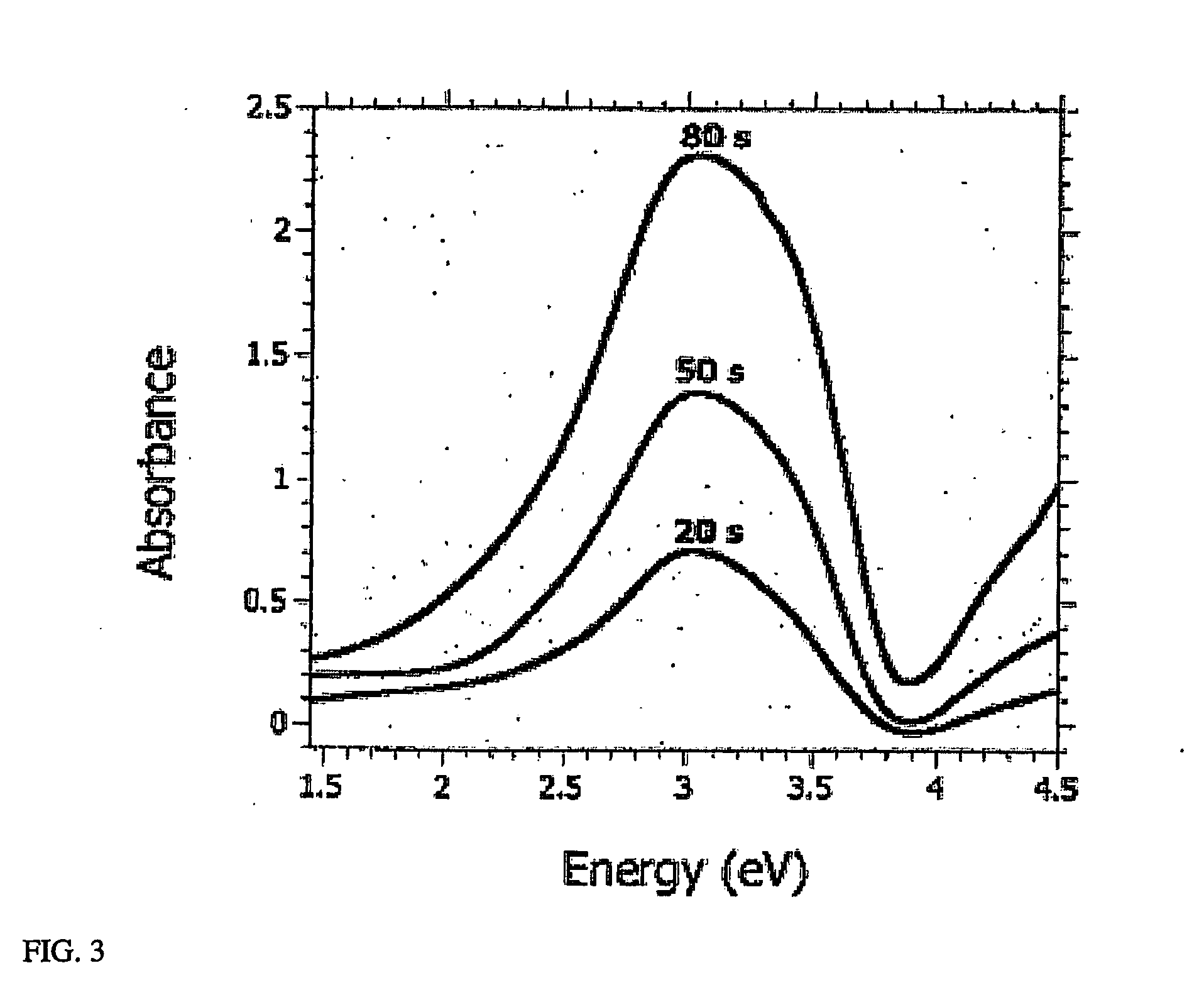

Nanoparticle coated nanostructured surfaces for detection, catalysis and device applications

InactiveUS20060141268A1Strong surface plasmon optical absorptionFine surfaceMaterial nanotechnologyNanomagnetismNano catalystNanostructured materials

A non-vacuum-based, non-collodial chemistry-based method of synthesizing metal nanoparticles and nanoparticle-nanostructured material composites obtained by that method. An embodiment of the method of this invention for fabricating a nanoparticle-nanostructured material composite and synthesizing nanoparticles includes preparing a nanostructured / nanotextured material, and, contacting the nanostructured / nanotextured material with a solution. Nanoparticles are synthesized on the nanostructured / nanotextured material as a result of the contact. The method of the present invention can be utilized to fabricate SPR and SERS substrates for sensing and detection. Additional systems based on this approach (e.g., surface plasmon resonance absorption and alloying sensors and nanocatalysts) are described.

