Patents

Literature

54results about How to "Reduce heat rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

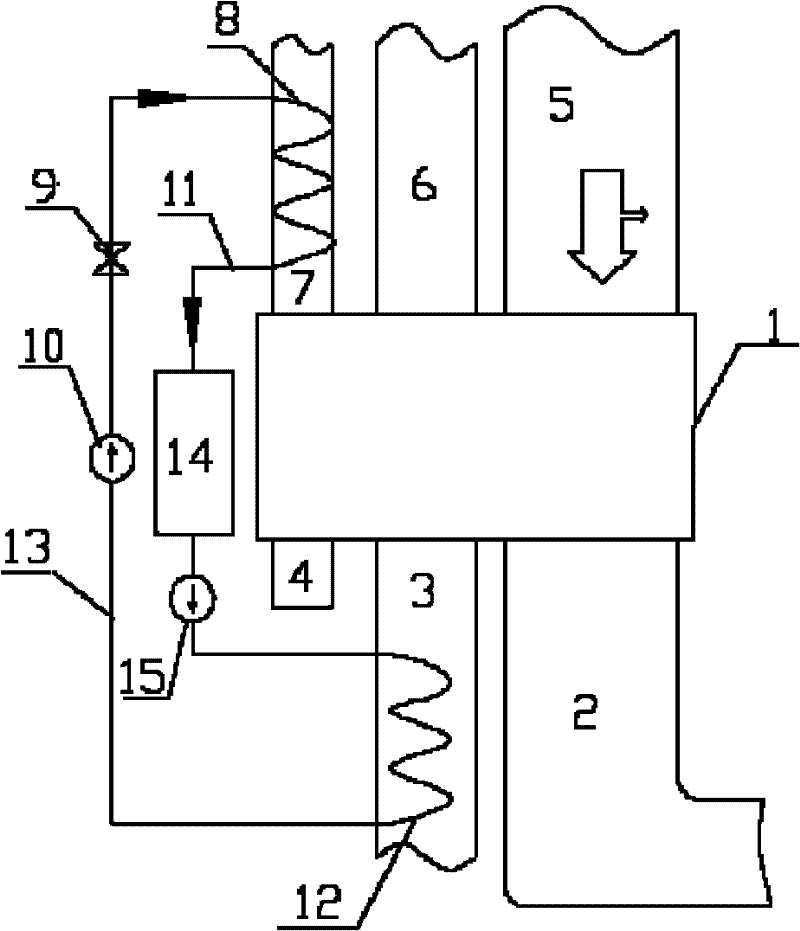

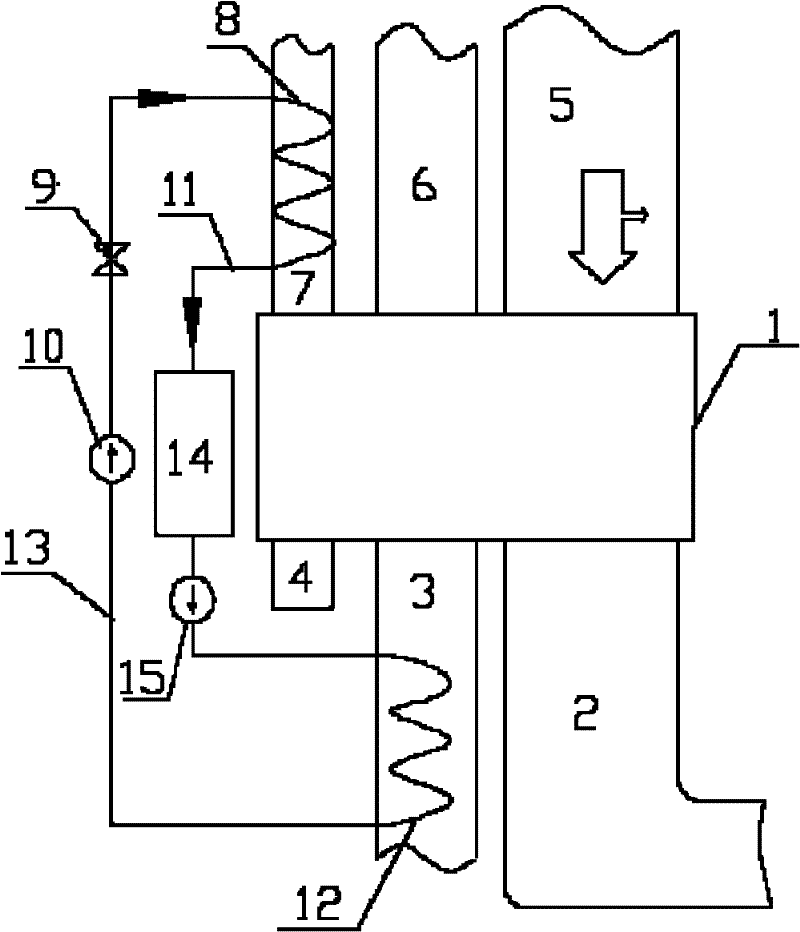

System for reducing discharge smoke temperature of power station boiler

InactiveCN102252339AReduce the temperatureIncrease temperatureCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a system for reducing discharge smoke temperature of a power station boiler and belongs to the technical field of waste heat recovery, and the system is characterized that a heat transfer pipeline is arranged in the hot primary air pipeline of the boiler, the two ends of the heat transfer pipeline are respectively connected with a water inlet pipeline and a water outlet pipeline, the other ends of the water inlet pipeline and the water outlet pipeline are connected to a heater on the secondary air inlet air flue of an air pre-heater; and simultaneously a bypass flue is additionally arranged, thus the original smoke is divided into two paths, one path of the original smoke is sent into the air pre-heater through the original flue, and the other path of the originalsmoke is sent into a low-pressure high-temperature economizer through the bypass flue. The hot primary air is utilized to heat the cold secondary air, thereby improving the air temperature of a secondary air inlet; the primary air temperature is controlled by changing the quantity of a cooling medium in the heat transfer pipeline, thereby reducing the amount of the cold primary air doped in a coal pulverizing system; and a method of increasing the amount of the smoke in the bypass flue is adopted, thereby reducing the temperature of the discharge smoke. On the premise of ensuring the temperature of the secondary air, the surplus heat of the primary air is recycled, thus the coal consumption of the boiler and the heat rate of a steam turbine are reduced, and the economical efficiency of a power plant is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

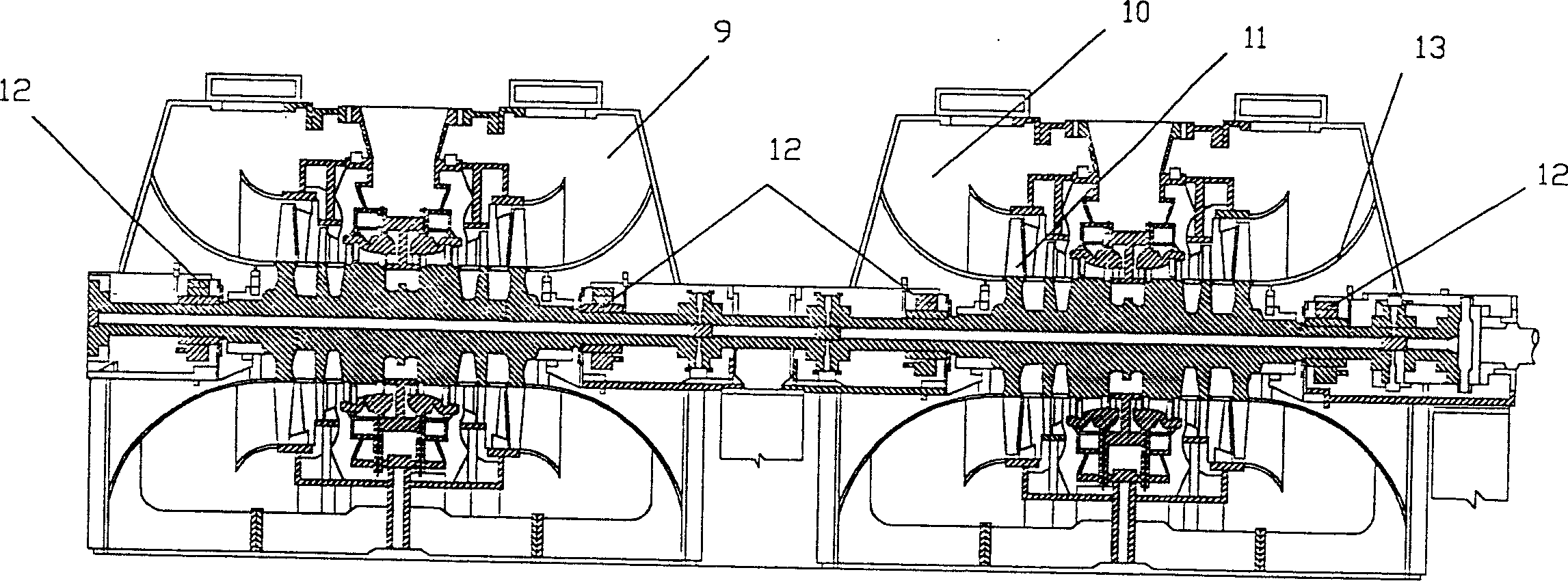

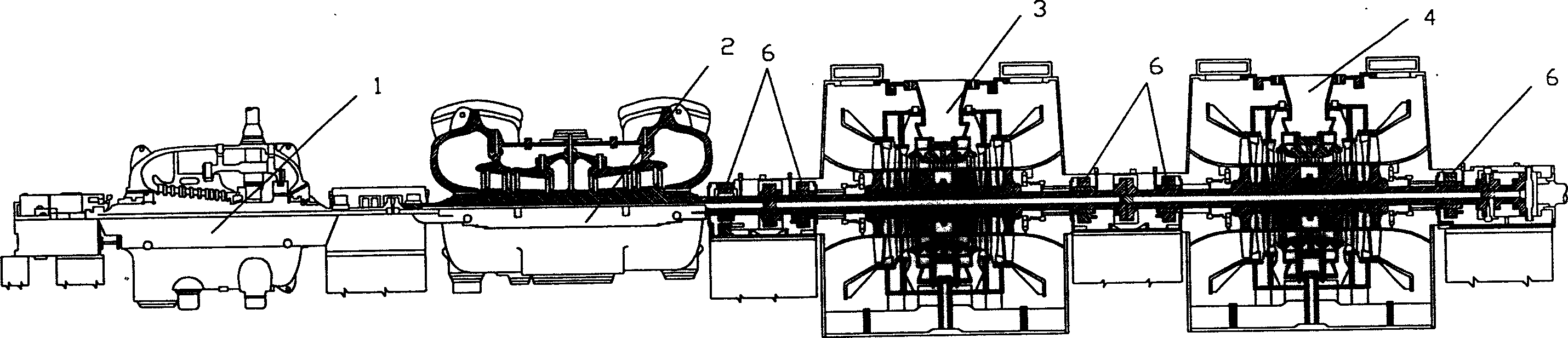

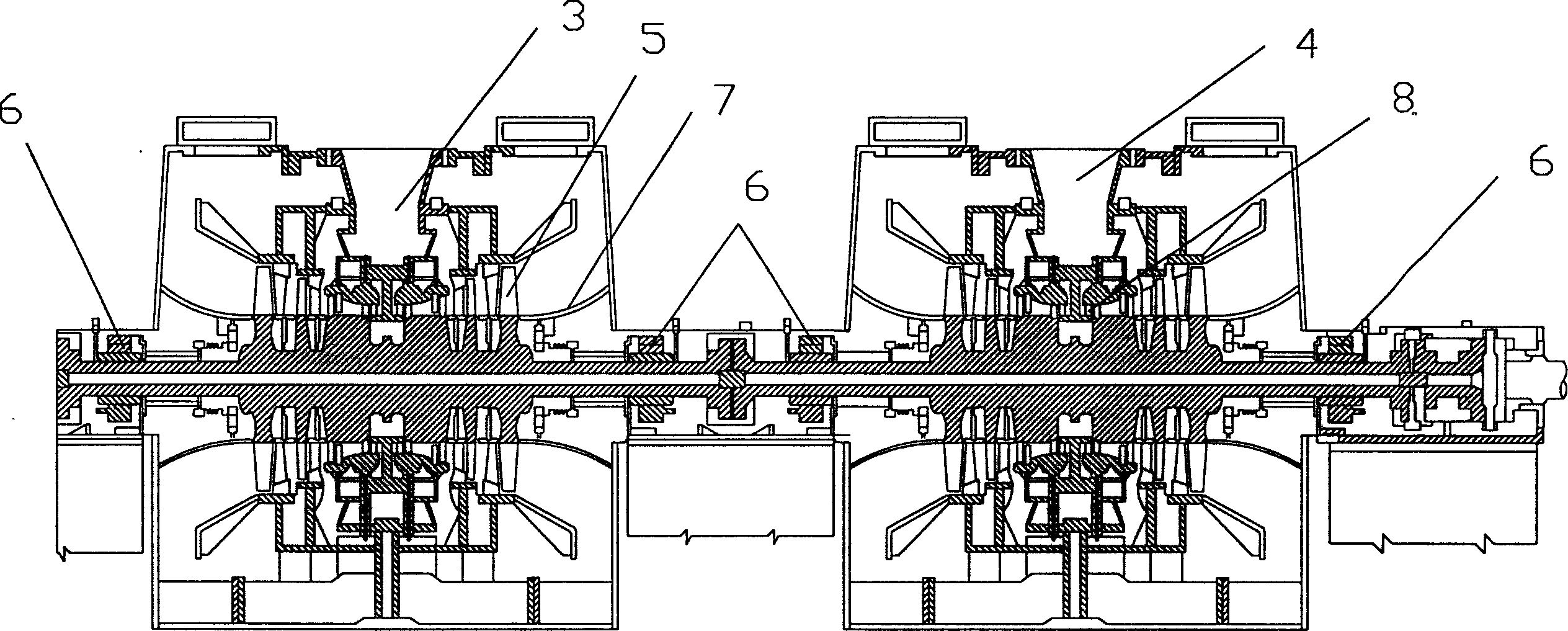

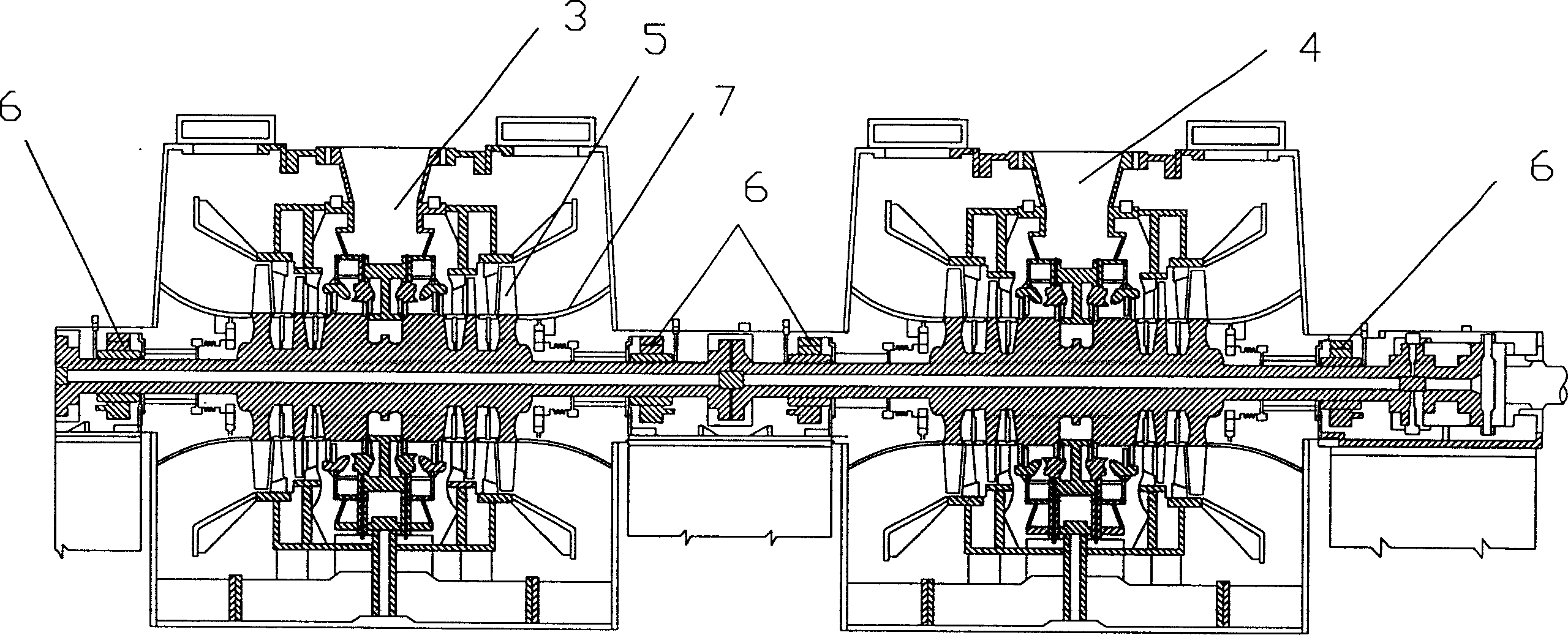

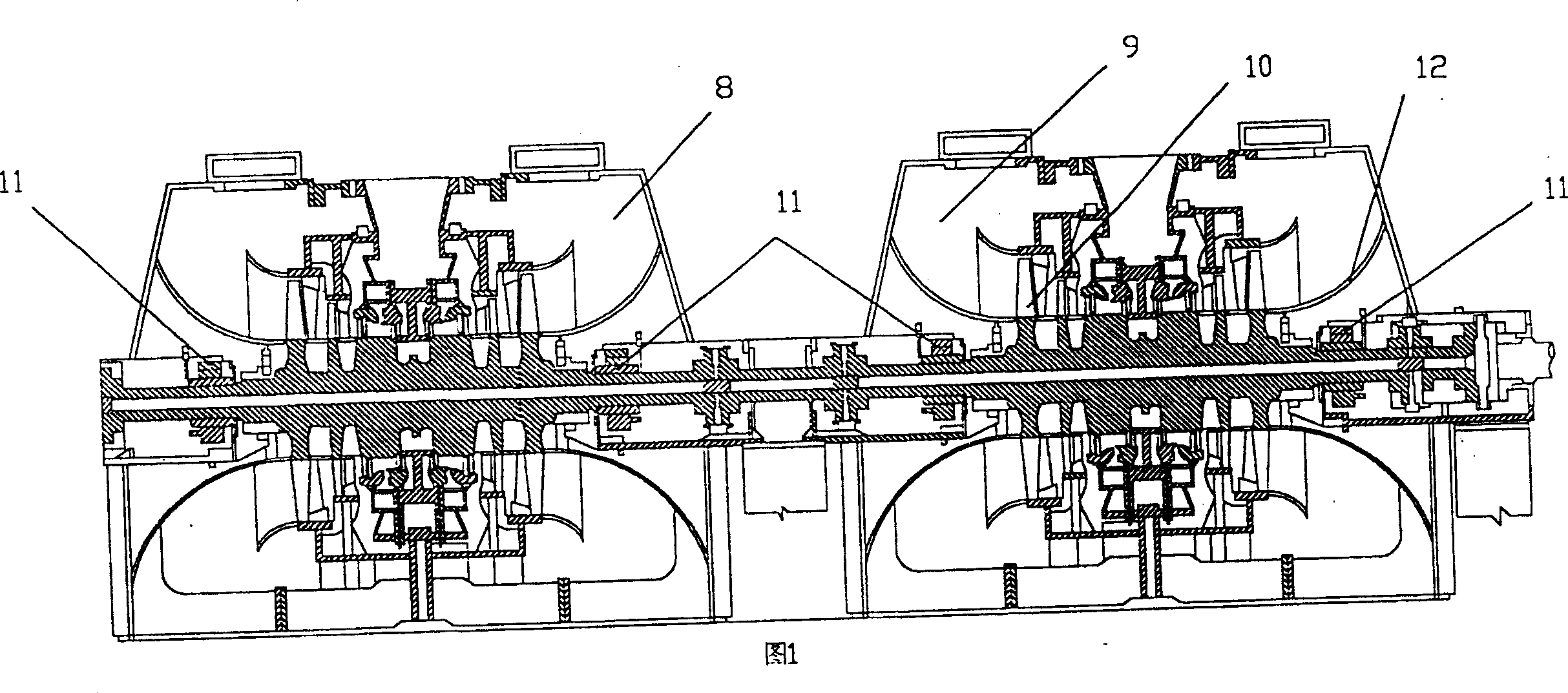

Super-supercritical air cooling steam turbine

InactiveCN1605717AImprove thermal efficiencyReduce heat rateMachines/enginesEngine componentsHeat lossesEngineering

The super-supercritical air-cooled steam turbine suitable for use in thermal power plant in unwatered area consists of super-supercritical wet cooled steam turbine high pressure cylinder, super-supercritical wet cooled steam turbine medium pressure cylinder and two low pressure cylinders. It features the two air cooled low pressure cylinders, the connection with low pressure cylinder bearing seat between the super-supercritical wet cooled steam turbine medium pressure cylinder and the air cooled low pressure cylinders and between the two air cooled low pressure cylinders, and the same structure of the high pressure cylinder and medium pressure cylinder in the super-supercritical air-cooled steam turbine and the high pressure cylinder and medium pressure cylinder in the super-supercritical wet cooled steam turbine. The two low pressure cylinders have improved structure and the present invention has air cooled exhaust. The present invention has low heat loss rate, high heat efficiency and low water consumption.

Owner:SHANGHAI POWER EQUIP RES INST

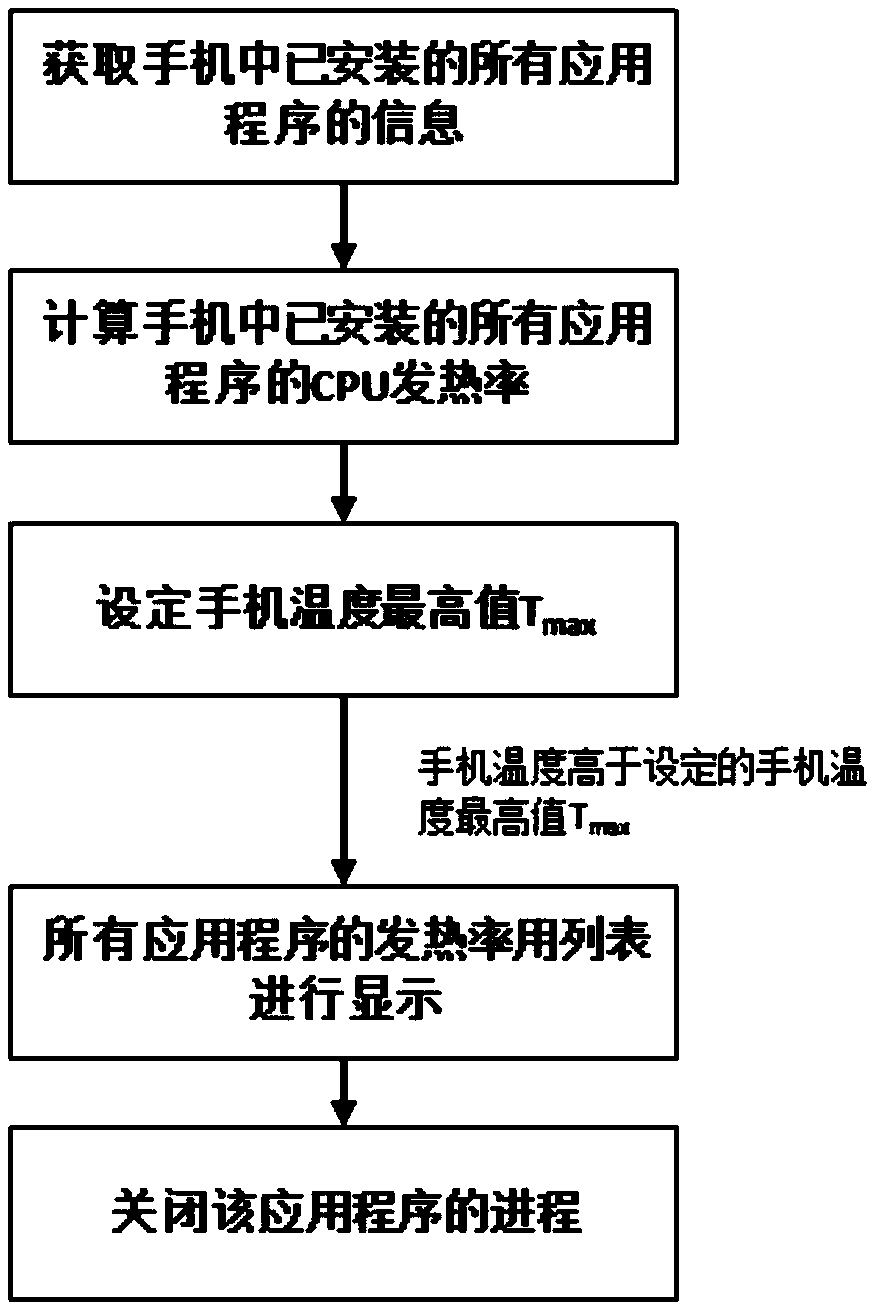

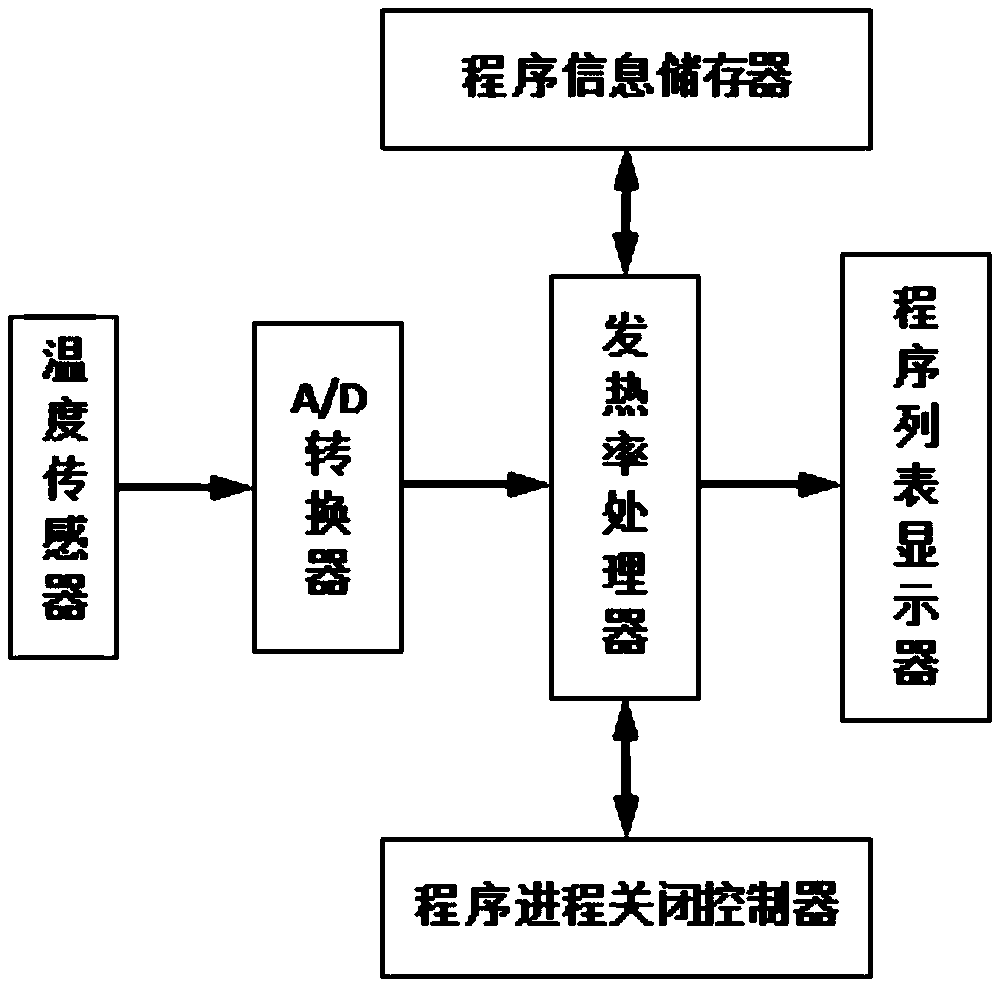

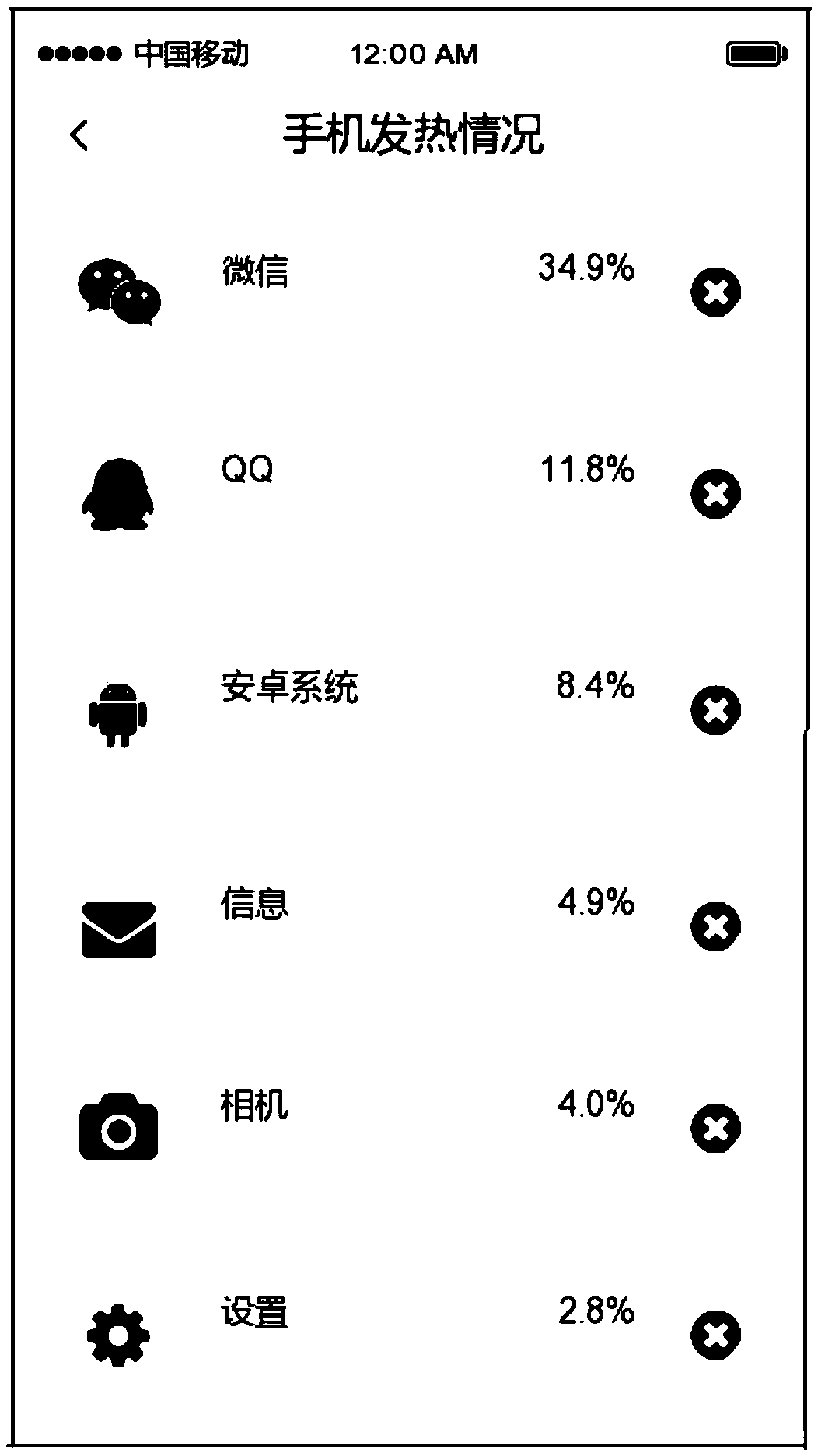

Method and system for monitoring heat generation rate of smart phone, and smart phone

InactiveCN105376378AReduce heat ratePrevent crashDigital data processing detailsHardware monitoringGeneration rateMonitoring system

Provided is a method for monitoring the heat generation rate of a smart phone. The method comprises steps of: A, acquiring application programs in the smart phone; B, computing the CPU heat generation rates of the application programs; C setting a temperature maximum value Tmax and displaying the acquired CPU heat generation rates of the application programs in a list; and D, closing the application program with the highest heat generation rate. A monitoring system comprises a heat generation rate processor, a program information memory, and a program process closing controller. The input end of the heat generation rate processor is connected with a temperature acquiring terminal. The output end of the heat generation rate processor is connected with a program list display terminal. The temperature acquiring terminal comprises a micro temperature sensor and an A / D converter. The invention also discloses a smart phone with a heat generation rate monitoring function. The method may monitor the CPU heat generation rates of all application programs in the smart phone. A heat generation rate list is displayed when temperature is over high and a user may selectively close the application programs with high heat generation rates in order to reduce CPU consumption and the heat generation rate of the smart phone.

