Patents

Literature

224results about How to "Improve temperature rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

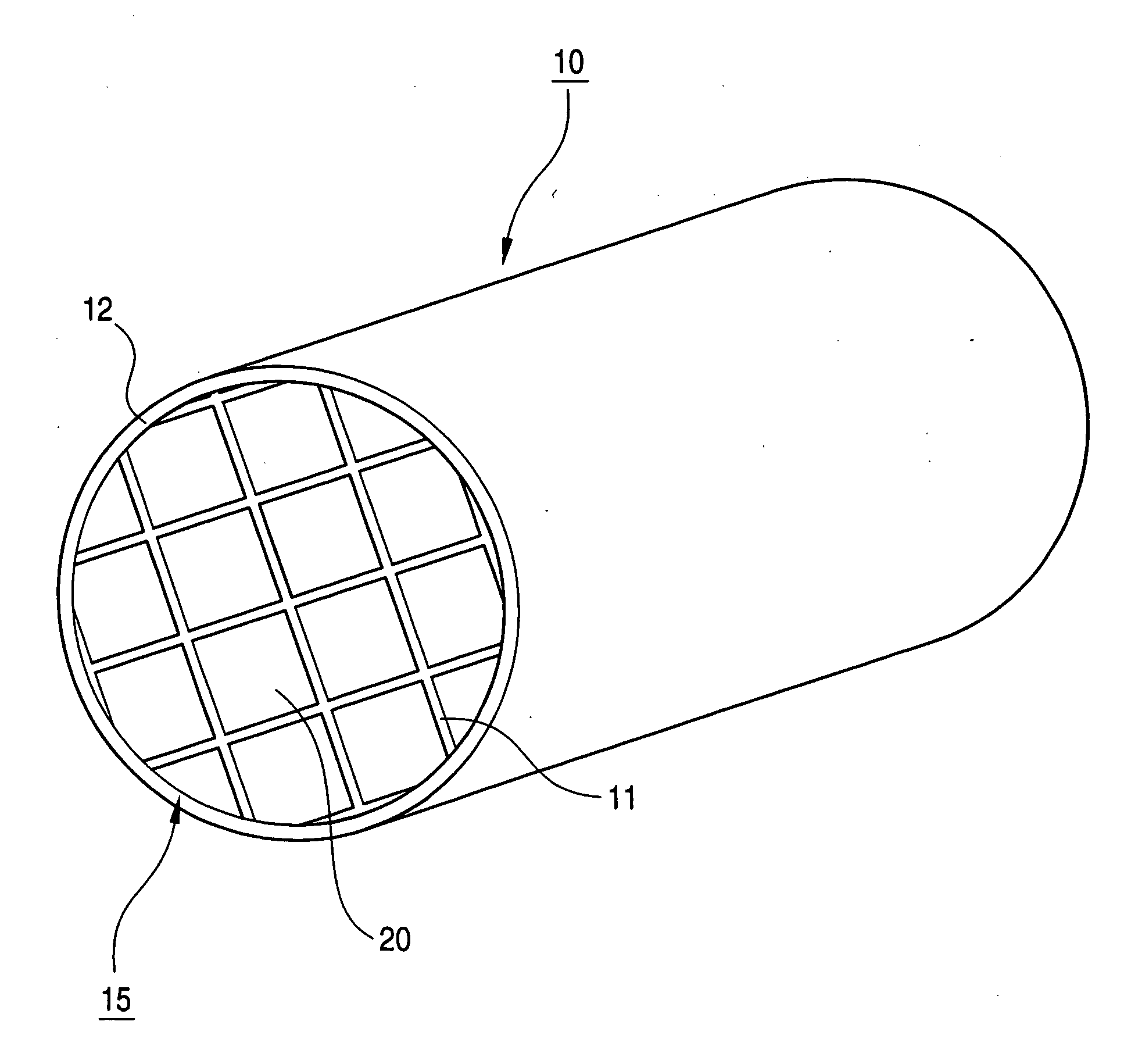

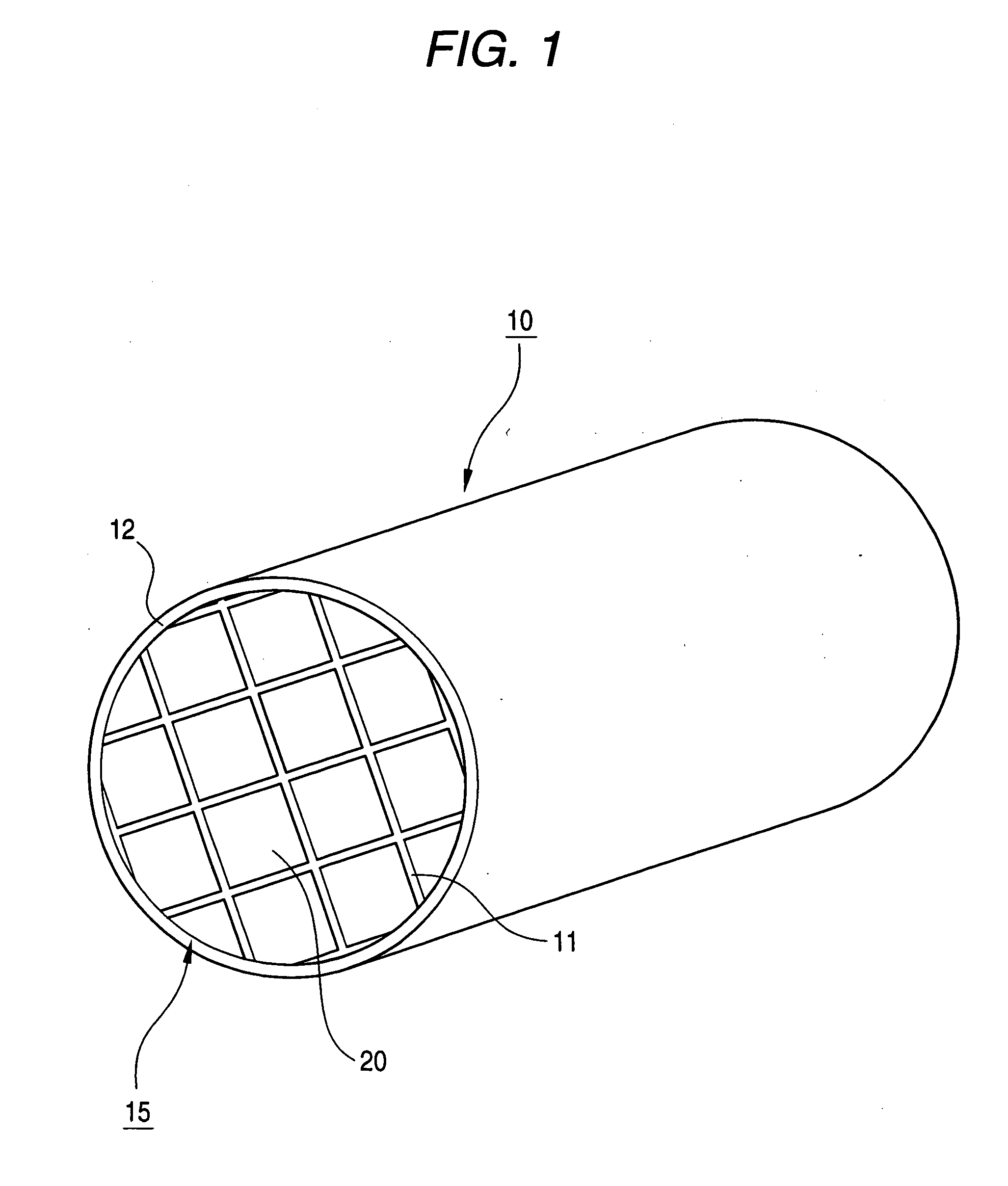

Honeycomb structure

ActiveUS20060230732A1Light weightSmall heat capacityDispersed particle filtrationOther chemical processesApparent densityYoung's modulus

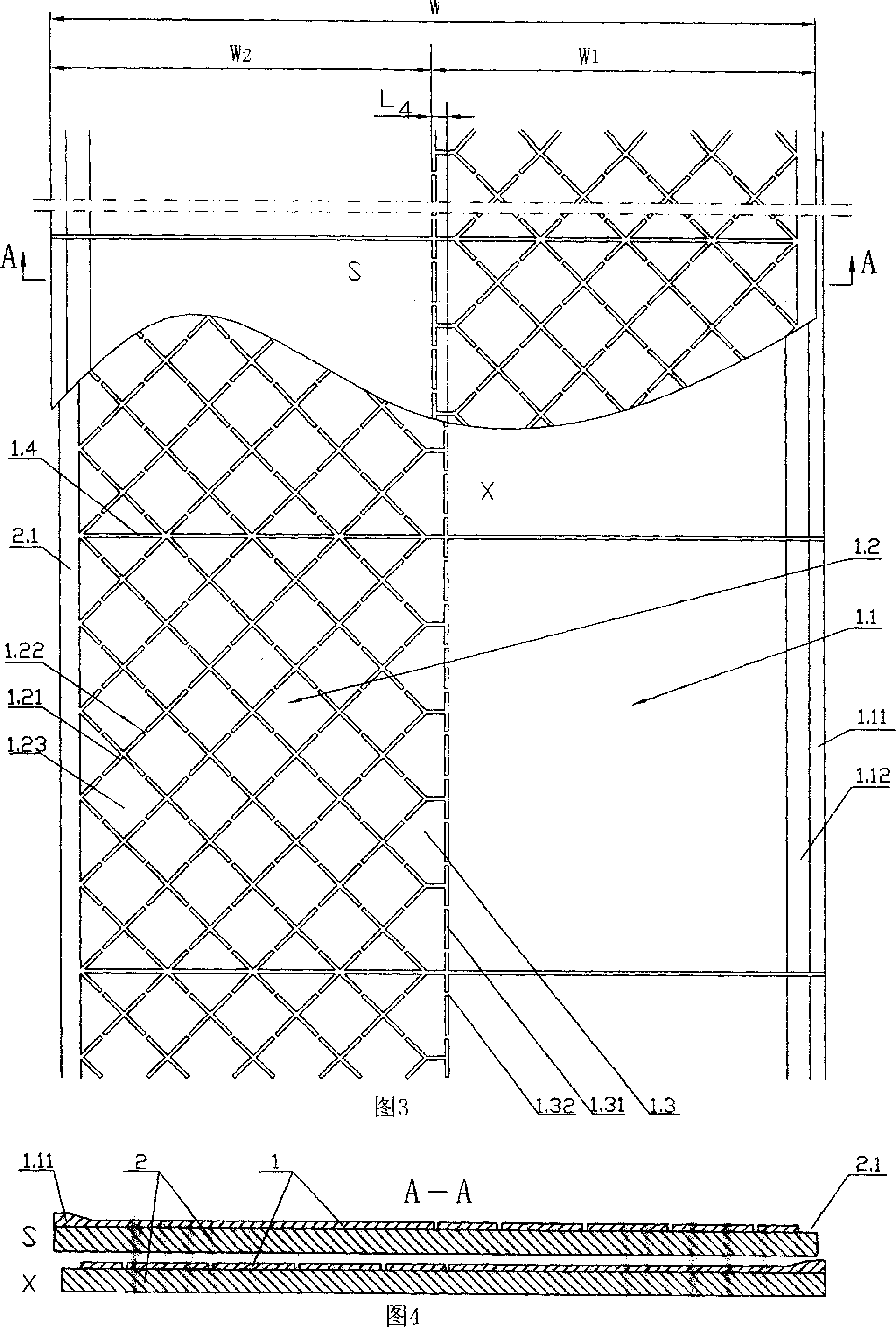

A honeycomb structure including a plurality of porous ceramic members which are bonded through an adhesive layer, each of the porous ceramic members has a plurality of cells, which are arranged in parallel while being separated by cell walls. The cells extend in a longitudinal direction of the honeycomb structure. In the honeycomb structure, the following relationship is satisfied: 2≦B≦100 / 3×A−10 / 3 (1) where A (g / cm3) designates apparent density of the porous ceramic members, and B (GPa) designates Young's modulus of the adhesive layer.

Owner:IBIDEN CO LTD

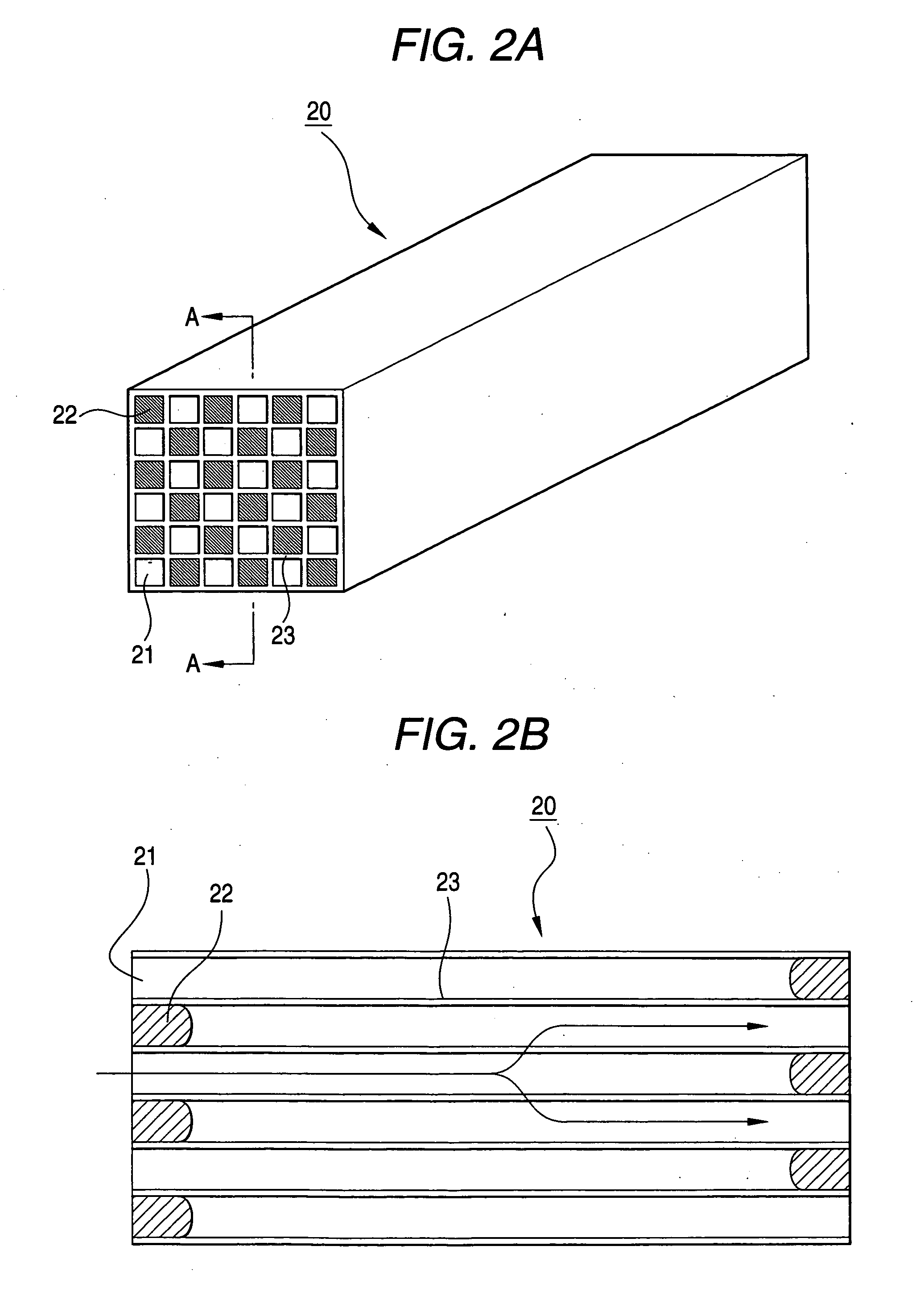

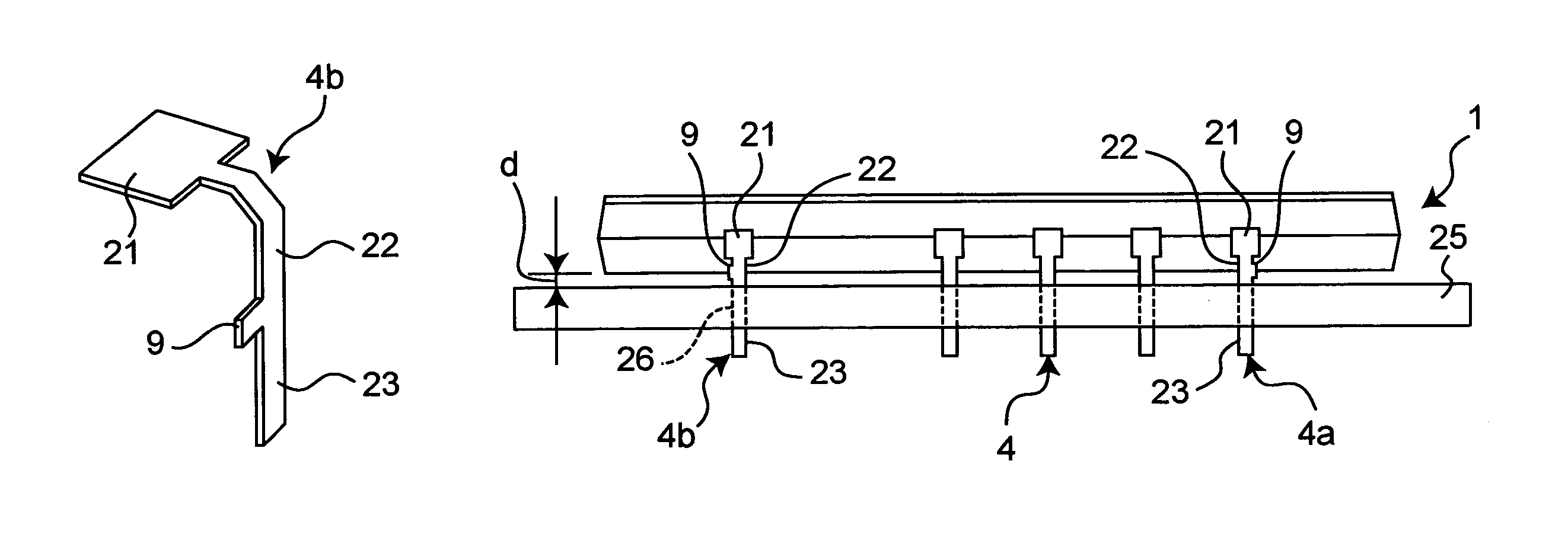

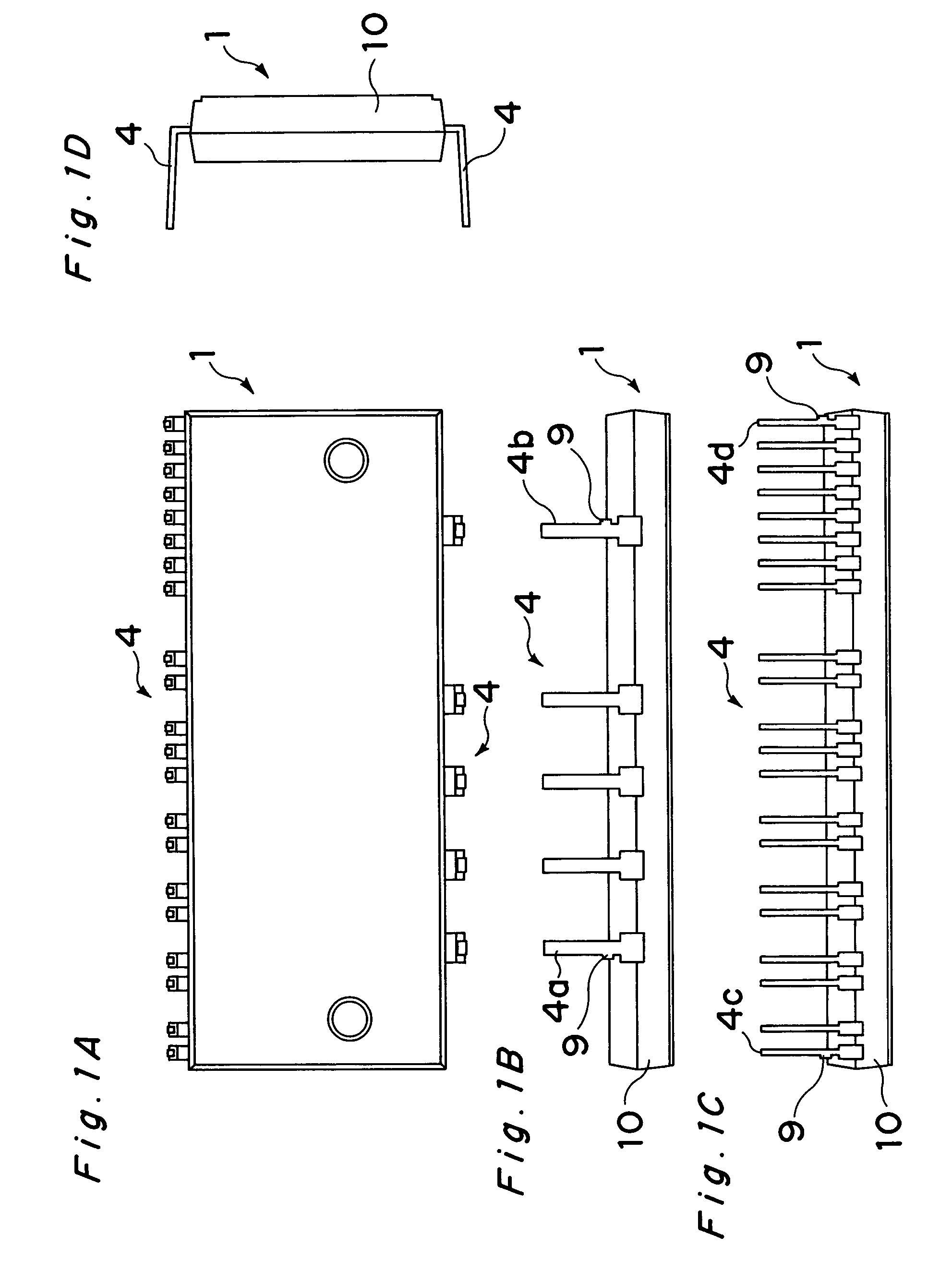

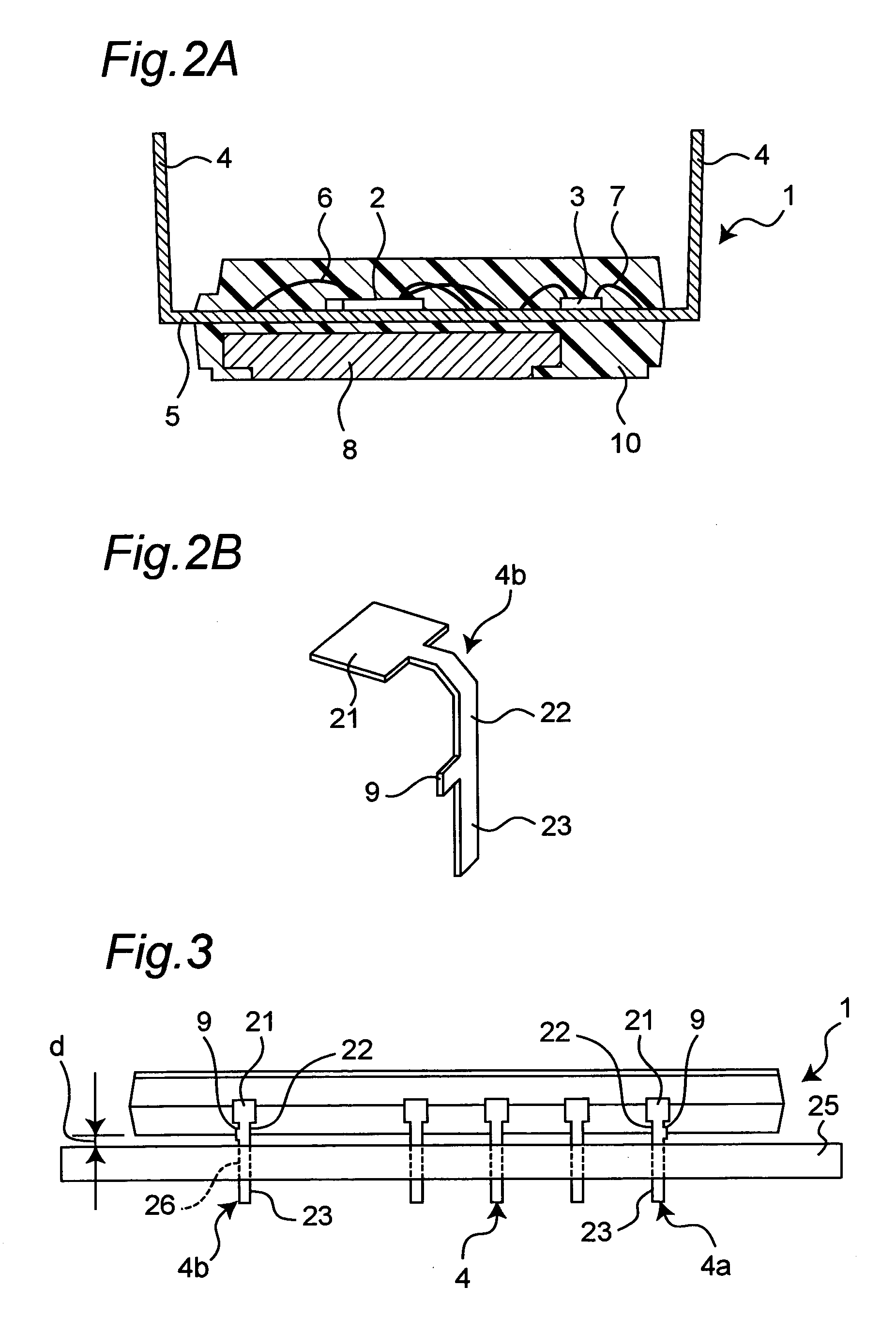

Semiconductor device and semiconductor assembly module with a gap-controlling lead structure

ActiveUS7361983B2Easiness be not deteriorateIncrease heat resistancePrinted circuit assemblingElectrically conductive connectionsLead structureSolderability

In a semiconductor device (1), semiconductor elements (2) and (3) are mounted on a lead frame (5) having leads (4). The semiconductor elements (2) and (3) are connected with the leads (4) by metallic wires (6) and (7). The semiconductor device (1) also has a heat sink (8). The members (2) to (8) are sealed with a plastic package (10). The leads (4) are exposed outward. Each of the end leads (4a) to (4d) has a wide first lead portion, a narrow second lead portion, a third lead portion to be inserted into an external substrate, and a protruding gap-controlling portion (9) for keeping the gap between the semiconductor device (1) and the external substrate constant. Because the heat resistance from the leads (4) to the plastic package (10) increases, the temperature-rise property of the lead is improved so that the solderability is improved.

