Wave electric power system

A technology of wave power generation and sliding vane, which is applied in ocean energy power generation, engine components, machines/engines, etc., can solve the unreported hydraulic transmission wave power generation system, affect the practicality and industrialization of wave power generation, and the engineering feasibility of wave power generation To achieve the effect of enhancing the ability to resist sea wind and wave damage, long trouble-free service life, and superior seawater corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Please refer to the following detailed description of a preferred embodiment of the present invention and accompanying drawings to further understand the technical content of the present invention and its purpose and efficacy.

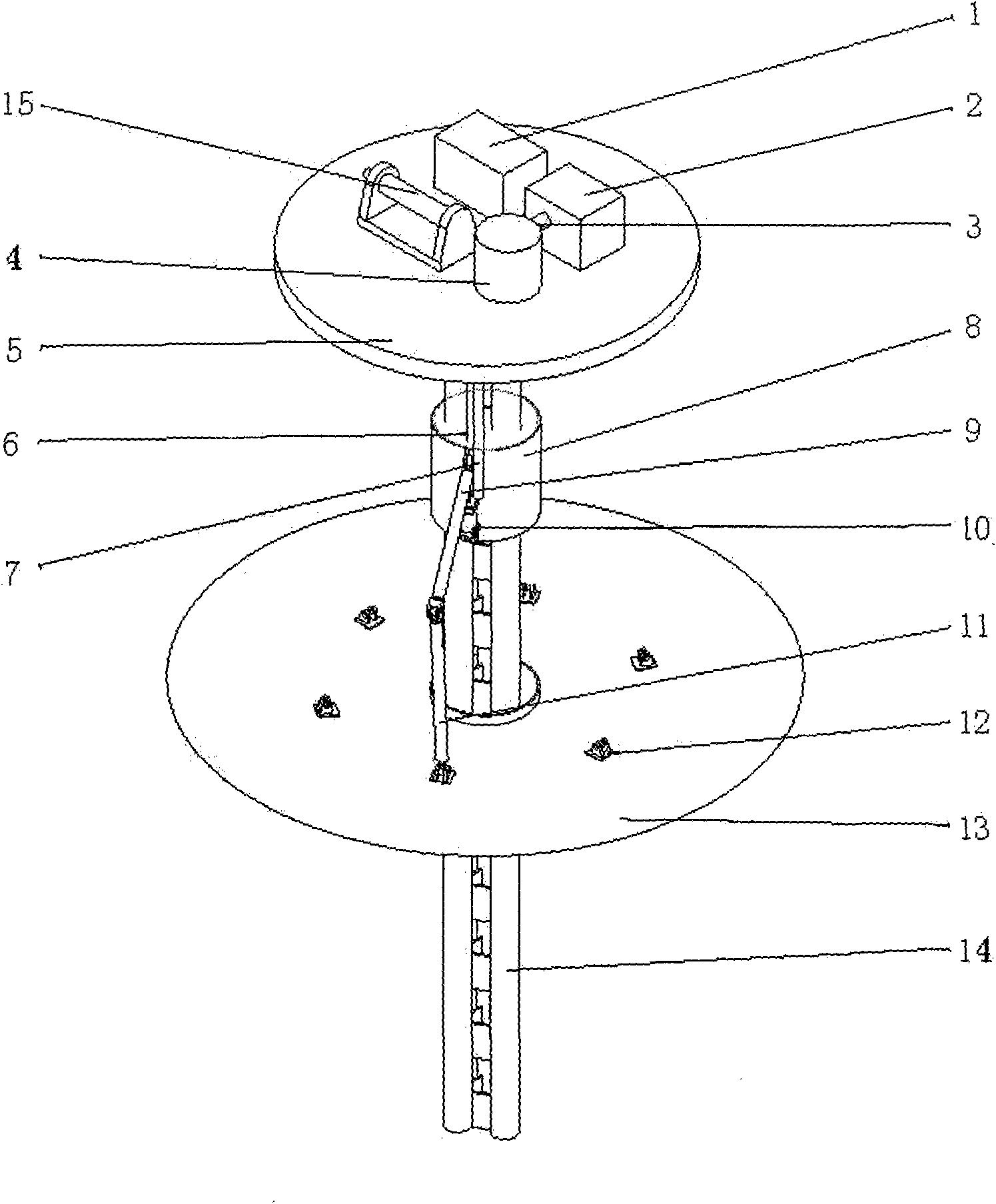

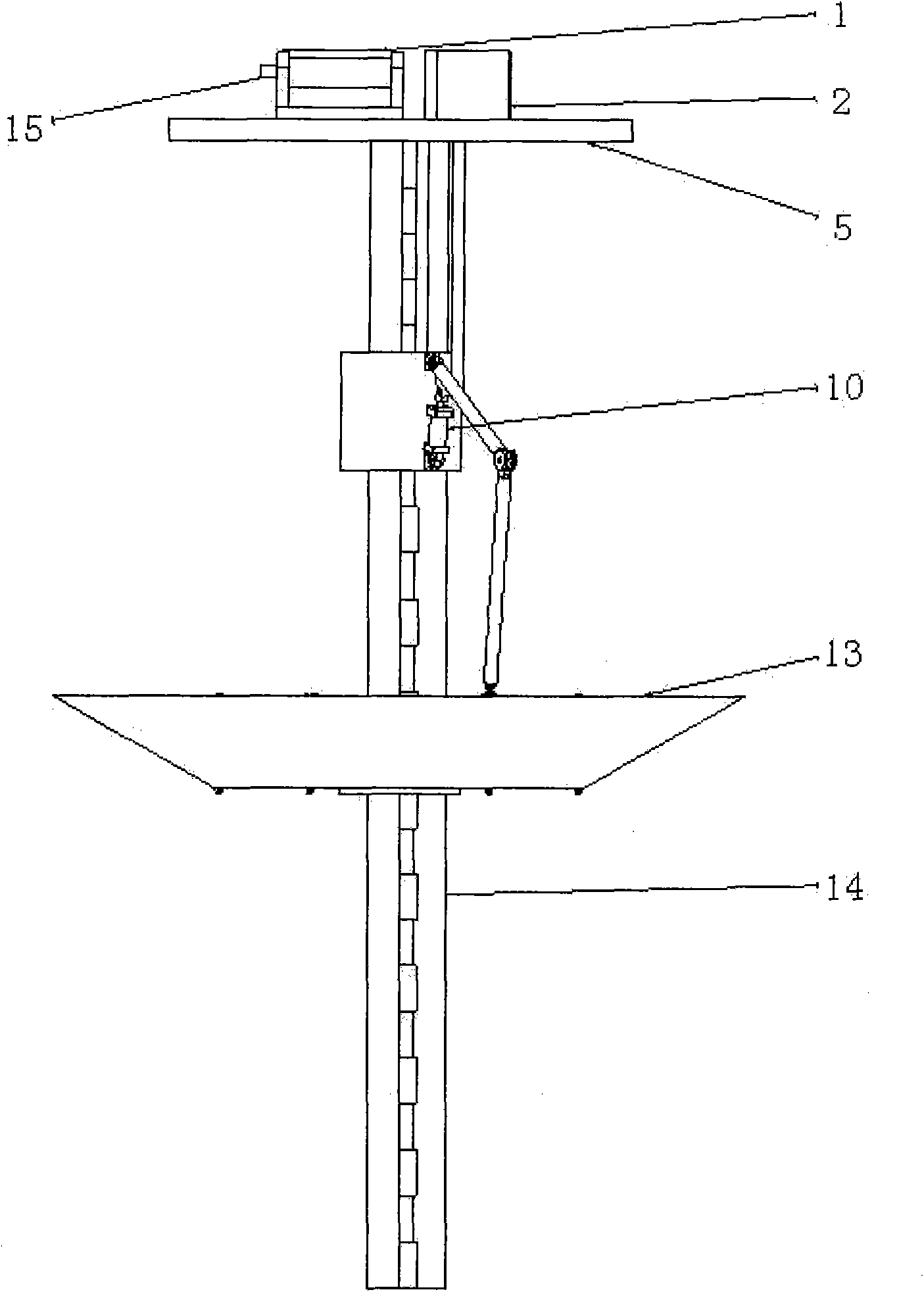

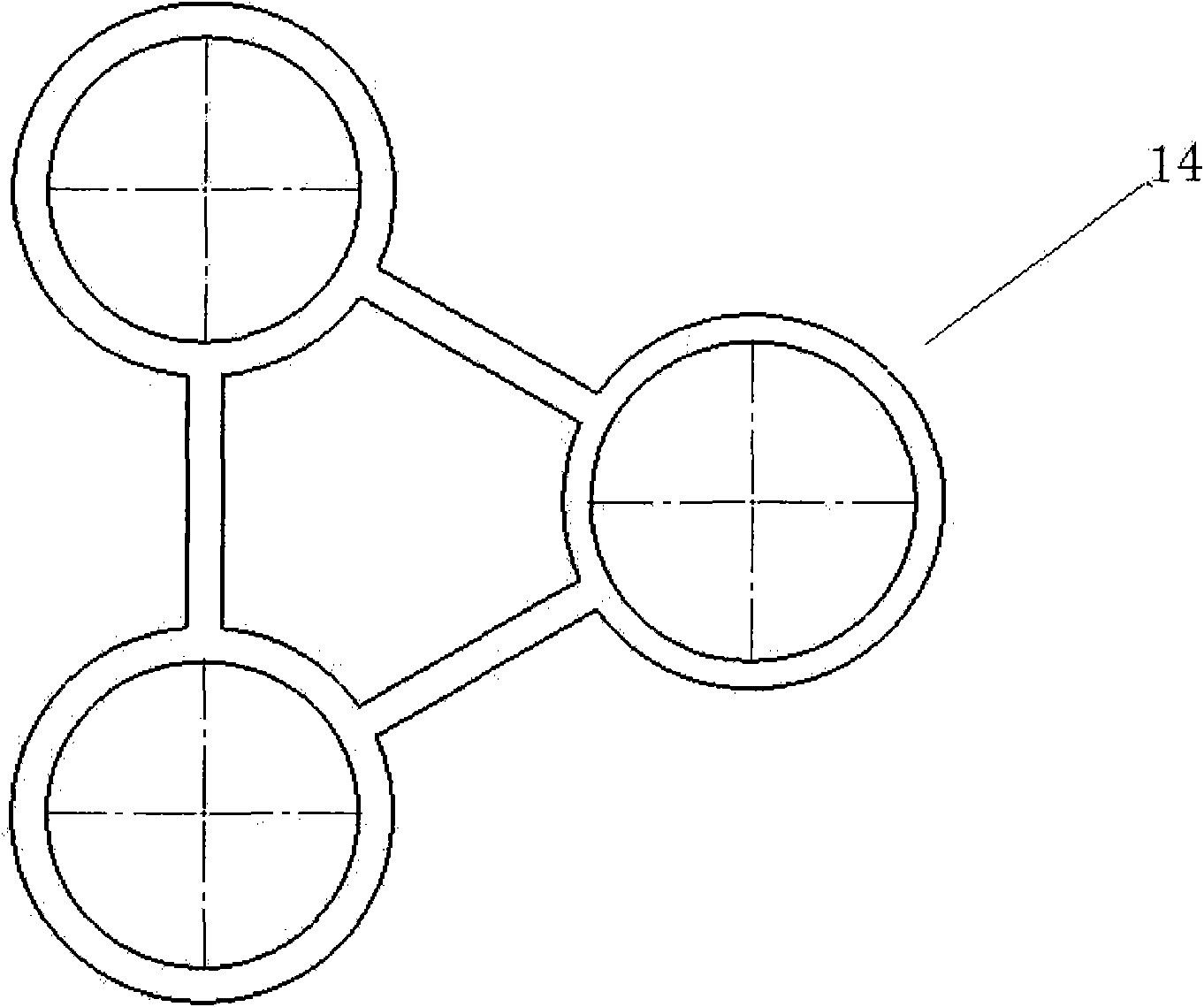

[0030] see figure 1 and figure 2 The lattice column type wave power generation system provided by the present invention has a working platform 5, which is used to place various devices such as the lifting mechanism 15, the hydraulic motor 2, and the generator 1; a control platform is arranged below the working platform 5 8. There is a hydraulic cylinder 10 on it, and the small platform is connected to the special-shaped dish-shaped buoy 13 at the lower part through the corrosion-resistant sliding piece connecting the pull rods 9 and 11; The disc buoy runs smoothly up and down. The special-shaped dish-shaped buoy moves up and down with the help of waves, and connects the pull rods 9 and 11 through corrosion-resistant slides to drive the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com