Split type wing

A composite and composite wing technology, applied in the field of aircraft wings, can solve problems such as the inability to smoothly transition to the state of level flight, the inability to meet the needs of use, and the large wind resistance of the wing, so as to eliminate unbalanced disturbance torque and ensure lateral stability. The effect of stability and stress dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

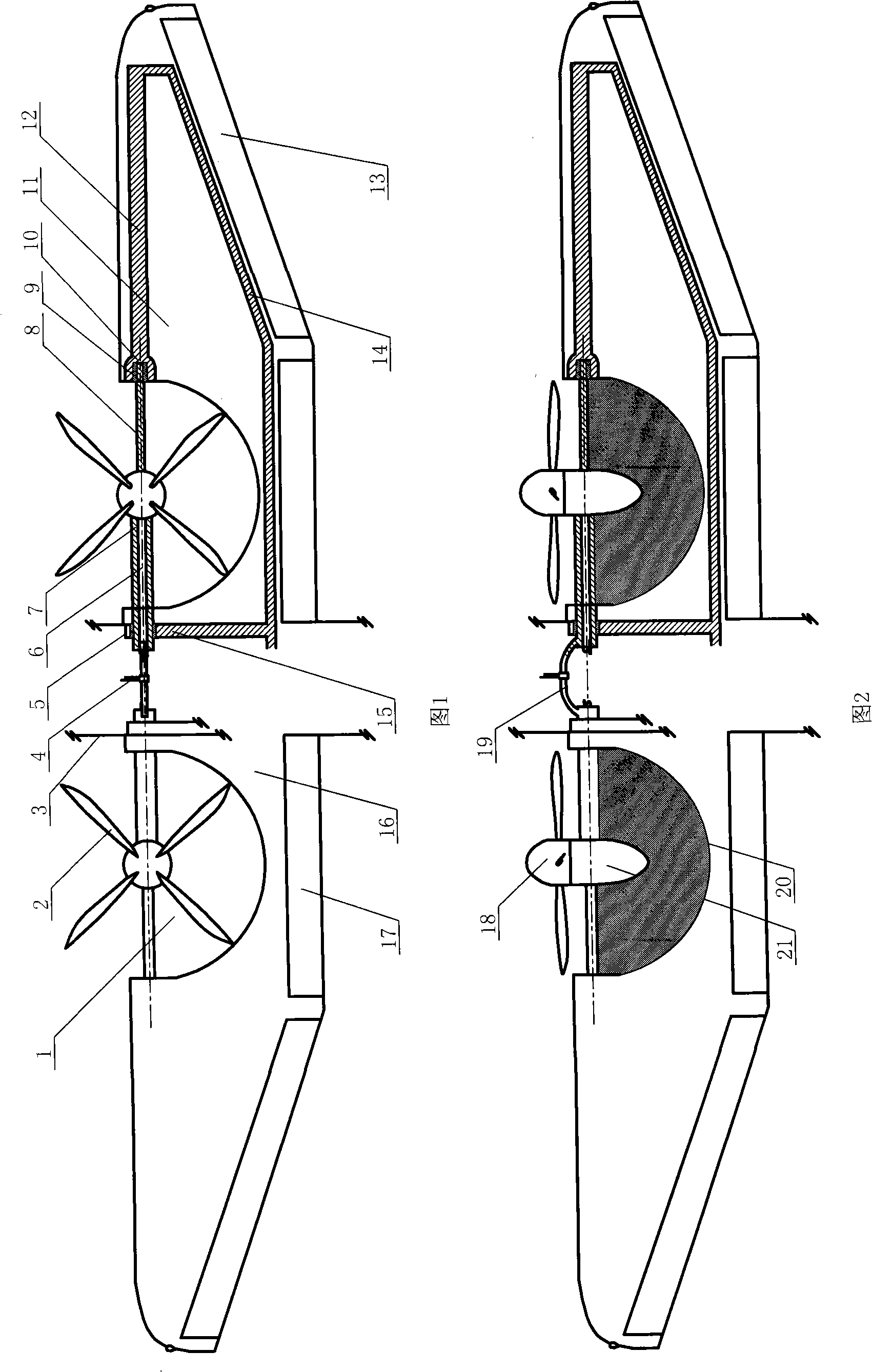

[0010] The cracked composite wing of the present invention comprises a wing main body 16, the wing main body 16 is connected with the main load-bearing frame 15 of the body, and the tiltable section of the main spar is movably installed on the main load-bearing frame 15 of the body, and the main spar can be tilted The two ends of the section are movably connected with the non-tilting section 12 of the main spar, and a split composite airfoil 20 is respectively installed on the left and right sides of the tiltable section of the main spar, and a group of tilting power devices are arranged in front of each split composite airfoil 20 . The wing main body 16 is provided with a cracked through space with the same shape as the cracked composite airfoil 20. The cracked composite airfoil 20 is located in the cracked through space, and the left and right sides of the wing main body 16 are fixedly connected to the outer wing with a large span. When taking off vertically, the tiltable se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com