Owner:HUNAN TRYINE TECH CO LTD

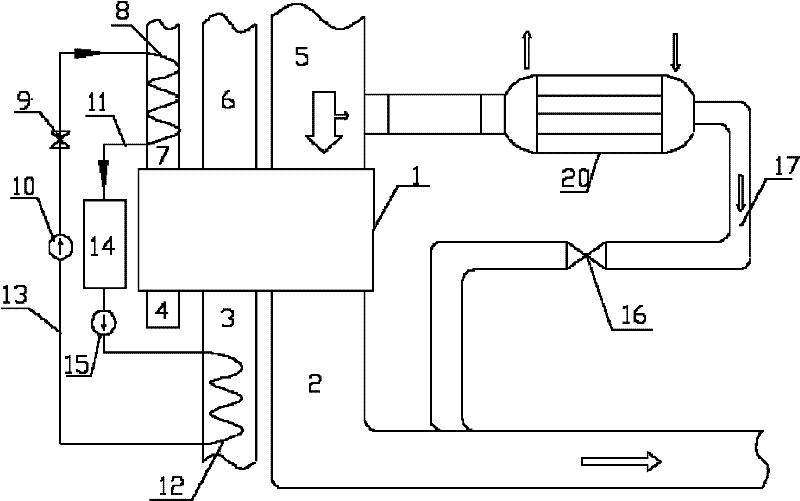

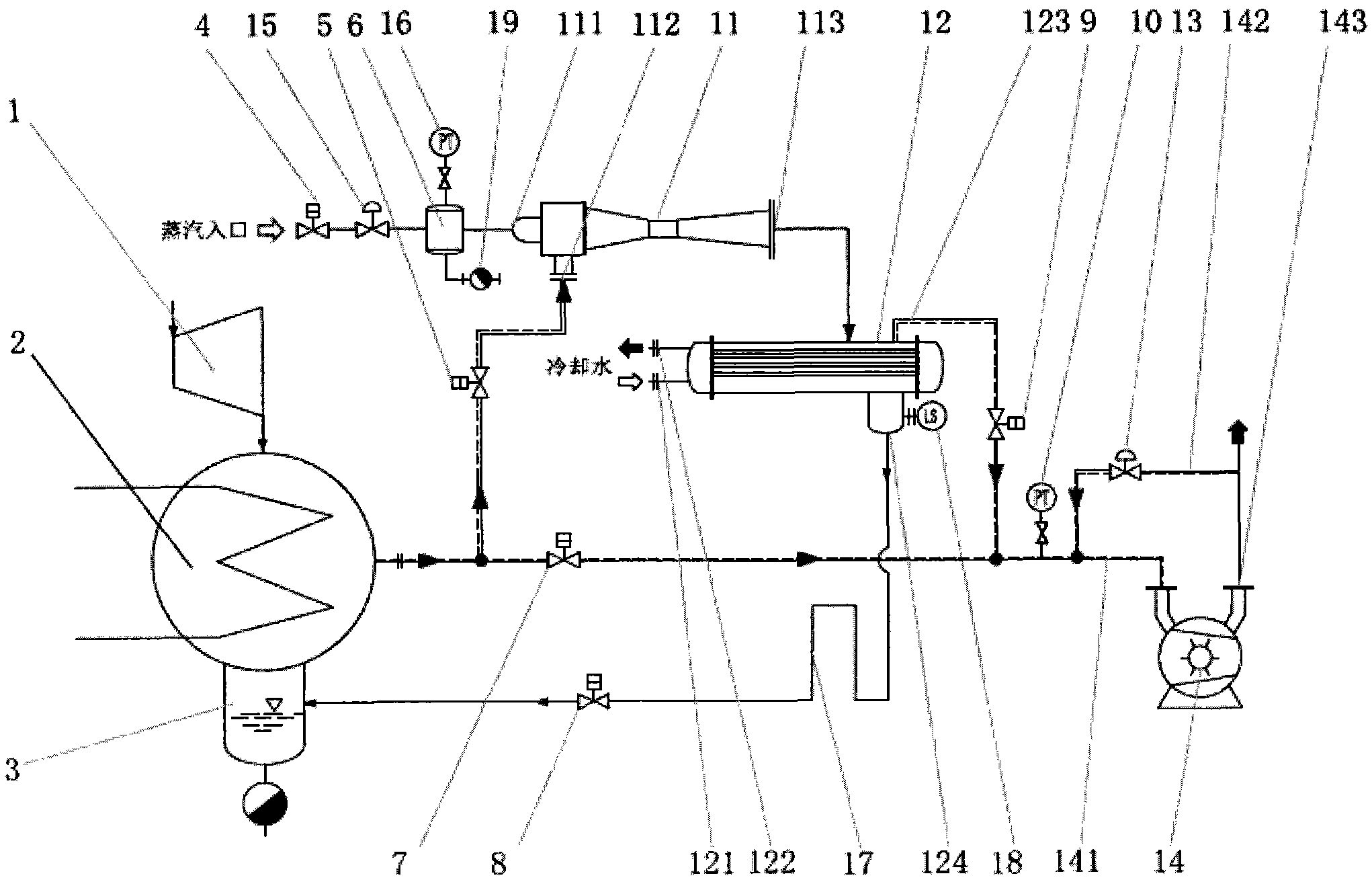

Power plant condenser steam jet and vacuumizing system with pressure control function

The invention provides a power plant condenser steam jet and vacuumizing system with a pressure control function. The system comprises a steam turbine (1), a condenser (2), a condenser hot well (3), a power steam pressurizer (6), a steam ejector (11), a steam condenser (12), a water ring vacuum pump (14), a condensate discharge valve (8) of the steam condenser, a condensate drain pipeline water seal (17), a condensate pipeline liquid level switch (18), a pressure adjusting valve (13) on the inlet of the water ring vacuum pump, multiple control valves and pipelines, wherein the control valves and the pipelines are arranged among the parts. Due to the fact that pressure control of power steam, control of the liquid level after condensates flow back to the condenser hot well and inlet pressure control of the water ring vacuum pump are adopted, the vacuumizing system can maintain the maximum vacuum degree of the condenser, force of the condenser is improved, the vacuum degree of the condenser is improved, the heat consumption rate of the steam turbine is lowered, and coal consumption for unit power generation is lowered. The system is safe and free of maintenance, guarantees 100% of force and can operate stably for a long time. A pressure backflow adjusting system is arranged on the final-stage exhaust device, namely the water ring vacuum pump, so that it is guaranteed that the cavitation phenomenon of the water ring vacuum pump does not happen.

Owner:浦江瑞尔科技有限公司

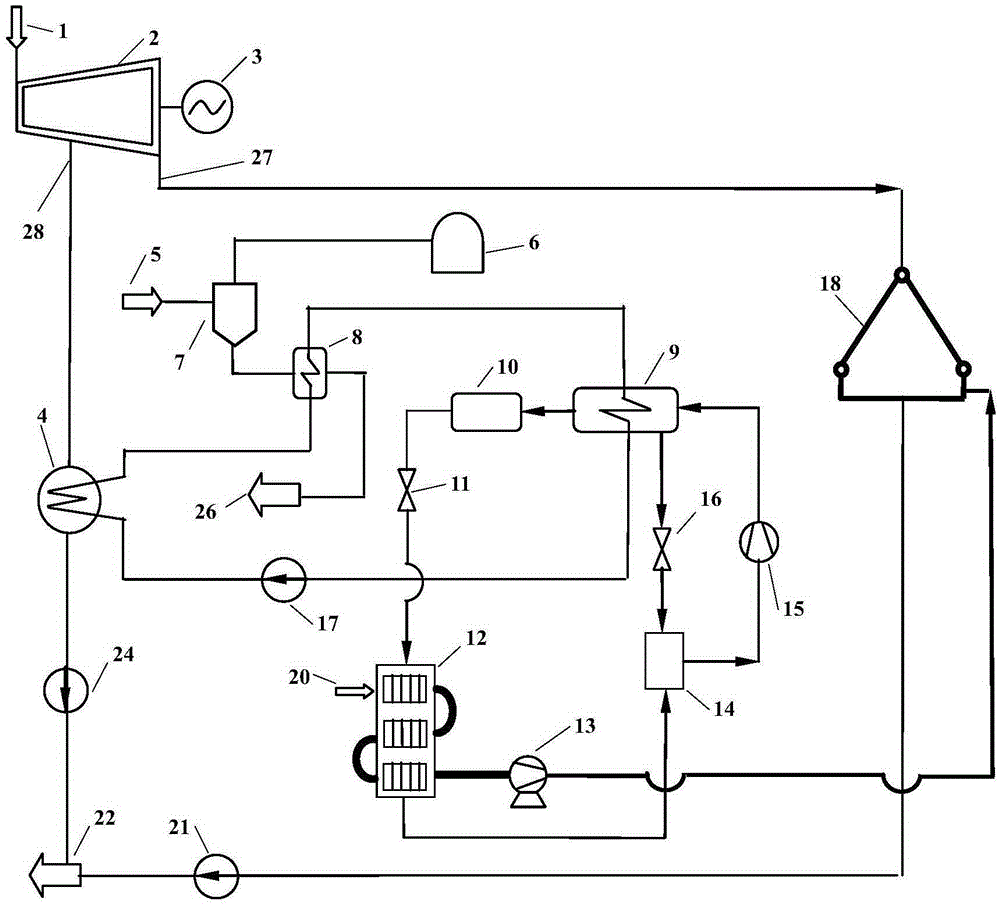

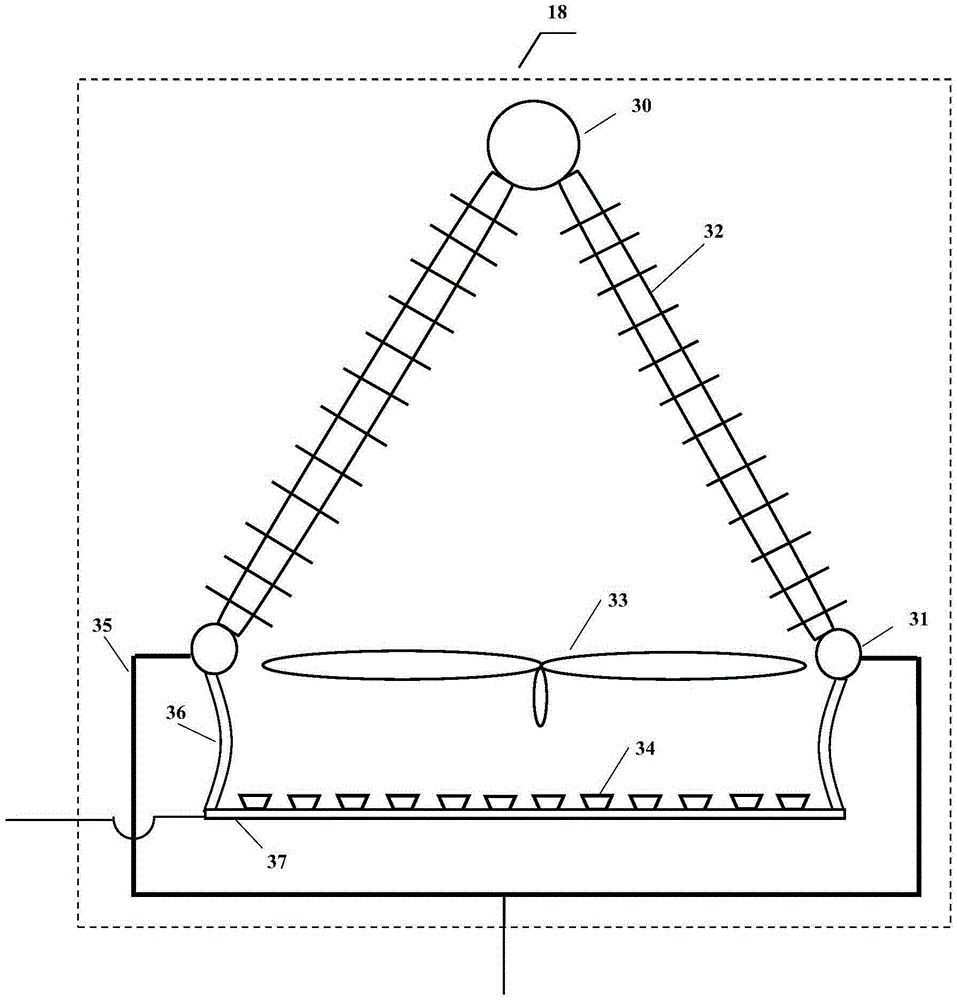

Power station air cooling system adopting combined refrigeration with shaft seal steam leakage of steam turbine and continuous blow-down waste heat of boiler as well as method for predicting heat-transfer coefficient of air-cooling condenser

ActiveCN105423772AReduce dust accumulationLower condensation temperatureHeat pumpsFeed water supplyEngineeringSuperheater

The invention discloses a power station air cooling system adopting combined refrigeration with shaft seal steam leakage of a steam turbine and continuous blow-down waste heat of a boiler. The system is characterized in that the steam turbine is communicated with a steam source, the steam turbine is connected with an electric generator, and the steam turbine is sequentially communicated with an air-cooling condenser, a condensate pump and boiler feedwater; the steam turbine is sequentially communicated with a steam leakage condenser, a steam leakage condensate pump and the boiler feedwater; boiler blow-down water is sequentially communicated with a flash tank, a deaerator, a working medium superheater and a drainage ditch; the steam leakage condenser is sequentially communicated with the working medium superheater, and a generator is communicated with the steam leakage condenser through a working medium circulating pump; the generator is sequentially communicated with a condenser, a first throttling valve and an evaporator, the evaporator is communicated with an absorber, and the generator is sequentially communicated with a second throttling valve, the absorber, a solution pump and a generator; and air is sequentially communicated with the evaporator, an induced draft fan and the air-cooling condenser. A method for predicting a heat-transfer coefficient of the air-cooling condenser is further provided.