Owner:PENN STATE RES FOUND

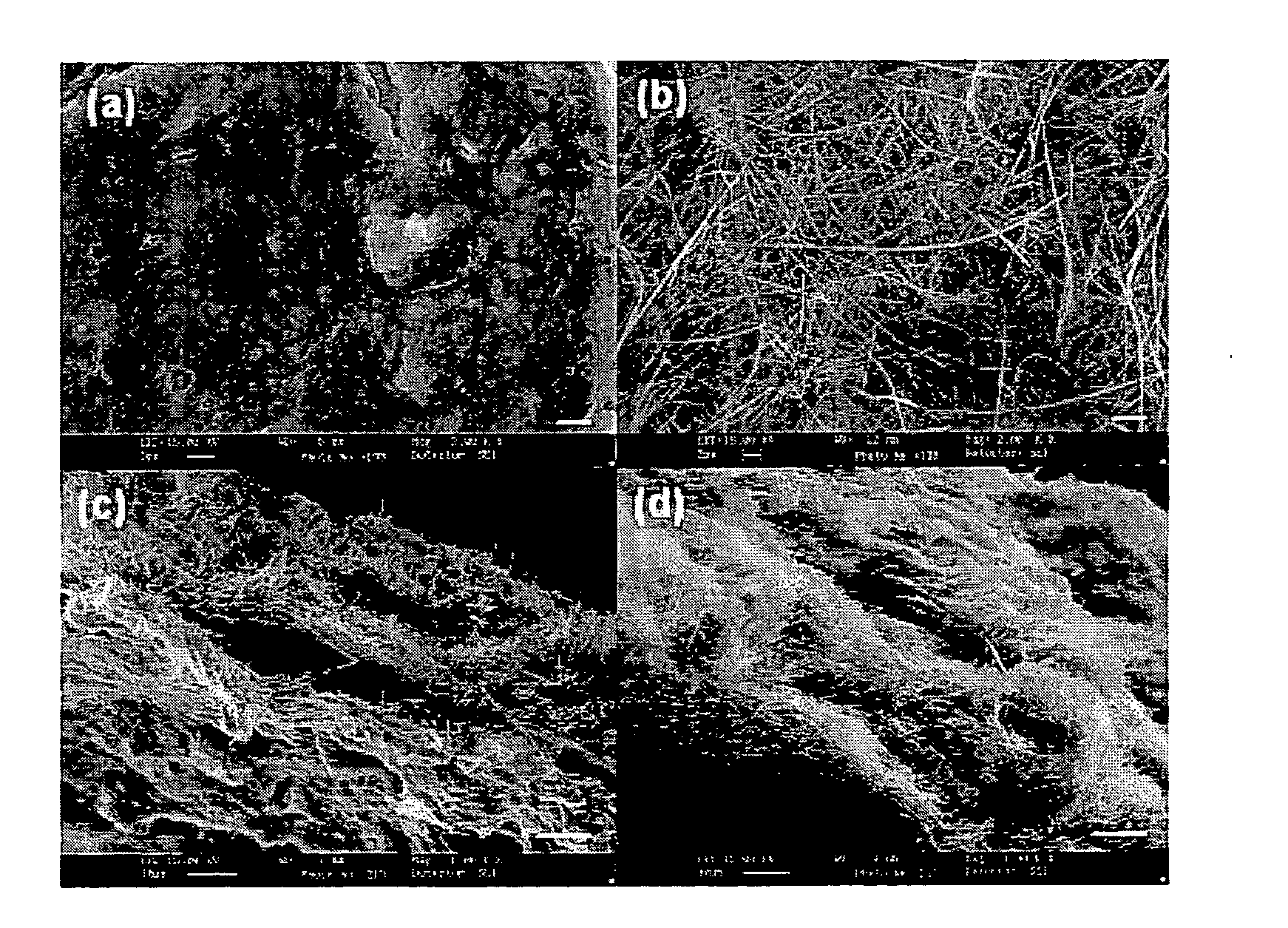

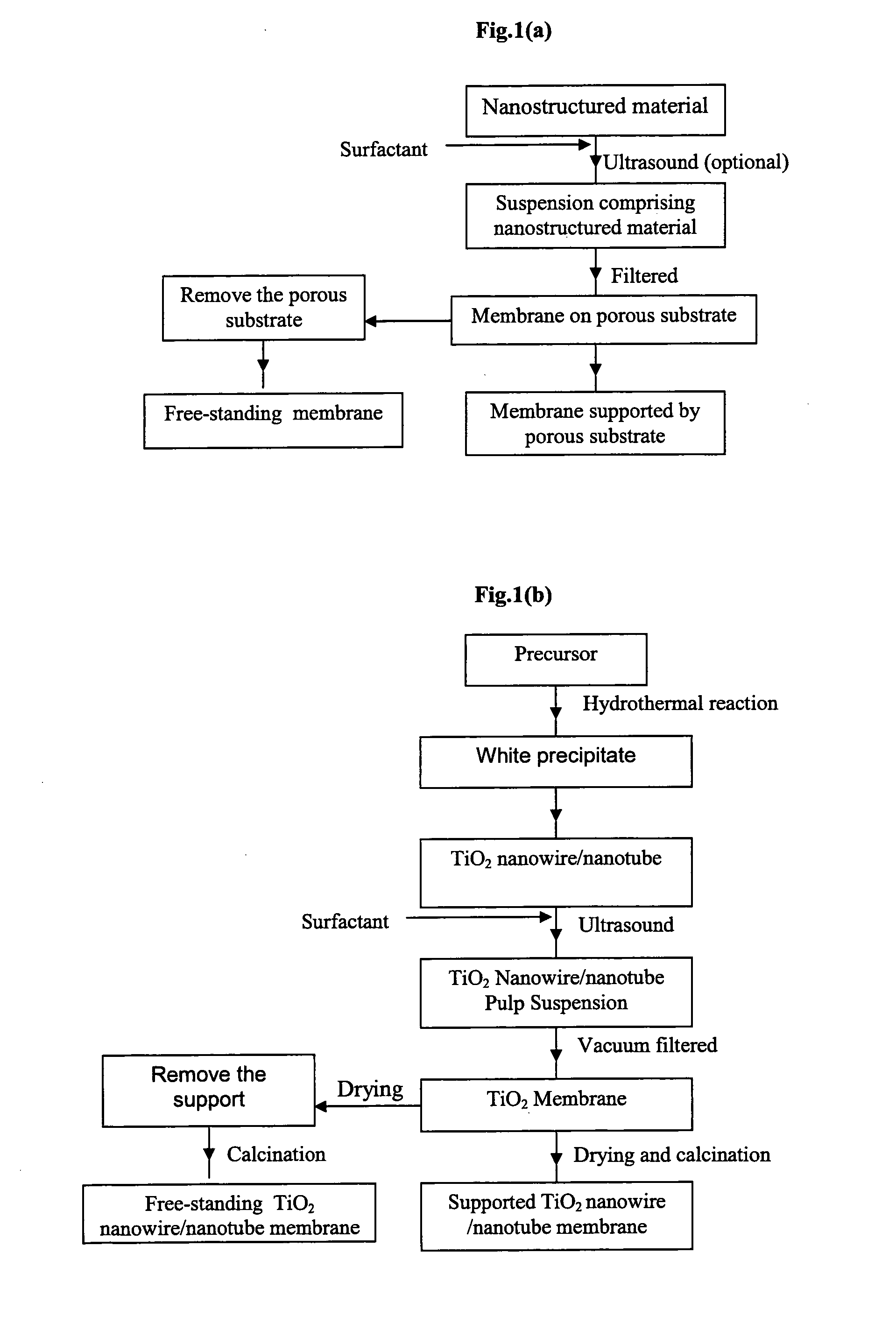

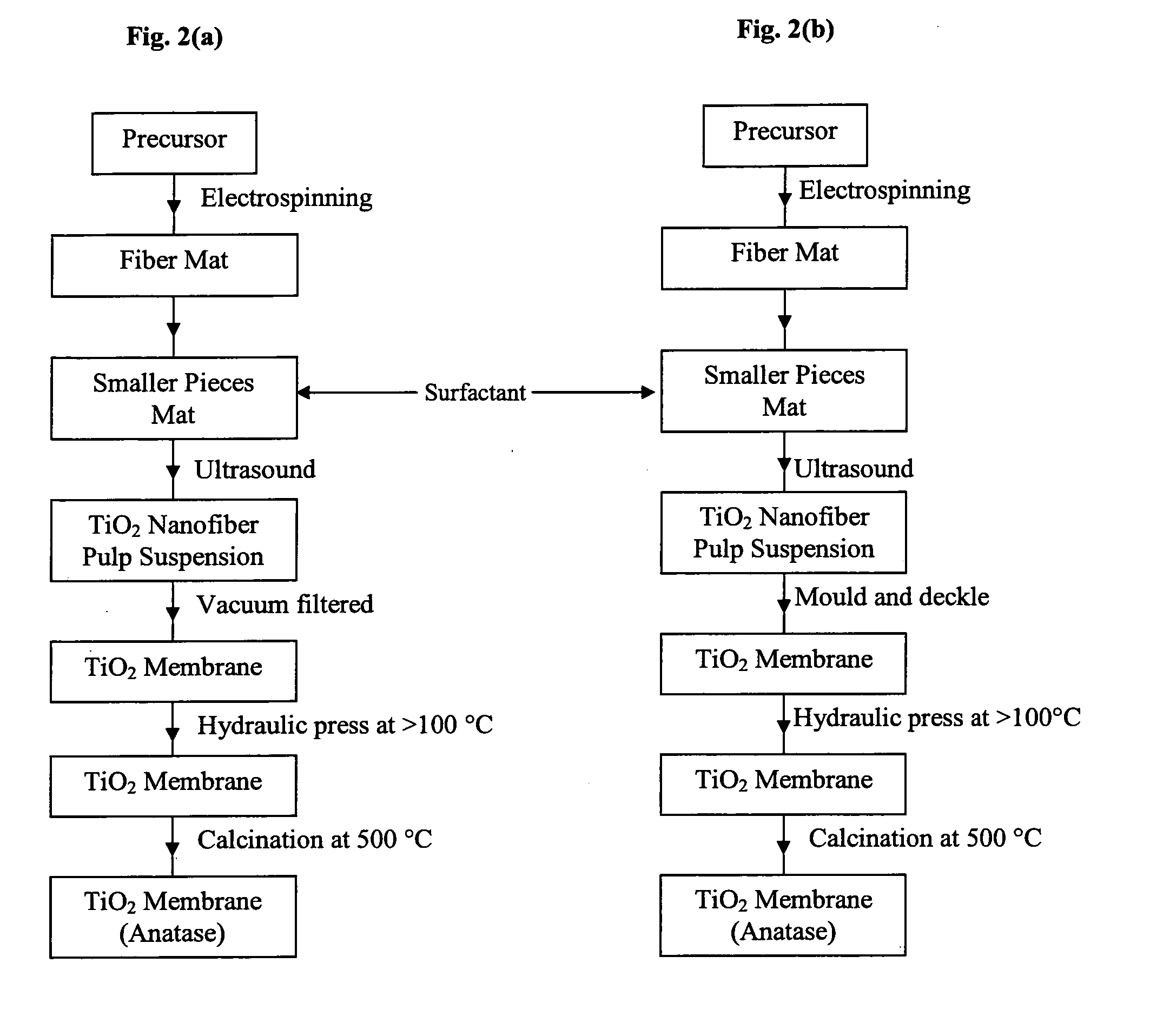

Membrane made of a nanostructured material

Owner:NANYANG TECH UNIV +1

Low platinum fuel cell catalysts and method for preparing the same

InactiveUS7351444B2Good dispersionEfficient CatalysisMaterial nanotechnologyConductive materialPlatinumFiber

