Patents

Literature

127 results about "Acenaphthene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acenaphthene is a polycyclic aromatic hydrocarbon (PAH) consisting of naphthalene with an ethylene bridge connecting positions 1 and 8. It is a colourless solid. Coal tar consists of about 0.3% of this compound.

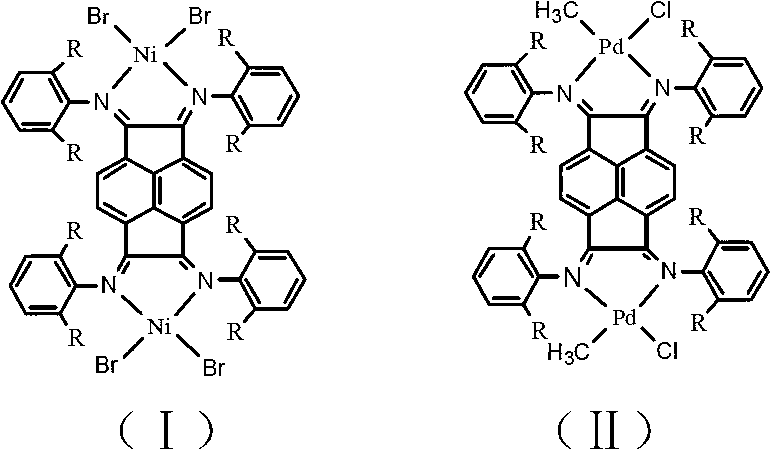

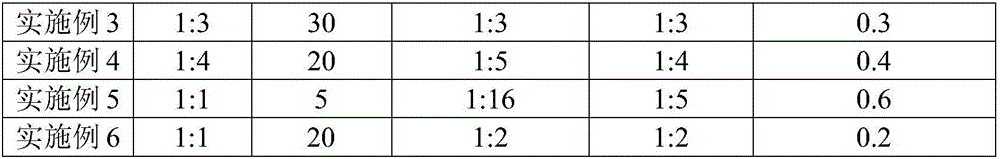

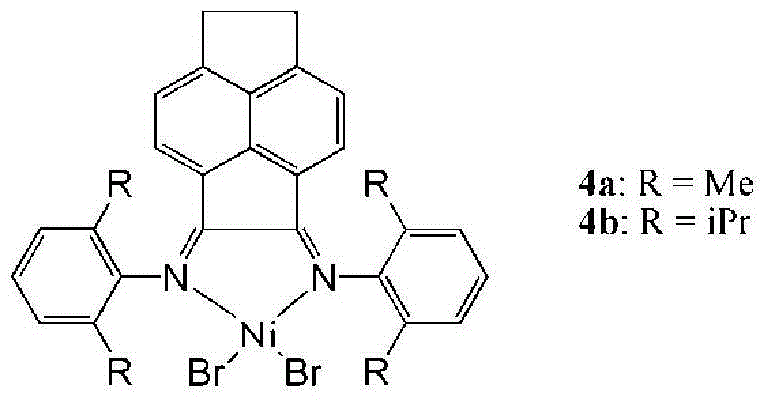

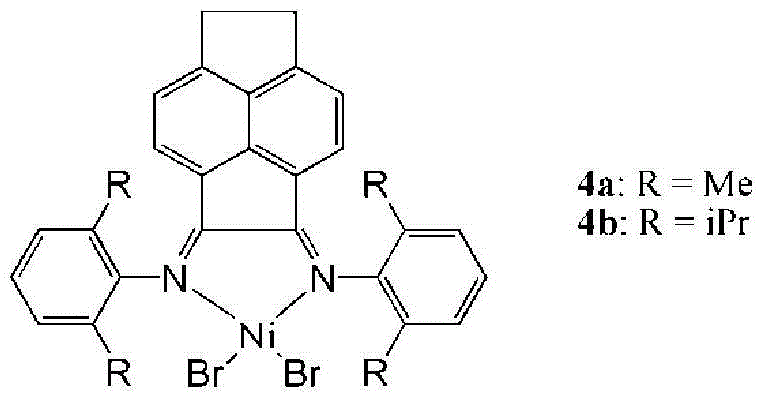

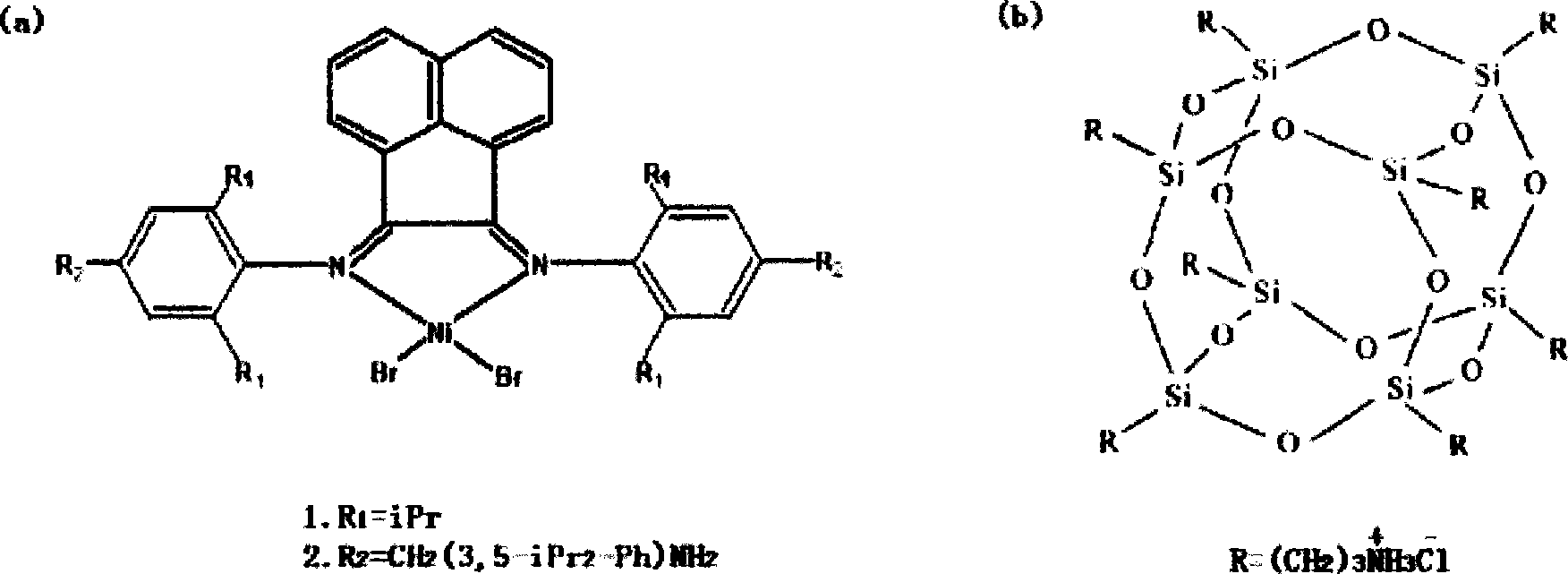

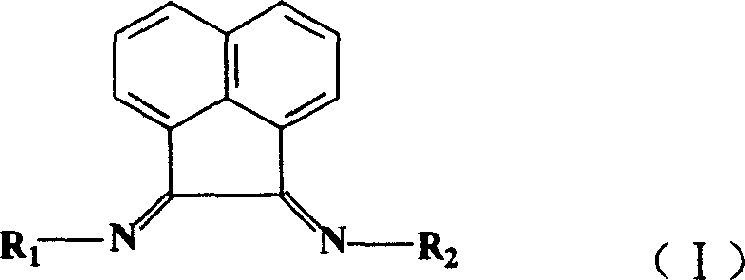

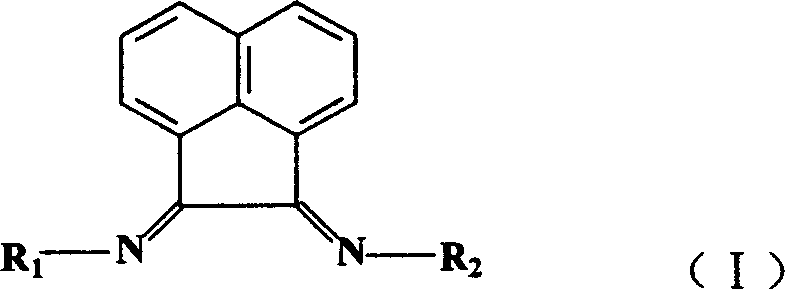

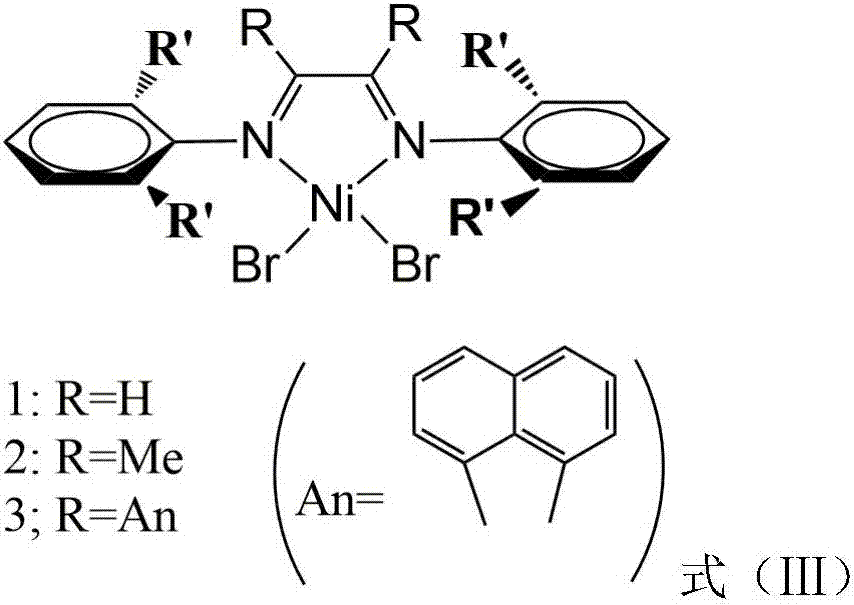

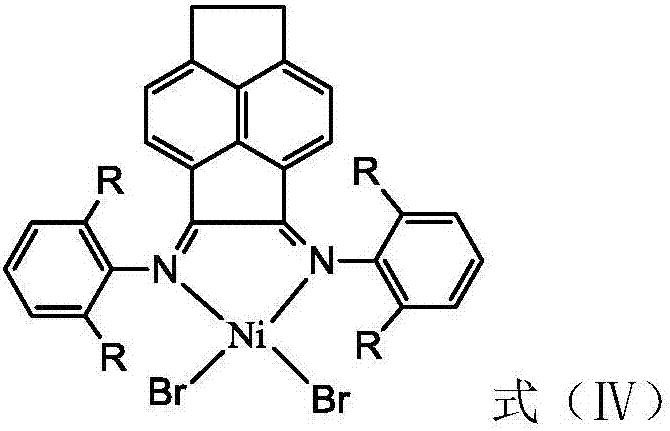

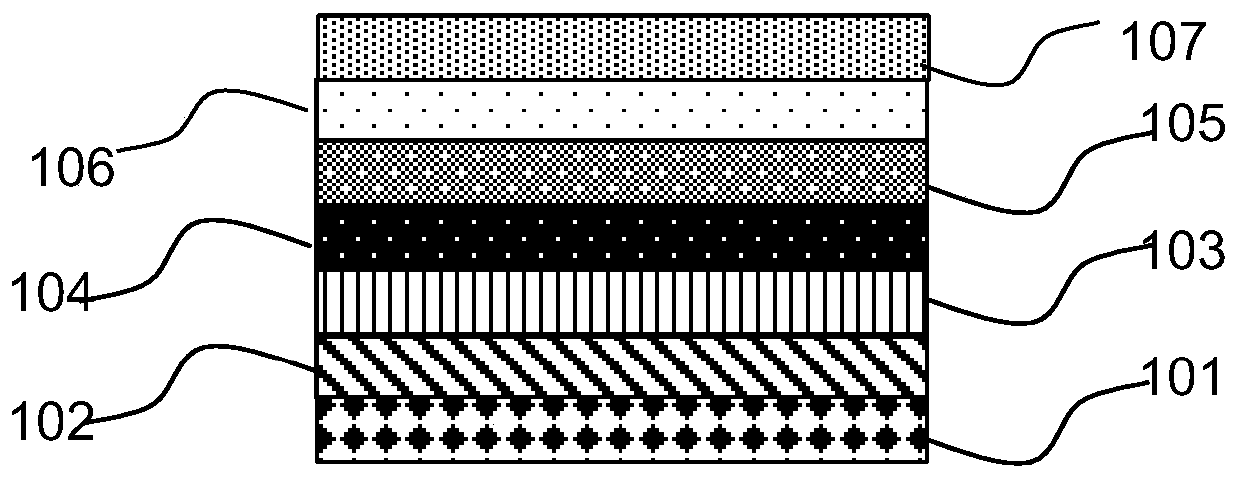

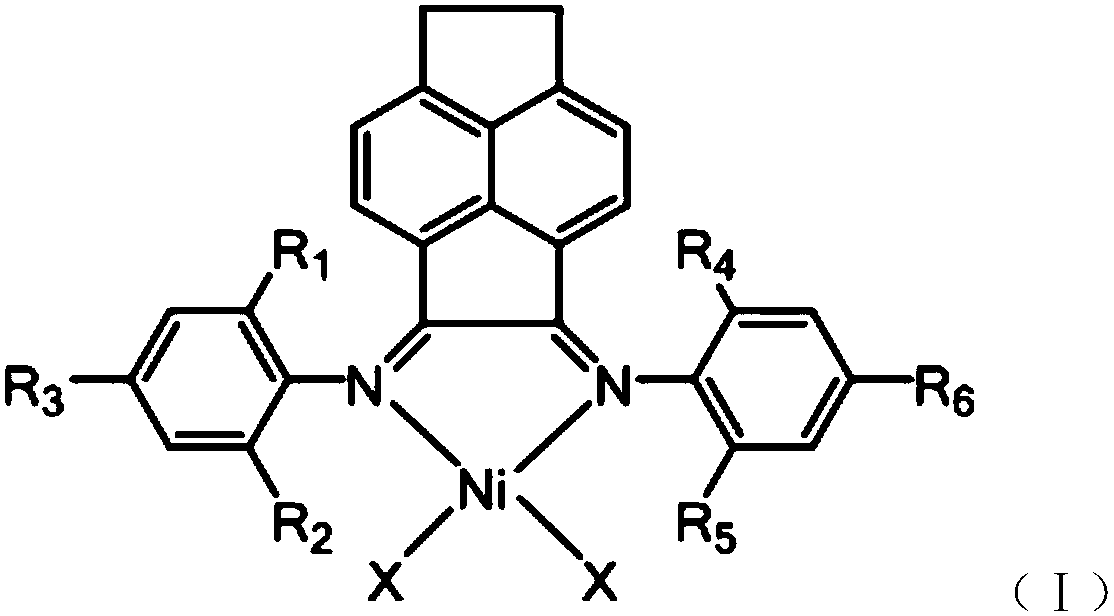

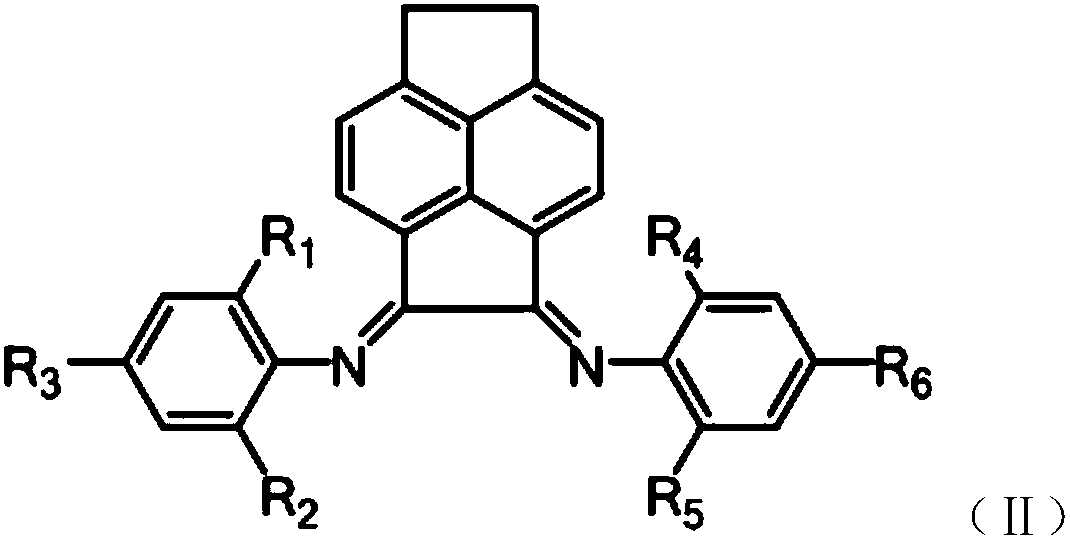

Binuclear acenaphthene (alpha-diimine) nickel/palladium catalysts for olefins, and preparation method and application thereof

ActiveCN102827311AHigh activityImprove stabilityNickel organic compoundsBulk chemical productionNickel catalystDiimine

The invention discloses a preparation method for binuclear acenaphthene (alpha-diimine) nickel / palladium catalysts for olefins and application of the catalysts in catalysis of polymerization of olefins. The binuclear acenaphthene (alpha-diimine) nickel / palladium catalysts for olefins in the invention have structural formulas as represented by formula (I) and formula (II) in the specification. The binuclear acenaphthene (alpha-diimine) palladium catalyst for polymerization of olefins has high activity and good stability and can be used for preparing high-molecular-weight hyperbranched polyethylene with bimodal distribution; the binuclear acenaphthene (alpha-diimine) nickel catalyst for polymerization of olefins has high activity and good stability and can be used for preparing polypropylene with a weight-average molecular weight of more than 100,000 and thermoplastic elastomers with elasticity and a high molecular weight. The preparation method for the synthesized catalysts used for polymerization of olefins has the advantages of a simple process, a short synthetic route, low cost, high yield and easy industrialization.

