Patents

Literature

55 results about "Motion coordination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

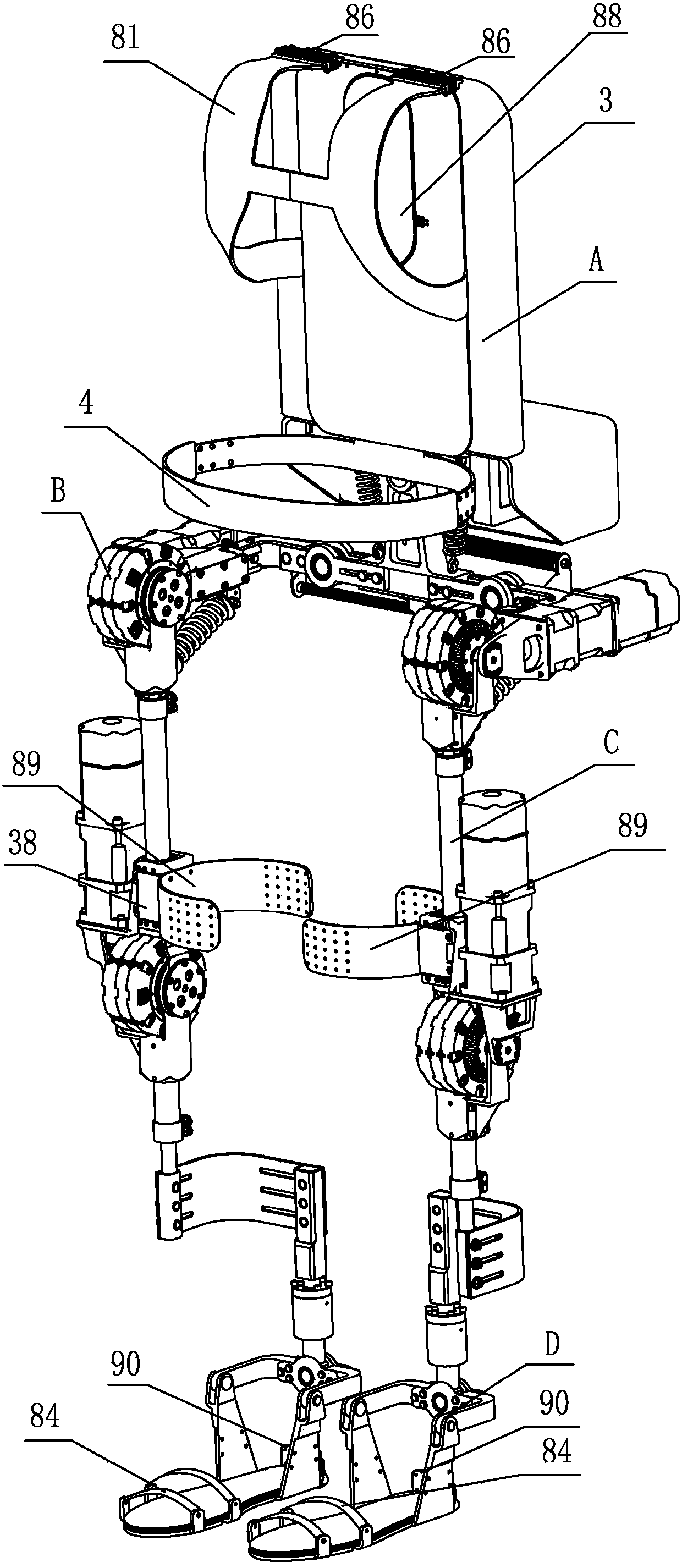

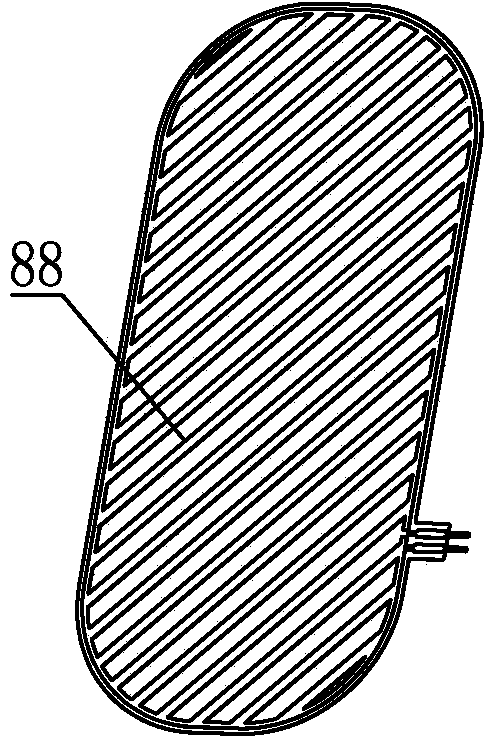

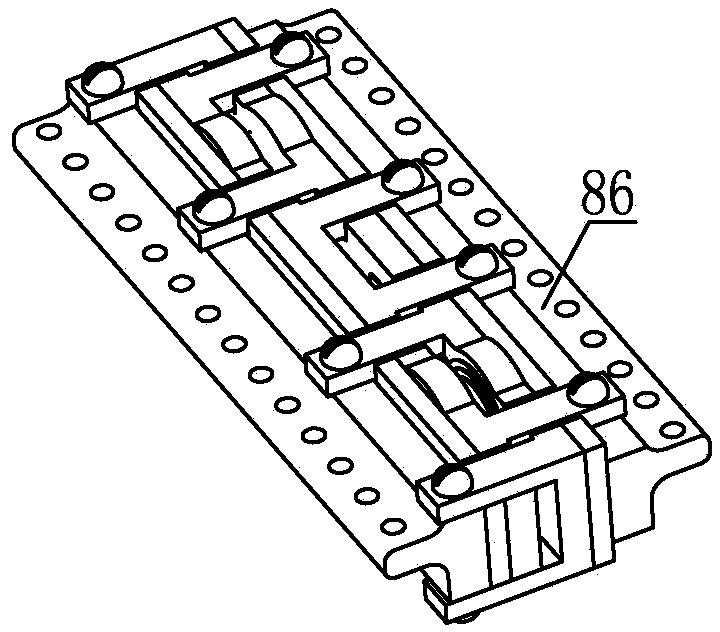

Exoskeleton robot system with human motion detecting function and control method of robot system

ActiveCN104188675AMeet the needs of correctly judging human motion intentionGuaranteed comfortWalking aidsArtificial legsHuman bodyThigh

The invention relates to an exoskeleton robot system with a human motion detecting function and a control method of the robot system and aims to solve the problems that an existing exoskeleton assistance robot often aims at the typical gait of walking on the flat ground, is poor in universality and cannot correctly judge human motion intensions, motion coordination between the exoskeleton robot and a human body cannot be kept, and good assistance effect on complex road surfaces cannot be achieved. The exoskeleton robot system comprises an upper body back, a left leg and a right leg. Each of the left leg and the right leg comprises a hip drive system, a thigh drive system and a shank wearing system. The upper body back comprises a back support and shoulder straps. Each thigh drive system comprises a thigh binding strap. Each shank wearing system comprises a leg binding strap, an upper rubber pad, a lower rubber pad and a heel plate. The exoskeleton robot system further comprises a sensing detecting control system. The exoskeleton robot system is applicable to assistance walking and human motion posture detecting and control.

Owner:HARBIN INST OF TECH

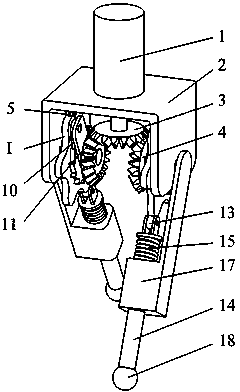

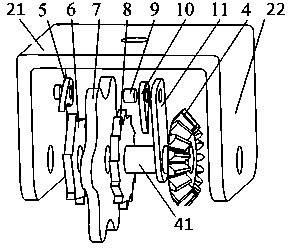

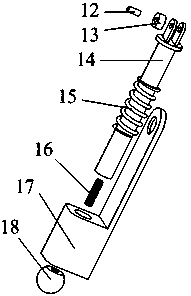

Biped robot capable of walking rapidly

ActiveCN104228993ASimplify the control problemSimplified Motion AlgorithmVehiclesRatchetControl engineering

The invention discloses a biped robot capable of walking rapidly. The biped robot is composed of a servo motor, a motor support, a driving bevel gear, driven bevel gears, check pawls, ratchet wheel cam sets, ratchet wheel connecting pins, a driving pawl, oscillating bars, roller connecting pins, rollers, shanks, compression springs, screws, thighs and feet. The servo motor drives the driving bevel gear to rotate so as to drive the symmetrically-arranged driven bevel gears to rotate oppositely and the thighs to swing forwards and backwards; the shanks always make contact with cams in the ratchet wheel cam sets through the compression springs and supporting legs are longer than swinging legs through telescopic motion of the shanks. Compared with the prior art, the biped robot has the advantages that the robot can be driven by one servo motor, so that the robot is convenient to control and high in control accuracy; except for the servo motor, other structures of the robot are all mechanical structures, so that motion cooperation is convenient; the structure is simple, machining and installation are convenient, and the robot can walk rapidly.

Owner:ZHEJIANG UNIV

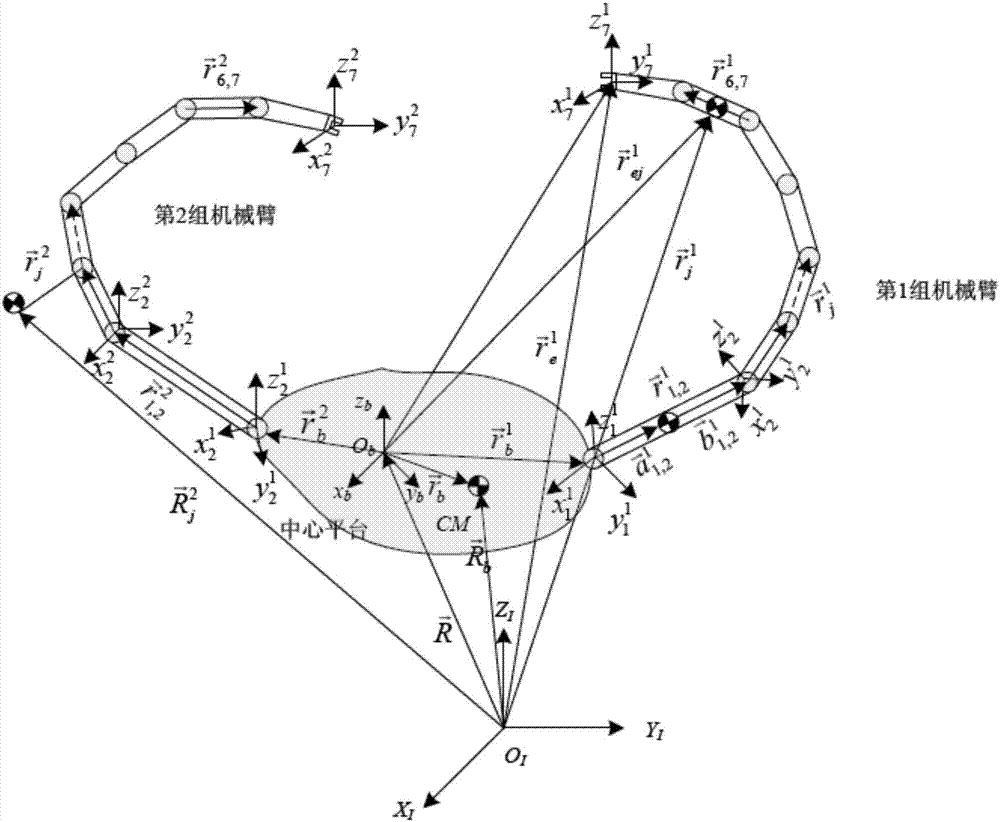

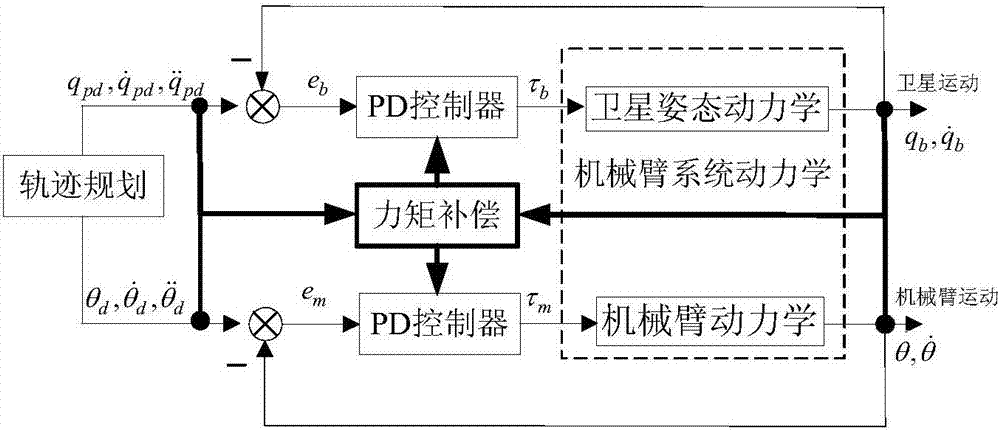

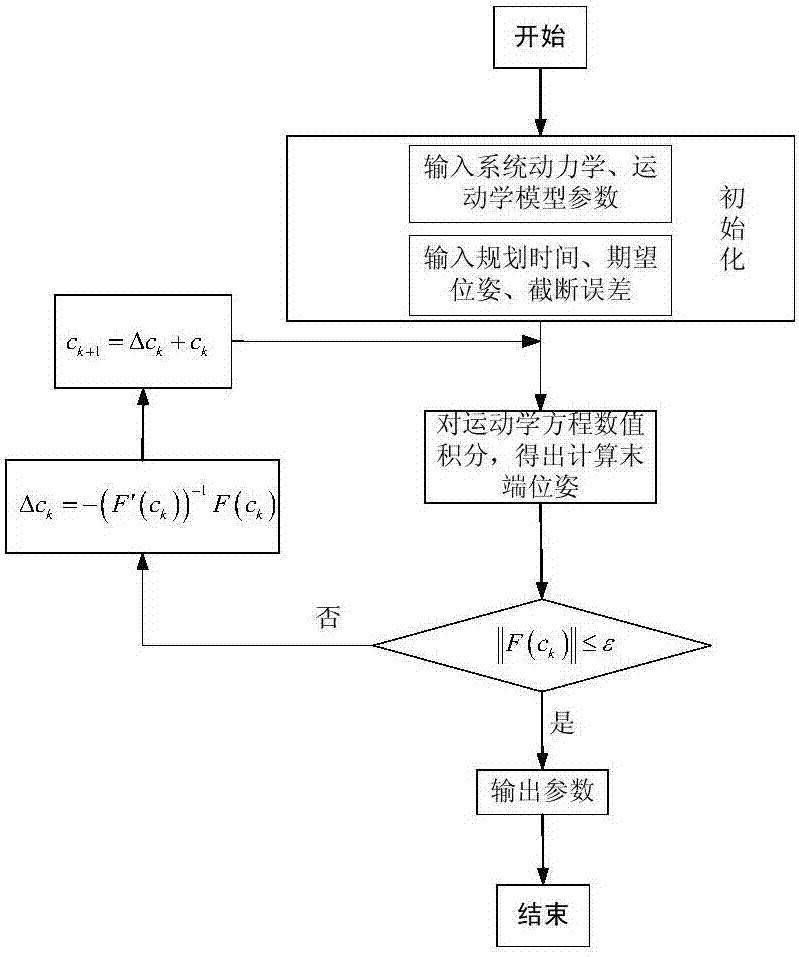

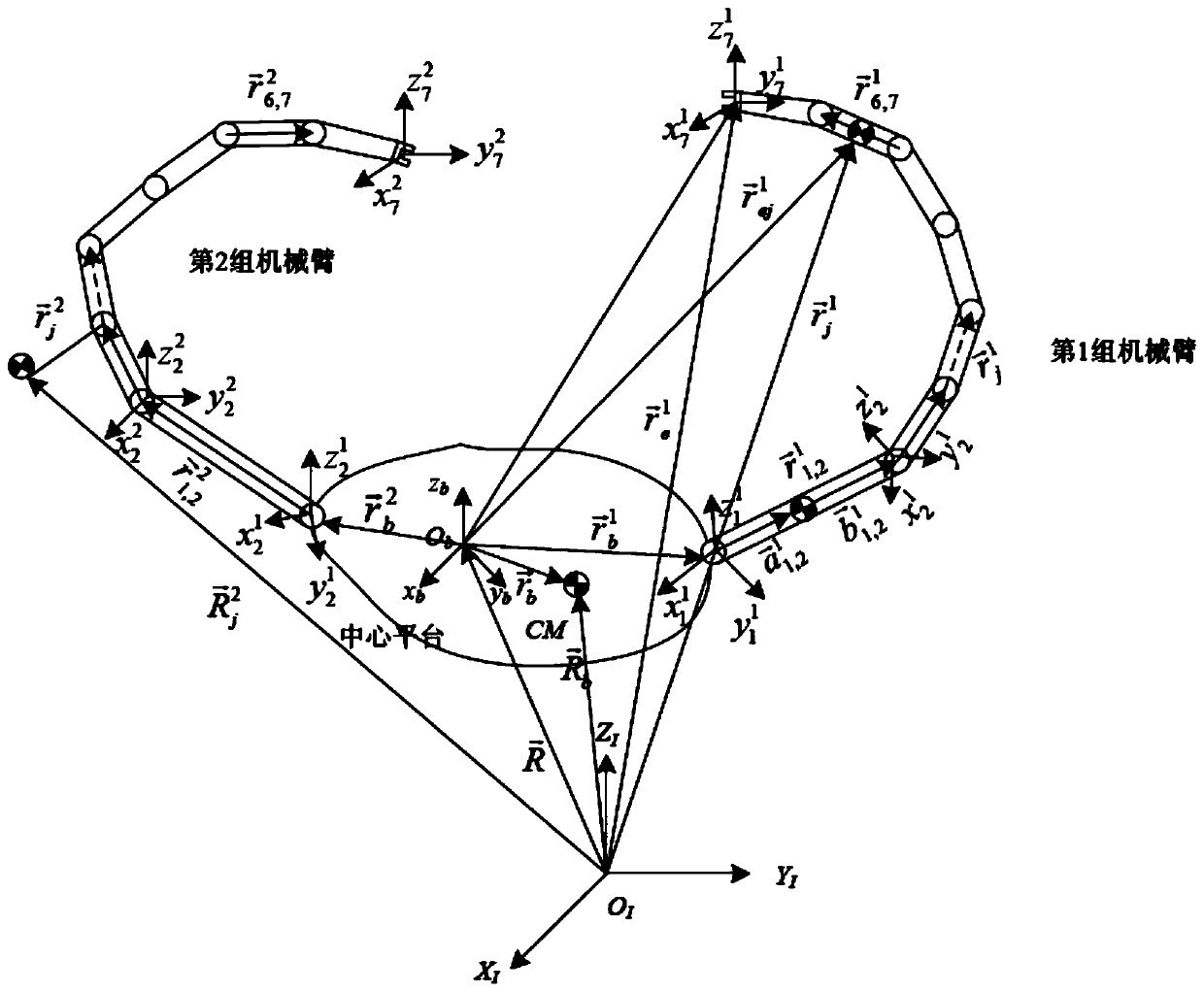

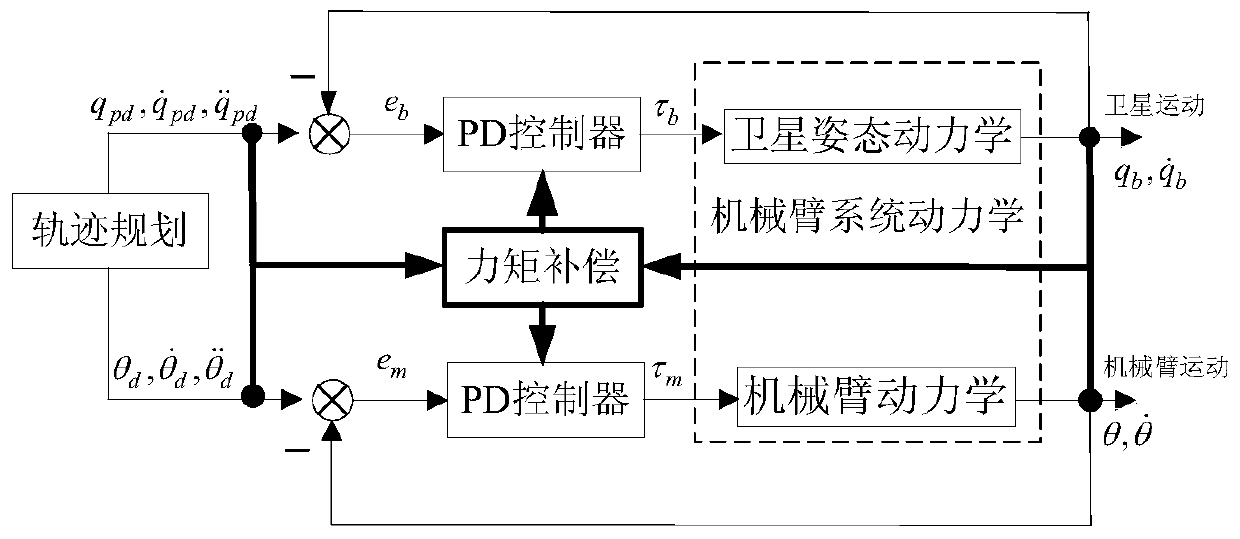

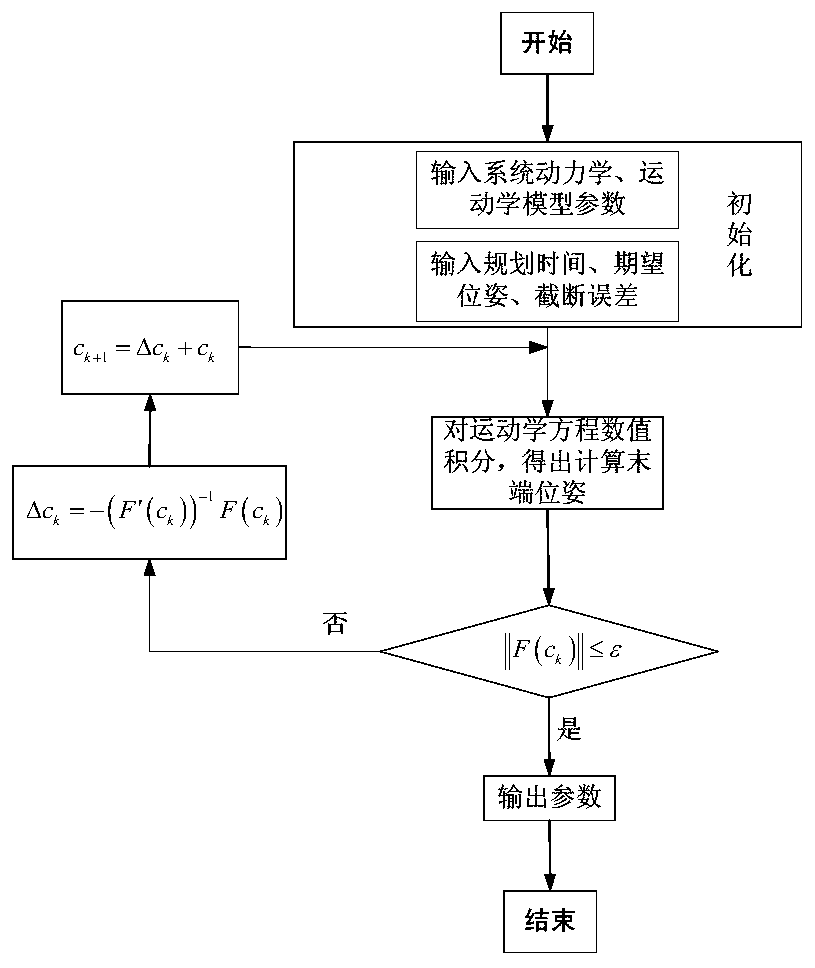

Motion coordination control method for space dual-manipulator system

ActiveCN106945020AFast trackImprove operating precisionProgramme-controlled manipulatorKinematics equationsControl system

The invention relates to a motion coordination control method for a space dual-manipulator system, and belongs to the technical field of space manipulators. In order to overcome the defects that no space manipulator system specific to dual manipulators exists at present, the coordinated relation between a manipulator and a satellite body is not considered in an existing space manipulator system and tracking errors are high, the motion coordination control method for the space dual-manipulator system is provided. The motion coordination control method for the space dual-manipulator system includes the steps that a kinematical equation and kinetic equation of the space dual-manipulator system are established; the space dual-manipulator system is subjected to trajectory planning according to the initial postures and tail-end postures of the manipulators; and trajectories of the space dual-manipulator system are subjected to tracking control through a PD controller. The motion coordination control method for the space dual-manipulator system is suitable for a space manipulator control system.

