Patents

Literature

339results about How to "Reduce turnover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Positive wakeup pharmaceutical sleep system with compatible pre-bedtime administration

InactiveUS20050031688A1Fine stepsAvoid accidentsBiocideCarbohydrate active ingredientsDialysis membranesOral medication

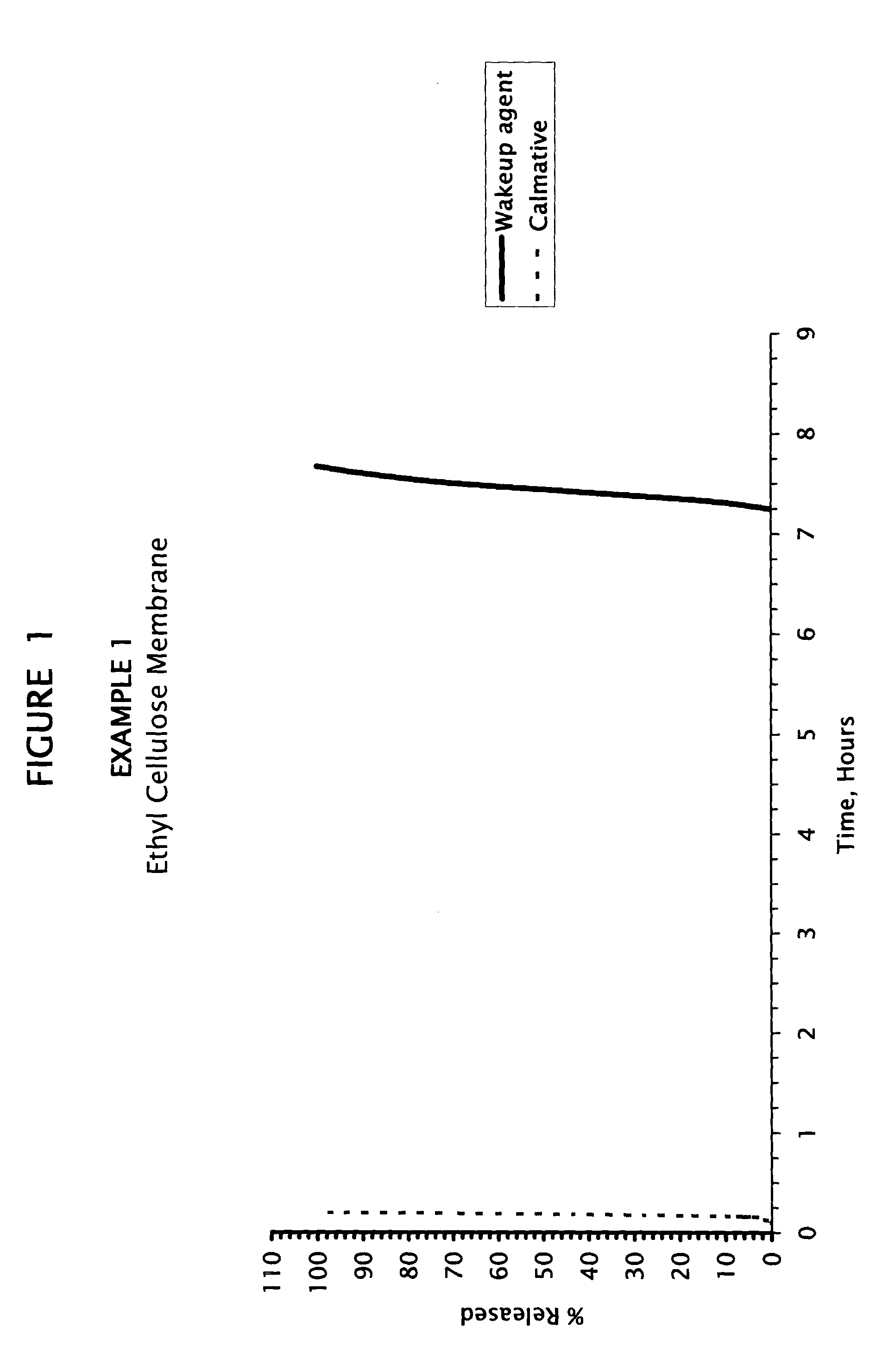

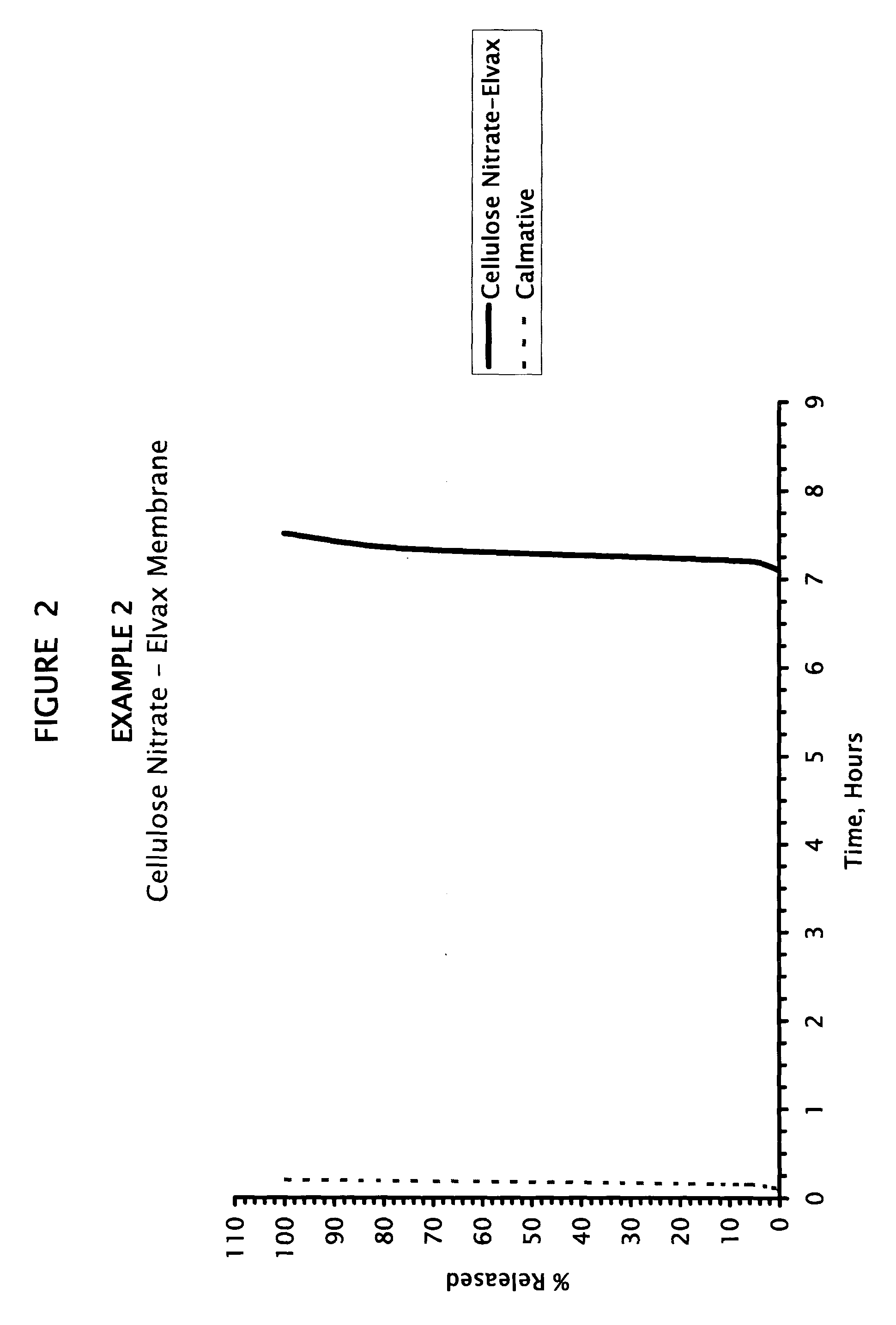

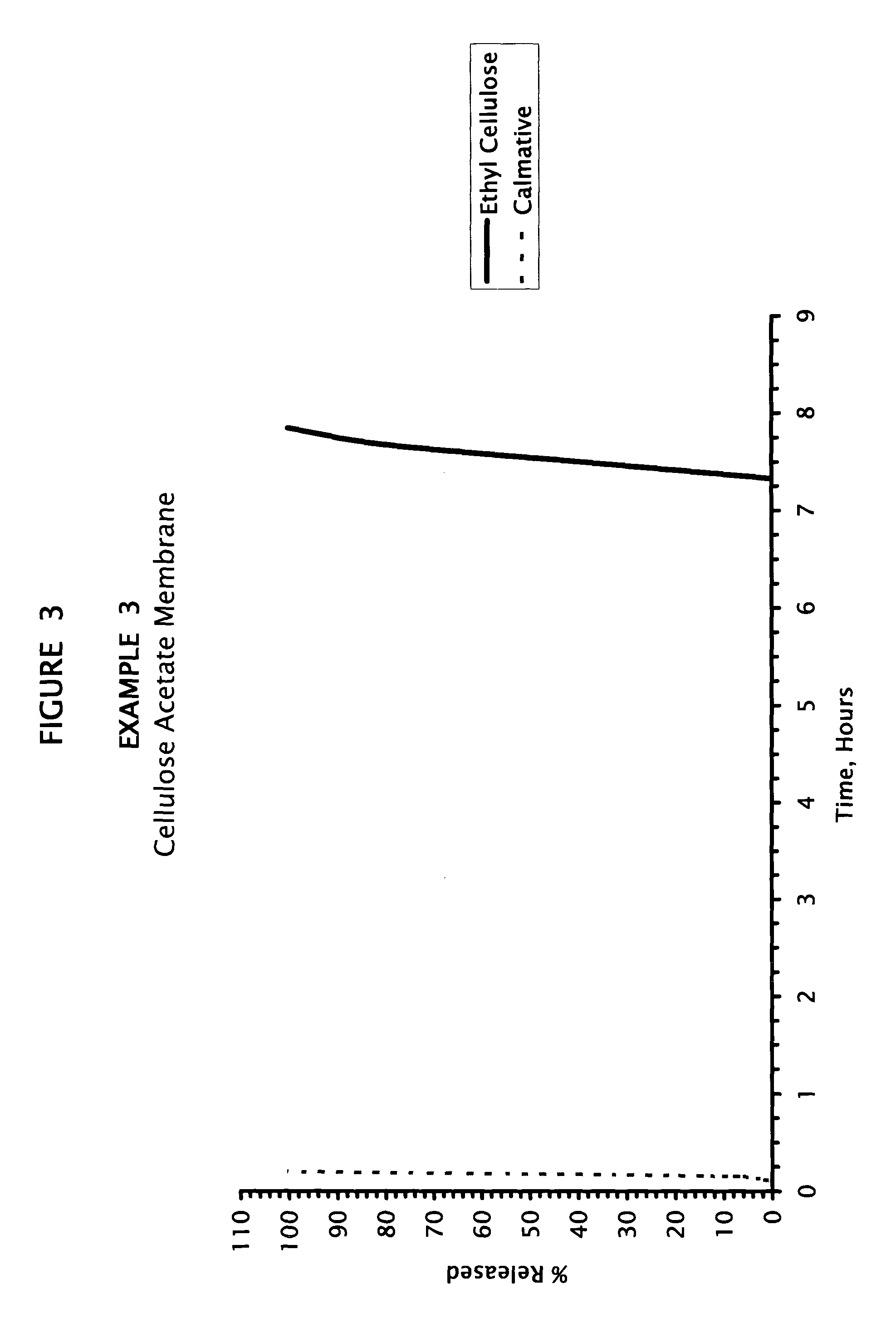

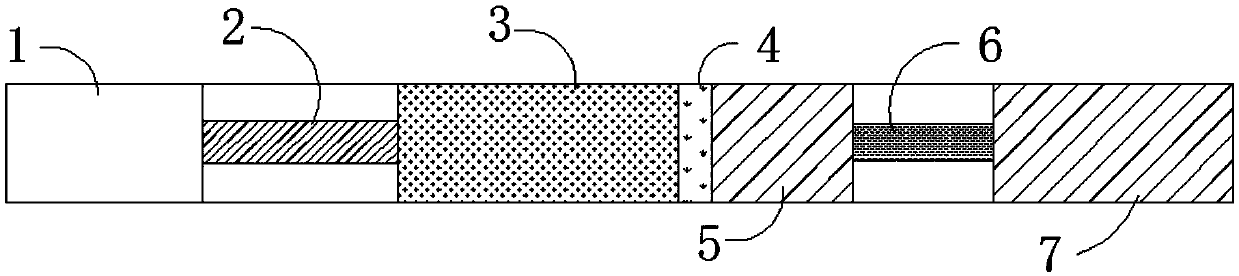

A novel sleep regulating pharmaceutical formulation is introduced, typically implementing two principal drugs having actions which are reversive to one another, yet incorporated into a unitary solid dosage, and prepared for oral administration before bedtime. Usually, structure is configured to initially release a calmative or other sleep-compatible substance by prompt dissolution. The initial release is followed by a specific period of delay, which in basic formulations entails no release of any drug, and which allows a nominal interval of sleep. At the terminus of the delay, a final agent is released to induce wakeup. Incorporation of agents of opposite action within a unitary dosage form renders utility which is uniquely appropriate to the invention. In a preferred embodiment, delay of release and final delivery of wakeup agent are arranged by a dialysis membrane which eventually bursts as a result of osmotic pressure generated by a hydrophilic core.

Owner:AYALA WILLIAM J

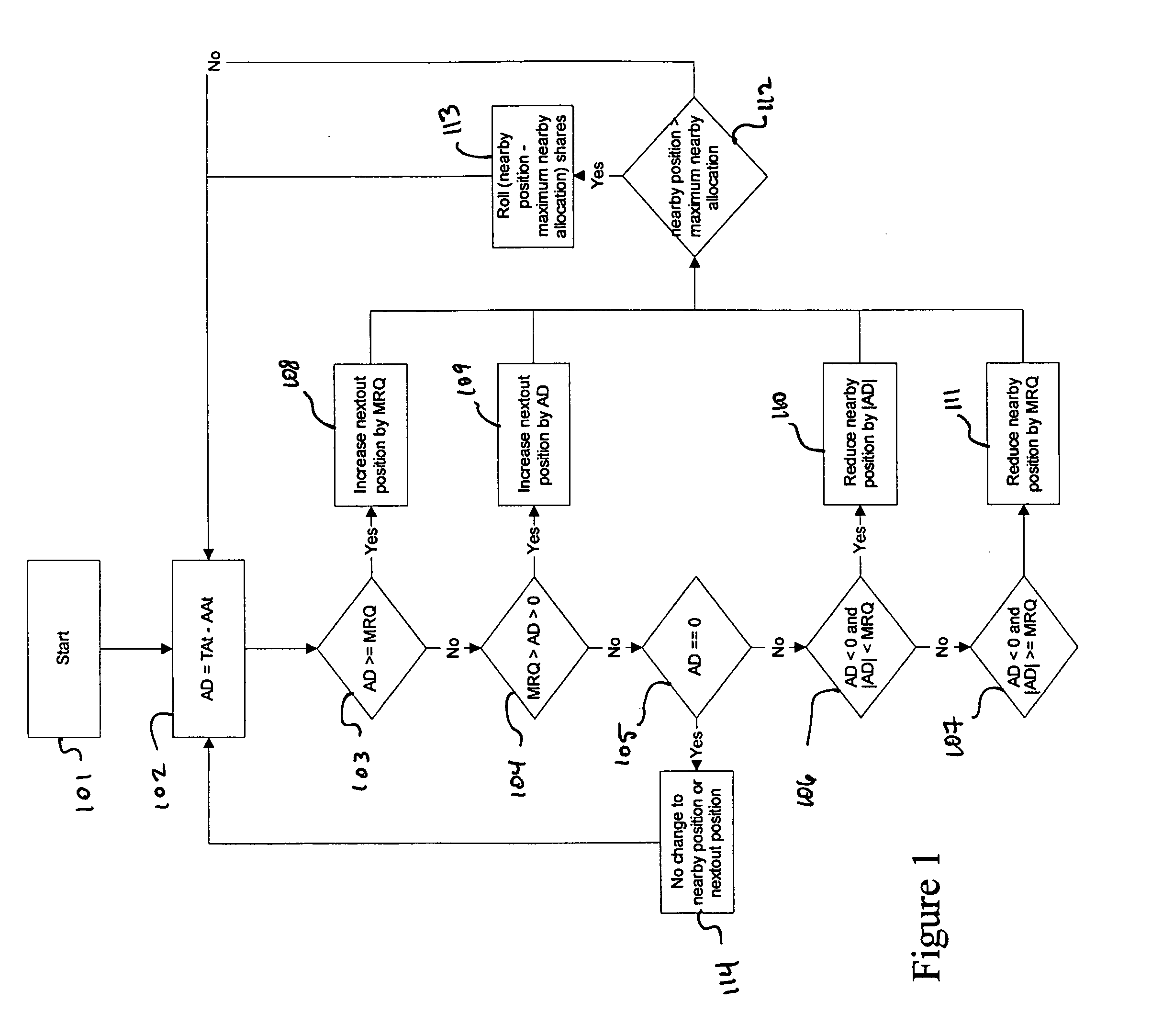

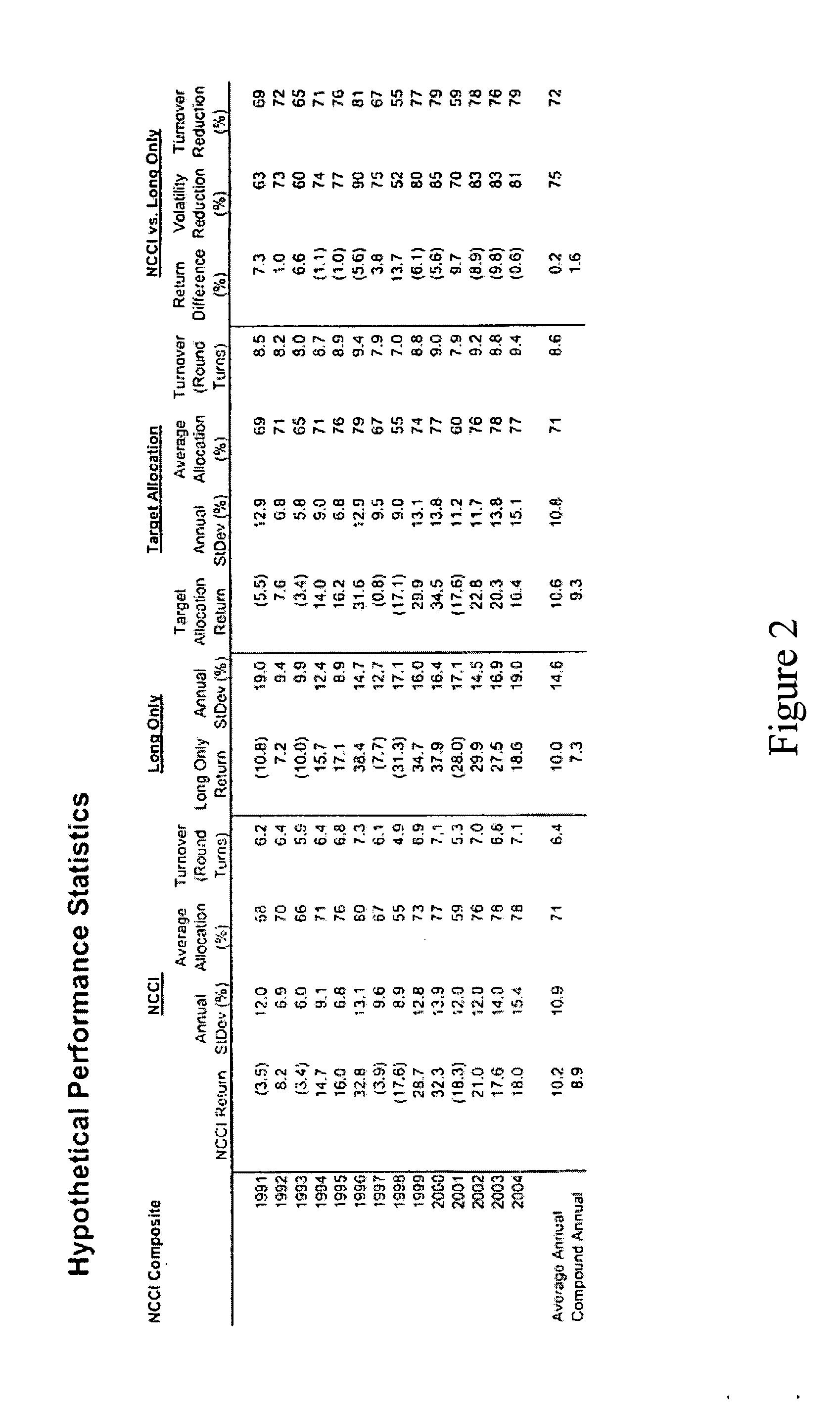

Commodity futures index and methods and systems of trading in futures contracts that minimize turnover and transactions costs

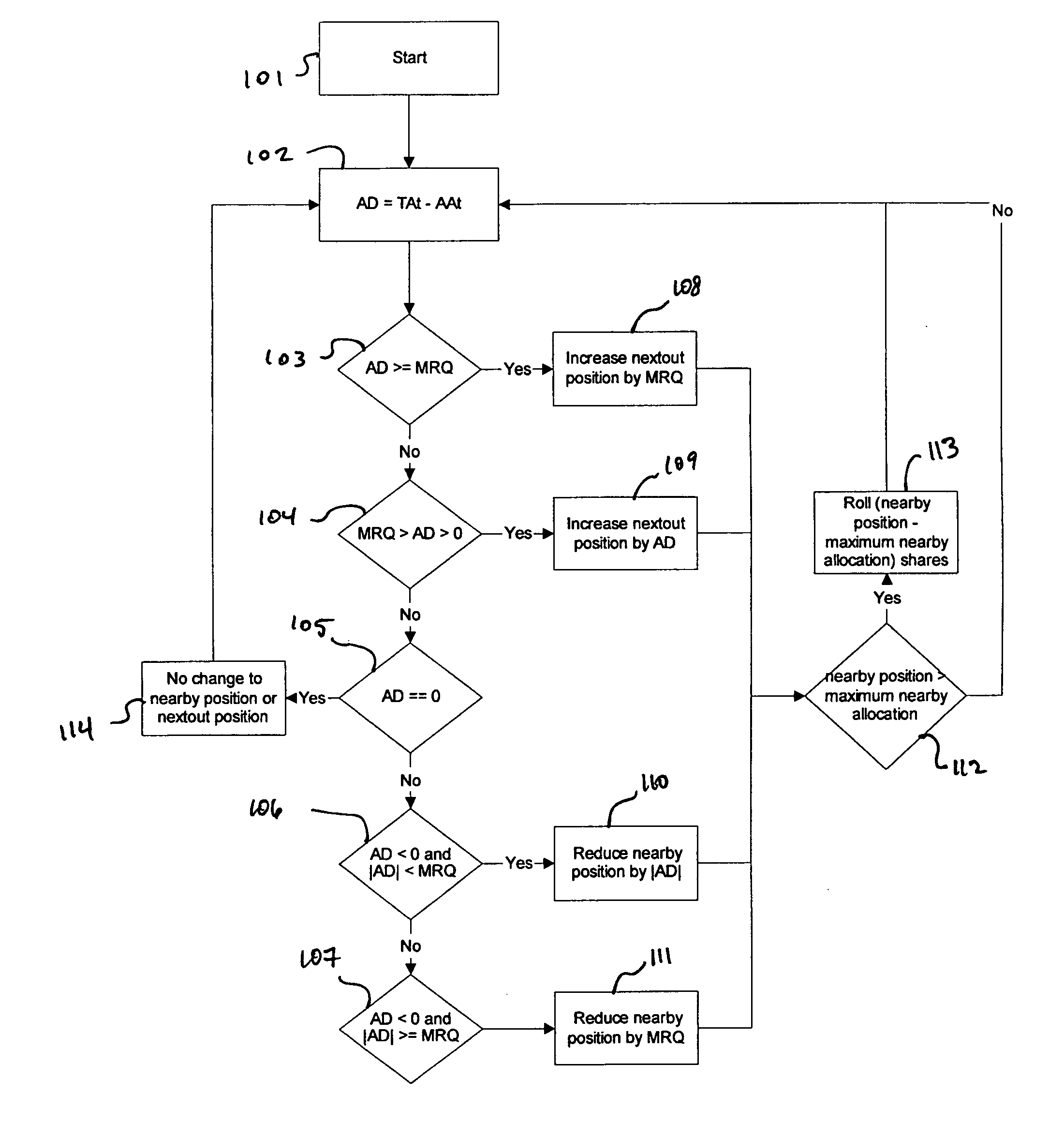

This invention relates to methods and systems for reducing transaction costs and minimizes turnover in the trading of futures contracts. The invention further describes an algorithm whose output is a unique method of investing in futures contracts that reduces the rate of turnover, and thus the cost of trading, of certain common trading strategies. The primary application of this method is to a class of strategies referred to as indexing strategies that incorporate a dynamic asset allocation approach using futures contracts.