Owner:ZHEJIANG UNIV

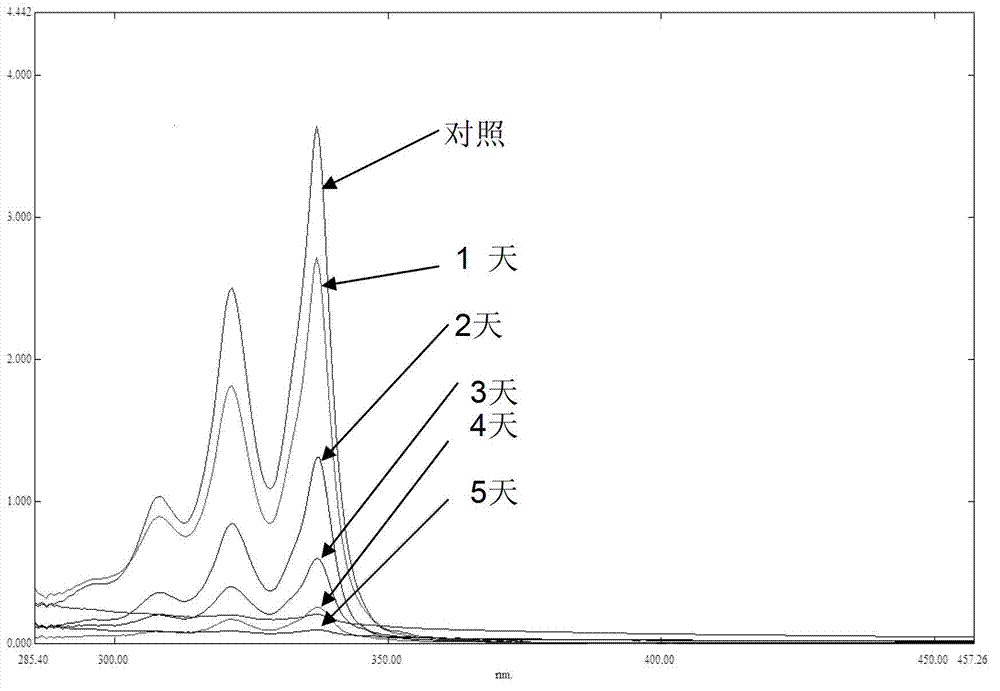

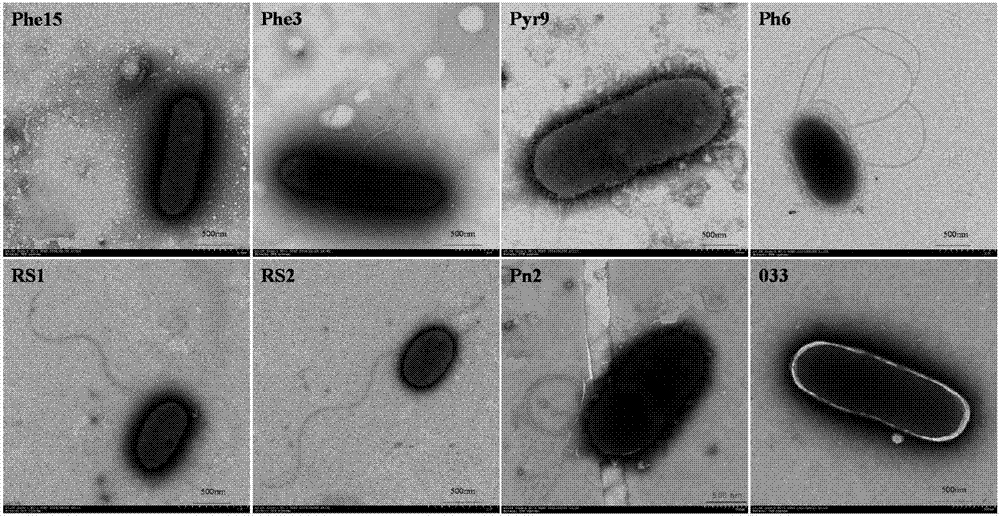

Mycobacterium 16F for efficiently degrading polycyclic aromatic hydrocarbons and benzene organic matters and application thereof

ActiveCN102899271AEfficient degradationDegradation safetyBacteriaMicrobiological testing/measurementKanamycinM-Xylene

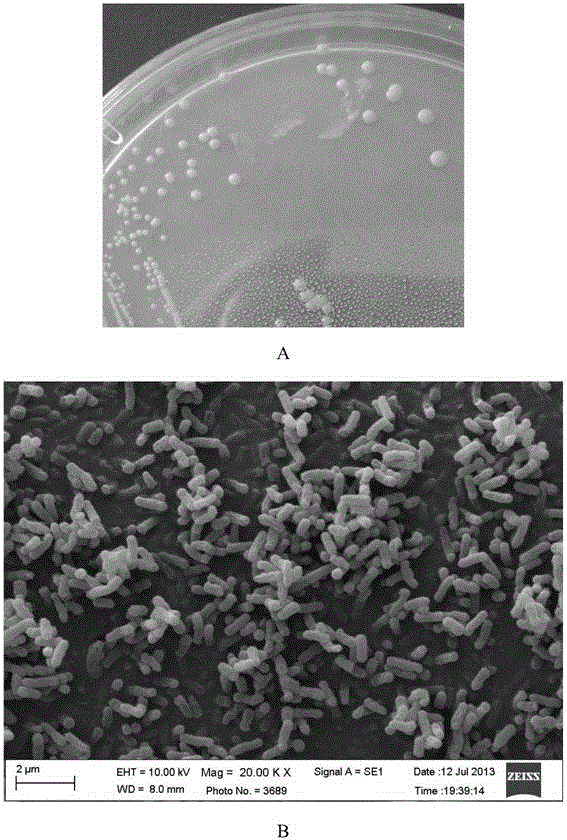

The invention provides a strain of Mycobacterium sp.16F for efficiently degrading polycyclic aromatic hydrocarbon and benzene organic matters, which has a preservation number of CGMCC No.6367. The mycobacterium 16F can efficiently, safely and rapidly degrade polycyclic aromatic hydrocarbons and benzene organic matters, can grow and degrade by using fluorene, naphthalene, anthracene, acenaphthene, phenanthrene, pyrene and benzopyrene as the sole carbon source and energy in aerobic condition, and can utilize benzene, m-xylene, toluene, salicylic acid, catechol and other multiple aromatic organic matters. The mycobacterium 16F is sensitive to streptomycin, rifampin, tetracycline, kanamycins and other antibiotics, has good degradation effects to mixed polycyclic aromatic hydrocarbons in aging soils and monocyclic benzene organic matters in water bodies, can be used for restoring and purifying the water-soil environment combinedly polluted by aromatic hydrocarbon organic matters, is important for promoting sustainable development, and has a wide application prospect.

Owner:ENVIRONMENTAL PROTECTION RES INST OF LIGHT IND

Preparation method of slump loss resistant naphthalene water reducer

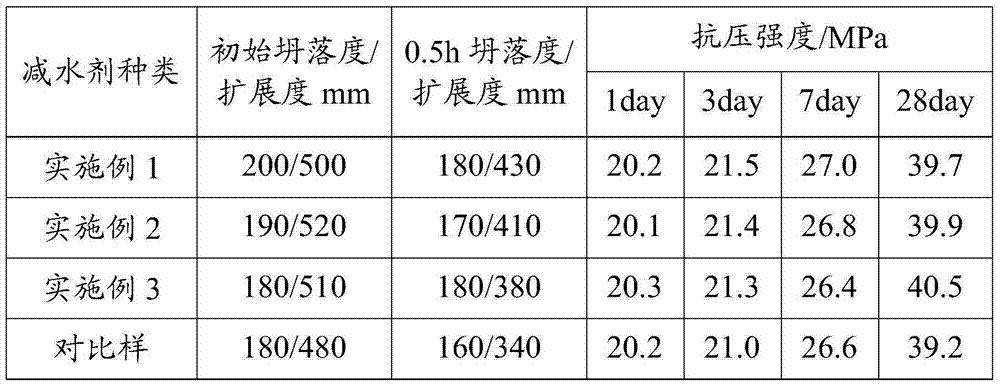

ActiveCN103864332AEnhanced controllability of molecular structureSave resourcesSodium metasilicateOrganic solvent

The invention discloses a preparation method of a slump loss resistant naphthalene water reducer. The naphthalene water reducer is prepared by sulfonating, hydrolyzing, condensing and neutralizing raw materials including crude naphthalene, naphthalene derivatives such as methylnaphthalene, concentrated sulfuric acid, formaldehyde, caustic soda liquid, water and the like. According to the production process, monomer substituents, such as methylnaphthalene and acenaphthene are introduced, an organic solvent azeotropic method is adopted for synthesizing, and finally sodium metasilicate is adopted for neutralizing to adjust pH to 7-10 to obtain the final naphthalene water reducer. The slump loss resistant naphthalene water reducer is prepared by the implementation mode disclosed by the invention, the crude naphthalene is replaced by partial naphthalene derivatives, an effective path of reducing the cost is proposed, naphthalene steam and a solvent are condensed to form a naphthalene solution to be recycled, and thus the product yield is improved and the environmental pollution is reduced.

Owner:SHAANXI KZJ NEW MATERIALS

Light yellow mycobacterium and its application in degradation of oil components polycyclic aromatic hydrocarbons

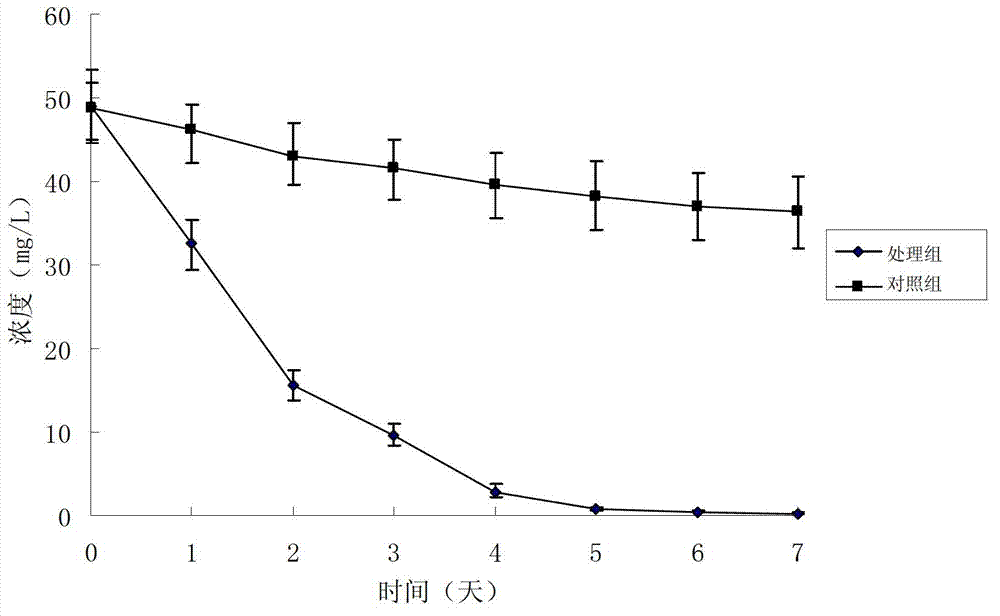

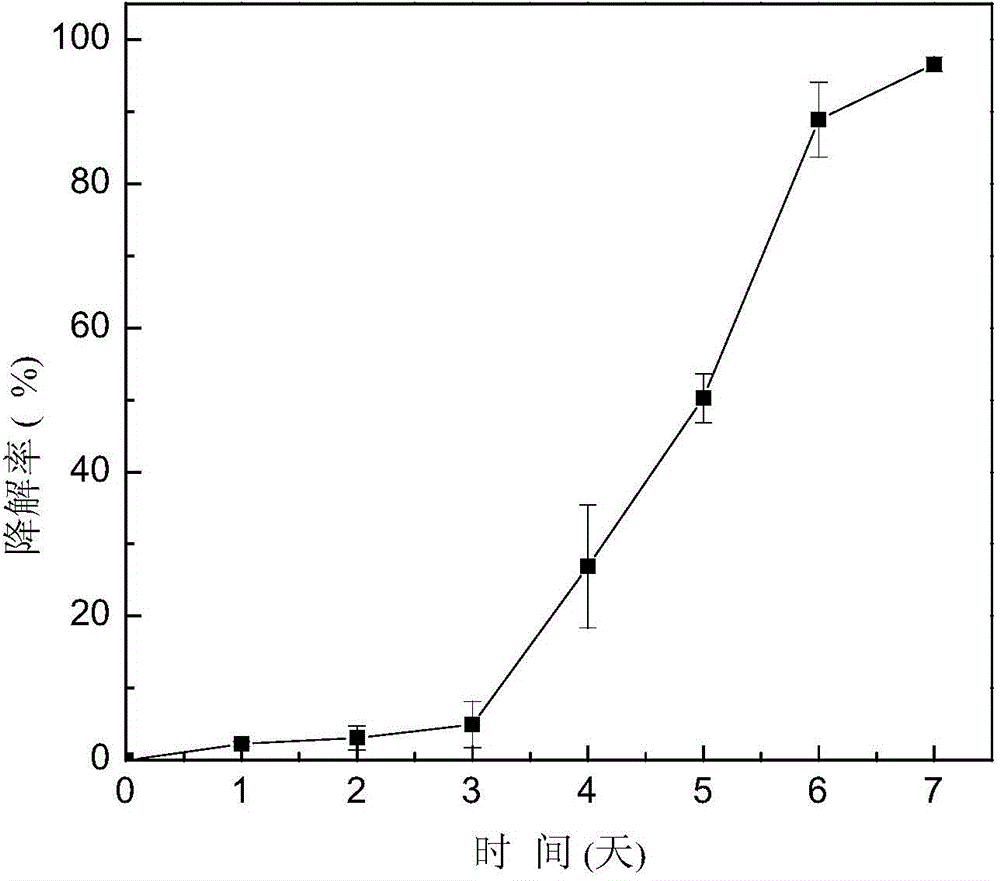

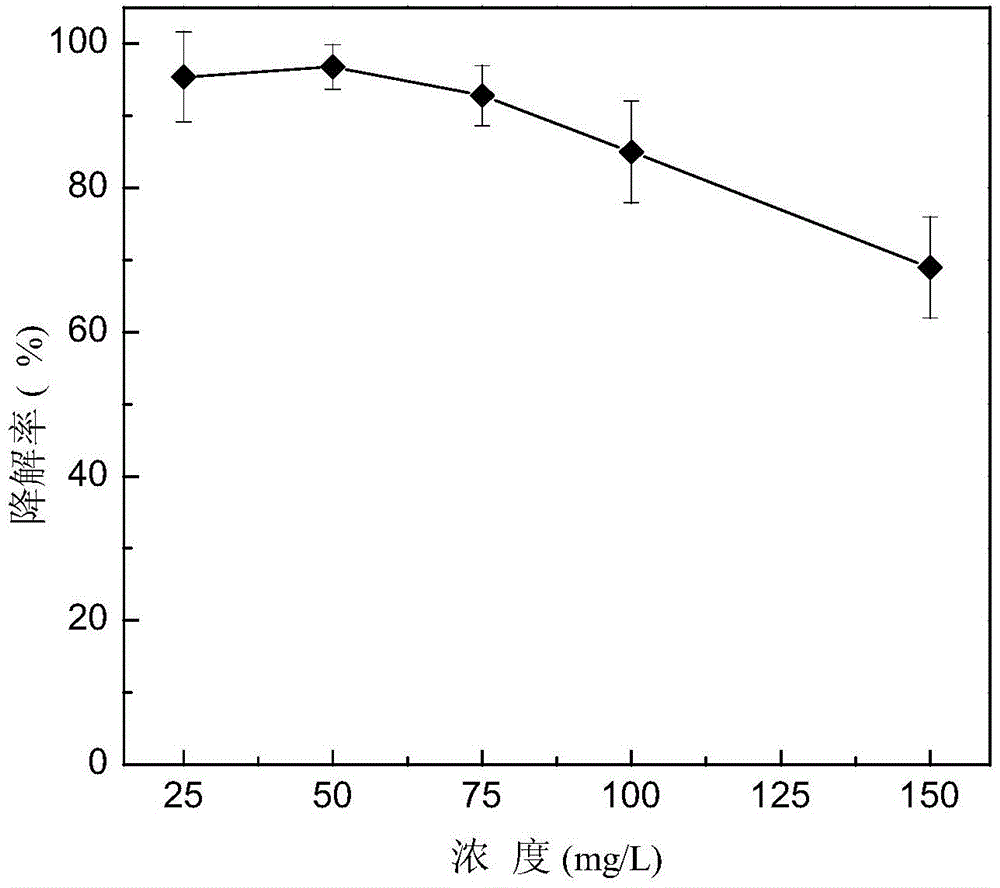

The invention discloses a light yellow mycobacterium and its application in degradation of oil components polycyclic aromatic hydrocarbons. The strain is Mycobacteriumgilvum CP13 and was collected in China General Microbiological Culture Collection Center (CGMCC for short) on July, 22nd, 2013. The collection number is CGMCC No.7963. The strain undergoes shake cultivation at pH of 7.0-10.0 at 30-35 DEG C at 150r / min for 7 days, and its degradation rate of pyrene with initial concentration of 50mg / L can reach more than 88%. The strain also has strong ability of degrading polycyclic aromatic hydrocarbons such as fluoranthene, phenanthrene, anthracene, fluorenes, acenaphthene, naphthalene and the like, and can be used in bioremediation of oil-polluted water body and soil as well as biological treatment of industrial wastewater containing polycyclic aromatic hydrocarbons.

Owner:SOUTH CHINA UNIV OF TECH

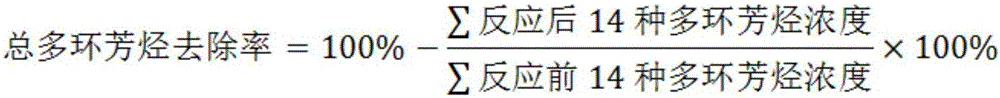

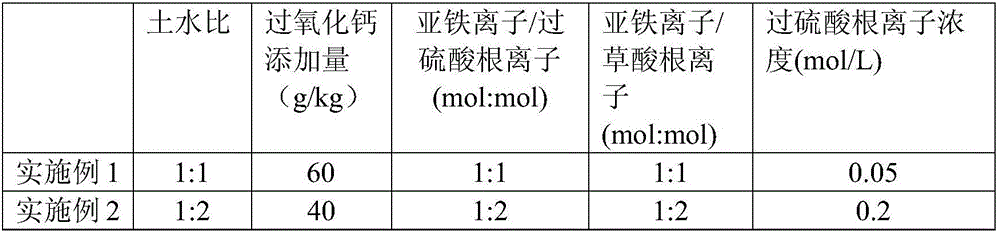

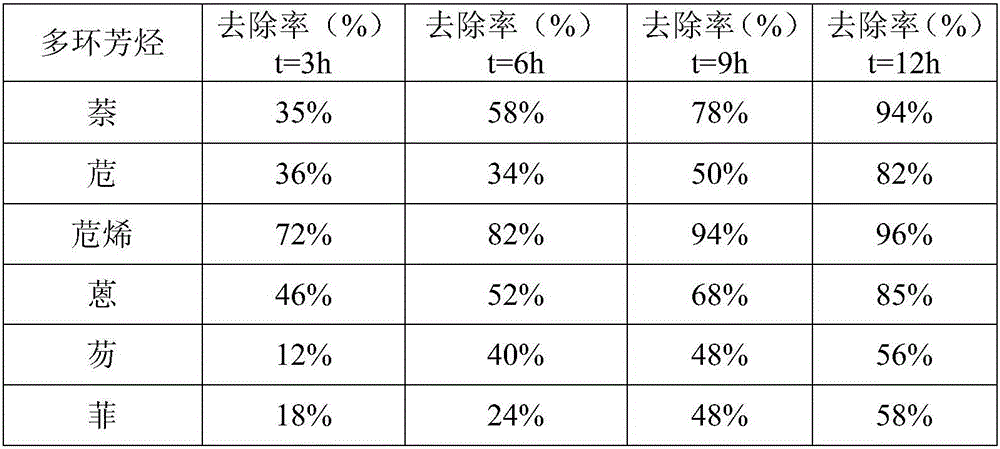

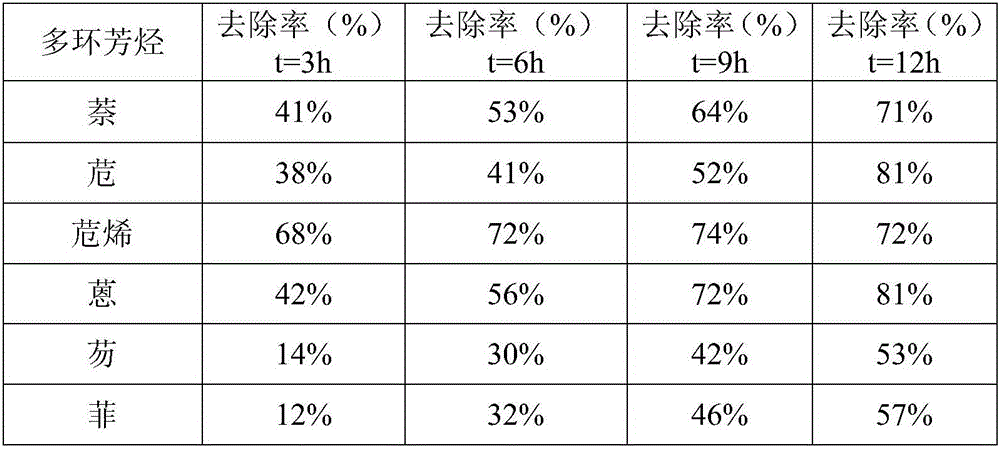

Method for removing polycyclic aromatic hydrocarbons in soil by using persulfate-calcium peroxide through compound oxidation

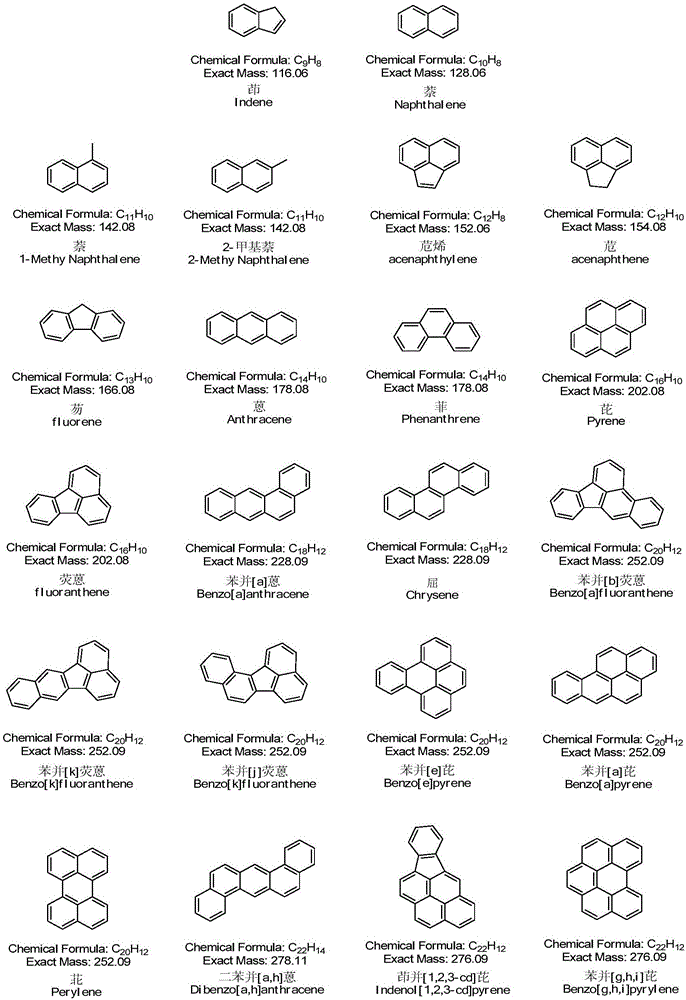

ActiveCN106345800AMaintain a neutral pHHigh removal rateContaminated soil reclamationAcenaphthylenePeroxydisulfate

The invention discloses a method for removing polycyclic aromatic hydrocarbons in soil by using persulfate-calcium peroxide through compound oxidation, and belongs to the field of soil repairing. The method comprises the following steps: after sieving to-be-measured air-dried soil, mixing the soil with calcium peroxide evenly; then adding distilled water to obtain slurry; successively adding oxalate ions, ferrous ions and peroxydisulfate ions, and stirring uniformly to obtain slurry reaction liquid; then leaving the slurry reaction liquid standstill in a dark place so that the polycyclic aromatic hydrocarbons in the soil can be removed after reaction is finished. By the method, naphthalene, acenaphthylene, acenaphthene, phenanthrene, anthracene, fluoranthene, pyrene, benzo[a]anthracene, a component as shown in the specification, benzo[b] fluoranthene, benzo[a]pyrene, dibenzo[a,b]anthracene, benzo[ghi] perylene and indeno[1,2,3-cd] pyrene in a complicated environment of the soil can be removed effectively, the removal rate of the polycyclic aromatic hydrocarbons is high, neutral pH of the soil can be maintained, acidized soil is improved, and a catalyst and a chelating agent are adopted, so that the removal effect and the removal efficiency are enhanced.