Owner:NORTHEAST DIANLI UNIVERSITY

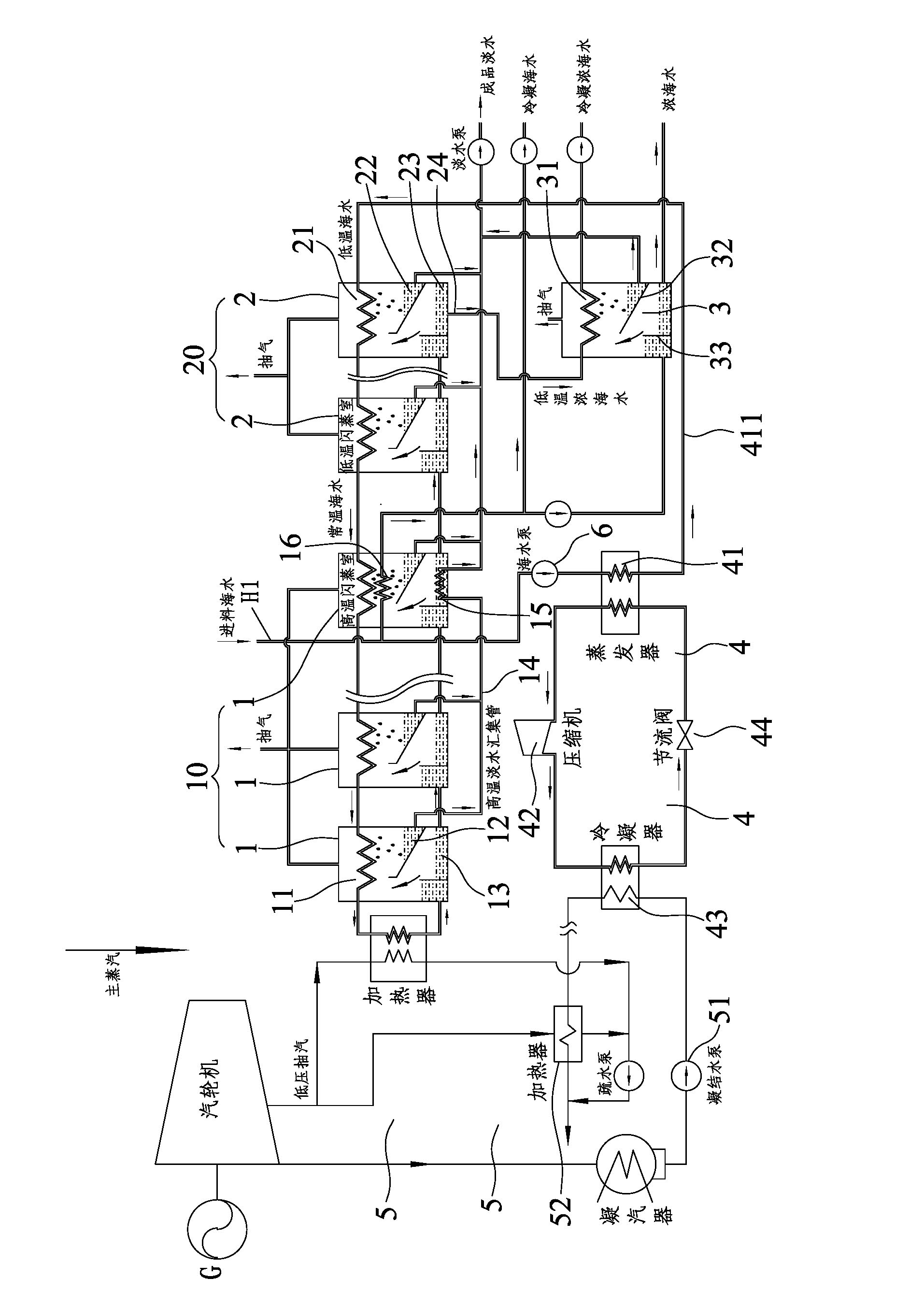

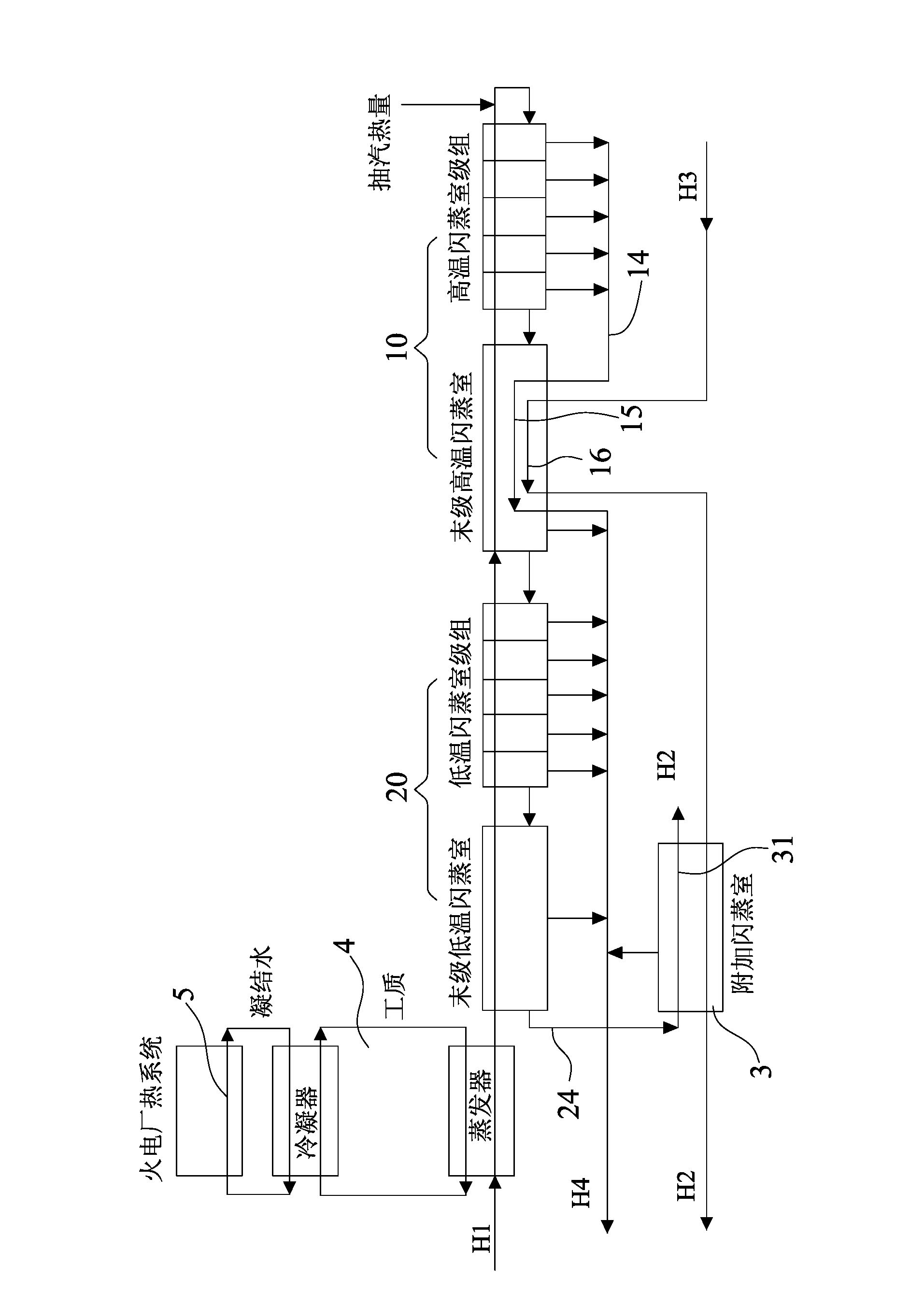

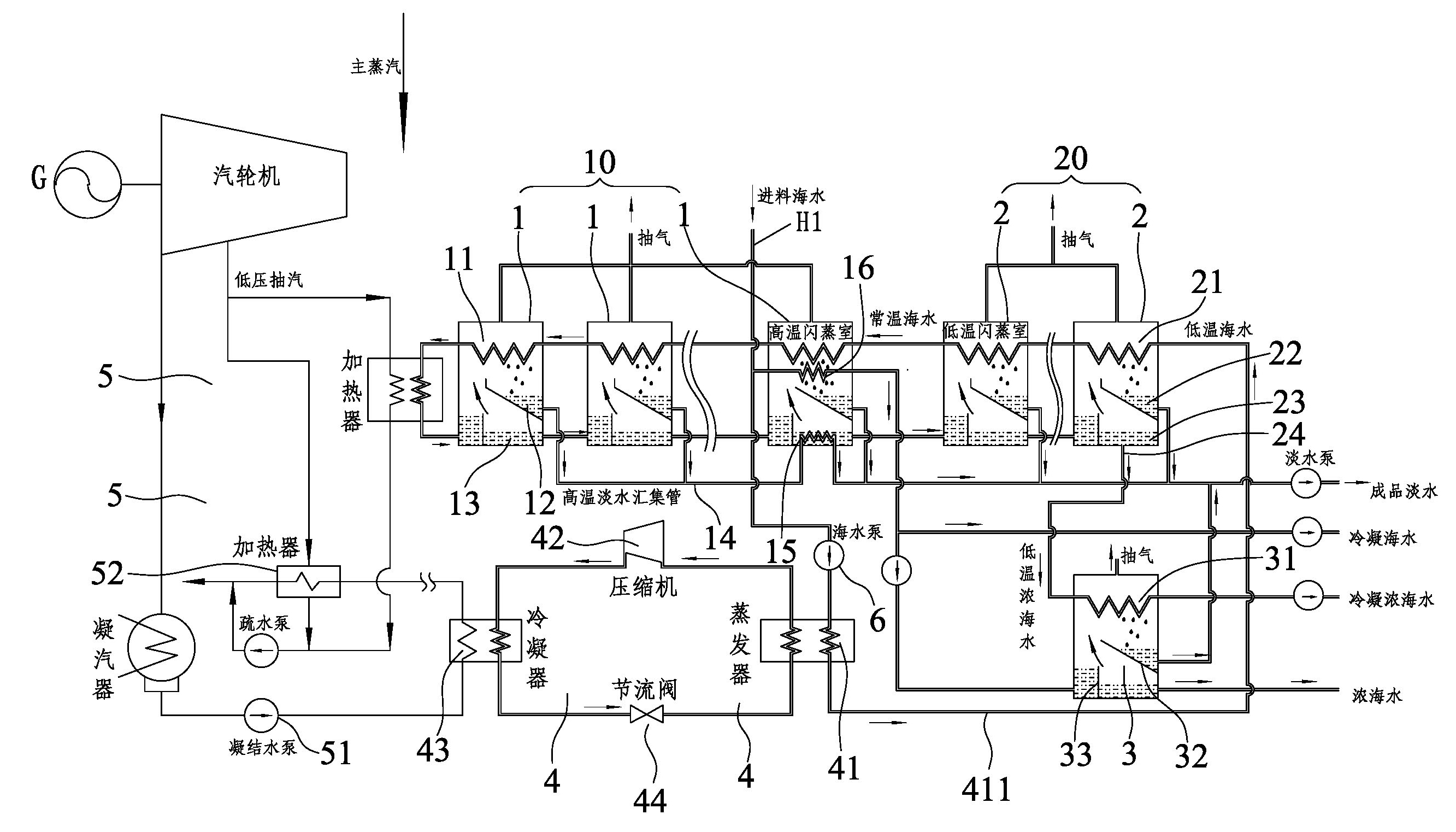

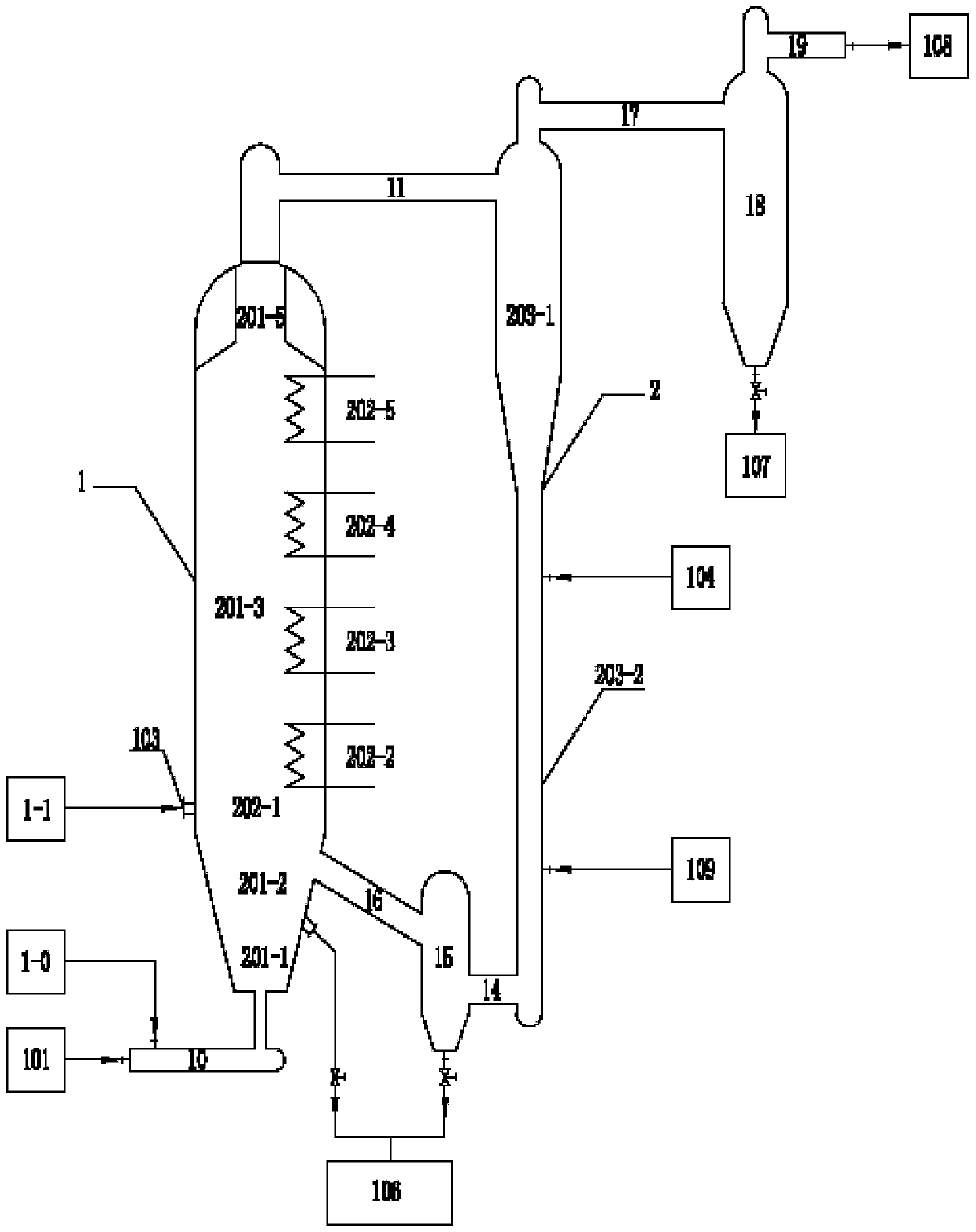

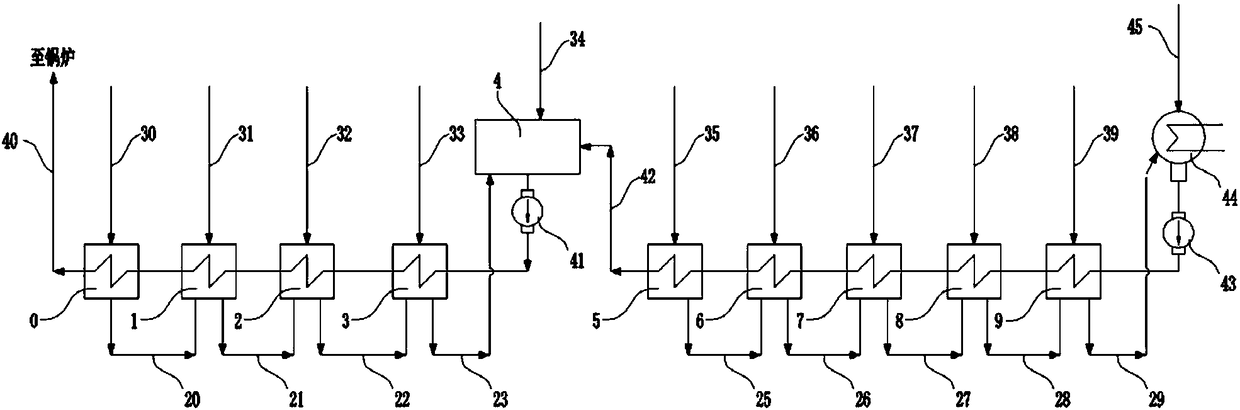

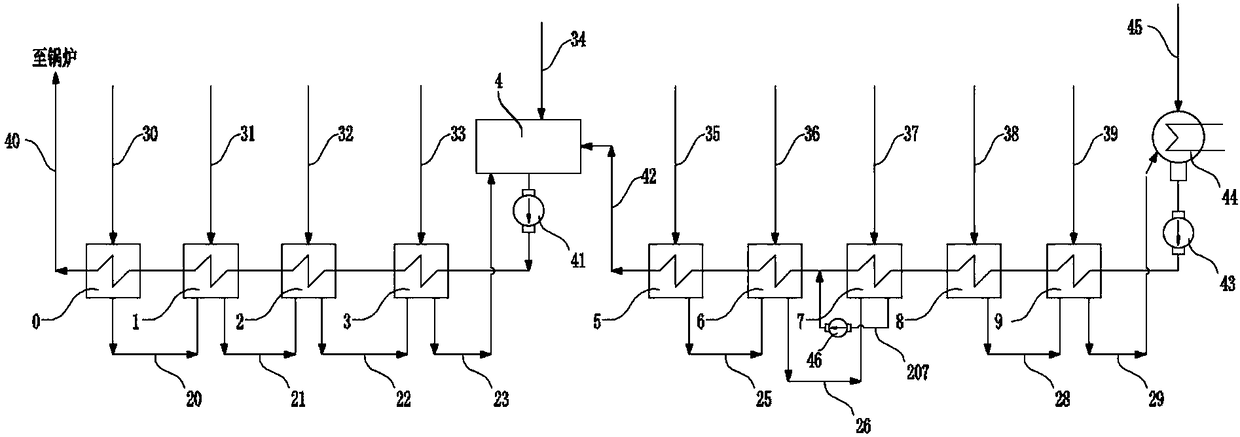

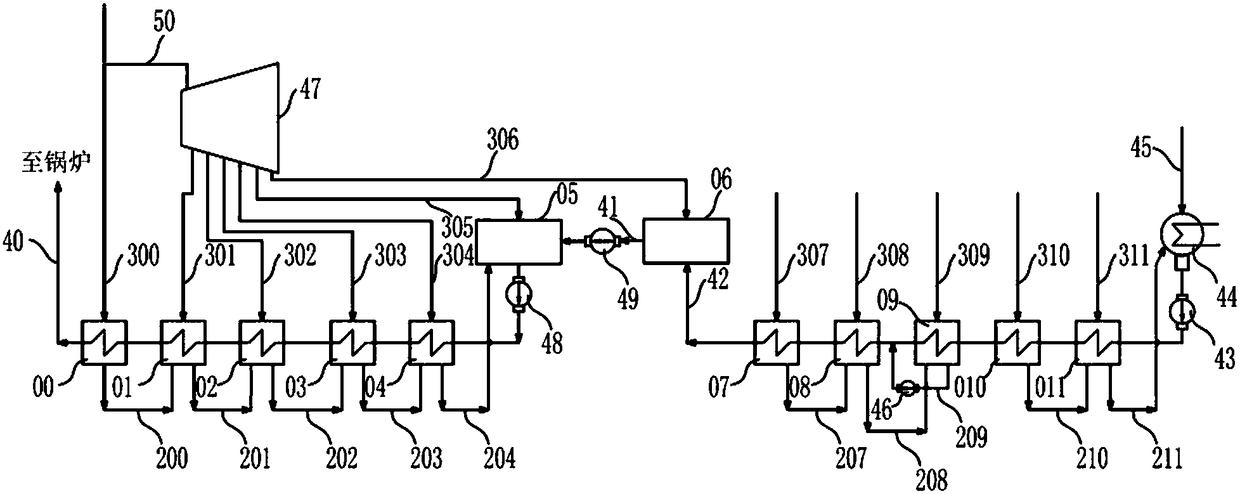

New multistage flash evaporation seawater desalting system of thermal power plant

InactiveCN102502902ALower discharge temperatureReduce cold source lossGeneral water supply conservationSeawater treatmentSeawaterEngineering

The invention discloses a new multistage flash-evaporation seawater desalting system of a thermal power plant. The seawater desalting system comprises high-temperature flash-evaporation chamber groups, low-temperature flash-evaporation chamber groups, an additional flash-evaporation chamber, a compression thermal pump system and a thermal power plant thermal system. According to the seawater desalting system, the low-temperature flash-evaporation chamber groups and the additional flash-evaporation chamber are increased, and the flash evaporation grade is increased, so the freshwater output isincreased; effective heat of high temperature products is recovered and utilized, so the freshwater output is further increased; and the thermal pump system sends pure heat to the thermal power plantthermal system, so the economic of the thermal power plant is improved. The seawater desalting system of the invention, which has the characteristics of much flash evaporation grade, large freshwateroutput, low freshwater cost, and improvement of the comprehensive utilization of the system energy, and is suitable for the low-cost large-scale production of the thermal power plant, can be widely applied to the seawater desalting field.

Owner:JIMEI UNIV

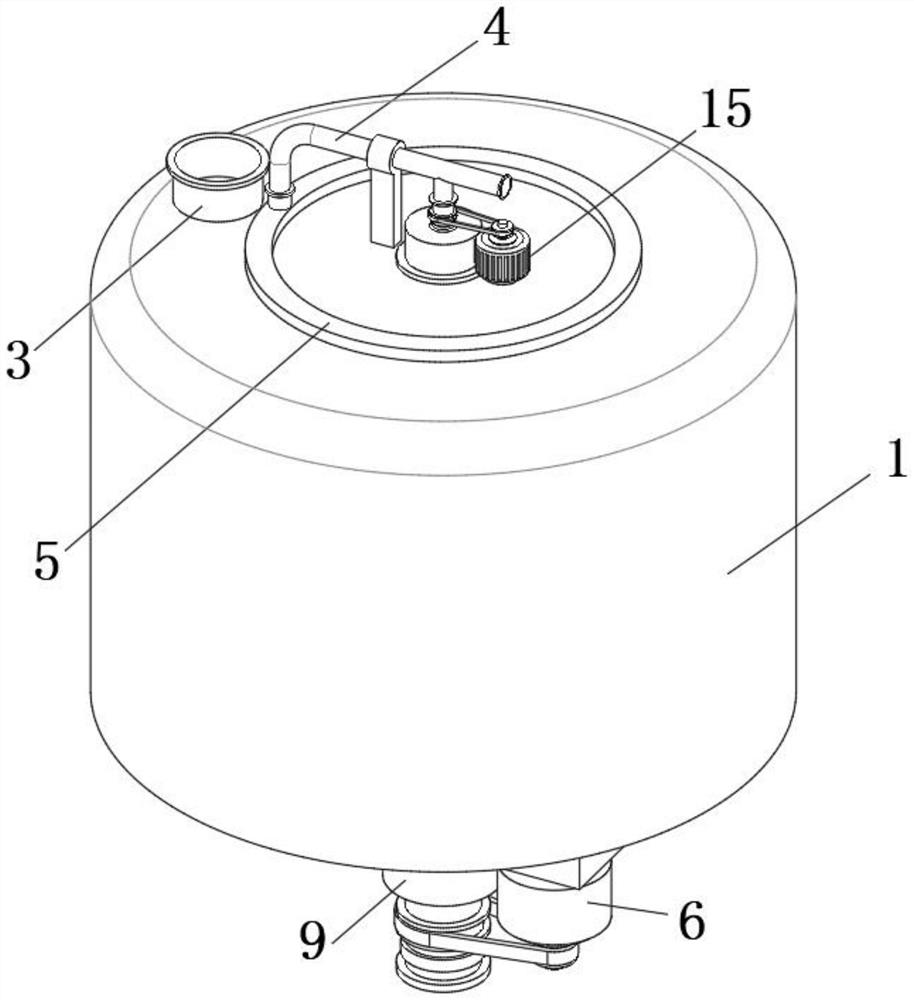

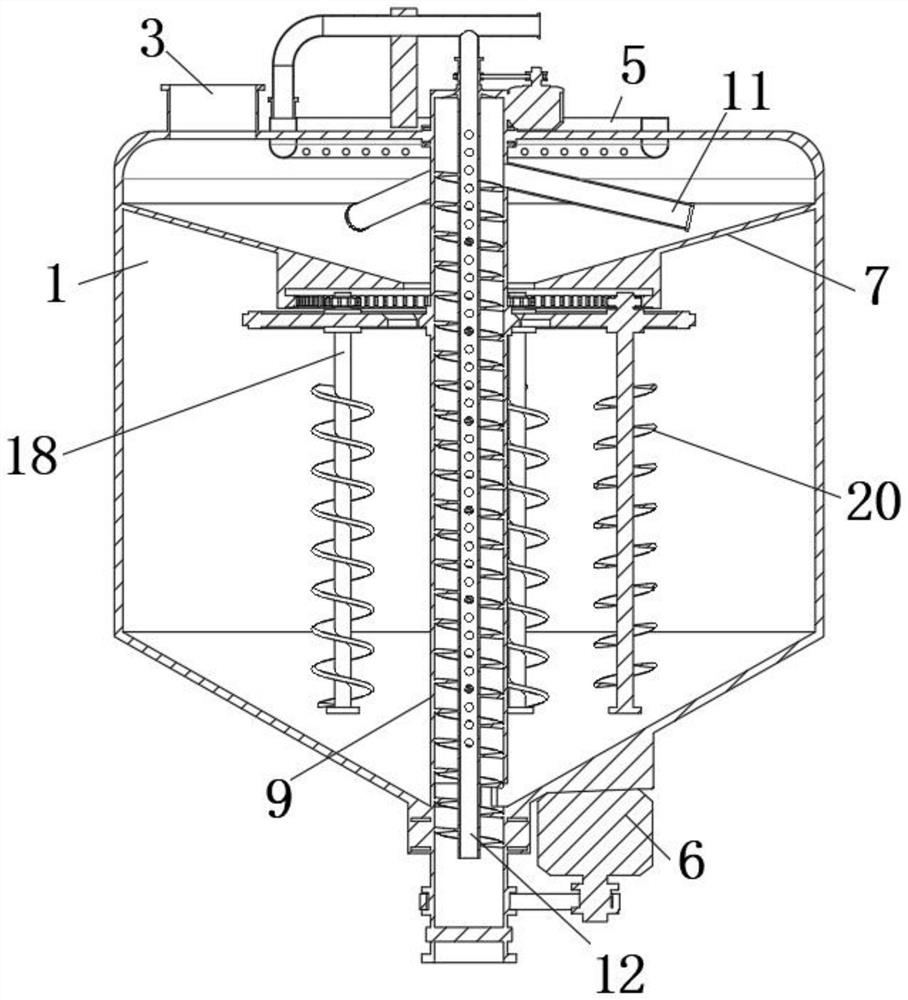

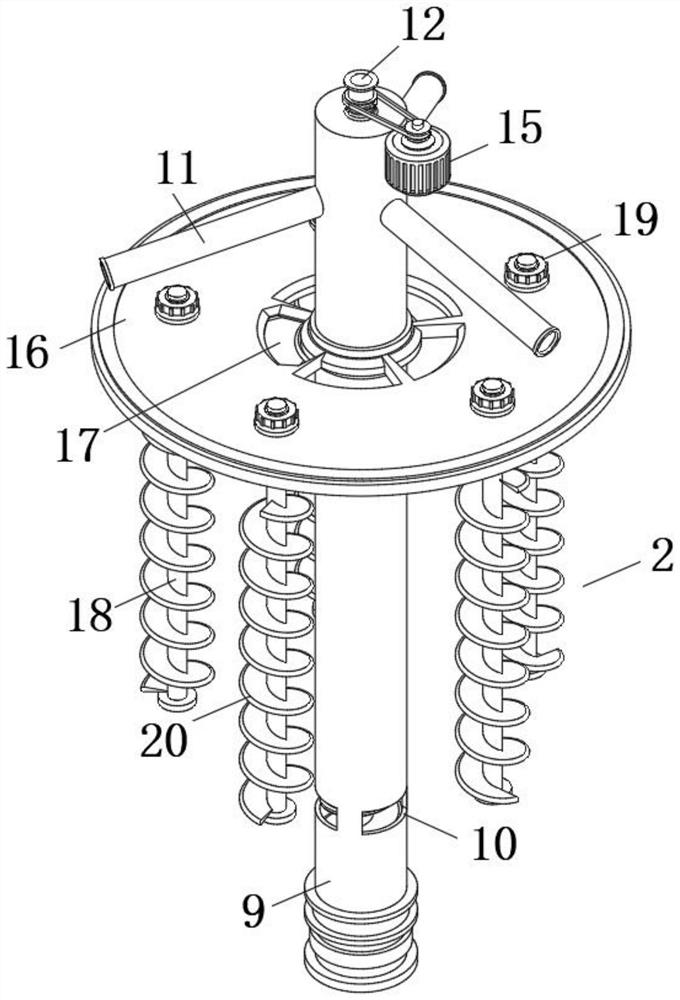

Cereal-storing integrated device based on drying equipment

InactiveCN111656973ARealize the drying functionReduce mildewAgriculture tools and machinesClimate change adaptationAgricultural scienceAgricultural engineering

The invention discloses a cereal-storing integrated device based on drying equipment, and relates to the technical field of cereal storage. The cereal-storing integrated device comprises a storage tank, wherein a cereal-storing cavity is fixedly formed in the storage tank, and a circulating mechanism is rotatably connected in the inner surface of the storage tank; a feeding pipe fixedly communicates with the top surface of the storage tank; a hot wind inlet pipe is further fixedly connected to the top surface of the storage tank; a wind-distributing annular pipe is fixedly connected to the topof the inner surface of the storage tank; one end of the hot wind inlet pipe communicates with the wind-distributing annular pipe; and a main driving motor is fixedly connected to the bottom of the storage tank. The circulating mechanism and the wind-distributing annular pipe are designed, and a drying mechanism and a circulating cereal turning mechanism are additionally arranged based on a traditional cereal-storing device, so that on one hand, a cereal drying function can be realized, on the other hand, cereals can flow in multiple directions through turning, and therefore, mildewing and heating probabilities of the cereals can be effectively decreased.

Owner:合肥德纳达信息科技有限公司

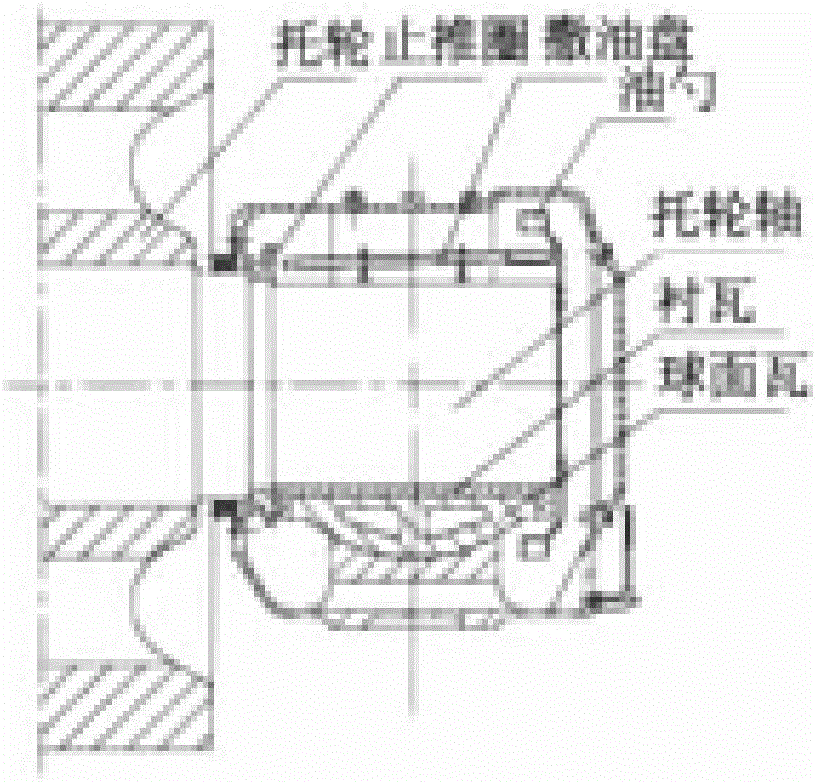

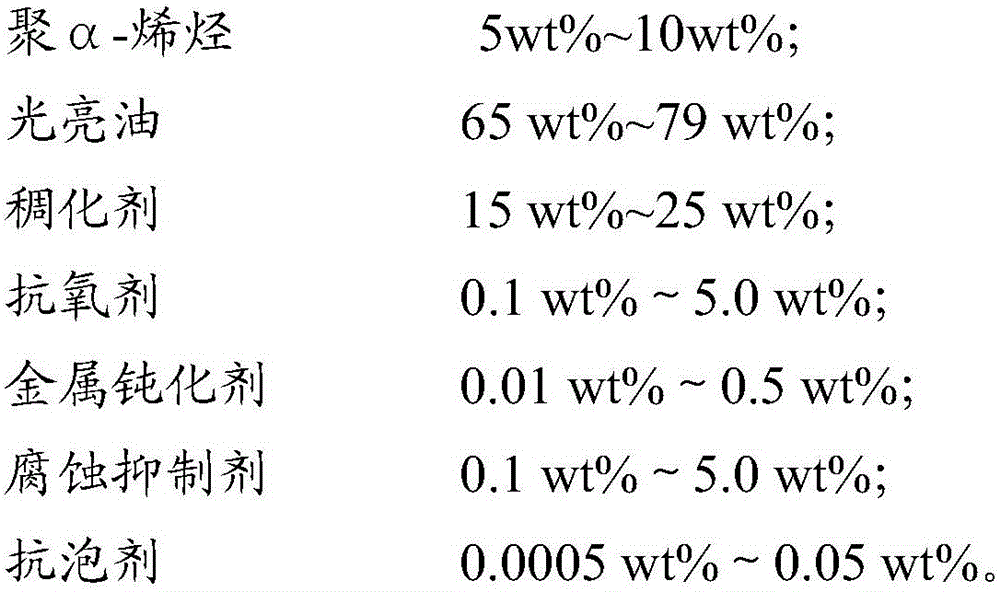

Lubricating oil composition for supporting roller large bearing shell of rotary kiln and preparation method thereof

InactiveCN105969488AImprove antioxidant capacityImprove wear resistanceLubricant compositionEngineeringContact friction

Compared with the prior art, the invention provides a lubricating oil composition for a supporting roller large bearing shell of a rotary kiln. The composition comprises the following components in percentages by mass: 5-10% of poly alpha-olefine, 65-79% of brightening oil, 15-25% of a thickener, 0.1-5.0% of an anti-oxidant, 0.01-0.5% of a metal deactivator, 0.1-5.0% of a corrosion inhibitor, 0.5-5.0% of an anti-wear reagent at extreme pressure, and 0.0005-0.05% of anti-foaming agent. The lubricating oil composition for the supporting roller large bearing shell of the rotary kiln has the performances of good abrasion resistance, oxidation resistance, emulsion resistance, corrosion resistance, extreme pressure resistance, high temperature resistance, etc. The lubricating oil composition has a high viscosity coefficient index, so that an oil film of a certain thickness can be formed during normal working of the supporting roller bearing shell, direct contact friction between a supporting roller bearing and a shell is avoided, the supporting roller bearing and the lining shell are effectively protected, and the probability of high temperature at the supporting roller bearing shell is reduced.