This invention provides novel fuel cell catalysts comprising new series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticales into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

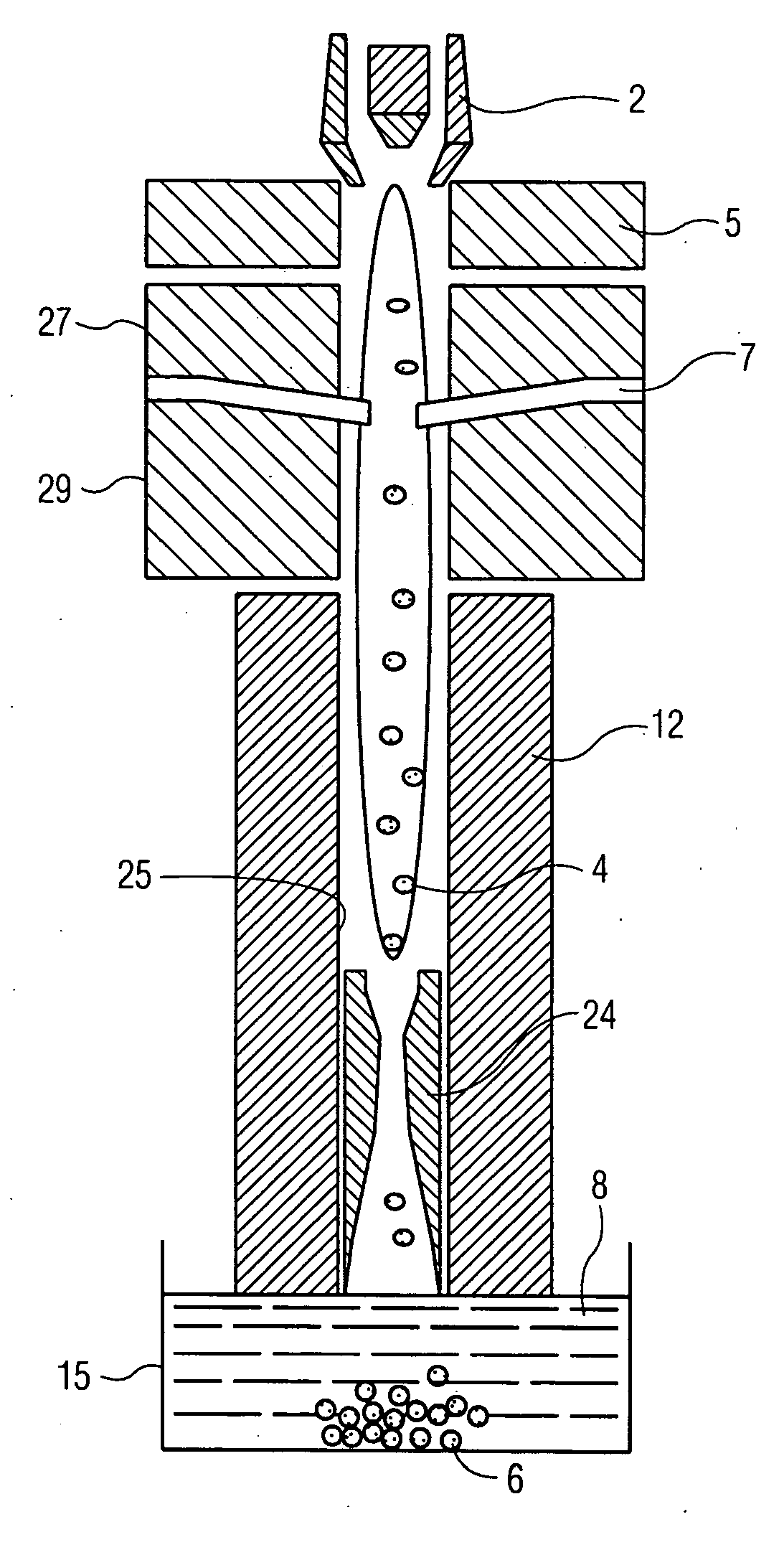

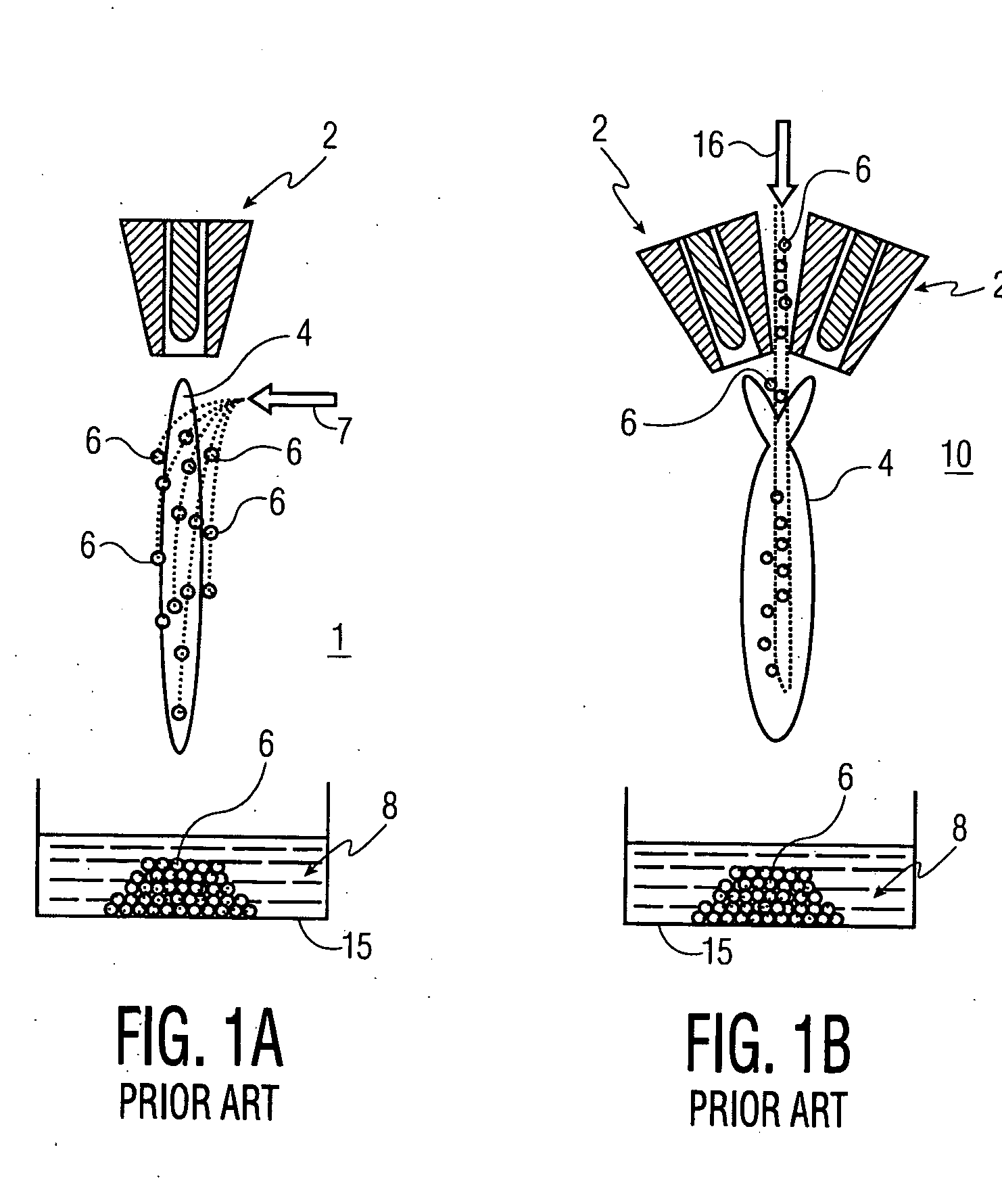

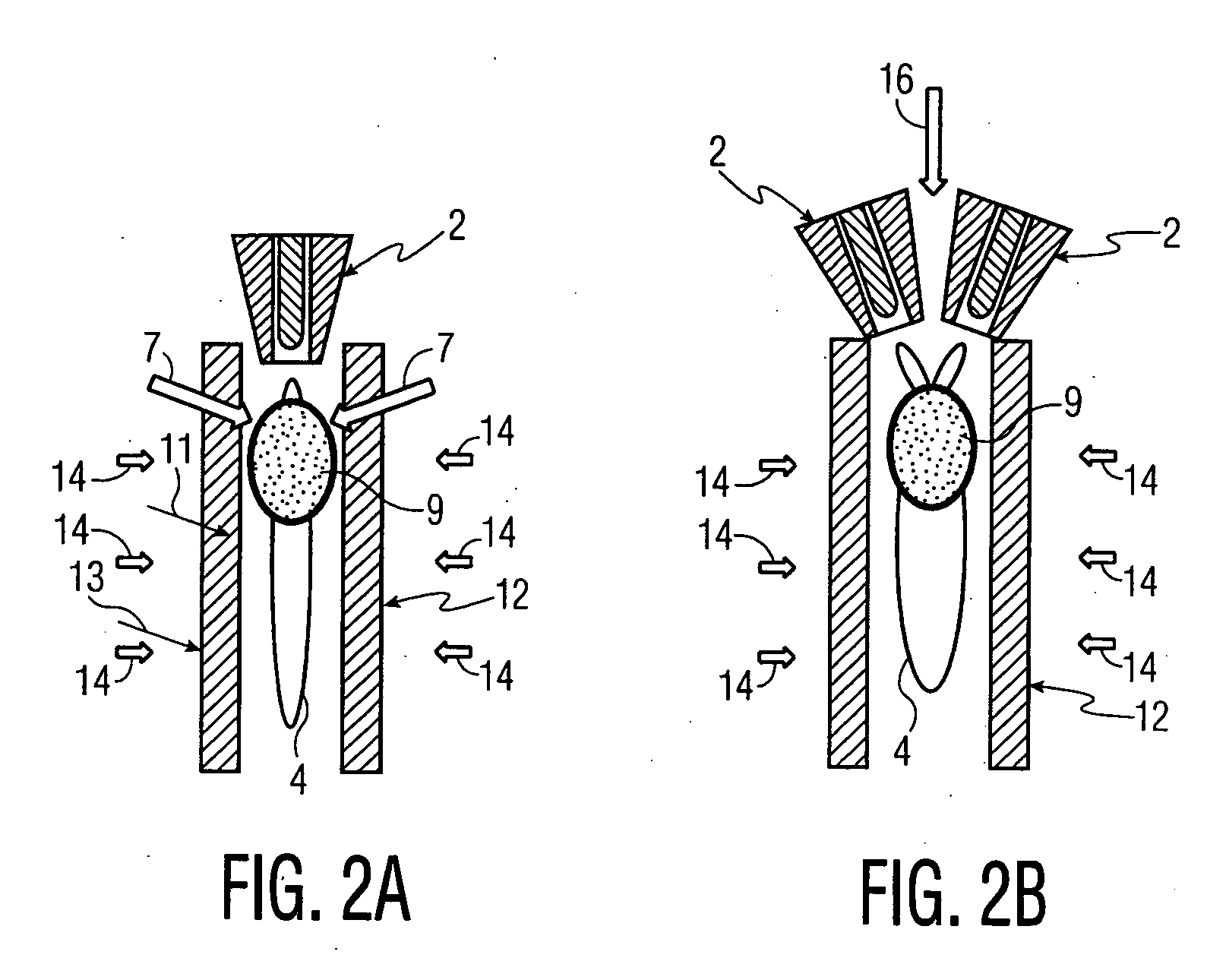

Shrouded-plasma process and apparatus for the production of metastable nanostructured materials

InactiveUS20070044513A1Improve compactnessImprove sintering performanceMaterial nanotechnologyNitrogen compoundsLiquid jetShort range order

A method and apparatus for producing metastable nanostructured materials employing a ceramic shroud surrounding a plasma flame having a steady state reaction zone into which an aerosol or liquid jet of solution precursor or powder material is fed, causing the material to be pyrolyzed, melted, or vaporized, followed by quenching to form a metastable nanosized powder that has an amorphous (short-range ordered), or metastable microsized powder that has a crystalline (long-range ordered) structure, respectively.

Owner:RUTGERS THE STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com