Patents

Literature

293results about How to "Easy to refine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

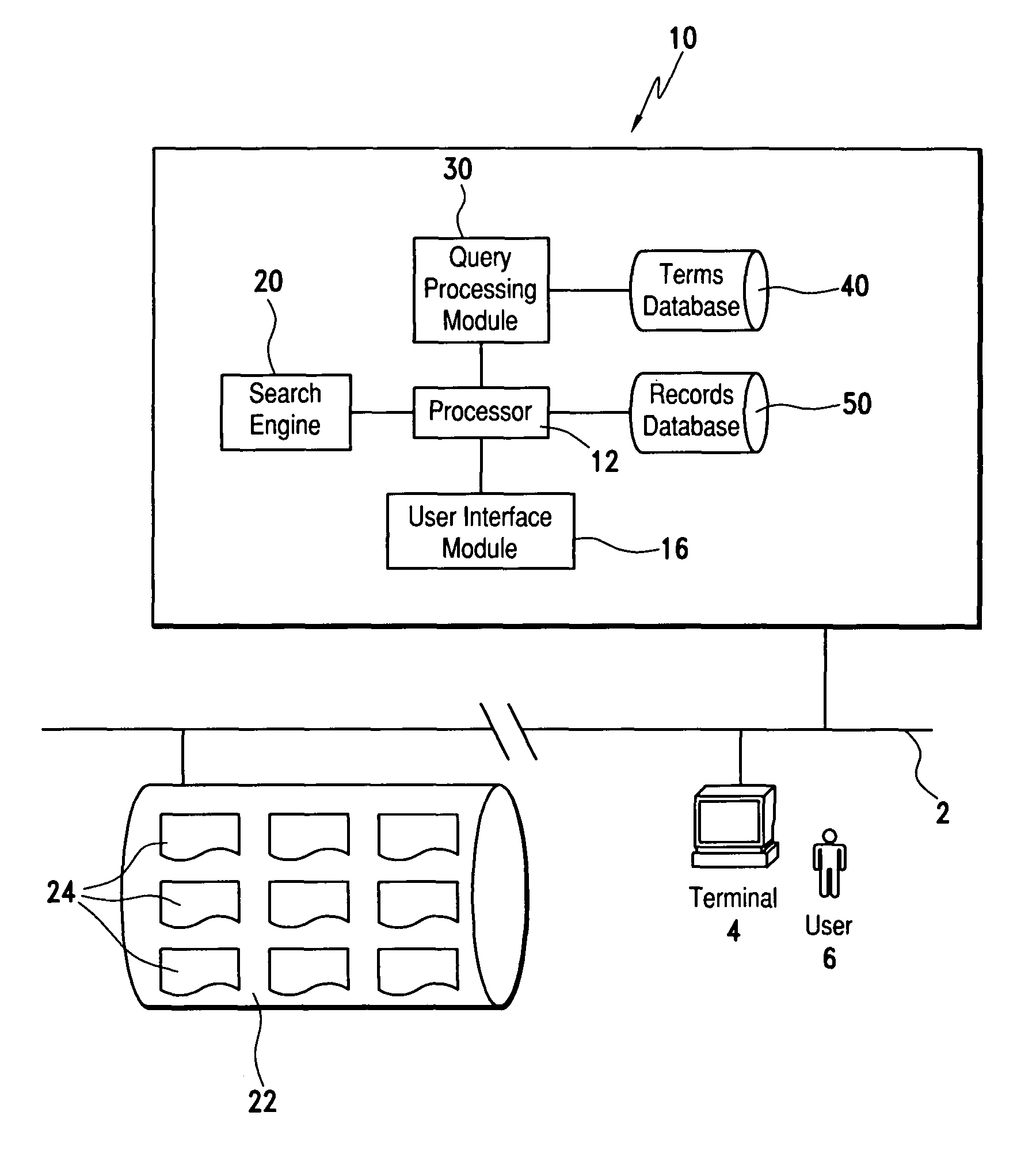

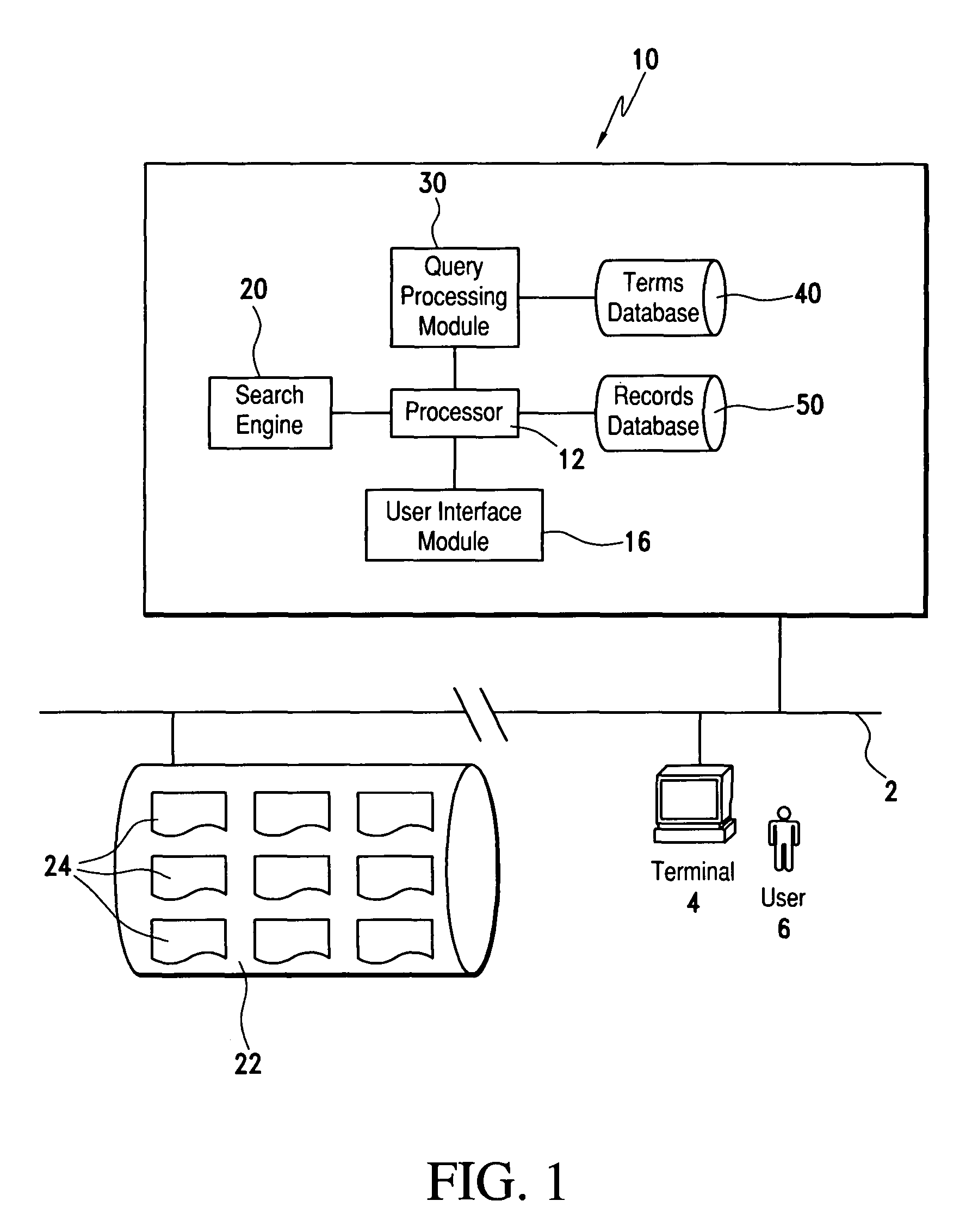

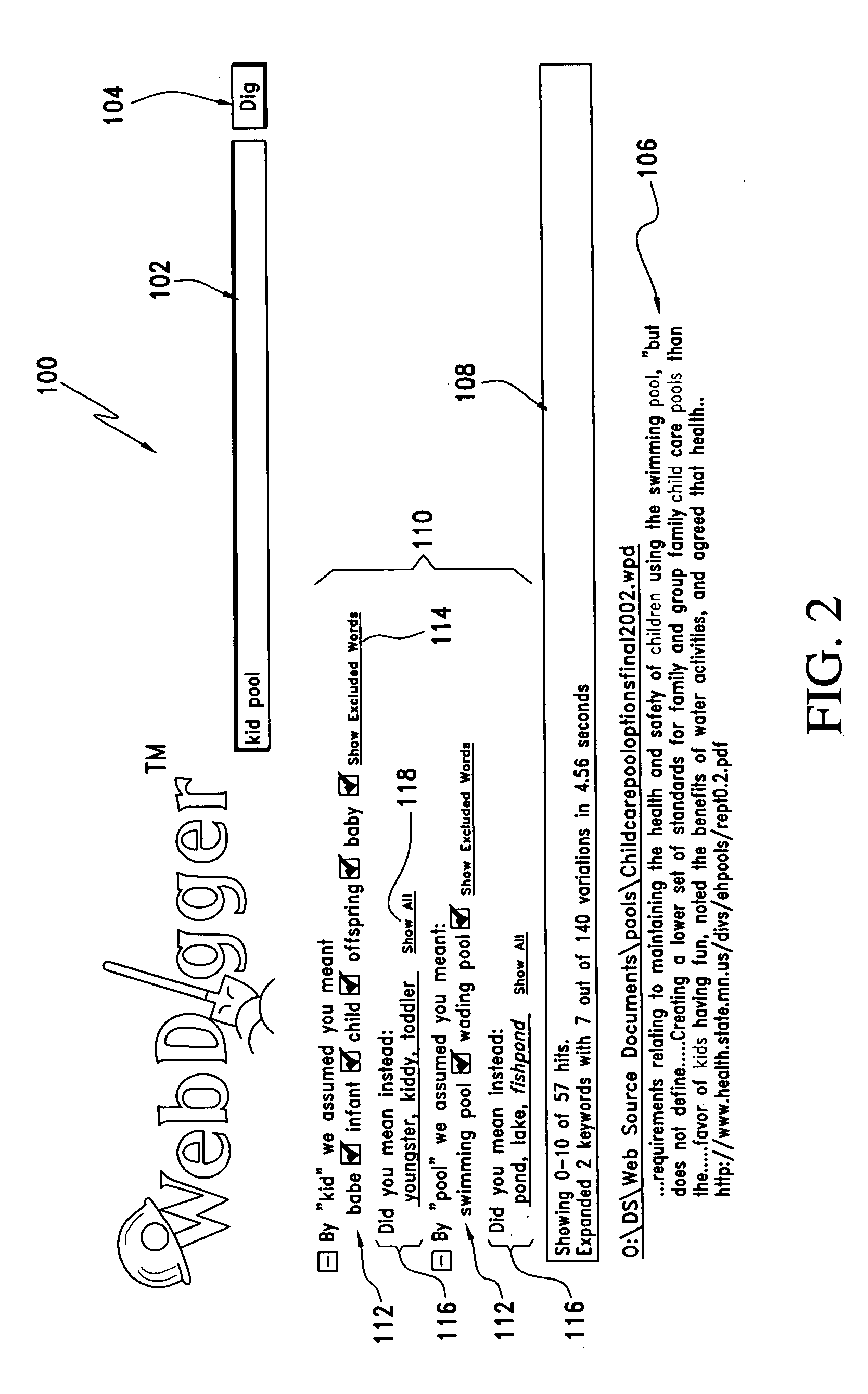

Search system with query refinement and search method

ActiveUS20070282811A1Easy to refineImprove refinementWeb data indexingSpecial data processing applicationsElectronic documentDocumentation

