Patents

Literature

300results about How to "Dynamic stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

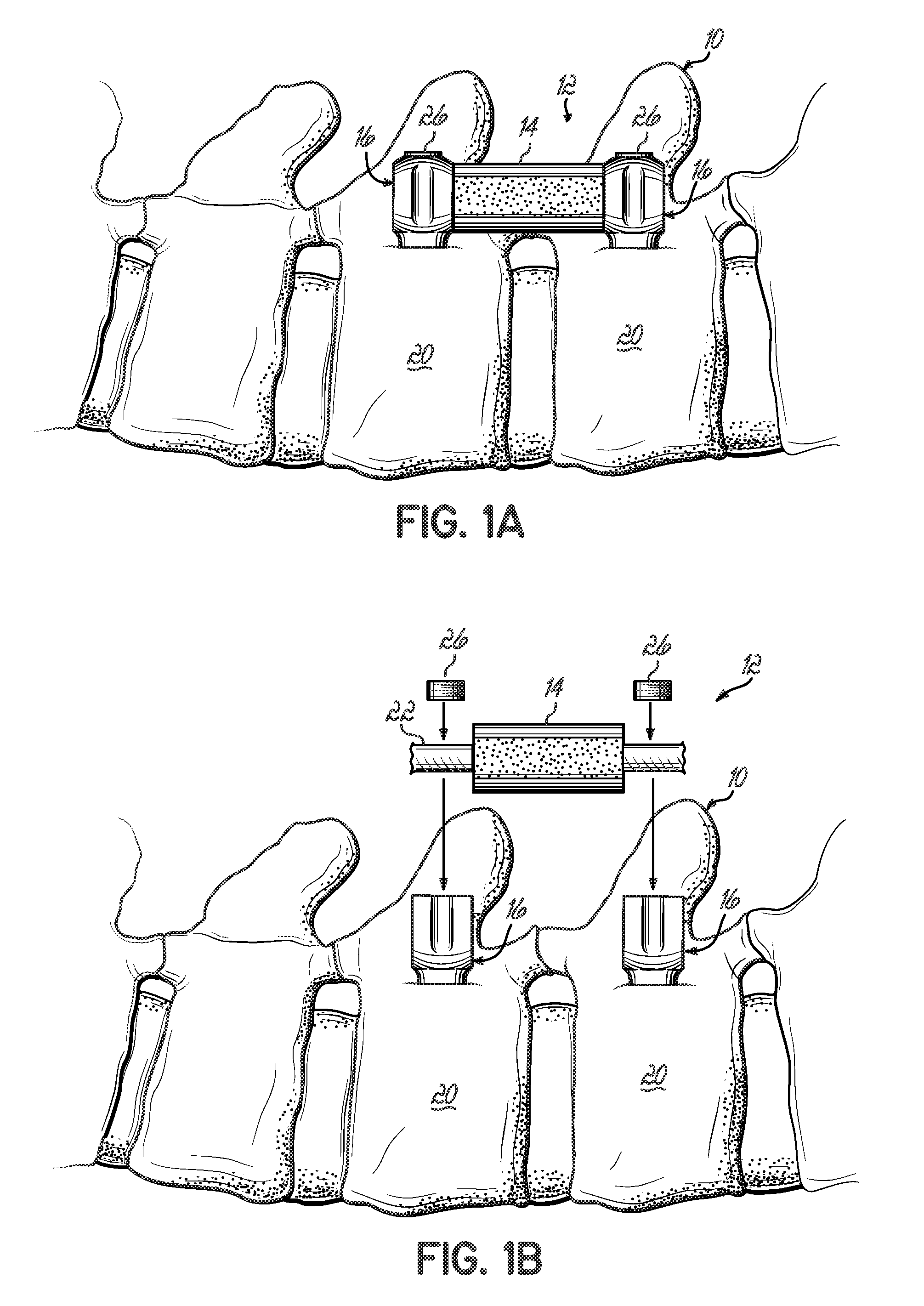

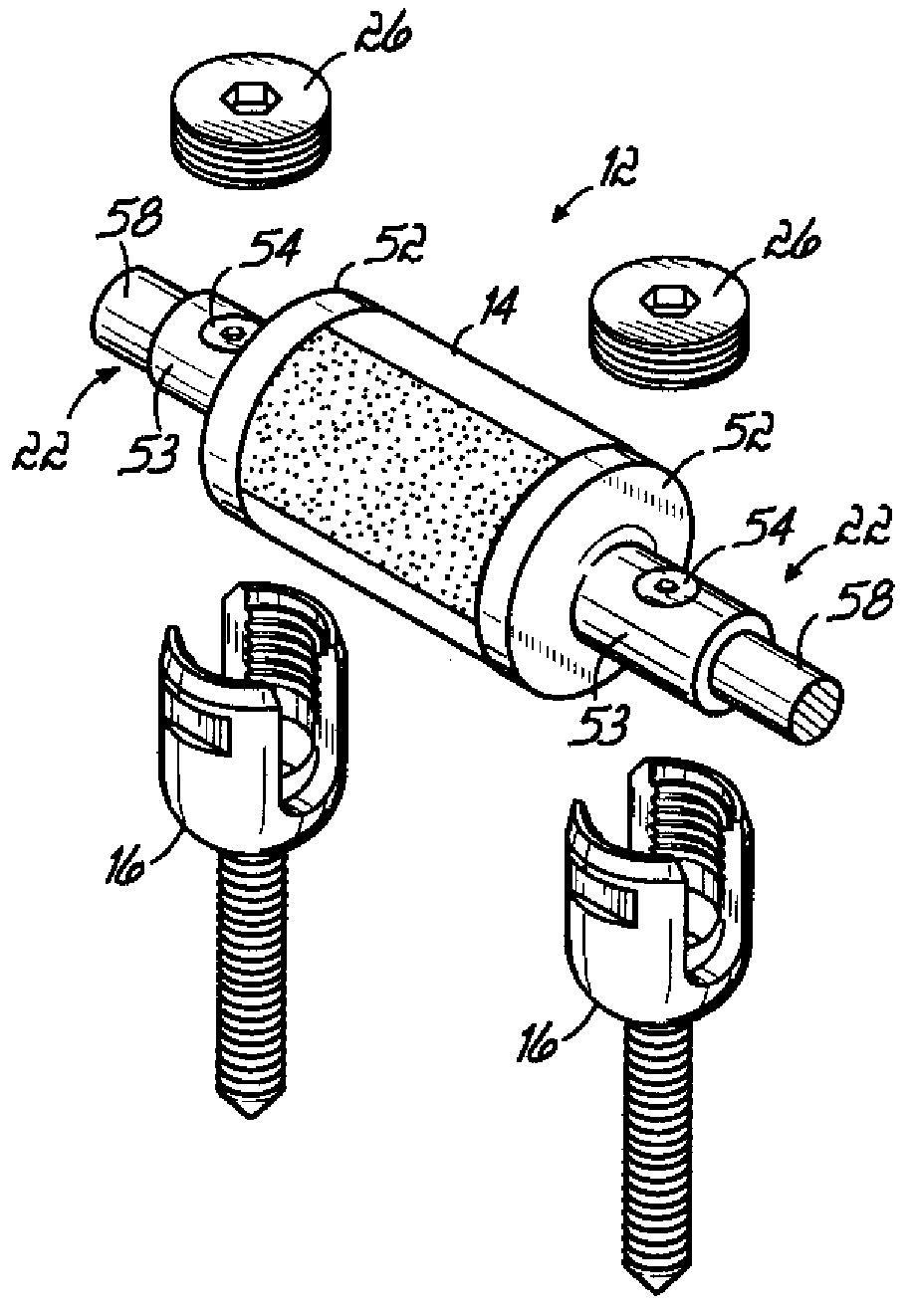

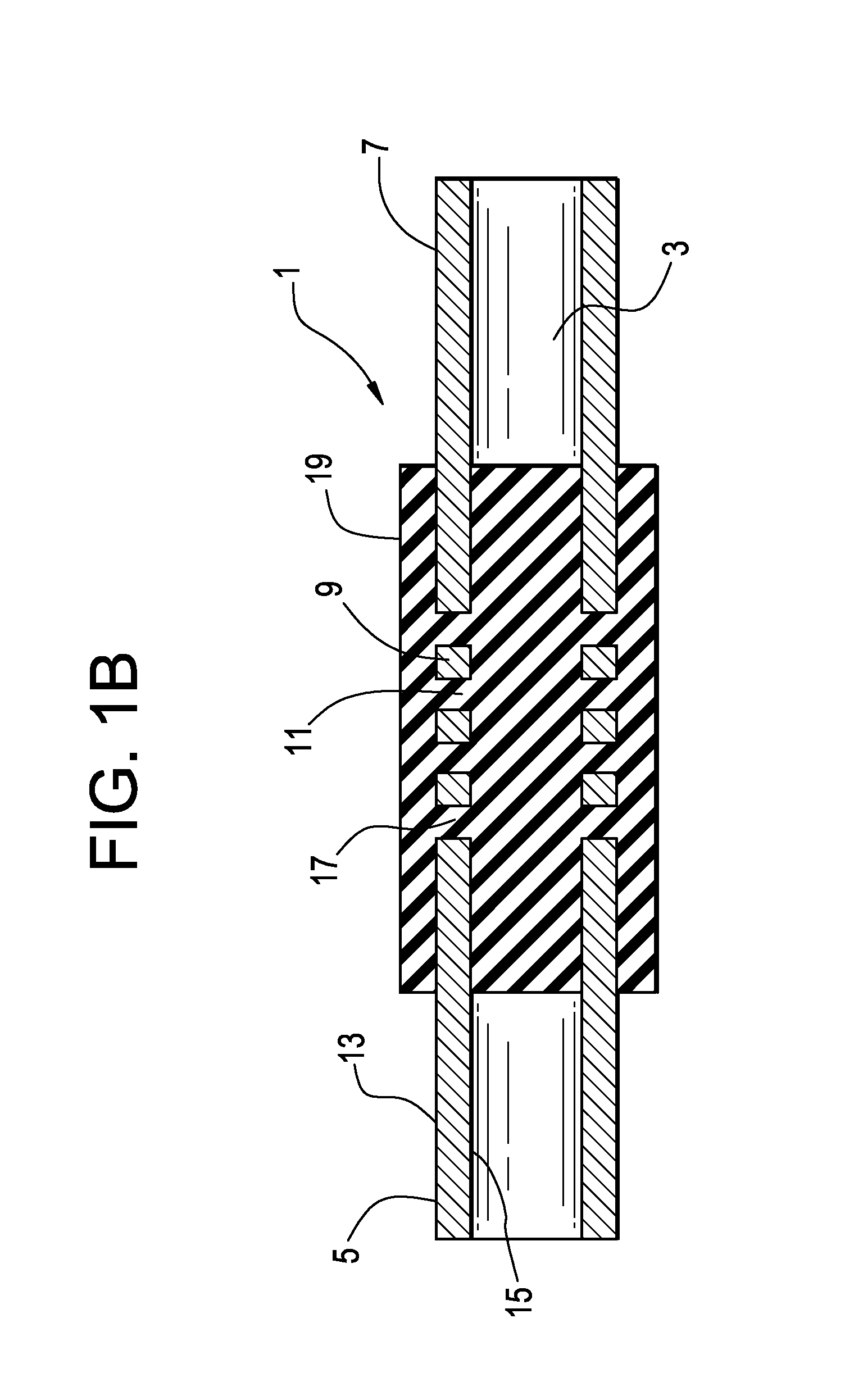

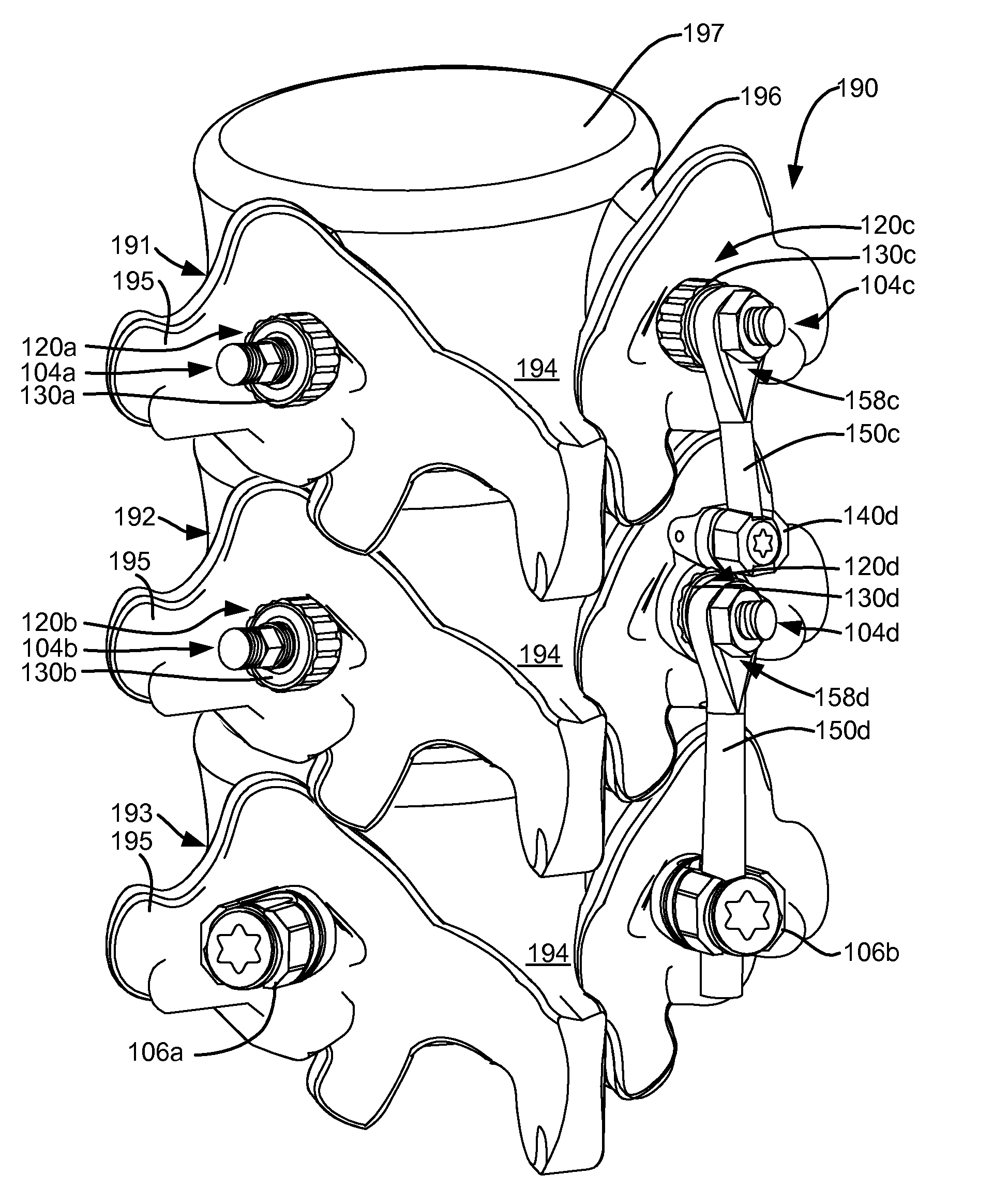

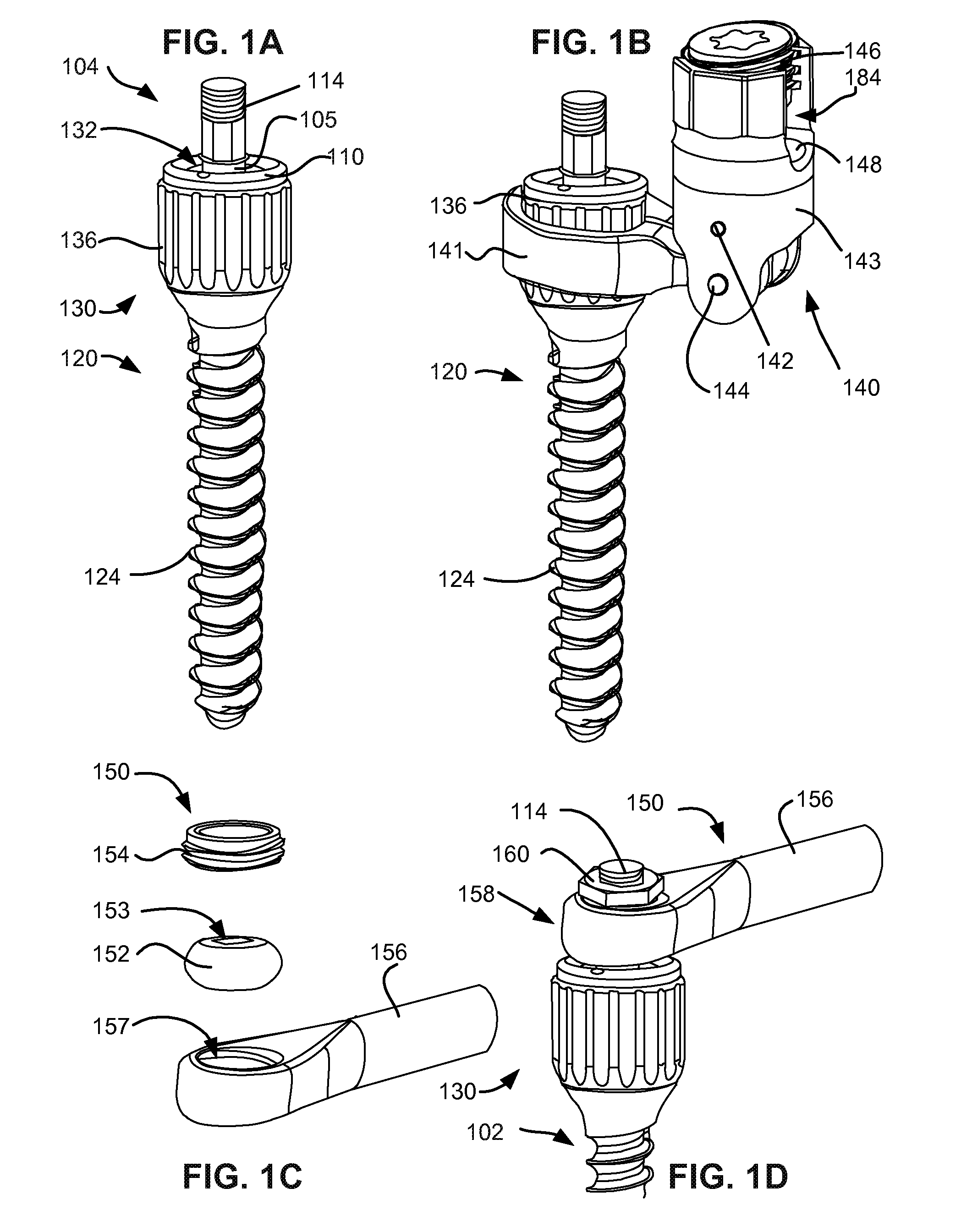

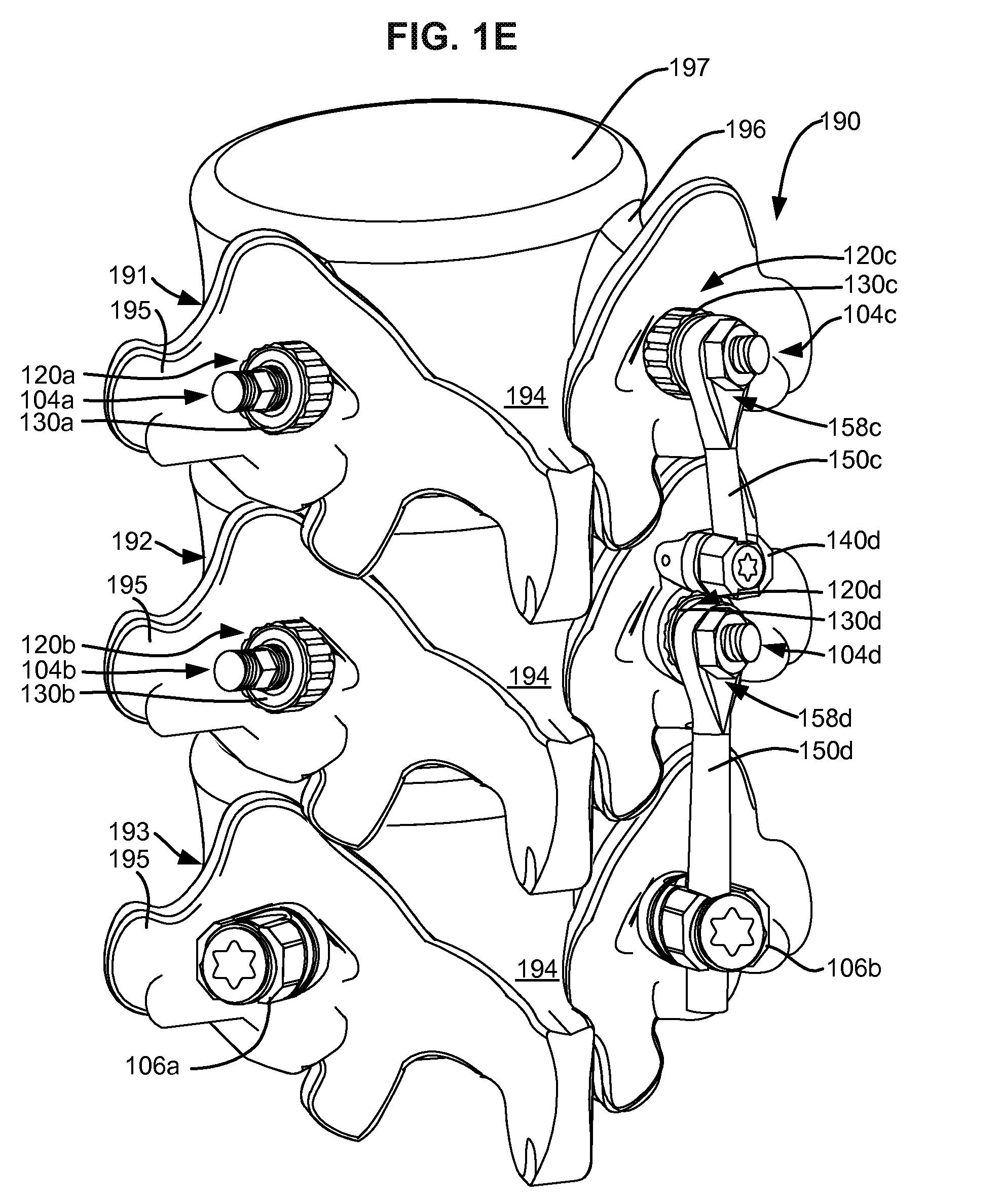

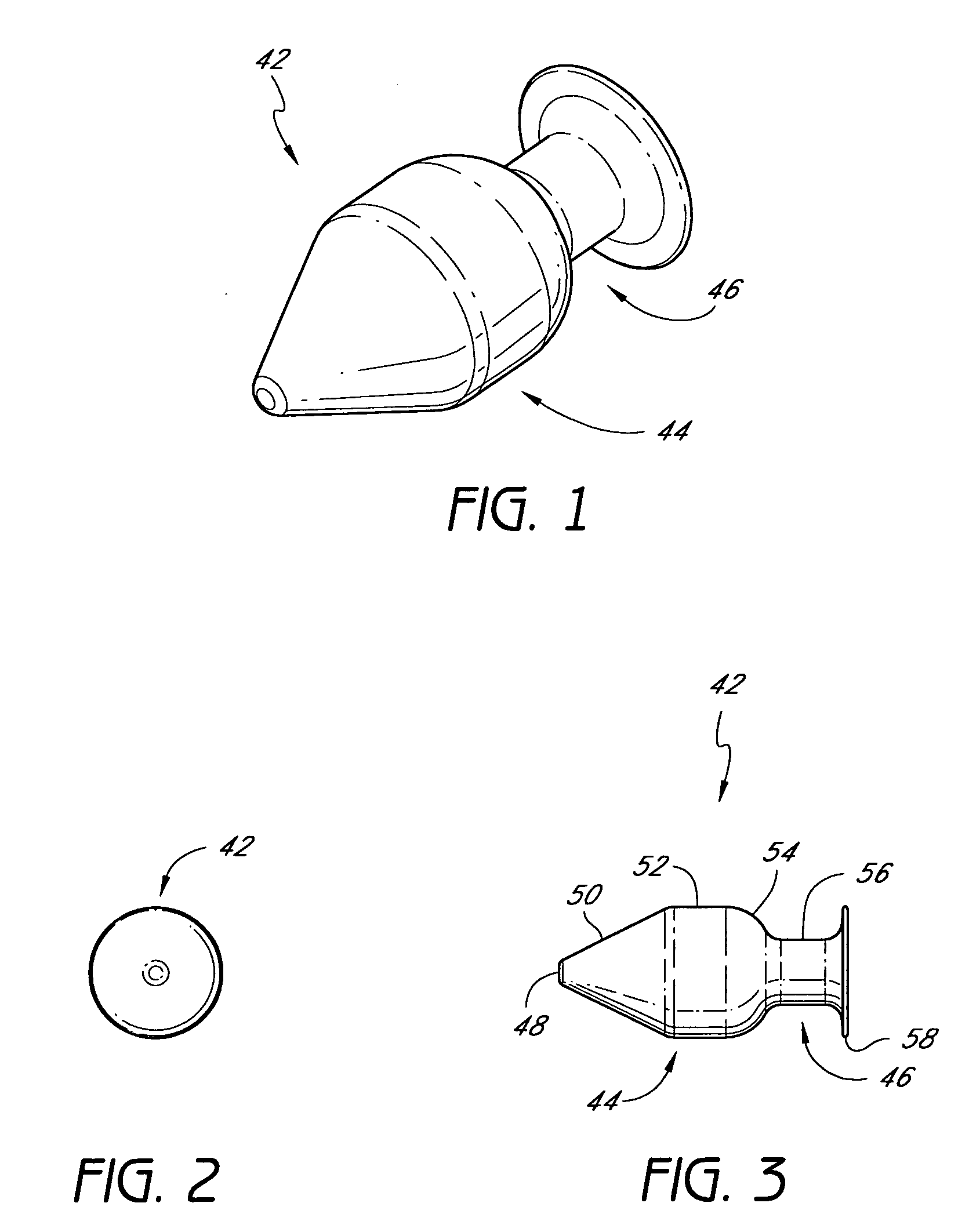

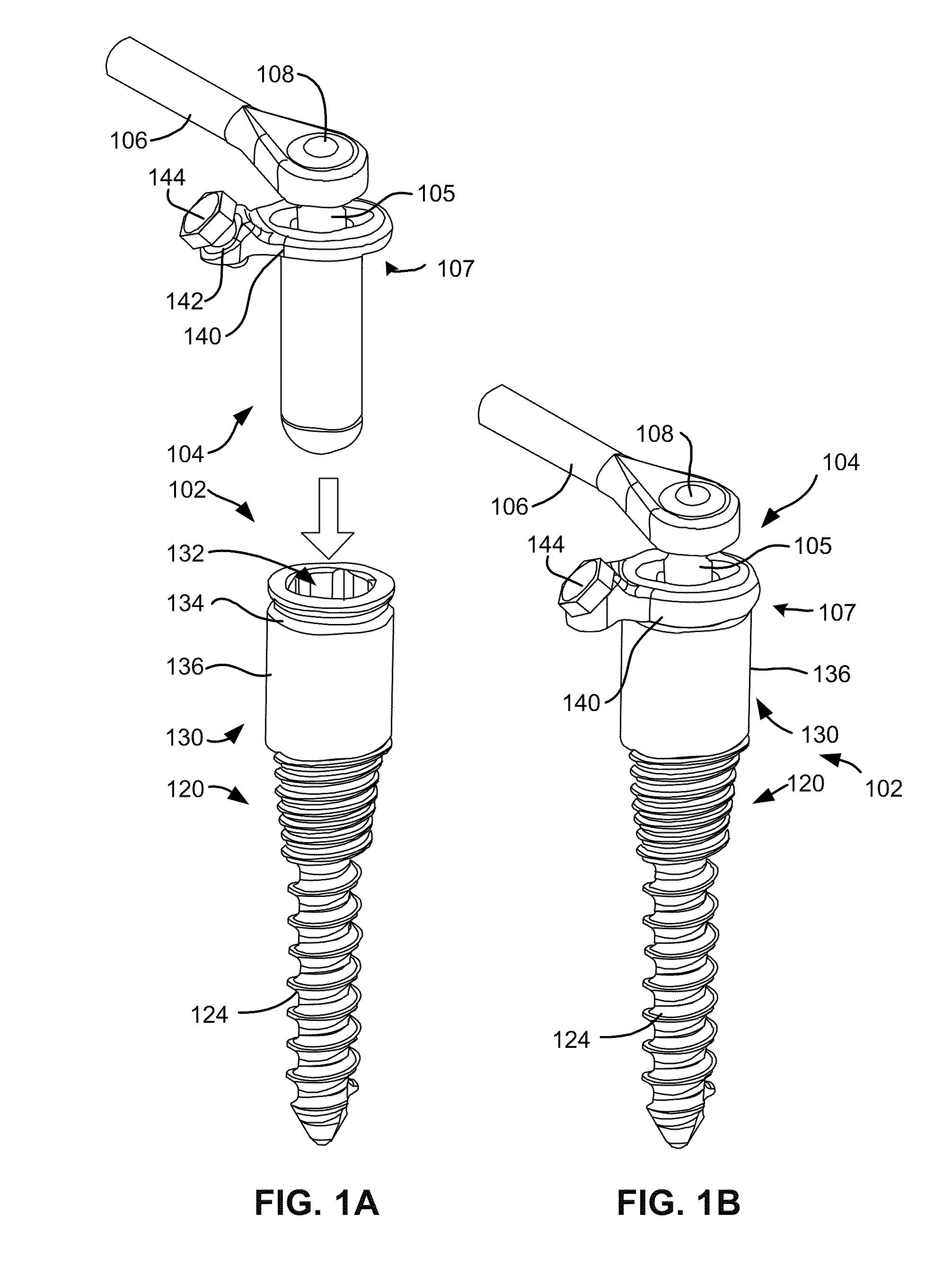

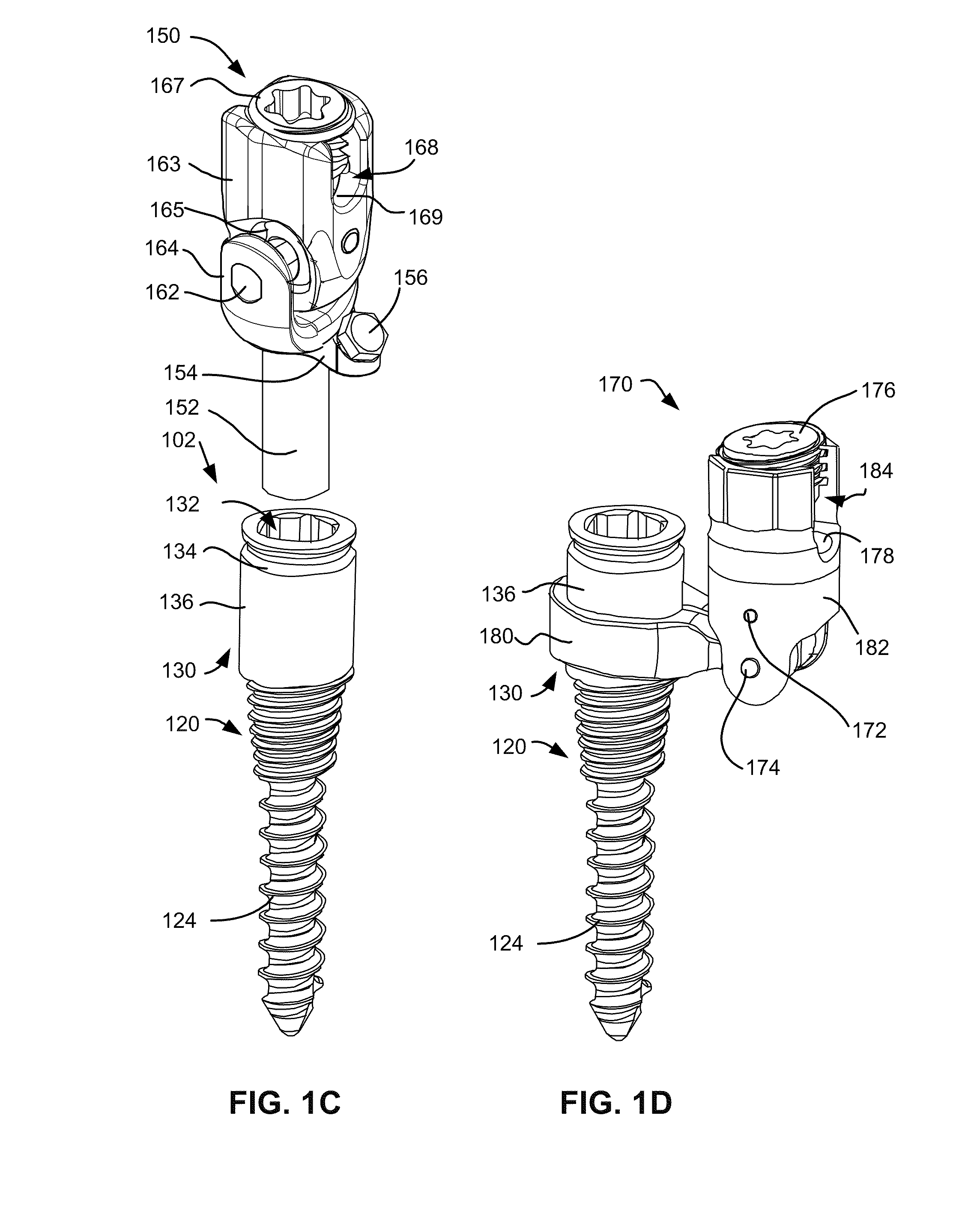

Dynamic/static facet fixation device and method

InactiveUS20070233092A1Facilitates dynamic and static stabilizationDynamic stabilityInternal osteosythesisJoint implantsSacroiliac jointFacet joint

A facet fixation system facilitates dynamic or static stabilization with few exposed components. A first anchor component is adapted for implantation through a facet joint and into intra-pedicle bone, and a second anchor component is adapted for fixation to the outer surface of the facet joint. A connector component connects the first and second anchor components. The connector component may be at least partially elastic, facilitating a dynamic stabilization of a facet joint, or rigid, facilitating a static stabilization of a facet joint.

