Fully-automatic production equipment for cold granulation of lead ingot

A production equipment, fully automatic technology, applied in the field of soft metal cold granulation equipment, can solve the problems of complex feeding and conveying mechanism, unfavorable maintenance and replacement of roller body, slow feeding action, etc., to achieve stable and reliable power system, smooth conveying without The effect of shaking and transmitting large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

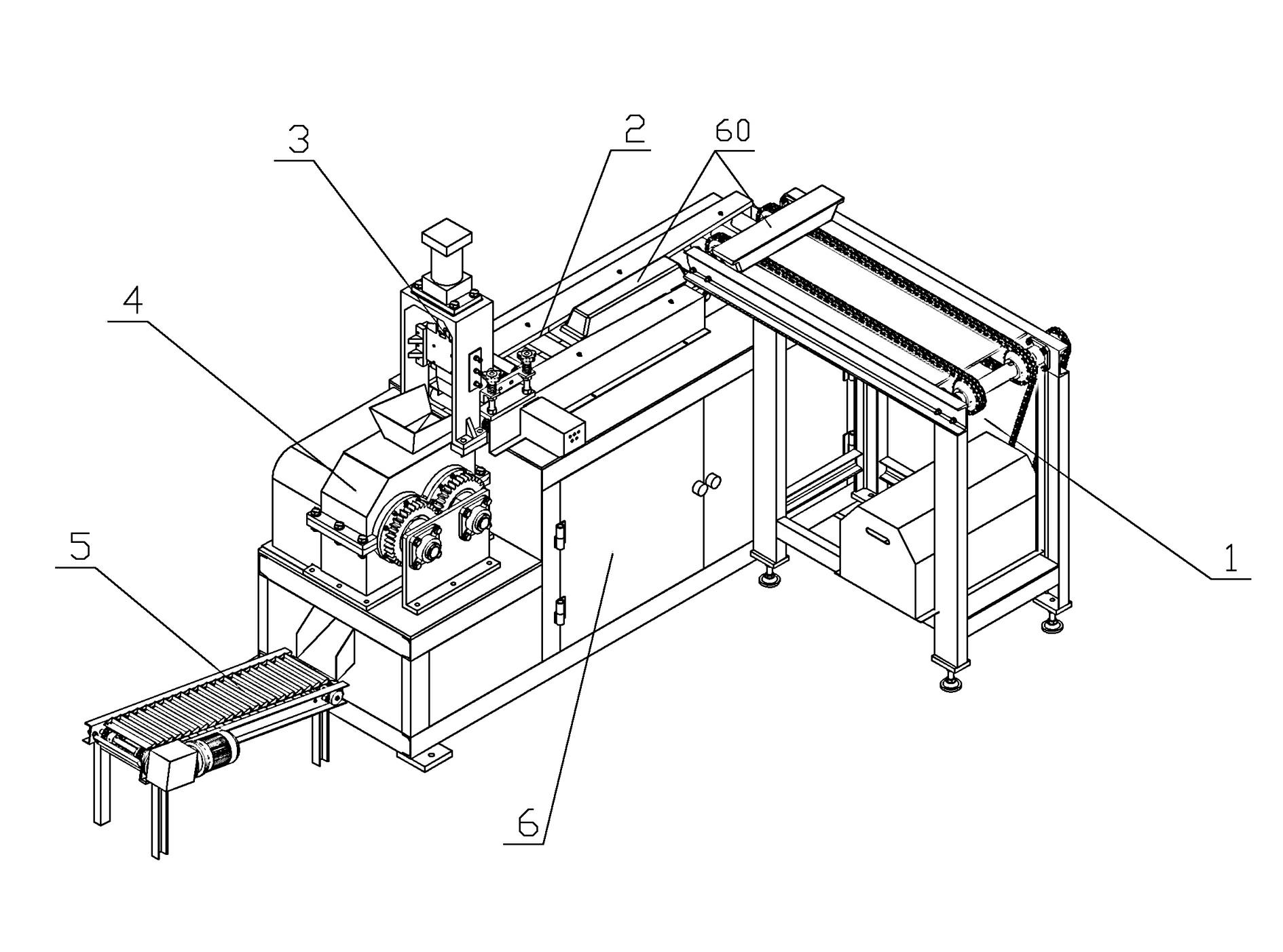

[0019] Such as figure 1 As shown, the lead ingot cold granulation automatic production equipment of the present invention comprises a feeding mechanism 1, a conveying mechanism 2, a slicing mechanism 3, a rolling cutting mechanism 4, a discharging mechanism 5, a power mechanism 6, a PLC control system and a power mechanism 6 The electrical connection realizes the automatic production of cold granulation of lead pellets. The lead ingots 60 are placed horizontally on the feeding mechanism 1, and the lead ingots 60 are sent to the conveying mechanism 2 by the feeding mechanism 1, and then sent longitudinally by the conveying mechanism 2 to the slicing mechanism 3 for slicing, and the cut lead pieces enter the rolling cutting mechanism 4 Extrude the lead pellets into a specific shape, enter the discharge mechanism 5 through the pellet outlet, and be transported to a specific storage device by the discharge mechanism 5.