Owner:PFDS HLDG

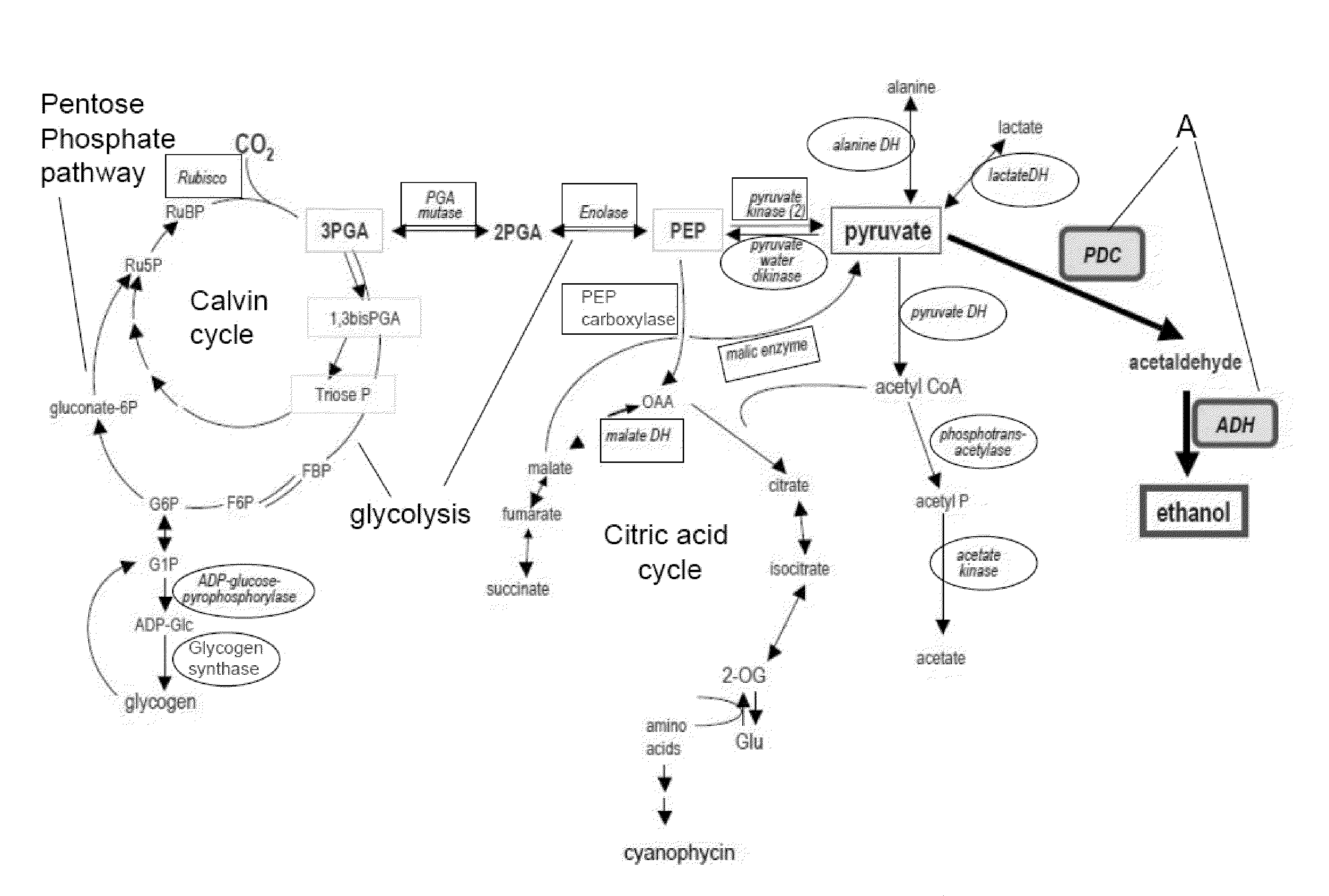

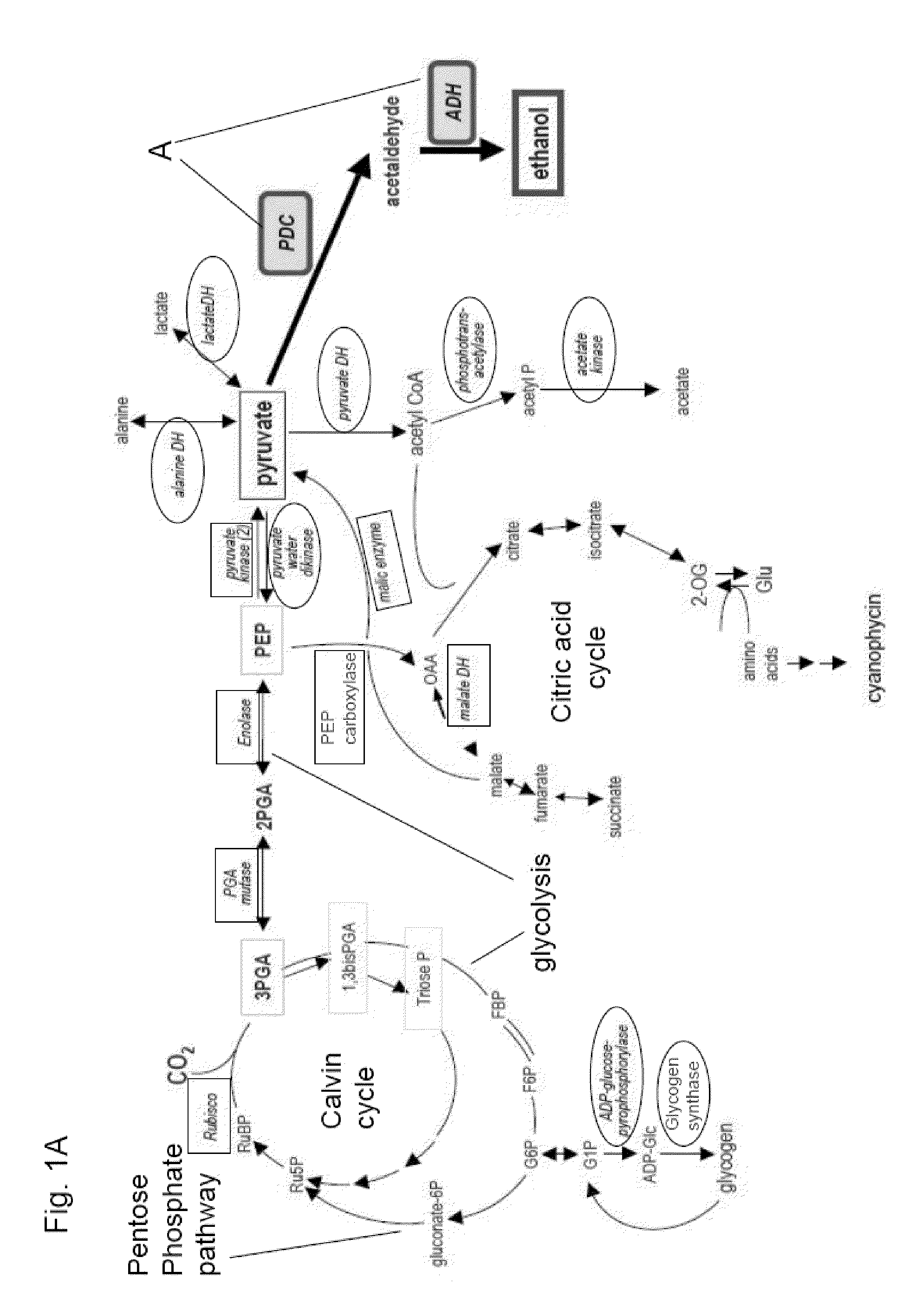

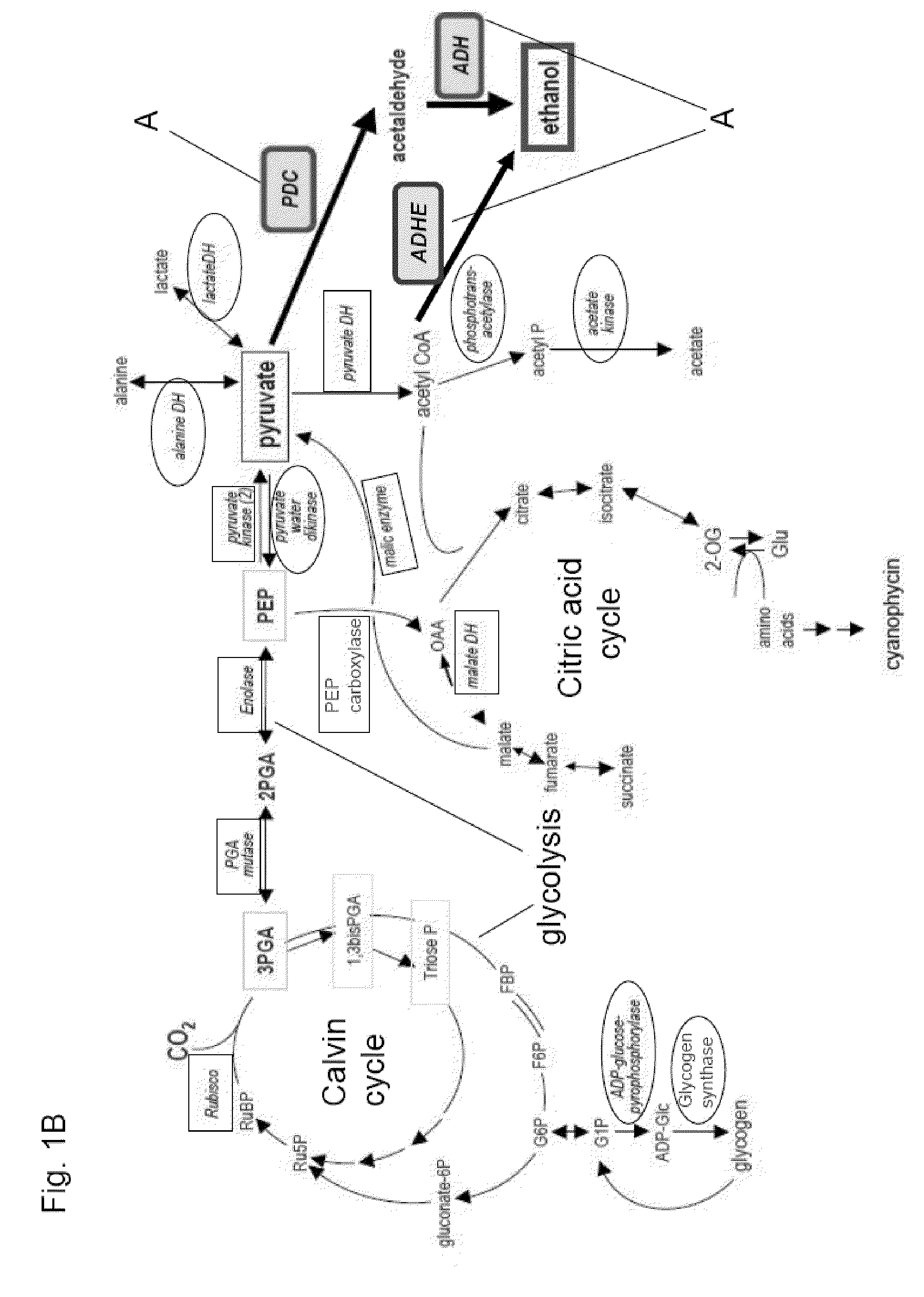

Genetically Modified Cyanobacteria for the Production of Ethanol

InactiveUS20100068776A1Increased biosynthetic levelsImprove the level ofBacteriaBiofuelsPhylum CyanobacteriaBiotechnology

The invention provides novel compositions of matter for the production of ethanol from carbon dioxide and water. Particularly, the invention provides photoautotrophic organisms having a first and second genetic modification, wherein the first genetic modification improves the ethanol production from organisms having the second genetic modification.

Owner:ALGENOL BIOFUELS

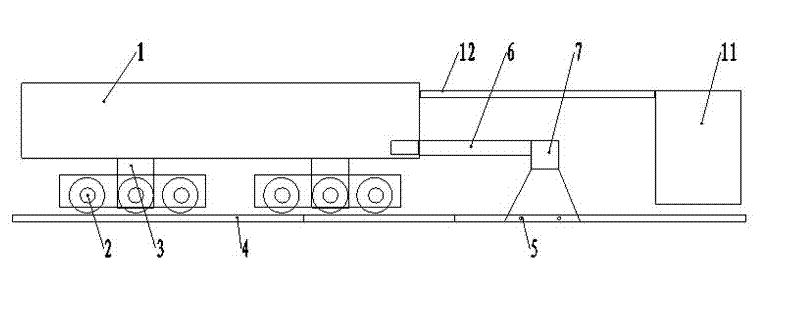

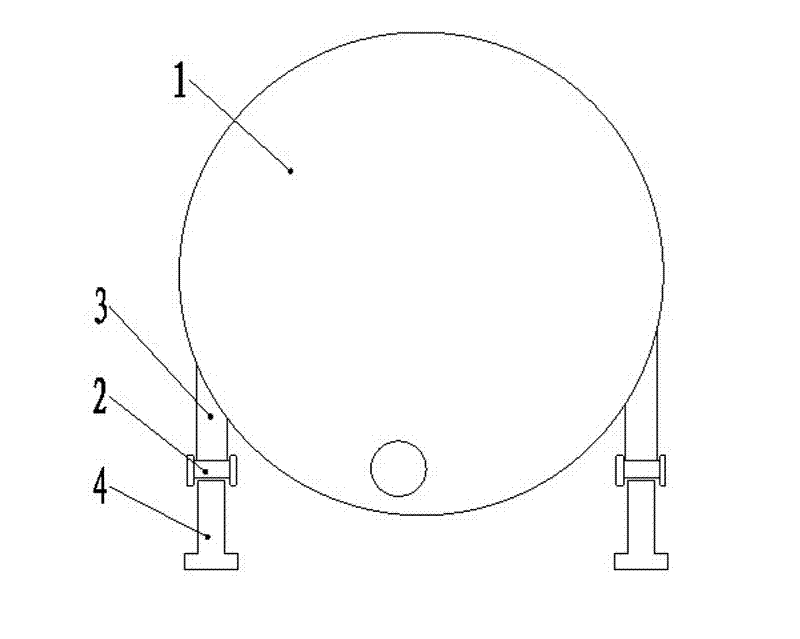

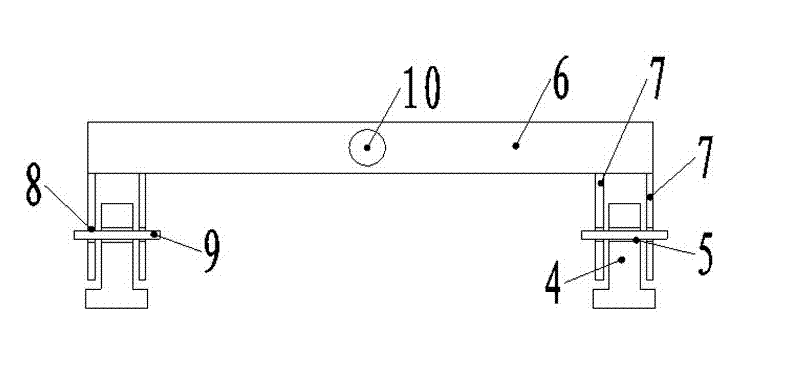

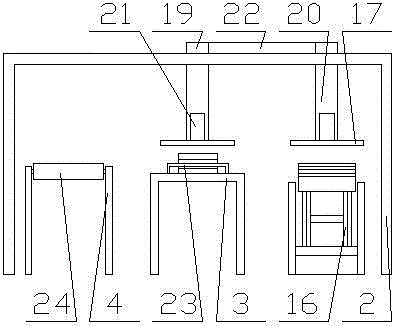

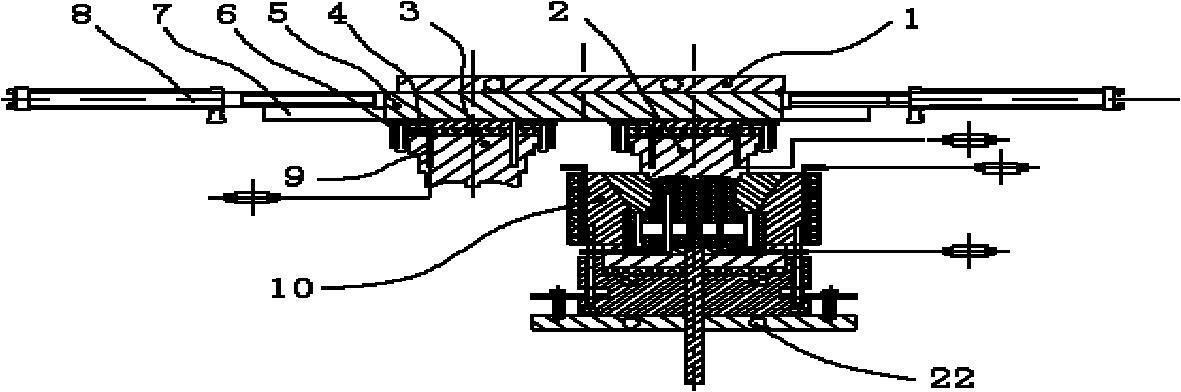

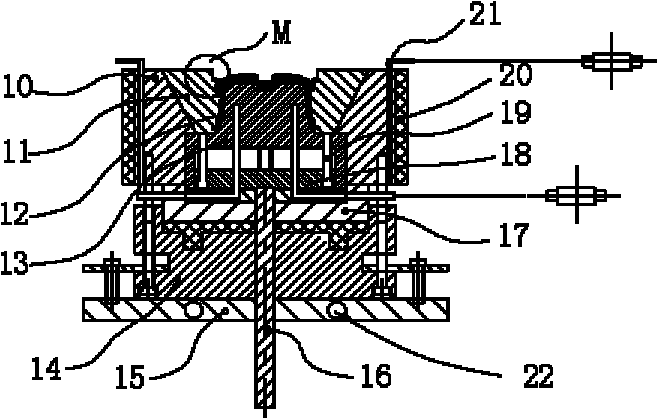

Roller guide rail station-passing construction method of whole shield machine

The invention relates to the field of tunneling shield construction, in particular to a roller guide rail station-passing construction method of a whole shield machine and solving the problems of high difficulty, high cost, long construction peroid and the like of the traditional method. The roller guide rail station-passing construction method comprises the following steps of: machining a shieldforward-moving roller, a forward-moving guide rail, a counter-force device and a rear matched track section; determining whether water stop fabric is arranged in a hole, carrying out shield receivingand welding the forward-moving roller while receiving; moving the whole shield machine forwards, cutting a U-shaped groove plate at a shield connecting bridge off, paving the shield forward-moving guide rail, installing the counter-force device, and enabling the shield to move continuously forwards under the actions of the counter-force device and an oil cylinder; cutting the forward-moving roller off in the process of moving the shield to an originated base forwards, arranging the oil cylinder to the originated base and the side wall of an originated wall, starting the oil cylinder so that the shield body and the originated base translate together along the articulation part of the connecting bridge and the shield body and subsequent associated equipment are in the same straight line, and carrying out second originating. The roller guide rail station-passing construction method has the advantages of simple process, short construction peroid, low cost, risk controllability and the like and has favorable economic and social benefits and wide application range.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

