Electrode structure of power capacitor with metal metallized safety film for reducing temperature rising

A power capacitor and electrode structure technology, applied in the direction of fixed capacitor electrodes, fixed capacitor parts, etc., can solve the problems of reducing the working life of capacitors, large capacitance, and reduction of film withstand voltage strength, so as to improve reliability and working life , Suppress heat deformation, reduce the effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

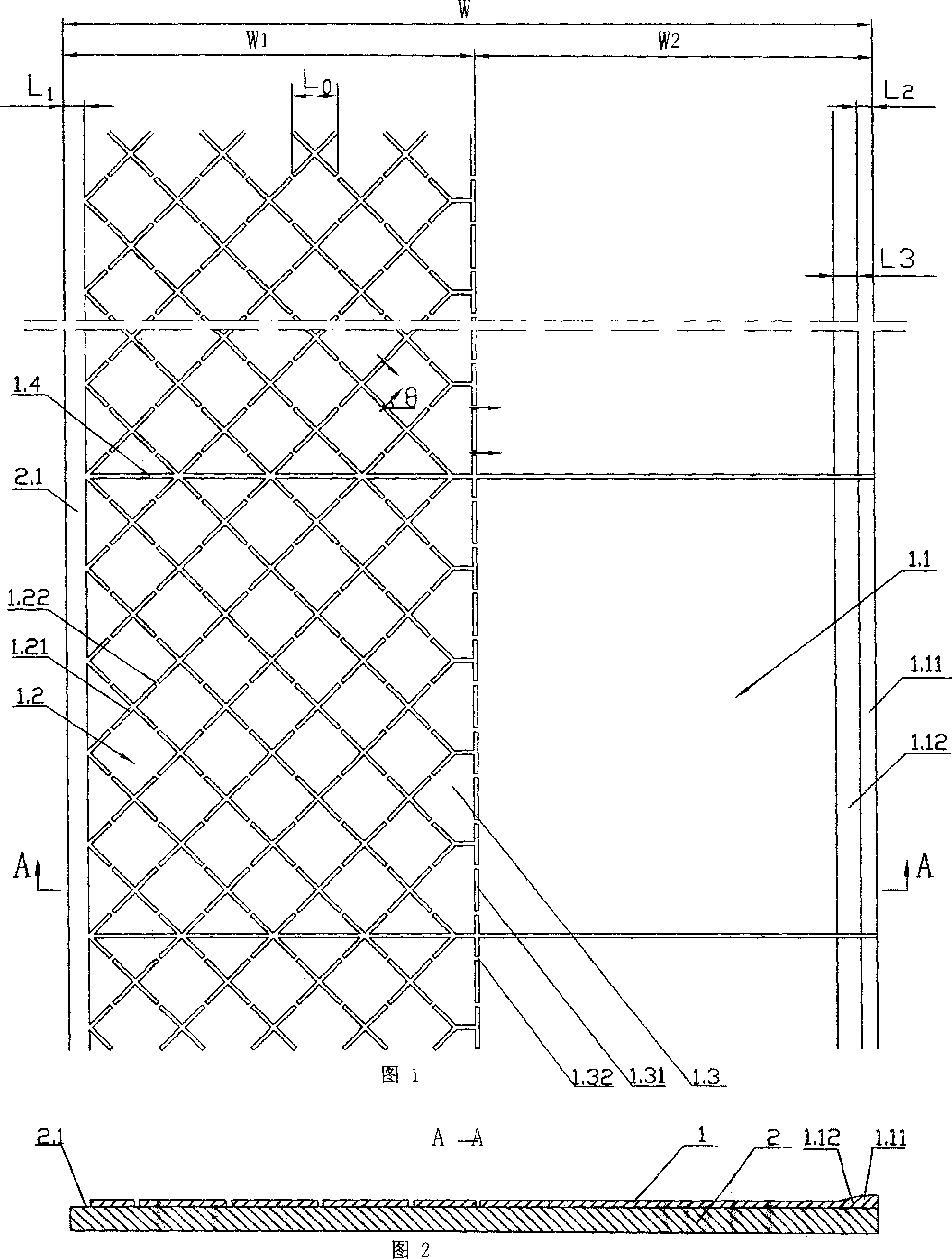

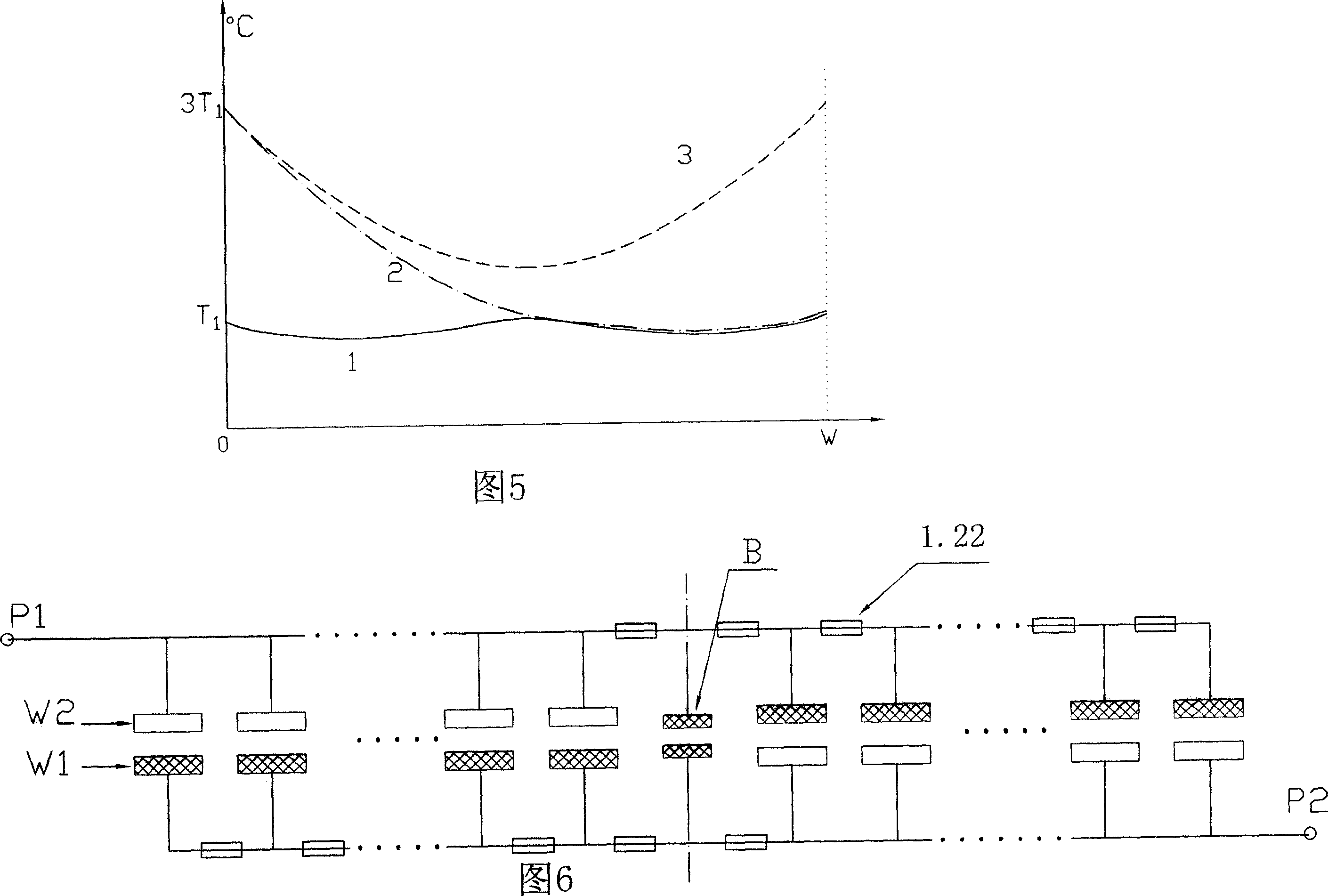

[0031] Embodiment 1: With reference to Fig. 1, Fig. 2, on the polypropylene base film 2 that width is W, the zinc / aluminum composite metal coating 1 of vacuum evaporation forms composite film, and metal coating constitutes the electrode of capacitor. The composite film is divided into left and right electrode structures by the longitudinal gap separator 1.31 in the transverse direction, and half of the W 2 The width range is continuous metal electrode coating partition 1.1, and the other half is W 1 The width range is grid safety film coating partition 1.2. The coating of the narrow strip on the outer edge of the continuous metal electrode coating partition 1.1 is thickened into a thickened side 1.11, which is connected with the external gold spray, and the gold spray at both ends is respectively connected to the lead wire P of the capacitor. 1 and P 2 Connected, thickened edge width L 2 with transition zone 1.12 width L 3 The sum is 3-5mm, and the metal coating thickness ...