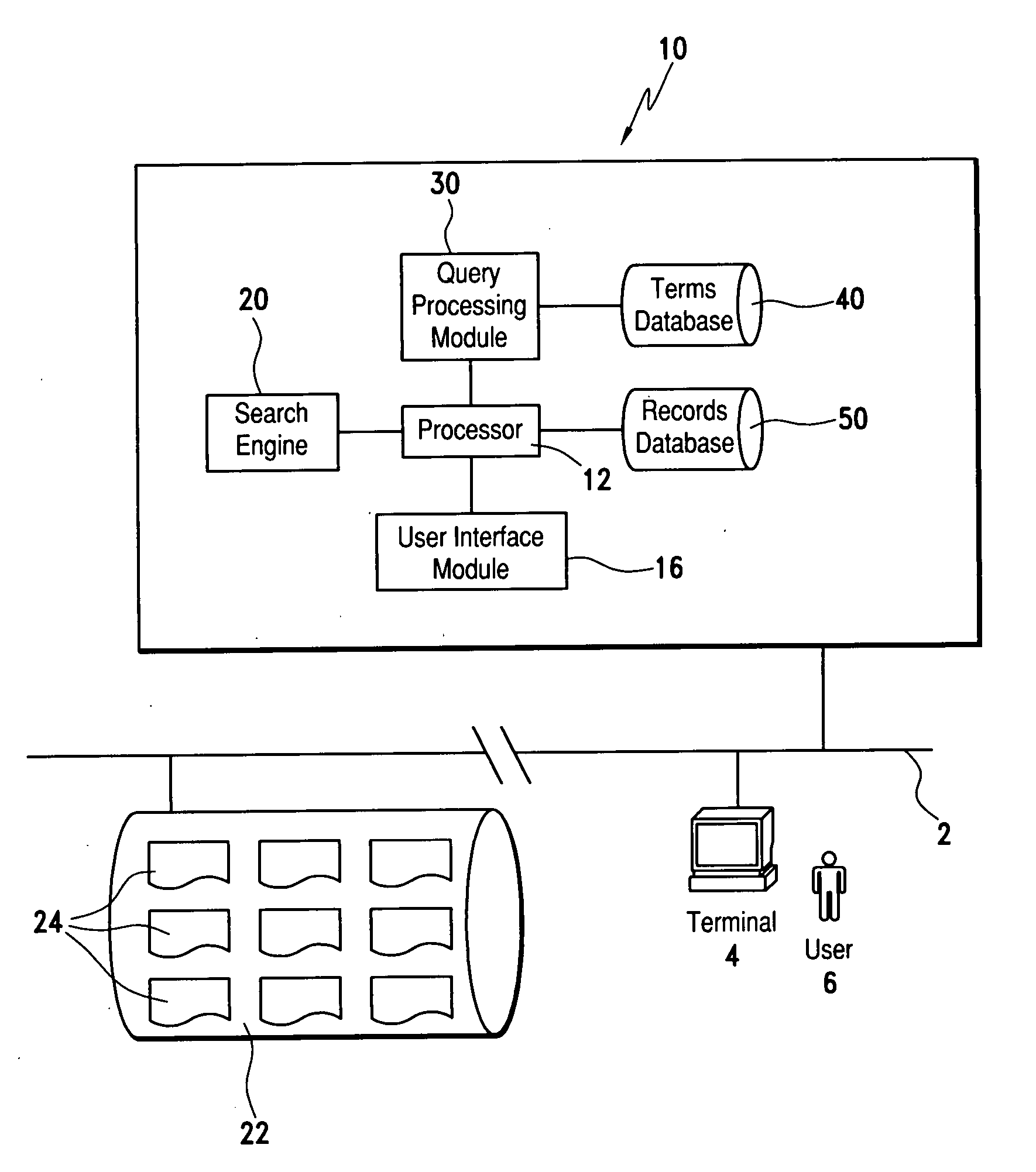

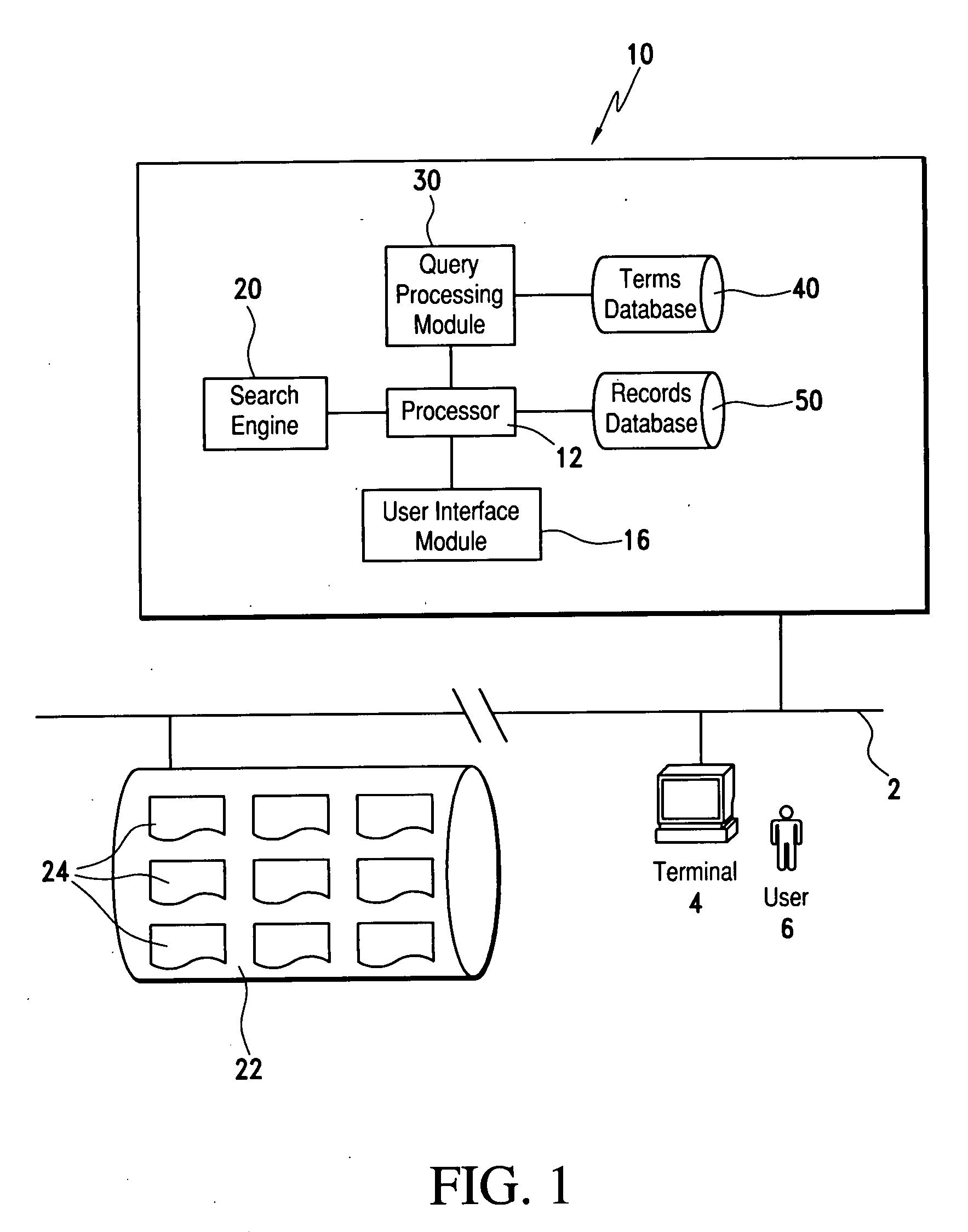

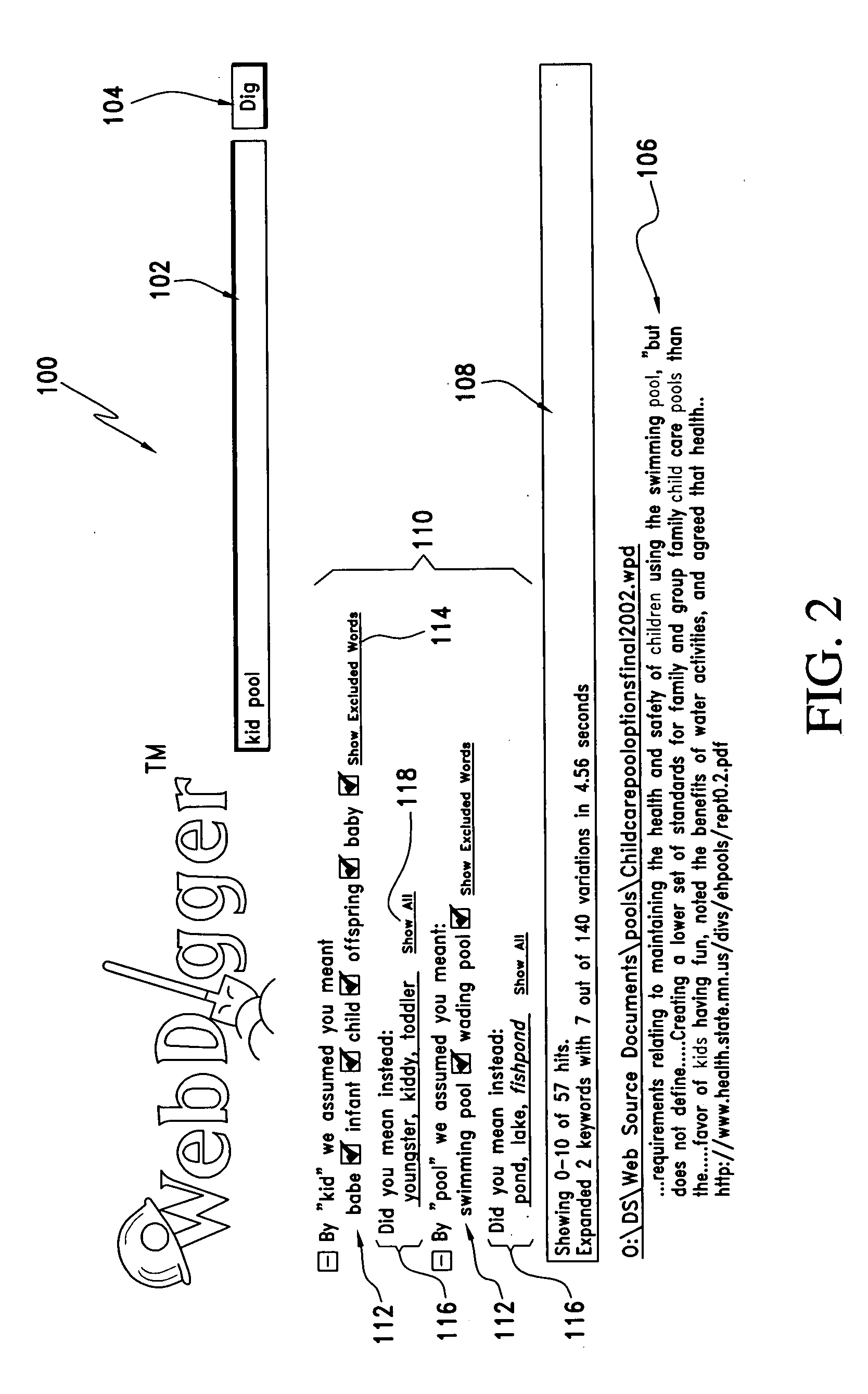

A search system and method for searching for electronic documents, and providing a search result in response to a search query. In one embodiment, the search system includes a processor, a user interface module adapted to receive a search query from a user that includes a search query term, a search engine that electronically searches for electronic documents that satisfy the search query term, and a query processing module that identifies at least one alternative term for the search query term, and provides the alternative term to the user interface module for display to the user, and also provides the alternative term to the search engine to search for electronic documents that satisfy the alternative term.

