Patents

Literature

172 results about "Spherical motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Float roll system with both rectification and tension controlling functions

ActiveCN103359521AShock absorbing tensionPlay a buffer roleWebs handlingEngineeringMechanical engineering

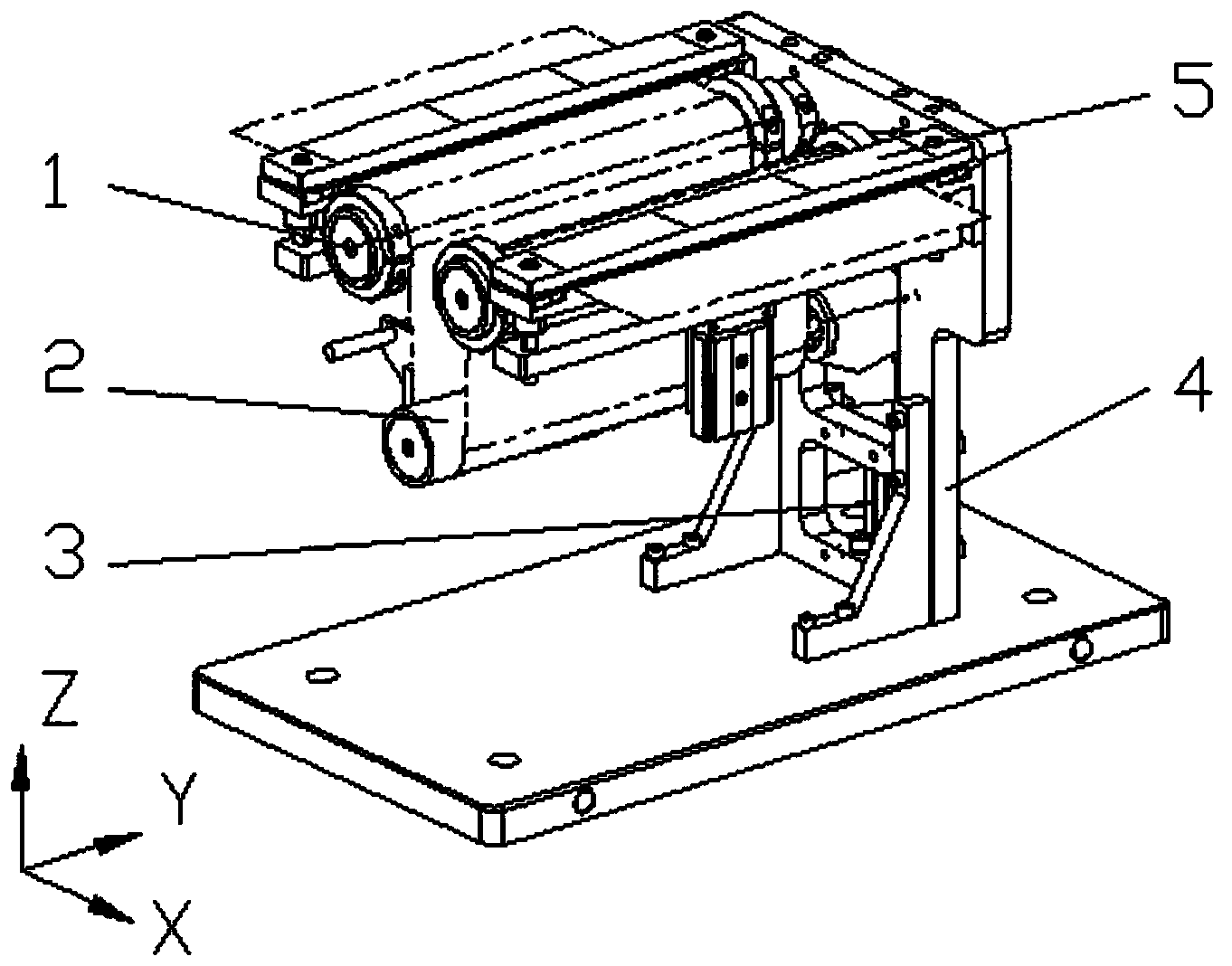

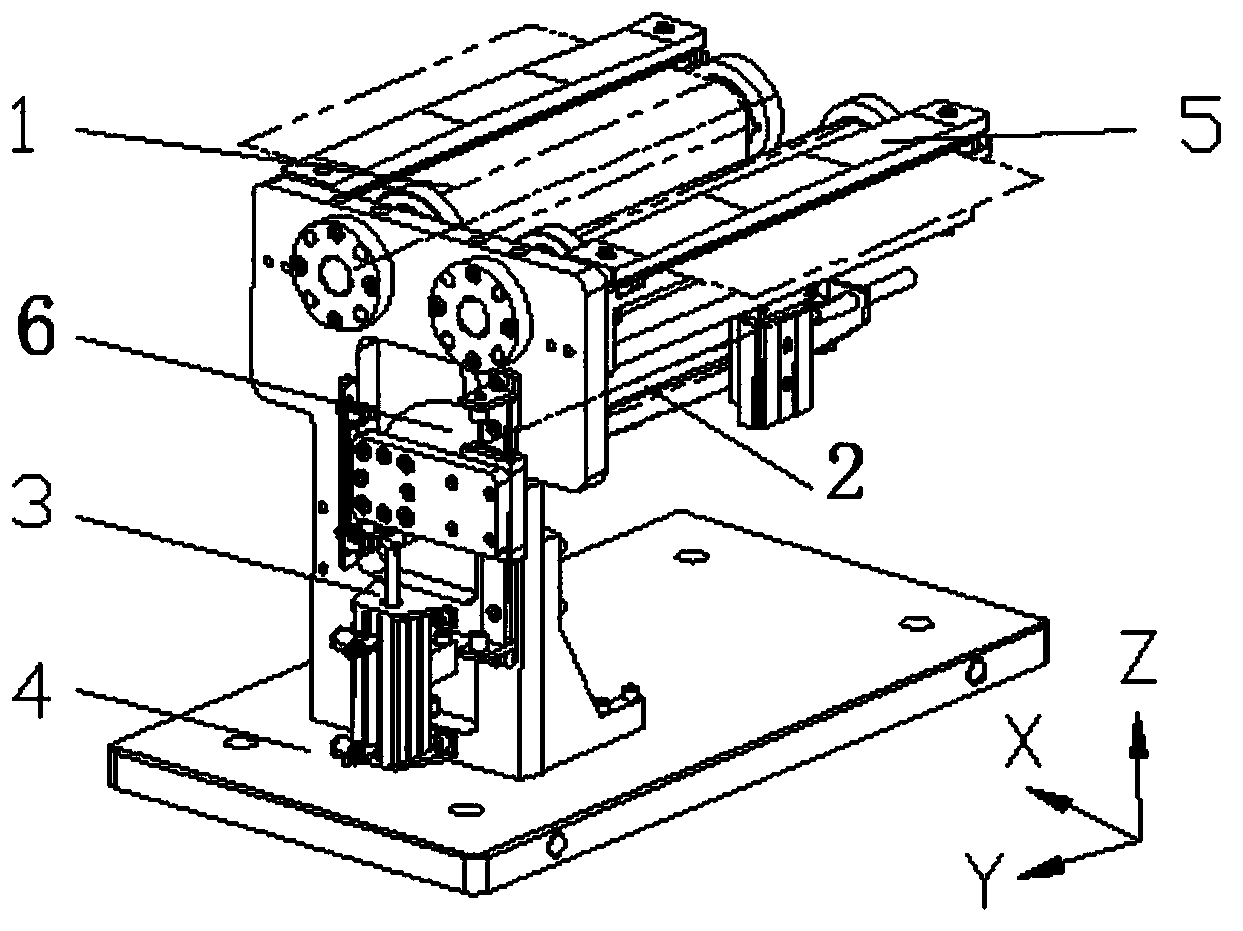

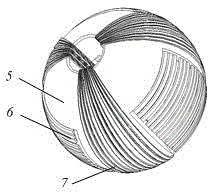

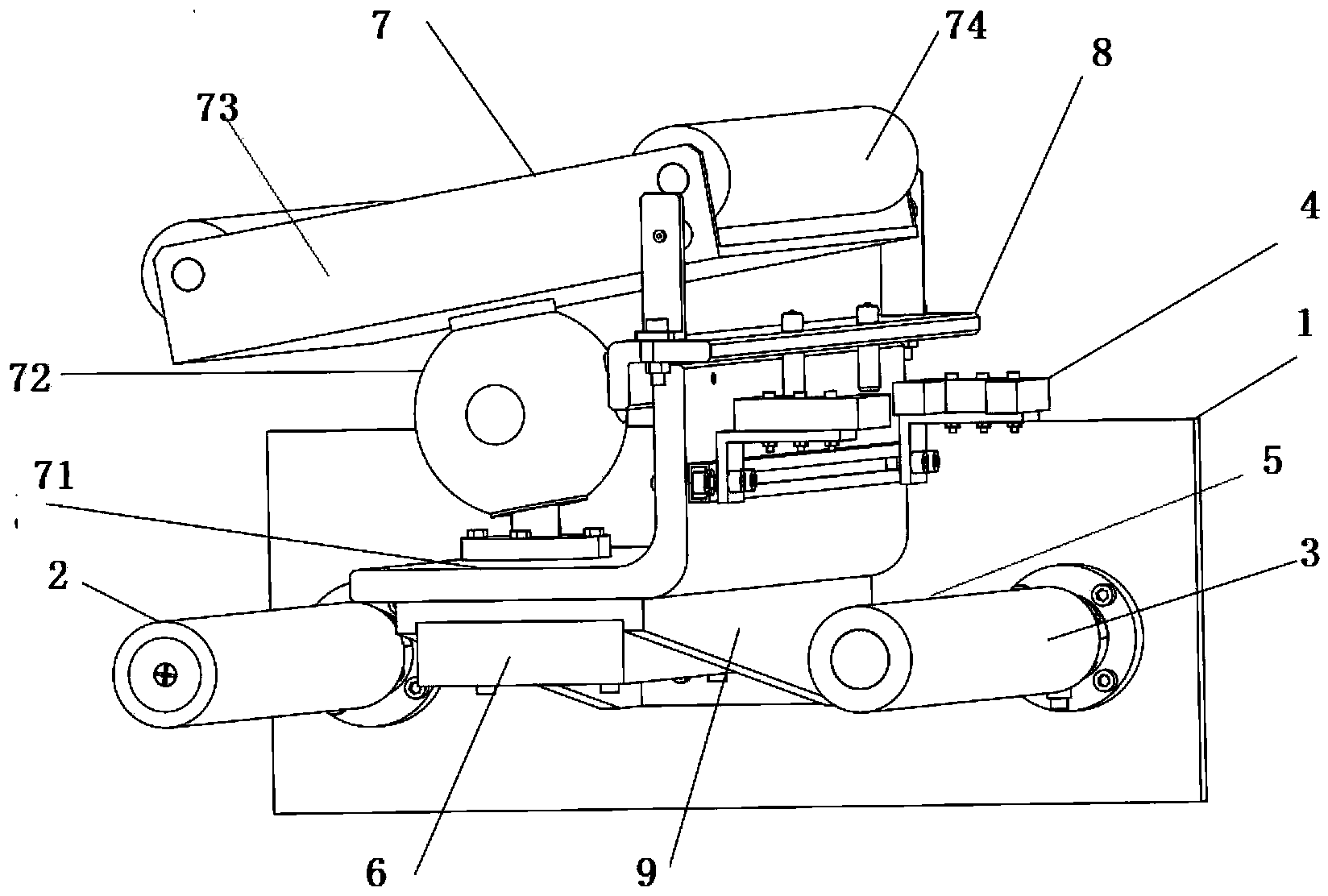

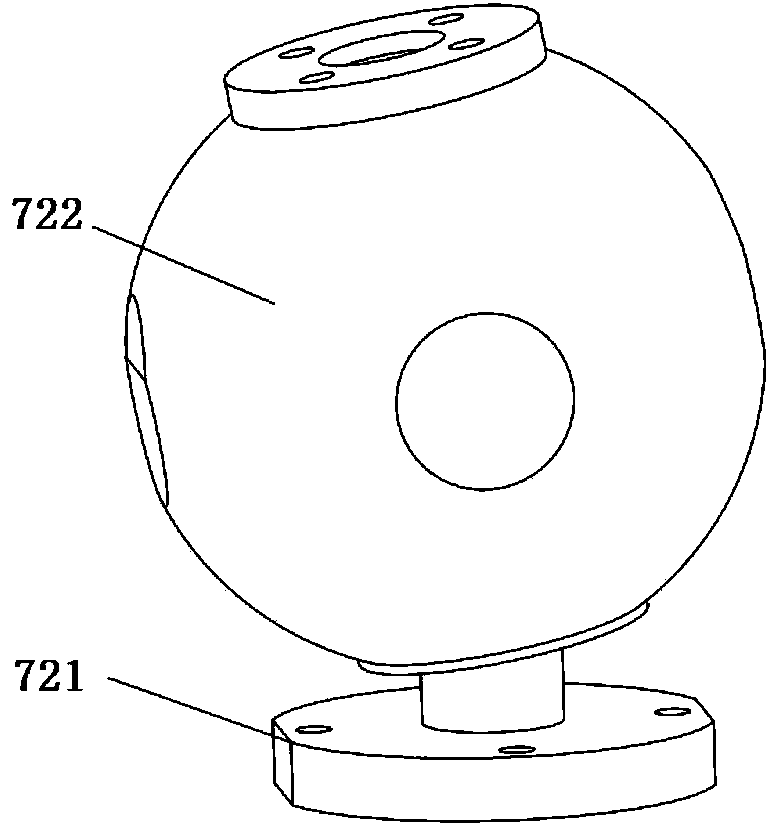

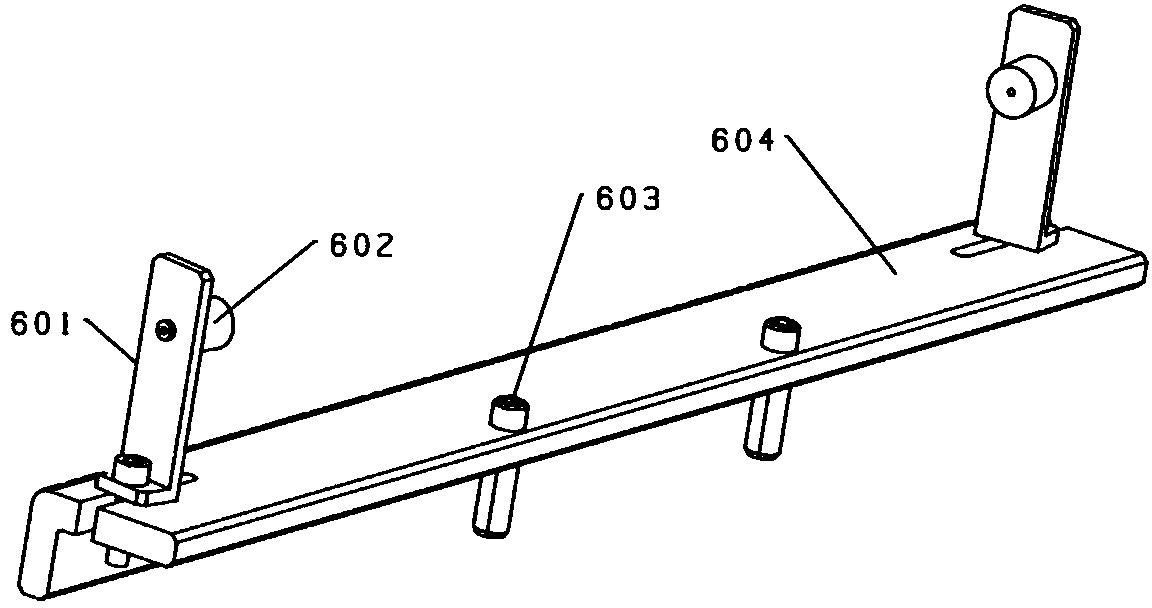

The invention discloses a float roll system with both rectification and tension controlling functions. The float roll system comprises a machine frame, an input guiding idler roll, an output guiding idler roll, a float roll longitudinal position adjusting mechanism, a float roll, and a rectification and tension accurate adjusting mechanism, wherein the rectification and tension accurate adjusting mechanism comprises a rectification sensor, a tension sensor and a spherical motor. Thin film offset is detected as long as a thin film shifts on a feed surface, the runner of the spherical motor is driven to drive the float roll to swing on the thin film feed surface, and the float roll swings in an inverse direction due to the friction between the float roll and the thin film, so as to realize rectification; the runner of the spherical motor is driven to drive the float roll to rotate according to the comparative result between detected tension of the thin film and target tension, so that the axes of the runner and the float roll are eccentric, and the float roll tensions or relaxes the thin film to control the tension of the thin film. As both rectification and tension controlling are realized through the spherical motor, the float roll system has the advantages that the structure is simple, the layout is compact, and the control is convenient.