Owner:黑龙江省工研院资产经营管理有限公司

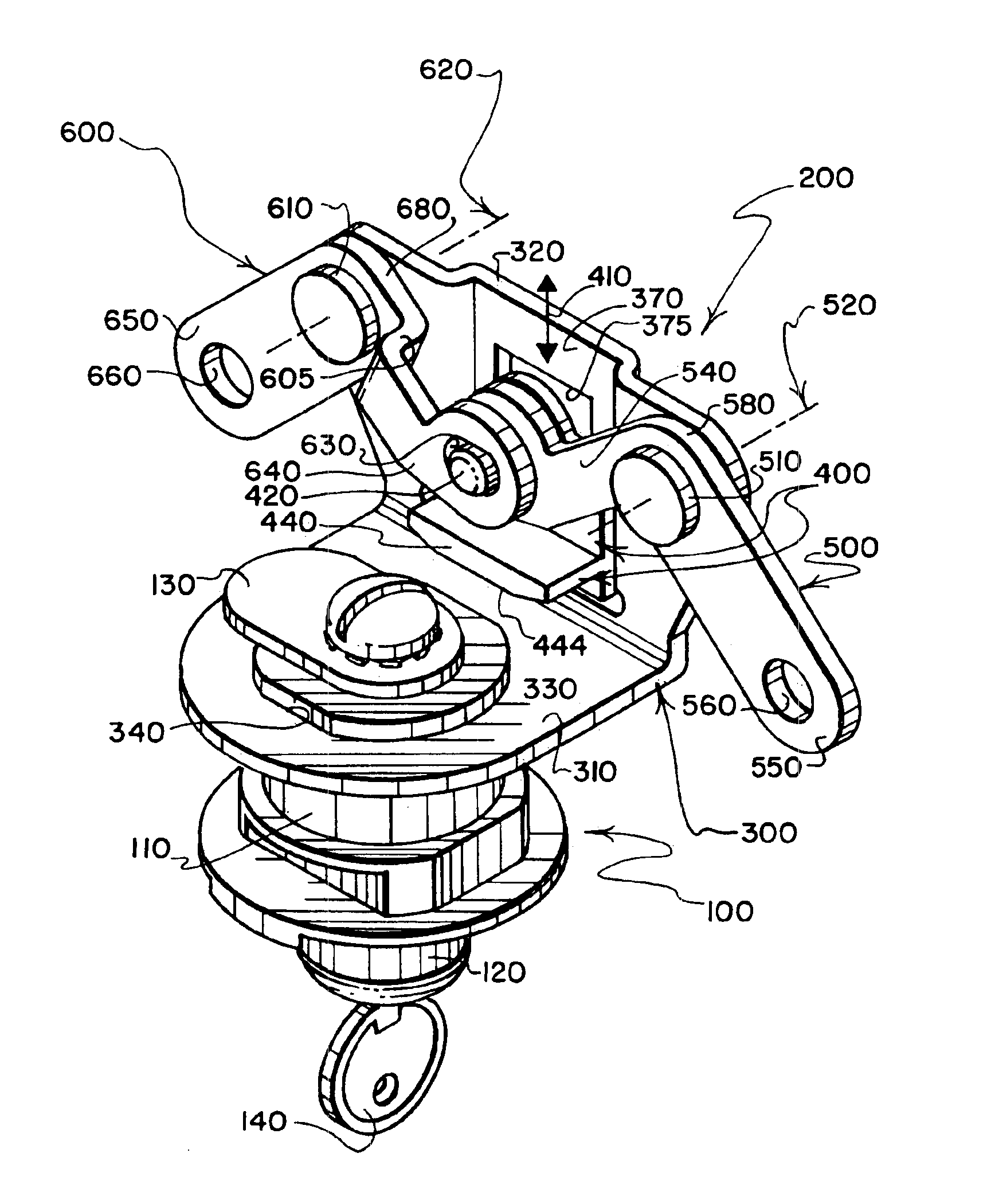

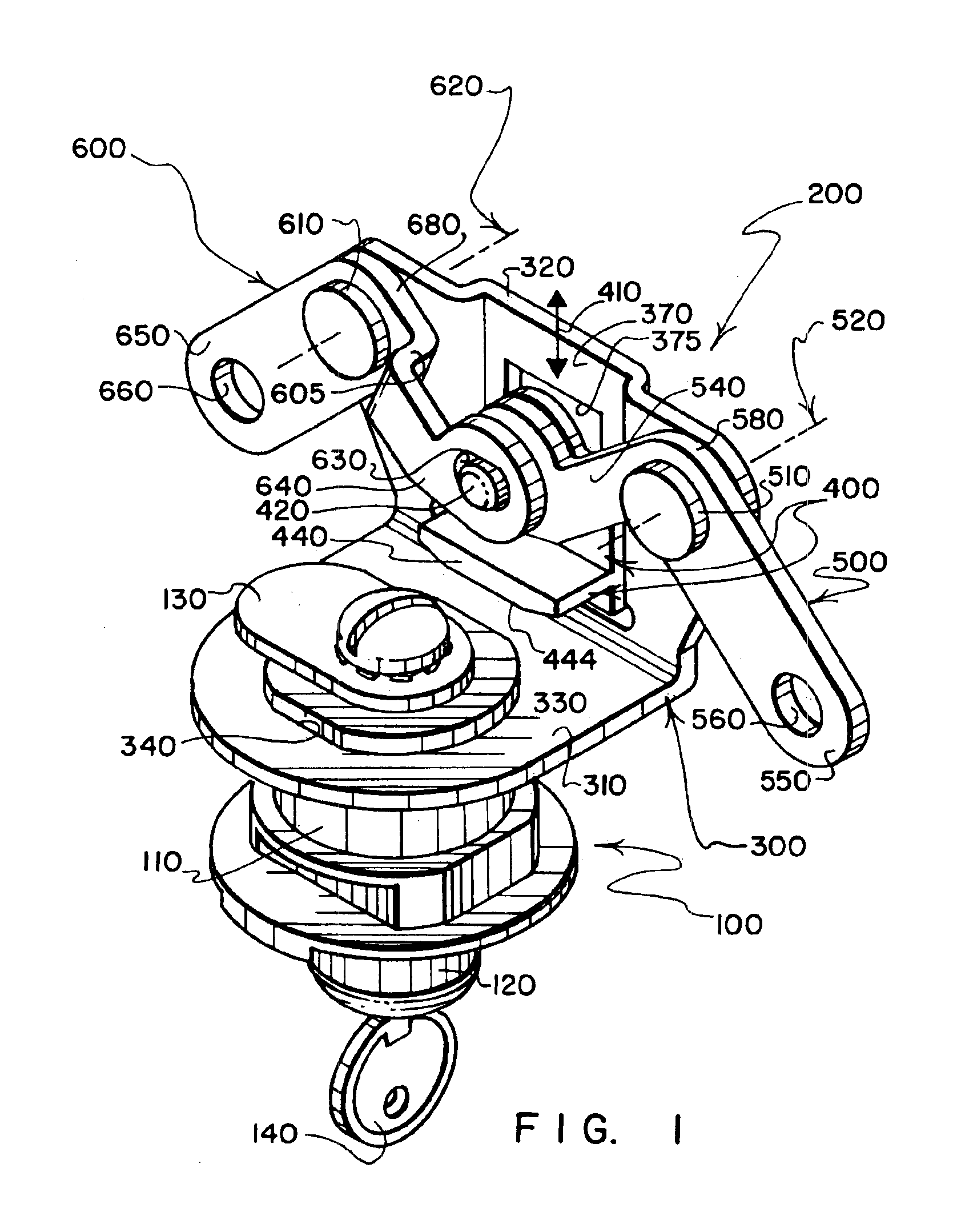

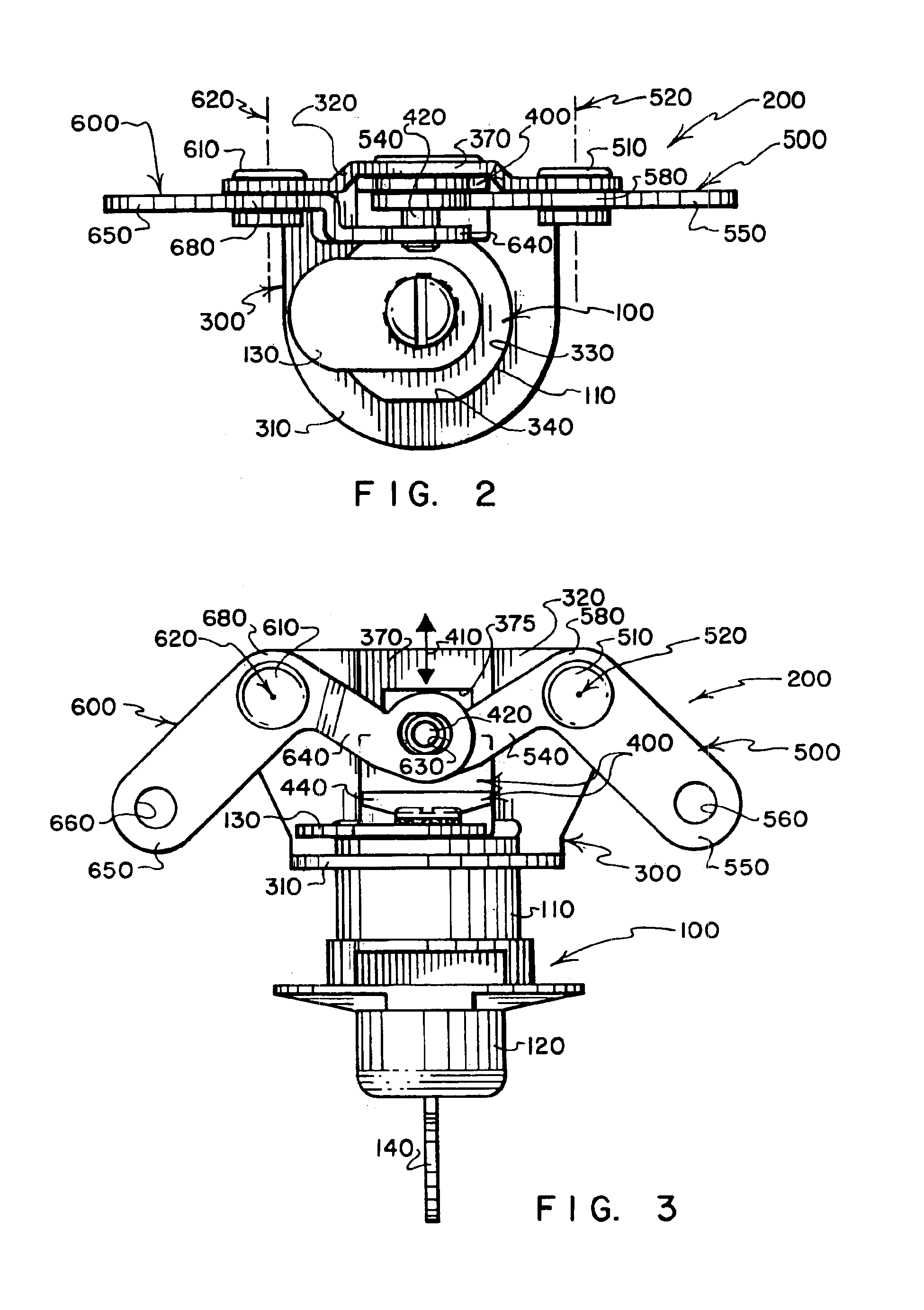

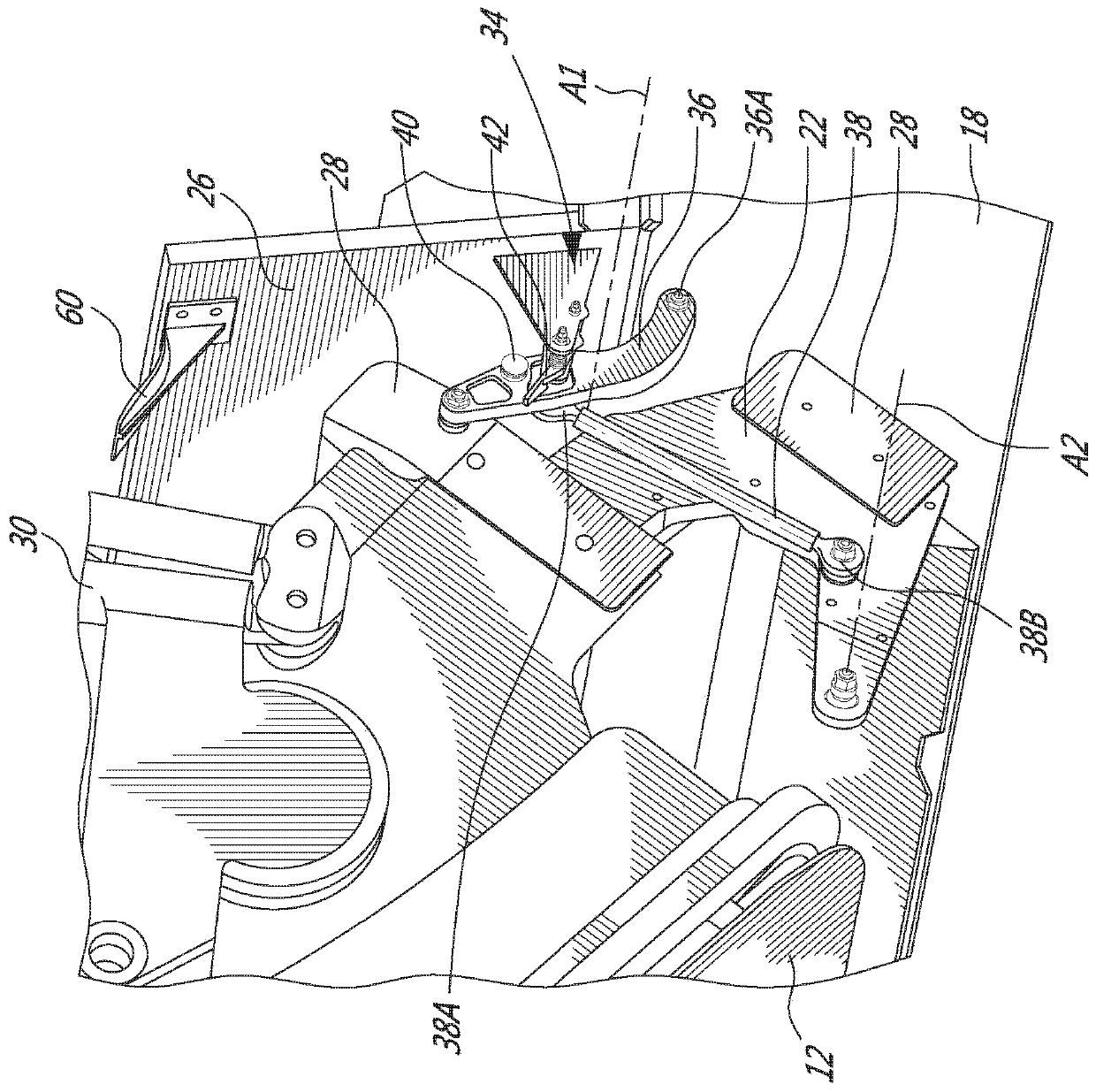

Linkage assembly for operating one or more latches

InactiveUS6899362B1Motor coordinationPrevent arm movementAnti-theft cycle devicesAnti-theft devicesPickup truckEngineering

A linkage assembly includes a frame, an arm movement coordinating member slidably supported by the frame, and a pair of arms pivotally connected to the frame and connected to the coordinating member to ensure that the arms pivot in unison when the coordinating member is slided relative to the frame by depressing a push button that is connected to the frame for translation relative thereto. Either of the arms can be link-connected to a latch assembly for operating either a single latch assembly or for concurrently operating a pair of latch assemblies in response to depression of the push button. An optional emergency release cable may connect with the arm movement coordinating member to facilitate latch operation from inside a tonneau cover of a pickup truck or the like that is held closed by the latch or latches.

Owner:THE EASTERN COMPANY

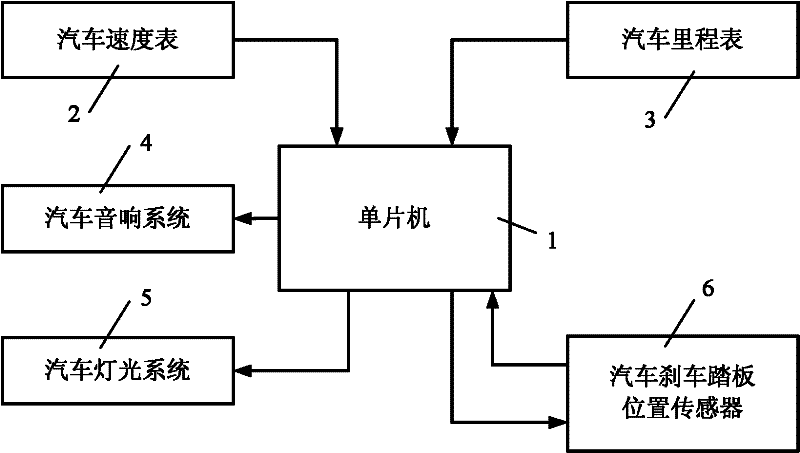

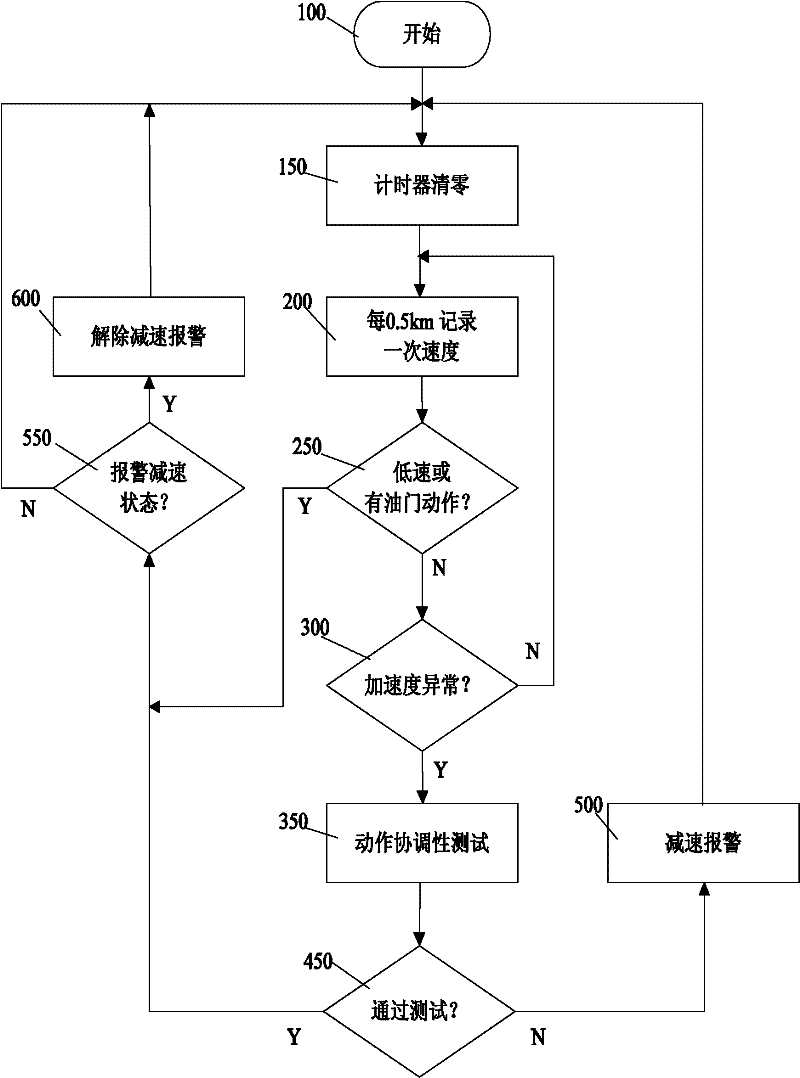

Early warning method for fatigue driving of automobile driver

InactiveCN102254403AEarly detection of fatigueImprove real-time performanceSignalling/lighting devicesAlarmsMicrocontrollerAlarm state

The invention discloses an early warning method for fatigue driving of an automobile driver. The method comprises the following steps that: a singlechip records a running speed of the automobile for one time every 0.5 km according to a speedometer and a milometer of the automobile; when the running speed of the automobile is lower than 40 km / h or the speed descends twice within 60 seconds, a driver is not fatigue during driving; the singlechip removes a deceleration alarm state or resets a system; if an absolute value delta a of an acceleration change value of the automobile is smaller than 1 m / s<2> or the acceleration a of the automobile is greater than 3 m / s<2>, the singlechip outputs a signal to a sound system of the automobile; the sound system of the automobile sends a sound to prompt that the driver is fatigue during driving, and the driver is subjected to a motion coordination test; if the driver continuously keeps the foot away from an accelerator pedal for three times within 30 seconds or continuously performs deceleration motion to make the running speed of the automobile descend by 15 km / h, the driver finishes the motion coordination test; otherwise, the singlechip gives a deceleration alarm. The invention adopts a method for actively testing the fatigue driving of the driver. The method has the advantages of relatively higher working real-time performance and reliability.