Owner:TEXTDIGGER

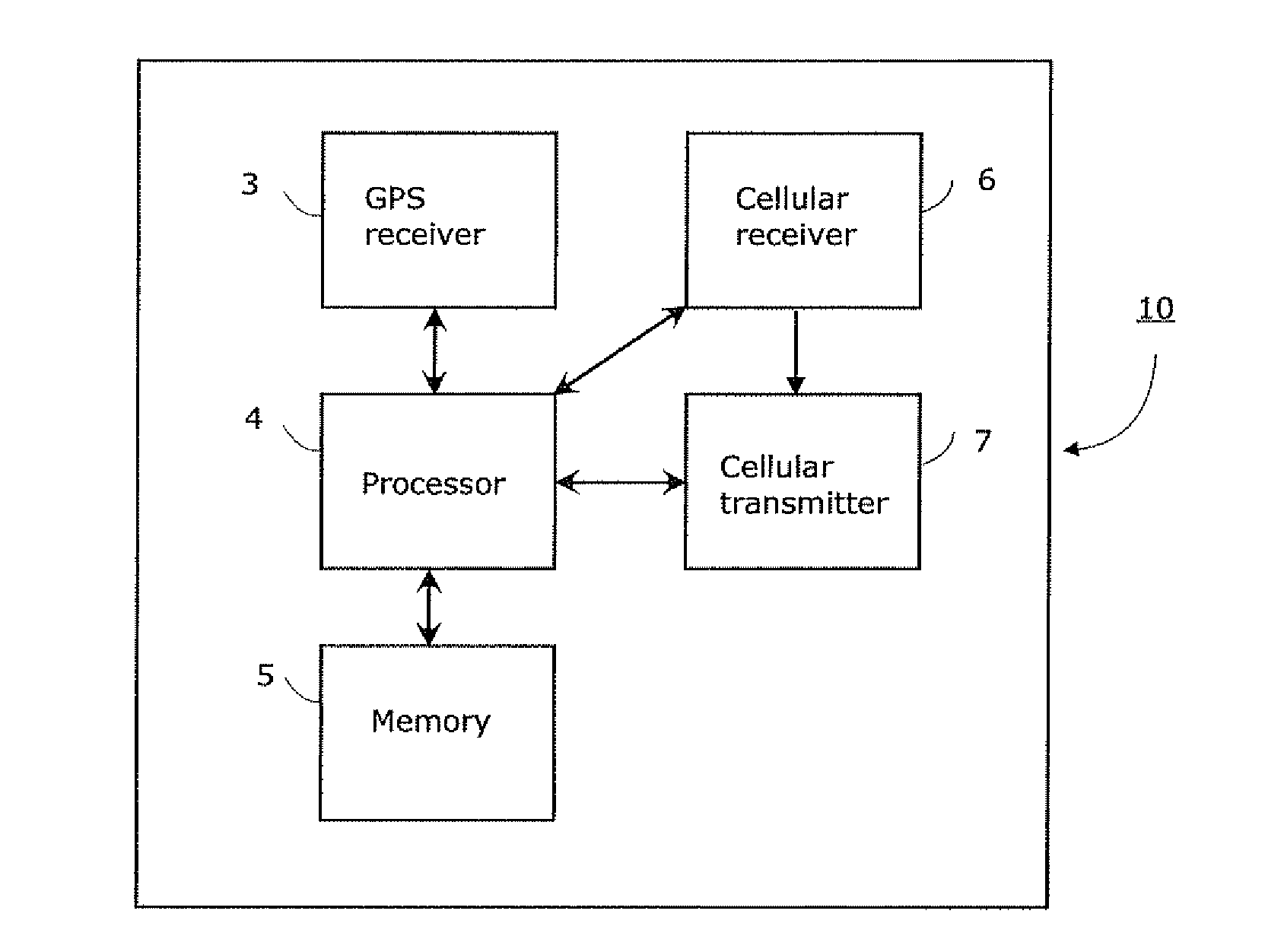

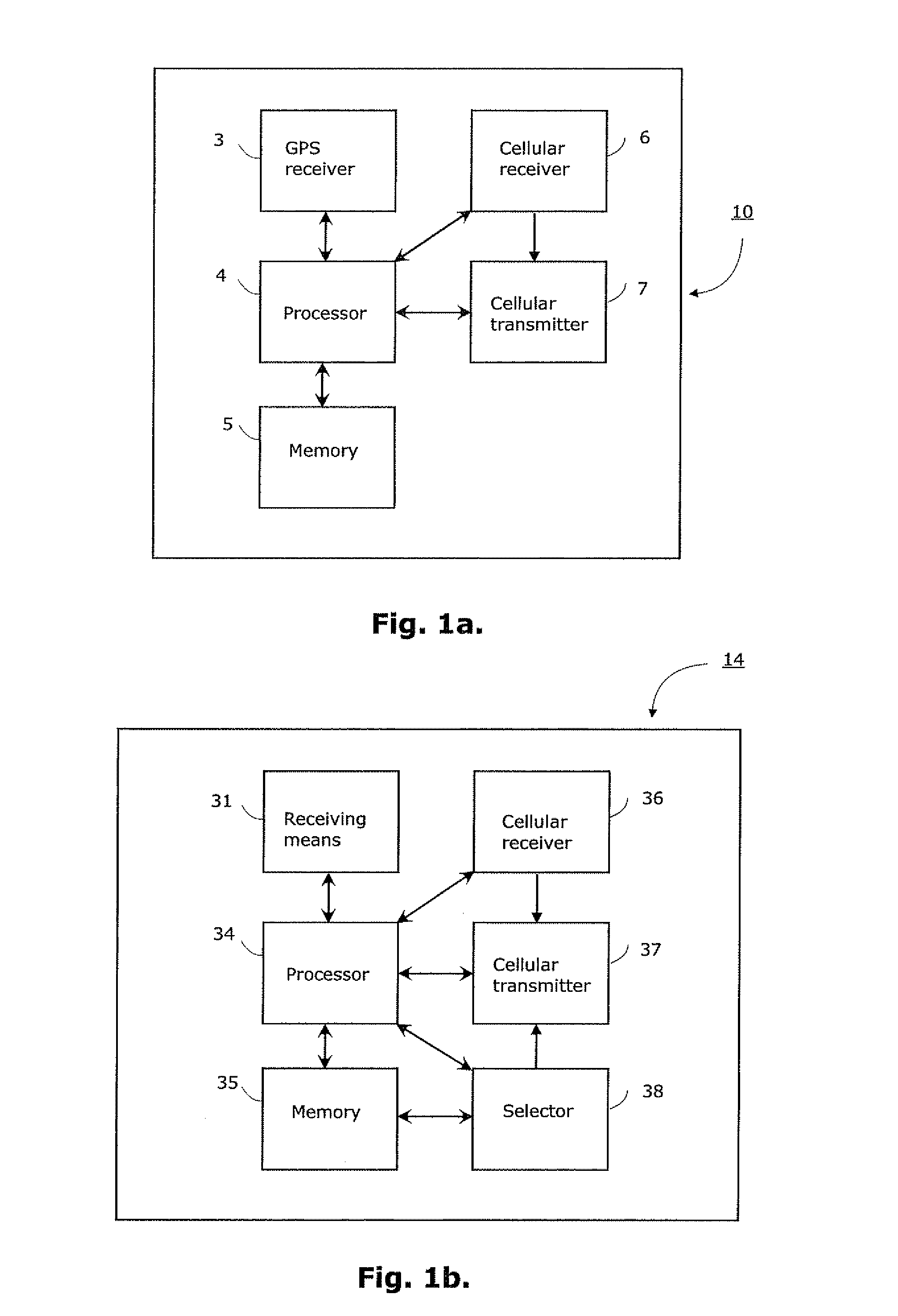

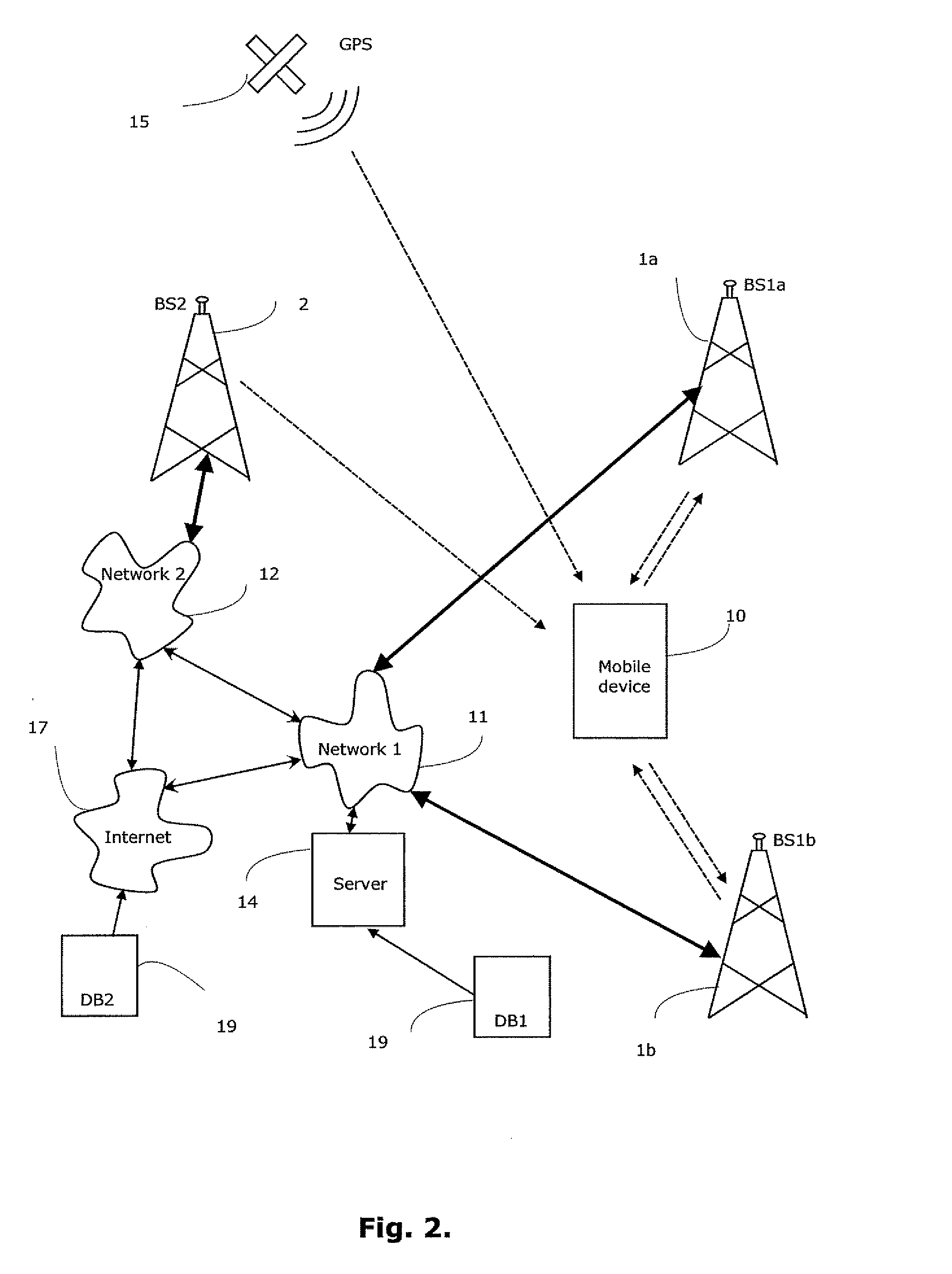

Method and system for refining accuracy of location positioning

ActiveUS20130079039A1Location determination can be fasterAccurate measurementPosition fixationSatellite radio beaconingEngineeringMobile device

To accurately determine the location of mobile device a multi-phase procedure incorporating mapping and location determination phases is suggested, wherein covered area estimation comprises (i) estimation of base station location, (ii) estimation of transmission range, (iii) estimation of signal map and / or (iv) estimation of area type. The actual location of the mobile device (10) is determined from the covered area estimation based on relative comparison between the actual environment data and estimations (i)-(iv) and weight numbers resulted from the comparison. During the both phases a database is stored in server (14) and updated whenever new environment data is received. The vertical position, or ‘elevation’, of mobile device is further estimated based on vertical level information associated with the covered area estimations during the mapping phase.