Owner:MITSUBISHI ELECTRIC CORP

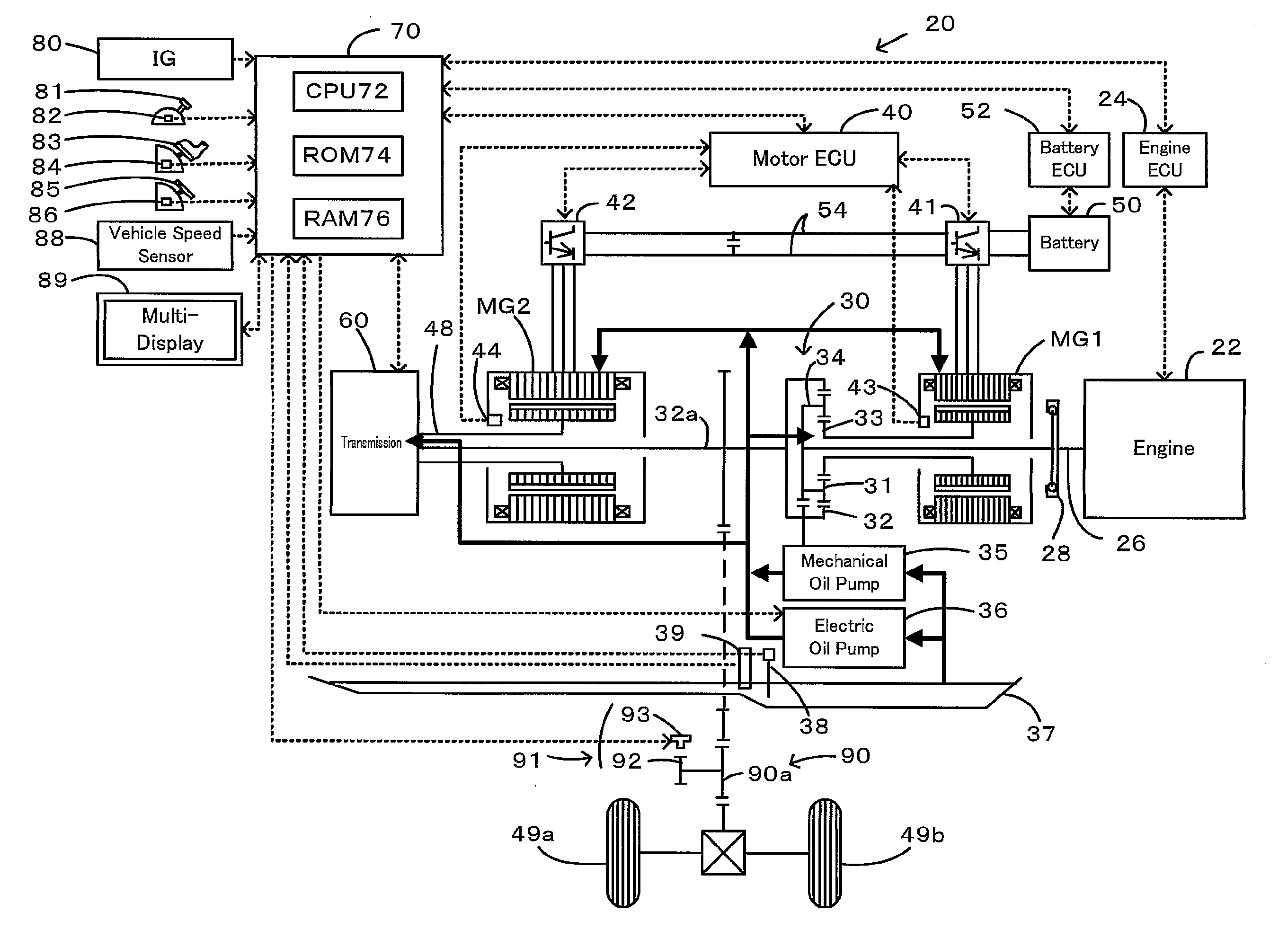

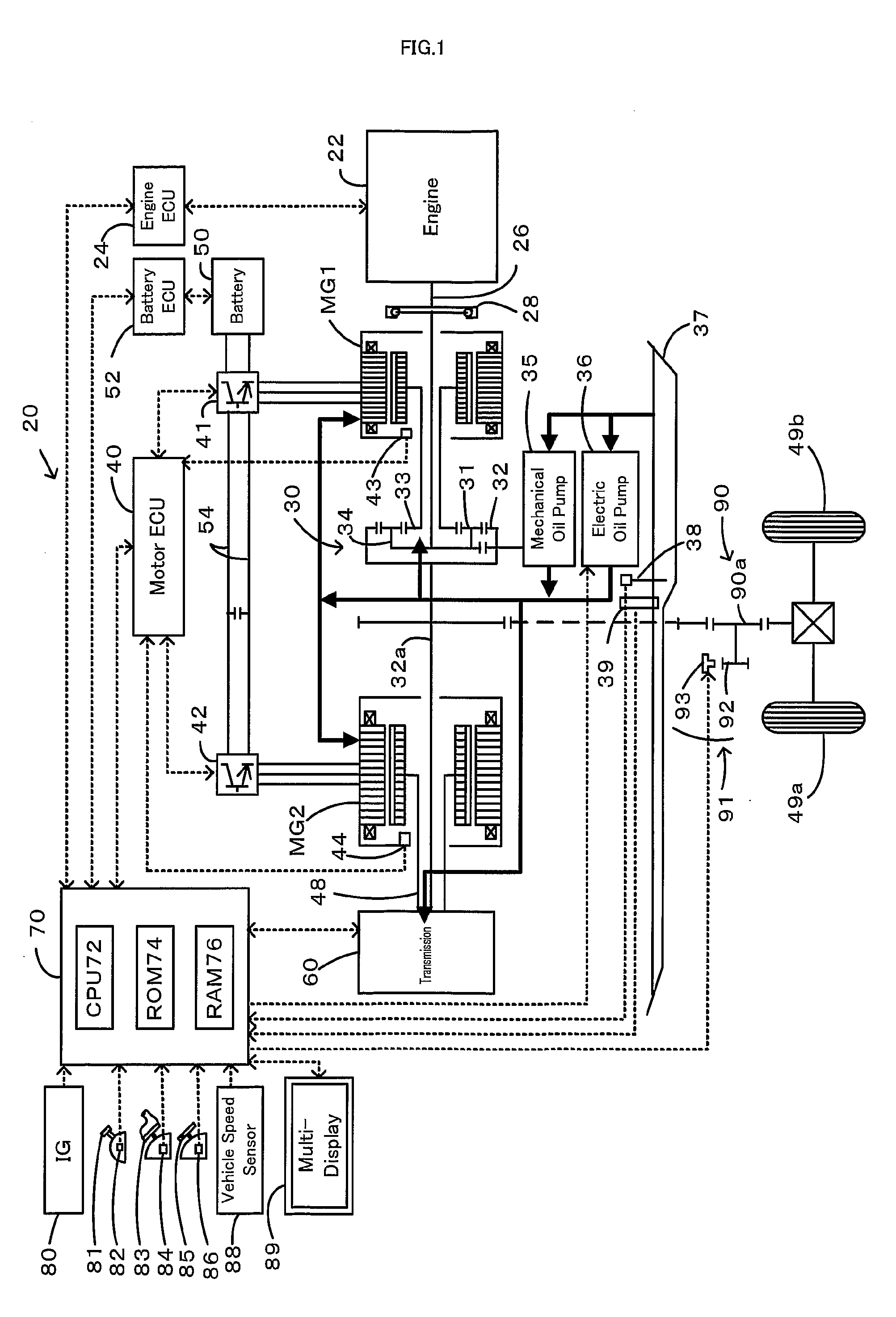

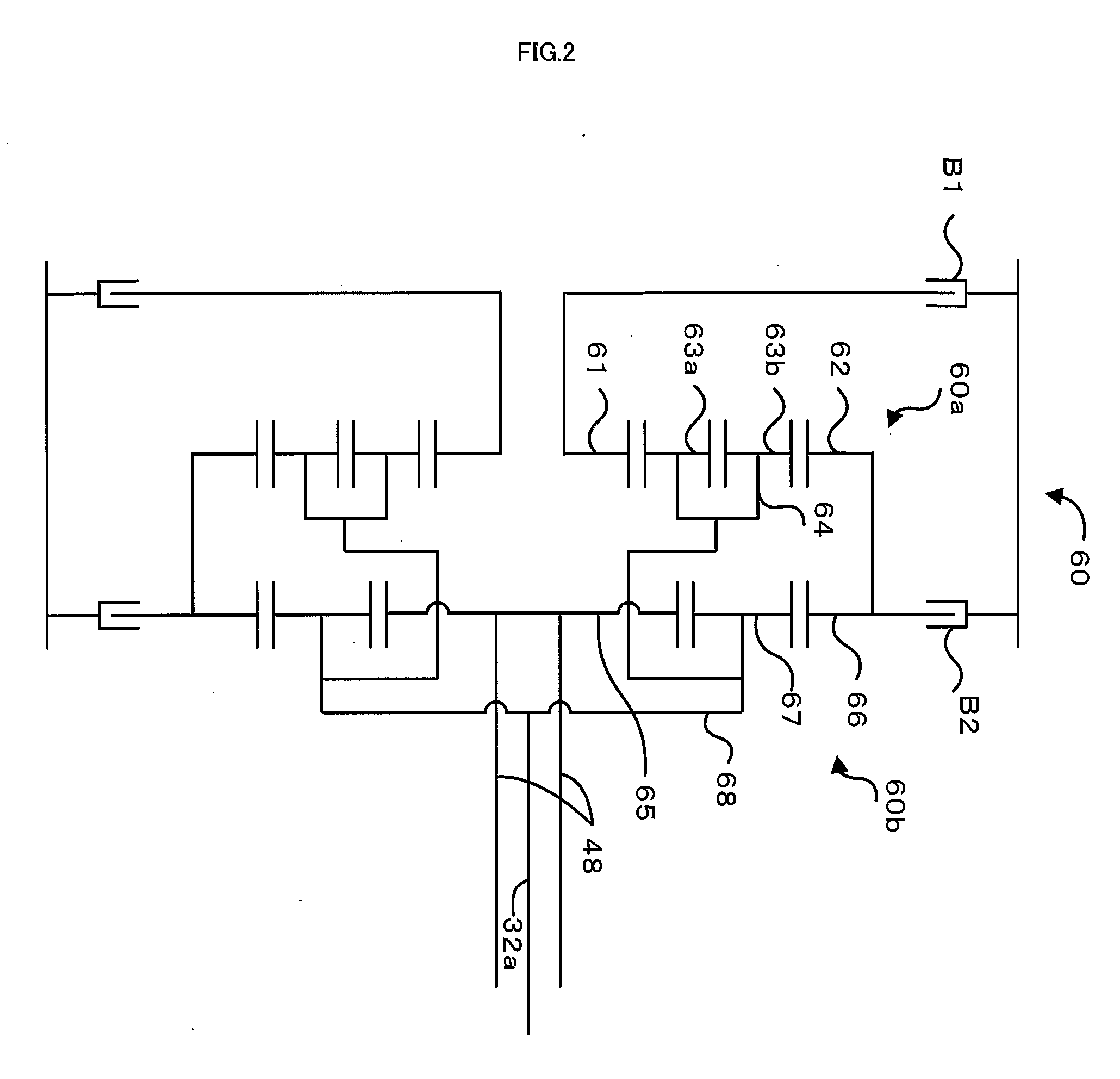

Driving Device, Motor Vehicle Equipped With Driving Device, and Control Methods of Driving Device and Motor Vehicle

ActiveUS20080135314A1Accelerate temperature riseEnhance heat exchangeHybrid vehiclesDigital data processing detailsHeat generationOil temperature

In setting of an oil temperature increasing process mode, the drive control technique of the invention starts an engine to actuate a mechanical oil pump that pressure feeds a flow of lubricating oil for lubricating the mechanical parts of a transmission and other relevant parts, actuates an electric oil pump that pressure feeds the flow of lubricating oil, and makes a brake B1 included in the transmission in a semi-engagement state. A motor arranged adjacent to the transmission is then driven with lowered output efficiency. This arrangement effectively accelerates heat generation by the motor and ensures a quick temperature rise of the lubricating oil.

Owner:TOYOTA JIDOSHA KK +1

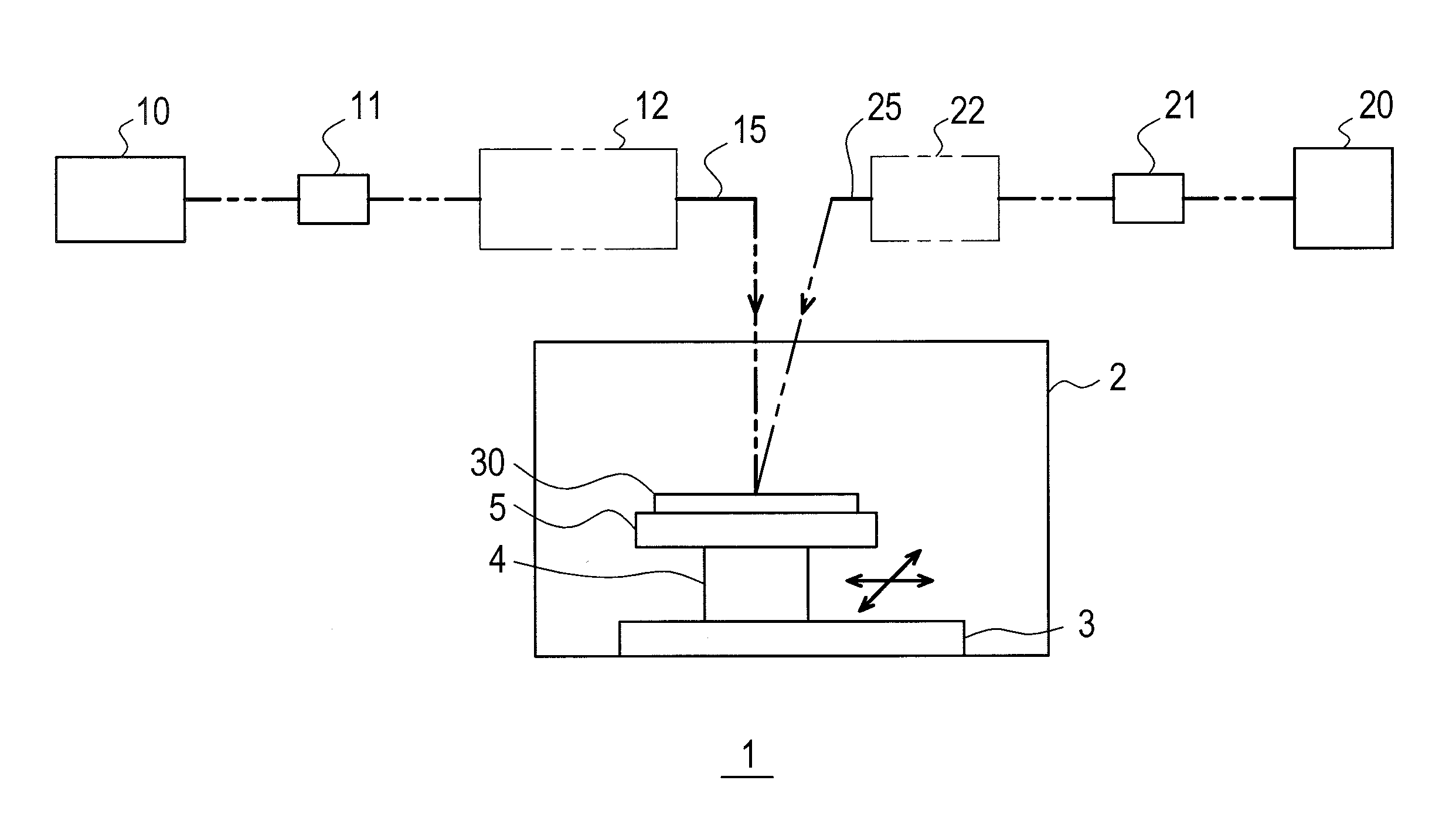

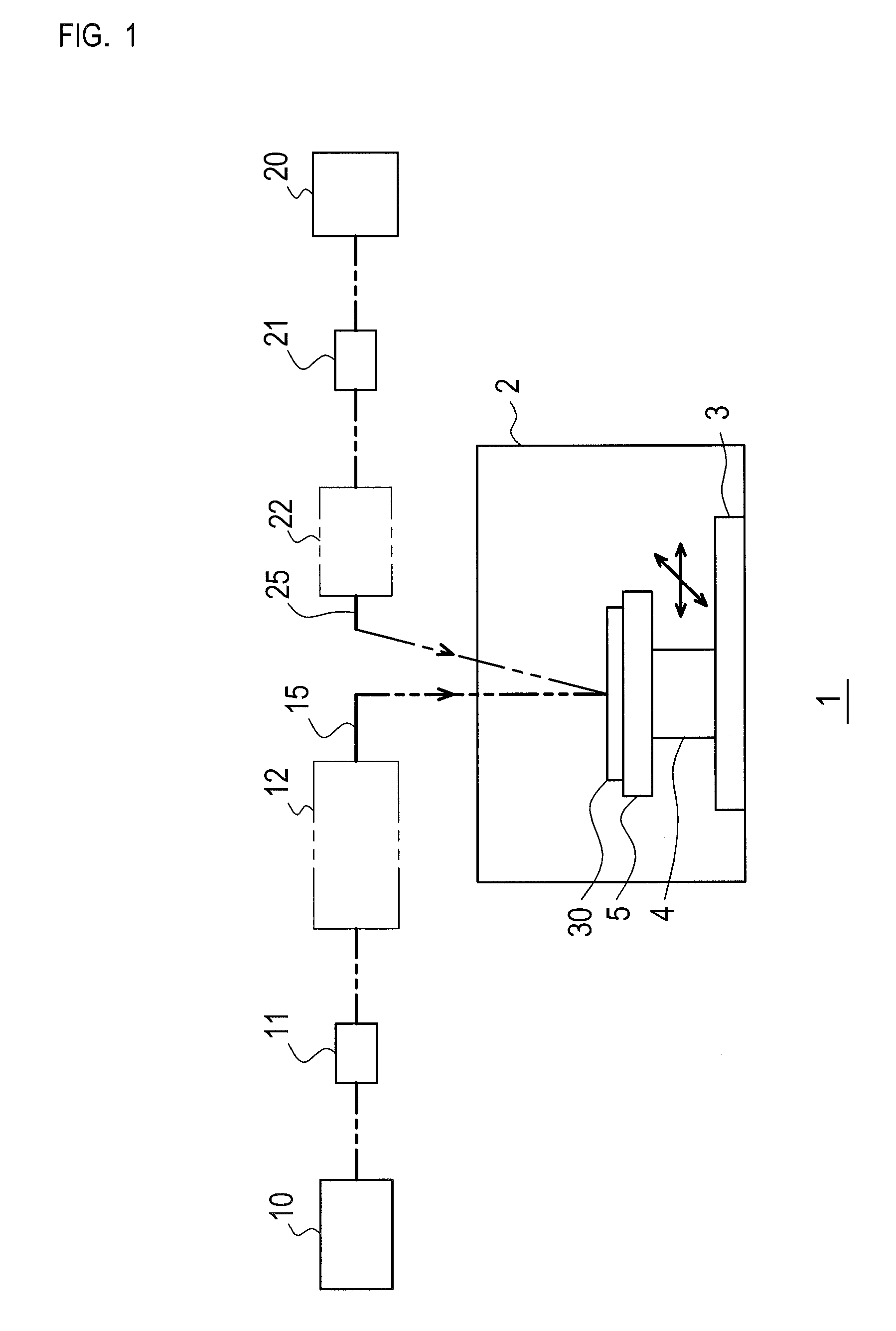

Laser annealing apparatus and laser annealing method

InactiveUS20120234810A1Avoid smallInhibit temperature riseTransistorSemiconductor/solid-state device manufacturingLaser sourcePenetration depth

The present invention provides an efficient heat treatment such as activation treatment of impurities on a substrate such as a thick silicon wafer with large heat capacity by laser annealing.Provided is a laser annealing apparatus 1 for heat-treating a surface of a substrate 30 comprising: a pulse oscillation laser source 10 which generates a pulse laser with gentle rise time and long pulse width; a continuous wave laser source 20 which generates a near-infrared laser for assisting annealing; optical systems 12, 22 which shape and guide beams 15, 25 of the two types of lasers respectively so as to irradiate the surface of the substrate 30 therewith; and a moving device 3 which moves the substrate 30 relatively to the laser beams 15, 25 to allow scanning of the combined irradiation of the two types of laser beams. According to this apparatus, deep activation of impurities can be performed in a thick semiconductor substrate with large heat capacity while securing sufficient light penetration depth and thermal diffusion length therefor.

Owner:JAPAN STEEL WORKS LTD

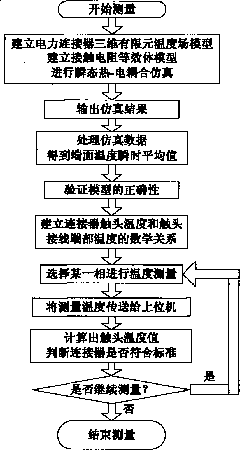

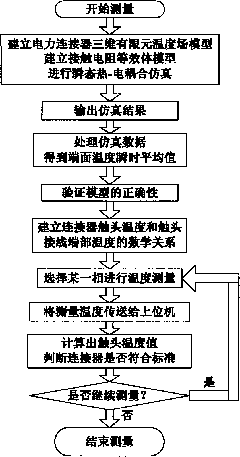

Method for measuring power connector contact temperature rise based on finite element analysis of three-dimensional thermal field

InactiveCN101825501AShorten the time of temperature rise testImprove efficiencyThermometer applicationsSpecial data processing applicationsFinite element limit analysisElement analysis

The invention provides a method for measuring power connector contact temperature rise based on finite element analysis of a three-dimensional thermal field. The method is used for displaying the measuring result and the room temperature in real time, is convenient for computing the contact temperature rise and is used for judging whether the connector is qualified or not with the testing standard. The method comprises the following steps: establishing a three-dimensional thermal field model of the power connector by utilizing finite element simulation analysis software (ANSYS), establishing a contact resistance equivalent phantom model through computation of the contact resistance and the contact area; carrying out data processing on the temperature of all the nodes on the end face of the connector contact and the temperature of all the nodes at the end of the contact wiring, wherein the temperature is obtained by simulation; verifying the correctness of the model by comparing the above temperature with the instantaneous value, which is measured in test, of the temperature at the end of the connector contact wiring; and an upper computer selecting one phase for measuring. The method can be used for displaying the measuring result and the room temperature in real time, is convenient for computing the contact temperature rise and can be used for judging whether the connector is qualified or not.

Owner:HARBIN INST OF TECH

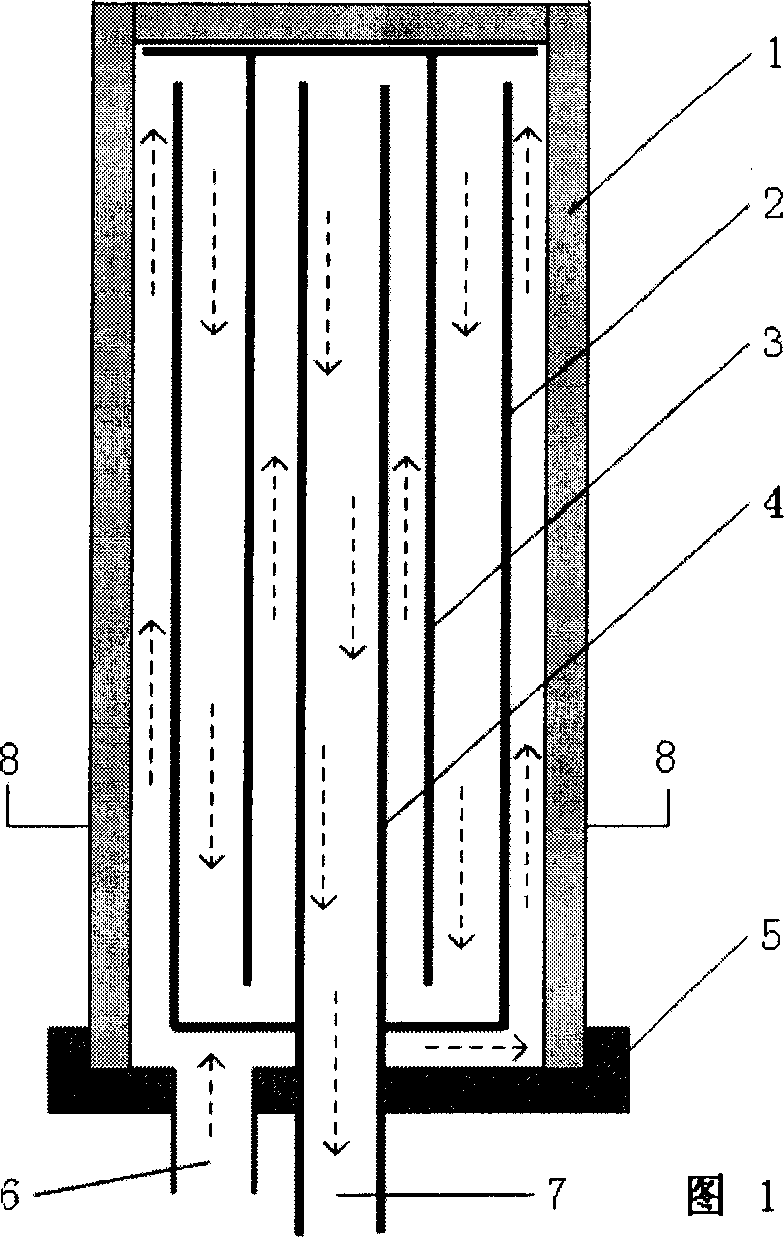

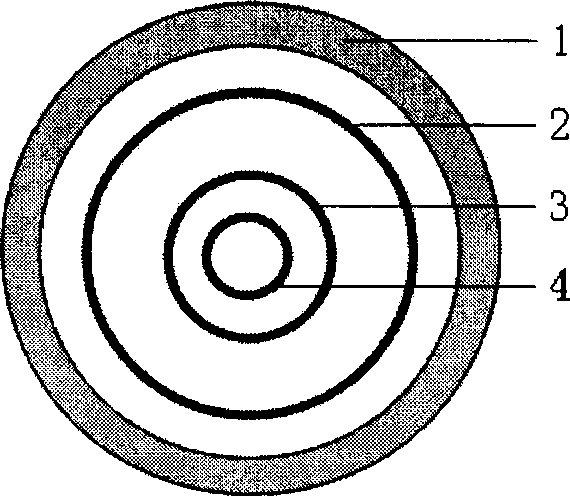

Electromagnetic water heater with modularized structure

InactiveCN1844777AEasy to combine in seriesRealize multi-stage heatingWater heatersElectricityWater flow

The invention discloses an electromagnetic water heater which uses electromagnetic heating theory to realize water-electricity separation and high safety. Wherein, the heating unit comprises: the outset part is a thermal-insulated ceramic cup sleeve coiled with electromagnetic coil; the inner part is a embedded multilayer metallic electromagnetic heating tube; the end is sealed by the a cover with cold water inlet and hot water outlet; the embedded structure and effectively increase the path of water; the water flows two surfaces of metallic electromagnetic heating tube, to increase the heated area and improve the heat exchange efficiency; the water will flow from outer to inner, therefore, the water will be stepped heated to decrease the heat loss most; the cold water first flows between the ceramic sleeve and the outset metallic electromagnetic heating tube, to cool the electromagnetic coil. The invention has simple structure, modularized processing and installment, while several heating units can be serially connected to realize multi-step heating.

Owner:杨杰

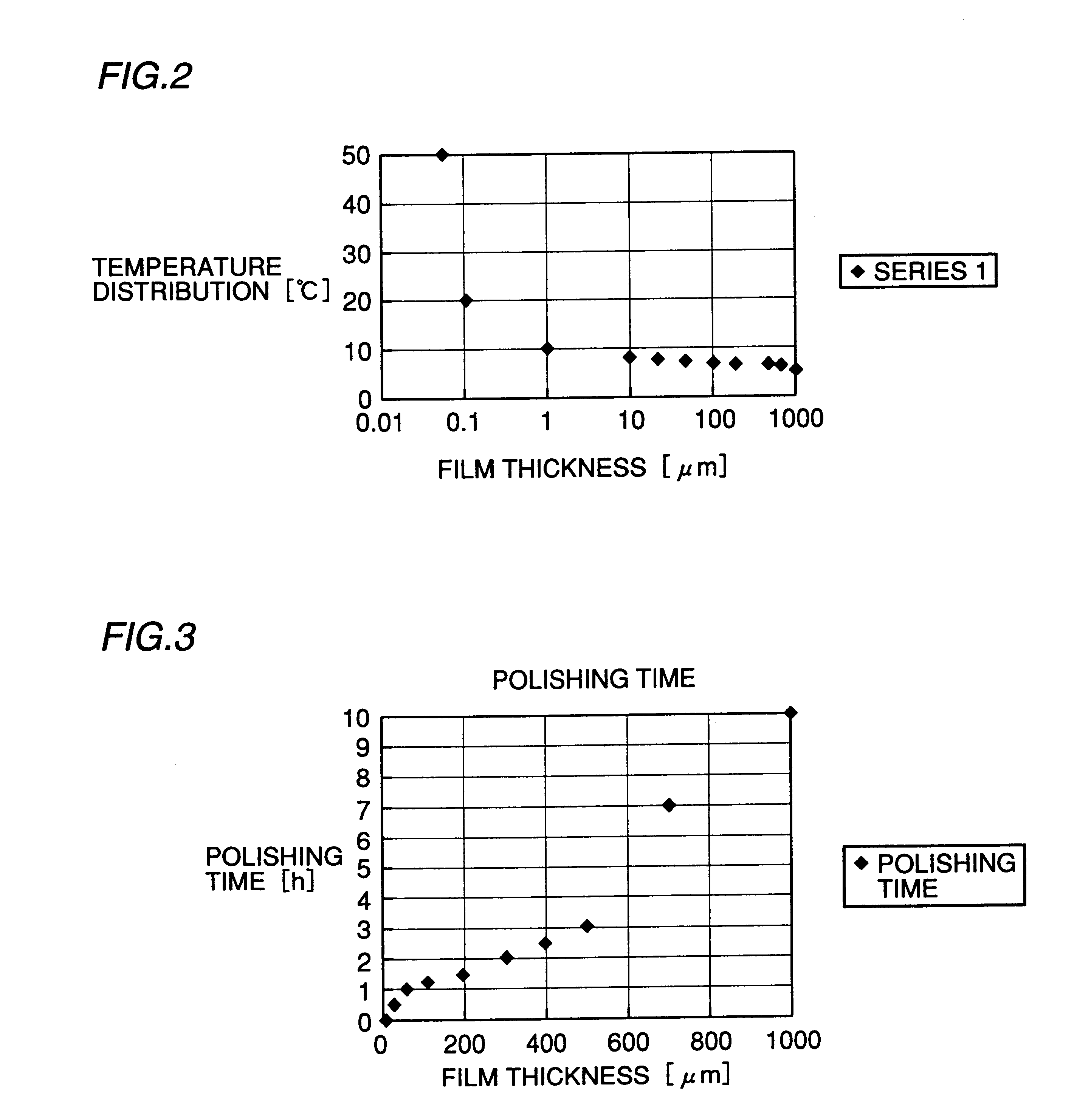

Tool tip and bonding tool comprising the tool tip and control method for the bonding tool

InactiveUS6270898B1High energyTemperature rise characteristic andDecorative surface effectsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceMetallurgy

A conductive polycrystalline diamond film having specific resistance of at least 1x10-4 OMEGAcm and less than 1x103 OMEGAcm, whose film thickness is in the range of at least 0.1 mum and not more than 500 mum, is film-formed by vapor-phase synthesis on a surface employed for pressure bonding, a surface opposite to this surface or at least two side surfaces intersecting with these surfaces on a substrate of a bonding tool tip that is applicable for bonding and packaging a semiconductor chip.