Owner:MEDICAL DESIGNS

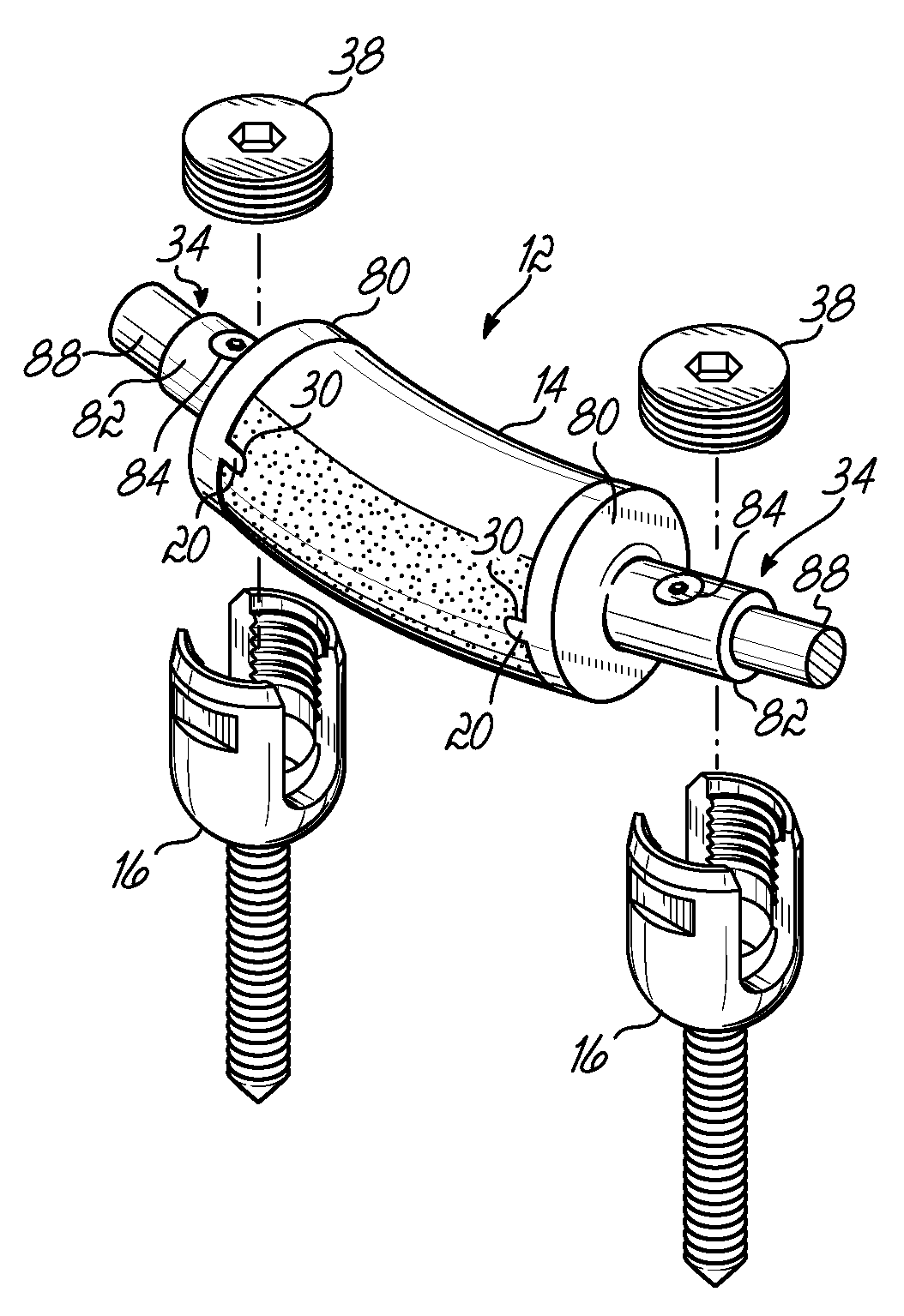

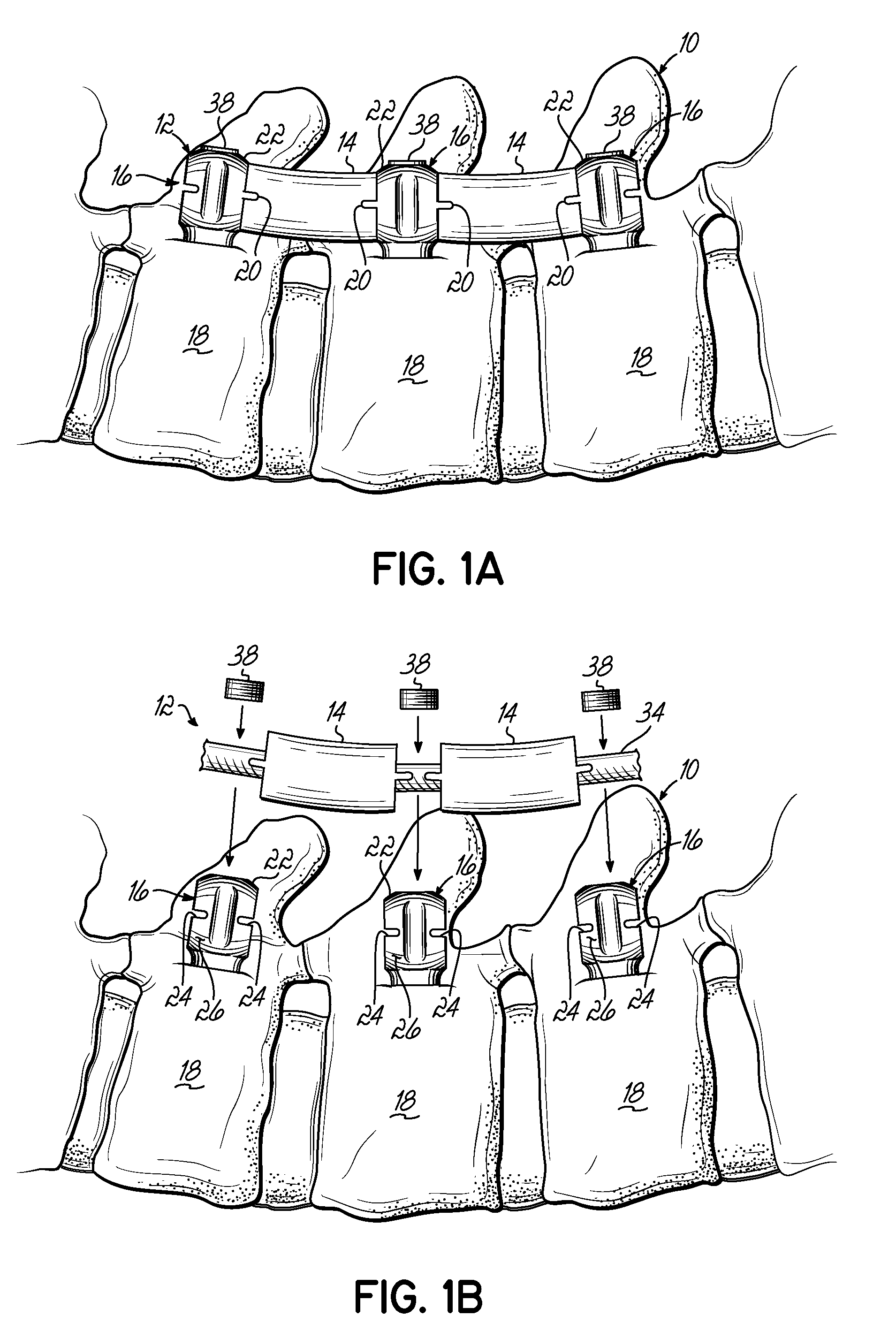

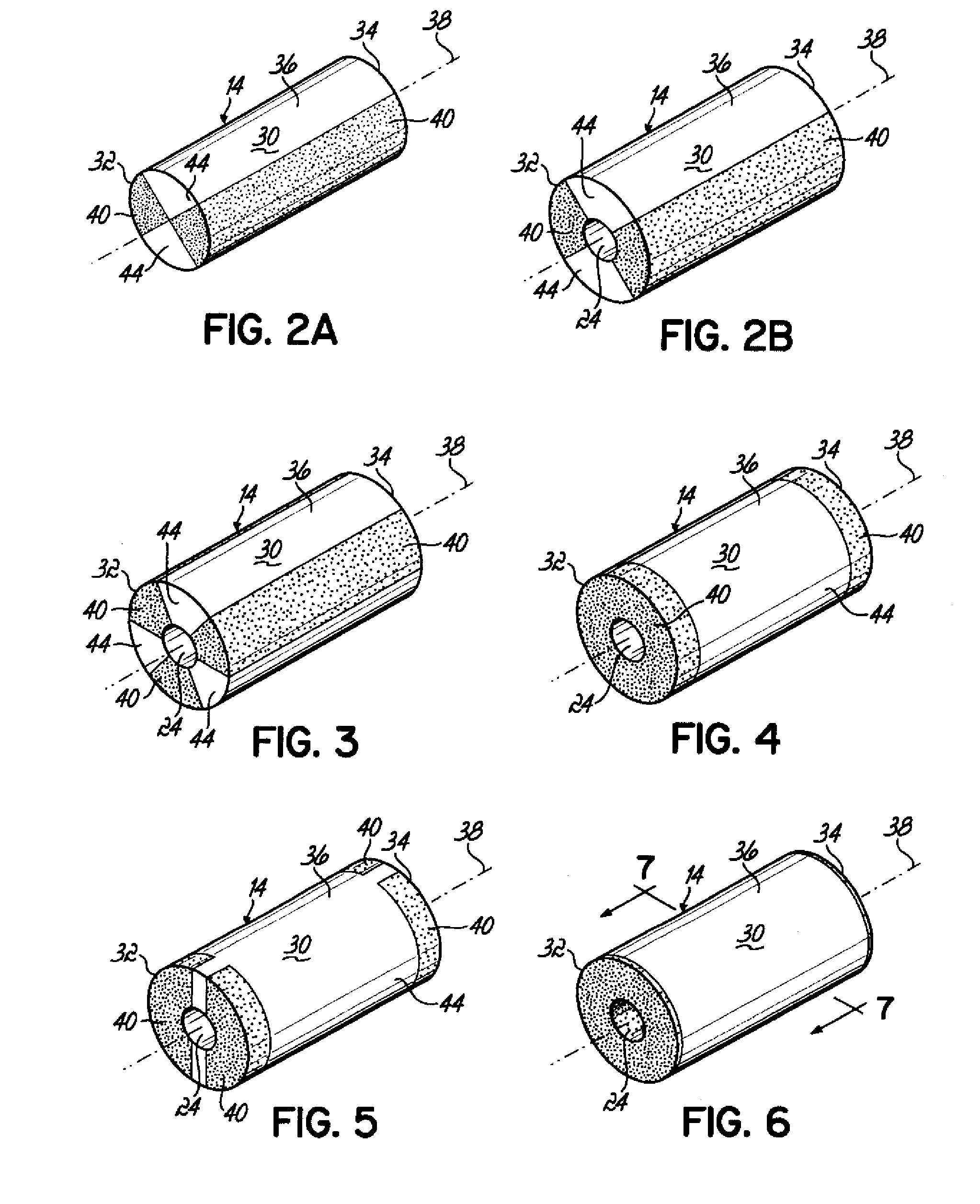

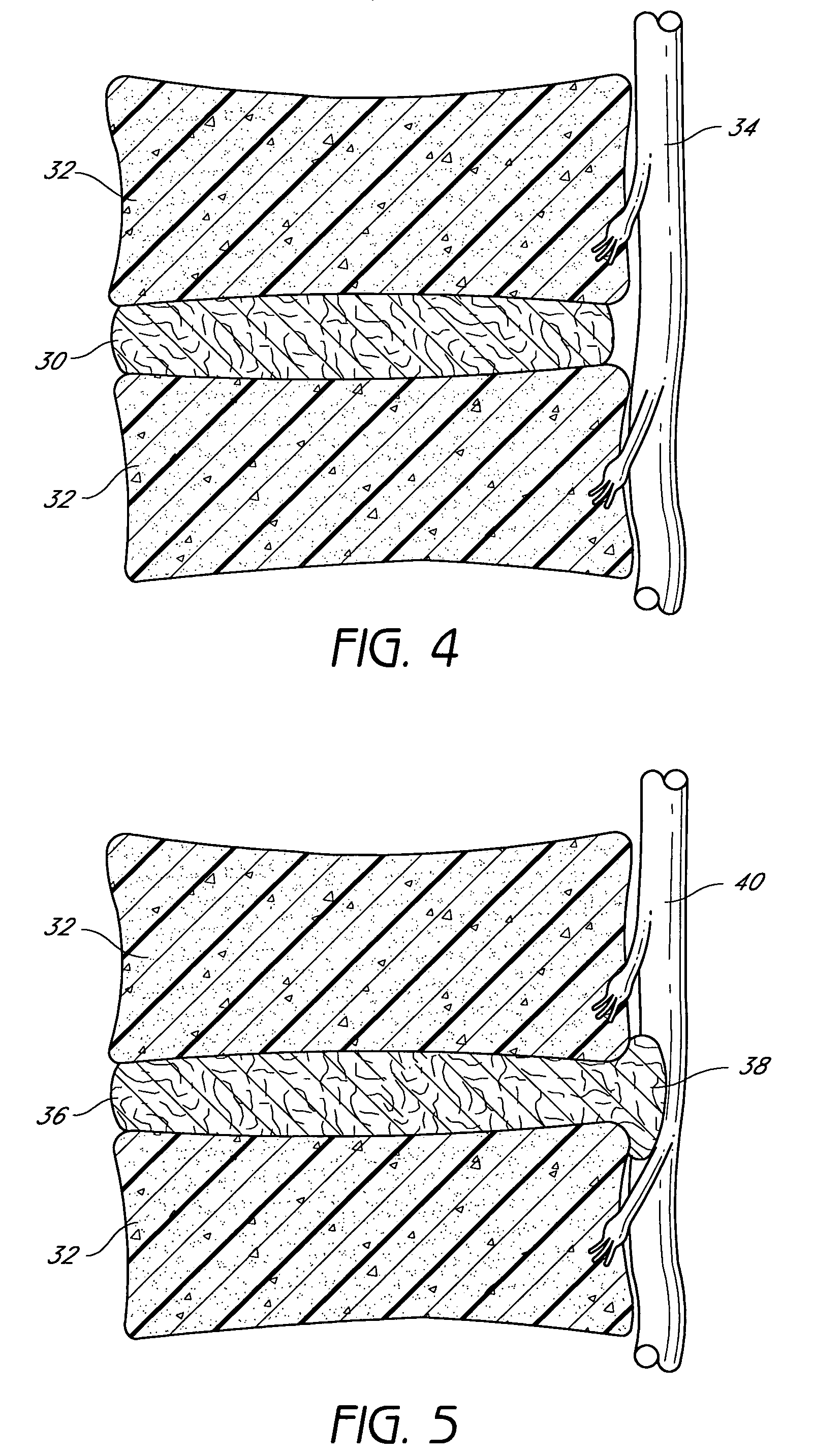

Pre-Curved Flexible Member For Providing Dynamic Stability To A Spine

InactiveUS20090093846A1Provide dynamic stabilityDynamic stabilitySuture equipmentsInternal osteosythesisEngineering

A pre-curved flexible member is provided for use with a dynamic stabilization system or implant to provide dynamic stability to a person's spine. In one embodiment, the pre-curved flexible member includes a pre-curved body having an outer surface and opposing ends with a curved intermediate portion extending therebetween. Each of the opposing ends includes retention features, for example notches and / or protrusions, for cooperation with retention features on a corresponding anchor member to securely retain the pre-curved flexible member therebetween.

Owner:ZIMMER SPINE INC

Spinal rod connectors, methods of use, and spinal prosthesis incorporating spinal rod connectors

InactiveUS8430916B1Dynamic stabilityReduces and prevents changeInternal osteosythesisJoint implantsProsthesisEngineering

A spinal rod connector is adapted to connect two spinal rods. The spinal rod connector includes first and second channels which are defined in a housing. The first and second channels can be urged together in order to capture first and second spinal rods when a fastener is actuated. The spinal rod connector allows the first and second rods to be positioned relative to each other in one of a parallel and a non-parallel manner prior to the fastener locking the first and second spinal rods in position.

Owner:SPARTEK MEDICAL

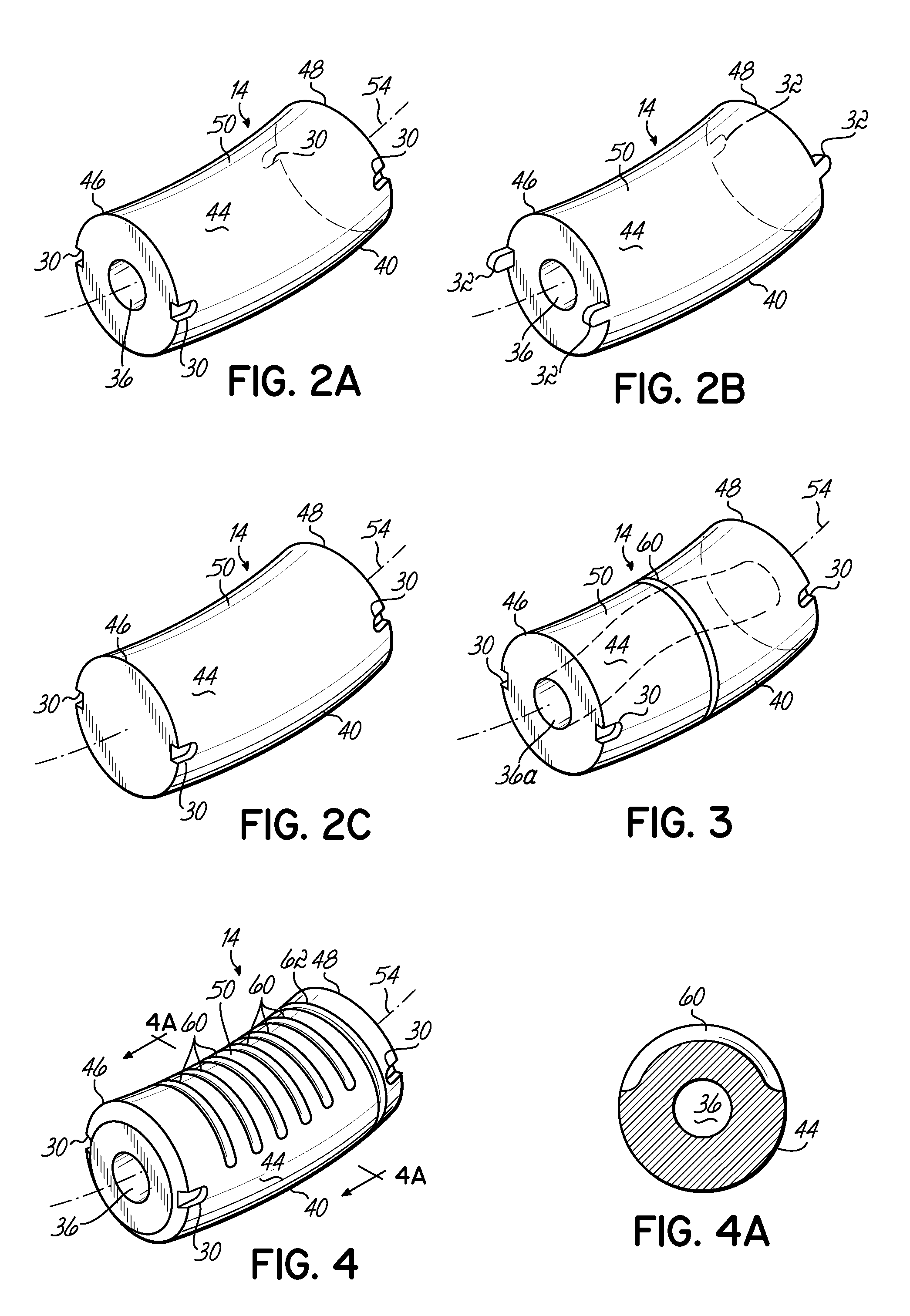

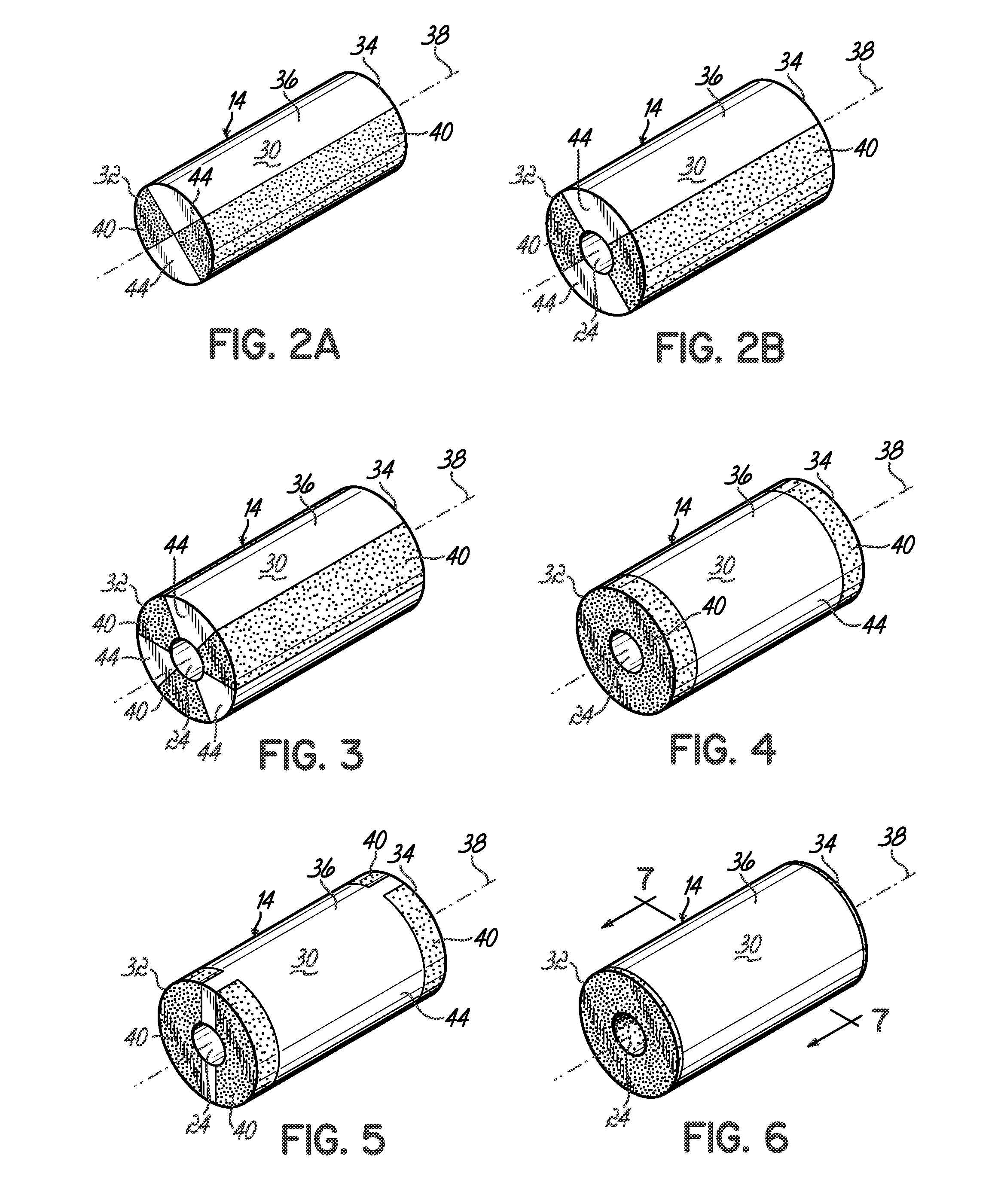

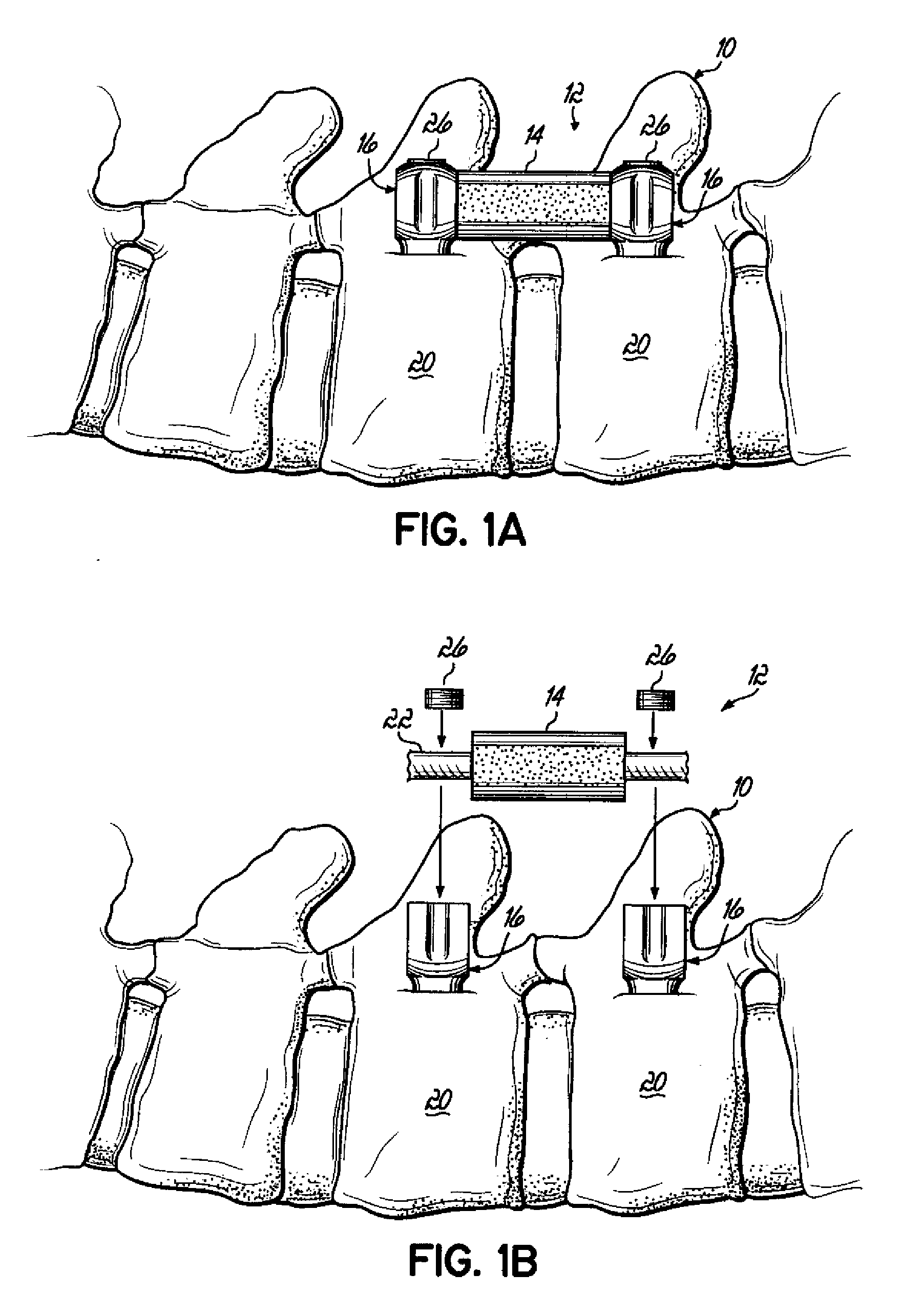

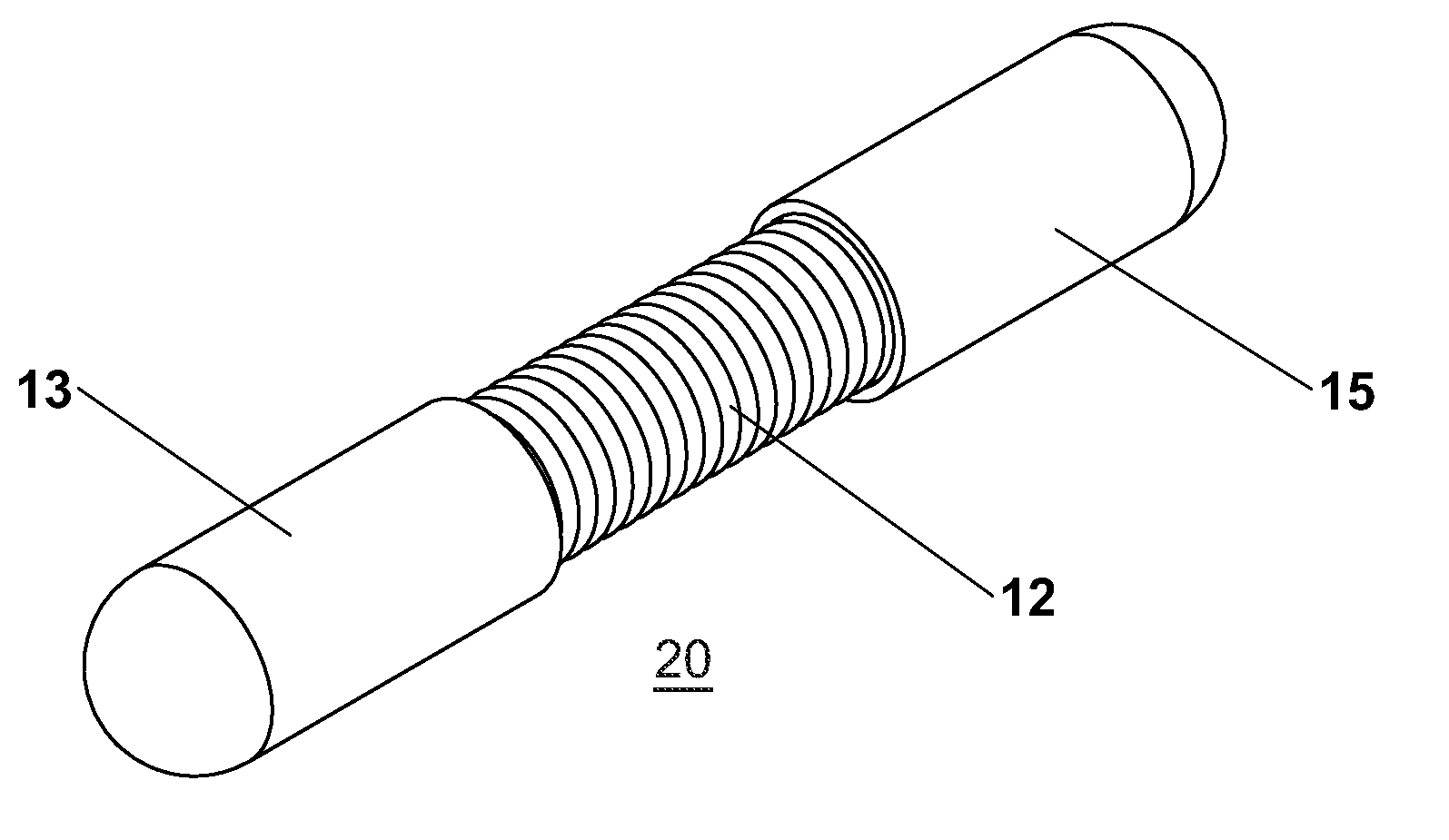

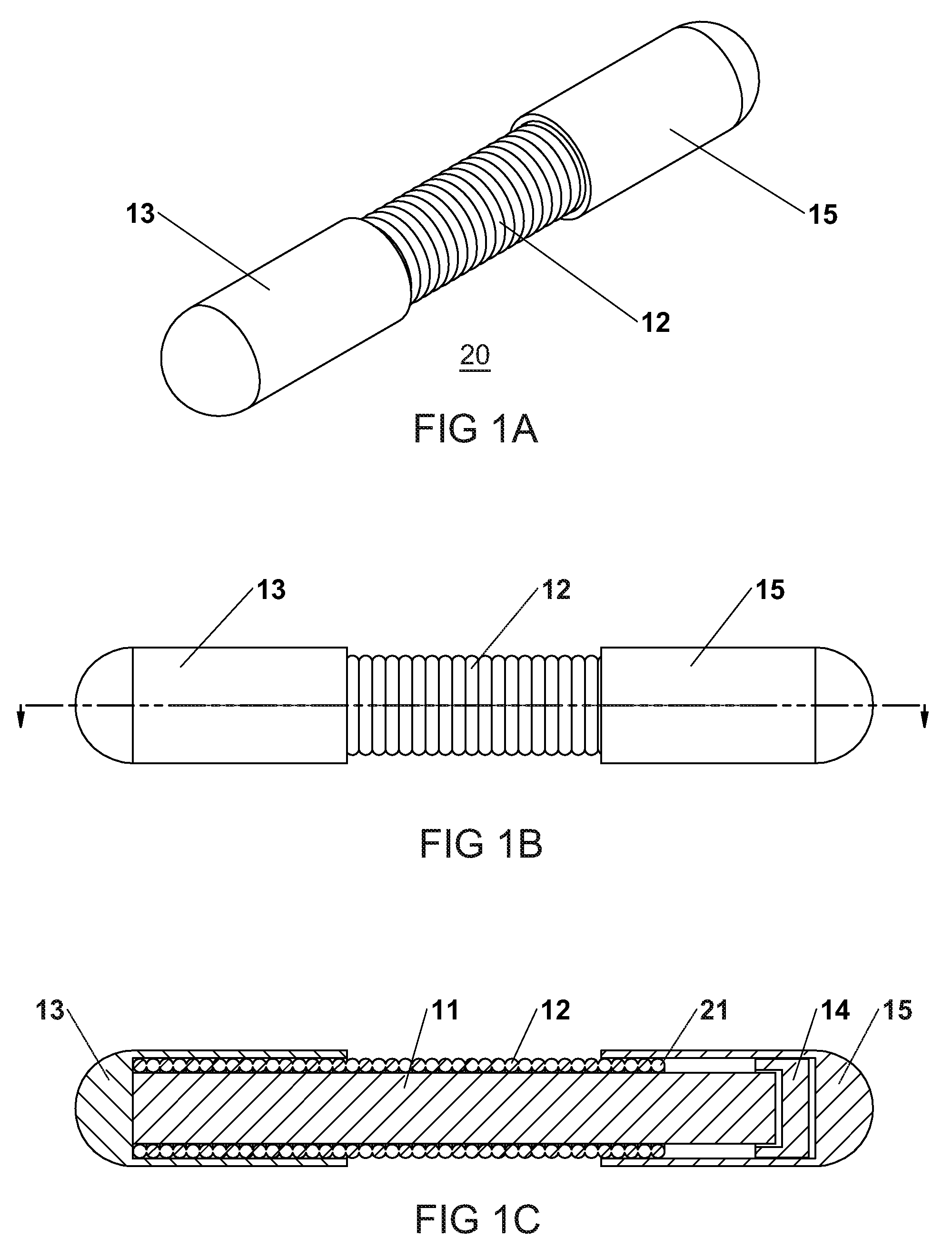

Flexible member with variable flexibility for providing dynamic stability to a spine

ActiveUS20080319486A1Variable flexibilityDynamic stabilityInternal osteosythesisDiagnosticsEngineering

The present invention relates to spinal support devices and, more specifically, to a flexible member having variable flexibility for use with a dynamic stabilization system or implant to provide dynamic stability to a person's spine. The flexible member generally includes a first material having a first portion including a first material having a first elasticity and a second portion including a second material having a second elasticity greater than the first to provide the flexible member with a variable flexibility.

Owner:ZIMMER BIOMET SPINE INC

Flexible Member with Variable Flexibility for Providing Dynamic Stability to a Spine

ActiveUS20090093845A1Dynamic stabilityVariable flexibilityInternal osteosythesisJoint implantsEngineering

The present invention relates to spinal support devices and, more specifically, to a flexible member having variable flexibility for use with a dynamic stabilization system or implant to provide dynamic stability to a person's spine. The flexible member generally includes a first material having a first portion including a first material having a first elasticity and a second portion including a second material having a second elasticity greater than the first to provide the flexible member with a variable flexibility.