Owner:HUAZHONG UNIV OF SCI & TECH

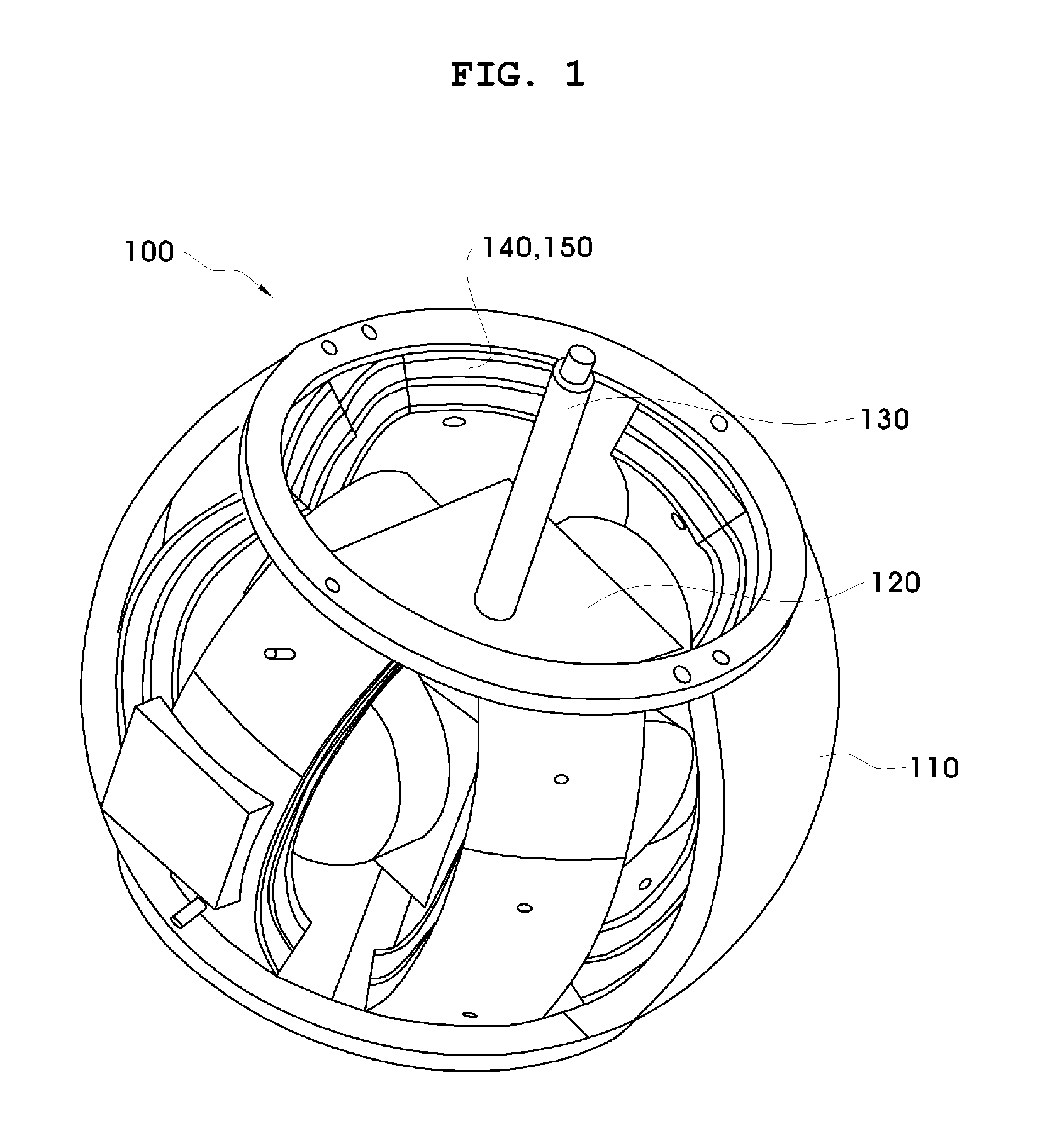

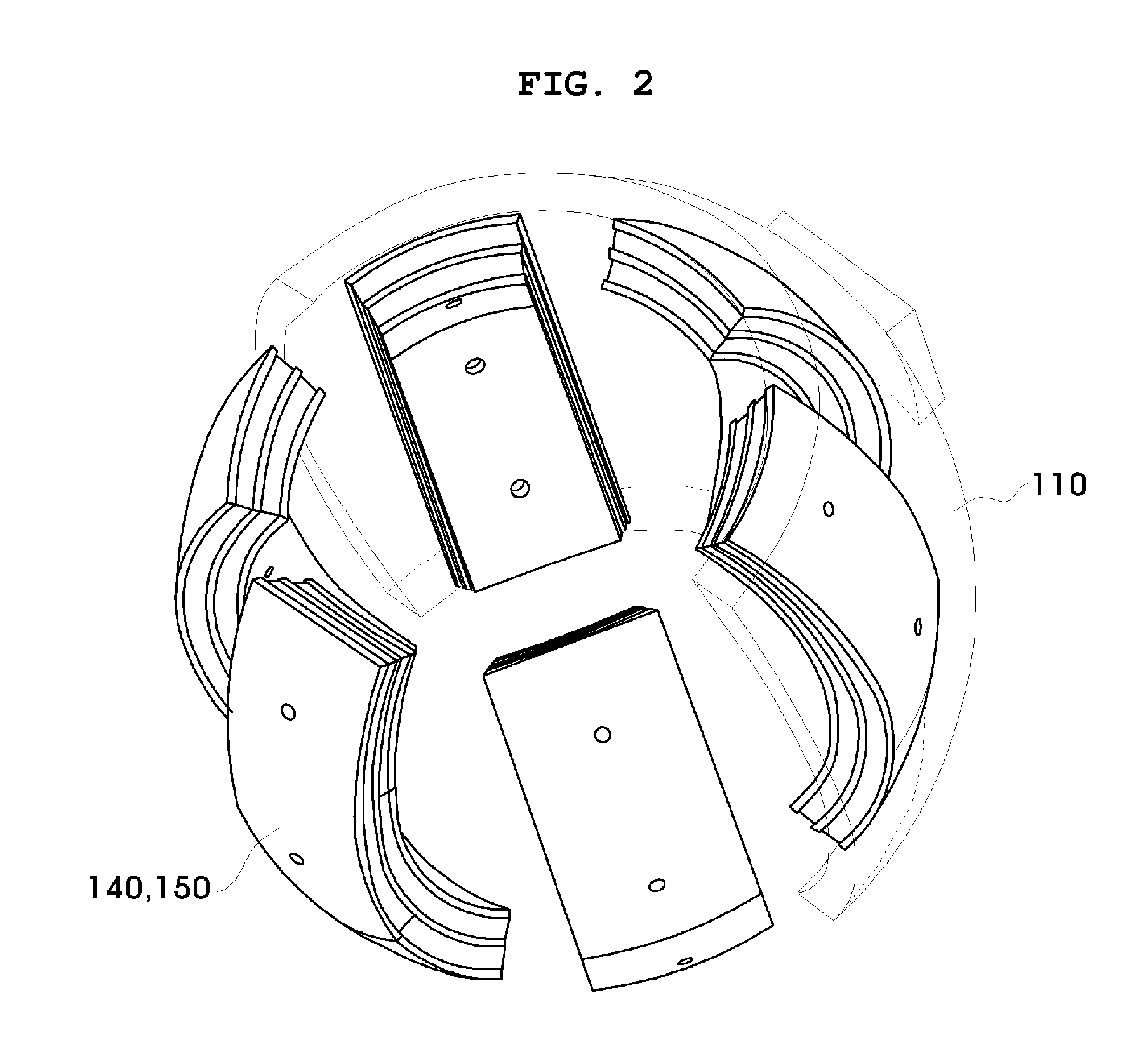

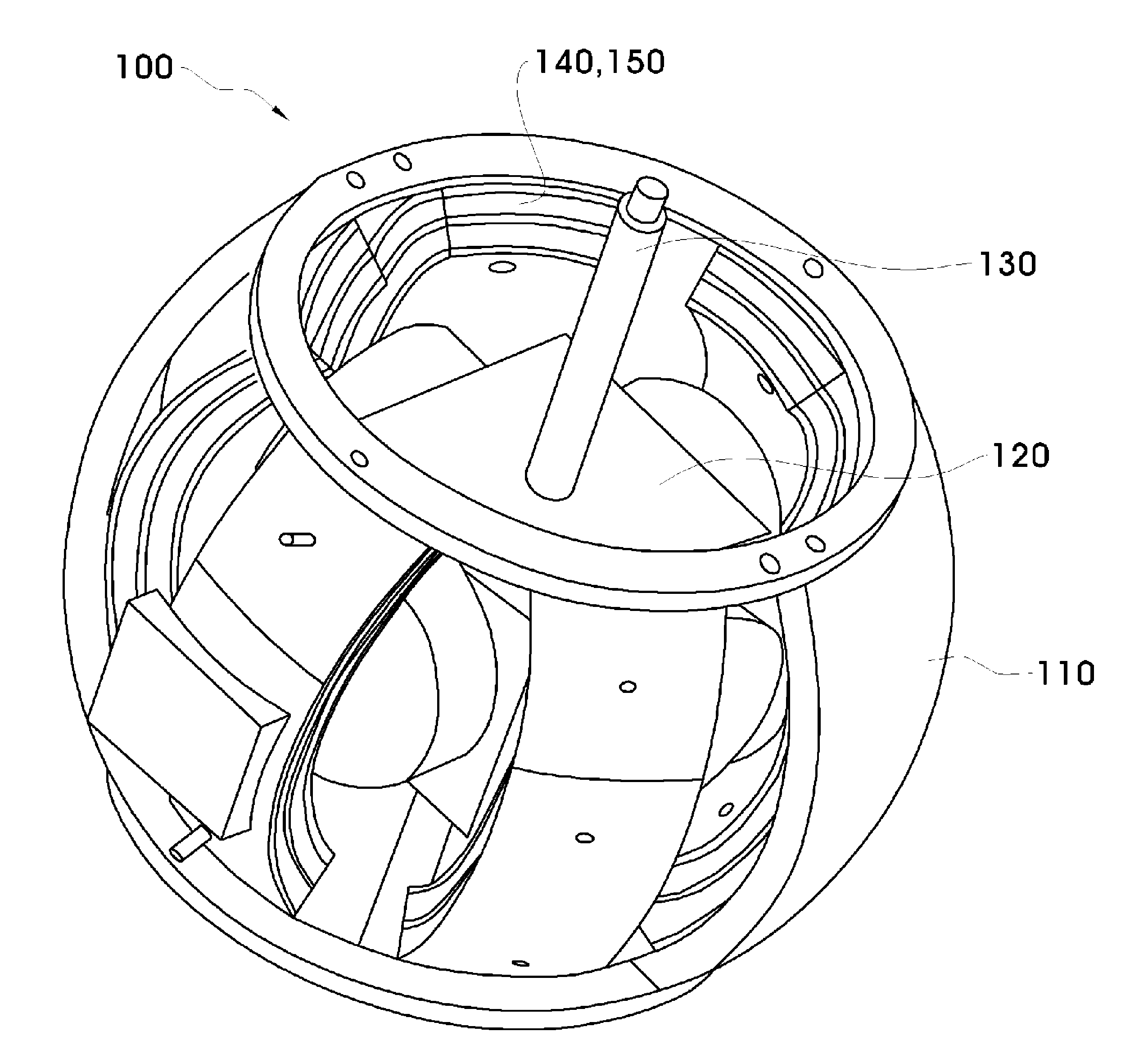

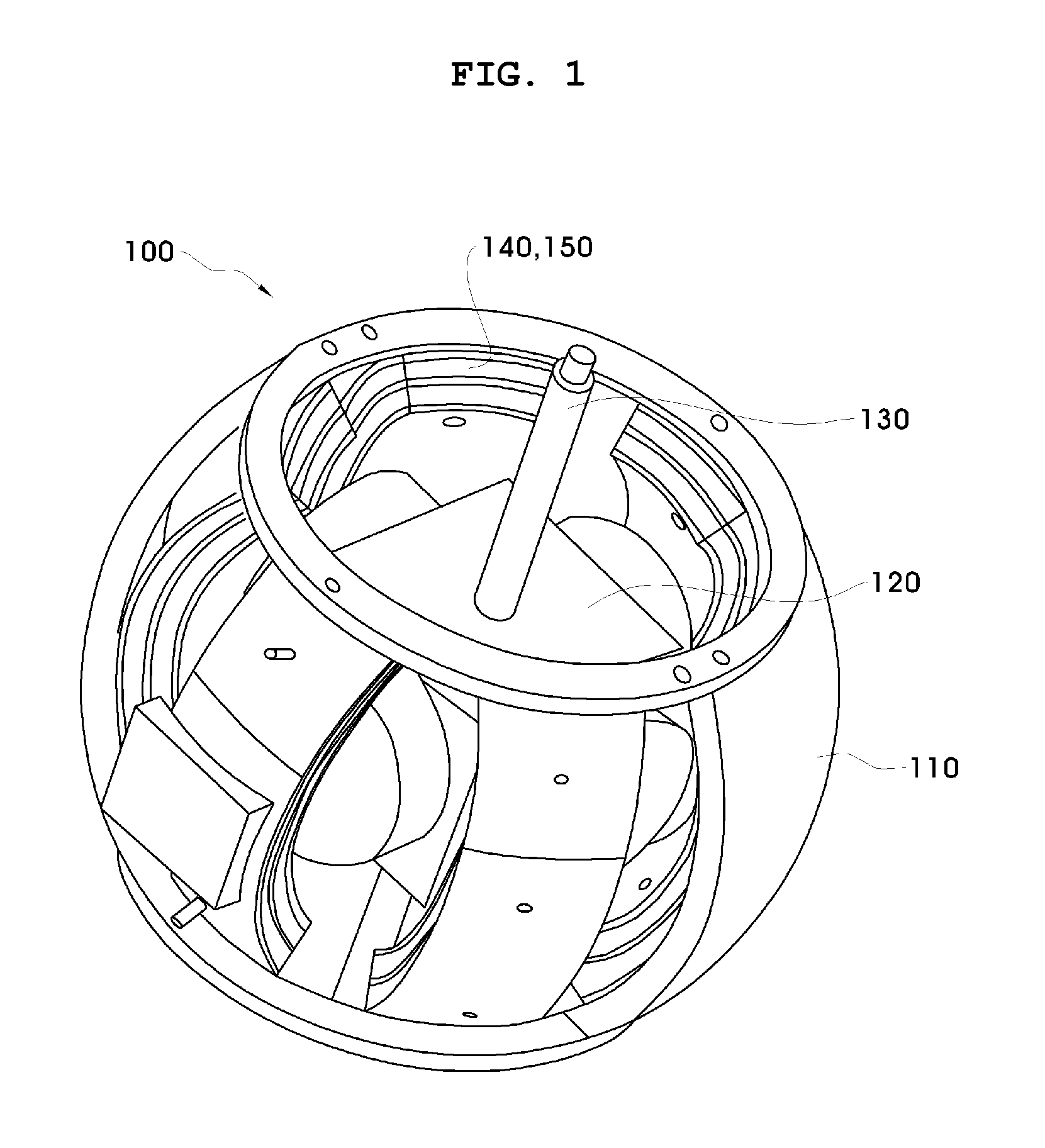

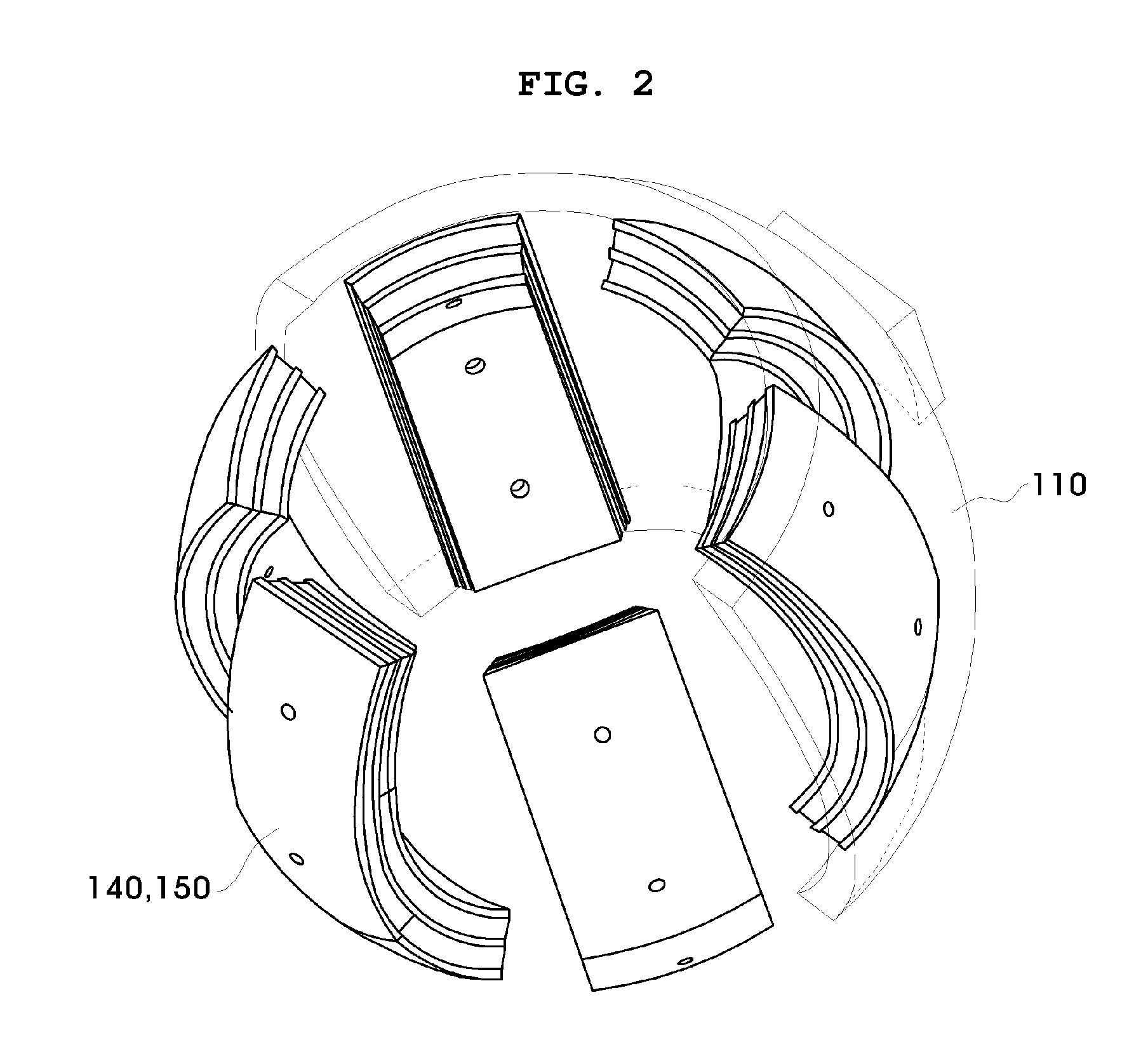

Spherical motor rotating in multiple degrees of freedom

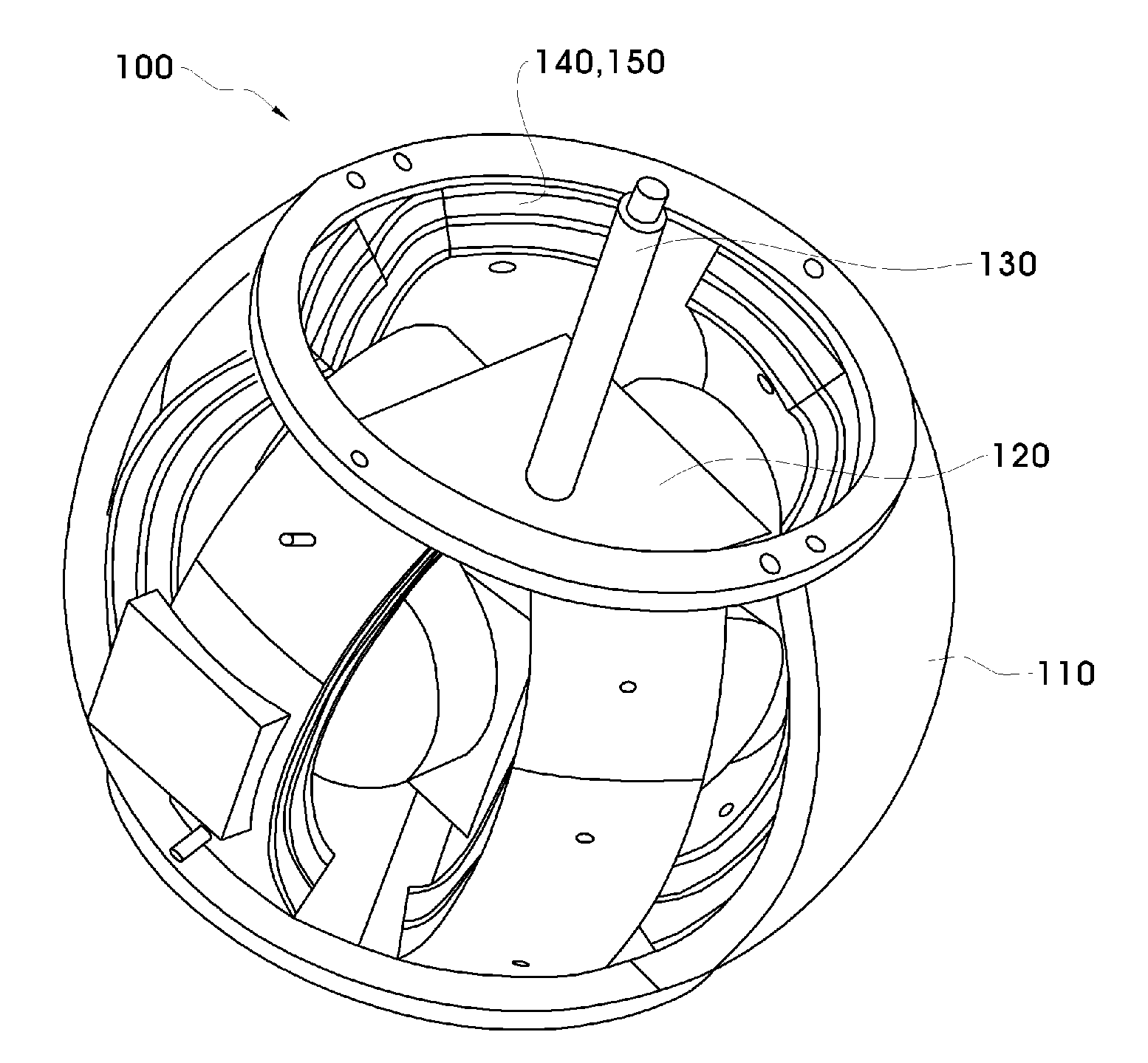

ActiveUS20090230787A1Improve joint efficiencySimple control systemMagnetic circuit rotating partsMagnetic circuit stationary partsBobbinMulti degree of freedom

A spherical motor rotating in multi degrees of freedom has a reliable capability of determining positioning. The spherical motor includes a hollow spherical-shaped stator installed with a bi-level bobbin wound by coil generating a synthesized magneto-motive force on an inner surface thereof; and a rotor formed inside the stator and rotating around a shaft, wherein a slope of the shaft is adjusted by the synthesized magneto-motive force. Two or more of the bobbins are provided and installed at regular intervals along the inner surface of the stator, and the rotor includes one or more permanent magnets. The spherical motor rotating in multi degrees of freedom, formed with the above mentioned figures, can embody multi degrees of freedom by the interaction between the flowing current in the winding coil around the bobbin and the permanent magnet.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

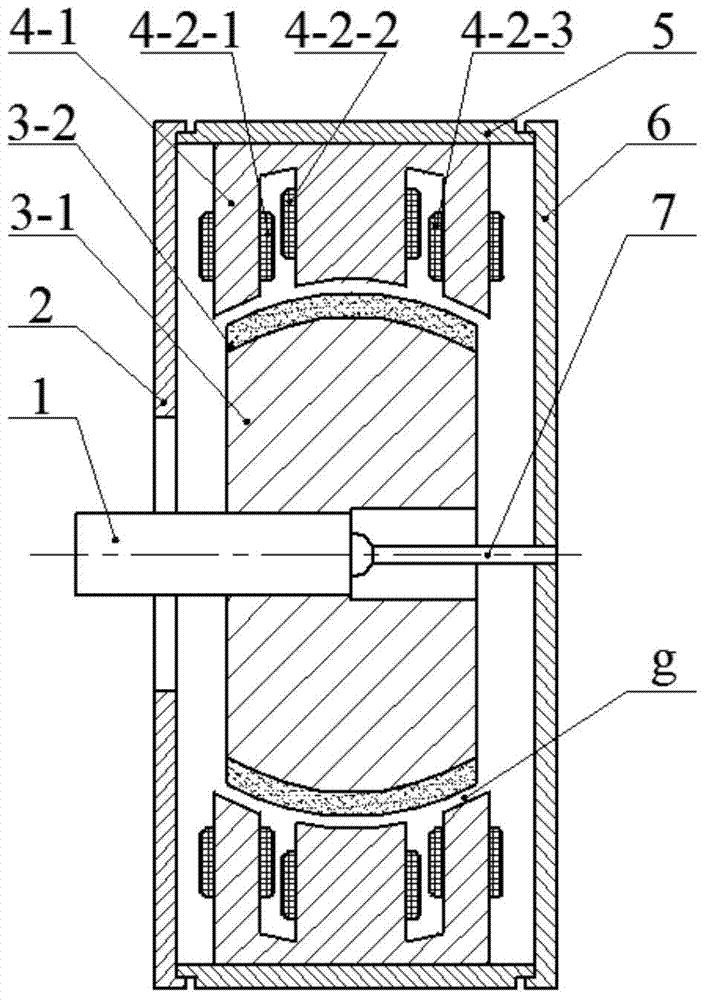

Permanent magnet bearing-free auto-suspension three-degree-of-freedom spherical motor and control method thereof

ActiveCN102412763AGood sports characteristicsIncrease flexibilityMagnetic holding devicesThree degrees of freedomControl system

The invention belongs to the technical field of design and control of motors and relates to a permanent magnet bearing-free auto-suspension three-degree-of-freedom spherical motor. The permanent magnet bearing-free auto-suspension three-degree-of-freedom spherical motor comprises a base, a spherical stator wall, stator coils and a rotor, wherein the rotor is positioned in the stator wall; the output shaft of the rotor extends out of an opening above the stator wall; the spherical motor is characterized in that: the stator coils have columnar ironless structures; three layers of stator coils are uniformly distributed along the equator of the spherical stator wall and wefts parallel to the equator and radially fixed on the spherical stator wall; permanent magnet poles are embedded on the surface of the rotor and divided into two layers, namely an upper layer and a lower layer, along the equator; the poles N and the poles S on each layer are staggered; and each stator coil is independently controlled by a driving circuit. The invention also provides a control method for the motor. By the motor and the control method thereof, controllability of a magnetic suspension force and bearing-free running of the motor are realized; furthermore, the movement characteristic of the motor and the flexibility of design of a motor control system are improved.

Owner:TIANJIN UNIV

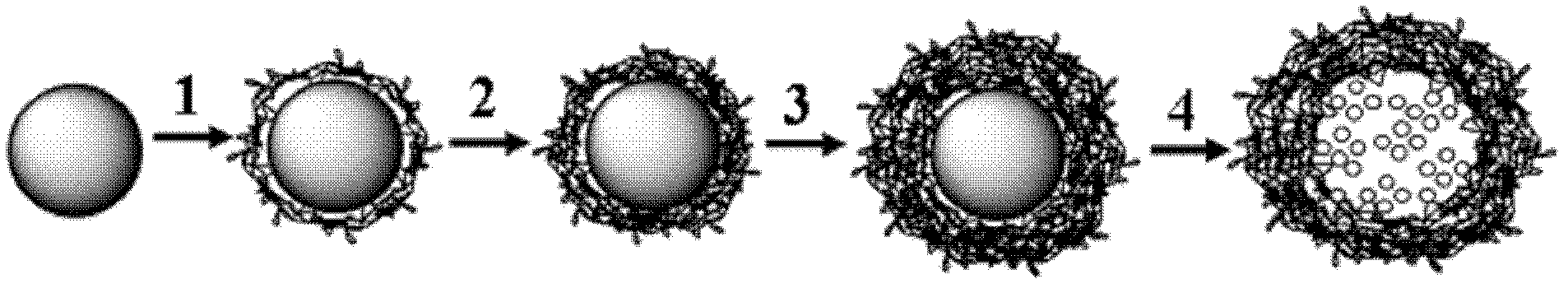

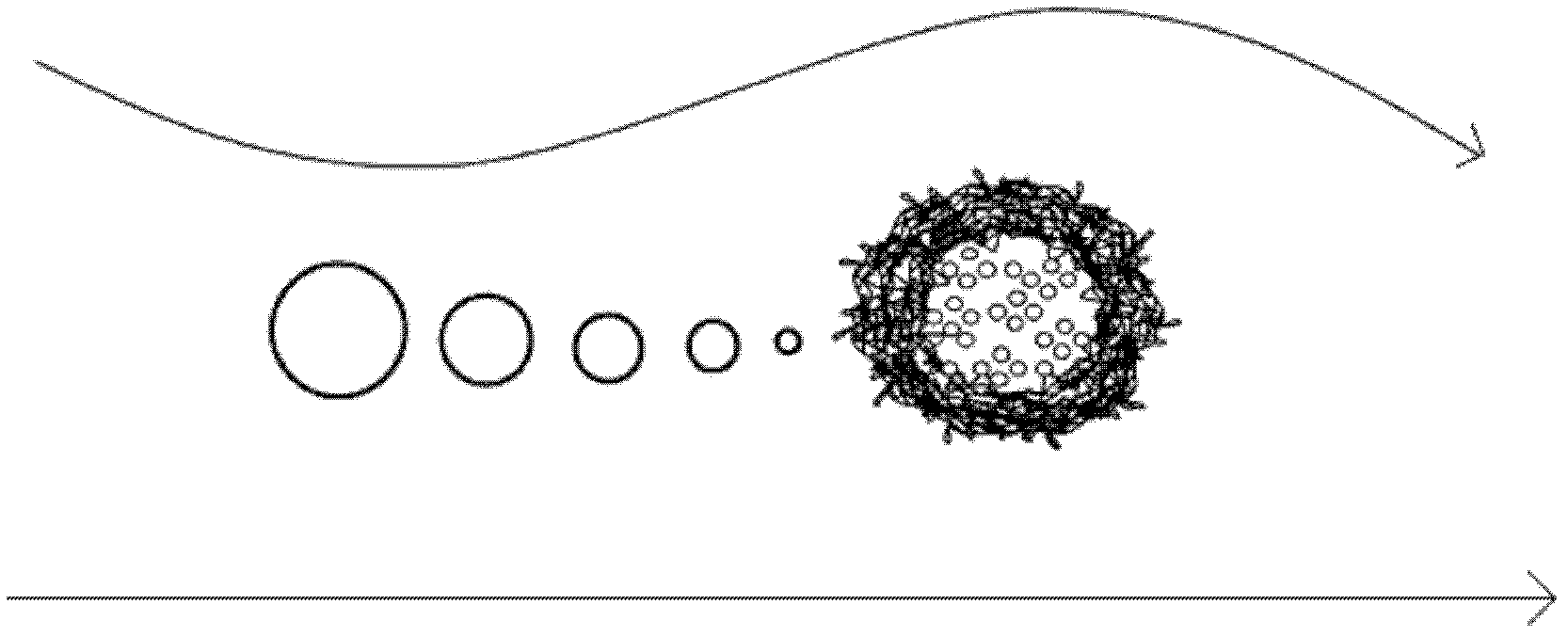

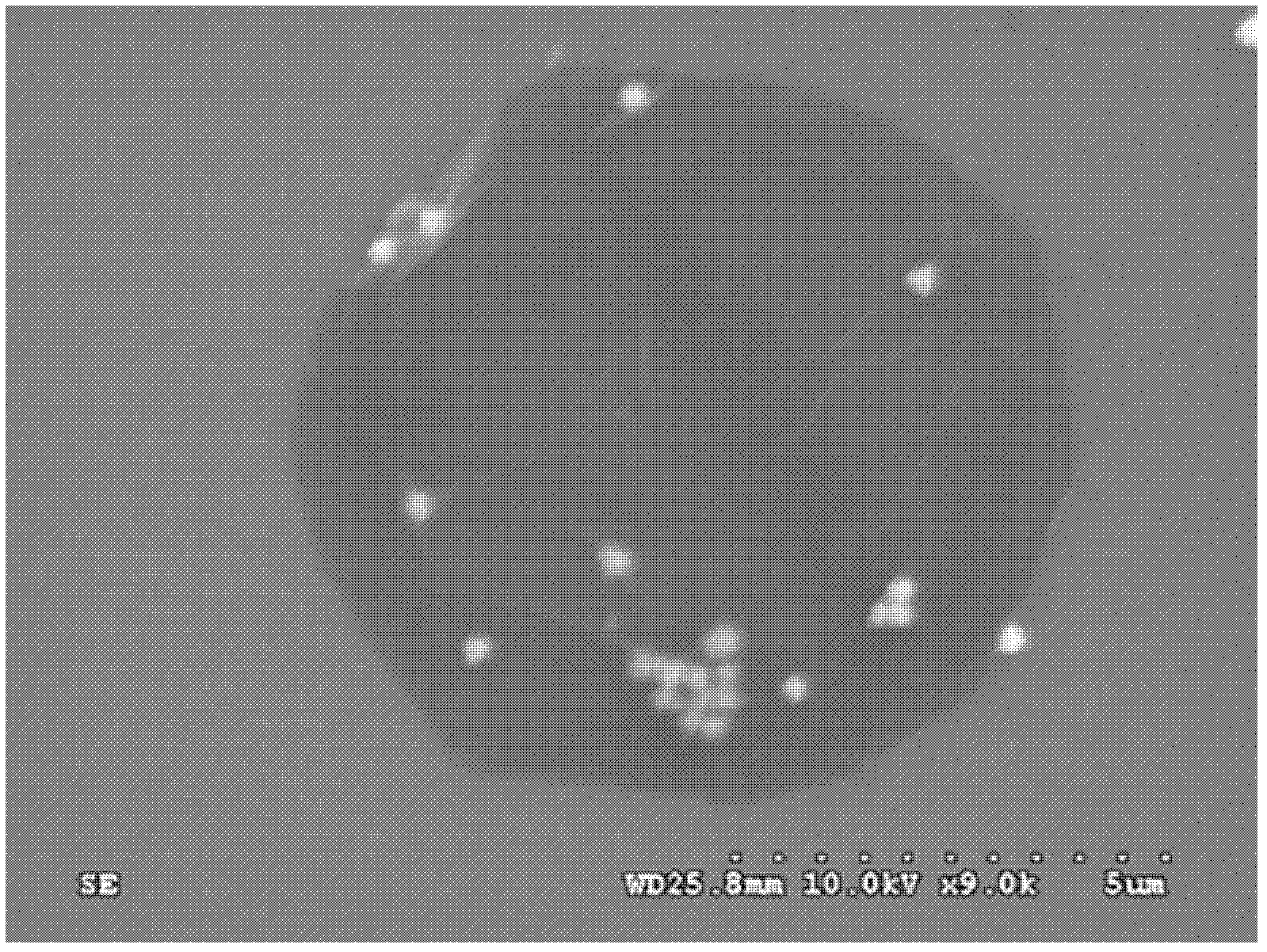

Artificial hollow micro-nano motor and preparation method thereof

InactiveCN102556935AGood load functionImprove transportation effectPrecision positioning equipmentPiezoelectric/electrostriction/magnetostriction machinesCationic polyelectrolytesEngineering

The invention provides an artificial hollow micro-nano motor and a preparation method thereof, relating to artificial motors and preparation methods thereof and solving the problem that the existing solid spherical motor, tubular motor and linear motor are poor in loading performance. The artificial hollow micro-nano motor is made from a polyelectrolyte double-layer skeleton and a catalyst or is made from a cationic polyelectrolyte skeleton and the catalyst; and the preparation method of the artificial hollow micro-nano motor comprises the following steps of: (1) preparing micro-nano catalyst particles; (2) synthesizing a core substrate; (3) synthesizing an artificial hollow micro-nano motor skeleton; and (4) removing the core substrate by using a template solvent so as to obtain the artificial hollow micro-nano motor. The preparation method has the advantages of simplicity and feasibility, stable process, good repeatability and convenience in mass production, and the prepared artificial hollow micro-nano motor is good in transportability and loading function, has a wide application prospect in a plurality of aspects, such as drug release control, blood purification, clinical diagnosis, and is simple in operation. The artificial hollow micro-nano motor prepared by the preparation method provided by the invention is applicable to the medical field.

Owner:HARBIN INST OF TECH

Angular motion tracking sensor

ActiveUS7868610B2Using electrical meansAcceleration measurementAbsolute orientationClassical mechanics

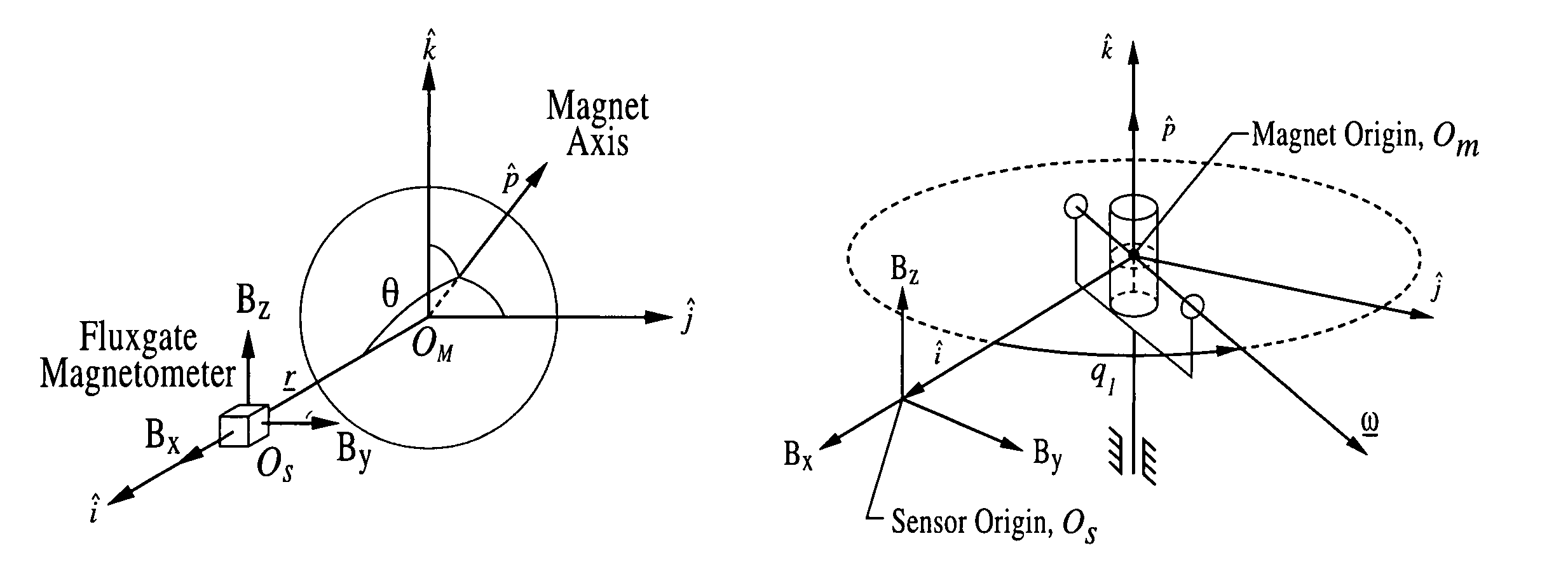

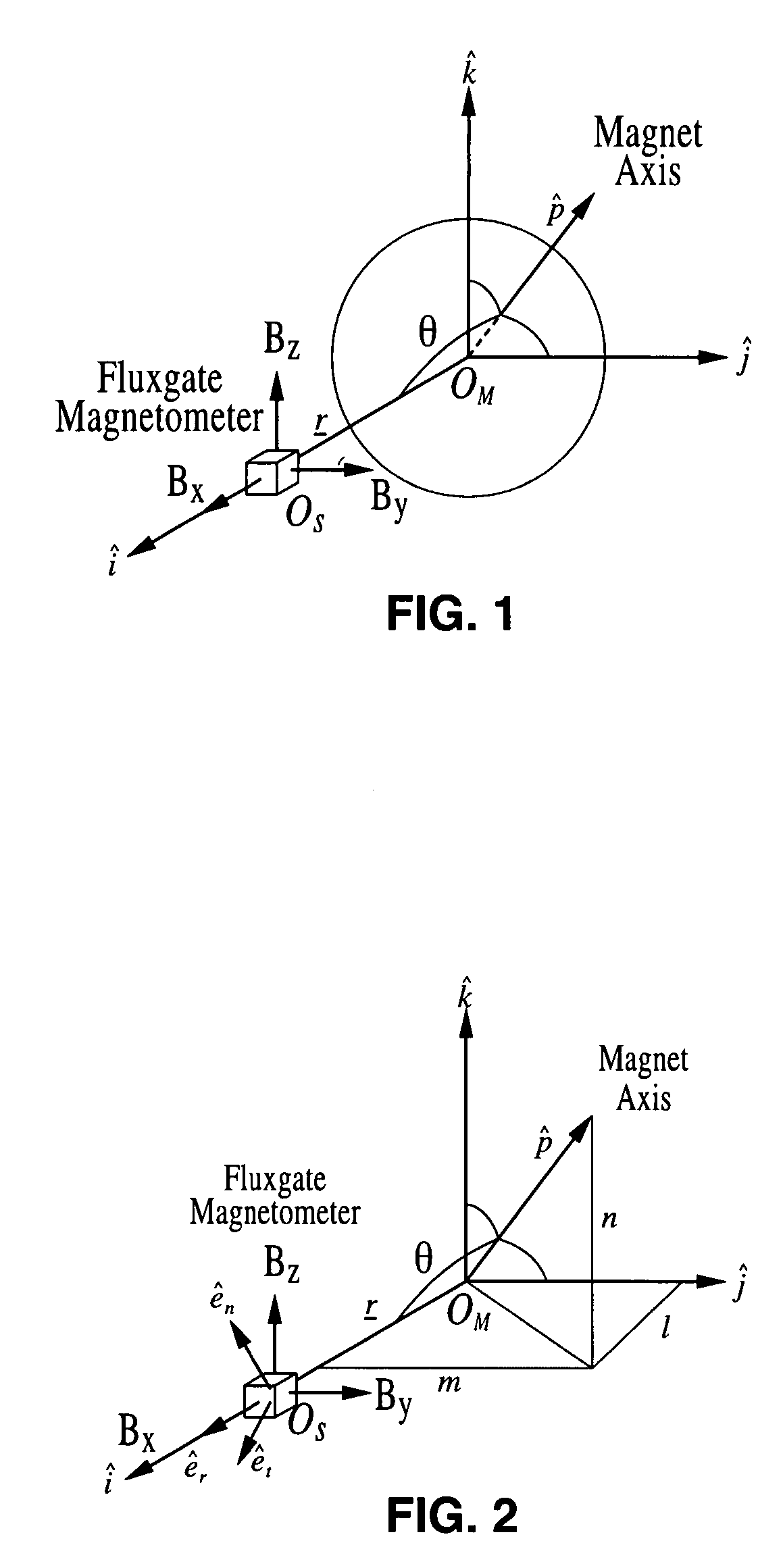

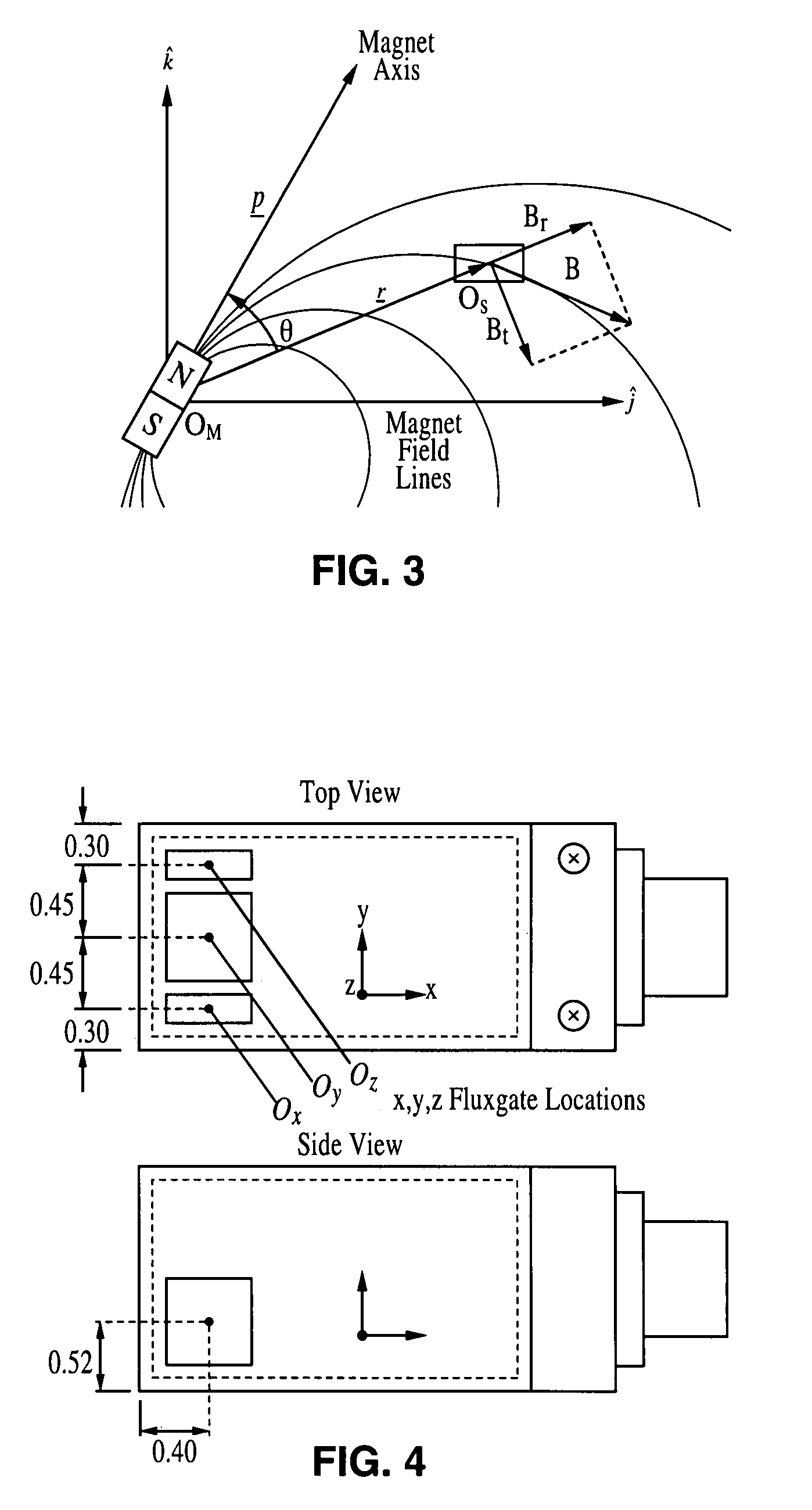

A motion tracking sensor apparatus configured for real-time, three-dimensional angular motion tracking that can determine the absolute orientation, axis of rotation and angular speed of a body rotating about a point, which is fixed relative to the sensor, without contacting the rotating body. The sensor obtains measurements of the three-dimensional magnetic field of a dipole fixed on the body. In one embodiment, a permanent magnet is embedded in the center of the rotating body, and the time-varying magnetic field is measured as the magnet rotates, and then the instantaneous magnet orientation from the field data is determined. The apparatus is particularly suited for use with devices that are based on a sphere rotating in a cradle such as spherical motors or spherical variable transmissions.