Owner:JIANGSU UNIV OF SCI & TECH

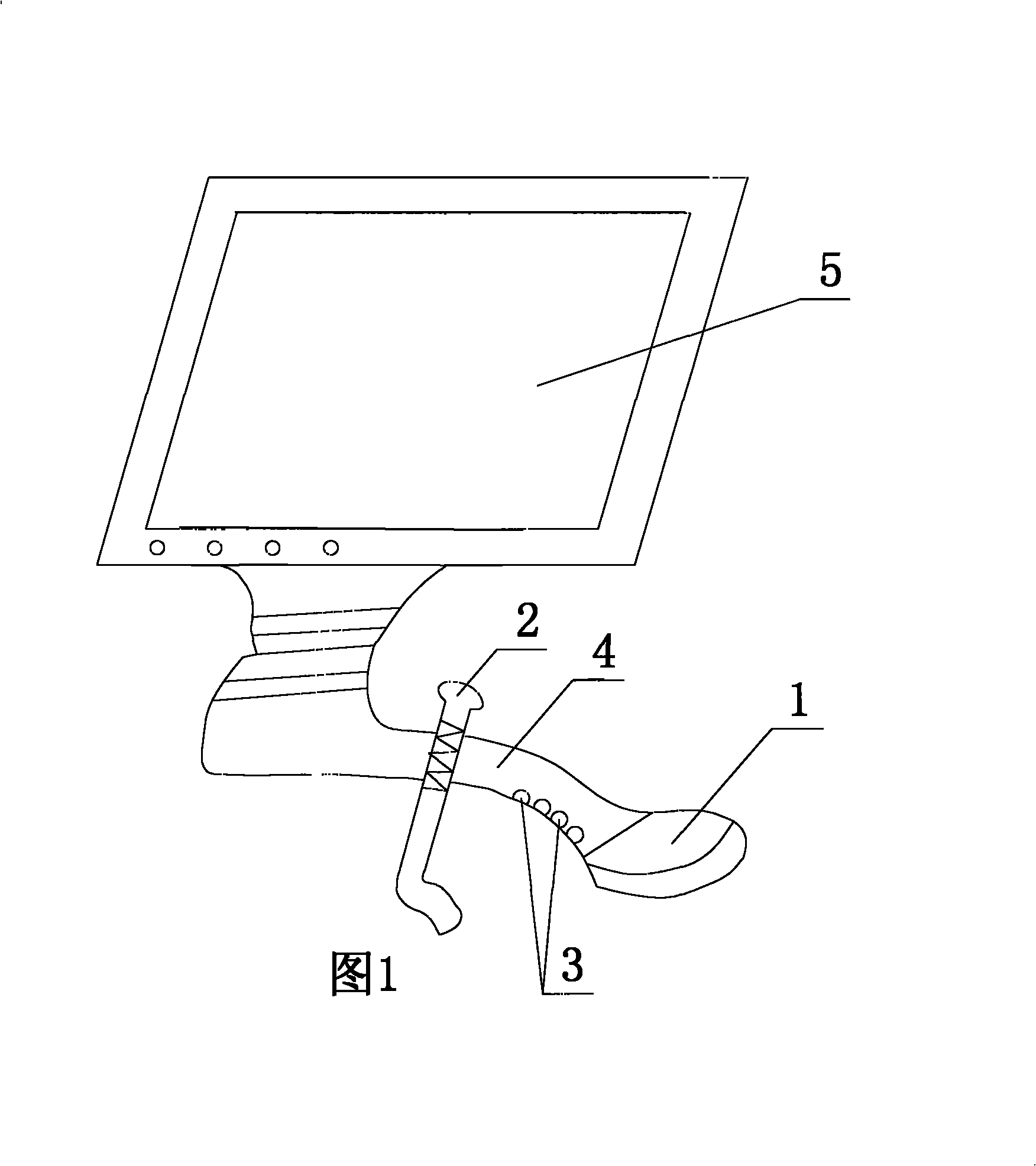

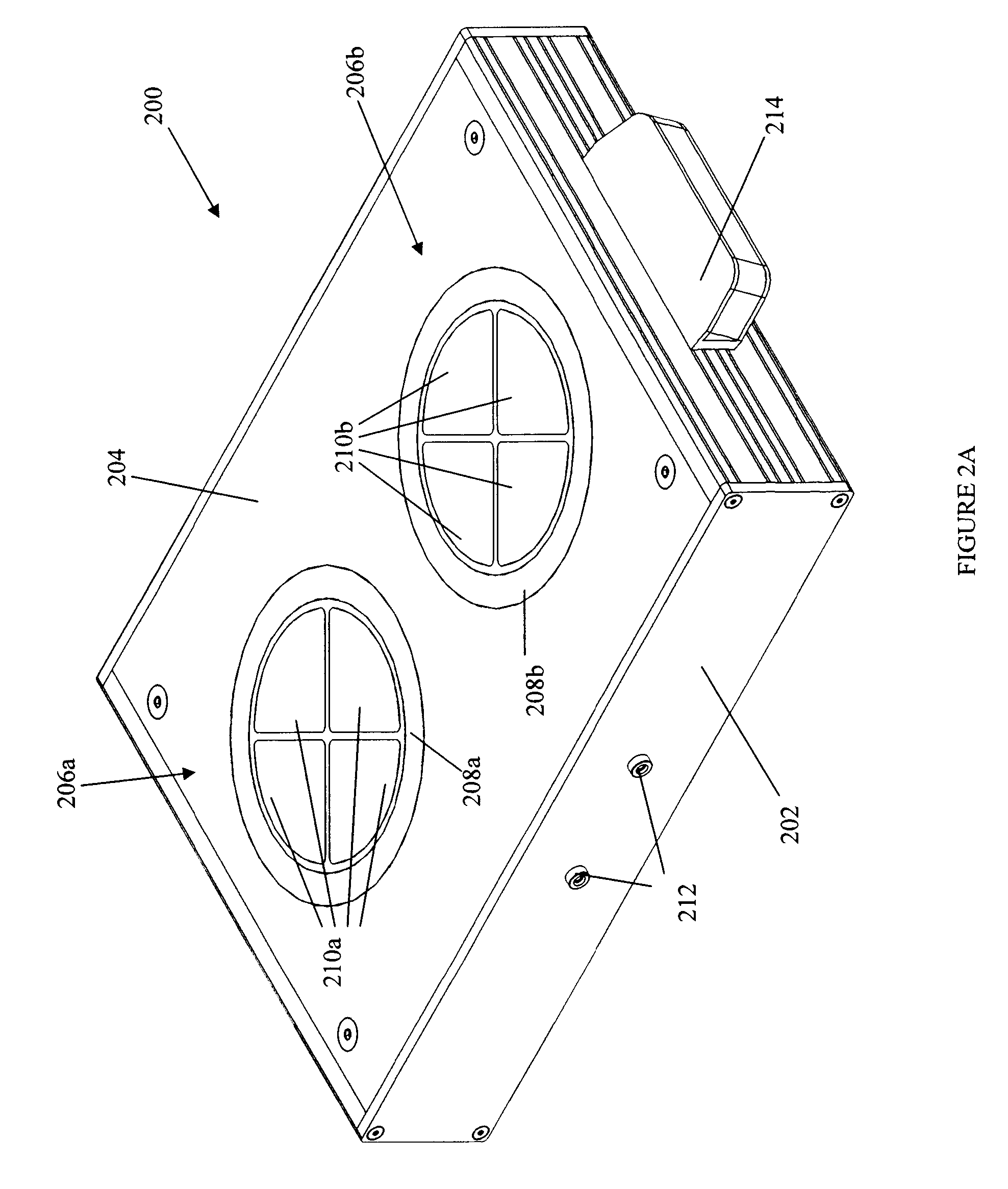

Anaesthesia monitoring device in ultrasonic guide operation

ActiveCN101268951AEasy to observeProcess stabilityUltrasonic/sonic/infrasonic diagnosticsAnaesthesiaDiseaseParacentesis

The invention relates to an ultrasonic induction surgery center which can be used by a single hand and an anesthesia monitoring device. The ultrasonic induction surgery center and the anesthesia monitoring device comprise an ultrasonic probe (1) and a hand-hold part (4), wherein, the ultrasonic probe (1) is positioned at the front end of the hand-hold part (4); the ultrasonic induction surgery center and the anesthesia monitoring device are characterized in that a display screen (5) of ultrasonic equipment is arranged at the rear end of the hand-hold part (4). The ultrasonic probe and the display screen or an integrated design of a miniaturized type-B ultrasonic help the doctors to carry out the operation and the observation in a way that the hands and the eyes are along the same direction when in actual use, more particularly, when being applied in the motion coordination such as anesthesia and paracentesis, etc. as well as in monitoring with extremely high requirements on the precision, so as to ensure the doctor to observe the ultrasound pattern more conveniently and directly; the doctor can directly observe the operational motion of the hands and the ultrasound real time imaging within the range of observation of the visual field right ahead, thereby being beneficial to the operation of the doctor, reducing the possibility of having misoperation, greatly improving the success rate of surgery in clinical work and reducing the incidence rate and the mortality rate of complicating disease of patients.

Owner:CAS OF CHENGDU INFORMATION TECH CO LTD

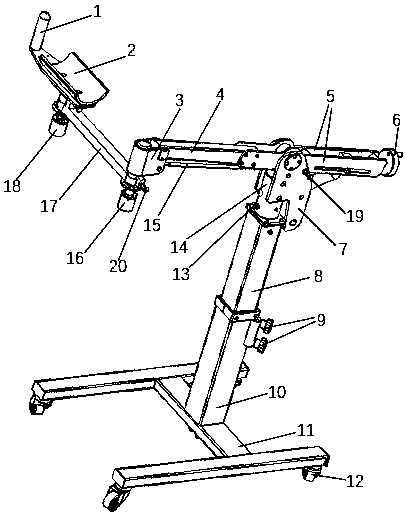

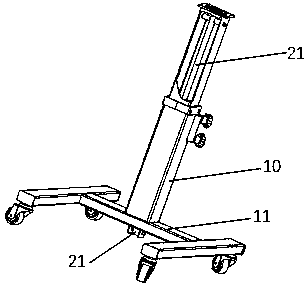

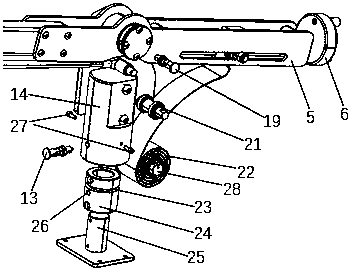

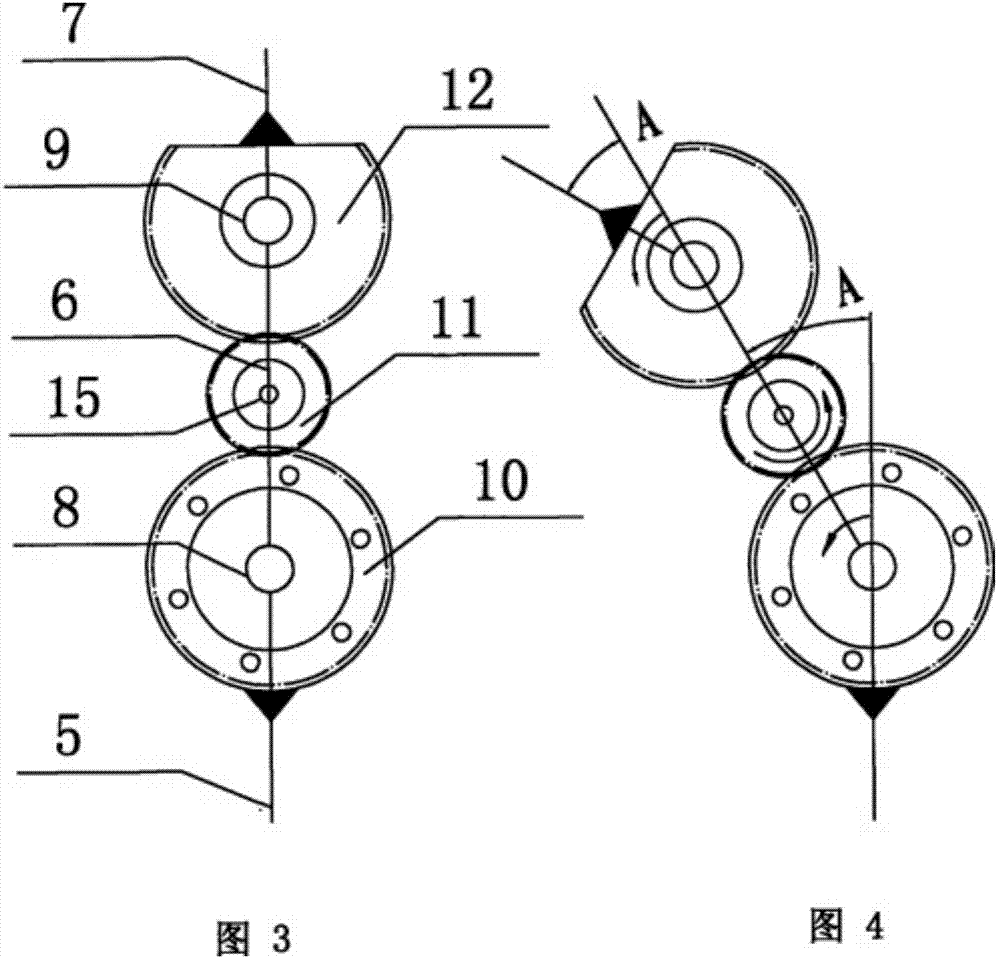

Oblique-inserting type fin evaporator automatic fin-inserting pipe expander

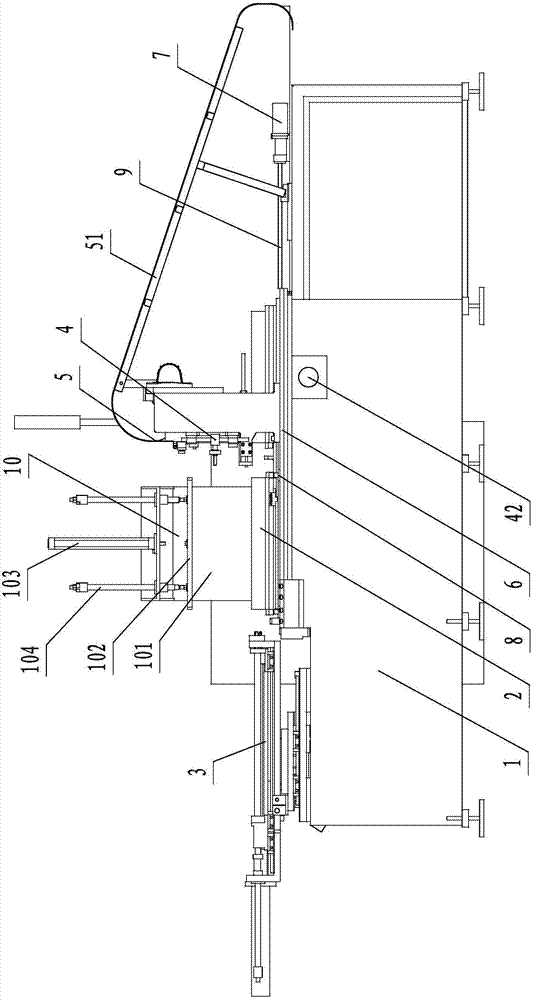

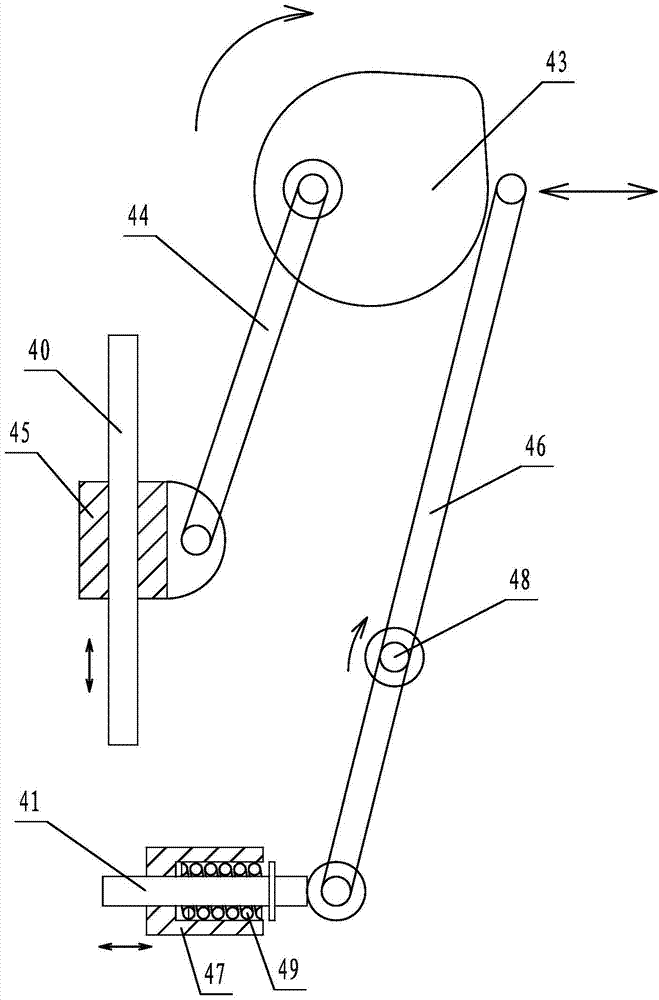

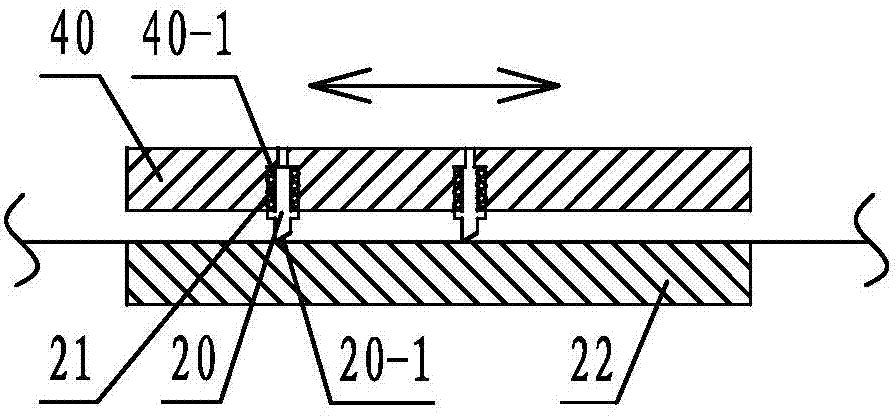

InactiveCN103785769AFully automatedImprove continuityHeat exchange apparatusMotion coordinationEngineering

The invention discloses an oblique-inserting type fin evaporator automatic fin-inserting pipe expander which comprises a machine frame, a fin-inserting die which moves in a stepping mode, a pipe expanding device, a guiding mechanism and a feeding device. The feeding device comprises a material stirring mechanism with a material stirring block, a cutting mechanism with a cutting rod and a cam which is driven by a driving motor to rotate. The cam drives the material stirring block to move up and down in a reciprocating mode to drive a fin to move down in a stepping mode and drives the cutting rod to move horizontally to cut off the fin which moves down. The material stirring block, the cutting rod and the fin-inserting die are matched in a motion-coordination mode. The blank of the fin evaporator industry in China is filled, the material stirring block, the cutting rod and the fin-inserting die are matched in a coordination mode and a stepping-moving mode, automatic fin inserting in the fin-inserting die of the fin is completed, an aluminum pipe is inserted into the fin obliquely through the pipe expanding device for expanding, accordingly, fin inserting, pipe expanding automation and continuity are achieved, the number of workers is reduced, unnecessary labor of fin storing, transferring and the like is lowered, and working efficiency and working safety are improved.

Owner:CHANGZHOU CHANGFA REFRIGERATION TECH CO LTD

Method for strengthening scraper by laser

ActiveCN101974749AHigh hardnessImprove wear resistanceMetallic material coating processesLaser beam welding apparatusMotion coordinationLight beam

The invention discloses a method for strengthening a scraper by laser, belonging to the technical field of laser cladding. The technical scheme of the invention is as follows: the method for strengthening the scraper by laser comprises the following steps: 1), polishing the surface of the scraper, scaling, deslagging, and carrying out deoiling cleaning on the surface with alcohol; 2), synchronously carrying out powder feeding and laser cladding in one work step under the feed motion coordination of an X linear axle and a Y linear axle of a laser head, wherein the laser output power is 6.8kw, the scanning speed is 600 mm / min, the powder feeding rate is 18g / min, and laser beams are 15*2.5 broadband rectangular light spots; and cladding metal powder at a wearing position to form a laser enhanced layer with cladding thickness of 3mm, wherein the selected metal powder materials comprises the following components in percentage by weight: 65.93% of Fe, 0.07% of C, 0.8% of Si, 0.6% of Mn, 18.1% of Cr, 12.2% of Ni and 2.3% of Mo. In the method, laser energy beams are adopted to strengthen the wearing position by using a laser cladding method, thereby improving the hardness and the wear-resistance of the wearing position, delaying the wear rate and enabling the wearing position and the whole machine to be simultaneously failed.

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD +1

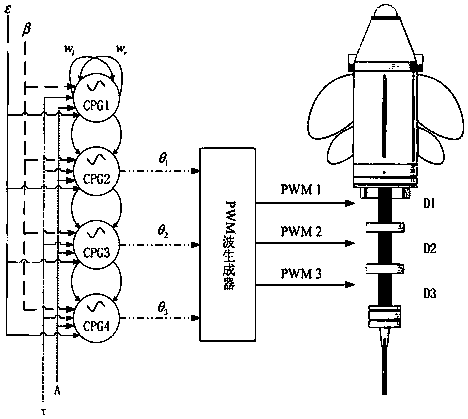

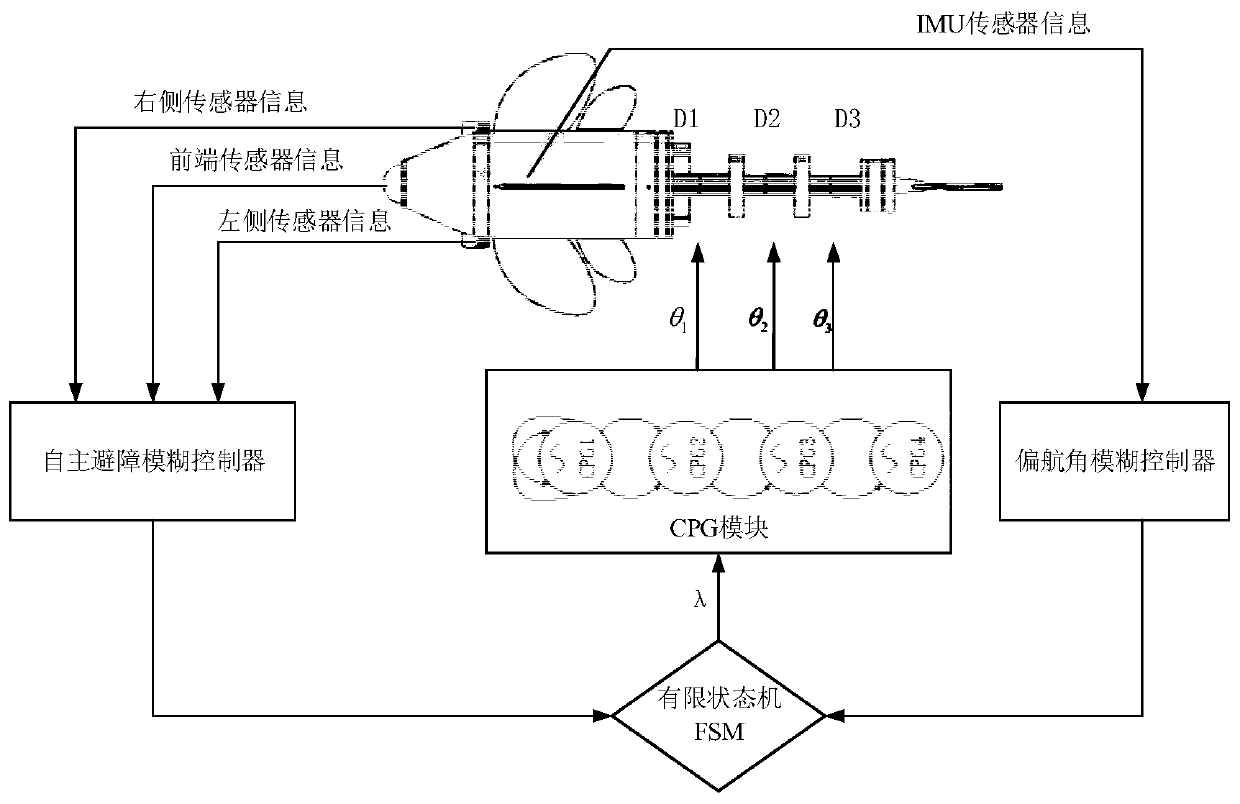

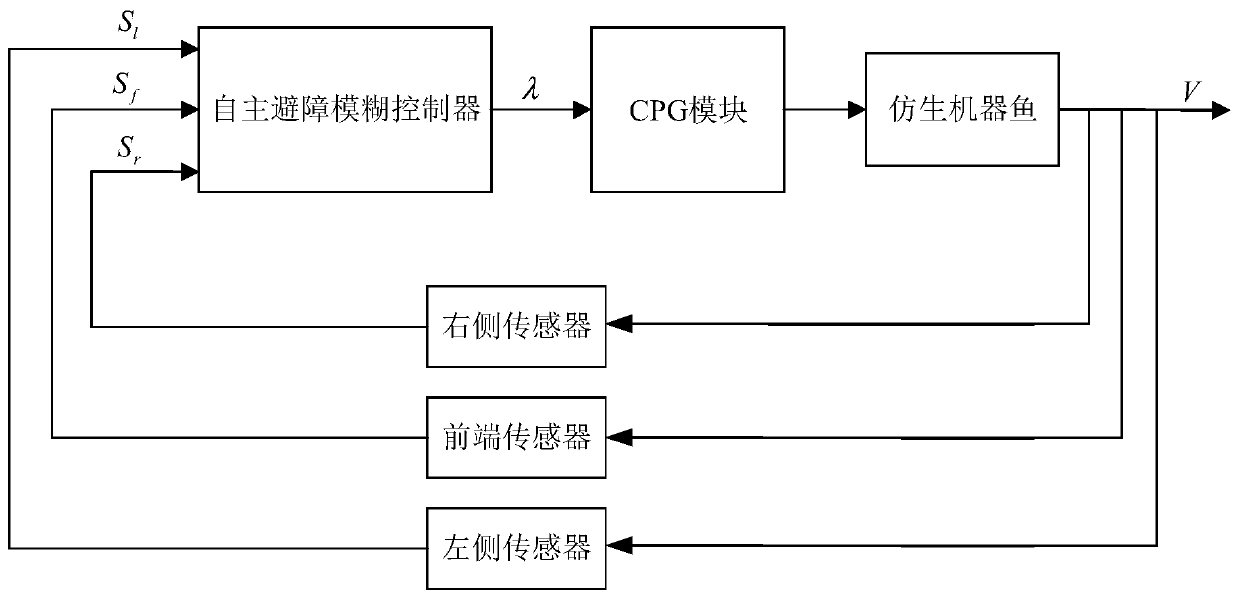

Robotic fish closed-loop feedback control method based on CPG model

ActiveCN111176116AReduce complexityImprove stabilityAdaptive controlLoop controlClosed loop feedback

The invention discloses a robotic fish closed-loop feedback control method based on a CPG model. For robotic fish, each CPG unit is used for controlling the motion angle of a joint driving steering engine. A CPG model of the bionic robotic fish is established based on a plurality of CPG units, the established CPG model can well represent the biological characteristics of motion neurons, meanwhile,the model can adjust the phase difference, the frequency and the amplitude to achieve rhythmic motion control over the robotic fish, and good parameter mutation adaptability is achieved; a CPG network structure topological graph is constructed according to the CPG model, acquired peripheral obstacle information and yaw angle information of the CPG model are used as feedback items, and the established CPG model is discretized by using an Euler method, so that the complexity of the model is reduced, and the solving is facilitated; according to the closed-loop control method based on the CPG model, the motion coordination stability and the environment self-adaptive capacity of the robotic fish are improved, the swimming flexibility of the bionic robotic fish can be improved, and the autonomous swimming of the robotic fish is achieved.