Owner:SUMITOMO ELECTRIC IND LTD

Lubricating device and method for gearbox

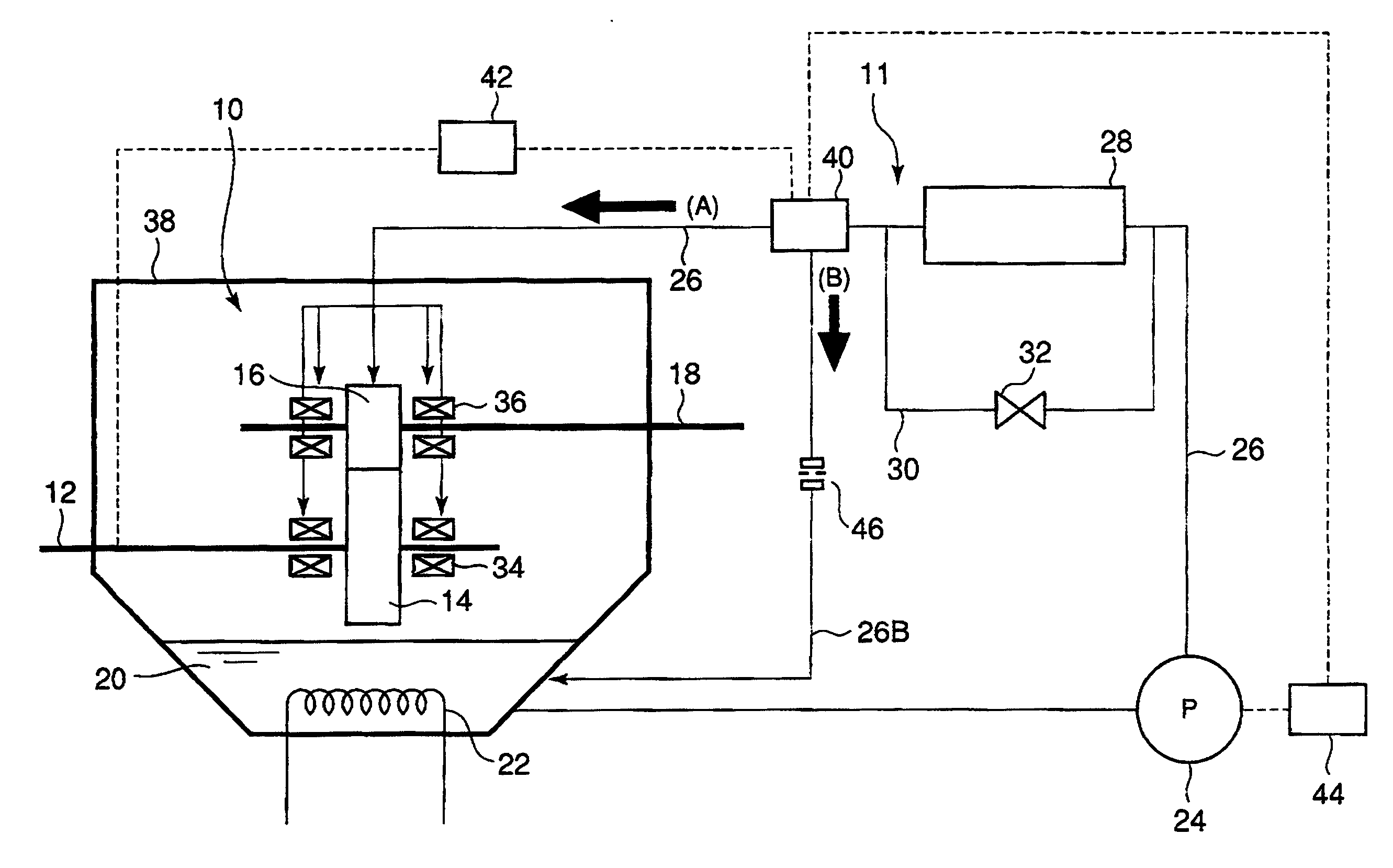

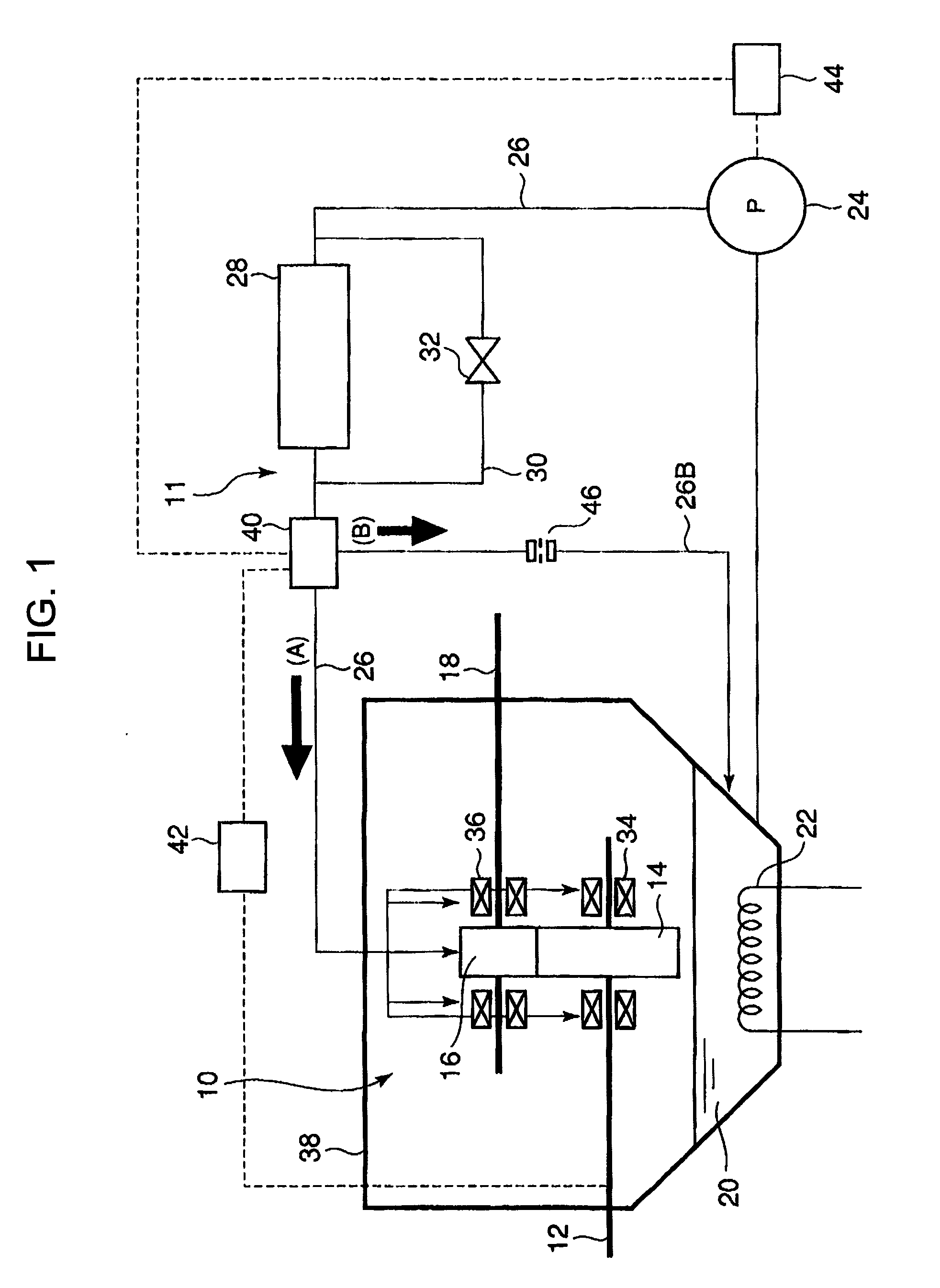

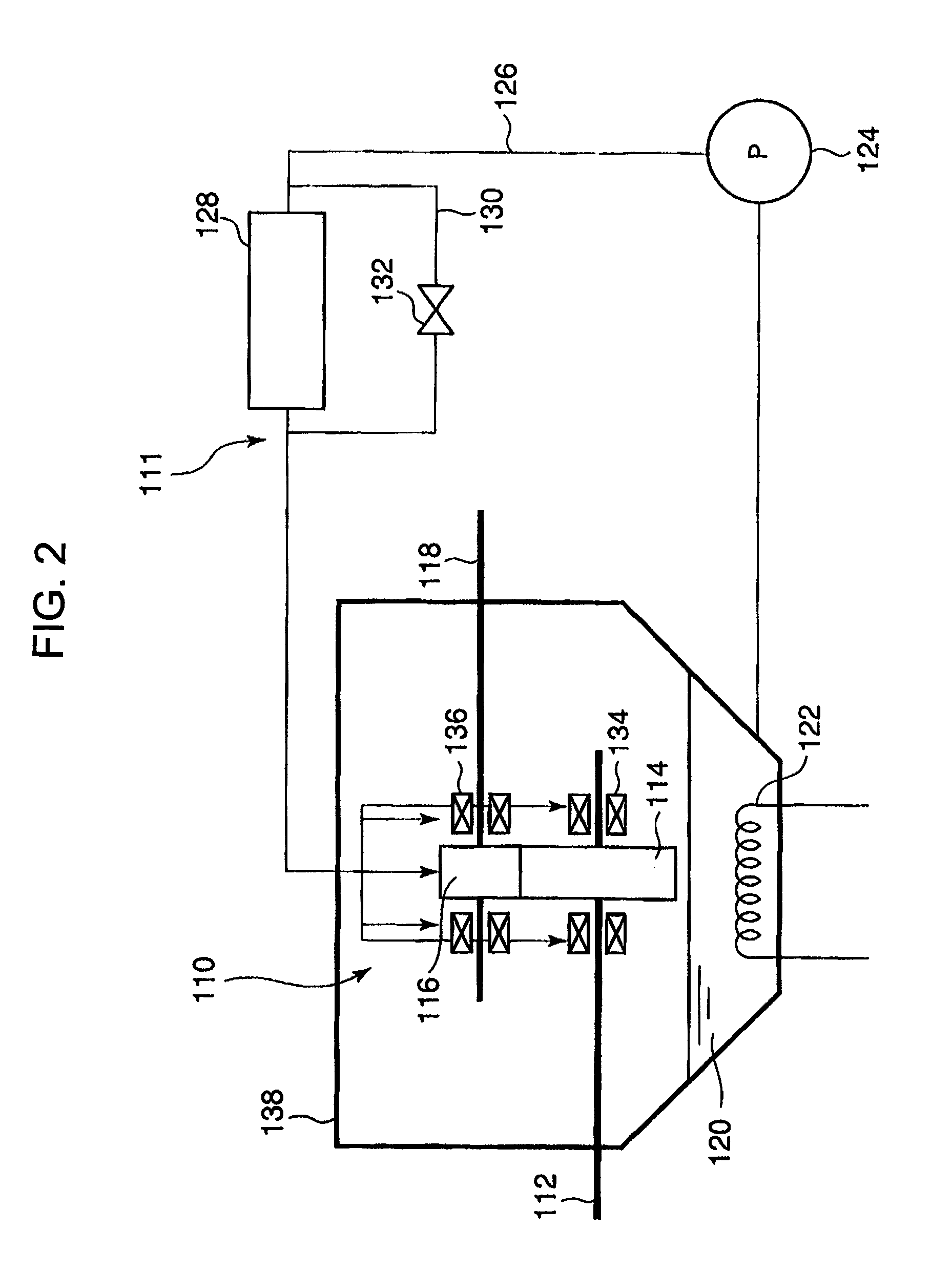

InactiveUS20110024236A1Prevents the air getting in the lubricant oilFew stepsGearboxesEngine fuctionsGear wheelLubricant

In order to provide a lubricating device and lubricating method for a gearbox which does not take long to heat the lubricant oil and prevents the aeration of the lubricant oil due to the splashing thereof during the activation of the gearbox, the present invention provides a lubricating device for a gearbox comprising: a gearbox which includes an input shaft, a group of gears rotated by the rotation of the input shaft, and an output shaft rotated by the rotation of the group of gears, the rotation of the input shaft being speeded up and outputted to the output shaft via the group of gears; an oil storage chamber which stores lubricant oil for lubricating the gearbox; a lubricant oil circulating line which includes a pump and through which the lubricant oil stored in the oil storage chamber is supplied to the gearbox by the pump and then returned to the oil storage chamber; a bypass line which is provided in the oil lubricant circulating line and bypasses the gearbox; and a switching valve which is provided in the oil lubricant circulating line and switches a supply path of the lubricant between supplying the lubricant oil to the gearbox and supplying the lubricant oil to the bypass line.

Owner:MITSUBISHI HEAVY IND LTD

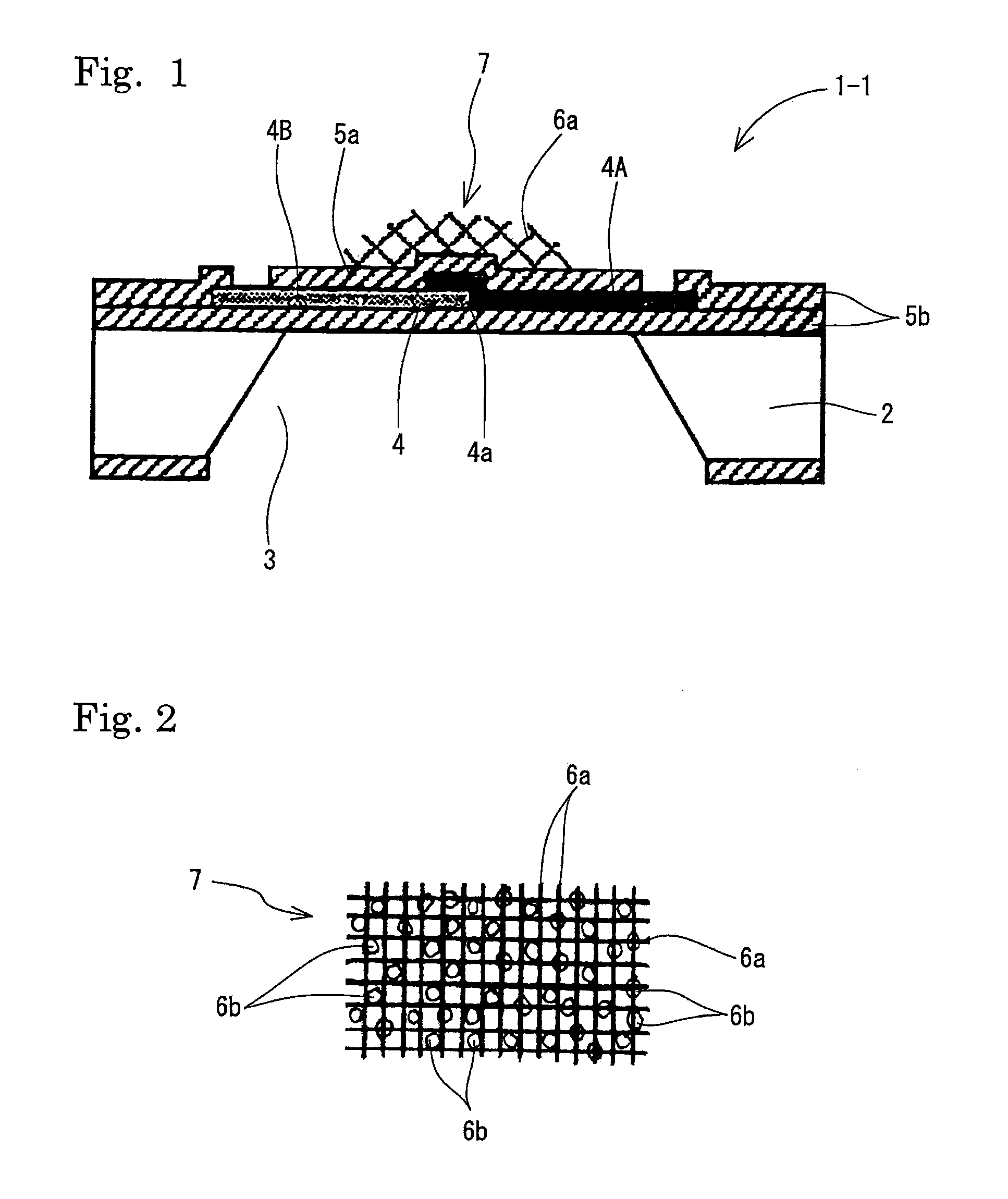

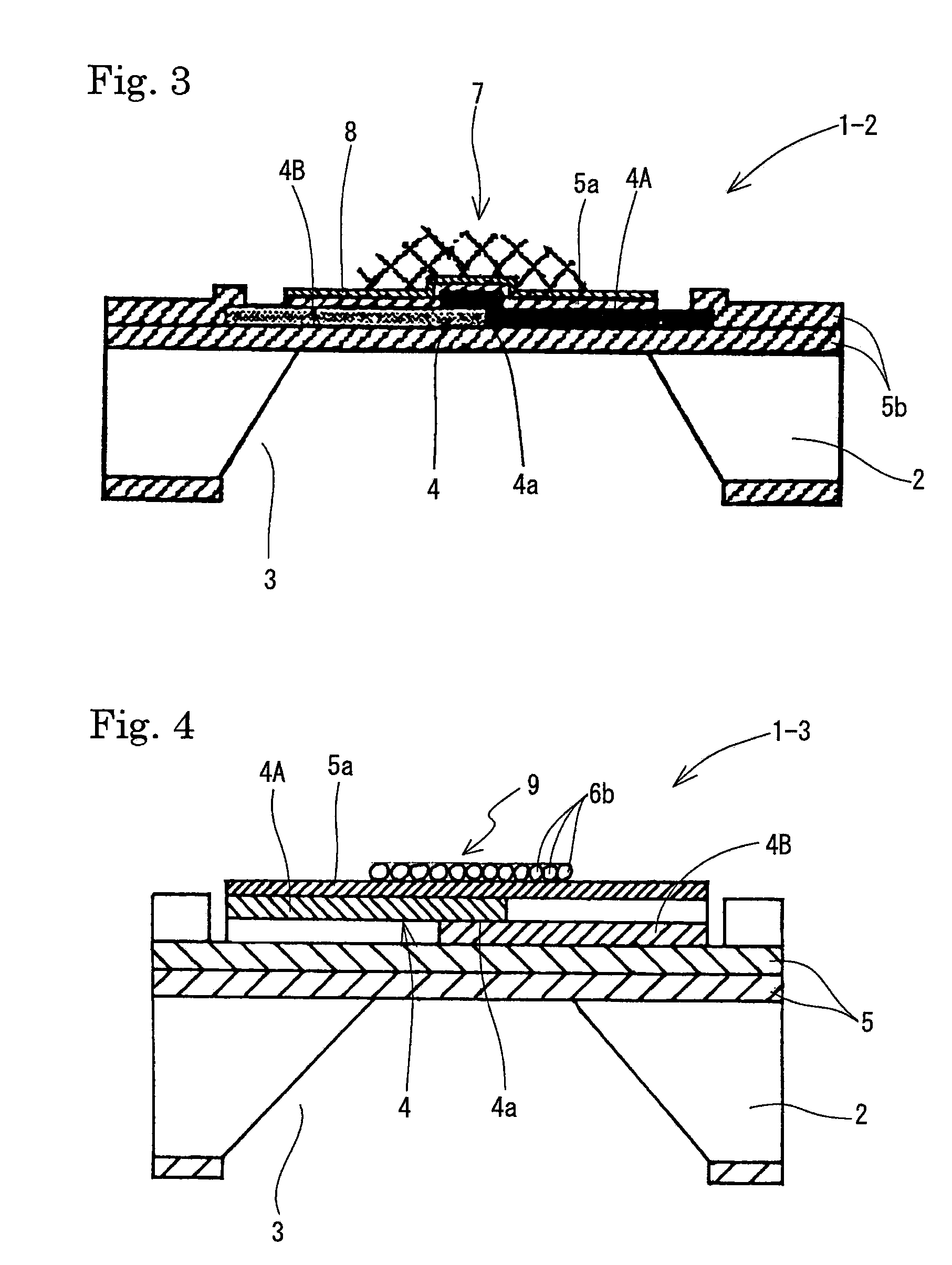

Combustible gas sensor

InactiveUS20100221148A1High measurement sensitivityHigh bonding strengthChemical analysis using combustionMaterial resistancePorous catalystThermopile

The present invention provides a combustible gas sensor that can realize a considerable improvement in the measurement sensitivity and the measurement precision by increasing the contact area between the measurement object gas and the oxidation catalyst particles, increasing the amount of heat generation of oxidation reaction in accordance therewith, and improving the transference of the oxidation reaction heat, while reducing the scale of the whole.In this invention, a temperature measurement element such as a thermopile obtained by joining different kinds of metals is formed on a top surface of a Si substrate; a porous catalyst layer made by allowing a porous material layer to carry oxidation catalyst particles such as Pt or a chain-form catalyst layer made by linking and bonding numerous oxidation catalyst particles in a chain form is provided on a heat-sensitive part of this temperature measurement element; and this porous catalyst layer or the chain-form catalyst layer is integrally bonded with the heat-sensitive part of this temperature measurement element.

Owner:HORIBA LTD

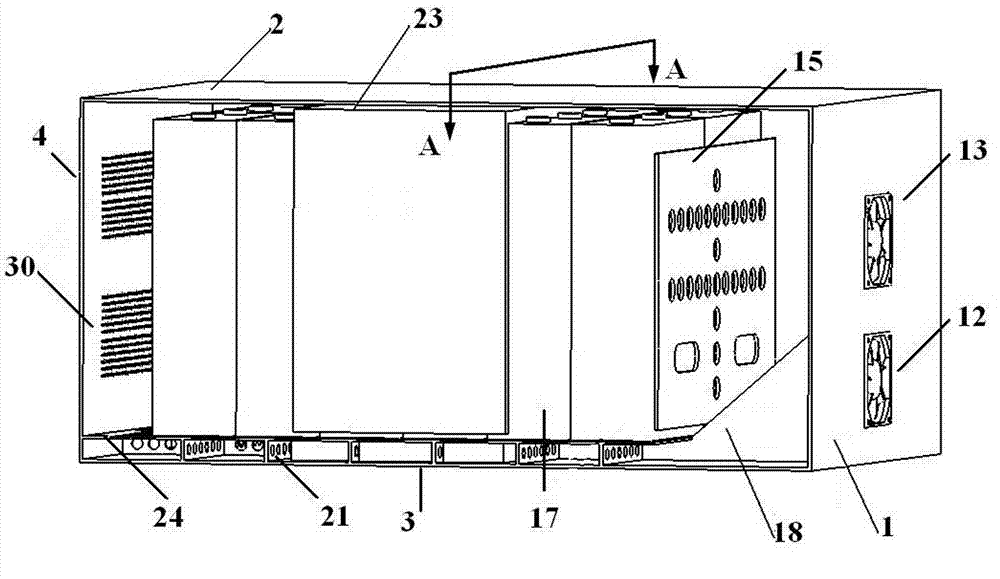

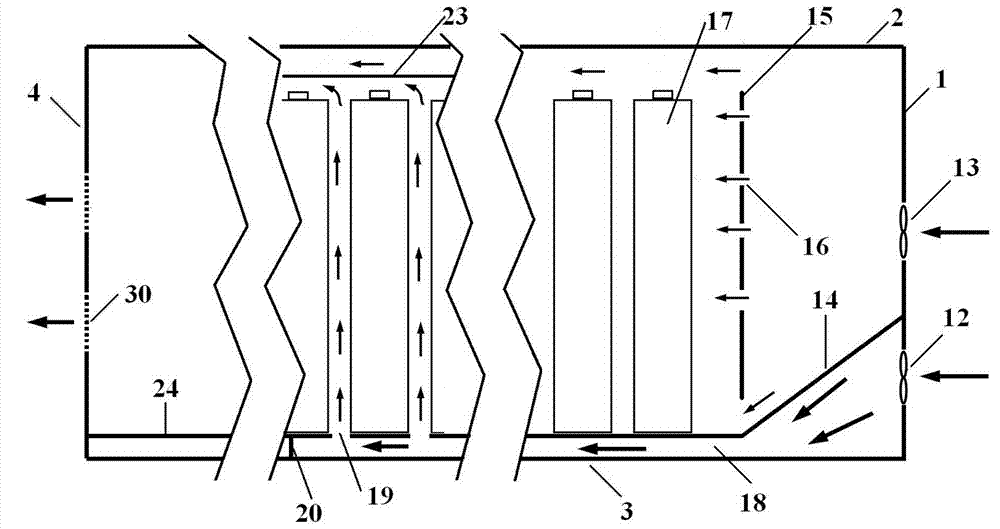

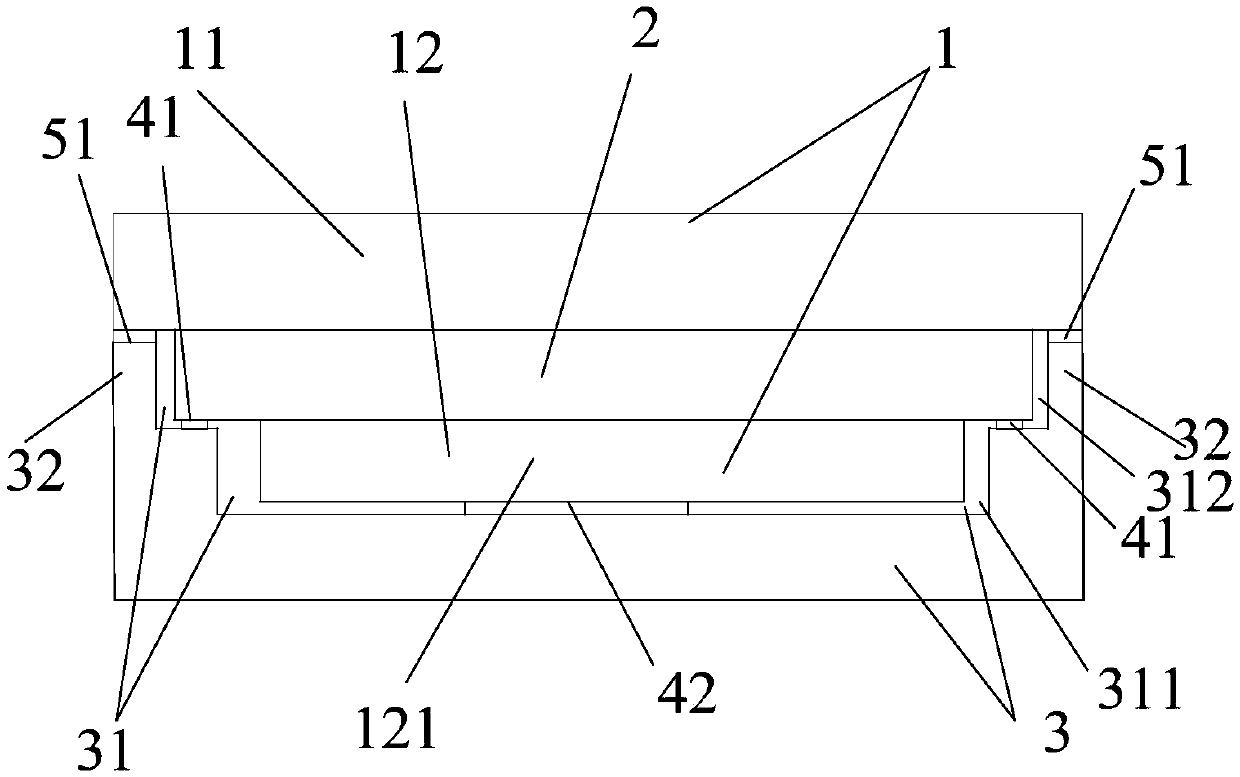

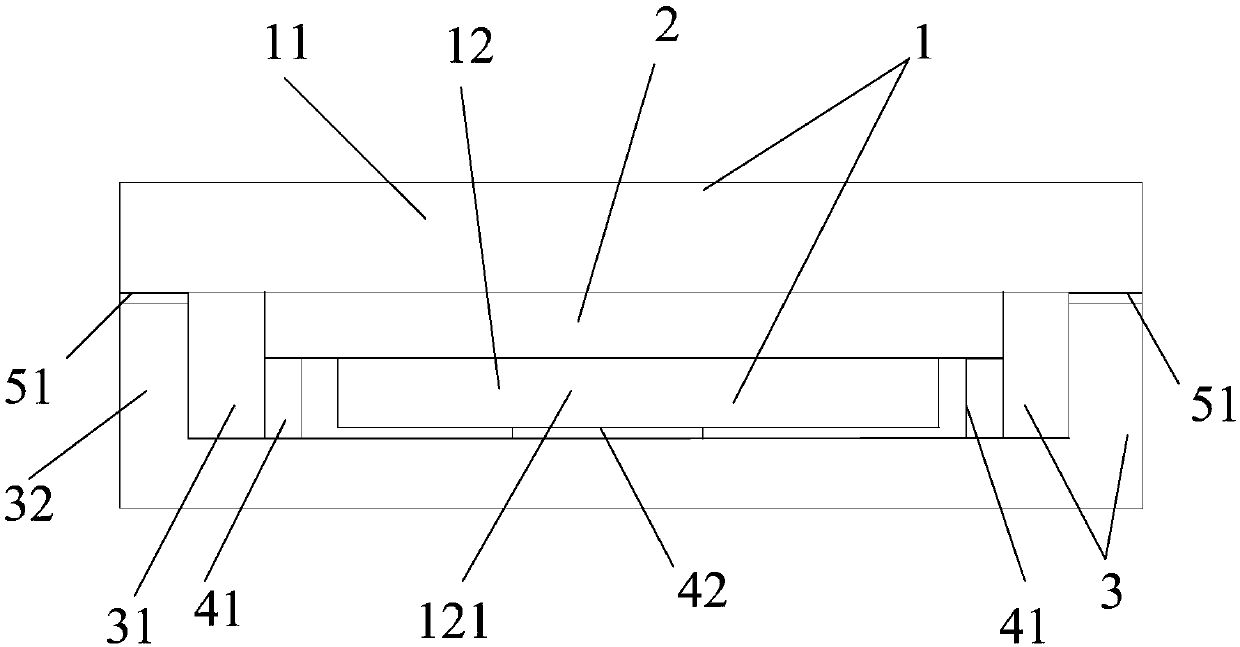

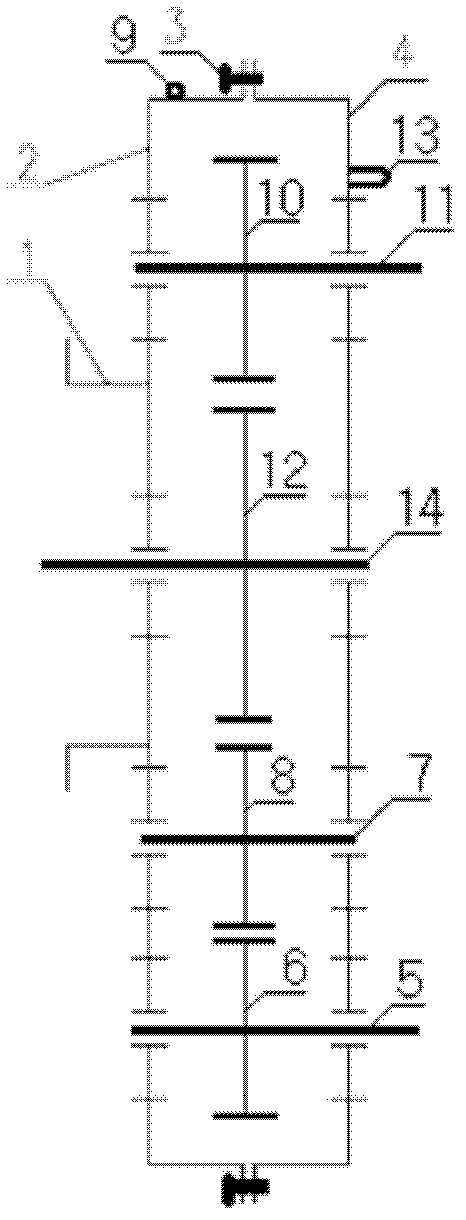

Lithium ion power battery box

ActiveCN103199203ACool evenlyObvious temperature differenceSecondary cellsCell component detailsLithiumPower battery