Owner:GLOPOS FZC

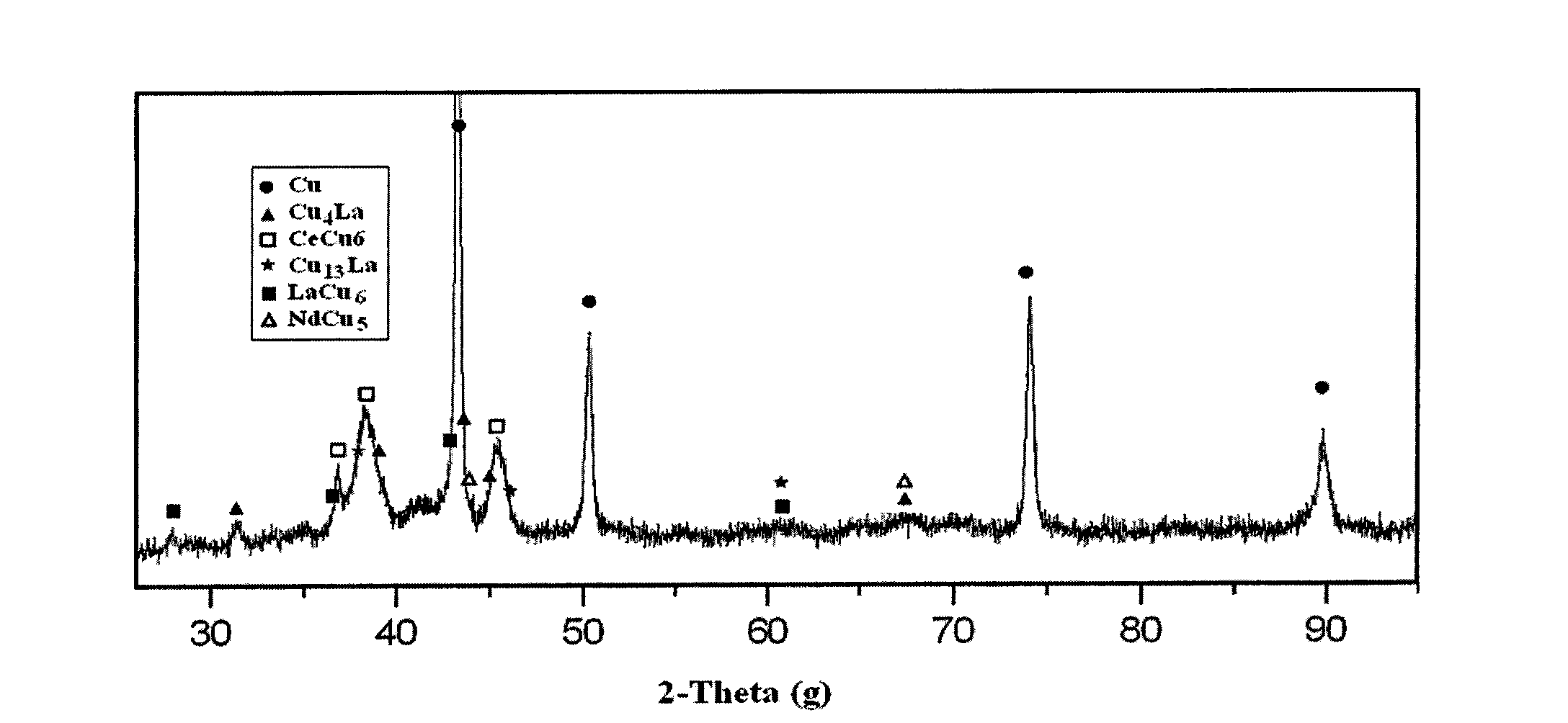

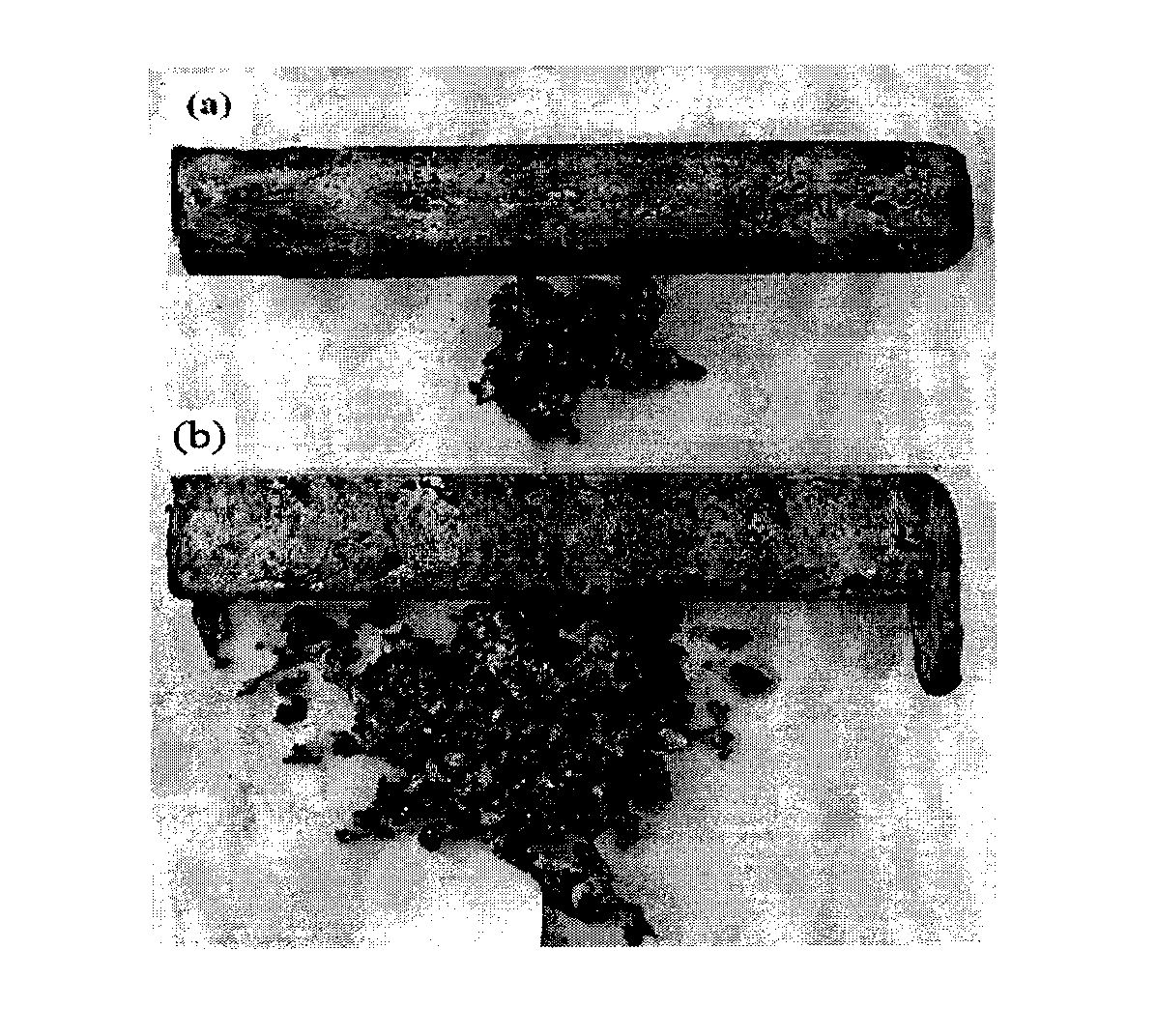

High Cu-RE interalloy refining agent for refining scrap copper and preparation and application thereof

The invention relates to a high Cu-RE refining agent which has high efficiency and low burning loss rate and can be used for copper and copper alloy, applied to mass refining of the copper and the copper alloy, especially applied to refining and modification of red impure copper and white impure copper. The Cu-RE interalloy refining agent is prepared by a vacuum melting method, wherein, rare earth content is up to 30-65%; and only 2-6g / kg refining agent is added while the Cu-RE interalloy refining agent is applied to remelting refining of scrap copper. The Cu-RE refining agent enhances slagging and deslagging of copper fused mass, reduces deleterious substances in the fused mass of the scrap copper, and improves texture and performance of the copper and the copper alloy, therefore, products prepared from the red impure copper as a raw material reach or exceed the quality of the products prepared from electrolytic copper as a raw material, and the white copper process waste can be used for directly producing high-quality products after remelting refined, thus promoting recycle and reutilization of the scrap copper, saving energy and resource, reducing environmental pollution and generating significant economic and social benefits.