Owner:XI AN JIAOTONG UNIV

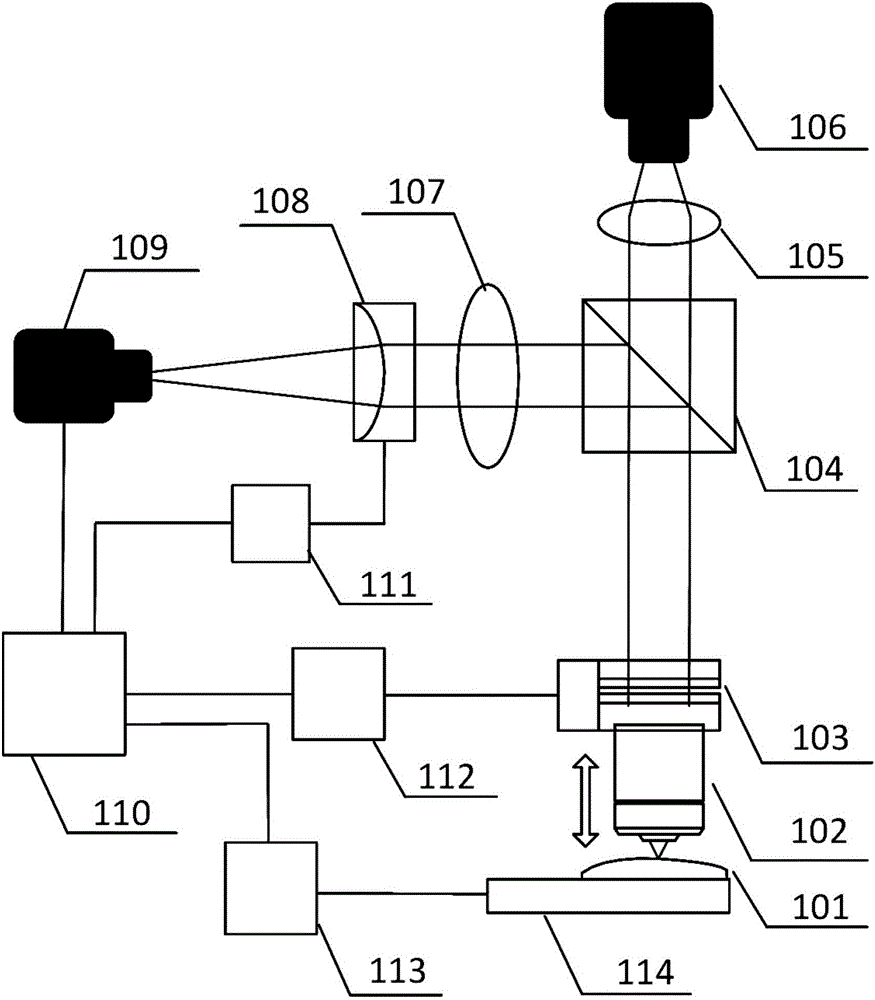

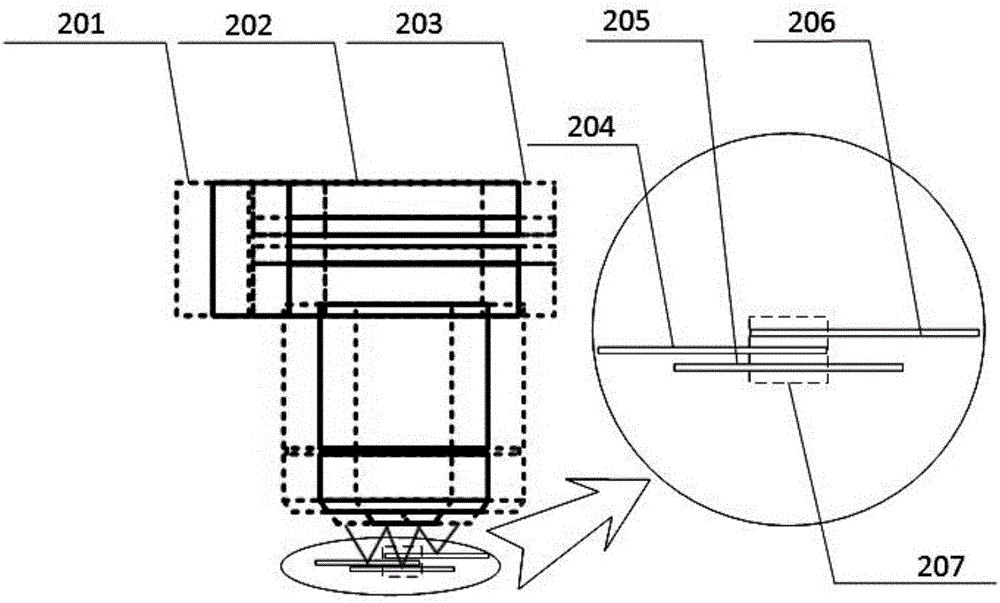

High speed micro scanning dynamic focusing device and focusing tracking method

The invention provides a high speed micro scanning dynamic focusing device and a focusing tracking method. The device comprises an objective lens, a liquid lens defocus detection module, an intelligent focusing camera, a focusing tracking execution module and a focusing control module. The liquid lens defocus detection module is used for imaging an object space of different object space faces of a continuous scanning process on the target surface of the intelligent focusing camera. The intelligent focusing camera continuously acquires and processes a defocus detection image for defocus offset coding. The focusing tracking execution module drives the objective lens and a sample to carry out XY plane scanning motion and Z-axis focusing motion at the same time. The focusing control module controls the liquid lens defocus detection module to carry out continuous defocus state detection, and controls the focusing tracking execution module to carry out scanning motion and focusing motion coordination according to defocus offset coding of the intelligent focusing camera. The method provided by the invention comprises an initial focusing phase and a focusing tracking phase, which can greatly improve focusing response speed and focusing tracking precision.

Owner:上海谱华森生物科技有限公司

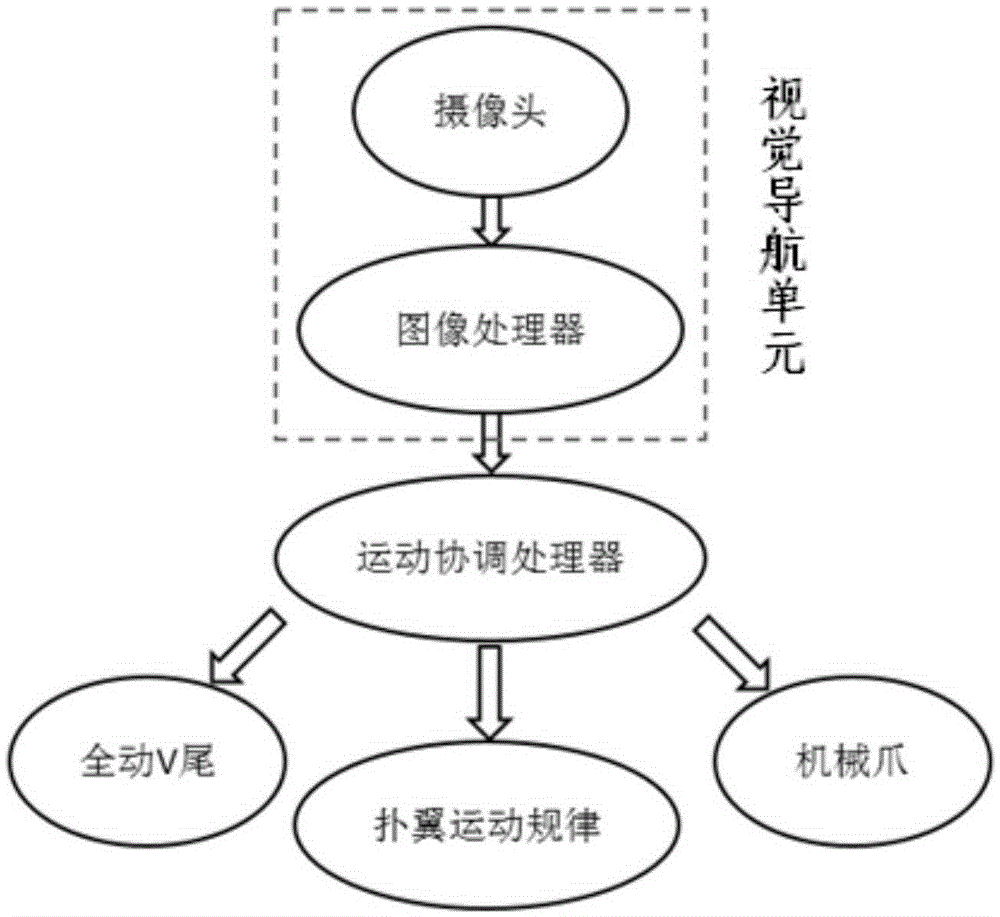

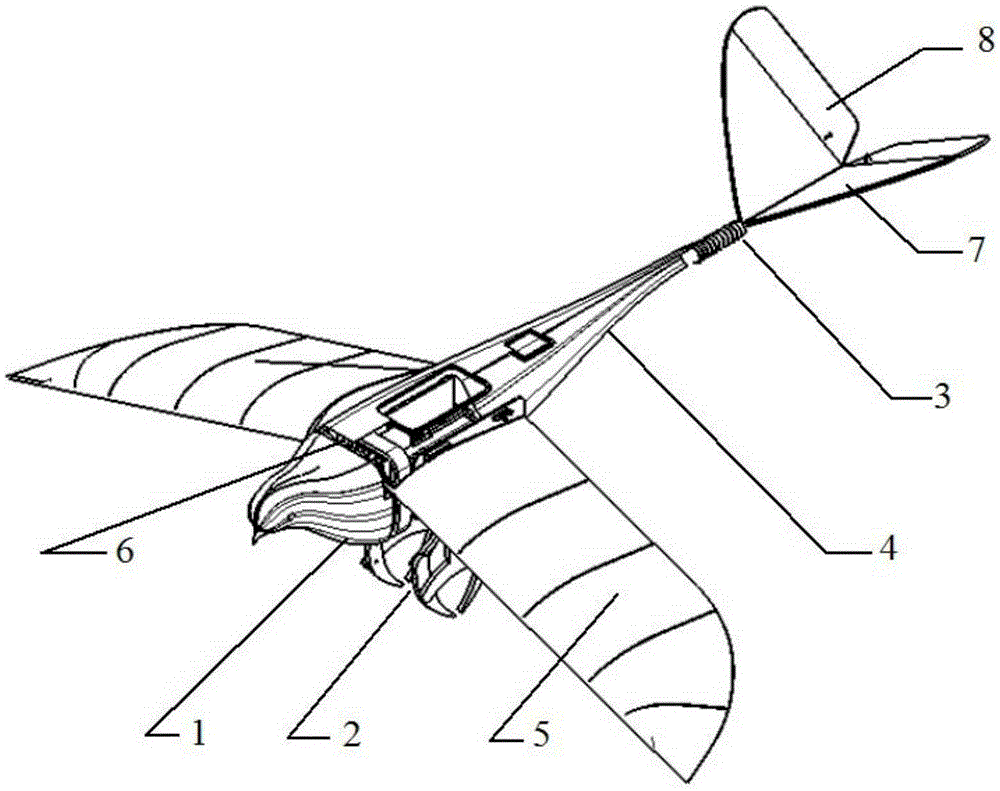

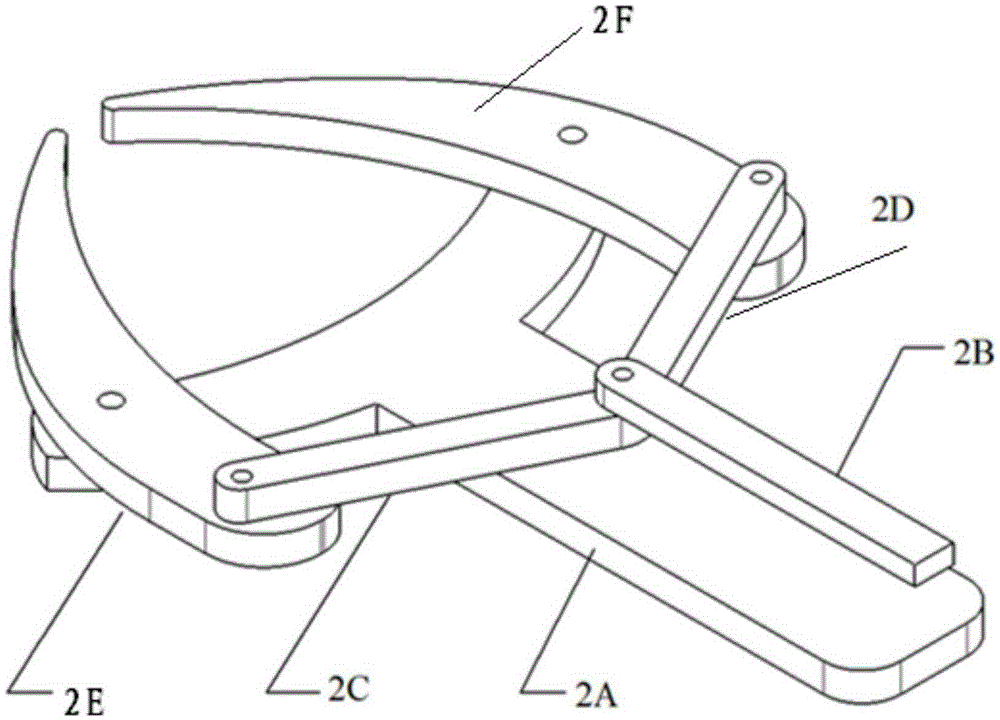

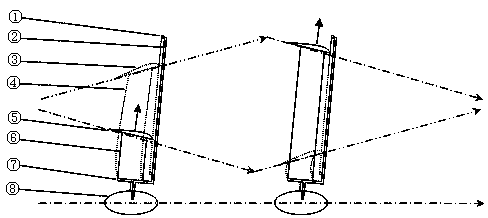

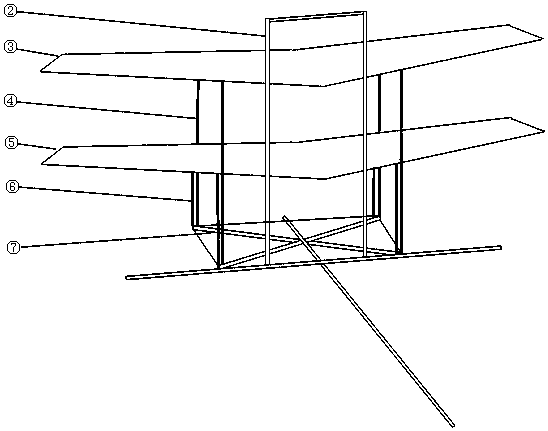

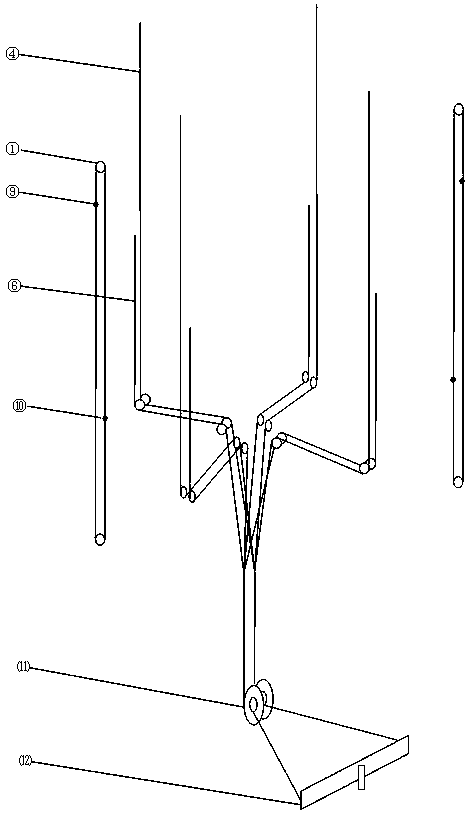

Bionic undercarriage system for flapping wing air vehicle and takeoff and landing control method

InactiveCN105416575AReduce energy consumptionExtend battery lifeOrnithoptersUndercarriagesFlapping wingActuator

The invention provides a bionic undercarriage system for a flapping wing air vehicle and a takeoff and landing control method. The bionic undercarriage system comprises a visual navigation unit, a motion coordination processor, a gripper unit and a full-motion V-tail actuator mechanism, wherein the visual navigation unit comprises a left camera, a right camera and an image processor; the left camera and the right camera are symmetrically installed in front of the abdomen of the flapping wing air vehicle; the left camera and the right camera are connected to the image processor; and the motion coordination processor is installed in the fuselage of the flapping wing air vehicle and is respectively connected with the image processor, a left gripper steering engine, a right gripper steering engine and the actuator mechanism. The bionic undercarriage system has the advantages that after the bionic undercarriage system is installed, the flapping wing air vehicle has takeoff and landing capabilities like birds, the efficient maneuverability of the flapping wing air vehicle is improved, the application range of the flapping wing air vehicle is expanded, and the capabilities of the flapping wing air vehicle are enhanced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

