Semicontinuous casting crystallizer for restraining cracking of magnesium alloy ingot blank and use method of semicontinuous casting crystallizer

A technology for casting crystallizers and magnesium alloys, applied in the field of casting, can solve the problems such as insufficient attention paid to a cold condition, and achieve the effects of reasonable methods and equipment, prevention of cracking, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

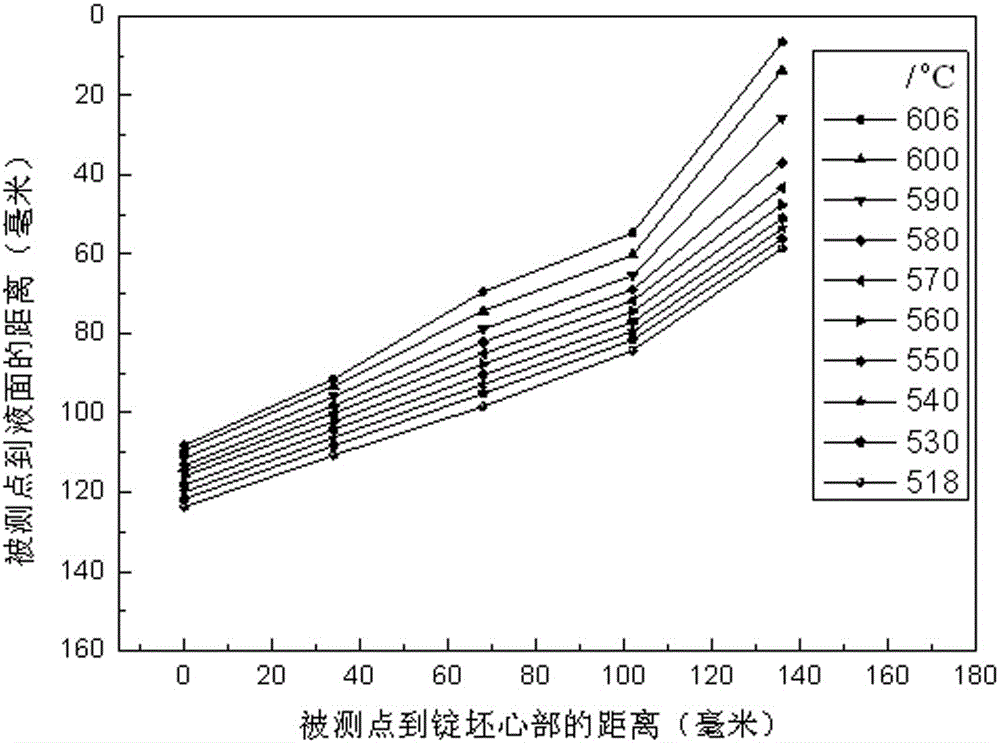

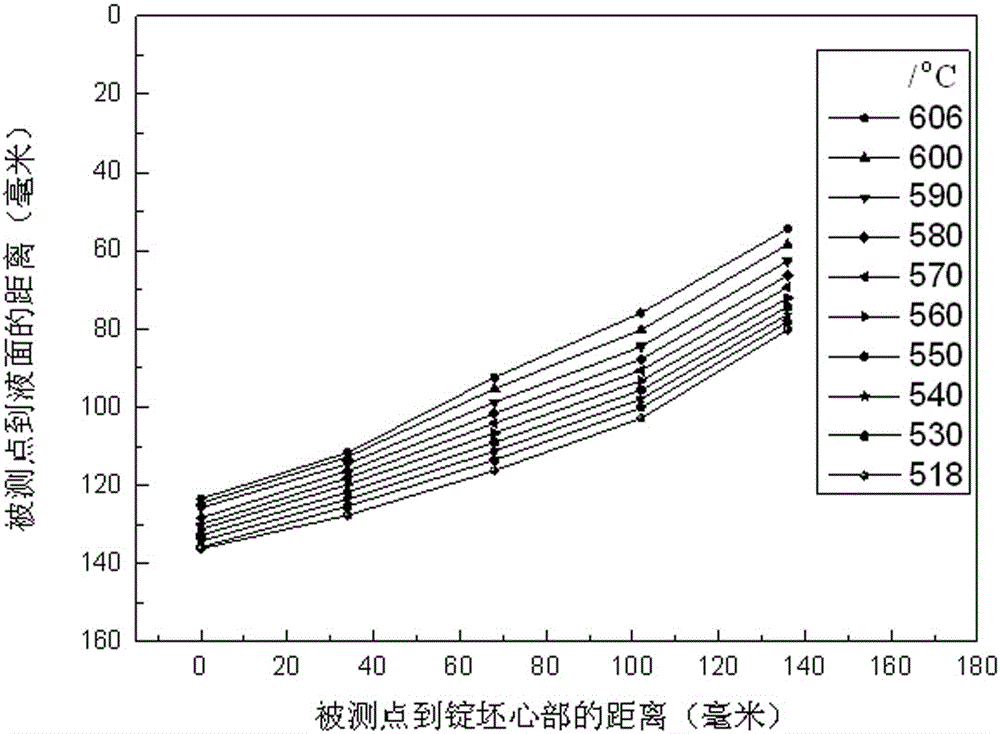

[0050] Semi-continuous casting crystallizer structure for inhibiting cracking of magnesium alloy billets such as figure 1 As shown, including the inner sleeve, insulation layer, cooling water tank, excitation coil and crystallizer shell, the insulation layer is set on the top of the inner wall and the outer wall at the same time; The bottom surface of the top plate is connected, and the height of the outer insulation layer is 50% of the height of the inner sleeve; the insulation layer set above the inner wall is the inner insulation layer, and its top is the same height as the top surface of the inner sleeve, and the height of the inner insulation layer is 50% of the height of the inner sleeve. %; the inner insulation layer is embedded in the inner sleeve and bonded to the inner wall, and the embedding depth is 20% of the thickness of the side wall of the inner sleeve; the outer insulation layer is embedded in the inner sleeve and bonded to the outer wall of the inner sleeve, a...

Embodiment 2

[0063] The structure of the semi-continuous casting crystallizer that suppresses the cracking of the magnesium alloy billet is the same as in Example 1, the difference is that:

[0064] (1) The insulation layer is set above the outer wall and is the outer insulation layer; the height of the outer insulation layer is 80% of the height of the inner sleeve; the embedding depth of the outer insulation layer is 40% of the thickness of the side wall of the inner sleeve;

[0065] (2) The inner sleeve is made of stainless steel;

[0066] (3) The material of the inner insulation layer is ceramic fiber paper, and the side of the ceramic fiber paper surface contacting the melt is coated with boron carbide paint;

[0067] (4) The inner surface of the inner insulation layer extends 8mm from the inner wall surface of the inner sleeve; the transition zone is made of a mixture of fatty acid glycerides and talcum powder at a weight ratio of 1:2; the angle between the inclined side of the trans...

Embodiment 3

[0074]The structure of the semi-continuous casting crystallizer that suppresses the cracking of the magnesium alloy billet is the same as in Example 1, the difference is that:

[0075] (1) The insulation layer is set above the inner wall of the inner sleeve as the inner insulation layer; the height of the inner insulation layer is 80% of the height of the inner sleeve; the embedded depth of the inner insulation layer is 40% of the thickness of the side wall of the inner sleeve;

[0076] (2) The inner sleeve is made of copper alloy;

[0077] (3) The material of the inner insulation layer is ceramic fiber paper, and the side of the ceramic fiber paper surface contacting the melt is coated with molybdenum disulfide coating;

[0078] (4) The inner surface of the inner insulation layer extends 10mm from the surface of the inner wall of the inner sleeve; the transition zone is made of a mixture of fatty acid glycerides and talcum powder at a weight ratio of 1:3; the angle between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com