Method for measuring power connector contact temperature rise based on finite element analysis of three-dimensional thermal field

A power connector and three-dimensional thermal field technology, applied in the field of measurement, can solve problems such as the difficulty of reflecting the growth trend of contact temperature rise in real time, and the inability to obtain accurate data on contact temperature rise, connector reliability, etc., and achieve the goal of shortening the temperature rise test Time, convenient calculation of contact temperature rise, and the effect of efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

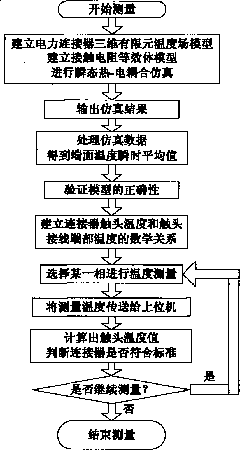

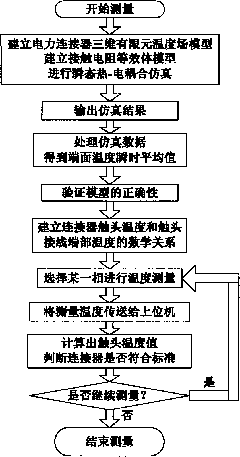

[0014] Example 1: Combining figure 1 , the present invention is based on the three-dimensional thermal field finite element analysis of the power connector contact temperature rise measurement method, the steps are as follows:

[0015] Step 1: Use the finite element simulation analysis software ANSYS to establish a three-dimensional thermal field model of the power connector, use the contact resistance value and the size of the contact area to establish the equivalent body model of the contact resistance through calculation, conduct transient thermal-electric coupling simulation analysis, and output the connection The temperature field distribution diagram of the connector, the instantaneous value and time-varying curve of the temperature of the connector contact and the temperature of the contact terminal;

[0016] Step 2: Perform data processing on the temperature of all nodes on the end face of the connector contact and the temperature of all nodes at the end of the contact...

Embodiment 2

[0021] Embodiment 2: The method for measuring the temperature rise of the contacts of the power connector based on the three-dimensional thermal field finite element analysis of the present invention includes the following contents:

[0022] (1) Use the finite element simulation analysis software ANSYS to establish a three-dimensional thermal field model of the power connector, and perform transient thermal-electric coupling simulation analysis, including selecting the unit type of the model and defining the material properties of the model; establishing a geometric model of the power connector; Using the contact resistance value and the size of the contact area, the equivalent body model of the contact resistance is established through calculation; the grid division accuracy is selected, and the grid is divided; the temperature boundary conditions, voltage boundary conditions and applied current load are set; the time step of the solution is set and carried out Transient therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com