Owner:ZIMMER BIOMET SPINE INC

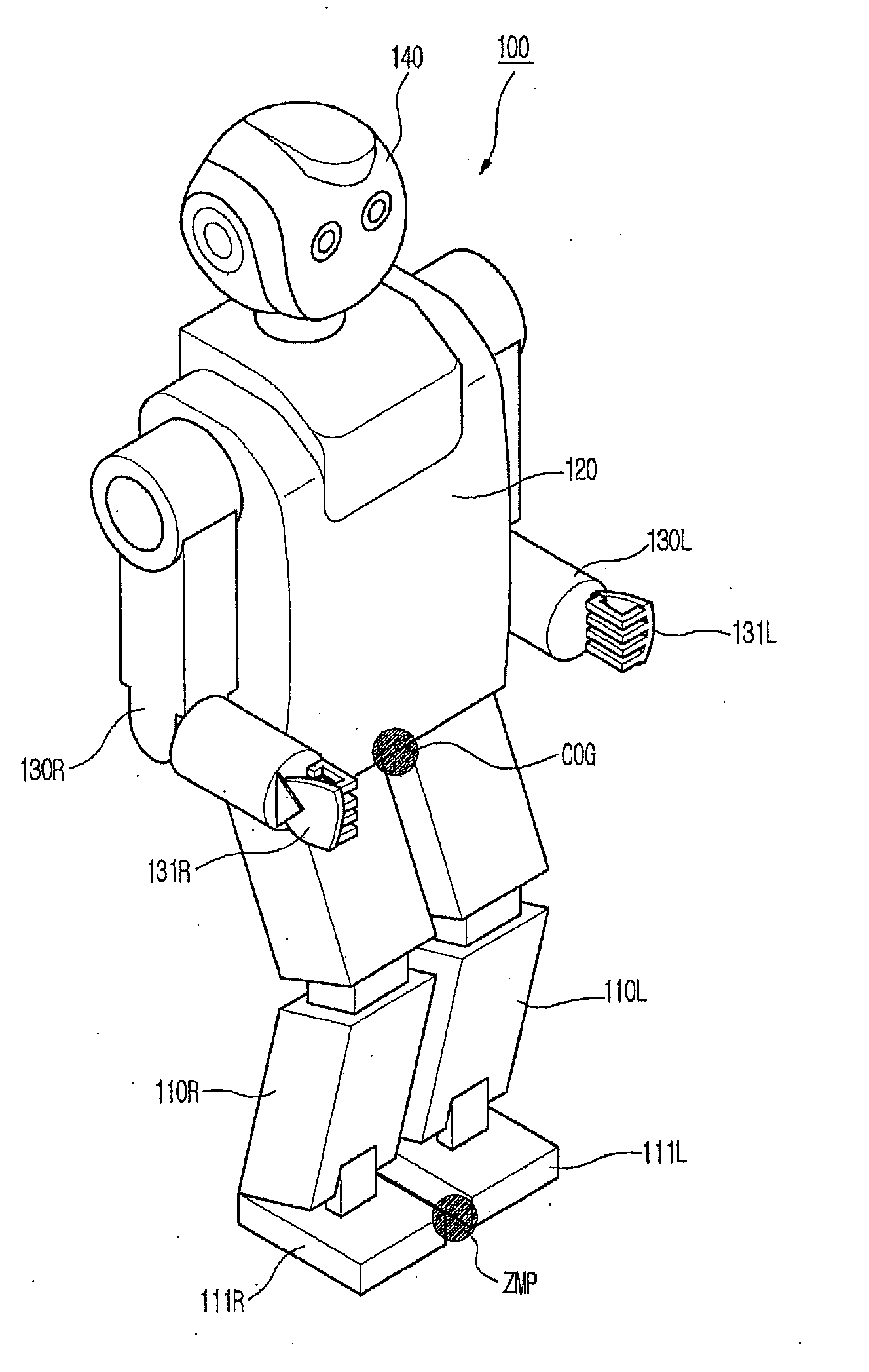

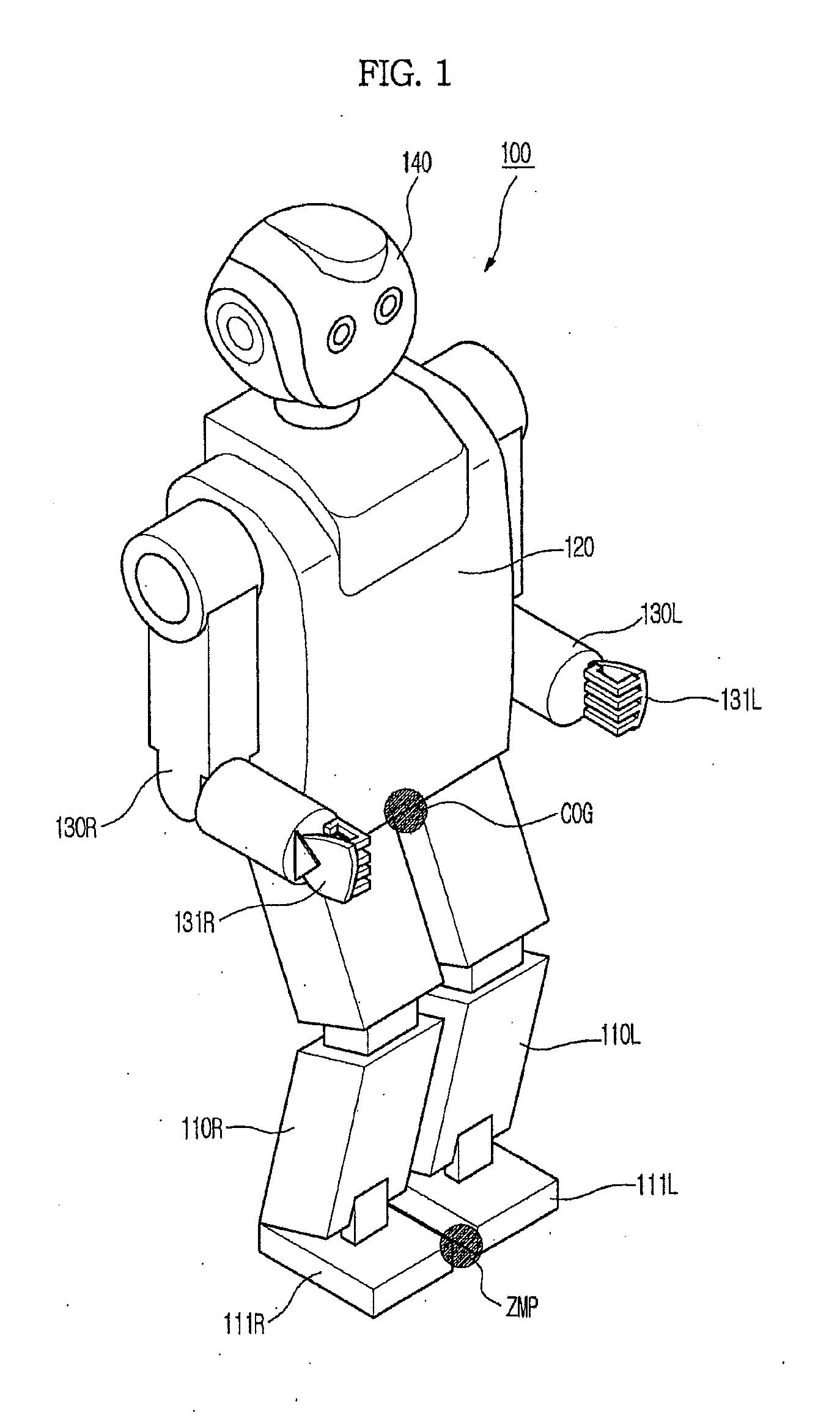

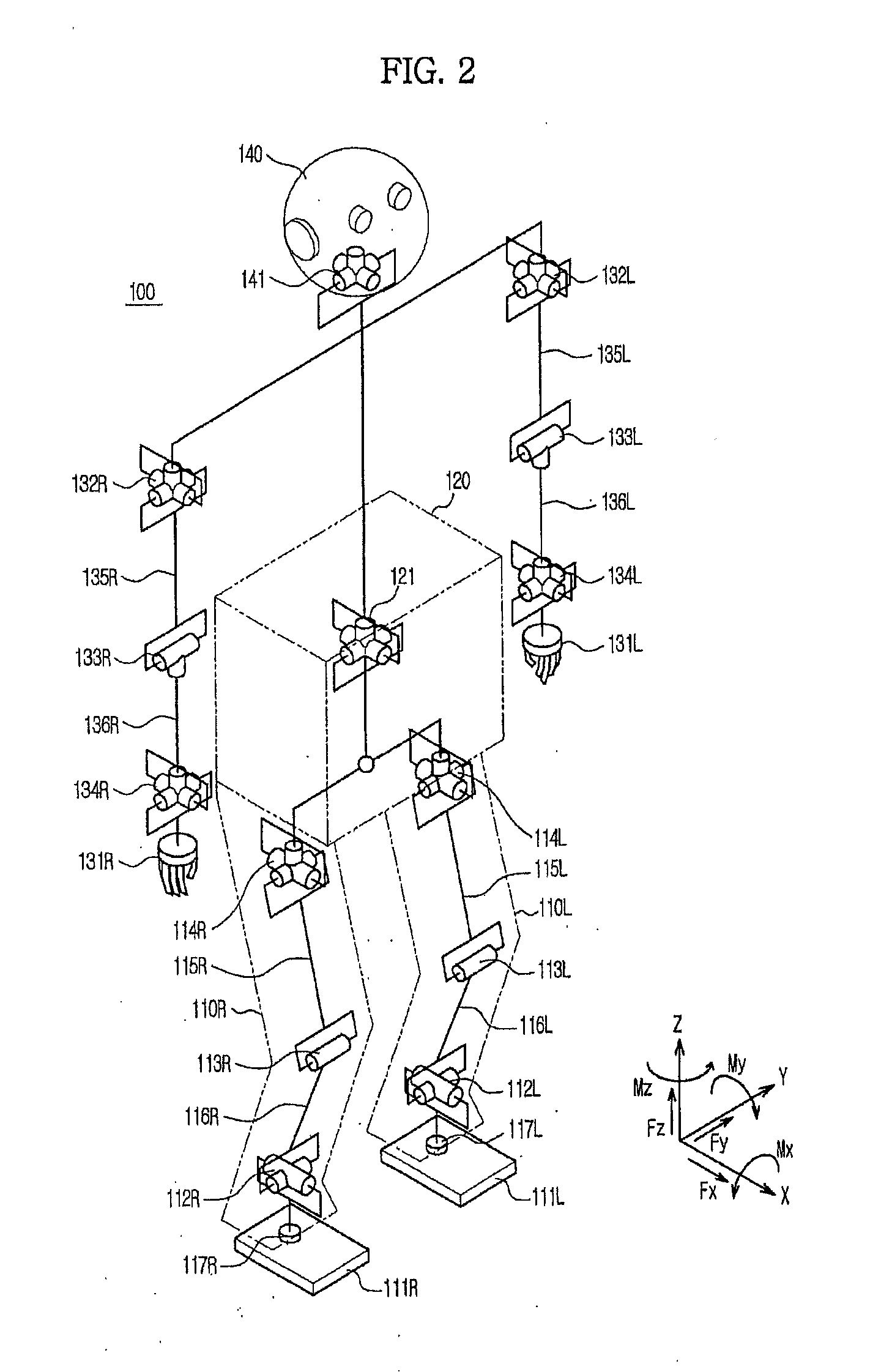

Path planning apparatus of robot and method and computer-readable medium thereof

ActiveUS20110106307A1Improves path planning performanceImprove performanceHybrid vehiclesProgramme-controlled manipulatorMomentumEngineering

An apparatus, method and computer-readable medium planning a path of a robot by planning an optimal path while satisfying a dynamic constraint. In a process of searching for a motion path from a start point to a goal point while extending a tree from a start point of a configuration space to generate a path, along which a manipulator of the robot is moved in order to perform a task, an optimal path is generated responsive to the dynamic constraint of the manipulator of the robot to generate stable motion satisfying momentum and Zero Moment Position (ZMP) constraint. Accordingly, path planning performance is improved and a path satisfying a kinematic constraint and a dynamic constraint is rapidly obtained.

Owner:SAMSUNG ELECTRONICS CO LTD

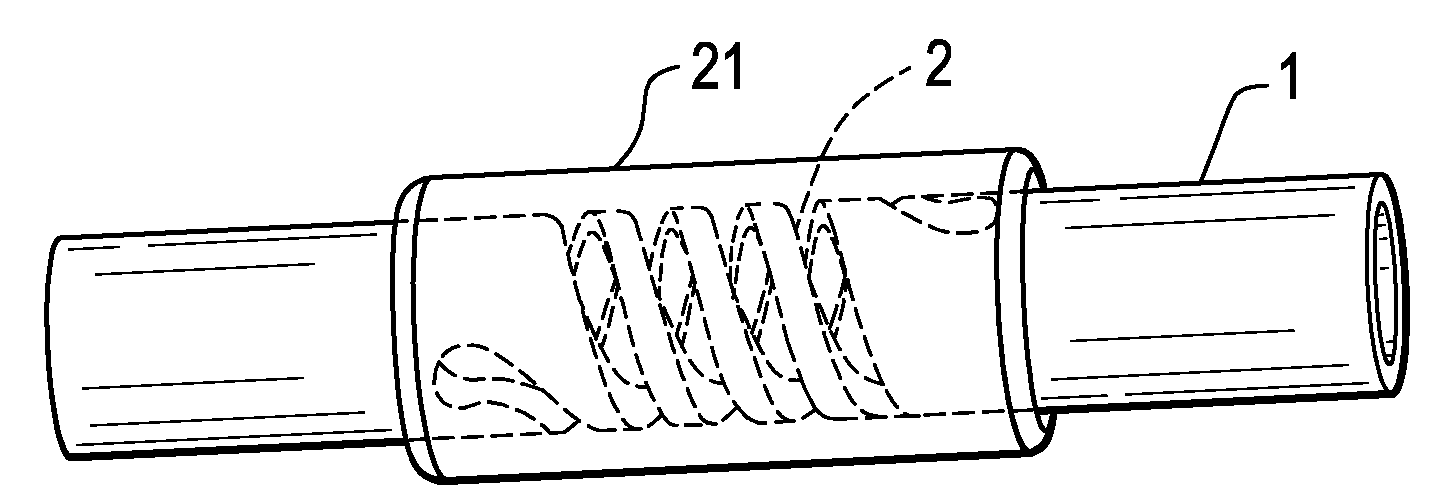

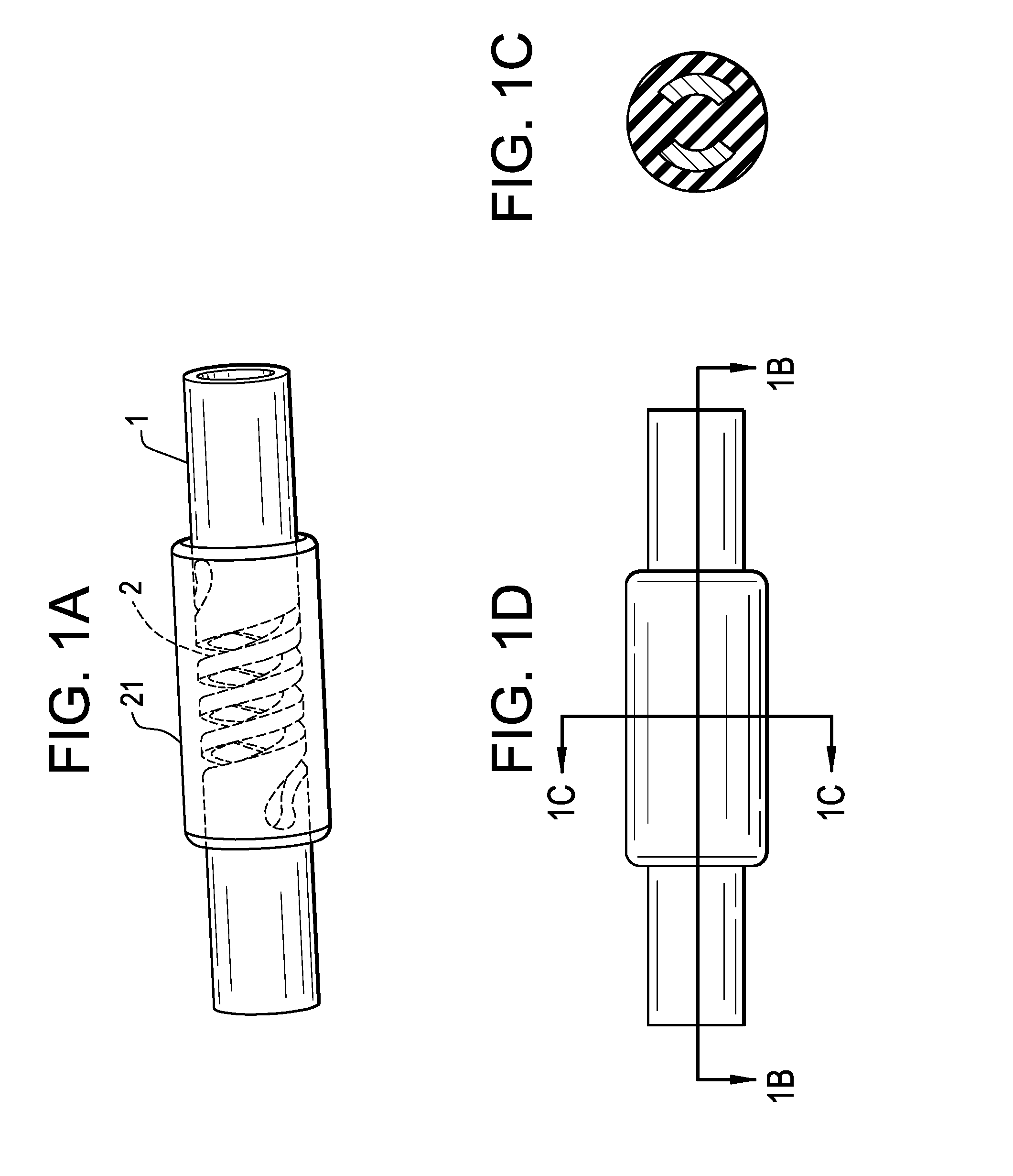

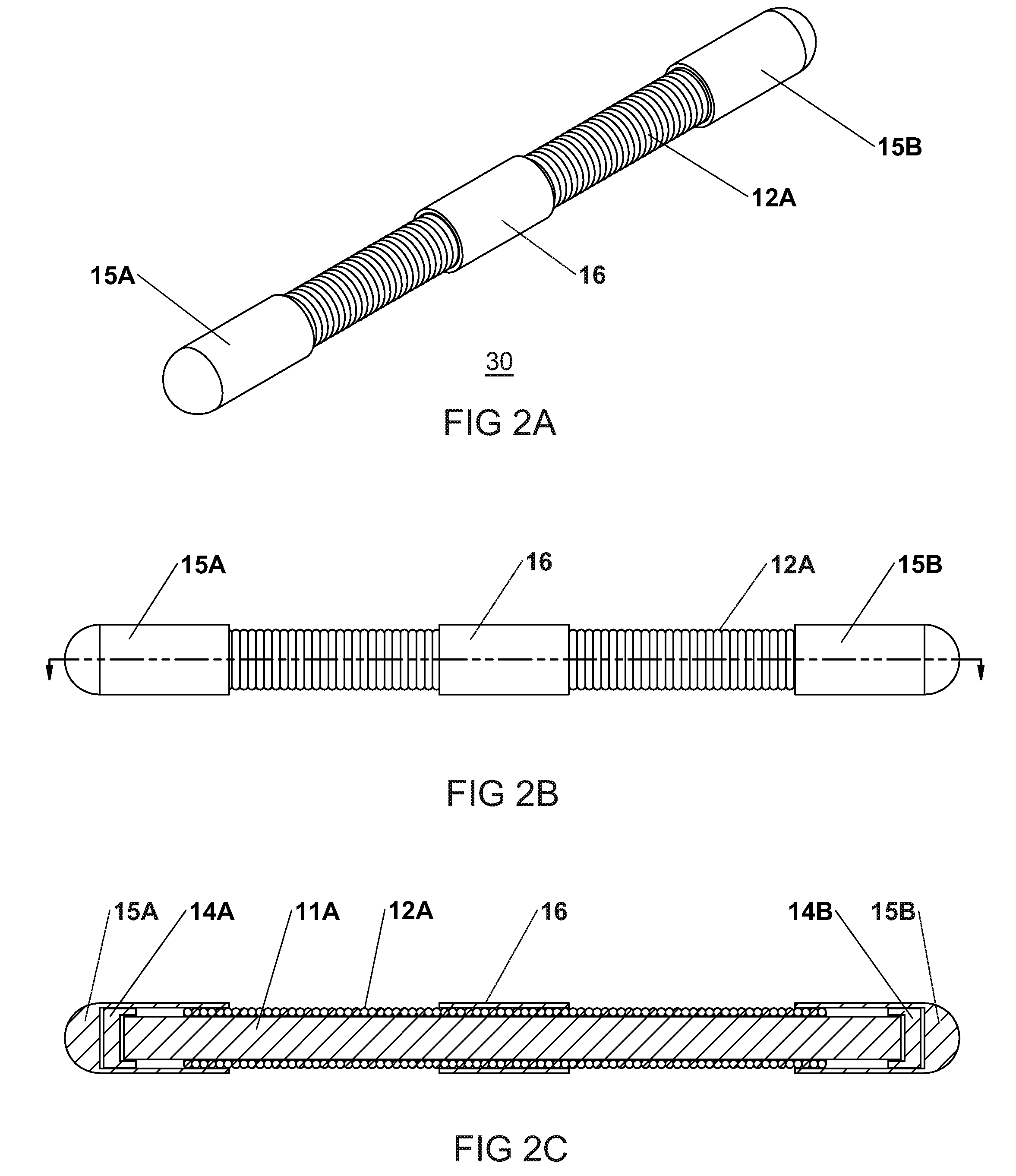

Flexible Spinal Rod With Elastomeric Jacket

InactiveUS20090088782A1Reduce strainRelieve pressureInternal osteosythesisProsthesisBiomedical engineeringSpinal column

A flexible rod for use in spinal stabilization having a tube having a helical slit defining a gap and an elastomeric jacket provided in the throughbore of the tube, within the gap, and upon the outer surface of the tube.

Owner:DEPUY SYNTHES PROD INC

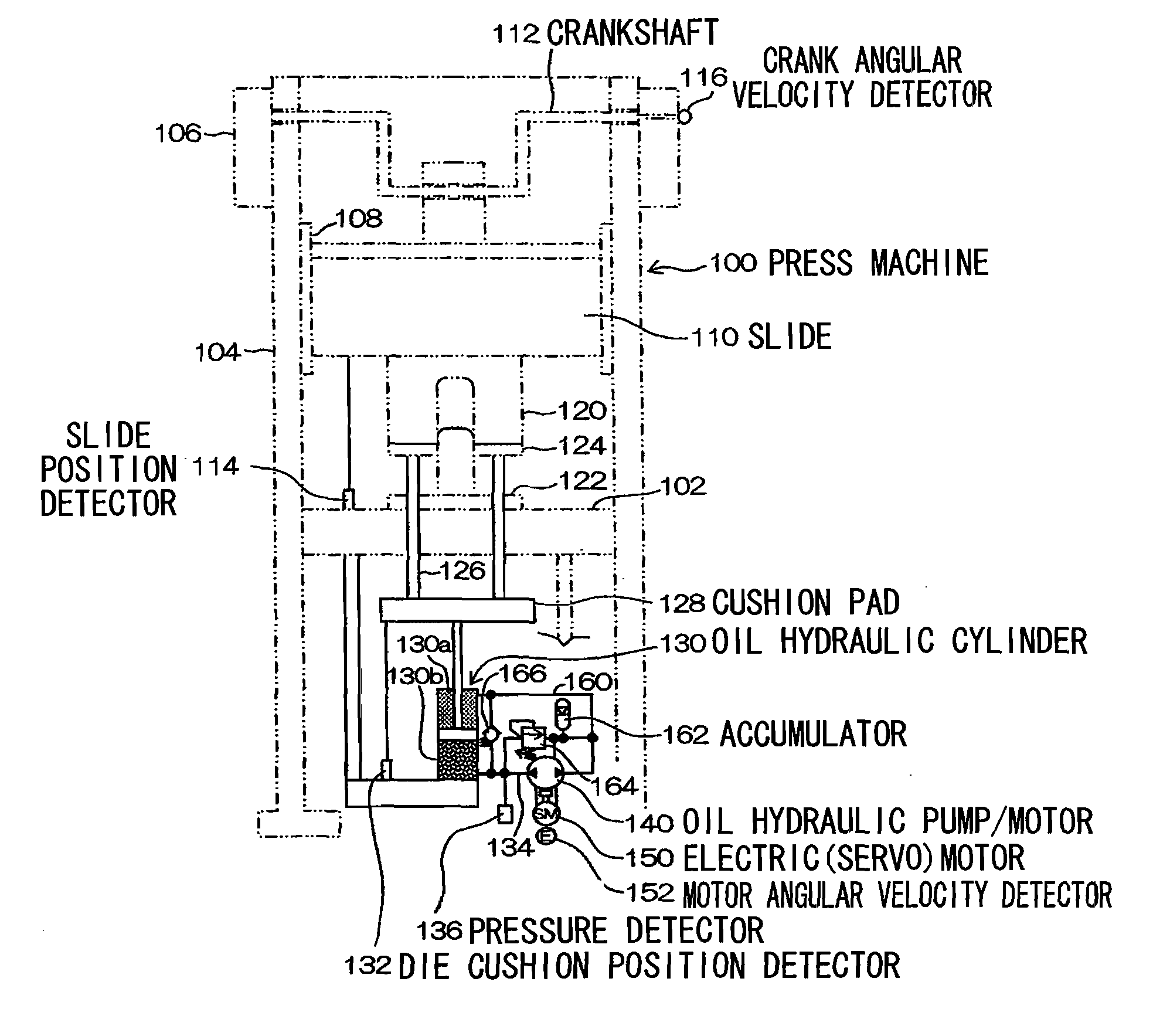

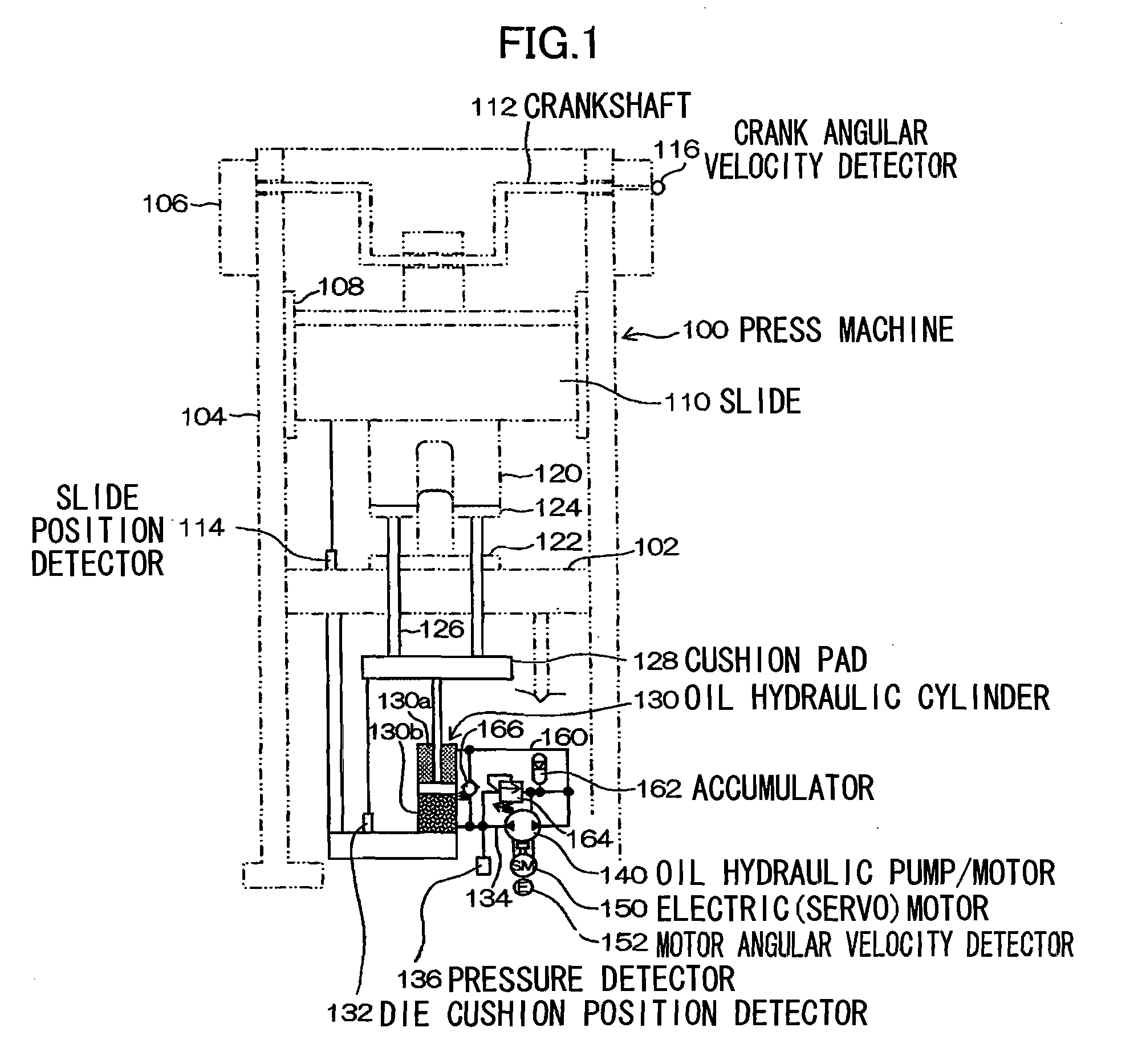

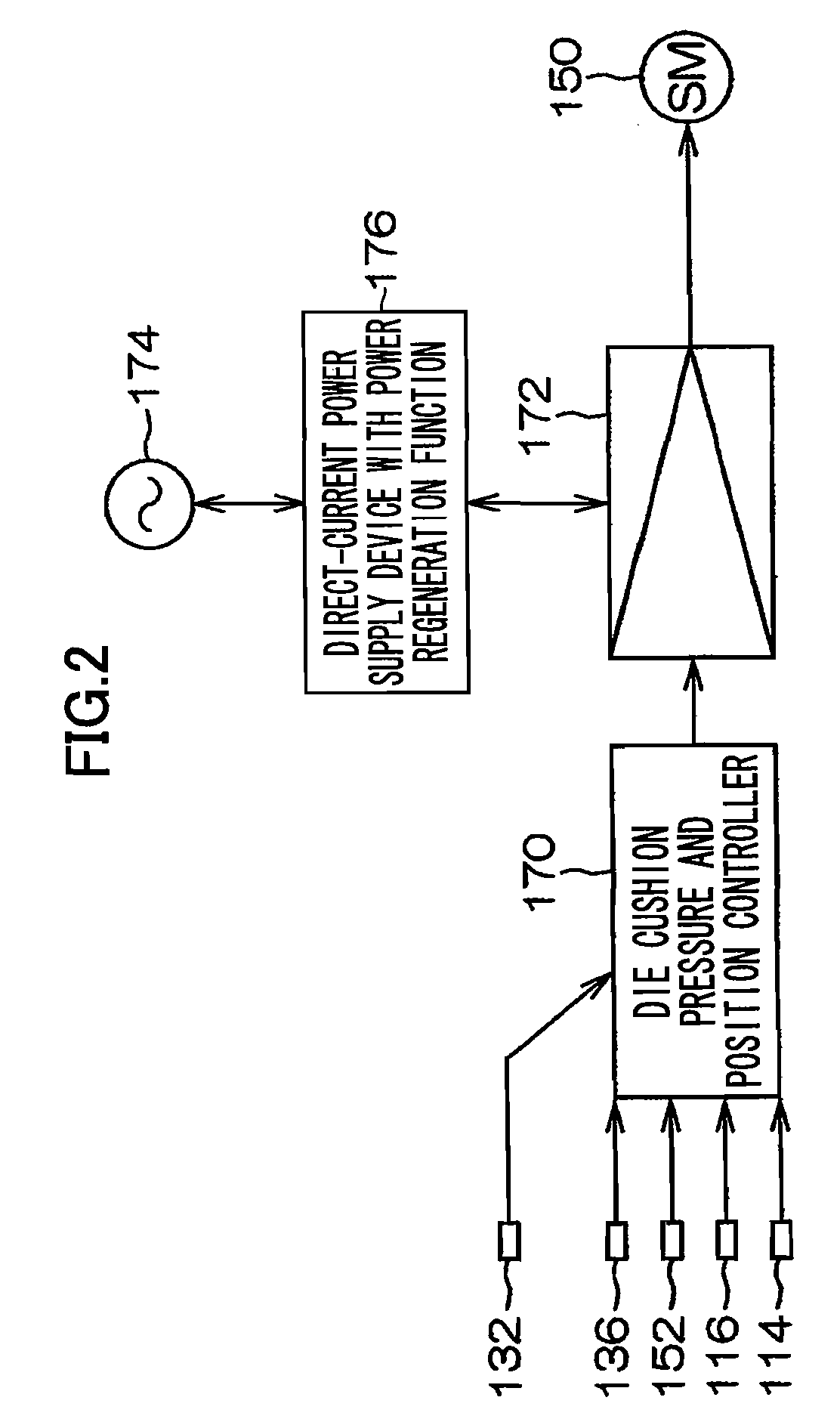

Die cushion device for press machine

ActiveUS20090071218A1Improve responseAvoid it happening againServometer circuitsForging press detailsHydraulic cylinderCushioning

A die cushion apparatus of a press machine in which a discharge opening of a fluid hydraulic pump / motor is directly connected to a pressure chamber on a cushion pressure production side of a fluid hydraulic cylinder and the torque of a rotating shaft of the fluid hydraulic pump / motor is controlled by an electric motor to control a pressure (die cushion pressure) of the pressure chamber on the cushion pressure production side. It is therefore possible to control the die cushion pressure with excellent responsiveness with respect to a die cushion pressure command and prevent occurrence of a surge pressure. The die cushion apparatus also has excellent energy efficiency since energy required for a die cushioning action that a cushion pad receives when effecting die cushioning of a press machine is regenerated as electrical energy through the fluid hydraulic cylinder, fluid hydraulic pump / motor, and electric motor.