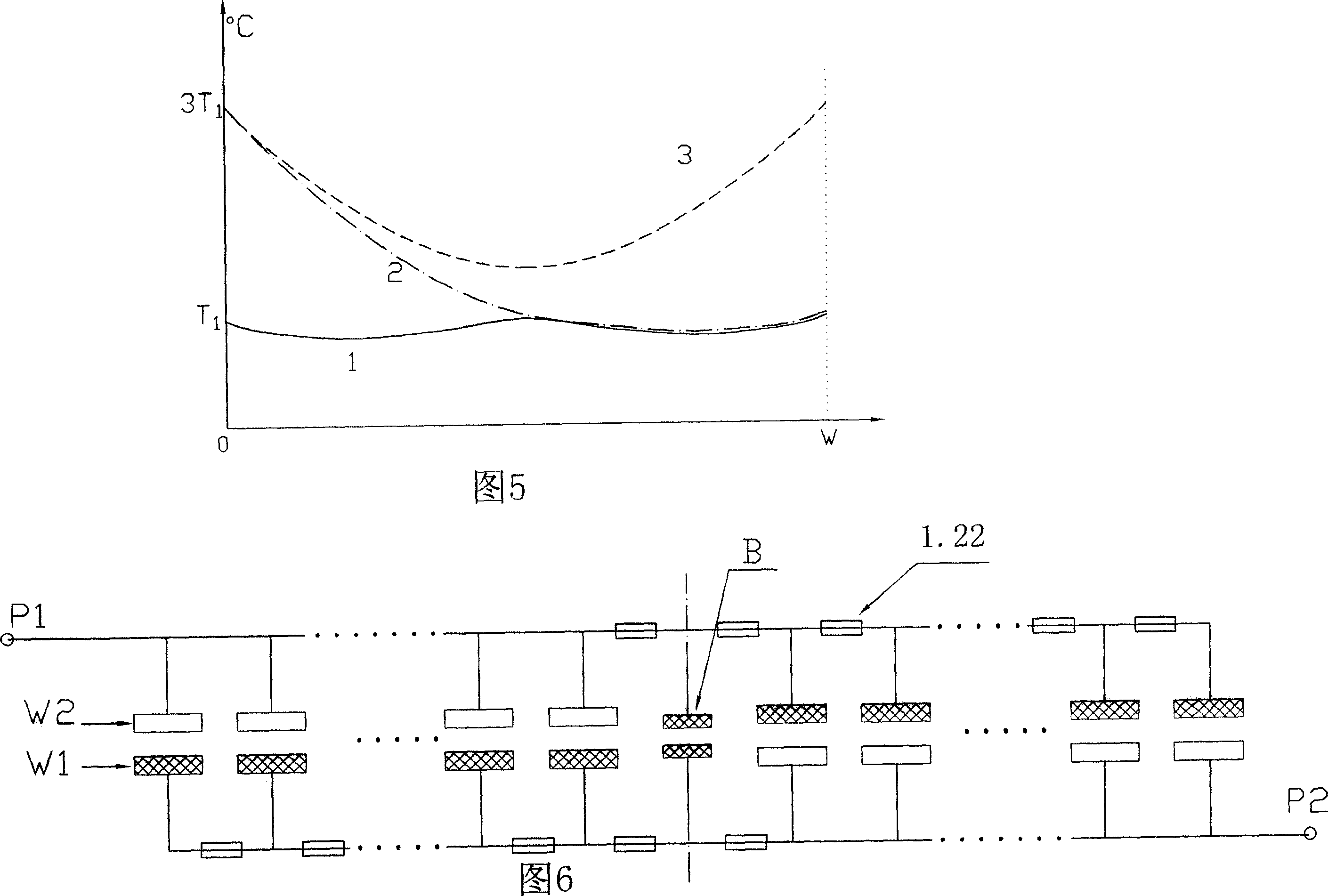

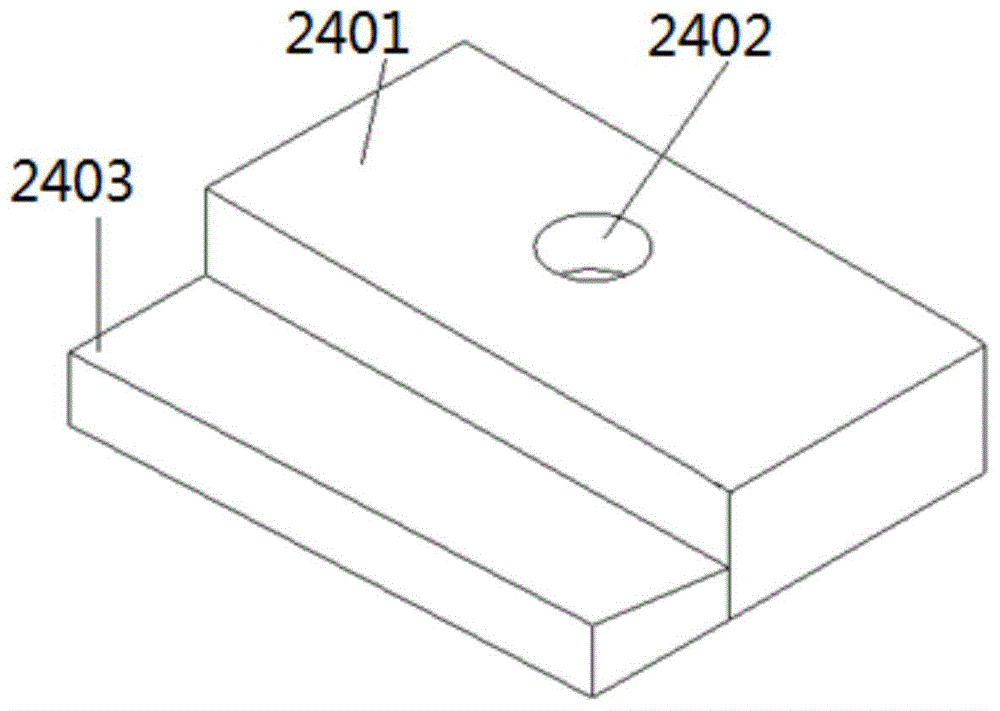

The invention relates to a lithium ion power battery box, which comprises a battery box body for alternately arranging batteries inside the body along a set arrangement direction, and a base air channel arranged in the battery box body, wherein the flow direction of the base air channel is consistent with the set arrangement direction; the battery box is also provided with a reinforced cooling air channel for delivering cooling air separated from the base air channel; the reinforced cooling air channel is provided with jet holes for directing the cooling air into a set cooling area in the battery box body; and the cooling area is a gap between front and back adjacent batteries along the battery arrangement direction in set positions or batteries in the set positions. By adopting the lithium ion power battery box, the problem in the prior art that cooling capacity distribution in various parts in the battery box body is non-uniform because the batteries are successively cooled along a single base air channel is solved; and the lithium ion power battery box of the invention can uniformly cool the batteries and improve the overall discharge performance and the service life of the batteries in the battery box.

Owner:CALB CO LTD

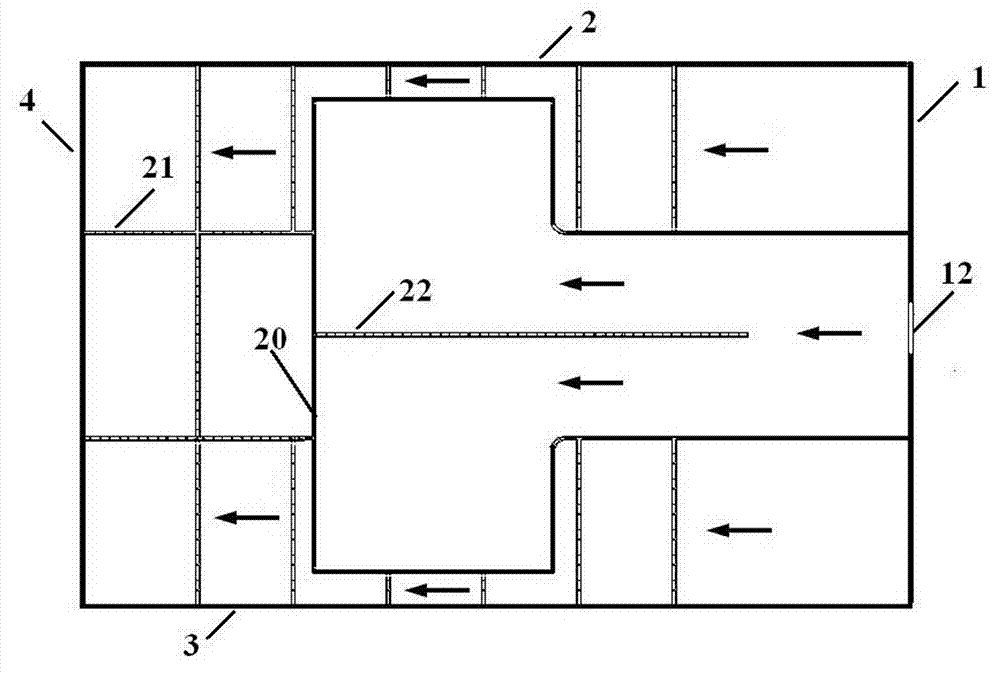

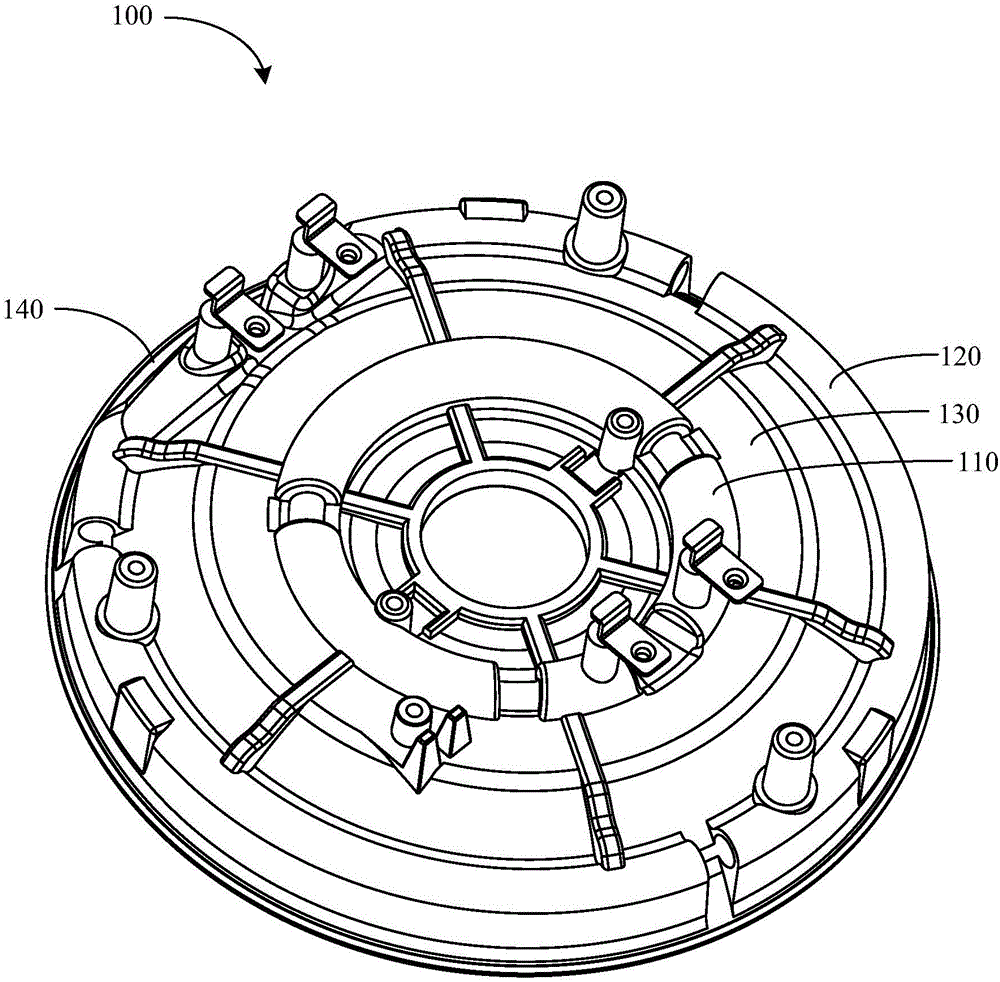

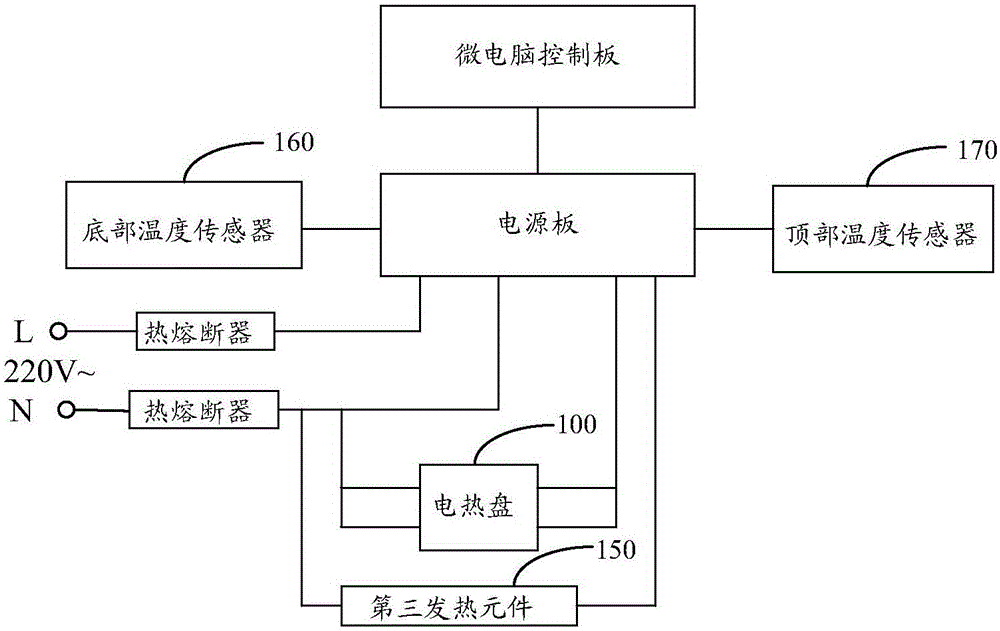

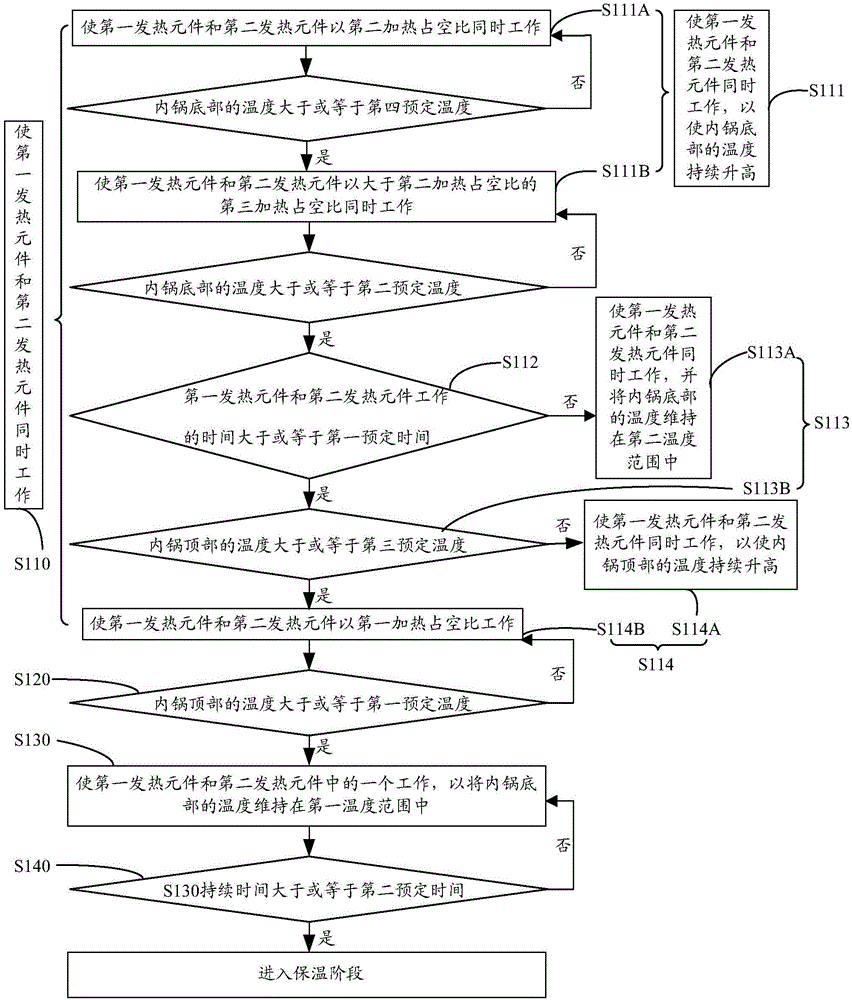

Heating control method for rice cooker

ActiveCN105078267AImprove temperature riseReduce temperature differenceWarming devicesCookerElectric heating

The invention discloses a heating control method for a rice cooker. The rice cooker comprises a main body, an electric heating tray, an inner pot and a cover body, wherein the electric heating tray comprises a first heating element arranged at the bottom of the electric heating tray and a second heating element on the side of the electric heating tray. The method comprises the following steps: a) enabling the first heating element and the second heating element to work simultaneously; b) making the first heating element and the second heating element sense temperatures of the bottom and the top of the inner pot when working; and c) when the temperature of the top of the inner pot is more than or equal to a first preset temperature, enabling either the first heating element or the second heating element to work, so as to keep temperature of the bottom of the inner pot within a first temperature range. The method can be used for respectively controlling the first heating element and the second heating element of the electric heating tray to work, which not only can reduce a temperature difference of the bottom and the side of the inner pot but also can avoid relatively high increase in the temperature of the first heating element of the electric heating tray, so as to reduce potential risk.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

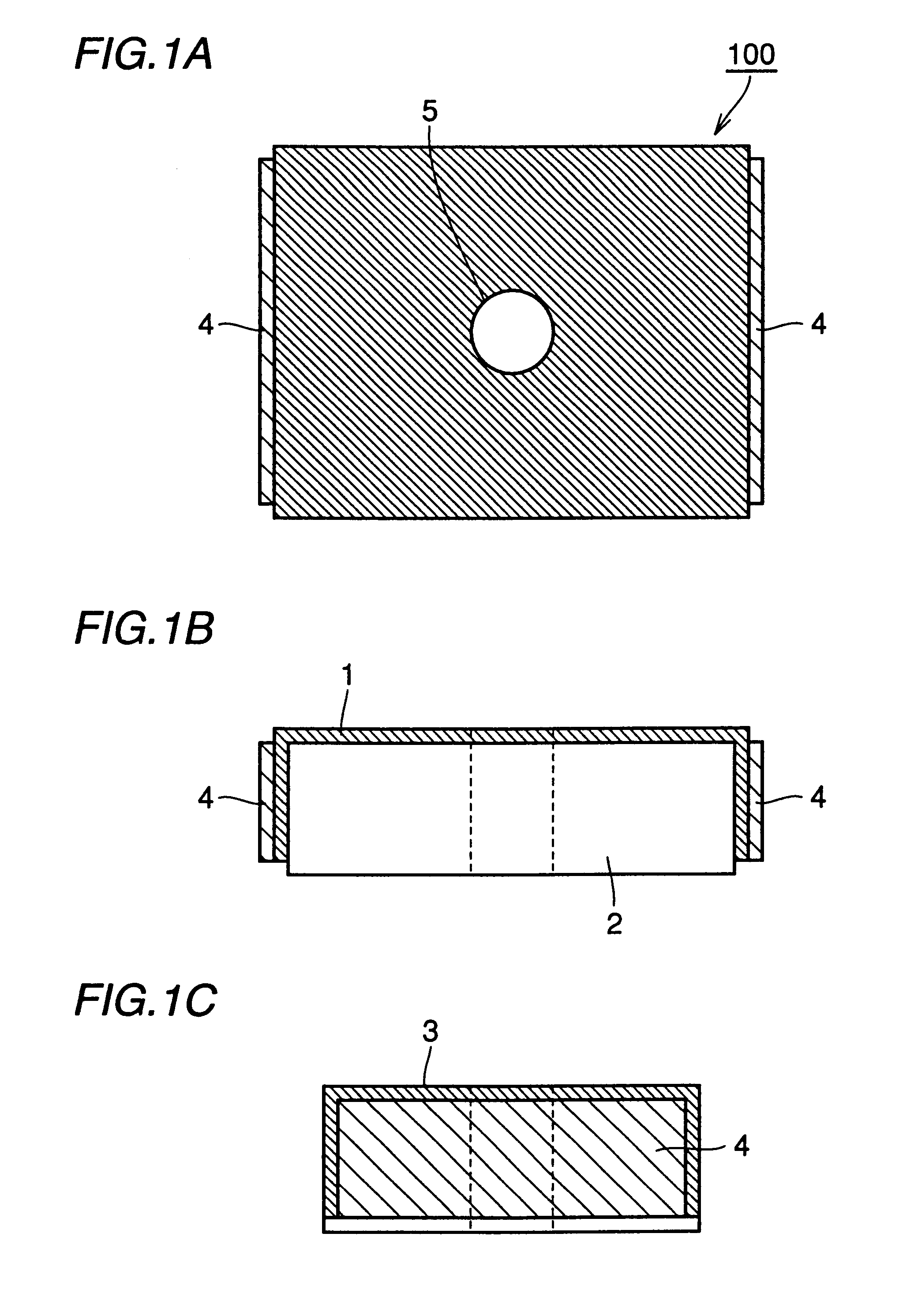

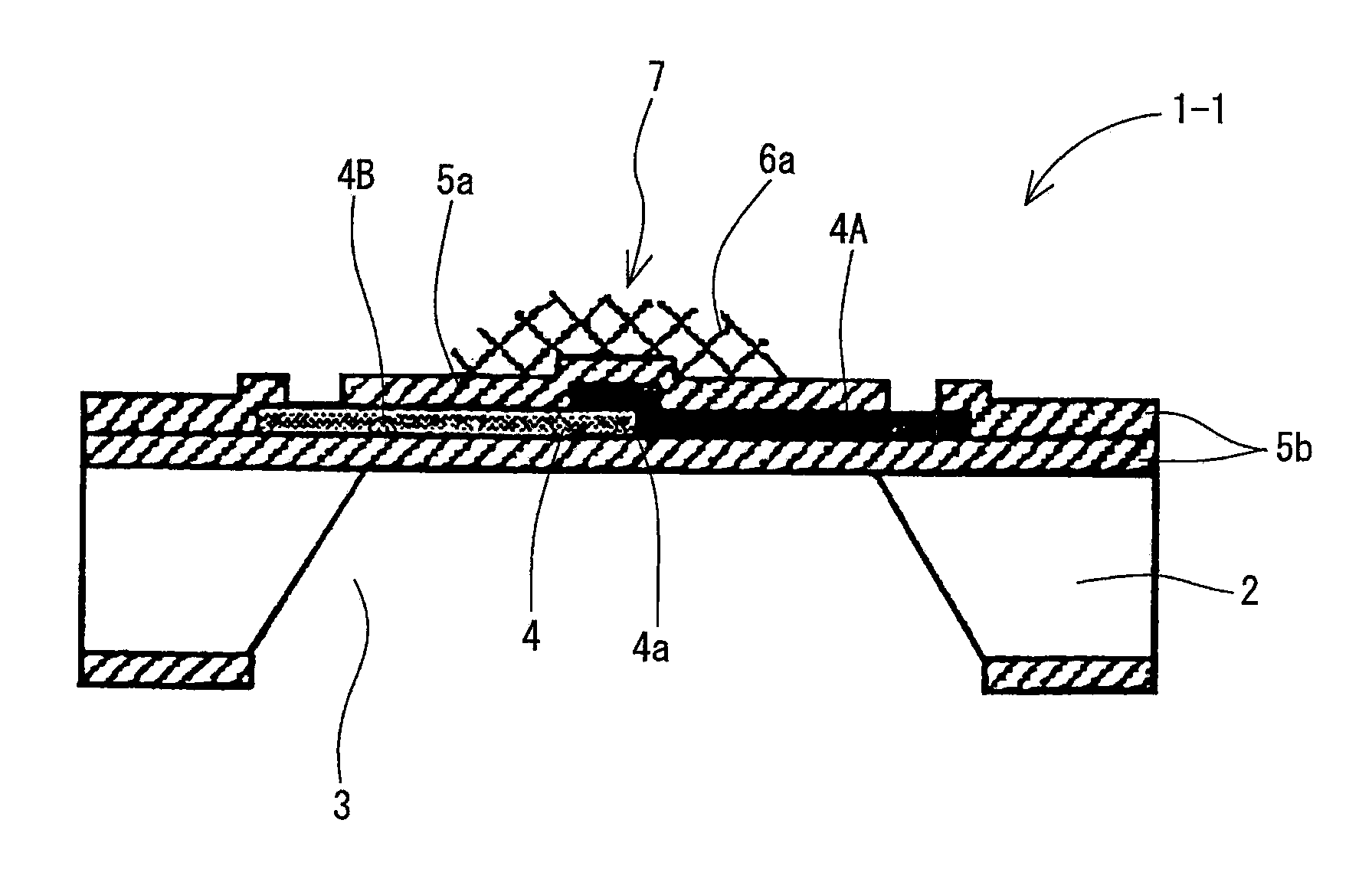

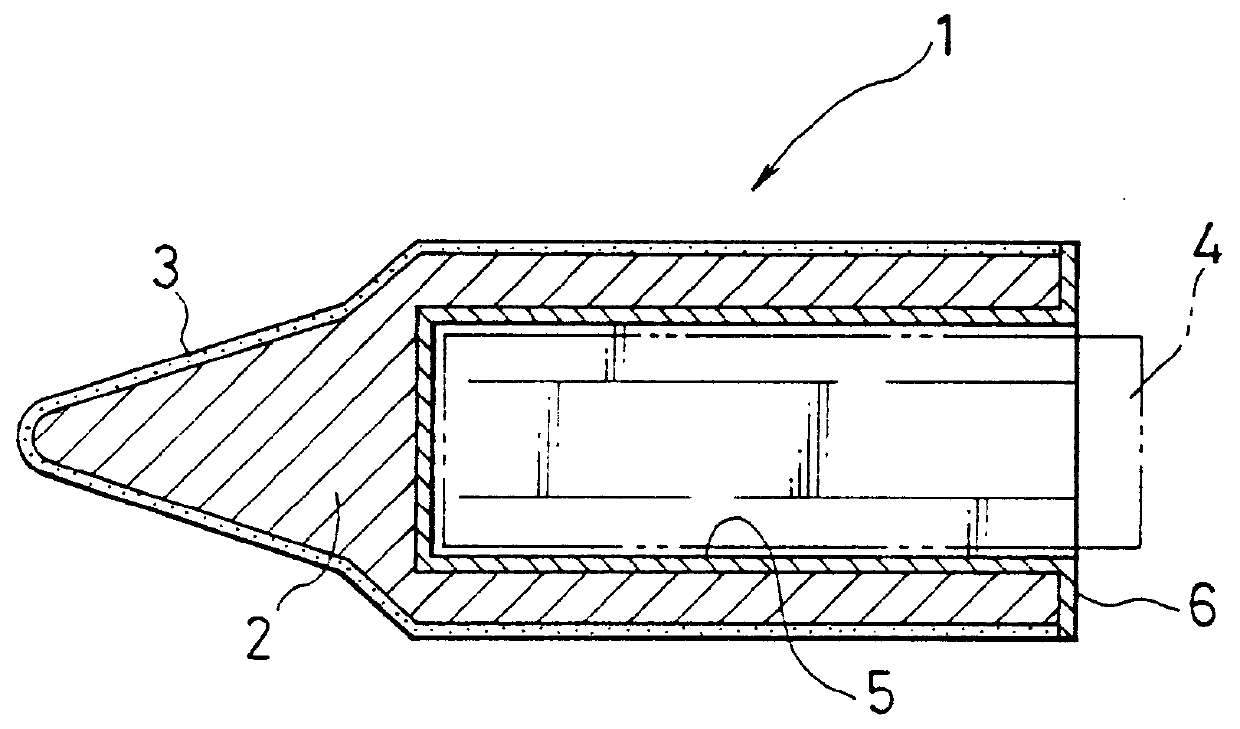

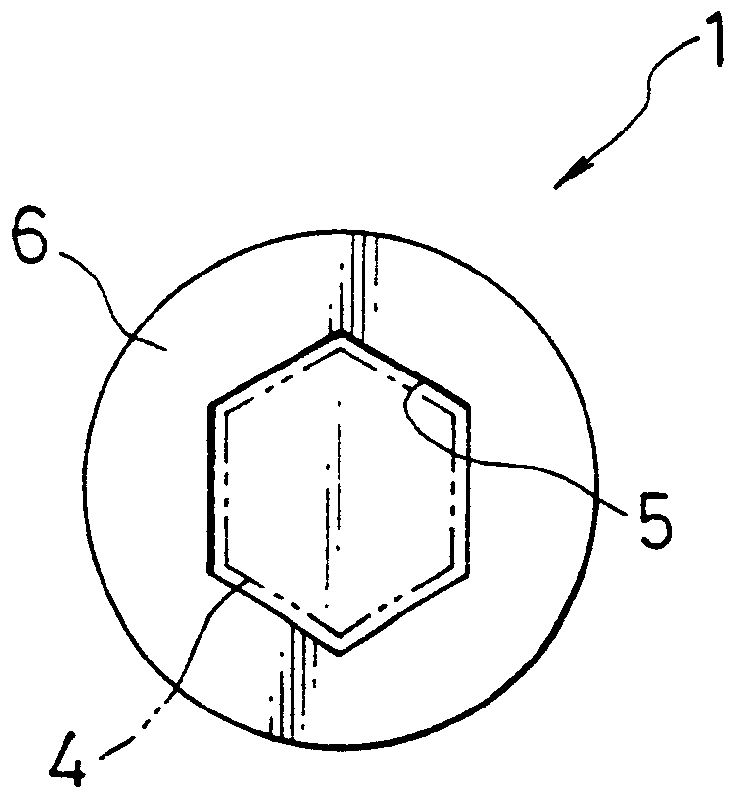

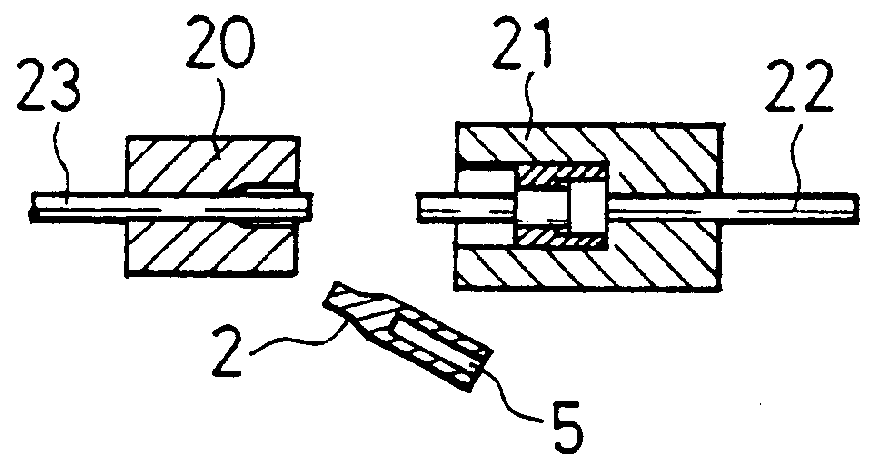

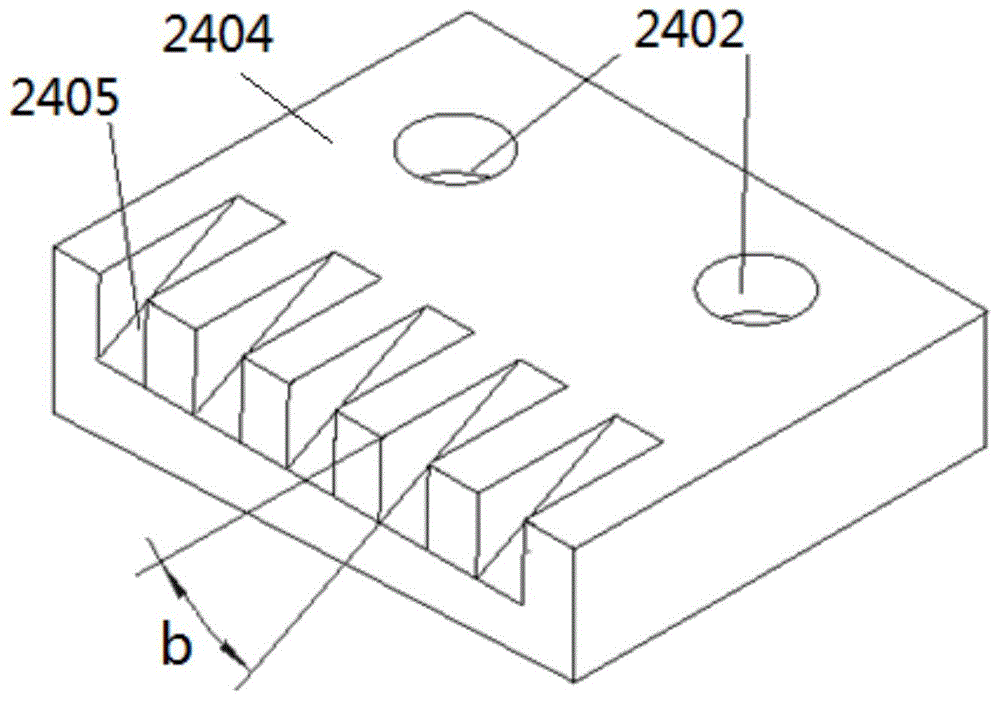

Heating tip and method of manufacturing the same

InactiveUS6039237AIncreasing heat conduction capacityImprove temperature riseSleeve/socket jointsLiquid/solution decomposition chemical coatingWorking lifeMetallurgy

A heating tip in which an insertion cavity is formed in a tip substrate made of copper or copper alloy for insertion and containment of a heat generating portion, wherein the inner circumferential wall surface of the insertion cavity is formed by forging into a non-circular cross sectional shape which is identical with a non-circular cross sectional shape on the outer circumferential surface of the heat generating portion. The insertion cavity has the non-circular cross sectional shape and, accordingly, the area of contact with the heat generating portion is enlarged compared with a case of a circular cross sectional shape with the hole volume being assumed identical, thereby increasing the heat conductivity from the heat generating portion and enhancing the temperature rising characteristics and the thermal response of the heating tip. Since the insertion cavity is formed by forging loss of the material can be decreased, neatly and easily and, in addition, working life of the tool can be extended.