Owner:CHINA PETROLEUM & CHEM CORP

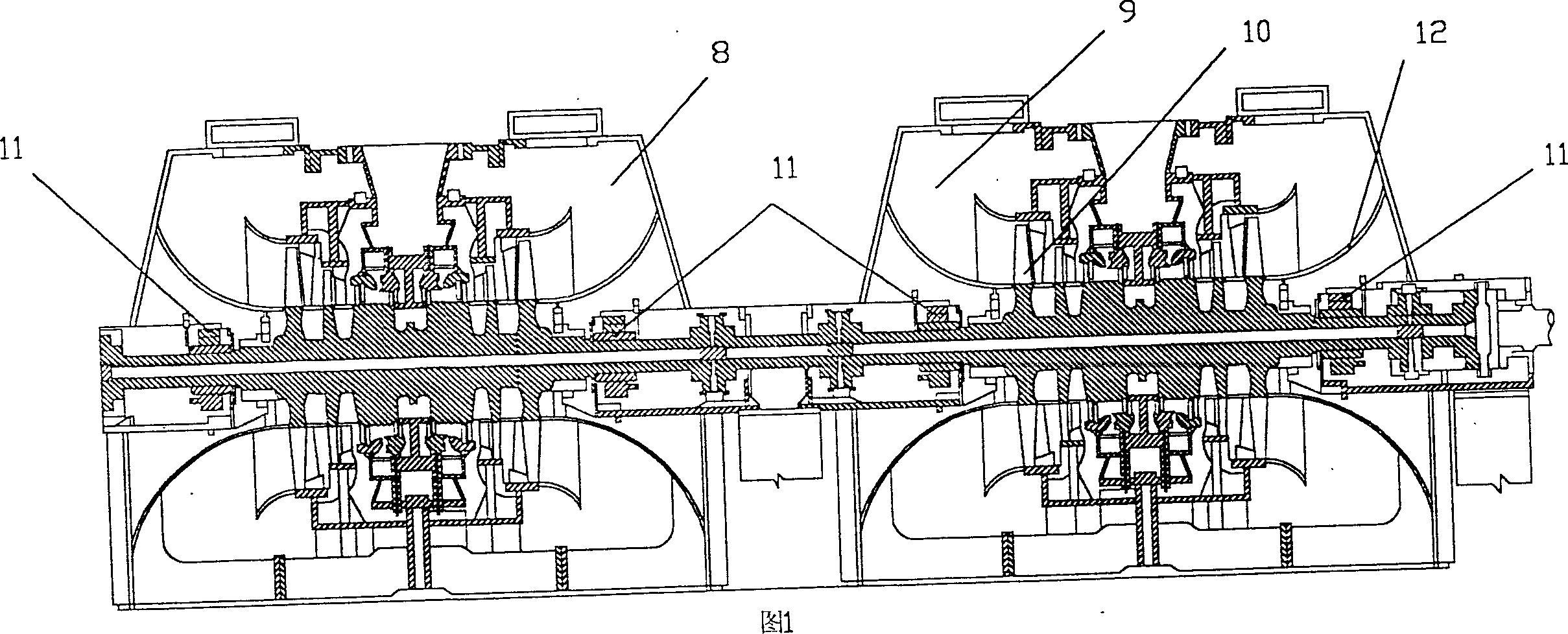

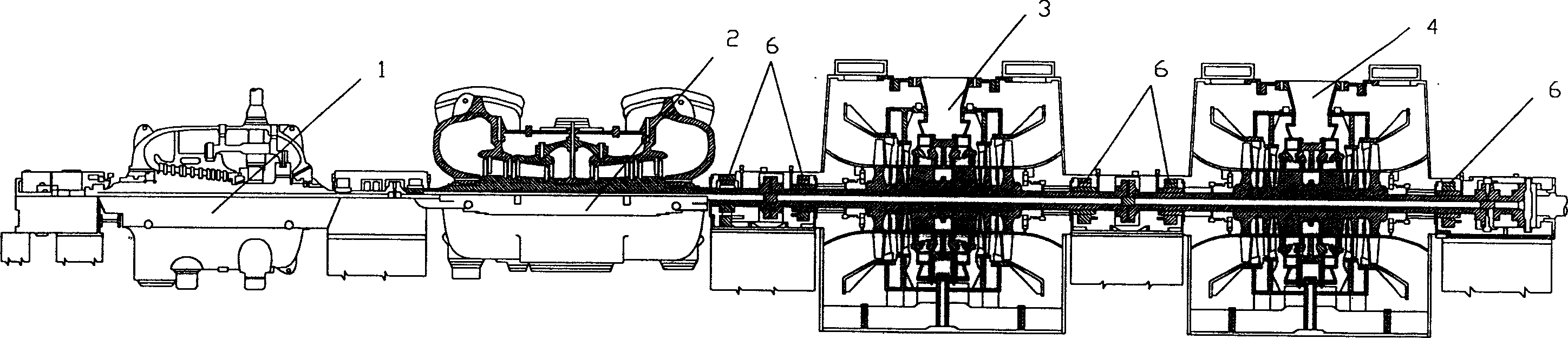

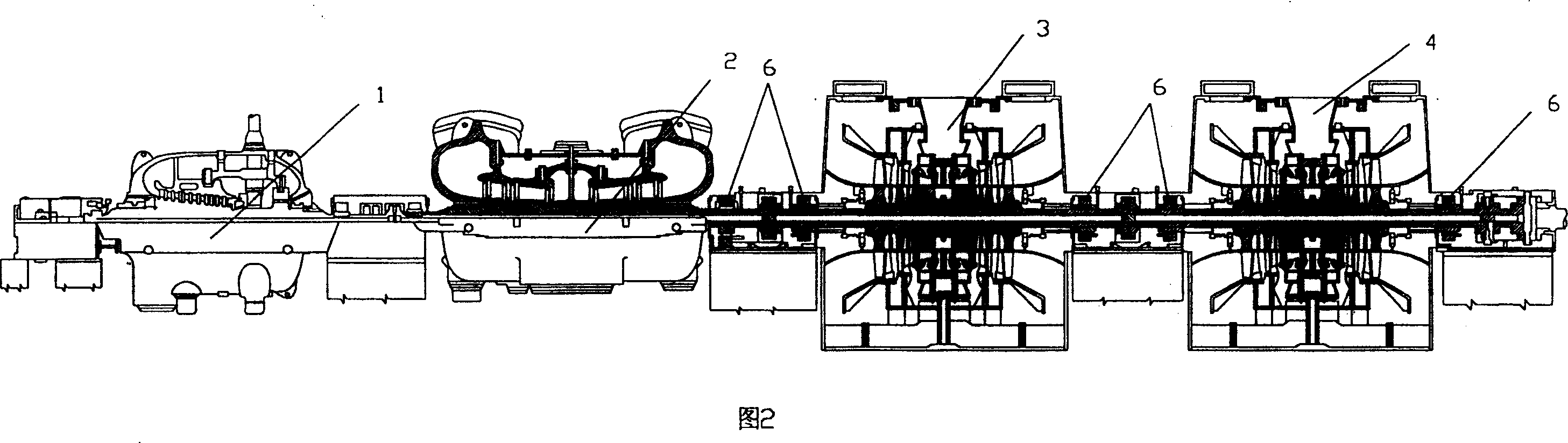

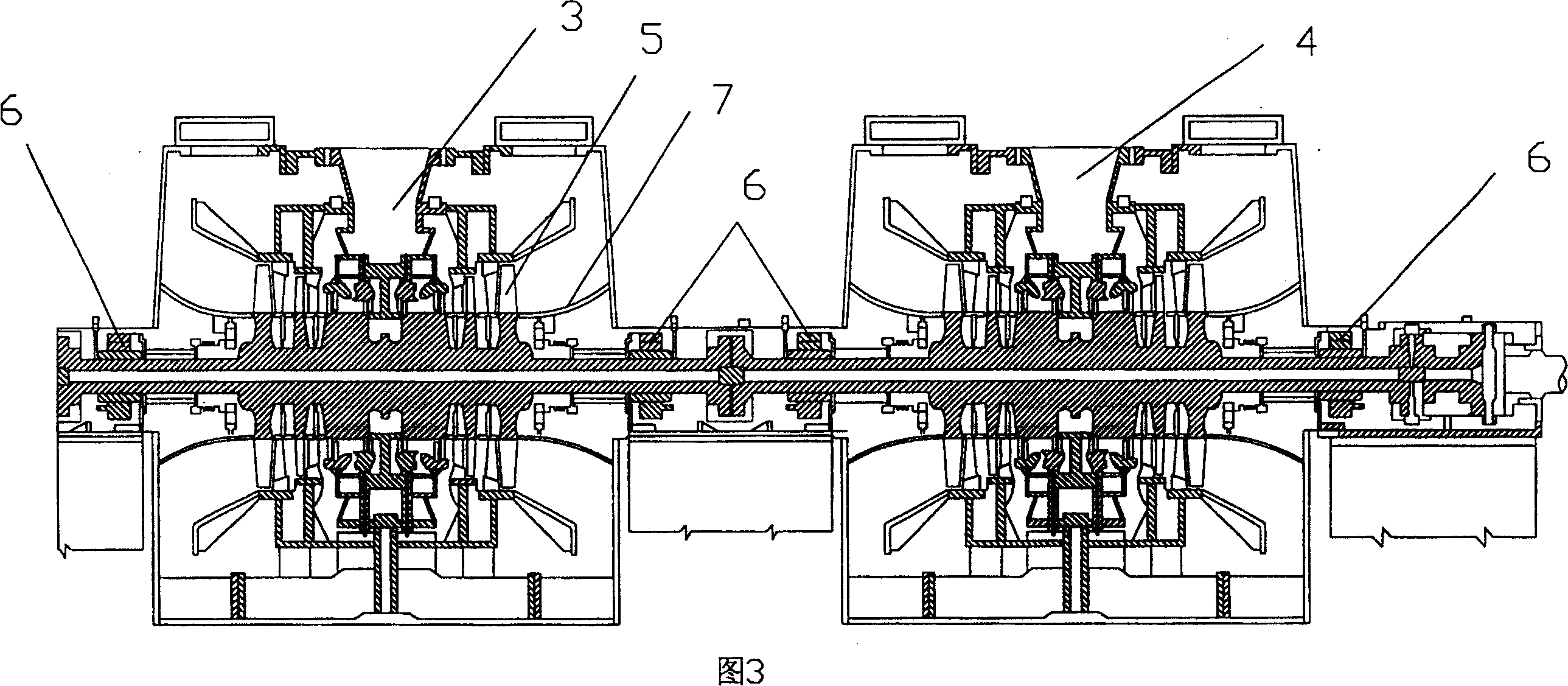

Supercritical air cooling steam turbine

InactiveCN1605716AImprove thermal efficiencyReduce heat rateMachines/enginesEngine componentsEngineeringHeat losses

The supercritical air-cooled steam turbine suitable for use in thermal power plant in unwatered area consists of supercritical wet cooled steam turbine high pressure cylinder, supercritical wet cooled steam turbine medium pressure cylinder and two low pressure cylinders. It features the two air cooled low pressure cylinders, the connection with low pressure cylinder bearing seat between the supercritical wet cooled steam turbine medium pressure cylinder and the air cooled low pressure cylinders and between the two air cooled low pressure cylinders, and the same structure of the high pressure cylinder and medium pressure cylinder in the supercritical air-cooled steam turbine and the high pressure cylinder and medium pressure cylinder in the supercritical wet cooled steam turbine. The two low pressure cylinders have improved structure and the present invention has direct air cooled exhaust. The present invention has low heat loss rate, high heat efficiency and low water consumption.

Owner:上海上发院发电成套设备工程有限公司

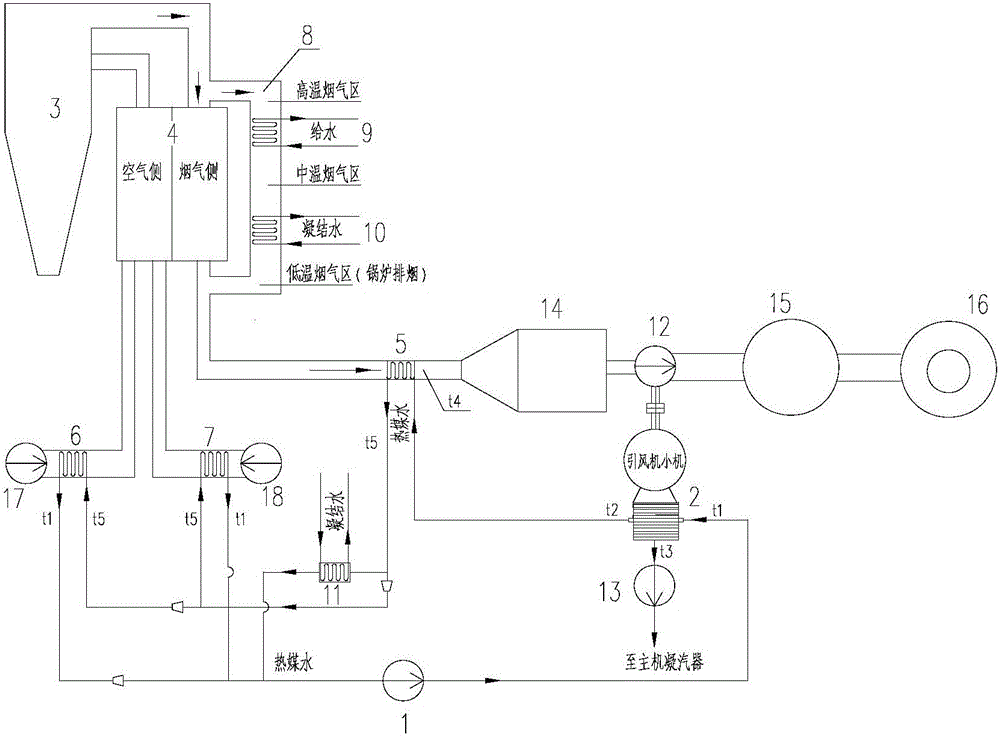

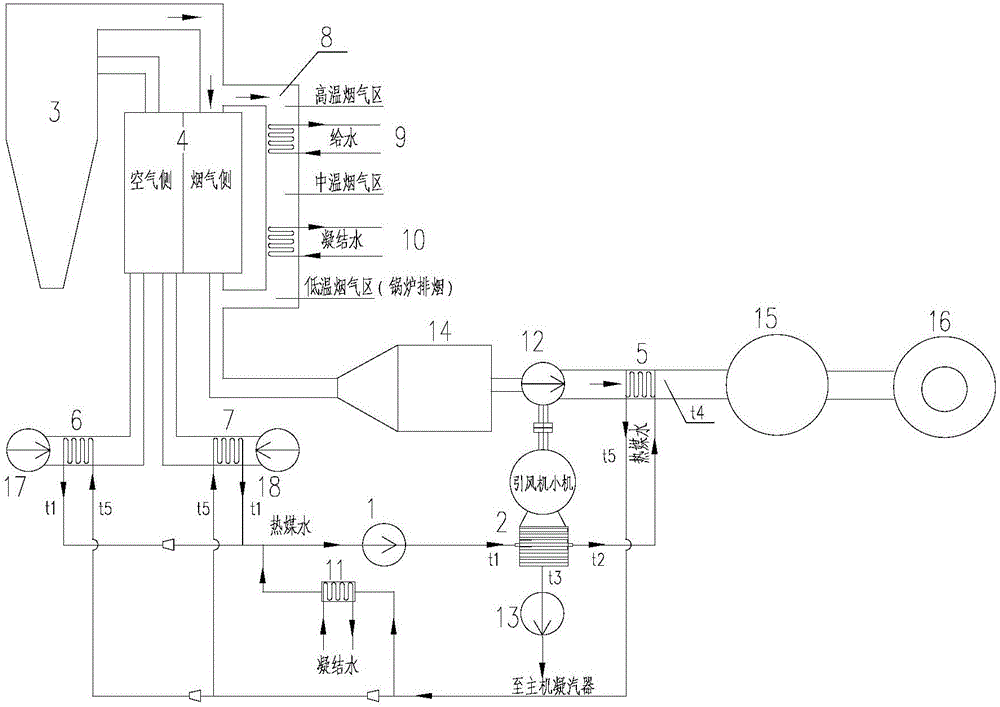

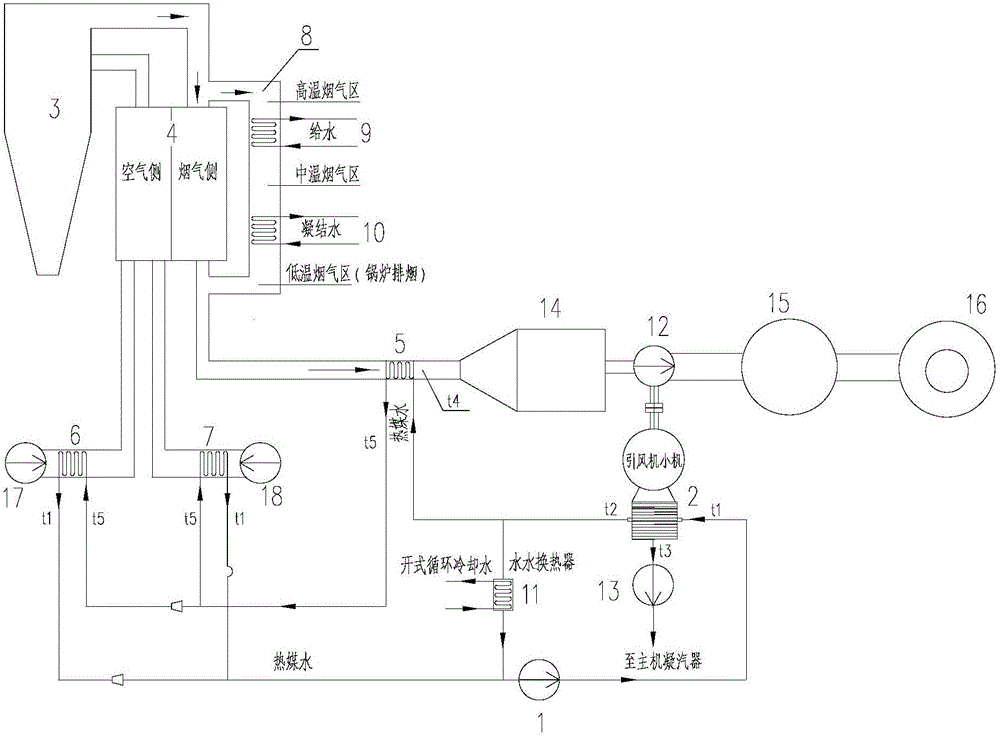

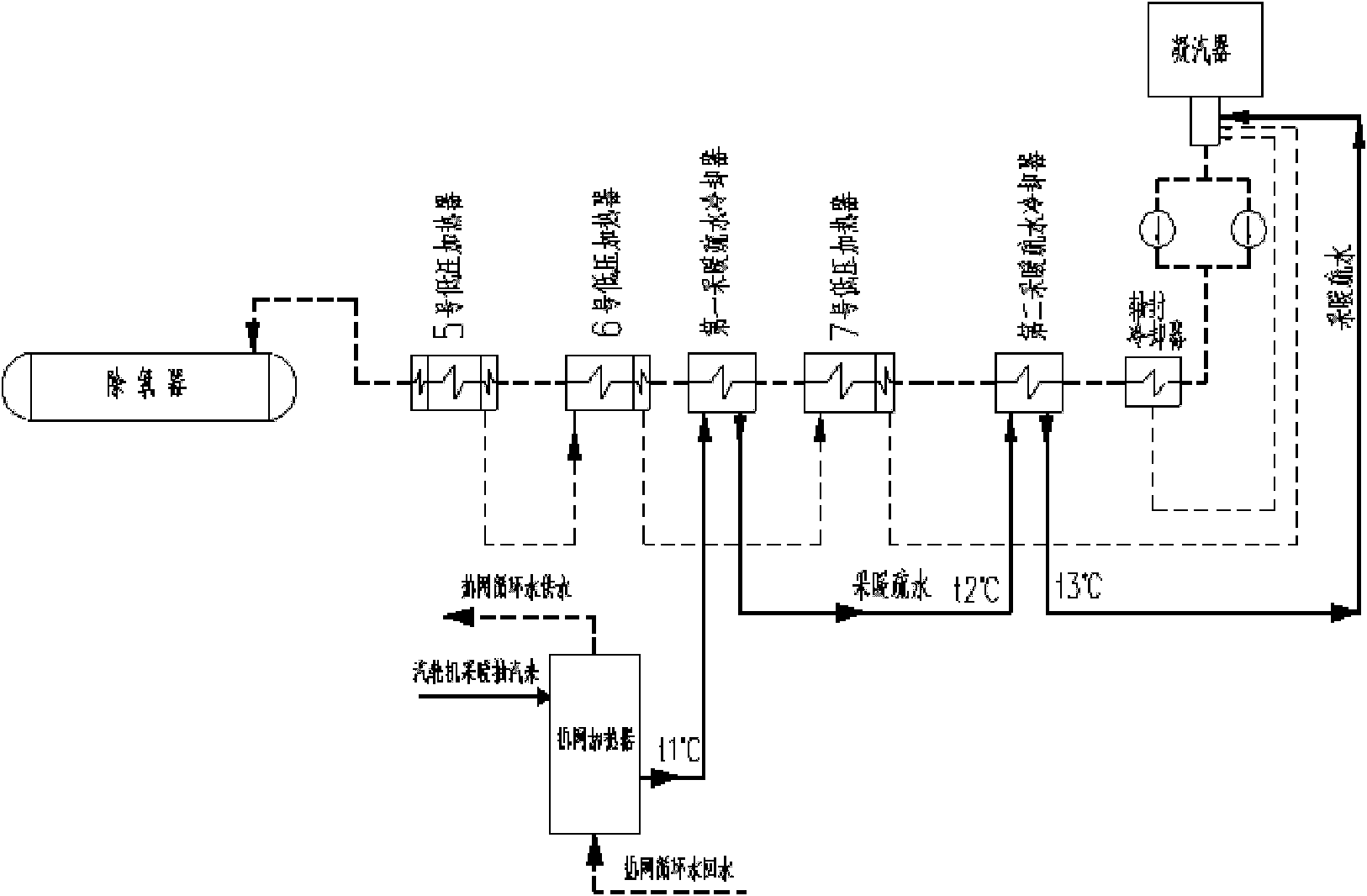

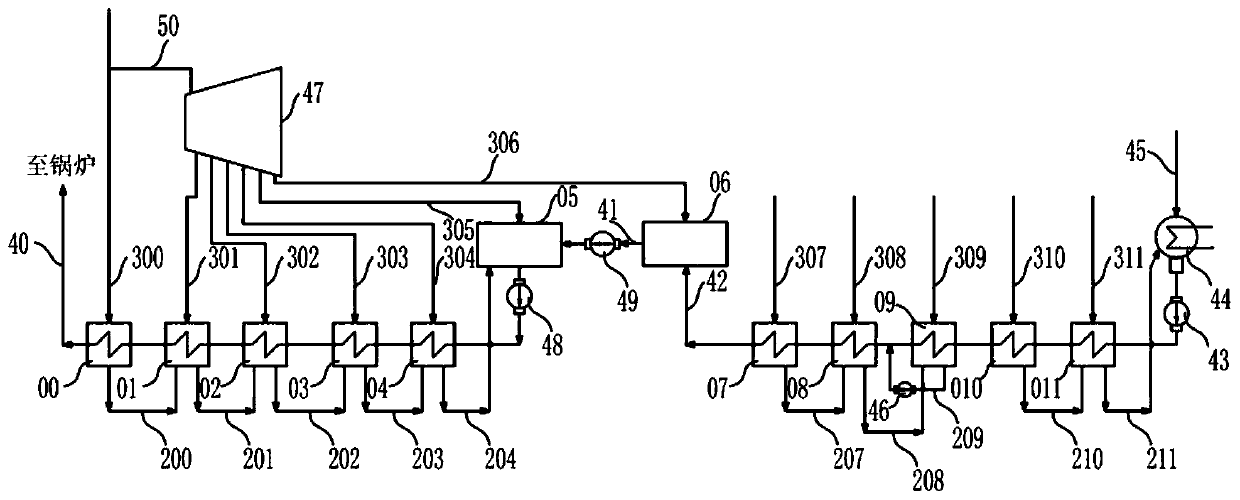

Comprehensive recycling system and method of waste heat in thermal power plant

ActiveCN105889897AReduce heat rateImprove temperature riseFeed water supplySteam useUnit operationCoal

The invention discloses a comprehensive recycling system and a method of waste heat in a thermal power plant. The comprehensive recycling system of the waste heat comprises a closed heating medium water cycle heat exchange system, recovers both steam exhaust waste heat of an induced draft fan driving a steam turbine and smoke discharge waste heat at the tail part of a boiler; on the one hand, the total heat of recovered whole plant waste heat is increased; and on the other hand, the system and the method can be used for replacing high-quality heat energy with higher heat energy utilization rate by two low-quality heat with low heat energy utilization rate and higher heat power value, so that the power consumption rate of whole plant can be reduced, the standard coal consumption of power generation can be reduced, and the unit operation economy is greatly improved.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

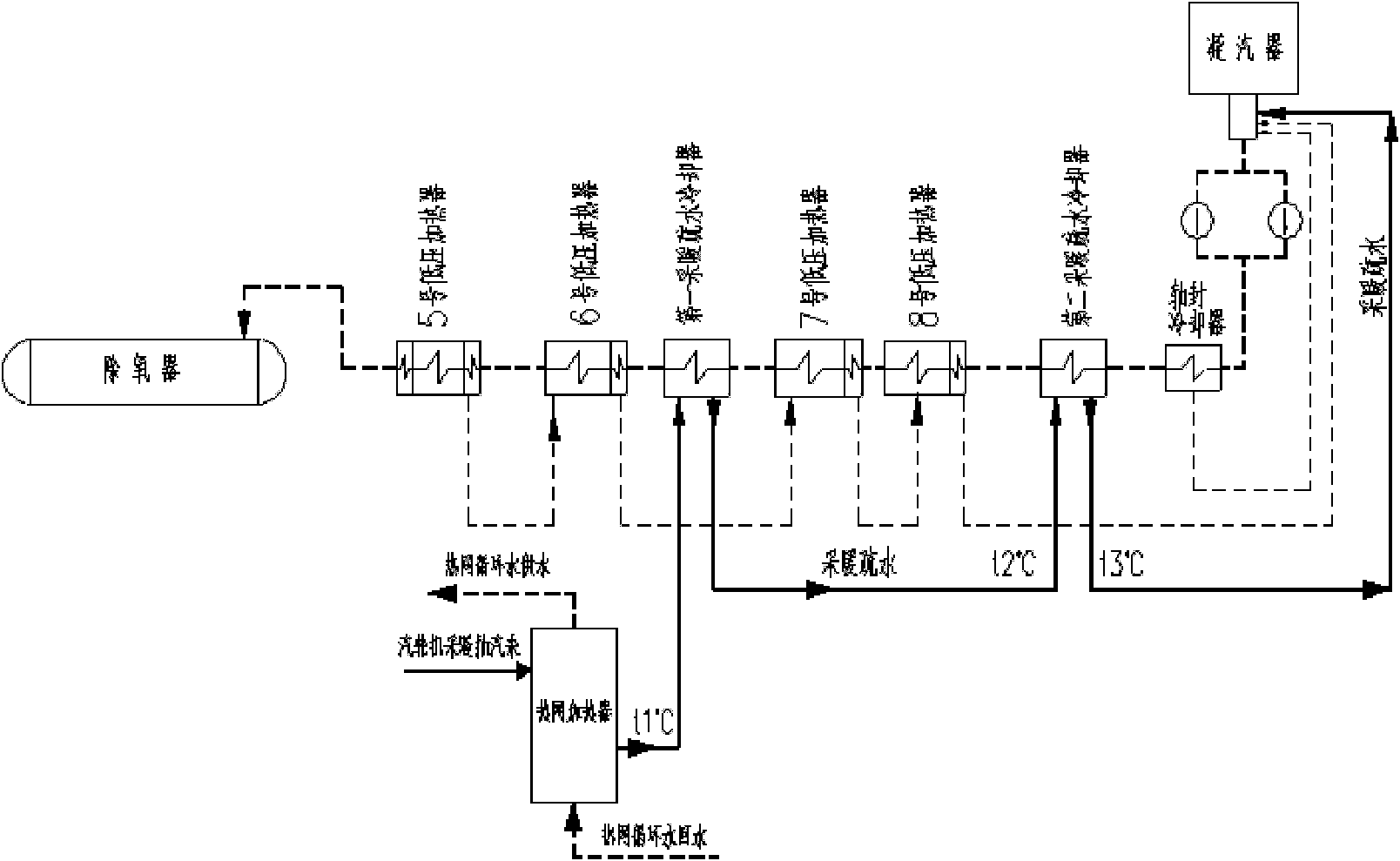

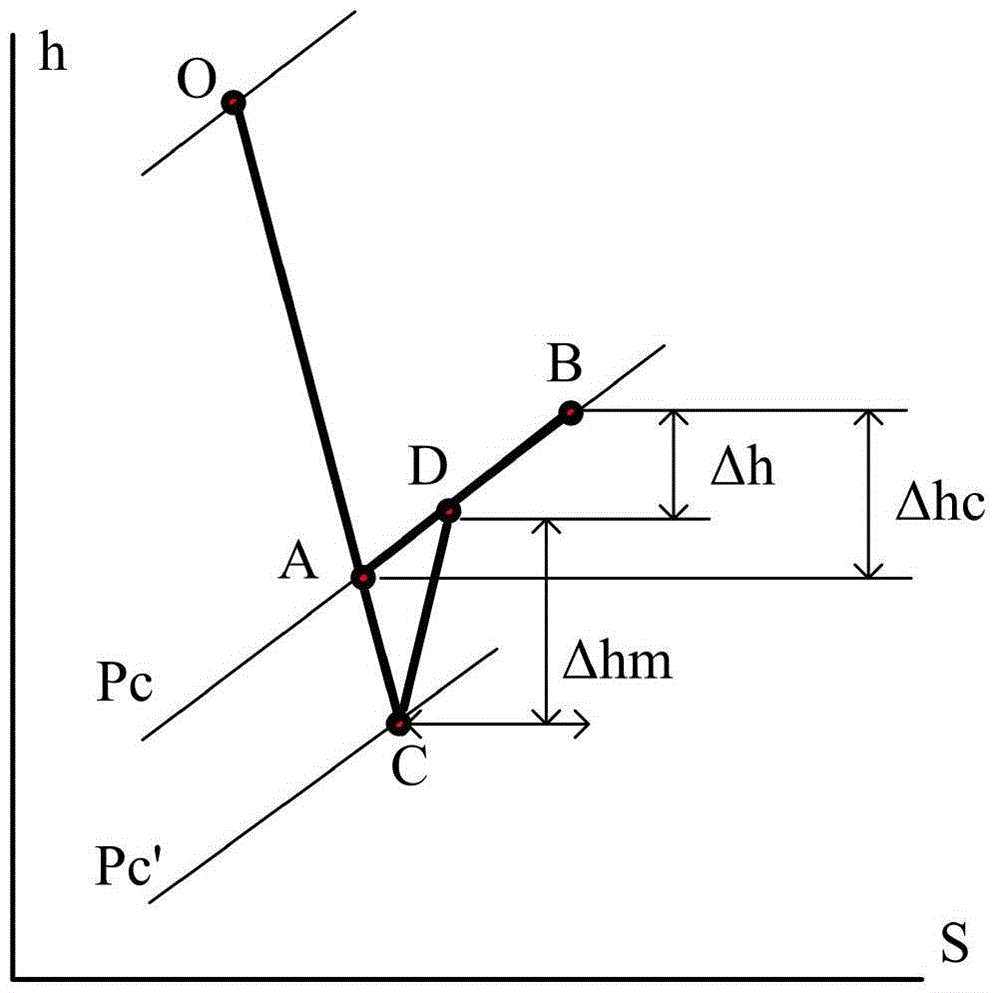

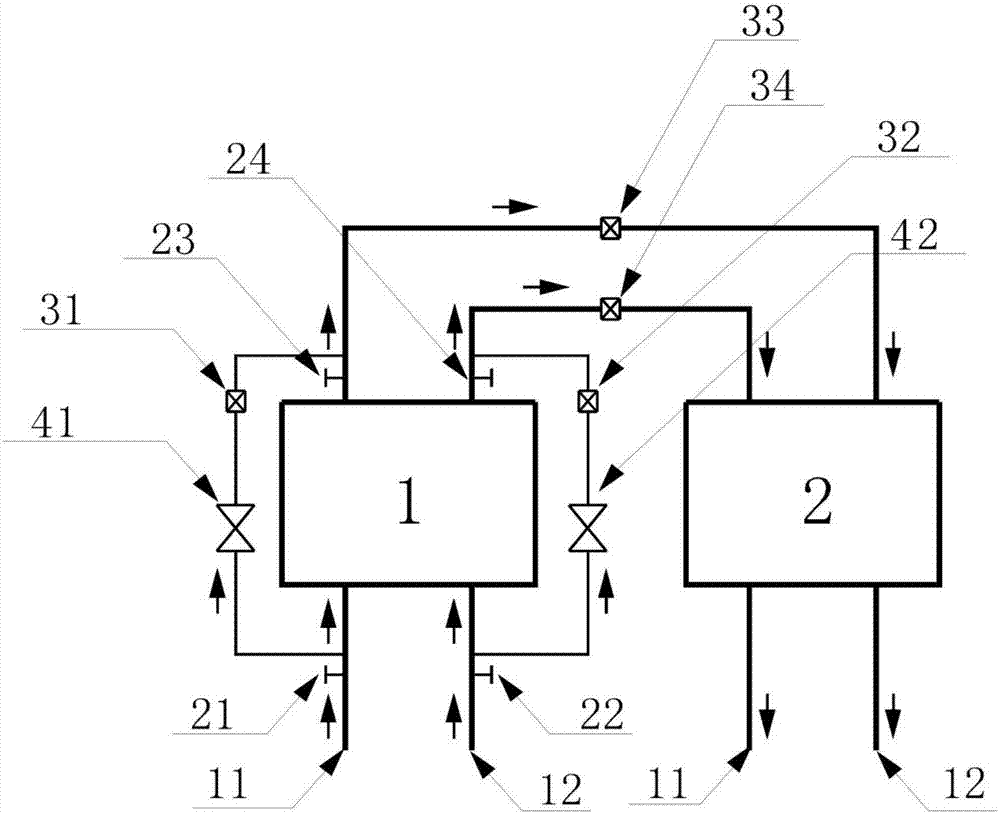

Supercritical/super-supercritical unit heating drain recovery method

ActiveCN102519033ADepreciationReduce heat rateSteam/vapor condensersFeed-water heatersRecovery methodEngineering