Owner:CENT SOUTH UNIV

Synchronous aqueous enzymatic ultrasonic extraction for walnut oil and walnut protein peptide

InactiveCN101280327AQuality improvementMild treatment conditionsCheese manufactureVegetable proteins working-upOil phaseDietary fibre

The invention relates to an enzyme method ultrasonic extraction method of walnut oil and walnut protein, which belongs to the food and the functional food field. Water is added into walnut kernel or walnut powder to be grinded into paste, protease or compound protease are added into to be performed hydrolization, and simultaneously ultrasonic processing is performed, then the walnut kernel or walnut powder is agitated to perform enzymatic extraction, and then centrifugal separation oil phase, protein peptide oil water phase and residual solid phase are performed; walnut oil is acquired by refining the obtained oil phase, which meets the requirements of green foods; the protein peptide aqueous solution can be directly used to produce degreased walnut protein nutrient milk, or to prepare walnut antioxidation peptide after performed nanofiltration, which is used in health products, food additives, cosmetics or daily chemical articles, or to produce nutrient condensed milk after being performed low temperature concentrating, or to produce walnut protein nutrition powder after performed spray drying; the solid phase residue is prepared into diet fiber food after being dried and grinded into powder; walnut nutrient protein peptide products can be obtained through performing vacuum concentration and spray drying to walnut protein peptide extracting solution containing nutrient content.

Owner:KUNMING UNIV OF SCI & TECH

Alloy ingot for automotive hub and production method thereof

The invention discloses an alloy ingot for an automotive hub and a production method thereof. The alloy ingot comprises the following components: 6.8-7.2% of Si, 0.28-033% of Mg, 0.10-0.15% of Ti, 0.015-0.030% of Sr, less than or equal to 0.10% of Fe, less than or equal to 0.05% of Mn, less than 0.01% of zinc, less than 0.01% of Cu, less than 0.003% of Ca, less than 0.002% of P, less than 0.02% of other single impurity content, less than 0.1% of total impurity content and the balance of aluminum. The production method of the alloy ingot for the automotive hub comprises the following steps of: adding 3303 industrial metallic silicon and electrolytic aluminum liquid for batching, heating at an appropriate temperature and melting, spreading a covering agent so as to reduce oxidation slagging, stirring so that the industrial metallic silicon rapidly melts, keeping uniform temperature, slagging off, keeping melt clean, spraying powder and refining by adopting high-purity N2 and a refined powder spraying agent, controlling the temperature of a smelting furnace to 740-750 DEG C, adding Al-Sr alloy to aluminium water, carrying out secondary degassing and slagging-off by adopting a powder spraying refinement method, filtering to remove slag, and casting the alloy ingot in line with requirements. The alloy ingot obtained by the method has the advantages of stable and uniform components, compact structure and clean surface; and the production method is the best production method for producing the A356.2 alloy ingot for the low-iron high-end automotive hub.