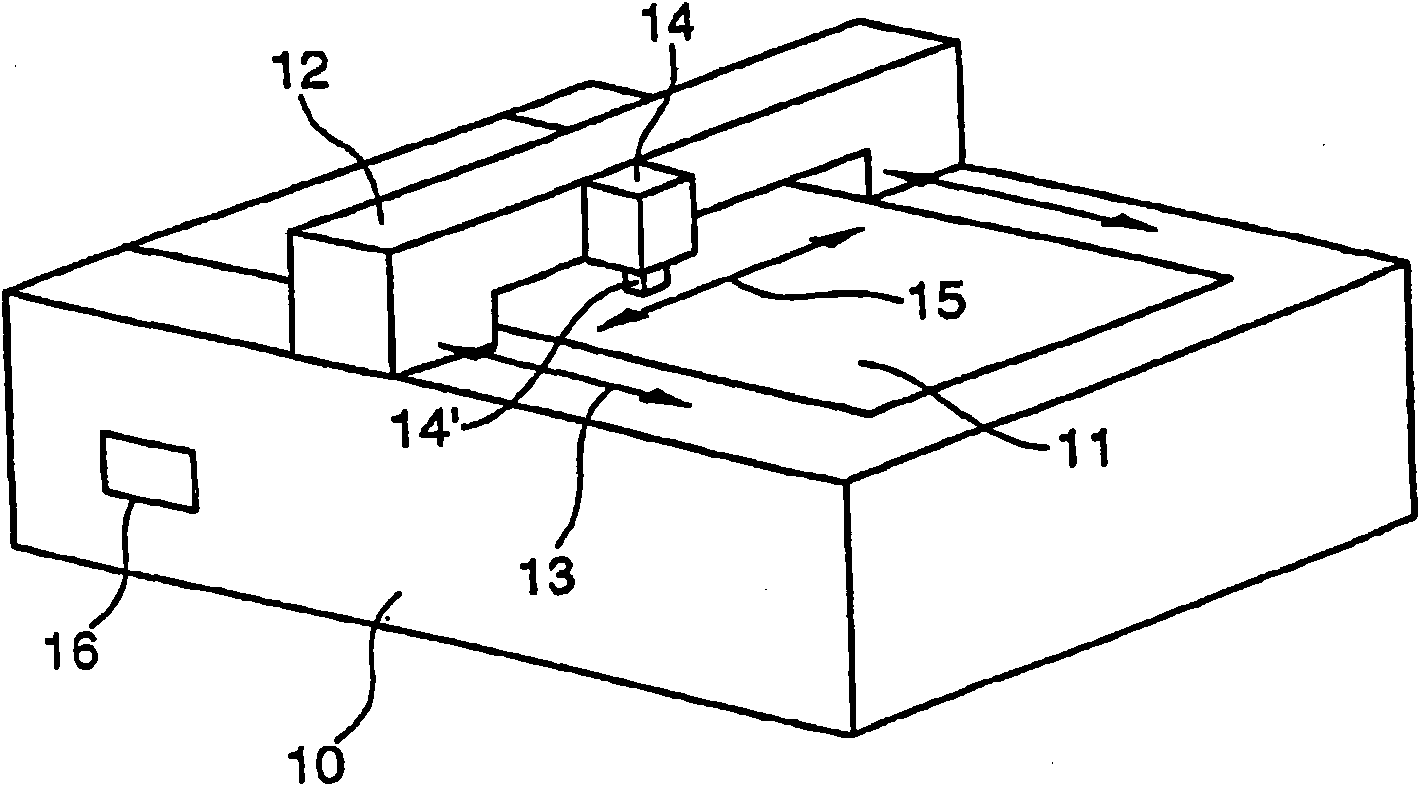

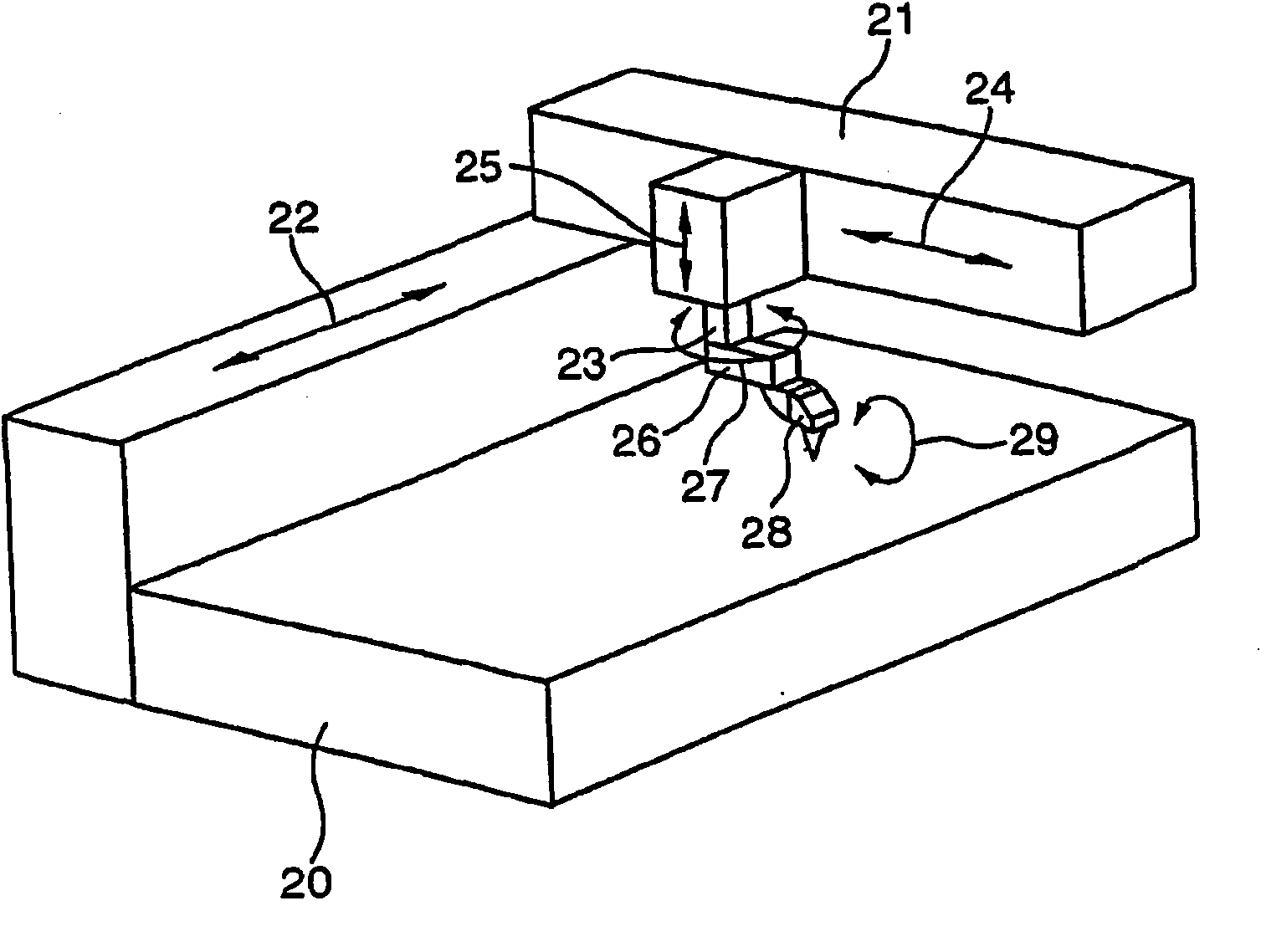

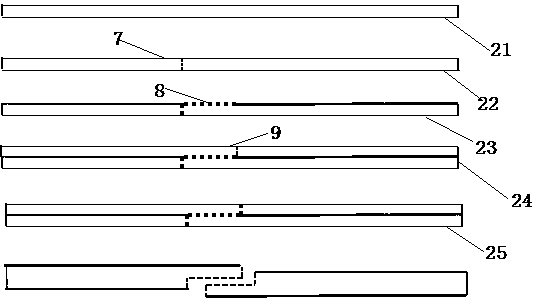

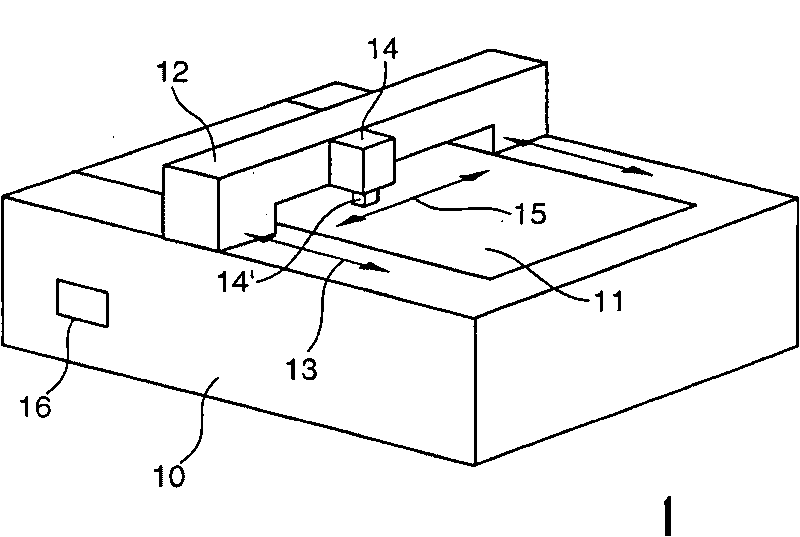

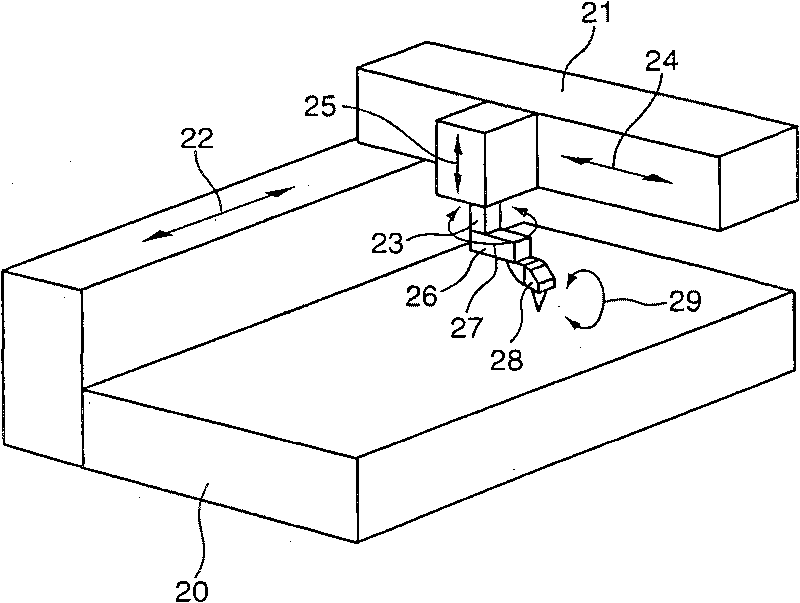

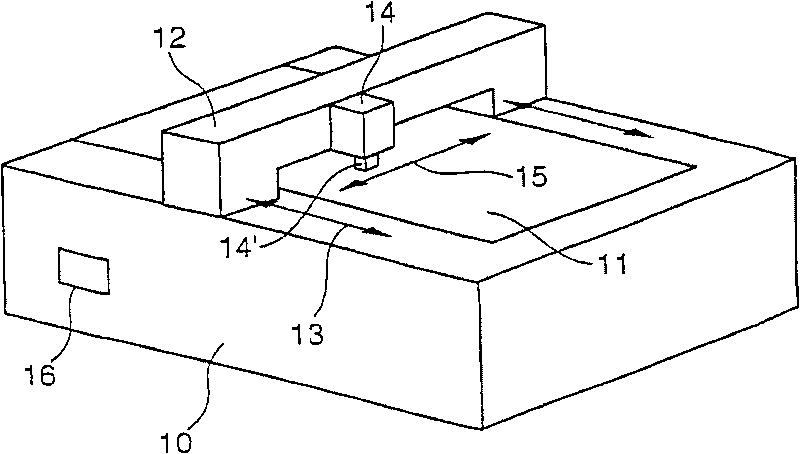

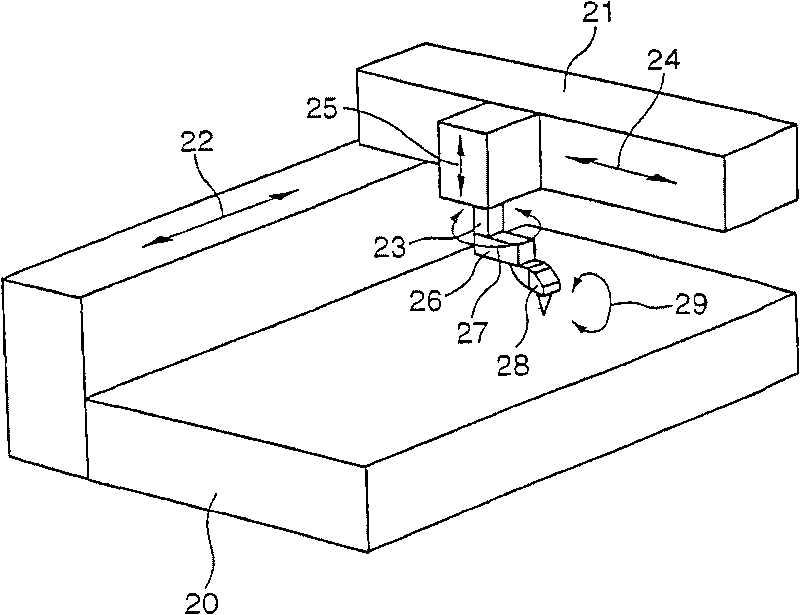

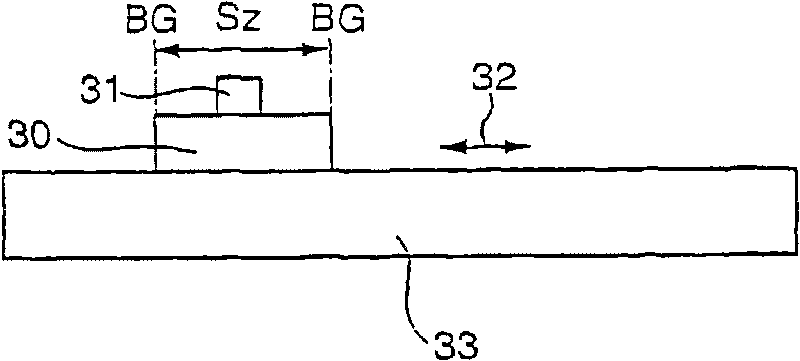

Method for the optimised movement co-ordination of measuring tools or machine-tools by means of redundant translatory axles

ActiveCN101784969ADoes not limit dynamicsPath component minimizationProgramme controlComputer controlEngineeringMachine tool

The invention relates to a method for the optimised movement co-ordination of measuring tools or machine-tools by means of redundant translatory axles, each longer partial axle enabling a relatively low-acceleration partial movement over a relatively large measuring or machining space, and each shorter partial axle carrying out, at an essentially generally constant measuring or machining speed, essentially the movement components of an entire movement, which require acceleration above the maximum determined for each longer partial axle. The invention is characterised in that, when positions are reached, which would otherwise not be reached in a non-divided movement, the base axles can brake correspondingly and even come to a complete standstill. The movement component of the base axles which is missing for the entire movement is compensated by the simultaneous displacement of the neutral starting point of the additional axles.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

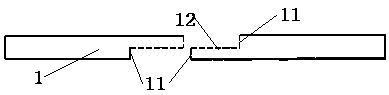

Technological cover plate of combined structure and preparation method

The invention discloses a technological cover plate of a combined structure. The technological cover plate comprises a plurality of split shaped panels in lap joint, and the split shaped panels comprise border parts provided with step surfaces and connecting parts connected with the ends, away from the step surfaces, of the border parts; the border parts and the connecting parts are molded throughone-time curing; and the split shaped panels are in lap joint through the step surfaces. According to the technological cover plate, the border parts with the step surfaces are adopted, motion coordination of internal structures of the technological cover plate is improved, the fitting degree of the technological cover plate and skin green bodies is optimized, and internal quality is guaranteed;lap joint clearances are prevented from being generated, the possibility of the material overflow problem is reduced, even though the material overflow problem occurs, only resin overflows, and overflowed materials can be treated through simple polishing; and the operation program is effectively simplified, the separated lap joint effect of the split shaped panels is improved, the possibility of material overflow at lap joint zones of the split panels is reduced, the structure is unique, the concept is novel, and the prepared technological cover plate of the combined structure has high structure motion coordination of rubber technological cover plates.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

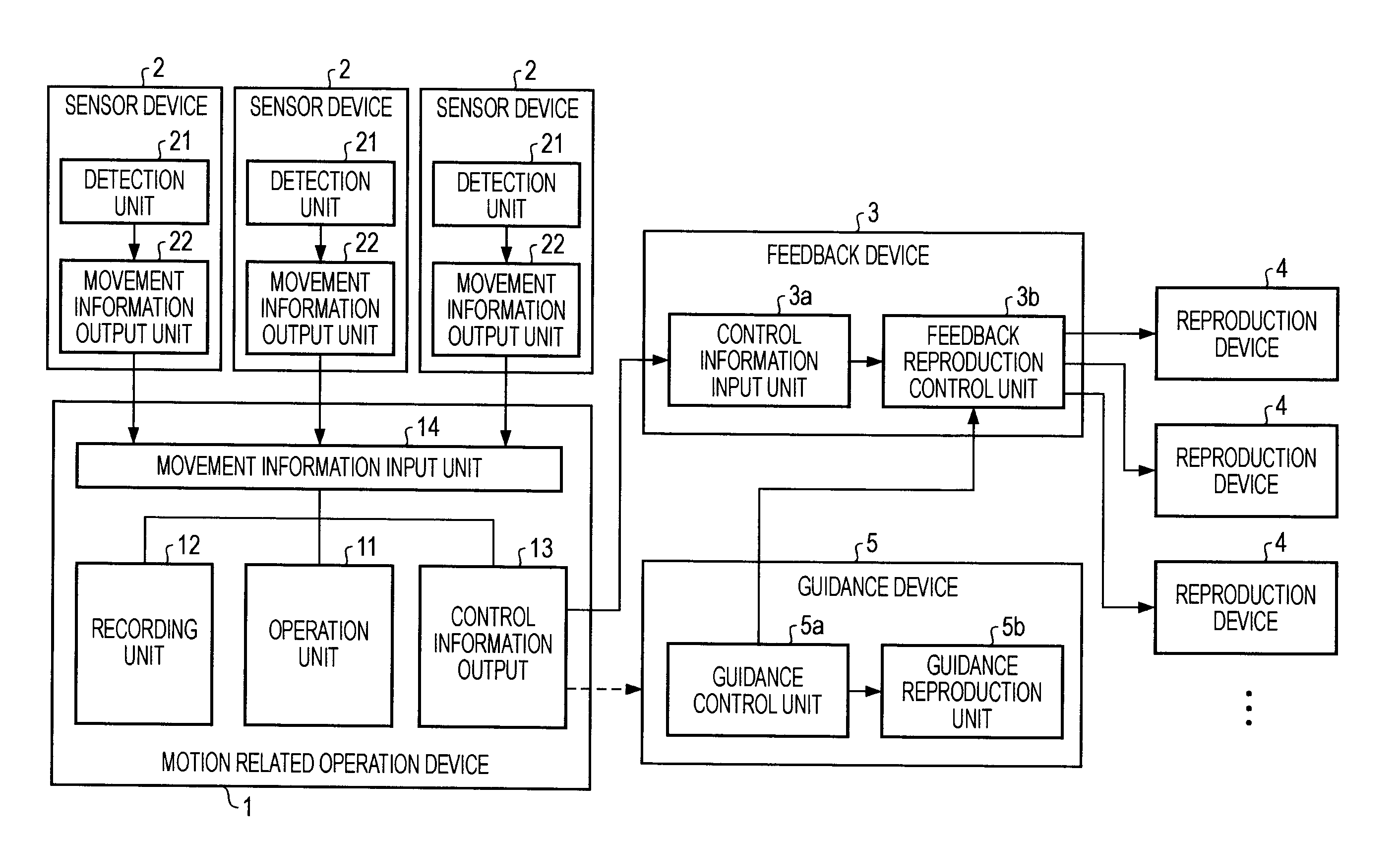

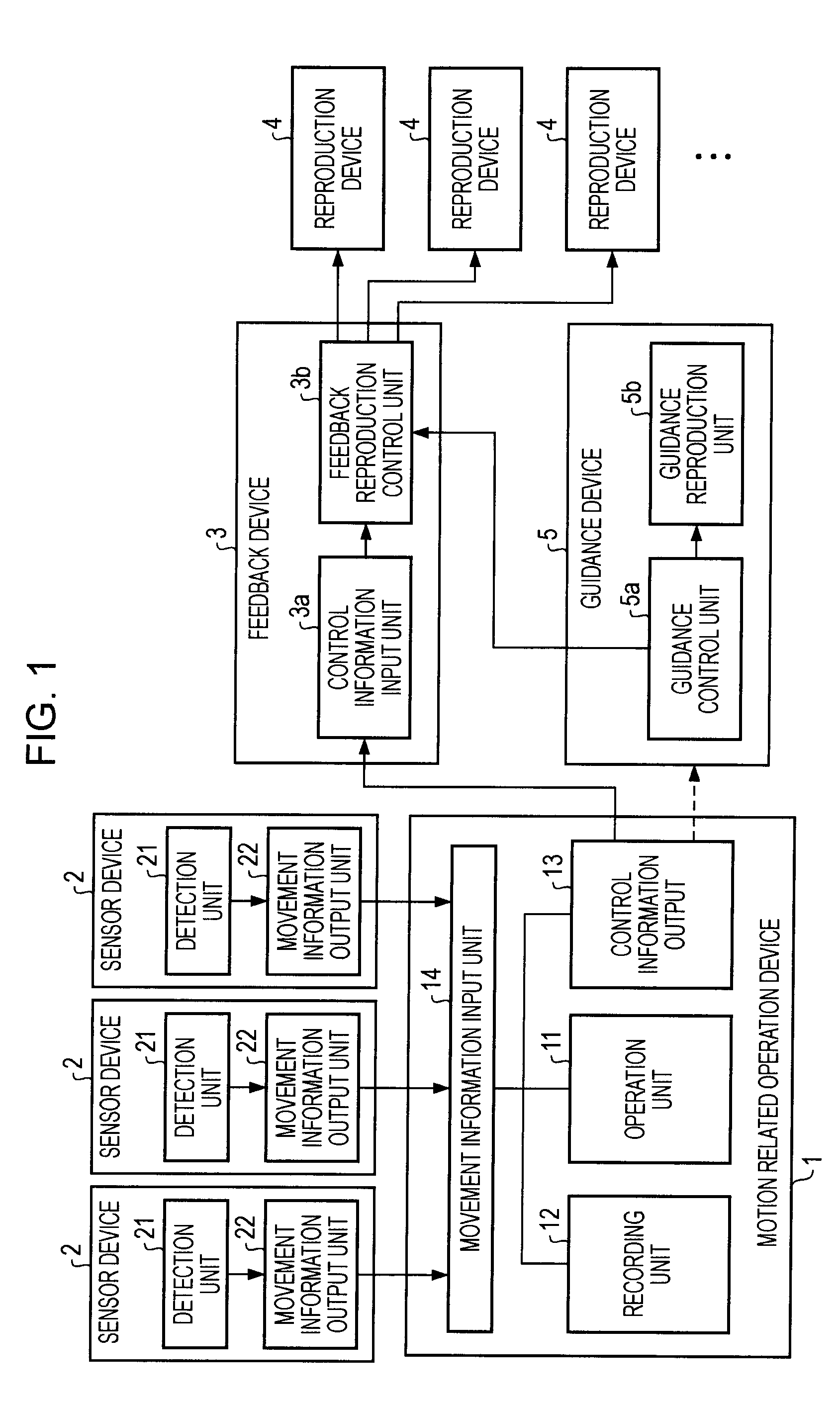

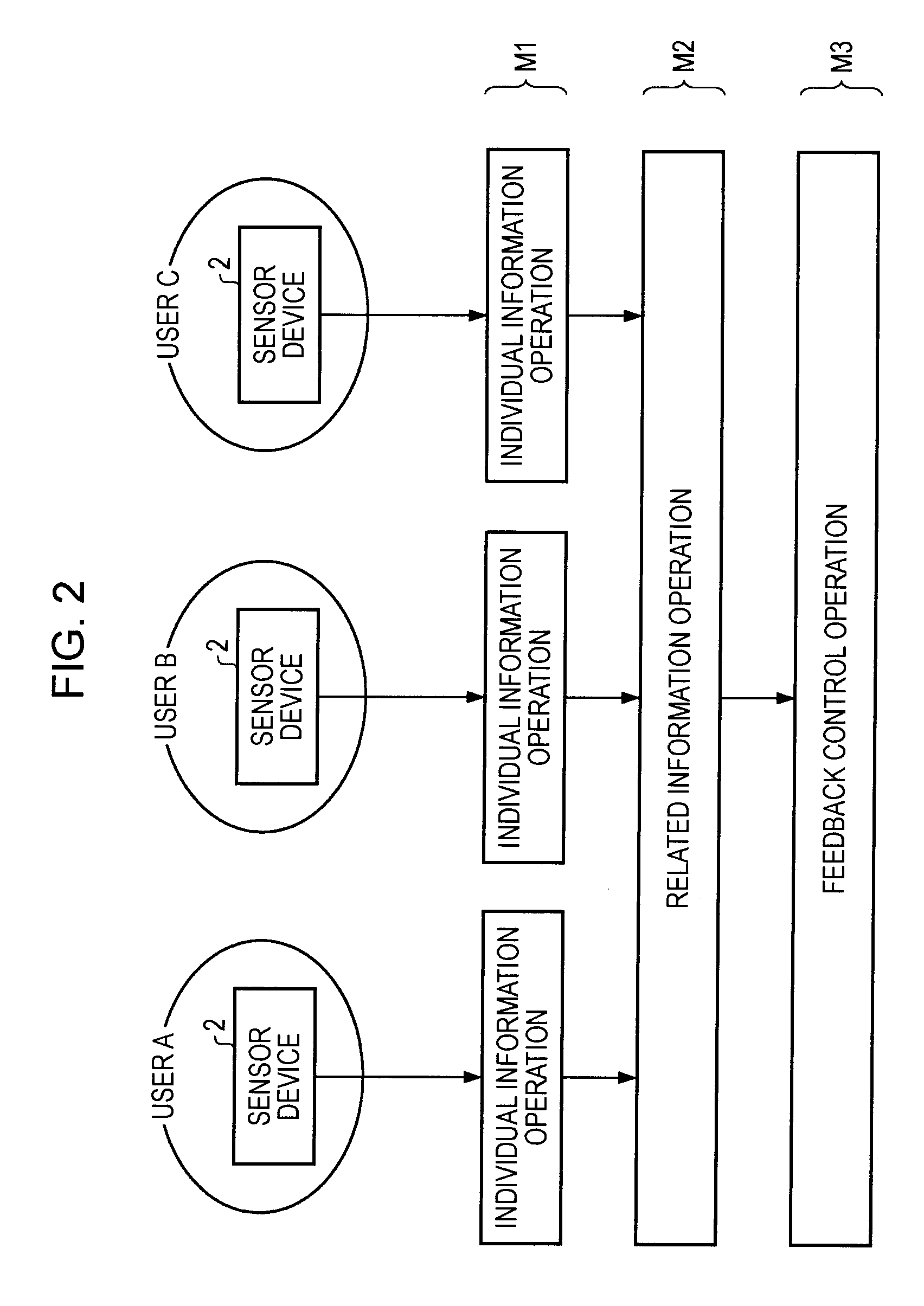

Motion coordination operation device and method, program, and motion coordination reproduction system

ActiveUS20110097695A1Quickly harmonyAdd funGymnastic exercisingElectrical appliancesMotion coordinationEngineering

A motion coordination operation device is provided, which includes a movement information input unit inputting movement information supplied from respective sensor devices mounted on a plurality of users; and an operation unit operating coordination information that indicates the synchronization of motions of bodies or parts of the bodies of the plurality of users from the input movement information from the respective sensor devices, and generating control information for feedback outputs for the users based on the coordination information.