Owner:NANJING AGRICULTURAL UNIVERSITY

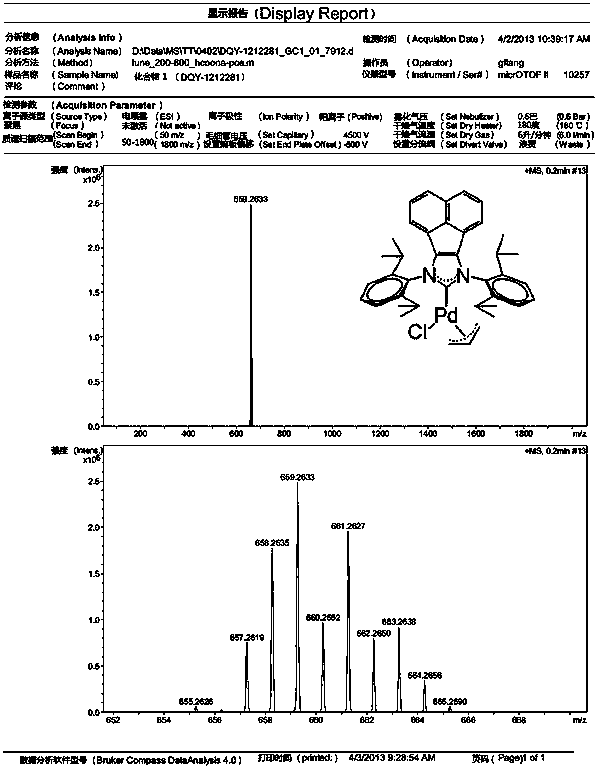

HBPE (hyperbranched polyethylene) functionalized with terminal hydroxyl groups and preparation method thereof

The invention relates to HBPE (hyperbranched polyethylene), and aims to provide HBPE functionalized with terminal hydroxyl groups and a preparation method thereof. According to the preparation of the HBPE functionalized with terminal hydroxyl groups, ethylidene acenaphthene (alpha-diimine) nickel catalyst is adopted as a main catalyst, aluminum alkyl is adopted as a cocatalyst, and diethyl zinc is adopted as a chain transfer agent; ethylene is catalyzed to be homopolymerized; the homopolymerized ethylene is subjected to ligand chain transfer polymerization to obtain diethyl zinc-terminated HBPE. The catalysts in the preparation require no precious metal, so that the synthesis cost of the HBPE is greatly reduced; diethyl zinc is adopted as the chain transfer agent, and the HBPE is prepared from the method of ligand chain transfer polymerization, so that the HBPE is high in polymerization activity and simple in technology; the method of obtaining terminal hydroxyl groups is simple and low in cost, and has good practical value; the hydroxyl in terminal hydroxyl groups HBPE is high in reaction activity, and a plurality of polymer chains with different properties can be introduced into the HBPE through condensation reaction, coupling reaction, click chemistry reaction, and the like, to prepare polymers with various properties and different functions.

Owner:ZHEJIANG UNIV

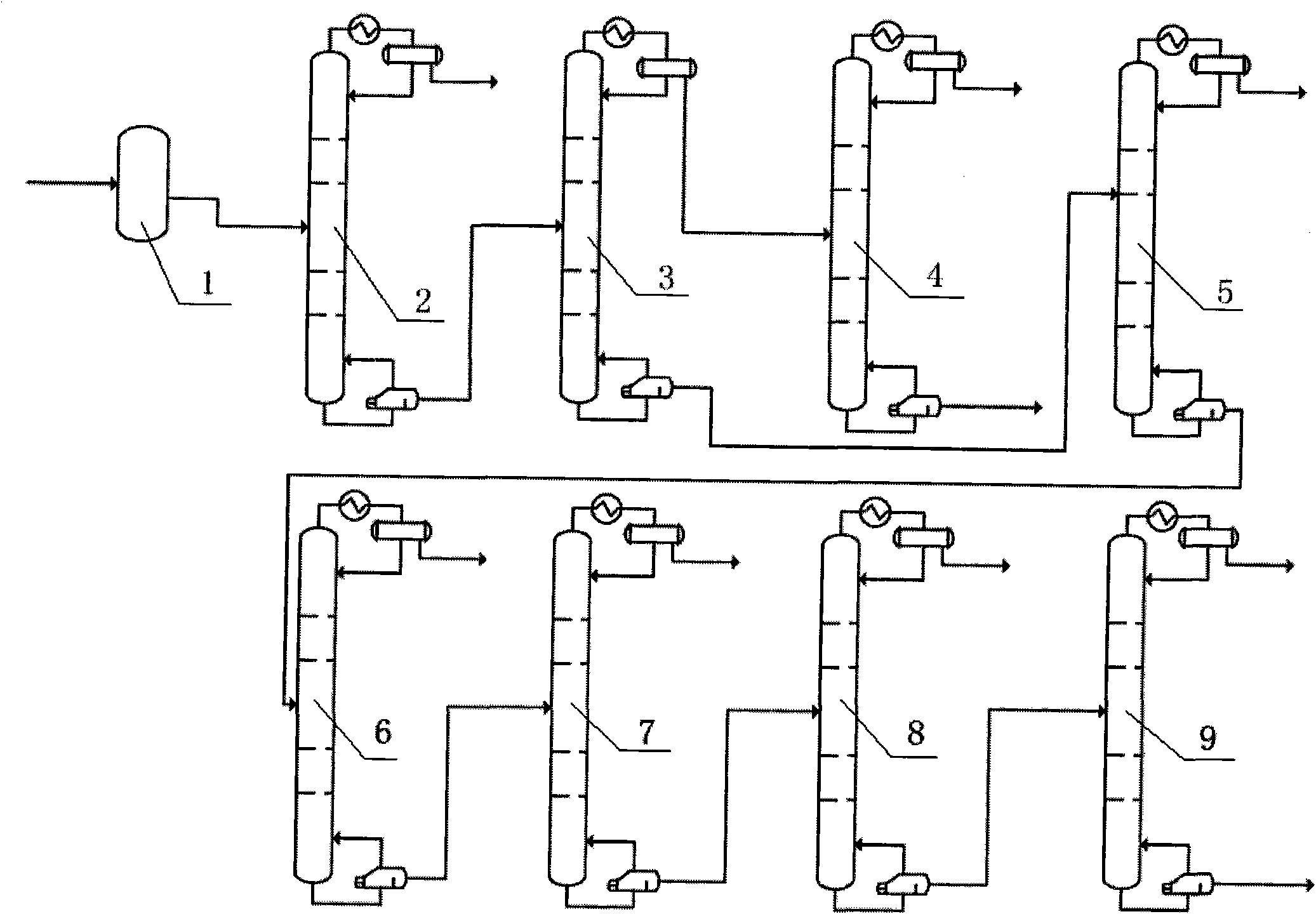

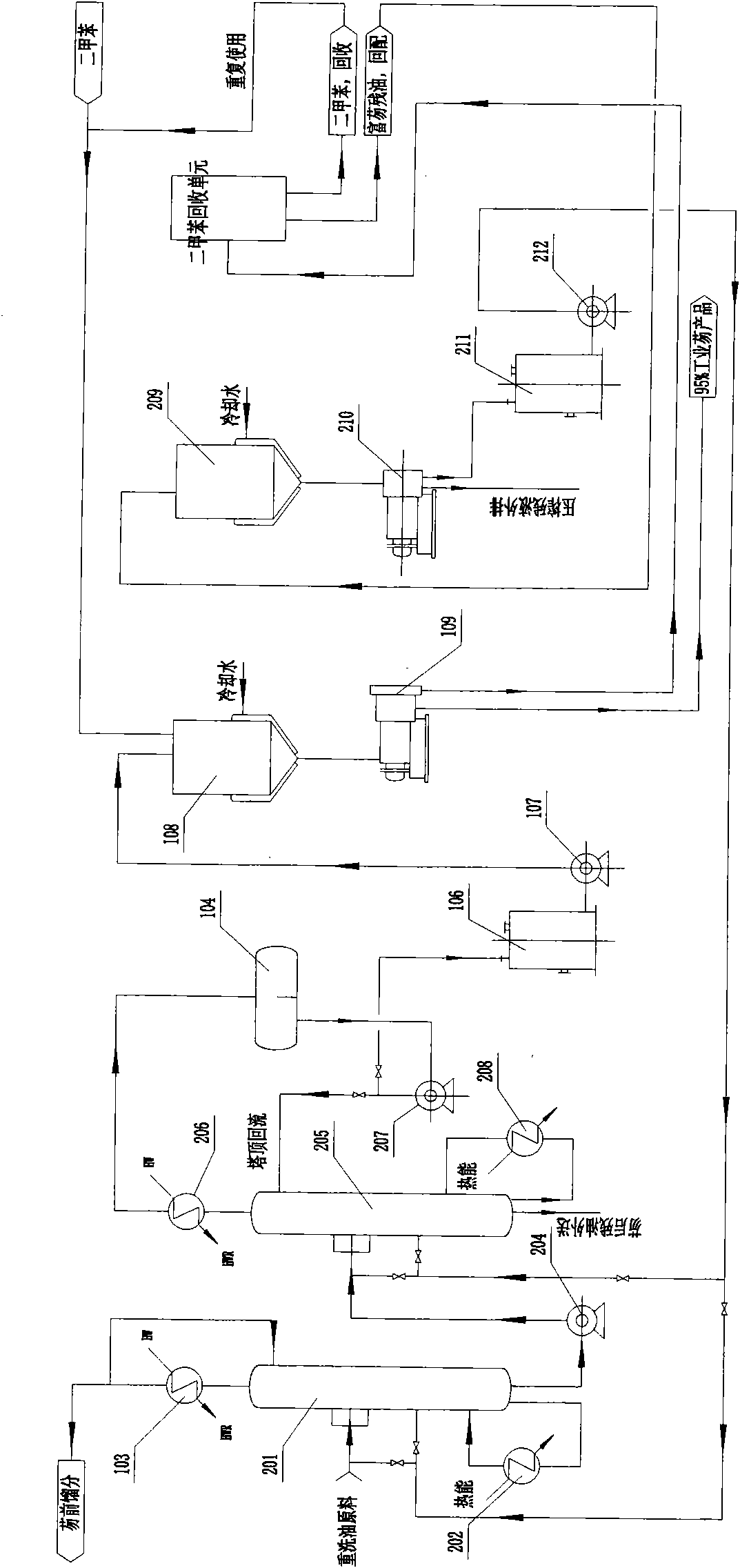

Oil-washing deep processing technology of coal tar

InactiveCN101899313AHigh economic valueReduce manufacturing costTar working-up by distillationDistillationDibenzofuran

The invention relates to an oil-washing deep processing technology of coal tar. An oil-washing fraction is a distillate with the distillation range of 230 to 300 DEG C, the oil-washing fraction sequentially passes through a washing tower (1), a naphthalene washing separation tower (2), a methyl naphthalene tower (3), a methyl naphthalene separation tower (4), an indole and biphenyl tower (5), a dimethyl naphthalene tower (6), an acenaphthene tower (7), a dibenzofuran tower (8) and a fluorene tower (9); and eight substances of 1-methyl naphthalene, 2-methyl naphthalene, and the like are separated to obtain the 1-methyl naphthalene with the mass percentage of more than 96 percent, the 2-methyl naphthalene with the purity of more than 98 percent, naphthalene with the purity of more than 99 percent, 2,6-dimethyl naphthalene, acenaphthene, dibenzofuran, fluorene, and other high value-added products.

Owner:BAOSHUN TECH CO LTD +1

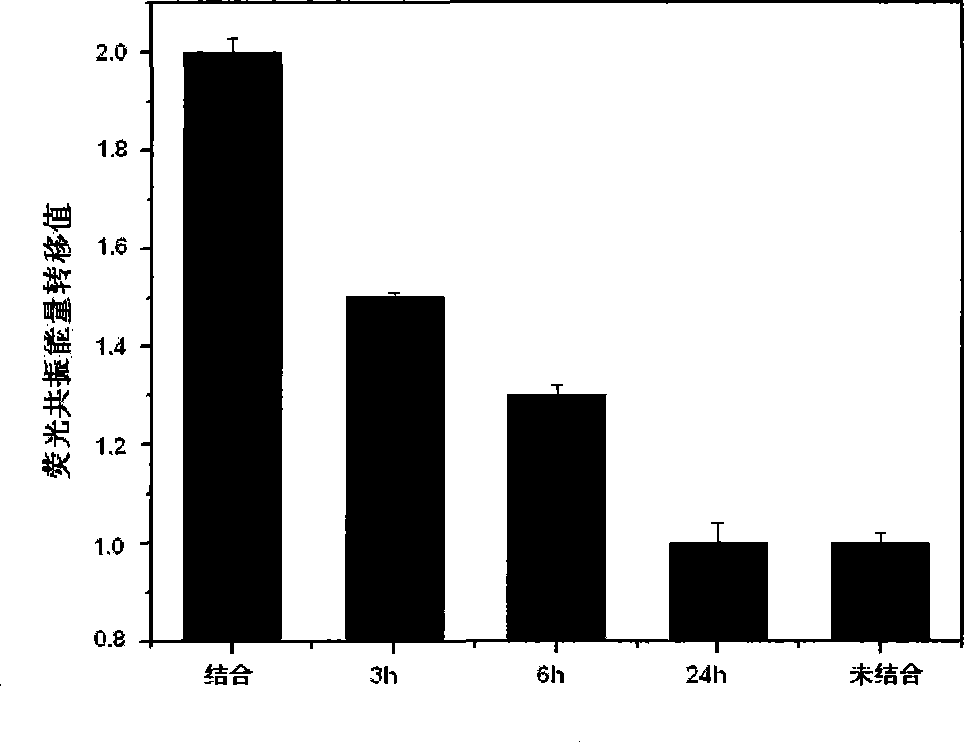

Acenaphthene heterocyclic compound and its cell fading inducing and anti-tumor use

InactiveCN1304370CGrowth inhibitionOrganic active ingredientsOrganic chemistryInducer CellsTumor cell apoptosis

