Multi-degree-of-freedom spherical motor and speed reducing mechanism thereof

A technology of reduction mechanism and spherical motor, applied in the direction of magnetic circuit shape/style/structure, electric components, electrical components, etc., can solve the problem that the reducer cannot follow the three-degree-of-freedom drive of the spherical motor, and the motor is difficult to achieve three-degree-of-freedom full circle rotation , high manufacturing cost and extremely high installation accuracy requirements, etc., to achieve the effect of high integration, large range of motion, and low installation accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

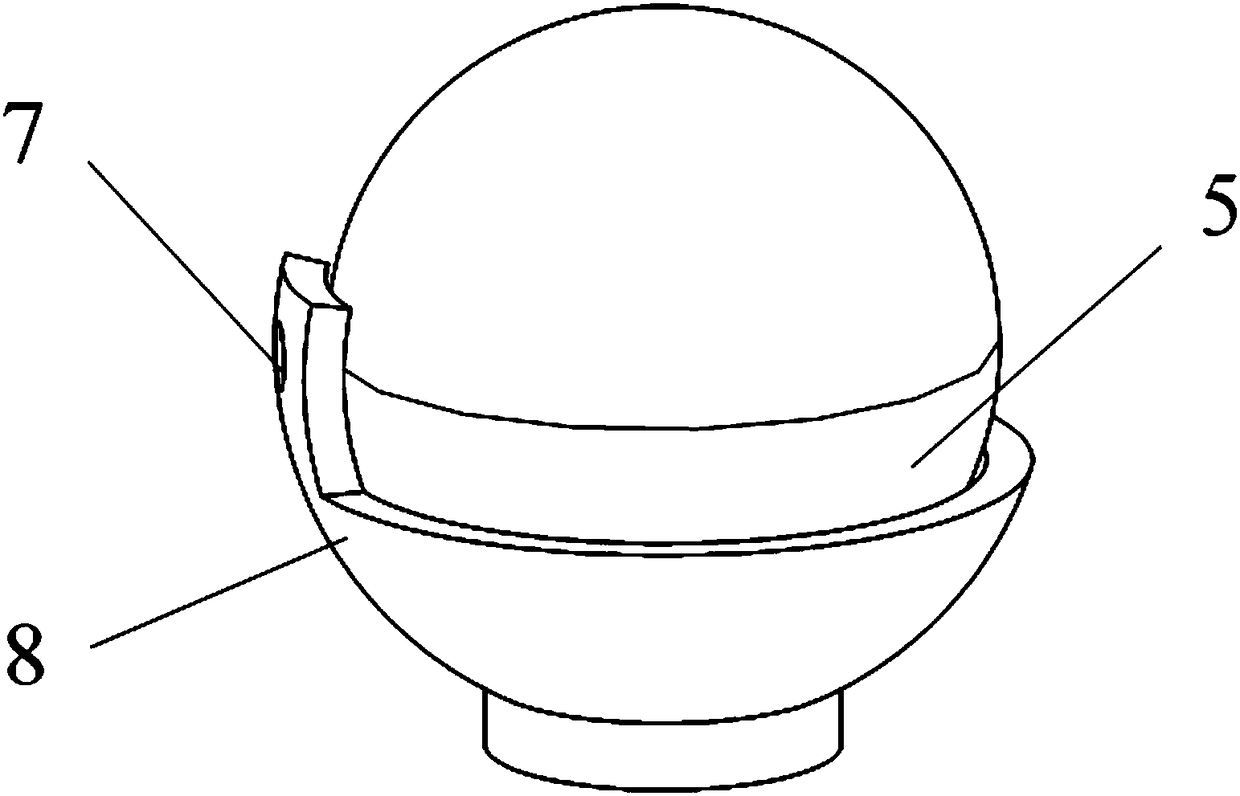

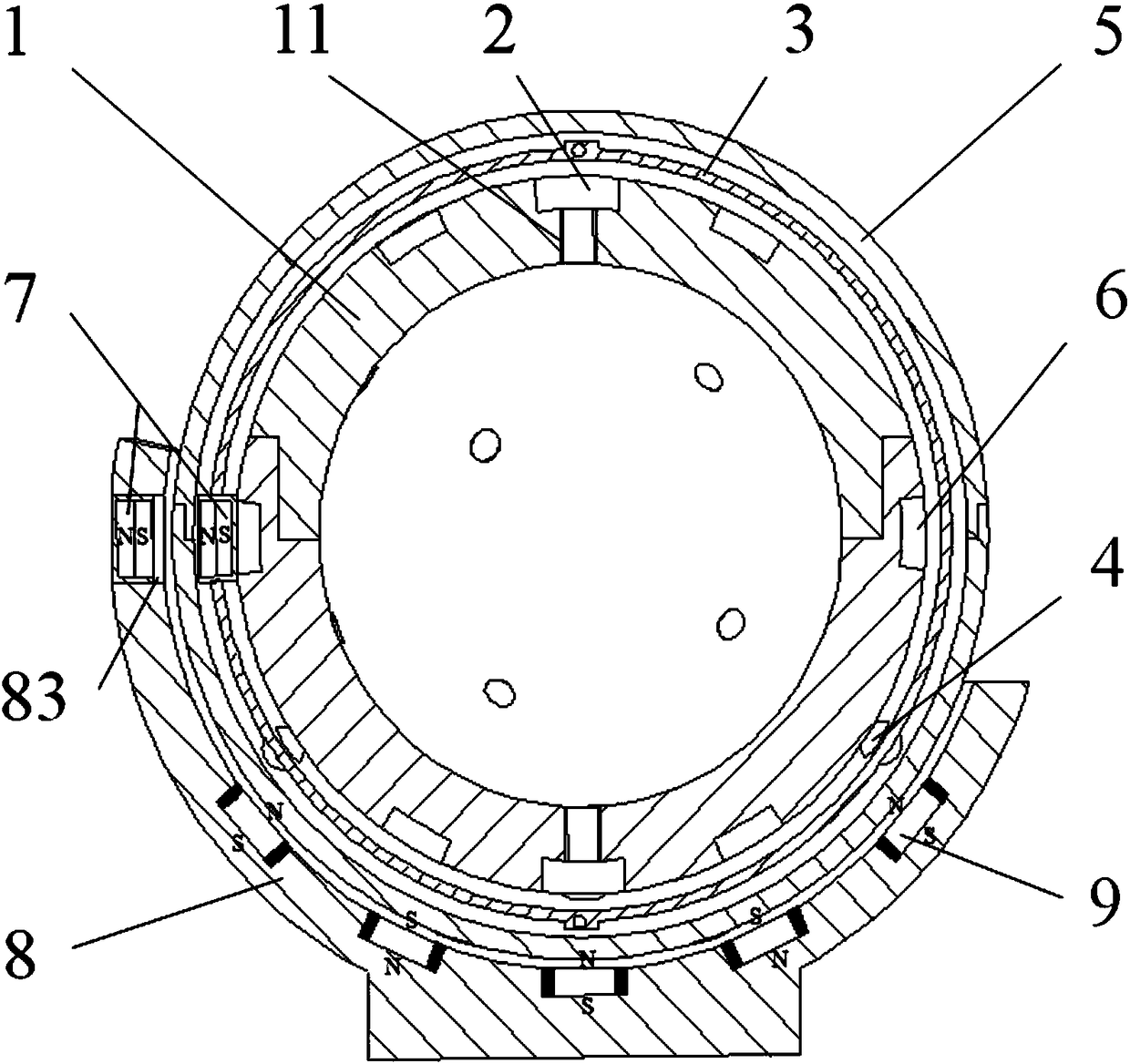

[0023] The invention provides a multi-degree-of-freedom spherical motor and its reduction mechanism (see Figure 1-7 , referred to as the device), it is characterized in that the device includes a motor rotor mechanism, a speed reduction mechanism and a motor stator mechanism;