The invention discloses a supercritical / super-supercritical unit heating drain recovery method. The method has the advantages that heating drain and two heating drain coolers arranged in different positions on a host machine condenser water pipeline are subjected to twice heat exchange, and the heat energy devaluation of a system is reduced, so the total heat efficiency of a unit heat recovery system is improved, and the heat consumption rate of a steam turbine is reduced. Simultaneously, on the premise that the unit steam inlet parameters and the flow rates are identical, the heat return steam pumping flow rate at a grade with high steam pumping pressure on a steam turbine low-pressure cylinder is reduced, and the part of high-quality steam is used for power generation, so the unit power generation quantity is increased.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

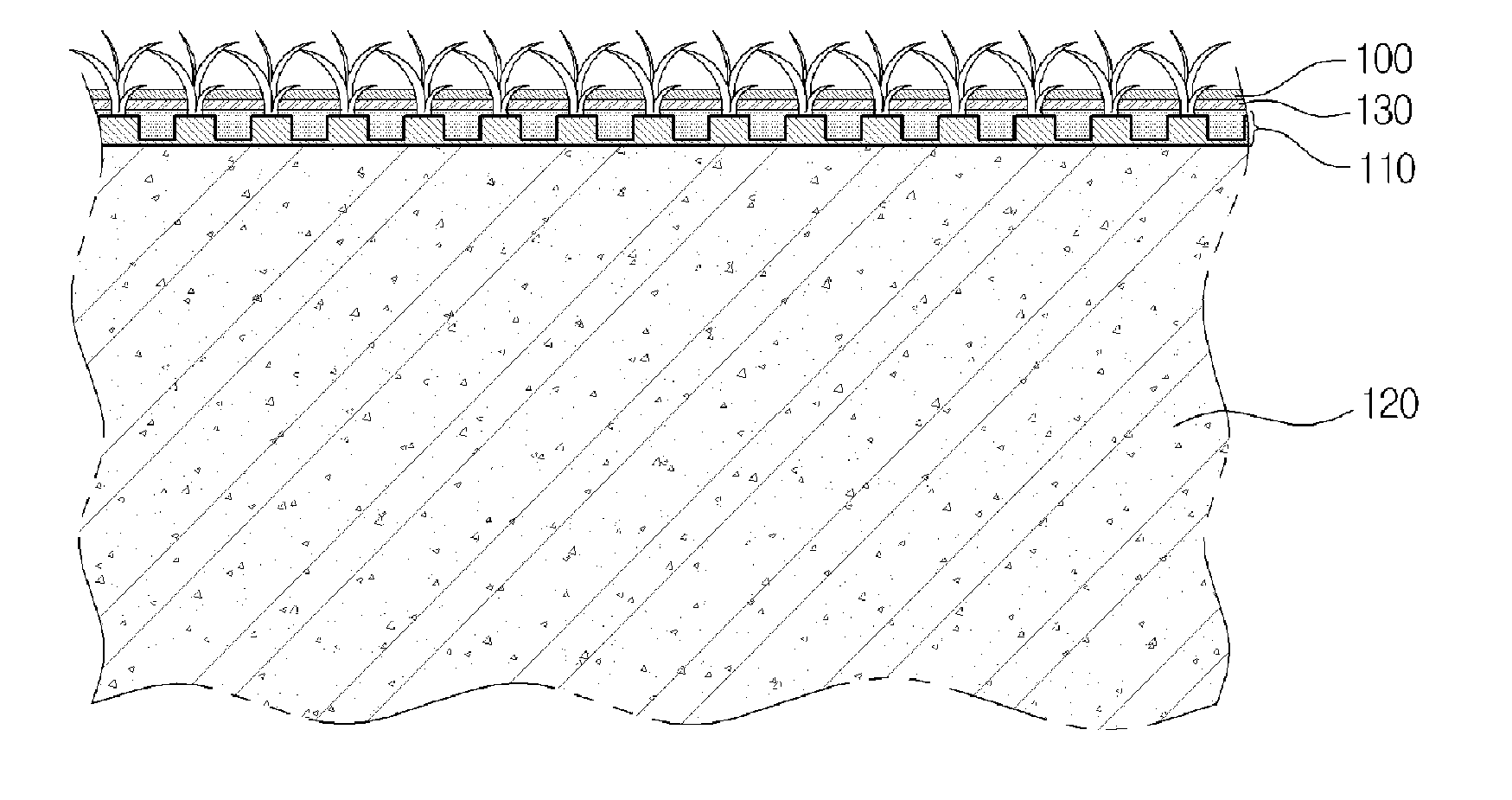

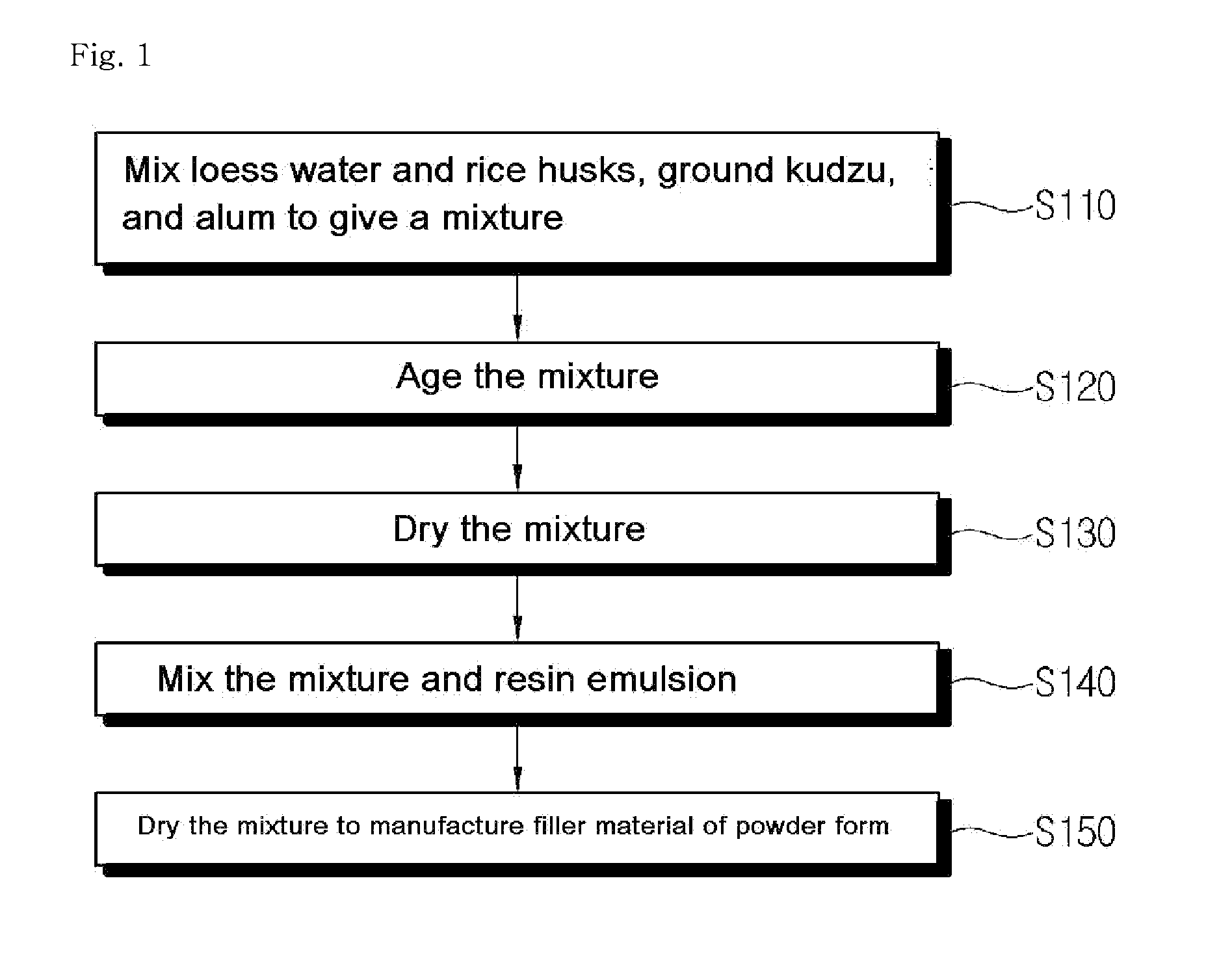

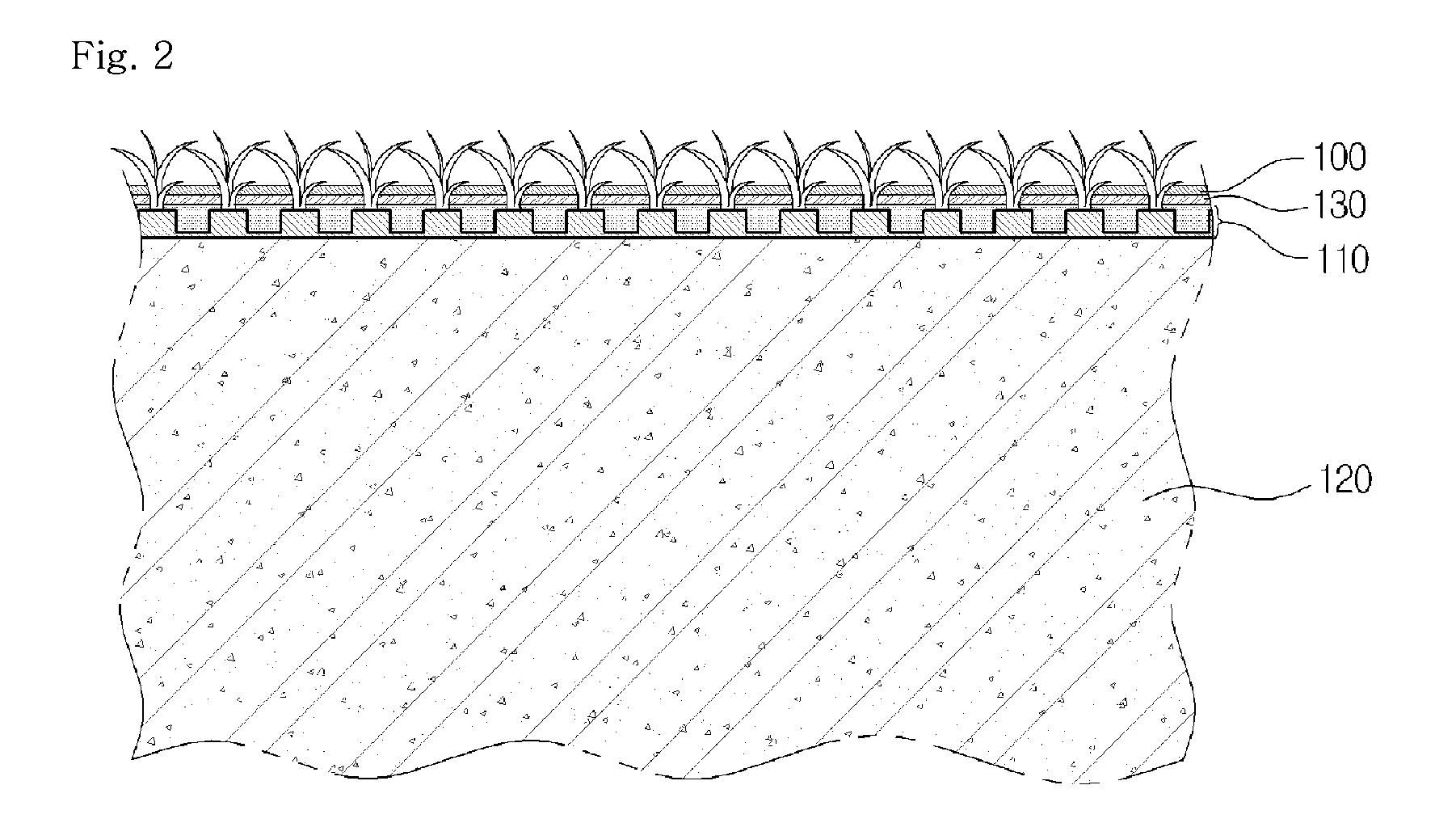

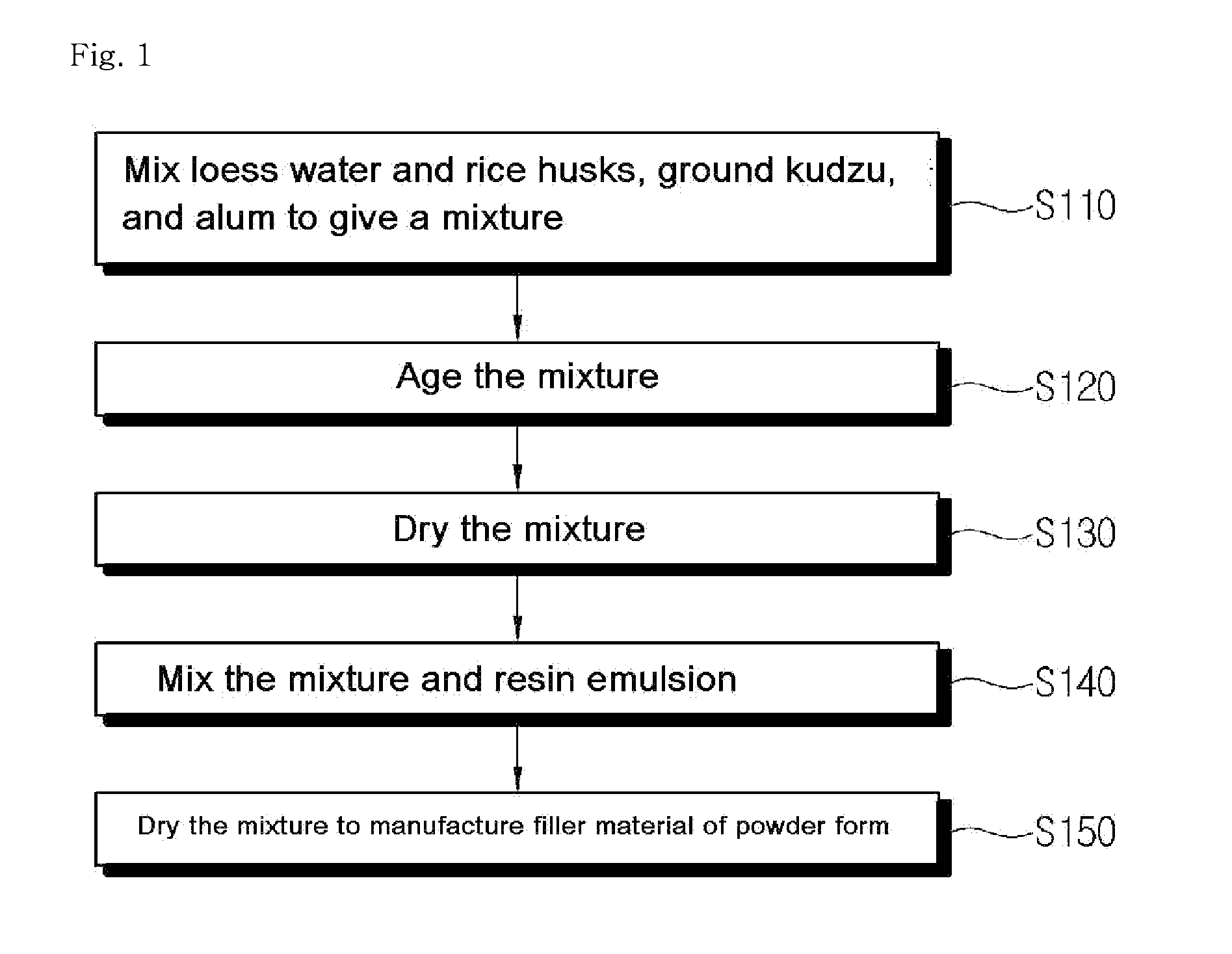

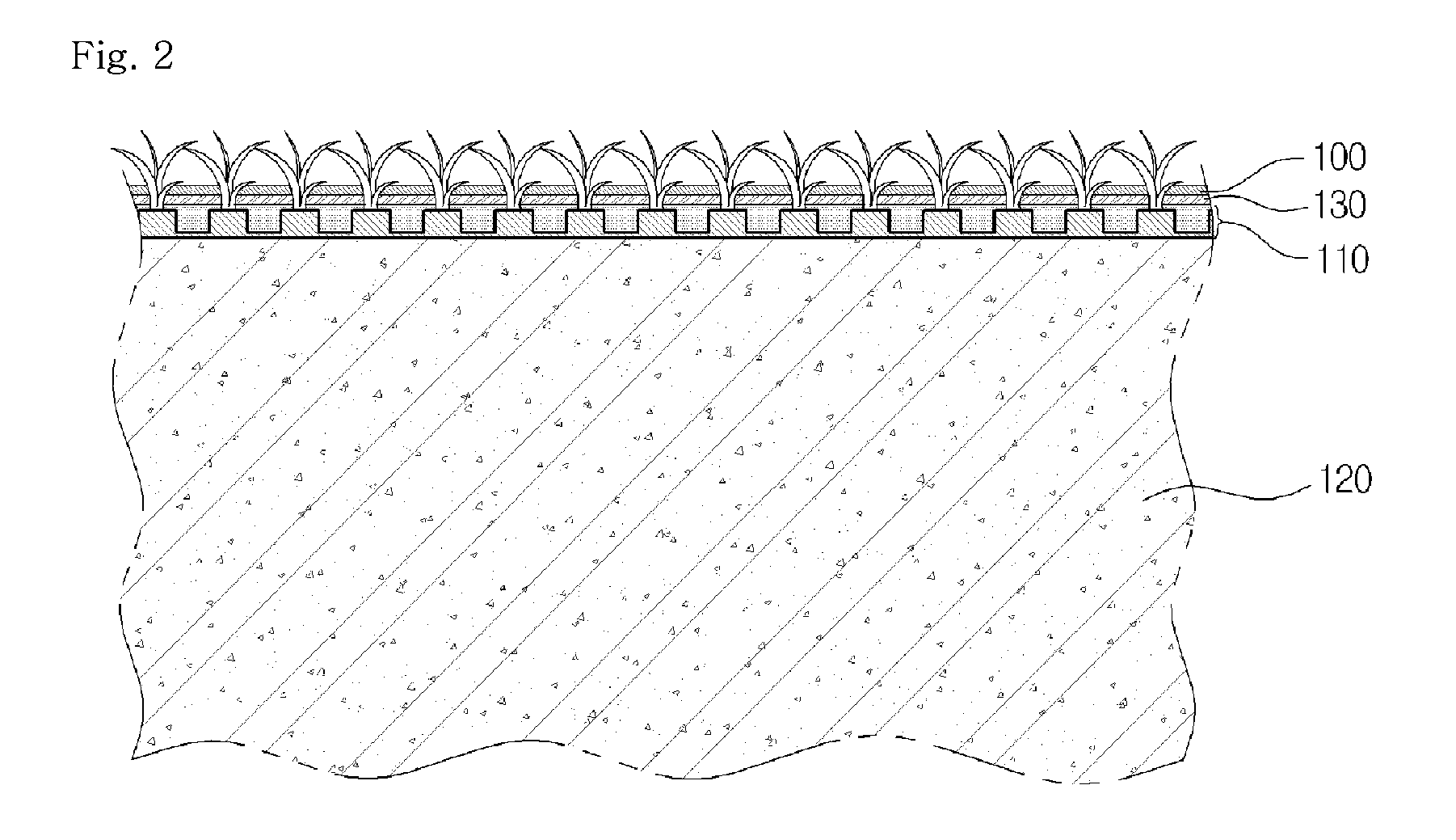

Filler material for a floor, and method for producing filler material for a floor

ActiveUS20110287263A1Reduce heat rateReduce riskMaterial nanotechnologyWood treatment detailsHuman bodyEmulsion

The present invention relates to a filler material for a floor, comprising a natural base material and a mixture containing loess and a resin in powder or pellet form, as well as to a method for producing the filler material. The filler material of the present invention uses the natural base material and is thus environmentally-friendly and not harmful to the human body. Further, in the event rice husks are used as the natural base material, a person slipping on the floor is protected from burning caused by friction as the rice husks have a high moisture content. In addition, the loess contained in the filler material keeps the floor from becoming moldy and emits far infrared radiation, and therefore is beneficial to the human body. The resin emulsion of the filler material prevents the natural base material from generating dust, thus preventing dust from entering the human body via the respiratory organs of the human body. Further, the filler material of the present invention can be easily produced through a simple process. Therefore, mass production of the filler material of the present invention can be accomplished even without employing experts.

Owner:JUNG MI SUK +1

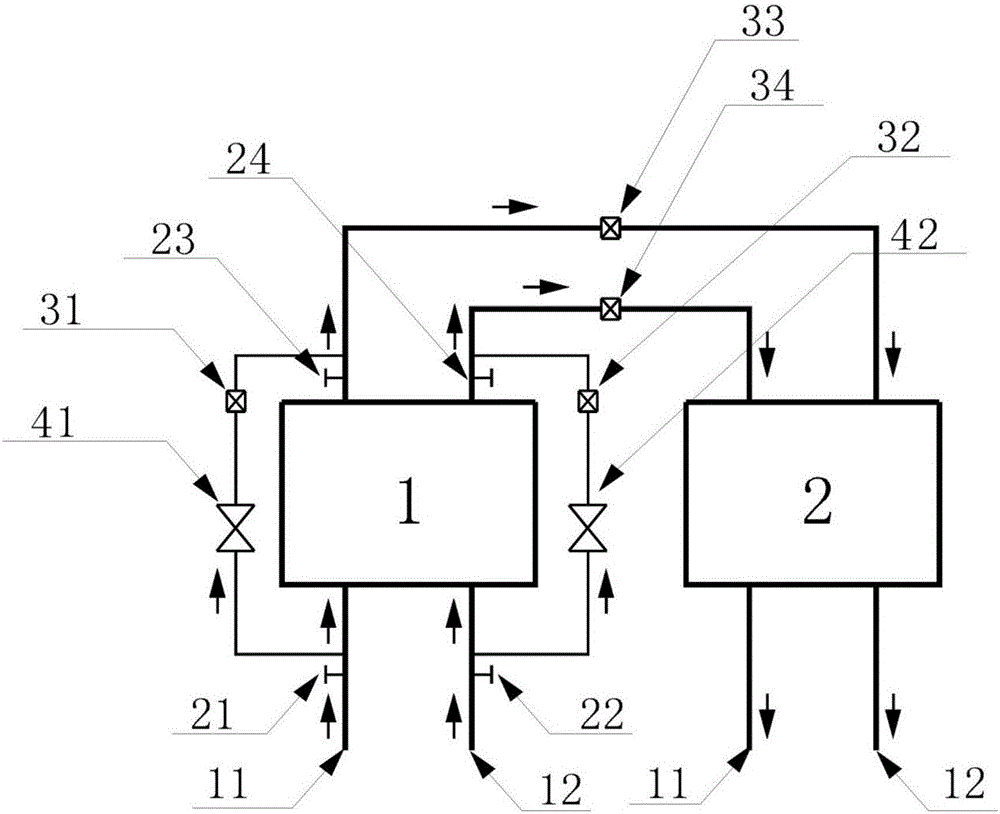

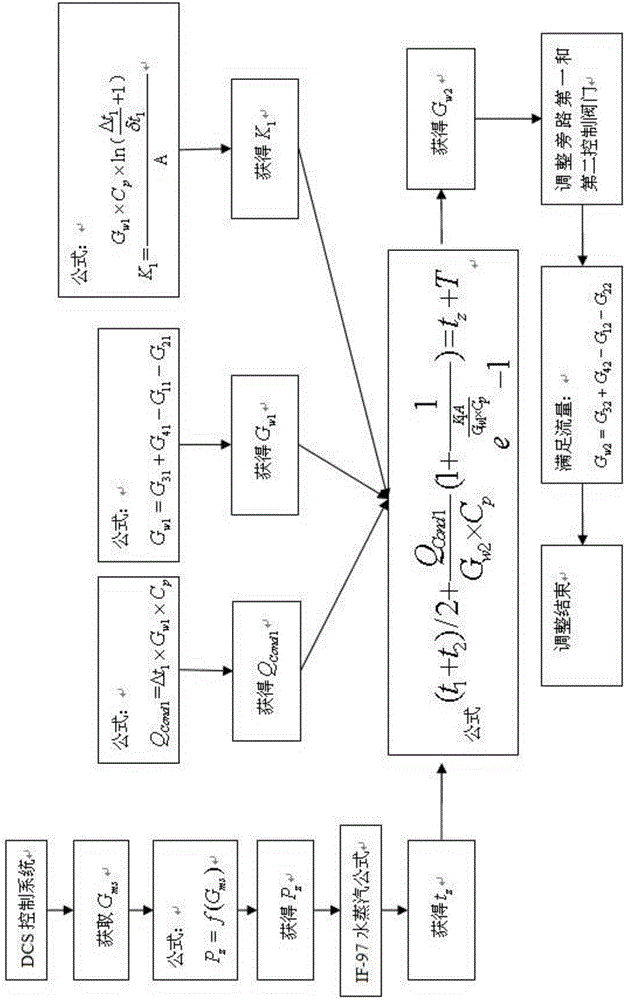

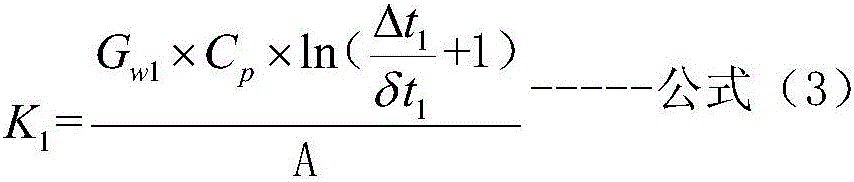

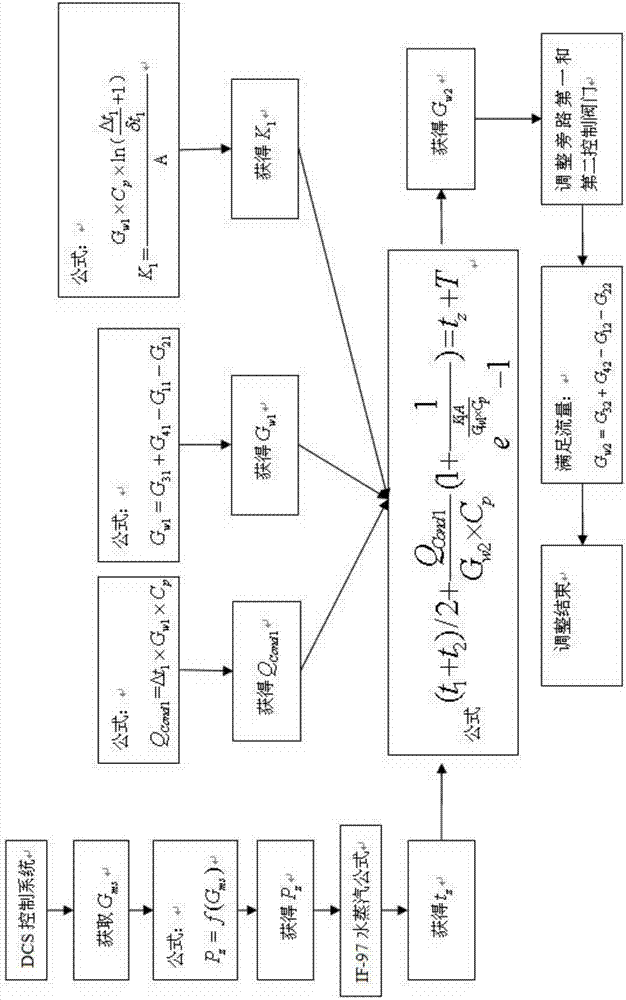

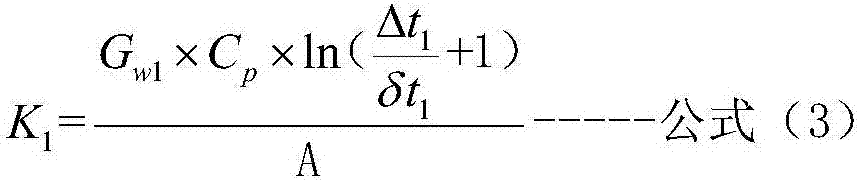

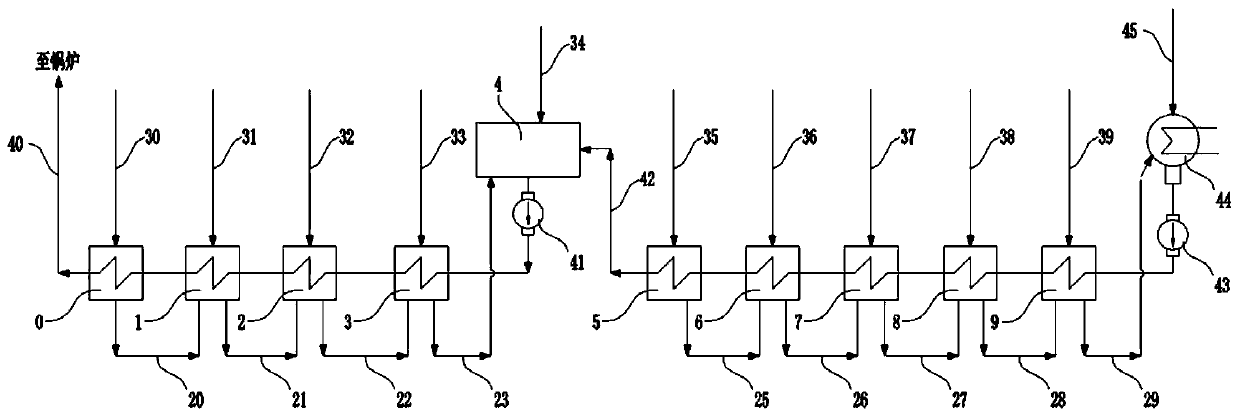

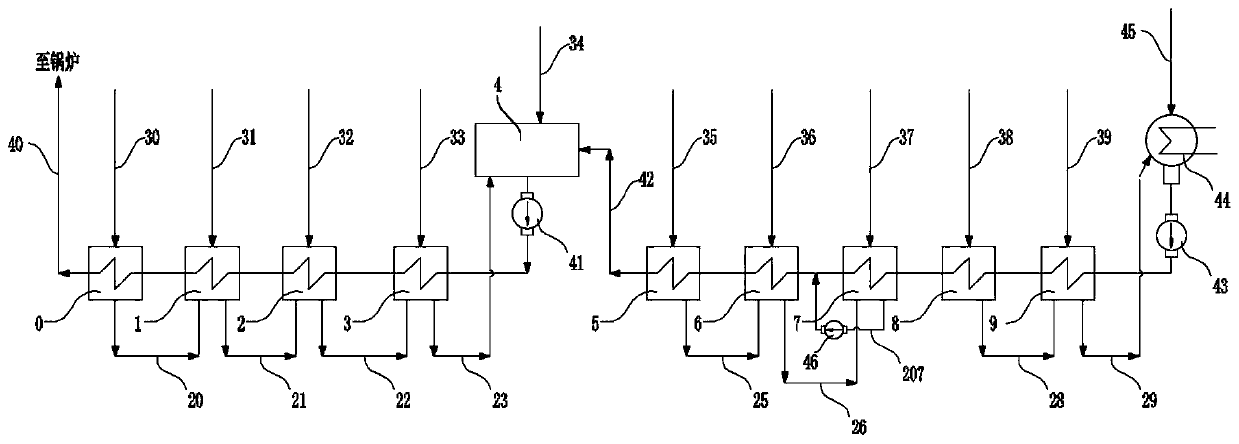

Double backpressure condenser optimized operation device and operation method thereof