Owner:AIDA ENG LTD

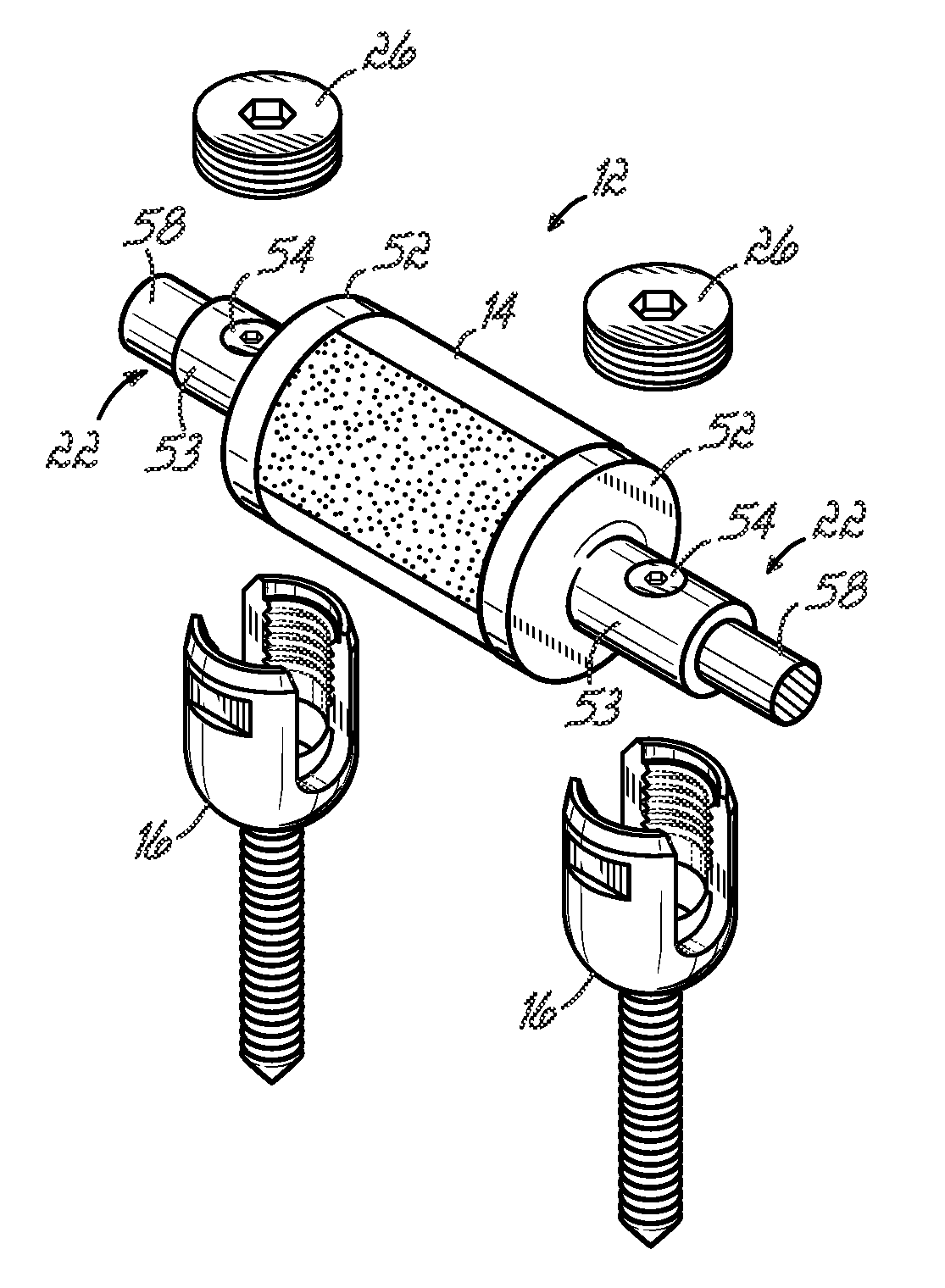

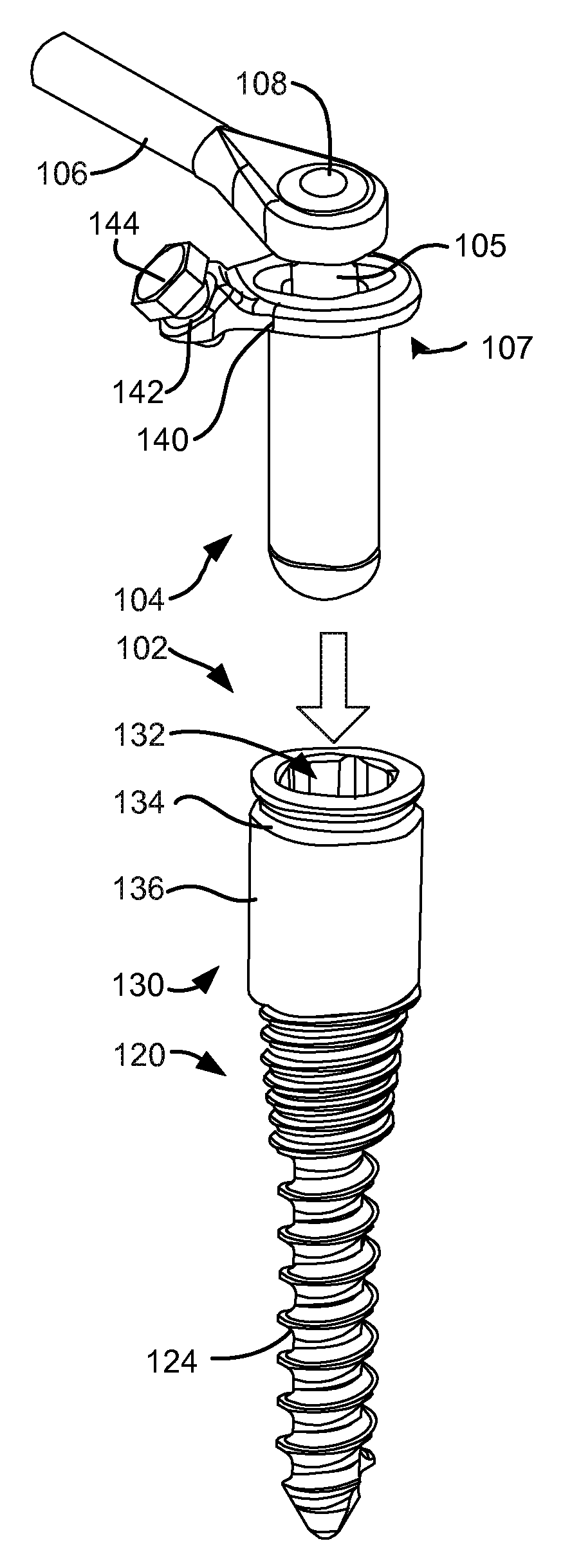

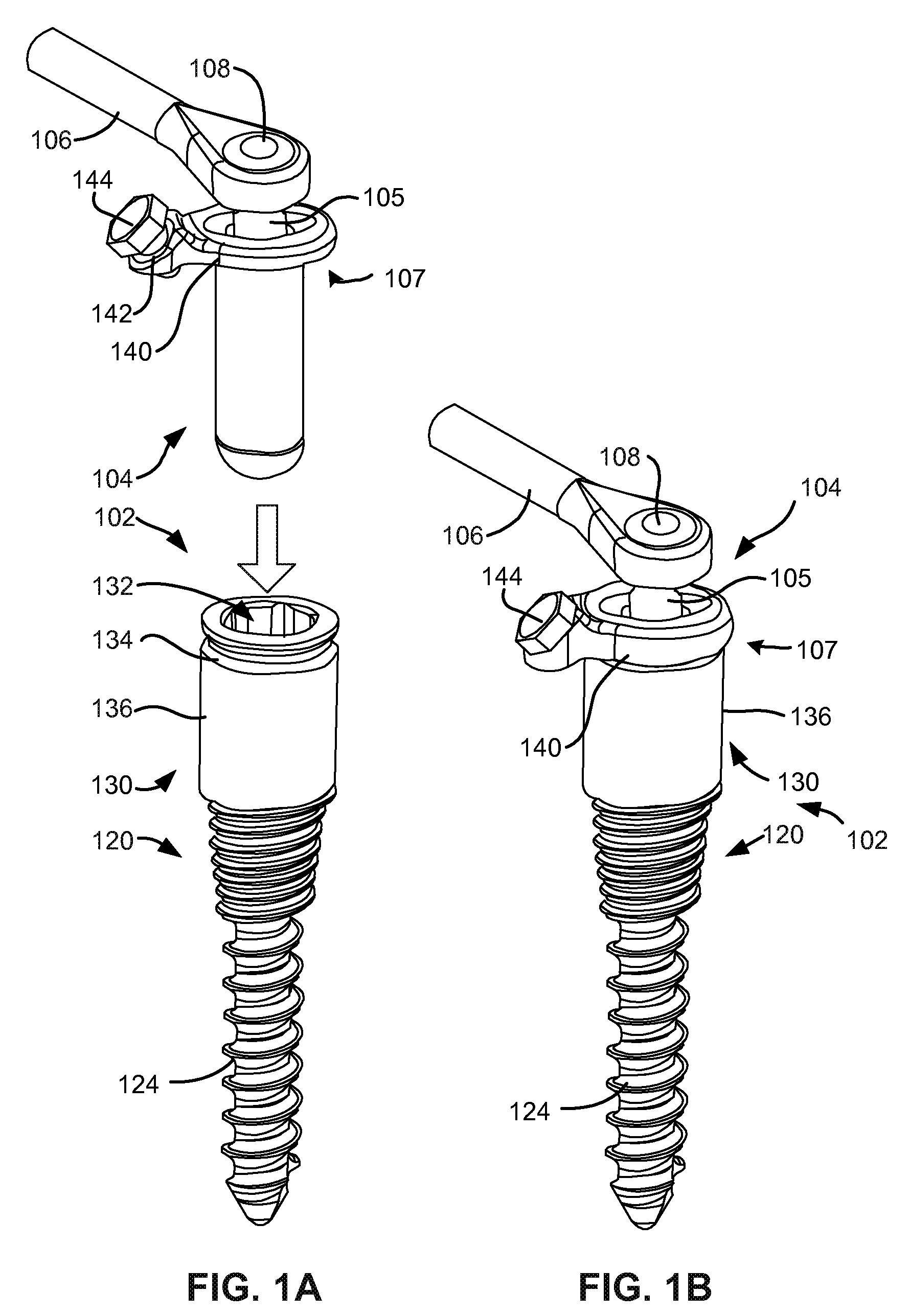

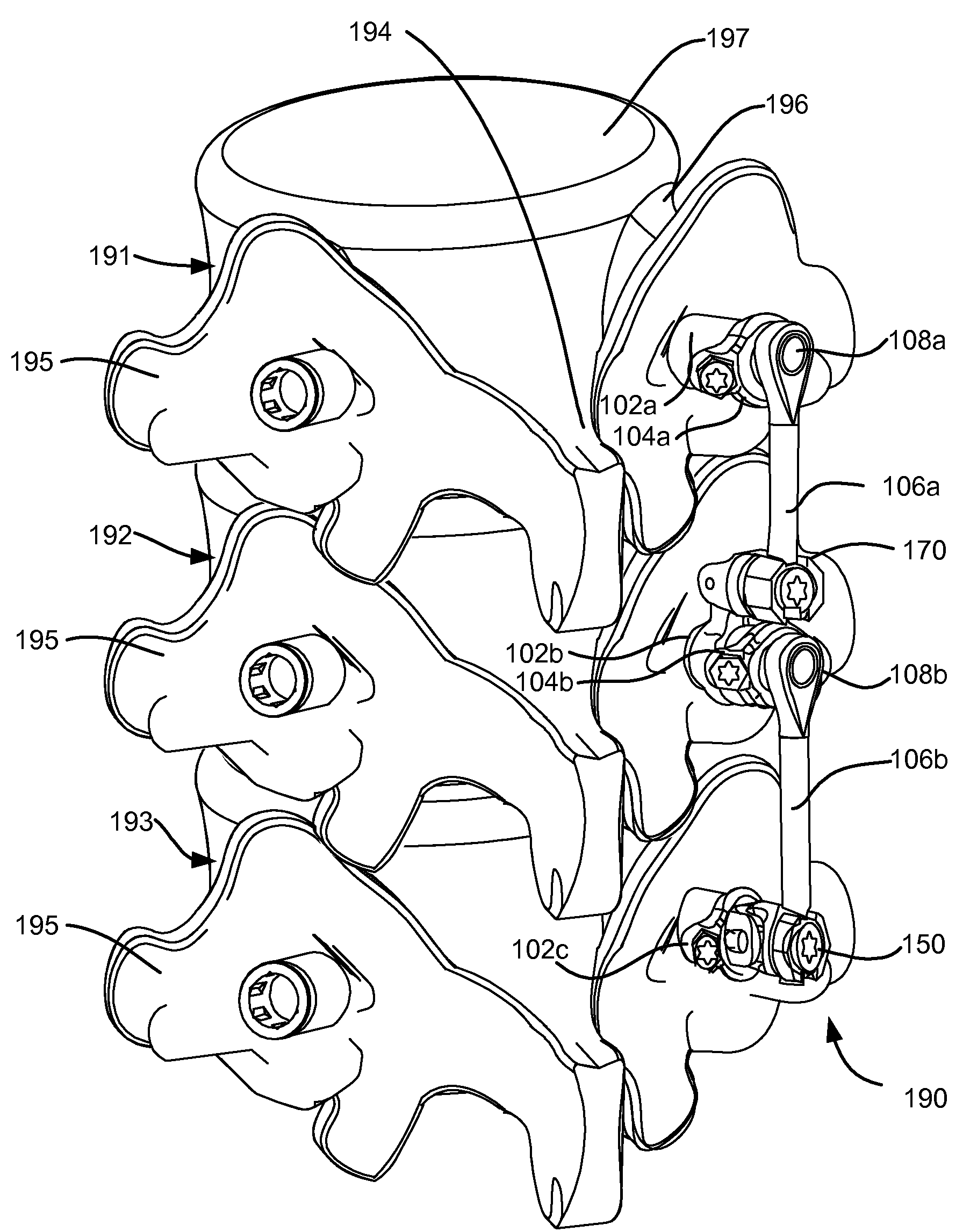

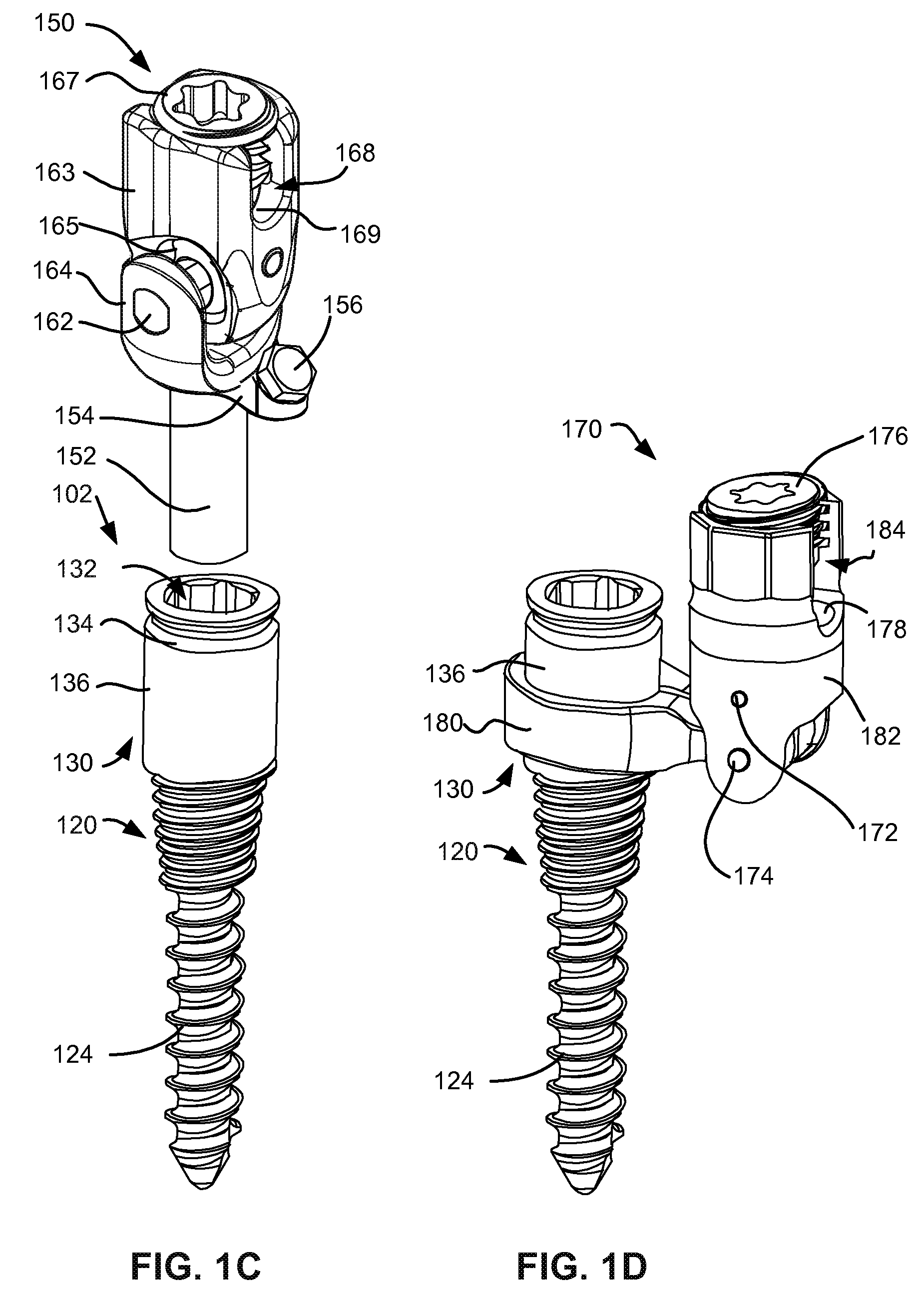

Load-sharing bone anchor having a durable compliant member and method for dynamic stabilization of the spine

InactiveUS20100036436A1Dynamic stabilityEasy to processSuture equipmentsInternal osteosythesisRange of motionSpinal anatomy

A dynamic bone anchor for anchoring a spine stabilization assembly which supports the spine while providing for the preservation of spinal motion. The dynamic bone anchor provides load sharing while preserving range of motion and reducing stress exerted upon the bone anchors and spinal anatomy. The dynamic bone anchor includes a deflectable post connected by a ball-joint to a threaded anchor. Deflection of the deflectable post is controlled by a durability enhanced compliant sleeve. The force / deflection properties of the dynamic bone anchor may be adapted to the anatomy and functional requirements of the patient. The dynamic bone anchor may be used as a component of a dynamic stabilization system which supports the spine while providing for the preservation of spinal motion.

Owner:SPARTEK MEDICAL

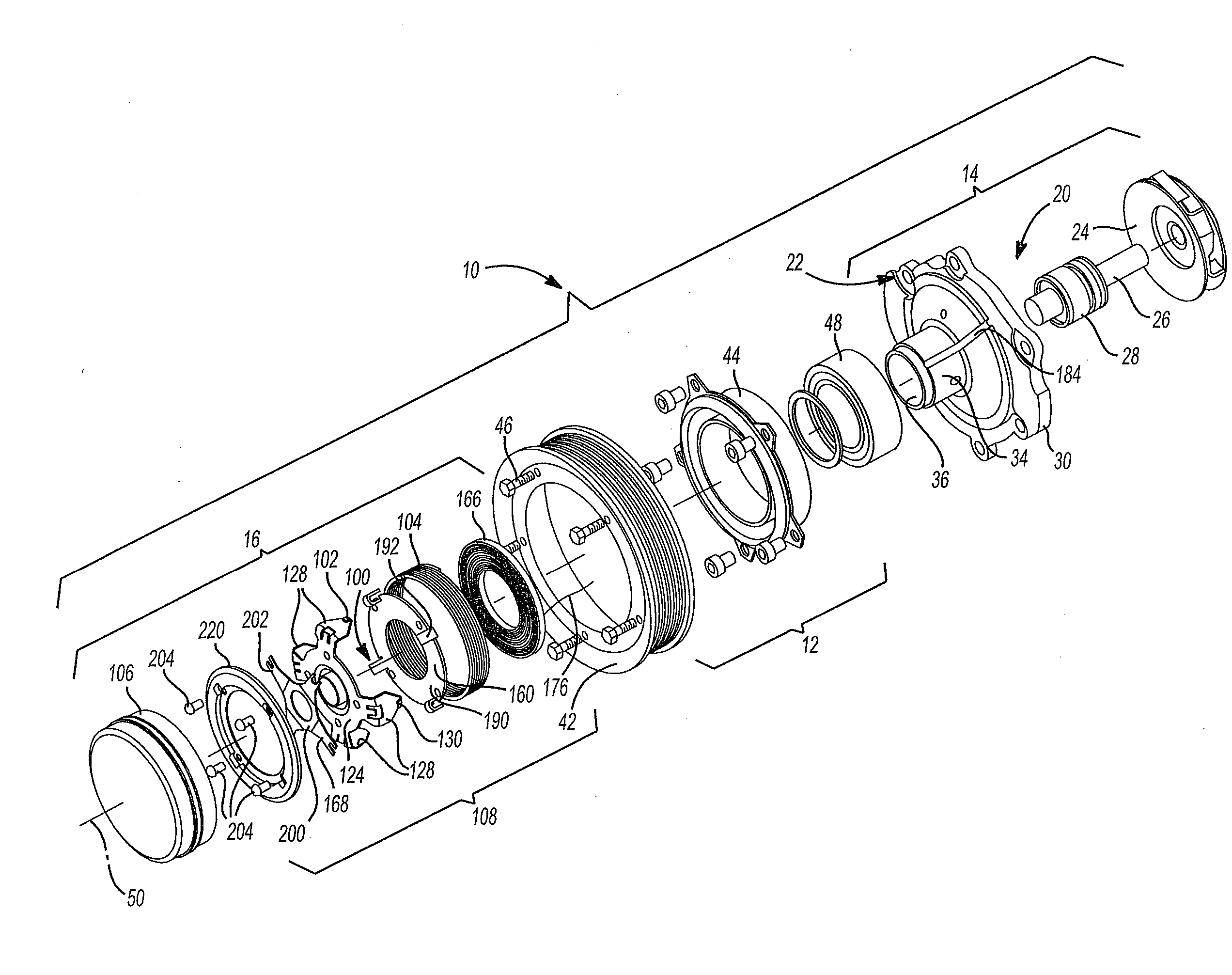

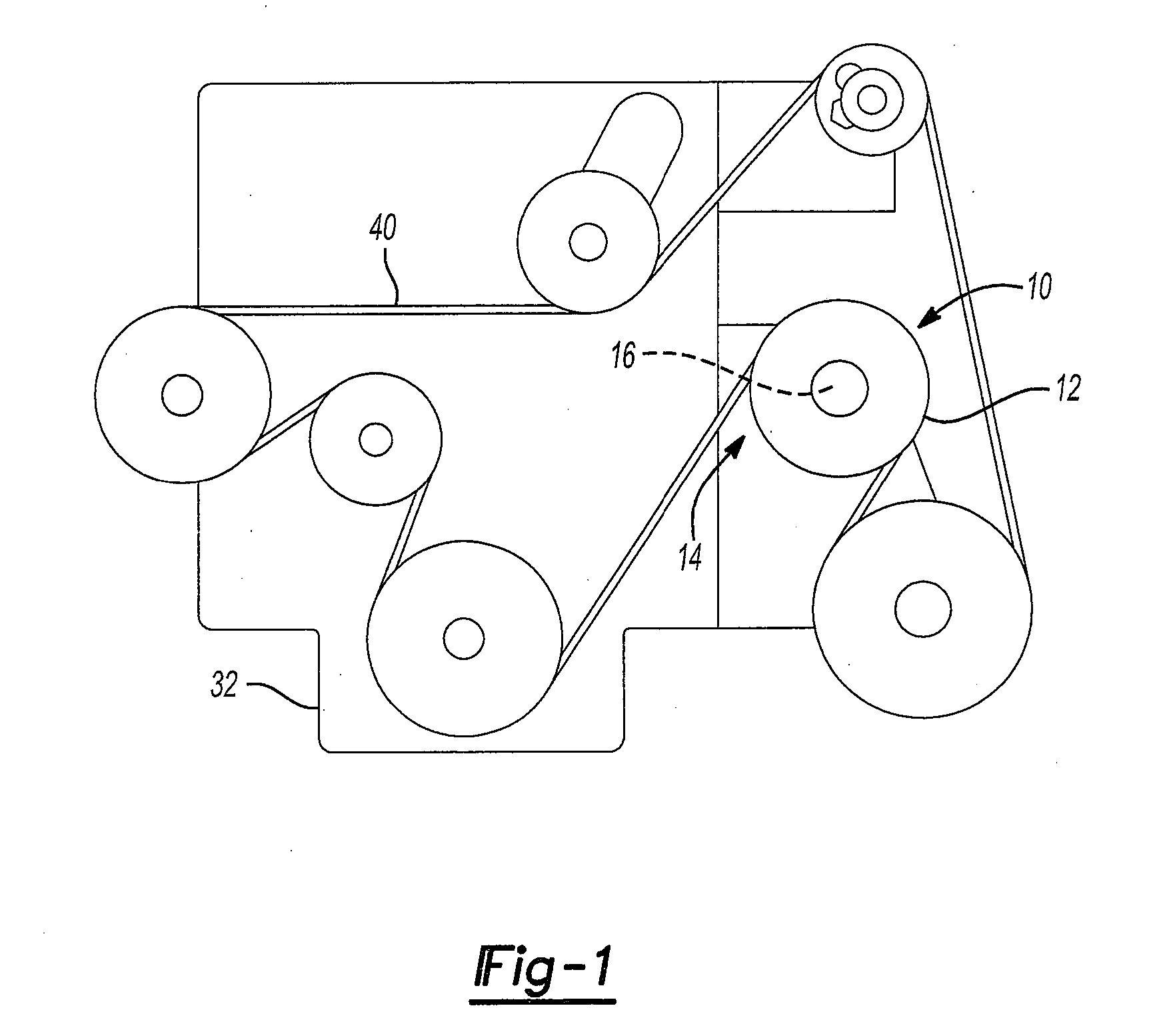

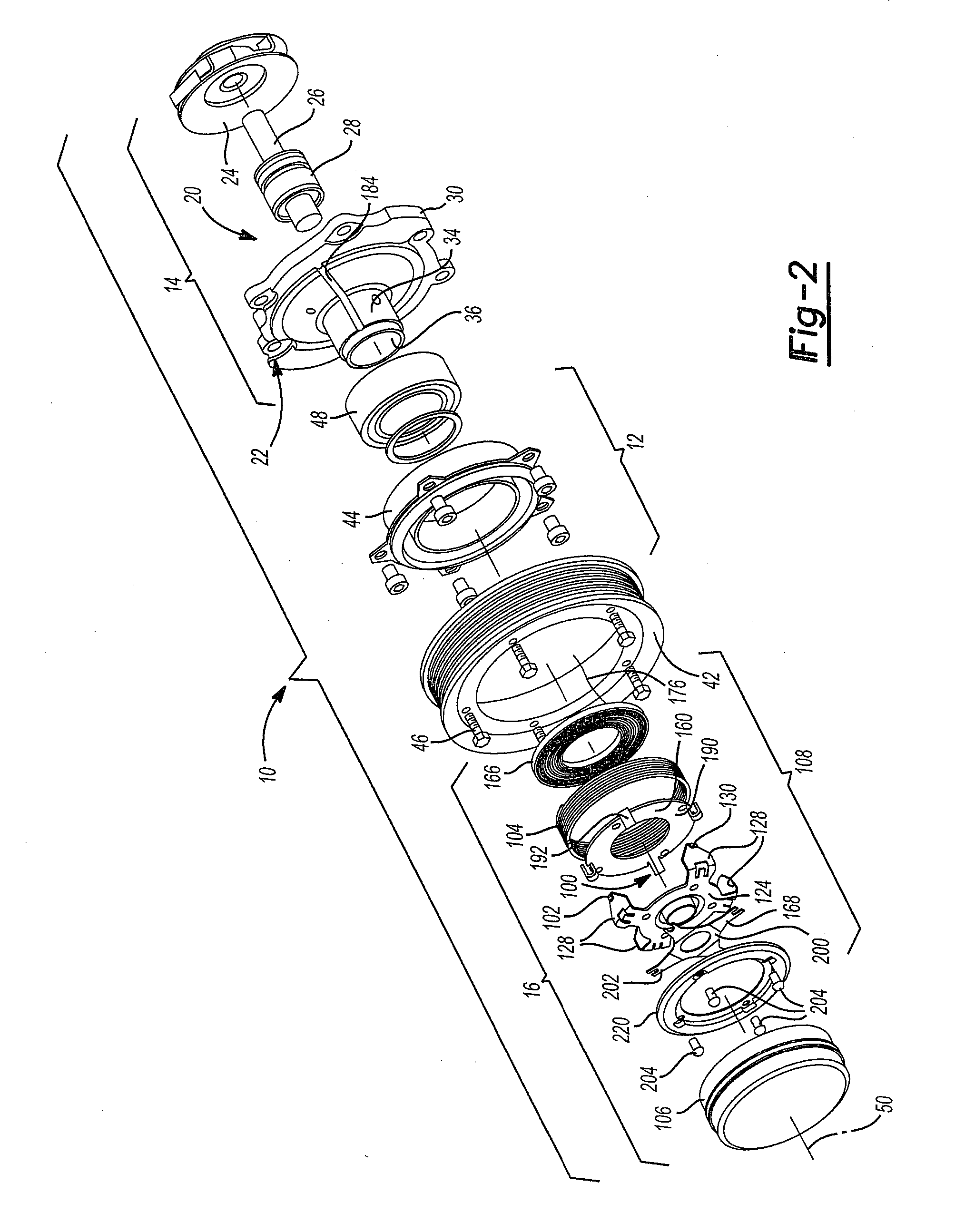

Driven accessory with low-power clutch for activating or de-activating same

ActiveUS20100230227A1Improve wear resistanceReduce noiseAuxillary drivesRoad transportEngineeringMoment of inertia

A driven accessory having a clutch that permits selective operation of an accessory portion. The clutch employs rotational inertia to control driving engagement of a wrap spring to an interior clutch surface on a drive member and / or driving disengagement of the wrap spring from the interior clutch surface.

Owner:LITENS AUTOMOTIVE INC

Flexible rod assembly for spinal fixation

InactiveUS20100318130A1Provides axial compressive strengthDynamic stabilityInternal osteosythesisJoint implantsCouplingEngineering

A flexible spinal fixation rod assembly that provides relatively stiff bending compliance provided by a core rod or tube that is connected to surrounding spring and associated couplings in such a way that when the core rod is bent, the spring extends and the associated couplings move away from each other, with the core rod generating a force tending to return the core rod to its unbent configuration thereof and the spring generating a force tending to return the couplings to there unextended configuration thereof. Couplings connect each end of the rod or tube to corresponding pedicle screws for attachment to corresponding vertebrae. As the spine bends, this arrangement allows the spine to bend against limited resistance, exhibiting the necessary axial and compressive strength, and applies force to return the spine to its original configuration.

Owner:S S WHITE TECH

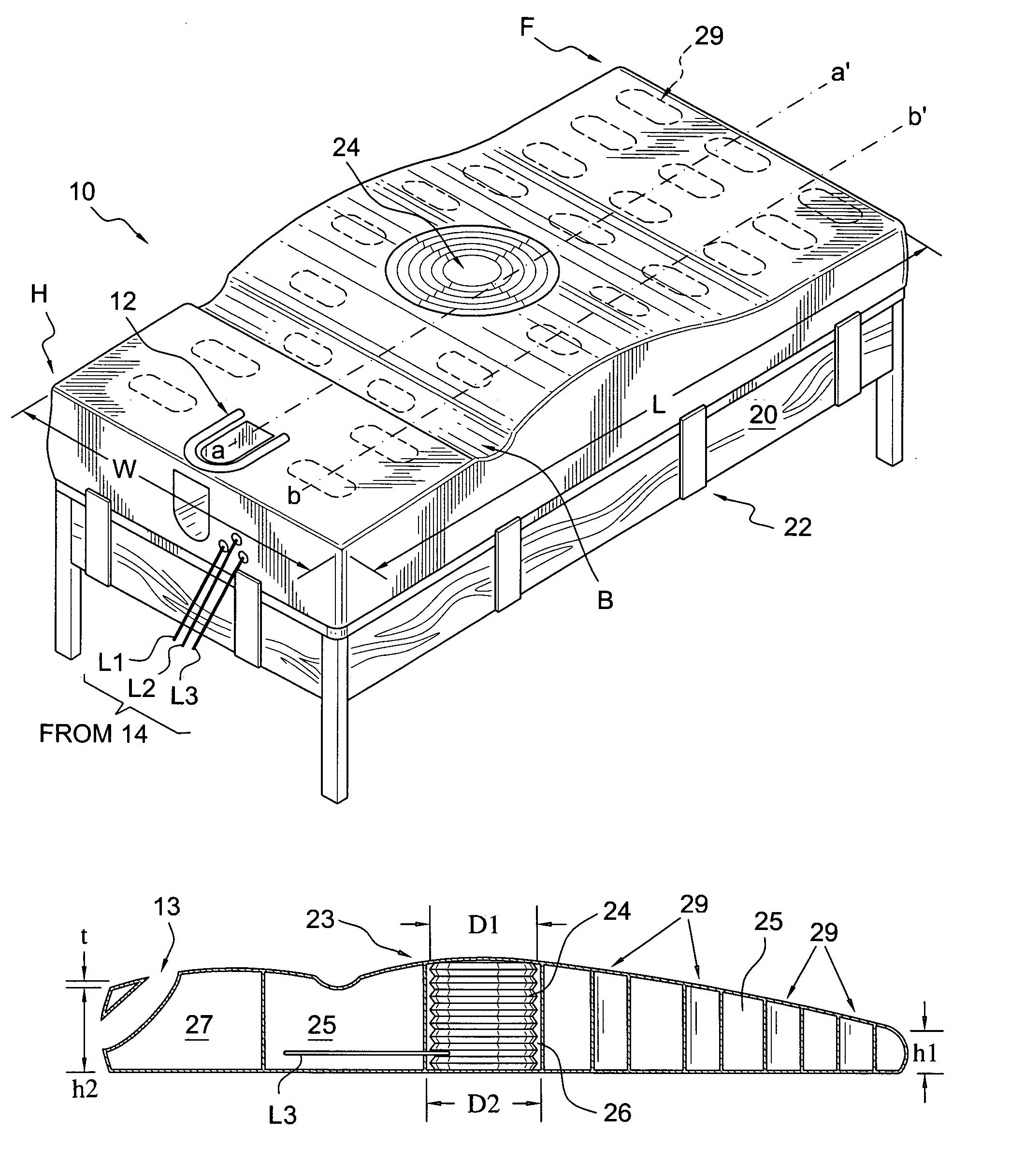

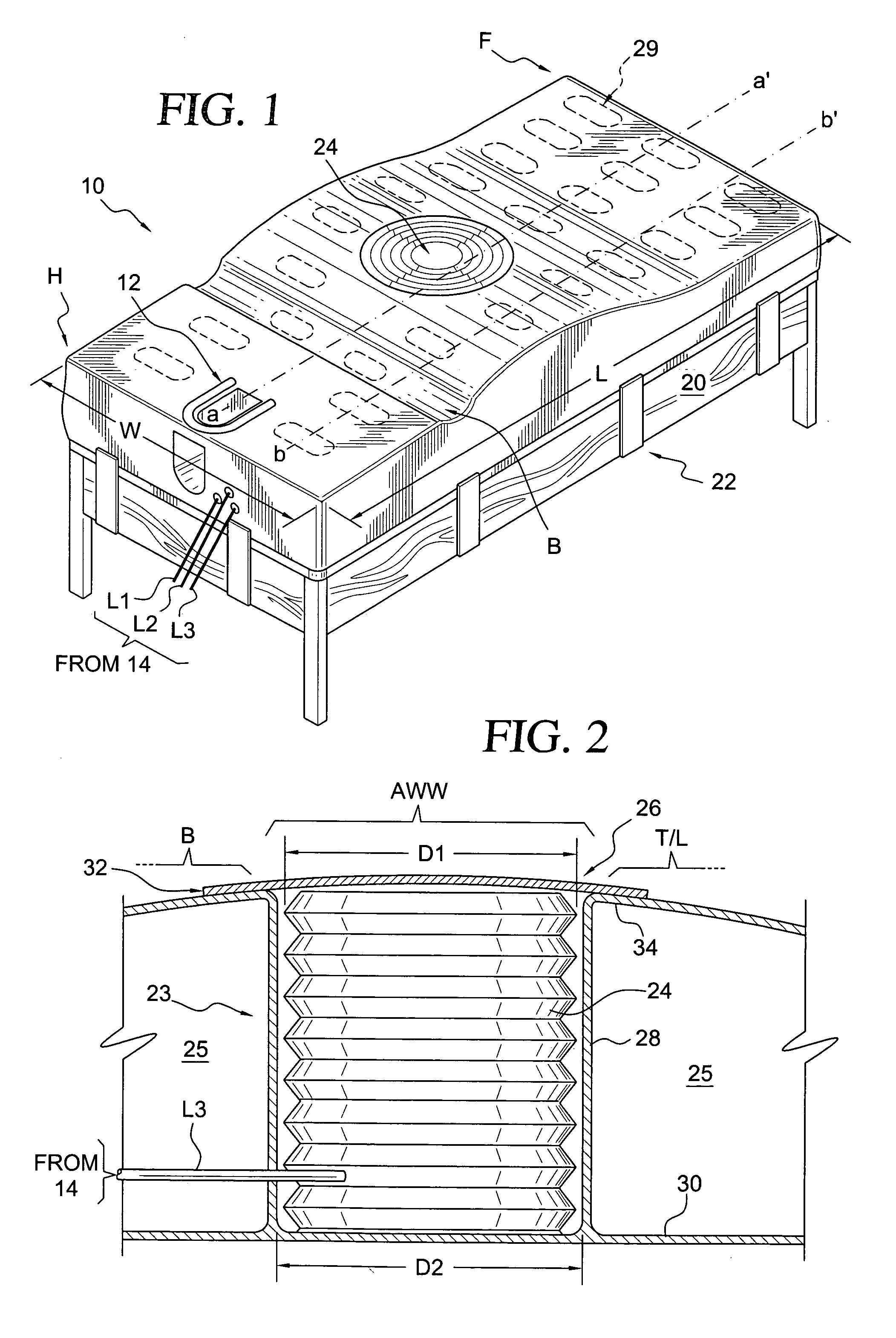

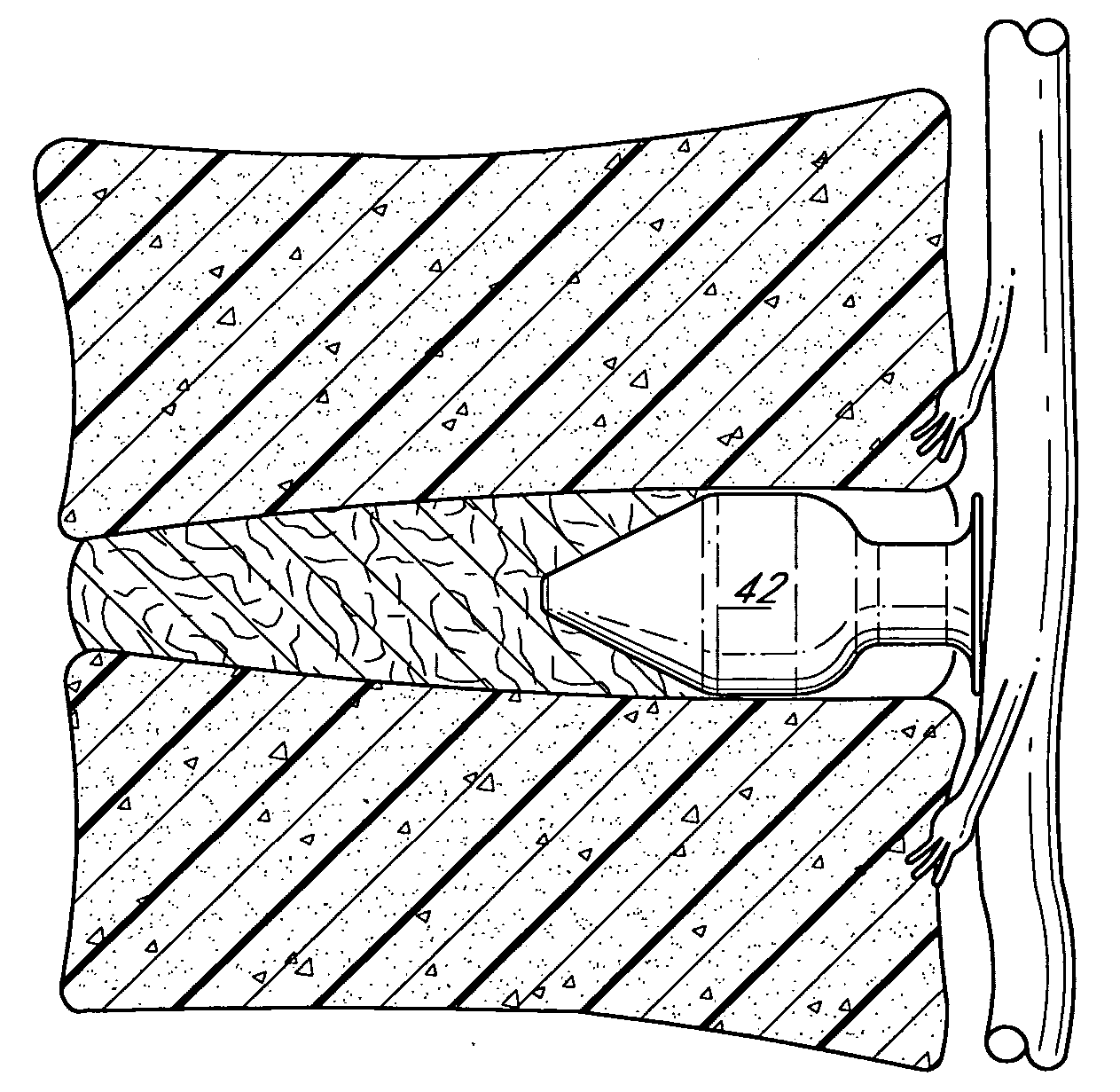

Maternity air mattress with adjustable bellows system

InactiveUS7127764B1Smooth adjustabilityProduce smoothStuffed mattressesSpring mattressesRemote controlEffective height

An improved multiple chambered maternity mattress (10) is specially configured to include a bellows (24) for providing fine-grained adjustability of size and firmness of its centrally disposed womb well region (AWW). The bellows (24) consisting of a plurality of accordion-like sections which are interconnected to form a single expandable air chamber that is inflatable under the control of the user while actually in use via a remote control unit (16). The womb well is formed as a cylindrical cavity or opening (26) which extends for the full height of the mattress (10) such that the bellows (24) may change its effective height thereby establishing the physical size of the womb well for optimum user comfort and benefit. Low friction materials and / or coatings on the cylindrical cavity walls (28) assure minimal friction of the contacting surfaces and bellows tips assuring an infinitely fine height / size / firmness adjustment.

