Cable Anchorage and Cable Force Testing Device for Low-tower Cable-Stayed Bridge Used in Large-scale Model Test

A model test and test device technology, applied in the direction of tension measurement, etc., can solve problems such as large error in experimental data, cable force adjustment, cable slippage, slack, etc., to achieve a strong structure at the bearing point, convenient and quick adjustment, and ease of vibration effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

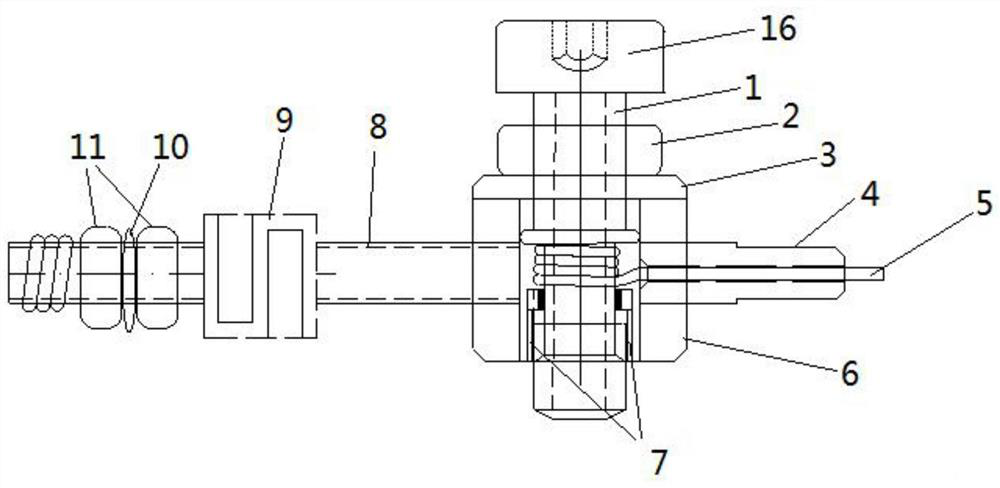

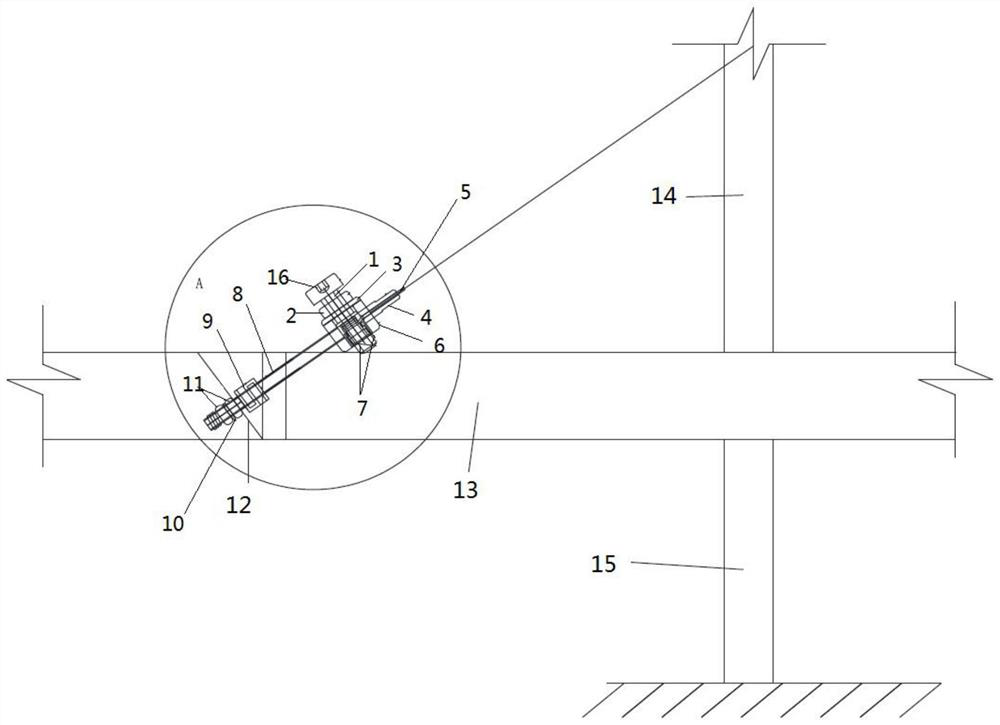

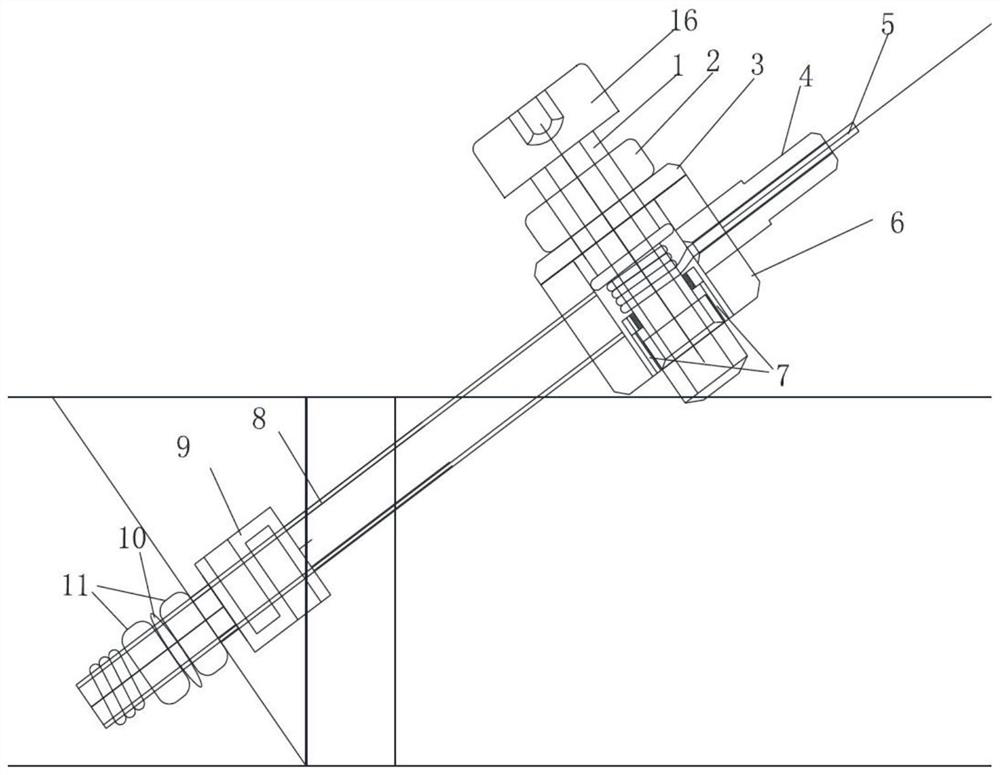

[0043] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0044] The present invention aims to solve the problem that the S-shaped steel bar meter is installed in the middle of the cable in the prior art. Because the cable is too thin, it is difficult to fix the sensor when connecting, and the quality of the sensor is relatively large compared with the cable of the test model. After being connected in series with the stay cable, the stay cable is prone to slipping and loosening, the anchorage system fails, and the quality, stiffness and other properties of the whole stay cable change, resulting in large errors in the experimental data; The problem of inconvenient cable adjustment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com