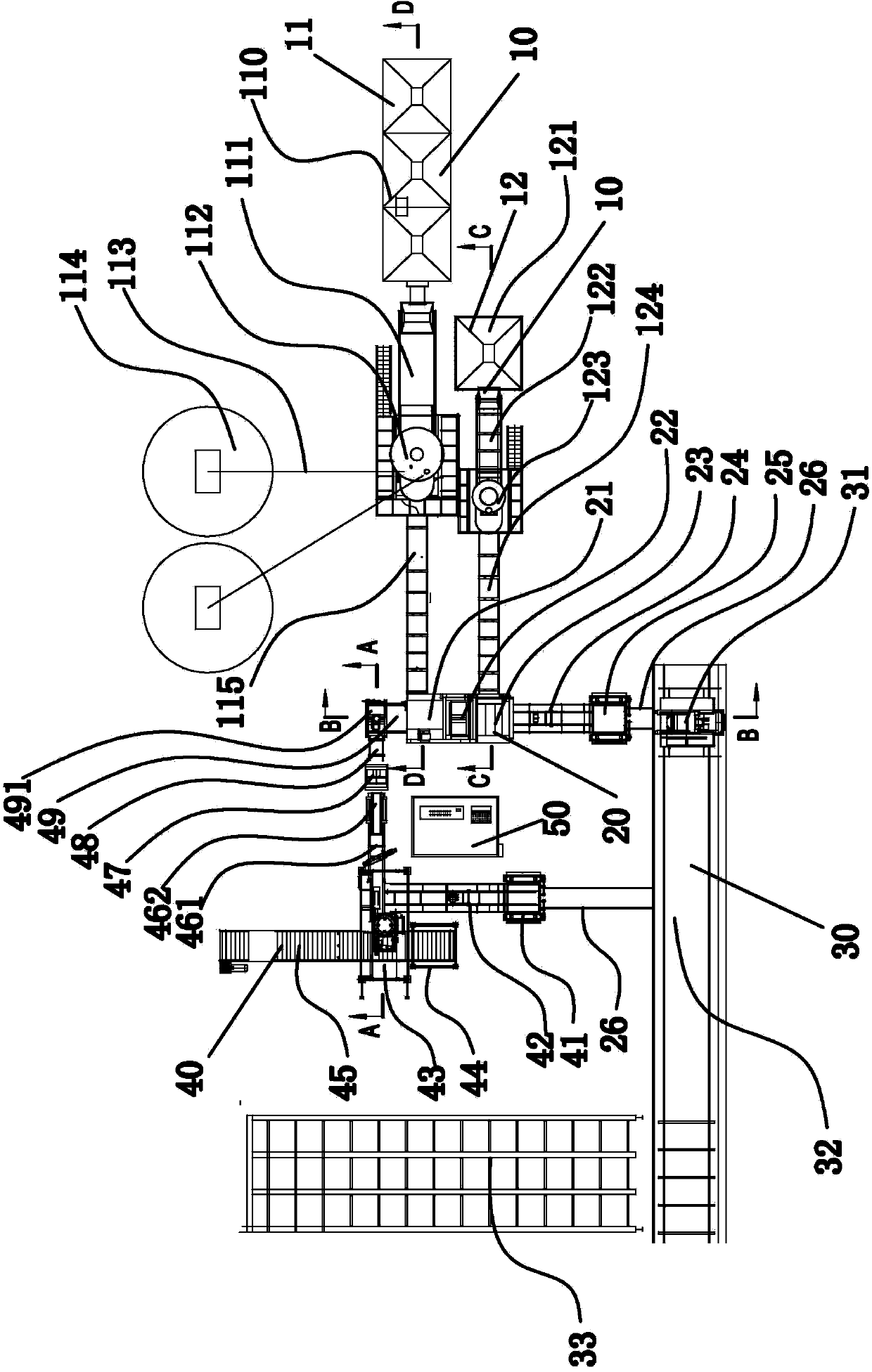

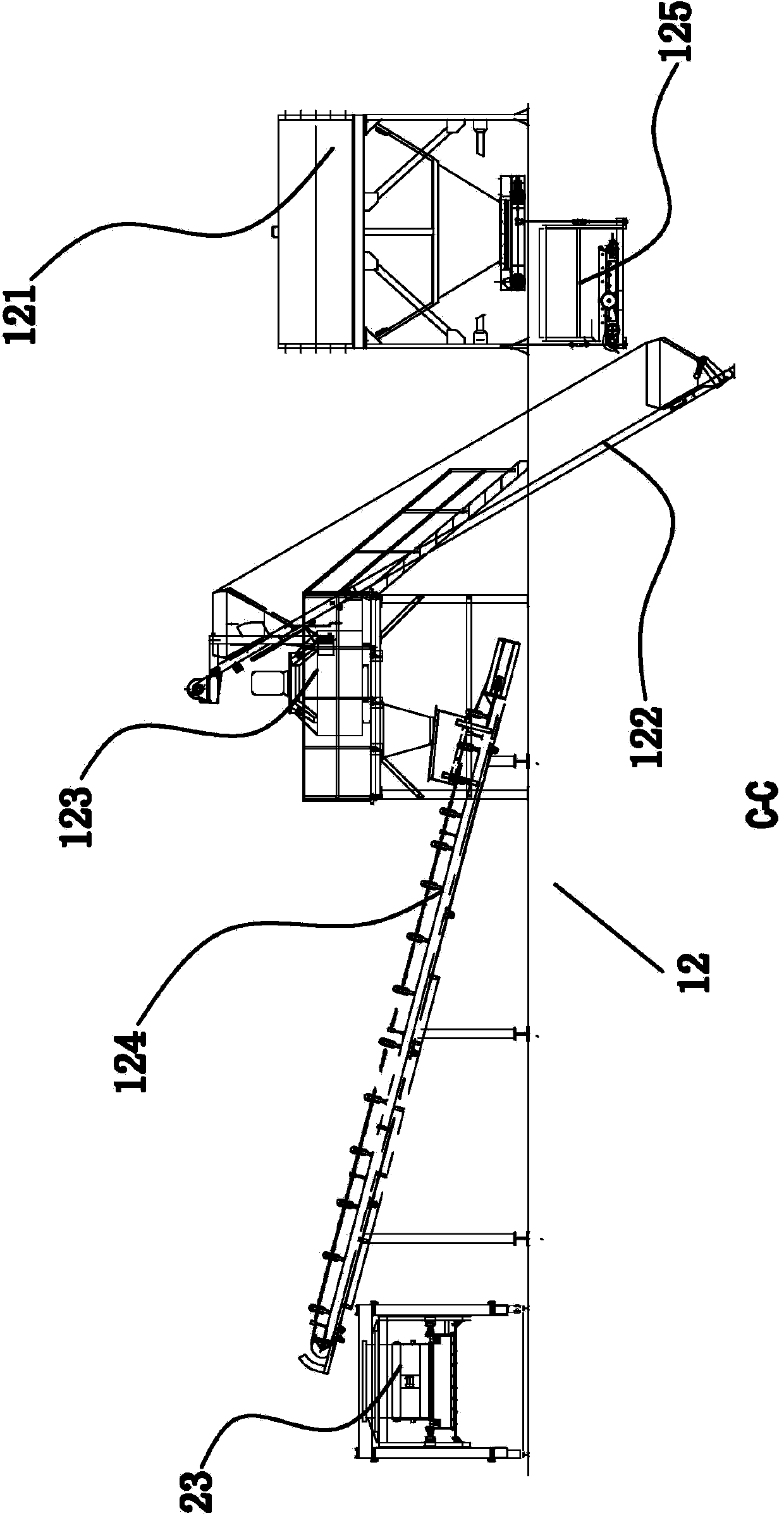

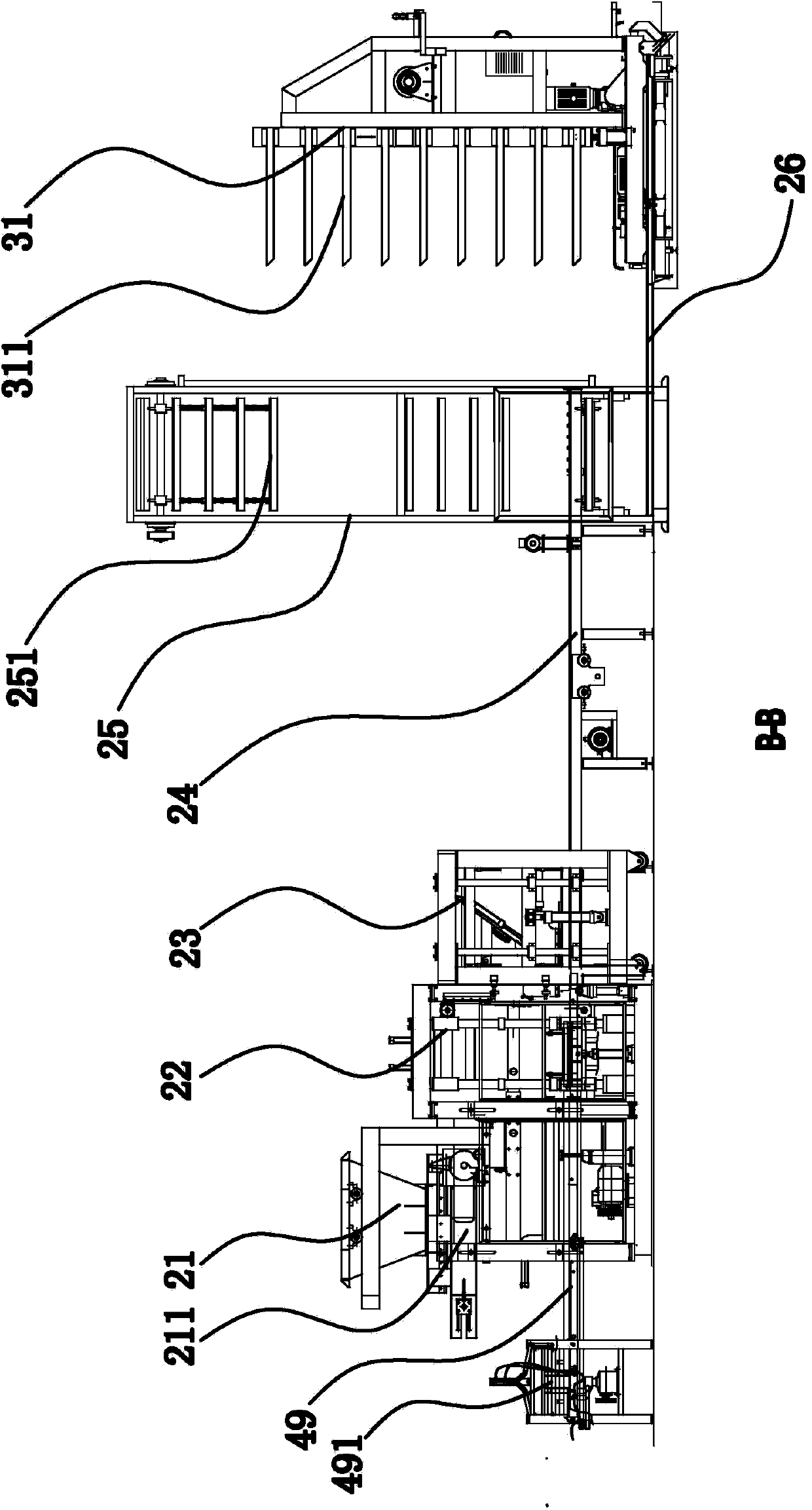

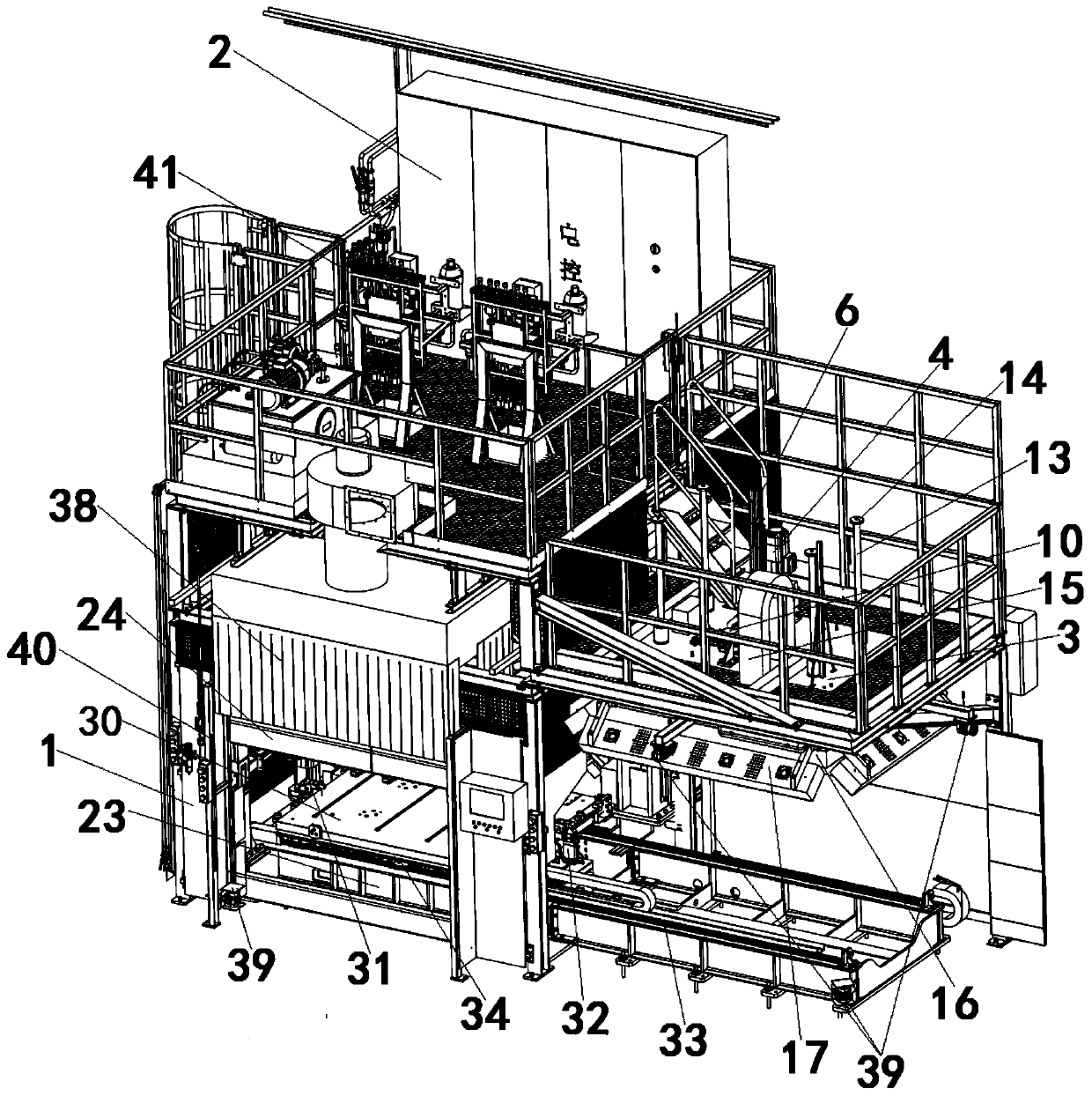

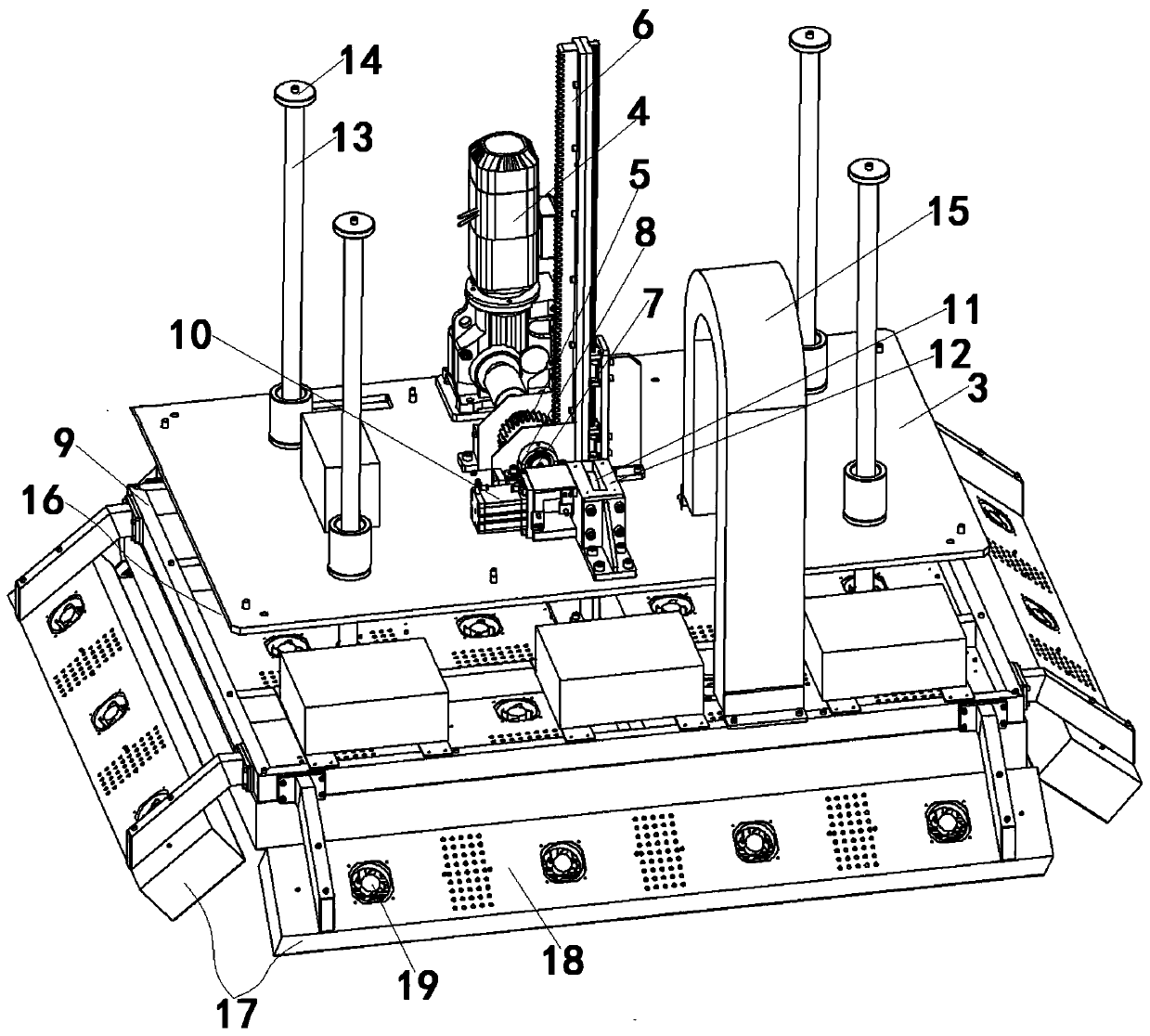

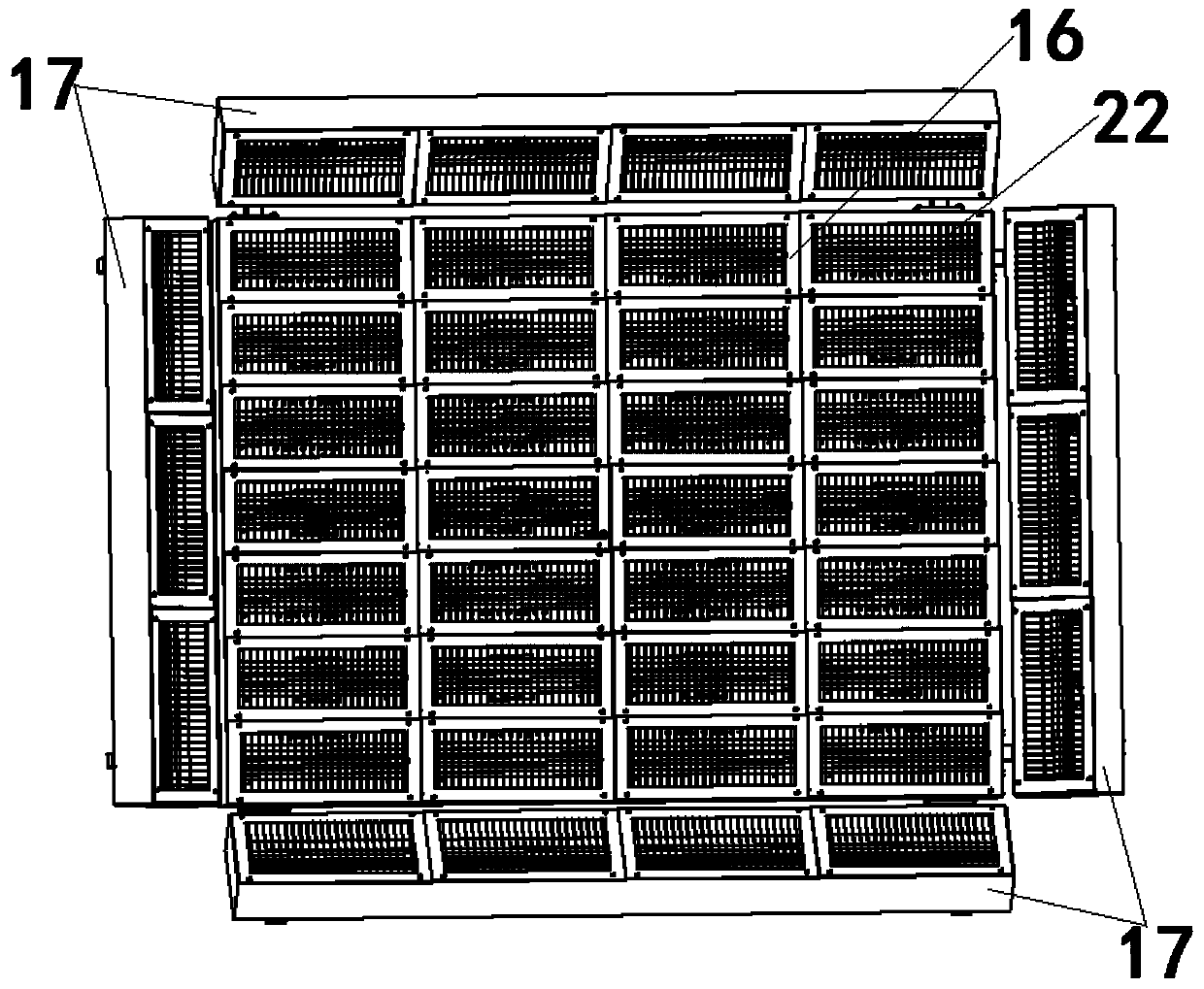

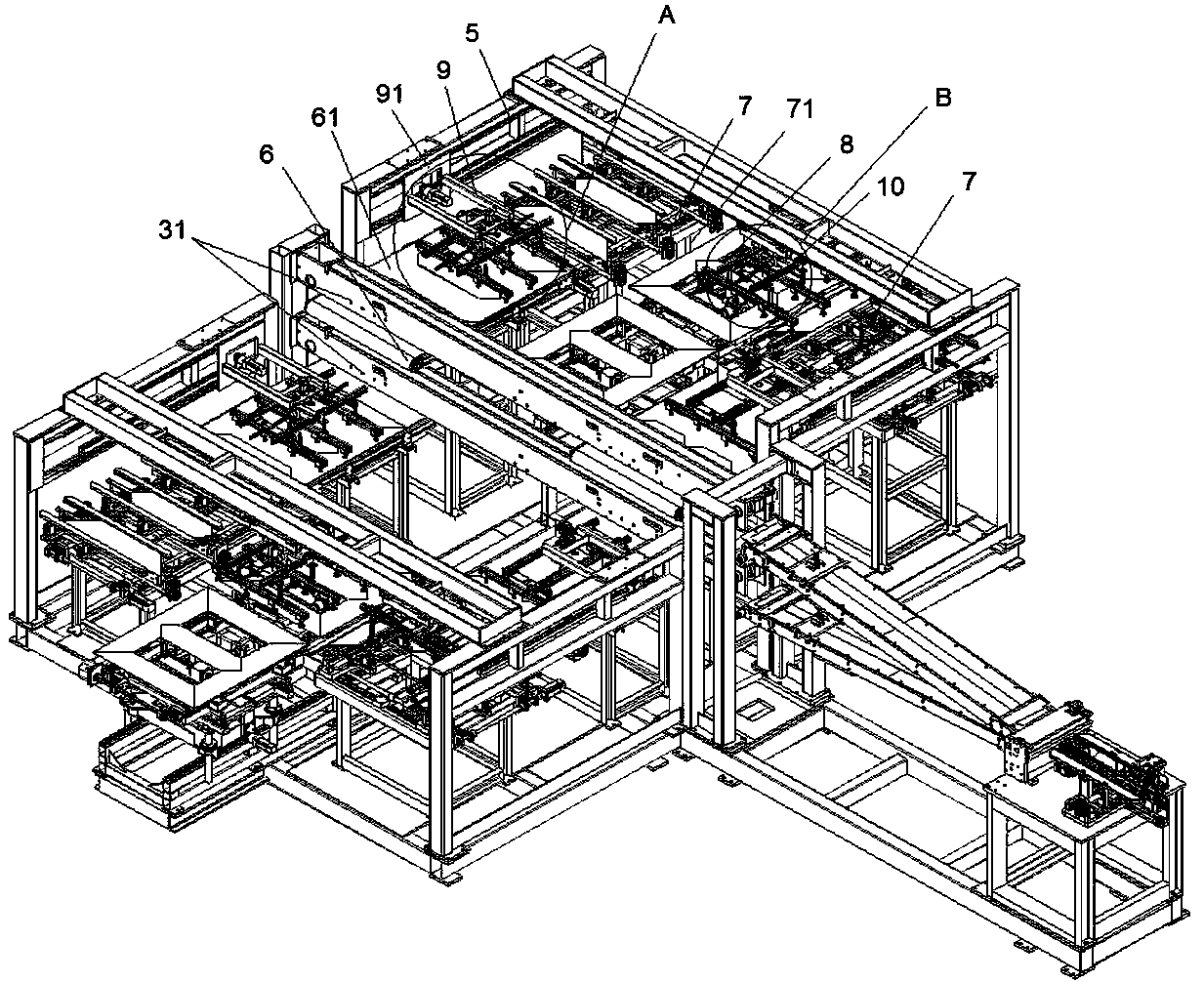

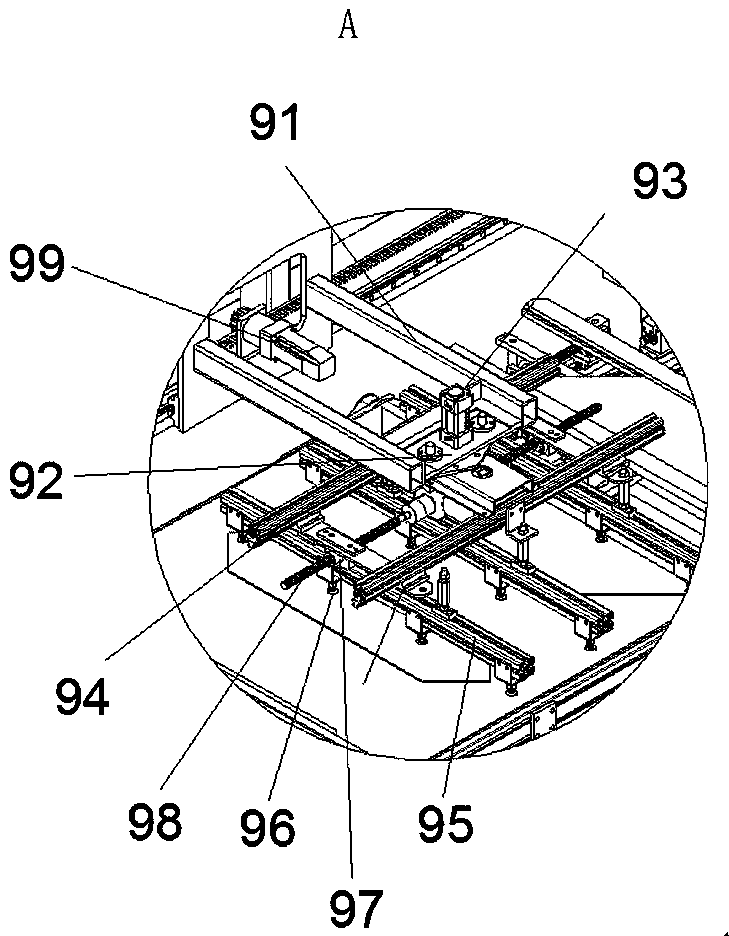

Automated building block production line

InactiveCN103737713AAccurate measurementControl the amount of fabricCeramic shaping plantsFeeding arrangmentsProduction lineAutomatic control

The invention provides an automated building block production line, and belongs to the technical field of operation and transportation. The automated building block production line solves the problems of an existing building block production line that control over feeding is inaccurate, the structure is unreasonable, and the system is not stable enough. The automated building block production line comprises a distributing system, a building block formation system, a maintenance system, a supporting plate recycling system and an automatic control system. The distributing system further comprises a shell fabric aggregate bin and a shell fabric weighing hopper used for weighing, so that a preset amount of shell fabric can be output accurately. The building block formation system further comprises a feeding machine and a secondary distributor, so that materials are fed to a blocking making machine in batches. The extension end of a supporting plate recycling conveyor line in the supporting plate recycling system is further provided with a supporting plate returning machine which pushes supporting plates on a plate overturning machine to a plate feeding machine. The automated building block production line has the advantages that feeding is accurate, stability is high, and arrangement is reasonable.

Owner:NINGBO NOAH INTELLIGENT EQUIP

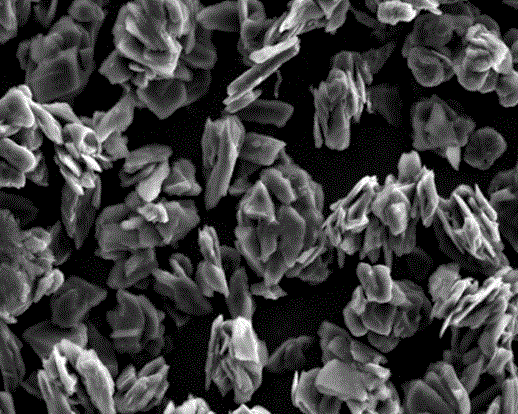

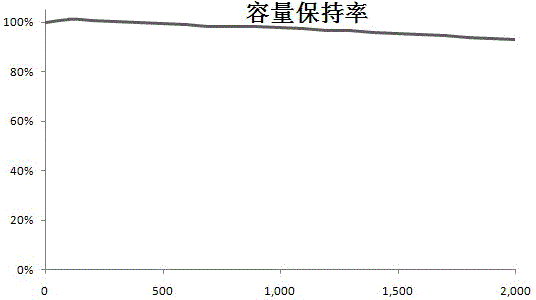

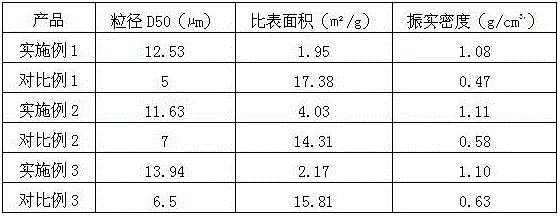

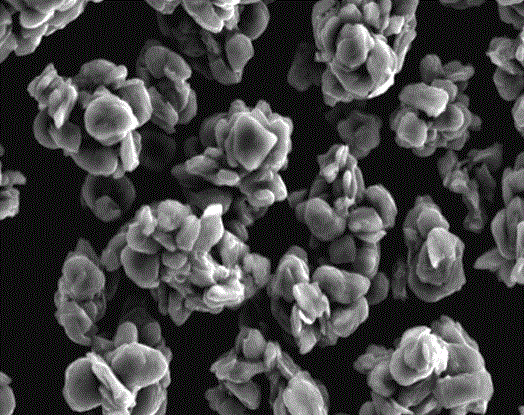

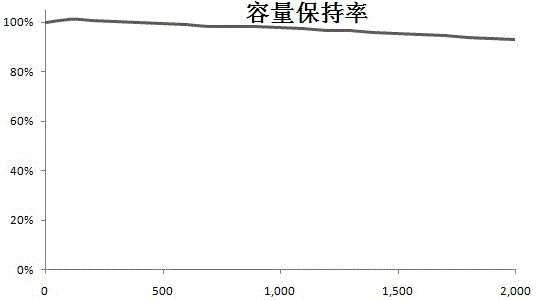

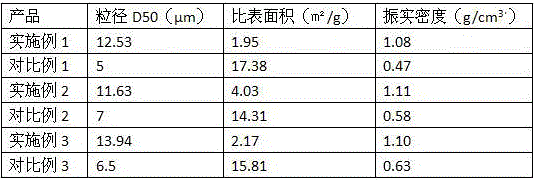

Preparation method for graphite anode material of lithium ion battery

InactiveCN105932281AReduce turnoverReduce lossesElectrode manufacturing processesSodium-ion batteryLithium-ion battery

The invention discloses a preparation method for a graphite anode material of a lithium ion battery. Fine graphite powder with a small particle size and an organic carbon source are taken as raw materials; through adoption of processes such as mixing, high temperature processing, graphitizing and sieving and through mixing of the fine powder and the organic carbon source in a heating environment, coating, kneading and secondary granulating effects can be realized; and under the adhering effect of the organic carbon source, the fine powder with the small particle size forms secondary particles. The anisotropy problem of the materials is solved, and the tap density of the materials is improved. According to the method, the turnover and device residual loss of the materials are reduced, the yield is high, the processes are simple, the energy consumption is low, the environment is protected, the surface coating effects of the materials are even, and the consistency is high. The prepared anode material is characterized in anisotropy, low iron impurity content, low initial irreversible capacity, low volume expansion, high liquid absorbency, high cycle performance, high cost performance and high comprehensive performance.

Owner:田东

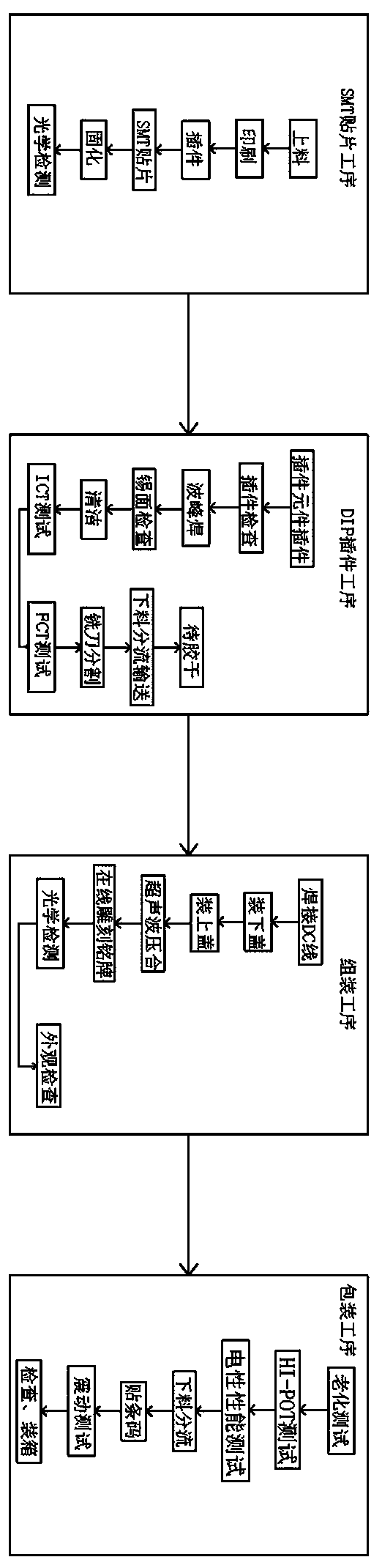

Automatic power supply production process

InactiveCN107801369AReduce logistics turnoverReduce manpowerElectrical componentsEngineeringMechanical engineering

An automatic power supply production process comprises the following steps of: sucking a PCB onto a transfer track, transferring to the SMT mounting and AI procedure, and carrying out SMT and automatic inserting and mounting operation on the PCB; after automatic PCB turnover, transferring to an AI machine via the track for the purpose of automatic insertion; transferring the PCB from the SMT / AI process to the transfer track, transferring along the transfer track to the DIP insertion process, and completing the insertion operation on the PCB; installing a PCBA board on a test carrier, then transferring by the transfer track, and automatically performing testing, dispensing, board dividing and blanking; transferring the PCBA board from the transfer track to a conveying belt, transferring thePCBA board to the assembly process via the conveying belt, performing DC wire welding on the PCBA board, and assembling the PCBA board in a shell to form a power supply product; transferring the assembled power supply product to the packaging process via the conveying belt, and completing the packaging automatically. By the invention, the production efficiency is high and the product quality is improved.

