Precision molding device and molding technology for magnesium alloy automobile hub

A technology for precision molding and automobile hubs, which is applied in the directions of wheels, vehicle parts, transportation and packaging, etc. It can solve the problems of less machining allowance, coarse crystal grains, shrinkage and porosity, and achieve fast exchange of punches and significant economic benefits , Strong self-locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

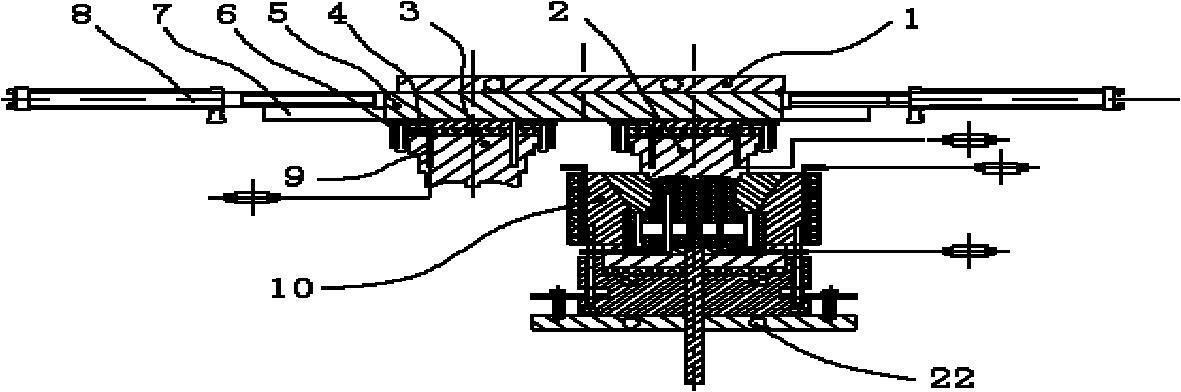

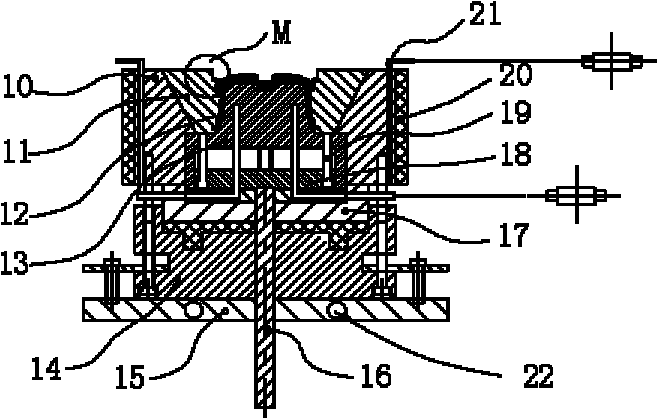

[0040] see figure 1 , figure 2 , present embodiment establishes a patrix assembly, the lower mold assembly that cooperates with it two major parts.

[0041] Push-pull oil cylinders 8 are respectively arranged on both sides of the upper mold assembly, and the push-pull oil cylinders 8 are connected with an upper mold conjoined seat plate 5, and the upper die head is fixed on the lower part of the upper mold conjoined seat plate 5, and the upper mold conjoined seat plate 5 The upper part of the upper mold track backing plate 1 is equipped with, and the movable track 7 is arranged symmetrically on both sides, and the upper mold track backing plate 1 is connected with the hydraulic press.

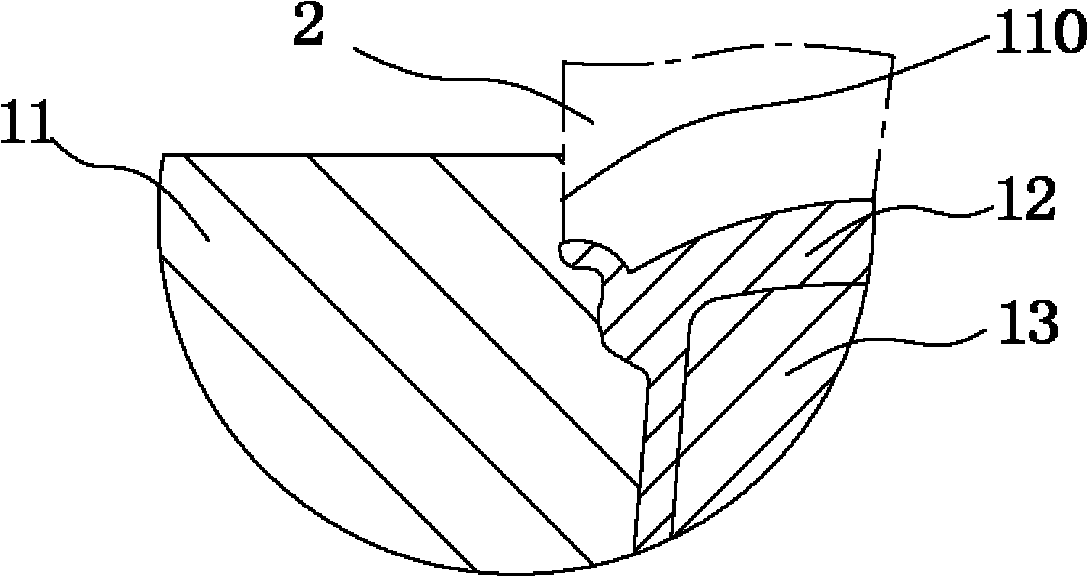

[0042] In this embodiment, the upper die head is provided with two pairs, namely the preforming punch 2 and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com