Turbine stator blade with interstage combustor

A turbine stator and combustion chamber technology, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of high temperature, large inlet airflow velocity, and reduce blocking ratio, etc., achieve simple structure, improve machine power and weight add small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

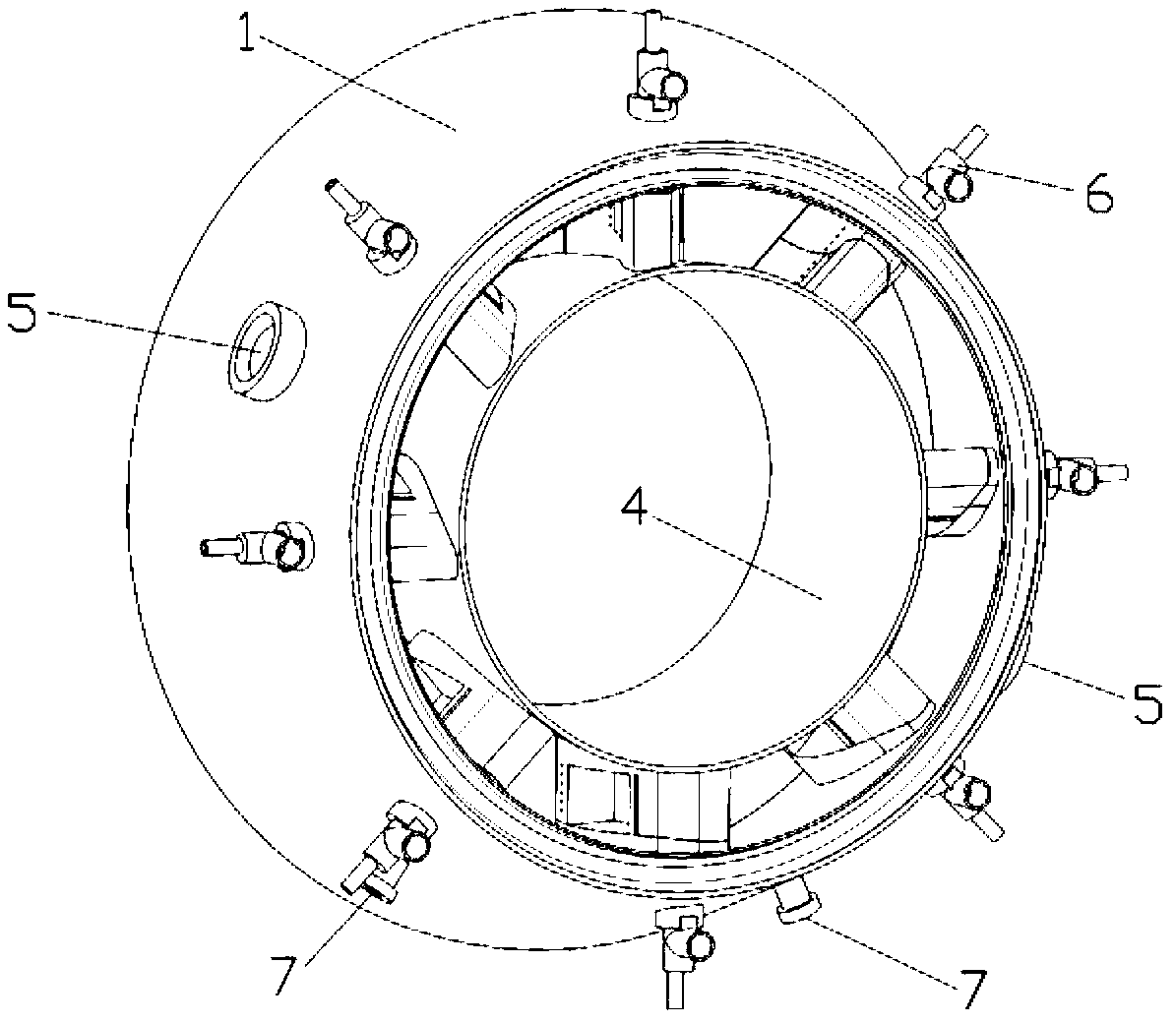

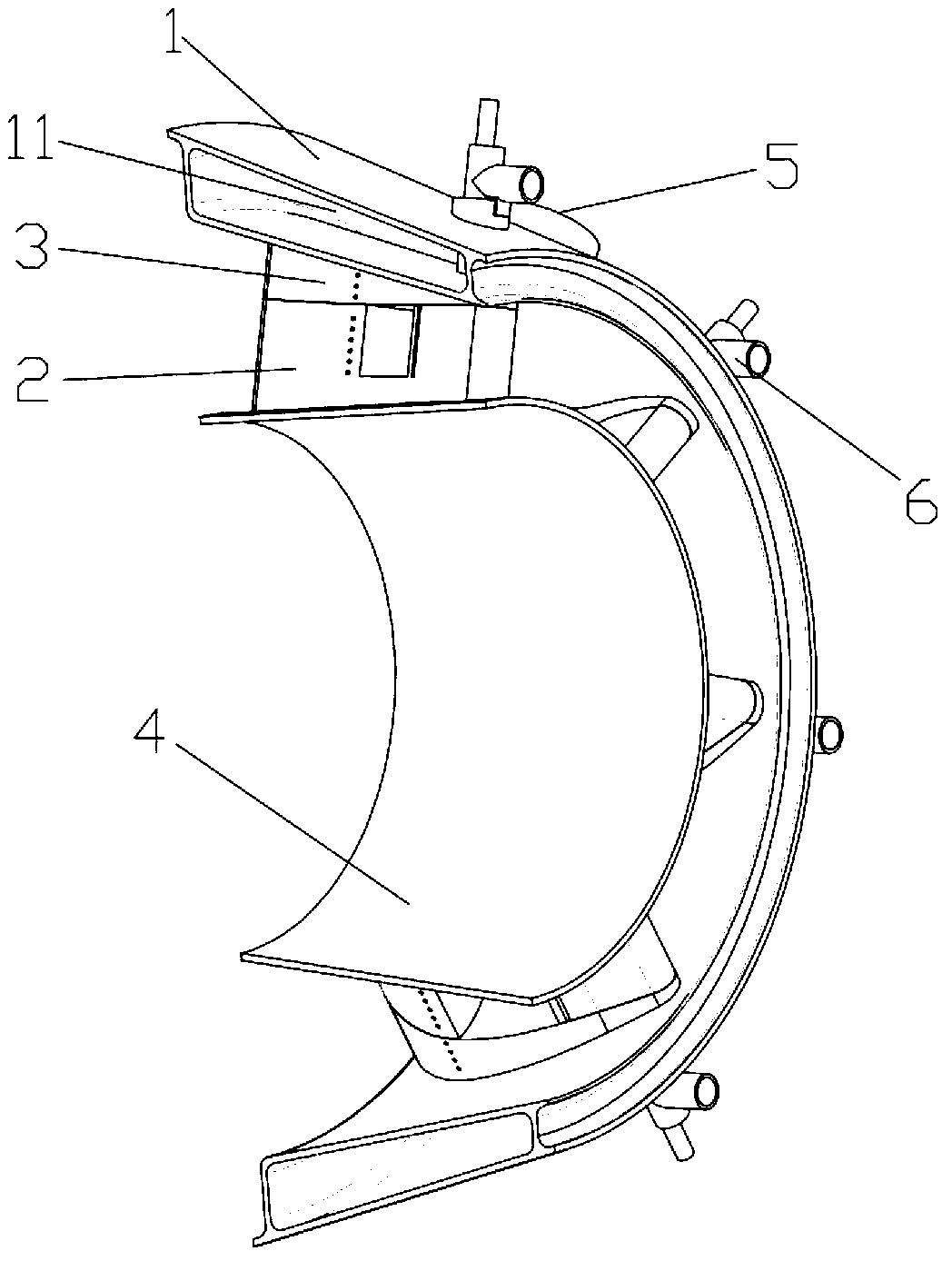

[0029] see Figure 1-7 , the embodiment of the present invention is provided with outer ring 1, guide vane body guide vane body 2, guide vane cover 3, inner ring 4, 2 ignition devices (including ignition seat 7 and ignition nozzle (not shown in the figure)) and 8 spray rod devices 6 are formed.