Owner:DONGGUAN MENTECH OPTICAL & MAGNETIC

Preparation method for artificial graphite negative electrode material for lithium ion battery

InactiveCN105958070ALow tap densityHigh tap densityCell electrodesSecondary cellsEnvironmental resistanceLithium-ion battery

Disclosed is a preparation method for an artificial graphite negative electrode material for a lithium ion battery. Artificial graphite coke powder with small grain diameter and an organic carbon source are taken as the raw materials; the raw materials are subjected to procedures of mixing, high-temperature treatment, graphitization treatment, sieving and the like; the coke powder and the organic carbon source are mixed in a heating environment, and the effects of coating, mixing and holding, secondary pelleting and the like can be achieved; the small-particle coke powder can form secondary particles under the cohesive action of the organic carbon source; therefore, the problem of anisotropy of the material is solved, and the tap density of the material is improved; meanwhile, the artificial graphite negative electrode material is capable of lowering the material turnover and equipment residual loss, high in yield, simple in procedures, low in energy consumption, environment-friendly, uniform in the coating effect on the surface of the material, and high in consistency; and in addition, the prepared negative electrode material has the characteristics of isotropy, low iron impurity content, low initial irreversible capacity, small volume expansion, high absorbency, high circulation performance, high performance cost ratio, excellent comprehensive performance and the like.

Owner:田东

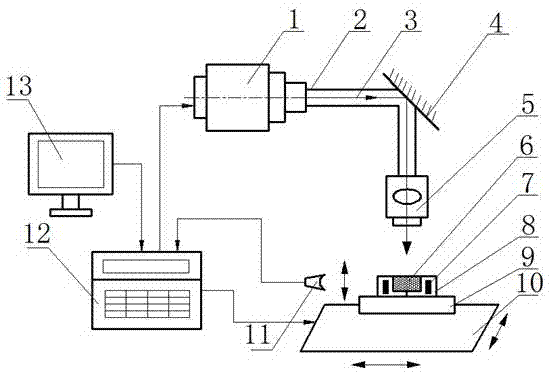

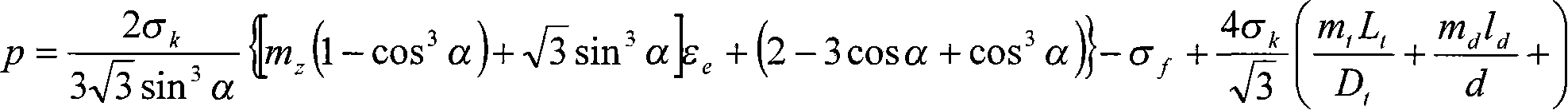

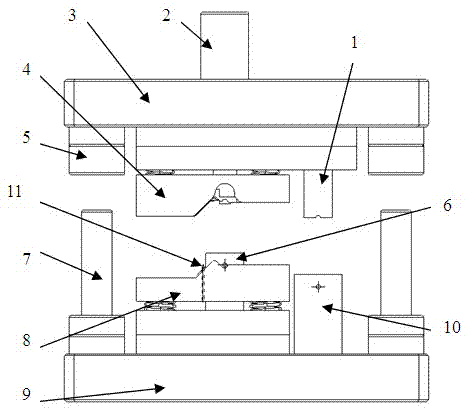

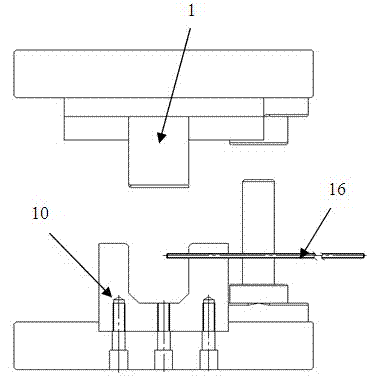

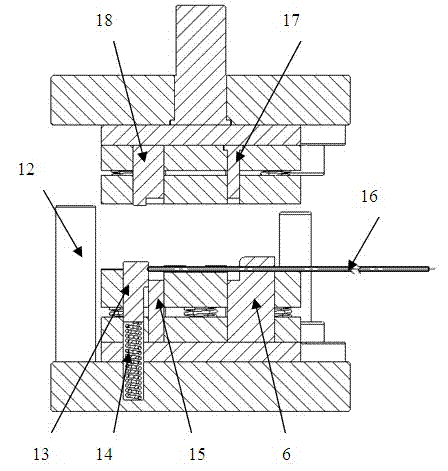

Forming method and device of anisotropic neodymium iron boron bonded permanent magnet

ActiveCN103170630AEasy to adjustImprove flexibilityInductances/transformers/magnets manufactureEpoxyMetallurgy

The invention discloses a forming method and device of an anisotropic neodymium iron boron bonded permanent magnet, belongs to the technical field of forming of bonded permanent magnets. According to the forming method and device, mixed powder of anisotropic neodymium iron boron magnetic powder, an epoxy resin binder and a curing agent is contained by adopting a split type mould, and is placed in a certain magnetic field for orientation, the mould and the mixed powder are heated to be up to a certain temperature through a resistor, and a laser impact irradiating the anisotropic neodymium iron boron powder directly is generated by using lasers to directly press the powder. According to the forming method and device, because a small amount of the binder is used and the pressure pressing of a higher laser impact wave is adopted, the magnetic property of a binding neodymium iron boron magnet is improved; and the powder is pressed when being heated, the forming procedure and the curing procedure are combined into one, and thus the circulation time of a product in the production process is reduced, the production period of the product is shortened, and the production efficiency is further improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

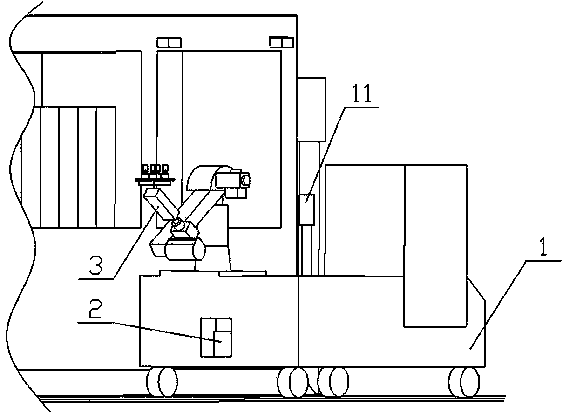

Full-automatic plate cleaning system

The invention discloses a full-automatic plate cleaning system, which comprises an AGV (automatic guided vehicle), wherein the AGV is provided with a laser navigation system, the front and back parts of the AGV are respectively provided with a radar scanning head, the AGV is provided with a robot, the front end of the robot is provided with a scraper combining device, and the robot of the AGV automatically travels and positions in a chemical fiber workshop, and automatically cruises and positions according to the position of the area needing plate cleaning, so the automatic plate cleaning is realized. The system has the advantages that the heavy manual plate cleaning is replaced, the uniformity of plate cleaning is guaranteed, the quality of plate surface is guaranteed, and the quality of products is improved; the labor strength of workers is decreased, so the demission rate of workers is reduced; the operation is flexible, the position and attitude of space are flexible, the moving speed is high, the plate cleaning efficiency and quality are high, the system is suitable for flexible automatic production lines, and the purposes of improving production efficiency and saving labor are realized.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