Owner:NAKAJIMA DOKOSHO CO LTD

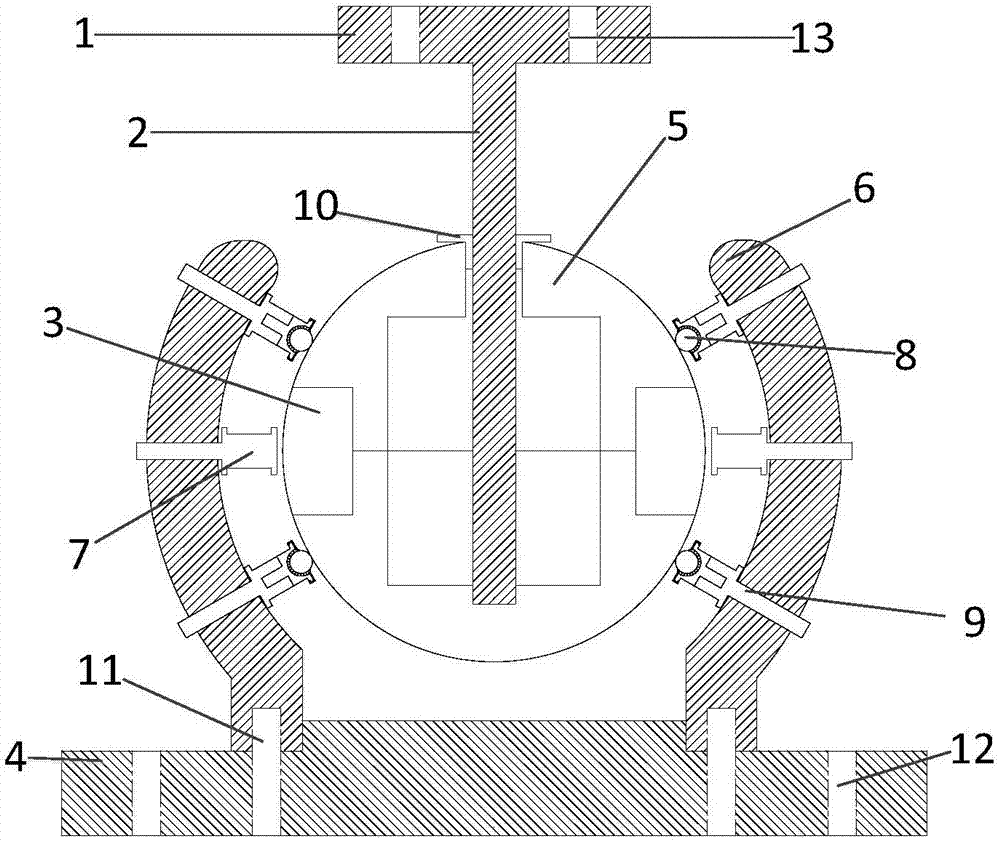

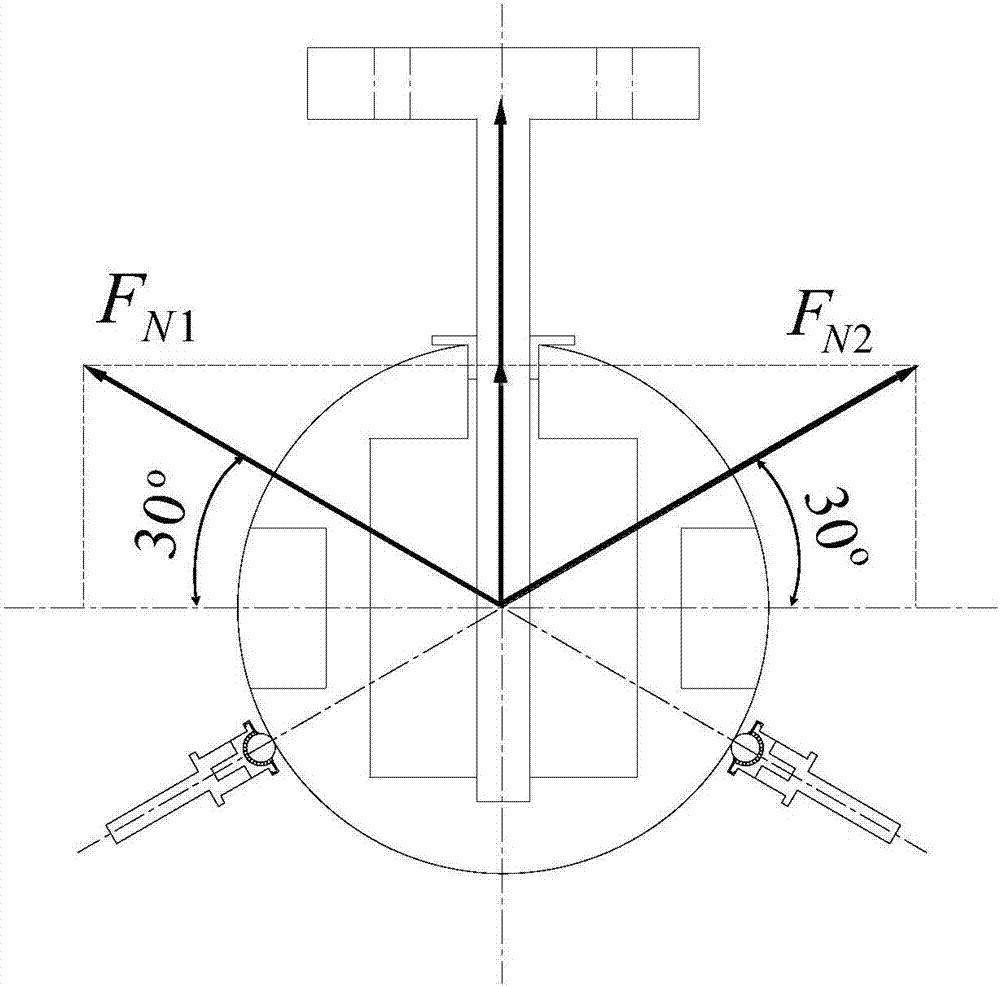

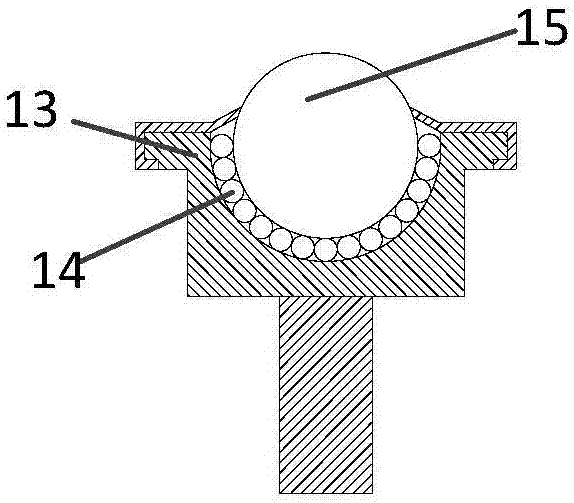

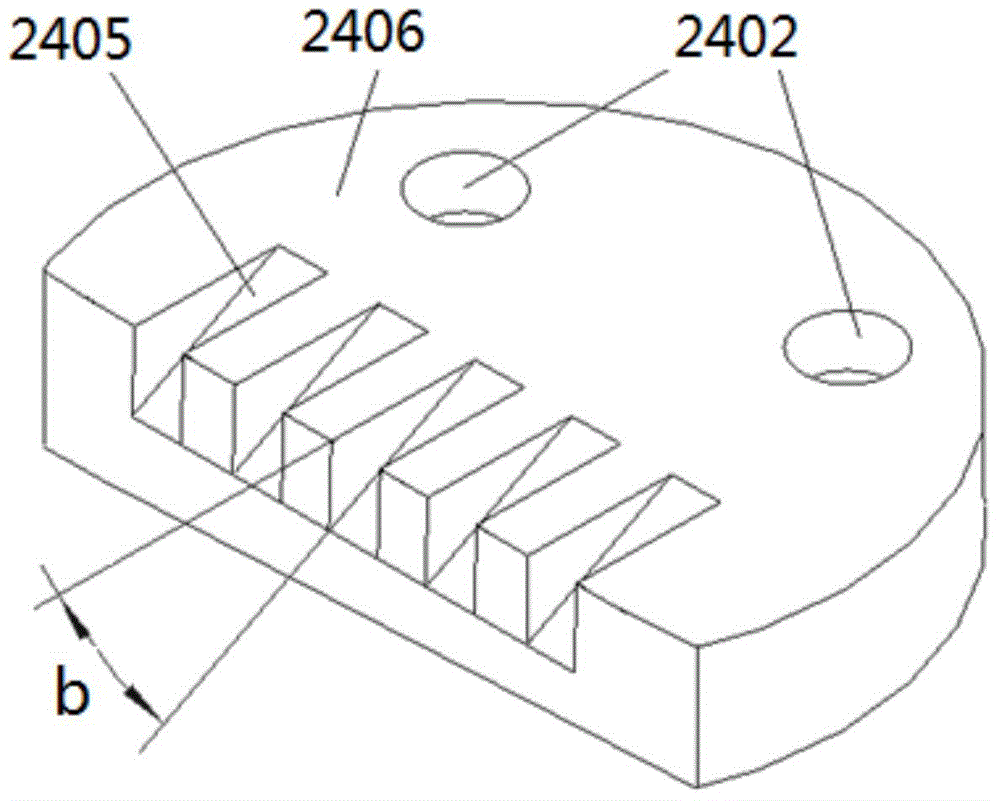

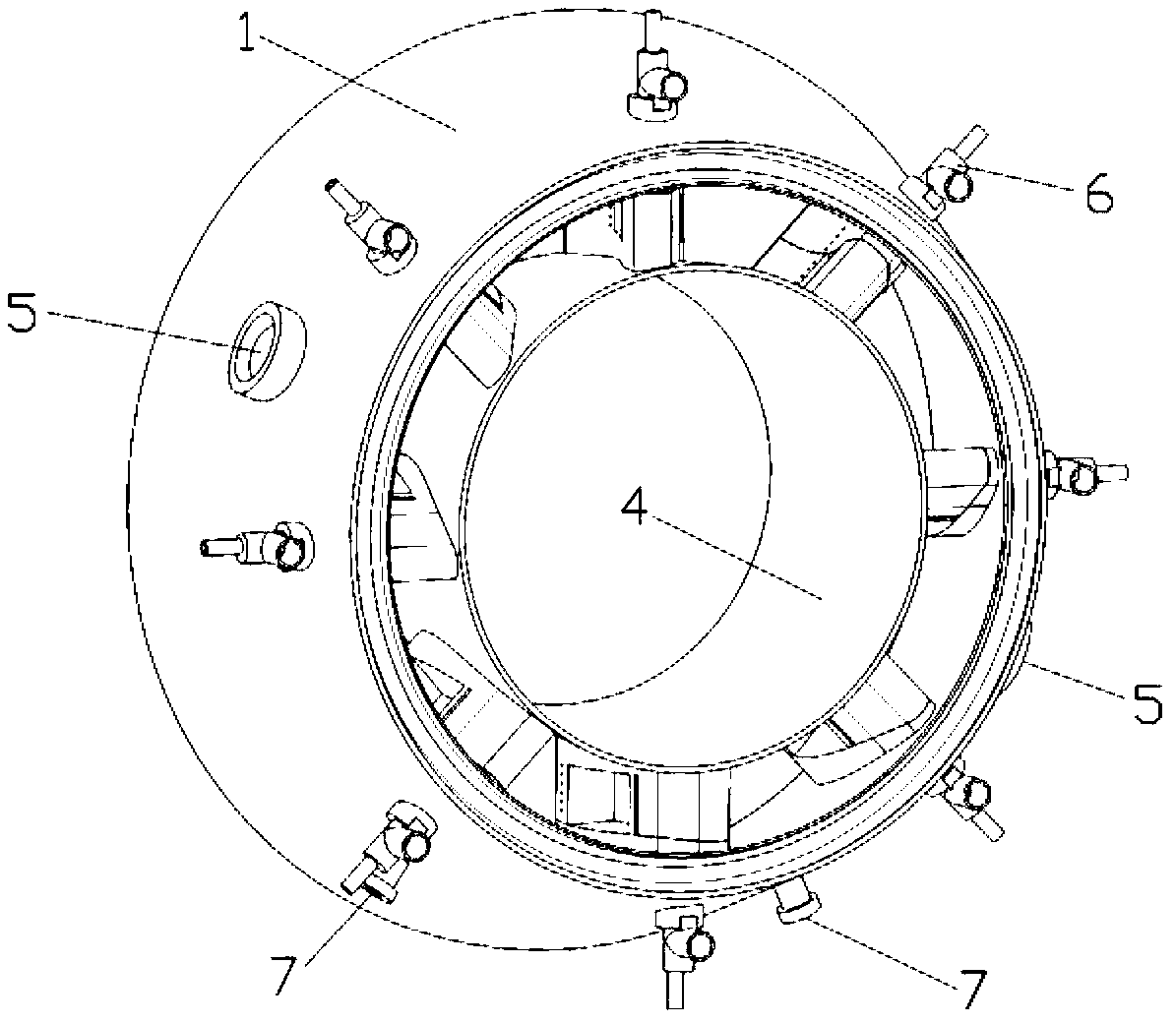

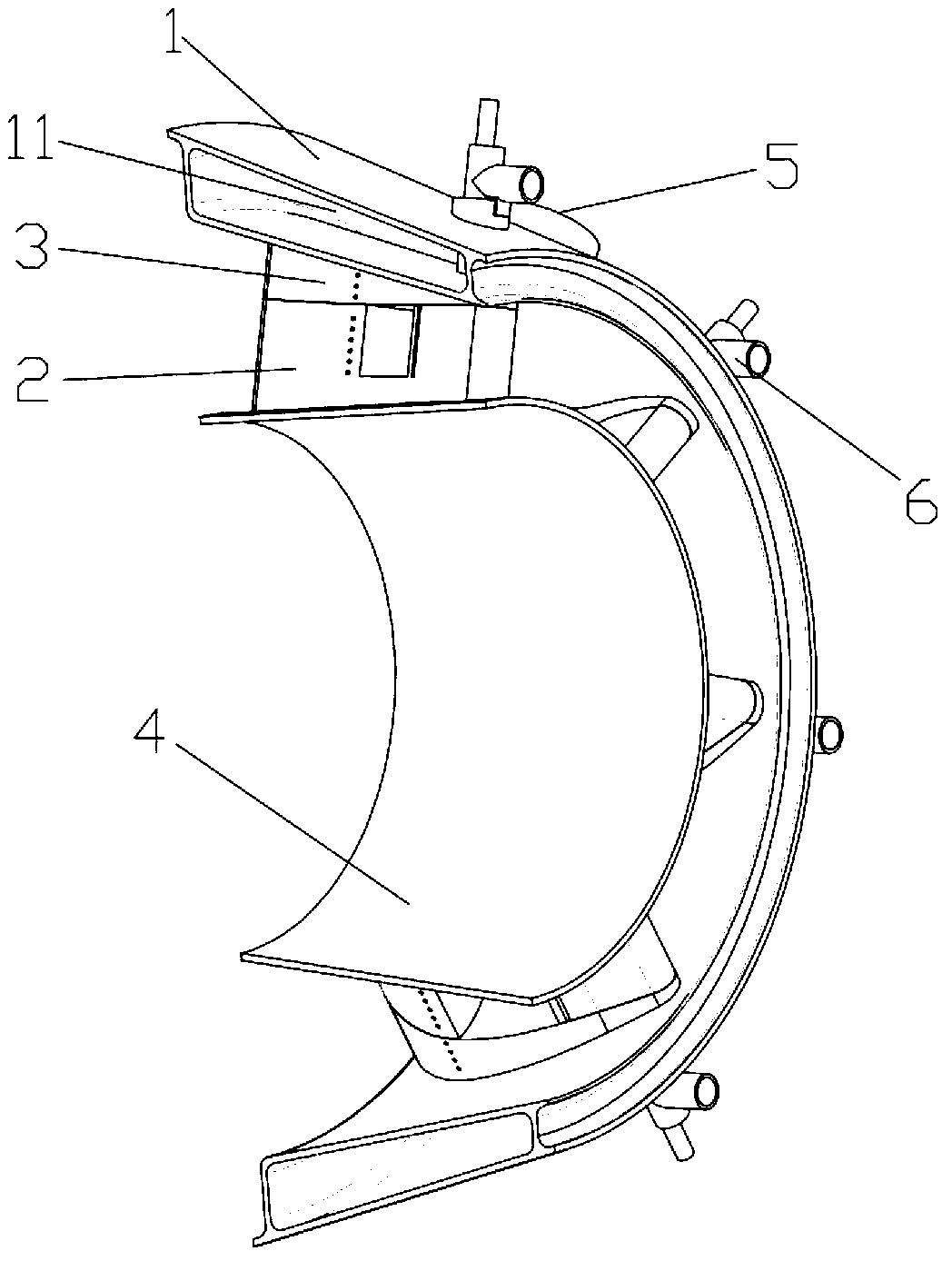

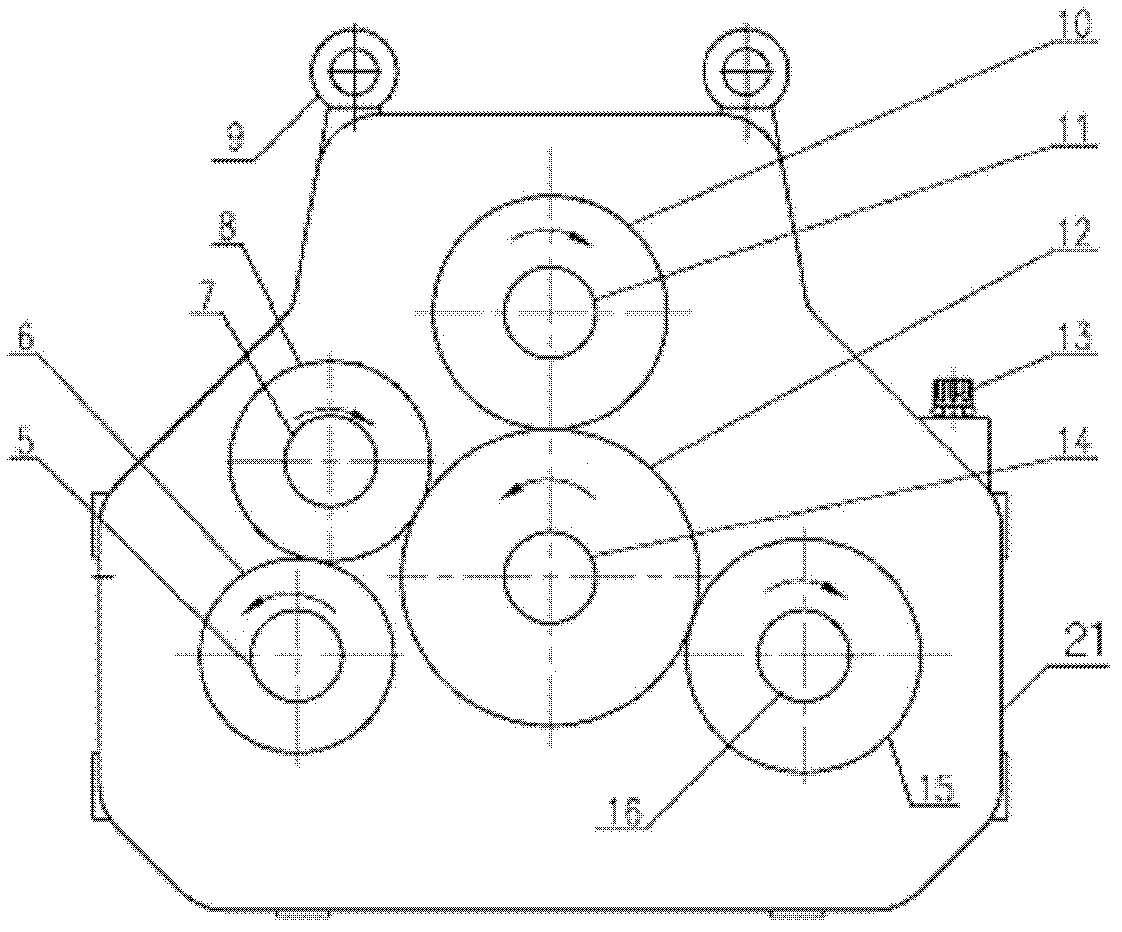

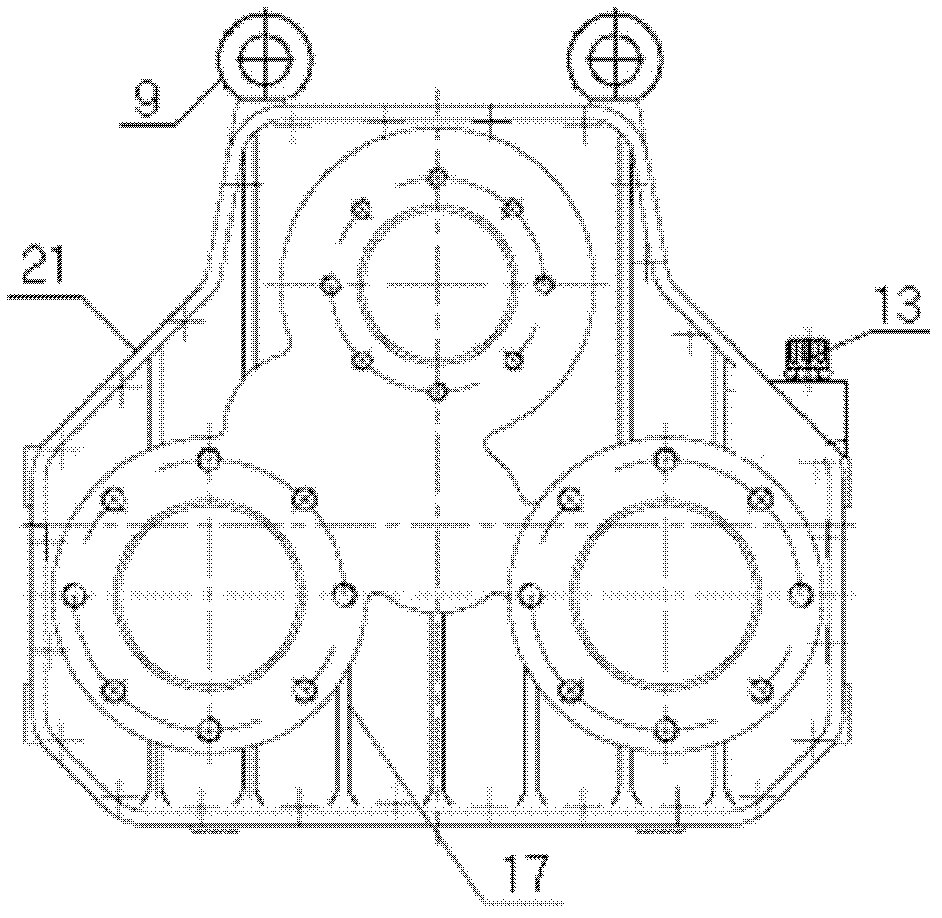

Three-degree-of-freedom permanent-magnet spherical motor

InactiveCN106877608AReduce frictionDoes not restrict exercise spaceWindingsMagnetic circuit rotating partsThree degrees of freedomStator coil

The invention relates to a three-degree-of-freedom permanent-magnet spherical motor. The three-degree-of-freedom permanent-magnet spherical motor comprises a base 4, a stator shell 6, universal balls 8, a spherical rotor body 5, an output shaft 2 and stator coils 7, wherein the stator shell 6 is fixed on the base 4, a rotor 5 is of a spherical shape and is fixedly connected with the output shaft 2, a cylindrical groove is formed in an equator position of the rotor and is used for embedding a permanent magnet, threaded holes are formed in the stator shell 6, a part of threaded holes are used for fixing the stator coils 7 by stator coil frames, the other part of threaded holes are used for fixing the stator coils 7 by combined stator coil frames 9, each combined stator coil frame 9 is in threaded connection with the universal ball 8 used for supporting the rotor, each universal ball 8 comprises a support tray 13, the support tray 13 is in threaded connection with the combined stator coil frame 9, a steel ball 14 is arranged in the support tray, and a nylon ball 15 is arranged on the steel ball 14.

Owner:TIANJIN UNIV

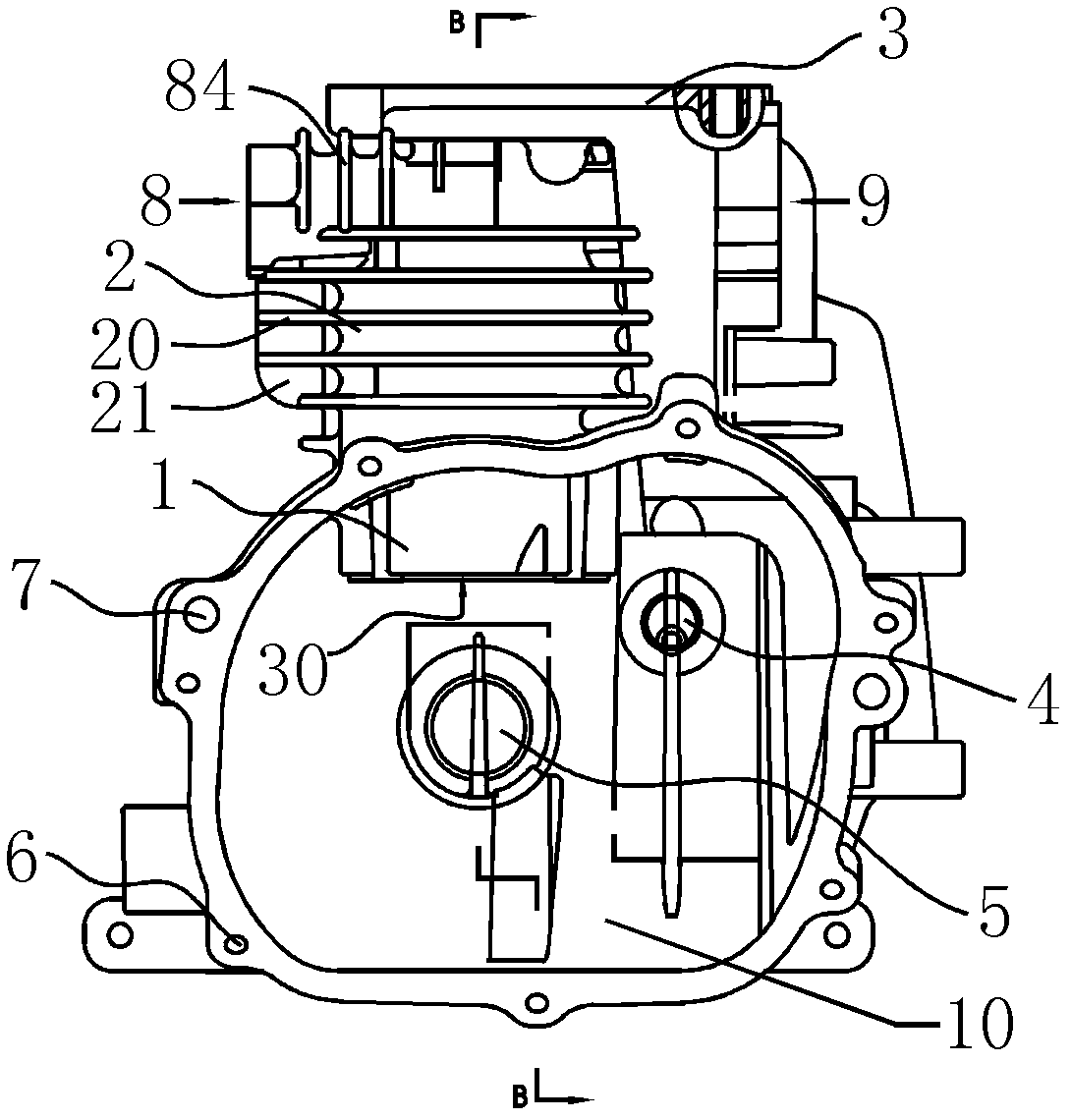

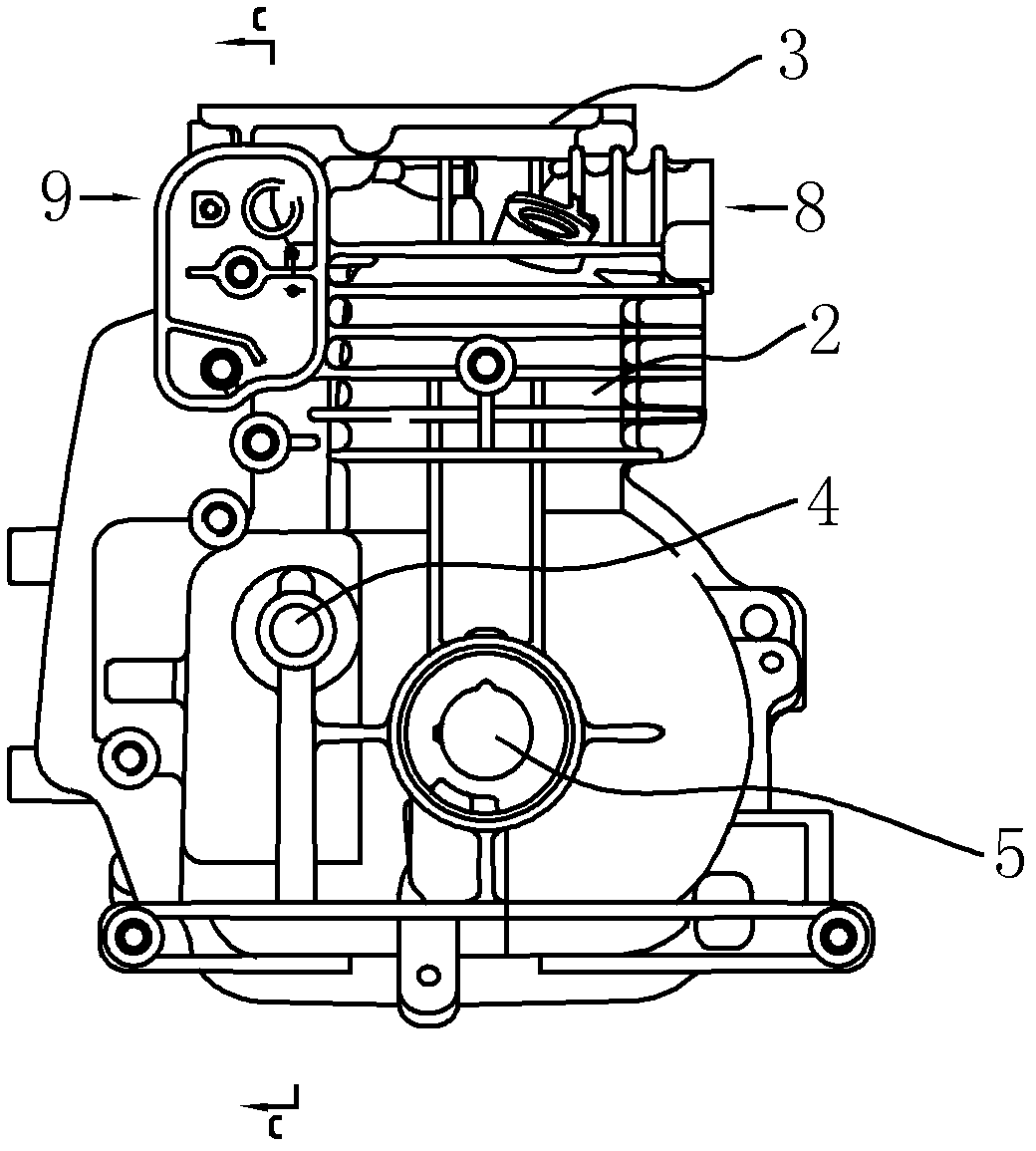

Integrated aluminum alloy tank

InactiveCN102562353AReduce intermediate connectorsLow costCasingsCylinder headsHeat sinkCylinder block

The invention relates to a general tank structure for a gasoline engine and a diesel engine, in particular to an integrated aluminum alloy tank. The integrated aluminum alloy tank comprises a cylinder body, a cylinder head, a cylinder cover and a crank chamber which are integrally formed by casting aluminum alloy materials; moreover, the cylinder head is provided with an air inlet and an air discharge port which are connected to a cylinder hole in the cylinder body respectively; the connection parts of the air inlet and the air discharge port on the cylinder hole are an inverted taper hole respectively; the large ends of the inverted taper holes are positioned on the end face of the cylinder hole; air valve push rod channels are arranged on the parts of the cylinder cover, which are opposite to the inverted taper holes; bushes are arranged in the air valve push rod channels; a stripped gating channel is formed on the outer wall of the cylinder hole and is intersected with a cooling fin on the outer wall of the cylinder hole; and a reinforcing rib is arranged on the outer wall of the air discharge port. The integrated aluminum alloy tank has novel design and a new structure, is manufactured by a new process, meets the requirements of energy saving and emission reduction and reduces manufacturing and assembly cost.