Owner:HARDING DIANE +1

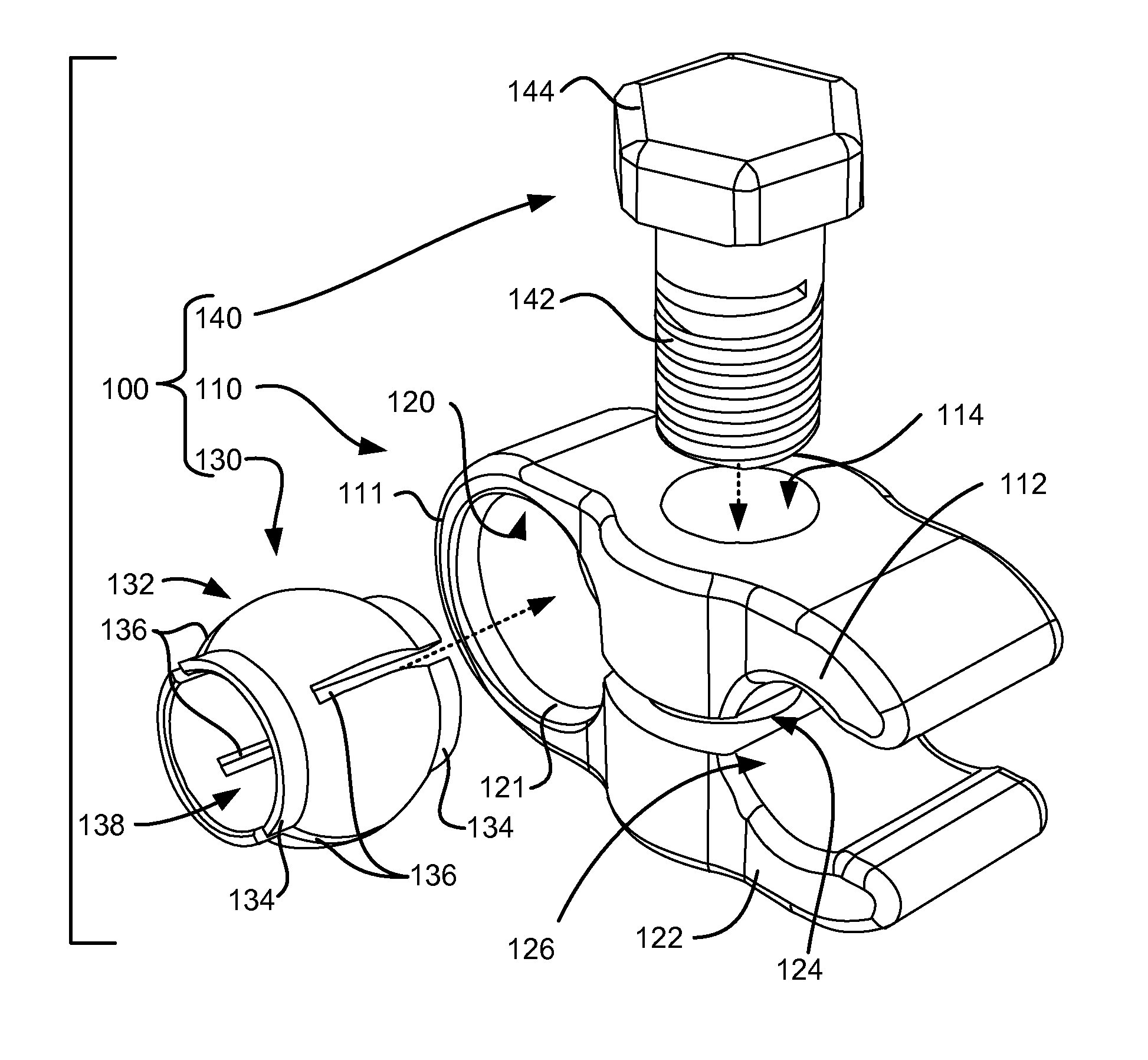

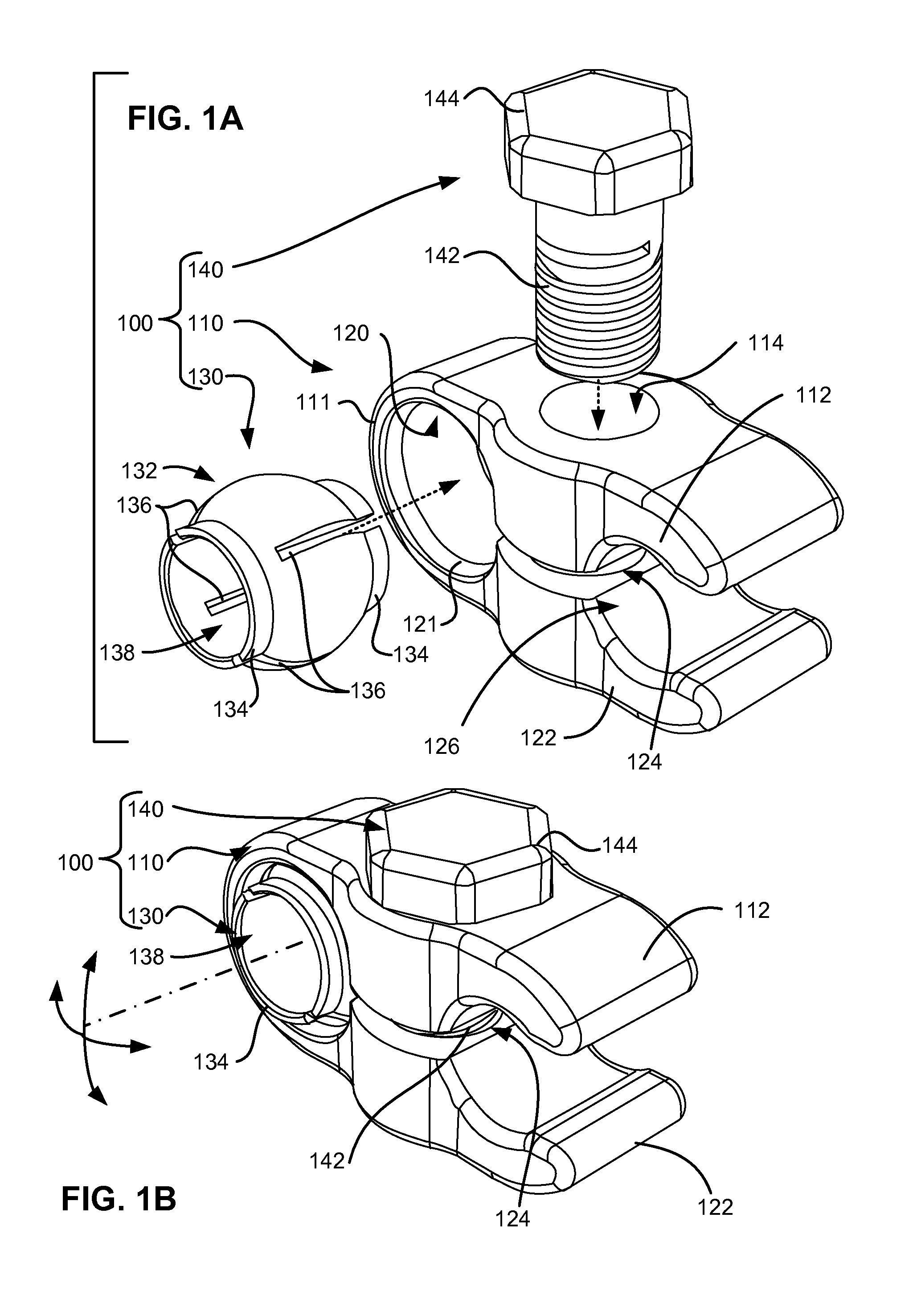

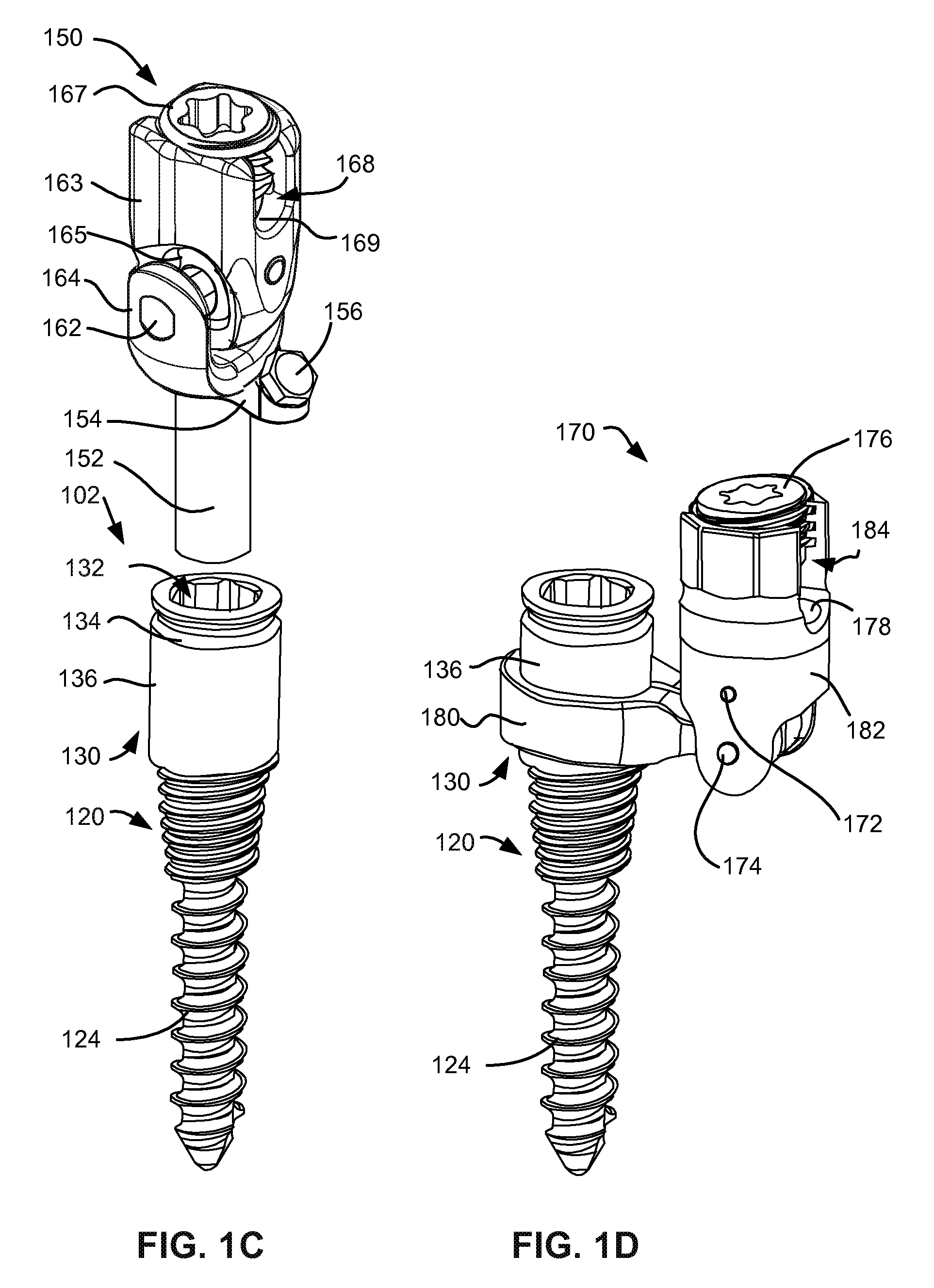

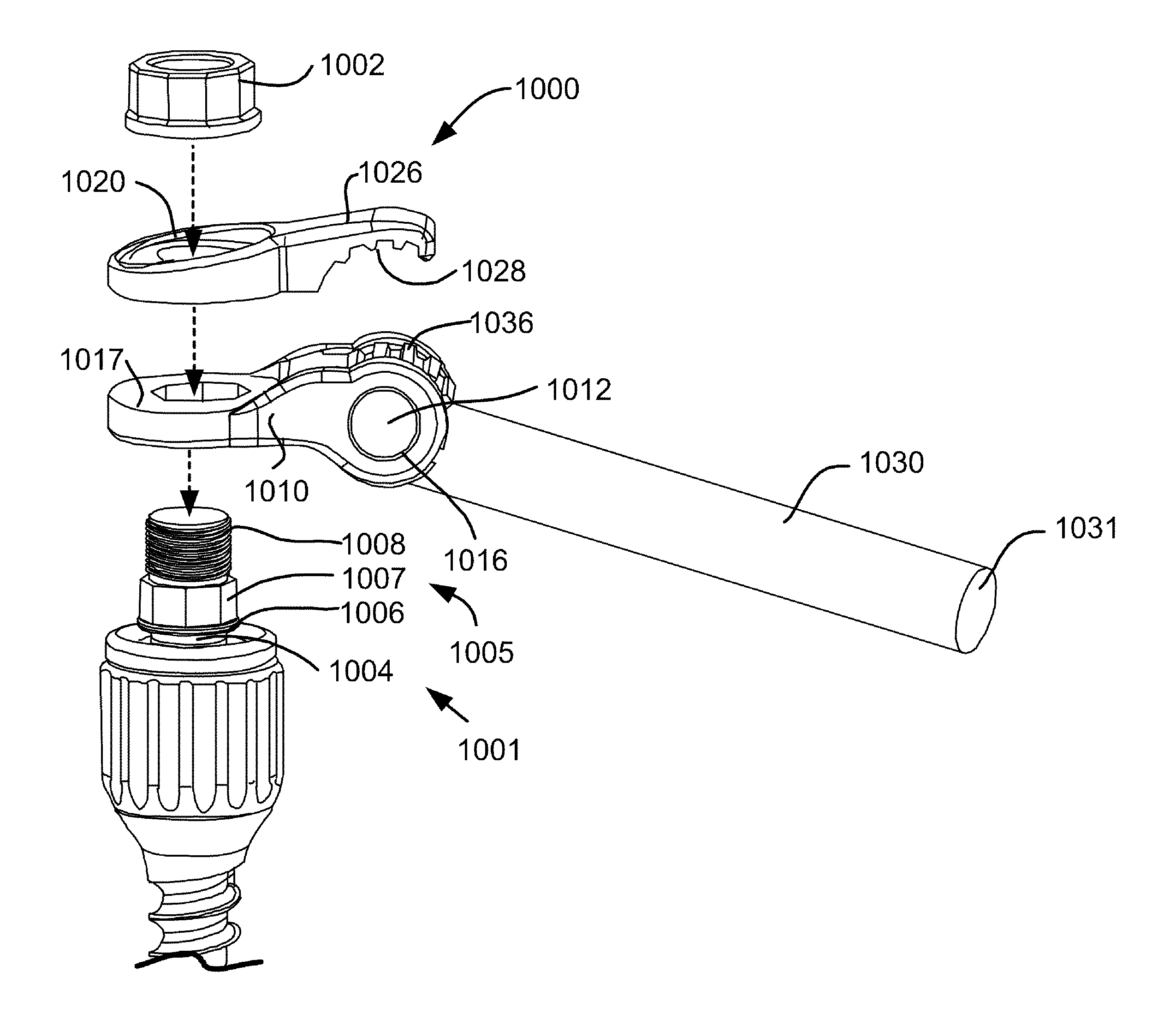

Load-sharing bone anchor having a deflectable post and axial spring and method for dynamic stabilization of the spine

InactiveUS20100030279A1Dynamic stabilityEasy to processSuture equipmentsInternal osteosythesisSpinal anatomyRange of motion

A dynamic spinal stabilization component which supports the spine while providing for the preservation of spinal motion. The component may be integrated in a bone anchor for implantation in a bone of the spine. The component and bone anchor provide load sharing while preserving range of motion and reducing stress exerted upon the bone anchors and spinal anatomy. The dynamic spinal stabilization component includes a deflectable post connected by a ball-joint to a threaded anchor. Deflection of the deflectable post is controlled by an axially compressible spring. The force / deflection properties of the dynamic bone anchor may be adapted to the anatomy and functional requirements of the patient. The dynamic spinal stabilization component may be used as a component of a dynamic stabilization system which supports the spine while providing for the preservation of spinal motion.

Owner:SPARTEK MEDICAL

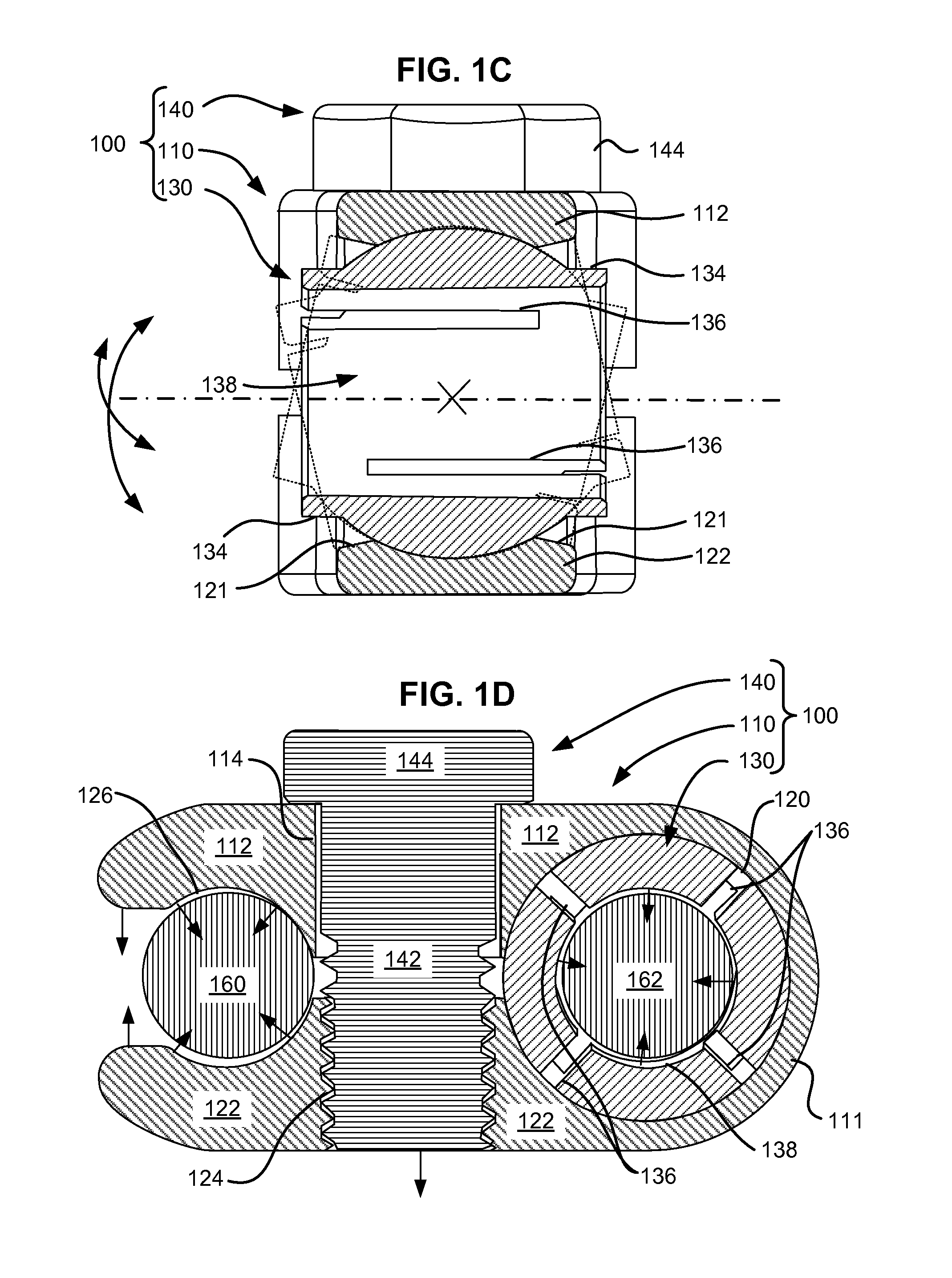

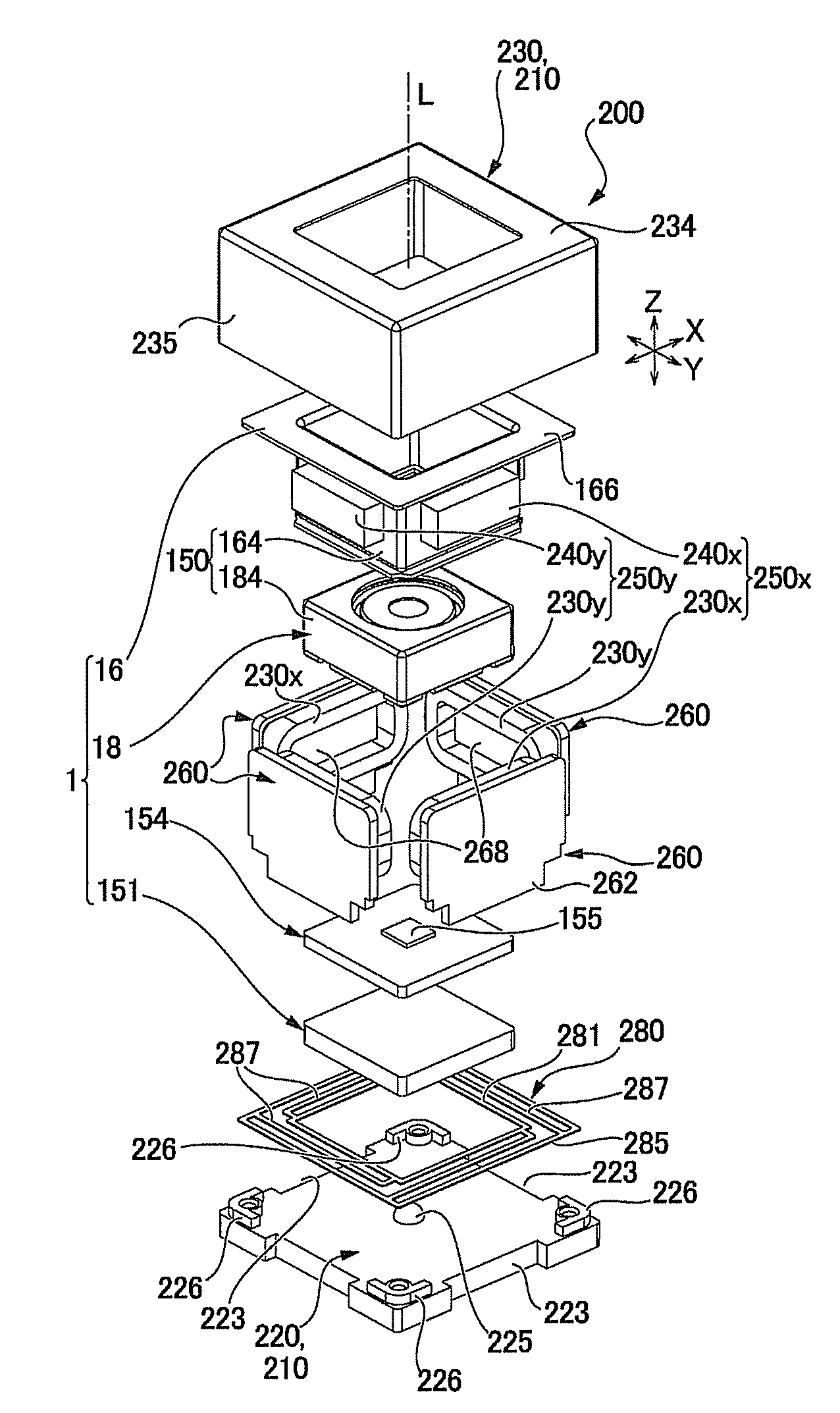

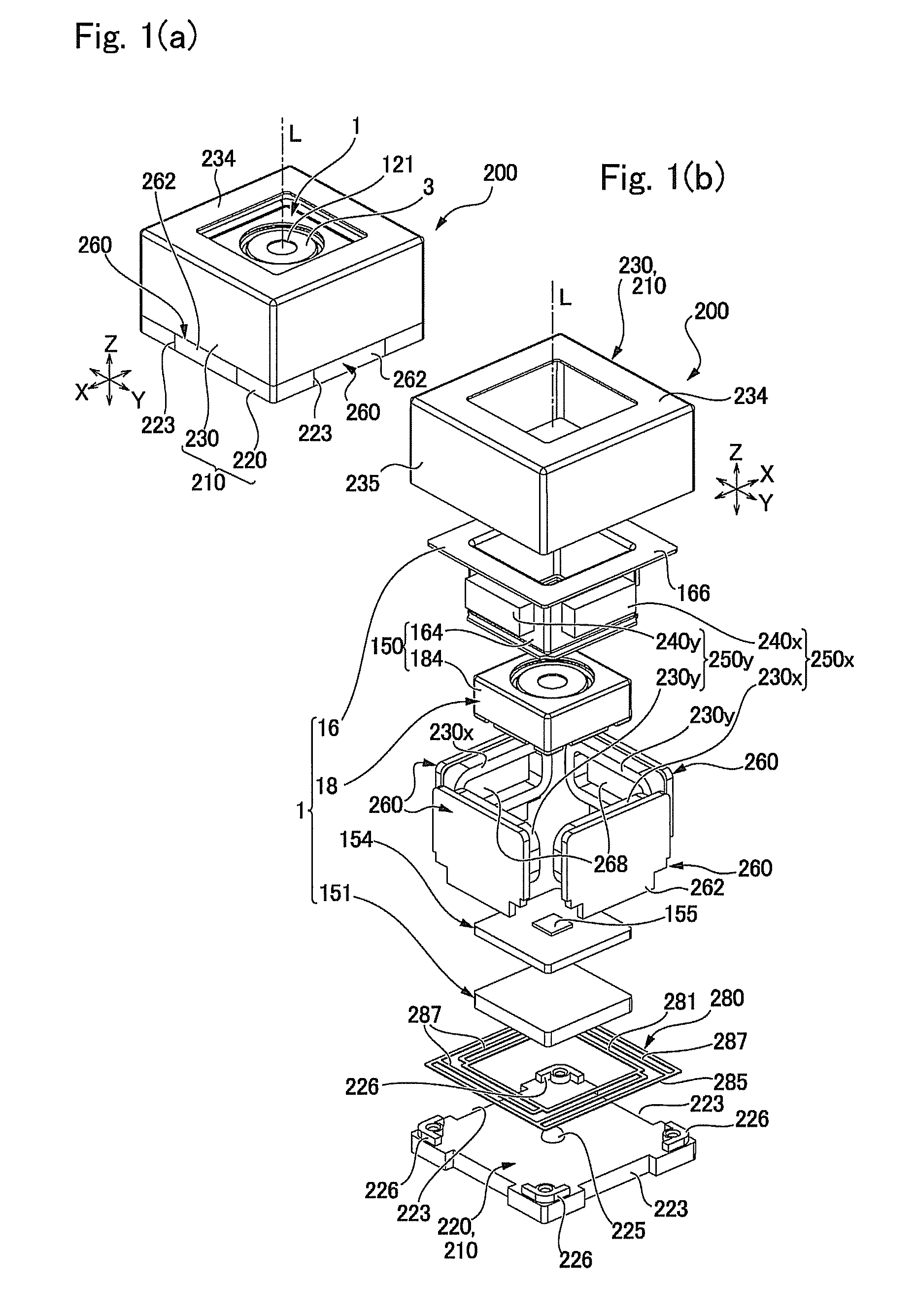

Optical unit with shake correcting function and photographic optical device

ActiveUS8238736B2Efficiently interlinkedHigh torqueTelevision system detailsPrintersEngineeringMagnet

Provided is a photographing optical device, which is able to reliably correct an unintentional movement by hand of a user by improving the constitution of a camera unit driving mechanism for correcting the deflection of a camera unit. In order that a camera unit is made to be rocked to correct the unintentional movement, a photographing optical device includes a first camera unit drive mechanism and a second camera unit drive mechanism, which are so disposed at two side portions sandwiching a pivot portion therebetween as to make a pair. In these camera unit drive mechanisms, camera unit driving magnets are held on the side of the camera unit as a movable body side, and camera unit driving coils are held on the side of a stationary body. The camera unit is pushed toward the pivot portion by a gimbal spring.

Owner:SANKYO SEIKI MFG CO LTD

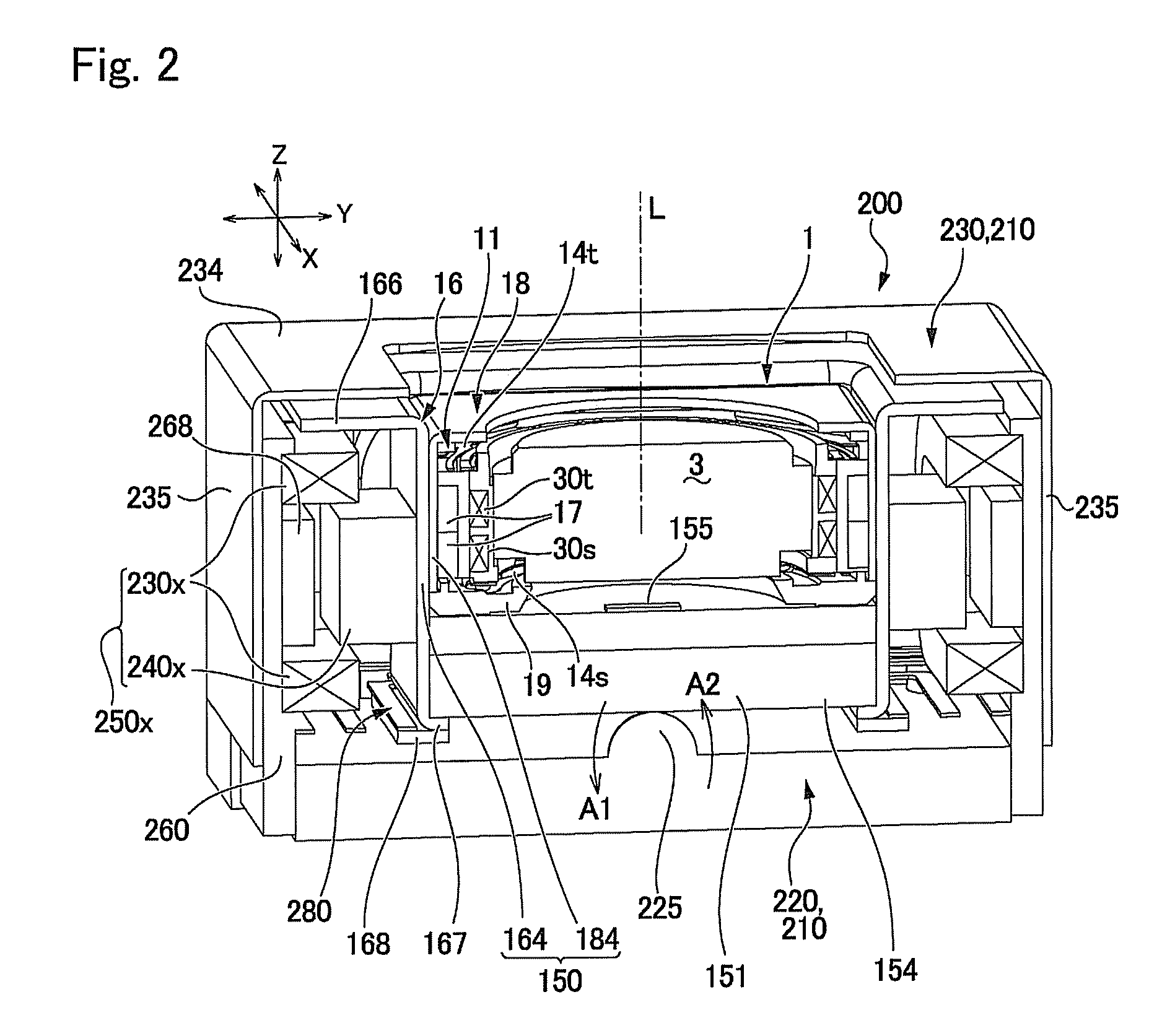

Load-sharing bone anchor having a deflectable post and method for stabilization of the spine

InactiveUS20100036427A1Dynamic stabilityEasy to processSuture equipmentsInternal osteosythesisRange of motionSpinal anatomy

A dynamic bone anchor for anchoring a spine stabilization assembly which supports the spine while providing for the preservation of spinal motion. The dynamic bone anchor provides load sharing while preserving range of motion and reducing stress exerted upon the bone anchors and spinal anatomy. The dynamic bone anchor includes a deflectable post connected by a ball-joint to a threaded anchor. Deflection of the deflectable post is controlled by a compliant member. The dynamic bone anchor may be used as a component of a dynamic stabilization system which supports the spine while providing for the preservation of spinal motion. The dynamic bone anchor has splines on the outside of the housing to facilitate installation and the secure attachment of spine stabilization components.

Owner:SPARTEK MEDICAL

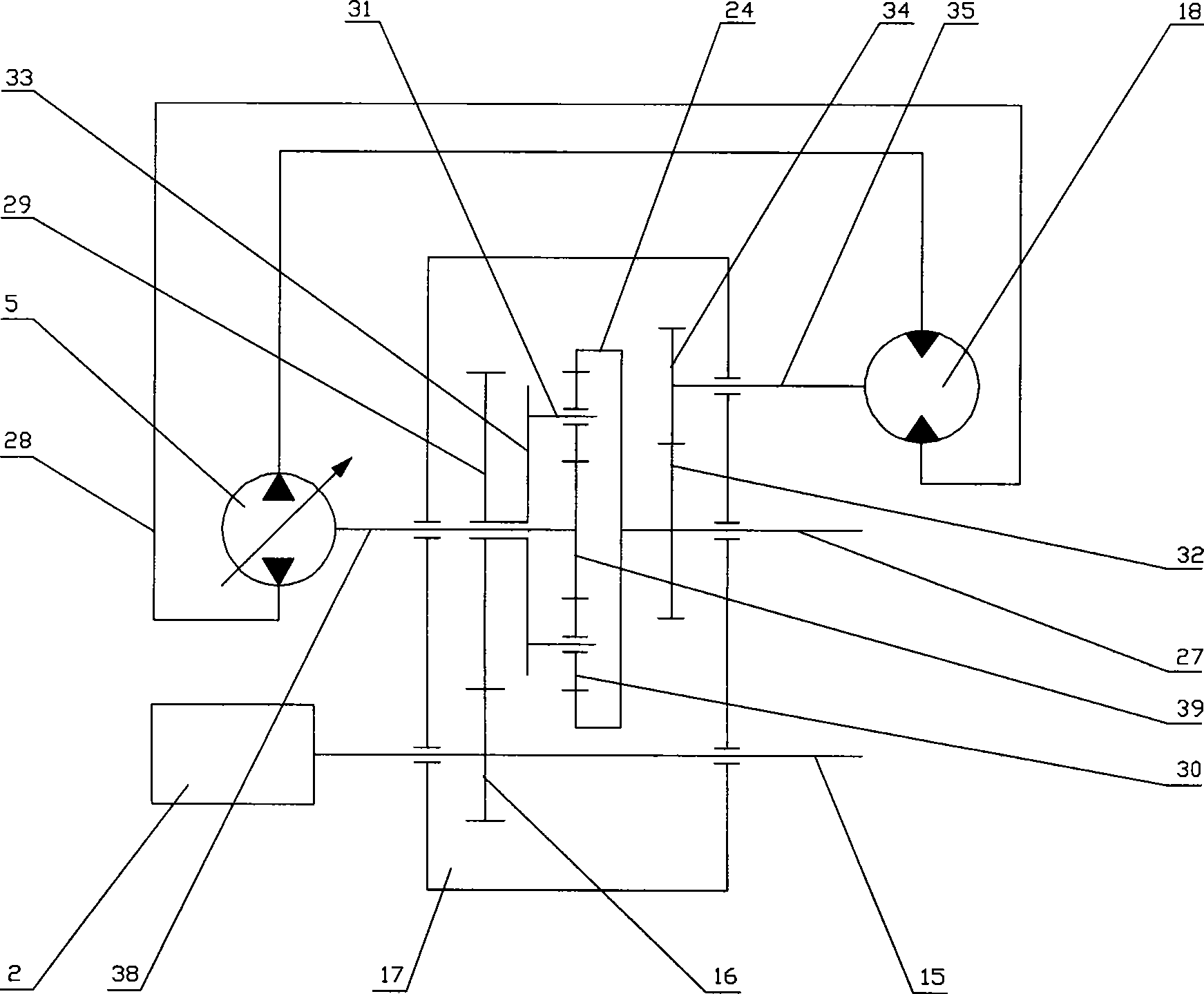

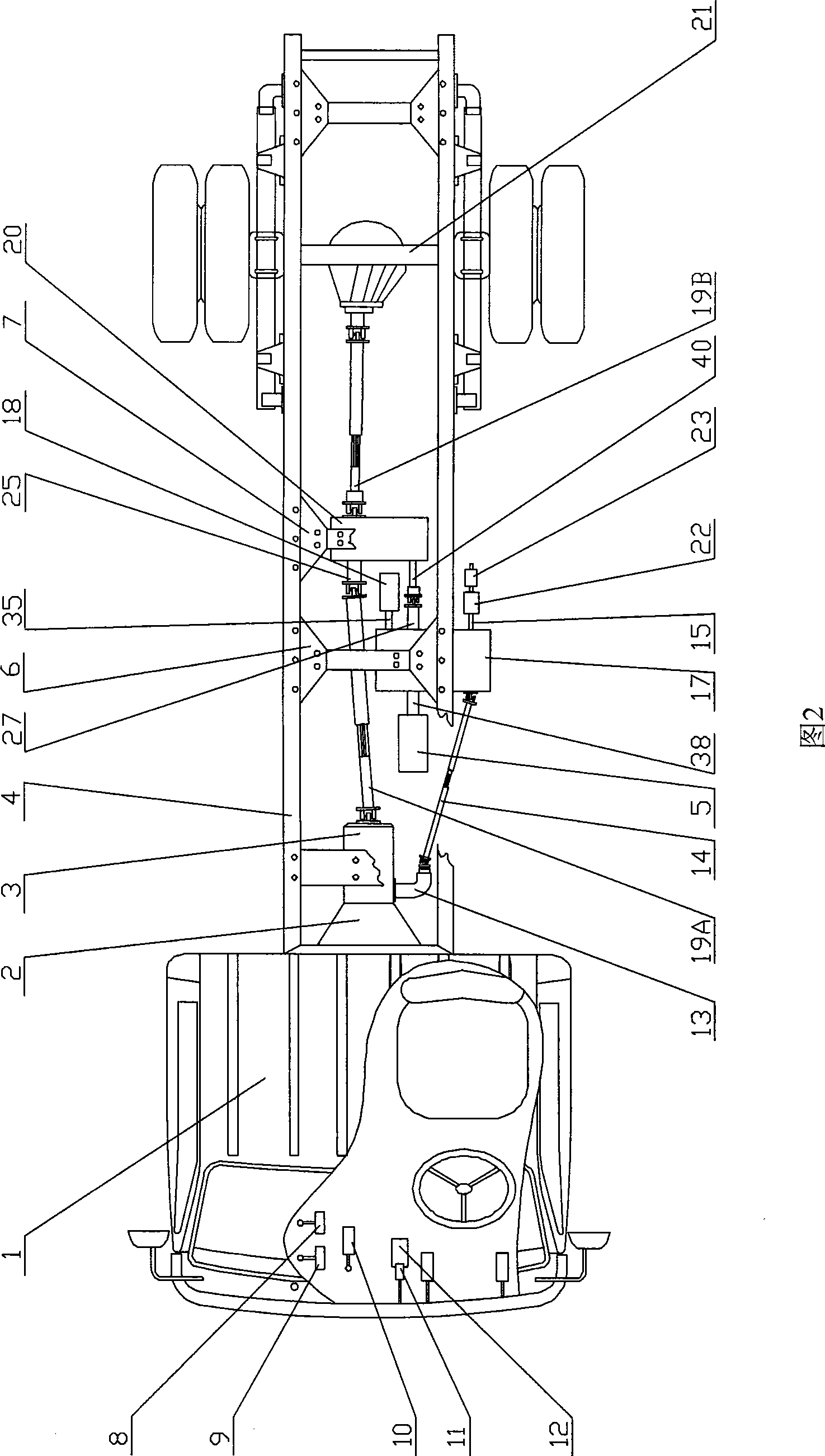

Mechanical and hydraulic combined transmission device

InactiveCN101413572AImprove transmission efficiencyReduce fuel consumptionFluid gearingsControl devicesHydraulic motorPower flow

The invention relates to a mechanical and hydraulic compound transmission device which comprises an engine, a speed changer, a planetary gear box, a hydraulic variable pump, a hydraulic motor and a reduction gearbox; the engine is sequentially connected with the transmission speed changer and the planetary gear box, and a planetary gear mechanism of the planetary gear box distributes the power driven by the motor to respectively drive the hydraulic variable pump and a center gear; the hydraulic variable pump is sequentially connected with a transmission hydraulic motor and a half shaft, the half shaft converges mechanical power flow driven by the center gear and hydraulic power flow driven by the hydraulic motor and protrudes outside the planetary gear box to output the power, and a transmission gear box is connected with the half shaft to redrive a rear shaft to drive a vehicle. A special vehicle refit by the technology with a single-engine configuration can run at a stepless variable speed in a mechanical and hydraulic compound transmission mode, meanwhile, the vehicle can drive a vehicle-mounted operating device in the mechanical transmission mode; during transition, the mechanical transmission mode can be adopted to cause the device to run quickly, the power system occupies little vehicle space, and has low emission, high transmission efficiency and low oil consumption.