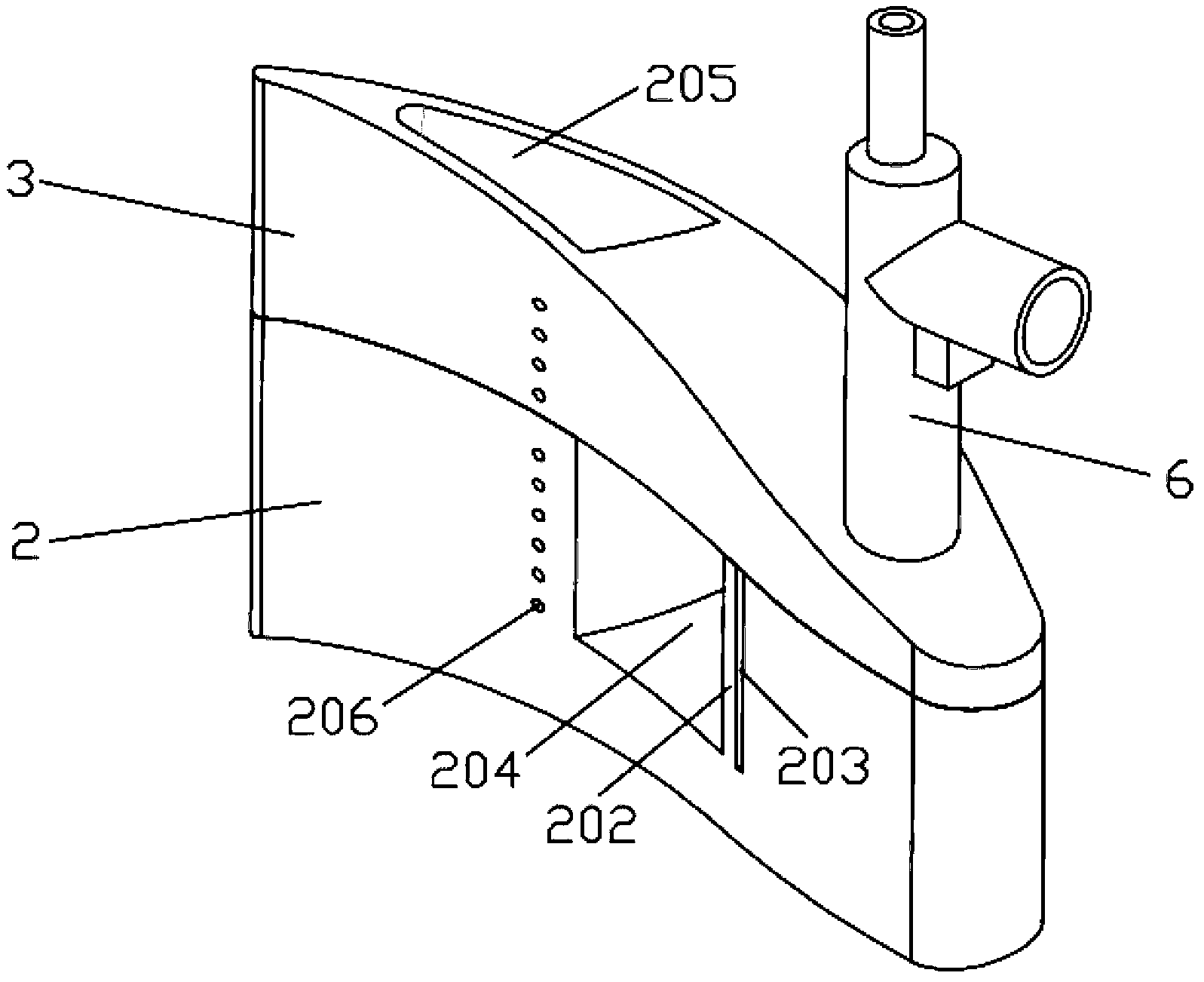

[0030] The outer ring 1 is provided with a cooling chamber 11 , and the cooling chamber 11 is provided with an air inlet 5 . The guide vane is arranged between the inner ring 4 and the outer ring 1 , the guide vane is provided with a guide vane main body 2 and a guide vane cover 3 , and the guide vane cover 3 is arranged on the upper end surface of the guide vane main body 2 . The main body 2 of the guide vane is provided with an oil injection cavity 201 at the front, a return flow cavity 204 at the middle and a cooling cavity 205 at the rear; there is a spray bar slot 207 inside the oil injection cavity 201, and a baffle 202 is provided at the end of the oil injection cavity 201 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com