Owner:重庆三华工业有限公司

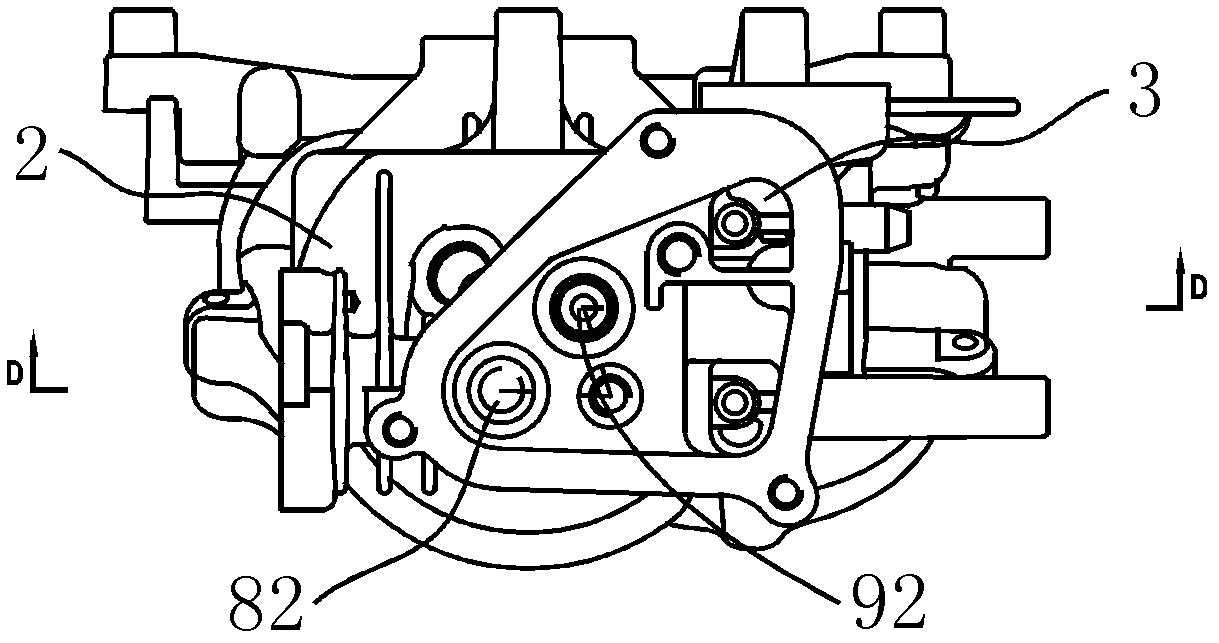

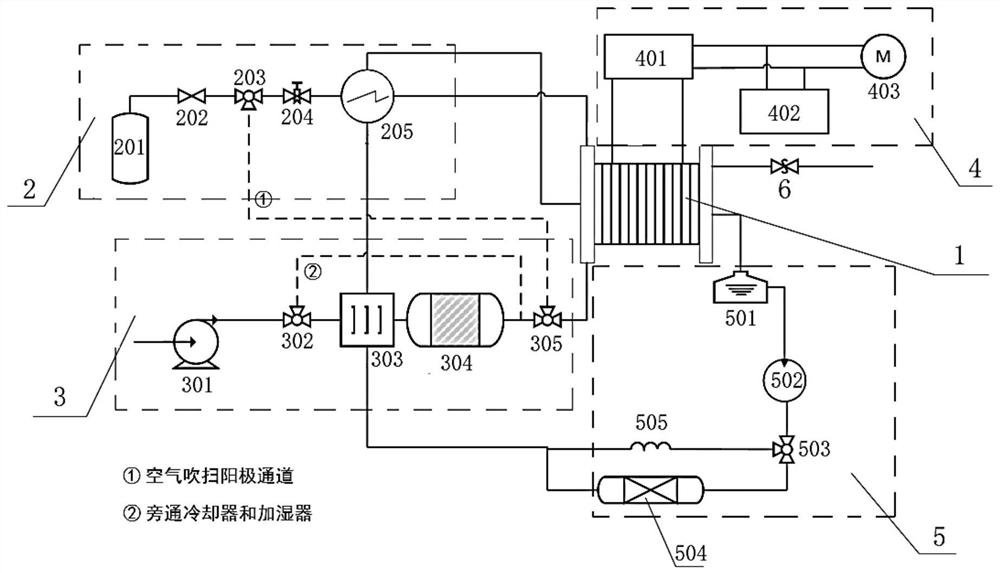

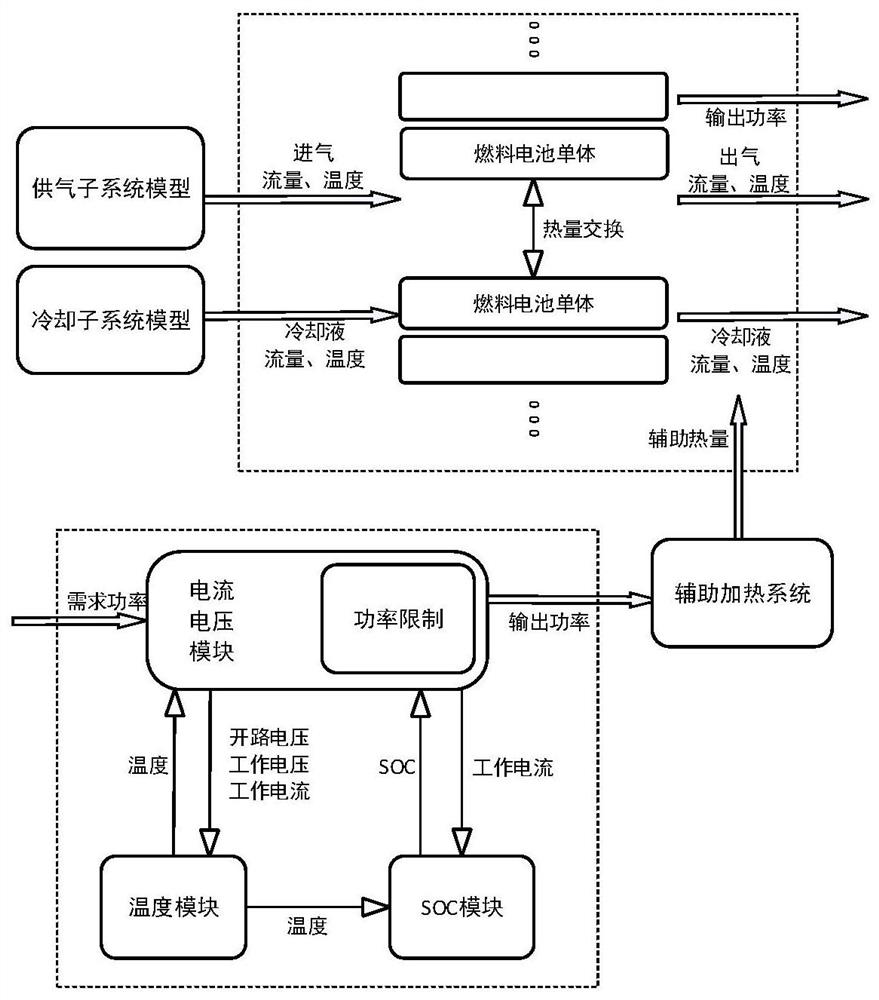

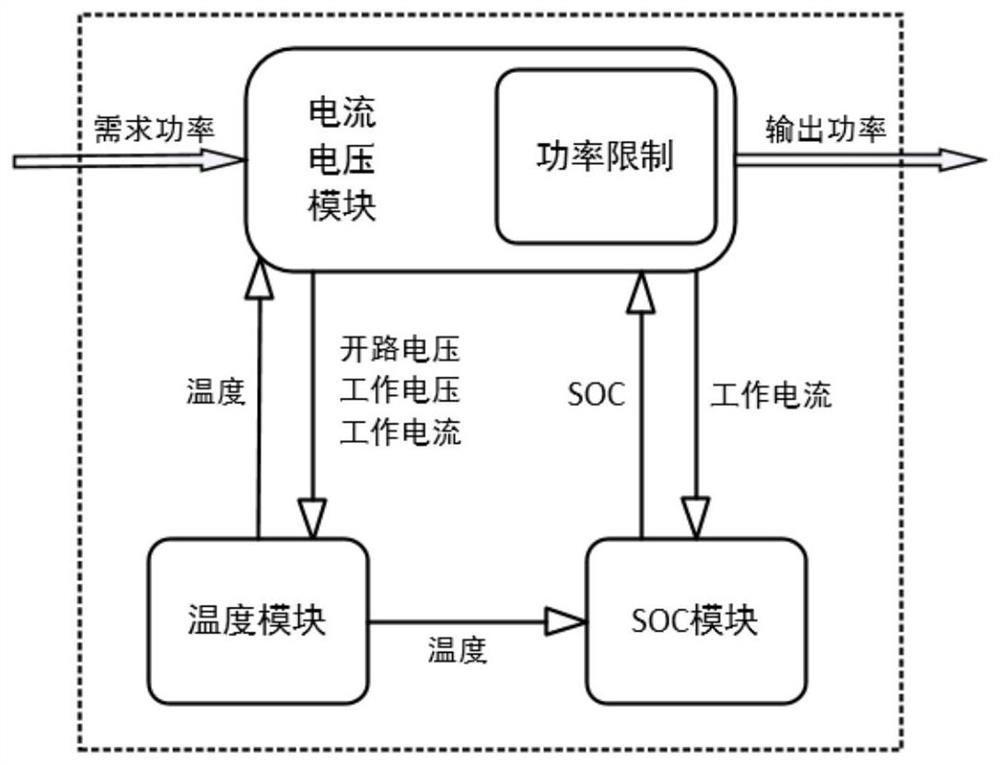

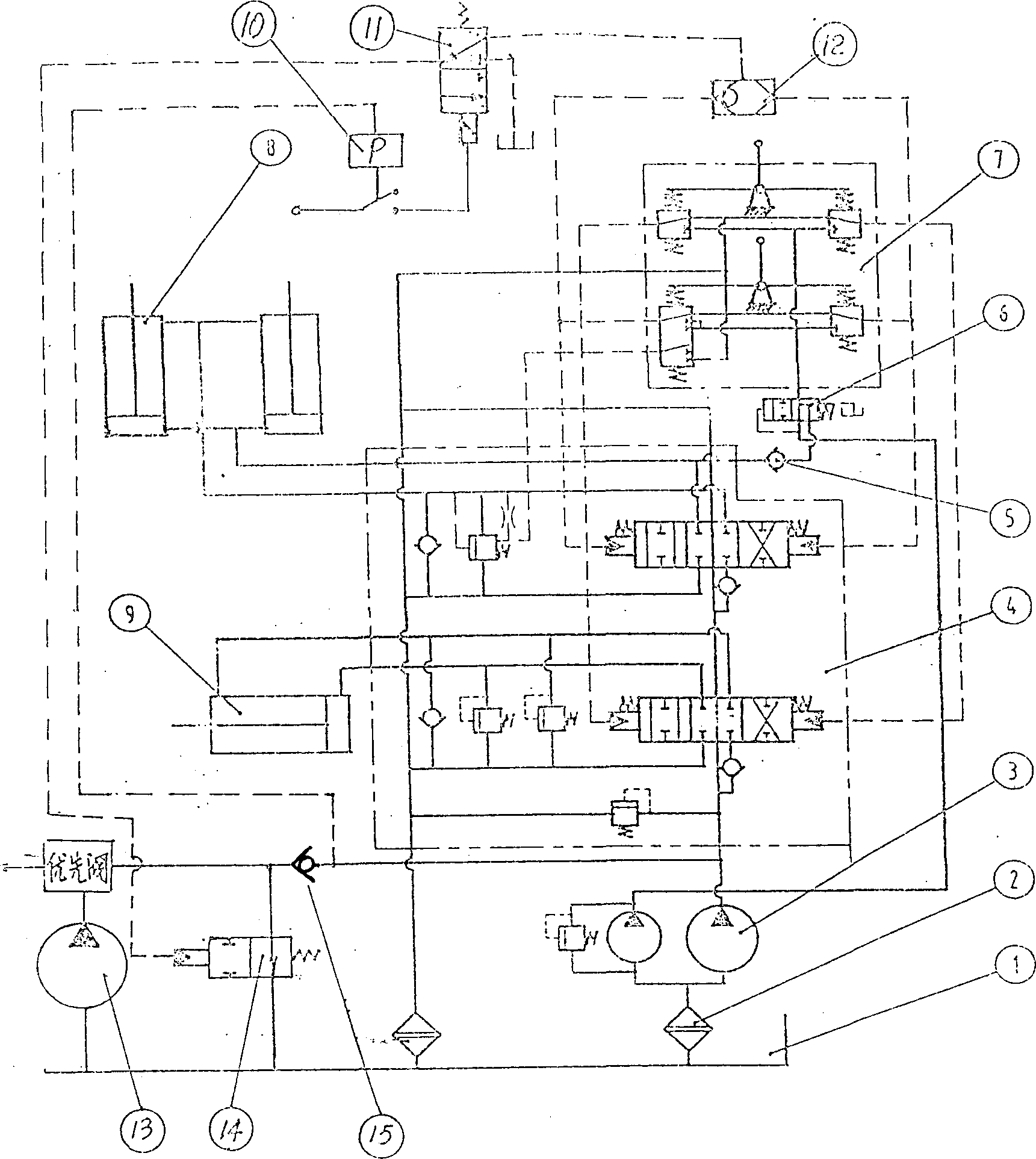

Fuel cell hybrid power supply system suitable for cold start and modeling method thereof

PendingCN112072138AAccelerate the temperature rise processImprove temperature riseFuel cell heat exchangeFuel cell controlElectrical batteryProcess engineering

The invention relates to a fuel cell hybrid power supply system suitable for cold start and a modeling method thereof. The system is additionally provided with a channel allowing cathode air to reachan anode, a channel bypassing an air cooler and a humidifier, and a heating resistor. According to the modeling method, a gas supply subsystem model, a cooling subsystem model, a storage battery low-temperature model, a fuel cell monomer model and a fuel cell stack model are separately established; and the phenomena of water generation, phase change, ice accumulation, transfer and the like in thelow-temperature starting process of a fuel cell are taken into consideration in the fuel cell monomer model, so the accuracy of the model is guaranteed . Compared with the prior art, all the parts inthe fuel cell are modeled respectively, and mass and heat transfer among all the layers is solved, so temperature distribution difference among all the layers of the cell can be reflected, the outputperformance of the fuel cell in the low-temperature starting process can be better predicted, and the accuracy and application value of the model are improved.

Owner:TONGJI UNIV

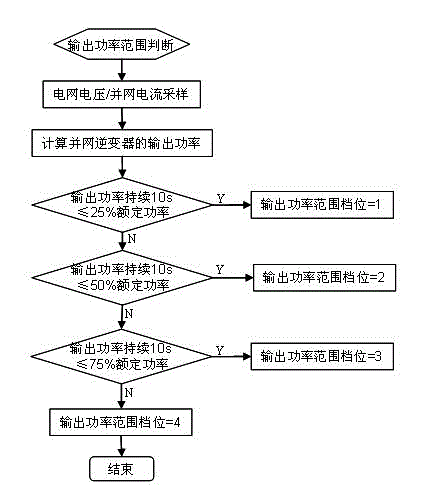

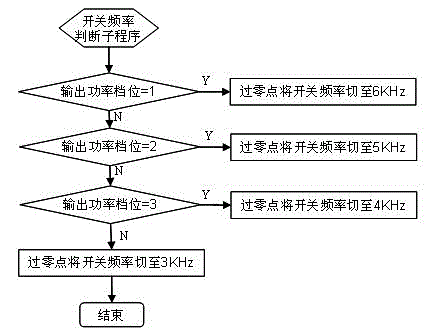

Method for improving grid-connected performance by variable switching frequency

ActiveCN102751742AReduce switching frequencyReduce pollutionSingle network parallel feeding arrangementsGrid-tie inverterHarmonic

The invention discloses a method for improving grid-connected performance by variable switching frequency. The method comprises the following steps of calculating the output power value of a grid-connected inverter by detecting the voltage value of a grid and the grid-connected current value of the grid-connected inverter in real time; and dynamically adjusting the switching frequency value of a power switching tube of the grid-connected inverter according to the output power value of the grid-connected inverter. With the adoption of the method for adjusting the switching frequency of the power switching tube, the problem that the grid-connected current harmonics are bad in case that the output power of the grid-connected inverter is smaller is solved and the pollution to the grid is reduced. Meanwhile the method has the advantages of improving the inversion frequency in case that the output power of the grid-connected inverter is larger, reducing the size of an LC filter, decreasing the cost, improving the temperature rise, and enhancing the system reliability.

Owner:ZHANGZHOU KEHUA ELECTRIC TECH CO LTD

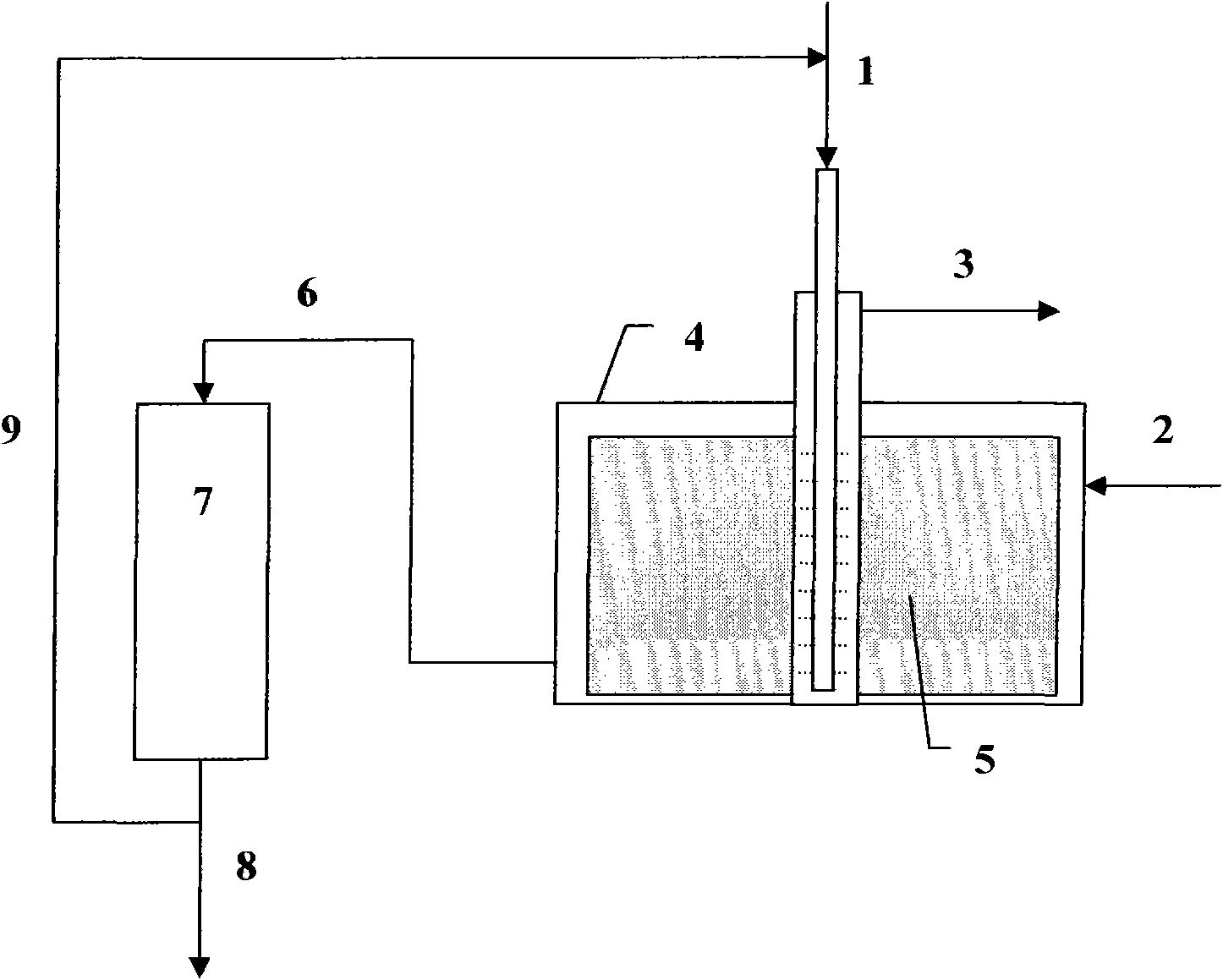

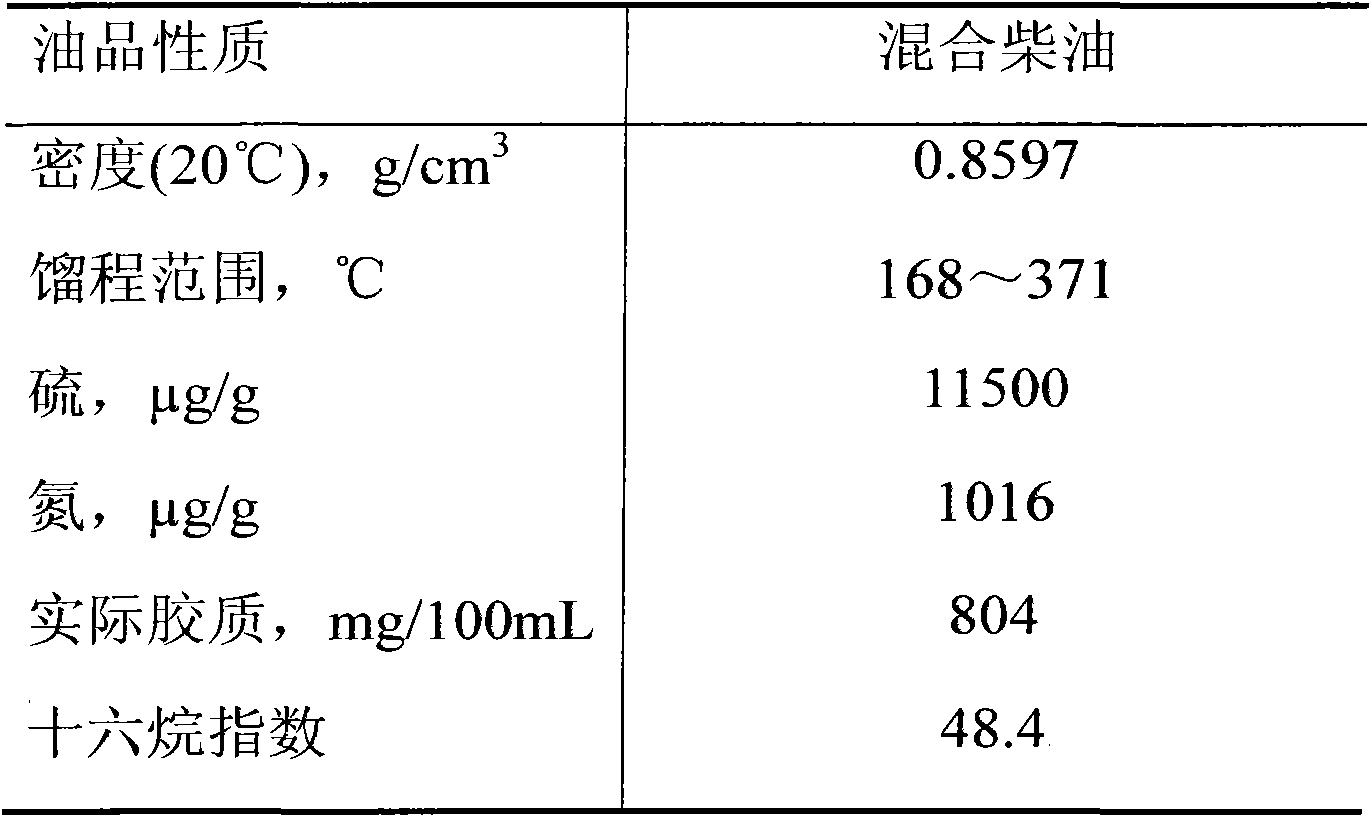

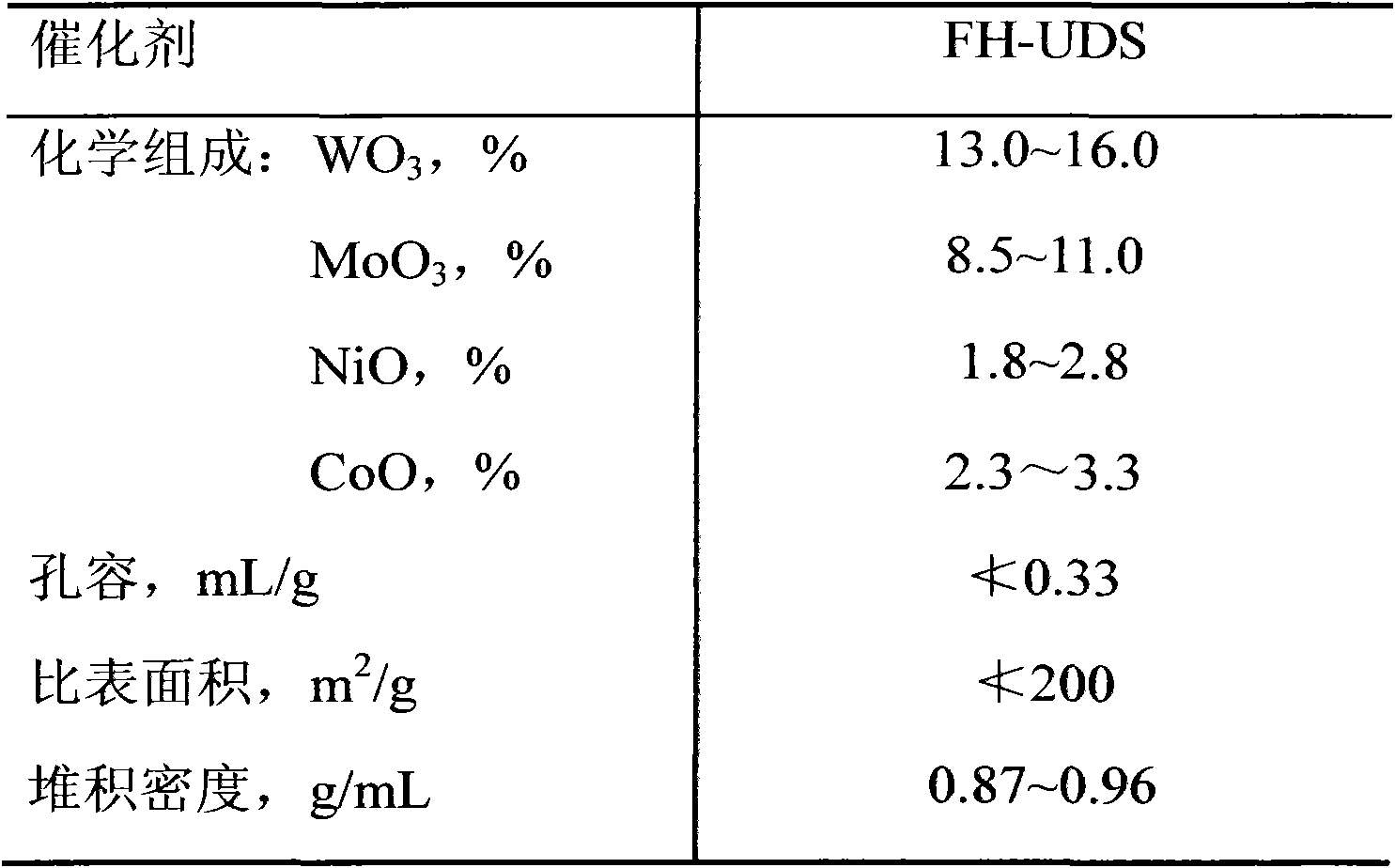

Liquid-phase circulating hydrogenation treatment method capable of reinforcing gas-liquid mass transfer

ActiveCN102311791AEasy to operateLess investmentTreatment with hydrotreatment processesHydrocarbon oils refiningHydrodesulfurizationMixed materials

The invention discloses a liquid-phase circulating hydrogenation treatment method capable of reinforcing gas-liquid mass transfer. The process flow adopted by the method comprises: part of hydrogenation circulating oil and a fresh raw material are mixed to form a liquid-phase mixed material to be filled into supergravity gas-liquid hydrogen dissolution equipment together with hydrogen; through the drive of the high-speed rotation of a feeding rotor, gas-liquid countercurrent full contact is formed; the mixed liquid-phase material in which hydrogen is dissolved is discharge out from the bottom of the supergravity gas-liquid hydrogen dissolution equipment and contacted with a catalyst to undergo a hydrogenation reaction, and part of a liquid phase obtained after reaction is circulated. Compared with the prior art, the method has the advantages that: the rotation of the feeding rotor in the gas-liquid hydrogen dissolution equipment forms a supergravity field, so the gas-liquid mass transfer efficiency is increased greatly, and the liquid phase material can fully dissolve hydrogen; meanwhile, gas impurities such as H2S and NH3 in a reaction system can be removed efficiently, so that the hydrodesulfurization, denitrification, aromatic saturation, cracking and other reactions are promoted.