Owner:SONY CORP

Method for the optimised movement co-ordination of measuring machines or machine-tools comprising redundant axles having a translatory action

InactiveCN101715572ACorrect track errorShort execution timeNumerical controlRange of motionEngineering

The invention relates to a method for the optimised movement co-ordination of measuring machines or machine-tools comprising redundant axles having a translatory action, the longer partial axles enabling a relatively slowly accelerated partial movement over a relatively large measuring or machining space, and the shorter partial axles essentially carrying out the movement components of an entire movement at an essentially generally constant measuring or machining speed, said components requiring an acceleration higher than a maximum set for the respective longer partial axles. The invention is characterised in that as soon as parameters or conditions that can lead to a collision of additional axles with the borders of the movement play thereof at a desired constant speed are identified, the acceleration specification for said shorter additional axles is reduced.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

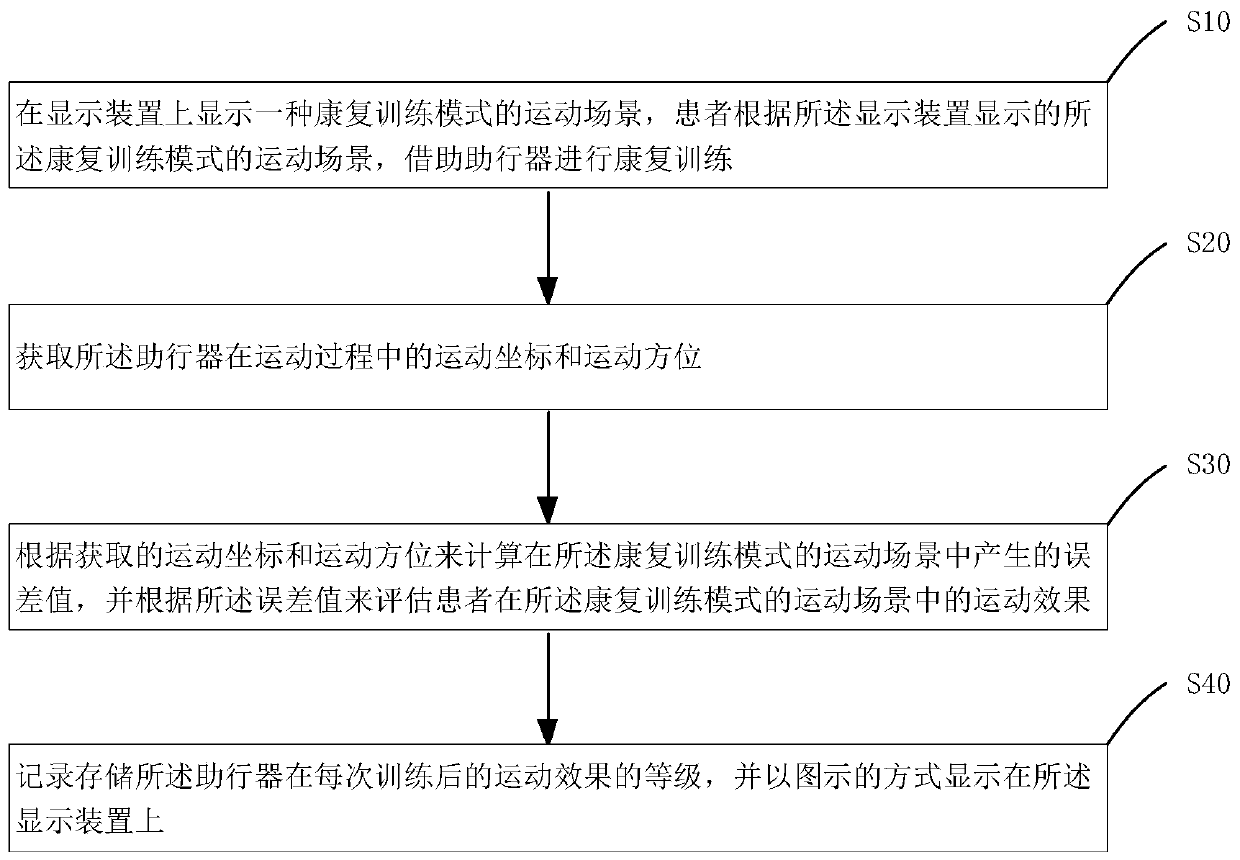

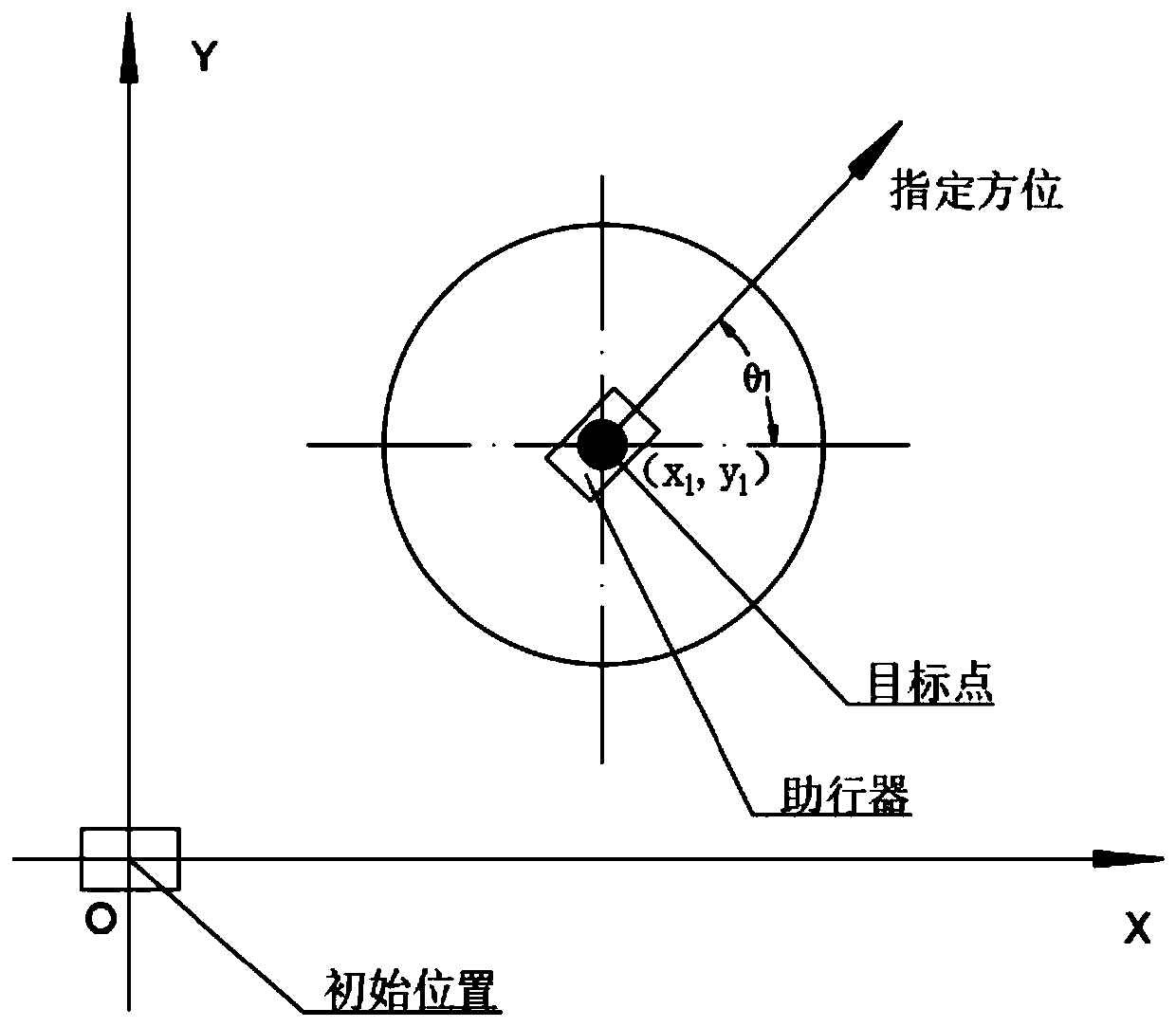

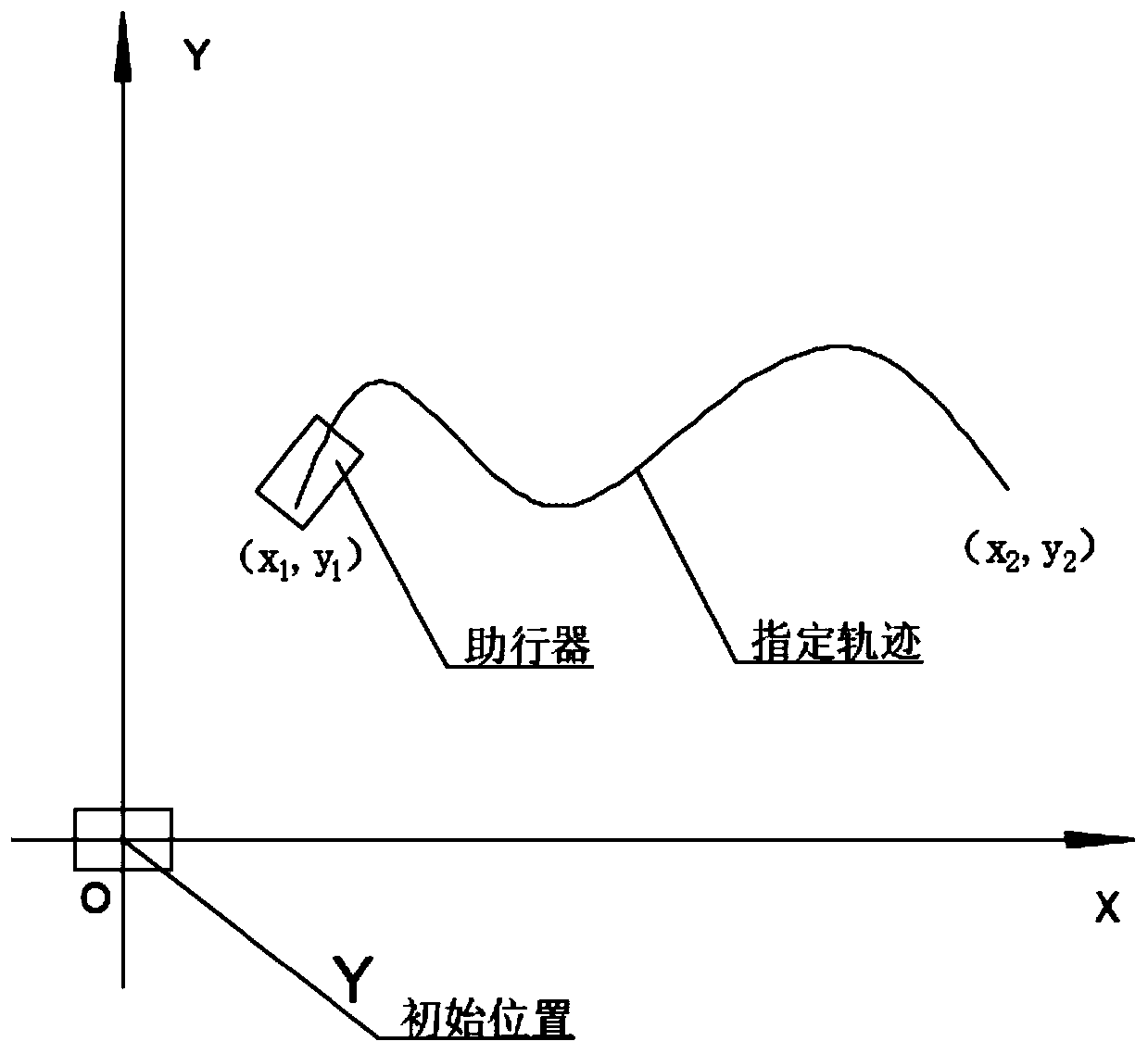

Rehabilitation training evaluation method and system

ActiveCN110379480AProportional evaluation of rehabilitation effectAchieve coordinationPhysical therapies and activitiesSport apparatusDisplay deviceMotion coordination

The invention provides a rehabilitation training evaluation method and a system. The rehabilitation training evaluation method comprises the steps of displaying the motion scene of a rehabilitation training mode in a display device, and performing rehabilitation training by a patient according to the motion scene of the rehabilitation training mode which is displayed in the display device; acquiring the motion coordinate and the motion orientation of a walking aiding device in a motion process; calculating an error value generated in the motion scene of the rehabilitation training mode according to the acquired motion coordinate and the motion orientation, and evaluating the motion effect of a patient in the motion scene of the rehabilitation training mode according to the error value. Bymeans of the method and the system, the patient can perform regular and systematical training in a daily training process, thereby realizing limb motion coordination, evaluating motion control capability and obtaining a rehabilitation effect.

Owner:HEFEI UNIV OF TECH

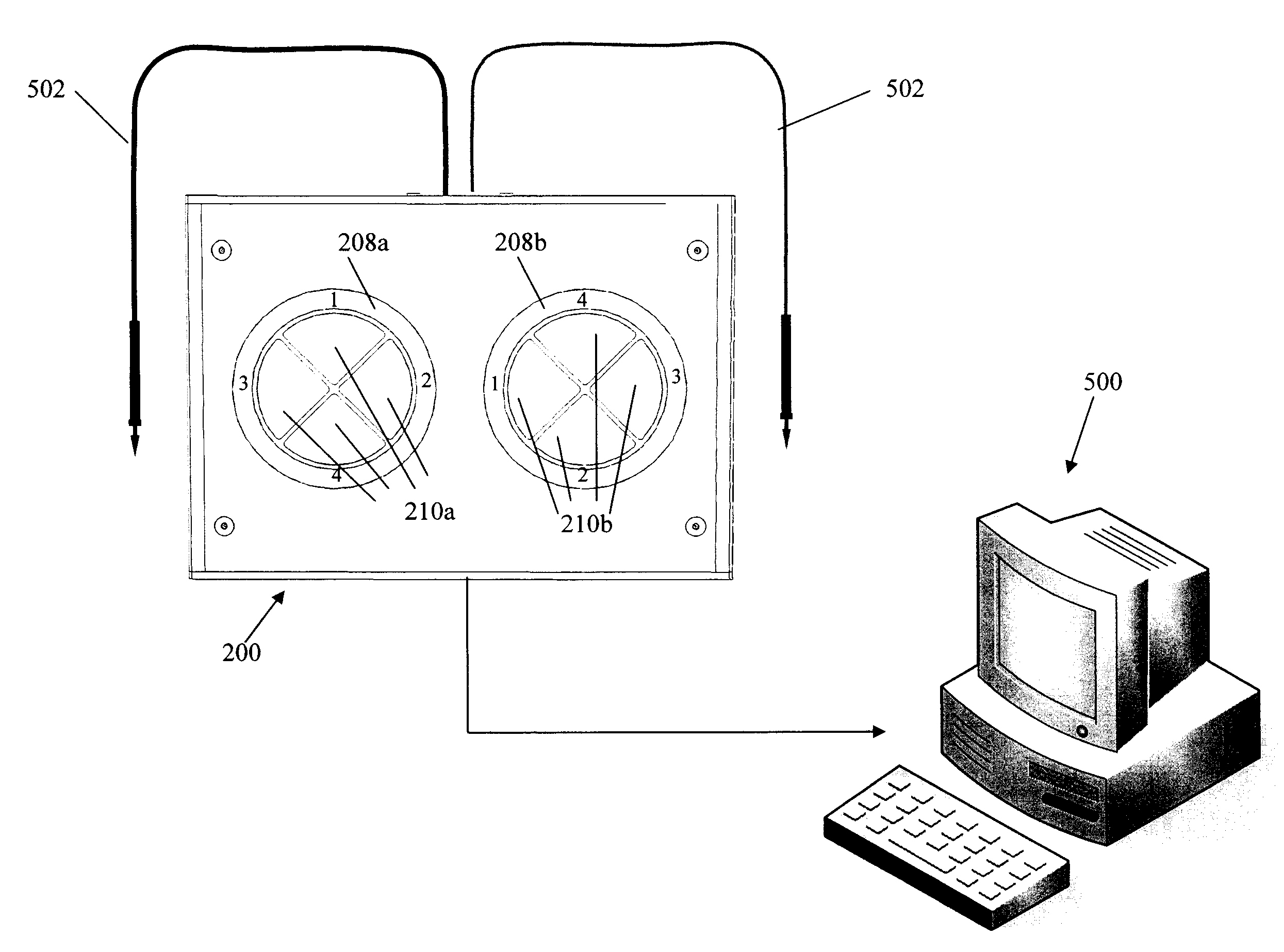

Motor coordination skills measurement and assessment

InactiveUS20120296237A1Easy to understandPerson identificationComputer-assisted medical data acquisitionPerseverationSkill sets

There is described a computer-interfaced hand coordination measuring device that can track performance over time and report various types of errors, such as sequential, misses, perseverations, and balancing. The apparatus may be coupled to a computer and accompanying software is used to collect data from the administered tests and provide a report of the subject's scores for each hand on simple repetitive, sequential, and bimanual in-phase and out-of-phase tapping.

Owner:MCGILL UNIV

Multi-joint upper limb rehabilitation trainer

PendingCN110064173AImprove coordinationIncrease flexibilityResilient force resistorsMuscle forceMotion coordination

Owner:ANYANG XIANGYU MEDICAL EQUIP

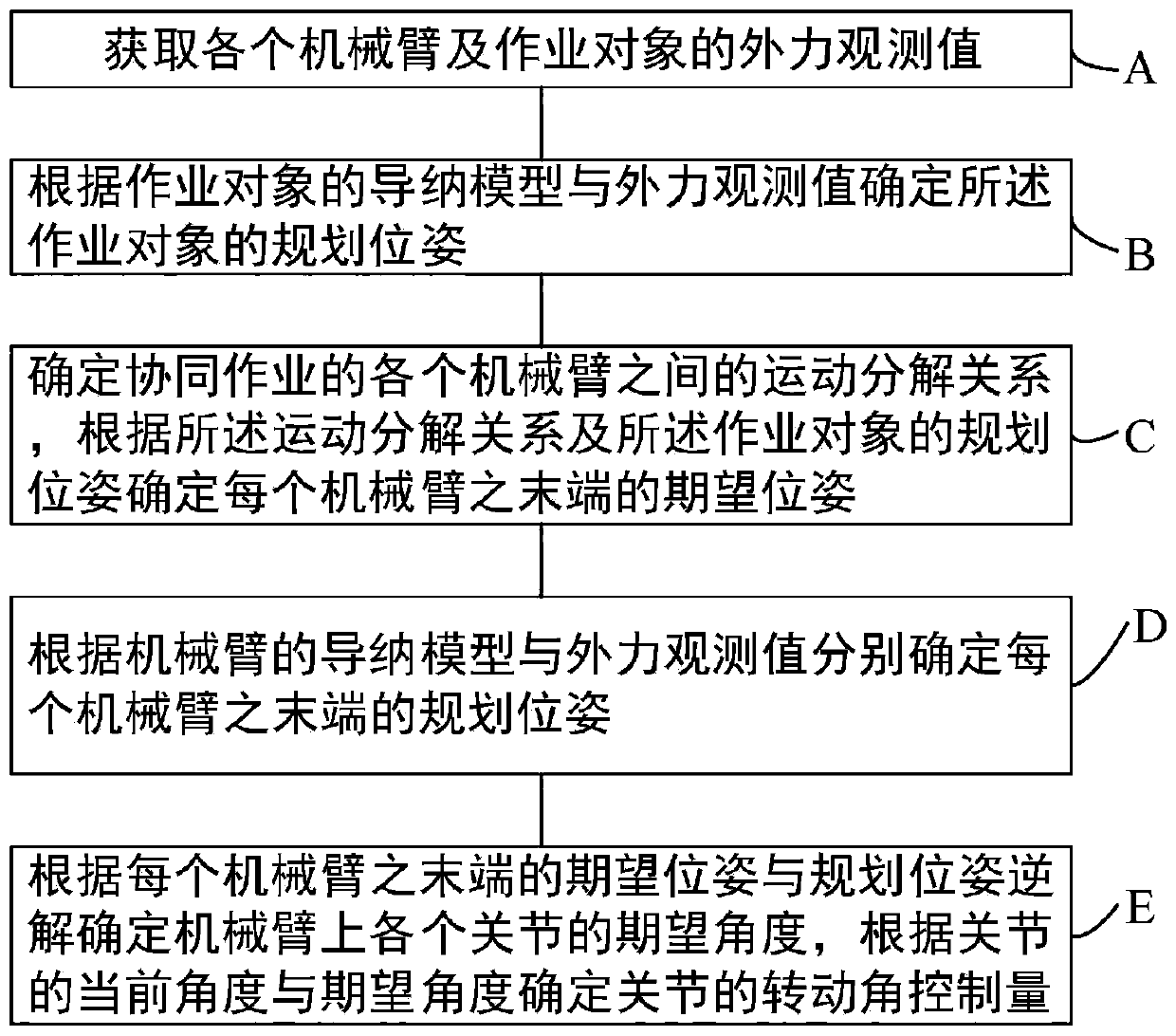

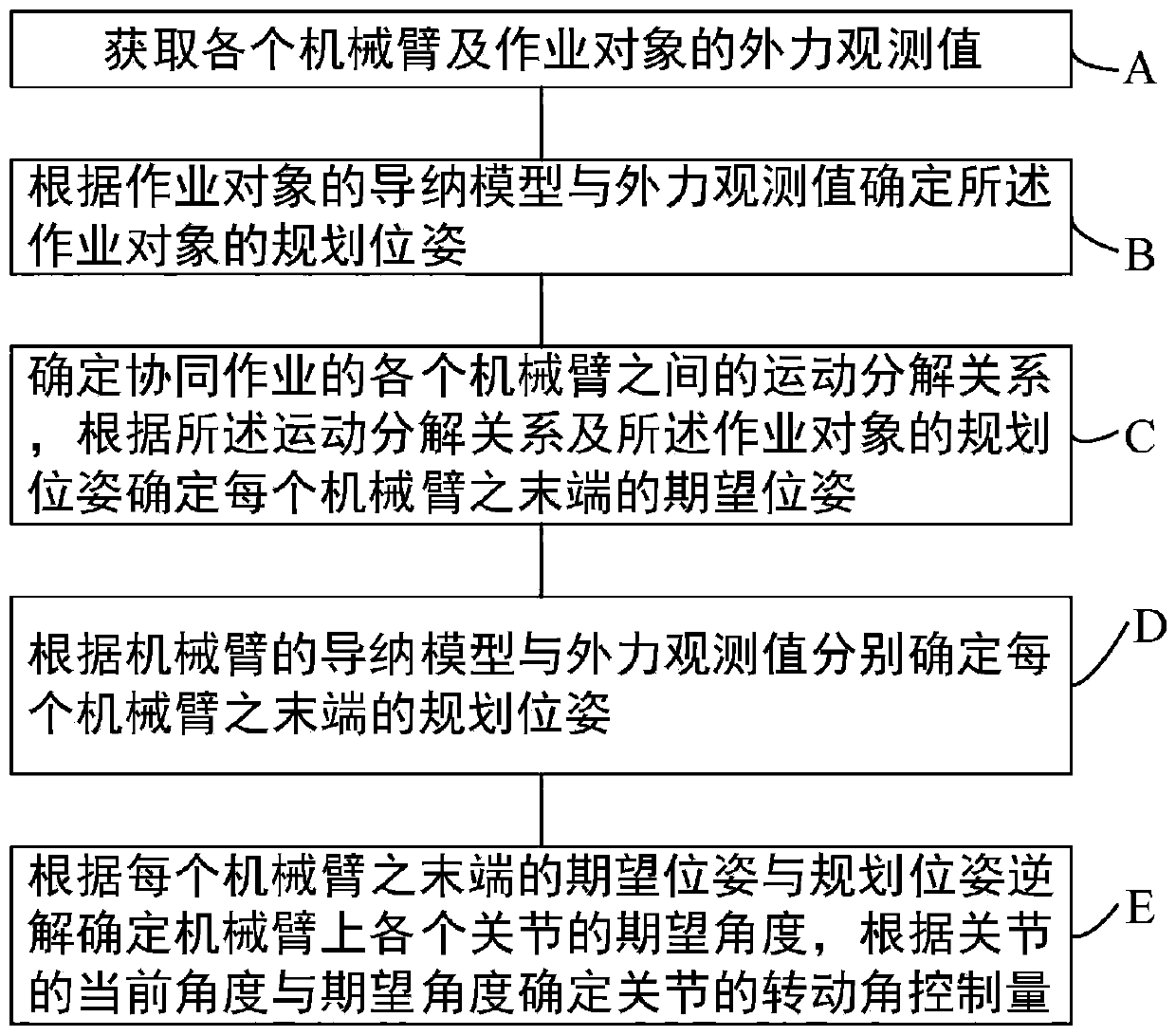

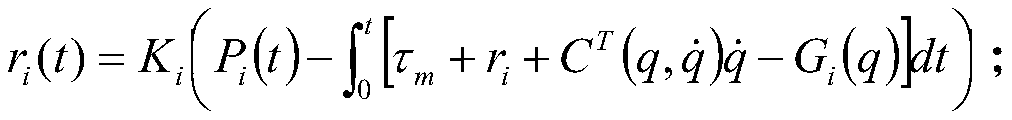

Multi-arm collaborative operation compliant control method

ActiveCN110026986AFor precise and compliant controlProgramme-controlled manipulatorDecompositionAngular degrees

The invention discloses a multi-arm collaborative operation flexibility control method. The method comprises the following steps of acquiring an external force observed value of each mechanical arm ofcollaborative operation and an external force observed value of an operation object; determining the planning pose of the operation object according to the admittance model of the operation object and the external force observed value of the operation object; determining the motion decomposition relation between the mechanical arms on the basis of the position constraint between the mechanical arms, and determining the expected pose of the tail end of each mechanical arm according to the motion decomposition relation and the planning pose of the operation objects; determining the planning pose of the tail end of each mechanical arm according to the admittance model of the mechanical arms and the external force observed value of the mechanical arms; determining the expected angle of each joint on each mechanical arm according to the inverse solution of the expected pose and the planning pose of the tail end of each mechanical arm, and determining the rotation angle controlling amount of the joint according to the current angle and the expected angle of each joint. According to the multi-arm collaborative operation compliant control method, the motion coordination requirements amongthe multiple arms are comprehensively considered, and accurate and compliant control under the collaborative operation is realized.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