Owner:RGT UNIV OF CALIFORNIA

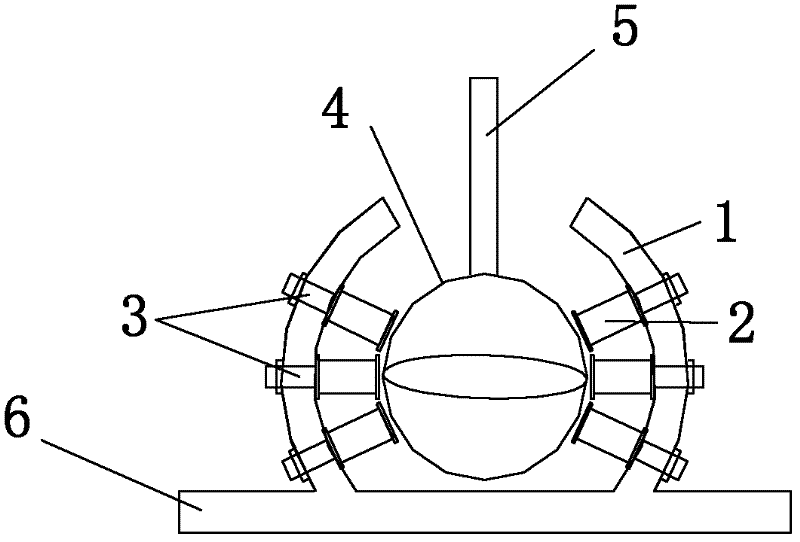

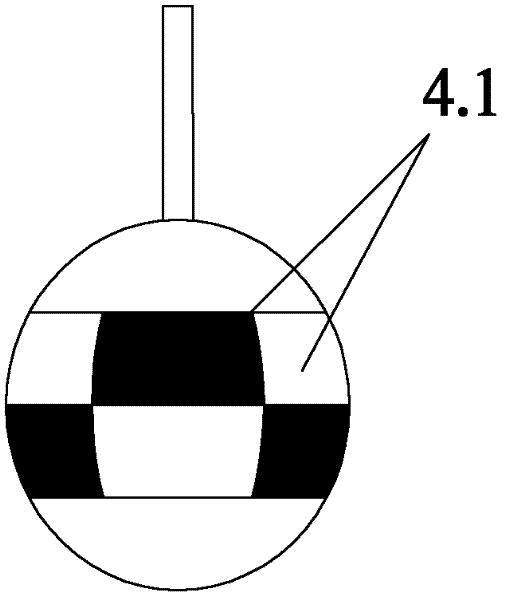

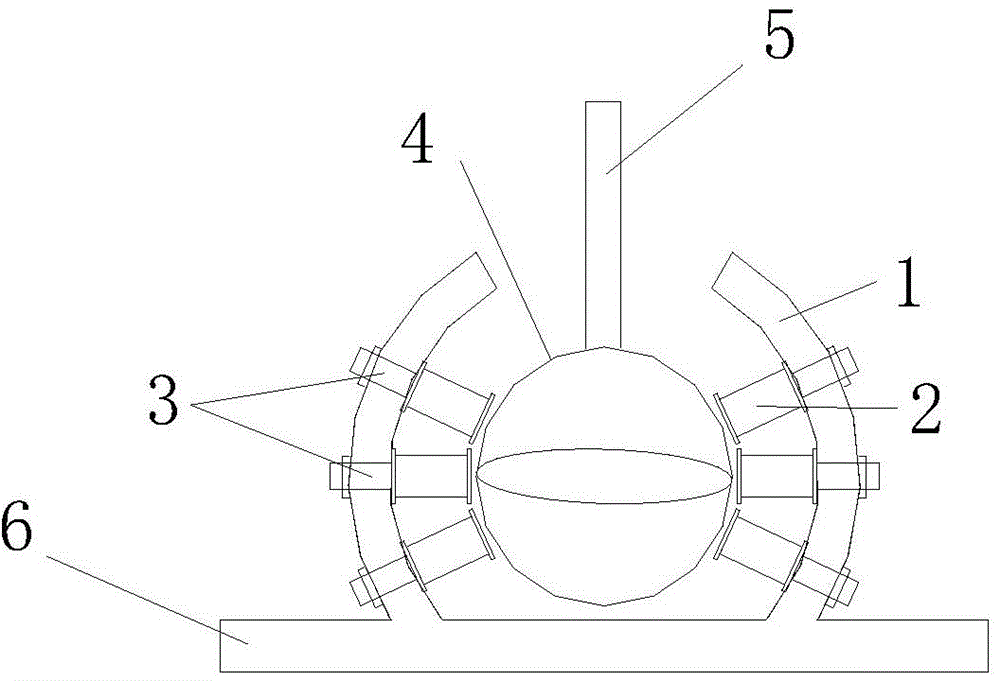

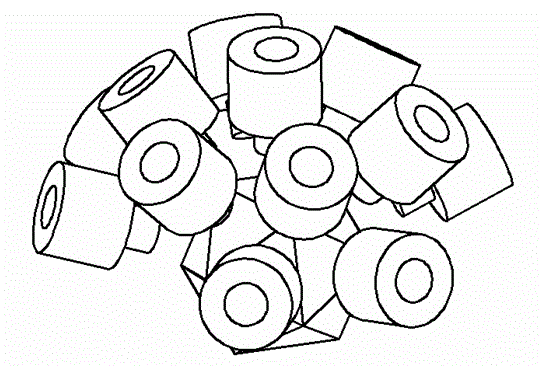

Three degree of freedom spherical motor with multiple physical field mixing driving

InactiveCN101777851ASimple designWith power-off self-locking abilityPiezoelectric/electrostriction/magnetostriction machinesThree degrees of freedomPhysical field

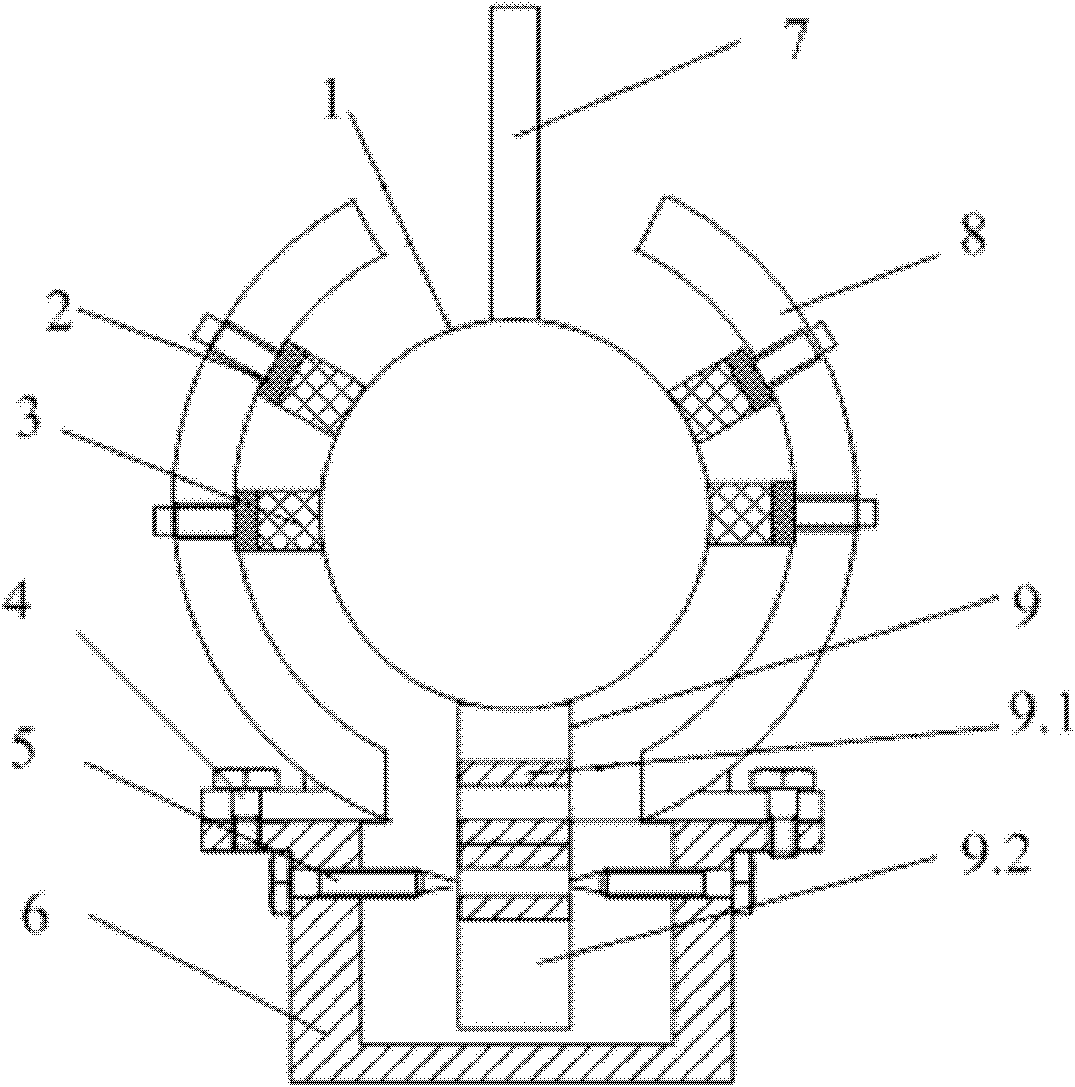

The invention belongs to the technical field of motor manufacture, and relates to a three degree of freedom spherical motor with multiple physical field mixing driving. The spherical motor comprises a supporting part, a stator and a spherical rotor, wherein the supporting part comprises a base and a spherical stator casing fixed on the base. The top end of the stator casing is provided with a circular hole. One layer or more than one layer of winding installation holes is uniformly distributed on the upper sphere of the stator casing in the direction parallel to the equator. The stator comprises a stator winding and an ultrasonic vibrator, wherein the stator winding consists of a winging shaft and a coil. The diameter of the winding shaft is slightly smaller than the inner diameter of the winding installation hole, and the top of the winding shaft penetrates through a compression spring and is arranged in the winding installation hole. The ultrasonic vibrator is fixed on the base, and the upper end of the ultrasonic vibrator is in an inner cone shape, and is matched with the spherical rotor. The spherical rotor is uniformly embedded in a multilayer permanent magnet pole along the direction parallel to the equator. The invention has reliable structure, improves the torque characteristic of the motor, and enhances the design flexibility of the motor control system.

Owner:TIANJIN UNIV

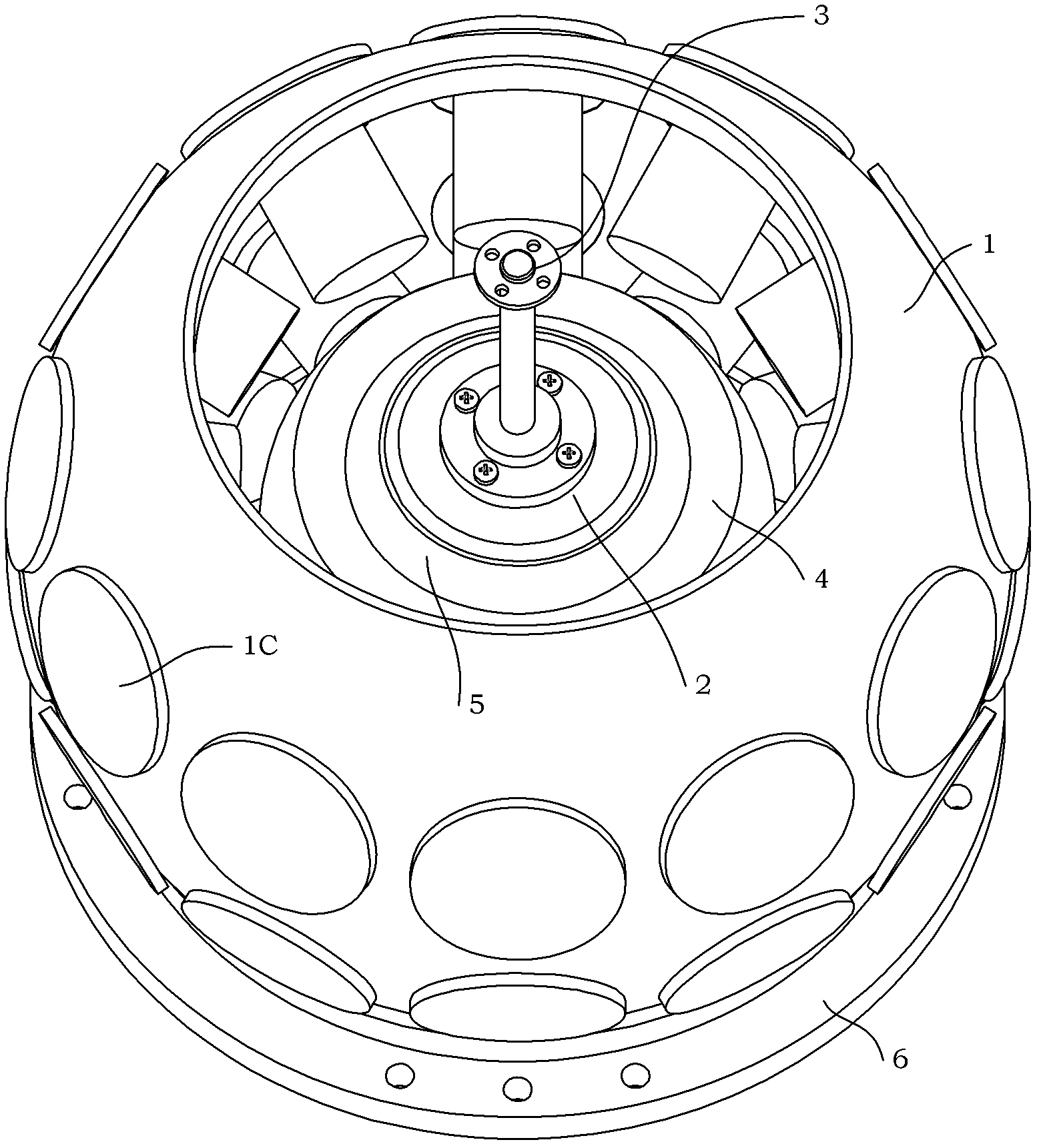

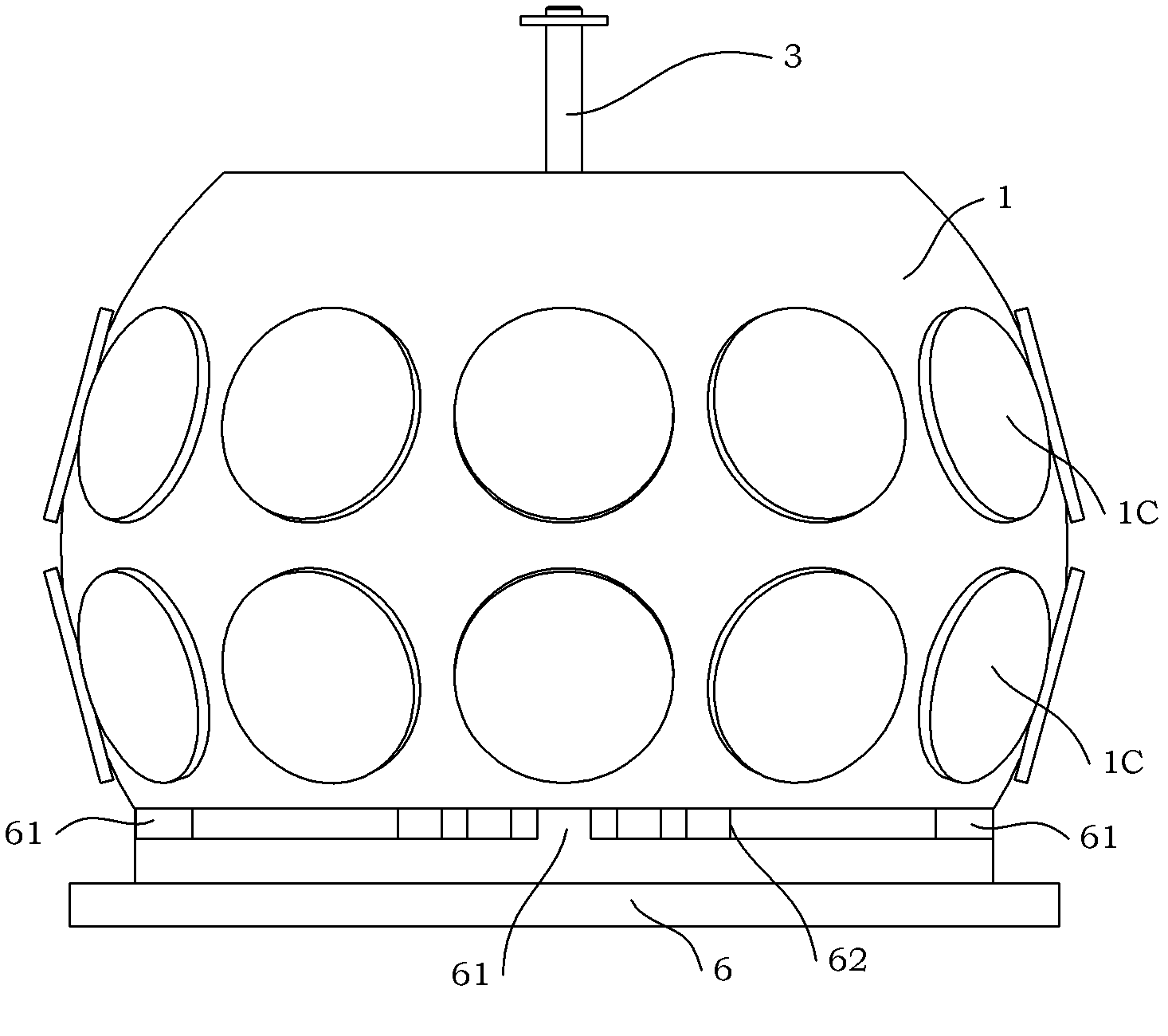

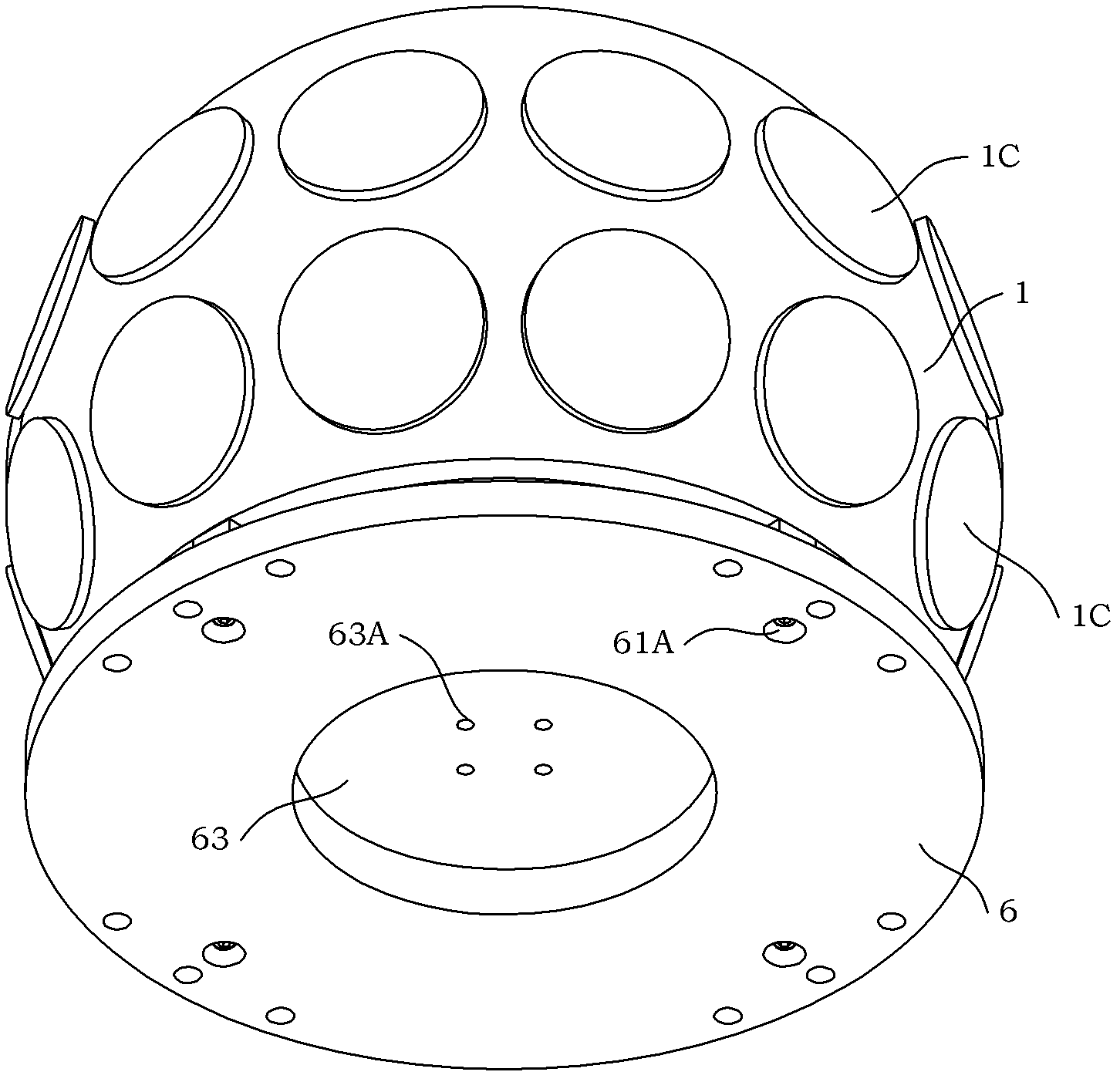

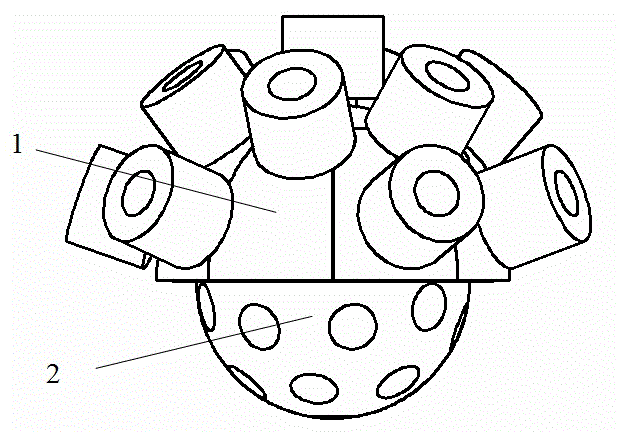

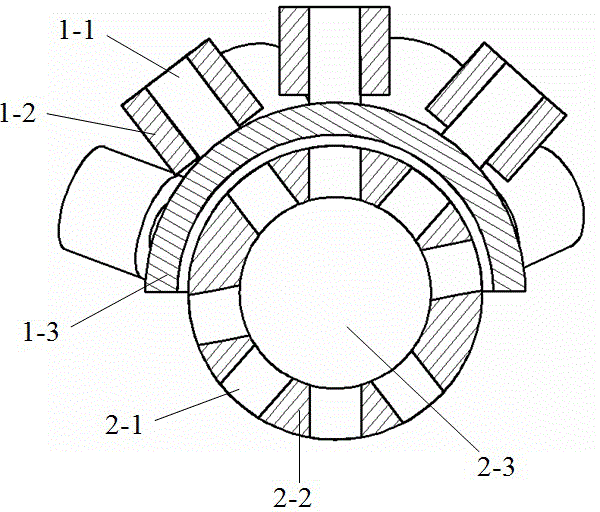

Six degrees of freedom permanent magnet synchronous magnetic suspension spherical motor

ActiveCN104836408ACapable of driving with multiple rotational degrees of freedomNo mechanical connectionMagnetic holding devicesSynchronous machines with rotating armatures and stationary magnetsClassical mechanicsMulti degree of freedom

The present invention discloses a six degrees of freedom permanent magnet synchronous magnetic suspension spherical motor. The six degrees of freedom permanent magnet synchronous magnetic suspension spherical motor comprises a spherical shell-shaped stator (1) and a spherical rotor (2), the spherical shell-shaped stator (1) and the spherical rotor (2) are not contacted, and the spherical rotor (2) suspends in the middle of the spherical shell-shaped stator (1) by depending on an electromagnetic force. By controlling the electromagnetic force to adjust the relative positions of the centers of the spherical shell-shaped stator (1) and the spherical rotor (2), and currents are accessed in a horizontal coil and a vertical coil in the spherical rotor (2) according to the dq0 decomposition, so that the spherical rotor (2) suspends in the spherical shell-shaped stator (1) by being applied with a centripetal buoyancy, and realizes the multi-degree of freedom rotation by being applied with the torque effect along any axis relative to the spherical shell-shaped stator (1). The six degrees of freedom permanent magnet synchronous magnetic suspension spherical motor of the present invention is compact in structure, has zero friction, can be used as a multi-degree of freedom joint of a robot, and provides the high-speed and high-precision control.

Owner:BEIJING MECHANICAL EQUIP INST

Film conveying deviation-rectifying device combining tension control

The invention provide a film conveying deviation-rectifying device combining the tension control, which comprises a film input guiding roller, an output guiding roller, a deflection detecting mechanism, a tension detecting mechanism, a controller and a deviation-rectifying actuating mechanism, wherein the film input guiding roller and the output guiding roller are used for inputting a film guide into the deviation-rectifying actuating mechanism and outputting the film guide from the deviation-rectifying actuating mechanism; the deflection detecting mechanism is used for detecting whether the film deflects or not; the tension detecting mechanism is used for detecting the film tension; the controller is used for generating deviation-rectification or / and tension control instruction as per the detection information; the deviation-rectifying actuating mechanism comprises a spherical motor, a deflection frame and a deviation-rectification roller; a runner of the spherical motor drives the deflection frame to rotate on a feeding surface of the film; the friction between the rectification roller and the film drives the inverse rotation of the film to realize the deviation-rectification; meanwhile, the runner of the spherical motor drives the deflection frame to rotate on the surface vertical to the feeding surface of the film, so as to tighten or loose the film to realize the tension control. According to the invention, the deviation-rectification and the tension control of the film can be realized simultaneously, the influence of the tension variation on the deviation-rectification is greatly reduced, the structure is simple, and the deviation-rectifying precision is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Spherical motor using oscillatory magnetic fields

Owner:NORTHROP GRUMMAN SYST CORP

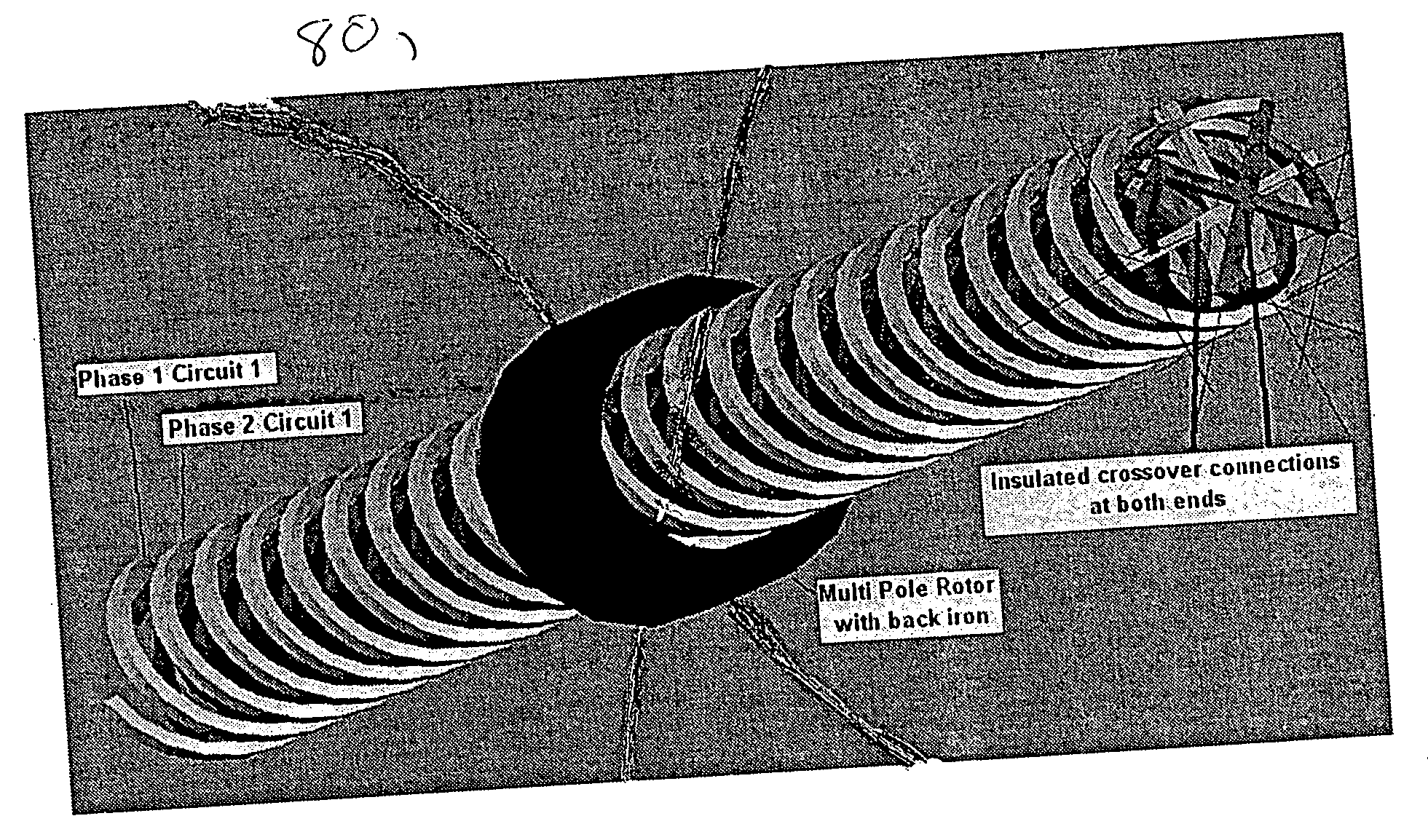

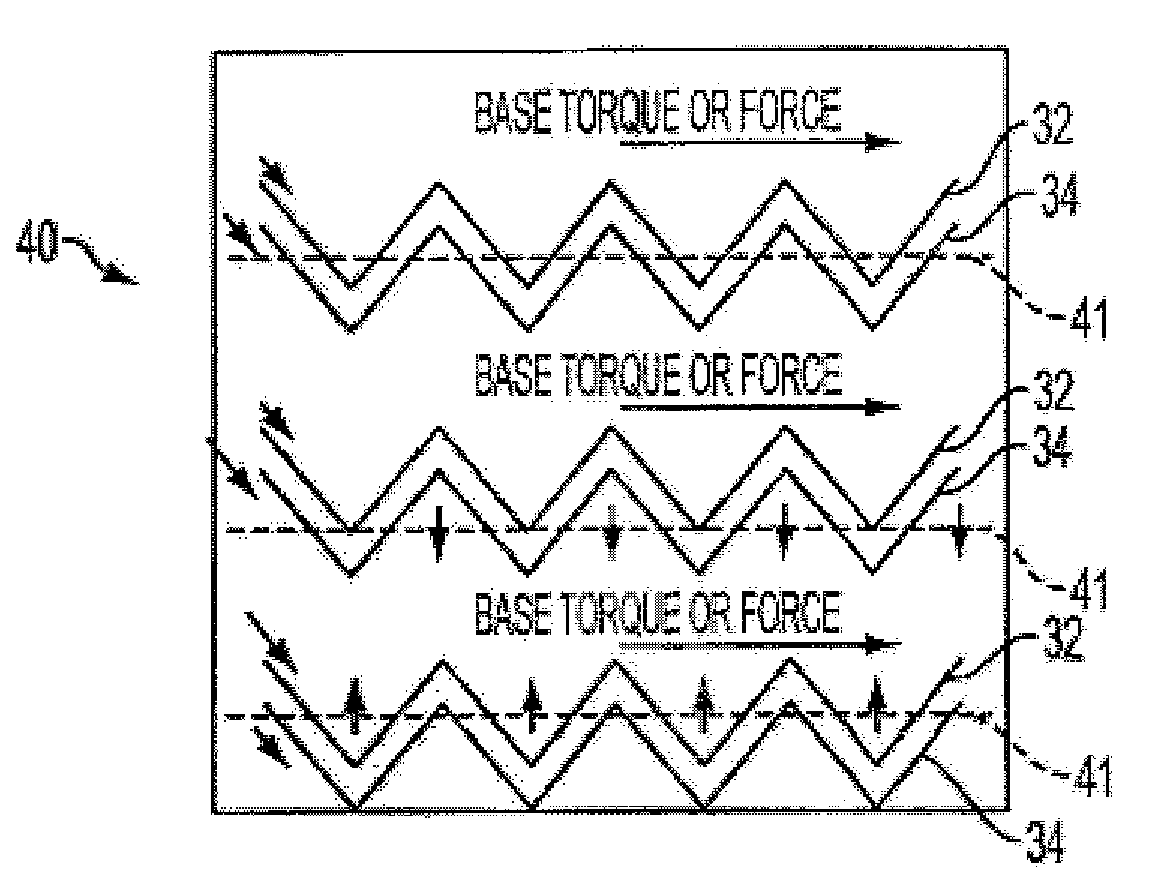

Magnetic bearing using displacement winding techniques

InactiveUS20050264119A1Magnetic circuitAsynchronous induction motorsPermanent magnet rotorMagnetic bearing

