Oblique-inserting type fin evaporator automatic fin-inserting pipe expander

A fin evaporator and oblique insertion type technology, which is applied in the field of inclined insertion type fin evaporator automatic fin tube expansion machine, can solve the problem of poor aluminum pipe threading, strong dependence on worker proficiency, and low operation efficiency. problems, to achieve the effect of improving work efficiency and work safety, shortening the process and production cycle, and reducing the storage of fins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

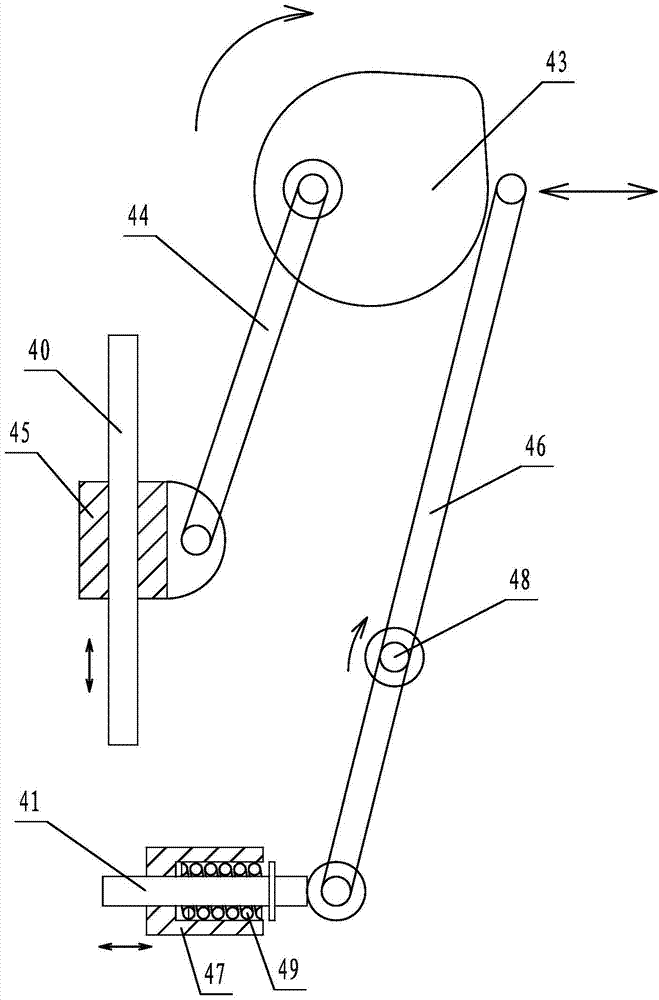

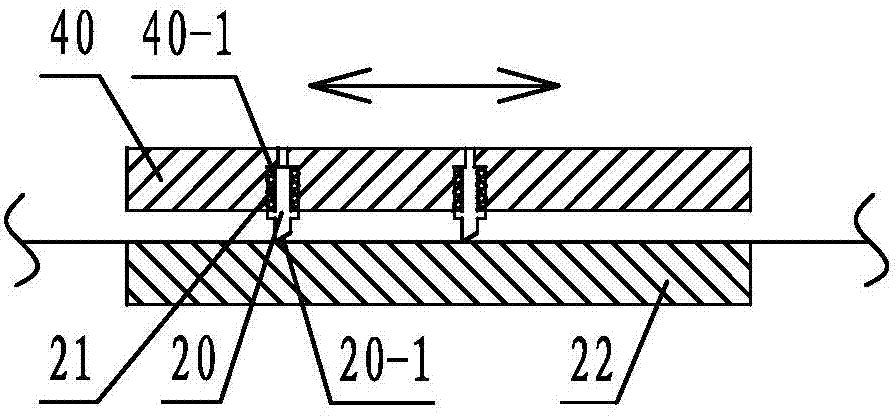

[0017] The present invention will now be further described in conjunction with the accompanying drawings and preferred embodiments. These accompanying drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention, wherein figure 2 , image 3 The middle arrow indicates the direction of motion.

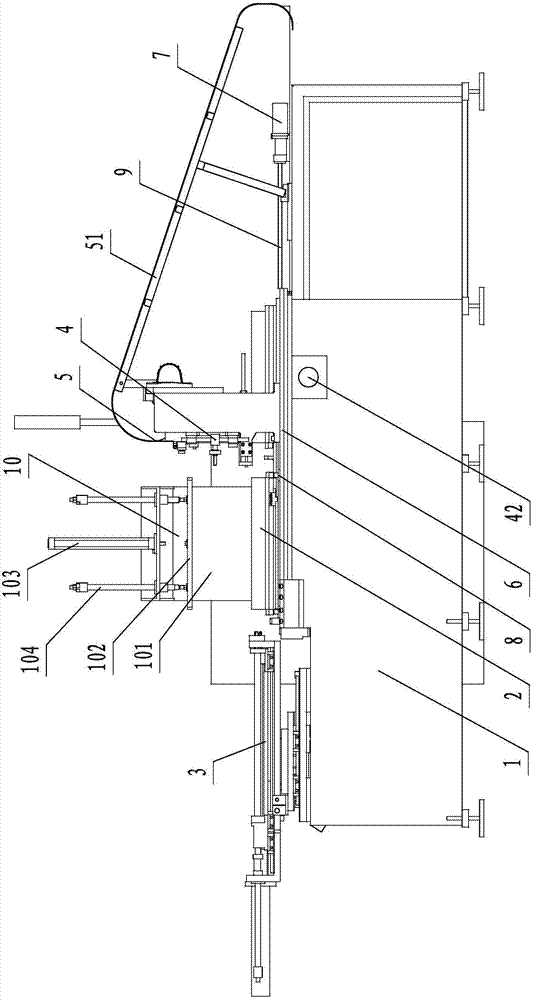

[0018] like Figure 1 ~ Figure 3 An automatic finned tube expander for obliquely inserted finned evaporators is shown, which is used for the arrangement of fins on obliquely inserted finned evaporators and the obliquely inserted and expanded fins and aluminum tubes, including frame 1, On the left side of the table of frame 1, there is a tube expansion device 3 with aluminum tubes placed. The tube expansion device 3 has a propulsion cylinder that pushes the aluminum tubes to penetrate into the fins to insert and tighten them obliquely. The rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com