Assembly mold and assembly method for car fuel filler cap hinge

A fuel filler cap and hinge technology, which is applied in the field of mold structure and technology, can solve the problems of difficulty in taking out the card mold, cannot be used directly, and difficult to assemble the shaft, and achieves the effect of eliminating batch quality problems, facilitating mold maintenance and fewer processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

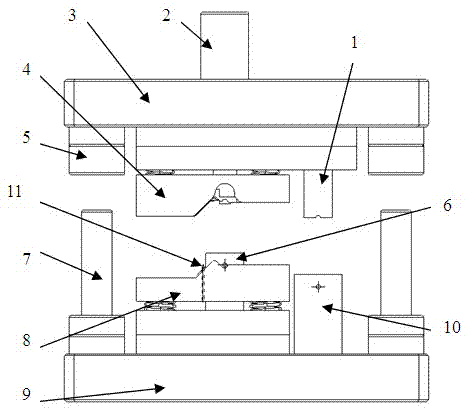

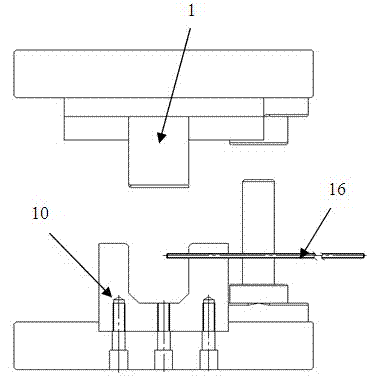

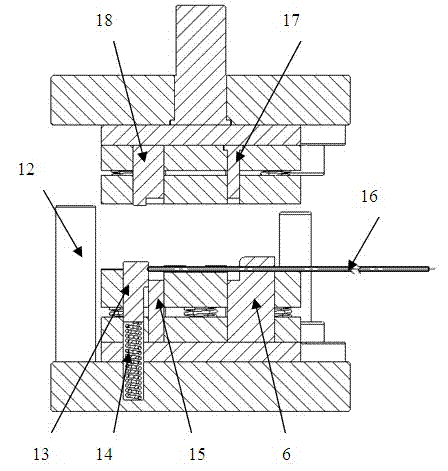

[0049] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

[0050] see Figure 1 to Figure 4 , the mold consists of an upper die 3, a lower die 9, a head cutting punch 1, a head cutting die 10, an upper shaping binder plate 4, a lower shaping pressing plate 8, a cutting and flattening punch 17, a cutting and flattening die 6. It is composed of flattening punch 18, flattening die 15, movable positioning mechanism, die handle 2, guide post 7, guide sleeve 5, limit post 12 and positioning pin 11, etc.

[0051] Die handle 2 is fixed on the upper die, plays the effect of installing the upper die, and is directly connected with the slide block of the machine tool.

[0052] Head cutting punch 1, cutting and flattening punch 17 and flattening punch 18 are fixed on the upper die side by side, head cutting die 10, cutting and flattening die 6 and flattening die 18 are correspondingly fixed on the lower die side by side, This p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com