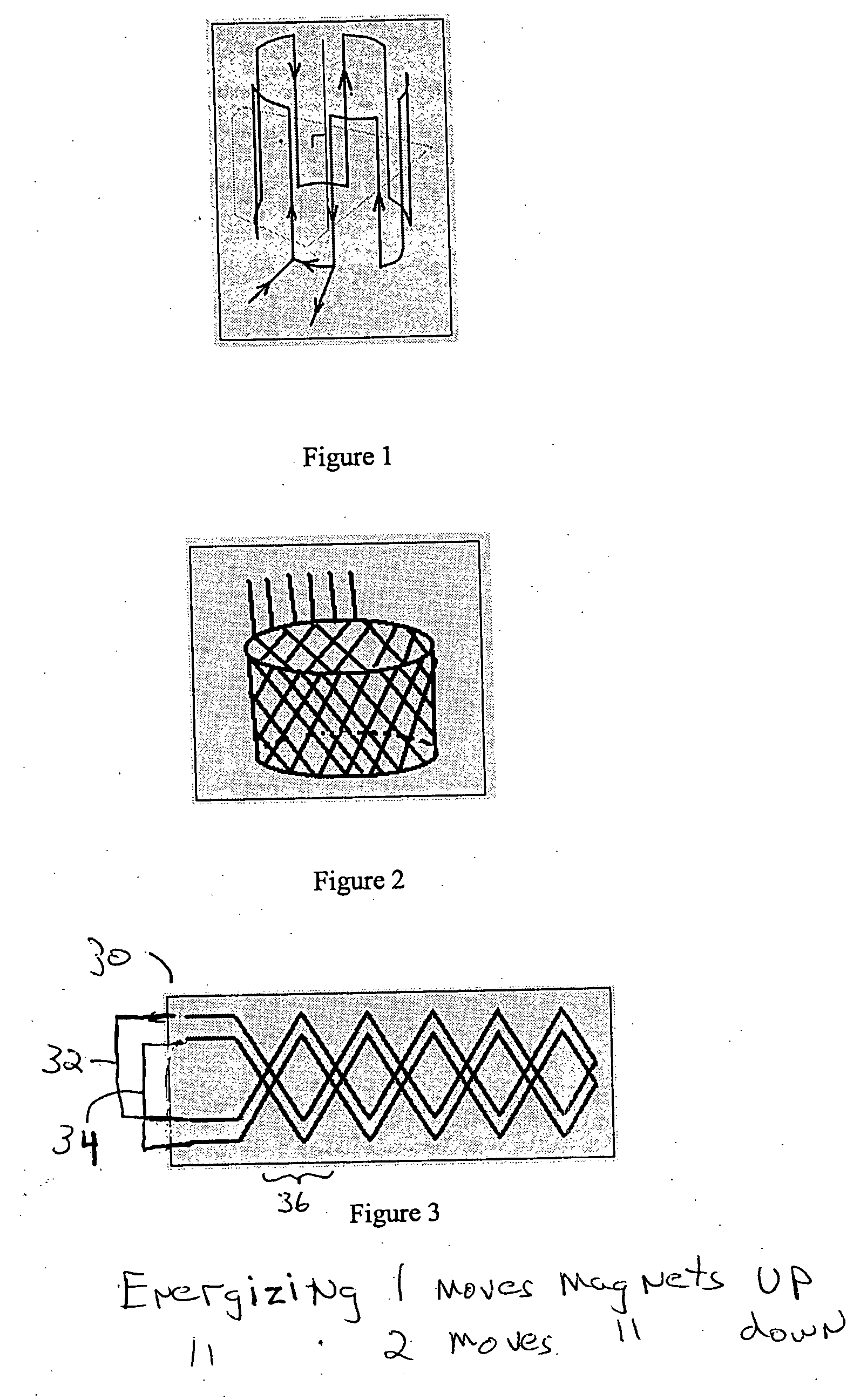

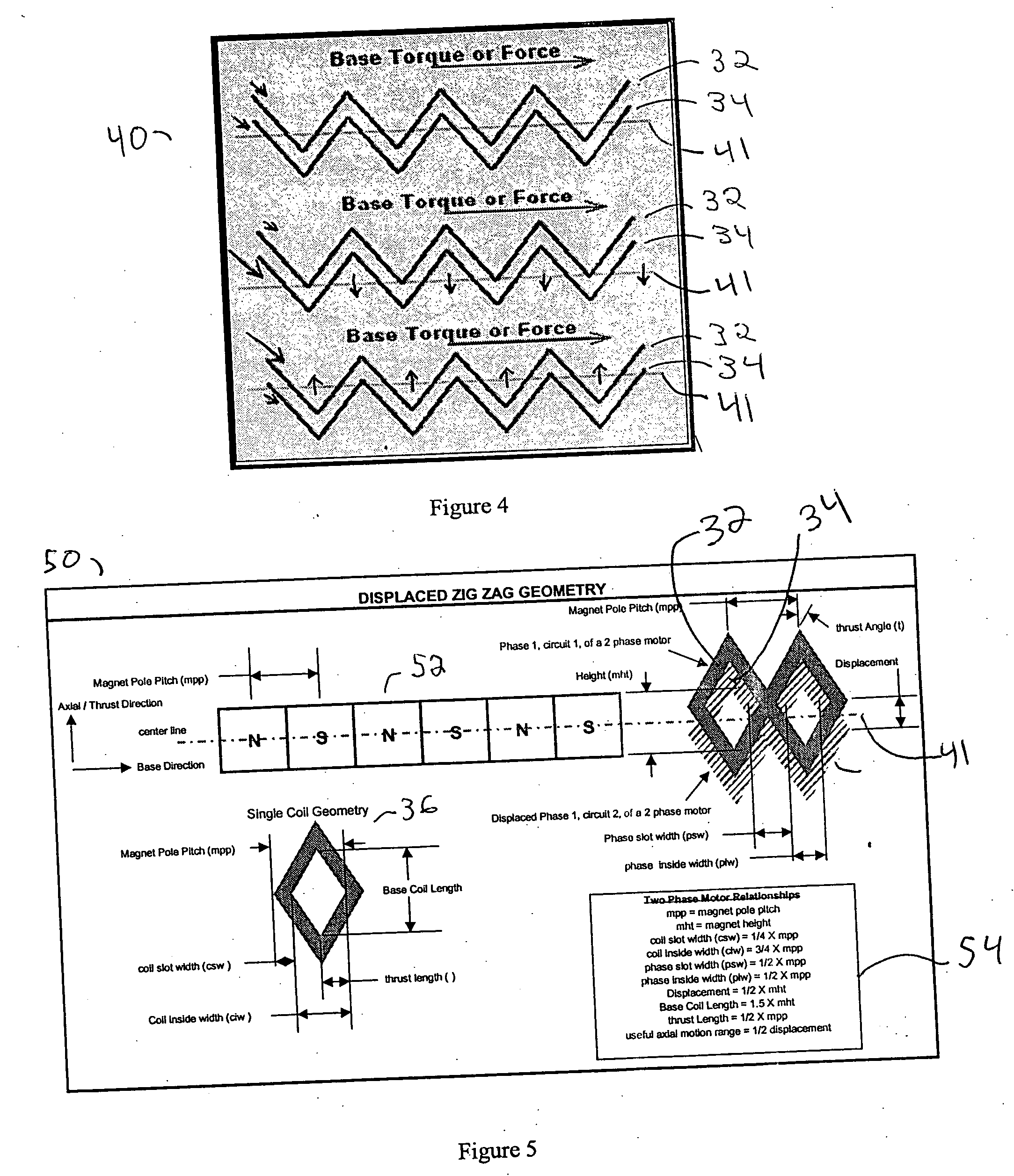

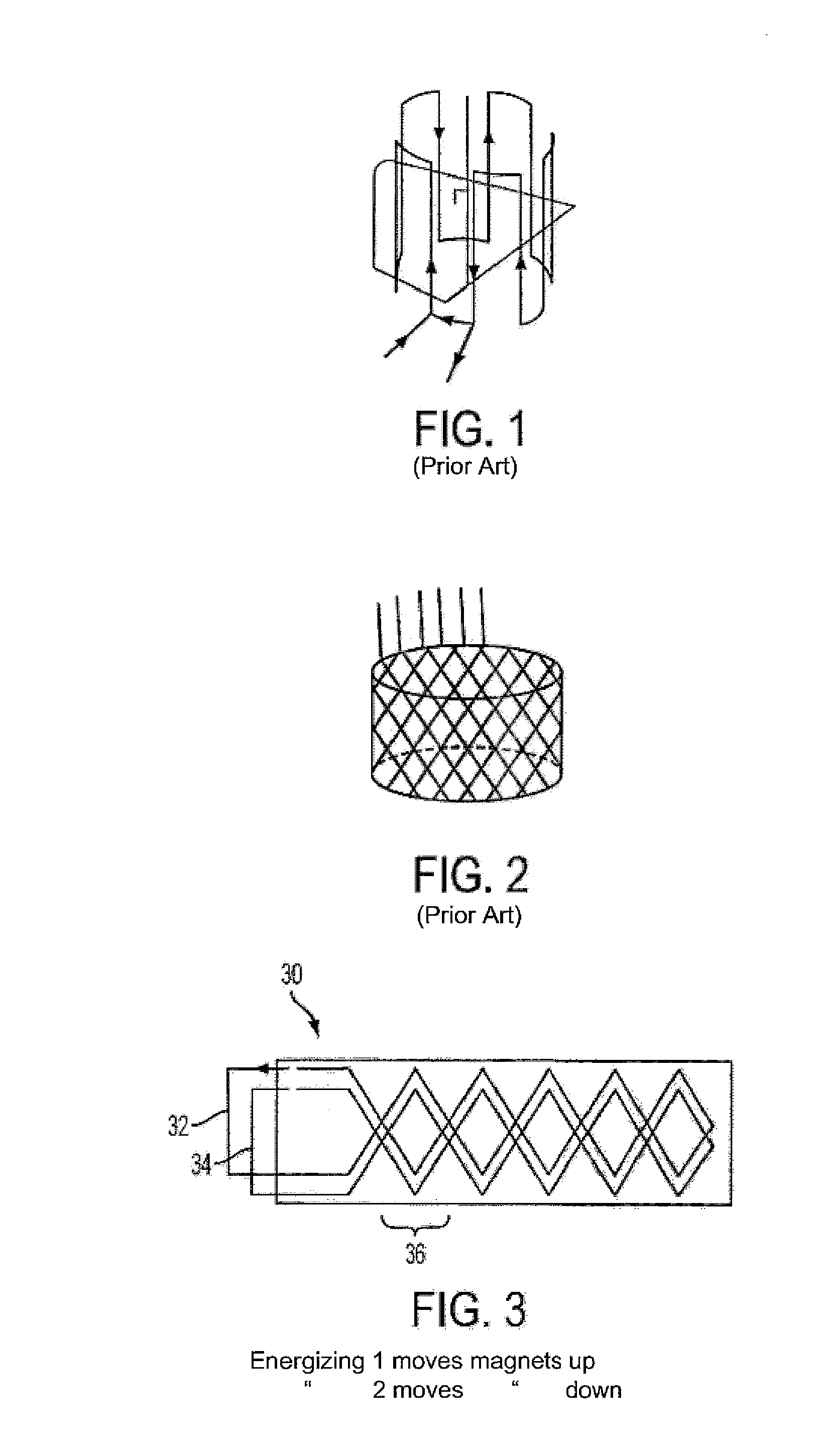

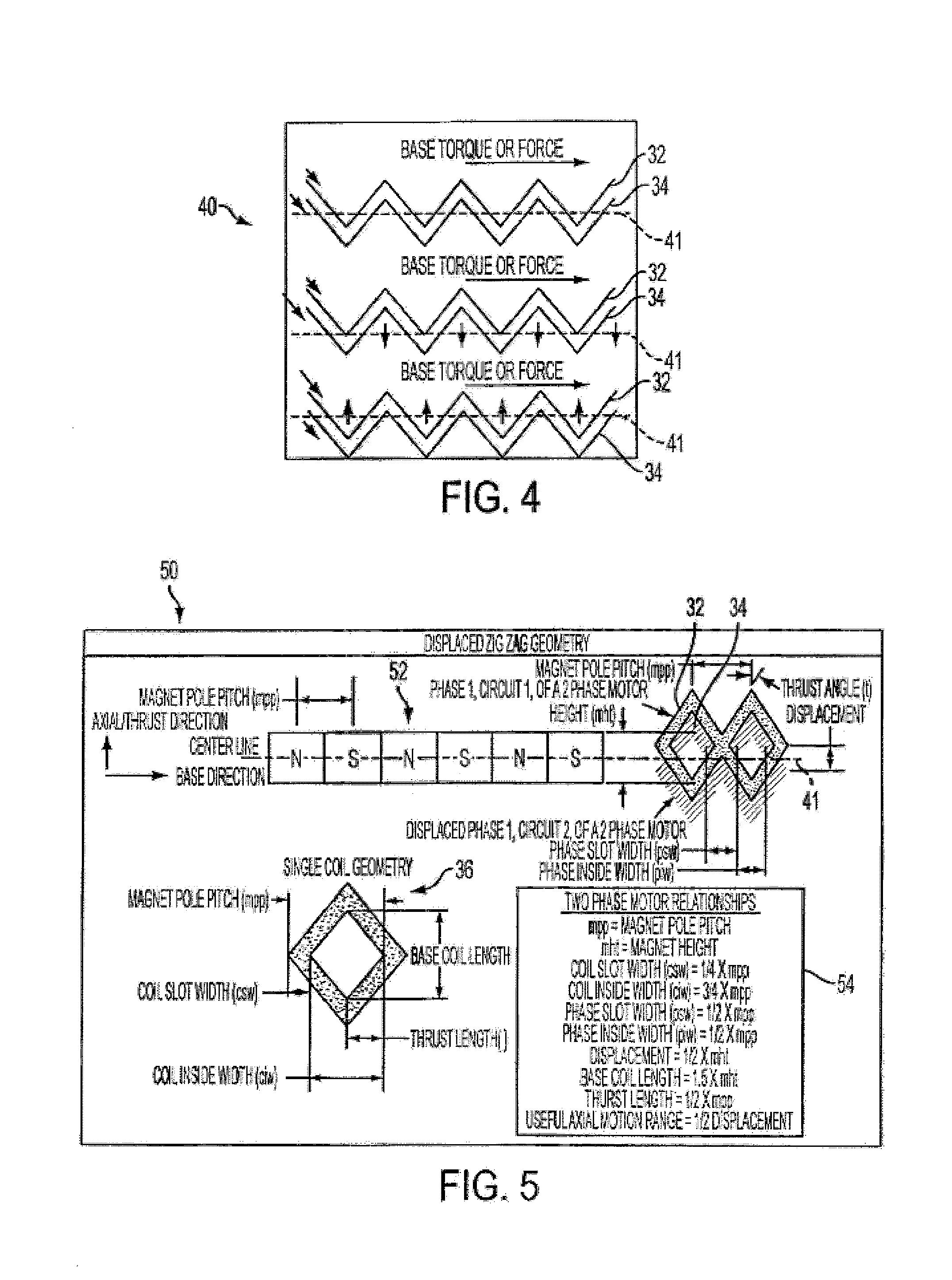

The present invention provides a linear, rotary spherical motor with an integrated magnetic bearing. The motor can be a toothless permanent magnet, BLDC design composed of a permanent magnet rotor and a Zigzag stator winding containing at least two-phase windings, where each phase is constructed of at least two circuits. Other exemplary embodiments include a trapezoidal winding configuration. The individual circuits of a phase are displaced away from each other along a line that is at right angles to the direction of the alternating polarity magnet array. The circuits forming a phase share the same “slot”, and each circuit resembles a complete phase winding, however each circuit contains a proportion of the total number of turns of the phase. Controllable axial bearing force is developed through the differential balance of the currents in the circuits, while required motor torque is generated by the sum of the individual currents in a given phase. The relative motion in the rotor can produce back EMF which can provide positional information; A) in the direction parallel to the magnet array via the sum of the voltages in a phase; B) in the direction normal to the magnet array via the difference in circuit voltages.

Owner:AIREX CORP

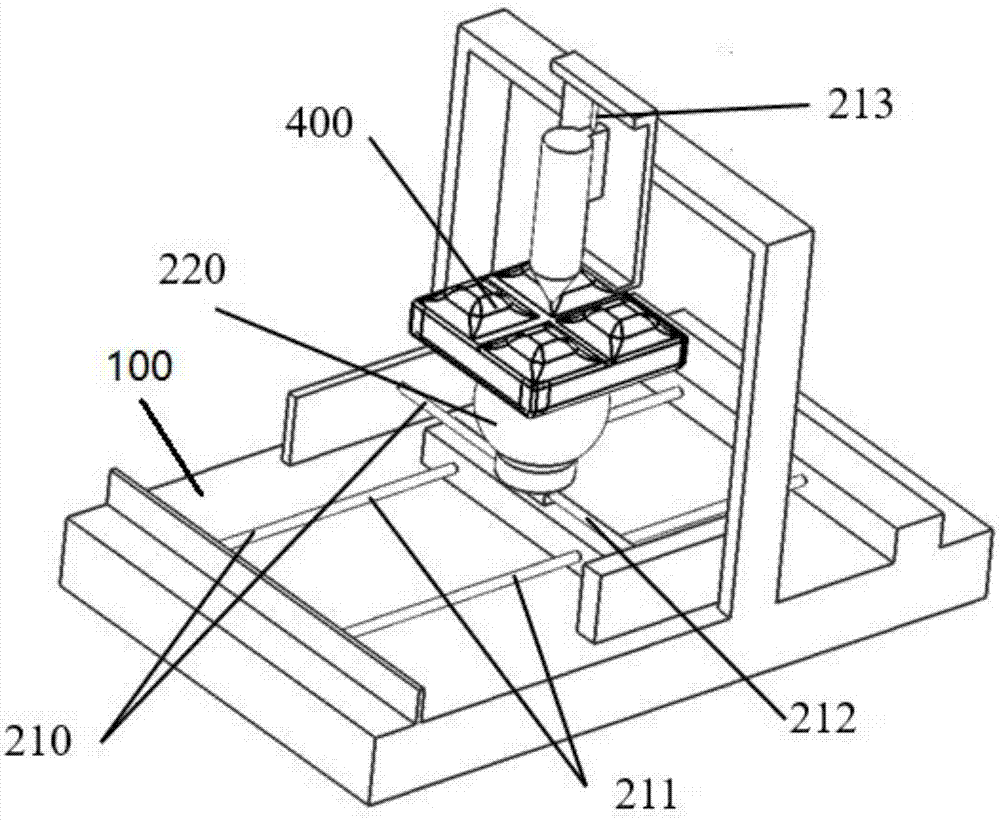

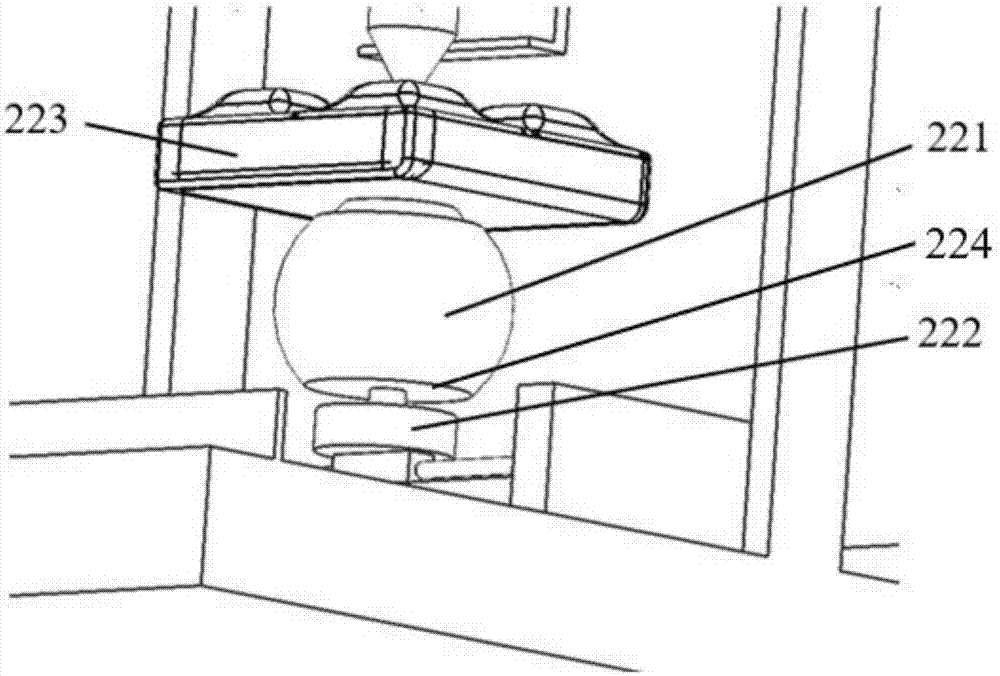

Complex surface circuit conformal spray printing method and equipment

ActiveCN107512083AOmit vector transformationSteady ejectionDuplicating/marking methodsTypewritersManufacturing cost reductionComputer module

The invention belongs to the field of electric fluid dynamics spray printing, and discloses a complex surface circuit conformal spray printing method and equipment. The equipment comprises a spherical motor module, a translation module and a conformal spray printing module. The translation module drives the spherical motor module to move in an X-axis direction and a Y-axis direction in a plane; the conformal spray printing module comprises a spray head part and an electric signal part; the spray head part moves up and down so as to realize a freedom degree of a Z-axis direction; the electric signal part applies voltage on an ink fluid and an electrode ring in an ink cartridge; the spherical motor module rotates around the X-axis direction, the Y-axis direction and the Z-axis direction so as to realize six-degree-of-freedom motion of an object to be spray-printed; a curve surface base plate is grounded, so that the electric potential of the object to be sprayed-printed is zero; and the voltage applied in the ink fluid is higher than the voltage applied in the electrode ring, so that a gradient electric potential difference is formed on the ink fluid, the electrode ring and the object to be spray-printed. Through the complex surface circuit conformal spray printing method and the equipment provided by the invention, a conformal patterning electric spray-printing process of a complex surface is realized, an application range of the electric spray-printing process is improved, the manufacturing cost is reduced, and the printing accuracy is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