Owner:CHINA PETROLEUM & CHEM CORP +1

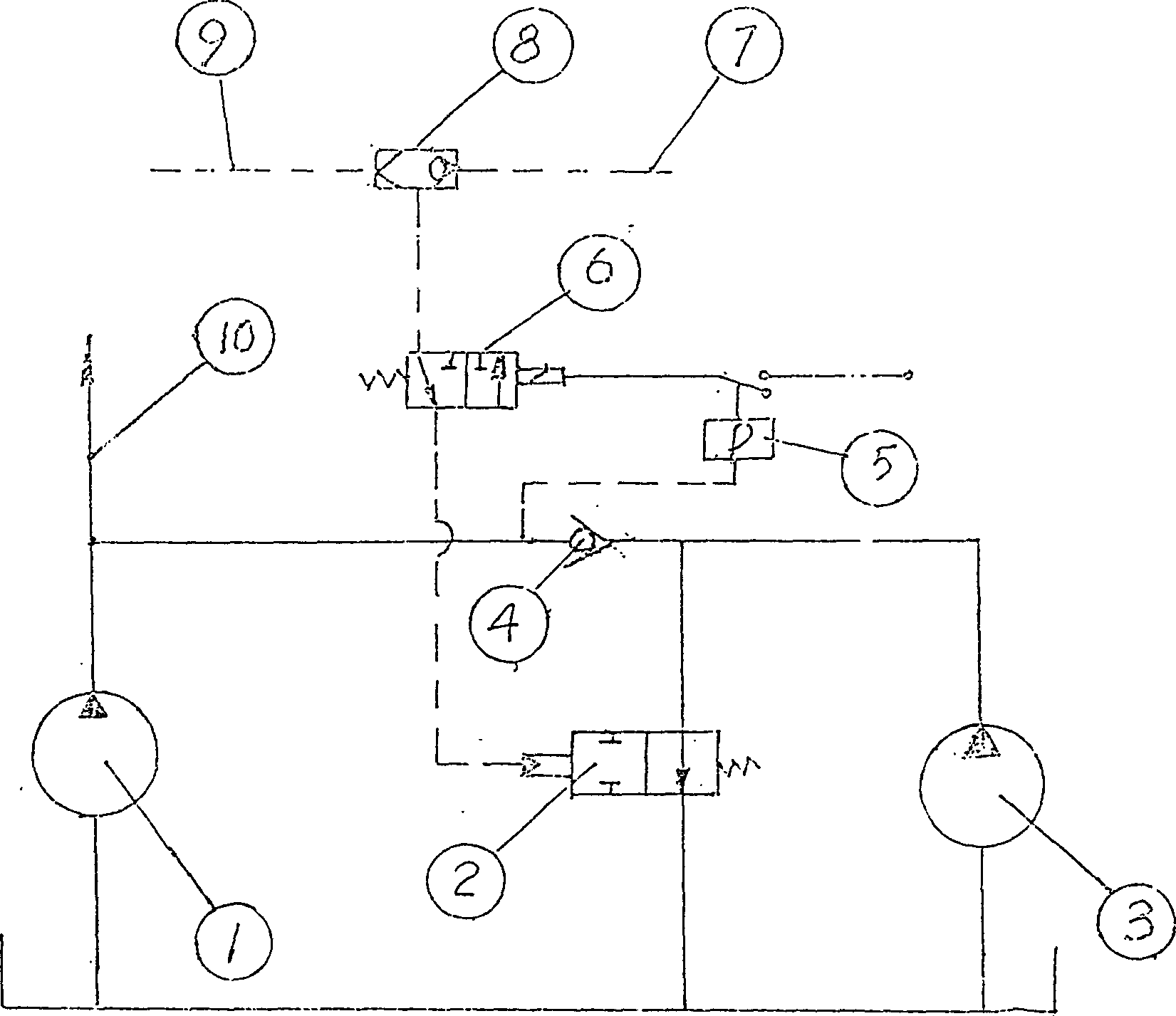

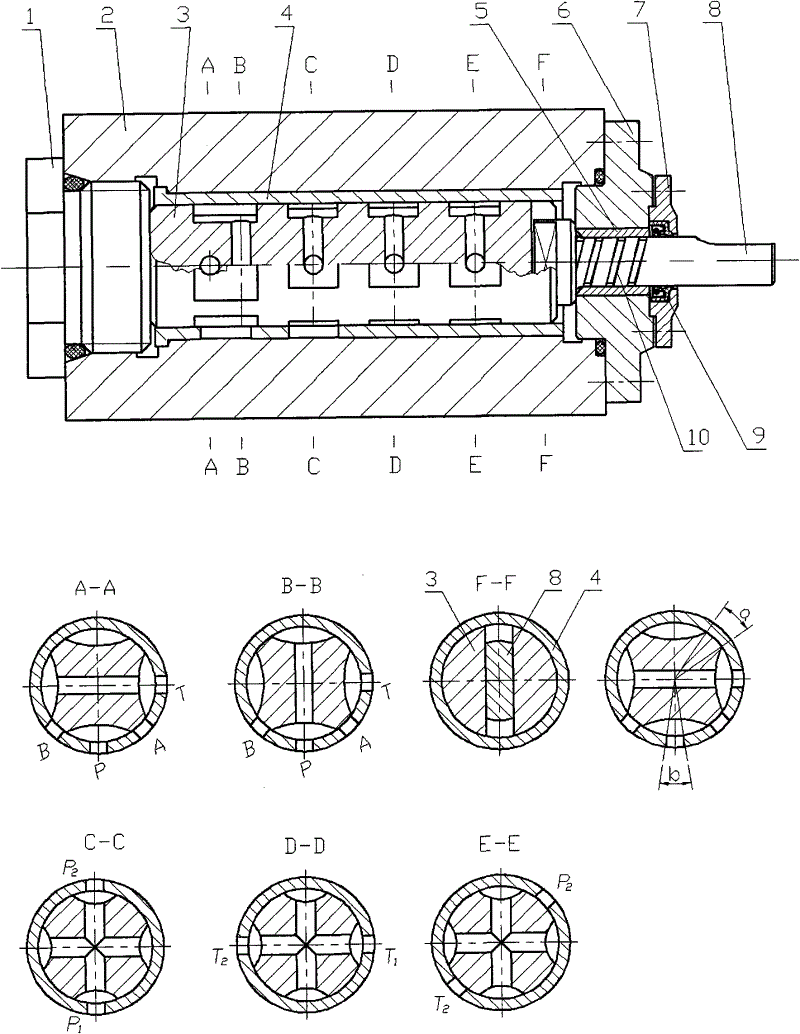

Current associating and unloading control method for multiple-pump hydraulic system

InactiveCN1432739AImplement class variablesReduce hydraulic powerServomotor componentsEngineeringMechanical engineering

The present invention relates to current association and unloading control method for multiple-pump hydraulic system, especially for loading machine and other heavy mechanical apparatus. The present invention uses hydraulically controlled change valve as current associating and unloading control element for multiple-pump hydraulic system, unlike available systems, which has unloading valve. Thus,the current associating and shutting of the pumps may be controlled at will to lower the power consumption and heat producing amount, raise the reliability of element and system and lower cost.

Owner:陈嘉川

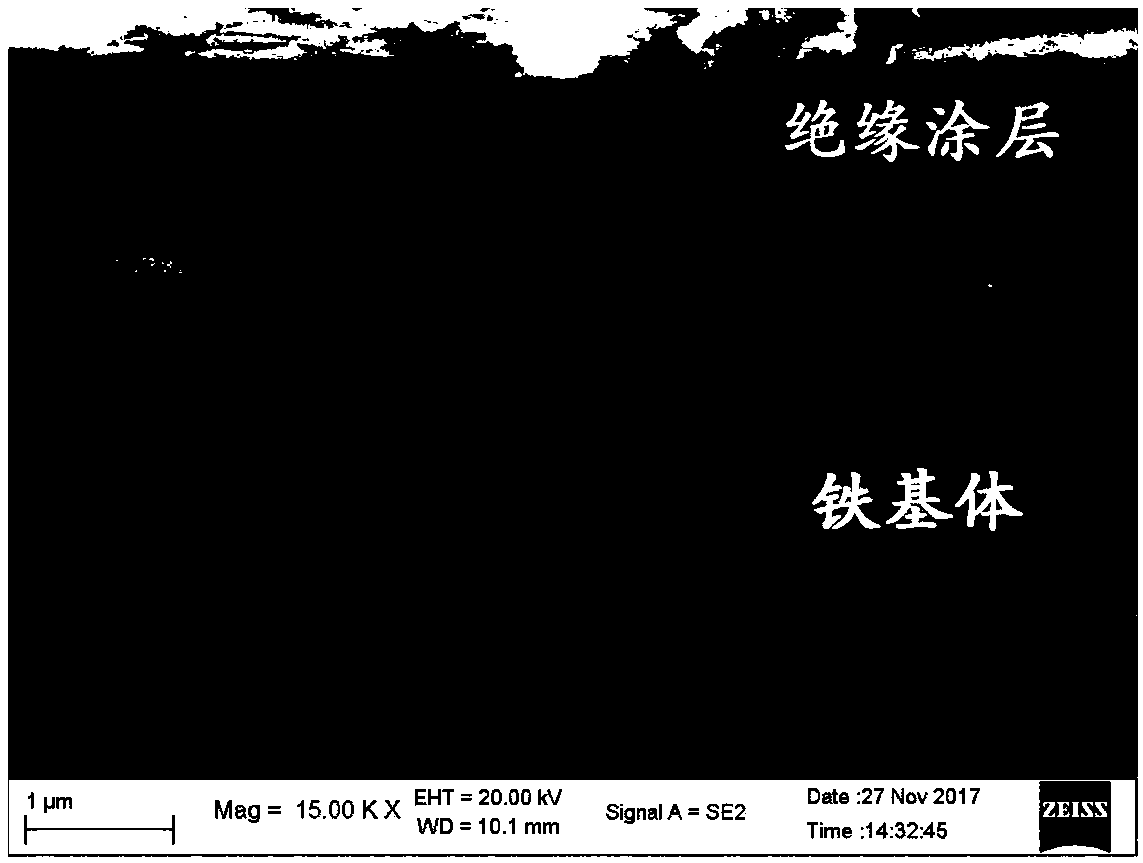

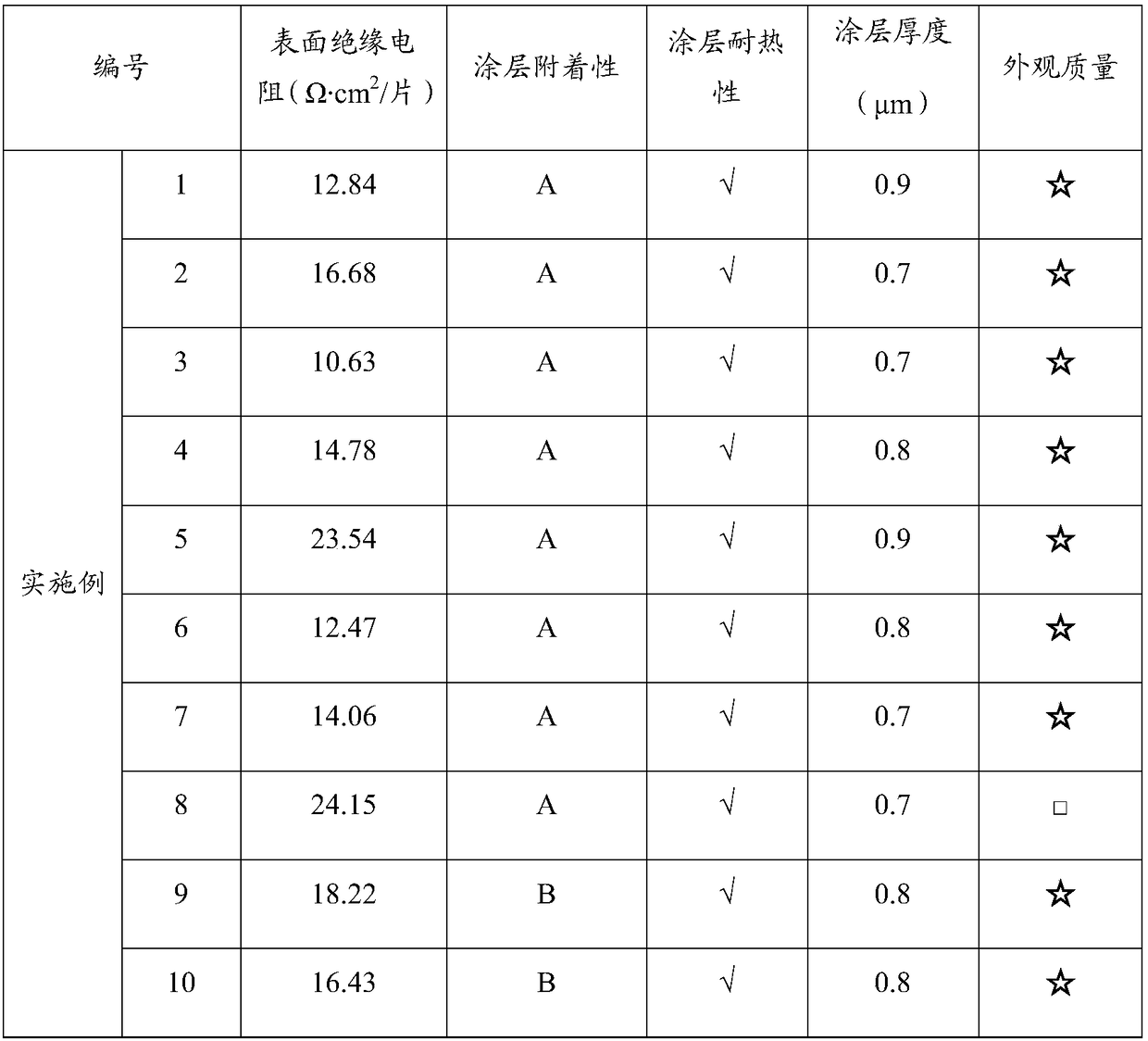

Ultra-thin silicon steel surface insulating coating and preparation method thereof

ActiveCN108659584AGood adhesionHigh insulation resistanceFireproof paintsMonomagnesium phosphatePhosphate

The invention belongs to the technical field of coating compositions, in particular to an ultra-thin silicon steel surface insulating coating and a preparation method thereof. The insulating coating provided by the invention is prepared from the following components: 65 to 85 parts of magnesium dihydrogen phosphate, 0.1 to 1.5 parts of insulating inorganic nanoparticles, 2 to 15 parts of silica sol, 2 to 4 parts of boric acid and 1 to 32.9 parts of deionized water. The coating formed by synergistic effects of all the components has excellent adhesion property to the surface of a bare steel sheet of ultra-thin silicon steel, and meanwhile, the insulation performance is ensured. The insulating coating provided by the invention is also prepared from 0.01 to 5 parts by weight of organic resin;by the addition of the organic resin, the adhesion of the ultra-thin silicon steel surface coating can be improved and subsequent high temperature sintering can be resisted, so that the ultra-thin silicon steel with the coating can be suitable for preparing a roll core of a saturation reactor, and further complex operating conditions such as strong vibration and high temperature rise of high pressure anode saturation reactors are met.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

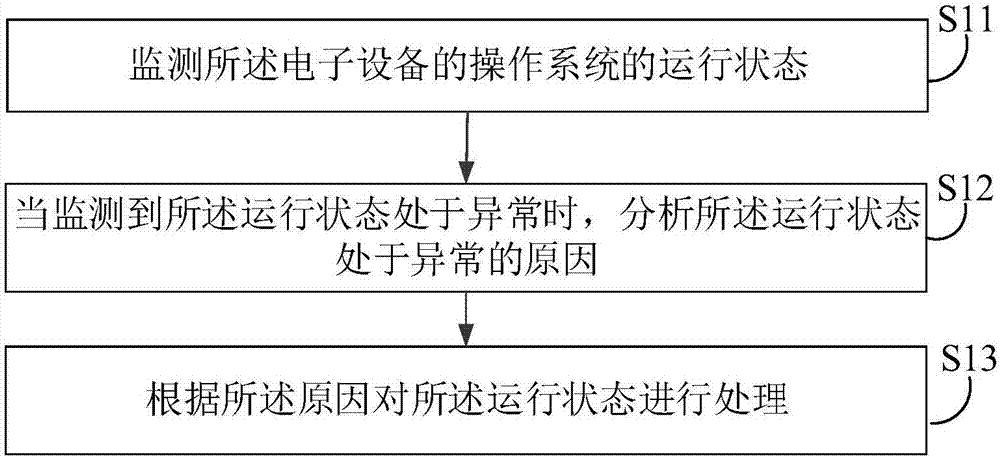

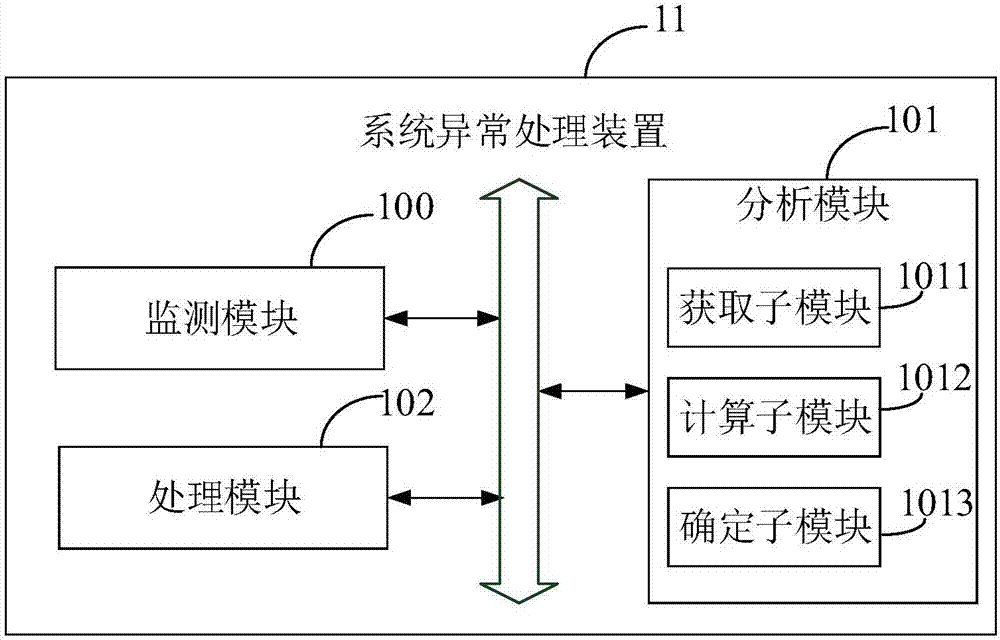

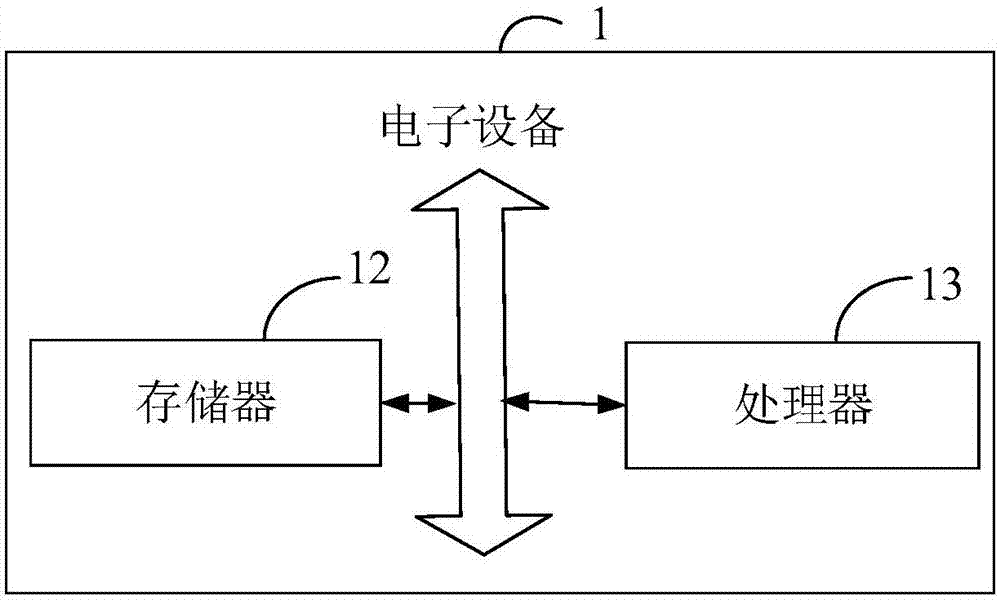

System abnormality processing method and device

InactiveCN106933677AImprove experienceImprove temperature riseResource allocationHardware monitoringOperational systemComputer science

A system abnormality processing method is applied to electronic equipment. The method comprises the steps of monitoring a running state of an operation system of the electronic equipment; when the running state is monitored in an abnormal state, analyzing the cause of the running state in the abnormal state; and processing the running state according to the cause. The invention also provides a system abnormality processing device. According to the system abnormality processing method and the system abnormality processing device, the problems of temperature rise and lagging of the operation system can be solved and the user experience is improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

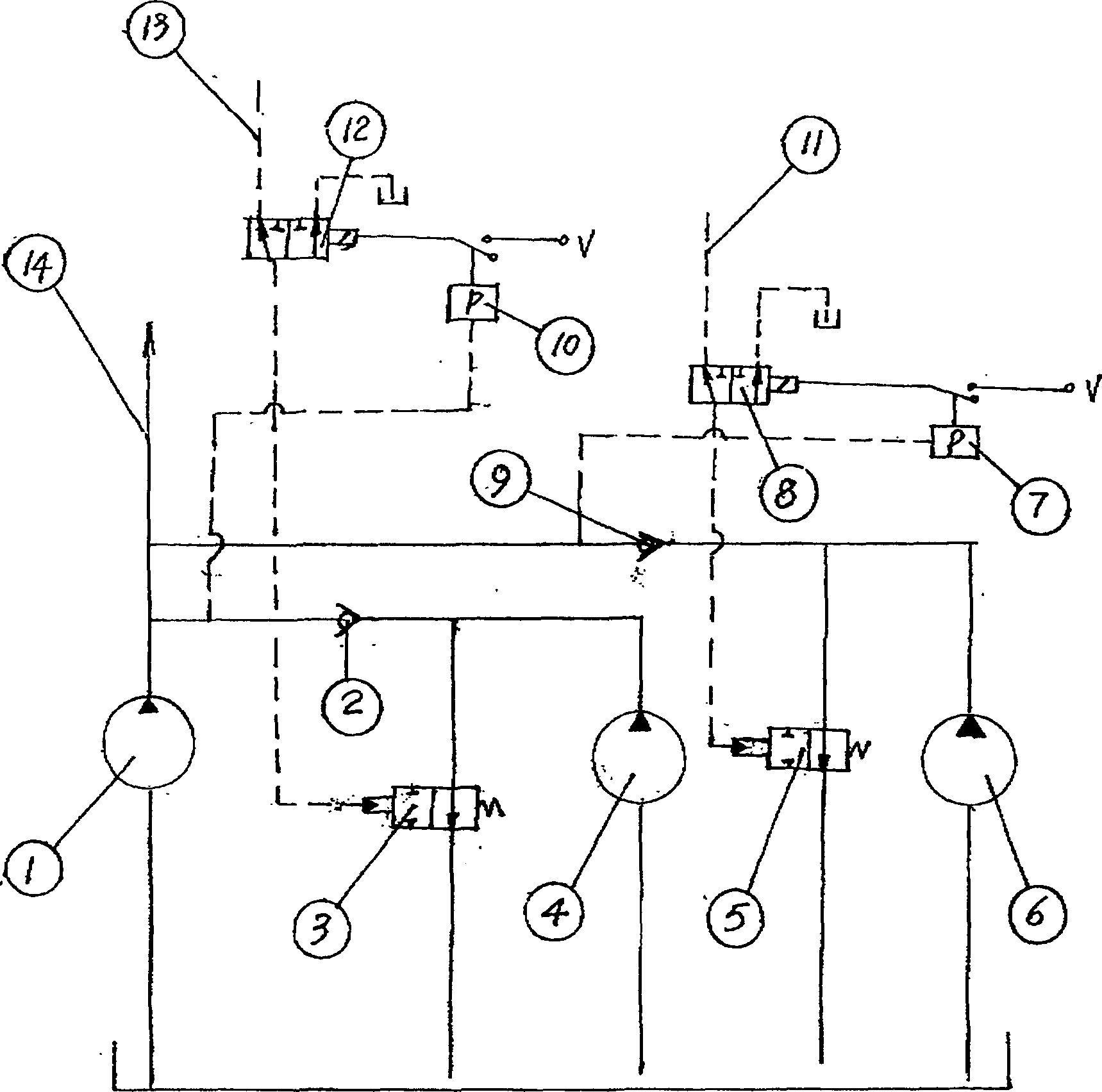

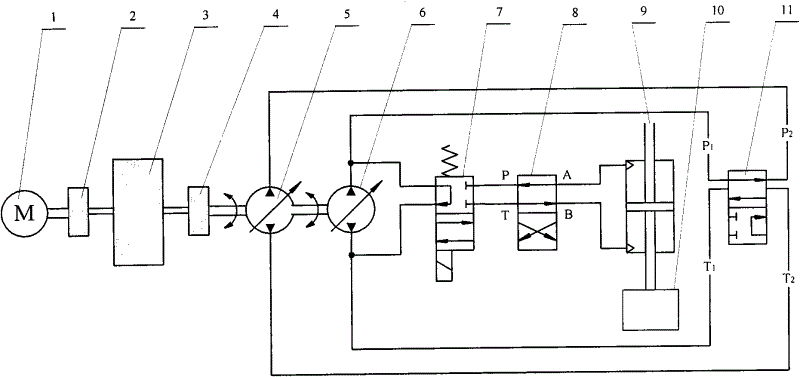

Flywheel energy-accumulating energy-saving-type hydraulic vibration system

ActiveCN102619817AImprove temperature riseHigh energy consumptionFluid-pressure actuator componentsHydraulic cylinderFluid coupling

The invention discloses a flywheel energy-accumulating energy-saving-type hydraulic vibration system, and belongs to the technical field of hydraulic vibration. In the system, a motor is connected with a flywheel through a hydraulic coupler; the flywheel is connected with a double hydraulic pump through an elastic coupling; the hydraulic pump and a hydraulic cylinder form an enclosed-type loop through a hydraulic valve; the hydraulic cylinder is connected with a vibration body, wherein the double pump has two working conditions of double-pump operation and single-pump operation; and when in double-pump operation, the output flow rate of the pump is increased, the hydraulic cylinder and the vibration body accelerate, and when in single-pump operation, the flow rate of the pump is decreased, the hydraulic cylinder drives the hydraulic pump depending on inertia to drive the flywheel to speed up, and the vibration body slows down. The flywheel energy-accumulating energy-saving-type hydraulic vibration system provided by the invention has the characteristics that the variation of the vibration body momentum is mainly realized through the momentum exchange between the flywheel and the vibration body. The momentum exchange is reversible and has no real power consumption, thus the flywheel energy-accumulating energy-saving-type hydraulic vibration system saves energy compared with the existing throttling speed-regulating-type hydraulic vibration system.