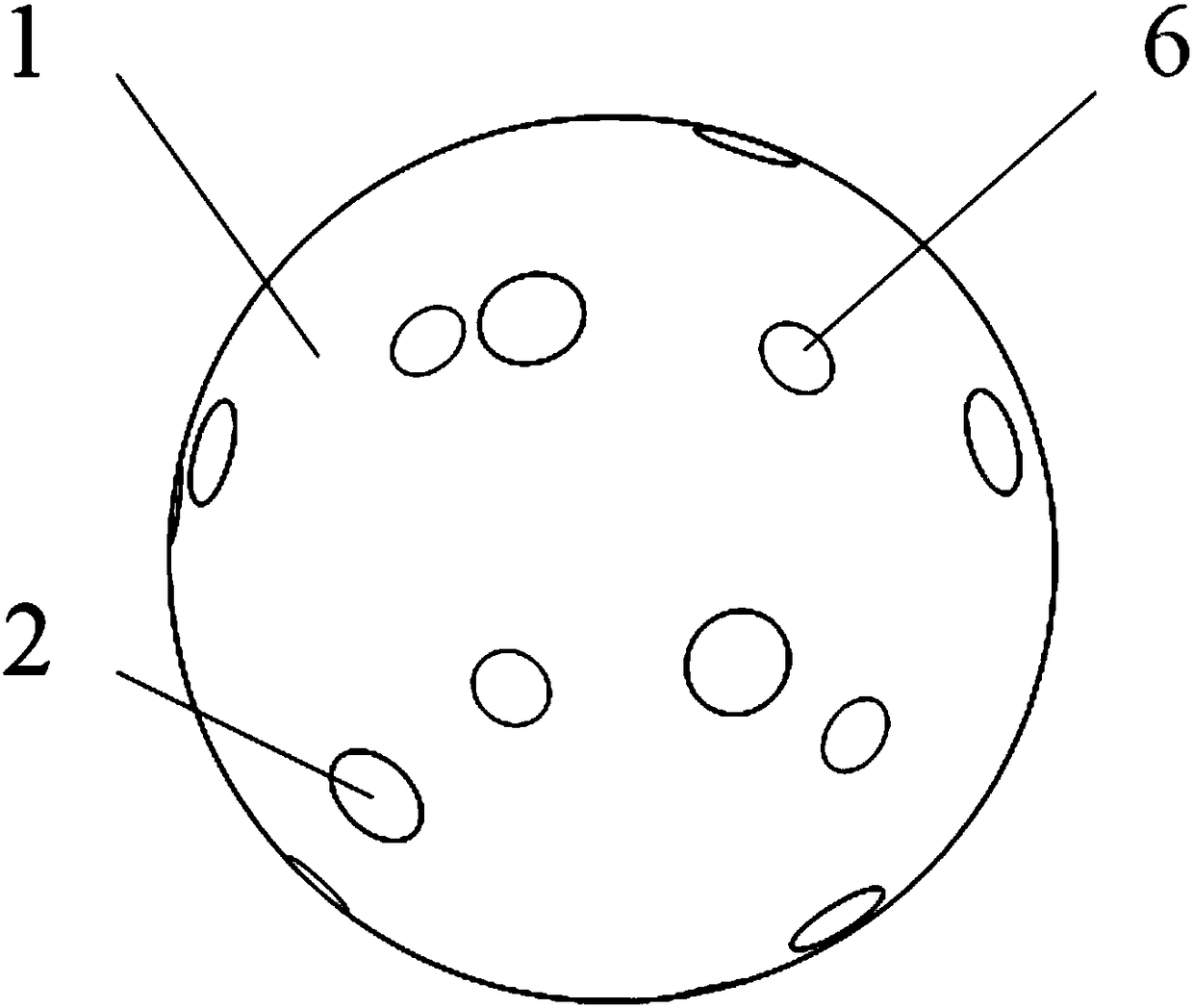

[0024] The motor rotor mechanism includes a rotor 1 and a permanent magnet 2; the reduction mechanism includes a cage 3, balls 4, an output housing 5, a label 6 and a fixed magnet 7; the motor stator mechanism includes a stator support 8 and an electromagnet 9;

[0025] The rotor 1 is a hollow sphere structure, and several (14 in this embodiment) stepped holes 11 are evenly opened on the surface of the rotor 1, and there are threads in the stepped holes 11; severa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com