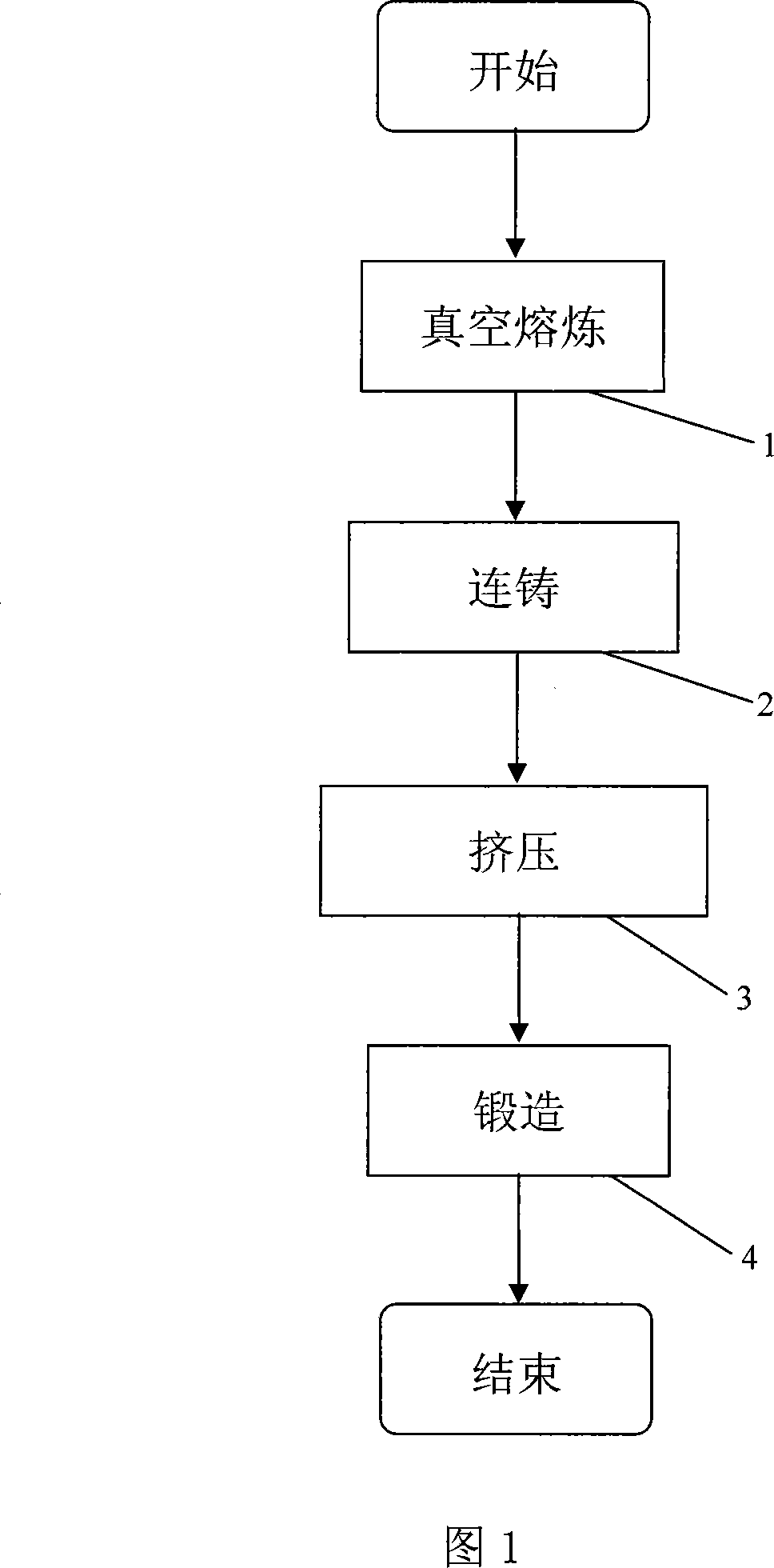

Technique for processing high-strength high-tractility magnesium alloy member

InactiveCN101121980AAvoid secondary oxidationGuarantee casting safetyExtrusion control devicesSteering controlElectromagnetic pump

The invention discloses a technology of processing a magnesium alloy with high intensity and flexibility, which subsequently includes vacuum melting, continuous casting, extrusion, forging and such procedures. The invention reasonably matches the solution body composition and the metamorphism liquid during casting process, and the grains are refined through the chilling action of a crystallizer at first; the magnesium alloy liquid is transmitted by an electromagnetic pump so as to prevent secondary oxidation and ensure safety in casting of the magnesium alloy; and then further refining the grains through electromagnetic mixing power, large ratio extrusion and heat treatment secondary crystallization, which effectively ensures tiny enough isometric crystals can be obtained from the alloy microstructure. The magnesium alloy elements of the automotive steering control arms, support elements of motorcycles and bicycles, can be obtained for the first time by the improvement, which are fully filled, good in surface quality, fine and even in grain size, reasonable in streamline distribution and without disordered streamline, vortexing and draining phenomena. The invention combines a plurality of technological processes into a production cycle, which reduces the turnover links, saves energy and reduces cost.

Owner:王仁辉

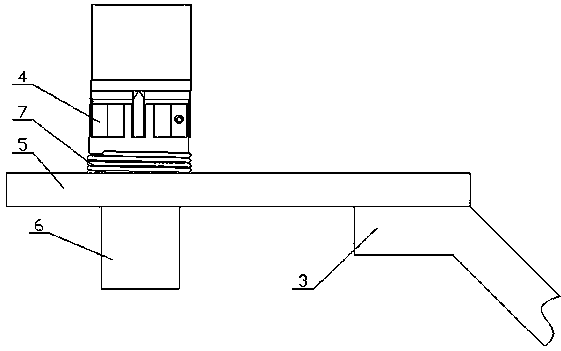

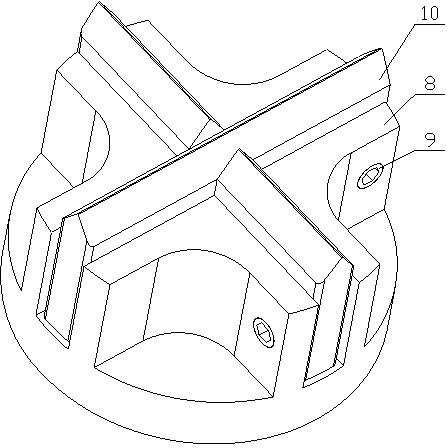

Special fixture of drill blade top centre hole for blade

ActiveCN101372046AReduce overall man-hoursReduce turnoverDrilling/boring measurement devicesPositioning apparatusEngineeringDrill bushing

The invention relates to a special clamp for drilling a blade tip centre hole and used for a blade. The special clamp is suitable for drilling blade tip centre hole of the blade with a plurality of sizes and has wide range of application. The special clamp comprises a jig body, an upper drill plate, a drill bush. The jig body is internally provided with a locating base; the two sides of the locating base and the side wall of the jig body are provided with a side locator key; the special clamp is characterized in that: the two side of the upper drill plate is embedded on the side locator key; the bit bush is inverted on the upper drill plate; the exit and the opening of the bit bush are arranged on the bottom of the upper bit panel; the jig body, the locating base and the upper drill plate have the same centre.

Owner:WUXI TURBINE BLADE

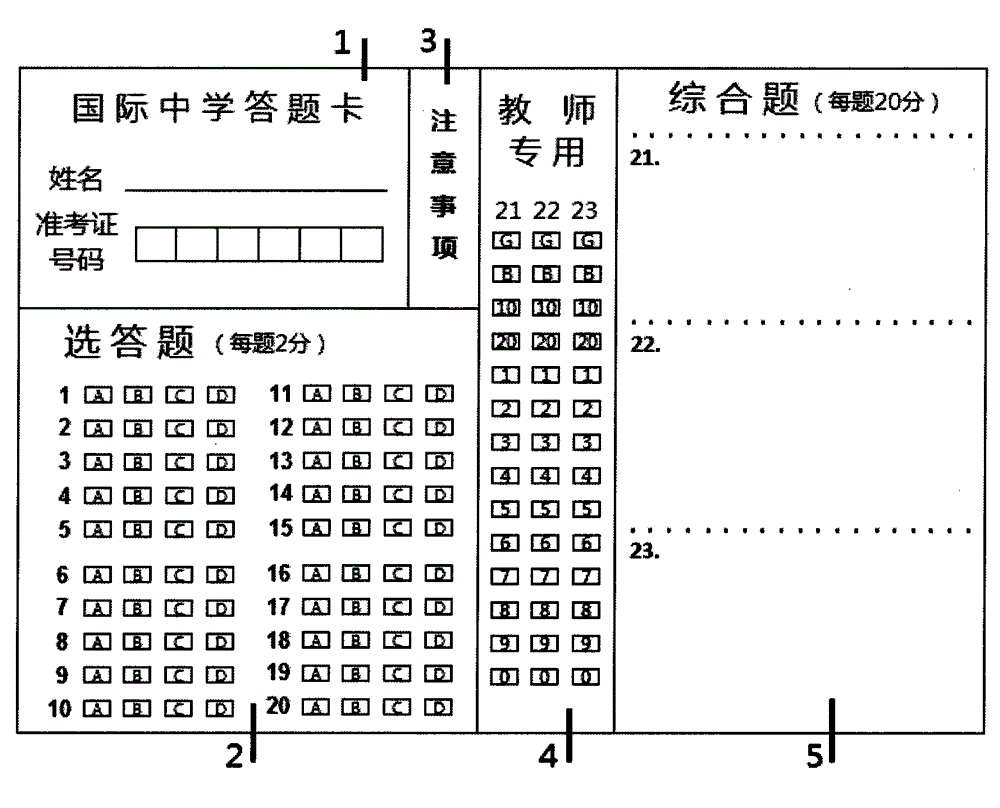

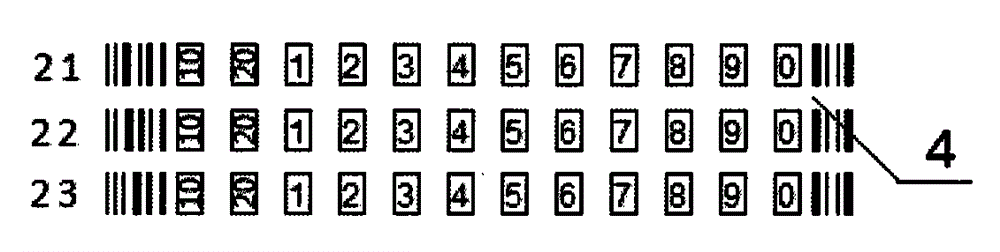

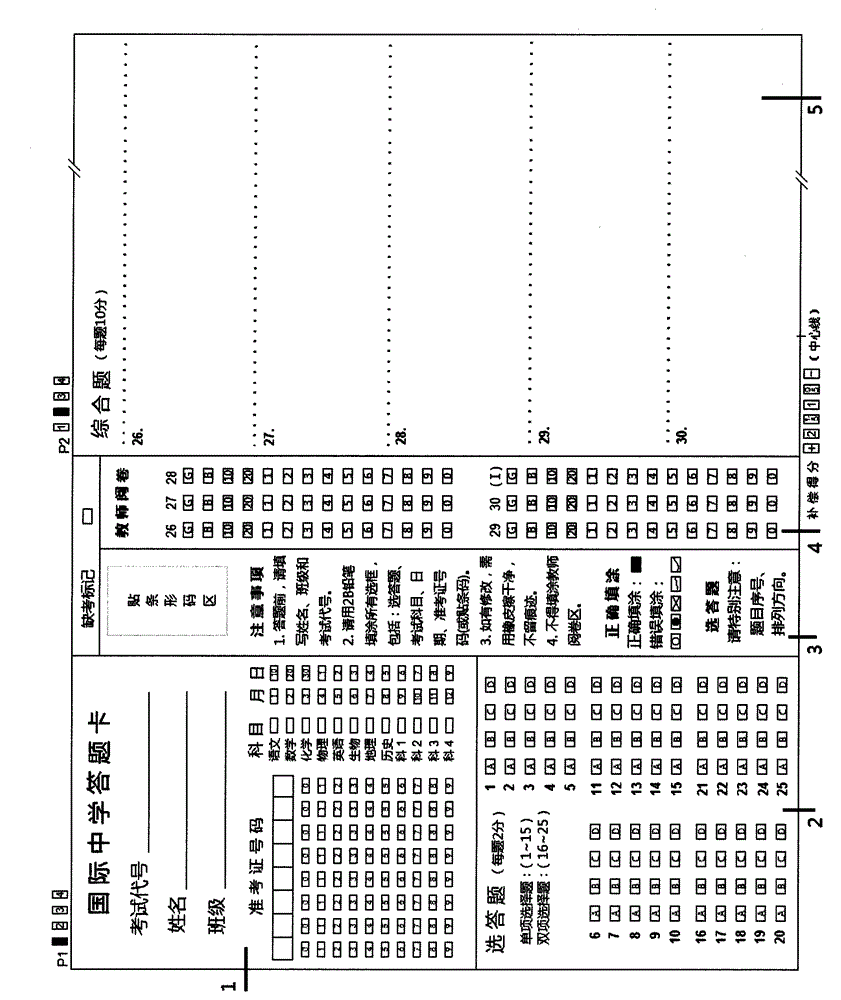

Answer sheet used for automatic paper scanning and inspecting and application method thereof

The invention provides an answer sheet used for automatic paper scanning and inspecting and an application method thereof, and belongs to the technical field of image-text printing, image recognition and automatic data acquisition. The answer sheet comprises an answer sheet information area, an objective item answer selecting area, a subjective item answering area and a subjective item score teacher-marking area. Especially, subjective item score marking frames are fixed and positioned, and the answer sheet can be a universal standard answering sheet, or, positions of answering bar codes are freely arranged. The application method of the answer sheet includes the following steps that the answer sheet is edited and manufactured, an examination is conducted, subjective items are read over by teachers, scores and good and bad answers are marked by the teachers, the answer sheet is scanned, objective items are automatically read over by a system, the scores of the subjective items are counted, and a score assessment report for all the items is generated. The system has the advantages that read-over of the objective items and scoring of the subjective items can be simultaneously completed and the scores of all the items can be assessed and reported through one-time scanning, and the answer sheet is easy to edit, high in image recognition efficiency and accuracy and convenient to use.

Owner:季争鸣

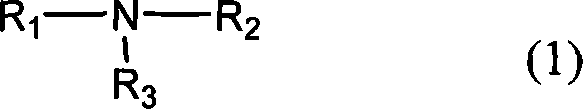

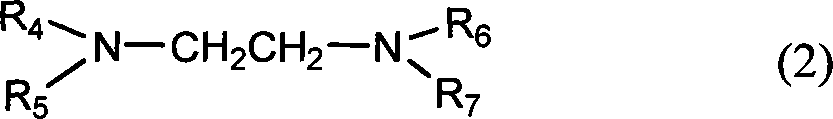

Composite liquid for increasing early strength of concrete mixed with polycarboxylate additive

The invention relates to a compound liquid for improving the early strength of the concrete mixed with polycarboxylate additive and a preparation method thereof. The compound liquid is prepared with the following components in weight proportion: 25-40percent of water soluble sulphate, 3-6 percent of organic alkoxyl amine and the rest is water. The preparation method is: 1) water is put into a reaction vessel and heated to 40DEG C- 60DEG C, and organic alkoxyl amine is added and well stirred; 2) water soluble sulphate is added and stirred to form a homogenous solution. The preparing process of the invention is simple and easy to apply; the invention does not corrode steel, and does not affect the condensation of concrete and reduce the later strength of concrete. The addition of the compound liquid is 0.5-1.5 percent of cementing material content and can improve the compressive strength of the concrete by 30-60 percent in 16h, by 25-40percent in 1d and by 15-25 percent in 3d, and the compressive strength of the concrete does not fall in 28d, which greatly shortens maintenance period, expedites construction progress, advances turnover rate of template, shortens construction period and lowers cost.

Owner:JIANGSU SUBOTE MATERIAL

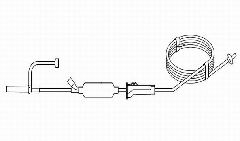

Infusion apparatus assembly process

InactiveCN101797407AEasy to assembleReduce pipe wrapping operationsInfusion devicesInfusion setWork in process

The invention relates to an infusion apparatus assembly process, which comprises four steps of conduit extrusion, accessory assembly, leakage detection and packaging. The accessory assembly is that assembled semi-finished accessories such as a puncture outfit, a drop funnel, a flow regulator and a liquid medicine filter are directly assembled on a conduit; and after extrusion and cutting, the conduit is directly wound, is shaped by a tape and always keeps the winding state in the operating processes of accessory assembly, leakage detection and packaging. After the leakage detection, the conduit is communicated with other accessories and then is directly packaged into a bag to form an infusion apparatus product. The process effectively combines conduit extrusion, cutting, winding, assembly, leakage detection and packaging, reduces the turnover to and fro between various working procedures, reduces overstocked products of the various working procedures, and has the advantages of high production efficiency and reliable work.

Owner:SHANDONG WEIGAO GROUP MEDICAL POLYMER

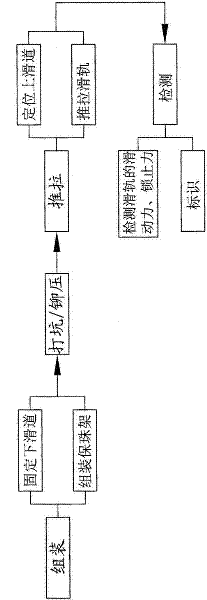

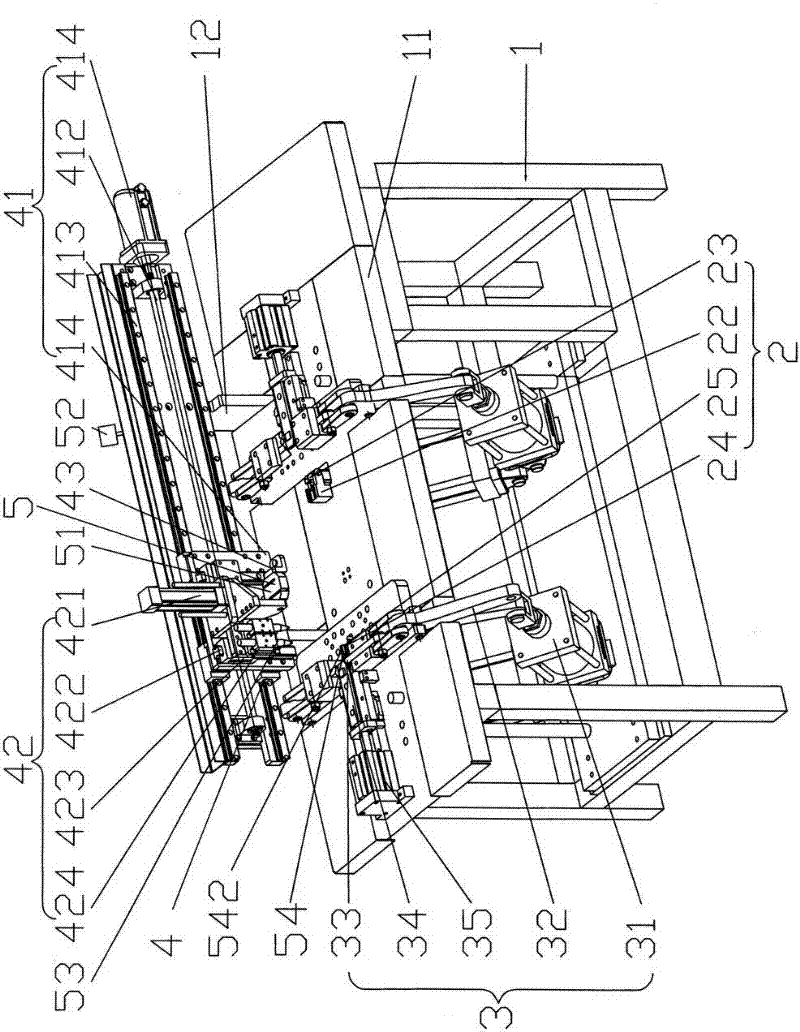

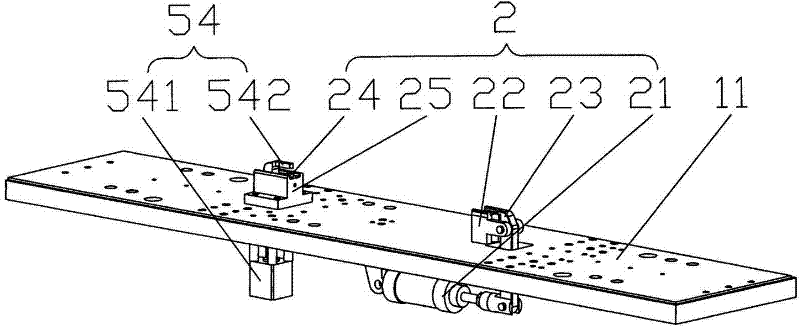

Method for automatically assembling and detecting sliding rail and device used in same

ActiveCN102513821AImprove consistencySave human effortAssembly machinesApparatus for force/torque/work measurementControl engineeringMachining

The invention provides a method for automatically assembling and detecting a sliding rail and a device used in the method and belongs to the technical field of assembly and detection of sliding rails. The method comprises an assembling step, a digging and / or riveting step, a pushing-pulling step and a detecting step, wherein the assembling step comprises of the following working procedures: fixing a lower sliding assembly of the sliding rail and assembling a bead protection frame; the digging and / or riveting step comprises the following working procedures: digging and / or riveting; the pushing-pulling step comprises the following working procedures: positioning an upper sliding assembly and pushing and pulling the sliding rail; and the detecting step comprises the following working procedure: detecting the sliding force, locking force and a mark of the sliding rail. The method disclosed by the invention has the following advantages: a machining flow integrating sliding rail assembling, digging and / or riveting, pushing-pulling and detecting can be realized without being operated by a plurality of people, so that the labor is saved, the turnover times can be reduced, the efficiency is improved, and the consistency of the assembled sliding rail is good; various properties of the sliding rail can be accurately detected; and the method disclosed by the invention has the advantages of high automation degree, reliable transmission balance, high precision and good consistency.