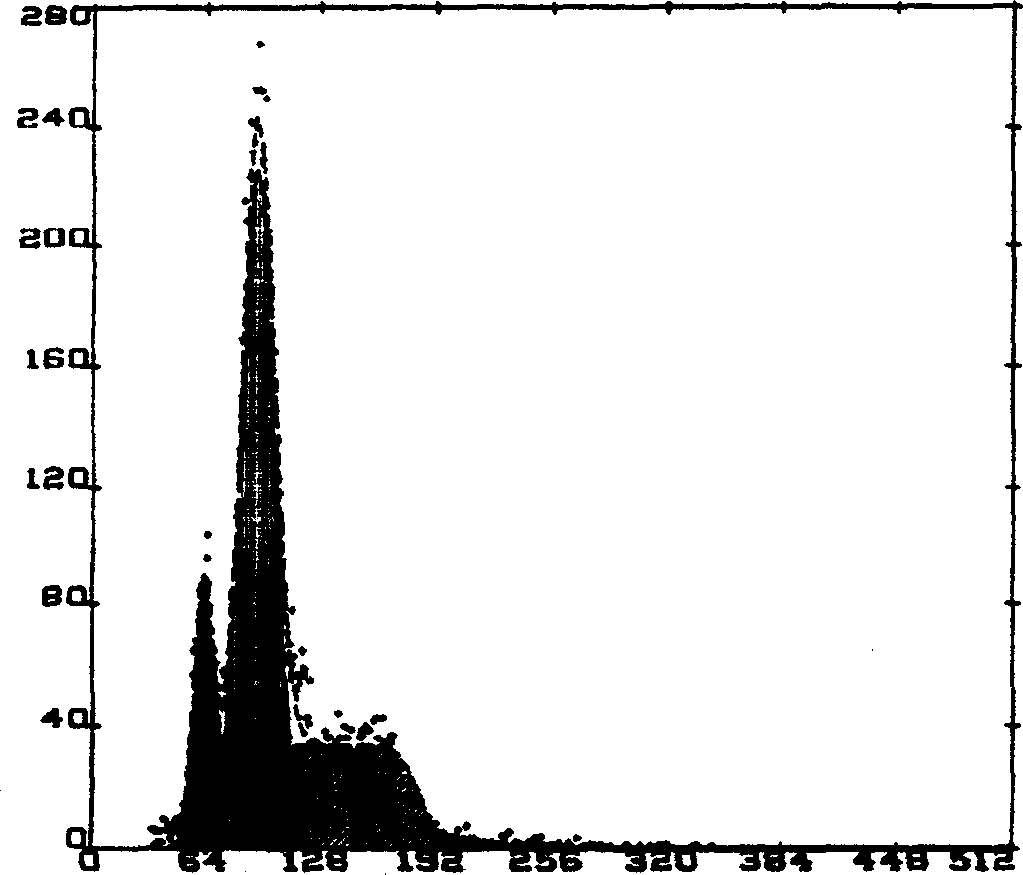

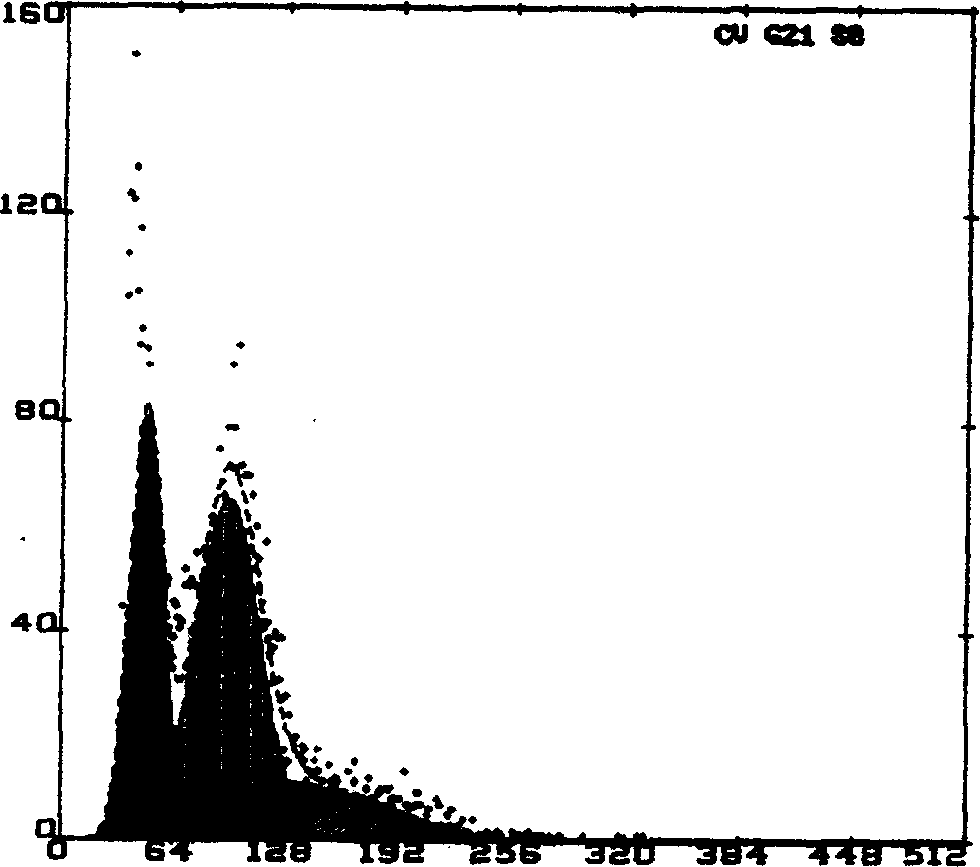

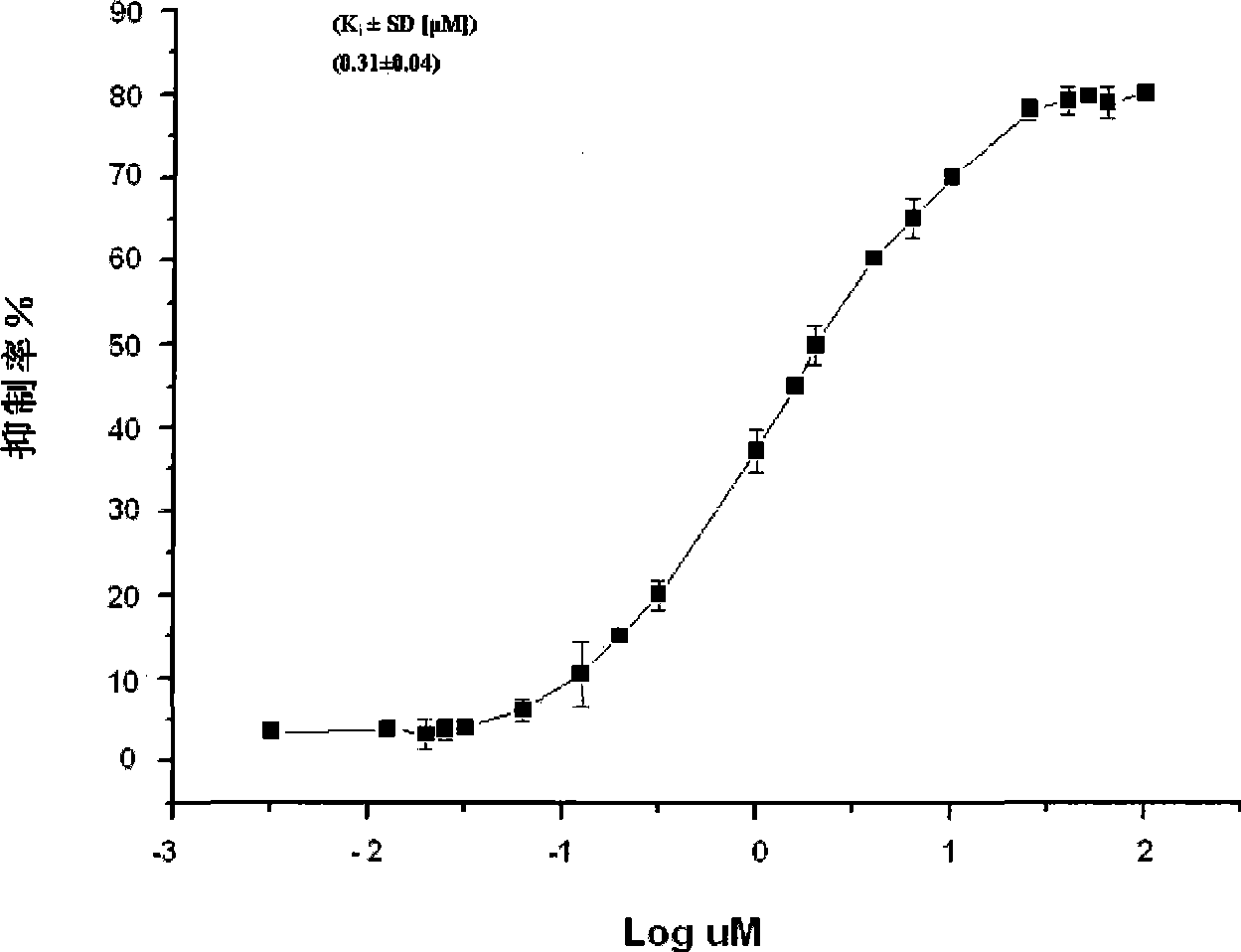

The present invention relates to a kind of amino group or halogen substituted 8-oxy-8H-acenaphthenee[1, 2-b] pyrrolyl-9-nitrile derivatives and their biological use. They are applied mainly in intracorporeal and extracorporeal inducing cell apoptosis and as anticancer compound. These compounds are 3, 6-disubstituted, 3-disubstituted or 6-substituted 8-oxy-8H-acenaphthenee[1, 2-b] pyrrolyl-9-nitrile derivatives. They can induce tumor cell apoptosis and block cell period in the dosage dependent mode within the wide concentration range of 0.01-10 micro mole. The highest activity compound B1 has IC50=0.17 micro mole (0.56 micro gram). When they are used in animal tumor model body, they can inhibit tumor growth obviously in inducing cell apoptosis mode. Therefore, the present invention is one kind of apoptosis inducing agent and antitumor compound with high activity.

Owner:DALIAN UNIV OF TECH

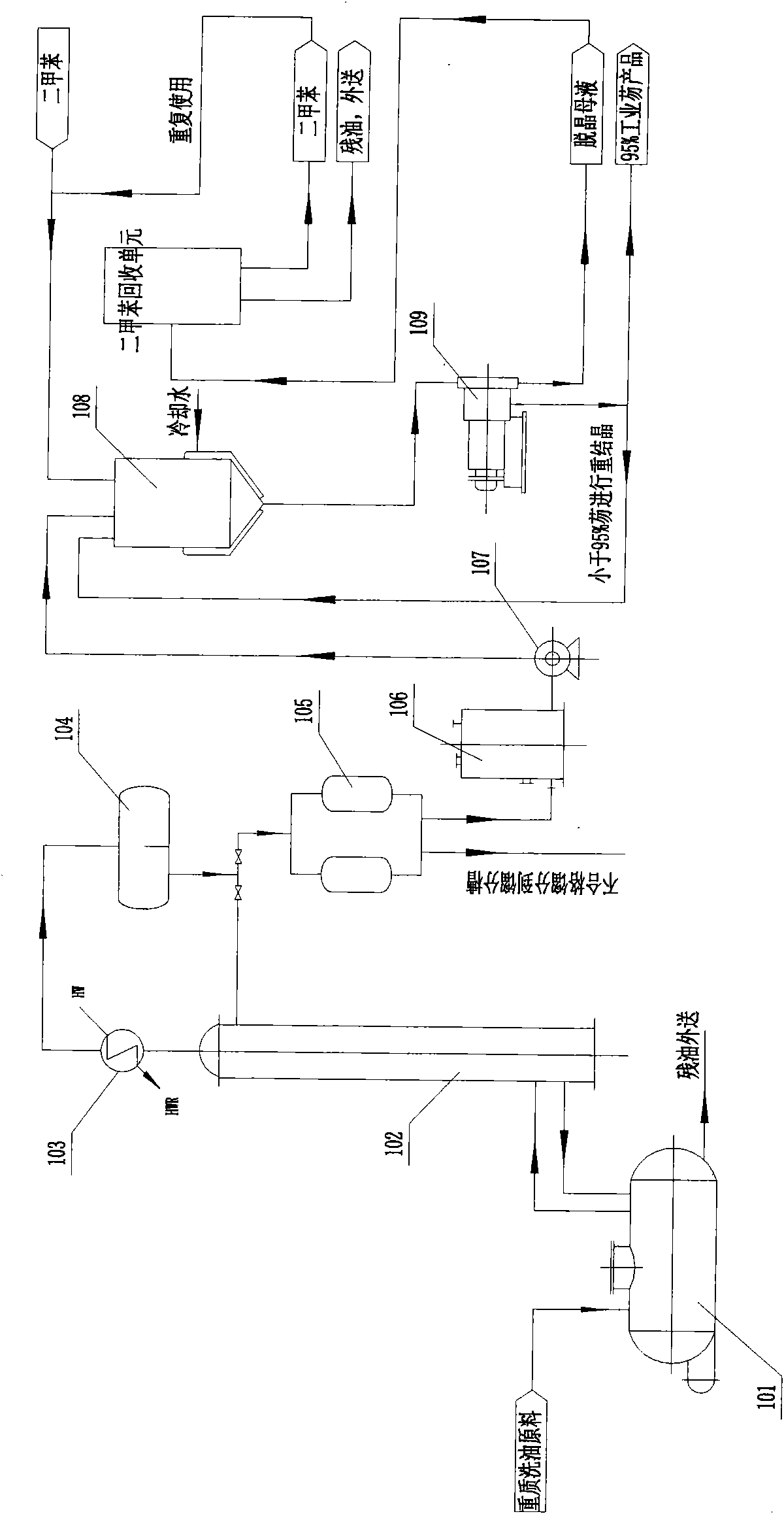

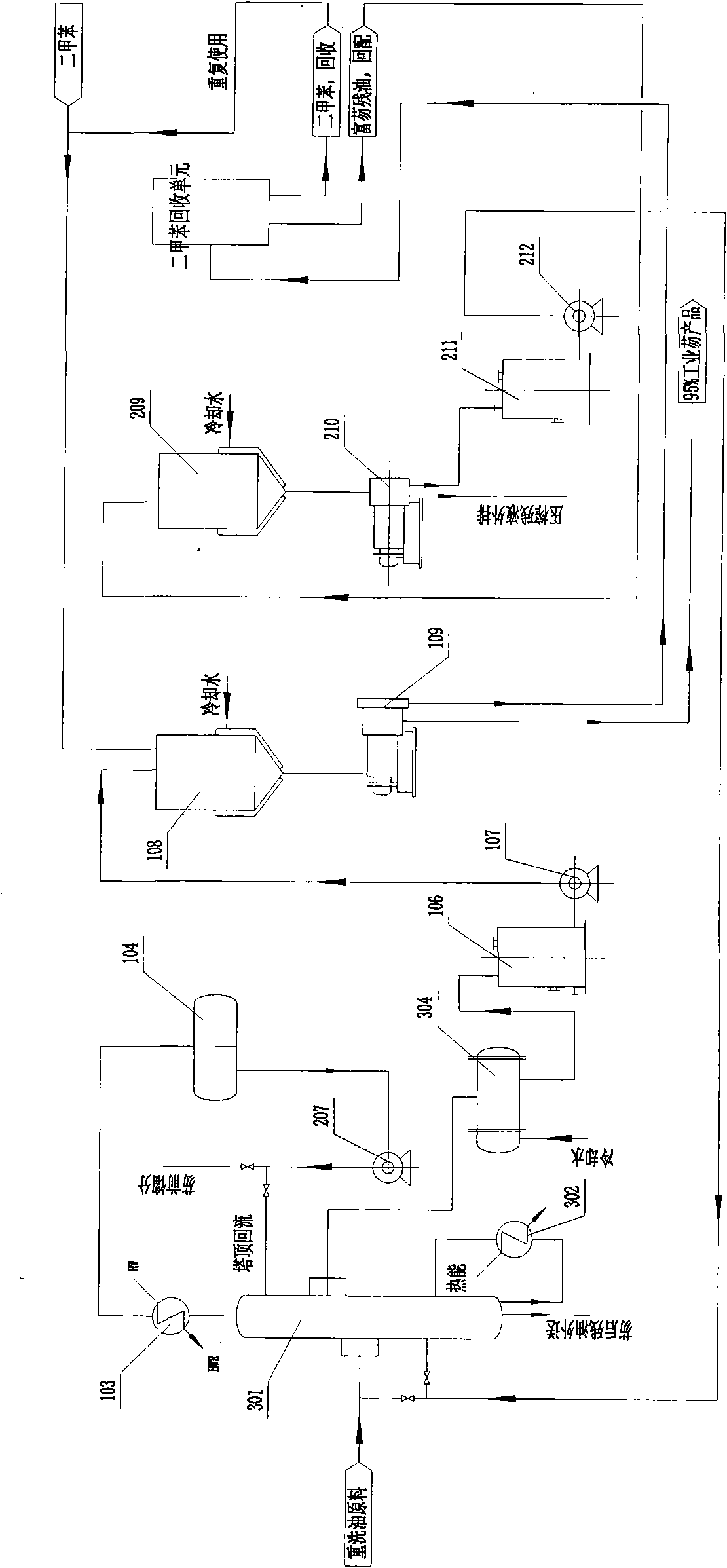

Process for producing industrial fluorene by coal tar wash oil

ActiveCN101643380AQuality improvementReduce power consumptionAbsorption purification/separationCrystallisation purification/separationOil processingProcess engineering

The invention relates to a process for producing industrial fluorene by coal tar wash oil, which produces the industrial fluorene by taking heavy washing oil obtained by removing naphthalene, methylnaphthalene, dimethylnaphthalene, acenaphthene, and the like from coal tar washing oil as raw materials, and is characterized in that the heaving washing oil is taken as raw materials, and a continuousrectification method is adopted to extract fluorene fraction which is used for producing the qualified industrial fluorene and fluorene rich residual oil through processes of solvent crystallization or cooling crystallization, solvent reclamation, recrystallization and squeezing separation (or processes of washing, crystallization and solvent reclamation); and the residual oil is returned to the raw materials of the continuous rectification process. The process is suitable for a large-scale coal tar washing oil processing device, has high automation level of the continuous rectification process, and realizes the extraction of the fluorene fraction through once rectification of the heavy washing oil. The process has the advantages of simple operation, easy control and regulation, stable acquired fraction quality, low power consumption, high production efficiency and the like; and the fluorene rich residual oil is returned to the raw materials of the continuous rectification, so the yield of an industrial fluorene product can be remarkably improved.

Owner:鞍钢集团工程技术有限公司

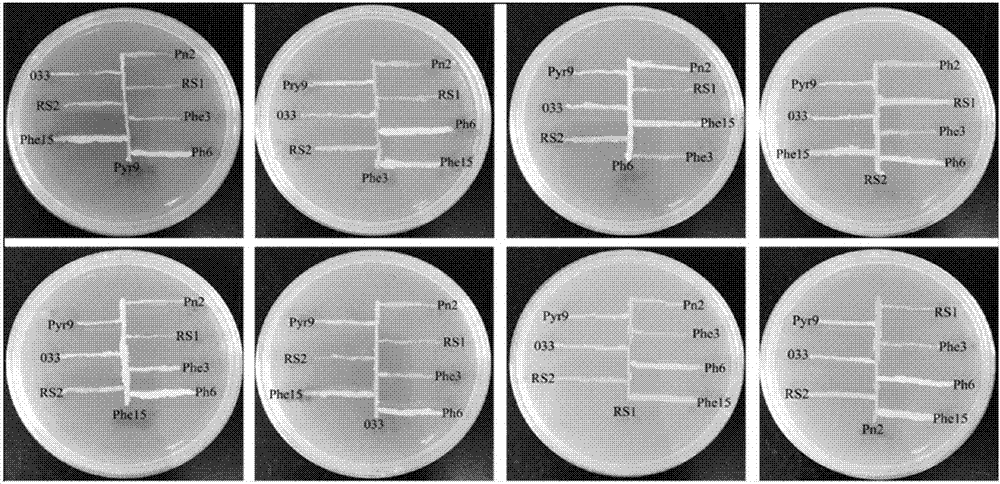

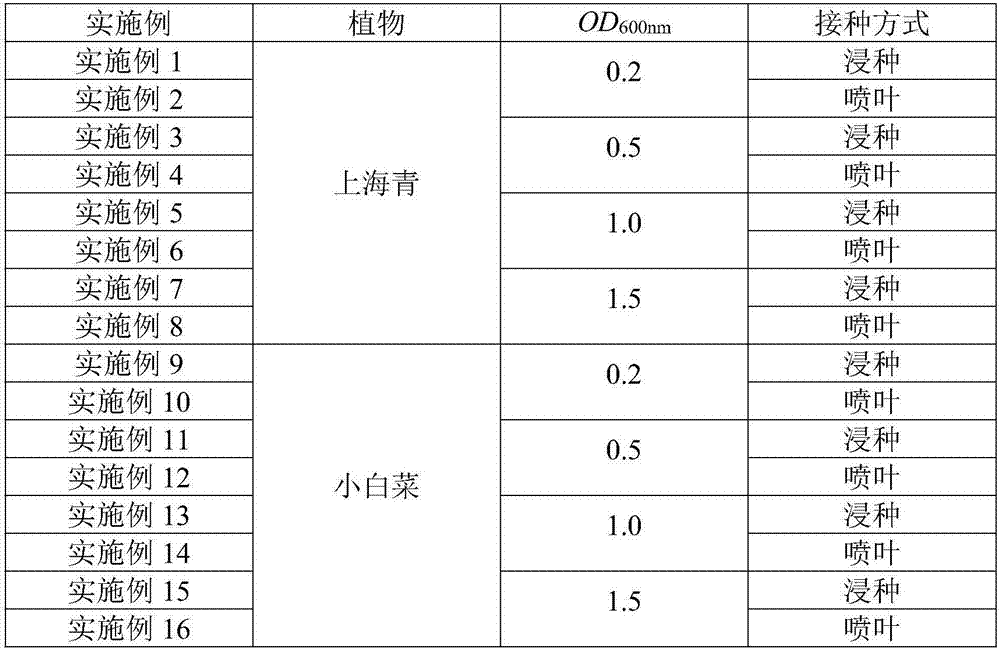

Method for simultaneously removing USEPA PAHs in plant bodies by utilizing compound PAHs degrading bacteria

ActiveCN107306532AEfficient removalEfficient degradationBiocidePlant growth regulatorsAcenaphthyleneFluoranthene

The invention discloses a method for simultaneously removing USEPA PAHs in plant bodies by utilizing compound PAHs degrading bacteria. Multiple functional bacteria are prepared into a microbial compound functional fungicide, a plant absorption promoter, cytokinin 6-BA or KT, auxin 2,4-D and cysteine are added to prepare a degradation agent, then the degradation agent is inoculated in the plant bodies, and the PAHs content in the plant body is reduced; the compound fungicide is prepared from 8 PAHs degrading bacteria different in degradation spectrum, wherein the degrading bacteria are Sphingobiumsp sp. RS1 and RS2, mycobacterium sp. Pyr9, 033, Diaphorobacter sp. Phe15 and Massilia sp. Pn2, Paenibacillus sp. Phe3, Pseudomonas sp. Ph6 respectively. The acenaphthylene, acenaphthene, fluorene, phenanthrene, anthracene, fluoranthene, pyrene, benzo[a] anthracene, benzo[b]fluoranthene, benzo[k]fluoranthene, benzo[a]pyrene, dibenzo[a,h] anthracene, benzo[ghi]indene and [1,2,3-cd] pyrene in each plant body in a contaminated area can be effectively removed and degraded, the removal rate of PAHs is high, and the method has the advantages of high efficiency, environmental protection and easy operation.