ActiveCN105865220AReduce heat rateCirculating water flow has no effectSteam/vapor condensersControl systemWater flow

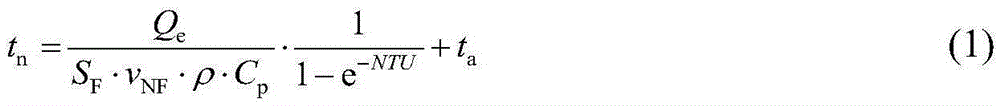

The invention discloses a double backpressure condenser optimized operation device and an operation method thereof. The double backpressure condenser optimized operation device comprises a high backpressure condenser, a lower backpressure condenser and a circulating water pipeline, wherein two bypasses and a control valve are arranged on the circulating water pipeline, the bypasses are connected with the two ends of the low backpressure condenser in a crossing manner, and a plurality of temperature measuring points and flow meters are arranged. Compared with the prior art, the double backpressure condenser optimized operation device has the advantages that circulating water flow rate of the low backpressure condenser is independently controlled, the circulating water flow rate of the high backpressure condenser is not influenced; by virtue of a calculation formula provided by the invention as well as the measuring points and a valve control system, the low backpressure side condenser is vacuum and does not enter a blockage backpressure region, and heat rate of a steam turbine is reduced; and due to influence of the circulating water bypasses, water inlet temperature of circulating water at the high backpressure side condenser is relatively low, and high backpressure side exhaust temperature is indirectly lowered, so that the heat rate of the steam turbine is further reduced.

Owner:CHINA DATANG CORP SCI & TECH RES INST CO LTD EAST CHINA BRANCH

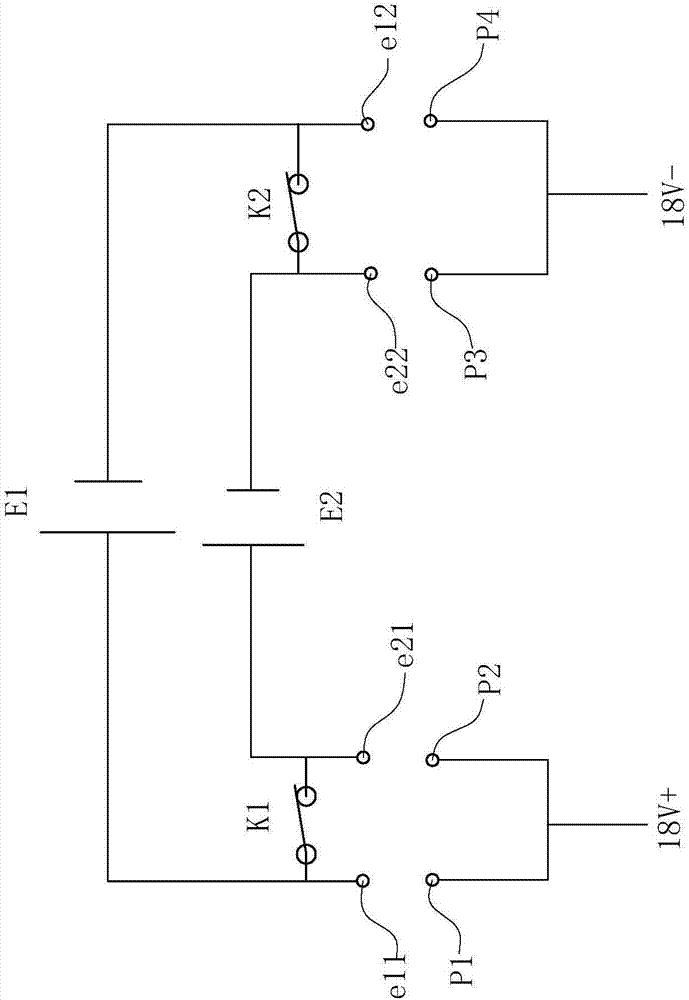

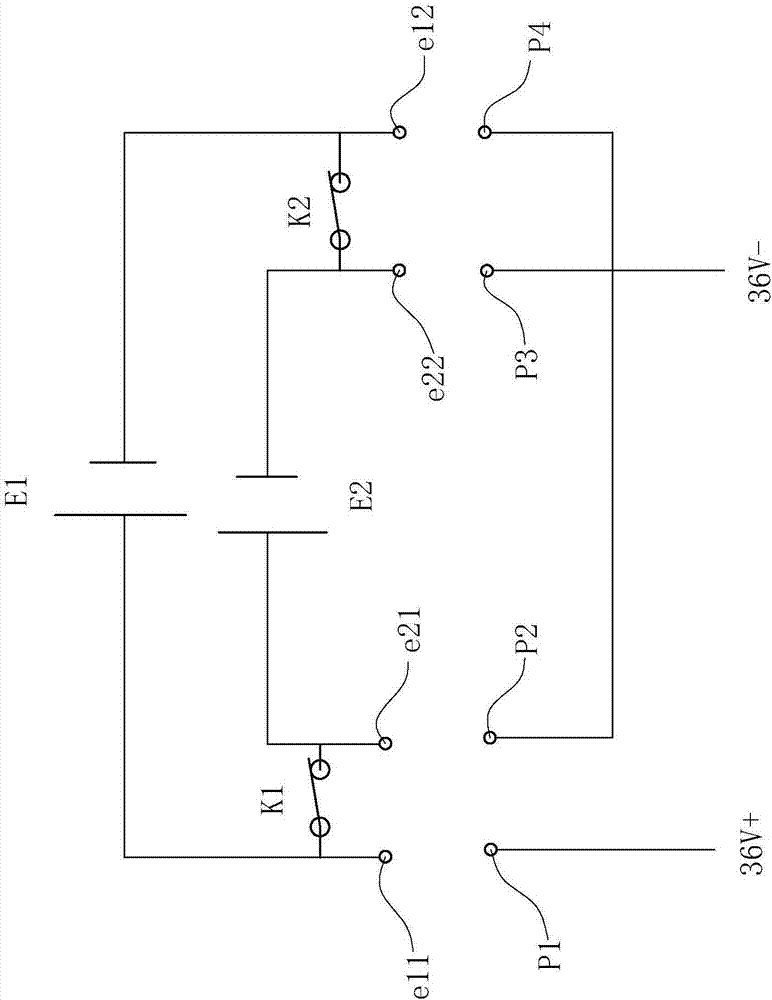

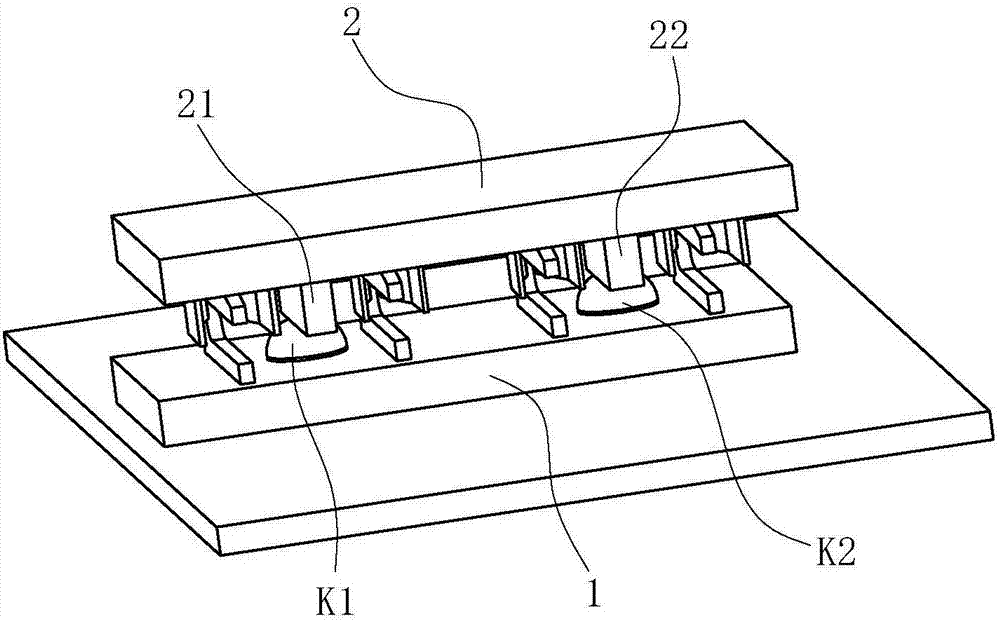

Electric tool

PendingCN107302248ASimple circuit structureSmall circuit sizeCharge equalisation circuitSafety/protection battery circuitsElectrical batteryEngineering

The invention provides an electric tool which comprises a battery pack assembly and a control component. The electric tool is characterized in that the battery pack assembly comprises a first battery group and a second battery group with the same voltage, a normally closed first micro switch is arranged between the anodes of the first battery group and the second battery group, and a normally closed second micro switch is arranged between the cathodes of the first battery group and the second battery group. The control component comprises a first terminal, a second terminal, a third terminal and a fourth terminal and also comprises a driving component which allows the first micro switch and the second micro switch to be switched on at the same time. The output end of the control component supplies power to the electric tool with first voltage obtained through the parallel connection of the first battery group and the second battery group or second voltage obtained through the series connection of the first battery group and the second battery group. The electric tool is characterized in that the series and parallel connection of the battery groups are completed by the control component, the circuit size is reduced, the heating rate and failure rate of the circuit are reduced, the battery pack assembly is internally provided with the two normally closed micro switches, two groups of battery ports are effectively inhibited to form a voltage difference, a lithium battery is protected, and the service life is prolonged.

Owner:宁波锂想电子有限公司

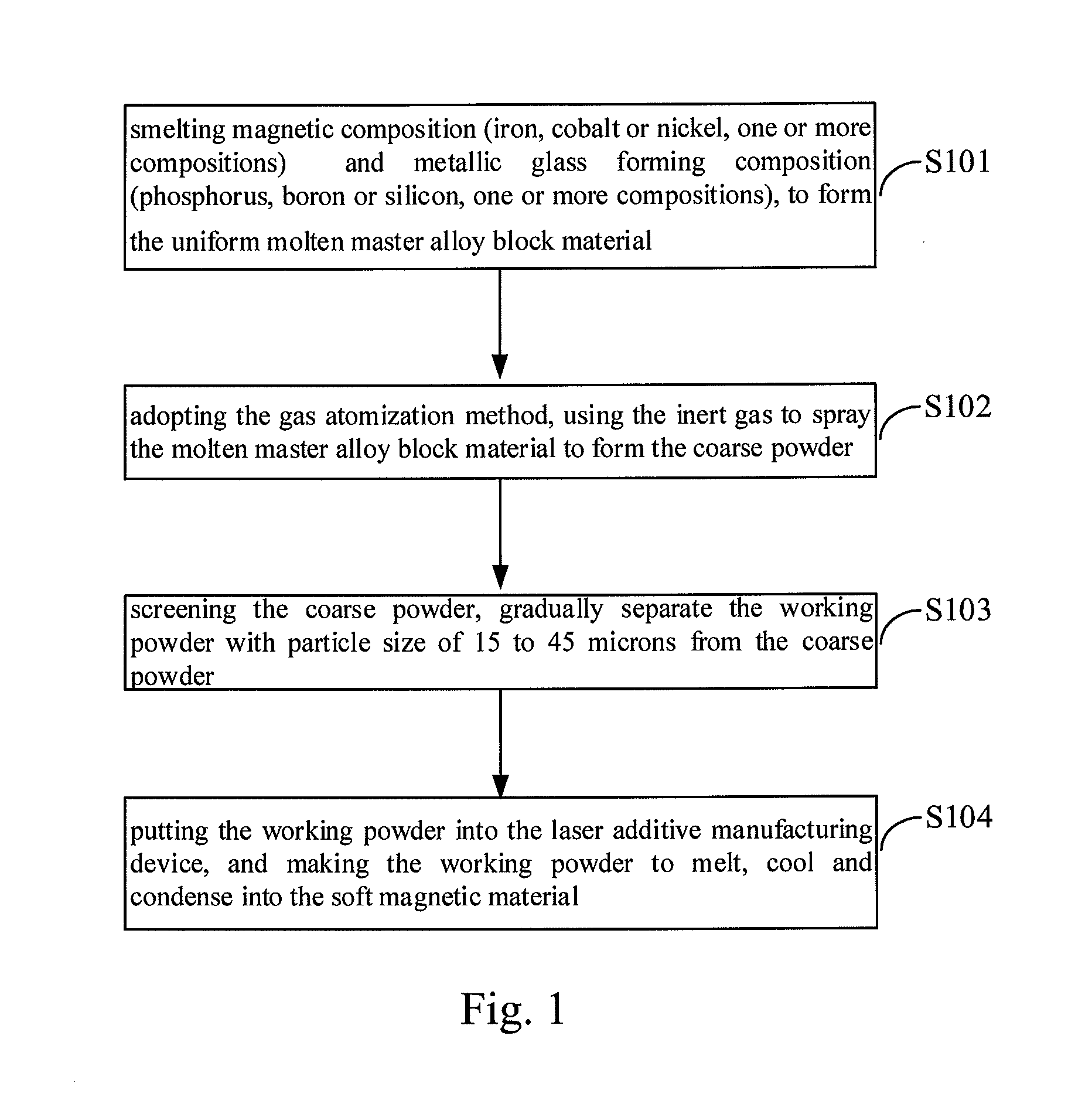

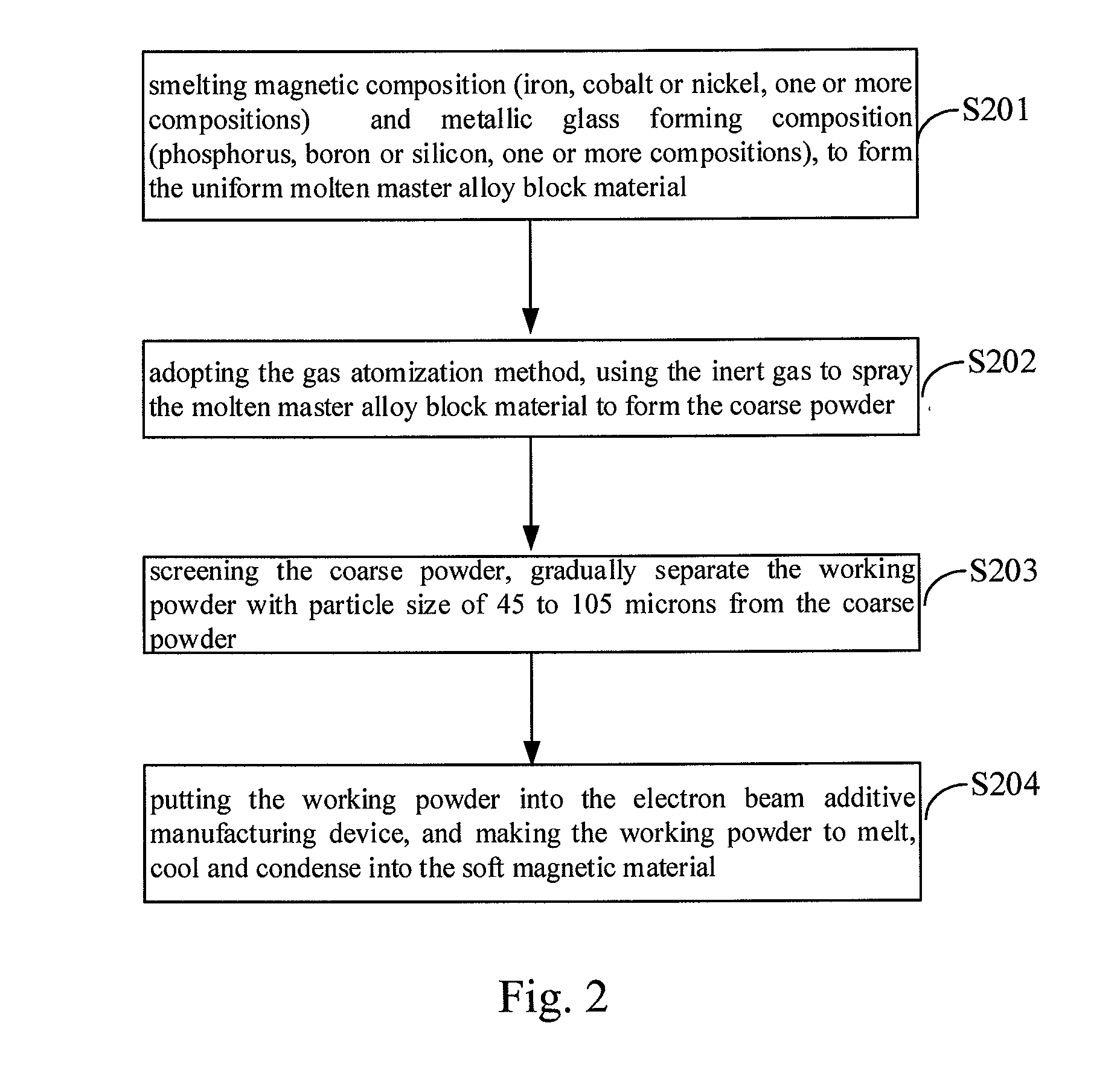

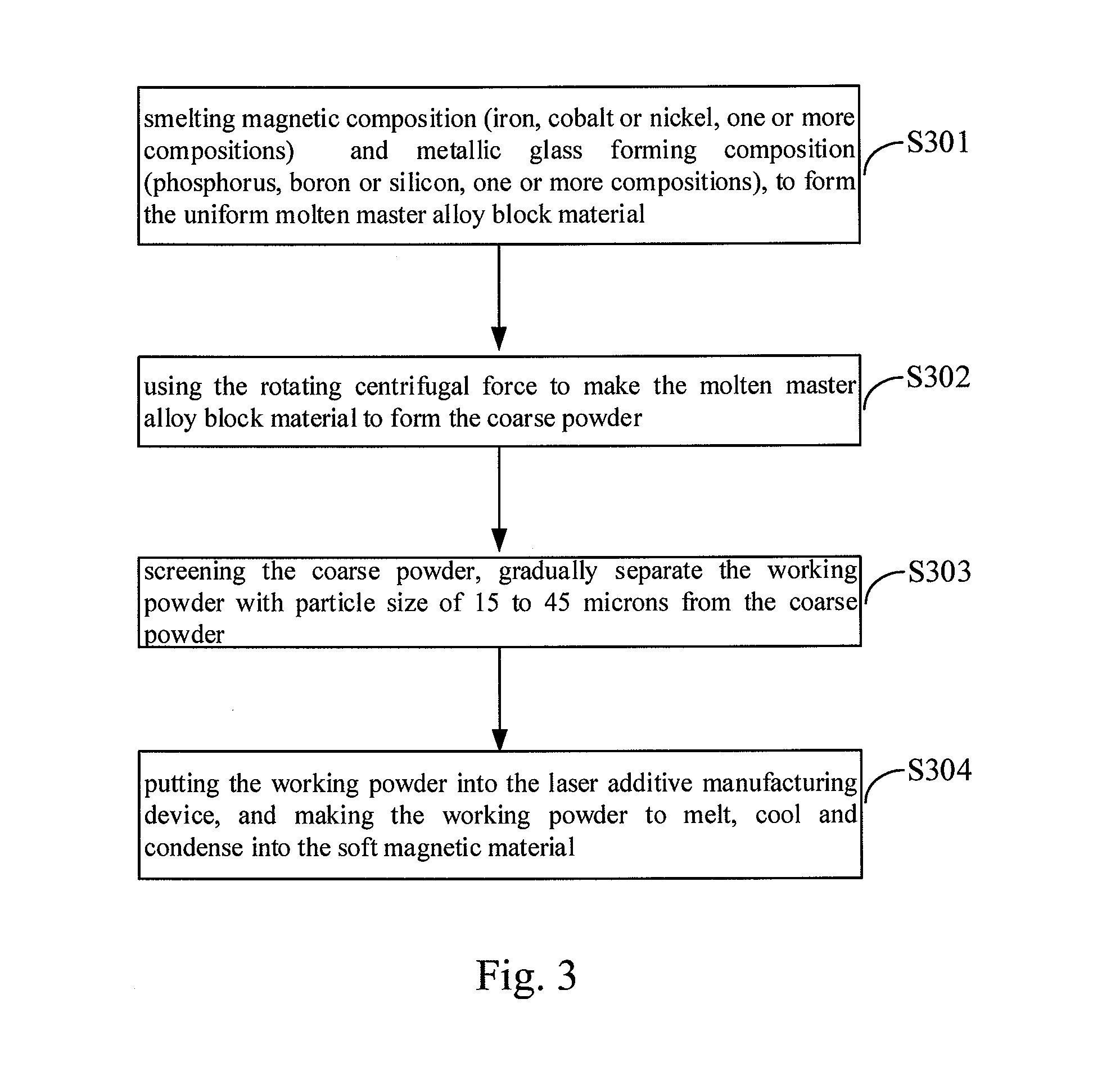

Method of manufacturing soft magnetic material

InactiveUS20160180994A1Simple manufacturing processReduce heat rateAdditive manufacturing apparatusArc welding apparatusLoss rateElectromagnetic shielding

A method of manufacturing soft magnetic material, including smelting magnetic and metallic glass forming compositions, to form a uniform molten master alloy block material, melting the master alloy material into liquid, and exerting a force on the liquid master alloy block material to make it into coarse powder. The coarse powder is screened to separate the working powder, and the working powder is put into an additive manufacturing device, to make the working powder melt, cool and condense into the soft magnetic material. The soft magnetic material is made by a simple process, with low iron loss rate and better electromagnetic shielding feature and other properties, and can improve magnetic permeability and save energy when applied to the electronic products.

Owner:METAL INDS RES & DEV CENT

Filler material for a floor, and method for producing filler material for a floor

ActiveUS8951634B2Reduce heat rateWithout riskWood treatment detailsGlass/slag layered productsEmulsionFilling materials

The present invention relates to a filler material for a floor, comprising a natural base material and a mixture containing loess and a resin in powder or pellet form, as well as to a method for producing the filler material. The filler material of the present invention uses the natural base material and is thus environmentally-friendly and not harmful to the human body. Further, in the event rice husks are used as the natural base material, a person slipping on the floor is protected from burning caused by friction as the rice husks have a high moisture content. In addition, the loess contained in the filler material keeps the floor from becoming moldy and emits far infrared radiation, and therefore is beneficial to the human body. The resin emulsion of the filler material prevents the natural base material from generating dust, thus preventing dust from entering the human body via the respiratory organs of the human body. Further, the filler material of the present invention can be easily produced through a simple process. Therefore, mass production of the filler material of the present invention can be accomplished even without employing experts.

Owner:JUNG MI SUK +1

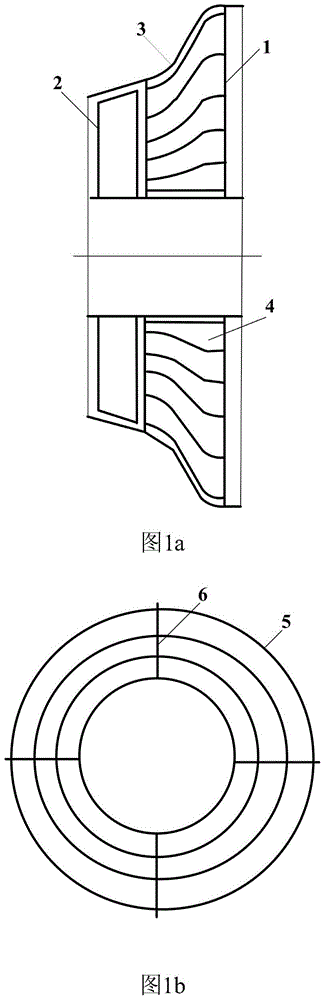

Fluid director using exhaust leaving velocity loss of steam turbine

ActiveCN105736076AReduce heat rateSignificant energy saving benefitsPump componentsSpraying apparatusTesla turbineEngineering

The invention discloses a fluid director using exhaust leaving velocity loss of a steam turbine. The fluid director is arranged at the downstream of a final moving blade of the steam turbine, is fixed on a cylinder of the steam turbine, and is formed by sleeving multiple annular fluid directing pieces with S-shaped sections; the adjacent annular fluid directing pieces are fixed in the radial direction through multiple fixators with streamlined sections; fluid directing channels are formed between the adjacent annular fluid directing pieces; the direction of inlets of the fluid directing channels is the same with the direction of steam current velocity behind the final blade of the steam turbine; the direction of outlets of the fluid directing channels is the horizontal direction; the fluid directing channels adopt gradually increased channels from the inlets to the outlets; and a ratio of the sectional area sum of the outlets of the fluid directing channels to the sectional area sum of the inlets of the fluid directing channels is 1.5-2. The fluid director can obtain a prominent pressure increasing effect in shorter channels to effectively use the leaving velocity loss of the steam turbine. Indicated through calculation, for a modern large thermal power generating unit, the technology can obviously reduce the heat rate of a turbogenerator under the precondition of not largely increasing the unit investment, and has prominent energy saving benefit.