Embodiment 2

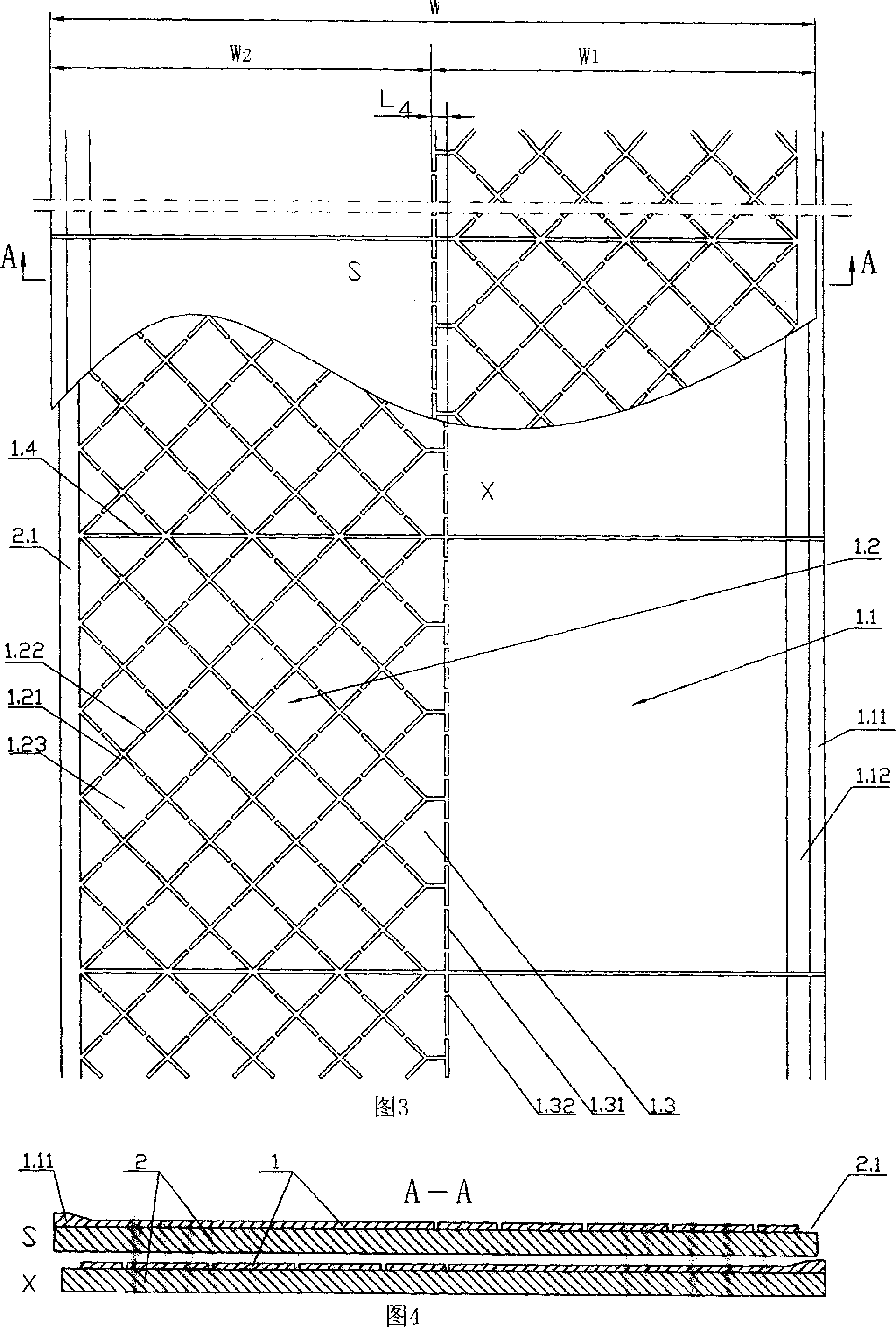

[0035]Embodiment 2: It involves the electrode structure of metallized internal series-connected safety film capacitors. As shown in Figures 7 and 8, the upper film layer S and the lower film layer X are closely laminated, and the upper and lower film layers of each series-connected unit The electrode structure and relative protection are basically the same as the electrode structure of the safety film capacitor in Example 1; the serial units are arranged in sequence horizontally, and the arrangement method is: if the outer side of the upper film of the first unit is a continuous coating thickening edge 1.11, it is connected with the outer spray Gold connection, the inner side of the unit is a margin, which is integrated with the margin of the second unit that is also on the upper film, and is synthesized into an inner margin 2.2, and the width of the inner margin is 1.5 to 2 times that of the outer margin 2.1; The outer side of the lower film layer of the first unit should be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com