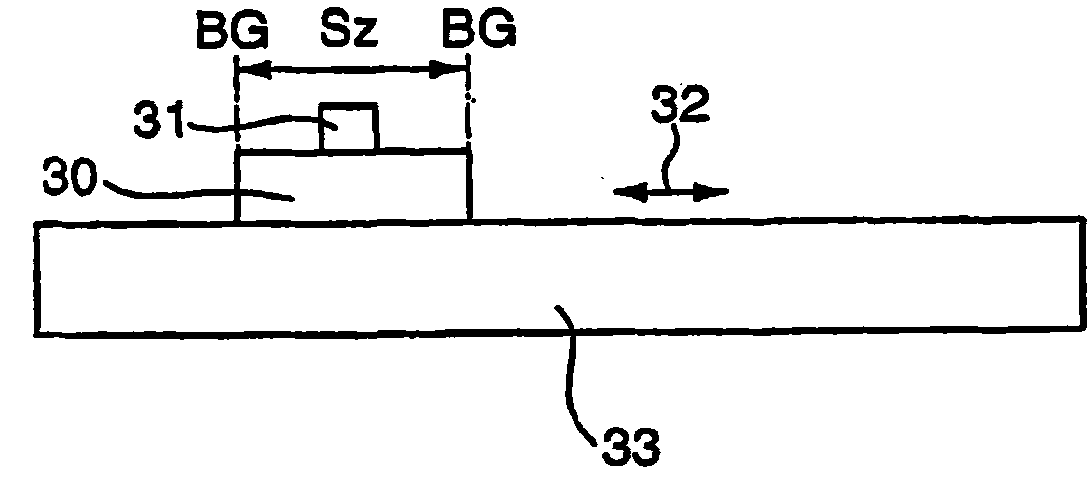

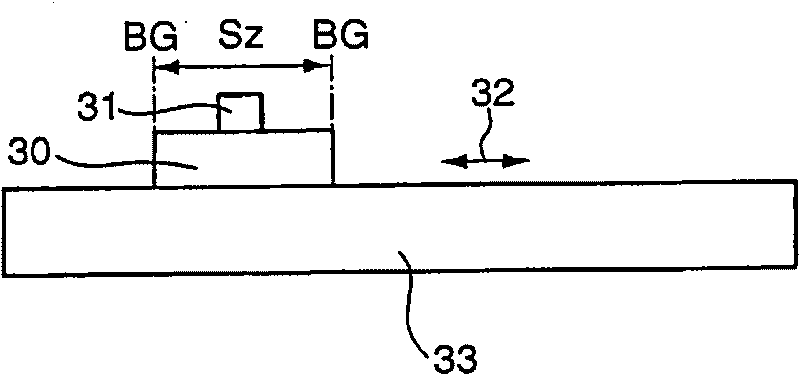

Method for the optimized movement coordination of measuring machines or machine tools having redundant translatory axes

A method for the optimized movement coordination of measuring machines or machine tools having redundant translatory axes, the respectively longer partial axes enabling a relatively low-acceleration partial movement over a relatively large measuring or machining space and the respectively shorter partial axes substantially carrying out the movement components of an overall movement at a substantially overall constant measuring or machining speed, characterized in that the highest possible and constant movement speed of a measuring device or a tool compared to the item to be measured or machined (Vmax) is determined in that first a simulation of the machining path is performed using a reference speed (Vref), and the ratio of the maximum deflection (Sz_ref_max) to the maximum deflectability (Sz) determined from said simulation is used in conjunction with Vref in order to determine Vmax.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

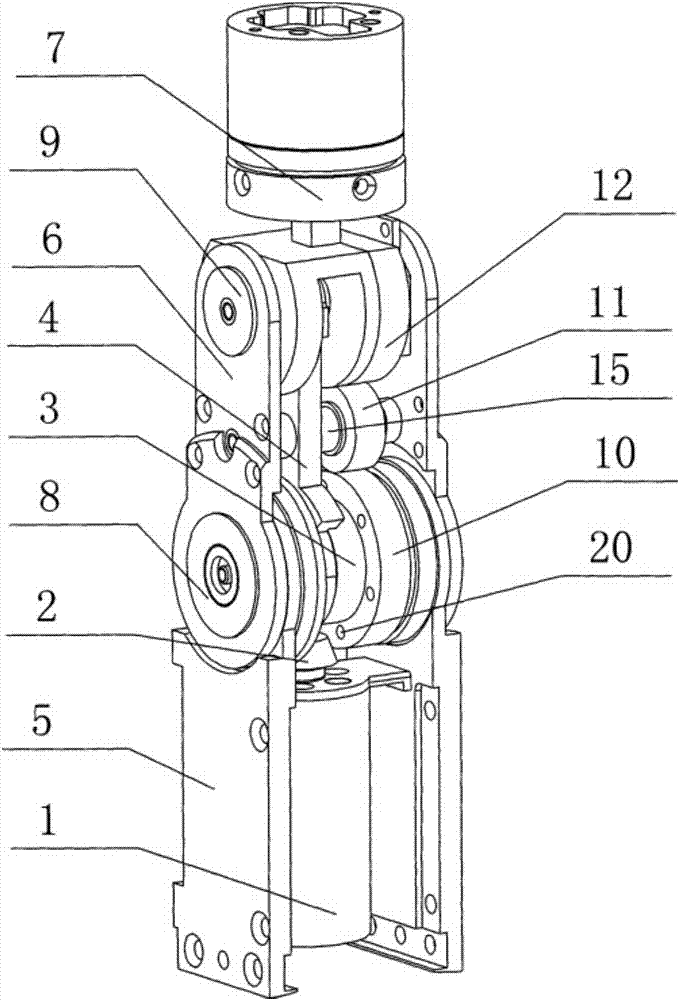

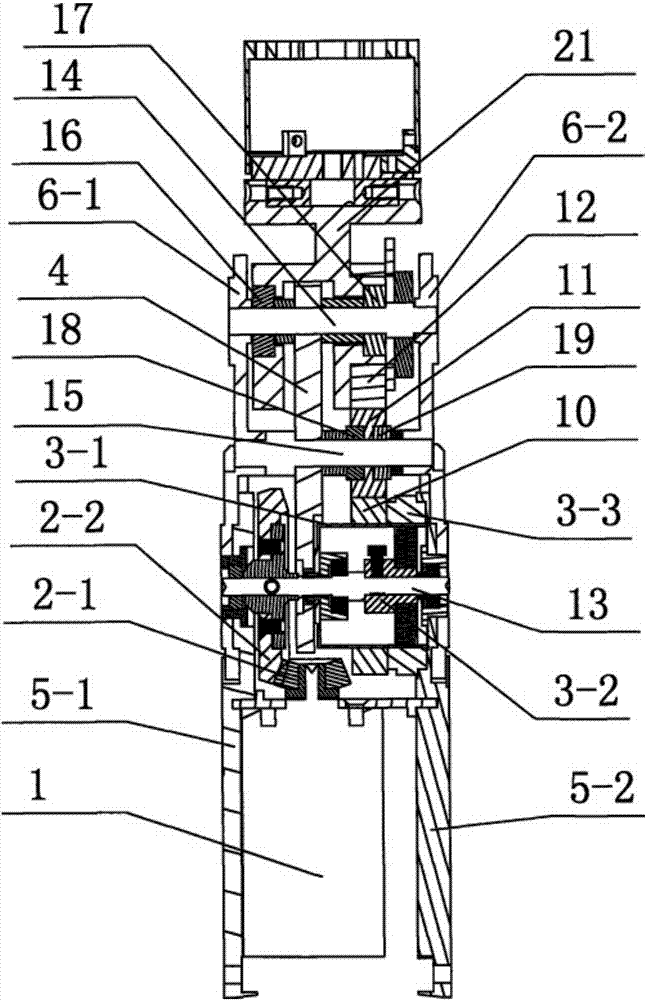

Coupling transmission mechanism of dexterous hand finger joint gear of robot

InactiveCN107351105AGood motor coordinationImproving the precision of dexterous hand movementsGripping headsCouplingMotion coordination

The invention provides a coupling transmission mechanism of a dexterous hand finger joint gear of a robot, and relates to a transmission mechanism of a robot finger. The coupling transmission mechanism solves the problems that an existing coupling transmission mechanism has a complex structure, poor reliability and poor motion coordination when a finger is bent, and easily appears coupling gaps. A fixed spur gear, a middle gear and a driven spur gear have the same modulus, and the fixed spur gear and the driven spur gear have the same number of teeth; the middle gear is meshed with the fixed spur gear and the driven spur gear simultaneously, and the fixed spur gear is sleeved with the flexible wheel of a harmonic reducer; the middle gear is mounted on a middle gear support shaft, and the driven spur gear is mounted on the one-dimension torque sensor of a fingertip. The coupling transmission mechanism achieves coupled motions, with the accurate syntropy 1:1 angle, of a middle joint and a tail end joint, and has the advantages of a simple structure, good reliability, good motion coordination when a finger is bent, an ability of high torque transmission and small coupling motion gaps.

Owner:CHANGSHA ZHANSHUO XUANXING INFORMATION TECH CO LTD

Out-of-phase multi-variable suspension full-motion flapping wing aircraft

InactiveCN108341055AAvoid wastingAvoid backward forceMan-powered aircraftsOrnithoptersLow noiseElevation angle

The invention discloses an out-of-phase multi-variable suspension full-motion flapping wing aircraft. The aircraft is suitable for medium and small flapping wing aircrafts and is especially suitable for human-powered aircrafts and power efficiency priority or low noise drones. Several flapping wings integrally moving can periodically move up and down with equal phase differences. The wing that moves downwards under the driving of the length variable suspension device bears and keeps the elevation angle provided by pitching control and can get a forward component force in down sliding motion (wherein the load height is kept because of reduction of suspension length). The downwardly moving wing is driven by the traction cable so that the wing moving opposite to the downwardly moving wing raises and thus height is recovered. The upwardly moving wing does not bear and the positive elevation angle is not limited. Under the action of air flows, the wing is lifted at almost zero elevation angle so that the negative lifting force produced by the positive elevation angle and the negative attack angle is avoided, and lifting force backward tilting produced by the positive elevation angle andnegative attack angle is avoided without moving time compensation of a single-layer flapping wing so that the load turbulence is reduced and the energy waste is avoided. The pitch control is not periodically changed along with the flapping wing so that the difficulty of motion coordination is observably reduced and the ability to adapt to different speeds and different pitch angles is improved.

Owner:魏朝阳

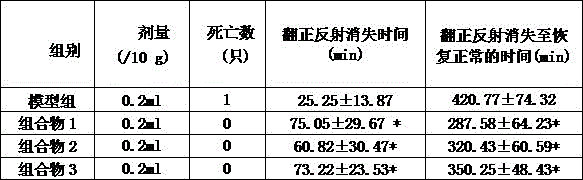

Green plum alcohol-effect relieving composition and preparation method thereof

InactiveCN106692355AExtended sleep timeImprove toleranceAntinoxious agentsFood ingredient functionsAlcoholMedicine

The invention relates to the technical field of medicines and health foods, and particularly relates to a green plum alcohol-effect relieving composition. The composition is prepared by using medicinal and edible medicinal material extracts as raw materials, including 5ml of green plum fermentation broth and 0.5-2g of hovenia dulcis thunb and semen ziziphi spinosae extract powder. The composition can be used for effectively relieving the alcohol effect, has a remarkable effect of improving motion coordination disorder caused by alcohol, and can be used as health foods, health products or medicines.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

Method for strengthening scraper by laser

ActiveCN101974749BHigh hardnessImprove wear resistanceMetallic material coating processesLaser beam welding apparatusAlcoholMotion coordination

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD +1

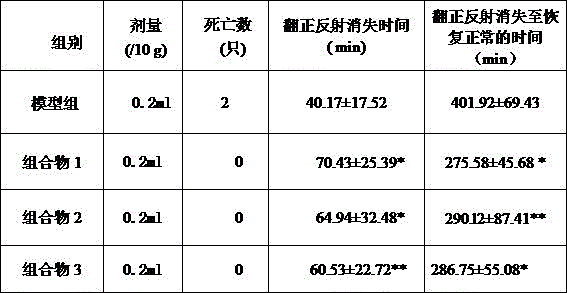

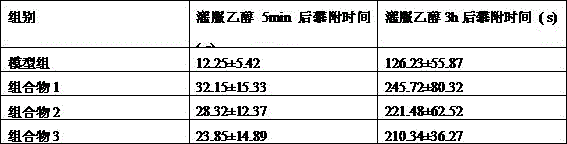

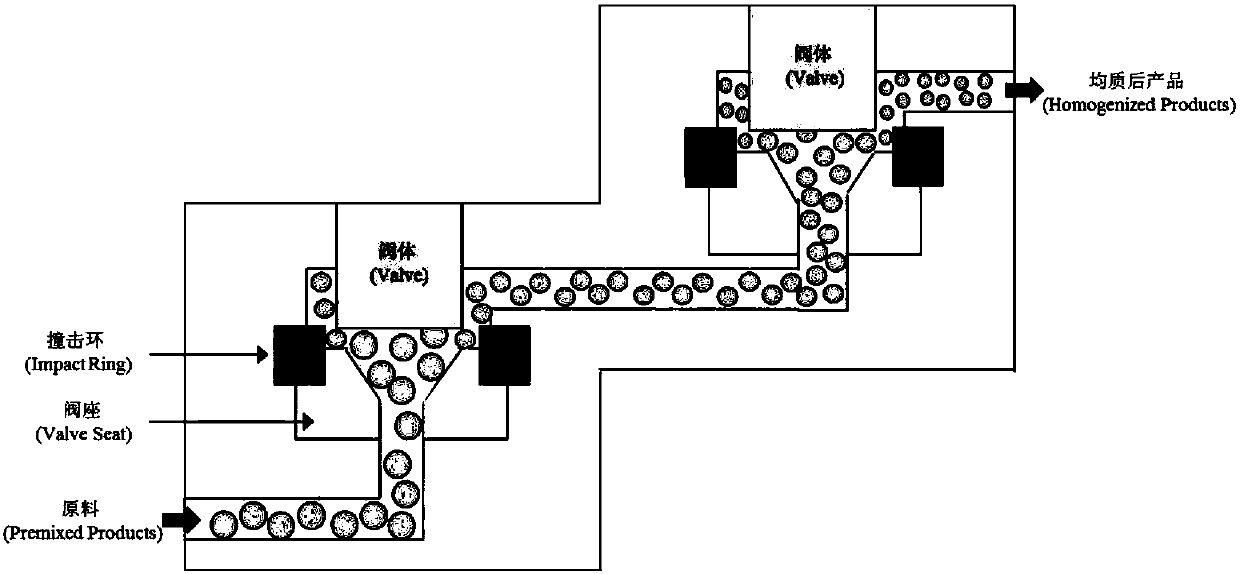

Compound for preventing and controlling alcoholic poisoning and preparation method thereof

PendingCN109810087ASolve the residual problemExtended service lifeOrganic active ingredientsOrganic chemistrySlagMotion coordination

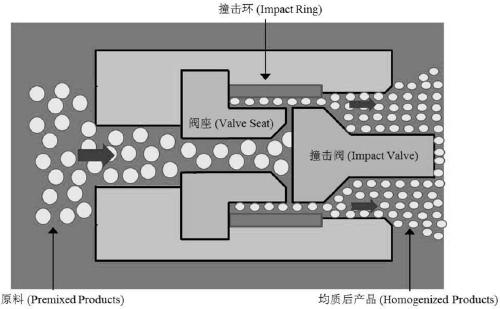

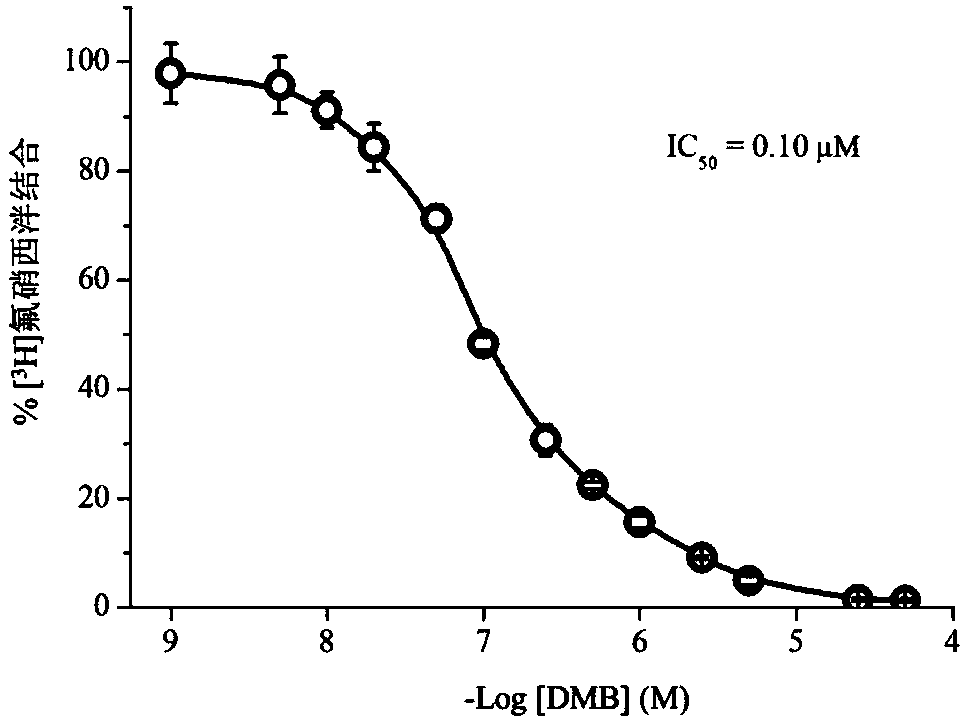

The invention relates to a compound for preventing and controlling alcoholic poisoning and a preparation method thereof. The method comprises the following steps that (1) medicinal material herb is subjected to manual picking, cleaning and impurity removal; then, indoor drying in shade is performed to obtain dry herb samples; through crushing and sieving, medicinal material powder is obtained; (2)the medicinal material powder is subjected to leaching by ethanol; leaching liquid is subjected to grinding by a colloid mill, high-pressure homogenization and centrifugal separation to obtain supernatant and filter slag; (3) the supernatant passes through macroporous resin to be adsorbed and is eluted by an ethanol solution; an obtained alcohol solution is concentrated to extractum; after extraction by petroleum ether, ethyl acetate and n-butyl alcohol, each extraction part is collected; (4) the extraction parts are treated by MCI and repeated silica gel columns; a two-dimensional reversal phase / hydrophilic chromatographic analysis preparation method is combined; a monomer compound is obtained; (5) on the basis of gamma-aminobutyric acid protein A receptor, the monomer compound is subjected to alcoholic poisoning and alcohol dependence resistant activity screening; through animal behavior experiments such as righting reflex losing tests, rotating rod tests and motion coordination tests, six active compounds are screened and prepared. The technology design is scientific and reasonable; the cost is low; the extraction rate and the preparation efficiency are high; the obtained compound has stable property; the content is high; a high alcoholic poisoning and alcohol dependence resistant effect is achieved.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

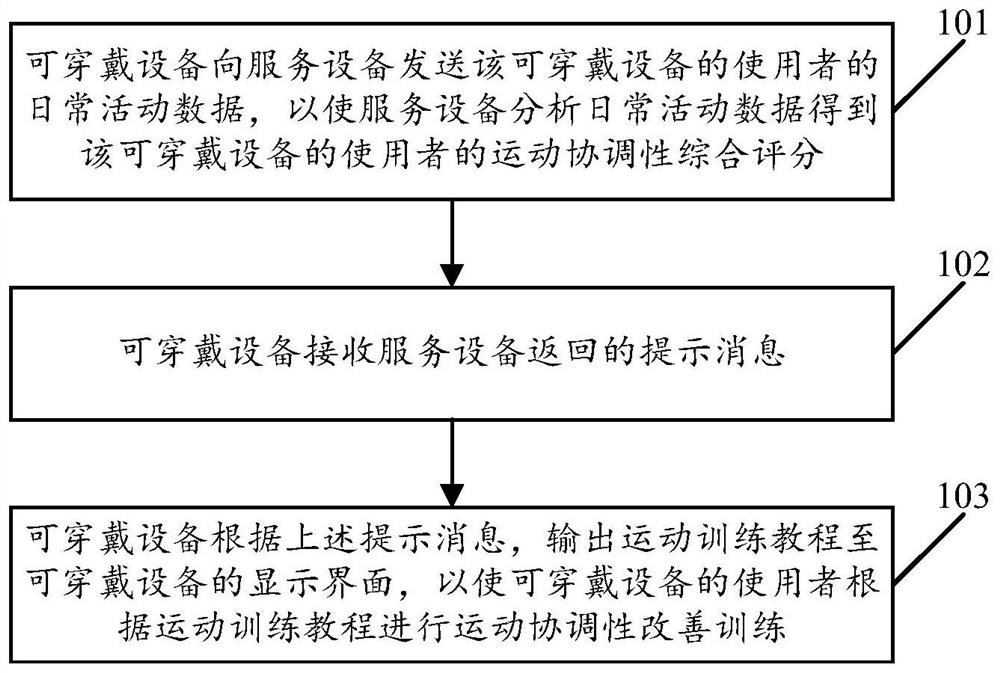

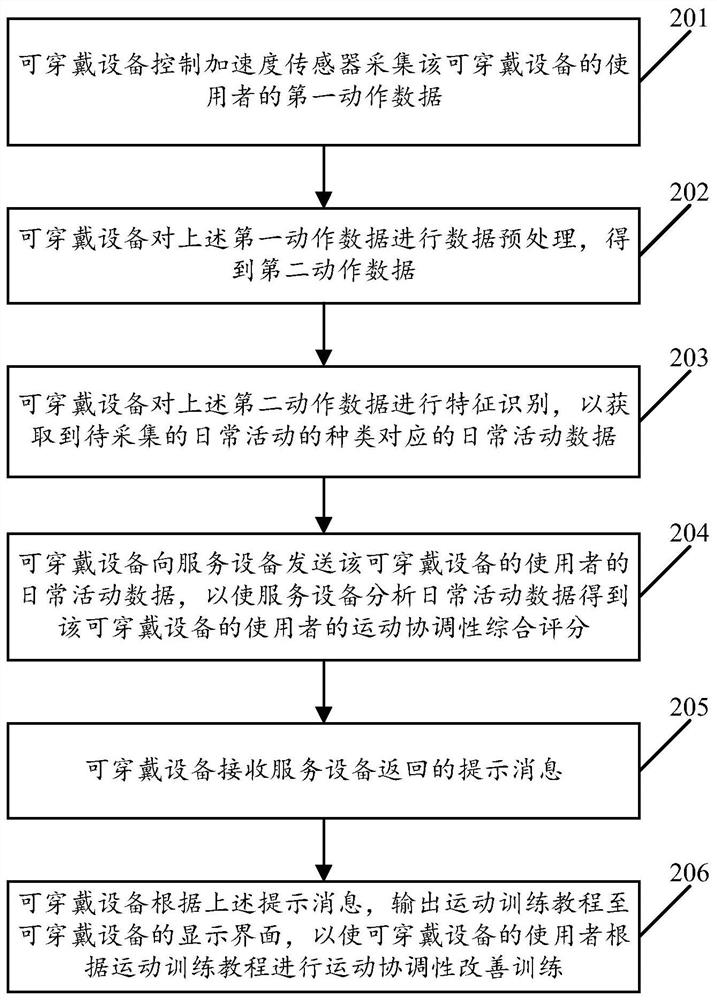

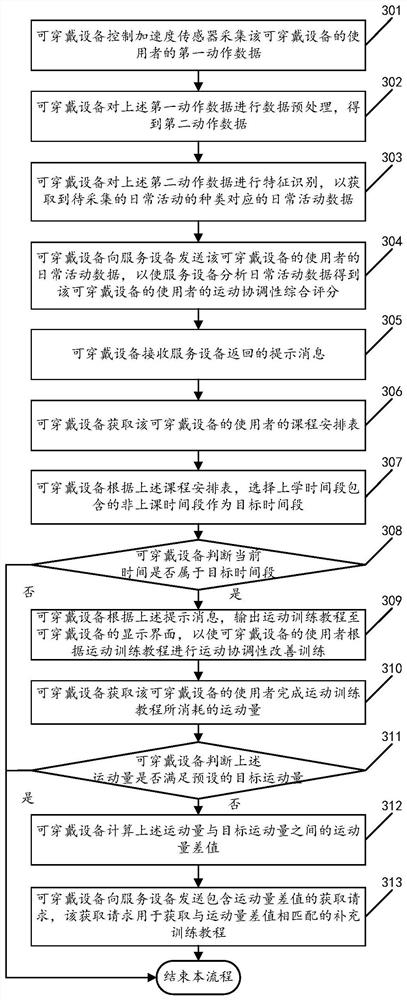

A method for monitoring motor coordination based on daily activities and a wearable device

ActiveCN108074633BMonitor motor coordinationPhysical therapies and activitiesDiagnostic recording/measuringPhysical medicine and rehabilitationMotion coordination

The present invention relates to the technical field of electronic equipment, in particular to a method for monitoring movement coordination based on daily activities and a wearable device, including: the wearable device sends the daily activity data of the user of the wearable device to the service device, so that the service The device analyzes the daily activity data to obtain the comprehensive sports coordination score of the user of the wearable device, and receives the prompt message sent by the service device when it judges that the comprehensive sports coordination score is lower than the normal scoring threshold, and then according to the prompt message, The sports training tutorial is output to the display interface of the wearable device, so that the user of the wearable device can perform exercise coordination improvement training according to the sports training tutorial. It can be seen that the embodiment of the present invention can effectively monitor the motor coordination of the child's daily activities.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