Owner:XI AN JIAOTONG UNIV

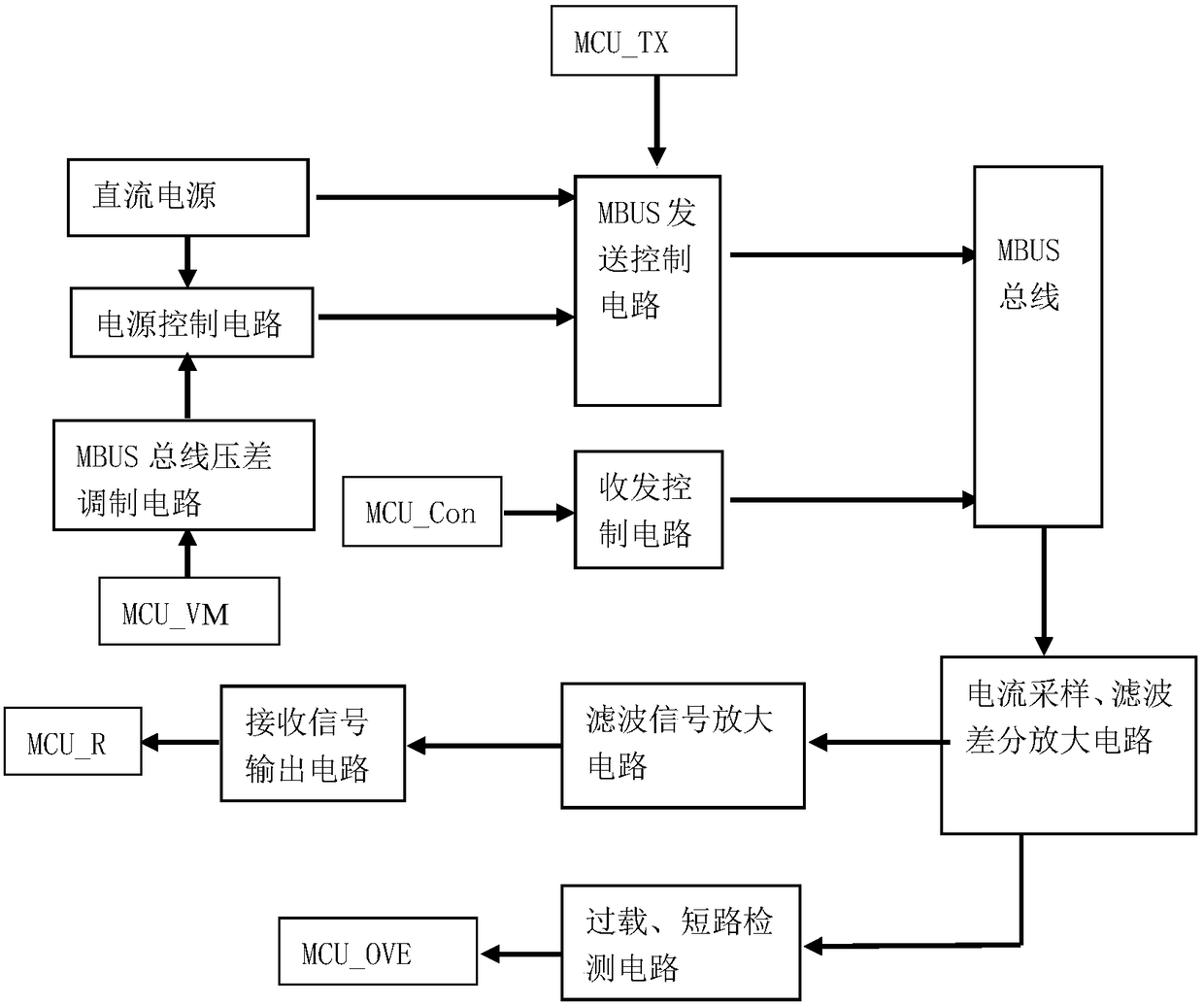

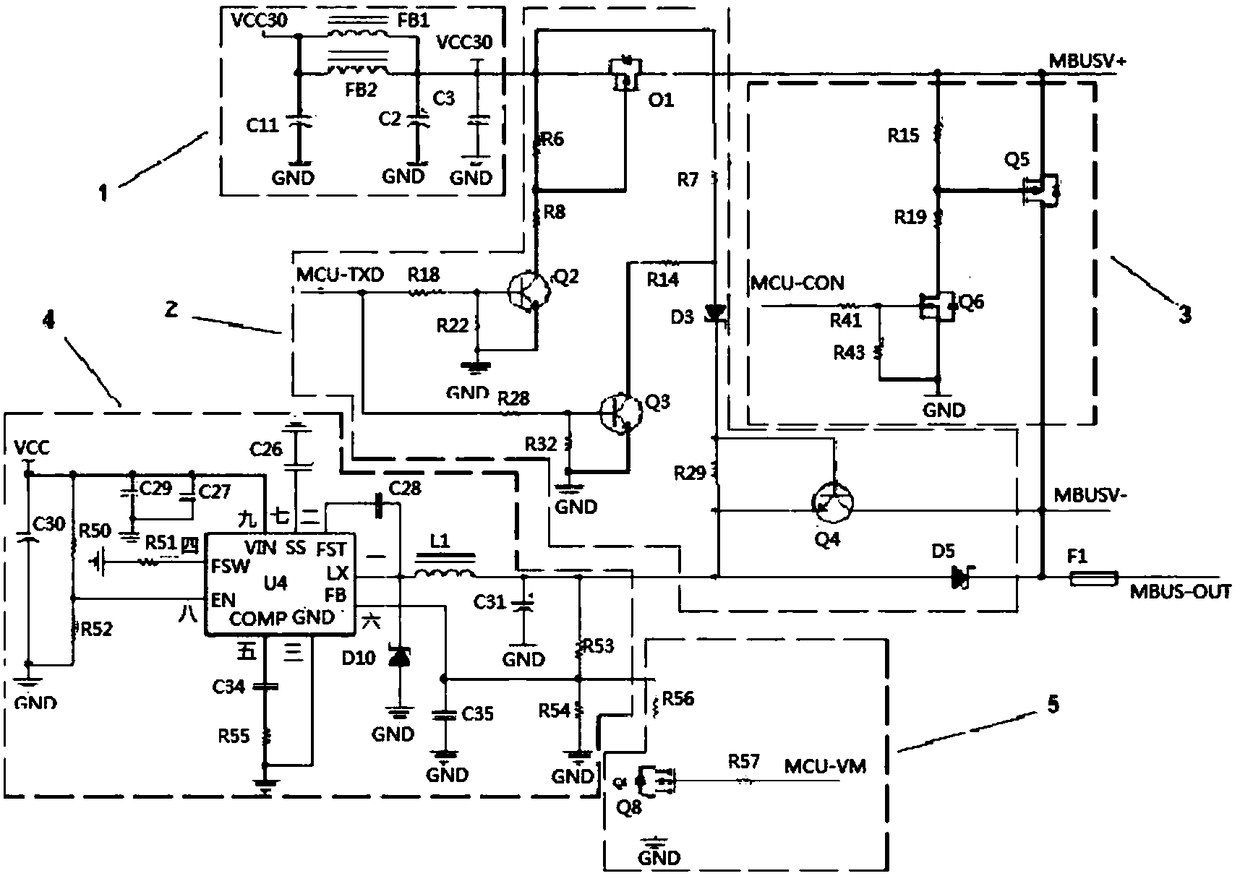

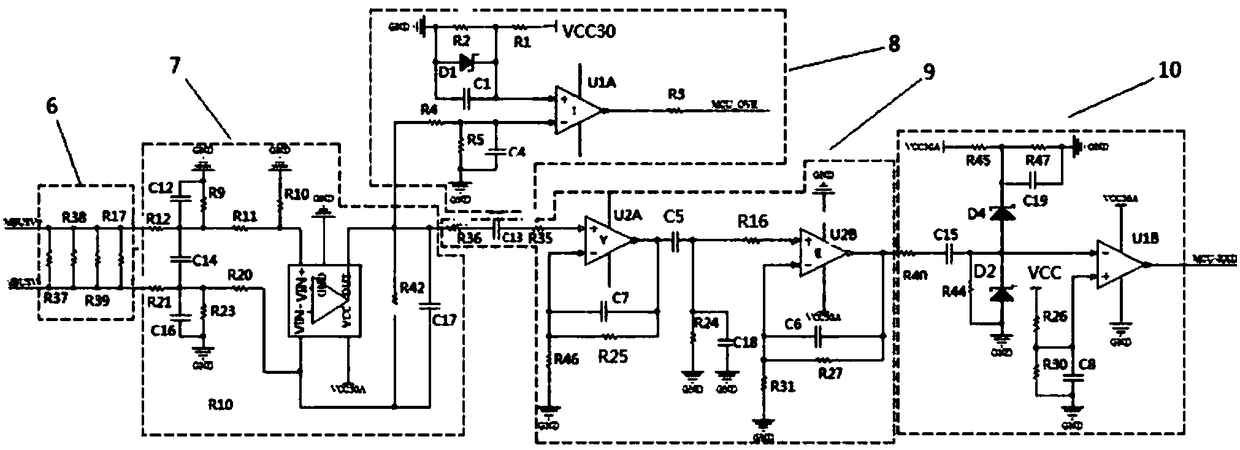

Large-power MBUS main controller circuit

PendingCN108230652AImprove remote power supply drive capabilityImprove adaptabilityElectric signal transmission systemsElectric digital data processingAudio power amplifierControl circuit

The invention provides a large-power MBUS main controller circuit which comprises a host computer sending circuit and a host computer receiving circuit; the host computer sending circuit comprises a direct-current power supply and a sending control circuit; the host computer receiving circuit comprises a sampling resistor, a pre-stage filter differential amplifier circuit and a signal output circuit; the pre-stage filter differential amplifier circuit comprises a pre-stage filter circuit and a differential amplifier circuit; the differential amplifier circuit comprises a computing amplifier; the pre-stage filter circuit comprises a first filter circuit and a second filter circuit; and the first filter circuit and the second filter circuit are output to the computing amplifier respectivelyand provide voltage output differential amplification signals through the computing amplifier. By adopting the large-power MBUS main controller circuit provided by the invention, the circuit design isconcise, the low-resistance value sampling resistor and the high-precision differential amplifier circuit are adopted to inhibit interference of a common mode signal and improve the stability of receiving the signal, and the slave node loading amount is increased.

Owner:RUINA INTELLIGENT EQUIP CO LTD

Efficient heat recovery and waste strong brine treatment integrated system and method

PendingCN110923021AImprovement of design conceptShort processCombustible gas chemical modificationCombustible gas productionNephelineSodium sulfate

The invention discloses an efficient heat recovery and waste strong brine treatment integrated system and method. High-concentration brine is jetted into a hydrothermal conversion zone from an atomizing nozzle, and make direct contact with 700-1100 DEG C mixed fluid consisting of agglomerated crude particles and crude synthesis gas to generate a hydrothermal conversion reaction; heavy metals, soluble salts such as sodium chloride and miscellaneous salt components such as sodium sulfate in the high-concentration effluent brine react with molten slag and fly ash particles in crude synthesis gasunder a high-temperature condition and are converted into mineral species which are solidified into two or more of wollastonite, nepheline, sodalite, soda-lime type aluminosilicate feldspar and soda-lime stone without leaching environmental risks, have stable physicochemical properties, have no dissolution risk under natural conditions and do not cause secondary pollution to the environment, especially underground water; organic carbon in the high-concentration waste brine is converted into CO and H2, and water absorbs sensible heat and then is converted into high-quality steam with the temperature of 400-500 DEG C and the pressure of 5.0-10.0 MPa for synthesis gas conversion.

Owner:西安旭华成能源科技有限公司

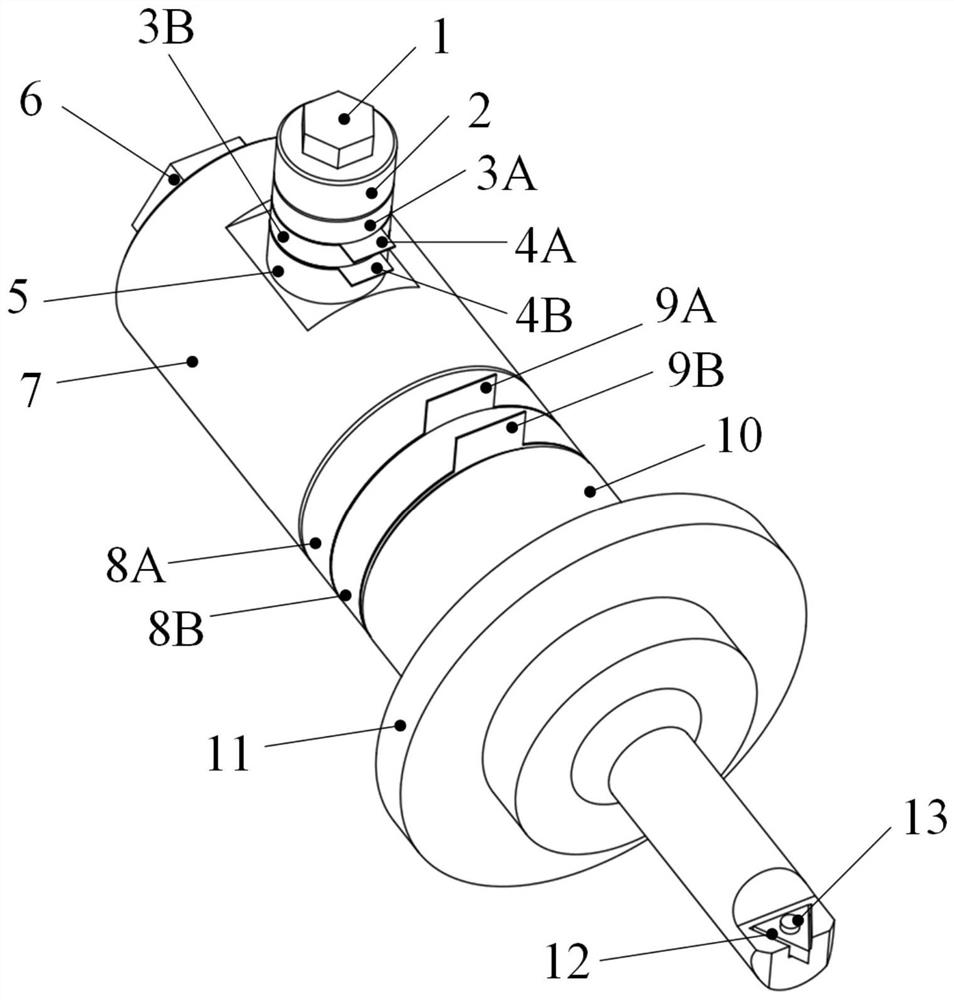

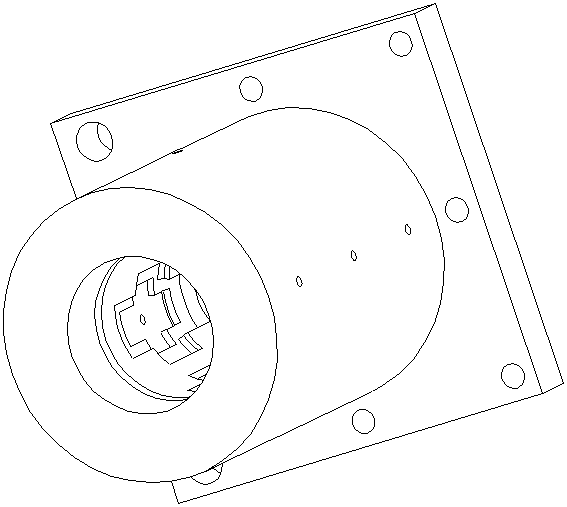

Ultrasonic elliptical vibration cutting device in longitudinal-flexural composite vibration mode

ActiveCN113510060AImprove the electro-acoustic conversion rateReduce roughnessMechanical vibrations separationEngineeringUltrasonic vibration

The invention provides an ultrasonic elliptical vibration cutting device in a longitudinal-flexural composite vibration mode. The device is formed by combining two longitudinal vibration ultrasonic vibrators and comprises a pre-tightening bolt, a longitudinal vibration rear cover plate, annular piezoelectric ceramics, an electrode plate, a longitudinal vibration front cover plate, a cutter and the like. The first longitudinal vibration ultrasonic vibrator is arranged in the radial direction of the second longitudinal ultrasonic vibrator and used for exciting flexural ultrasonic vibration of the device, and the first longitudinal vibration ultrasonic vibrator and longitudinal ultrasonic vibration excited by the second longitudinal ultrasonic vibrator enable the device to present an ultrasonic longitudinal-flexural composite vibration mode together, so that an elliptical vibration track is output on the cutter installed at the tail end of the device. The device is remarkable in effect in high-integrity machining of hard and brittle materials difficult to machine, cutting force and cutting heat can be effectively reduced, the shape precision of a workpiece is improved, cutter abrasion is remarkably reduced, and plasticity removal of the brittle materials is achieved.

Owner:DALIAN UNIV OF TECH

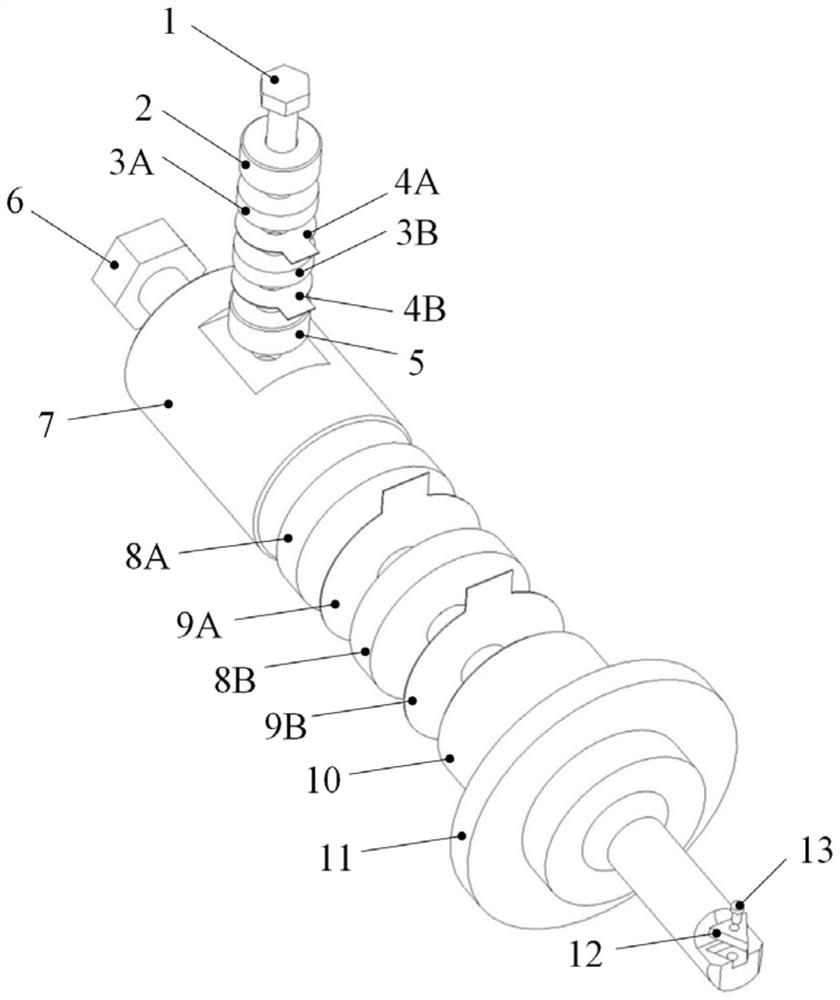

Device special for sanding surfaces of wooden plates

InactiveCN103659532ANot easy to stickReduce feverBelt grinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

The invention discloses a device special for sanding surfaces of wooden plates. The device comprises a base and a housing. A pressing device is arranged on the base, and a sanding device is arranged above the pressing device and disposed in the housing. The sanding device comprises rollers and abrasive cloth. The rollers include a first roller, a second roller, a third roller, a fourth roller and a fifth roller, and the abrasive cloth include first abrasive cloth and second abrasive cloth; the first roller is arranged above the second roller, the first abrasive cloth is arranged on the outer walls of the first roller and the second roller, and the first roller and the second roller are arranged inside the first abrasive cloth. The device is simple in structure, convenient to maintain, small in size and low in manufacturing cost and power consumption. Wood chips are not easy to attach onto abrasive belts so that heating probability of the abrasive belts is reduced, service life thereof is prolonged, and sanding quality and production efficiency are improved.

Owner:CHENGDU TIANPAN TECH

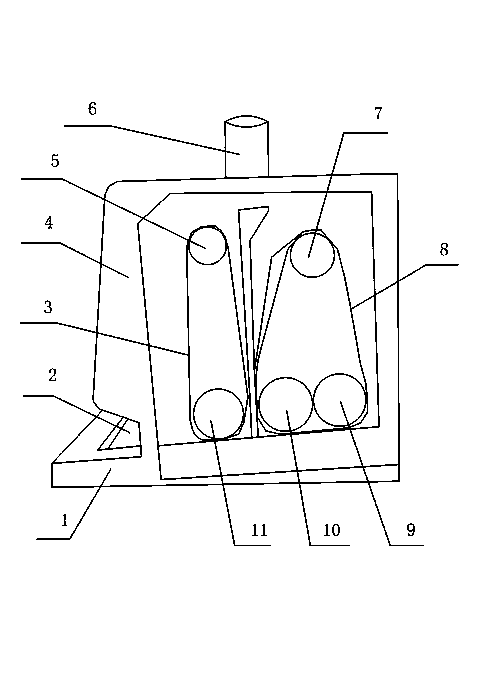

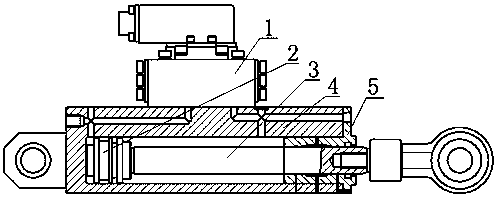

Servo hydraulic cylinder static pressure seal guiding sleeve with double cross-shaped cavities

PendingCN109958669AIncrease frictionReduce frictionFluid-pressure actuatorsHydraulic cylinderReciprocating motion

The invention discloses a servo hydraulic cylinder static pressure seal guiding sleeve with double cross-shaped cavities. The servo hydraulic cylinder static pressure seal guiding sleeve comprises a guiding sleeve body, the double cross-shaped oil cavities, an oil unloading groove and a dustproof groove. A hydraulic cylinder matched with the servo hydraulic cylinder static pressure seal guiding sleeve structurally comprises a cylinder barrel, a piston rod and the like. Due to the rapid reciprocating motion of the piston rod of the hydraulic cylinder, the number of shearing times of hydraulic oil in an oil cavity is too large, heating of the hydraulic oil is caused, and the phenomenon is called as hot oil carrying. To avoid the phenomenon, the double cross-shaped oil cavities are adopted inthe servo hydraulic cylinder static pressure seal guiding sleeve, the number of shearing times of hydraulic oil in the oil cavities is reduced, and little heat is generated; and the material of the guiding sleeve is a high-hardness aluminum alloy good in heat dissipation, the weight of the hydraulic cylinder is reduced, the heat dissipation speed is increased, and the cost of the hydraulic cylinder is reduced.

Owner:HARBIN UNIV OF SCI & TECH

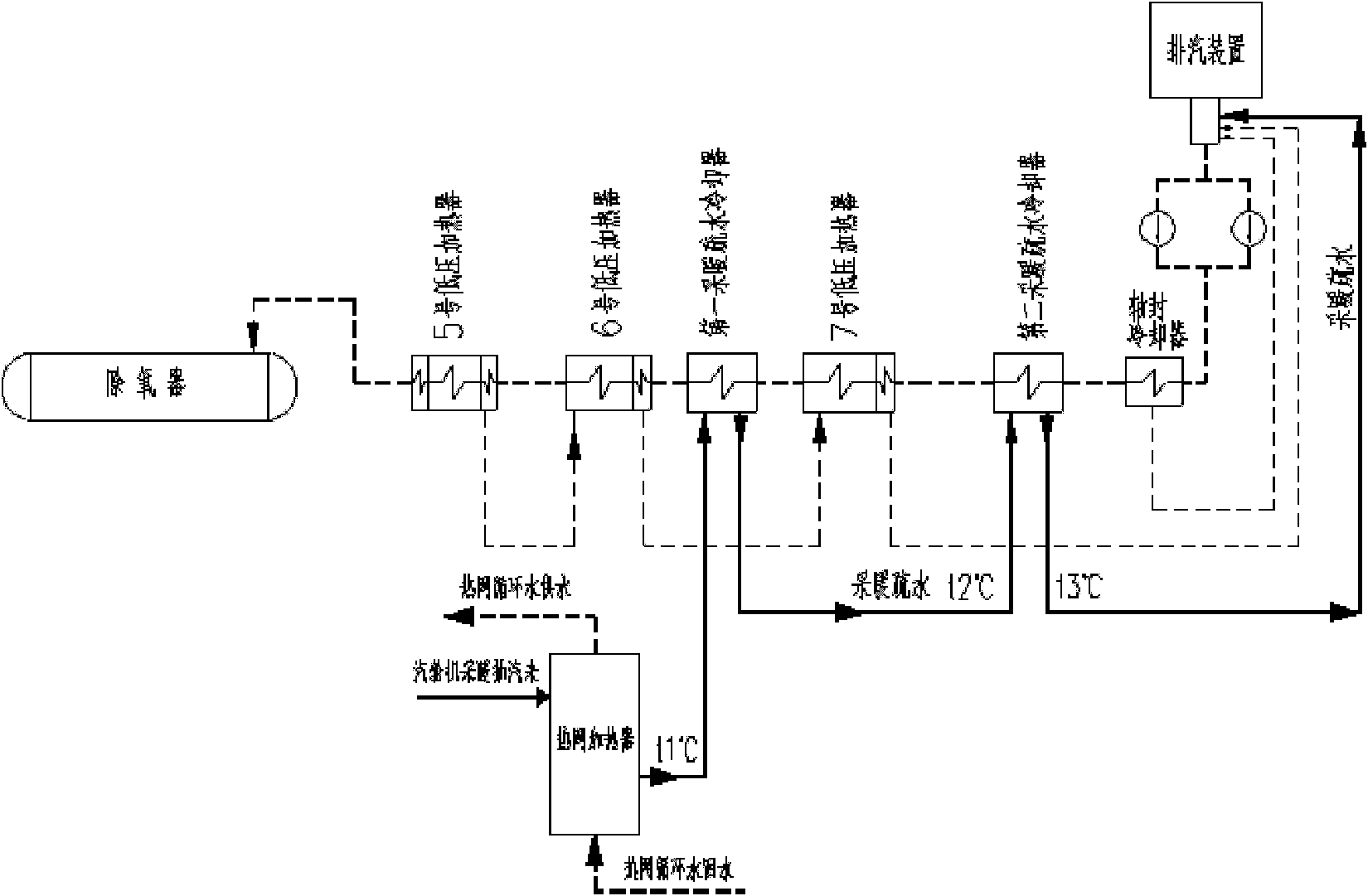

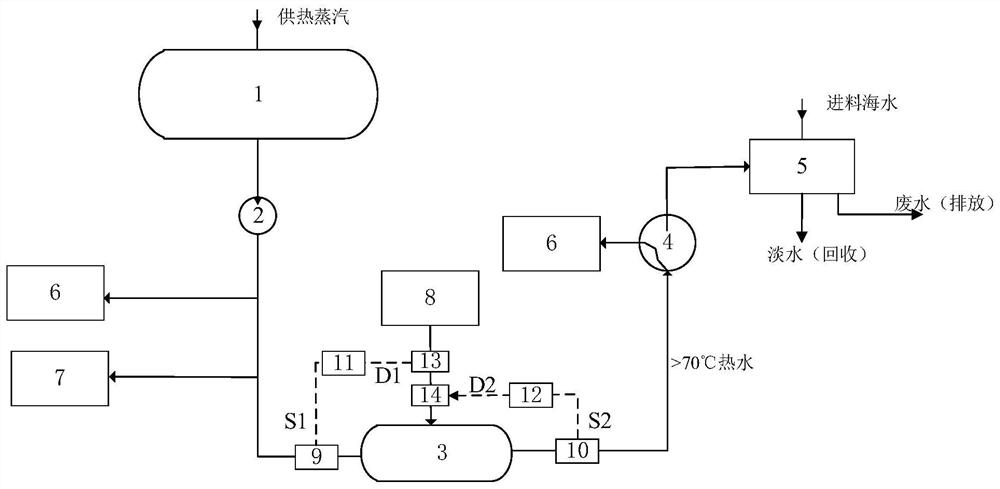

Heat-engine plant heat supply network drainage waste heat recovery device and method based on seawater desalination technology

PendingCN111792687AIncrease steam extractionReduce heat rateGeneral water supply conservationSeawater treatmentWater savingWastewater

The invention discloses a heat-engine plant heat supply network drainage waste heat recovery device and method based on a seawater desalination technology. The device comprises a heat supply network system, a heat regeneration system and a seawater desalination system. Heat supply extraction steam heats heat supply network primary water in a heat supply network heater to form heat supply network drain water, the drain water enters a drain heater through a heat supply network drain pump, the temperature of outlet water of the heater is guaranteed to be 70 DEG C or above through closed-loop control over the temperature of the drain heater, the outlet water enters a flash evaporator, obtained steam enters a low-temperature distillation seawater desalination device, seawater desalination is conducted on the steam in the low-temperature distillation seawater desalination device to obtain freshwater, meanwhile, wastewater is discharged, and low-temperature water generated by the flash evaporator returns to the condenser. The device can effectively realize safe, energy-saving and water-saving recovery of heat supply drain water, and has good economic and environmental benefits.