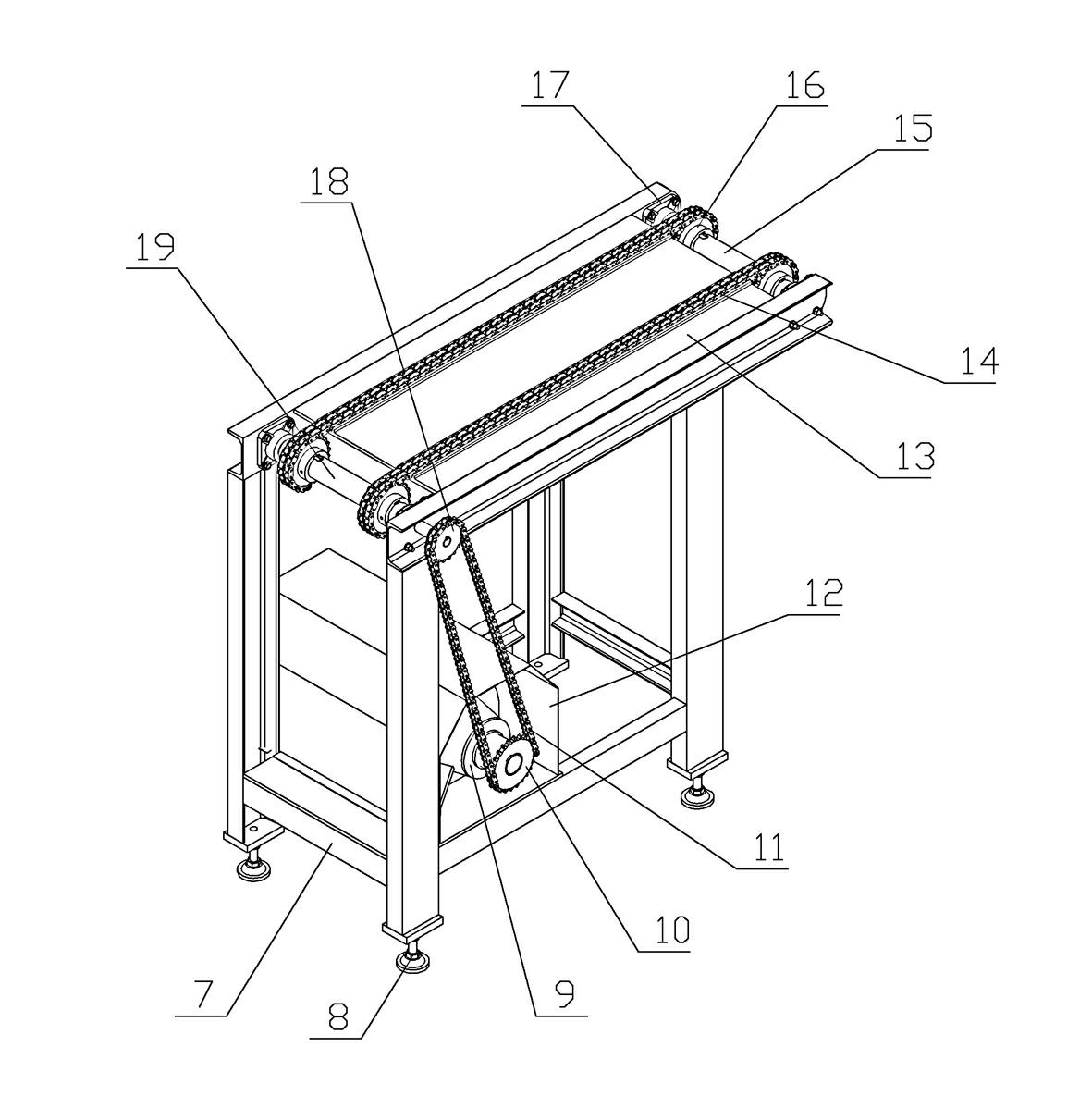

[0020] Such as figure 2 As shown, the feeding mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com