Three-degree-of-freedom permanent-magnet spherical motor

A motor and degree of freedom technology, applied in synchronous motors with static armatures and rotating magnets, electric components, magnetic circuit rotating parts, etc., can solve the deterioration of dynamic performance of spherical motors with friction torque, and limit the development of miniaturization of spherical motors , occupying the installation space of the stator coil, etc., to achieve the effect of simplifying the processing, improving the temperature rise problem, and improving the heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

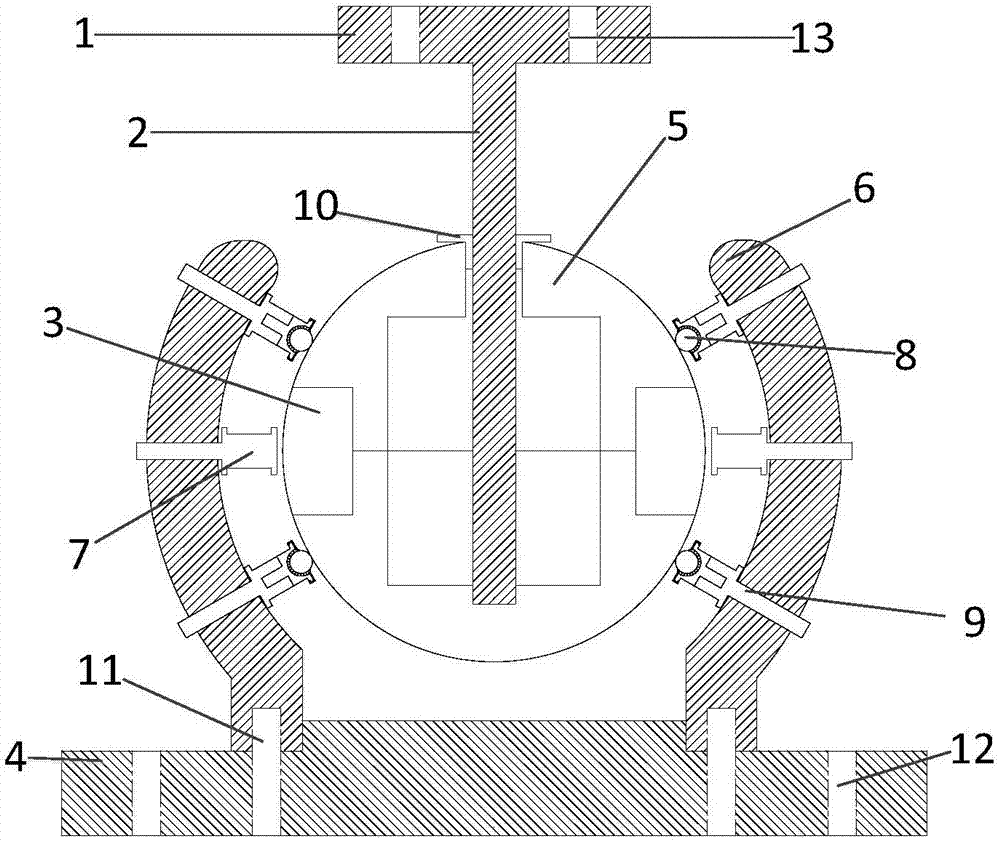

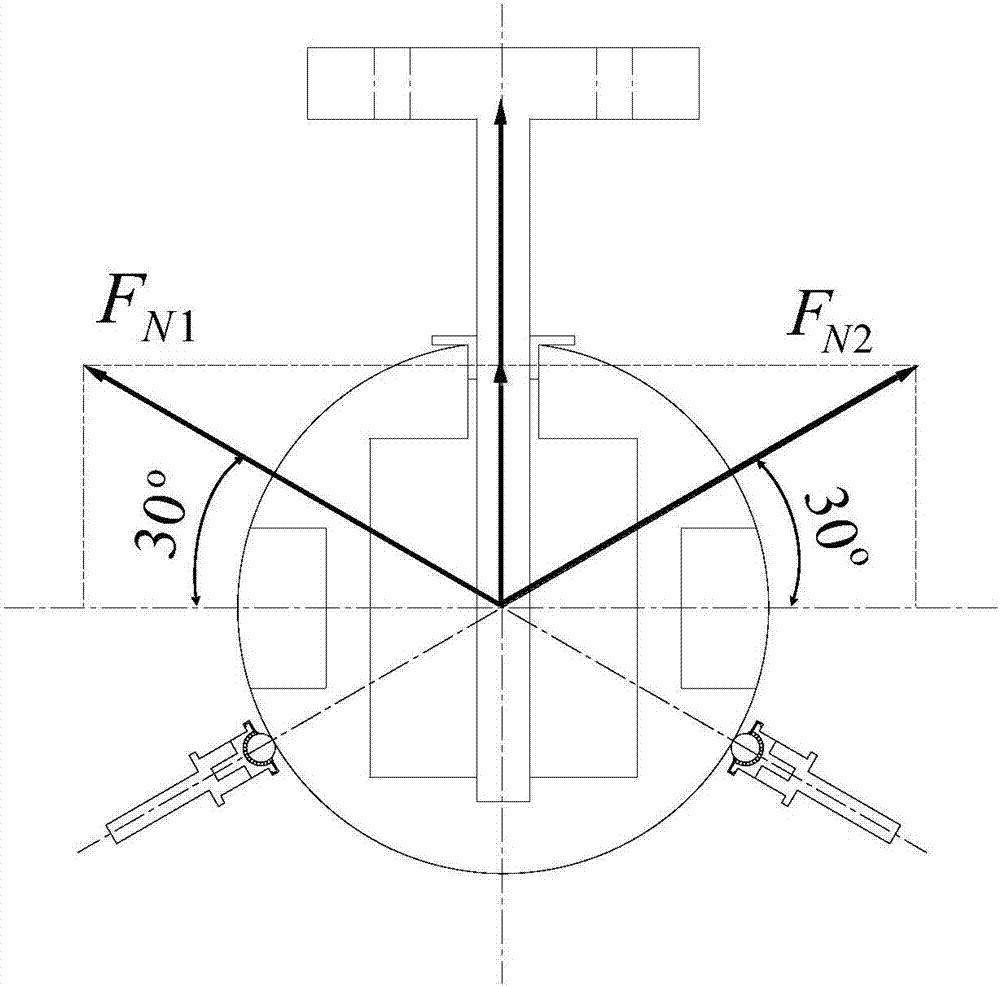

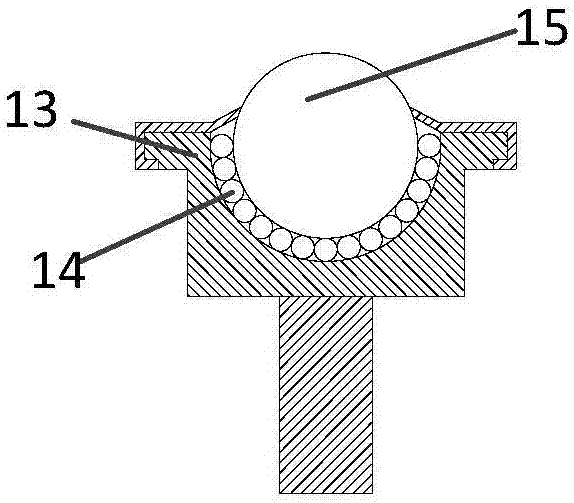

[0026] The present invention proposes a three-degree-of-freedom permanent magnet spherical motor supported by universal balls, including a base 4, universal balls 8, a spherical rotor body 5, an output shaft 2, a stator coil 7, an outer stator 6, an output shaft 2, Flange 1 etc., wherein the rotor 5 is two hollow hemispheres made of aluminum to reduce the moment of inertia of the spherical motor, wherein the upper and lower rotor hemispheres are fixed by tightening bolts and the output shaft. A cylindrical groove 3 is provided at the equator of the rotor for inlaying permanent magnets, and resin is used to seal the gap. Four universal balls 8 are evenly installed on the combined stator coil frame 9 to support the rotor 5. The universal balls 8 are of SP15-FL type, and the eight supporting points are respectively located at the vertices of the cuboid. By adopting the universal ball to support the rotor, the frictional force during the operation of the spherical motor can be sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com