Owner:NANJING AGRICULTURAL UNIVERSITY

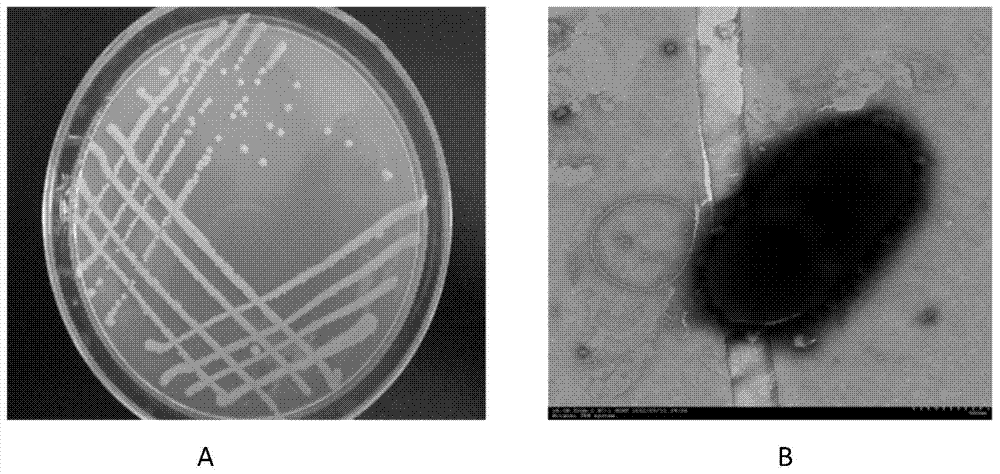

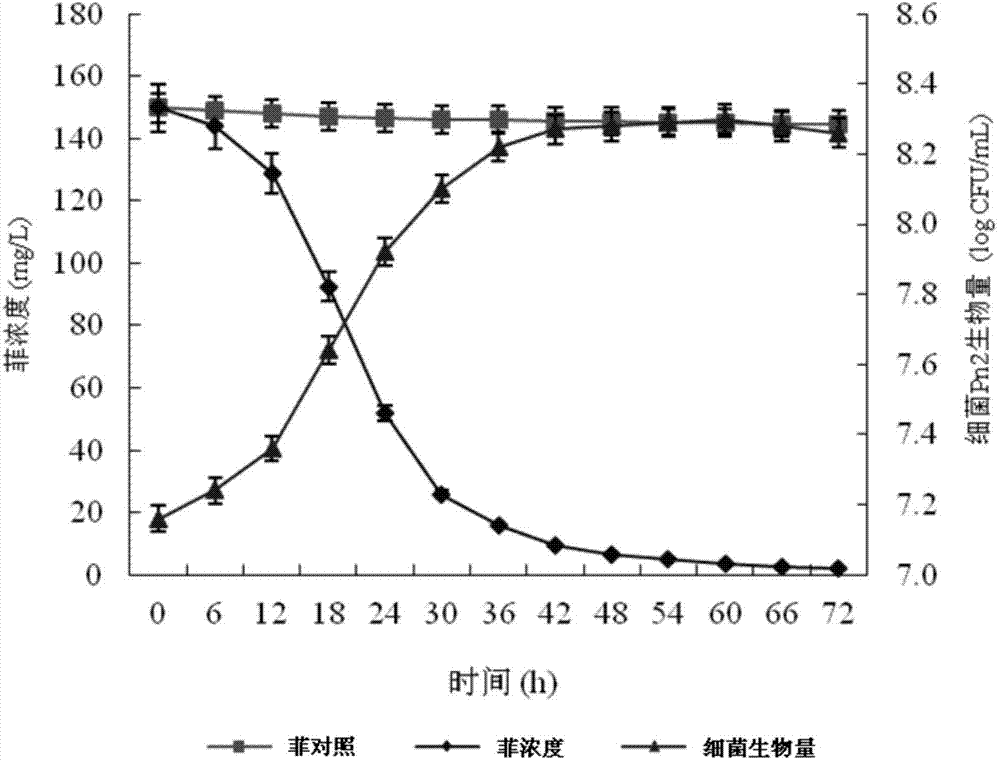

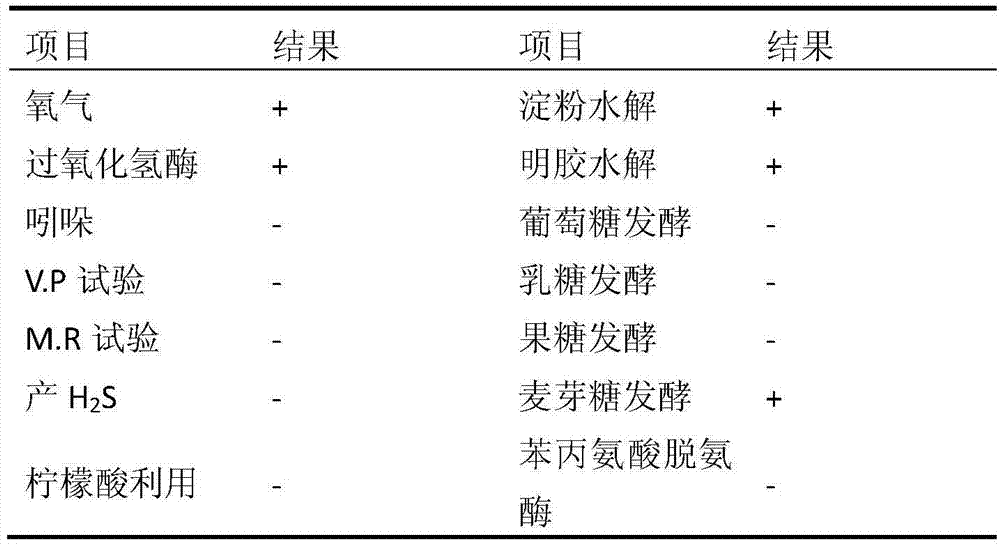

Plant-growth-promoting endophytic bacterium having polycyclic aromatic hydrocarbons degrading function and application thereof

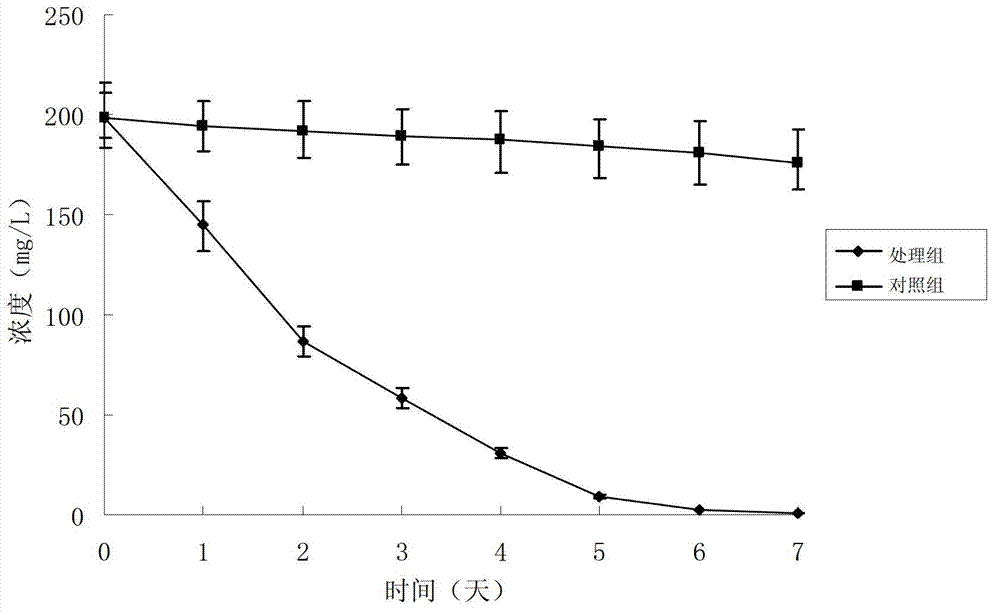

ActiveCN104263682AReduce the risk of pollution in the PhilippinesPhenanthrene content decreasedBacteriaWater contaminantsBacteroidesPlant roots

The invention discloses a plant-growth-promoting endophytic bacterium having a polycyclic aromatic hydrocarbons degrading function and application thereof. The plant-growth-promoting endophytic bacterium having the polycyclic aromatic hydrocarbons degrading function, namely Massilia bacterium Pn2 is preserved in China General Microbiological Culture Collection Center and has the preservation number of CGMCC 1.12927. By virtue of a microbial agent prepared by the strain, the degradation rate of phenanthrene of which the initial concentration is 150mg.L<-1> can reach up to above 95% within 3 days under the condition of laboratory shake-flask culture and meanwhile, naphthalene, acenaphthene, anthracene and pyrene can be degraded in different degrees by virtue of the bacterium, the microbial agent is colonized on the surface of a plant root by virtue of a root dipping treatment and then the plant is planted in a nutrient solution contaminated by virtue of phenanthrene so that the content of phenanthrene within a plant body can be reduced by above 50% within short time, the risk of phenanthrene contamination of the plant body is obviously reduced and the endophytic bacterium has a significant plant growth promoting effect.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for extracting biphenyl from middle washing oil

InactiveCN101182277AHigh extraction rateSimple processDistillation purification/separationBenzeneTheoretical plate

The invention discloses a method of extracting biphenyl from medium wash oil. The medium wash oil containing 15 percent of biphenyl is used as the raw material to be processed for three times of batchdistillations inside a rectifying still and a distillation column with the theoretical plate number of 50 to 80 pieces to obtain the biphenyl product, the purity of which is more than 95 percent, andat the same time, industrial methylnaphthalene, mixed dimethyl naphthalene fraction and acenaphthene fraction are obtained. The technology of the invention is simple and is easy for grasping. Under thetechnical condition that the devices for the three times distillations, the theoretical plate number of the distillation column, the pressure of the rectifying still, the reflux ration and the temper ature of the rectifying still are same, the required products can be produced just by slightly adjusting the temperature of the rectifying still and the top temperature of the distillation column. Theextraction rate of the biphenyl can be more than 70 percent. A coking plant which produces 4000t medium wash oil yearly can produce 400t biphenyl product yearly, the biphenyl content of which is more than 95 percent, and the coking plant can obtain 1000t industrial methylnaphthalene, 1300t mixed dimethyl naphthalene fraction and 1200t acenaphthene fraction at the same time, so the comprehensiveeconomic benefit is very considerable.

Owner:ANGANG STEEL CO LTD

Method for producing polythene/POSS modified tough clay nano composite material

InactiveCN101173071AIn situ polymerization preparation method is simpleImprove thermal stabilityClay mineralsSolvent

The invention provides a preparation method of a polyethylene / POSS modified clay nanocomposite material. In the method, the layered inorganic clay is firstly modified with POSS with amino groups, and then the POSS modified clay is treated with alkyl aluminum and then N, N'-bis(2,6-diisopropylphenyl) acenaphthylenediimide (ArN=C(An)-C(An)=NAr, An=acenaphthene, Ar=2,6-( The i-Pr)2C6H3) nickel complex is used as a supported catalyst, and diethylaluminum chloride is used as a cocatalyst, and the supported catalyst is used to catalyze ethylene polymerization in situ in a non-polar solvent to prepare a polyethylene / POSS modified clay nanocomposite. The invention uses POSS to modify the inorganic clay, which avoids the disadvantage of thermal instability, and at the same time makes N, N'-bis(2,6-diisopropylphenyl)acenaphthyldiimide (ArN=C(An )-C(An)=NAr, An=acenaphthene, Ar=2,6-(i-Pr)2C6H3) Nickel complexes can be effectively fixed between the clay sheets, which is beneficial to the clay sheets in the ethylene polymerization process in the stripping. Compared with pure polyethylene, the heat stability and dynamic mechanical storage modulus of the polyethylene / POSS modified clay nanocomposite prepared by the invention are greatly improved.

Owner:SUN YAT SEN UNIV

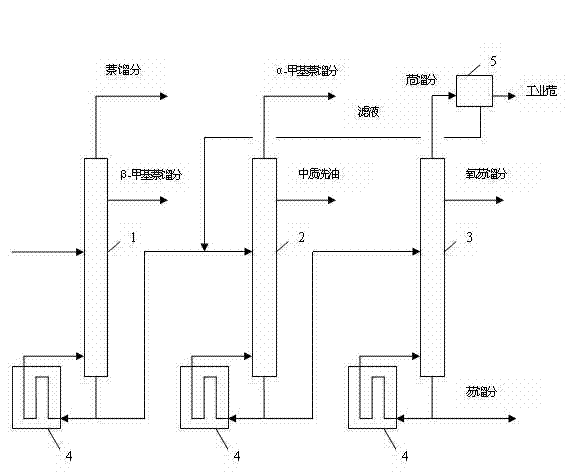

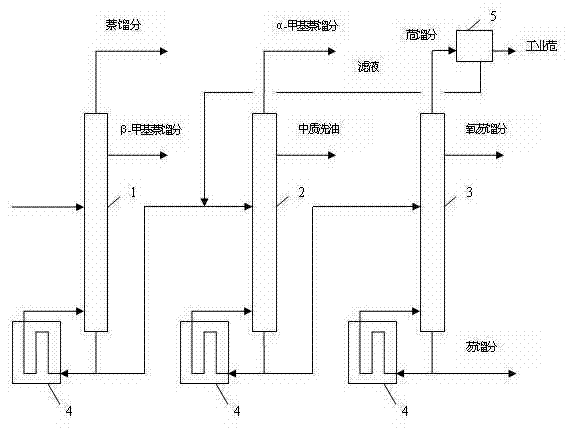

A deep processing technology for coking washing oil

The invention relates to a deep processing technology for coking wash oil. The coking wash oil serving as a raw material passes through three continuous rectification towers respectively provided with a side extraction port in sequence, so that a naphthalene fraction with naphthalene content of more than 80 percent, a beta-methyl naphthalene fraction with beta-methyl naphthalene content of more than 70 percent, an alpha-methyl naphthalene fraction with alpha-methyl naphthalene content of more than 60 percent, medium wash oil, an acenaphthene fraction with acenaphthene content of more than 60 percent, a dibenzofuran fraction with dibenzofuran content of more than 55 percent and a fluorene fraction with fluorene content of more than 50 percent can be extracted at one step. The technology iseasy to operate and low in equipment investment, has various types of product fractions, provides great convenience for further obtaining industrial products of naphthalene, beta-methyl naphthalene, alpha-methyl naphthalene, acenaphthene, fluorene and the like, and is particularly suitable for being matched with wash oil fraction deep processing of coal tar processing enterprises with scale of 15-30 megatons / year.

Owner:LIAONING INST OF SCI & TECH

Composite catalist of titanium substitued nickle acenaphthene diimine of synthesizing branched polyvinyl and its preparation process

InactiveCN1560092AImprove performanceIncrease the degree of branchingLow-density polyethyleneDiimine

The invention relates to a Ti-substituted acenaphthene diimine nickel compound catalyste for synthesizing branched polyethylene and its preparing method, supporting Ti compound and substituted acenaphthene diimine nickel complex on a SiO2-MgCl2 compound carrier to act as a main catalyst and using alkyl Al and AlEt2Cl as aid-catalyst. The preparing method adopts dip-reaction method, and the obtained compound catalyst has a spherical particle shape and can make highly branched low-density polyethylene plastics.

Owner:SUN YAT SEN UNIV

Acenaphthene heterocyclic compound and its cell fading inducing and anti-tumor use

InactiveCN1616428AGrowth inhibitionOrganic active ingredientsOrganic chemistryInducer CellsTumor cell apoptosis

The present invention relates to a kind of amino group or halogen substituted 8-oxy-8H-acenaphthenee[1, 2-b] pyrrolyl-9-nitrile derivatives and their biological use. They are applied mainly in intracorporeal and extracorporeal inducing cell apoptosis and as anticancer compound. These compounds are 3, 6-disubstituted, 3-disubstituted or 6-substituted 8-oxy-8H-acenaphthenee[1, 2-b] pyrrolyl-9-nitrile derivatives. They can induce tumor cell apoptosis and block cell period in the dosage dependent mode within the wide concentration range of 0.01-10 micro mole. The highest activity compound B1 has IC50=0.17 micro mole (0.56 micro gram). When they are used in animal tumor model body, they can inhibit tumor growth obviously in inducing cell apoptosis mode. Therefore, the present invention is one kind of apoptosis inducing agent and antitumor compound with high activity.

Owner:DALIAN UNIV OF TECH

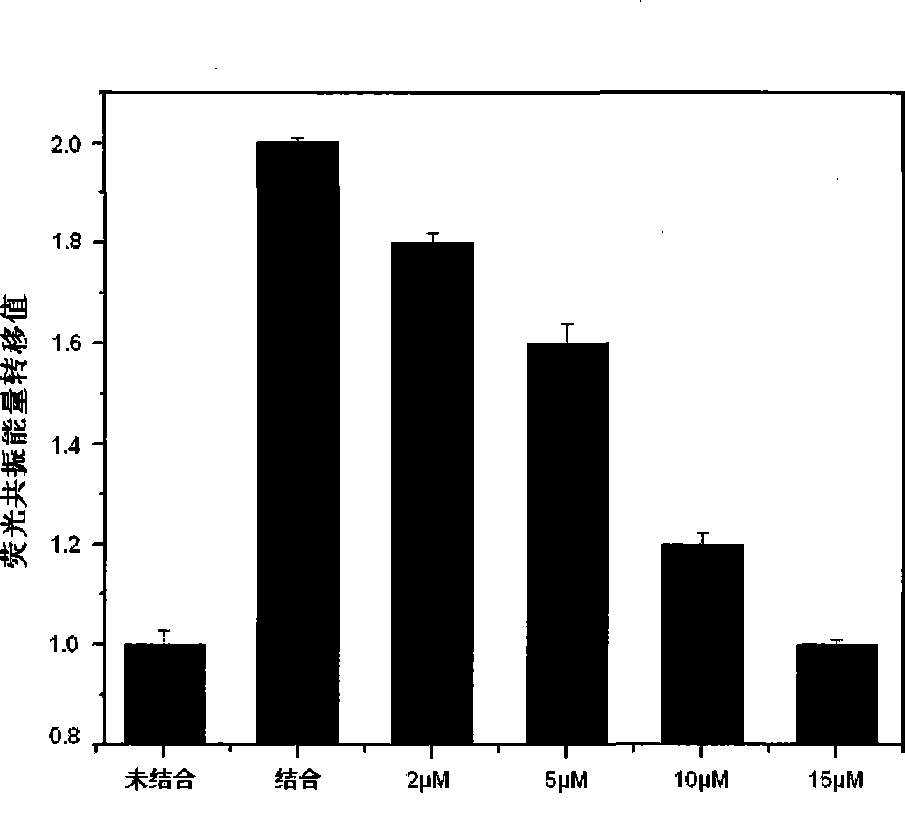

Acenaphtho-heterocycles compounds and application thereof in preparation of BH3 analogue Bcl-2 family protein inhibitor

Owner:DALIAN UNIV OF TECH

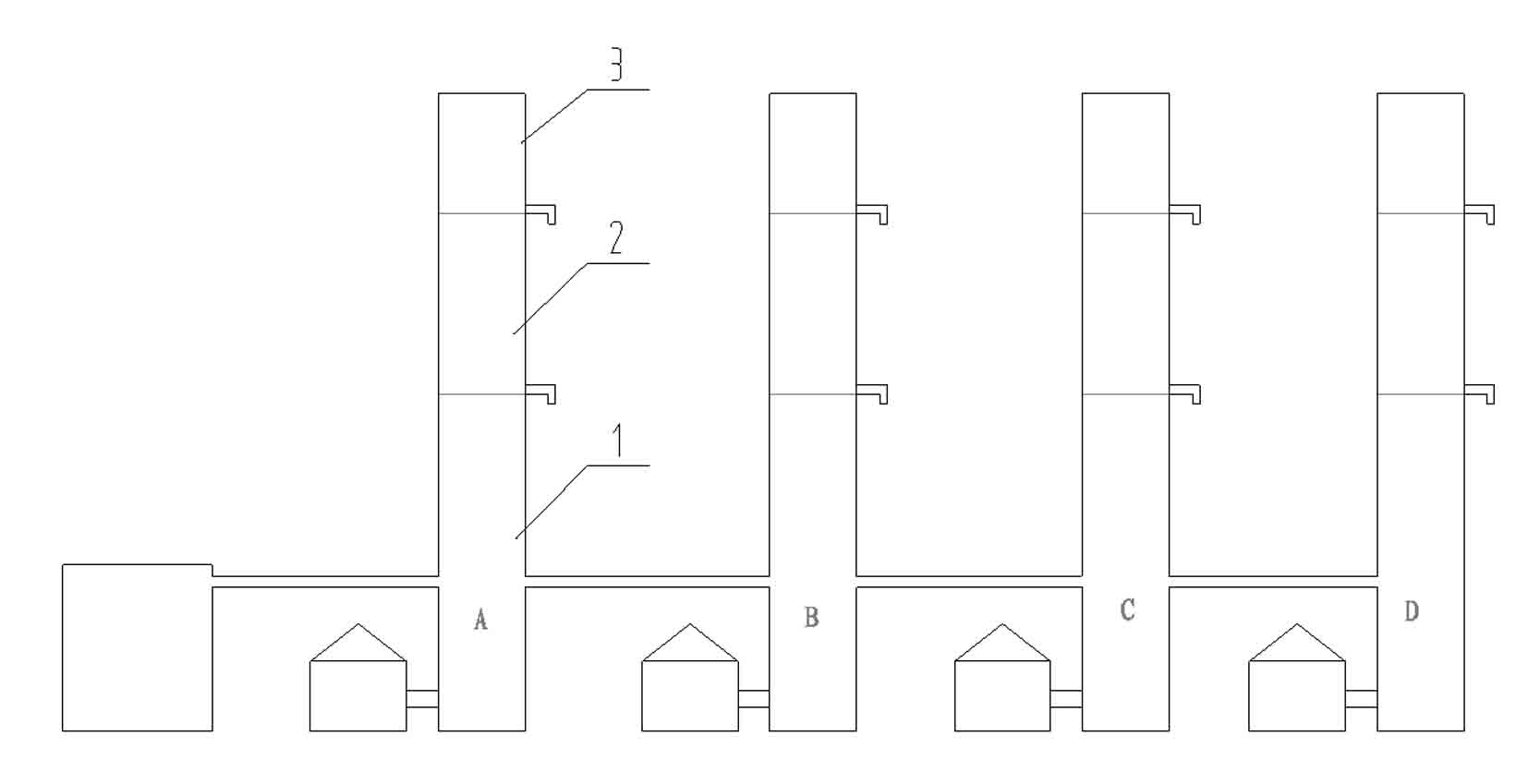

Washing oil continuous processing method

ActiveCN101982523AIncrease productionImprove product qualityDistillation purification/separationTar working-up by distillationOil processingDibenzofuran

The invention discloses a continuous washing oil processing method. Reaction is taken place in four rectifying towers (A, B, C and D) sequentially, raw material washing oil is pumped into a rectifying tower A, naphthalene oil is extracted at the top of tower, methylnaphthalene is extracted at the lateral line, residual oil at the bottom of tower is pumped into a rectifying tower B; middle grade washing oil is extracted at the top of the rectifying tower B, acenaphthene fraction is extracted at the lateral line, crystallization and separation are carried out, thus obtaining industrial acenaphthene, and residual oil at the bottom of tower enters into a rectifying tower C; acenaphthene fraction is extracted at the top of the rectifying tower C again, dibenzofuran fraction is extracted at thelateral line, and residual oil at the bottom of tower is pumped into a rectifying tower D; dibenzofuran fraction is extracted at the top of the rectifying tower D, acenaphthene fraction is extracted at the lateral line, and the acenaphthene fraction is subject to solvent treatment, thus obtaining industrial acenaphthene. The invention has the characteristics of high production capacity, stable product quality and low energy consumption.