Owner:淮安市清江浦区市场监管综合服务中心

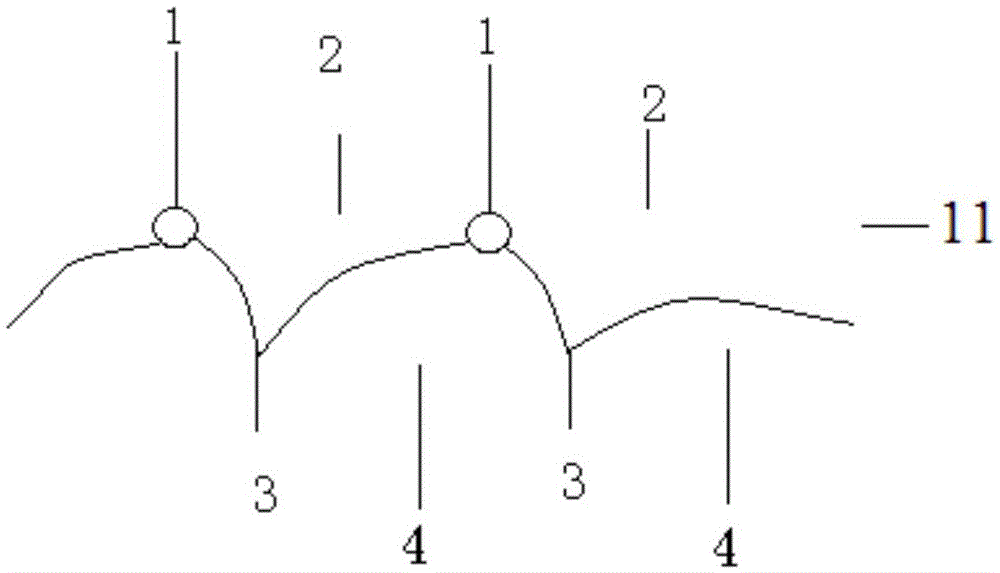

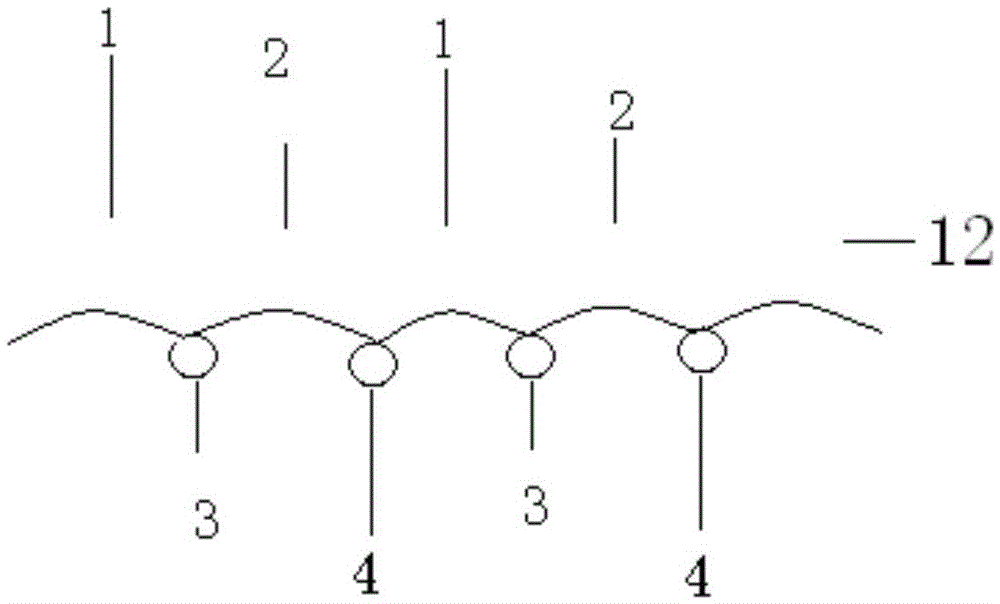

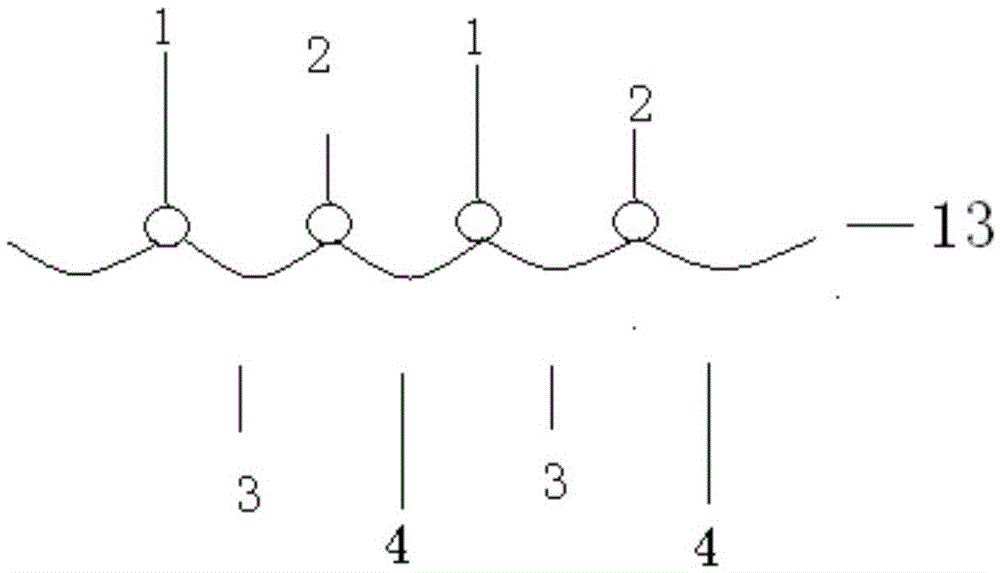

Hodo fleece fabric with far infrared heating function

ActiveCN105420901ALight textureImprove temperature riseWeft knittingOrnamental textile articlesYarnEngineering

The invention relates to Hodo fleece fabric with a far infrared heating function. The fabric is knitted by a double-side weft knitting machine, a second yarn line and a fifth yarn line are treated with far infrared nano-mineral finishing liquid before knitting, a fourth yarn line forms loops with purl of the upper dial, does not form loops with knit of the upper dial and does not form loops with knit of a lower work drum in a knitting process, knitted fabric is treated with sanding and napping processes, and the Hodo fleece fabric with the far infrared heating function is obtained. The prepared fabric is light and elastic, the far infrared heating efficiency is higher than 0.88% and the far infrared irradiation temperature rise is 2.4 DEG C.

Owner:无锡红豆纺织服装有限公司

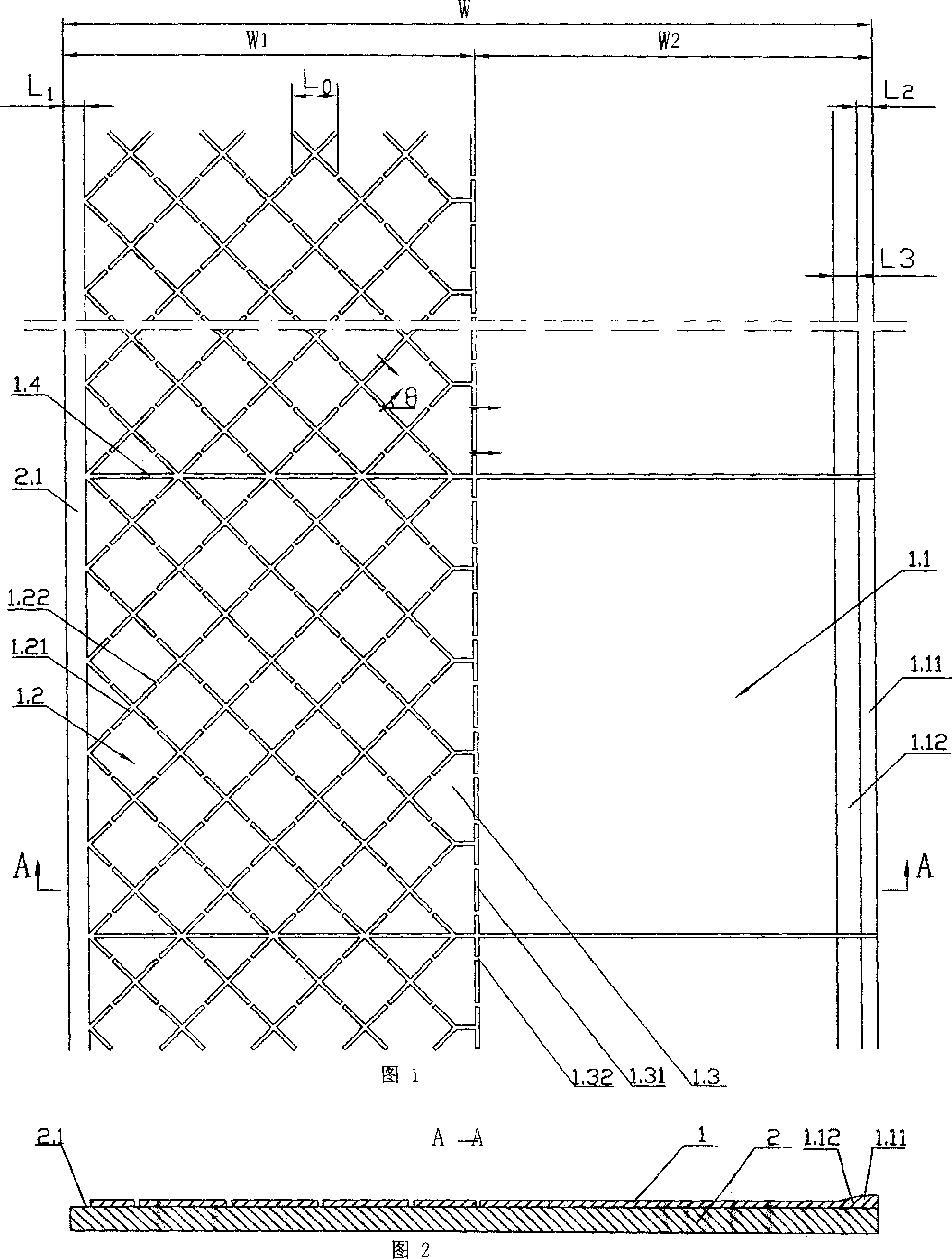

Electrode structure of power capacitor with metal metallized safety film for reducing temperature rising

ActiveCN101013629AImprove reliabilityExtend working lifeFixed capacitor electrodesPolymer capacitorEngineering

The invention relates to one power element, which is to reduce temperature lift of metal safe film capacitor electrode structure and comprises upper and down compound layers, wherein, each layer has two different electrode structures with its half as metal electrode coating layer and other half coated with safe film; the compound layers are symmetric covered with tight layers; the continuous metal electrode coating layers are processed into thick one connected with outer spray metal.

Owner:浙江南洋华诚科技有限公司

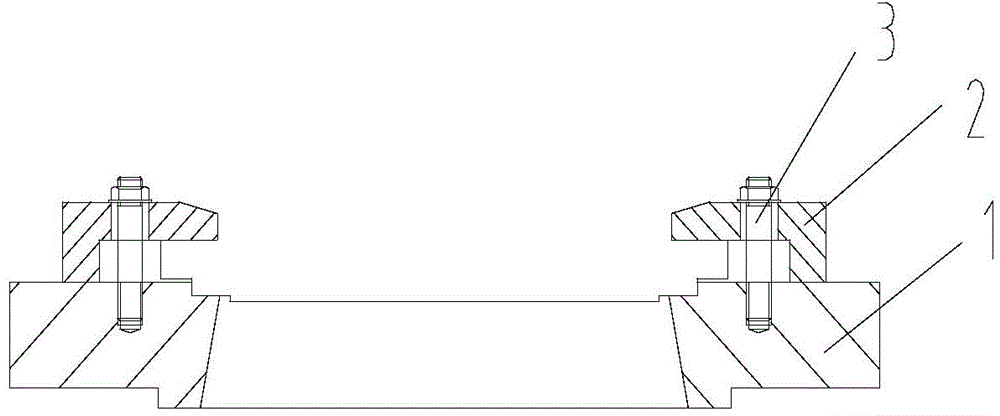

Machining device of large-capacity circuit breaker contact system

ActiveCN104816081AReduce operational riskReduce welding distortionResistance electrode holdersMetal working apparatusForcepsEngineering

The invention discloses a machining device of a large-capacity circuit breaker contact system. The machining device comprises a feeding mechanism, a clamp and a welding mechanism. A linear rail is fixedly arranged on a working table board, and the clamp is arranged on the linear rail; and the welding mechanism is vertically arranged on the inner segment of the linear rail. The machining device is small in operation error, good in operation environment, small in personnel operating risk, low in cost and capable of achieving continuous efficient work; the size control precision of operation clamp forceps is high; the welding deformation of a welding electrode is small, and the welding energy consumption losses are small; hardening of a soft connection and a touch panel is relieved, the welding quality is stable, a step plate area of a welding table is large, and assembling, current bearing capacity, touch on-off synchronization, ultimate breaking capacity, service life, temperature rising, dynamic thermal stability and use safety and performance are obvious facilitated.

Owner:嘉兴彩虹光学膜片科技有限公司

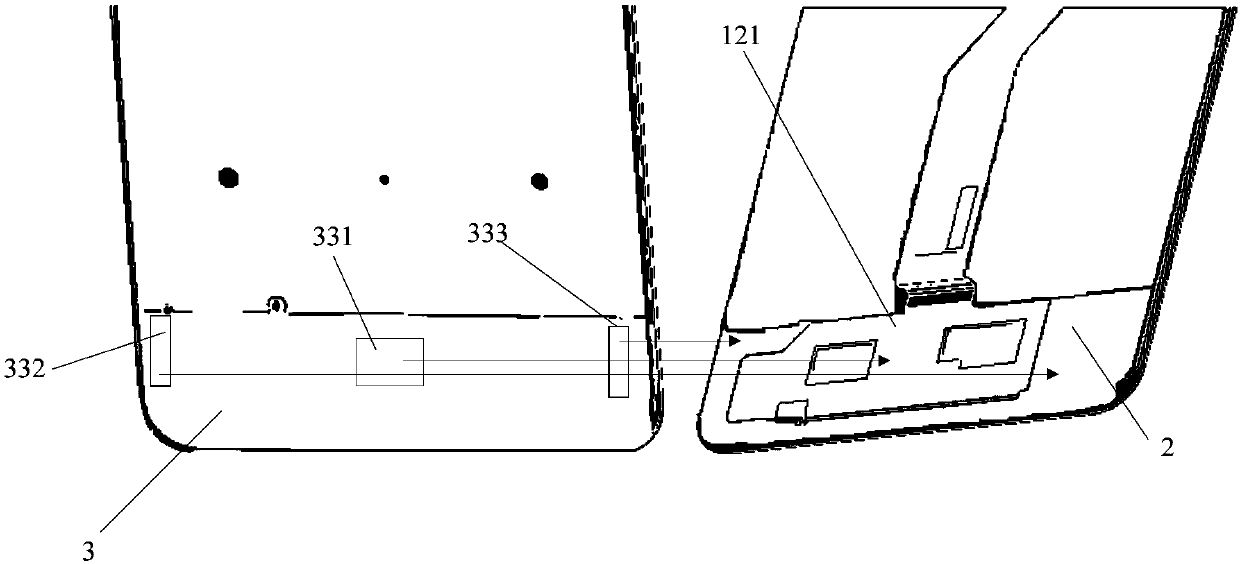

Terminal device

ActiveCN109618030AImprove temperature riseImprove cooling effectModifications by conduction heat transferTelephone set constructionsFlexible circuitsTerminal equipment

The invention provides a terminal device, comprising the following parts: a display module, comprising a display structure and a flexible circuit board; a metal structure, arranged between the displaystructure and the flexible circuit board and respectively attached to the display structure and the flexible circuit board, wherein the area of the attaching end surface of the metal structure the islarger than the area of the attaching end surface of the preset area of the flexible circuit board, and is smaller than the area of the attaching end surface of the display structure; a metal middleframe, comprising a groove and ends disposed on both sides of the groove, wherein the predetermined area of the flexible circuit board and the metal structure are disposed in the groove, and the endsare in contact with the display structure. The terminal device provided by the embodiment of the invention can reduce the stack thickness of the whole machine, provide a ground return path and excellent shielding performance, and can improve the temperature rise problem of the terminal device and improve the heat dissipation effect of the terminal device.

Owner:VIVO MOBILE COMM CO LTD

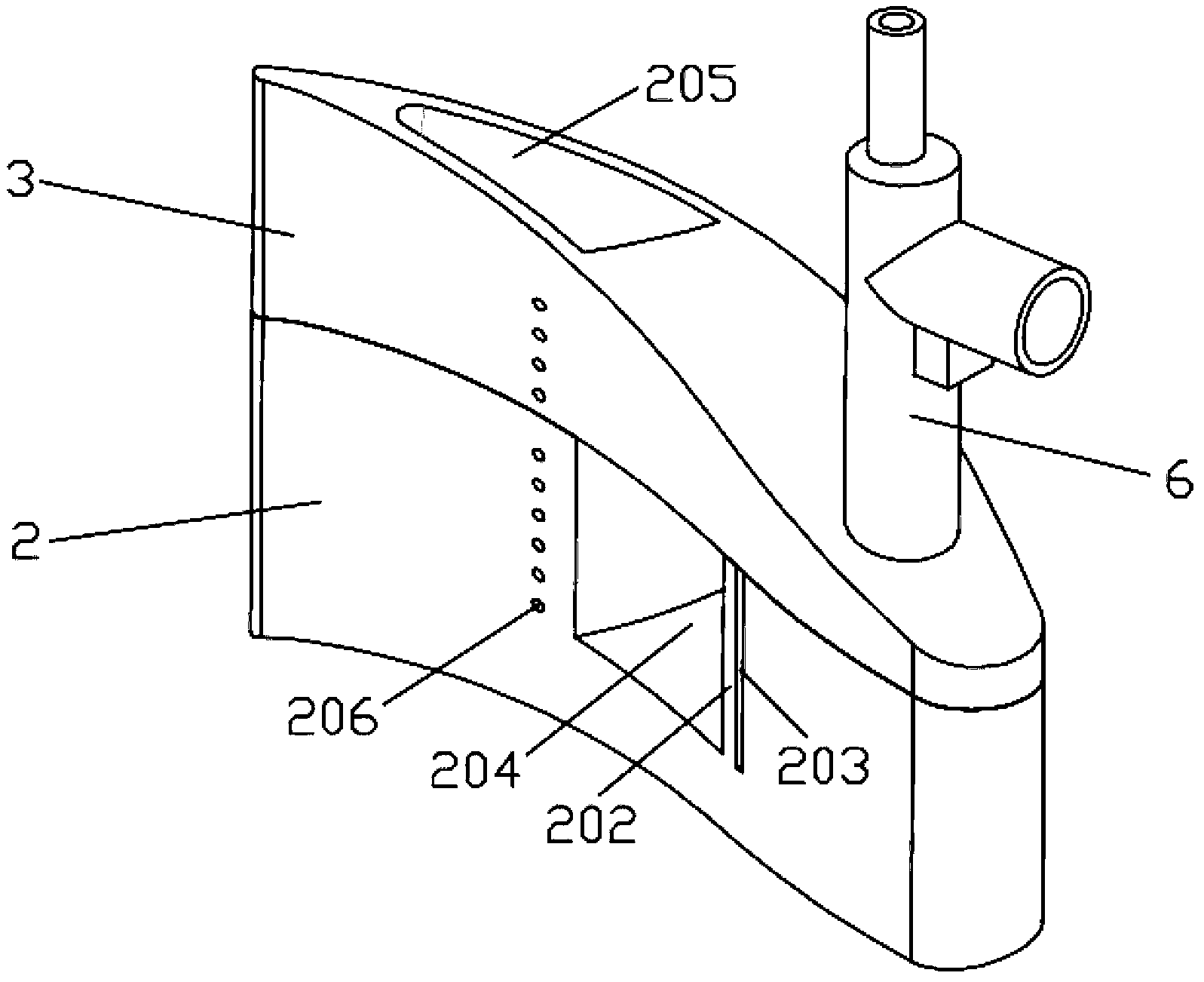

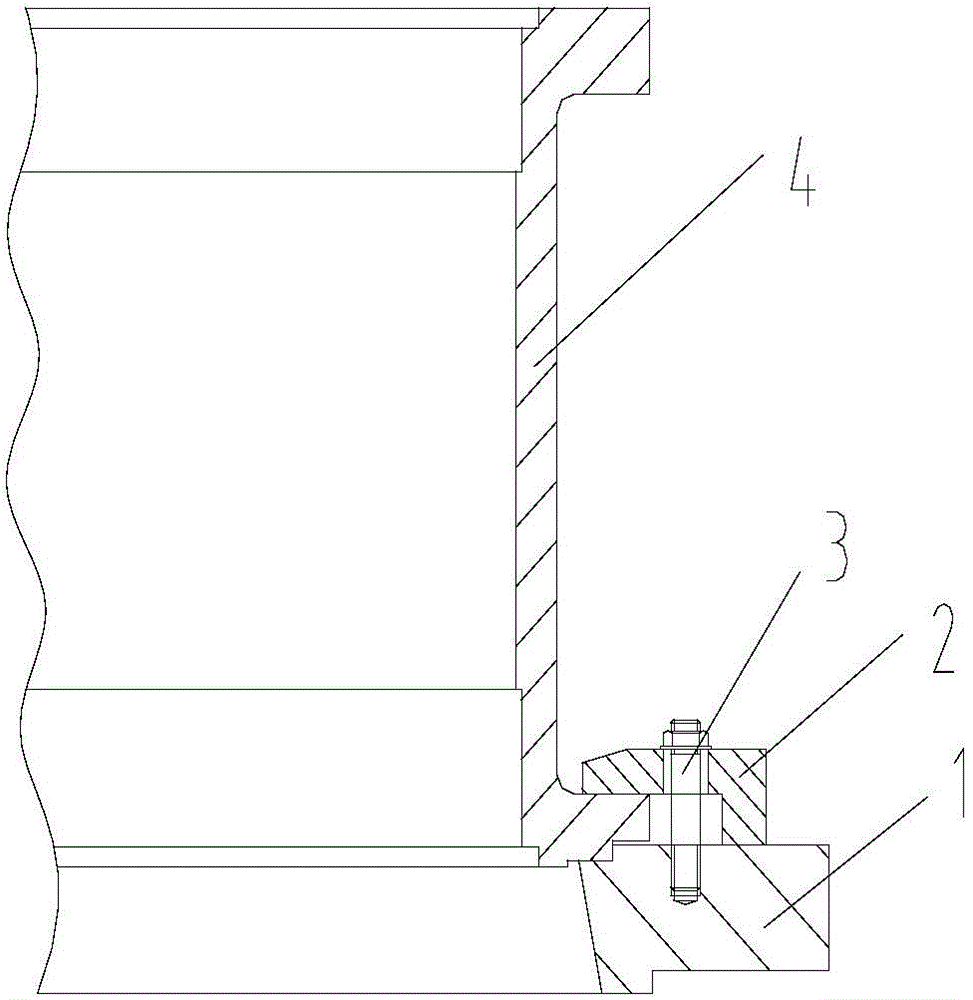

Turbine stator blade with interstage combustor

InactiveCN103266922AIncrease motivationLower blocking ratioContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

The invention discloses a turbine stator blade with an interstage combustor, and relates to turbine stator blades of aero-engines or gas turbines. The turbine stator blade comprises an inner ring, an outer ring and multiple guide blades, wherein the guide blades are provided with a guide blade main body and a guide blade cover; the guide blade cover is arranged on the upper end of the guide blade main body, and the guide blade main body is provided with a front oil injection cavity, a middle backflow cavity and a rear cooling cavity; another cooling cavity is formed at the rear of the guide blade cover, and the oil injection cavity is internally provided with a spraying rod slot; the cooling cavity of the guide blade main body and the cooling cavity of the guide blade cover respectively have cooling holes; the turbine stator blade is also provided with ignition devices and multiple spraying rod devices, and the ignition devices are provided with ignition bases and ignition electric nozzles; the spraying rod devices are arranged on the guide blades, the outer ends of the spraying rod devices pass through and are exposed of the outer ring, and the inner ends of the spraying rod devices stretch into oil injection cavities of the guide blades; and the spraying rod devices are provided with oil pipes, gas pipes and nozzles, oil spraying ports and multiple gas spraying ports are formed in the nozzles, and the oil pipes and the air pipes are respectively connected with an oil supplying pipe and a gas supplying pipe.

Owner:XIAMEN UNIV

Production process of ceramic ball bearing

The invention provides a production process of a ceramic ball bearing. The process comprises the steps of 1 silicon nitride powder mixing, 2 ceramic blank ball forming, 3 ceramic bland sintering, 4 ceramic ball rough grinding, 5 ceramic ball finishing, 6 ceramic ball fine grinding and 7 ceramic ball bearing assembling. Compared with a traditional steel bearing, the silicon nitride ceramic bearing is high in rotating speed, large in rigidity, little in friction heating, low in temperature rise, good in heat stability and long in service life. While sintering is carried out in the step 3, hot isostatic pressing is carried out on a ceramic blank ball through high-pressure nitrogen, the internal defects of the ceramic ball can be effectively reduced, and performance and quality are obviously improved. Superhard grinding materials adopted in the processing process are high in processing efficiency, high in precision and relatively low in cost. The composite grinding materials are prepared from diamond particles, a dispersing agent, calcium hydrophosphate, sodium tripolyphosphate, sodium dodecyl sulfate and sodium silicate. The adhesive ability and grinding efficiency of a grinding medium and the grinding materials on the ceramic balls are effectively improved.

Owner:刘平

Motor case one-step turning method and clamp

InactiveCN104439284AGuaranteed machining accuracyImprove ergonomicsManufacturing dynamo-electric machinesTurning machinesNumerical controlMetal machining

The invention relates to the technical field of metal machining, in particular to a motor case one-step turning method and a clamp. The problem that finish machining of an inner hole and two end faces of an existing motor case needs to be completed by two steps, and is low in precision is solved. The motor case one-tool turning method comprises the steps that a, an inner hole, the end face and an inner spigot joint on the end face of a motor case are roughly machined in a two-face rough-boring machine tool; b, one end A is selected, then, an outer spigot joint is machined in circumferentially-arranged lugs for motor end cover installation at the end A, and the end A is machined to enable the annular plane at the position, attached to the motor end cover end face, on the end face to form an annular boss; c, the motor case end A is fixedly installed on the clamp of a numerically-controlled machine tool, wherein the clamp is annular, and the inner ring of the clamp is provided with an inner spigot joint in tight fit with the outer inner spigot joint at the motor case lugs; d, the numerically-controlled machine tool is used for finish machining of the inner hole and the two end faces of the motor case, and only the annular boss of the end face A is cut to reach the needed motor case axial size except that the inner spigot joint of the end face A is machined.

Owner:JIANGSU DAZHONG ELECTRIC MOTOR

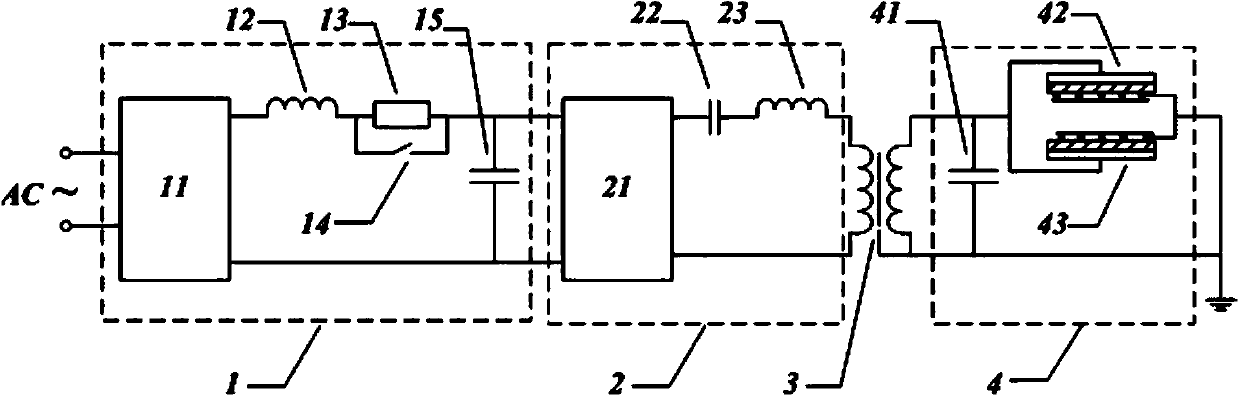

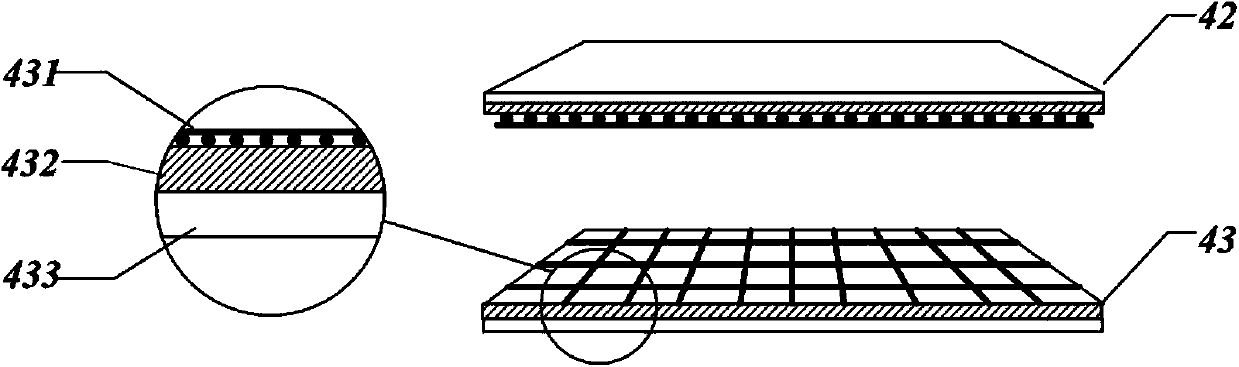

Circuit generated low temperature plasma

InactiveCN103747606ANo adverse effectsModerate energy densityLavatory sanitoryDisinfectionHigh energyTransformer

The invention discloses a circuit generated low temperature plasma, which comprises a rectifying circuit, a sine inverter circuit, a high-frequency step-up transformer and a discharge circuit. The rectifying circuit is used for converting a AC voltage into a DC voltage. The sine inverter circuit is used for converting the DC voltage into a certain frequency sine AC voltage. The high-frequency step-up transformer is used for boosting the sine voltage. The discharge circuit is used for forming a dielectric barrier corona discharge to generate the low-temperature plasma. According to the invention, the appropriate corona discharge and the dielectric barrier are combined to form stable and uniform than the dielectric barrier discharge, the energy utilization efficiency is higher than the dielectric barrier corona discharge of the corona discharge, and the circuit can be used to obtain the low temperature plasma. A disinfection box made by the circuit of the invention solves the problem that the traditional sterilization mode has high energy consumption, low efficiency, residual after sterilization, damage to the operating personnel and instruments, and influence on the surrounding environment.

Owner:HUAZHONG UNIV OF SCI & TECH

One-to-three pump transmission transfer box

InactiveCN102359551AImprove the lubrication effectSolution to short lifeGearboxesToothed gearingsTransfer caseIdler-wheel

The invention discloses a one-to-three pump transmission transfer box which comprises a transfer box shell, a power input end arranged in the shell and provided with an input gear, and three spline output shafts with output gears. The one-to-three pump transmission transfer box is characterized in that a high-elasticity coupler is connected with a power shaft of an engine, the input gear is respectively meshed with the output gears and an idler wheel, power of the engine is transferred to the three output gears through the input gear and the idler wheel, and the three output gears are used for transferring power of the engine to the three output shafts at different rotating speeds and rotating directions. A lubricating oil pool and a lubricating oil tube are arranged on the shell, and a heat-radiating rib plate is arranged outside the shell. The one-to-three pump transmission transfer box has the advantages of simple structure, small volume, easiness in manufacture and low cost, one path of power input, three paths of power output at different rotating speeds and rotating directions, good lubricating effect of bearings and long service life because the lubricating oil pool and the lubricating oil tube are arranged on the shell, good heat radiating effect and small operation temperature rise because the heat-radiating rib plate is arranged outside the shell, and good safety and reliability because a pressure limiting valve is arranged on a rear shell.

Owner:ZHUZHOU ACCURATE DRIVETRAIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com