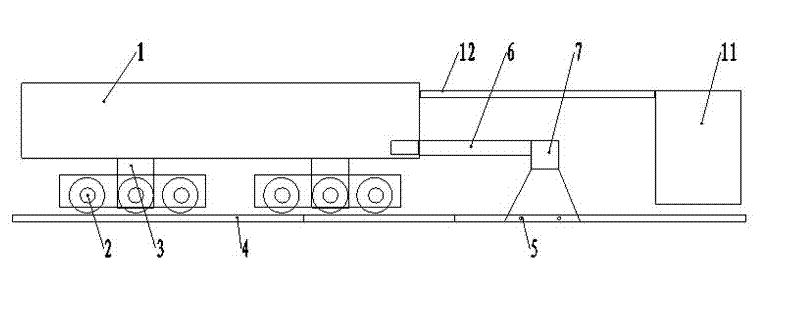

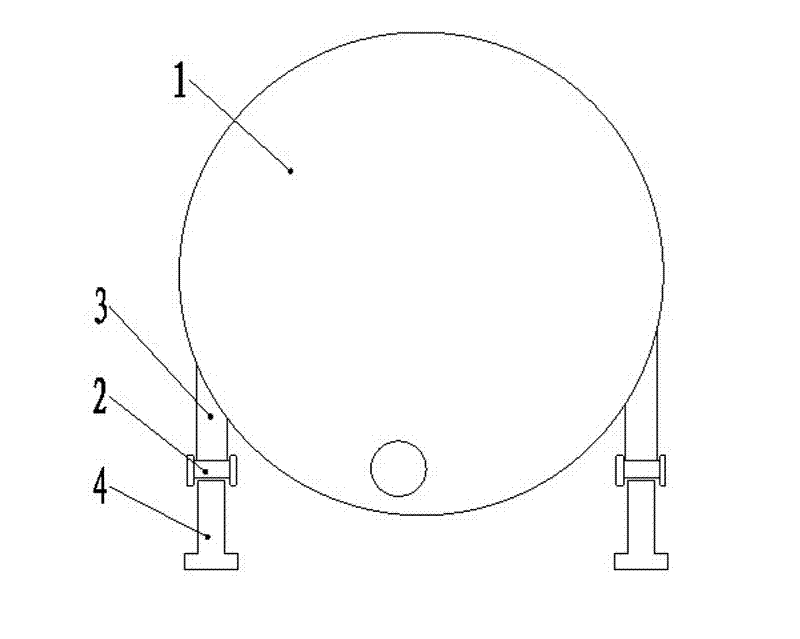

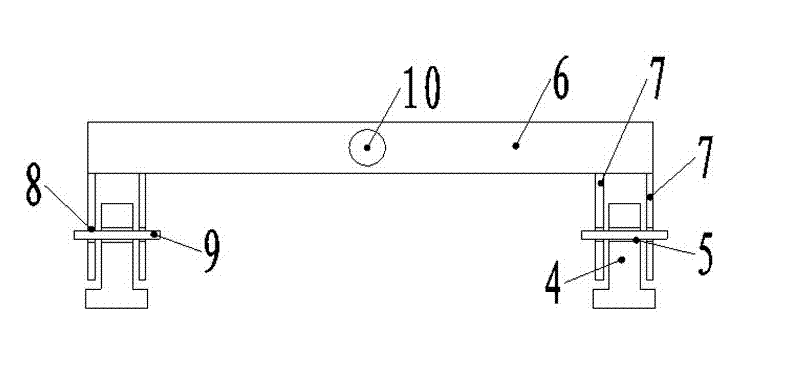

Roller guide rail station-passing construction method of whole shield machine

A construction method and the technology of roller guide rails, which are applied to earth drilling, mining equipment, tunnels, etc., can solve the problems of long construction period, high cost, and high difficulty, and achieve the effects of short construction period, convenient use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0035] Changsha Metro Line 2 has three sections in standard 7, which need to pass twice. They are Furong Square Station and Wuyi Square Station. Since Furong Square Station is 142 meters long, the left line adopts the traditional method of station floor construction and crossing. , the whole station-crossing time is 32 days, and the right line has only used 12 days to pass the station by adopting the method of the present invention because the station-passing conditions are provided in advance.

[0036] The construction of Wuyi Square Station was completed ahead of schedule. The length of the station is 184 meters. Among them, there is still a 92-meter section of open excavation on the left line, and the length of the crossing station is 376 meters. The realization of the second initiation fully proves that the method of the present invention has strong applicability.

[0037] At present, the urban subway shield method basically adopts station passing. There are more than 30 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com