Owner:孝义市金精化工有限公司

Method of extracting high purity acenaphthene from coat tar scrubbing oil

InactiveCN1651367AHigh recovery rateReduce energy consumptionDistillation purification/separationOrganic solventTar

A process for extracting high-purity acenaphthene from the washing oil of tar includes such steps as single-tower vacuum rectifying to obtain acenaphthene fraction at 235-245 deg.C mixing it with organic solvent, and recrystallizing. Its purity is more than 99%.

Owner:HARBIN ENG UNIV

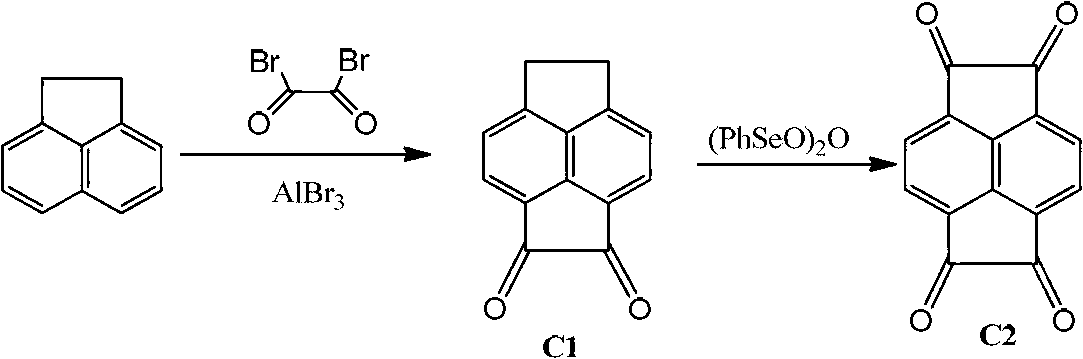

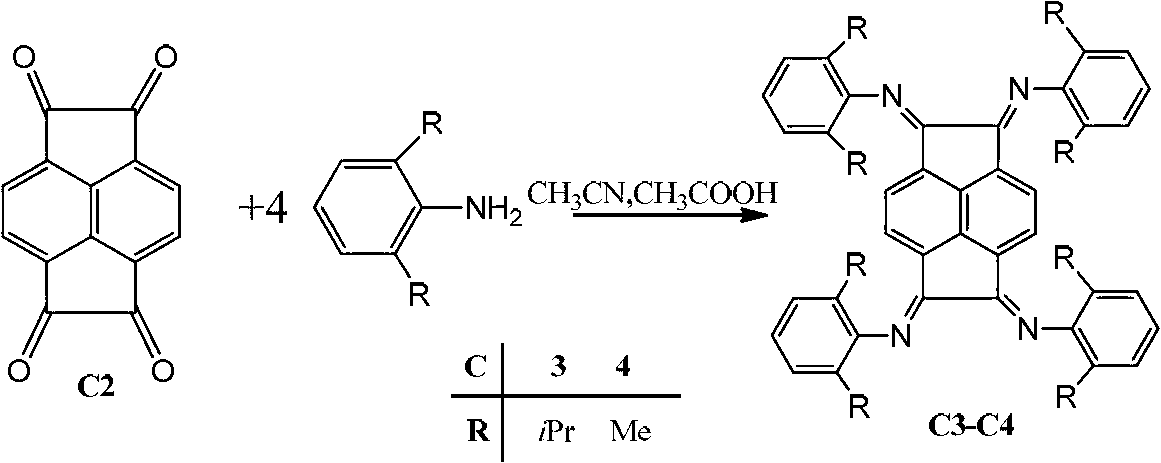

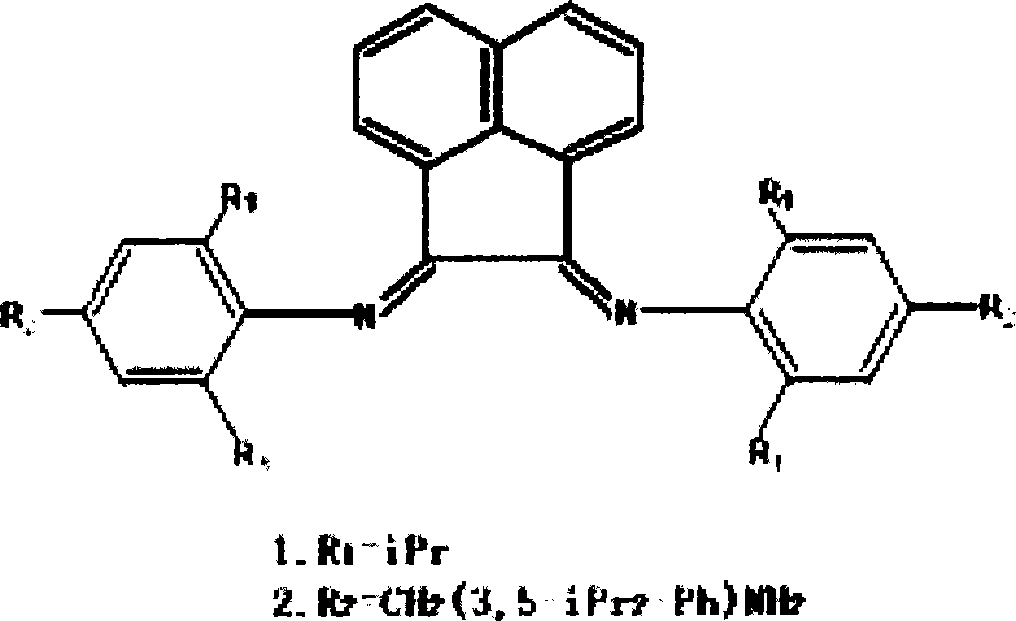

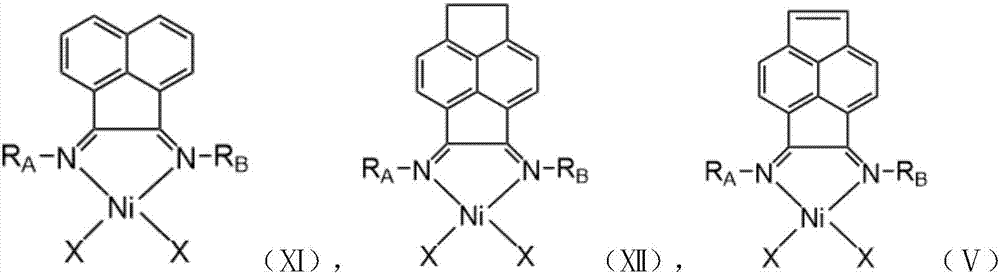

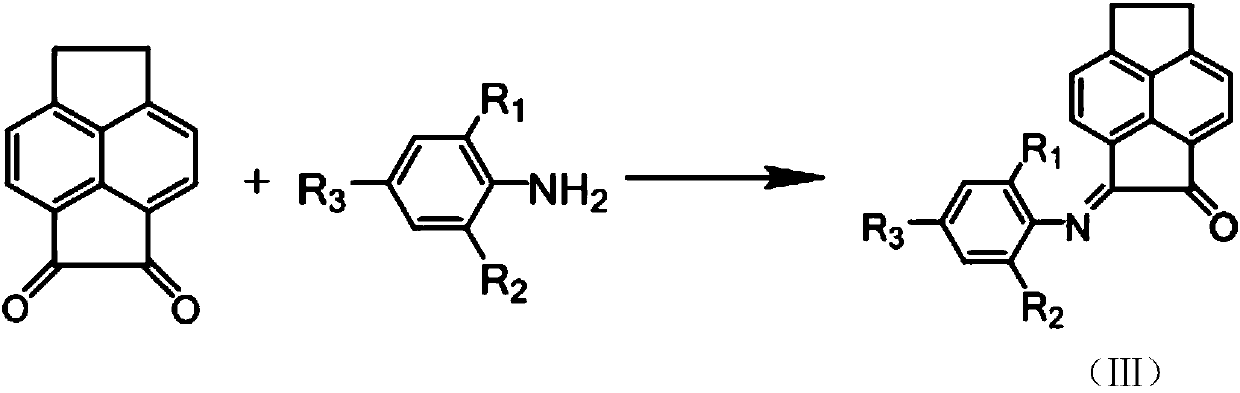

Vinylene acenaphthene (alpha-diimine) nickel olefin catalyst, and preparation method and application thereof

ActiveCN108003259AHigh activityImprove thermal stabilityNickel organic compoundsBulk chemical productionKetoneAniline

The invention relates to the field of olefin catalytic polymerization, and aims at providing a vinylene acenaphthene (alpha-diimine) nickel olefin catalyst, and preparation and an application thereof.The preparation comprises the typical synthetic steps: carrying out a diacylation reaction of acenaphthene to obtain a compound C1; carrying out a bromination reaction of the compound C1 and N-bromosuccinimide (NBS) to obtain a compound C2; carrying out an elimination reaction of the compound C2 to obtain a compound C3; carrying out ketone amine condensation reaction of the compound C3 with symmetric aniline, to obtain alpha-diimine ligands C4-C8; and under anhydrous and anaerobic conditions, complexing the alpha-diimine ligands C4-C8 with ethylene glycol dimethyl ether nickel dibromide to obtain a final product. The catalyst has higher activity and better thermal stability, and can catalyze ethylene with high activity at the temperature of greater than or equal to 60 DEG C to obtain high-molecular-weight hyperbranched polyethylene. Under the same polymerization conditions, ethylene can be catalyzed to polymerize to obtain branched polyethylene with higher molecular weight, so as to meet more application requirements. The cost of raw materials is low, the reaction yield is high and industrialized production can be achieved.

Owner:ZHEJIANG UNIV

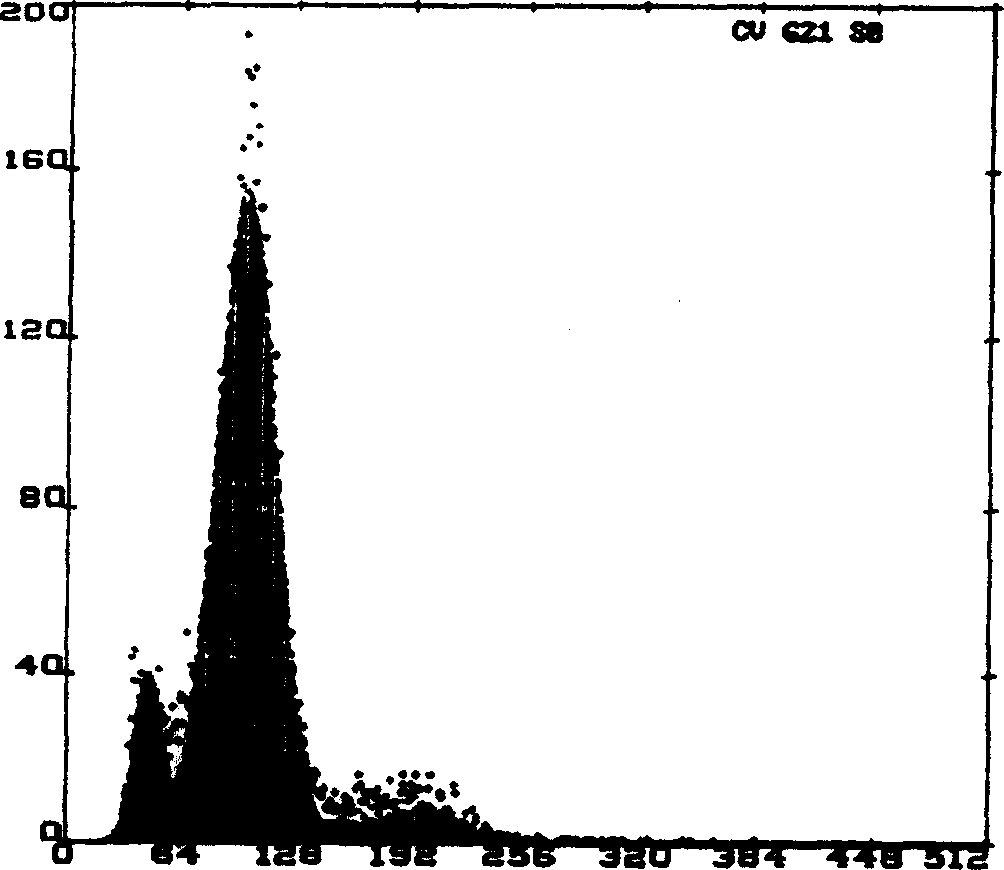

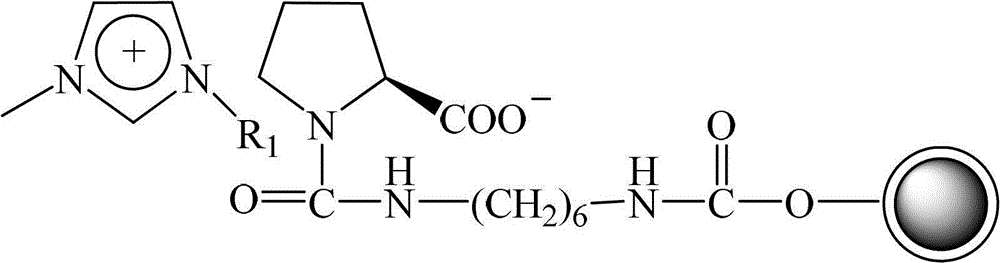

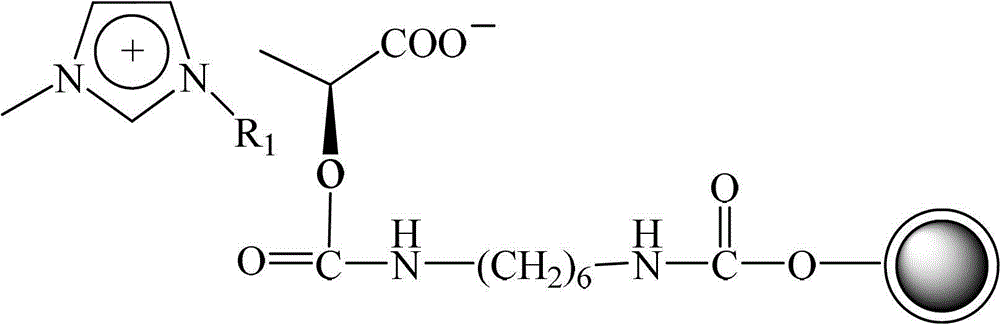

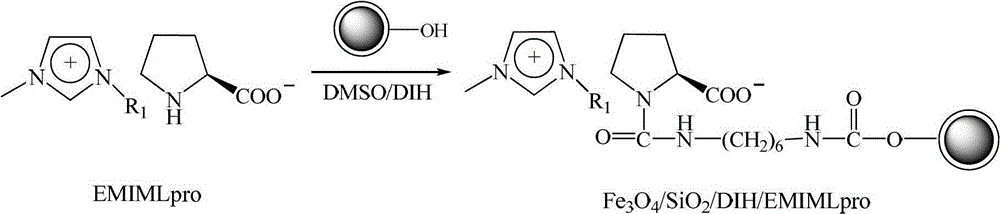

Chiral ionic liquid magnetic nanoparticle product and preparation method and application thereof

InactiveCN102718713AEasy to separateCreate pollutionMaterial nanotechnologyNanomagnetismMagnetite NanoparticlesSuccinic acid

The invention relates to a chiral ionic liquid magnetic nanoparticle product and a preparation method and application thereof. The preparation method comprises the following steps: dissolving FeCl3.6H2O, succinic acid and urea into 1,2-propanediol, putting the solution into a reaction kettle, and reacting to obtain an Fe3O4 magnetic nanoparticle; adding the Fe3O4 magnetic nanoparticle into a mixed solvent of H2O and EtOH, adding NH3.H2O and TEOS (tetraethoxysilane), and reacting to obtain Fe3O4 / SiO2; and adding the Fe3O4 / SiO2 into dimethyl sulfoxide, adding 1-alkyl-3-methylimidazolyl-L-proline salt or 1-alkyl-3-methylimidazolyl-L-lactate ionic liquid, and adding hexamethylene-1,6-diisocyanate to obtain the chiral imidazole ionic liquid magnetic nanoparticle. During application of the chiral ionic liquid magnetic nanoparticle to chiral separation of 1-phenyl-1,2-ethylene glycol and 1-hydroxy acenaphthene, the separation time is short, the operation is simple and convenient, and the separation effect of a chiral compound is good.