Owner:赵宏坚 +1

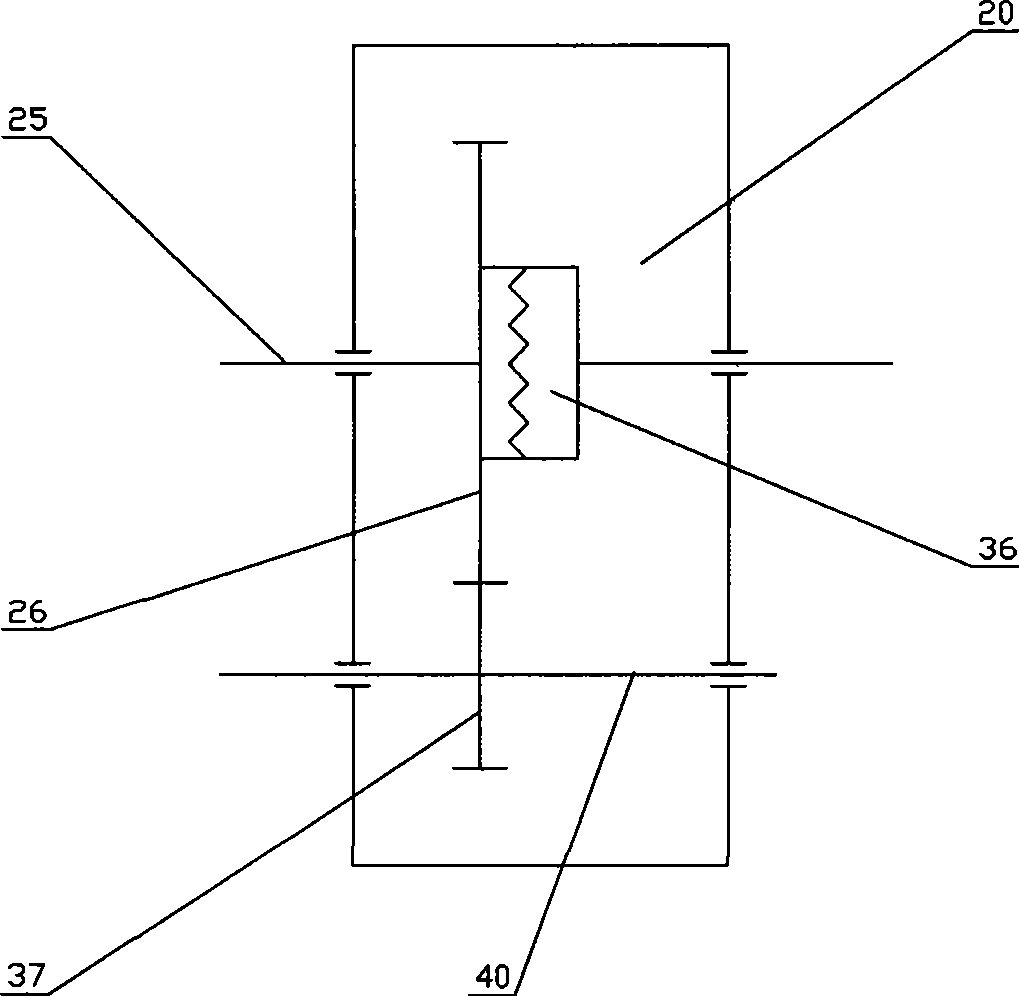

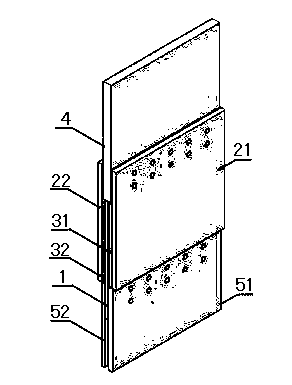

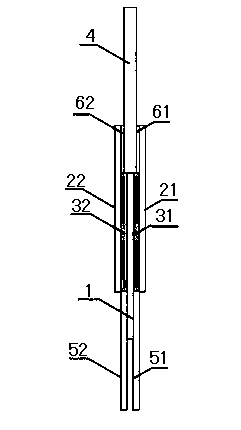

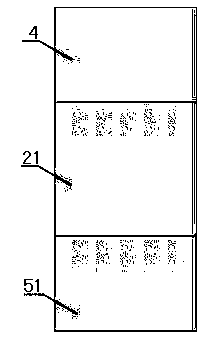

Assembly-type viscoelastic damping wall

InactiveCN103233531AThe mechanical model is simpleDynamic stabilityWallsShock proofingViscoelastic dampingBonding process

The invention relates to the field of energy dissipation and vibration damping control of architecture structures, particularly to an assembly-type viscoelastic damping wall. The damping wall includes a middle steel plate, viscous-elastic material layers, two outside steel plates, an upper portion wall connecting steel plate, backing boards and two lower portion wall connecting steel plates, wherein the middle steel plate, the viscous-elastic material layers and the two outside steel plates are bonded together, the viscous-elastic material layers are respectively arranged between the middle steel plate and the two outside steel plates, the viscous-elastic materials are high attenuation rubber series viscous-elastic materials, and the viscous-elastic material layers are respectively firmly and reliably bonded with the middle steel plate and the two outside steel plates by utilizing a rubber and steel plate bonding process. The two outside steel plates, the upper portion wall connecting steel plate and the backing boards are firmly connected together through high-strength bolts, and the middle steel plate and the two lower portion wall connecting steel plates are firmly connected together through high-strength bolts. The assembly-type viscoelastic damping wall is high in energy-dissipating capacity, can provide relatively more use space for the architecture structures, facilitates installation and maintenance and meets the requirements of the design and functionality of the architecture structures.

Owner:欧进萍

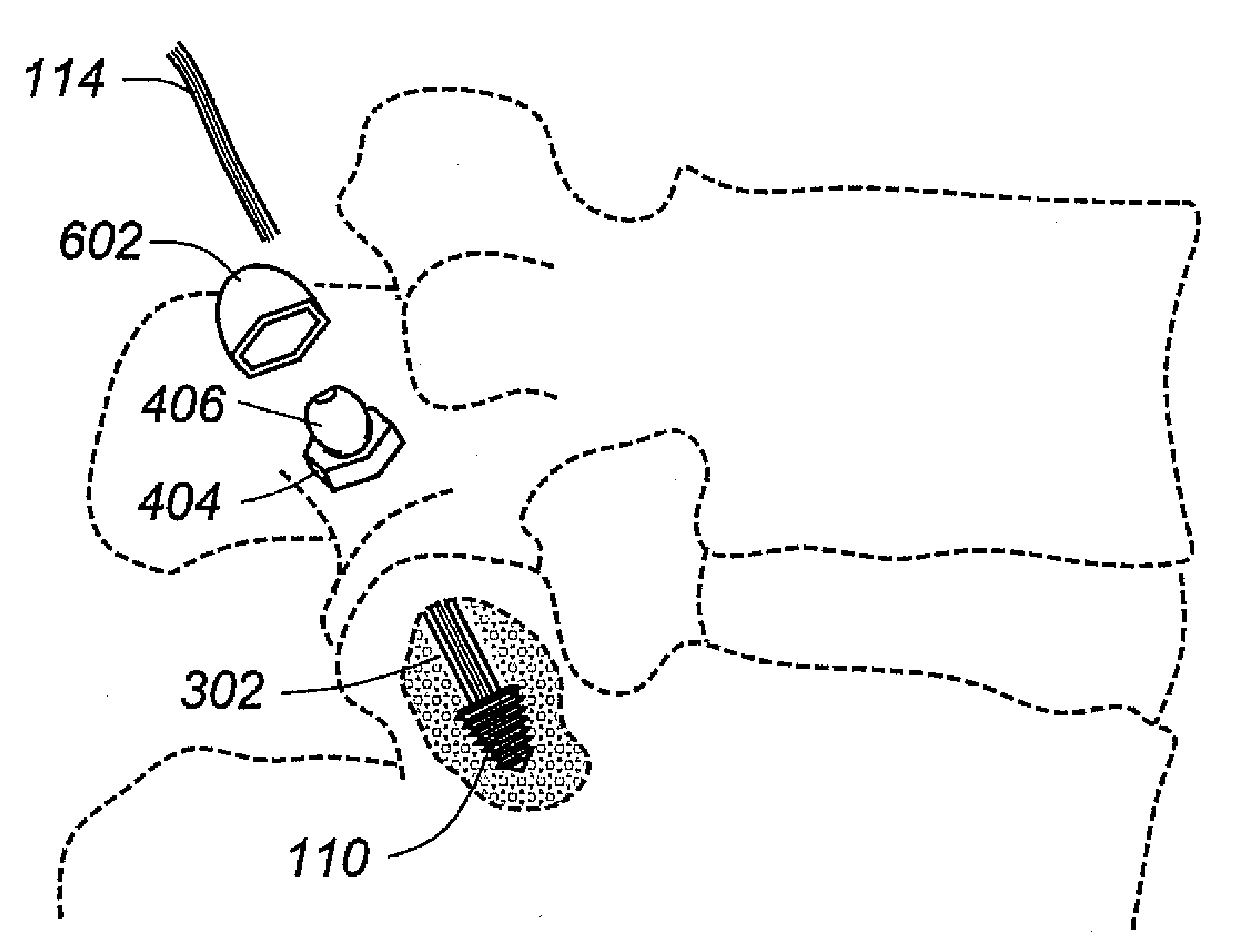

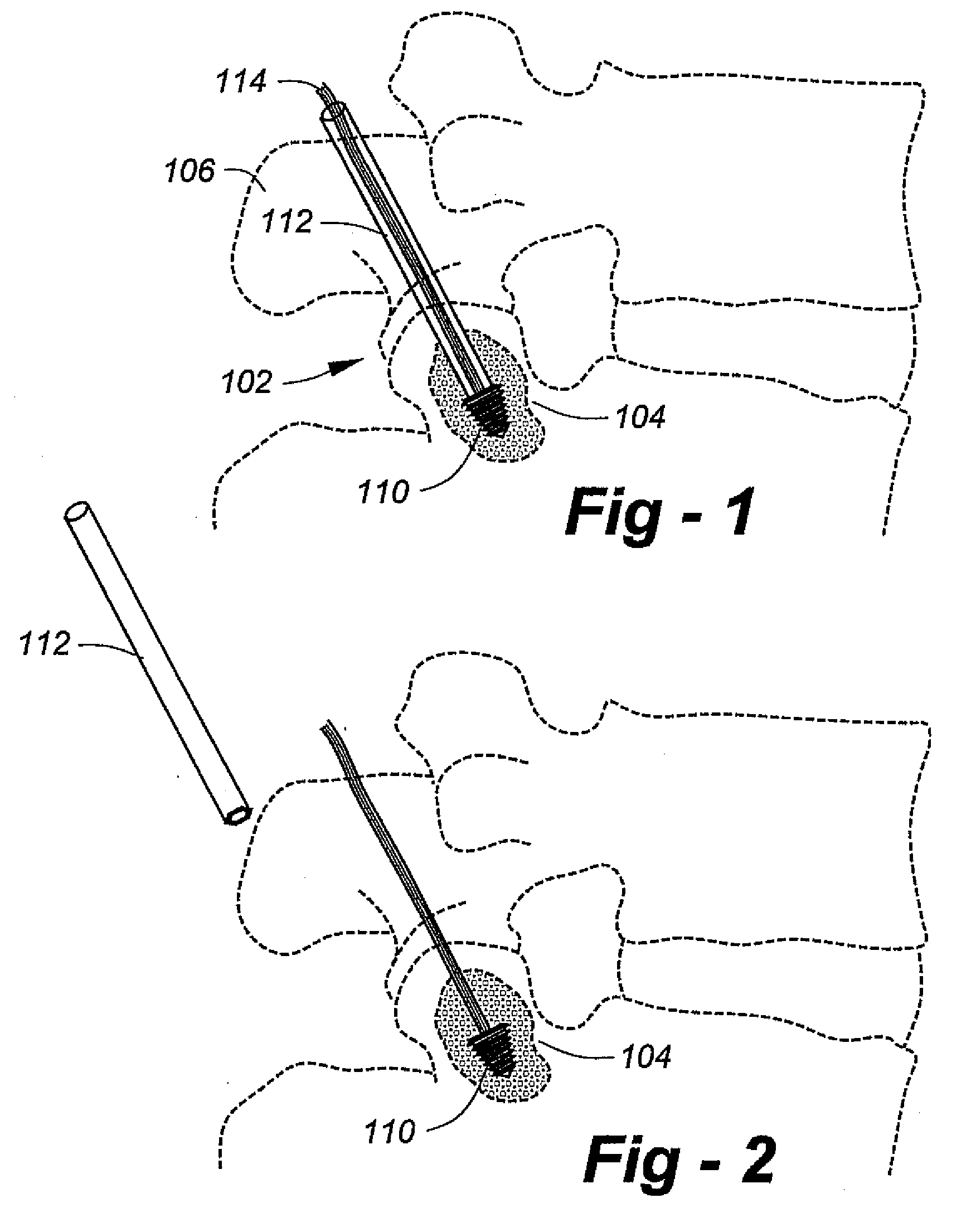

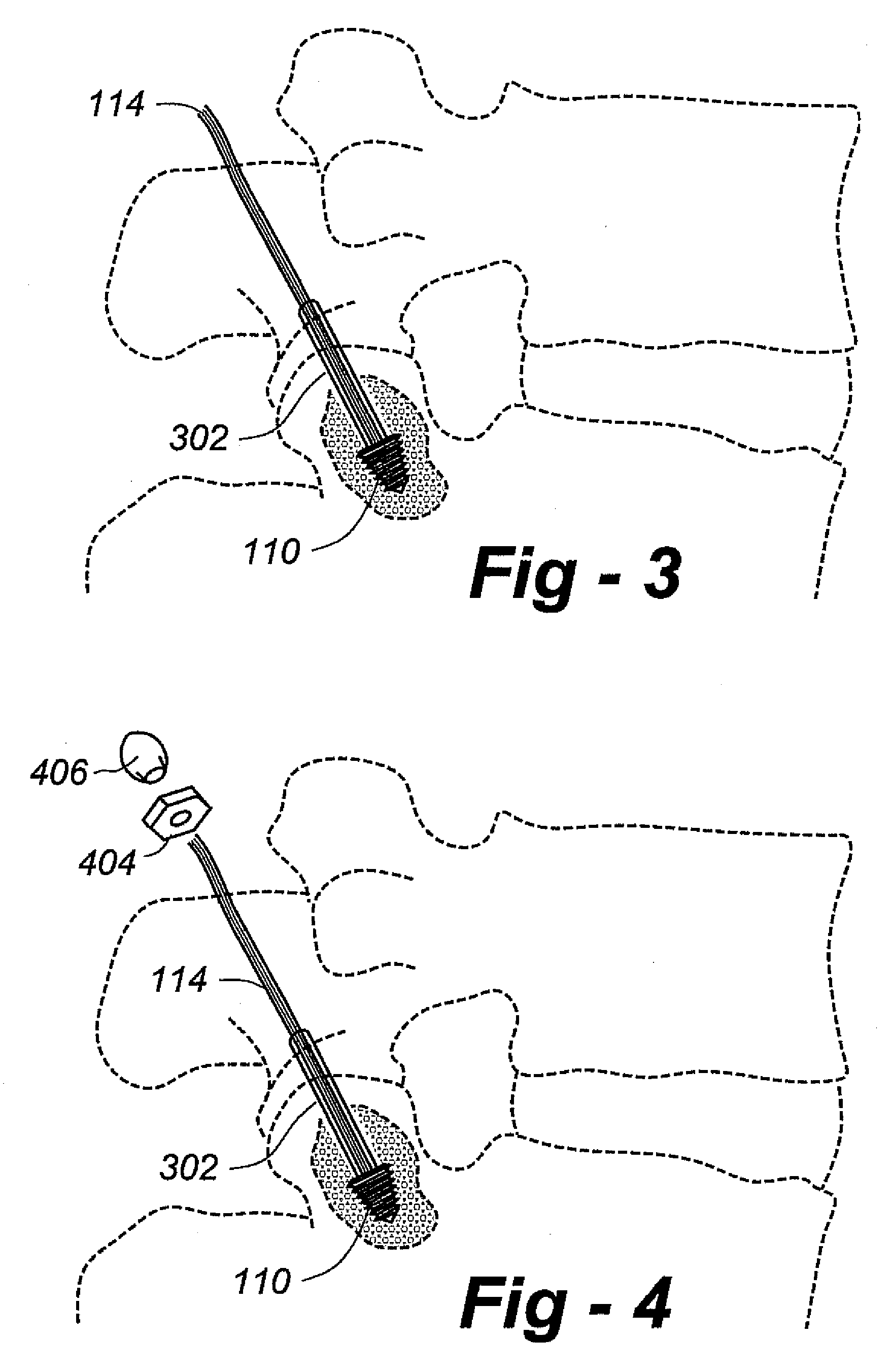

Spinal implants and methods of providing dynamic stability to the spine

InactiveUS20070050028A1Reduce relative motionSimple structureInternal osteosythesisDiagnosticsSpinal implantVertebra

The present application discloses a plurality of spinal implants and methods for repairing annular defects in intervertebral discs and for providing dynamic stability to the motion segment of the spine in the vicinity of the repaired disc. Each of the implants comprises a head portion and a tail portion. In the illustrated embodiments, the head portion of each implant is enlarged relative to the tail portion. Each of the head portions and tail portions is adapted to support adjacent vertebrae and resist collapse of the intervertebral disc. A tapered portion of each implant engages end plates of the adjacent vertebrae to resist forces tending to push the implant out of the intervertebral space. The tail portion of each implant includes a tail flange (which in some embodiments is of similar diameter to the head portion) that abuts extradiscal lips of the adjacent vertebrae and resists forces tending to push the implant deeper into the intervertebral space.

Owner:MAGELLAN SPINE TECH

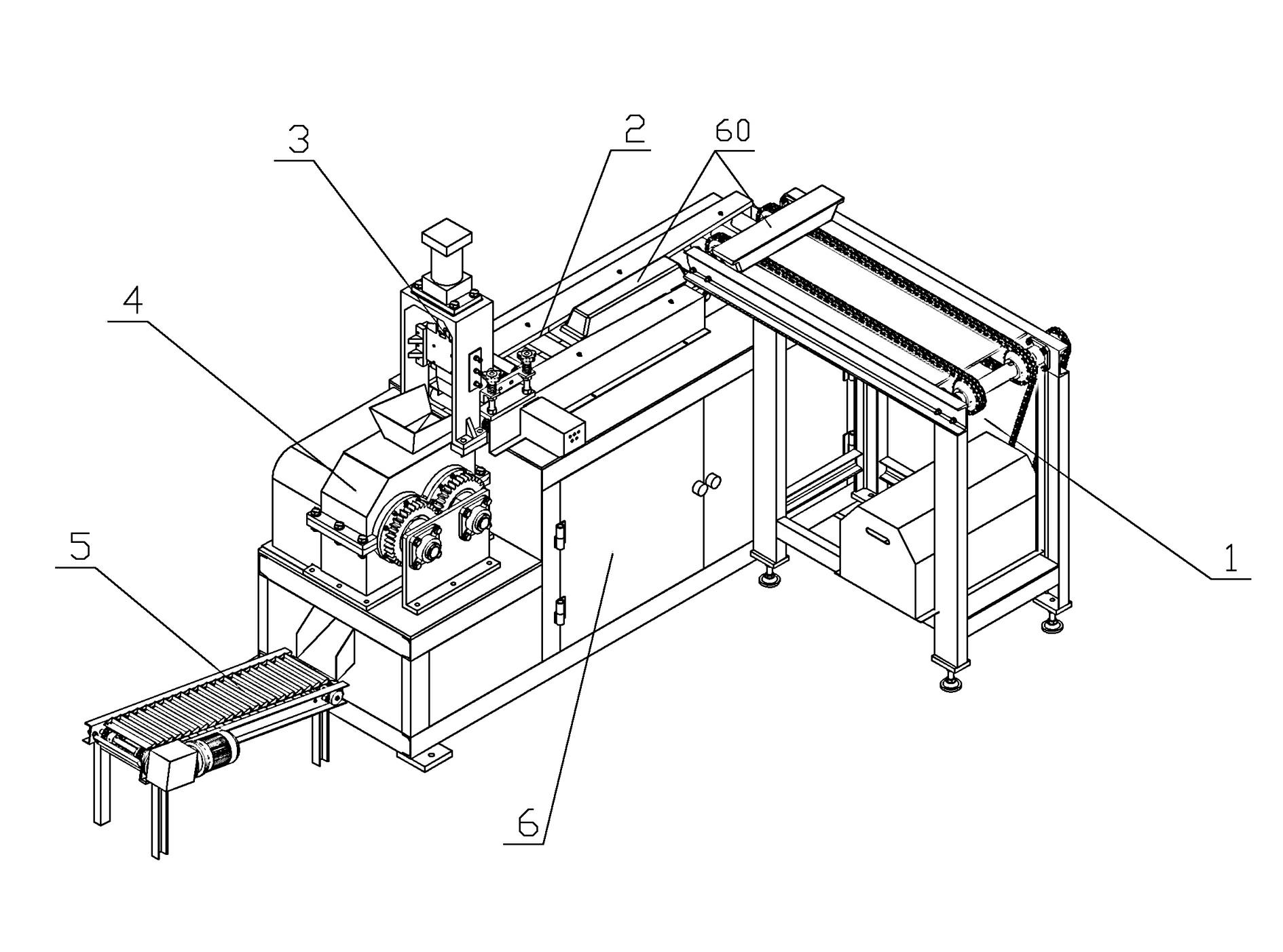

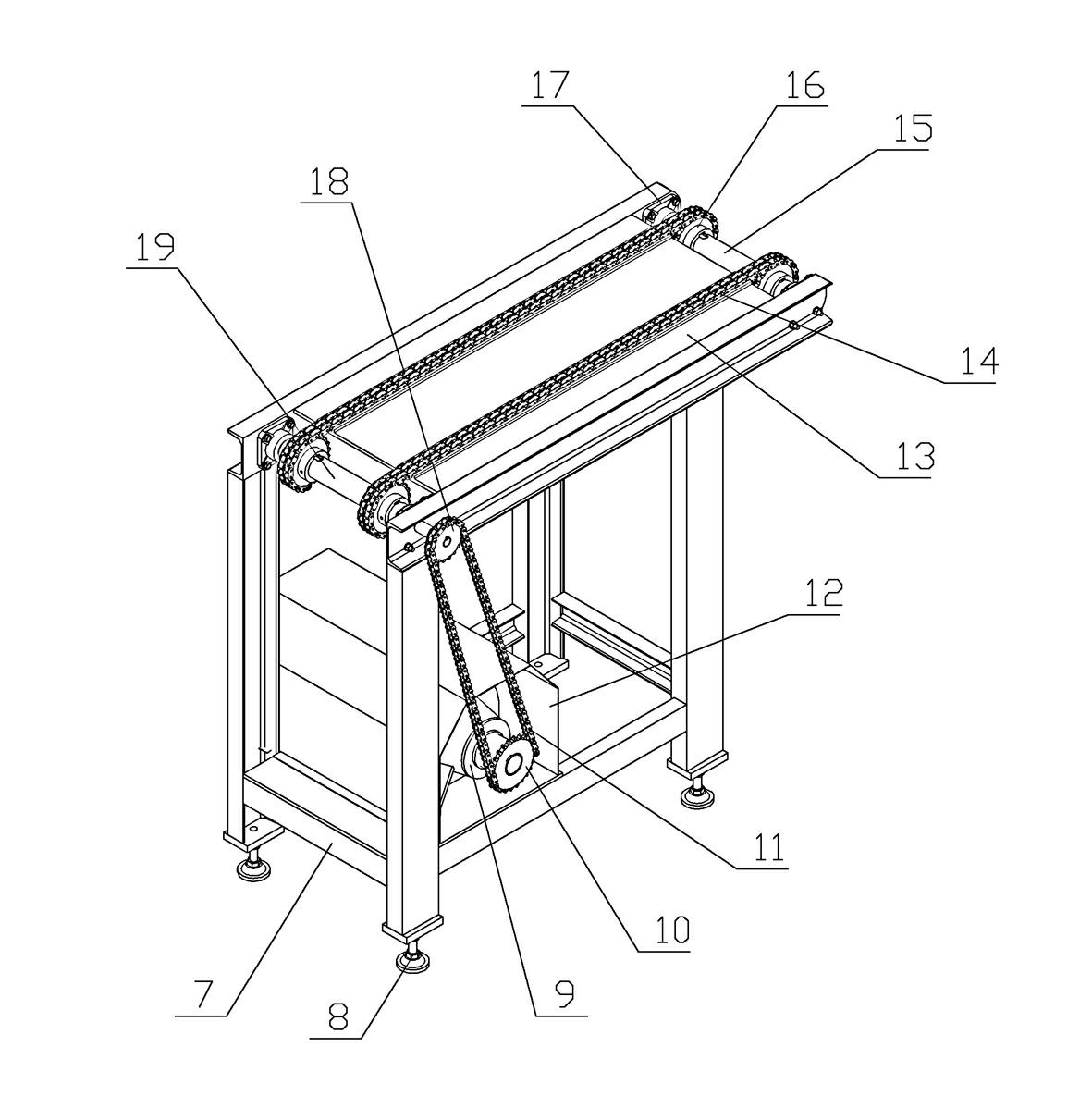

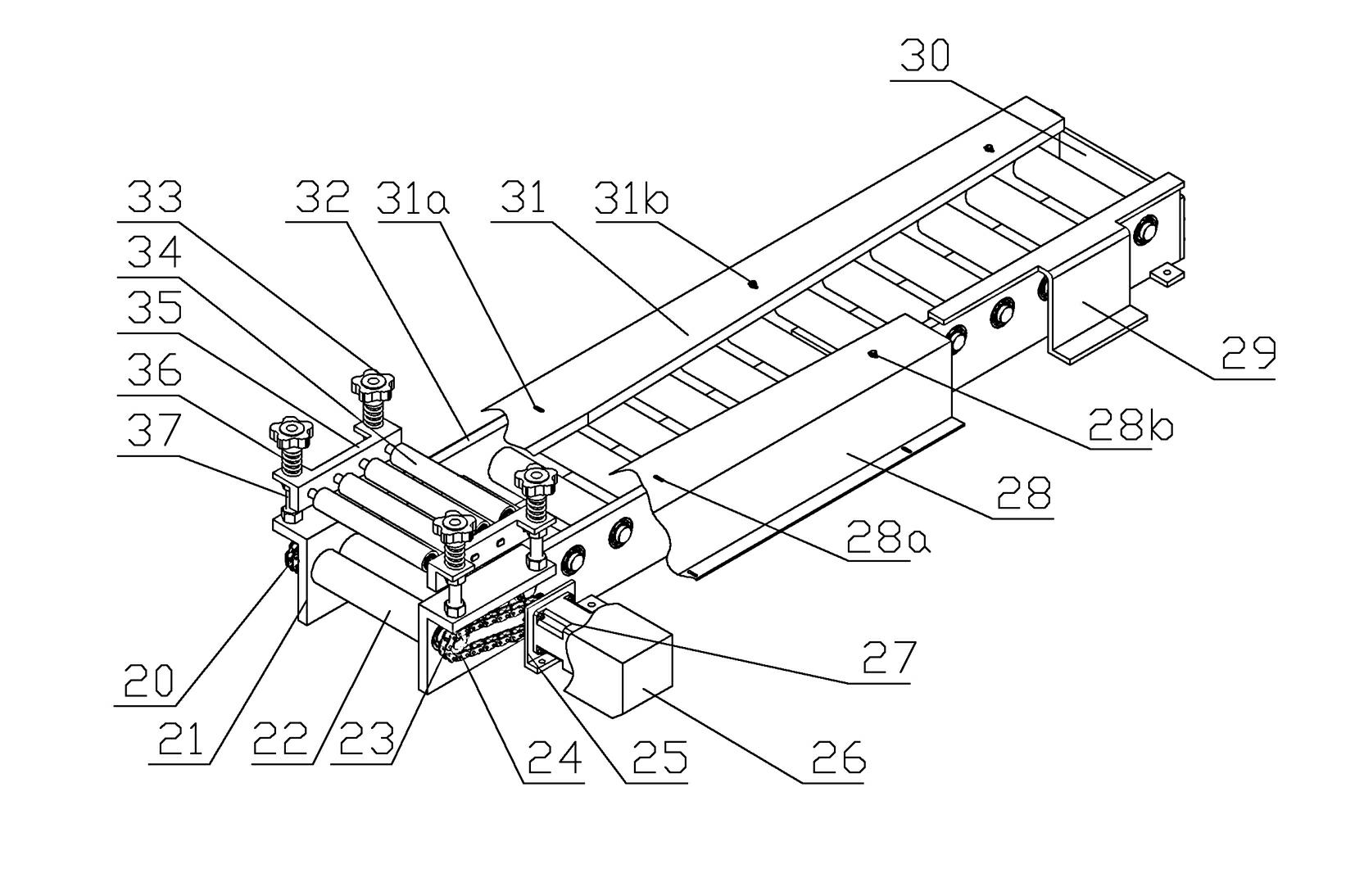

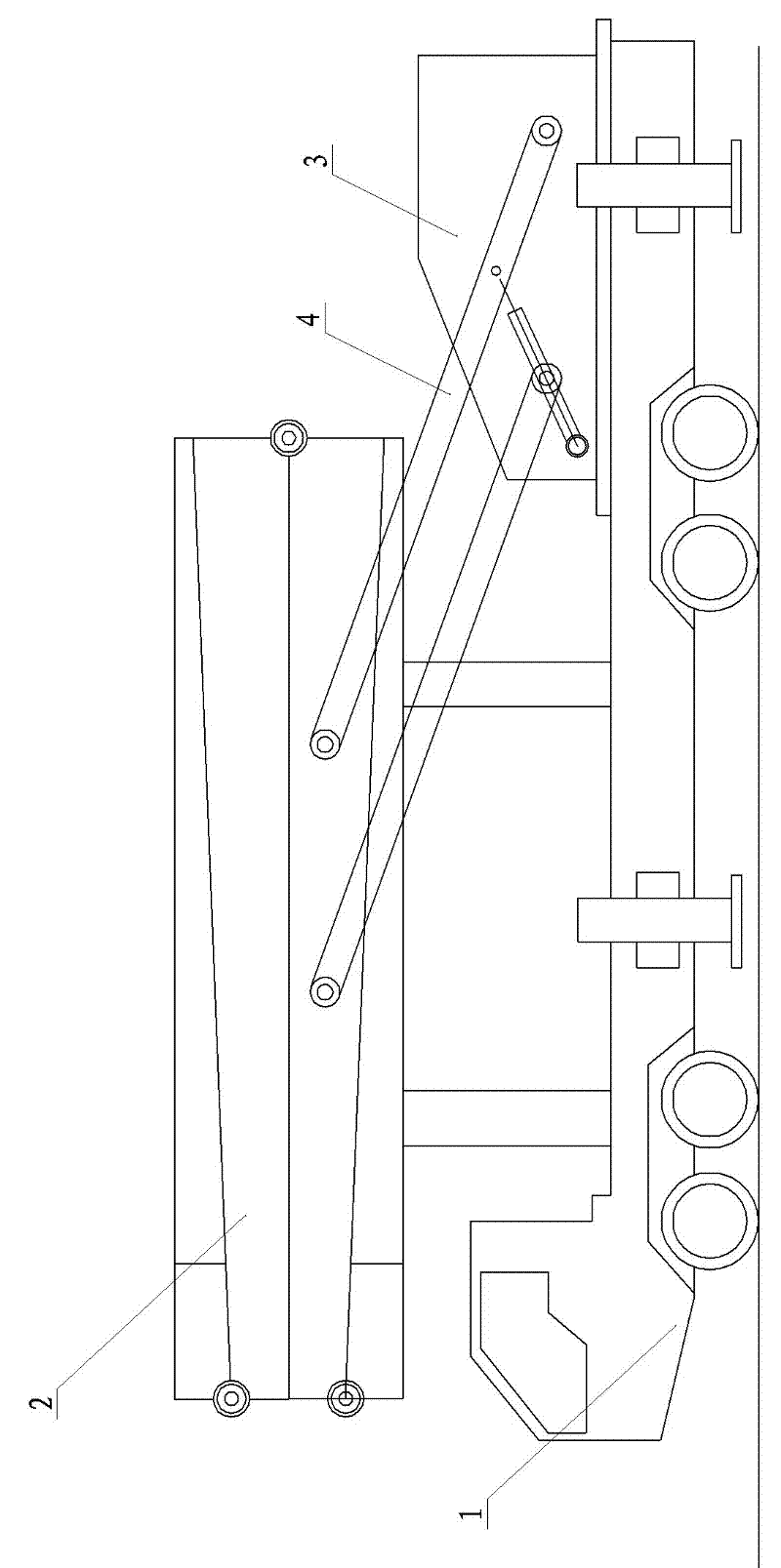

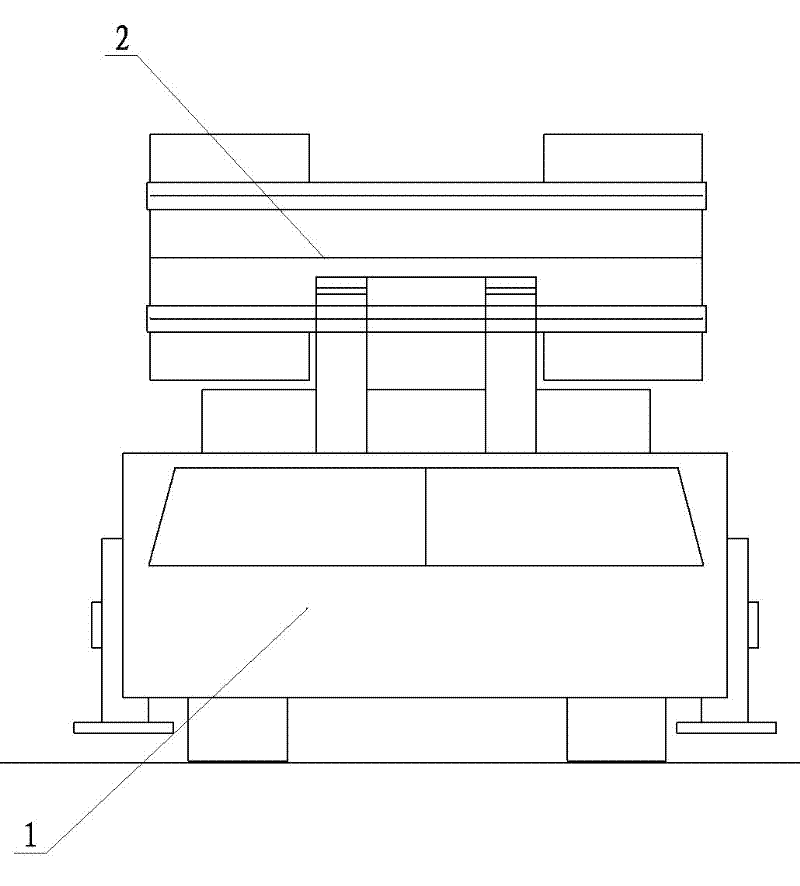

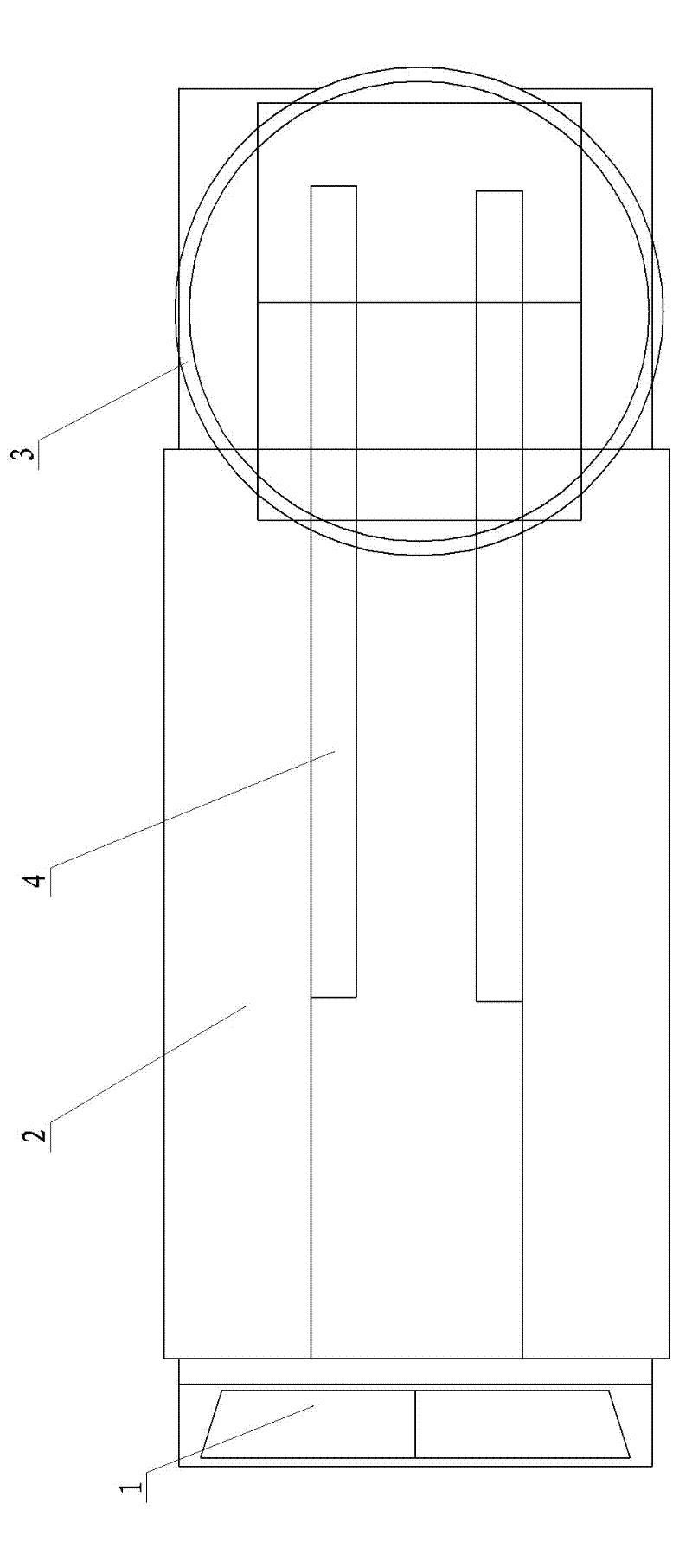

Fully-automatic production equipment for cold granulation of lead ingot

ActiveCN102328090APowertrain is reliableImprove reliabilityAutomatic controlProgrammable logic controller