Owner:JIANGSU ZHONGMING XIANGHE SEIKO

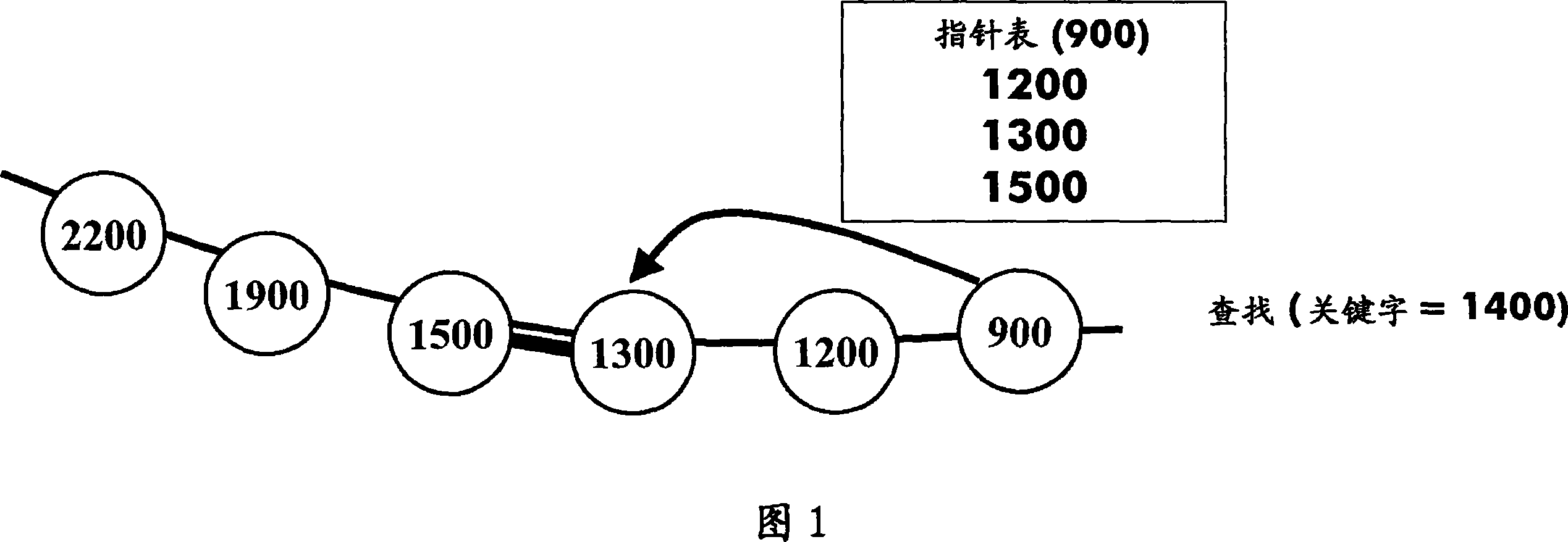

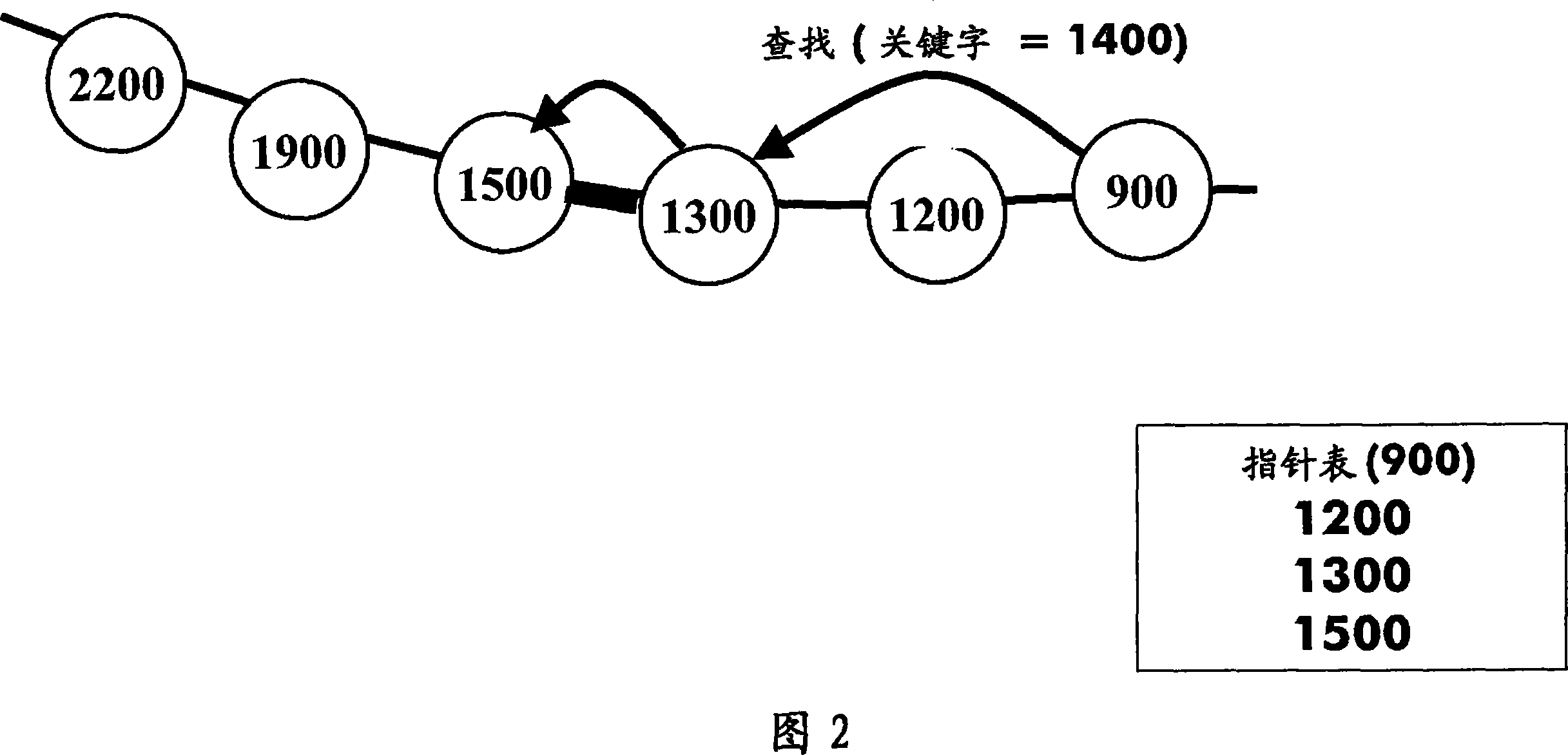

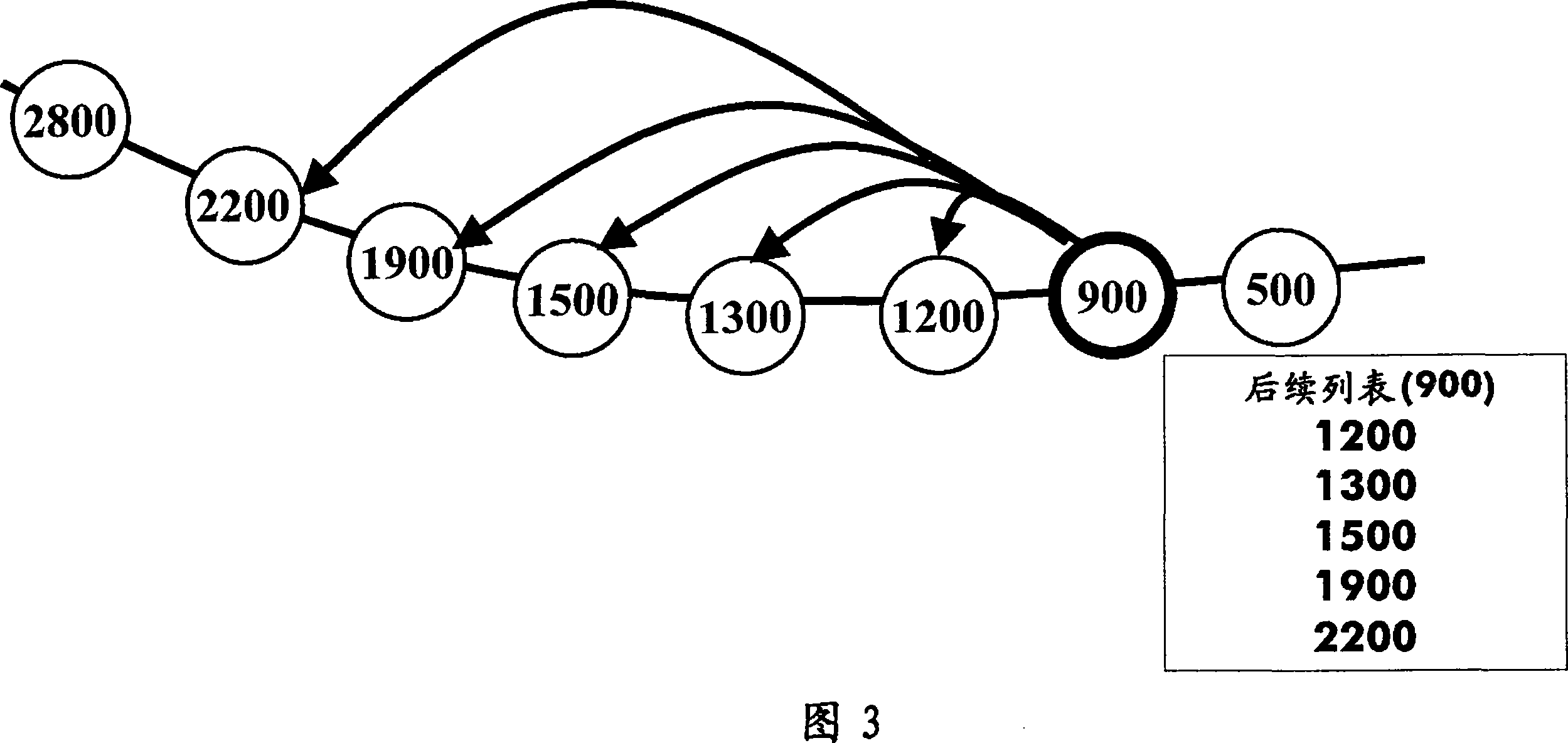

Distributed hashing mechanism for self-organizing networks

InactiveCN101102250AReduce loadHigh Data Consistency LevelDigital data information retrievalError preventionHash functionComputer software

The invention concerns a method for retrieving content of a distributed directory of a telecommunication system comprising a plurality of nodes (900,..., 2200) arranged in a directed ring topology, the method comprising the steps of identifying a storage location of said content by means of a distributed hashing function, where the hashing function maps an element onto a node, where the node (1300) is responsible carrying elements with a hash value between the node and its successor node. The invention further concerns a corresponding computer software product, telecommunication device, and a telecommunication system.

Owner:ALCATEL LUCENT SAS

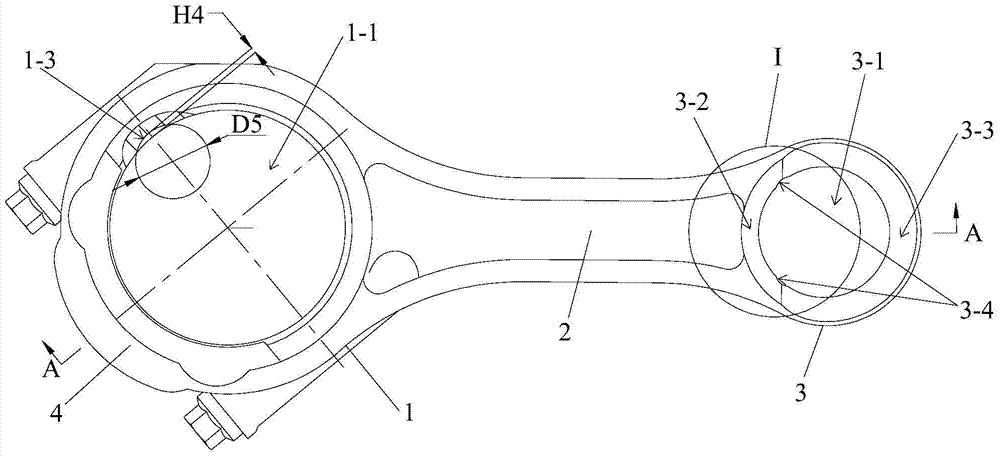

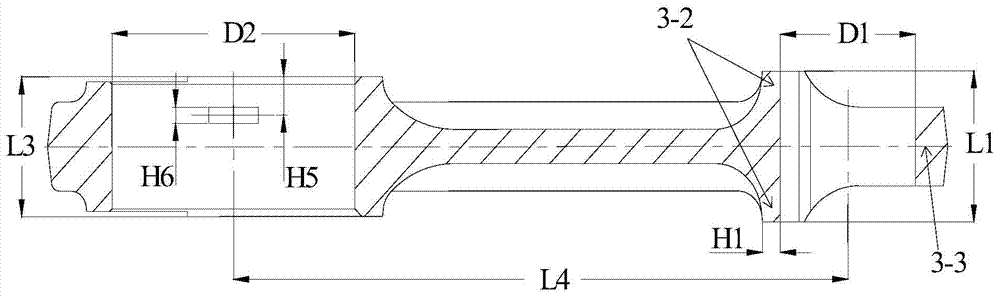

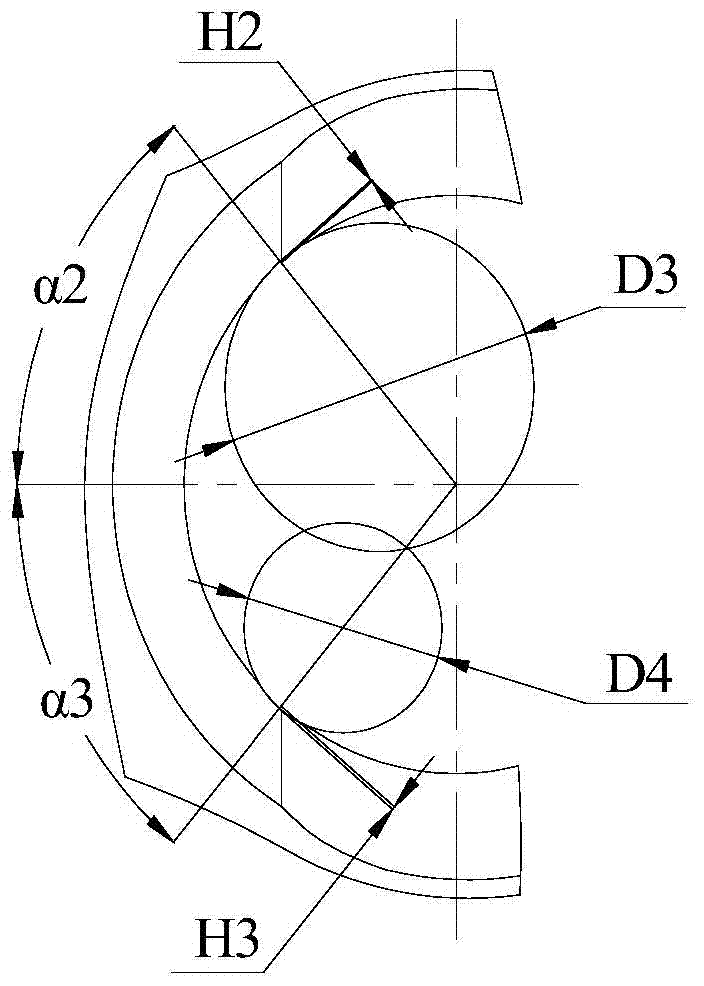

Manufacturing method of hard-base soft-structure internal combustion engine connecting rod

ActiveCN103921097AThe principle is simpleSimple and reliable manufacturing processMetal working apparatusBatch productionEngineering

The invention discloses a manufacturing method of a hard-base soft-structure internal combustion engine connecting rod. The method includes the following steps of forging of a blank, coarse grinding of end faces, boring, rough boring of a large-head hole and a small-head hole, chamfering of the large-head hole, threaded hole machining, fracture splitting of a large-head end and assembling, accurate grinding of the end faces, semi-fine boring of the large-head hole and the small-head hole, tegular groove milling and oil groove boring, fine boring of the large-head hole and the small-head hole, flat grinding of the large-head end, parkerizing of the small-head hole, and cover removing, cleaning and assembling. The connecting rod comprises the large-head end, a rod body and a small-head end, the large-head end and the small-head end are arranged at two ends of the rod body respectively, the connecting rod is of an integral structure, and a connecting rod cover is arranged at the large-head end of the connecting rod. The manufacturing method is simple in principle, a manufacturing technique of a traditional internal combustion engine connecting rod is improved to provide a feasible and reliable manufacturing technique for the hard-base soft-structure internal combustion engine connecting rod, and particularly precision and performance of a soft structure of the small-head end of the connecting rod are guaranteed. Meanwhile, the method has the advantages of simple technique and low manufacturing cost, and is convenient for batch production.

Owner:广东四会实力连杆有限公司

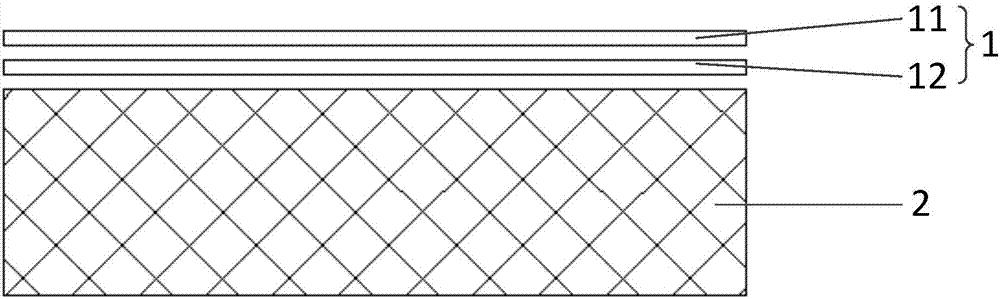

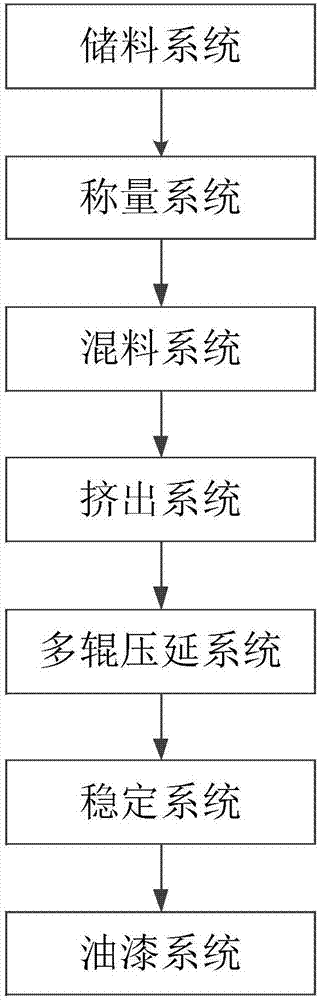

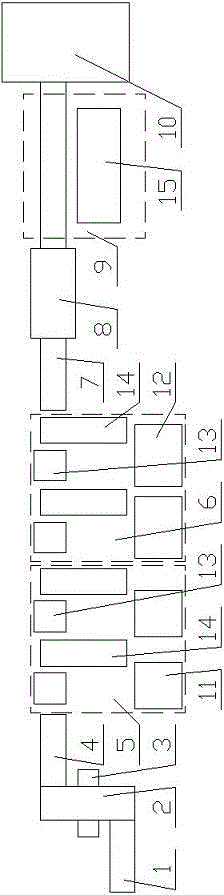

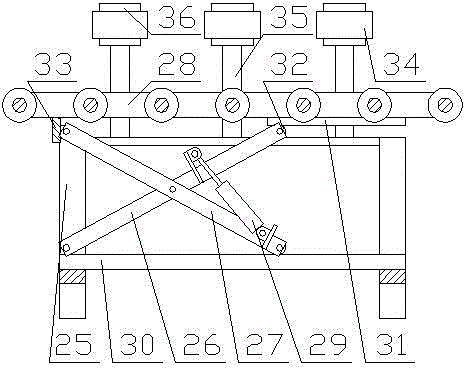

Resin composite board and production method thereof

InactiveCN107031136AWill not containReduce turnoverSynthetic resin layered productsPaper/cardboard layered productsSurface layerAdhesive

The invention provides a resin composite plate and a production method thereof. The resin composite board includes a surface layer and a resin composite base material, and the surface layer and the resin composite base material are bonded by melting without using an adhesive. The resin composite substrate is extruded through the extrusion system, and the surface layer and the newly extruded resin composite substrate are sent to the multi-roll calendering system together, and the surface layer is formed by using the heat of the multi-roll calender system and the newly extruded resin composite substrate It is melted and pressed together with the resin composite substrate. The resin composite board of the present application will not contain toxic and harmful substances such as formaldehyde due to the use of adhesives. In the production method of the resin composite plate of the present invention, continuous production can be realized by using the extrusion system and the multi-roller calendering system, which can reduce material turnover, reduce labor costs, reduce material loss, and achieve low energy consumption and stable product performance , short production cycle and so on.

Owner:WELLMADE FLOOR IND CO LTD

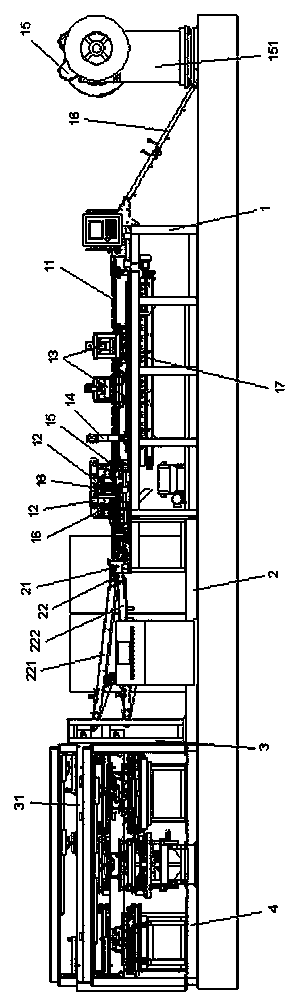

Elevator door plate production line

ActiveCN105728583AFully automatedIncrease productivityMetal-working feeding devicesStripping-off devicesProduction linePunching

The invention discloses an elevator door plate production line. The elevator door plate production line sequentially comprises a blank feeding device, a feeding transfer rack, a punching device, a bending device, a riveting device, a rib applying area and a blanking transfer rack. A conveying rack A is disposed between the punching device and the bending device. A conveying rack B is mounted between the bending device and the riveting device. The feeding transfer rack is disposed above the feeding device, the punching device and the conveying rack A. The conveying rack B is connected with the blanking transfer rack through the riveting device and the rib applying area. According to the structure of the elevator door plate production line, automatic production of elevator door plates is achieved, the production efficiency of the elevator door plates is improved, and the labor cost is effectively reduced.