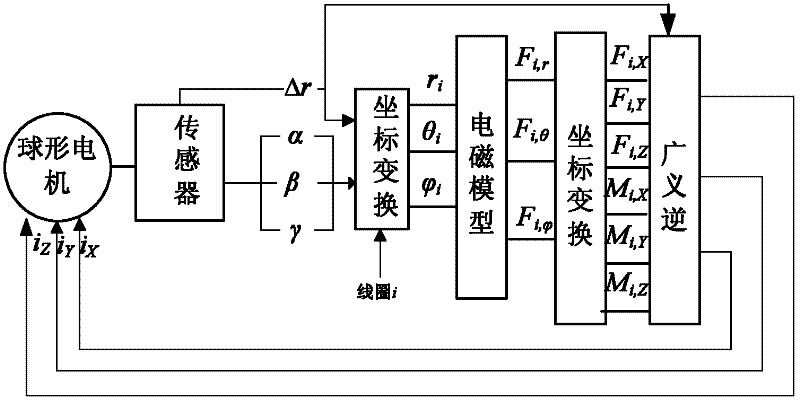

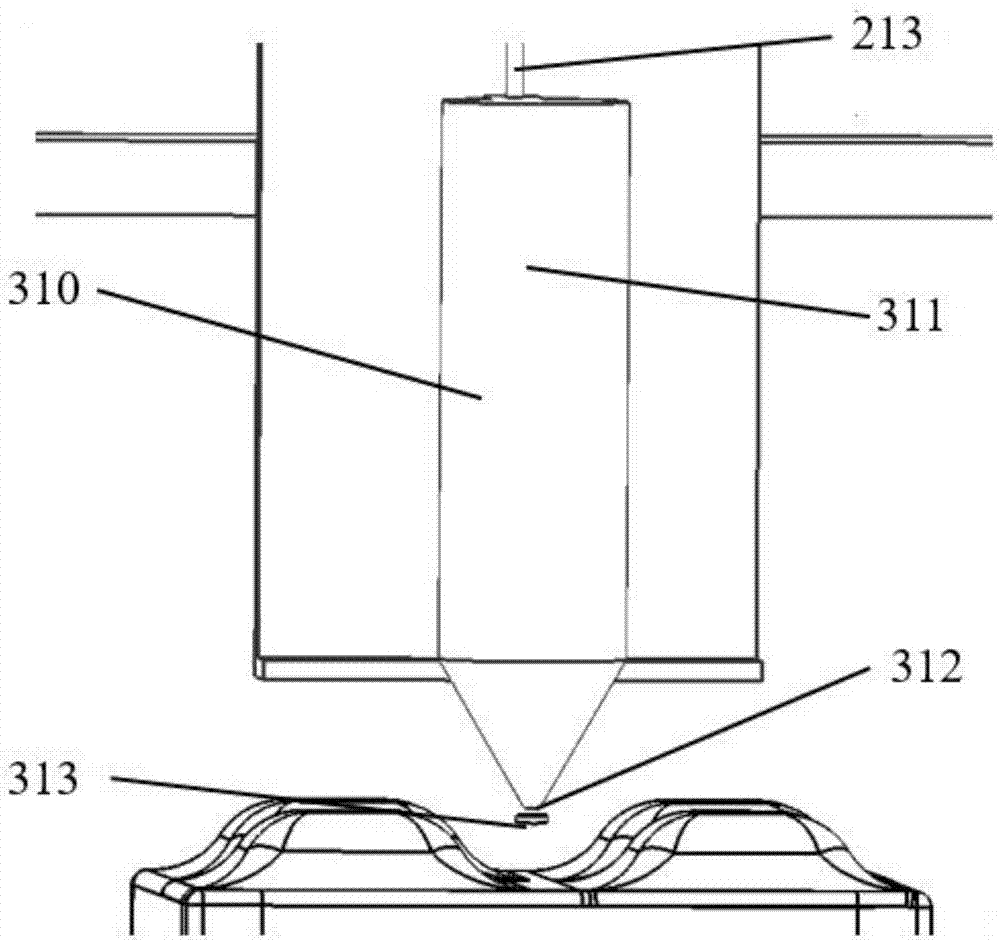

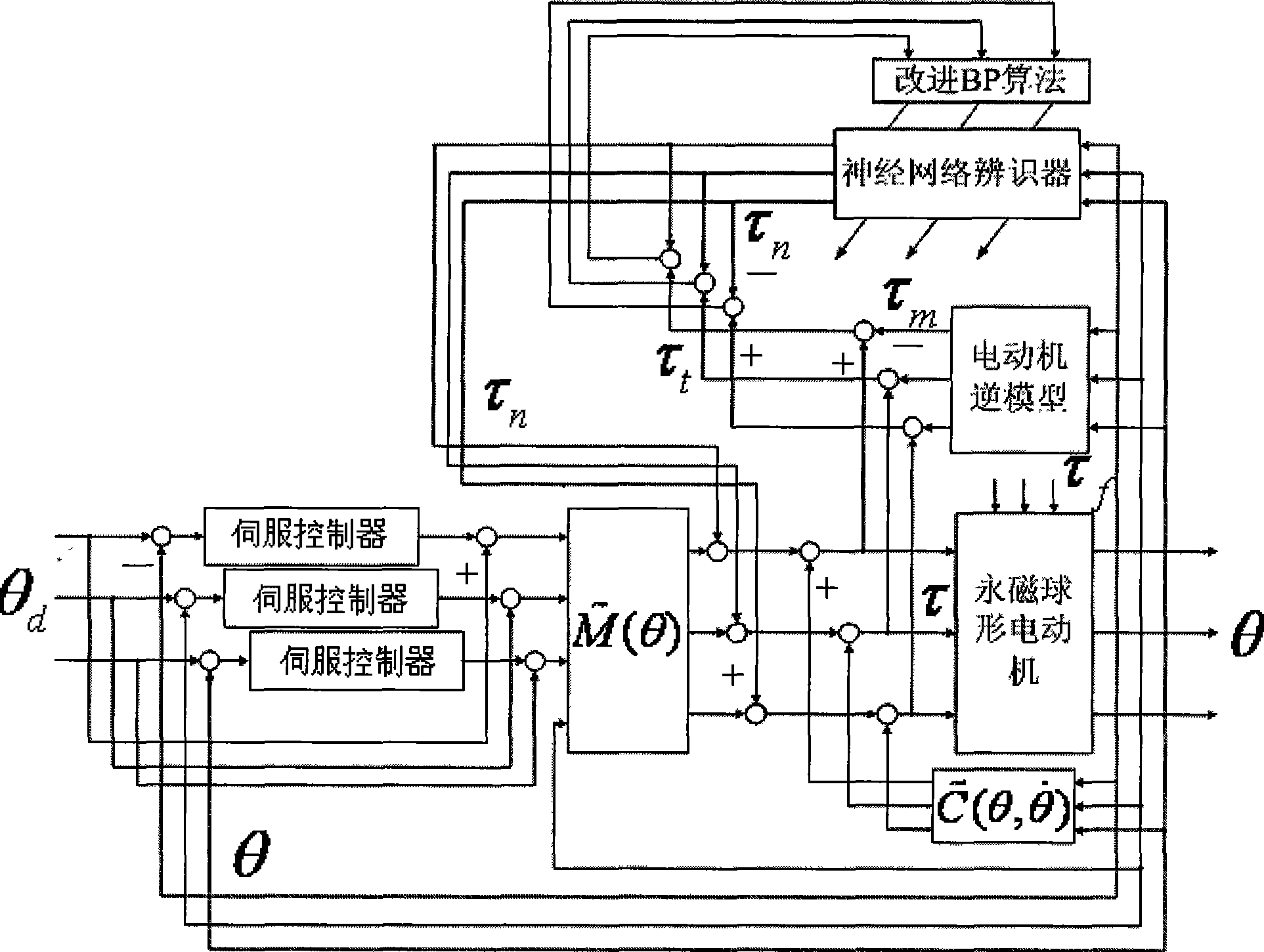

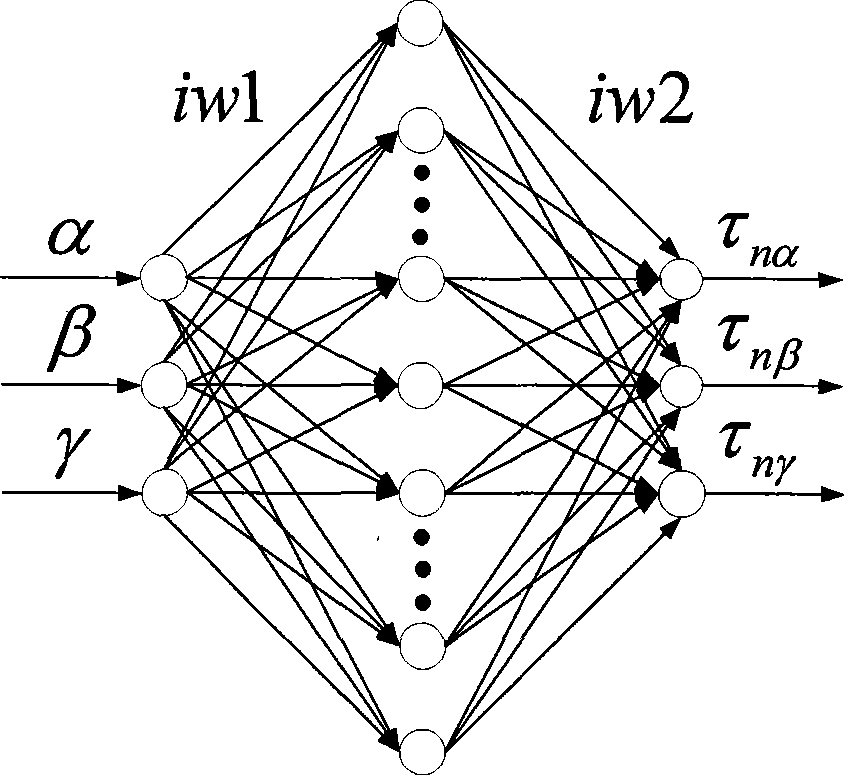

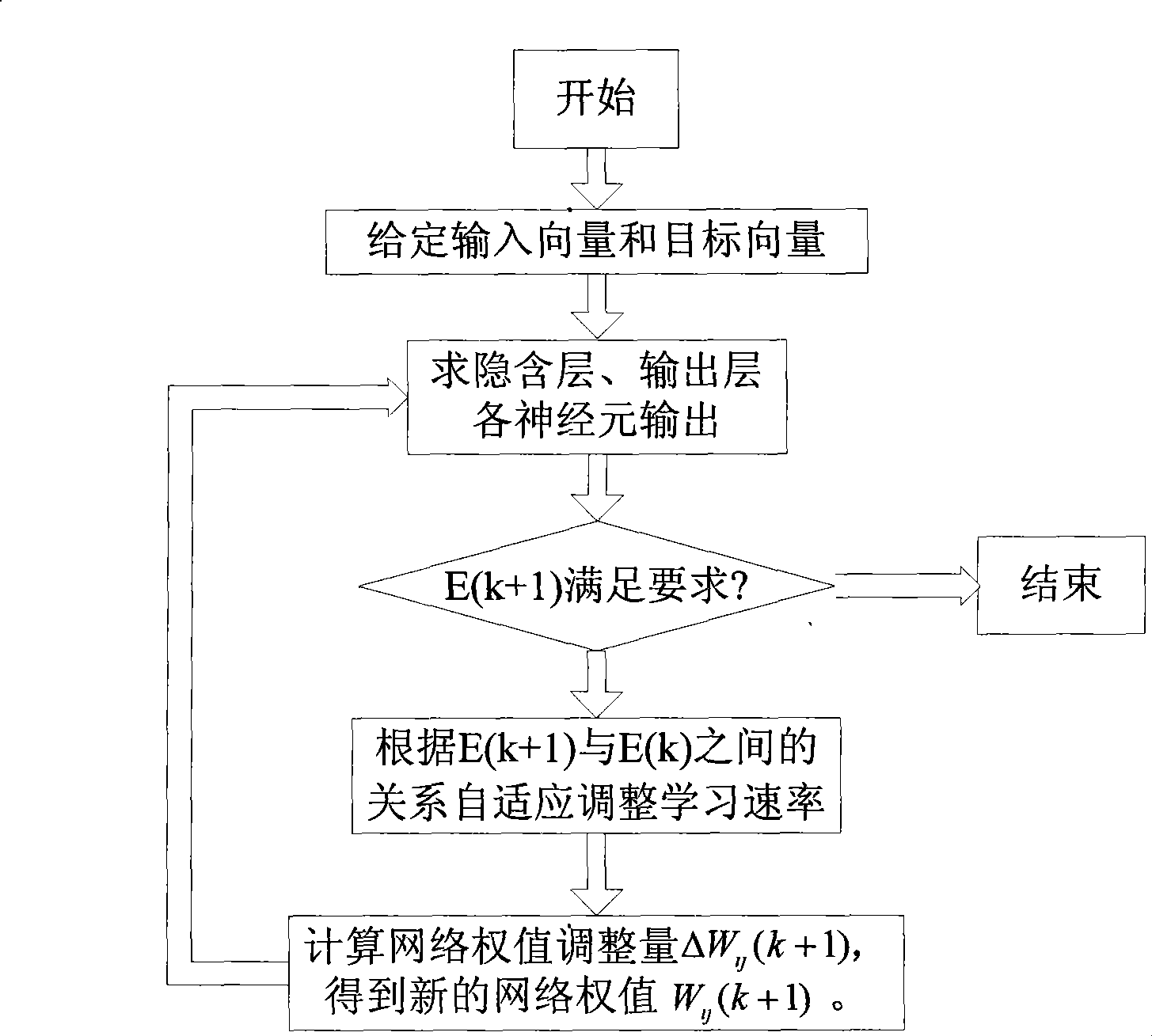

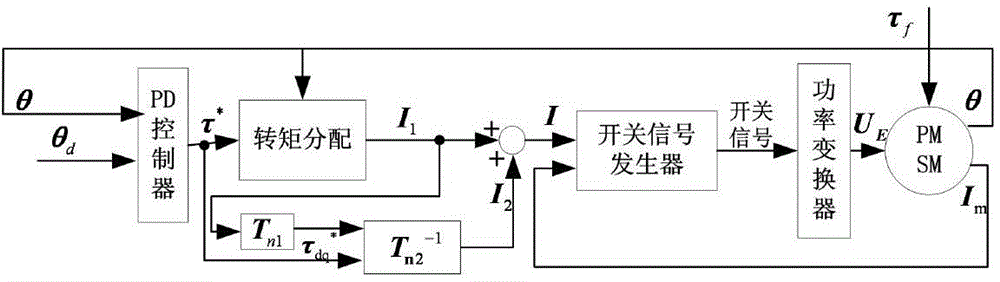

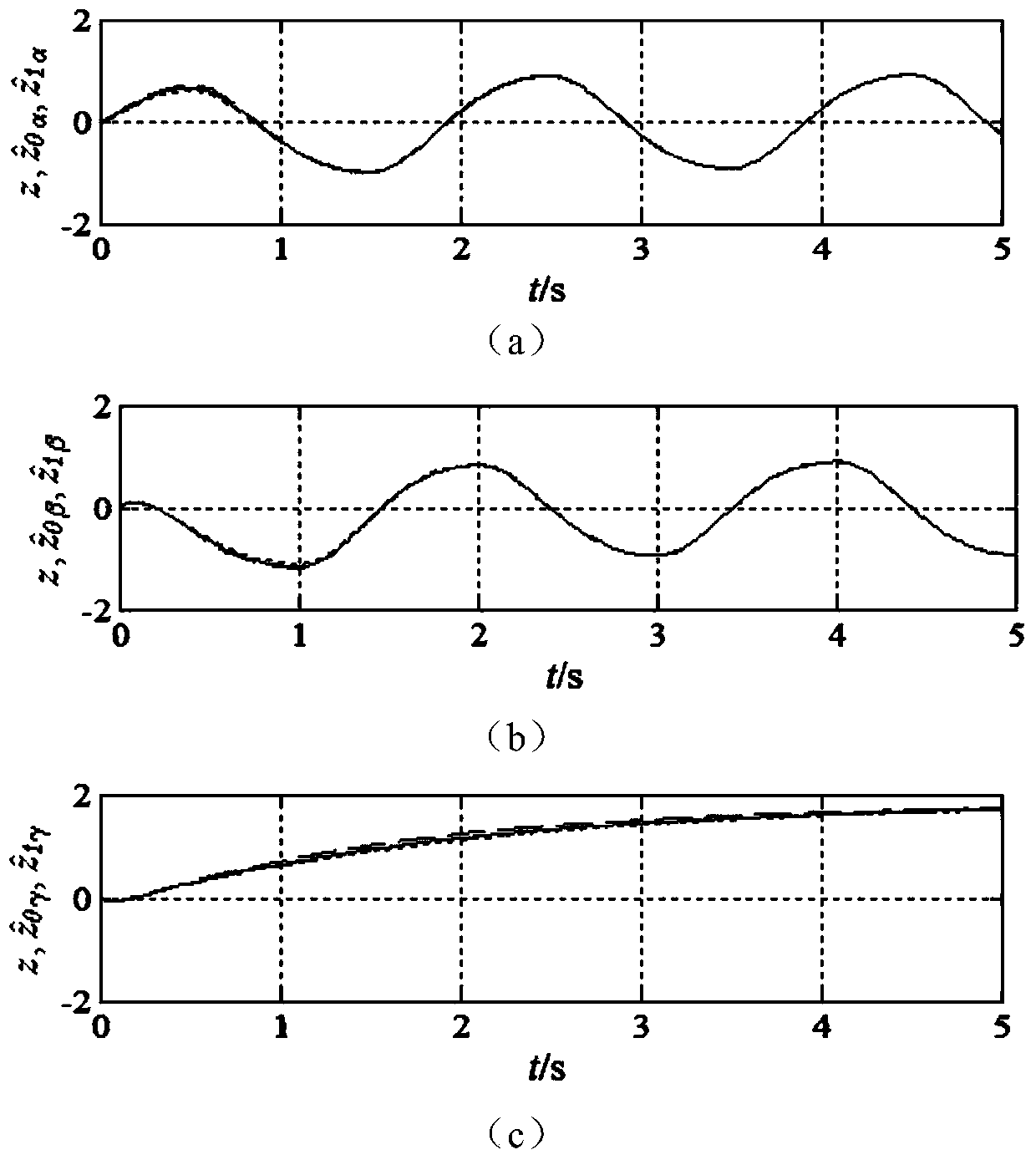

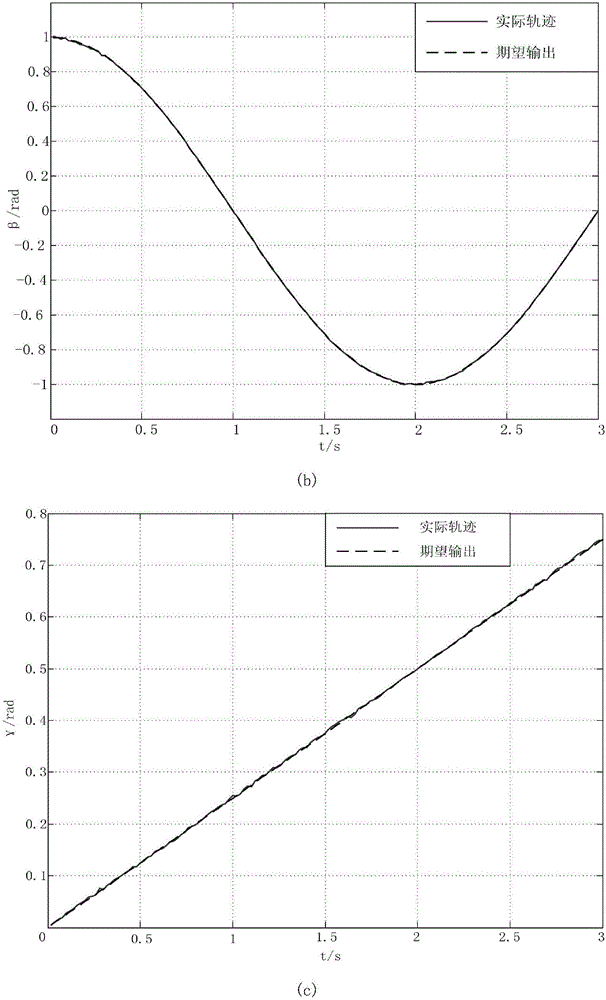

Permanent magnet spherical motor mechanical decoupling control method based on neural network identifier

The invention belongs to the dynamic control technique field of the permanent magnet spheric electromotor, and relates to a decoupling method for the electromotor dynamics. The method comprises a servo controller and a neural network feedforward controller; wherein, the neural network feedforward controller can be established according to the following steps: a dynamical equation of the spheric electromotor is established; two layers of neural network identifiers are established, input signals of the neural network identifiers are position angle vectors Theta (Alpha, Beta, Gamma ) which are output by the spheric electromotor, and output signals thereof are feedforward compensation torque vectors (Tau[nAlpha], Tau[nBeta], Tau[nGamma]); a weight adjusting equation which is provided with additional momentum can be used to train the neural network identifiers; the neural network identifiers are identified online, so as to achieve the feedforward compensation of the torque vectors (Tau[nAlpha], Tau[nBeta], Tau[nGamma]). The method can effectively weaken module estimation errors and interference effects outside the system.

Owner:TIANJIN UNIV

Electromagnetic-piezoelectric-mixed-driving-based three-degree-of-freedom spherical motor

InactiveCN102355103ALarge output torqueIncrease output torqueDynamo-electric machinesElectricityThree degrees of freedom

The invention discloses an electromagnetic-piezoelectric-mixed-driving-based three-degree-of-freedom spherical motor, which comprises a first stator, a rotor, an output link, a second stator, a rotor protection film, a base, a piezoelectric ceramic driver A, a piezoelectric ceramic driver B, a piezoelectric ceramic driver C, 24 coils arranged on the first stator 1 and 8 magnetic poles arranged onthe rotor. A land of the output link is arranged on the rotor. The rotor protection film is coated on the outer surface of the rotor. The second stator is arranged outside the rotor protection film. The first rotor is arranged outside the second stator. The second stator is arranged on the base by support columns. The bottom of the first stator is positioned on L-shaped connecting pieces of the base. The spherical motor provided by the invention adopts a structure with the single rotor and the dual stators; and simultaneously, an electromagnetic driving mode and a piezoelectric ceramic driving mode are fused, compensate for the shortcomings of each other and coact to effectively increase the output torque of the spherical motor.

Owner:BEIHANG UNIV

Magnetic bearing using displacement winding techniques

InactiveUS7235906B2Magnetic circuitAsynchronous induction motorsPermanent magnet rotorMagnetic bearing

Owner:AIREX CORP

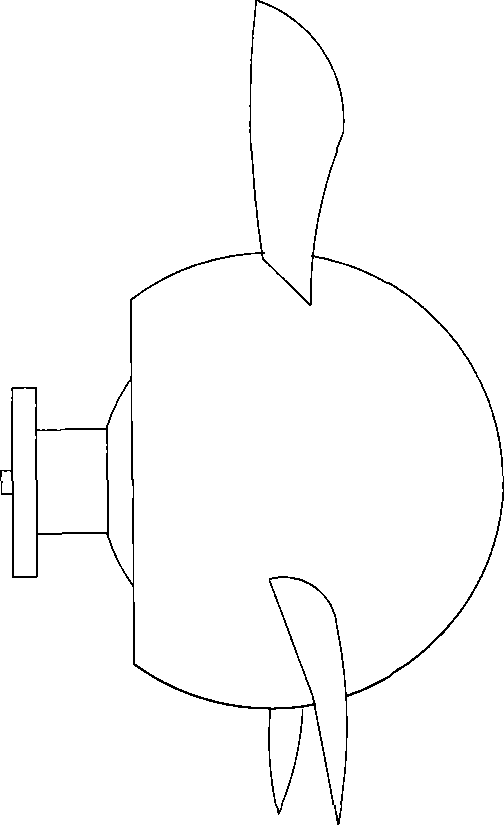

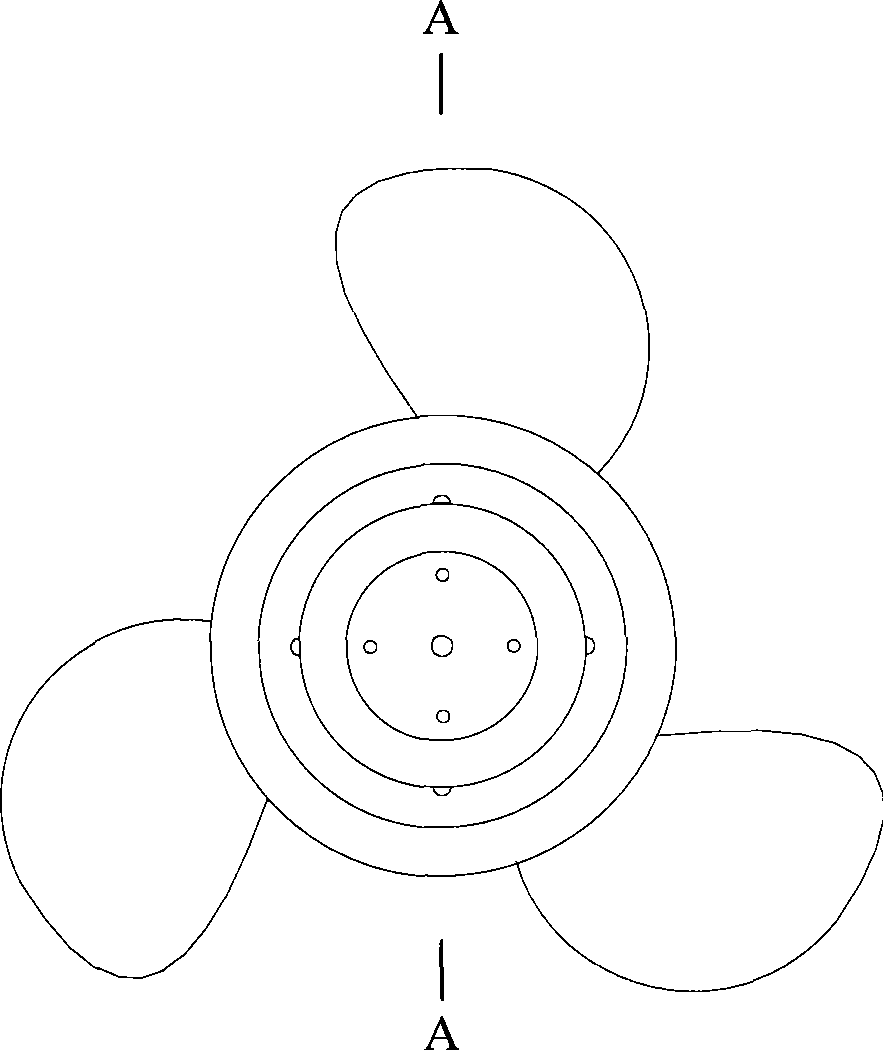

Underwater globular motor propeller

InactiveCN101505076AReduce volumeImprove efficiencyPropulsion power plantsPropulsive elementsEngineeringSpherical shaped

The invention provides an underwater spherical motor propeller. A stator core is in a spherical shape, the surface of the spherical stator core is provided with three grooves which are perpendicular to one another along a big circle, three-phase concentrated windings are placed in the grooves respectively and are pairwise perpendicular, the coils of the three-phase windings are connected to an underwater sealing plug by cables, a spherical sealed shell which is fixed with the stator core wraps the stator core, a spherical shell-shaped outer rotor is sleeved on the sealed shell through rubber bearings, the surface of the rubber bearings are provided with flumes, a rotor core is arranged between two rubber bearings, a slim clearance is reserved between the rotor core and the sealed shell, the rotor core, the rubber bearings and a rotor shell are combined together, and propeller blades are fixed on the rotor shell directly. In the invention, the vectored propulsion of the underwater spherical motor propeller is realized, the performance of the propeller is improved and the mechanical structure of the underwater working device is simplified, the mass and the volume of the underwater working device are reduced; therefore, the underwater working device has better utility and higher reliability.