Owner:蚌埠市华鼎机械科技有限公司

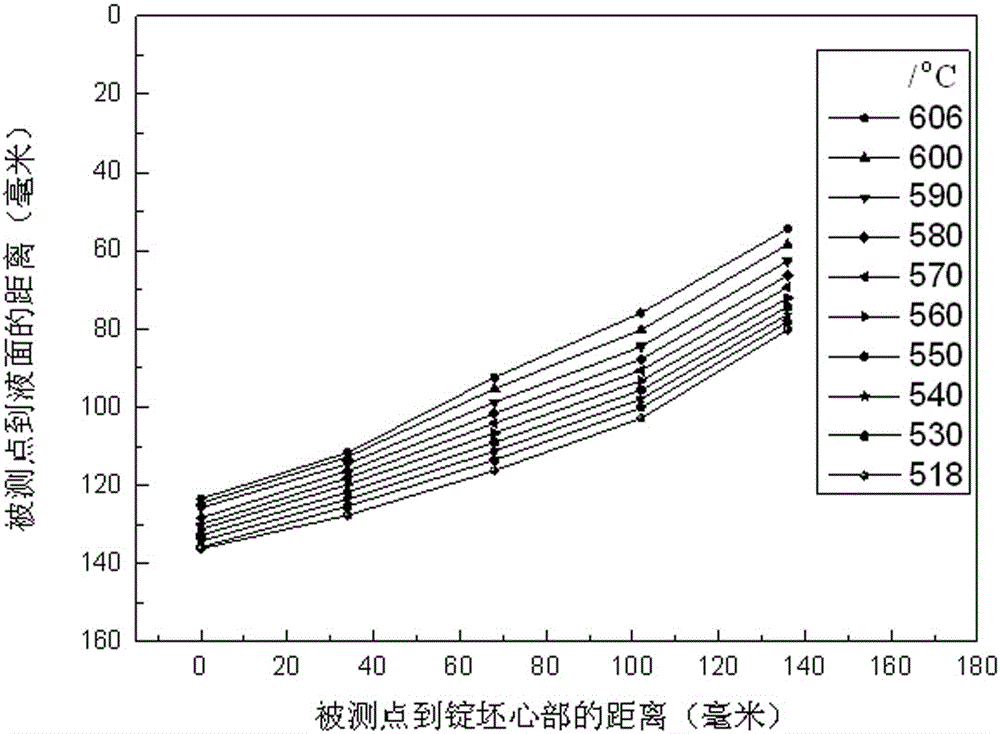

System and control method for drawing crystal bar

PendingCN111020691AAchieve growthPrecise control of temperature gradientPolycrystalline material growthBy pulling from meltThermodynamicsCrucible

The invention provides a system and a control method for drawing a crystal bar. The system comprises: a first control unit which is used for controlling the drawing speed of the drawn crystal bar to be constant; an obtaining unit which is used for obtaining a distance between a solid-liquid interface and a reference surface, wherein the solid-liquid interface is an interface between a crystal liquid and the current crystal bar; a crucible used for containing the crystal liquid; a heating device used for heating the crucible; a second control unit used for adjusting the crucible lifting ratio under the condition that the distance is different from the preset distance in order to make the distance reach the preset distance, wherein the crucible lifting ratio is the ratio of the crystal growth rate to the crucible lifting rate; and a third control unit connected with the heating device and used for controlling the heating power of the heating device to make the diameter of the crystal barat each position is within a preset range. The system makes the ratio v / G of the drawing speed of the drawn crystal bar to the temperature gradient of the solid-liquid interface kept unchanged, so that the defect concentration of the drawn crystal bar is reduced.

Owner:XUZHOU XINJING SEMICON TECH CO LTD +1

Adaptive spinal rod and methods for stabilization of the spine

ActiveUS20110307013A1Dynamic stabilityEasy to processInternal osteosythesisJoint implantsSpinal anatomySpinal locomotion

An adaptive spinal rod is provided for connecting levels of an adaptive stabilization system to support the spine while providing for the preservation of spinal motion. Embodiments of the adaptive stabilization rod include a ball having an anchor system, a deflection system, a vertical rod system and a connection system. The deflection system provides adaptive stabilization and load-sharing. The adaptive spinal rod connects different levels of the construct in a multilevel construct. The adaptive spinal rod cooperates with the deflection system to further reduce stress exerted upon the bone anchors and spinal anatomy.

Owner:FOUNDERS SPINE RES LLC

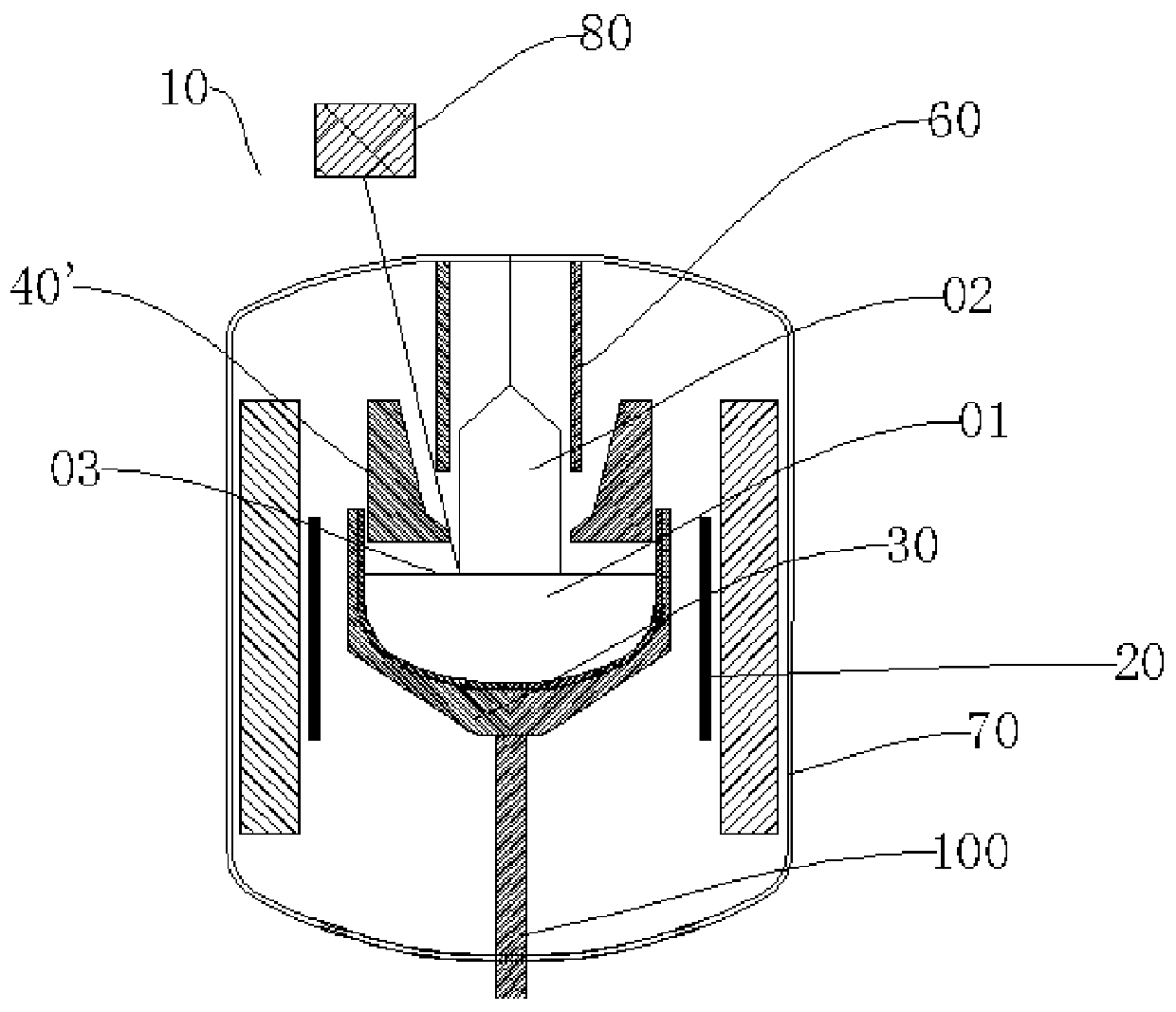

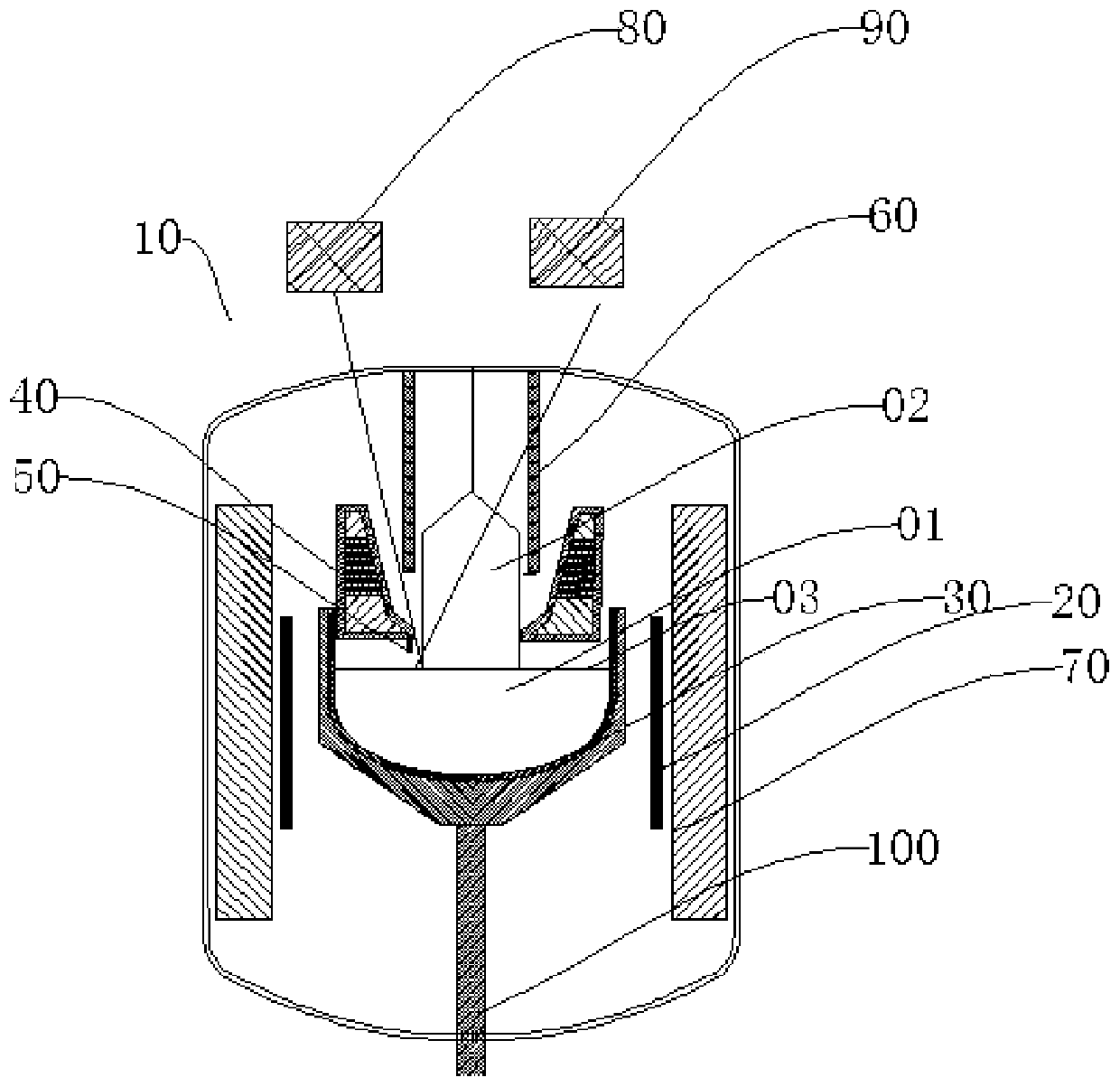

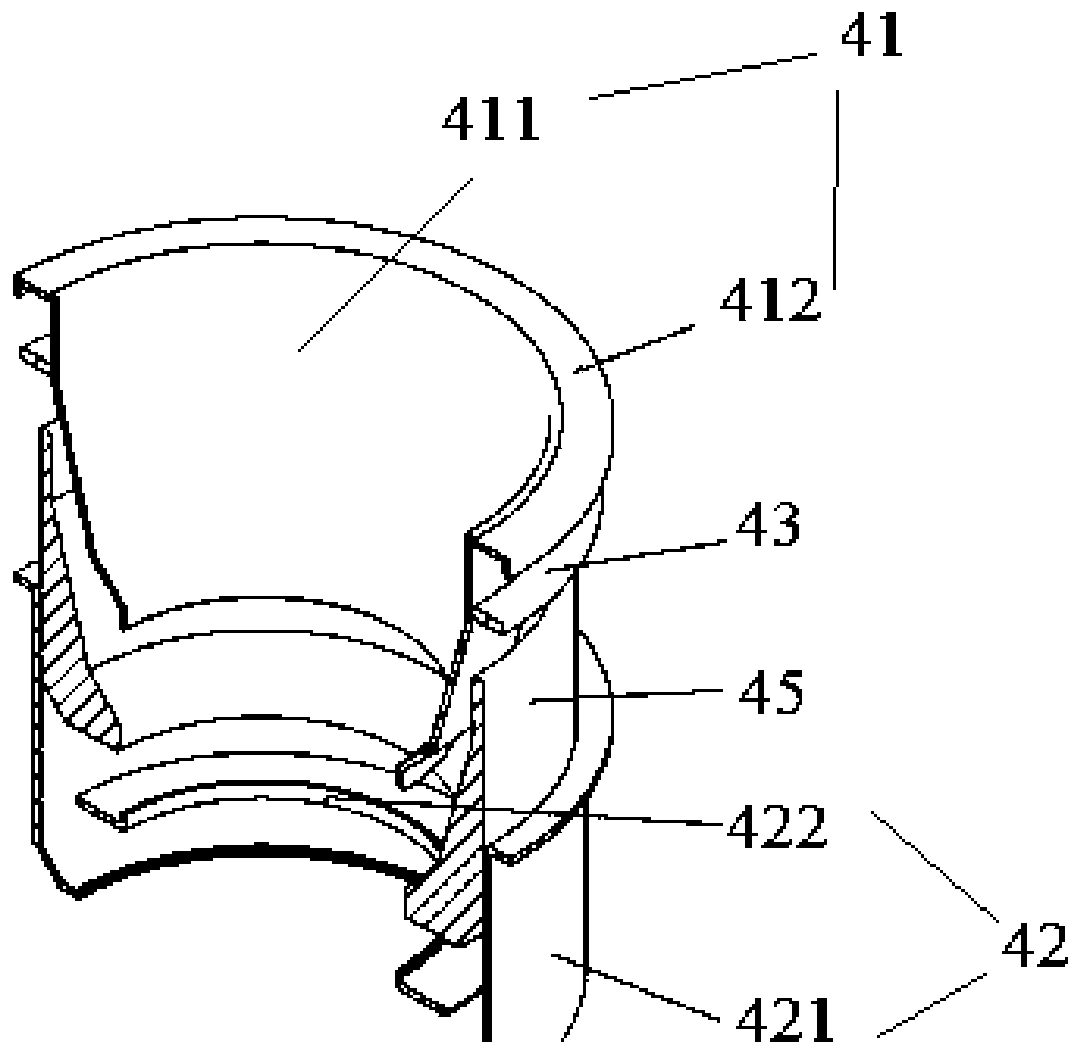

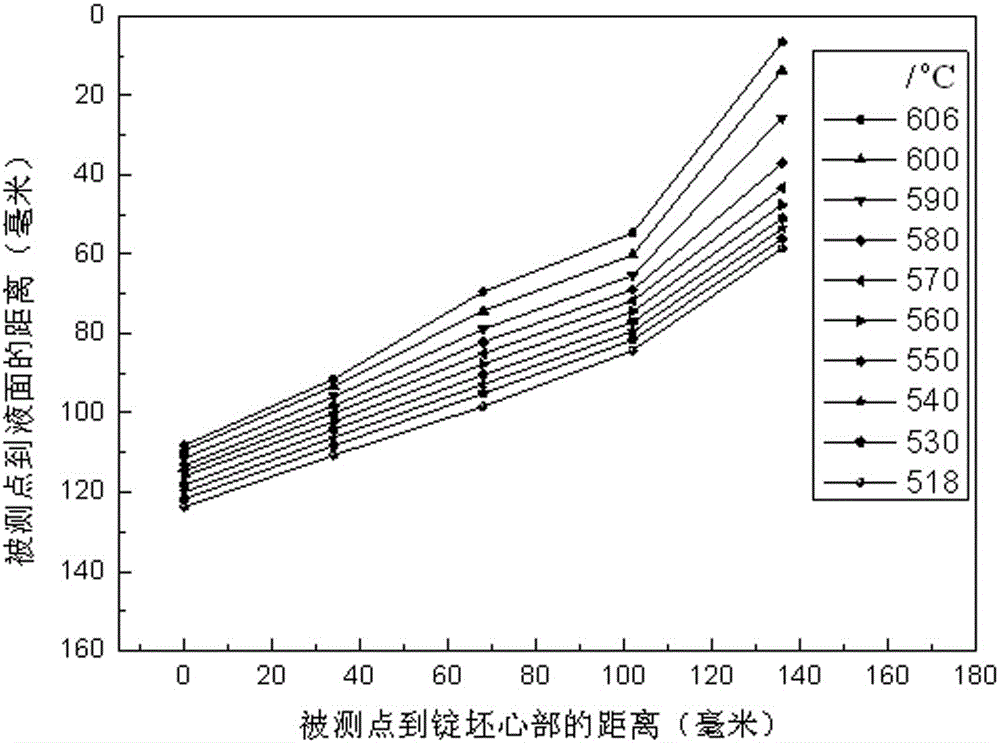

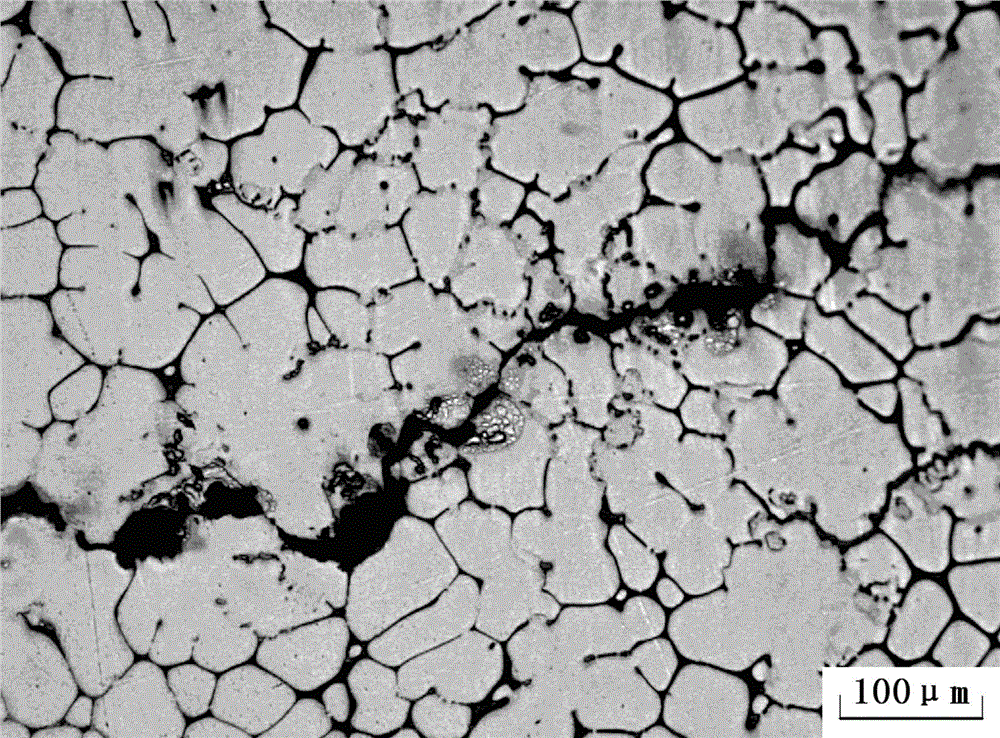

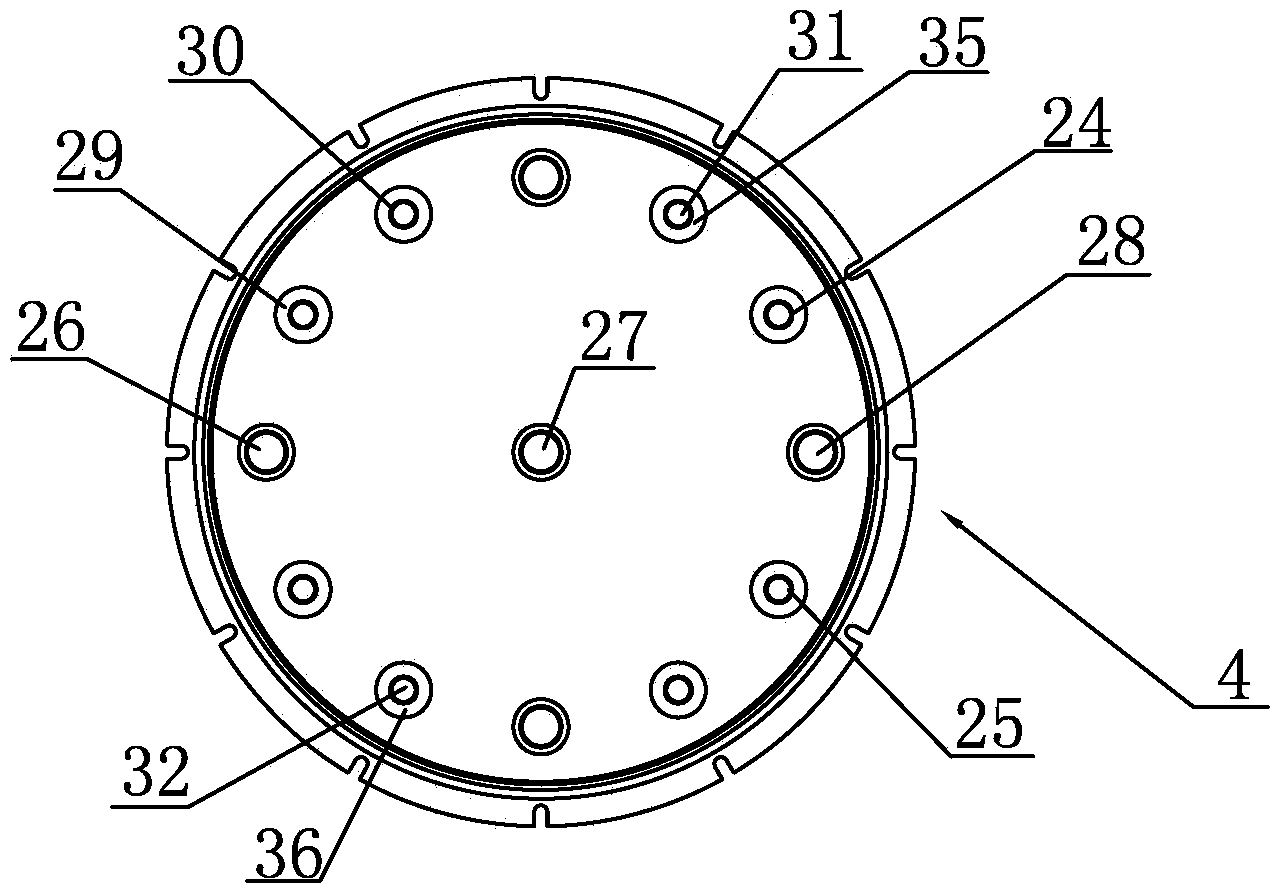

Semicontinuous casting crystallizer for restraining cracking of magnesium alloy ingot blank and use method of semicontinuous casting crystallizer

The invention discloses a semicontinuous casting crystallizer for restraining cracking of a magnesium alloy ingot blank and a use method of the semicontinuous casting crystallizer and belongs to the technical field of casting. The crystallizer comprises an inner sleeve, heat preservation layers, a cooling water tank, a magnet exciting coil and a crystallizer shell. The heat preservation layers are arranged above the inner wall of the inner sleeve or arranged above the outer wall of the inner sleeve or arranged above the inner wall and the outer wall of the inner sleeve at the same time. The inner heat preservation layer is embedded into the inner sleeve and spliced to the inner wall. The outer heat preservation layer is embedded into the inner sleeve and spliced to the outer wall of the inner sleeve. The use method comprises the steps that 1, a dummy ingot is lifted into the crystallizer; 2, cooling water is opened, and the magnet exciting coil is provided with alternating current; 3, magnesium alloy melt is stirred through Lorentz force generated by the magnet exciting coil; and 4, after a stable solidified shell is formed, a casting machine is started, and the ingot blank is pulled out of the crystallizer. The method and crystallizer are reasonable, and the cracking tendency of alloy ingot blanks prone to crack and flat blanks and round blanks of large specifications in the semicontinuous casting process can be effectively lowered.

Owner:NORTHEASTERN UNIV

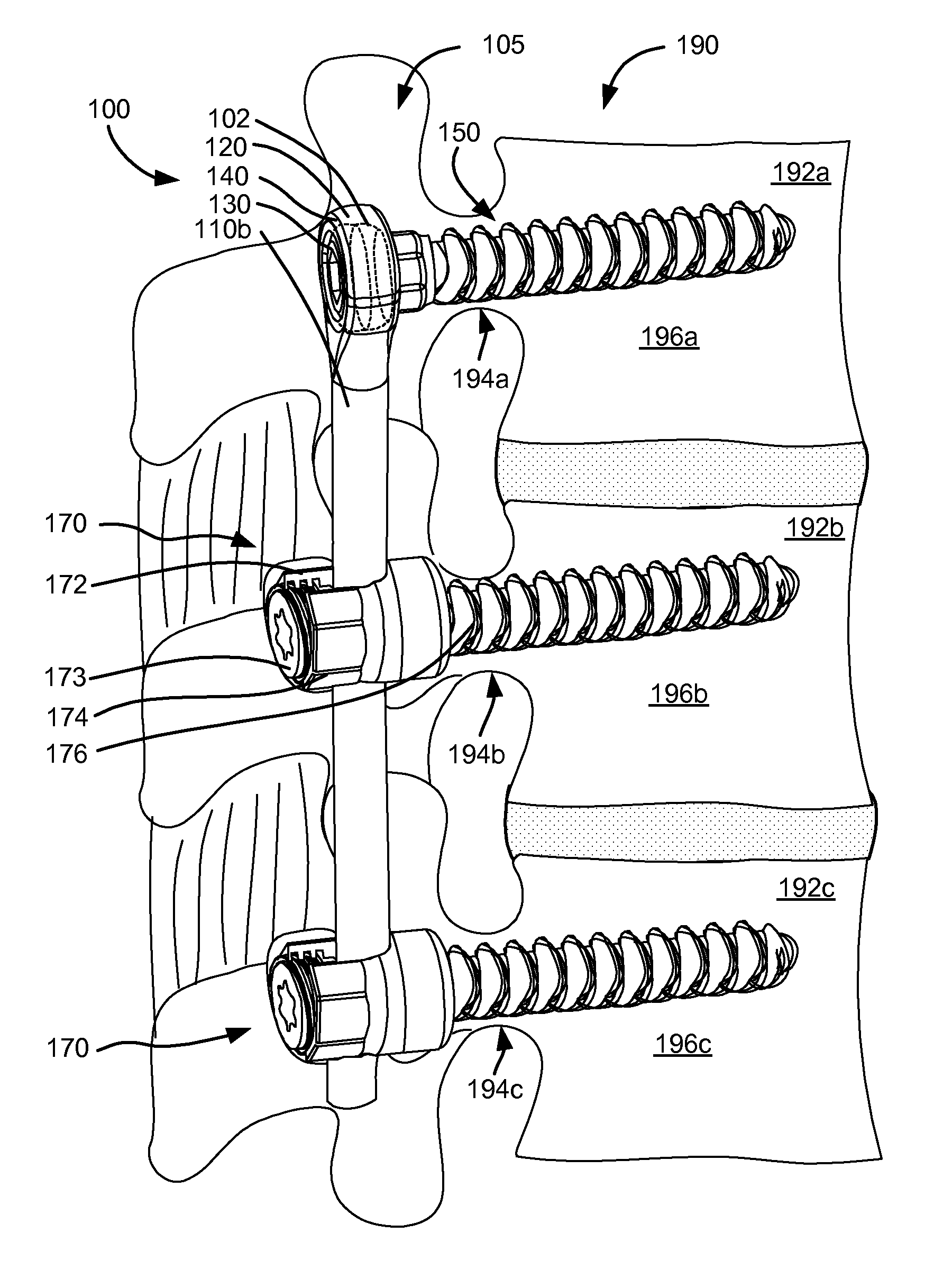

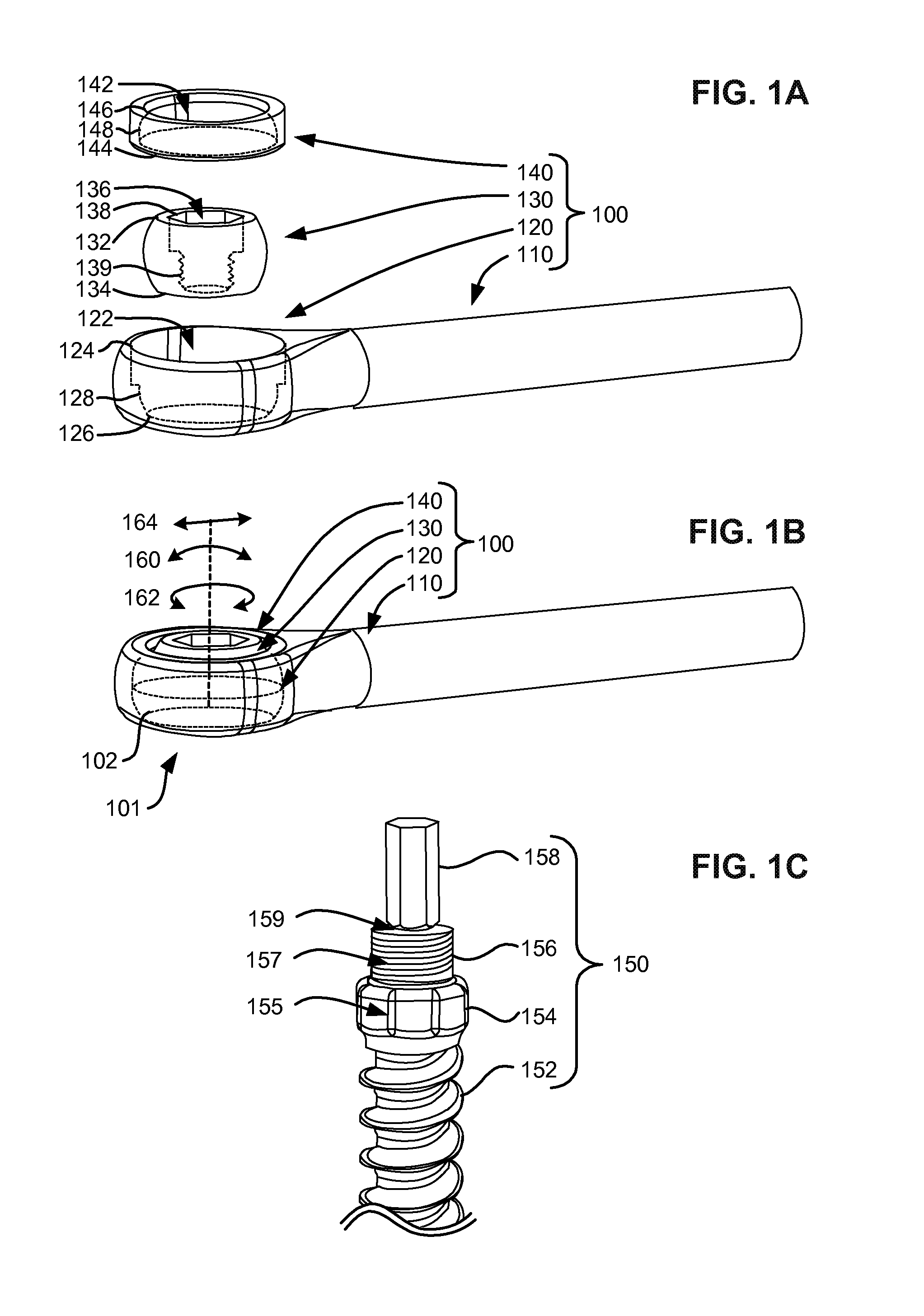

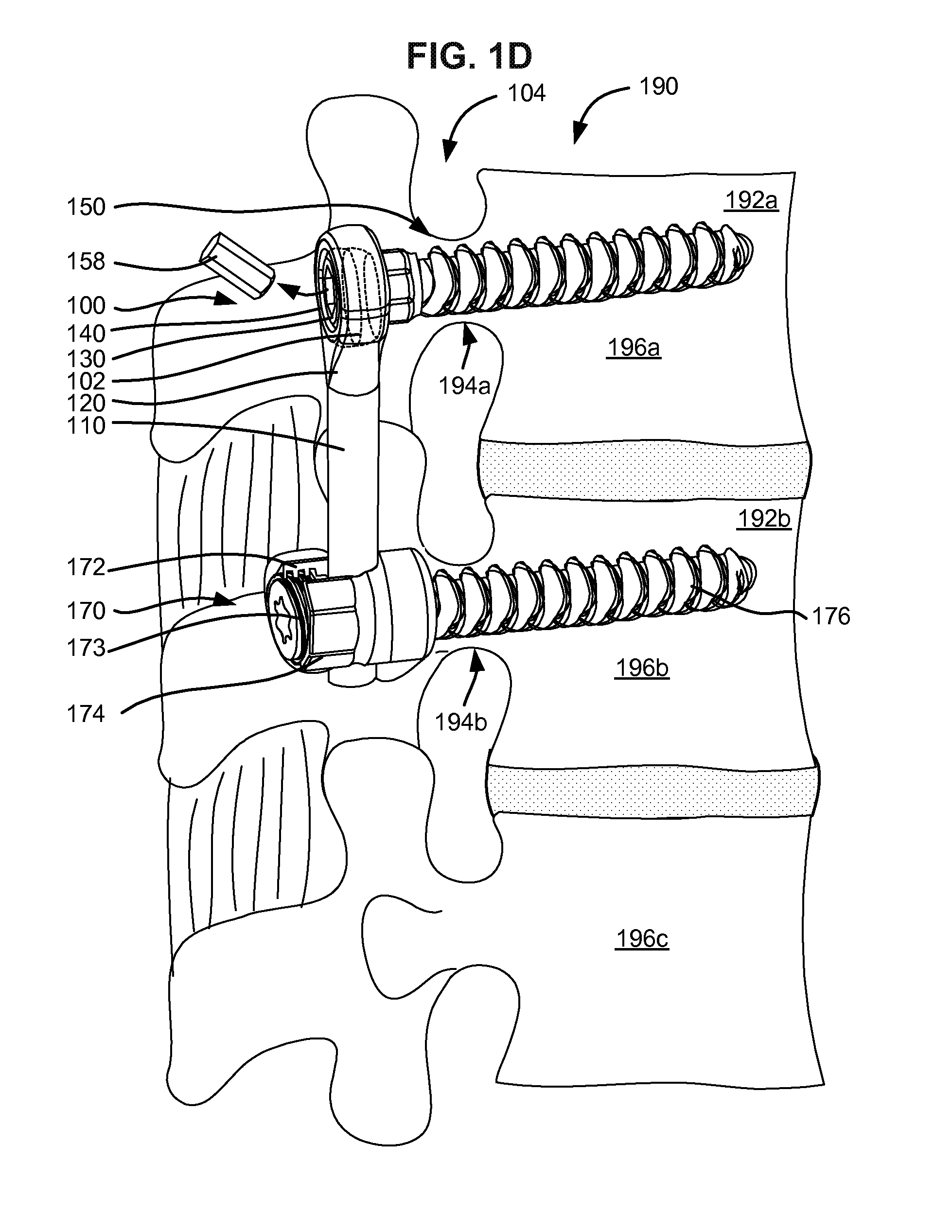

Configurable dynamic spinal rod and method for dynamic stabilization of the spine

InactiveUS8021396B2Dynamic stabilityStabilize twoSuture equipmentsInternal osteosythesisBone anchorSpinal anatomy

A configurable dynamic spinal rod for connecting levels of a dynamic stabilization system to support the spine while providing for the preservation of spinal motion. Embodiments of the dynamic stabilization system have an anchor system, a deflection system, a vertical rod system and a connection system. The deflection system provides dynamic stabilization and load-sharing. The dynamic spinal rod connects different levels of the construct in a multilevel construct. The dynamic spinal rod cooperates with the deflection system to further reduce stress exerted upon the bone anchors and spinal anatomy. A configurable lock is provided which can selectably lock an angle between the dynamic spinal rod and a dynamic bone anchor.