Owner:XIAN THERMAL POWER RES INST CO LTD

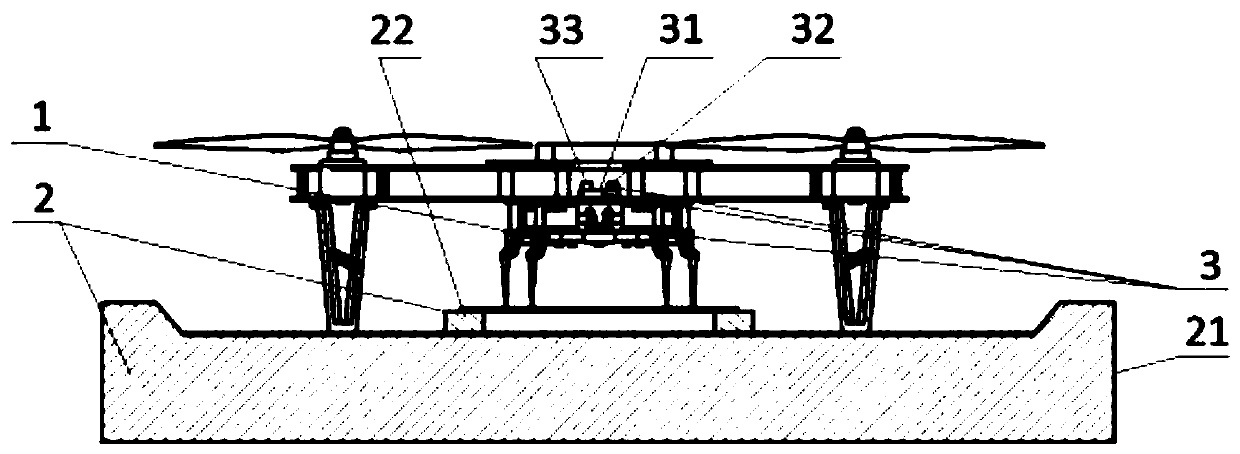

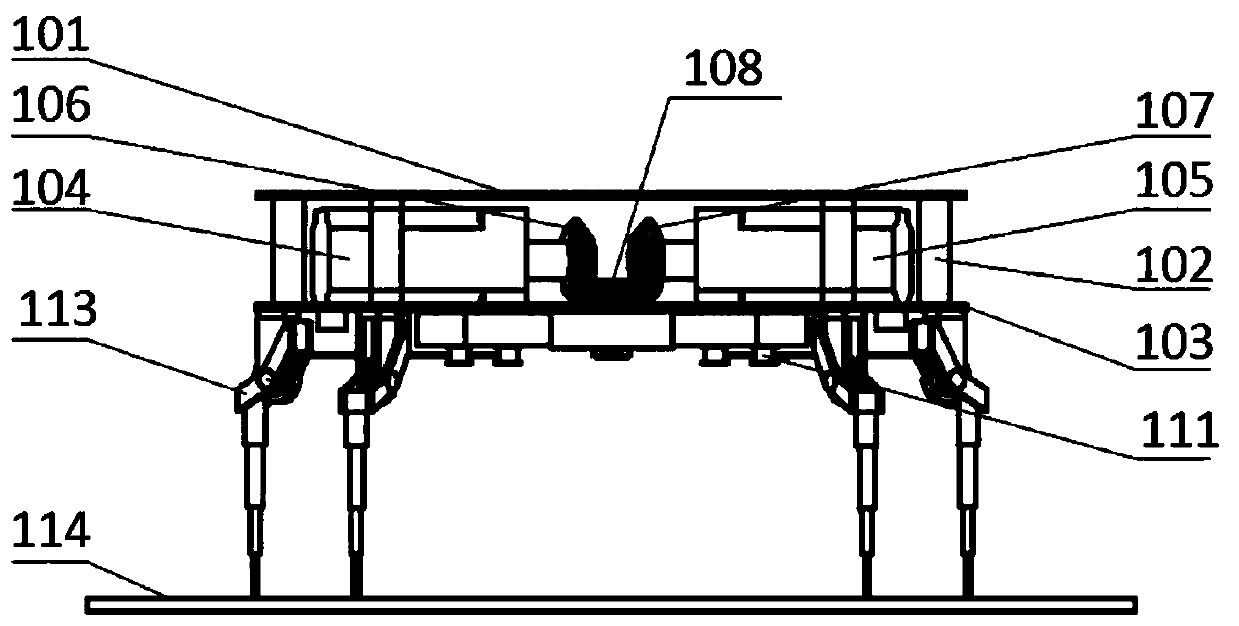

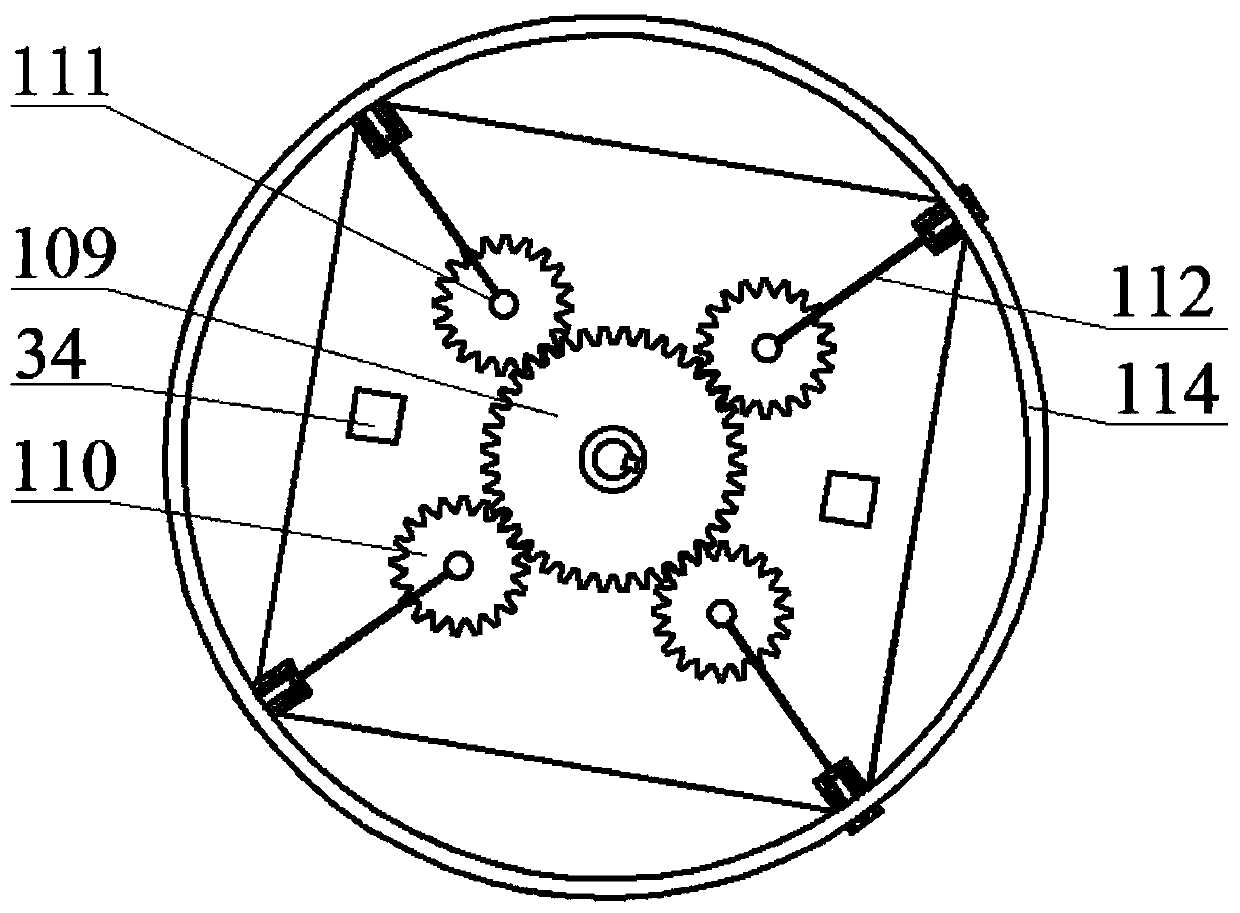

Unmanned aerial vehicle automatic supplementing wireless charging device

ActiveCN110450657APrecise positioningSave human effortBatteries circuit arrangementsCharging stationsUncrewed vehicleEngineering

The invention discloses an unmanned aerial vehicle automatic supplementing wireless charging device. The unmanned aerial vehicle automatic supplementing wireless charging device comprises a wireless charging device, a power supply device and a navigation module; the upper end of the wireless charging device is connected with an unmanned aerial vehicle; the lower end of the wireless charging deviceis connected with the power supply device; the navigation module is mounted in the unmanned aerial vehicle and the wireless charging device and realizes accurate docking and automatic supplementing of a wireless charging position by combining positioning navigation and vision navigation; a motor in the wireless charging device rotates to drive a bevel gear; the bevel gear rotates to drive a straight gear; the straight gear rotates to drive a lead take-up and pay-off device to take up and pay off a lead to cause the lifting of a take-up and pay-off foot stool, and therefore, the lifting of a charging receiving coil is caused; and the charging receiving coil is in docking contact with a charging transmitting coil in the power supply device to perform charging. The unmanned aerial vehicle automatic supplementing wireless charging device has the advantages of novel and original creation, simple structure and accurate positioning and can be widely applied to different unmanned aerial vehicle equipment.

Owner:XI'AN POLYTECHNIC UNIVERSITY

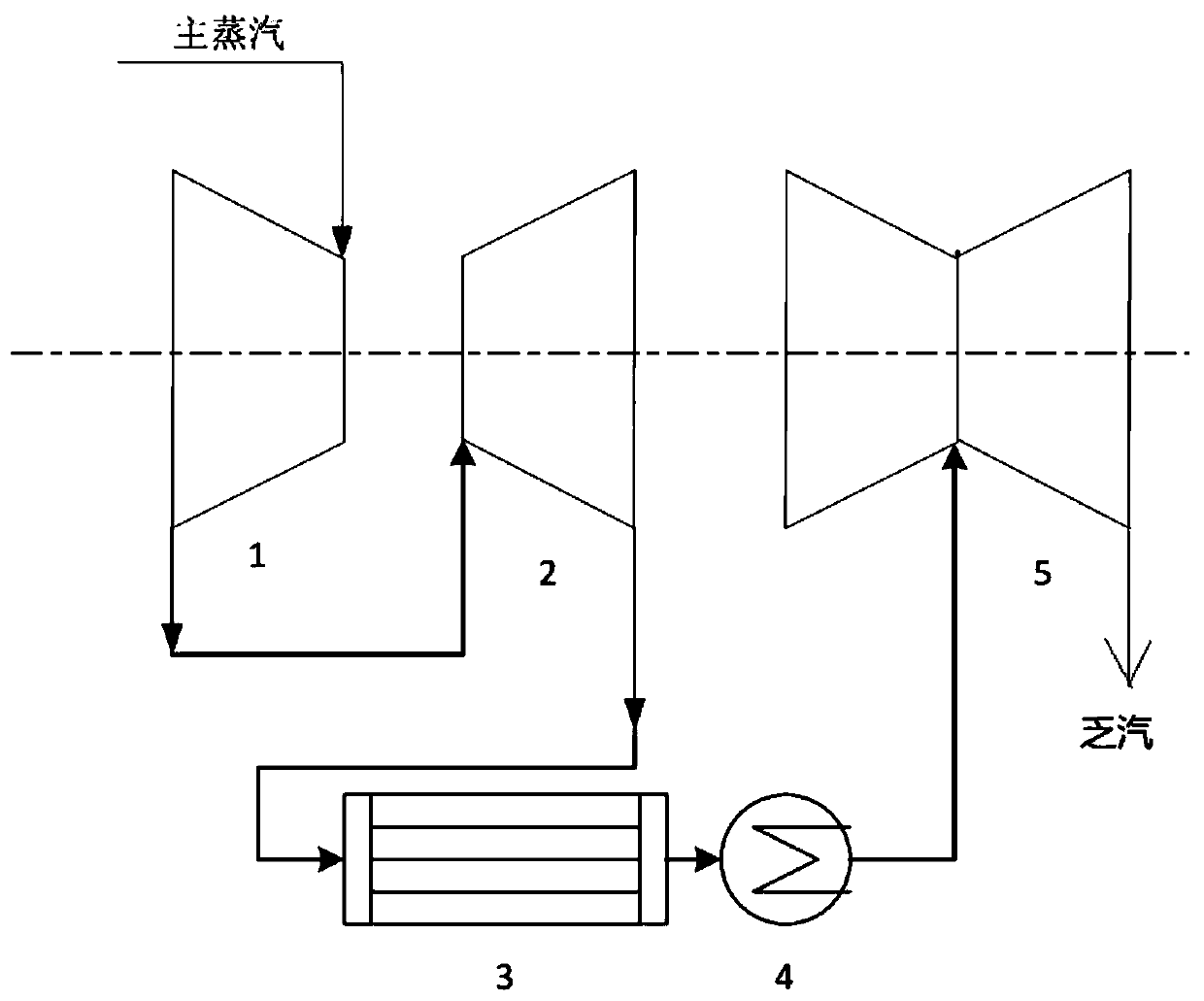

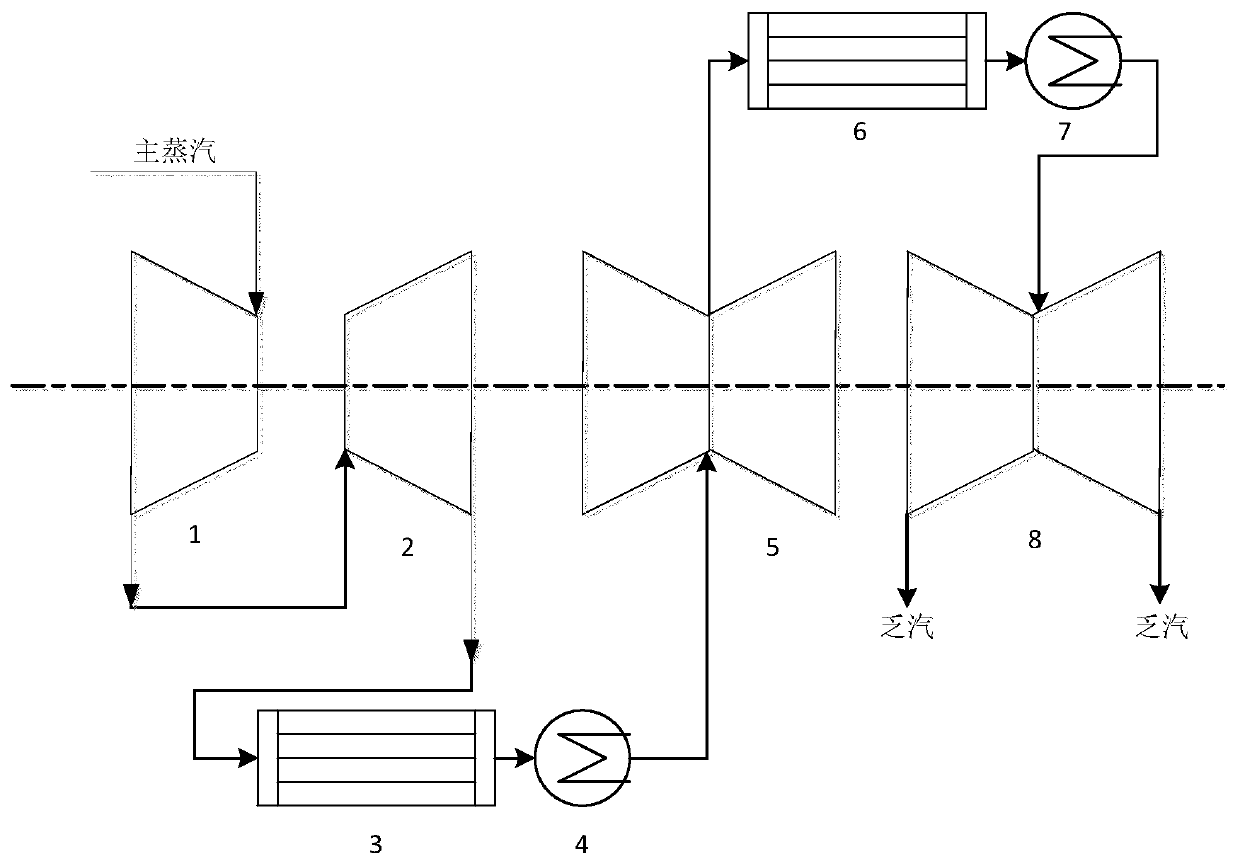

Thermodynamic system of steam turbine and method of improving efficiency thereof

PendingCN111485962AReduce total exhaust steamReduce the ratioSteam engine plantsProcess engineeringThermal efficiency

The invention discloses a thermodynamic system of a steam turbine and a method of improving efficiency thereof. The system comprises a primary high pressure cylinder, a primary intermediate pressure cylinder and primary first low pressure cylinder. Main steam is directly input into the primary high pressure cylinder, then is input into the primary intermediate pressure cylinder and then is input into the primary first low pressure cylinder through a primary water-steam separator and a primary reheater to become dead steam input to a condenser. At a subcritical parameter, the heat consumption of the system can be reduced to 7256 kJ / kWh, the thermal efficiency of the steam turbine can be improved to over 49%, and the exhausting mass proportion of the low pressure cylinder is reduced to 48.5%of total admission mass. The thermodynamic system reaches a conventional energy consumption level which exceeds that of a supercritical steam turbine.

Owner:广东粤电靖海发电有限公司

Heat recovery system with multiple stages of deaerators

ActiveCN108626715ALess design parametersLow costLiquid degasificationFeed-water heatersWater flowEngineering

The invention discloses a heat recovery system with a plurality of stages of hybrid heaters. Specifically, the heat recovery system comprises a BEST machine, five high-pressure heaters, five low-pressure heaters, the two to five hybrid heaters, boosting pumps and a condensate pump; each hybrid heater is configured with the corresponding boosting pump; the condensate pump is positioned between thelow-pressure heaters and a steam condenser; extraction steam of the first high-pressure heater is from a main steam turbine; the extraction steam of the second high-pressure heater to the fifth high-pressure heater is from the BEST machine; steam sources of the hybrid heaters are all from the BEST machine, wherein the steam source of the last stage hybrid heater is from the exhaust steam of the BEST machine; the extraction steam of the five low-pressure heaters is from the main steam turbine; and the last stage hybrid heater is connected with one of the low-pressure heaters, and the water supply of the last stage hybrid heater is from the low-pressure heater. According to the heat recovery system with the plurality of stages of deaerators, the circulating efficiency of the system is improved; the superheat degree of the steam is fully utilized; the project cost is reduced; the cold end loss of the steam is reduced; and the heat recovery system with the multiple stages of deaerators isparticularly suitable for the situation that the steam extracting steam of a plurality of heaters are close to the saturation pressure of the steam, and the feed water flow is large.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

An operation method for an optimal operation device of a double back pressure condenser

ActiveCN105865220BReduce heat rateCirculating water flow has no effectSteam/vapor condensersControl systemWater flow

The invention discloses a double backpressure condenser optimized operation device and an operation method thereof. The double backpressure condenser optimized operation device comprises a high backpressure condenser, a lower backpressure condenser and a circulating water pipeline, wherein two bypasses and a control valve are arranged on the circulating water pipeline, the bypasses are connected with the two ends of the low backpressure condenser in a crossing manner, and a plurality of temperature measuring points and flow meters are arranged. Compared with the prior art, the double backpressure condenser optimized operation device has the advantages that circulating water flow rate of the low backpressure condenser is independently controlled, the circulating water flow rate of the high backpressure condenser is not influenced; by virtue of a calculation formula provided by the invention as well as the measuring points and a valve control system, the low backpressure side condenser is vacuum and does not enter a blockage backpressure region, and heat rate of a steam turbine is reduced; and due to influence of the circulating water bypasses, water inlet temperature of circulating water at the high backpressure side condenser is relatively low, and high backpressure side exhaust temperature is indirectly lowered, so that the heat rate of the steam turbine is further reduced.

Owner:CHINA DATANG CORP SCI & TECH RES INST CO LTD EAST CHINA BRANCH

Heat recovery system with multi-stage deaerator

ActiveCN108626715BLess design parametersLow costLiquid degasificationFeed-water heatersWater flowProcess engineering

The invention discloses a heat recovery system with a plurality of stages of hybrid heaters. Specifically, the heat recovery system comprises a BEST machine, five high-pressure heaters, five low-pressure heaters, the two to five hybrid heaters, boosting pumps and a condensate pump; each hybrid heater is configured with the corresponding boosting pump; the condensate pump is positioned between thelow-pressure heaters and a steam condenser; extraction steam of the first high-pressure heater is from a main steam turbine; the extraction steam of the second high-pressure heater to the fifth high-pressure heater is from the BEST machine; steam sources of the hybrid heaters are all from the BEST machine, wherein the steam source of the last stage hybrid heater is from the exhaust steam of the BEST machine; the extraction steam of the five low-pressure heaters is from the main steam turbine; and the last stage hybrid heater is connected with one of the low-pressure heaters, and the water supply of the last stage hybrid heater is from the low-pressure heater. According to the heat recovery system with the plurality of stages of deaerators, the circulating efficiency of the system is improved; the superheat degree of the steam is fully utilized; the project cost is reduced; the cold end loss of the steam is reduced; and the heat recovery system with the multiple stages of deaerators isparticularly suitable for the situation that the steam extracting steam of a plurality of heaters are close to the saturation pressure of the steam, and the feed water flow is large.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

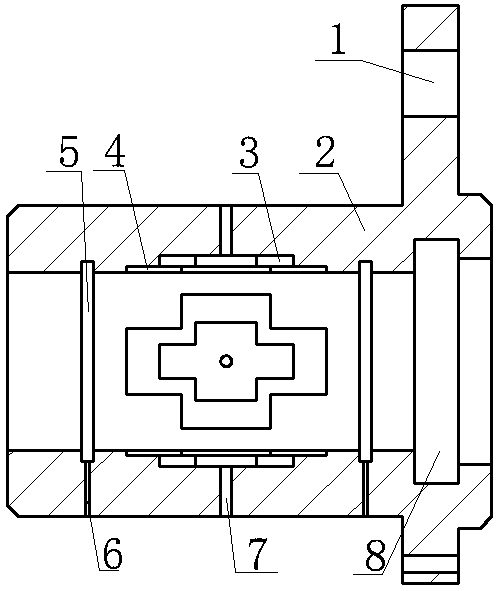

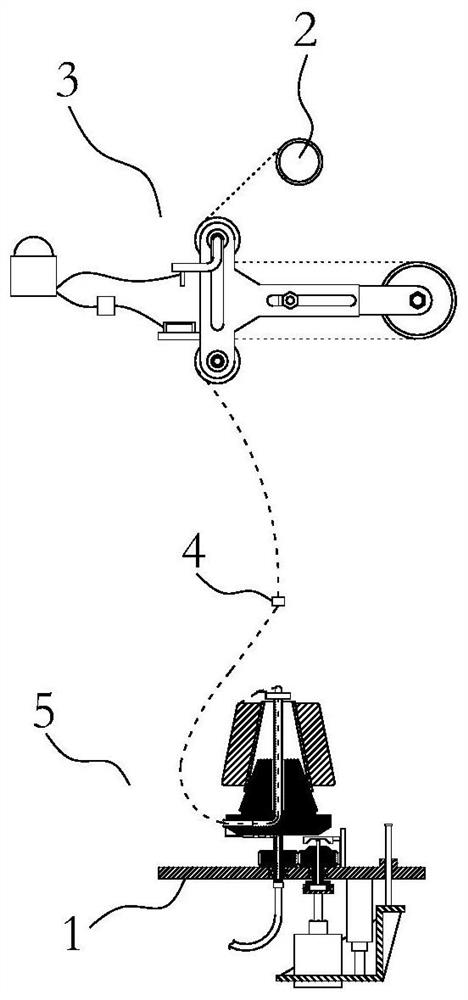

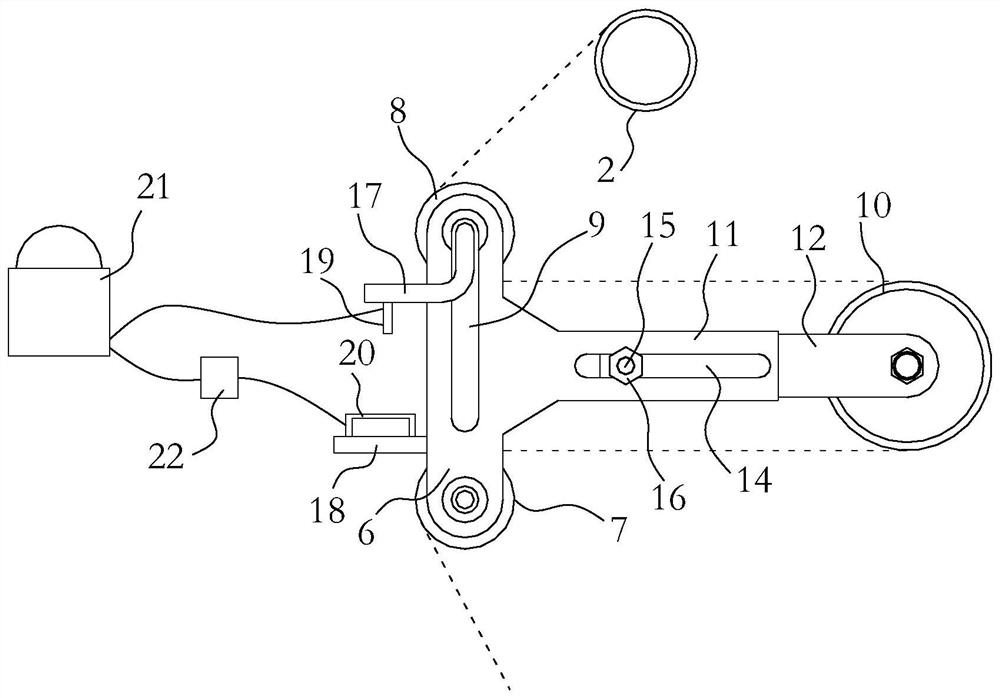

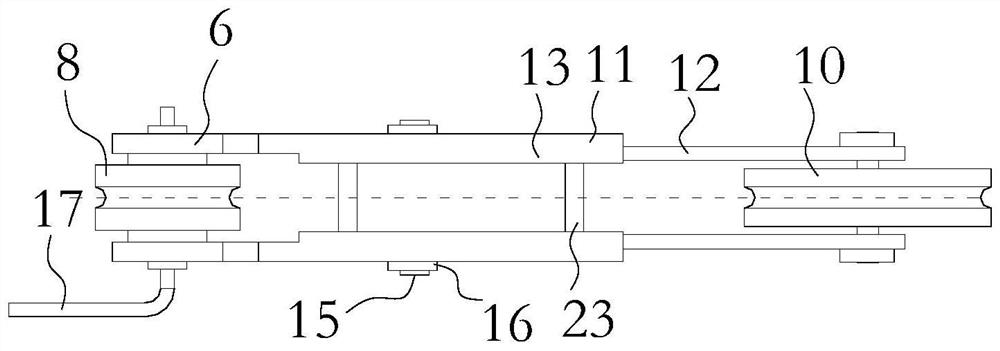

A two-for-one twister with automatic brake for broken yarn

The invention relates to the field of textile technology. The purpose is to provide a two-for-one twister with long service life and automatic braking of broken wires, including a winding device, a wire breaking detection device, a yarn collector and a twisting device arranged on the frame from top to bottom; After successively passing through the twisting device, the yarn collector, and the broken wire detection device, it is wound on the winding device; the twisting device includes a twisting mechanism and a driving mechanism for driving the action of the twisting mechanism; the driving mechanism includes a The second transmission rod on one side of the first transmission rod is installed on the frame through the second bearing; the lower end of the second transmission rod is connected to the rotating shaft of the twisting motor through a magnetic clutch transmission assembly. The invention can quickly disconnect the power connection between the driving mechanism and the twisting mechanism, reduces the load on the driving mechanism during braking, lays the foundation for the emergency stop of the twisting mechanism, and greatly prolongs the operating time of the driving mechanism. service life.

Owner:SHENGZHOU KELONG AUTOMATION EQUIP

Supercritical air cooling steam turbine

InactiveCN1328484CImprove thermal efficiencyReduce heat rateEngine componentsSteam engine plantsEngineeringHeat losses

The supercritical air-cooled steam turbine suitable for use in thermal power plant in unwatered area consists of supercritical wet cooled steam turbine high pressure cylinder, supercritical wet cooled steam turbine medium pressure cylinder and two low pressure cylinders. It features the two air cooled low pressure cylinders, the connection with low pressure cylinder bearing seat between the supercritical wet cooled steam turbine medium pressure cylinder and the air cooled low pressure cylinders and between the two air cooled low pressure cylinders, and the same structure of the high pressure cylinder and medium pressure cylinder in the supercritical air-cooled steam turbine and the high pressure cylinder and medium pressure cylinder in the supercritical wet cooled steam turbine. The two low pressure cylinders have improved structure and the present invention has direct air cooled exhaust. The present invention has low heat loss rate, high heat efficiency and low water consumption.

Owner:上海上发院发电成套设备工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com