Owner:JIANGYIN FIVE STAR WELDING COPPER

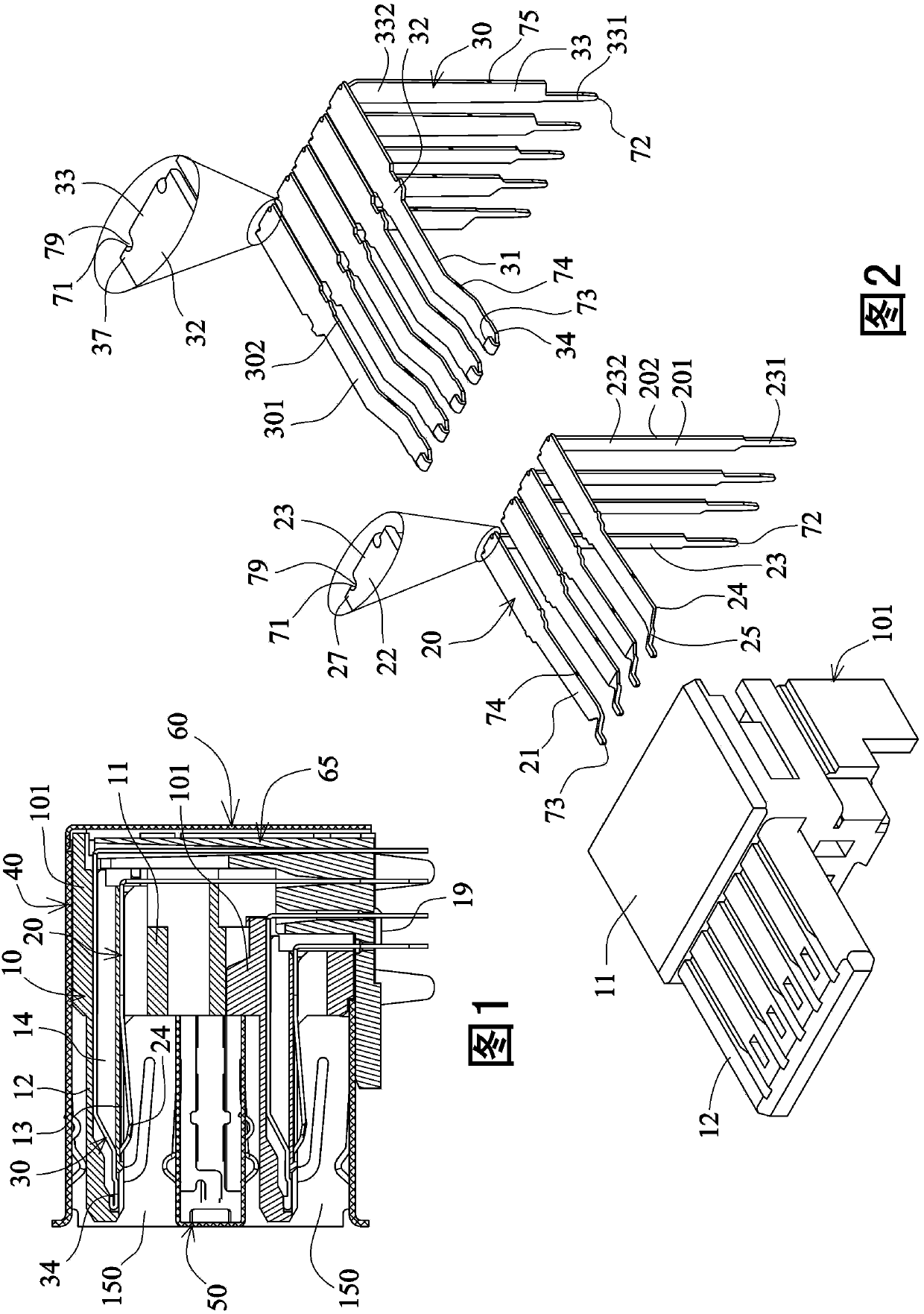

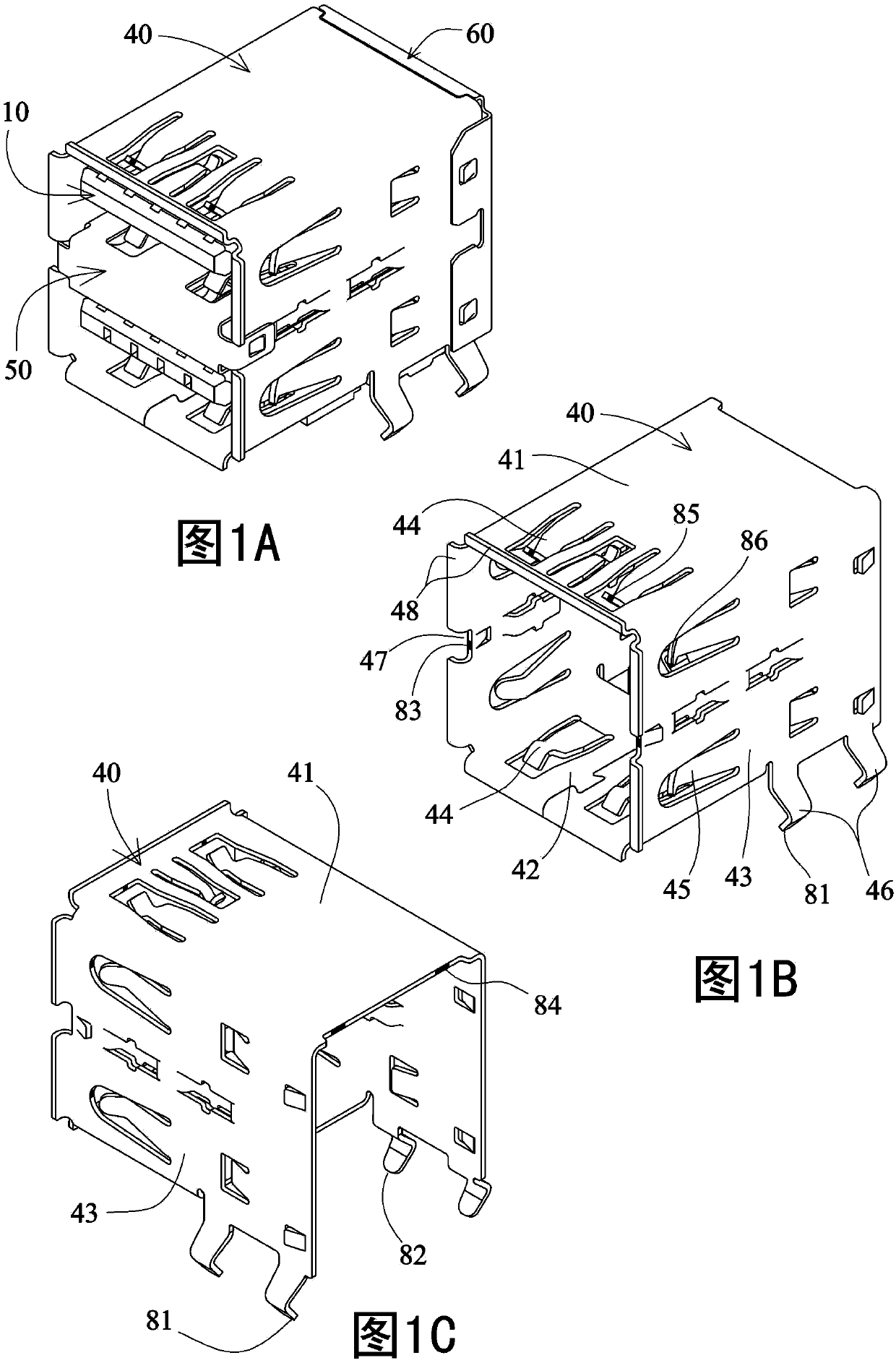

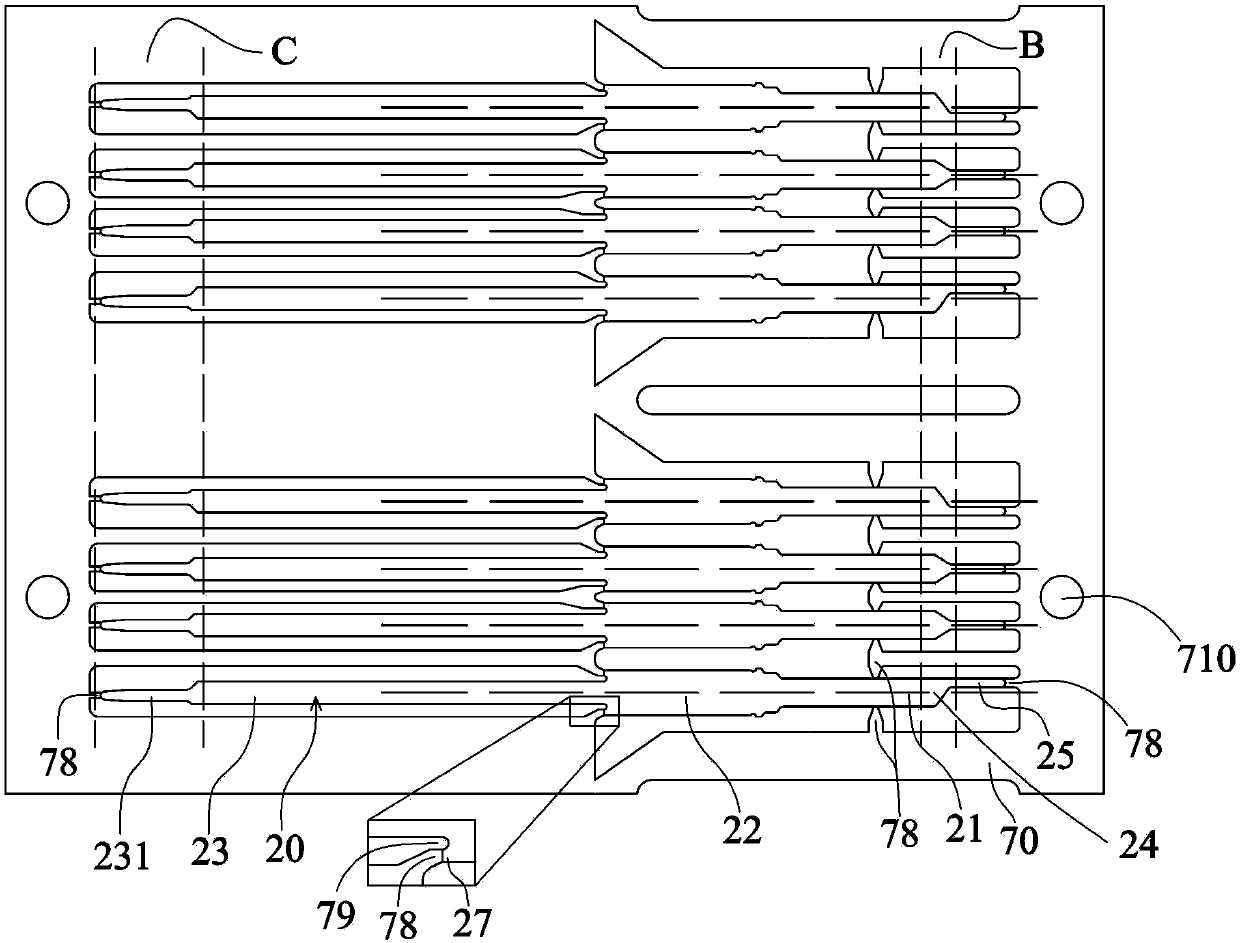

Electric connector and manufacturing method thereof

InactiveCN103996956AImprove efficiencyImprove yieldContact member manufacturingContact member assembly/disassemblyElectricityPunching

The invention provides an electric connector comprising an insulated seat body, at least one connecting portion, and at least one terminal. The at least one connecting portion is arranged at one end of the insulated seat body. The at least one terminal is arranged at a plastic seat body; a board plane and a punching plane are arranged at the outer surface of the terminal; the board plane of the terminal is provided with an extending portion, a fixed portion and a connecting pin by punching and bending in an integrated mode and an electroplating layer is arranged at the outer surface; the fixed portion and the insulated seat body are fixed; the extending portion is connected to one end of the fixed portion and is provided with a contact portion that is arranged at the connecting portion; and the connecting pin is connected to one end of the fixed portion and extends out of the insulated seat body, wherein the board plane of the fixed portion is wider than that board plane of the connecting pin. The electric connector is characterized in that at least one side of one end, connected to the connecting pin, of the fixed portion of the terminal is provided with a first electroplating layer-free fracture surface; and the terminal is also provided with at least another electroplating layer-free fracture surface beside the first electroplating layer-free fracture surface.

Owner:蔡周贤

Integrated heating incombustible smoking product

PendingCN110839953AAvoid Monopoly RestrictionsSimplify the manufacturing processCigar manufactureProcess engineeringIndustrial engineering

The invention discloses an integrated heating incombustible smoking product, which comprises a smoking product; the smoking product comprises a lip-close section and a lip-far section; and, a different-unit section consists of a filtering unit, a gel cooling fragrant-carrying unit, a hollow special particle unit, a hollow supporting unit, a cavity unit, a separation film unit and a smoking unit. The integrated heating incombustible smoking product is unnecessary to be compositely prepared by a filter stick compound machine and is unnecessary to be refitted by a cigarette making machine; and compared with the prior preparation method, the preparation process is simplified, the turnover link is reduced, the current tobacco monopoly limitation is evaded, the preparation cost is reduced, and simultaneously the combinations and the selections of more functional units are given.

Owner:YUNNANHENGGANGSCIENCE&TECH LTD

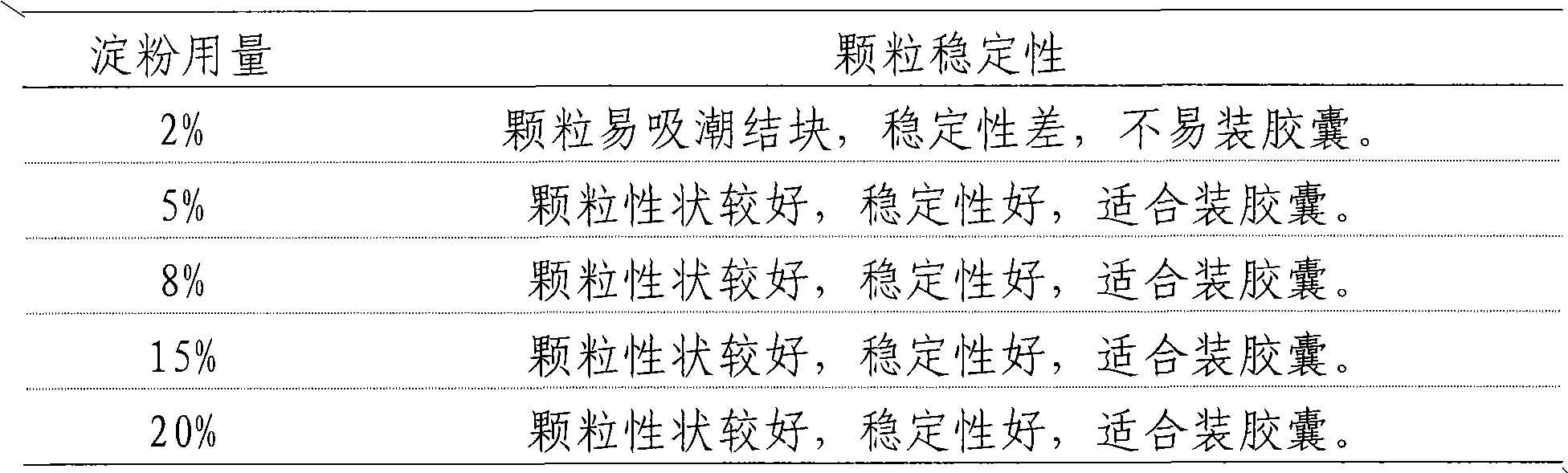

Preparation method and quality control method of traditional Chinese medicine preparation for treating bronchitis and bronchial asthma

ActiveCN101829216ADisintegrates quicklyImprove bioavailabilityAnthropod material medical ingredientsComponent separationChronic asthmatic bronchitisClinical efficacy

The invention discloses a preparation method and a quality control method of a traditional Chinese medicine preparation for treating bronchial asthma, chronic asthmatic bronchitis, emphysema and early pulmonary heart diseases. The preparation method is characterized by being a preparation method of a cough-relieving capsule as a traditional Chinese medicine preparation formed by reforming a cough-relieving tablet, optimization and screening are carried out on an extraction process, and modern new equipment and new method are adopted so as to be suitable for large-scale industrial production; the research on the quality standard is to perfect and improve on the basis of the original standard to establish a perfect method for thin bed identification and content determination so that the quality standard of a product is advanced and controllable, and the clinical effect is ensured.

Owner:SHANDONG MINGREN FURUIDA PHARMA

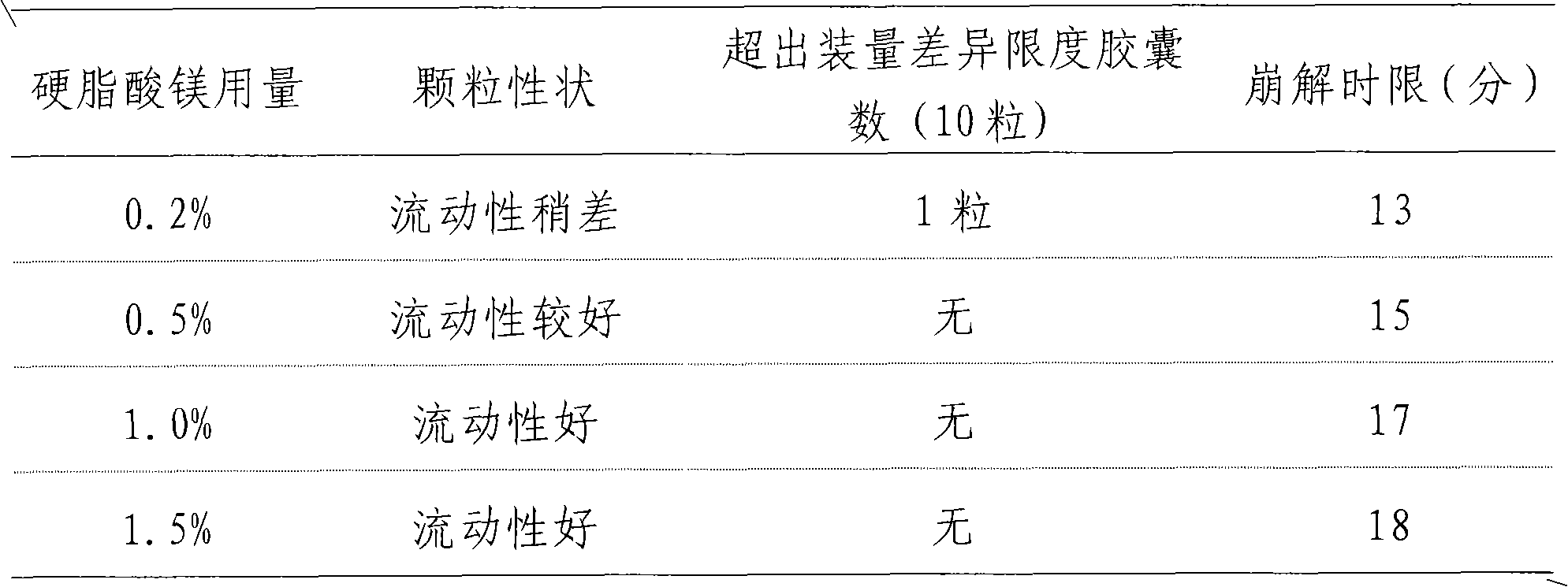

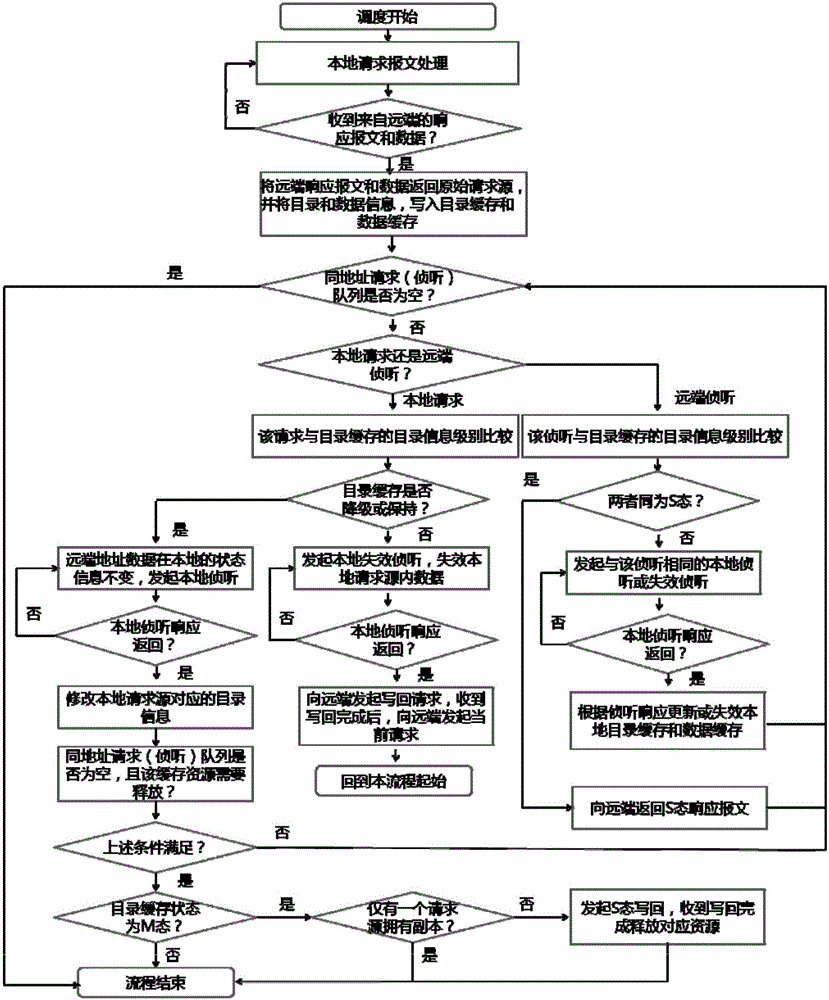

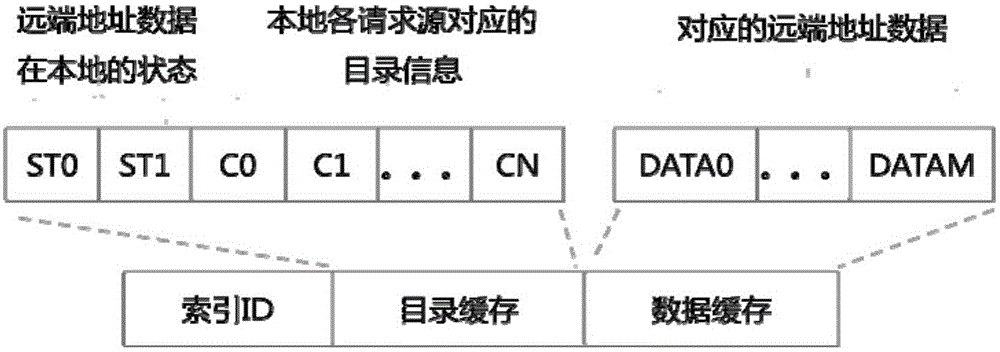

Method and system for conducting consistency processing on caches with catalogues of far-end agent

ActiveCN105045729AReduce turnoverNo need to operate across nodesMemory adressing/allocation/relocationMessage flowOperating system