Owner:SPARTEK MEDICAL

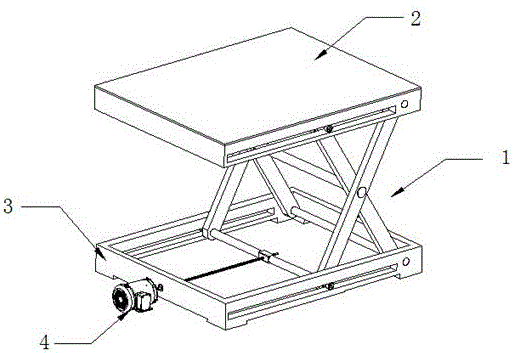

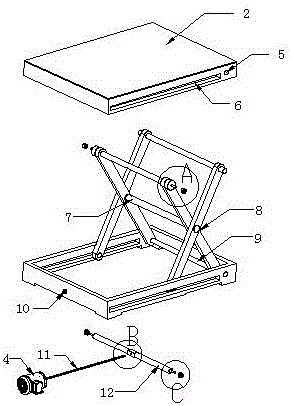

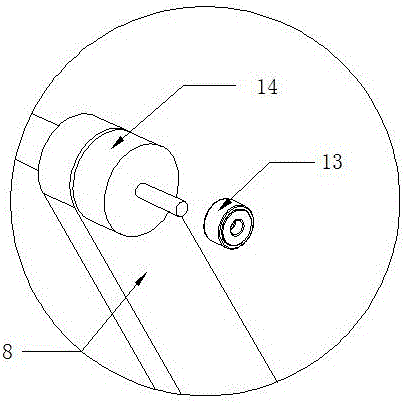

Lifting device with height adjusting function

InactiveCN106698251AIt has the function of bearing noonEasy to adjustLifting framesEngineeringMechanical engineering

Owner:李理

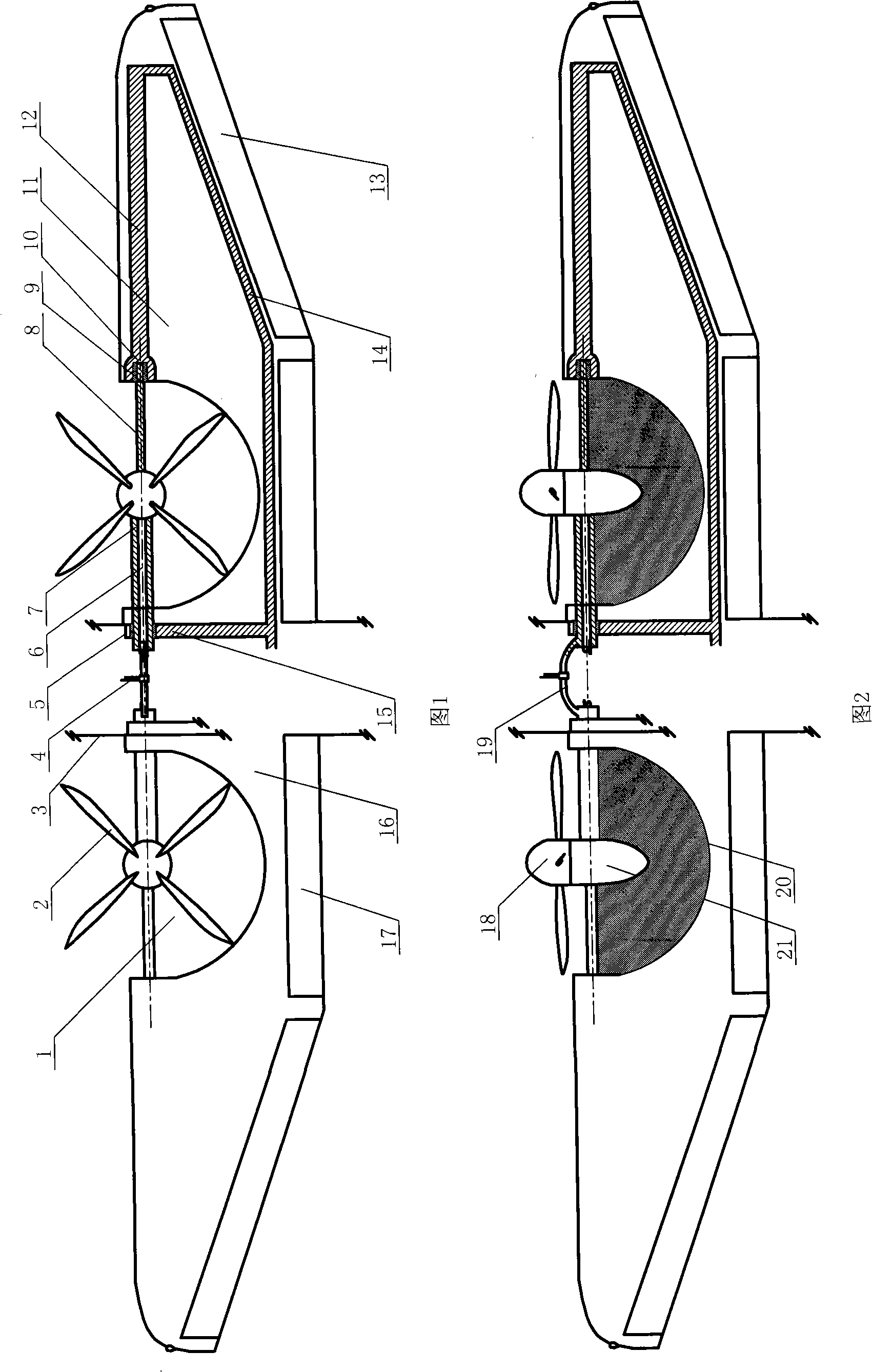

Split type wing

InactiveCN101274666AStrong bearing structureEnsure lateral stabilityVertical landing/take-off aircraftsRotocraftLevel flightAirframe

The invention discloses a cracking combined type wing which comprises a wing body which is connected with the main force-bearing frame of an airframe. The main force-bearing frame of the airframe is moveably provided with the rotatable section of a main wing beam and the two ends of the rotatable section of the main wing beam are connected with the unrotatable section of the main wing beam. The left and right sections of the rotatable section of the main wing beam are respectively provided with a cracking combined aerofoil which is provided with a set of rotating power devices at the front part. The cracking combined type aerofoil is positioned in a cracking communicating space of the wing body while the shape of the space is the same as that of the aerofoil. The left side and the right side of the wing body are fixedly connected with an external wing with a large span. The cracking combined type wing can minimize unbalanced moments caused during the vertical take-off and landing of an aircraft and resistance against the wind of the wing during the transition flight, meanwhile, the whole wing, more particularly the external wing with large span, remains stationary horizontally all the time, thus ensuring the stability of the aircraft during the vertical take-off and landing as well as smooth transition to the level flight so as to meet the user requirements.

Owner:穆骞

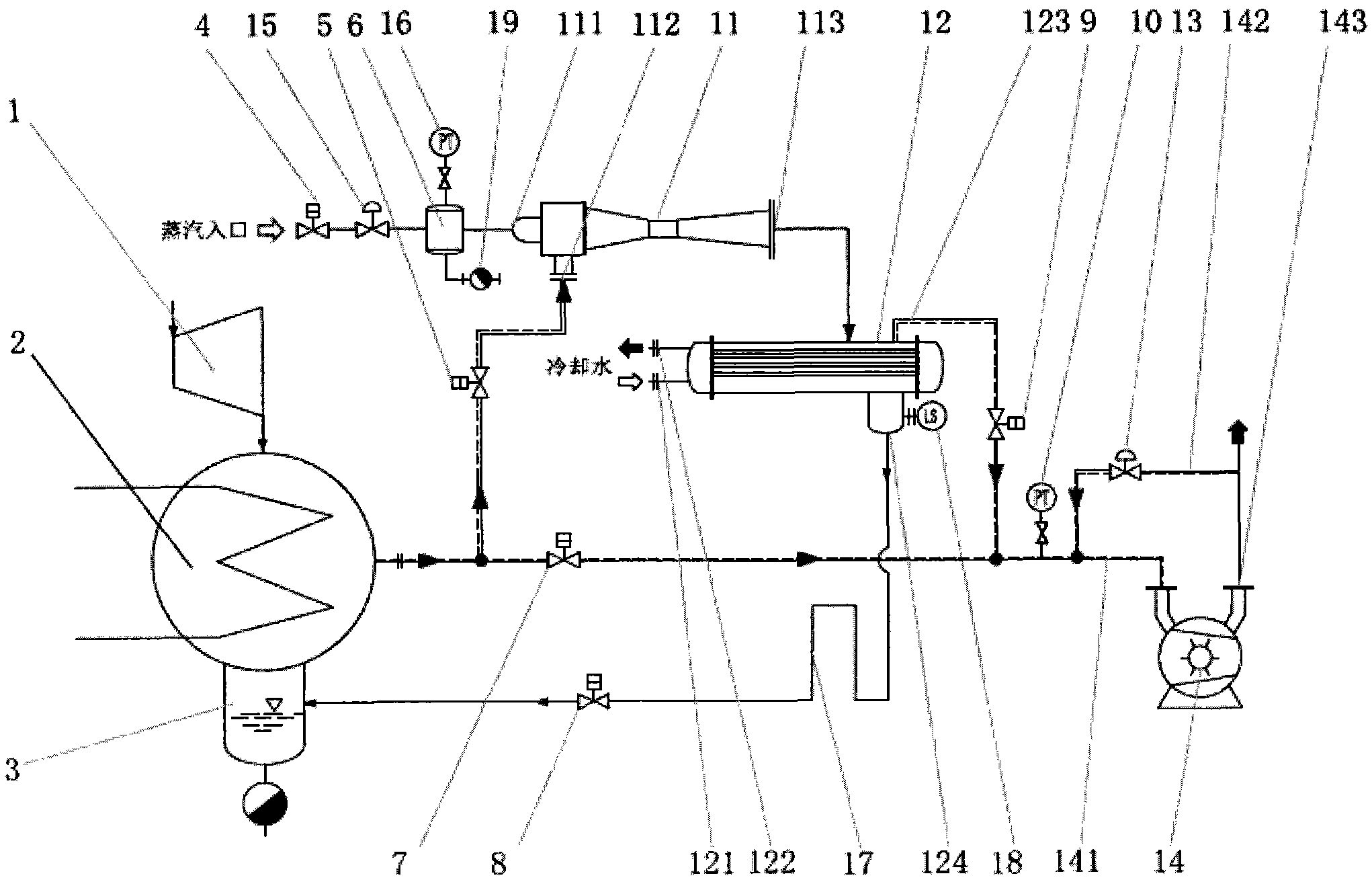

Power plant condenser steam jet and vacuumizing system with pressure control function

The invention provides a power plant condenser steam jet and vacuumizing system with a pressure control function. The system comprises a steam turbine (1), a condenser (2), a condenser hot well (3), a power steam pressurizer (6), a steam ejector (11), a steam condenser (12), a water ring vacuum pump (14), a condensate discharge valve (8) of the steam condenser, a condensate drain pipeline water seal (17), a condensate pipeline liquid level switch (18), a pressure adjusting valve (13) on the inlet of the water ring vacuum pump, multiple control valves and pipelines, wherein the control valves and the pipelines are arranged among the parts. Due to the fact that pressure control of power steam, control of the liquid level after condensates flow back to the condenser hot well and inlet pressure control of the water ring vacuum pump are adopted, the vacuumizing system can maintain the maximum vacuum degree of the condenser, force of the condenser is improved, the vacuum degree of the condenser is improved, the heat consumption rate of the steam turbine is lowered, and coal consumption for unit power generation is lowered. The system is safe and free of maintenance, guarantees 100% of force and can operate stably for a long time. A pressure backflow adjusting system is arranged on the final-stage exhaust device, namely the water ring vacuum pump, so that it is guaranteed that the cavitation phenomenon of the water ring vacuum pump does not happen.

Owner:浦江瑞尔科技有限公司

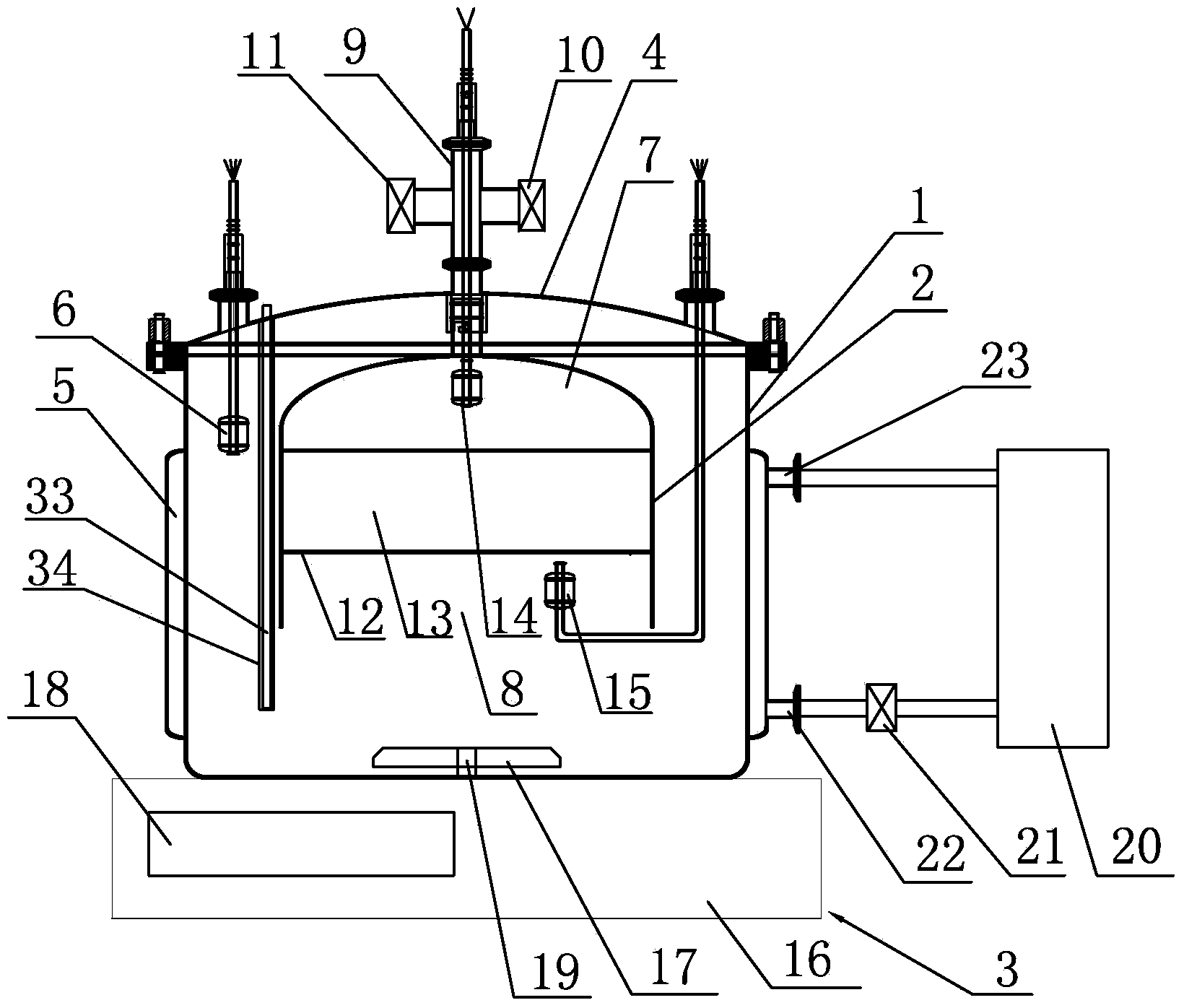

Pneumatic self-circulation animal cell culture bioreactor and application method thereof

ActiveCN103589638AGuaranteed uniformityReasonable structural designBioreactor/fermenter combinationsBiological substance pretreatmentsHeating systemEngineering

The invention discloses a pneumatic self-circulation animal cell culture bioreactor and an application method thereof. The bioreactor is characterized by comprising a large tank, a small tank located in the large tank, a magnetic stirring system located at the bottom of the large tank, a heating system and a controlling system, wherein a sealing cover is arranged at the upper end of the large tank, jackets connected with the heating system are arranged on two sides of the large tank, and a highest liquid level sensor of the large tank is arranged at the upper part in the large tank; and a sealing head is arranged at the upper end of the small tank, an opening is formed in the lower end, the sealing head is fixedly connected in a sealing manner with the sealing cover through a breathing pipe, the upper end of the breathing pipe penetrates out of the sealing cover and is connected with a vacuum air pump and an air pressure pump respectively, the lower end penetrates out of the sealing head and enters the small tank, a cavity used for accommodating a cell carrier is defined by two up-and-down horizontal stainless steel wire mesh boards in the middle of the small tank and the inner wall of the small tank, an upper liquid level sensor of the small tank is arranged above the cavity, and a lower liquid level sensor of the small tank is arranged below the cavity. The pneumatic self-circulation animal cell culture bioreactor has the advantages of good air tightness, simplicity in operation, low contamination rate, good cell quality and high yield.

Owner:罗火生

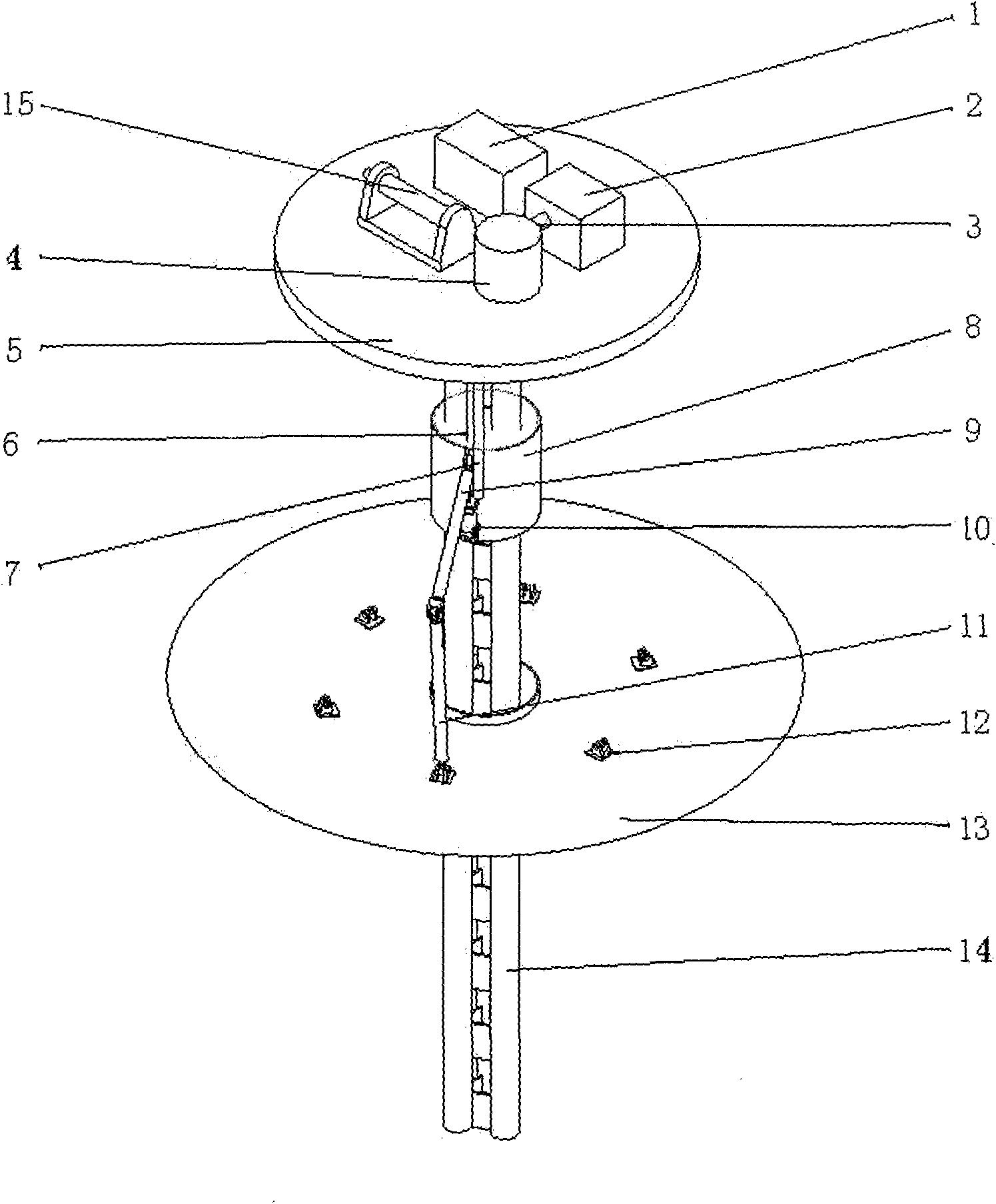

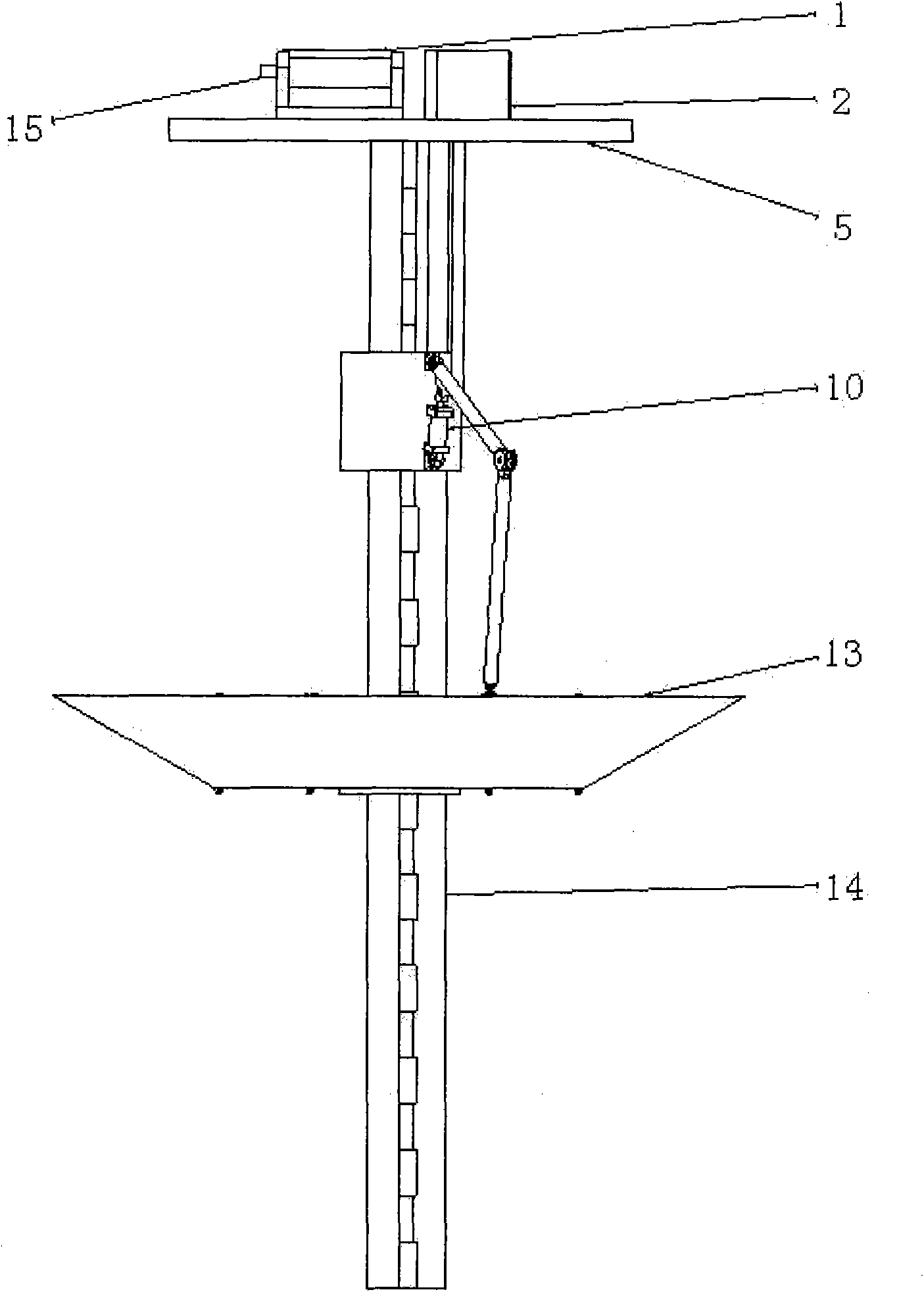

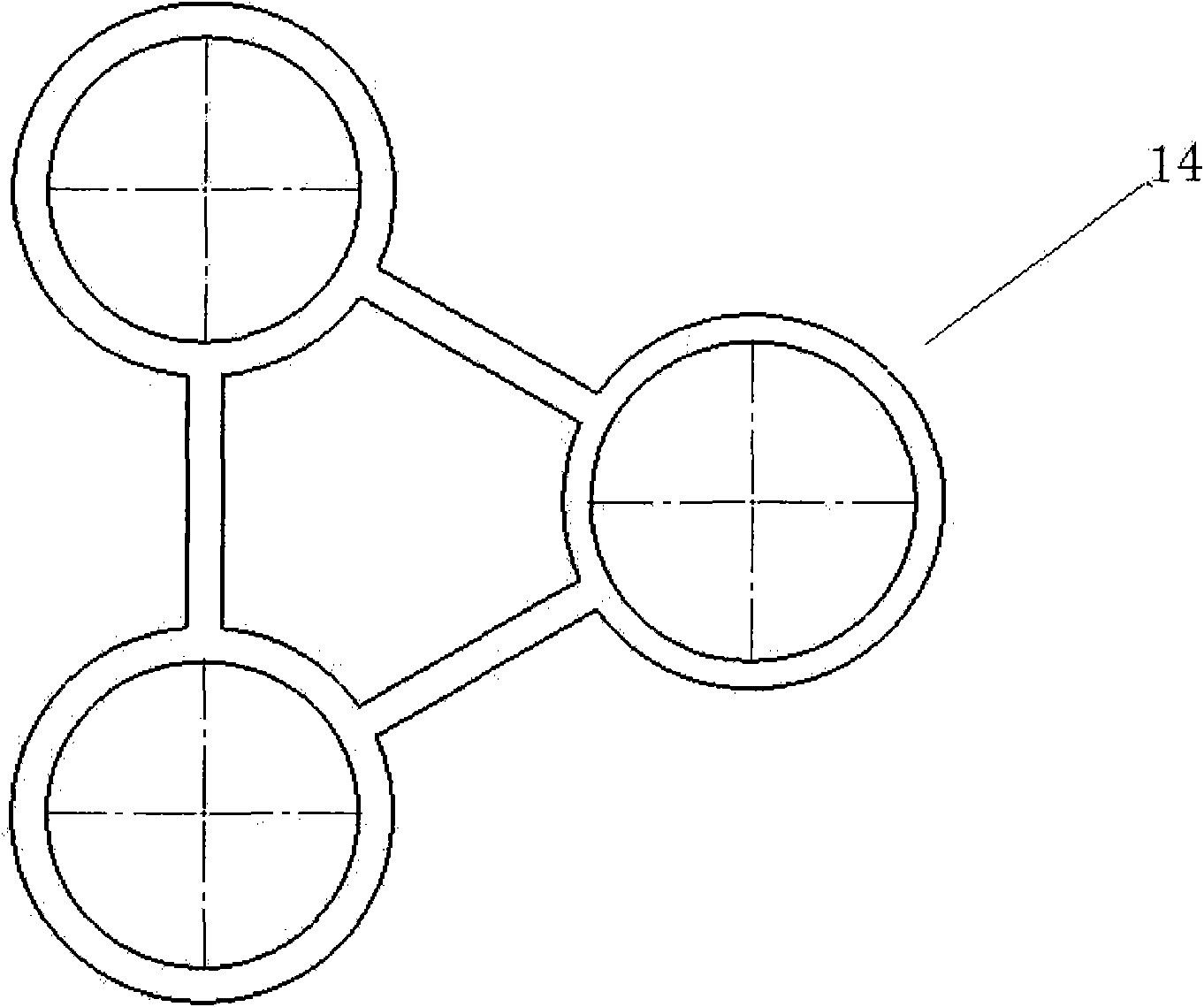

Wave electric power system

InactiveCN102400840ALow costImprove bending resistanceMachines/enginesEngine componentsElectric power systemEngineering

The invention discloses a pontoon-hydraulic lattice column type wave electric power system connected with a corrosion-resistant slip sheet linkage mechanism. The wave electric power system is characterized in that: a main fixed pile 14 consists of N (N is more than or equal to 3) subpiles which are arranged in a lattice column mode; a primary transduction system consists of a special disk-shaped pontoon 13 which is connected with the linkage mechanism and sleeved on the linkage mechanism, a hydraulic transmission mechanism and a control mechanism; wherein the linkage mechanism consists of slip sheets which are made of materials such as seawater corrosion-resistant resin and the like, a connecting rod fixing base 12, a buffer rope and connecting rods (9 and 11); the hydraulic transmission mechanism consists of a hydraulic motor 2, an oil tank 4, N( N is more than or equal to 3) hydraulic cylinders 10 and hydraulic oil pipes (3, 6 and 7); the control mechanism consists of a lifting mechanism 15 and a control platform 8; a second transduction system consists of a generator 1 on a working platform 5 and converts mechanism energy into electric energy. The wave electric power system has the advantage of high conversion efficiency, facilitates project implementation and has high seawater corrosion resistance and high capacity of resisting damage of wind and wave.

Owner:TAIHE WAVE ENERGY RES CENT QINGDAO ECONOMIC TECH DEV ZONE

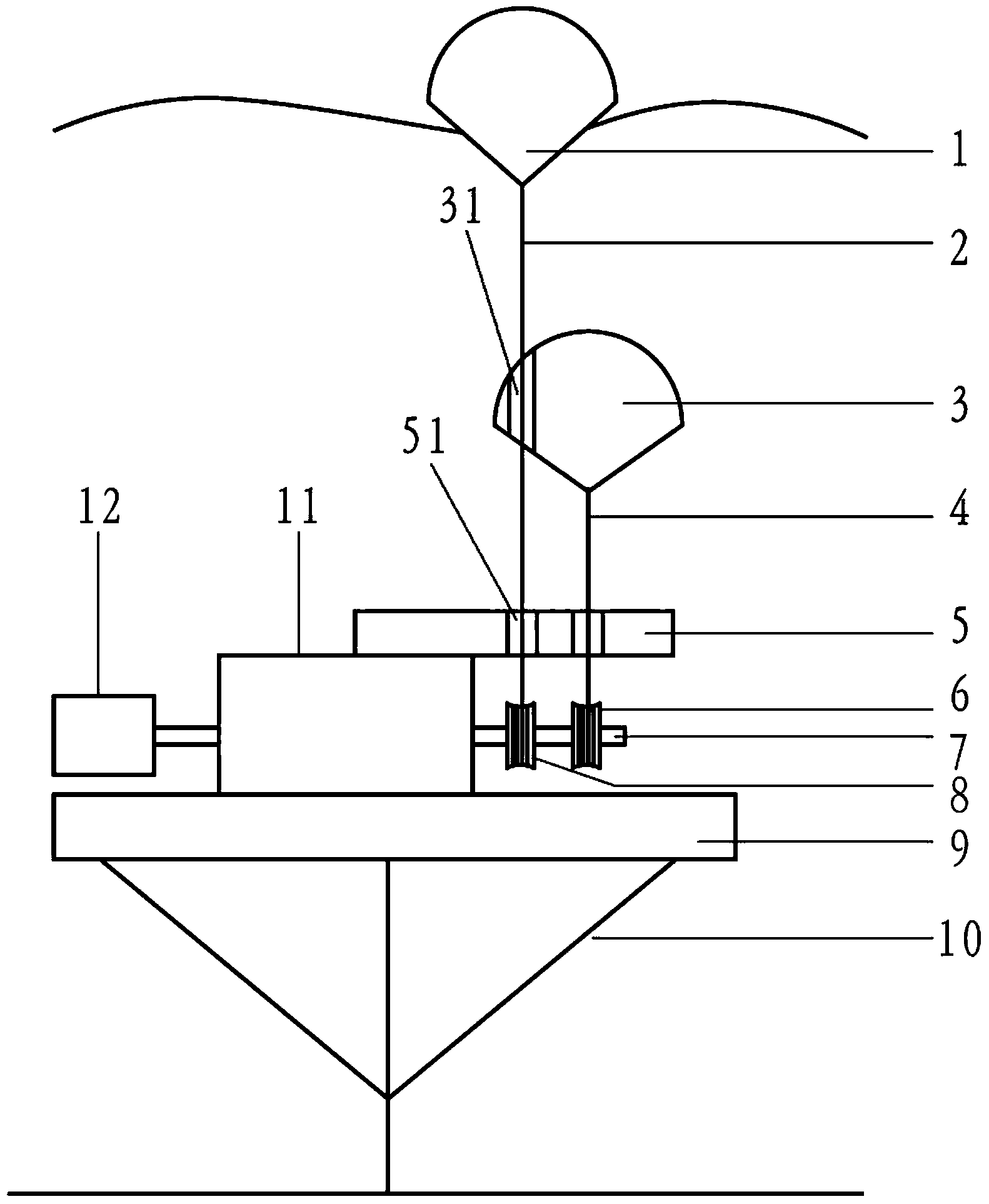

Wave power generation device and wave power generation method for underwater balanced type dual floating bodies

InactiveCN103452743AImprove power generation efficiencyDynamic stabilityMachines/enginesEngine componentsOcean bottomWave power generation

The invention discloses a wave power generation device and a wave power generation method for underwater balanced type dual floating bodies. The device comprises a submarine bench, a transmission case and a pair of balanced type dual floating bodies, wherein the submarine bench is anchored on the seabed by virtue of a group of anchor chains or mooring ropes; the transmission case is arranged on the submarine bench, a first rope pulley and a second rope pulley are sleeved on one side end of a main shaft of the transmission case, and the output end of the transmission case is connected to a power generator; the pair of balanced type floating bodies comprises a group of surface floating bodies positioned on the water surface so as to collect wave energy and a group of underwater floating bodies soaked in the sea and positioned at a static water layer; the surface floating bodies and the underwater floating bodies are respectively pulled by one mooring rope; the lower ends of the mooring rope used for pulling the surface floating bodies and the mooring rope used for pulling the underwater floating bodies are respectively wound on the first rope pulley and the second rope pulley. According to the device and the method, a mode that the balanced type dual floating bodies work alternately and perform circulating continuous full-wave acting is adopted, so that the wave power generation efficiency is improved, and technical support is provided for realizing the commercialization of wave power generation.

Owner:祁国英

Emergency equipment for quickly clearing traffic congestion

InactiveCN102644239ASolve traffic jamsImprove work efficiencyConstructionsDelivery vehicleLocking mechanism

The invention discloses emergency equipment for quickly clearing traffic congestion. The emergency equipment comprises a motorized delivery vehicle and a folding simple steel bridge which is arranged on the motorized delivery vehicle, wherein the folding simple steel bridge has a hinge structure which is formed by connecting a plurality of sections of bridge bodies by using hinges; a stretch driving mechanism and a locking mechanism are arranged between adjacent sections of bridge bodies; the motorized delivery vehicle is provided with a rotary disc; and the rotary disc is connected with one section of bridge body through a lifting mechanism. The emergency equipment for quickly clearing traffic congestion can quickly reach a site of traffic congestion through the vehicle-mounted folding simple steel bridge, and the folding simple steel bridge can be stretched by standing on an unblocked half-range road on the other side of one-way traffic congestion, so that vehicles on the half-range road in traffic congestion can be drained, and the problem of traffic congestion is solved.

Owner:HENAN AUSPIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com