Owner:如皋市生产力促进中心

Spherical motor using oscillatory magnetic fields

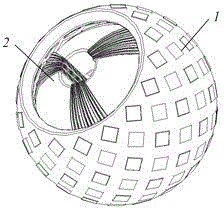

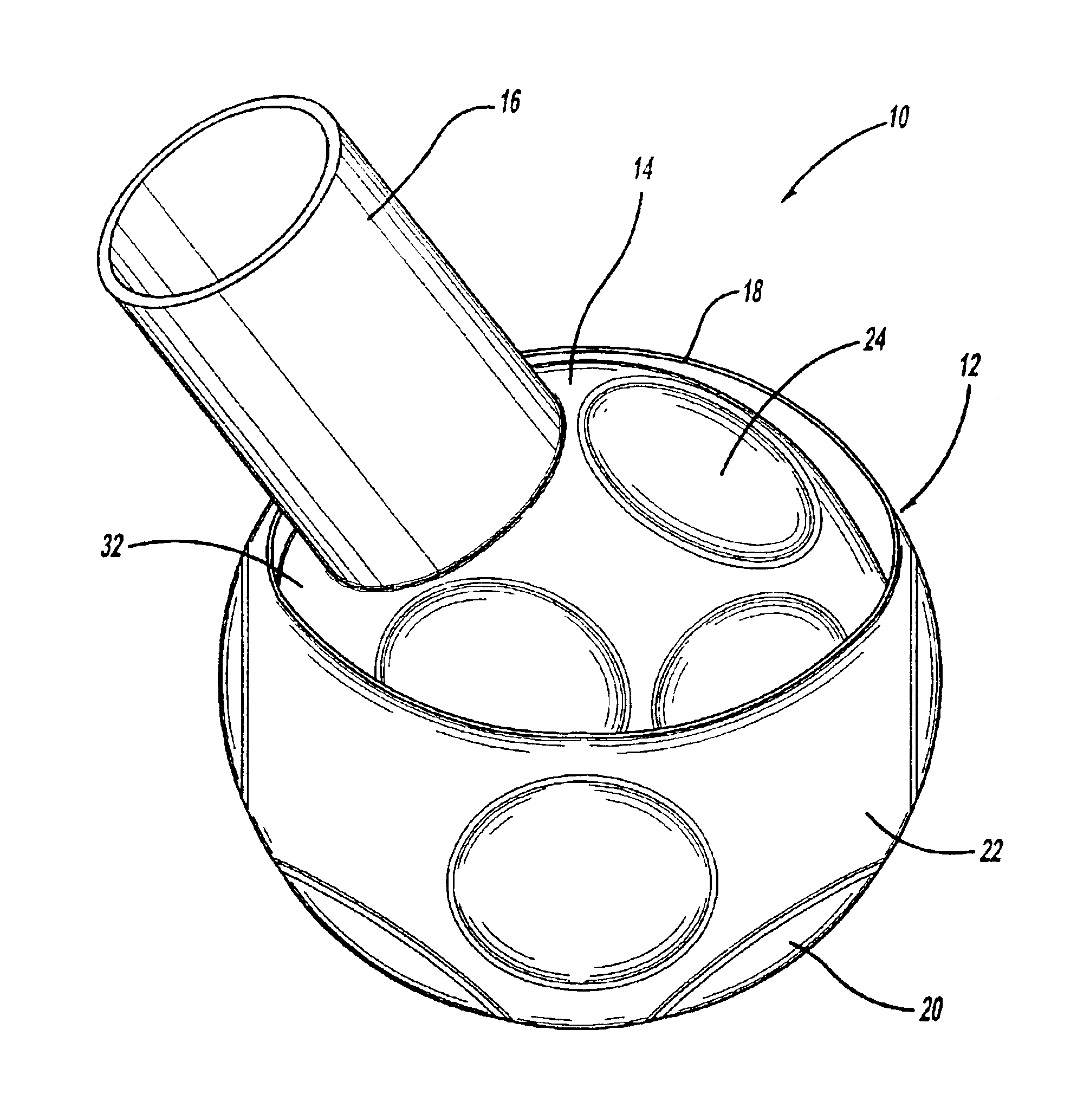

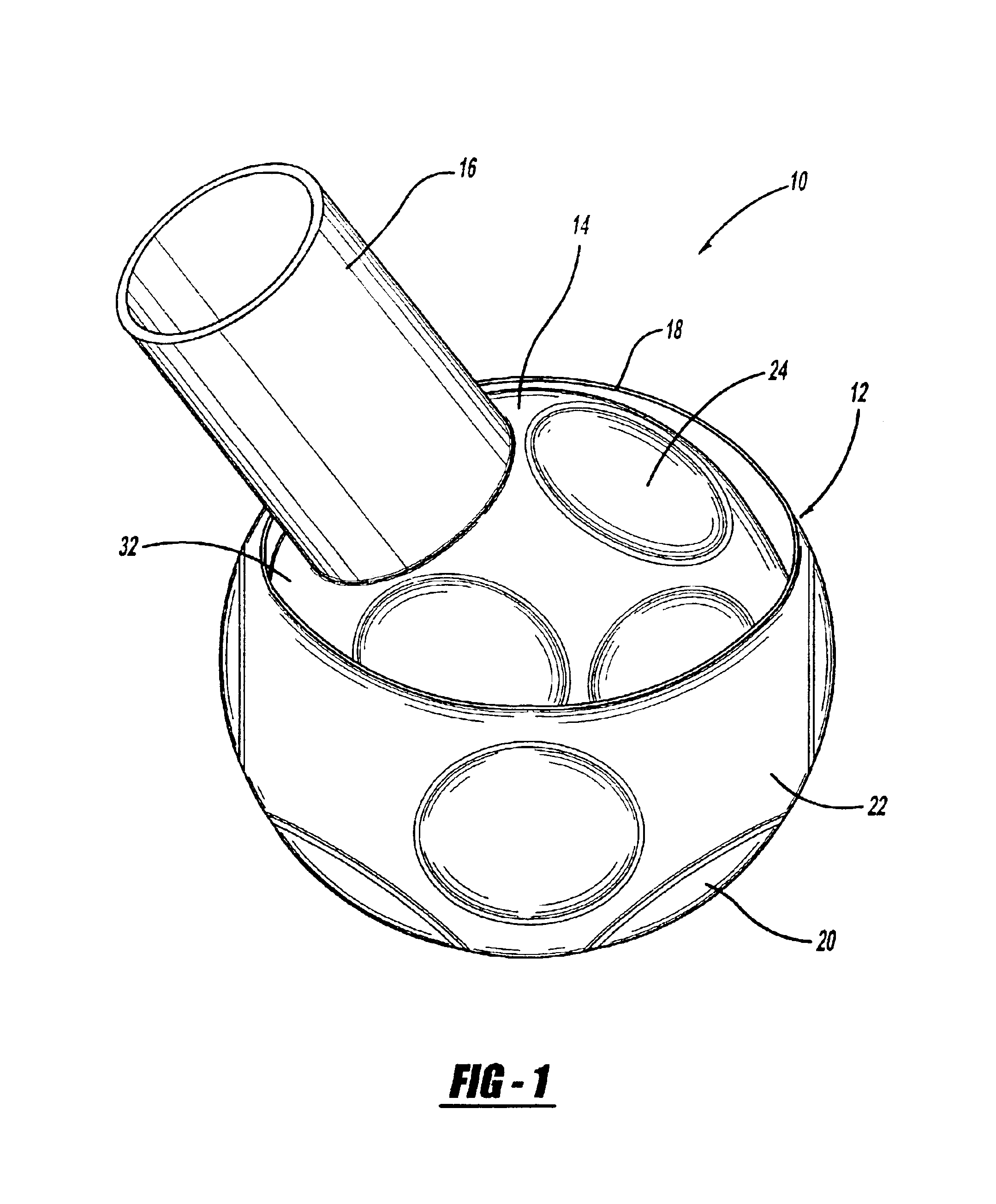

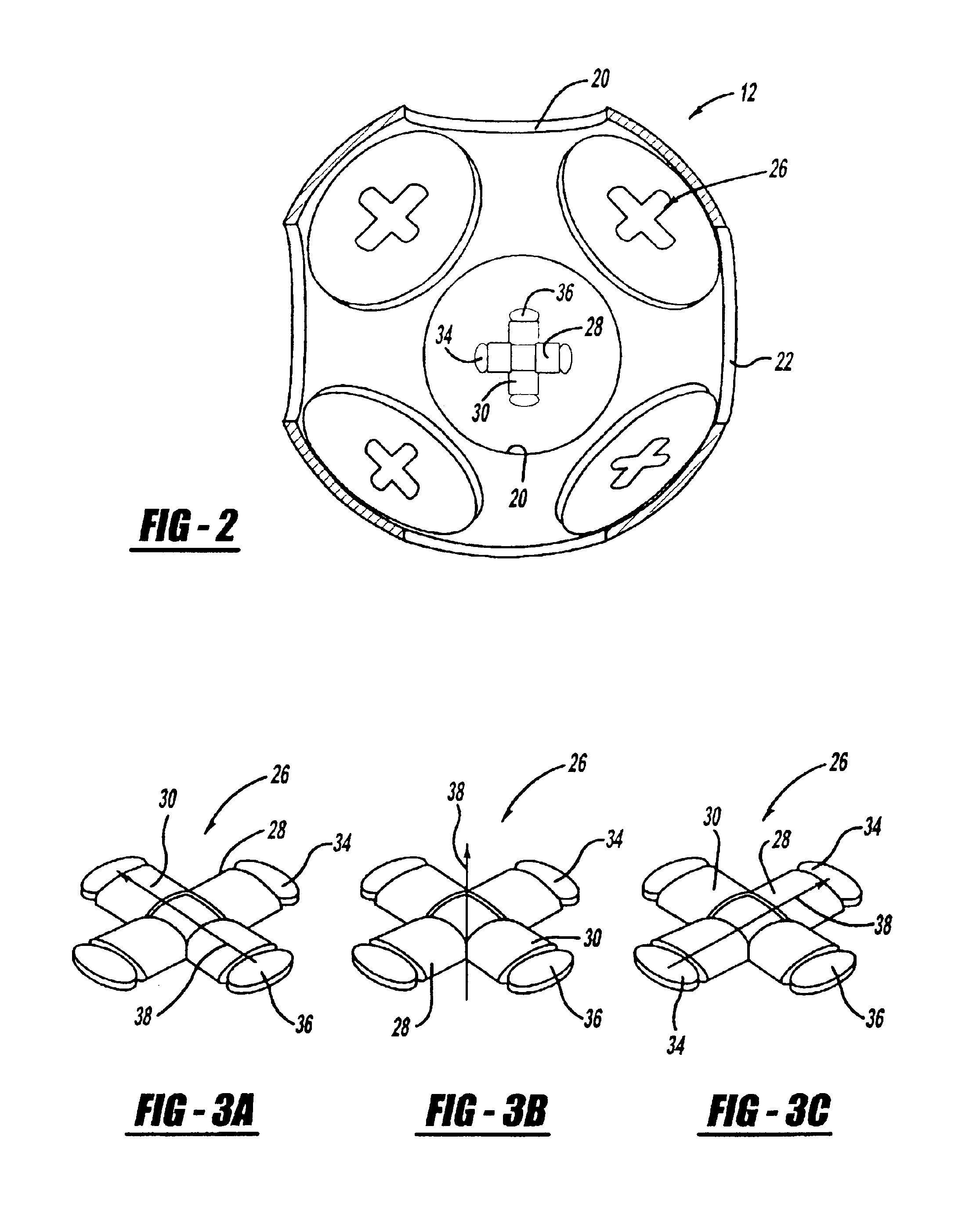

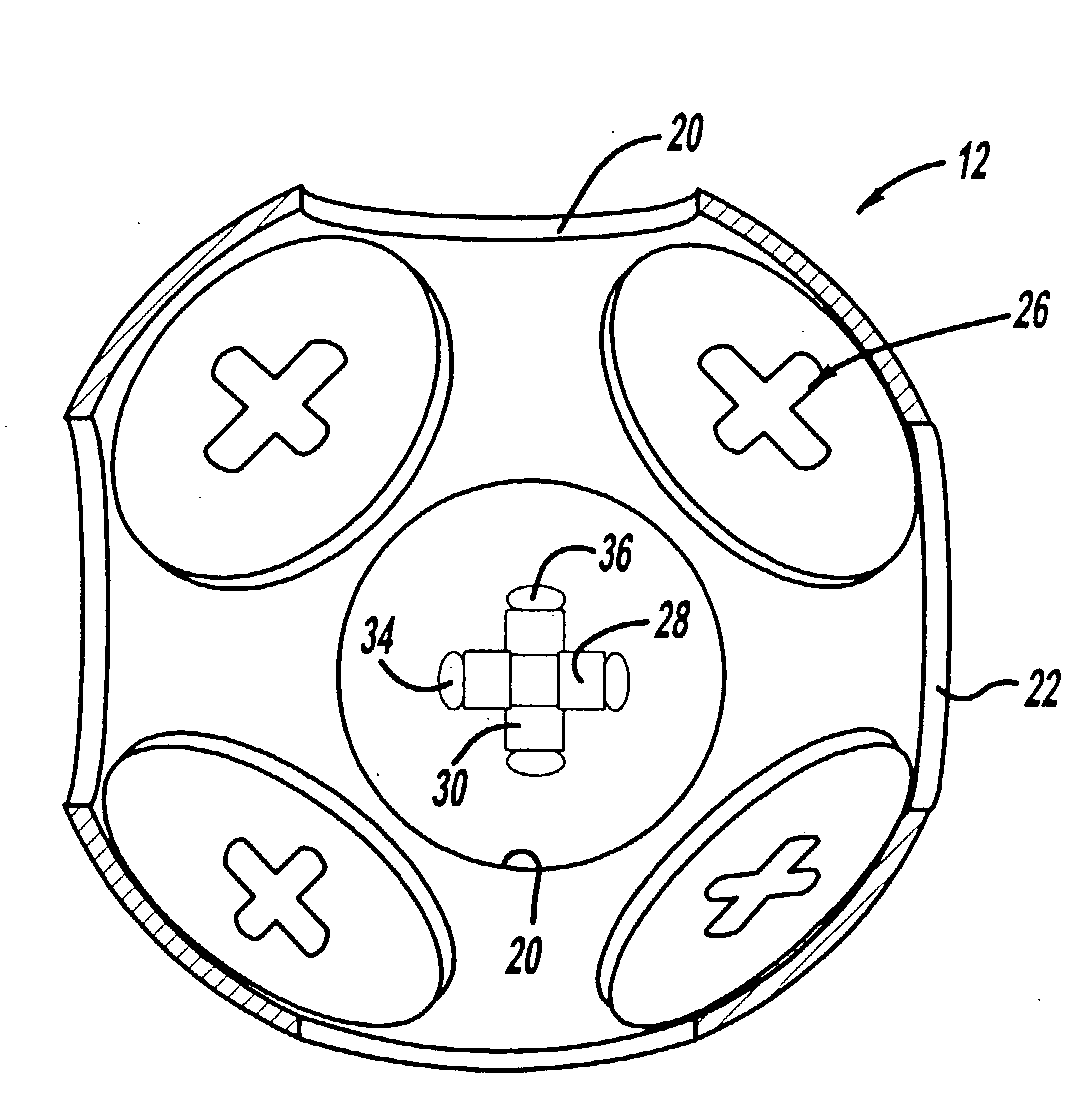

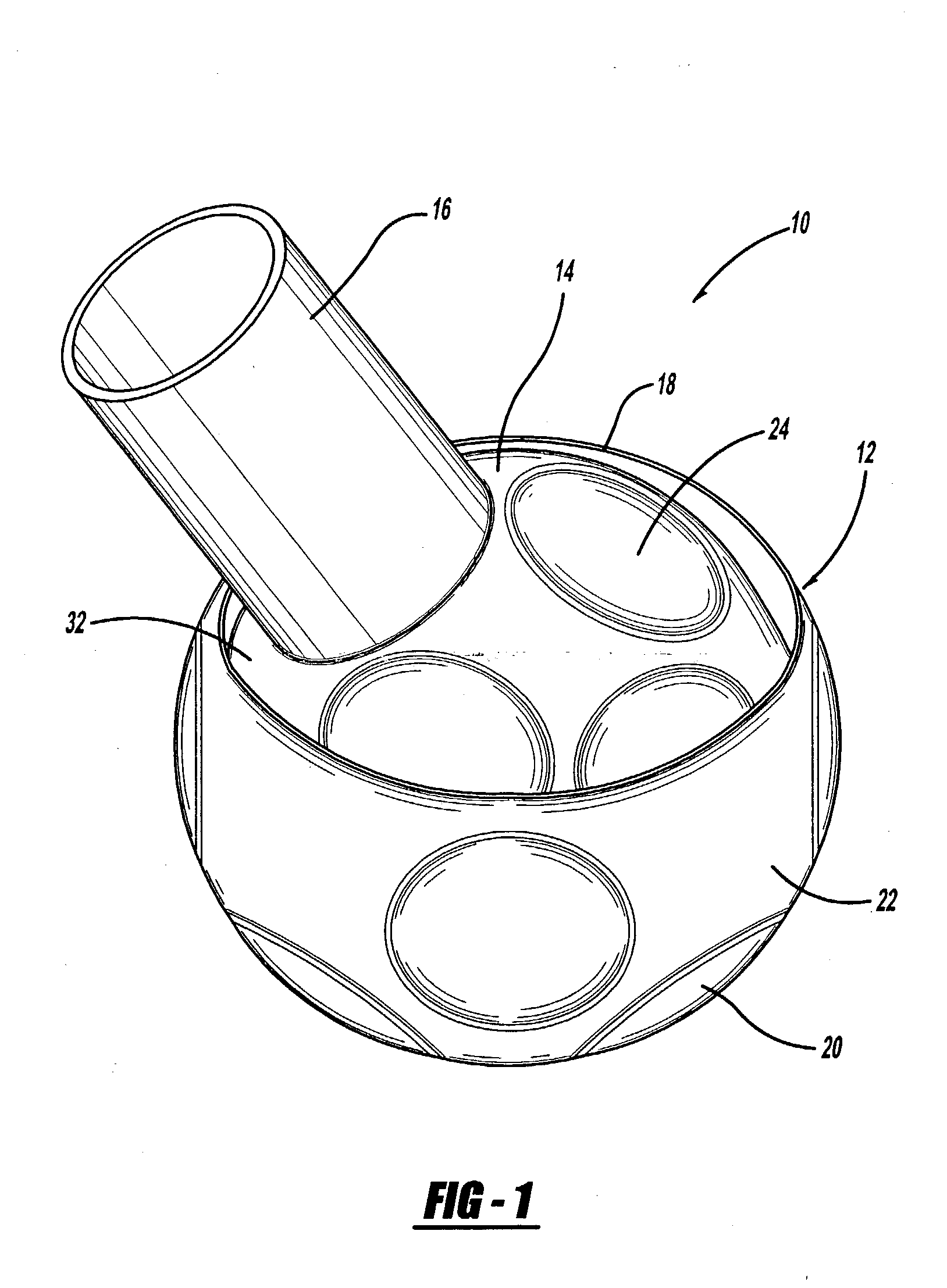

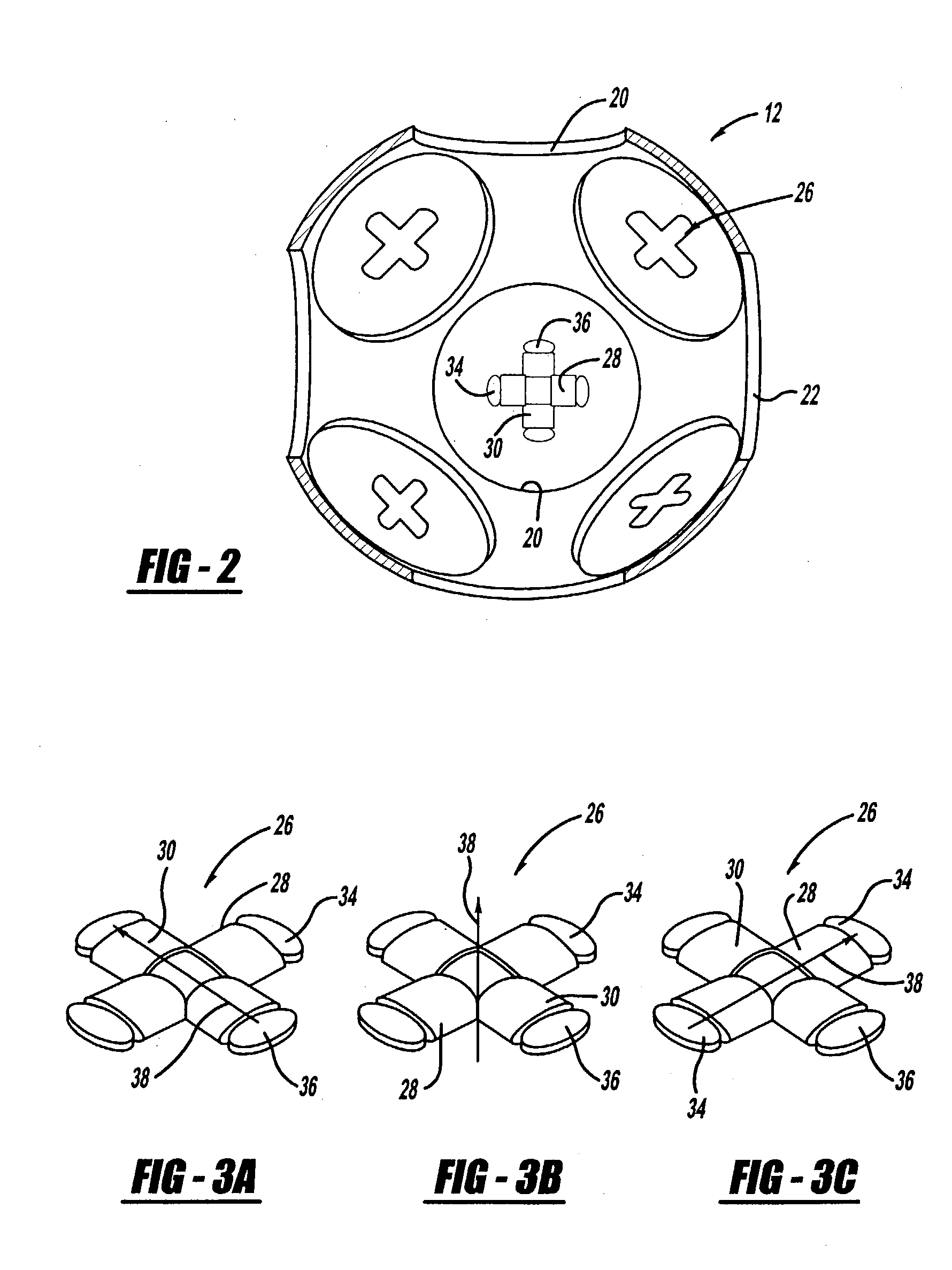

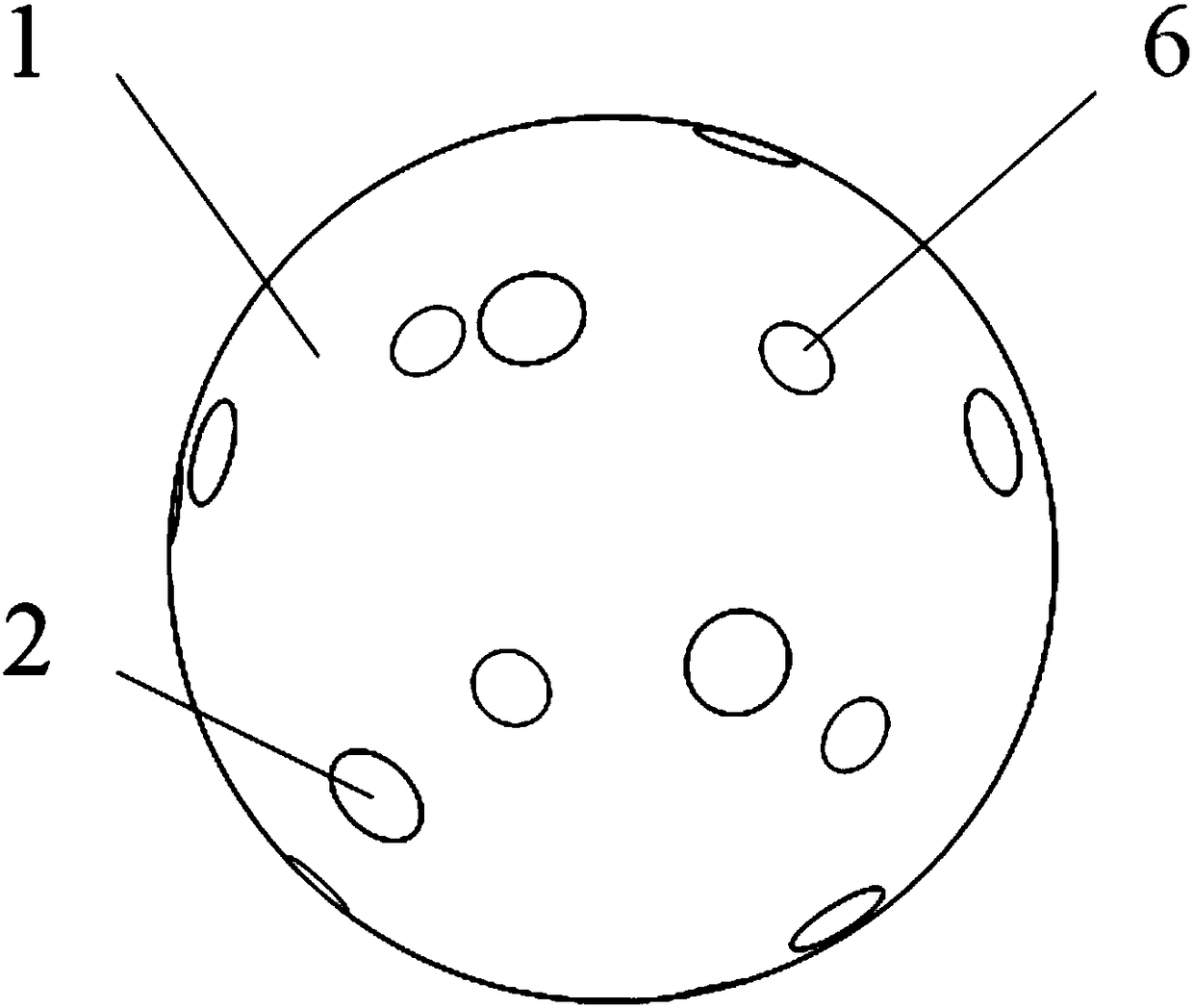

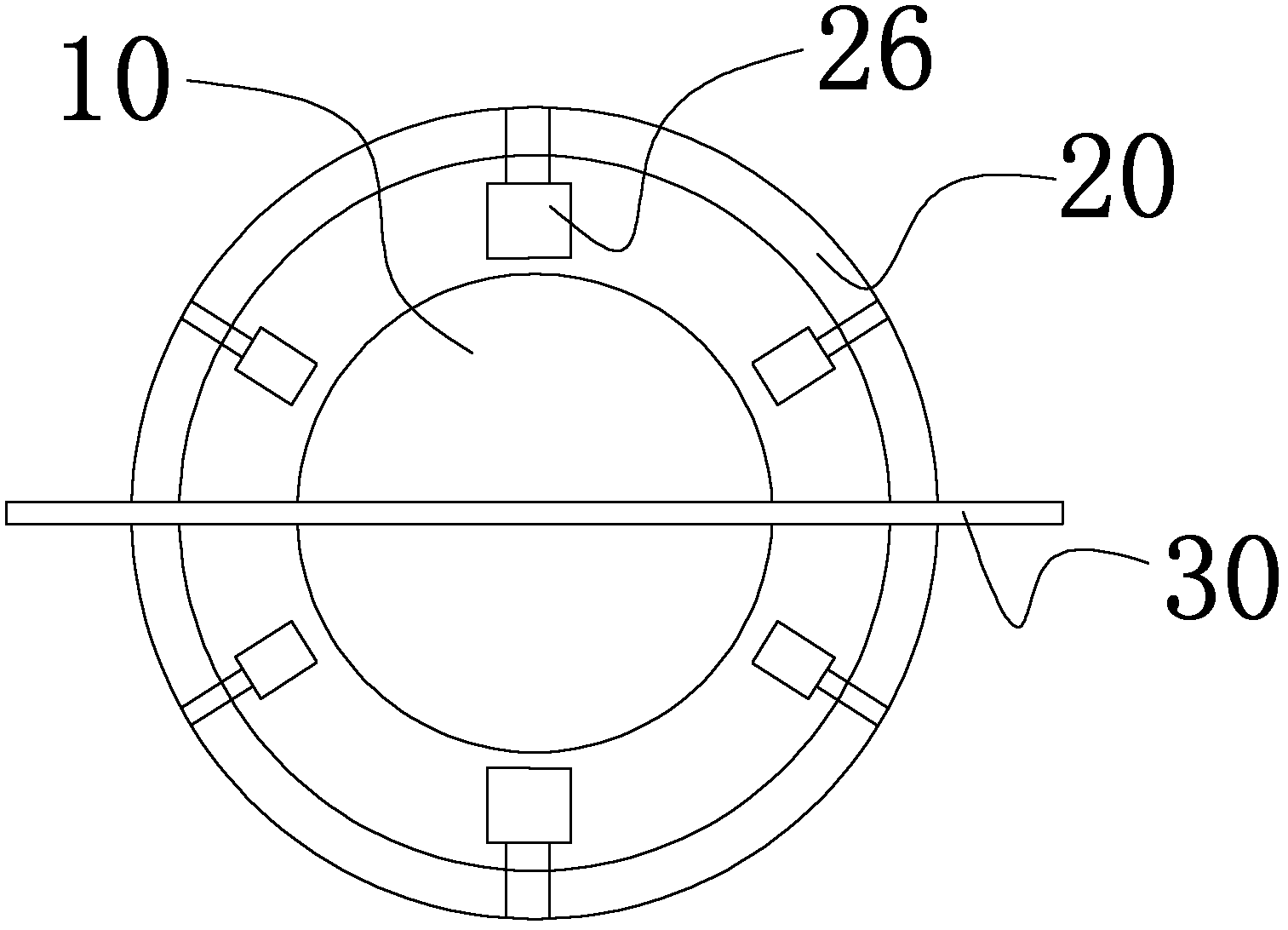

ActiveUS20040232790A1Synchronous generatorsMagnetic circuit rotating partsExternal fieldSpherical motor

A spherical motor (10) that includes an outer field sphere (12) and an inner armature sphere (14) rotatable therein. Field magnetic elements (26) are disposed on the field sphere (12) and sensor / actuator magnetic elements (42) are disposed on the armature sphere (14). The field magnetic elements (26) include two coils (28, 30) providing regularly varying magnetic fields in two axes. The sensor / actuator magnetic elements (42) include coils (44-54) providing magnetic fields in three axes. Each sensor magnetic element (42) senses its localized magnetic field variations and generates a torque relative thereto. Over one complete field variation of the field magnetic elements (26), each sensor magnetic element (42) can produce torque about all three axes.

Owner:NORTHROP GRUMMAN SYST CORP

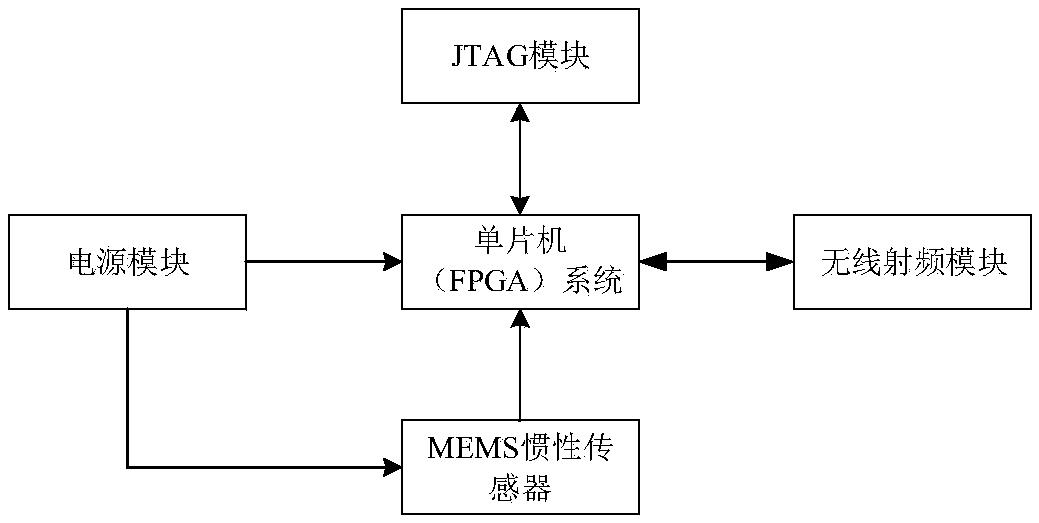

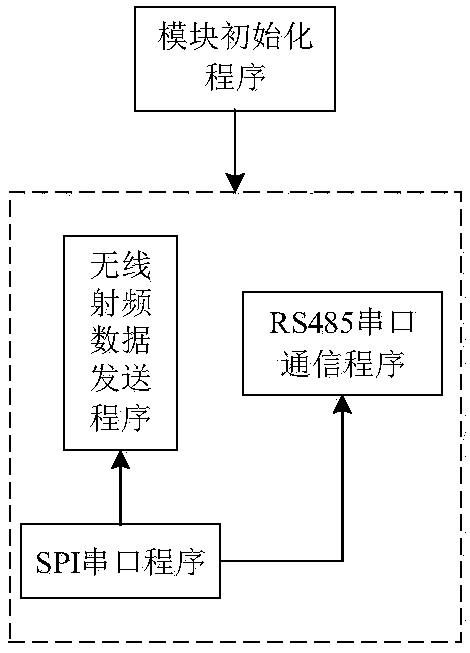

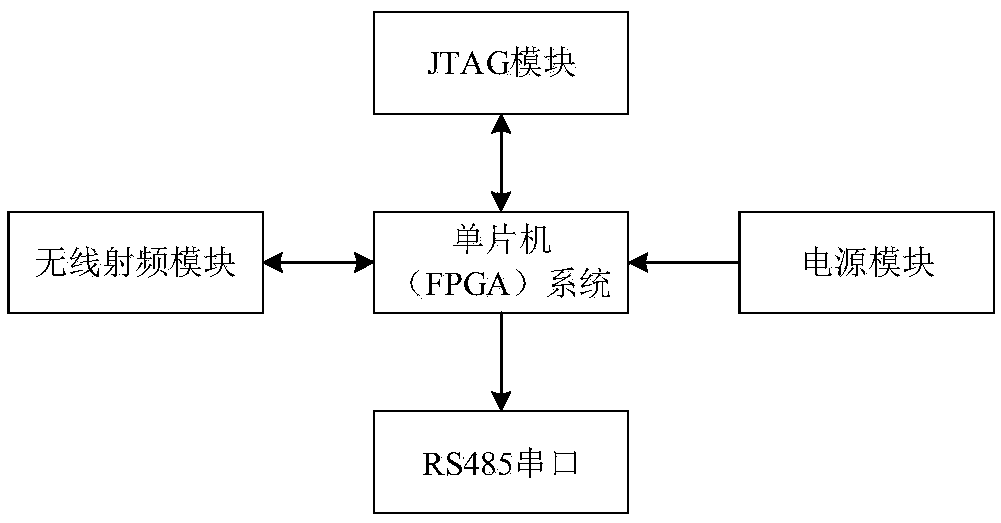

Spherical motor rotor position detection method based on MEMS sensor

InactiveCN108061855ASimple hardware structureEliminate errorsDynamo-electric machine testingOriginal dataComplementary filter

The invention relates to a spherical motor rotor position detection method based on an MEMS (Micro Electron Mechanical Systems) sensor. The method comprises steps: the original data of the MEMS sensorare acquired; zero bias error compensation is carried out on an angular velocity, and ellipsoid fitting compensation is carried out on an acceleration and a magnetic induction intensity; the angularvelocity, the acceleration and the magnetic induction intensity data after compensation are subjected to complementary filter-based data fusion and are substituted to a quaternion differential equation to obtain an attitude updating quaternion; the attitude updating quaternion is converted to an Euler angle, the change characteristics of the Euler angle in different intervals are combined, accurate interval transfer judgment is made, and conversion of the Euler angle in a full angle range change condition can be realized.

Owner:TIANJIN UNIV

Cambered surface type two-degree-of-freedom permanent magnet in-wheel motor

InactiveCN104753285ASimplify Mechanical PartsStrong original innovationMagnetic circuit rotating partsElectric machinesHarmonicSurface type

The invention discloses a cambered surface type two-degree-of-freedom permanent magnet in-wheel motor and relates to the field of motors. The cambered surface type two-degree-of-freedom permanent magnet in-wheel motor has two degrees of freedom, including rotation and deflection, thereby integrating a driving function of an in-wheel motor and a steering function of a steering motor in an electric vehicle skillfully. A stator core of the permanent magnet in-wheel motor is divided into a plurality of portions effectively, each portion is provided with an armature winding in a specific arrangement mode, and a rotor is provided with a permanent magnet. Based on a magnetic field harmonic theory and a self-bearing magnetic levitation principle, rotation of the motor can be achieved by a driving winding in the middle of a stator, and deflection motion of the motor can be achieved by deflection windings on two sides of the stator. An even air gap is arranged between the stator core and the rotor, the lateral surface of the air gap of the stator core and the lateral surface of the air gap of the rotor are concentric spherical cambered surfaces, and during rotation and deflection motion of the rotor, the air gap at any position between the stator and the rotor is kept unchanged constantly. A bearing can be a spherical motor bearing and the like. The cambered surface type two-degree-of-freedom permanent magnet in-wheel motor is applicable to driving of the electric vehicle.

Owner:HARBIN INST OF TECH

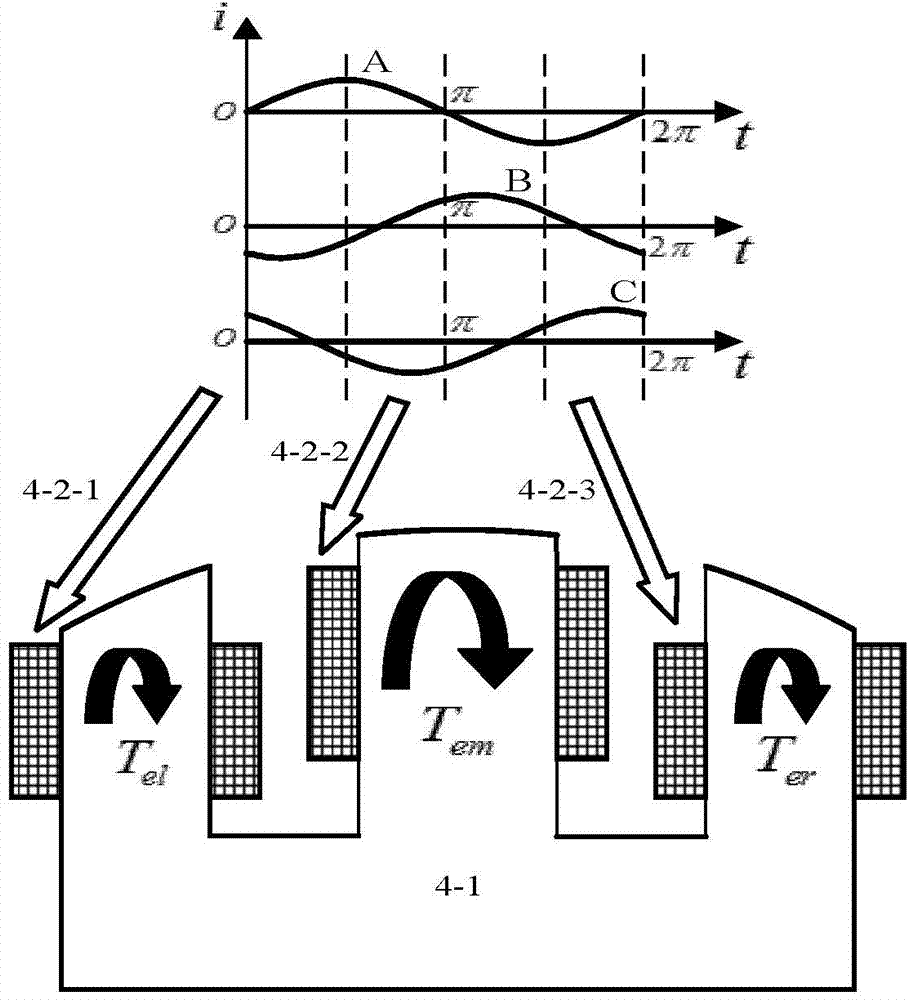

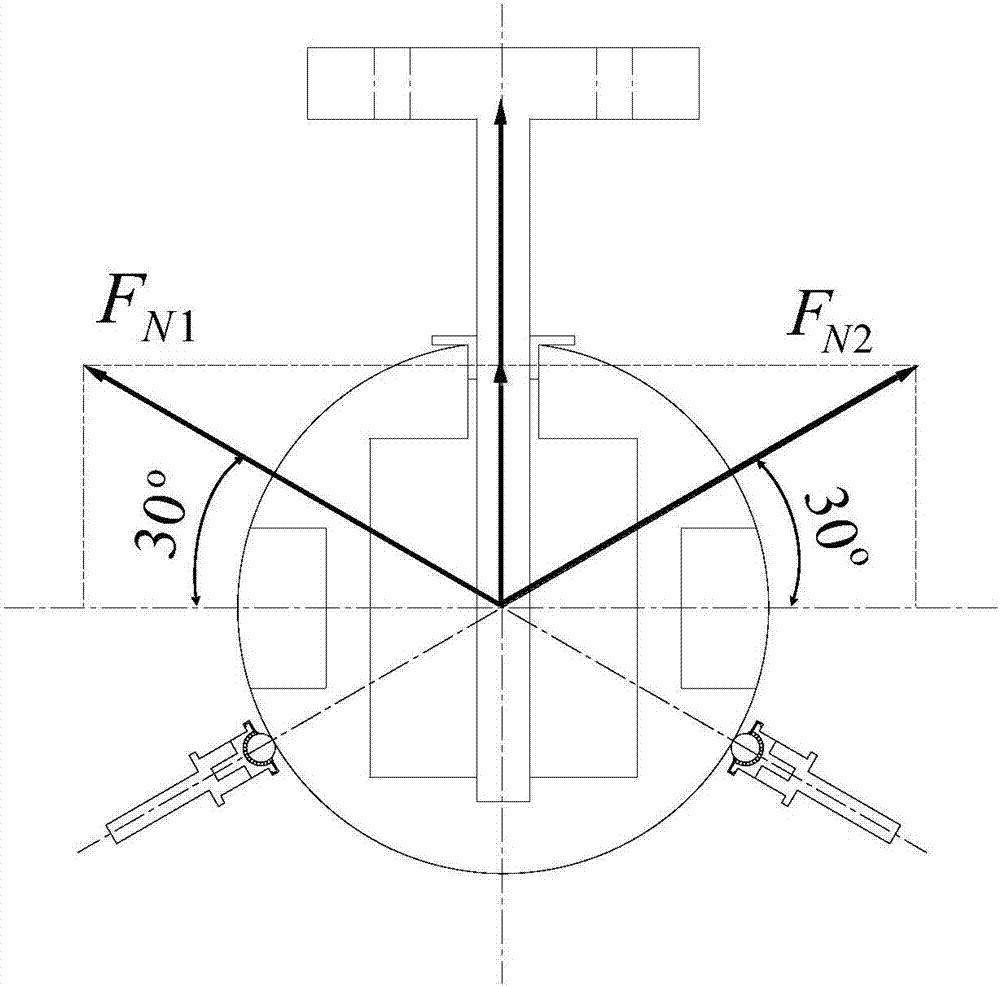

Torque control strategy for three degree-of-freedom permanent magnet spherical motor

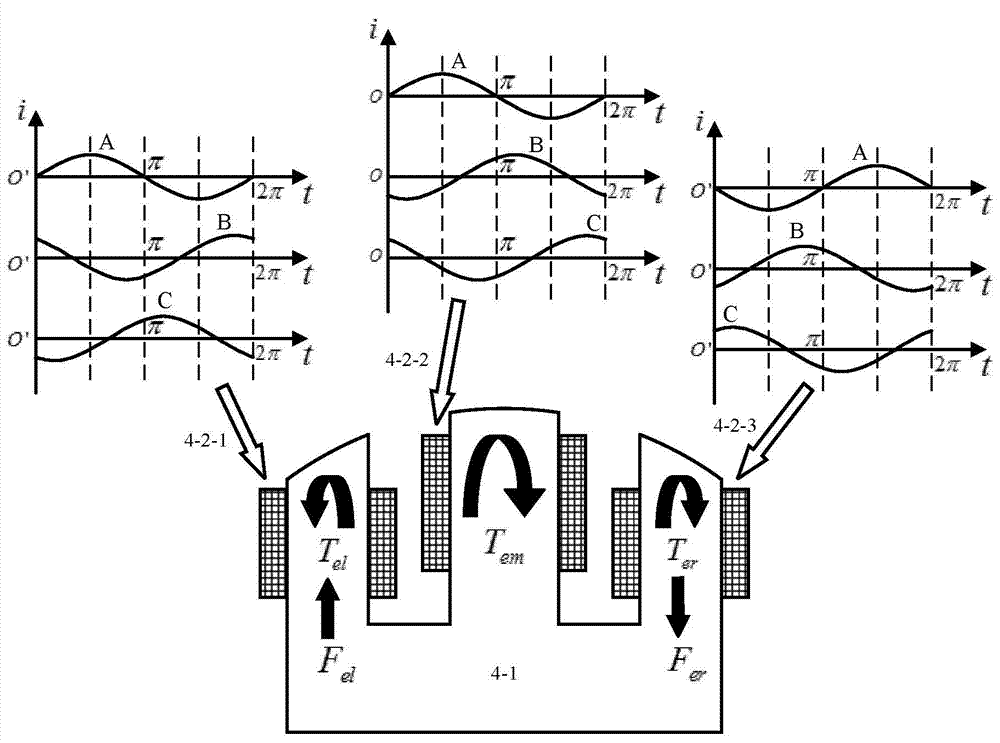

InactiveCN104022704AReal-time size controlDirection control in real timeElectronic commutation motor controlAC motor controlPower flowControl system

The invention relates to a torque control strategy for a three degree-of-freedom permanent magnet spherical motor. The control strategy is characterized by, to begin with, decomposing a control torque into autoroatation torques and incline torques; and on this basis, allocating the autoroatation torques to different stator phase windings; with the difference of autoroatation torques of the different stator phase windings when the spherical motor rotor inclines being taken into consideration, obtaining a two-dimension torque distribution function; and finally, obtaining control current of antorotation motion directly according to the torque characteristics of the permanent magnet spherical motor. For the incline torques, according to the relative position of the incline torques and each winding torque vector, and through comparing ratio power consumption of different combination modes, incline control windings can be determined; a dimension-reduced incline torque control matrix is obtained; and the control current of incline motion can be obtained through calculating an inverse matrix of the dimension-reduced incline torque control matrix. The control strategy can improve response speed and control precision of a permanent magnet spherical motor control system, reduce torque pulsation in antorotation motion, and prevent increasing stator control current excessively.