Owner:BEIJING UNIV OF CHEM TECH

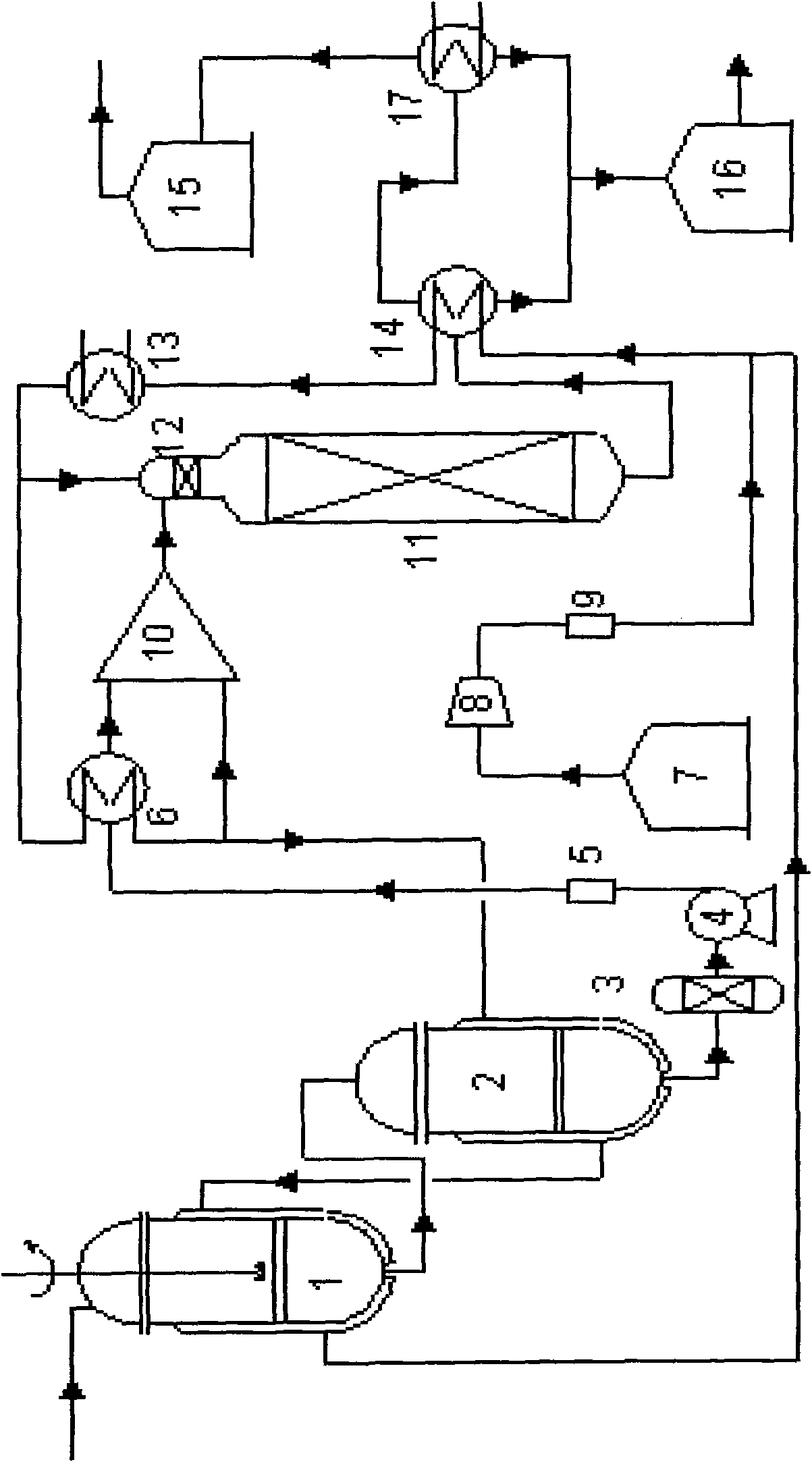

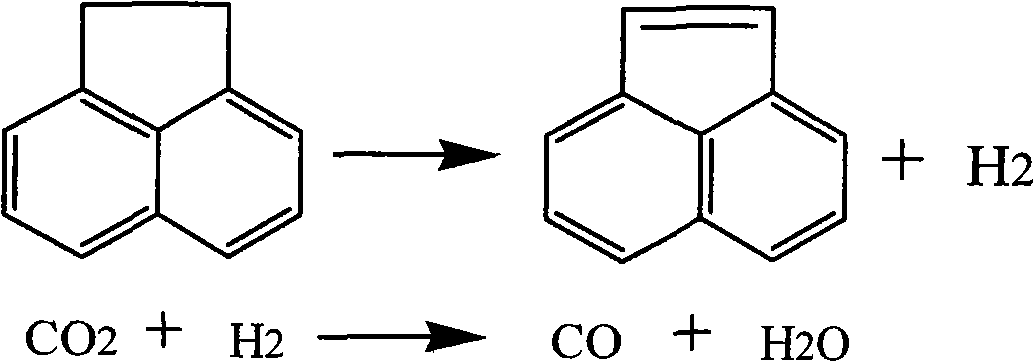

Preparation method and reaction device of acenaphthylene

InactiveCN101955407AImprove conversion rateHigh selectivityFractional condensation purification/separationHydrocarbonsAcenaphthyleneFixed bed

The invention relates to a preparation method and reaction device of acenaphthylene. The preparation method adopts the continuous gas-solid catalytic reaction process of the fixed bed reactor and comprises the following specific steps: A, melting the raw material acenaphthene; B, vaporizing the molten acenaphthene at 290-350 DEG C; C, vaporizing acenaphthene under the liquid space velocity of 0.1-1.0h<-1>, then fast mixing CO2 with gaseous acenaphthene in the molar ratio of 1:1-60:1 at 350-400 DEG C; and D, preheating the mixed gas to 560-700 DEG C, sending the preheated gas mixture in a reactor to flow through a catalyst bed layer, and performing catalytic oxydehydrogenation at 560-700 DEG C to prepare a liquid reaction product mainly containing acenaphthylene. The preparation method of the invention has the advantages of simple flow, continuous and convenient operation, low cost, low energy consumption and environmental friend; and the greenhouse gas CO2 is competely recycled and a new technical way for synthesizing acenaphthylene is provided.

Owner:EAST CHINA UNIV OF SCI & TECH

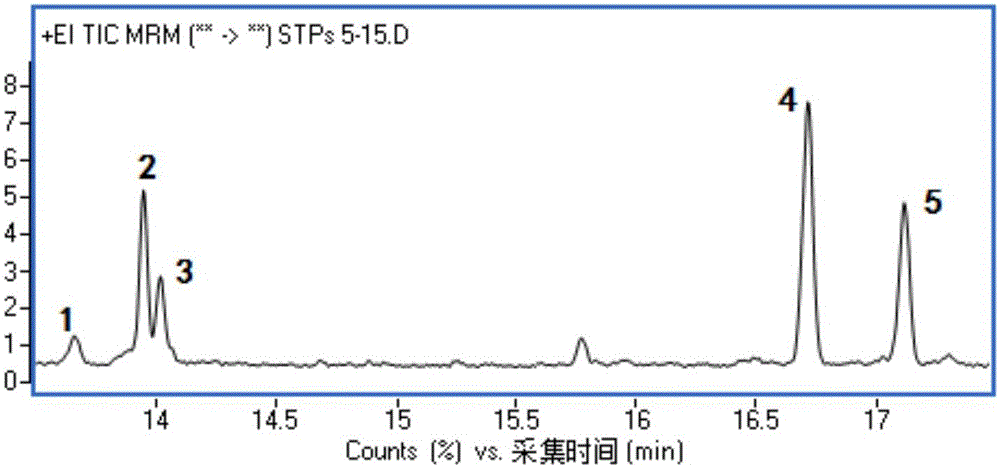

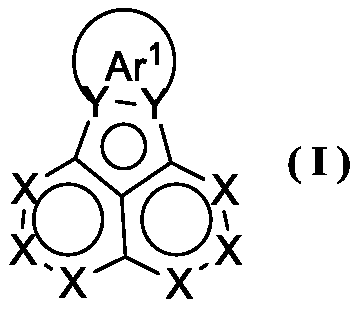

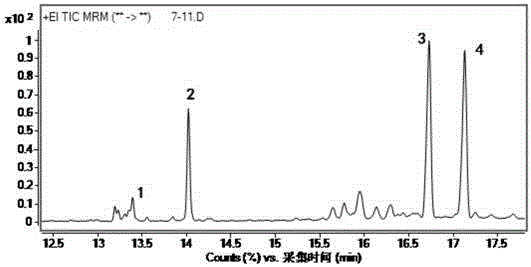

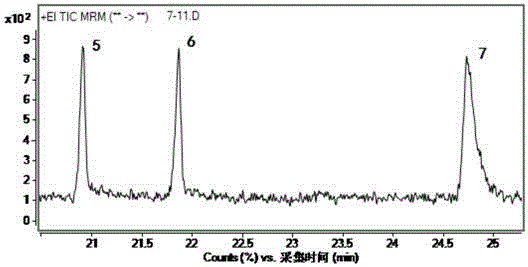

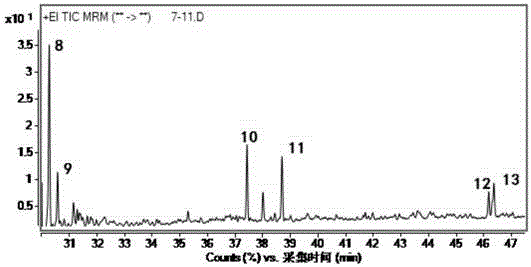

Method for detecting polycyclic aromatic hydrocarbon content in smokeless tobacco products

ActiveCN106645444AGood effectLow requirements for matrix purityComponent separationAcenaphthyleneGas chromatography–mass spectrometry

The invention discloses a method for detecting polycyclic aromatic hydrocarbon content in smokeless tobacco products. The method includes the steps: extracting the smokeless tobacco products by the aid of extraction agents; detecting filtered extraction solution by the aid of a GC-MS / MS (gas chromatography-mass spectrometry). The method can simultaneously measure content of indene, naphthalene, 1-methylnaphthalene, 2-methylnaphthalene, acenaphthylene, acenaphthene, fluorine, phenanthrene, anthracene, fluoranthene, pyrene, benzo [a] anthracene, chrysene, benzo [b] fluoranthene, benzo [k] fluoranthene, benzo [j] fluoranthene, benzo [e] pyrene, benzo [a] pyrene, perylene, indene [1, 2, 3-cd] pyrene, diphenyl [a, h] anthracene, benzo [g, h, i] pyrene and the like in the smokeless tobacco products. The method fills in gaps of the prior art and has the advantages that the method is simple, convenient and rapid in sample pretreatment, goof in detection accuracy and repeatability and high in analytical test flux, and the method is applicable to rapid analysis of large-batch samples.

Owner:YUNNAN TOBACCO QUALITY SUPERVISION MONITORING STATION

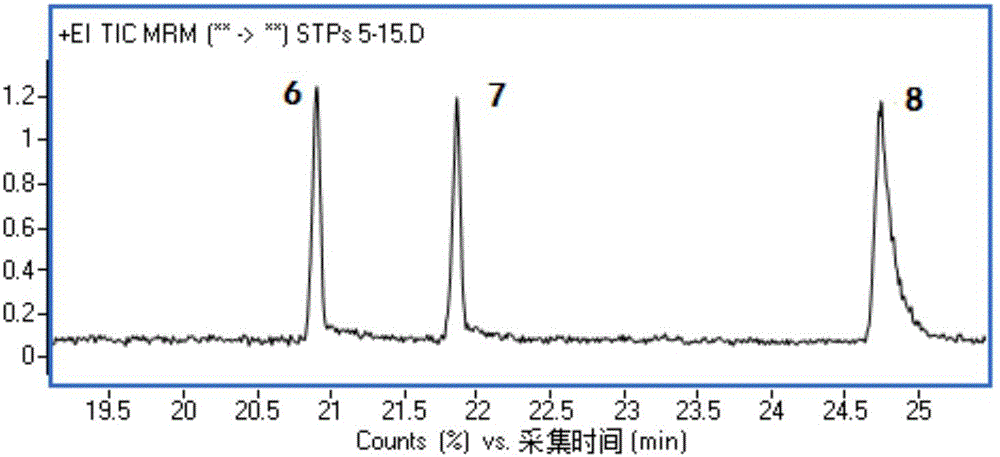

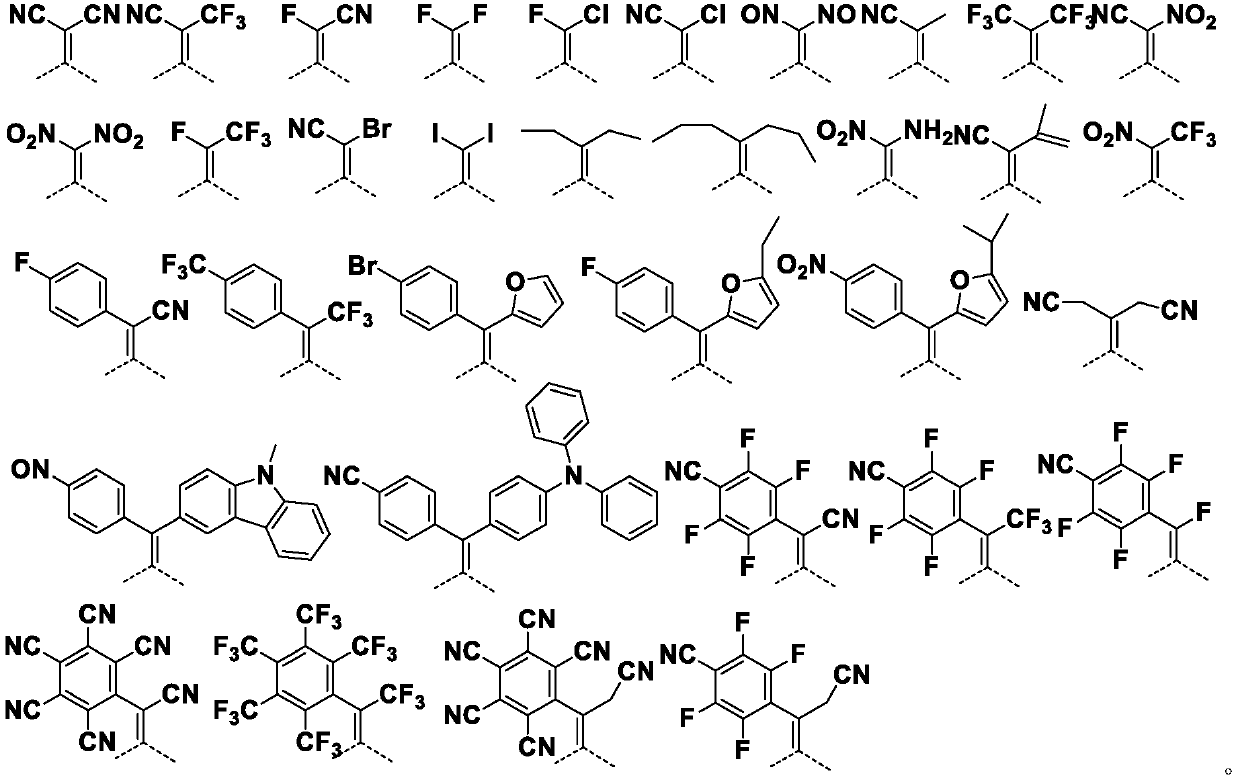

Acenaphthene quinone organic compound and application thereof

InactiveCN110746364AExtend your lifeGood hole transport propertiesOrganic chemistrySolid-state devicesQuinoneDopant

The invention relates to an acenaphthene quinone organic compound represented by a general formula (I) shown in the description and an application thereof. The acenaphthene quinone organic compound has excellent hole transport property and stability, can serve as a hole injection layer material in an organic electroluminescent cell and can also serve as a dopant doped in a hole injection layer orhole transport layer, so that driving can be carried out with low voltage, the efficiency of electroluminescence can also be increased, and the service life of a device is prolonged.

Owner:GUANGZHOU CHINARAY OPTOELECTRONICS MATERIALS

Method for simultaneously detecting content of 22 polycyclic aromatic hydrocarbon matters in cigarette smoke

ActiveCN106248835AGood effectLow requirements for matrix purityComponent separationAcenaphthyleneTrapping

The invention discloses a method for simultaneously detecting content of 22 polycyclic aromatic hydrocarbon matters in cigarette smoke. The method comprises the following steps: trapping total particular matters in cigarette main stream smoke by adopting a filter; extracting the trapping filter by utilizing an extraction agent; and detecting the filtered extract liquor by adopting gas chromatography-tandem mass spectrum (GC-MS / MS), and simultaneously detecting the contents of 22 polycyclic aromatic hydrocarbon matters, including indene, naphthalene, 1-methylnaphthalene, 2-methylnaphthalene, acenaphthylene, acenaphthene, fluorene, phenanthrene, anthracene, fluoranthene, pyrene, benzo [a] anthracene, chrysene, benzo [b] fluoranthene, benzo [k] fluoranthene, benzo [j] fluoranthene, benzo [e] pyrene, benzo [a] pyrene, perylene, indene [1,2,3-cd] perylene, dibenzo [a, h] anthracene, benzo [g, h, i] pyrene, and the like, in cigarette main stream smoke. The method fills the blank of the prior art, has the characteristics of simple, convenient and quick sample pretreatment, high detection accuracy and repeatability and large analysis test flux and is fit for quick analysis of mass samples.

