Preparation method for graphite anode material of lithium ion battery

A lithium-ion battery and graphite negative electrode technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of mutual adhesion of coated graphite particles, low irreversible capacity, uneven coating, etc., to reduce equipment residual loss, The effect of low irreversible capacity and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

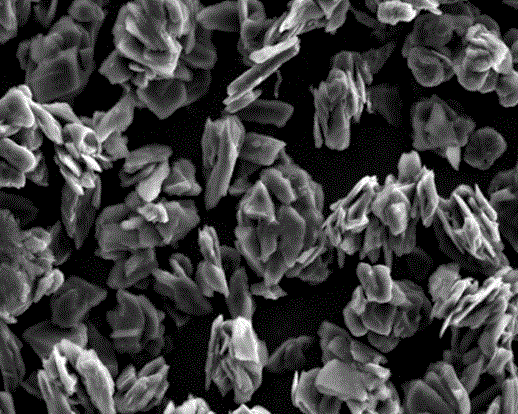

Image

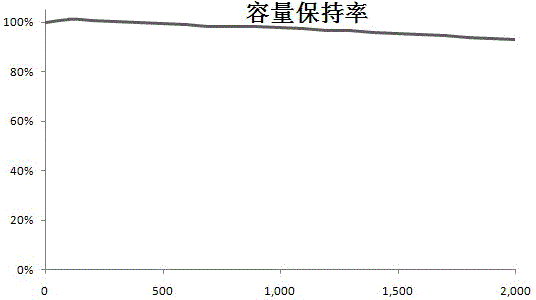

Examples

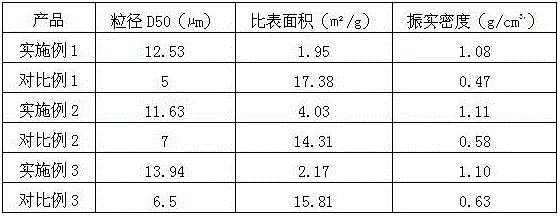

Embodiment 1

[0031] Use natural graphite fine powder as raw material (average particle size D50 is 5μm), petroleum pitch (softening point: 100°C) as organic carbon source, the mass ratio of the two is 10:3, weigh 100Kg natural graphite fine powder and 30Kg petroleum pitch , together into the reactor to stir, the temperature is 120 °C, and the stirring time is 6 hours.

[0032] Afterwards, the temperature was raised to 800°C at a heating rate of 5°C / min, and kept at a constant temperature for 5 hours, then cooled to room temperature, and then the material was graphitized above 2600°C.

[0033] Finally, the powder is sieved, and the under-sieve is collected to obtain the finished product.

Embodiment 2

[0035] Use natural graphite fine powder as raw material (average particle size D50 is 7μm), coal tar pitch (softening point: 150°C) as organic carbon source, the mass ratio of the two is 10:3.5, weigh 100Kg natural graphite fine powder and 35Kg coal tar pitch , together into the reactor to stir, the temperature is 170°C, and the stirring time is 5 hours.

[0036] Afterwards, the temperature was raised to 900°C at a heating rate of 5°C / min, and kept at a constant temperature for 4 hours, then cooled to room temperature, and then the material was graphitized above 2600°C.

[0037] Finally, the powder is sieved, and the under-sieve is collected to obtain the finished product.

Embodiment 3

[0039] Use natural graphite fine powder as raw material (average particle size D50 is 6.5 μm), petroleum pitch (softening point: 120°C) as organic carbon source, the mass ratio of the two is 10:2.5, weigh 100Kg natural graphite fine powder and 25Kg petroleum Asphalt is added to the reactor and stirred together, the temperature is 150°C, and the stirring time is 4.5 hours.

[0040] Then the temperature was raised to 850°C at a rate of 4°C / min, and kept at a constant temperature for 4 hours, then cooled to room temperature, and then the material was graphitized above 2600°C.

[0041] Finally, the powder is sieved, and the under-sieve is collected to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com