Owner:TIANJIN UNIV

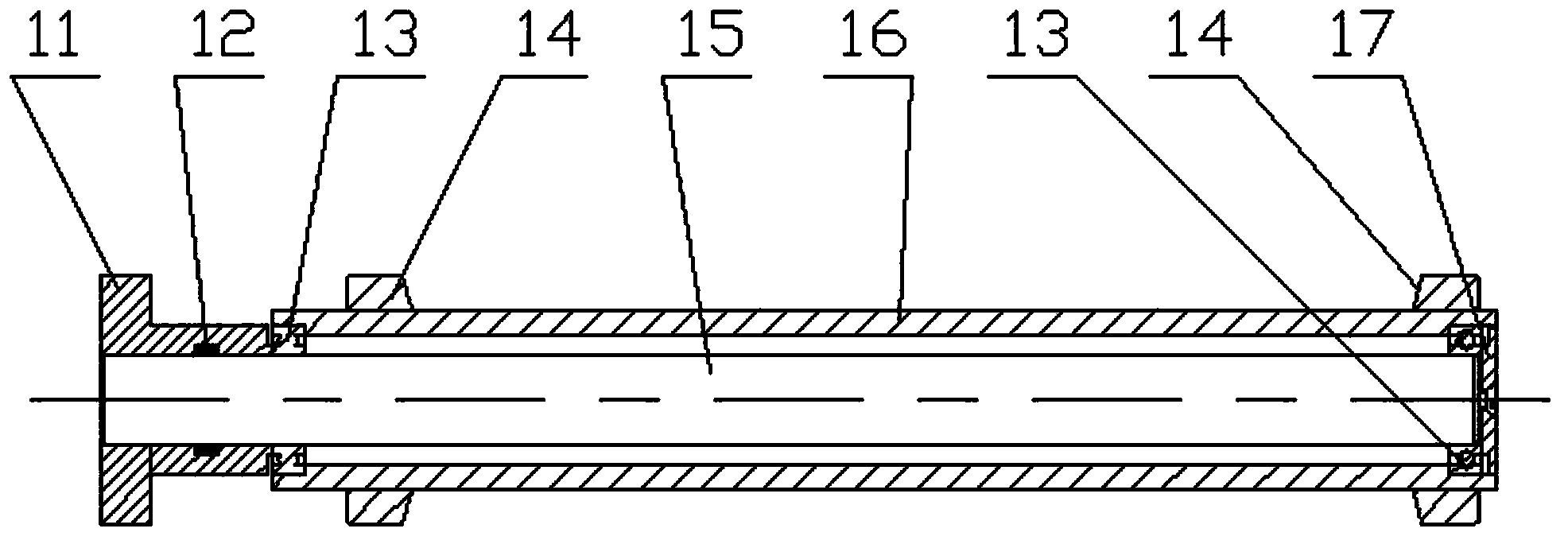

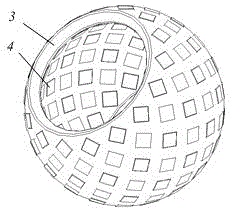

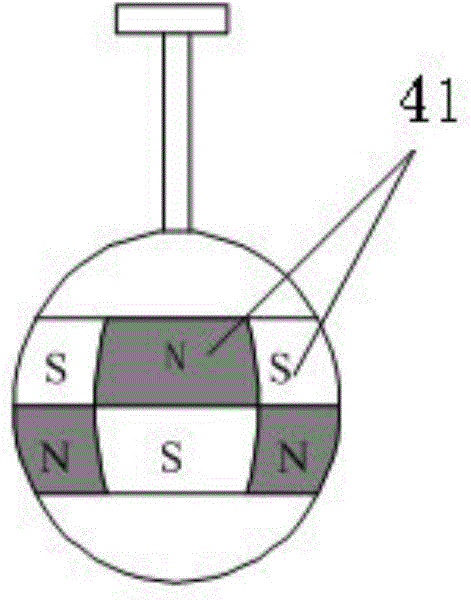

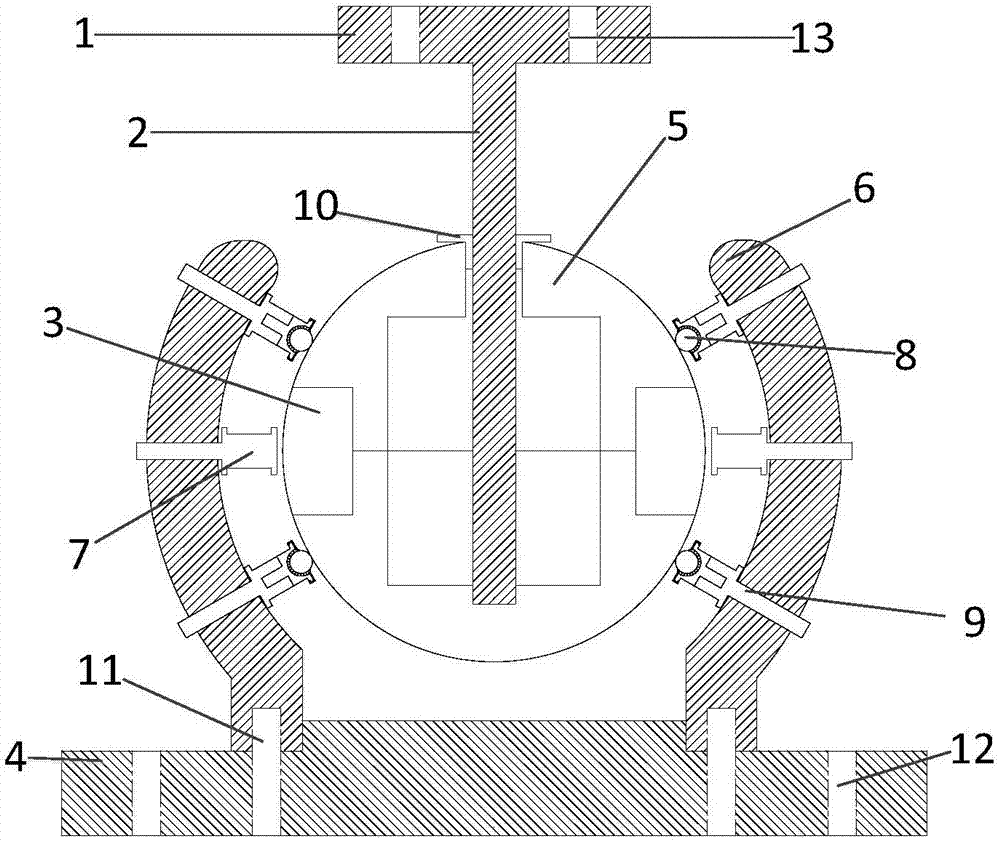

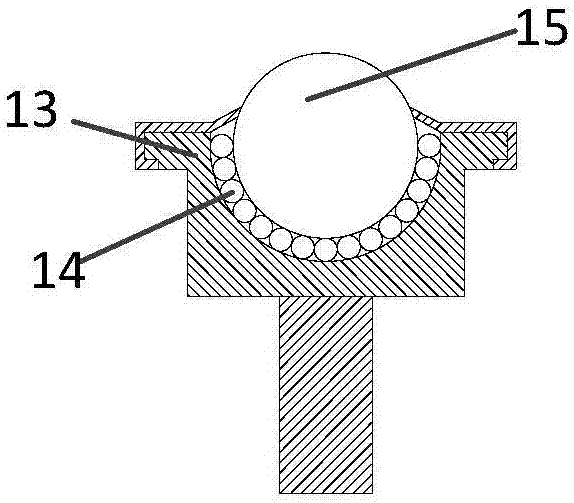

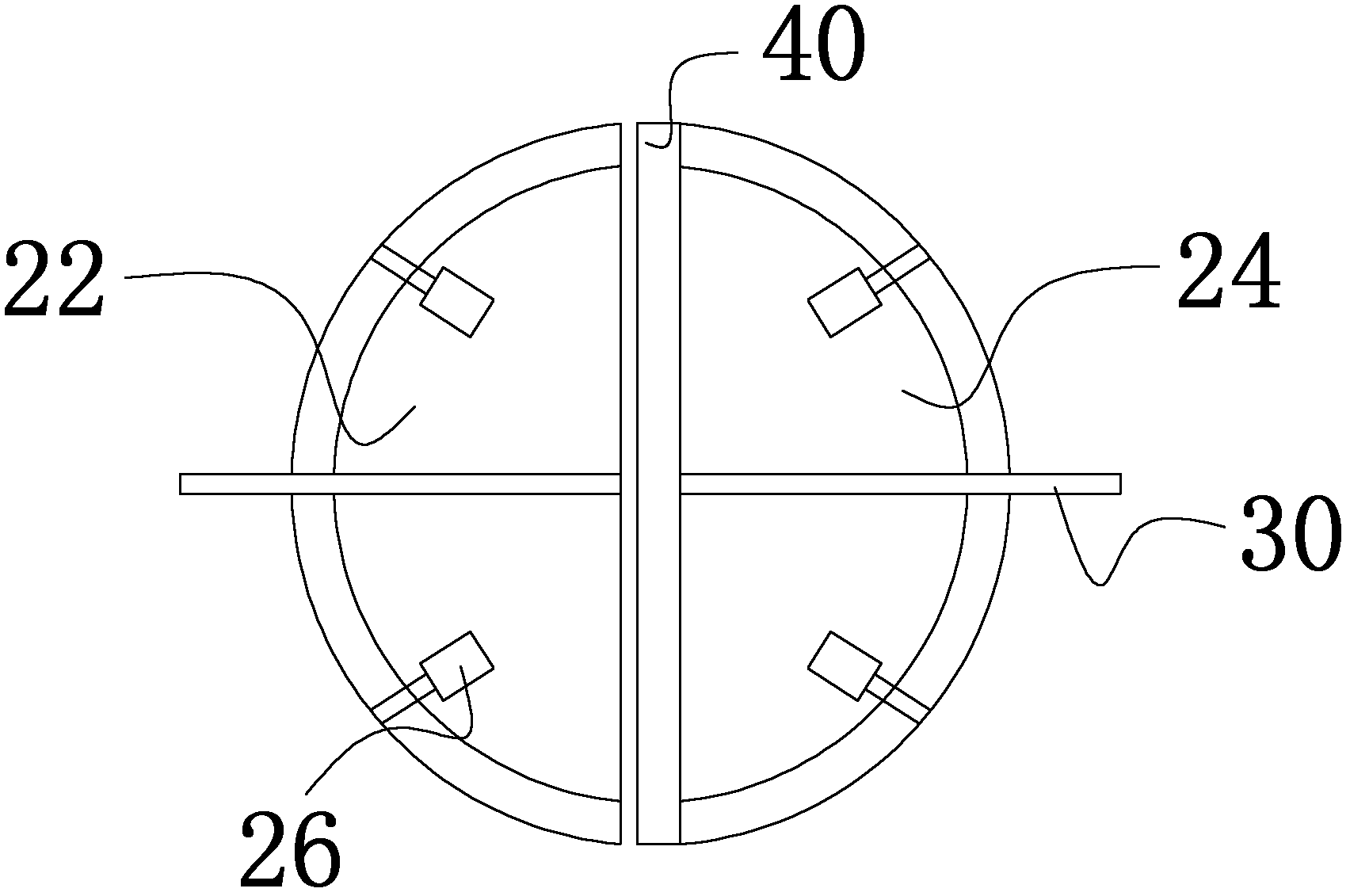

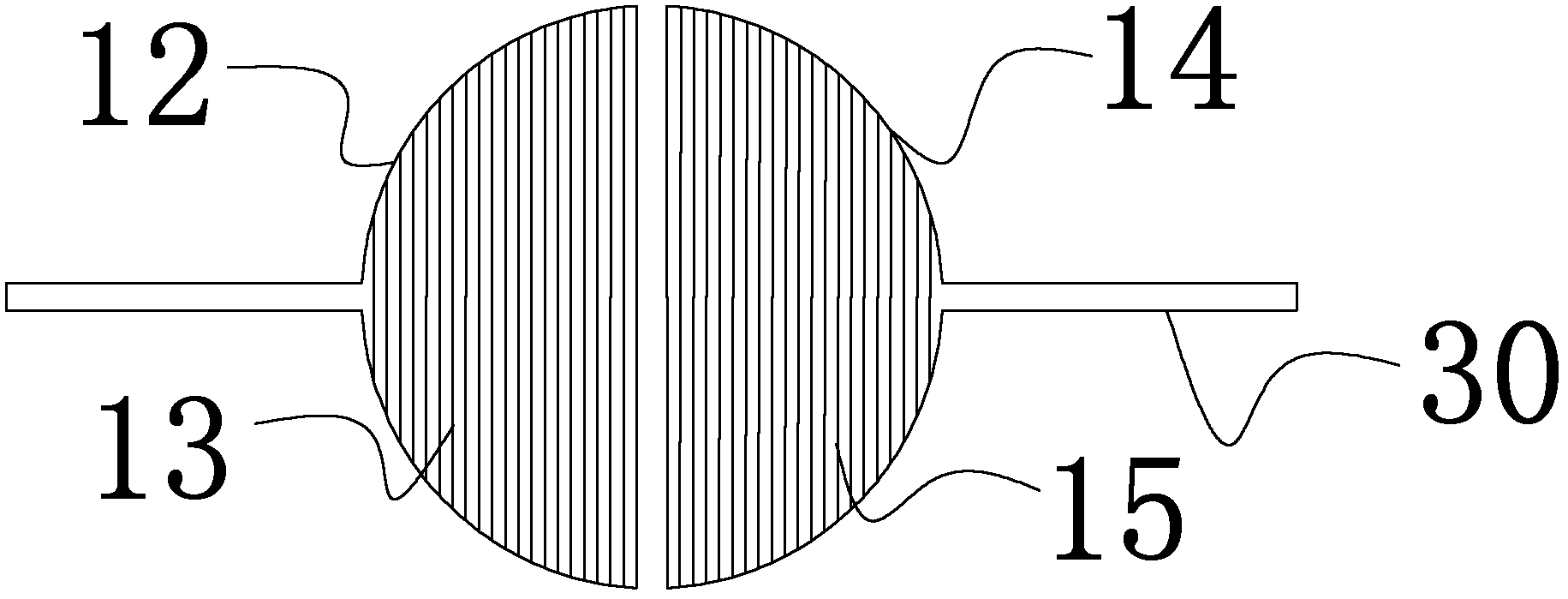

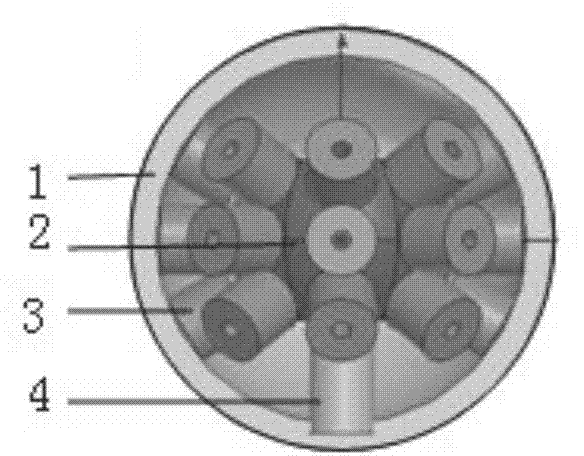

Three-degree-of-freedom permanent-magnet spherical motor

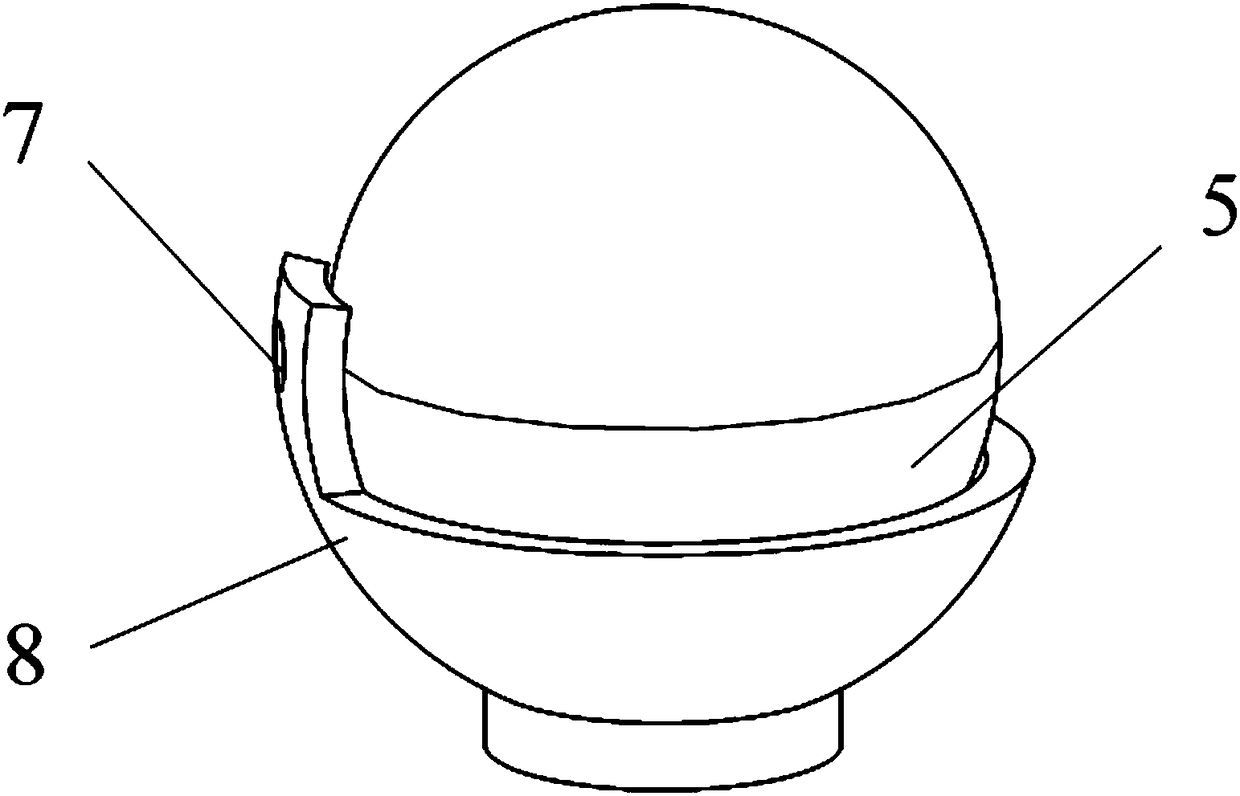

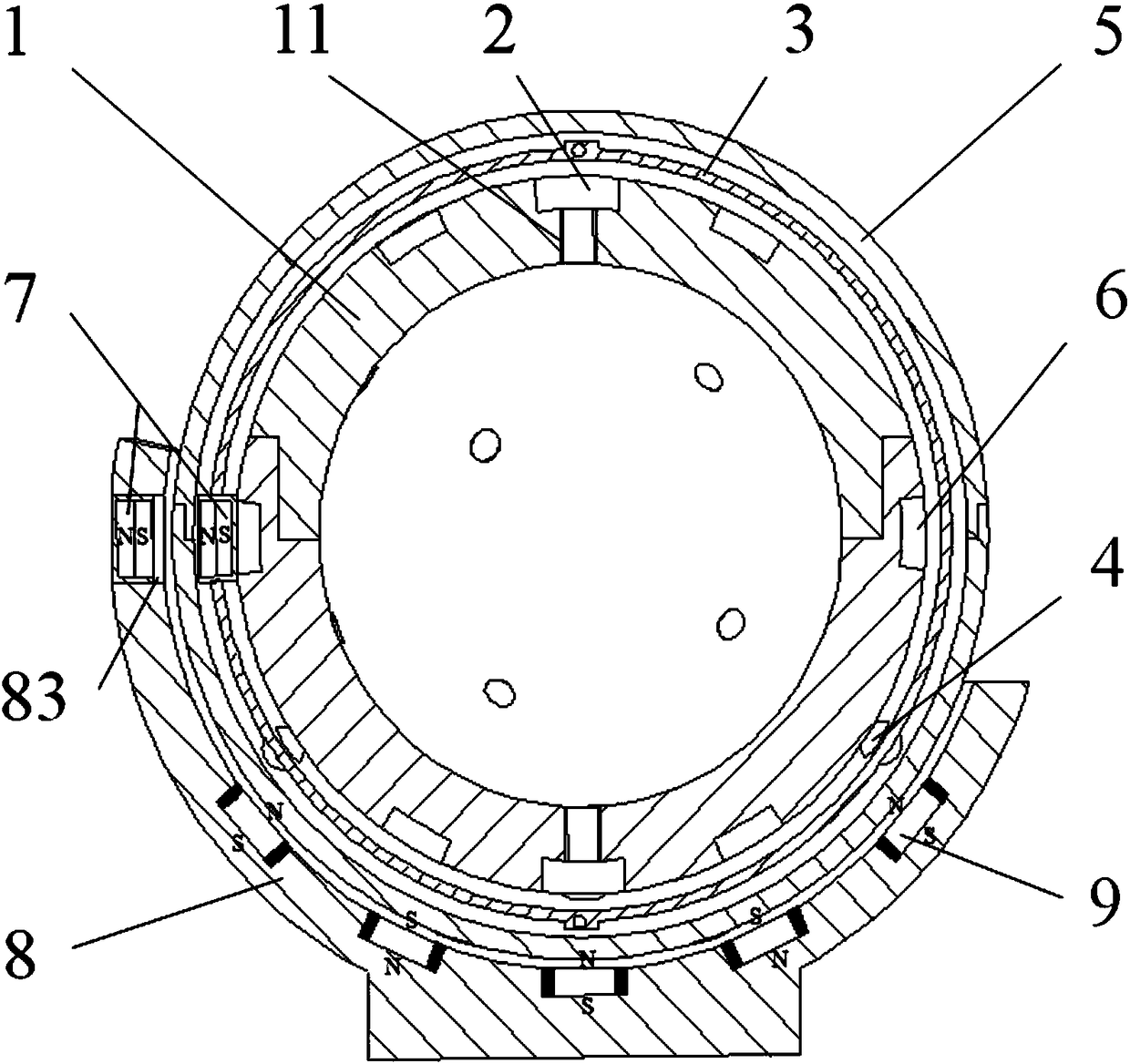

InactiveCN106877608AReduce frictionDoes not restrict exercise spaceWindingsMagnetic circuit rotating partsThree degrees of freedomStator coil

The invention relates to a three-degree-of-freedom permanent-magnet spherical motor. The three-degree-of-freedom permanent-magnet spherical motor comprises a base 4, a stator shell 6, universal balls 8, a spherical rotor body 5, an output shaft 2 and stator coils 7, wherein the stator shell 6 is fixed on the base 4, a rotor 5 is of a spherical shape and is fixedly connected with the output shaft 2, a cylindrical groove is formed in an equator position of the rotor and is used for embedding a permanent magnet, threaded holes are formed in the stator shell 6, a part of threaded holes are used for fixing the stator coils 7 by stator coil frames, the other part of threaded holes are used for fixing the stator coils 7 by combined stator coil frames 9, each combined stator coil frame 9 is in threaded connection with the universal ball 8 used for supporting the rotor, each universal ball 8 comprises a support tray 13, the support tray 13 is in threaded connection with the combined stator coil frame 9, a steel ball 14 is arranged in the support tray, and a nylon ball 15 is arranged on the steel ball 14.

Owner:TIANJIN UNIV

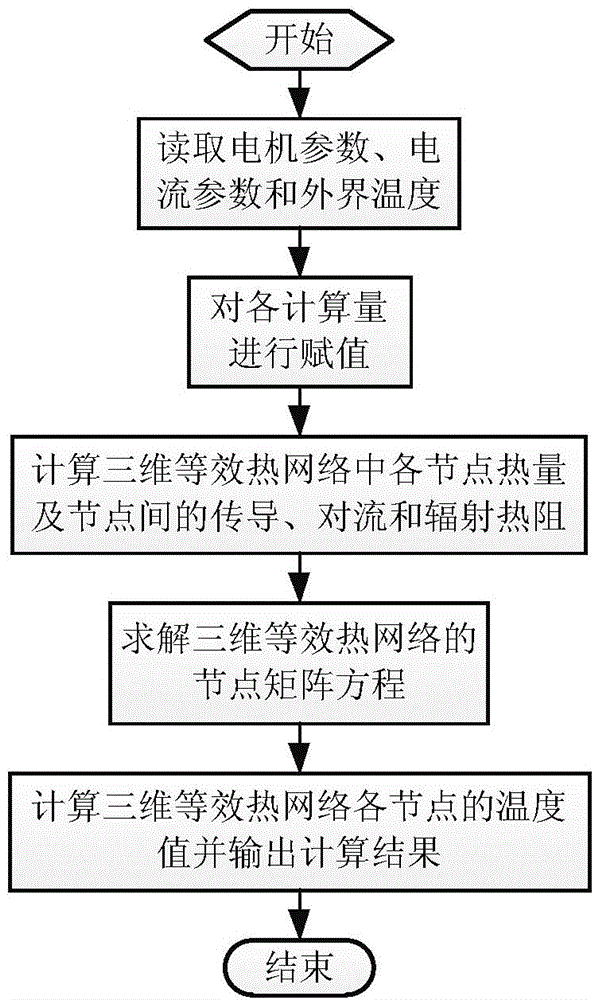

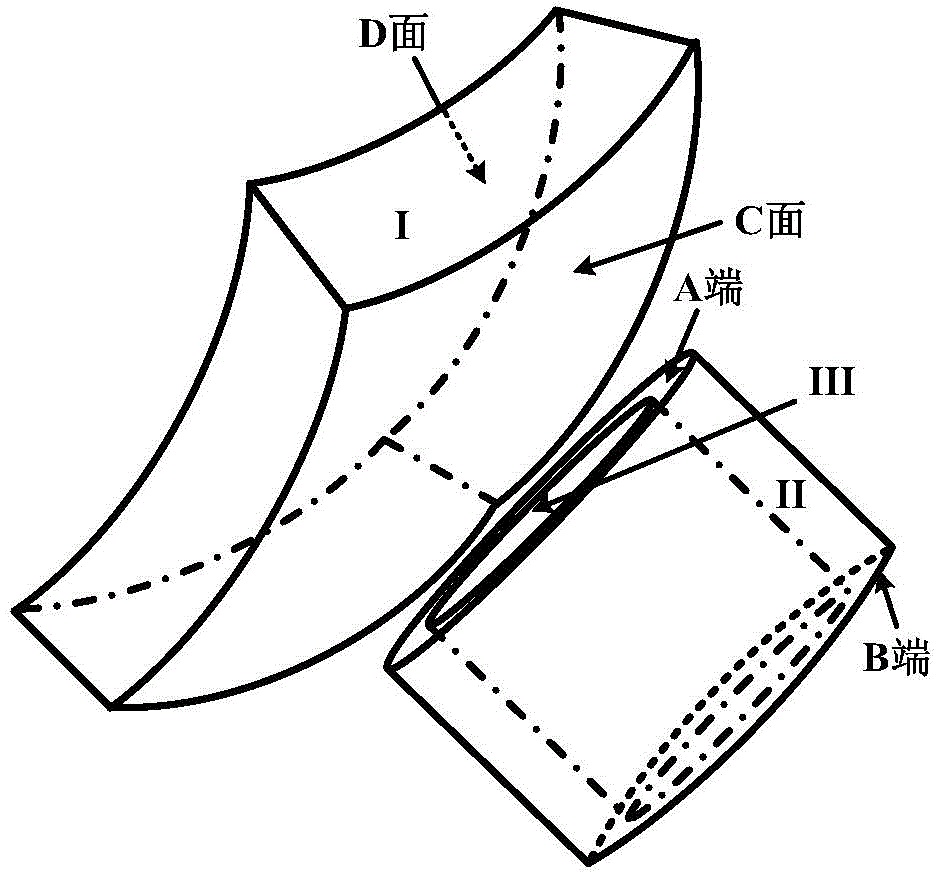

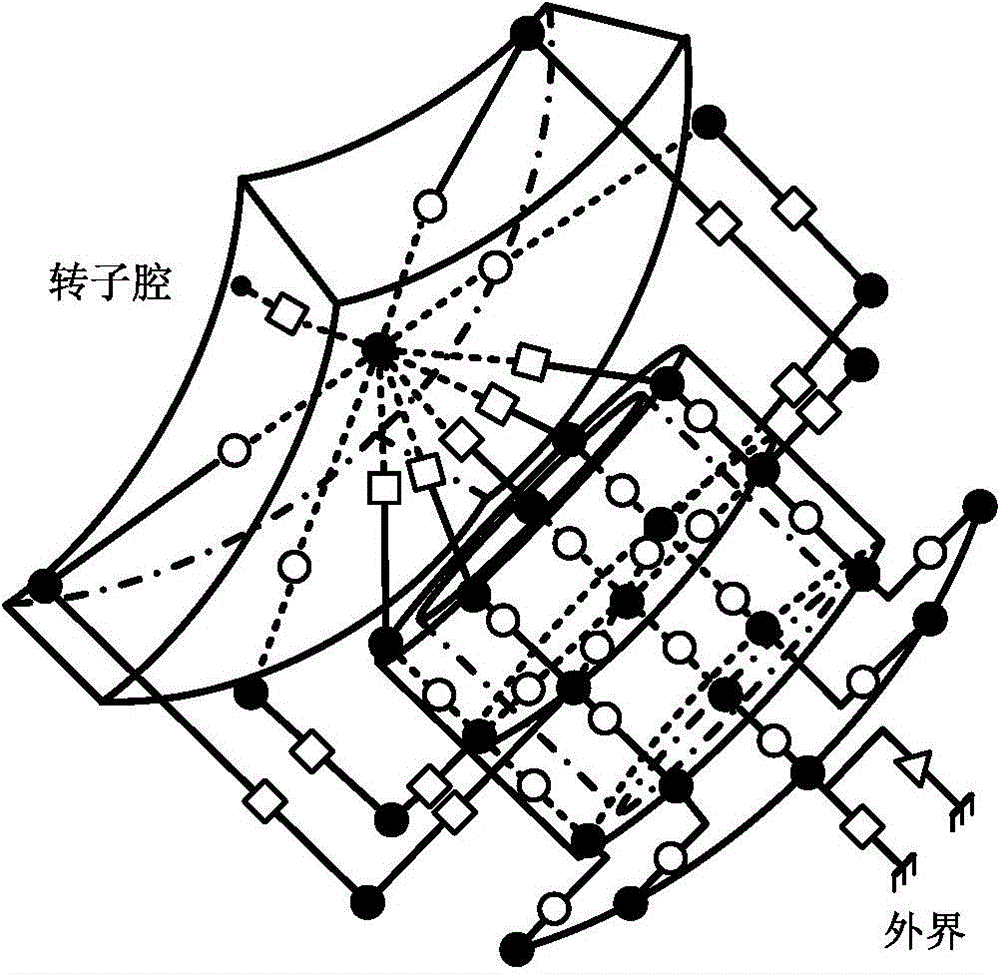

Permanent magnetic spherical motor temperature rise forecasting method based on three-dimensional equivalent heat network model

ActiveCN104537154AResolved an issue preventing accurate analysis of permanent magnet spherical motorsImprove accuracySpecial data processing applicationsData acquisitionMagnetic poles

The invention relates to a permanent magnetic spherical motor temperature rise forecasting method based on a three-dimensional equivalent heat network model. The method includes the steps: (1) building the three-dimensional equivalent heat network model meeting a real space structure of a motor according to a special spherical structure of the permanent magnetic spherical motor; (2) determining heat sources, and taking magnetic pole consumption, stator coil copper consumption, stator aluminum consumption and rotor aluminum consumption as corresponding nodes of the heat sources distributed in the three-dimensional equivalent heat network model; (3) calculating equivalent heat resistance, and diving the equivalent heat resistance into conduction heat resistance, convection heat resistance and radiation heat resistance according to different types of heat spread modes among the nodes in the model; (4) acquiring data; (5) forecasting temperature rise of the nodes in the model, and acquiring the temperature of the nodes of the permanent magnetic spherical motor by solving the three-dimensional equivalent heat network model. The permanent magnetic spherical motor temperature rise forecasting method is short in consumed time, easy to operate and high in accuracy and has high applicability to a system with a complex structure or incapable of performing analysis by the aid of a two-dimensional heat network model.

Owner:TIANJIN UNIV

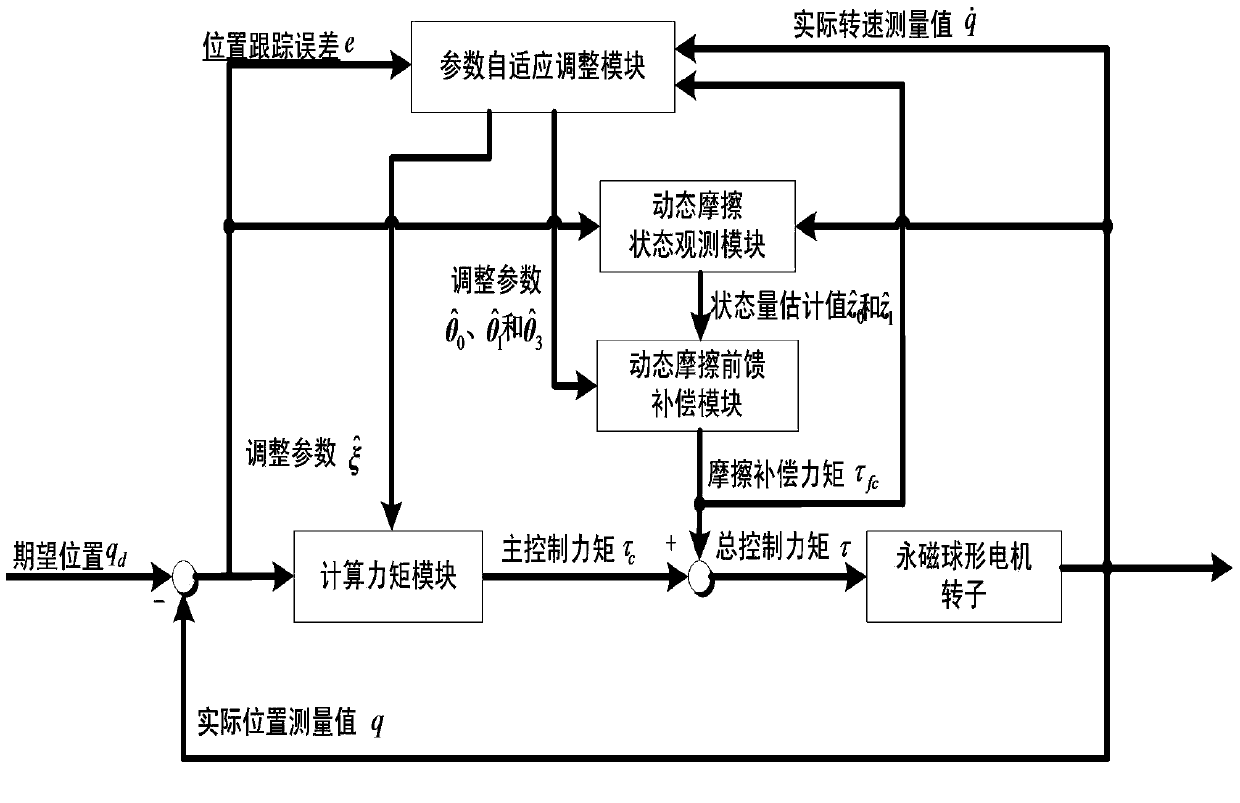

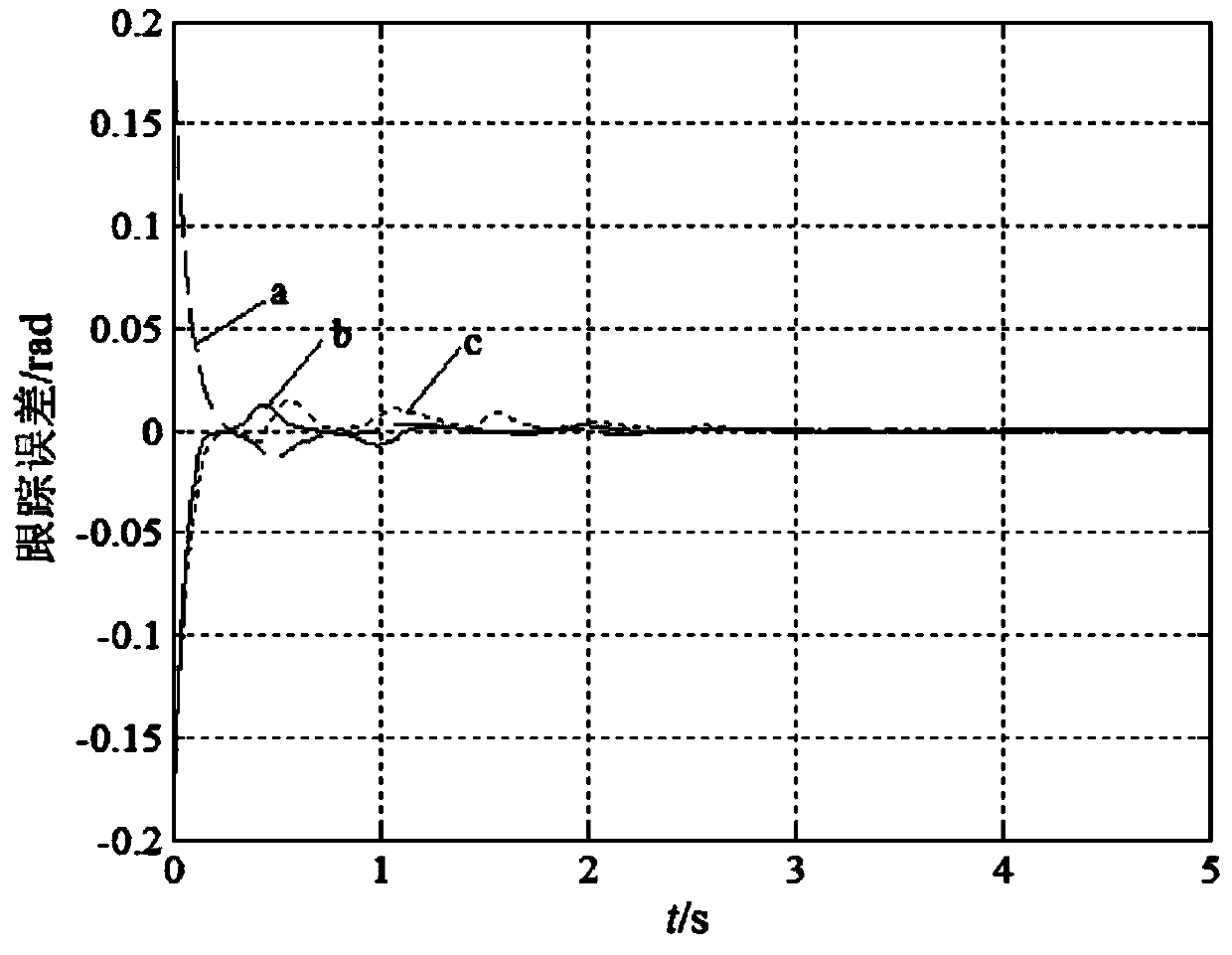

Permanent-magnet spherical motor rotor self-adapting control system based on dynamic friction compensation

ActiveCN103780188AReduce complexityLow hardware requirementsElectronic commutation motor controlVector control systemsControl systemState observer

The invention discloses a permanent-magnet spherical motor rotor self-adapting control system based on dynamic friction compensation. The system is characterized in that a permanent-magnet spherical motor rotor servers as a controlled object, and the control system is set to comprise a parameter self-adaptation adjustment module, a dynamic friction state observation module, a dynamic friction feedforward compensation module and a calculation moment module. The parameter self-adaptation adjustment module obtains adjustment parameters of the calculation moment module and the dynamic friction feedborward compensation module by real-time calculation achieved in a self-adaptation algorithm. The dynamic friction state observation module is composed of two state observers with two different dynamic items and is used for calculating state quantity estimation value in a dynamic friction model in real time. The dynamic friction feedforward compensation module calculates in real time to obtain a friction compensation moment tfc. The calculation moment module calculates to obtain a main control moment tc. The total control moment t of the controlled object is set to be t=tfc+tc. According to the control system, dynamic friction compensation of the permanent-magnet spherical motor rotor is achieved, and accordingly control precision is improved, and starting moment is reduced.