The invention discloses a method and system for conducting consistency processing on caches with catalogues of a far-end agent. The far-end agent is made to obtain and process a local request initiated by a local request source; a response message and data are returned to the local request source when the response message and data from the far-end agent are received, and corresponding catalogues and data are written into a catalogue cache and a data cache respectively; whether other target requests with the same address as that of the far-end agent exist or not is judged; if yes, the target requests are processed in sequence; starting from the moment when the local request is sent to the far-end agent to occupy one catalogue and one data cache till the response message of the request returns, if a request of the same address as that of the far-end agent and meeting a certain condition or a monitoring message enters the far-end agent within the time before the internal cache resources in the far-end agent is invalid, the request can be directly processed in the far-end agent, message flow in reduced, a response is conducted quickly, across-node operation is not needed, and expense is reduced.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

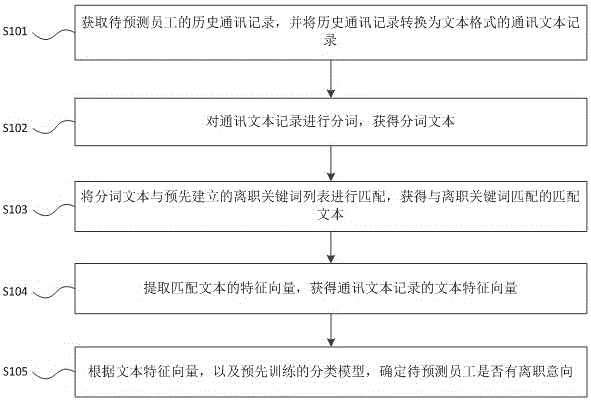

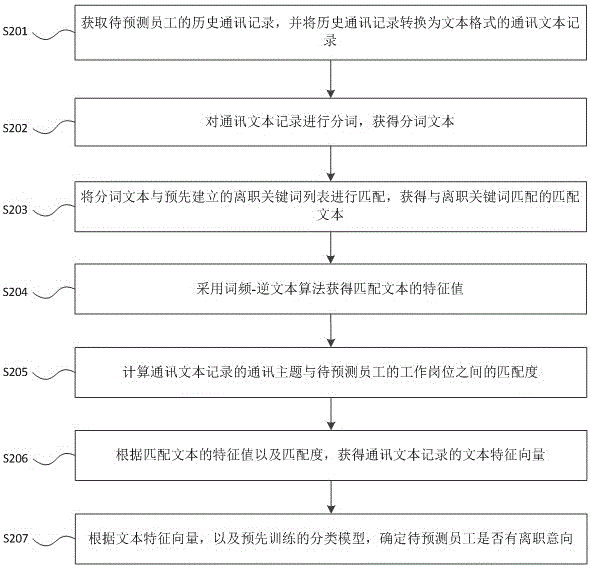

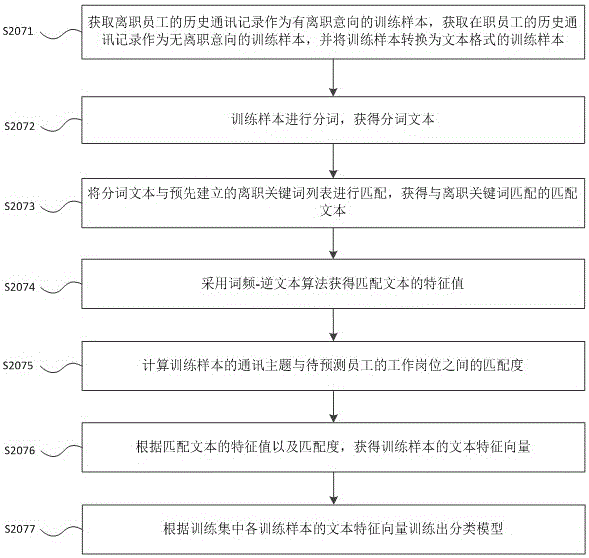

Method and device for predicting staff demission

ActiveCN105868183AReduce turnoverSave human effortNatural language data processingSpecial data processing applicationsFeature vectorCategorical models

The invention provides a method and device for predicting staff demission. Historical communication records of staff to be predicted are acquired and converted into communication text records in a text format; the communication text records are subjected to word segmentation, a segmented word text is obtained and matched with a pre-established demission keyword list, a matching text matched with demission keywords is obtained, feature vectors of the matching text are extracted, text feature vectors of the communication text records are obtained, and whether the staff to be predicted have a demission intention or not is determined according to the text feature vectors and a classification model trained in advance. The technical problem about hollow to predict staff demission is solved, whether the staff to be predicted has the demission intention or not can be predicted according to the historical communication records of the staff to be predicted, and therefore an enterprise can know whether the staff have the demission intension or not as early as possible and take corresponding measures to reduce the demission rate.

Owner:长沙鸽儿们智能技术有限公司

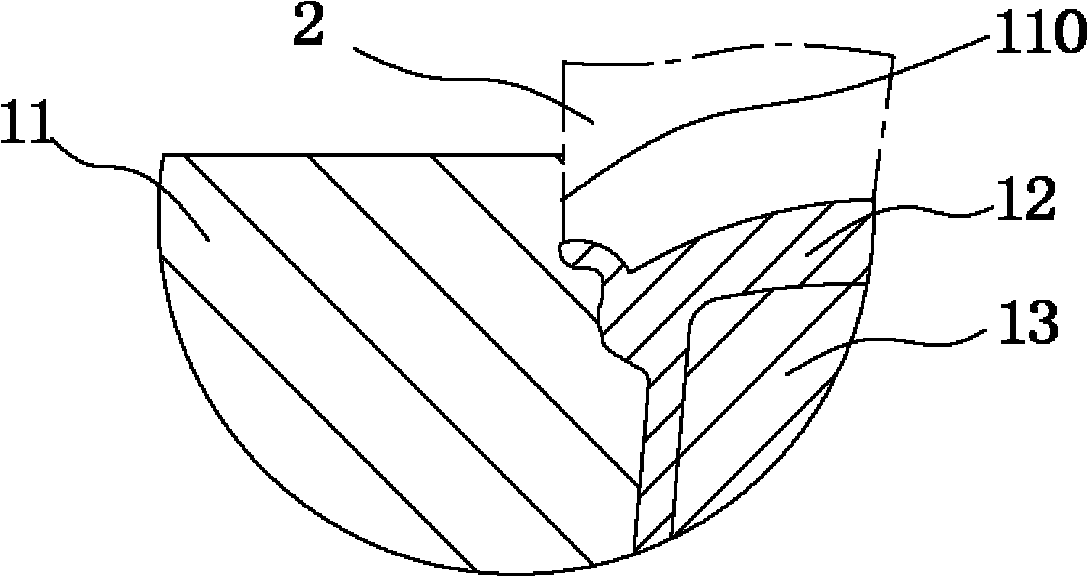

Precision molding device and molding technology for magnesium alloy automobile hub

The invention relates / belongs to the technical field of precision molding devices, in particular to a precision molding device and molding technology for a magnesium alloy automobile hub, and solves the problems of shrinkage porosity, shrinkage cavity, cold lap, large grain size, and the like in the casting process of the magnesium alloy automobile hub. The precision molding device comprises an upper mold assembly and a lower mold assembly, and is characterized in that: the upper mold assembly is provided with a push-and-pull oil cylinder perpendicular to the motion direction of a mold; the push-and-pull oil cylinder is connected with an upper mold connected base plate; an upper mold head is fixed on the lower part of the upper mold connected base plate; and the lower mold assembly is provided with a molding area and a demolding area, wherein the molding area comprises a molding slider and a lower mold core; the molding slider is arranged in a barrel-shaped mold bed, and an outer surface of the barrel-shaped mold bed is provided with a barrel-shaped insulating device; an ejector rod mechanism is arranged in the demolding area. The precision molding device and the molding technology for the magnesium alloy automobile hub have the advantages of less allowance for machining, simple process, convenient operation, fine and dense crystal grains of a wheel, high intensity, and excellent rigidity.

Owner:刘绍东

Automobile interior trim part foaming production line

The invention relates to the technical field of automobile part foaming, and particularly discloses an automobile interior trim part foaming production line. The automobile interior trim part foaming production line comprises a rack, a heating mechanism, a main die frame, a foaming mechanism and a control unit; the heating mechanism and the main die frame are sequentially arranged on the rack; the foaming mechanism is arranged over the main die frame; and the control unit is used for controlling the heating mechanism, the main die frame and the foaming mechanism. According to the automobile interior trim part foaming production line, the structure is compact, arrangement is reasonable, and the automation degree is high; a heating production line is additionally arranged and slidably connected with the foaming line, therefore, a product directly enters the foaming process after being heated, product turnover is reduced, the working efficiency is improved, and the product quality is guaranteed; an upper die installing portion is provided with a turning die frame, therefore, an upper die can be conveniently cleaned and taken, and the labor intensity of operating personnel is reduced; and in addition, multiple radar alarms and grating alarms are arranged, therefore, the safety performance of the whole production line is improved, and potential safety hazards are reduced.

Owner:NANTONG CHAODA EQUIP CO LTD

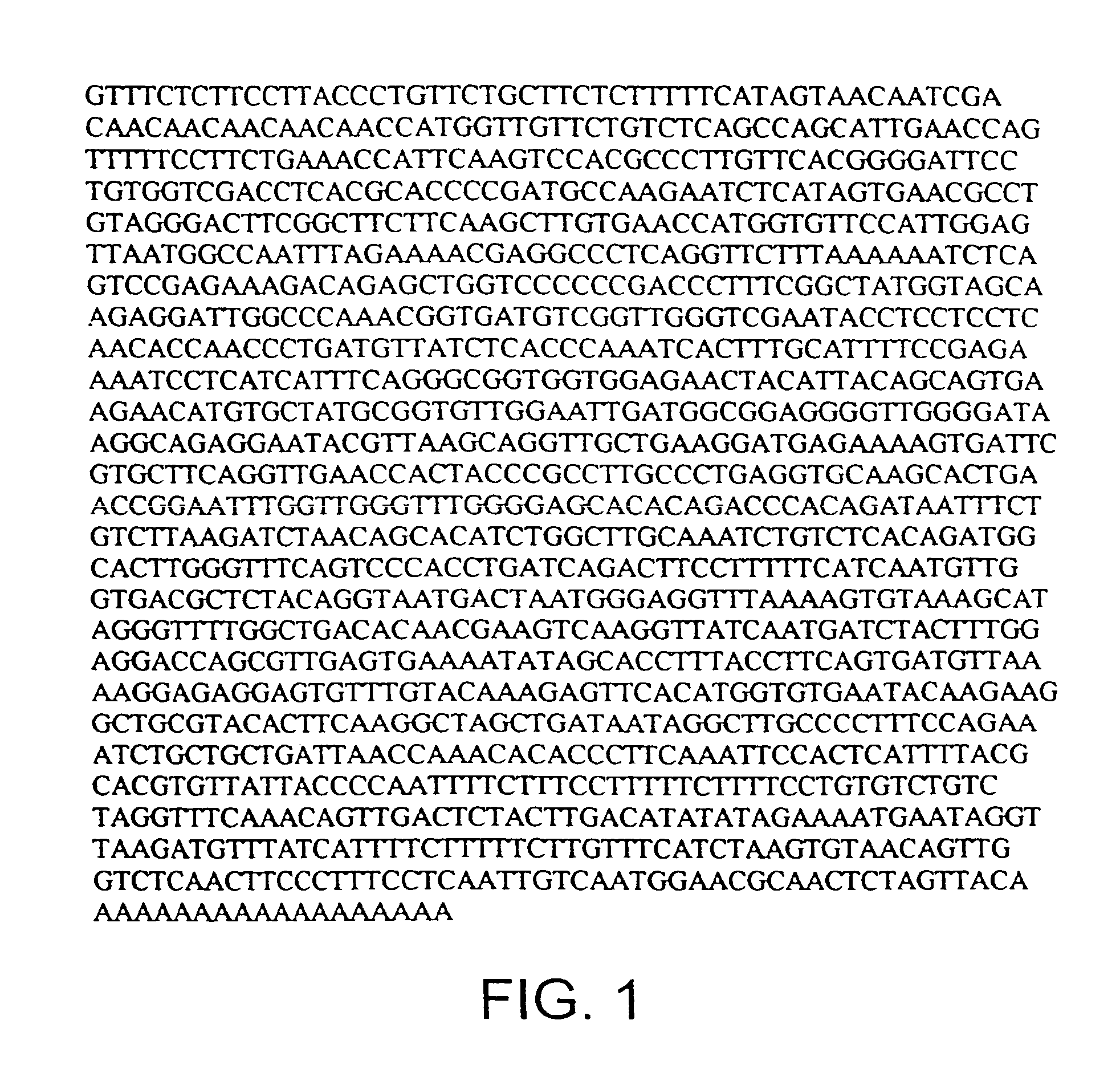

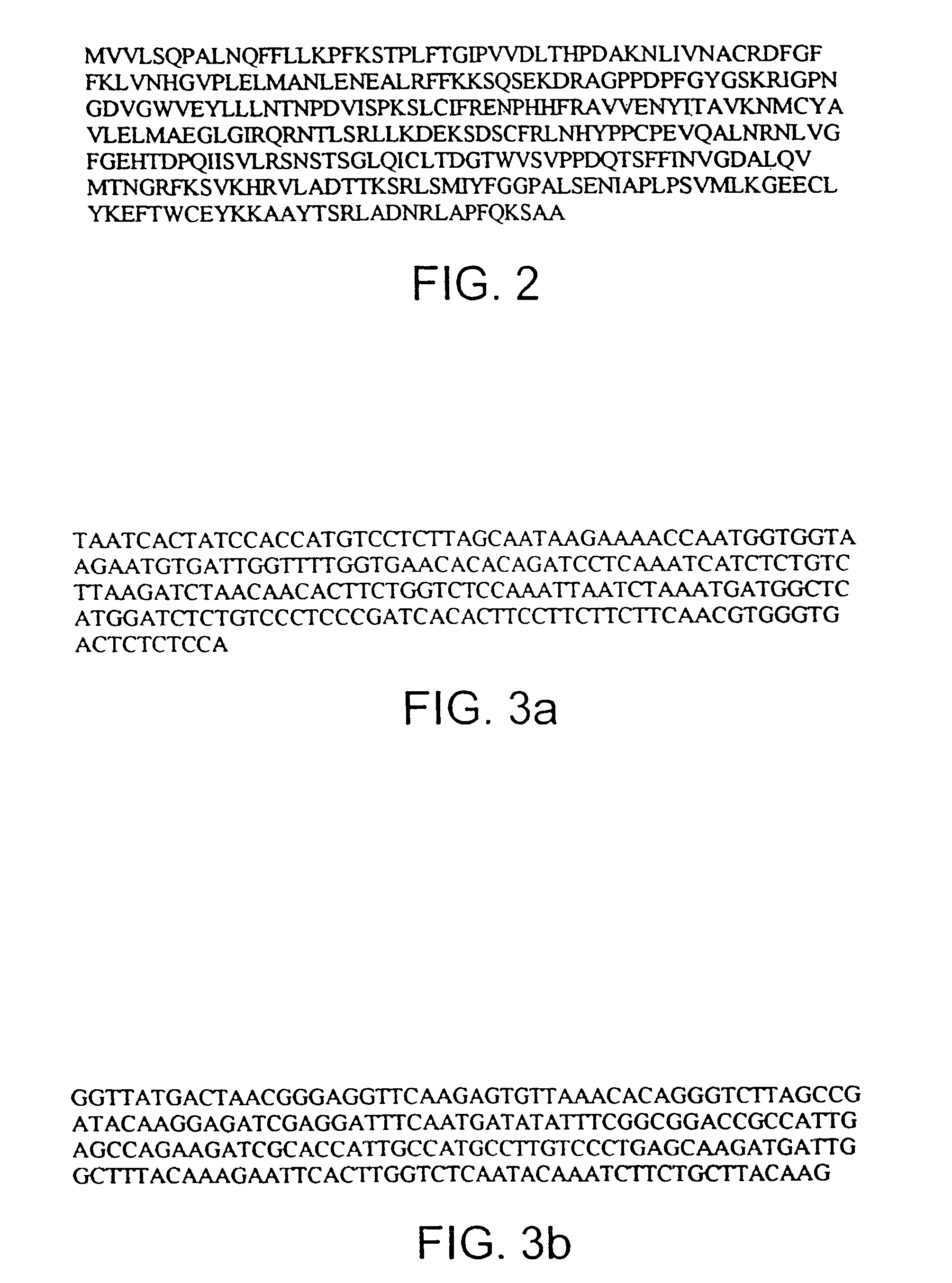

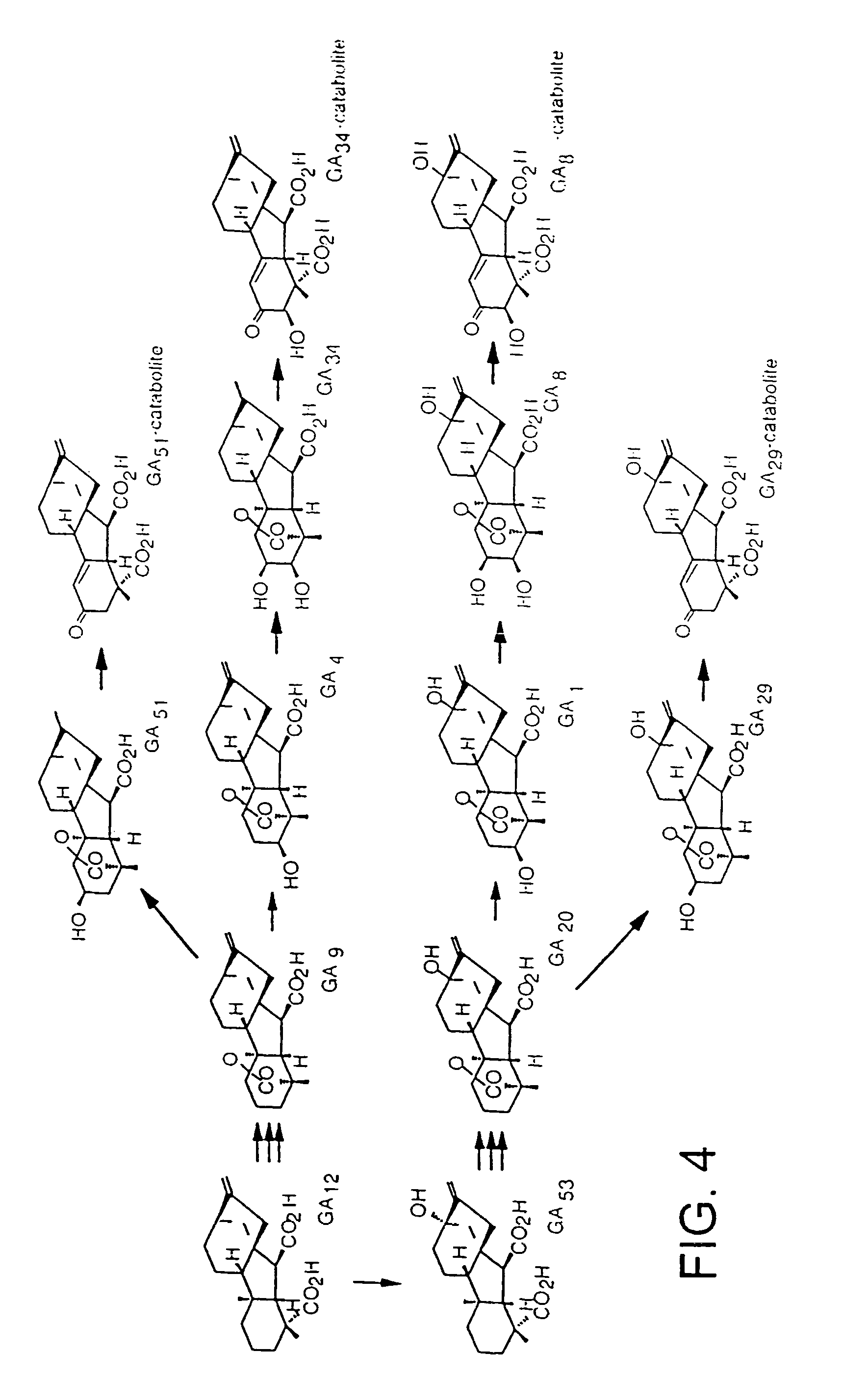

Gibberellin 2-oxidase

A nucleic acid sequence is provided which encodes a gibberelin 2-oxidase gene which catalyzes the 2β-oxidation of a gibberelin molecule to introduce a hydroxyl group at C-2 and further catalyzes the oxidation of the hydroxyl group introduced at C-2 to yield the ketone derivative. Such sequences can find application in the preparation of transgenic plants with altered levels of gibberelin 2-oxidase.

Owner:ROTHAMSTED RES LTD

Assembly mold and assembly method for car fuel filler cap hinge

The invention relates to an assembling mould for a car oil filler cap hinge, and the assembling mould provided by the invention comprises an upper mould, a lower mould, a crop convex mould, a crop concave mould, an upper reshaping pressing plate, a lower reshaping pressing plate, a cutting beating convex mould, a cutting beating concave mould, a beating convex mould, a beating concave mould, a moveable positioning mechanism, a positioning pin, and the like. A plurality of processes, such as shaft cutting, shaft baiting, hinge and shaft assembling, shaft beating, hinge forming, and the like, are simultaneously finished on one mould, thereby achieving the purposes of low cost, high efficiency and low energy consumption.

Owner:LIAN WEI AUTO PARTS CHONQGING

Transformer silicon steel sheet shearing and stacking machine

PendingCN110722359AEasy to assemble directlyAdjustable distanceOther manufacturing equipments/toolsMetal working apparatusPunchingTransformer

The invention discloses a transformer silicon steel sheet shearing and stacking machine, and relates to the technical field of transformer silicon steel sheet manufacturing equipment. An unwinding device, a supporting device and a conveying guide channel of the machine are sequentially connected, and the conveying guide channel is provided with a transverse shearing device, a V-shaped shearing device and a punching device. The conveying guide channel is connected with reverse suction and material arranging devices, and initial positioning devices and fine positioning devices are arranged on the lateral sides of the reverse suction and material arranging devices. Carrying devices are arranged above the initial positioning devices and the fine positioning devices, and a stacking table deviceis arranged between the fine positioning devices. The machine has the advantages that after silicon steel sheets are cut, the assembling process is directly started, the intermediate manual carryingand material arranging procedures are omitted, the labor intensity is reduced, few circulation links are needed, the damage to the silicon steel sheets is reduced, the placement time is short, rust isavoided, shearing, stacking and assembling are integrated, the production floor area is reduced, the energy consumption is reduced, the production efficiency is improved, corresponding distance adjustment can be carried out on silicon steel sheet iron cores with different specifications, and the application range is wider.

Owner:NANTONG SIRUI ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com