Owner:YUNNAN TOBACCO QUALITY SUPERVISION MONITORING STATION

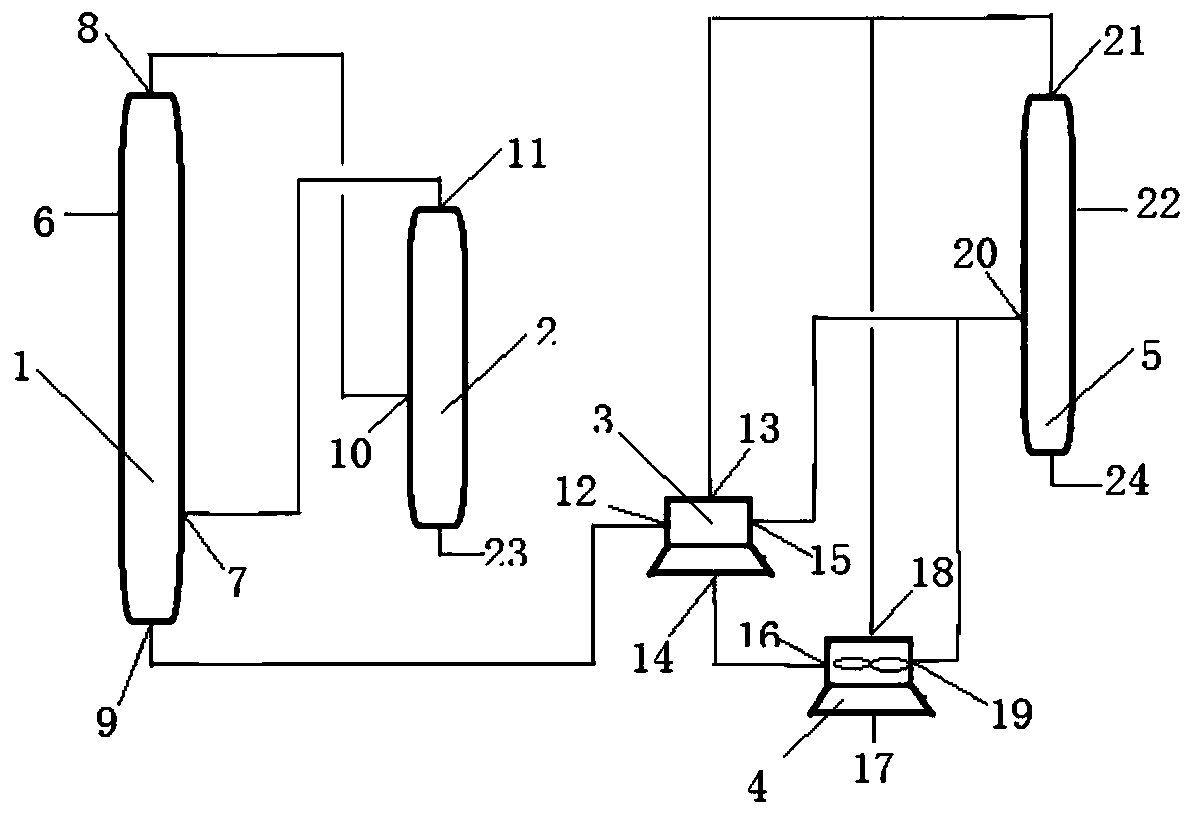

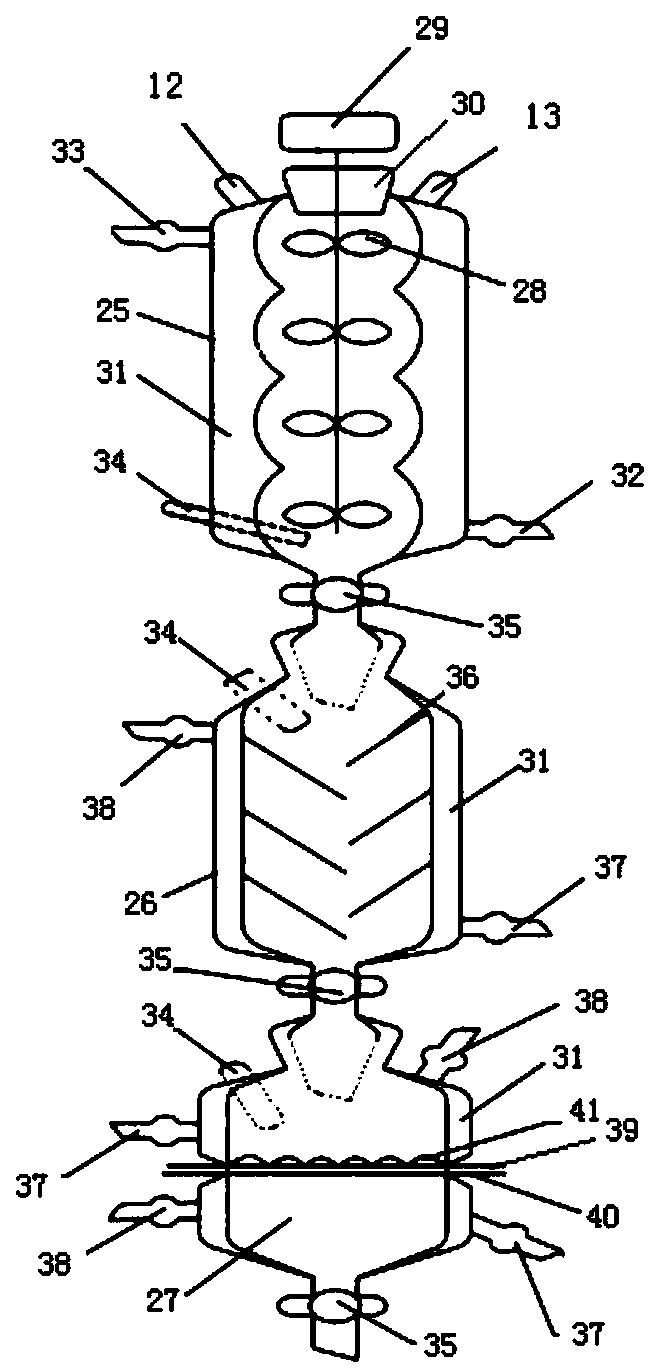

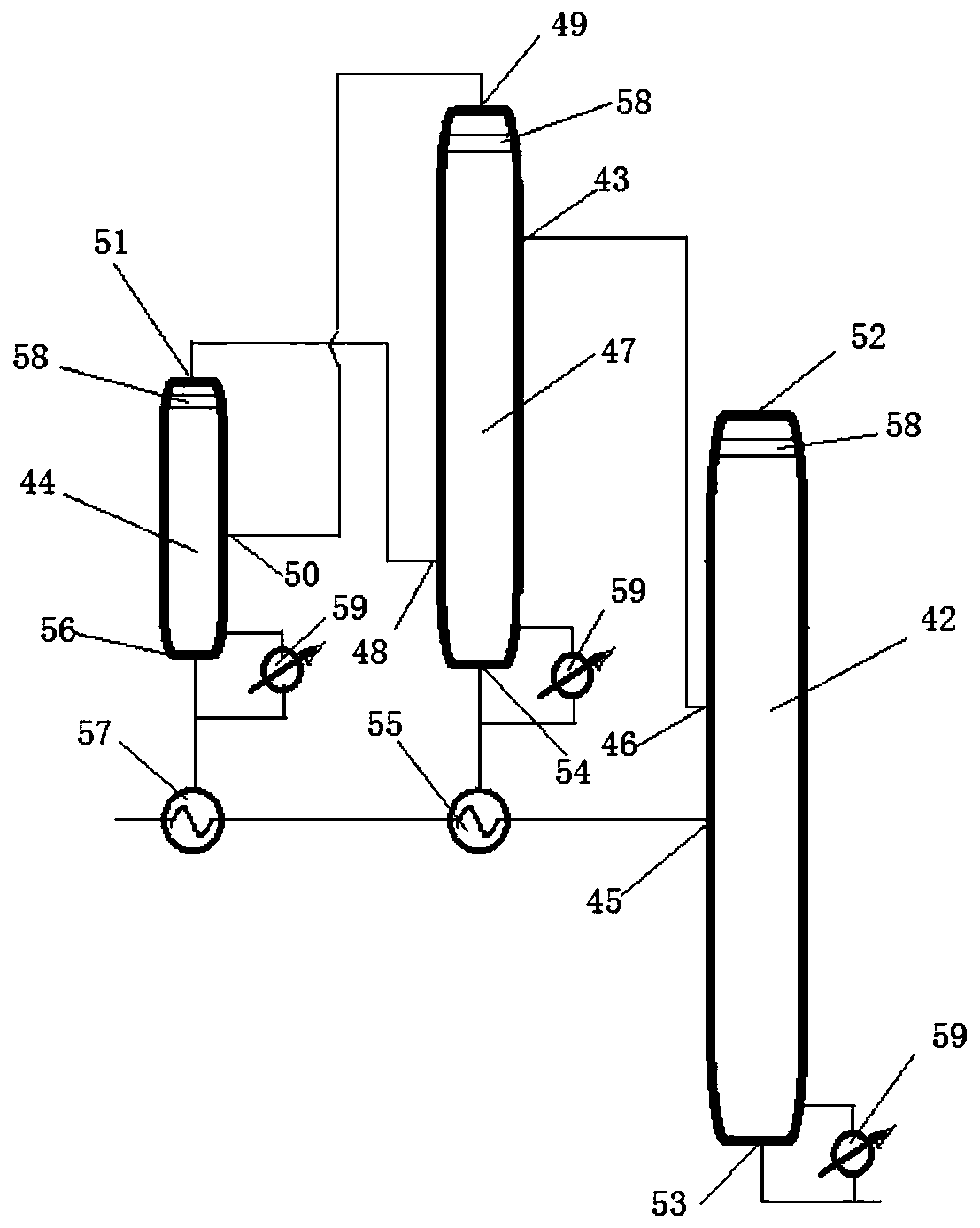

Device and method for extracting acenaphthene and acenaphthylene in LCO bicyclic aromatic hydrocarbon

ActiveCN109438164AEffective purityEffective yieldDistillation purification/separationHydrocarbonsAcenaphthyleneSolvent

The invention discloses a device and method for extracting acenaphthene and acenaphthylene in LCO bicyclic aromatic hydrocarbon. The device comprises an extraction rectifying tower, a regeneration tower, a crystallizing device, a washer and a sidestream rectifying tower. The method comprises the following steps: during preparation, firstly, adding a mixed liquid containing acenaphthene and acenaphthylene and an extractant from a raw material feed inlet and an extractant feed inlet of the extraction rectifying tower for extraction and rectification; feeding a fraction containing the extractantand dimethylnaphthalene into the regeneration tower for regeneration; recycling the regenerated extractant fraction to the extraction rectifying tower; feeding the fraction containing acenaphthene andacenaphthylene at the bottom of the extraction rectifying tower into the crystallizing device; adding a crystallizing solution for crystallization at the same time; feeding the obtained coarse acenaphthene into the washer; washing the coarse acenaphthene to obtain crystal acenaphthene; feeding the crystallizing mother liquor and washing agent mother liquor into the sidestream rectifying tower tobe rectified to obtain an acenaphthylene fraction; and recycling the crystallizing solvent to the crystallizing device and the washer. According to the device, the purity and the yield of acenaphtheneseparately reach 99.57% and 80.60% and the purity and the yield of acenaphthylene separately reach 98.53% and 77.59%.

Owner:NANJING NORMAL UNIVERSITY

Oxidation removing method for polycyclic aromatic hydrocarbon in soil through Fenton reagent bag

InactiveCN105855286AEfficient removalReduce processing timeContaminated soil reclamationAcenaphthylenePolycyclic aromatic hydrocarbon

The invention discloses a method for oxidizing and removing polycyclic aromatic hydrocarbons in soil by using a Fenton reagent bag, and belongs to the technical field of soil restoration. The method is to mix the air-dried soil to be tested with distilled water to make mud, add acid reagents to the mud to adjust the pH value of the mud to 3-5 to obtain acid mud, add Fenton reagent packs to the acid mud and stir evenly to obtain Slurry reaction liquid, then the mud reaction liquid is left to react, and the polycyclic aromatic hydrocarbons in the soil can be removed after the reaction; wherein the Fenton reagent package is made of FeSO 4 、H 2 o 2 and K 2 C 2 o 4 composition. This method can effectively remove naphthalene, acenaphthene, acenaphthylene, anthracene, fluorene and phenanthrene in soil, and the treatment time is shortened and the removal rate is improved compared with the traditional Fenton reagent.

Owner:NANJING AGRICULTURAL UNIVERSITY

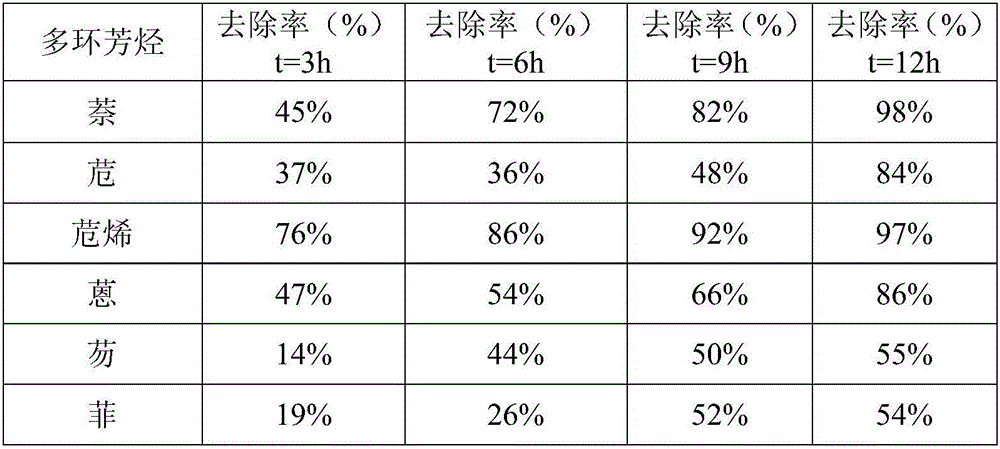

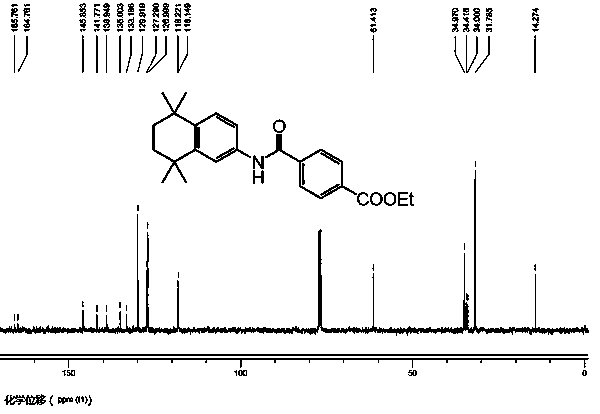

Method for catalytically synthesizing tamibarotene through acenaphthene imidazole n-heterocyclic carbine allyl palladium chloride compound

InactiveCN103408450AShort synthetic routeGood atom economyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPharmaceutical Substances

The invention belongs to the technical field of medicine pharmaceutical synthesis, and particularly relates to a method for catalytically synthesizing tamibarotene through an acenaphthene imidazole n-heterocyclic carbine allyl palladium chloride compound, aiming at providing a novel synthesis method of tamibarotene. The method comprises the following steps of: by taking a novel acenaphthene imidazole n-heterocyclic carbine allyl palladium chloride compound with high catalytic activity as a catalyst; performing amide carbonylation coupled reaction under carbon monoxide in order to directly synthesize a key precursor of tamibarotene by such one step; and then simply hydrolyzing to obtain the target compound, namely, tamibarotene. According to the method, the catalyst adopted has high catalytic performance, so that the catalytic coupling reaction brings high yield; and the catalyst is naturally easily synthesized, the raw materials adopted in the synthetic line are easily available, so that such synthetic line has high competitive advantages and high utility value in industrial production.

Owner:FUDAN UNIV

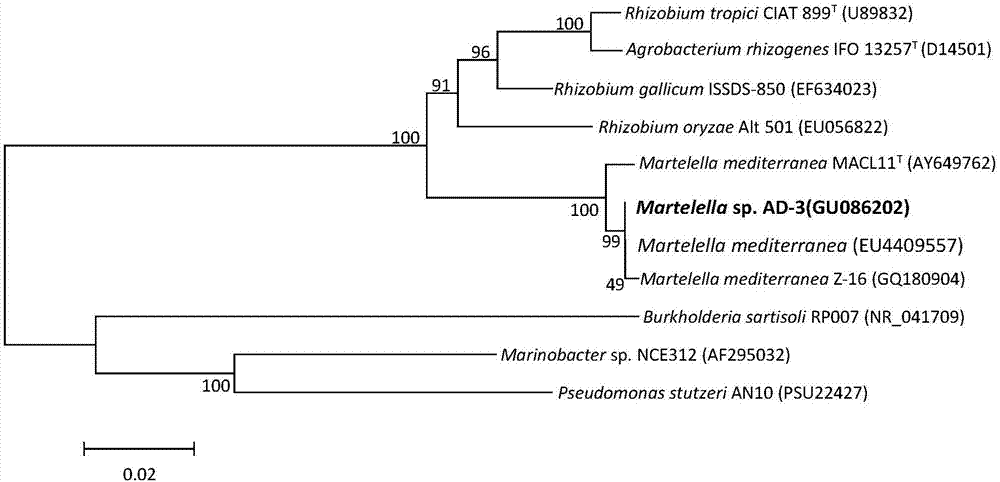

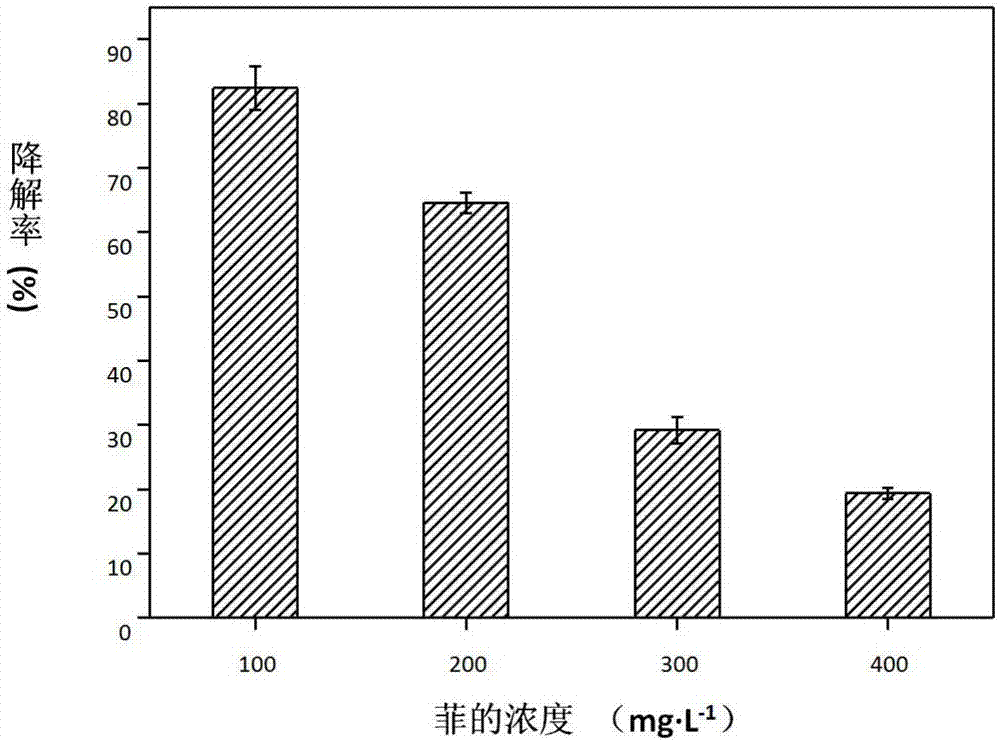

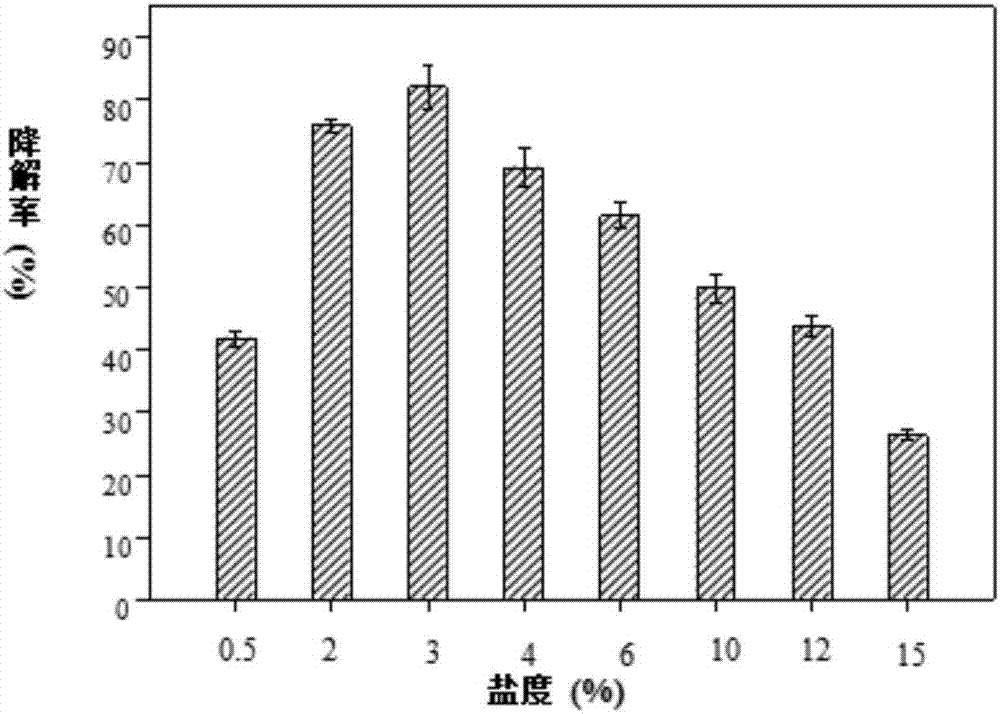

Moderate halophilic aromatic pollutant degrading bacteria and application thereof

PendingCN107881126ALow ecotoxicityReduce concentrationBacteriaContaminated soil reclamationAcenaphthyleneAlkali soil

The invention discloses moderately halophilic bacteria capable of efficiently degrading multiple polycyclic aromatic hydrocarbons and application thereof, wherein the moderately halophilic bacteria are enriched and screened from polycyclic aromatic hydrocarbon contaminated saline alkali soil in Shengli Oil Field, are identified and named as Martelella sp.AD-3(CCTCC M2011218). The bacteria can efficiently degrade multiple pollutants such as biphenyl, acenaphthylene, acenaphthene, fluorene, phenanthrene, anthracene, fluoranthene and benzo[a]anthracene, and chrysene under the condition that the salinity is 0.5-15% and the pH value is 6-10. In 36h, degradation rate for fluorene with concentration of 100mg / L can reach 100%. The optimal degradation conditions of AD-3 bacteria are that pH is 9.0,salinity is 15g / kg, moisture content is 25%, and temperature 30 DEG C. Under the optimal conditions, AD-3 bacteria have an obvious removal effect for acenaphthylene, biphenyl, fluorene, phenanthreneand anthracene, and the removal rate for acenaphthylene and biphenyl can reach 100%.

Owner:EAST CHINA UNIV OF SCI & TECH

Ethylidene acenaphthene(asymmetric alpha-diimine)nickle catalyst and production method and application thereof

ActiveCN109956980AImprove thermal stabilityHigh polymerization activityNickel organic compoundsBulk chemical productionDiimineHydrogen

The invention discloses a large-steric hindrance asymmetric(alpha-diimine)nickle olefin catalyst based on an ethylidene acenaphthenequinone skeleton and a production method and application thereof. Astructural formula of the large-steric hindrance asymmetric(alpha-diimine)nickle olefin catalyst based on the ethylidene acenaphthenequinone skeleton is as shown in the formula (I), wherein R1 is benzhydryl or bis(4-fluorophenyl)methyl, R2 is one of benzhydryl, bis(4-fluorophenyl)methyl and methyl, R3 is one of methyl, ethyl, isopropyl, benzhydryl, bis(4-fluorophenyl)methyl, halogen, trifluoromethyl and methoxyl, R4 is one of methyl, ethyl and isopropyl, R5 is one of one of methyl, ethyl and isopropyl, R6 is one of hydrogen, methyl, ethyl and isopropyl, and X is chlorine or bromine. The catalyst is simple in production technology, can catalyze vinyl polymerization under the action of a cocatalyst, shows good thermal stability and polymerization activity, and has good industrial applicationprospects.

Owner:HANGZHOU XINGLU TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com