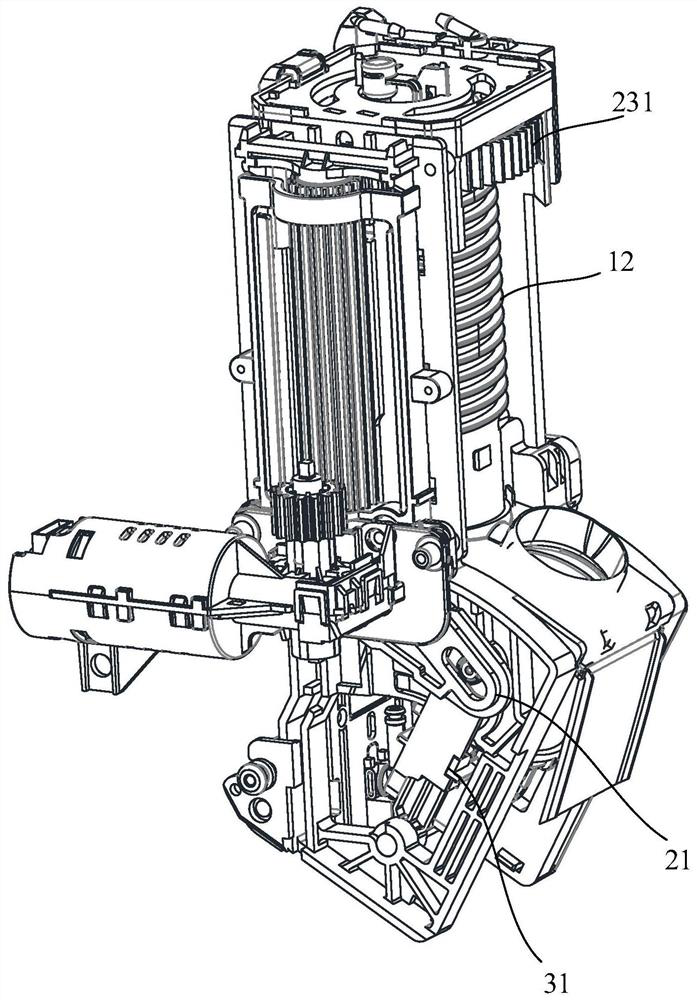

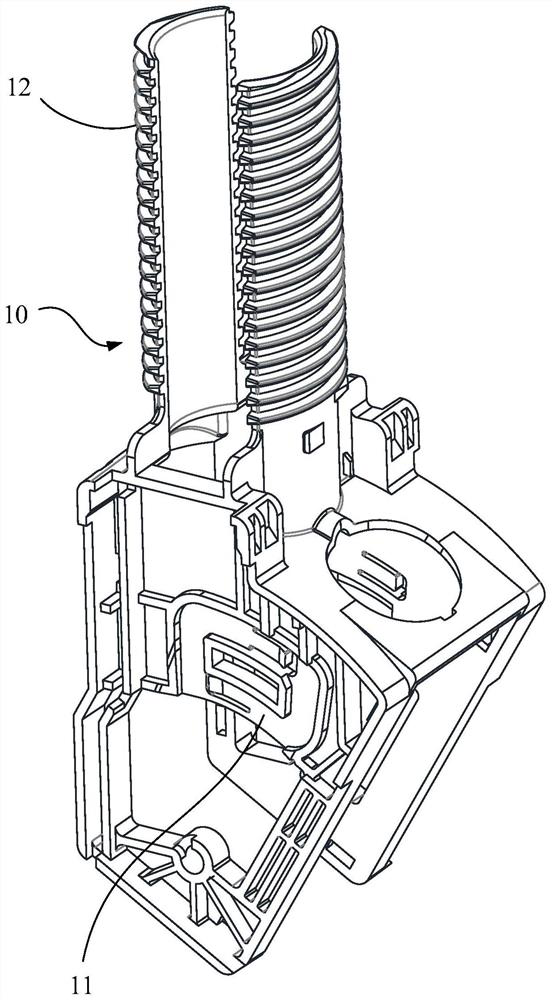

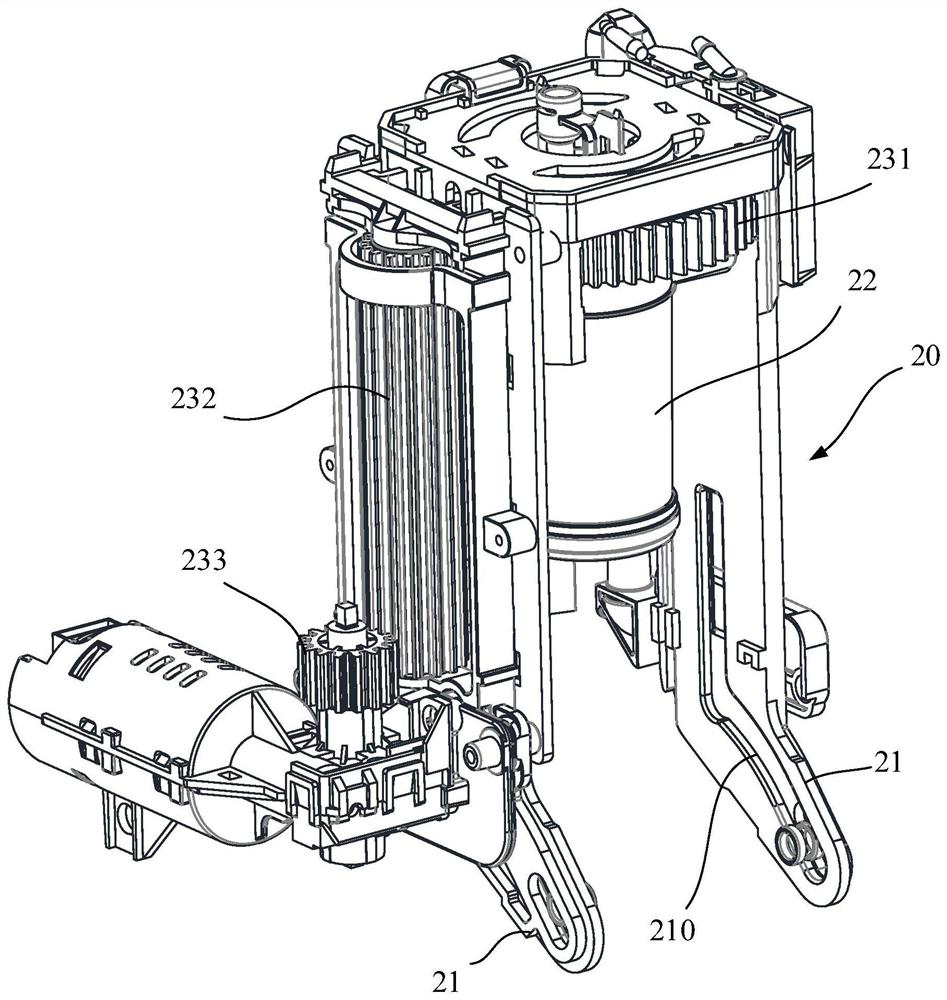

Modulation assembly movement mechanism and beverage machine comprising the same

InactiveCN113693443ALess prone to failureSmooth movementBeverage vesselsControl engineeringMotion coordination

The invention discloses a modulation assembly movement mechanism and a beverage machine comprising the modulation assembly movement mechanism. The modulation assembly movement mechanism comprises a brewing unit provided with an outer track component and a compaction component, a containing unit and a main body support, wherein the containing unit comprises a connecting rod support, a rotating support, an ejection piece and an extraction cylinder, an inner track component is arranged on the main body support and comprises four sections of tracks connected end to end, the two sides of the connecting rod support are connected with coupling parts, and the coupling parts on the two sides are matched with the inner track component and the outer track component respectively and slide in the tracks of the inner track component and the outer track component. In the whole movement process, the movement of the extraction cylinder and the ejection piece is coordinated, and faults are not prone to occurring, and smooth movement can be ensured, and stable and efficient operation of the whole movement process is ensured.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

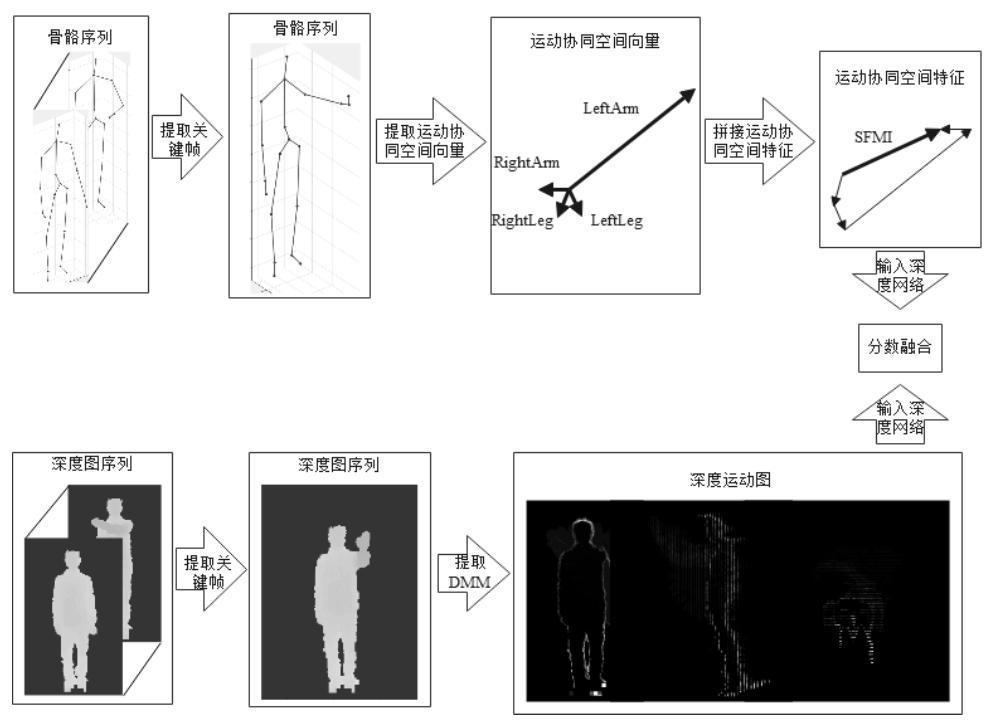

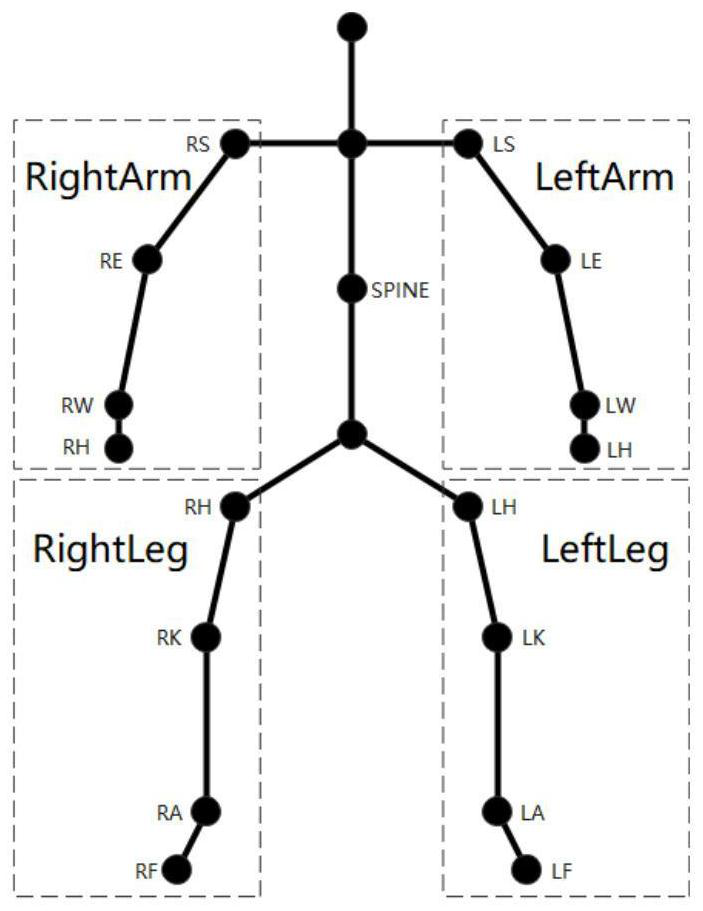

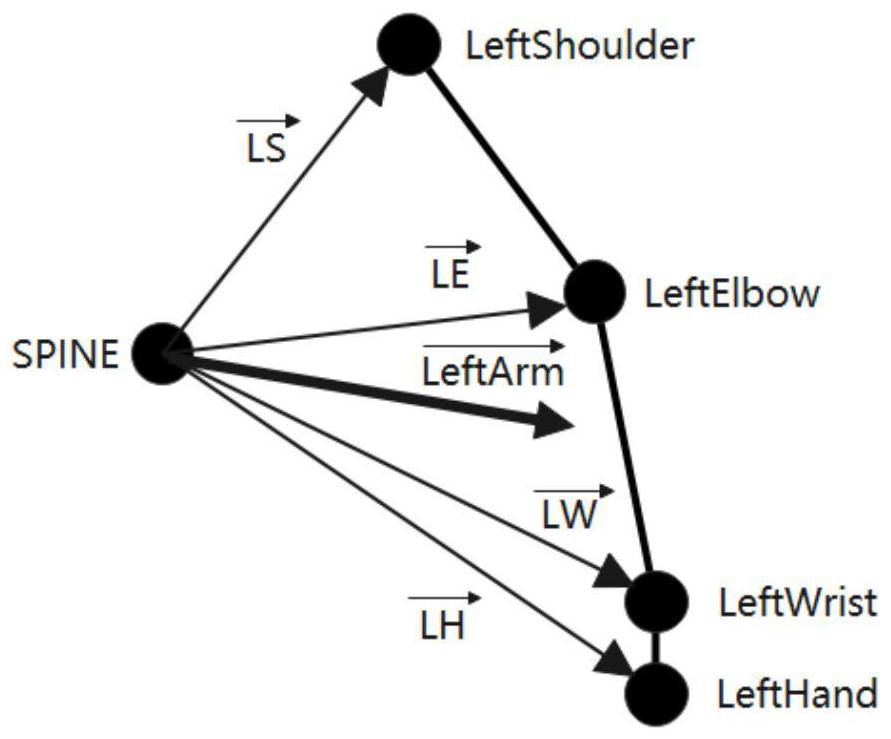

Human body behavior recognition method based on motion cooperation space

PendingCN114677621AImprove computing efficiencyStrong complementarityBiometric pattern recognitionNeural architecturesHuman bodyMotion coordination

The invention discloses a human body behavior identification method based on a motion cooperation space. The method comprises the following steps: S1, respectively carrying out key frame extraction based on a motion state measurement coefficient on an initial skeleton sequence and a depth map sequence; s2, extracting motion coordination space vectors from the skeleton sequence processed in the step S1, and splicing the motion coordination space vectors into motion coordination space features; extracting DMM features from the depth map sequence processed in the step S1 to obtain a depth motion map; and S3, inputting the deep motion map and the motion collaborative spatial features into a deep network at the same time, and performing score fusion. Based on the idea of multi-modal fusion, skeleton data and depth data are combined, so that the data are more complete, complementation of various heterogeneous information is realized, redundancy among modals is eliminated, a new behavior recognition method system is established, and a new thought and theoretical basis are provided for research and application of a human body behavior recognition method.

Owner:CHANGZHOU UNIV

A Coordinated Motion Control Method for Space Dual Manipulator System

ActiveCN106945020BFast trackImprove operating precisionProgramme-controlled manipulatorKinematics equationsControl system

The invention relates to a motion coordination control method for a space dual-manipulator system, and belongs to the technical field of space manipulators. In order to overcome the defects that no space manipulator system specific to dual manipulators exists at present, the coordinated relation between a manipulator and a satellite body is not considered in an existing space manipulator system and tracking errors are high, the motion coordination control method for the space dual-manipulator system is provided. The motion coordination control method for the space dual-manipulator system includes the steps that a kinematical equation and kinetic equation of the space dual-manipulator system are established; the space dual-manipulator system is subjected to trajectory planning according to the initial postures and tail-end postures of the manipulators; and trajectories of the space dual-manipulator system are subjected to tracking control through a PD controller. The motion coordination control method for the space dual-manipulator system is suitable for a space manipulator control system.

Owner:黑龙江省工研院资产经营管理有限公司

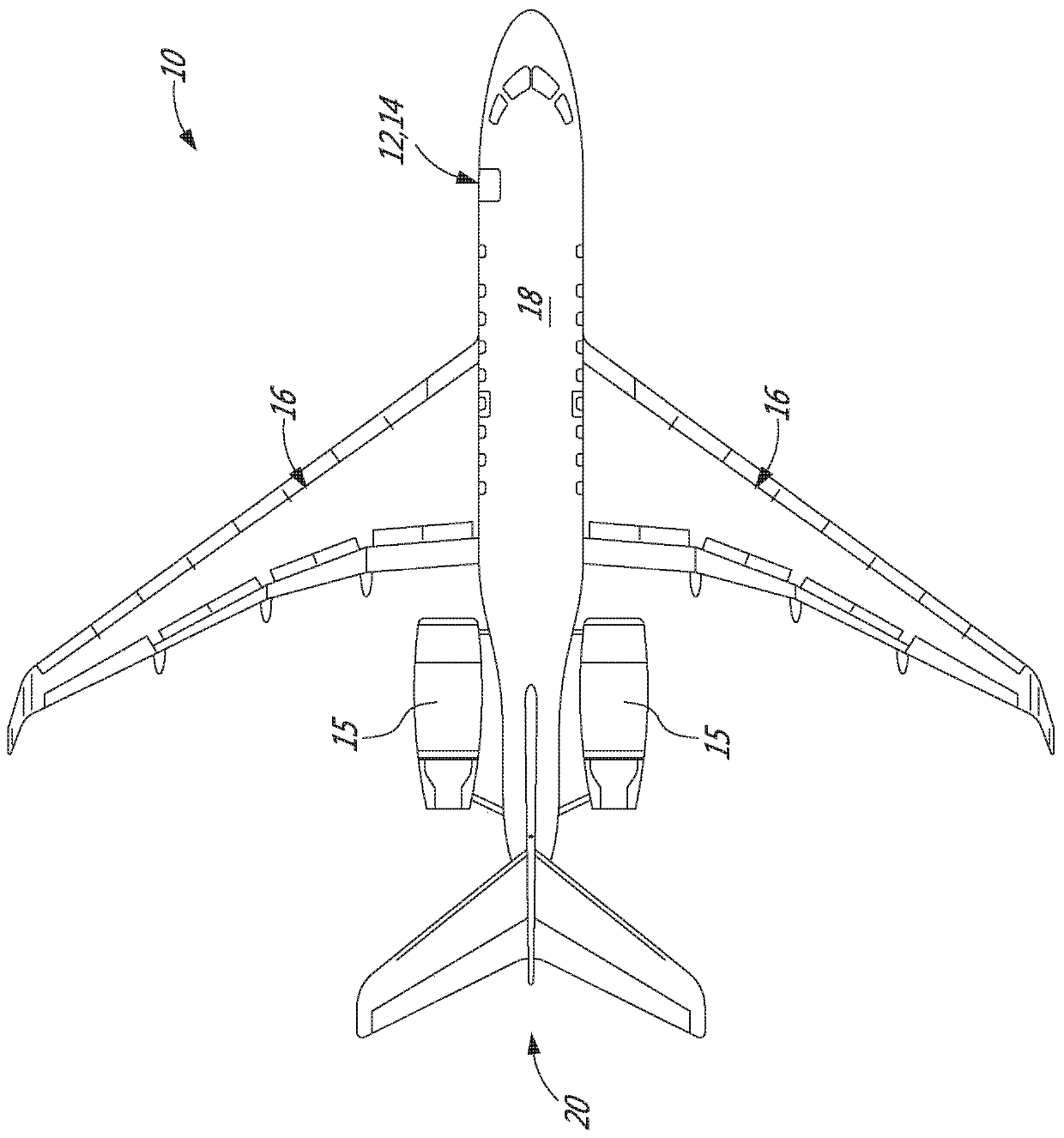

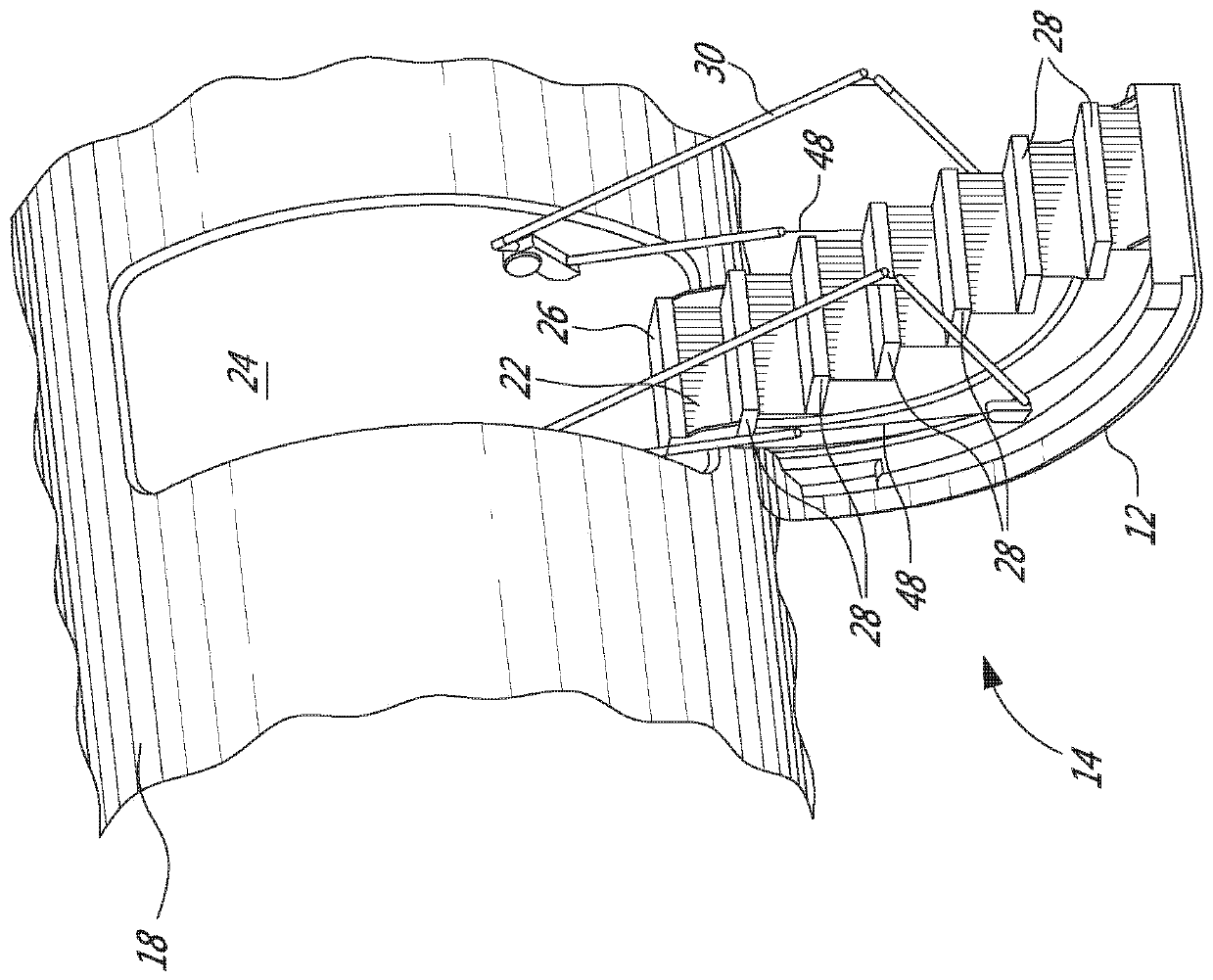

Airstair system with deployable upper step

An airstair system with a deployable upper step. Airstair systems and associated methods are disclosed. In one embodiment, the airstair comprises a deployable upper step, a primary deployment device and a secondary deployment device. The upper step is movable between a stowed configuration when a door of the aircraft is closed and a deployed configuration when the door is open. The primary deployment device resiliently biases the upper step toward the deployed configuration. The secondary deployment device is movable in coordination with a movement of the door and configured to drive the deployable upper step toward the deployed configuration during opening of the door and during a failure of the primary deployment device.

Owner:BOMBARDIER CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com