Owner:ANHUI UNIVERSITY

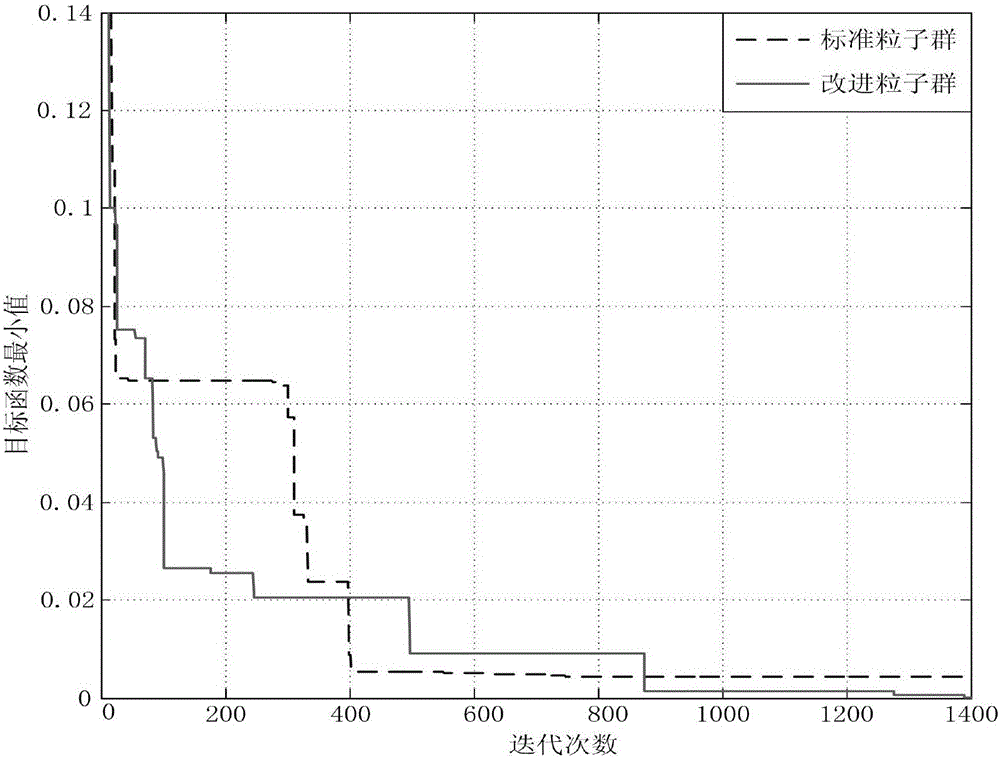

Improved particle swarm algorithm based inverse kinematics calculation method for permanent magnetic spherical motor

ActiveCN105046004AHigh solution accuracyDiversity guaranteedSpecial data processing applicationsLocal optimumSimulation based

The invention relates to an improved particle swarm algorithm based inverse kinematics calculation method for a permanent magnetic spherical motor. The method is carried out by the following steps of: step 1: determining a coordinate position of an output shaft of a rotated rotor according to initial position coordinates of the output shaft of the rotor and an obtained Euler angle, and taking a distance between the given coordinate position of the output shaft of the rotated rotor and an actually obtained coordinate position as a fitness function; and step 2: calculating the Euler angle corresponding to inverse kinematics of the permanent magnetic spherical motor by applying an improved particle swarm algorithm based on a simulated annealing algorithm. The method can effectively calculate a local optimal solution and has relatively high calculation precision.

Owner:TIANJIN UNIV

Magnetic levitation spherical motor

InactiveCN104410241ASmooth rotationQuick responseDynamo-electric machinesLevitationMulti degree of freedom

The invention discloses a multi-degree-of-freedom magnetic levitation spherical motor. The magnetic levitation spherical motor comprises a stator structure and a mover structure, wherein a plurality of permanent magnets are uniformly distributed on the spherical surface of the mover structure; the stator structure comprises magnetic levitation coils and thrust coils; a plurality of magnetic levitation coils are arranged on a levitation coil framework in a certain array form; the circumferential thrust coils are uniformly and radially distributed on the circumference of an incomplete spherical surface; and the top thrust coils are uniformly distributed in parallel and vertically on the top of the incomplete spherical surface. Through design of a novel form of structure, the mover can rotate in any direction in a plane. The structure is simple. The magnetic levitation spherical motor has a very good application prospect in multi-degree-of-freedom equipment.

Owner:UNIV OF JINAN

Multi-degree-of-freedom spherical motor and speed reducing mechanism thereof

PendingCN108494203AAchieve speedImplementation locationSynchronous machine detailsMagnetic circuit rotating partsMulti degree of freedomPosition sensor

The invention discloses a multi-degree-of-freedom spherical motor and a speed reducing mechanism thereof. The motor comprises a rotor, a permanent magnet, a holding rack, a ball, an output shell, a plurality of labels, a fixed magnet, a stator support and electromagnets, wherein the plurality of labels are uniformly embedded onto the surface of the rotor; the permanent magnet is connected to a step hole of the rotor; the holding rack is embedded onto the outer side of the rotor; the fixed magnet is placed in the fixed magnet seat of the holding rack; the output shell is embedded onto the outerside of the holding rack; the ball is placed in a ball through hole of the holding rack, and the outer surface is separately in contact with the outer surface of the rotor and the inner surface of the output shell; the electromagnet is fixed in the electromagnet seat of the stator support, the pole directions of adjacent two electromagnets are opposite, and the electromagnets are matched with thepermanent magnet; a plurality of positioning sensors are uniformly arranged on the inner surface of the stator support, and the positioning sensors are matched with the labels; and the fixed magnet is fixed in the magnet seat of the stator support, and is matched with the fixed magnet in the holding rack. The motor is simple and compact in structure, high in integrating degree and high in universality.

Owner:HEBEI UNIV OF TECH

Spherical motor

ActiveCN102570755AImprove cooling effectAchieve conversionElectric machinesMechanical energy handlingPower flowSpherical shaped

The invention discloses a spherical motor for an electric bicycle. The spherical motor comprises a stator and a rotor, wherein the stator is fixedly arranged on a fixing shaft, the rotor can rotate in the circumferential direction of the fixing shaft, a wire winding group is arranged on the stator, a plurality of permanent magnetic bodies are arranged on the rotor, the rotor is in a hollow spherical shape, the permanent magnetic bodies are fixedly arranged on a hollow inner case of the rotor, the fixing shaft passes through the spherical center of the rotor, the stator is in a solid spherical shape provided with the wire winding group at the inside, the fixing shaft passes through the spherical center of the stator, the radius of the stator is smaller than the radius of the rotor and is arranged in the hollow part of the rotor, and the direction of a magnetic field generated after current is introduced into the wire winding group is vertical to the spherical surface of the rotor in the corresponding position. The spherical motor provided by the invention has the advantages that the rotor and the stator are both designed into the spherical shape, the sum of the sizes of the permanent magnetic bodies accommodated inside the spherical rotor is great, meanwhile, the heat radiation area is large, the distance between the spherical stator and the rotor is small, the energy conversion rate is higher, and meanwhile, the heat radiation performance is better.

Owner:GUANGZHOU SAIDAO ELECTRONICS TECH

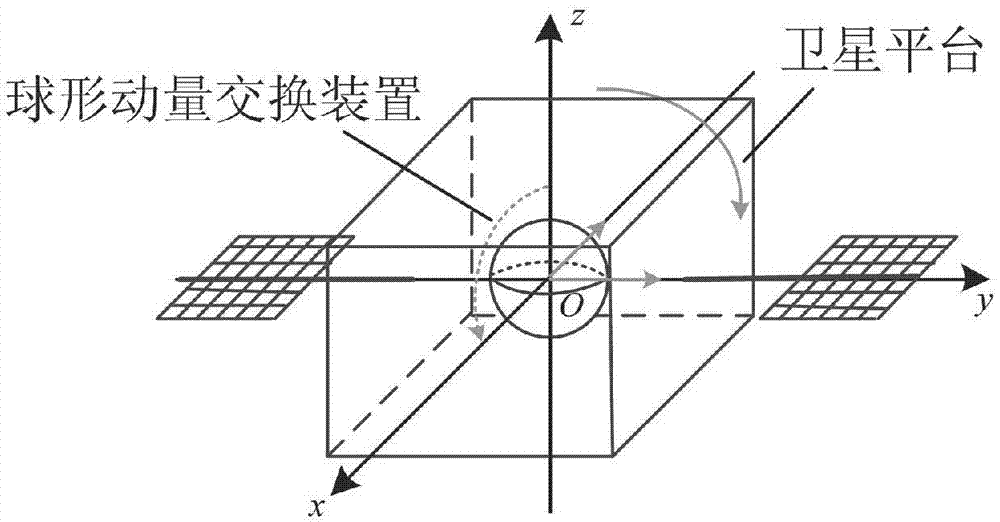

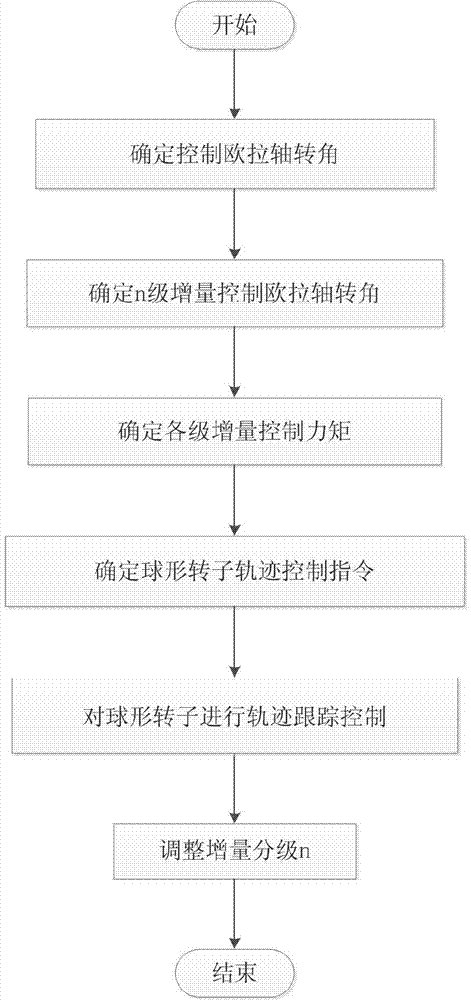

Satellite attitude control method based on three-freedom-degree momentum exchange of spherical motor

InactiveCN104724301AAvoid complex mechanical structuresReduce weightSpacecraft guiding apparatusNatural satelliteMomentum

The invention relates to a satellite attitude control method based on three-freedom-degree momentum exchange of a spherical motor. According to the satellite attitude control method, a spherical momentum exchange device is the spherical motor, and the spherical motor is connected with a satellite platform through a stator shell. The satellite attitude control method comprises the following steps that 1, a control Euler axis rotating angle is determined; 2, a hierarchical control Euler axis rotating angle is determined; 3, the incremental control torque of each level is determined; 4, a spherical rotor track control command is determined; 5, trajectory tracking control over a spherical rotor is conducted; 6, the increment grades n are adjusted. By the adoption of the satellite attitude control method, the weight of an aircraft can be reduced, satellite-borne space is reduced, and control is easy.

Owner:TIANJIN UNIV

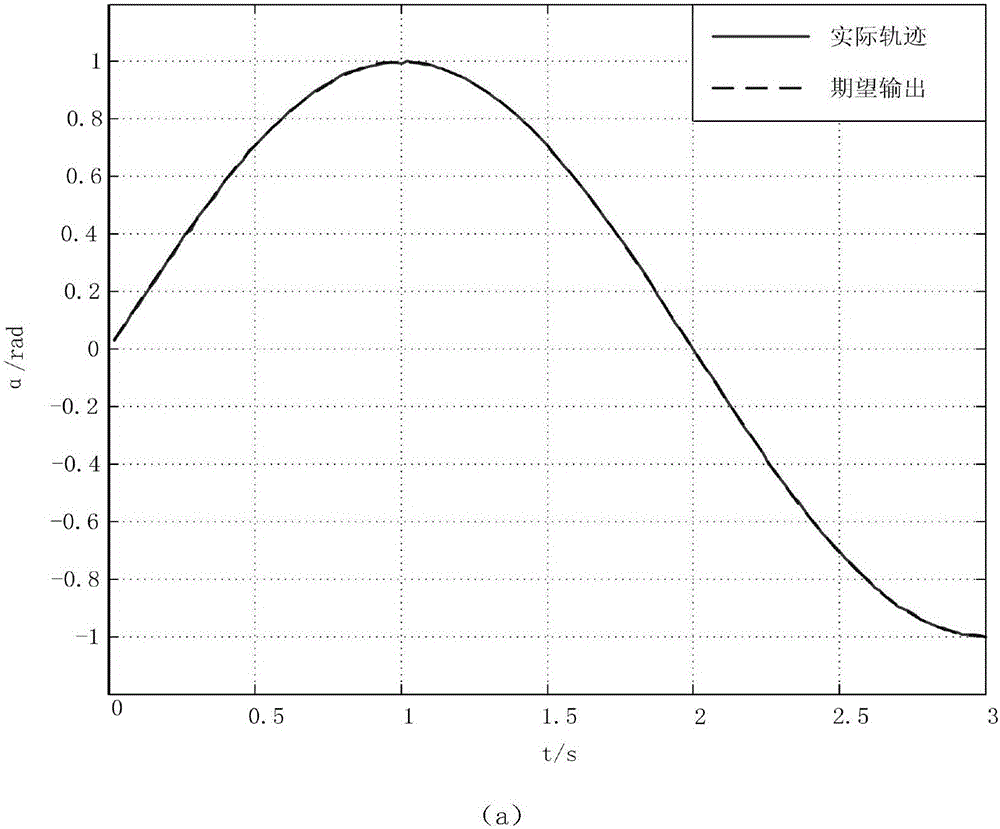

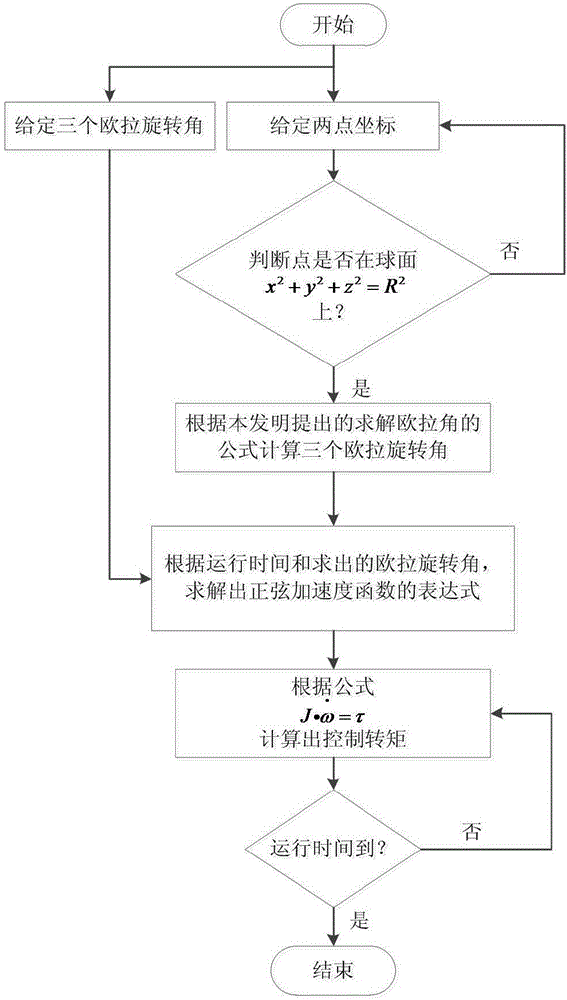

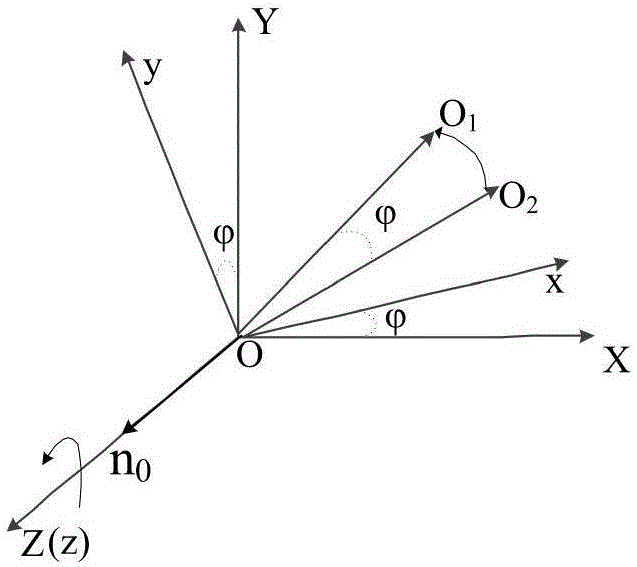

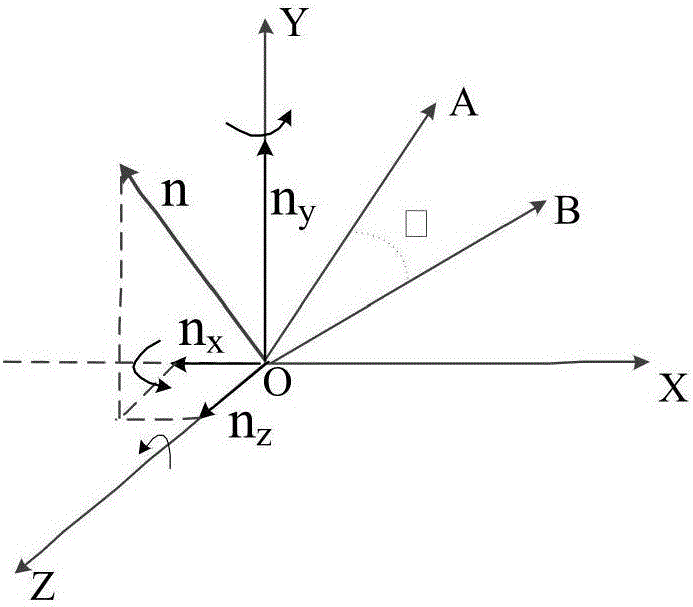

Permanent magnet spherical motor point-to-point motion track planning method based on sine acceleration function and application thereof

ActiveCN106292337AAchieve basic movementPoint to point movement is simpleSimulator controlResearch ObjectDynamic equation

The invention discloses a permanent magnet spherical motor point-to-point motion track planning method based on a sine acceleration function and application thereof. The method is characterized in that a permanent magnet spherical motor rotor is regarded as a research object, firstly a Euler rotation angle or coordinates of two points are given, and the Euler rotation angle is inversely solved by adopting a method of reversely solving the Euler rotation angle according to the coordinates of the two points; then, an expression of the sine acceleration function is solved according to the operating time and initial conditions, and finally a final control torque is obtained according to a rotor dynamics equation. By the adoption of the method, permanent magnet spherical motor point-to-point motion track planning is achieved, the method is applied to complicated and continuous track planning, the adverse influence of input signal impact, non-continuous change and other factors on a control object can be effectively reduced, and accordingly the control accuracy of a control system and the stability of motor operation are improved.

Owner:ANHUI UNIVERSITY

Spherical motor rotating in multiple degrees of freedom

ActiveUS8080911B2Stable positioning torqueSimple control systemMagnetic circuit rotating partsMagnetic circuit stationary partsBobbinMagneto

A spherical motor rotating in multi degrees of freedom has a reliable capability of determining positioning. The spherical motor includes a hollow spherical-shaped stator installed with a bi-level bobbin wound by coil generating a synthesized magneto-motive force on an inner surface thereof; and a rotor formed inside the stator and rotating around a shaft, wherein a slope of the shaft is adjusted by the synthesized magneto-motive force. Two or more of the bobbins are provided and installed at regular intervals along the inner surface of the stator, and the rotor includes one or more permanent magnets. The spherical motor rotating in multi degrees of freedom, formed with the above mentioned figures, can embody multi degrees of freedom by the interaction between the flowing current in the winding coil around the bobbin and the permanent magnet.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

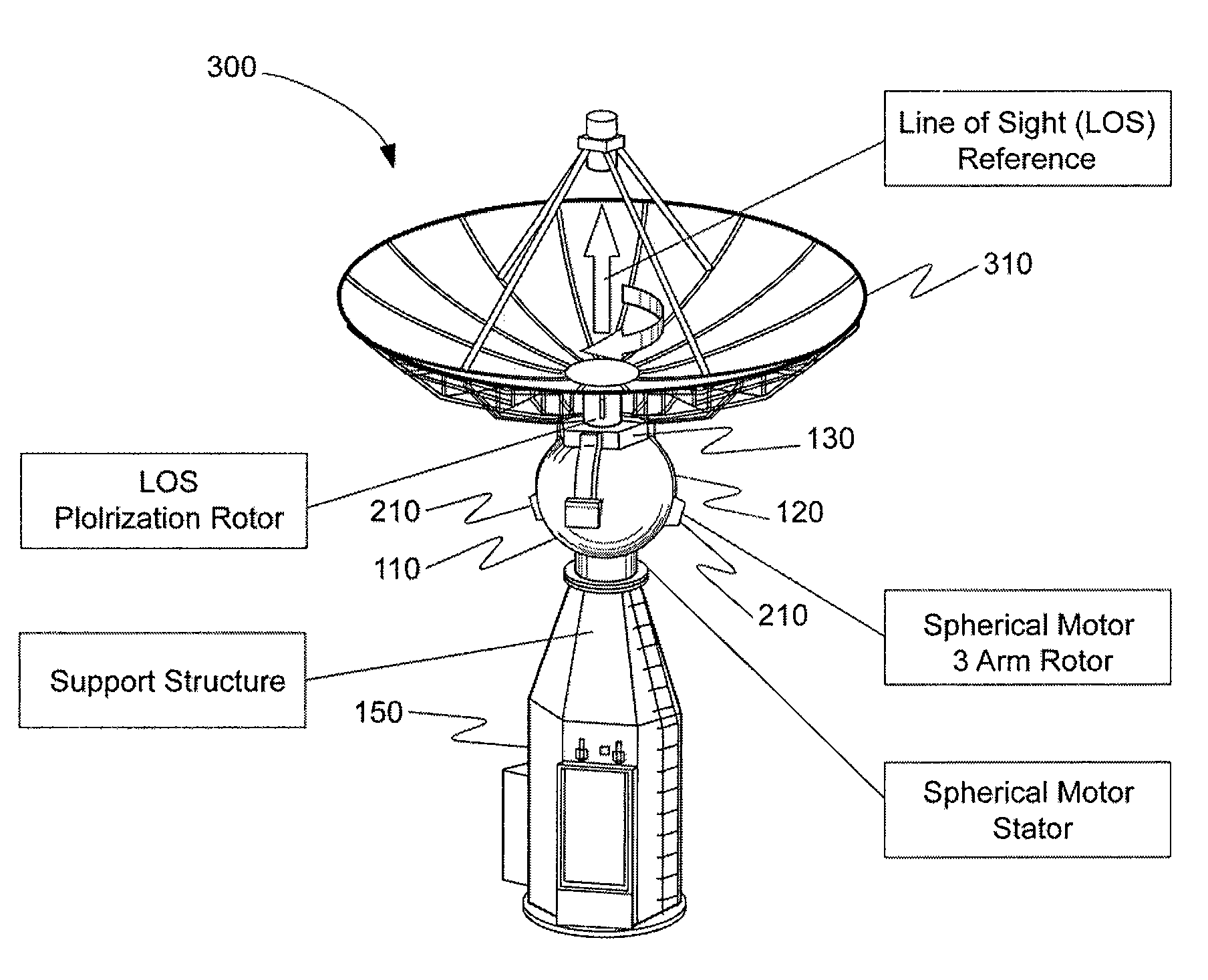

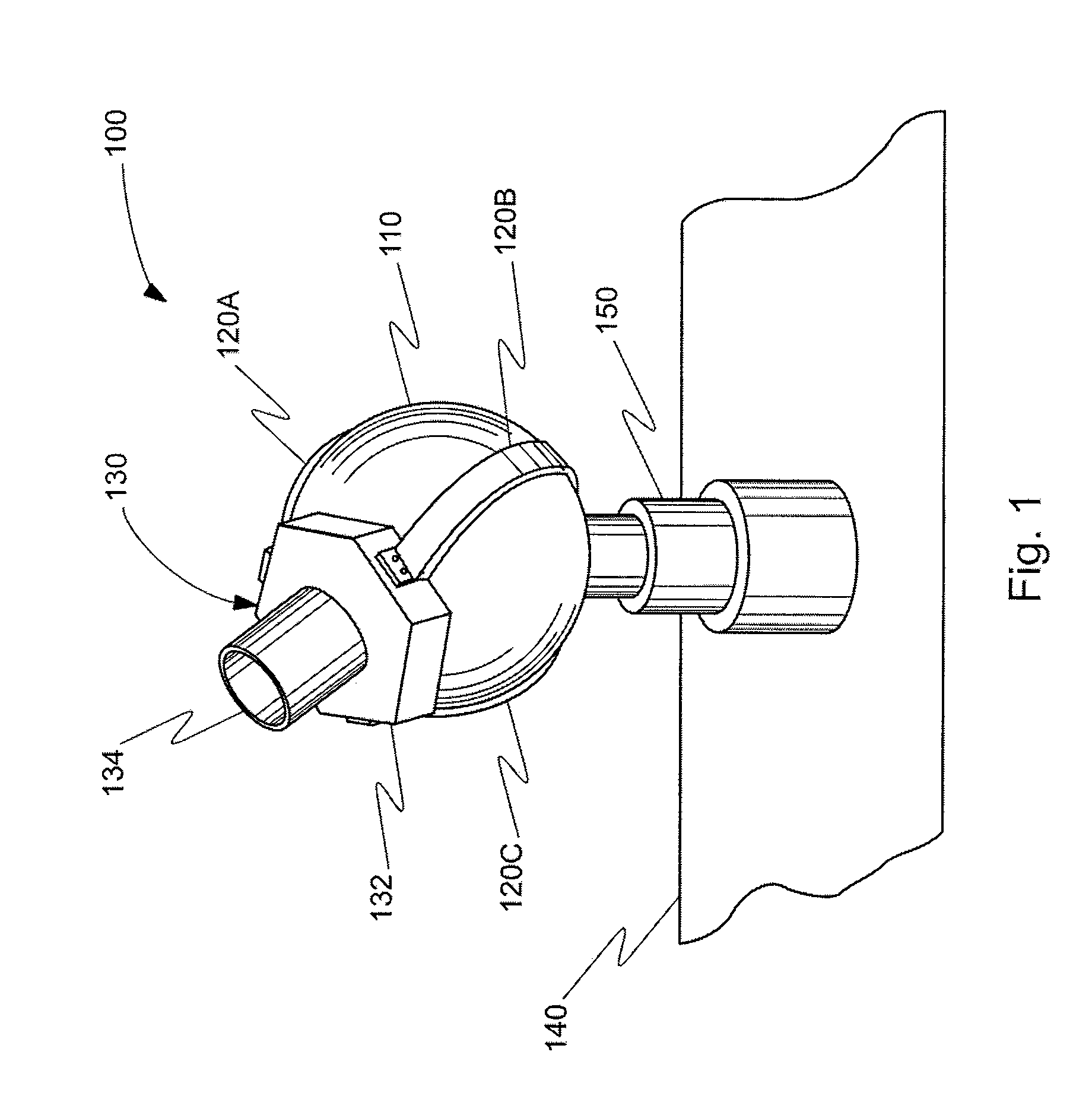

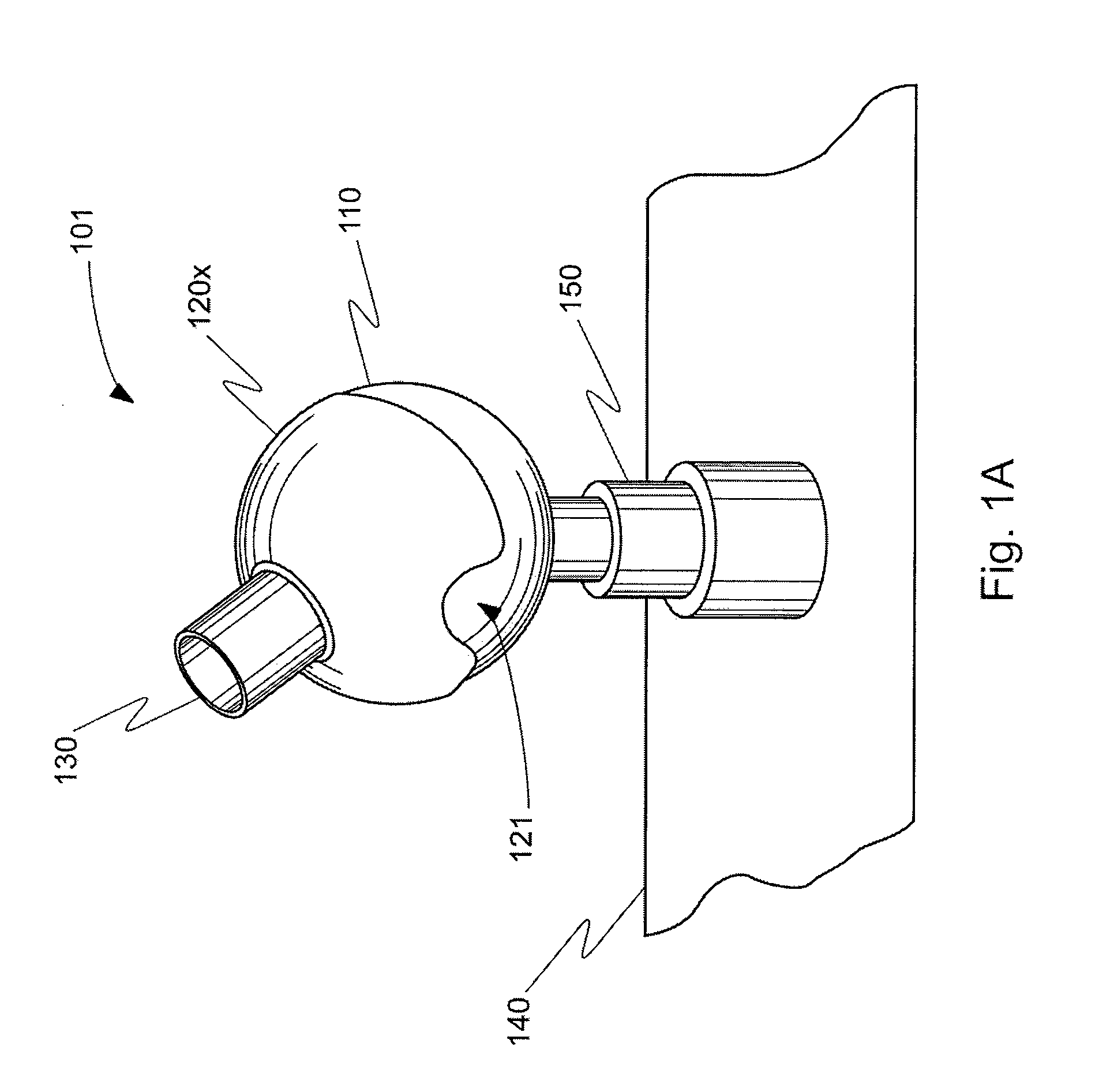

Spherical motor positioning

According to the invention, a system for rotating a parabolic antenna about a central point is disclosed. The system may include a support member, a spherical structure, and at least one arm. The support member may be coupled with a surface and may also be coupled with the support member. The spherical structure may be at least partially spherical in shape about the central point. The spherical structure may include a first plurality of magnets. The at least one arm may be in proximity to the spherical structure and may also include a second plurality of magnets. The at least one arm may be coupled with the parabolic antenna, and at least a portion of the magnets in either one of, or both of, the first plurality of magnets and the second plurality of magnets may be configured to be selectively activated to rotate the arms about the central point.

Owner:VIASAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com