Owner:河南省银湖铝业有限责任公司

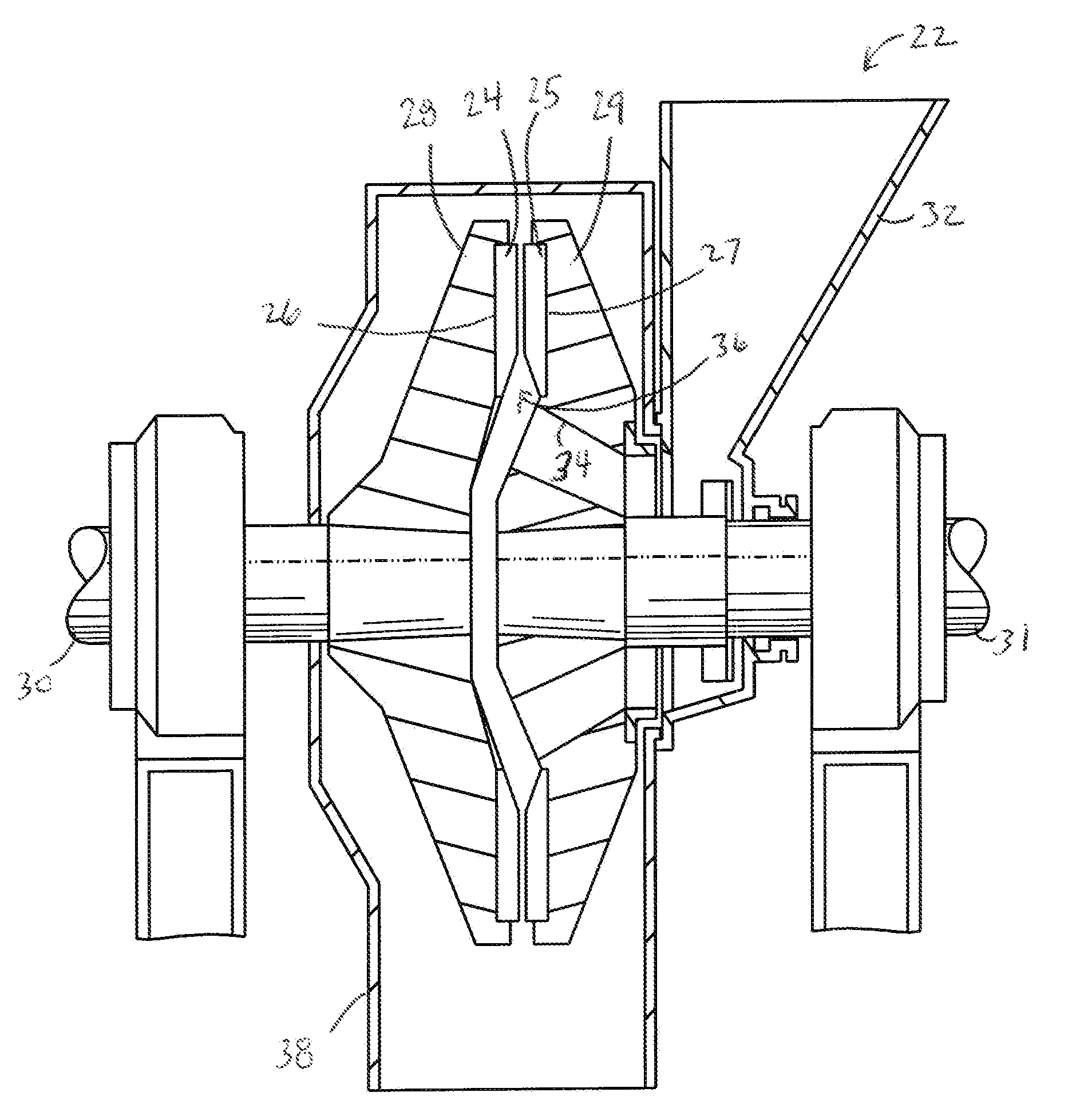

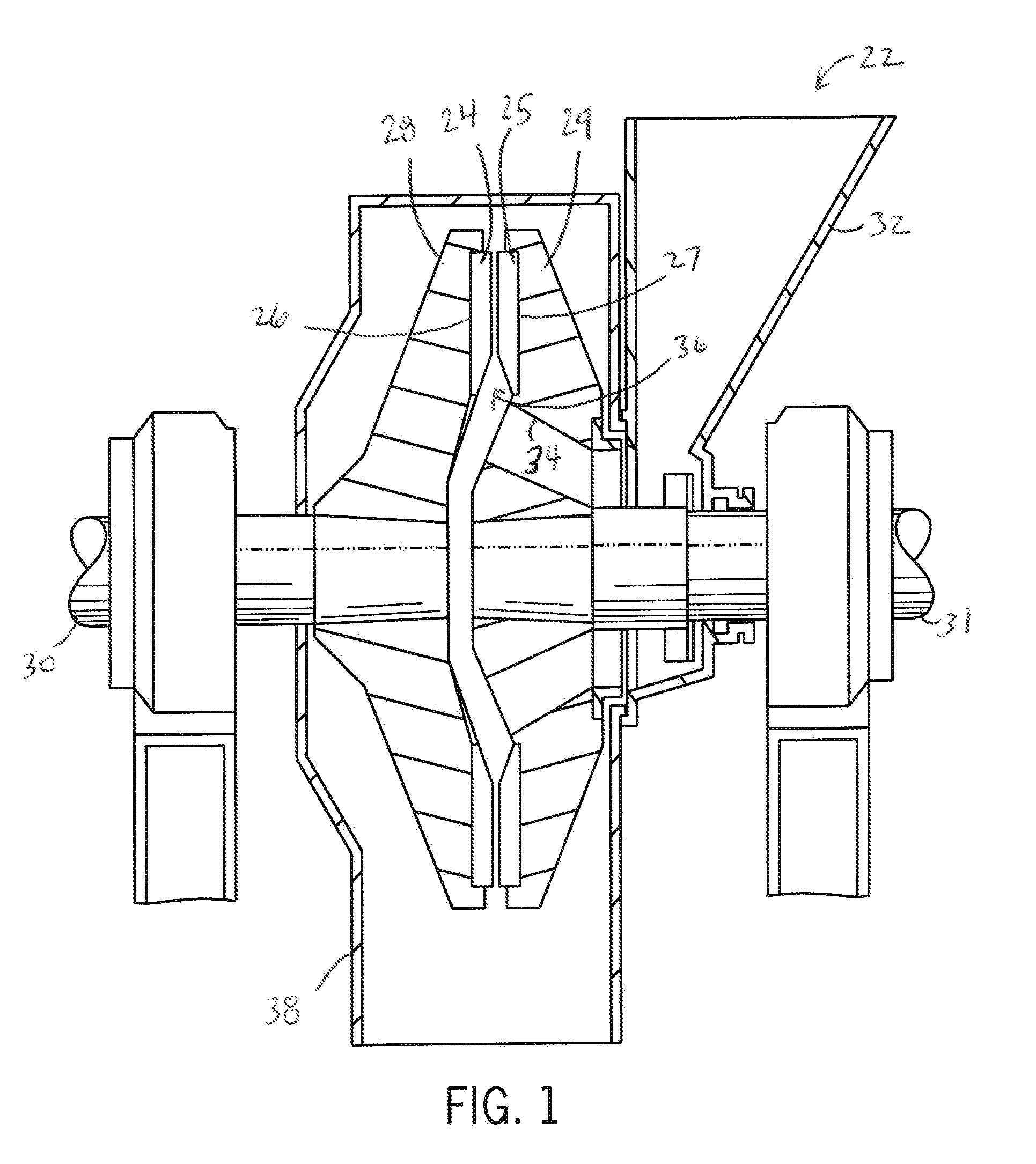

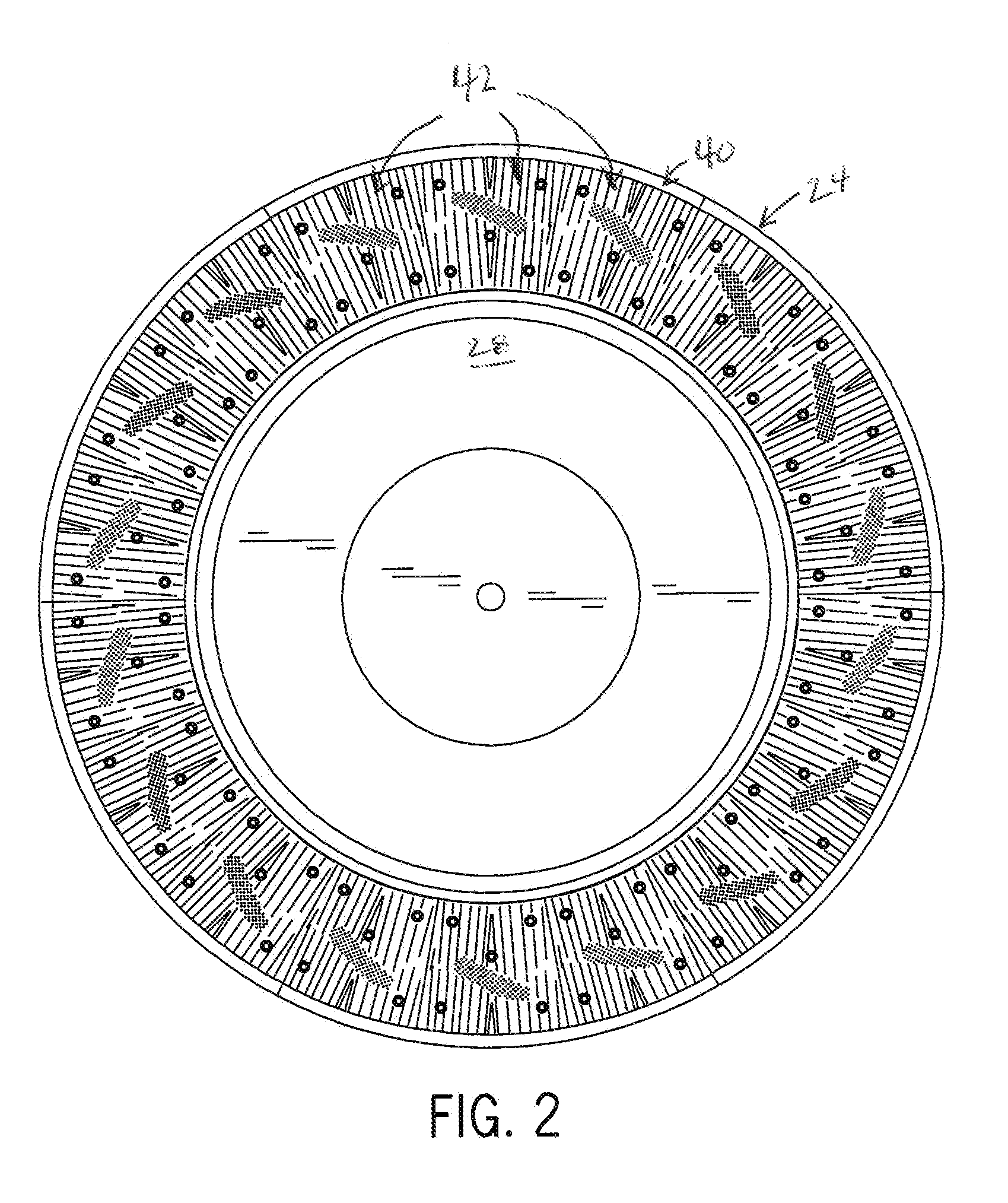

Refiner Plate Assembly and Method With Evacuation of Refining Zone

A refiner plate assembly and method includes an annular arrangement of adapter subplates that mount to a refiner disk of a disk refiner using a conventional mounting technique, such as bolted in a standard pattern associated with the particular disk refiner. The adapter subplate arrangement remains mounted to the disk and provides a universal mounting surface for an annular arrangement of individual removable refiner segments. A steam and / or accept evacuation channel is provided in this assembly via filter passages at a radially intermediate location in one or more refiner segments which communicate with a recess or channel in one or more associated adapter subplates that direct the steam and / or accepts through outlet ports in the outer rim of the adapter subplate(s). Refining efficiency is provided in a universal refiner plate assembly by eliminating steam volume and already refined pulp from outer portions of the refining zone. The filter section(s) can be placed at an optimal location of high volume fraction of pulp fibers where mounting hardware is typically located in conventional refiner segments.

Owner:VALMET TECH OY

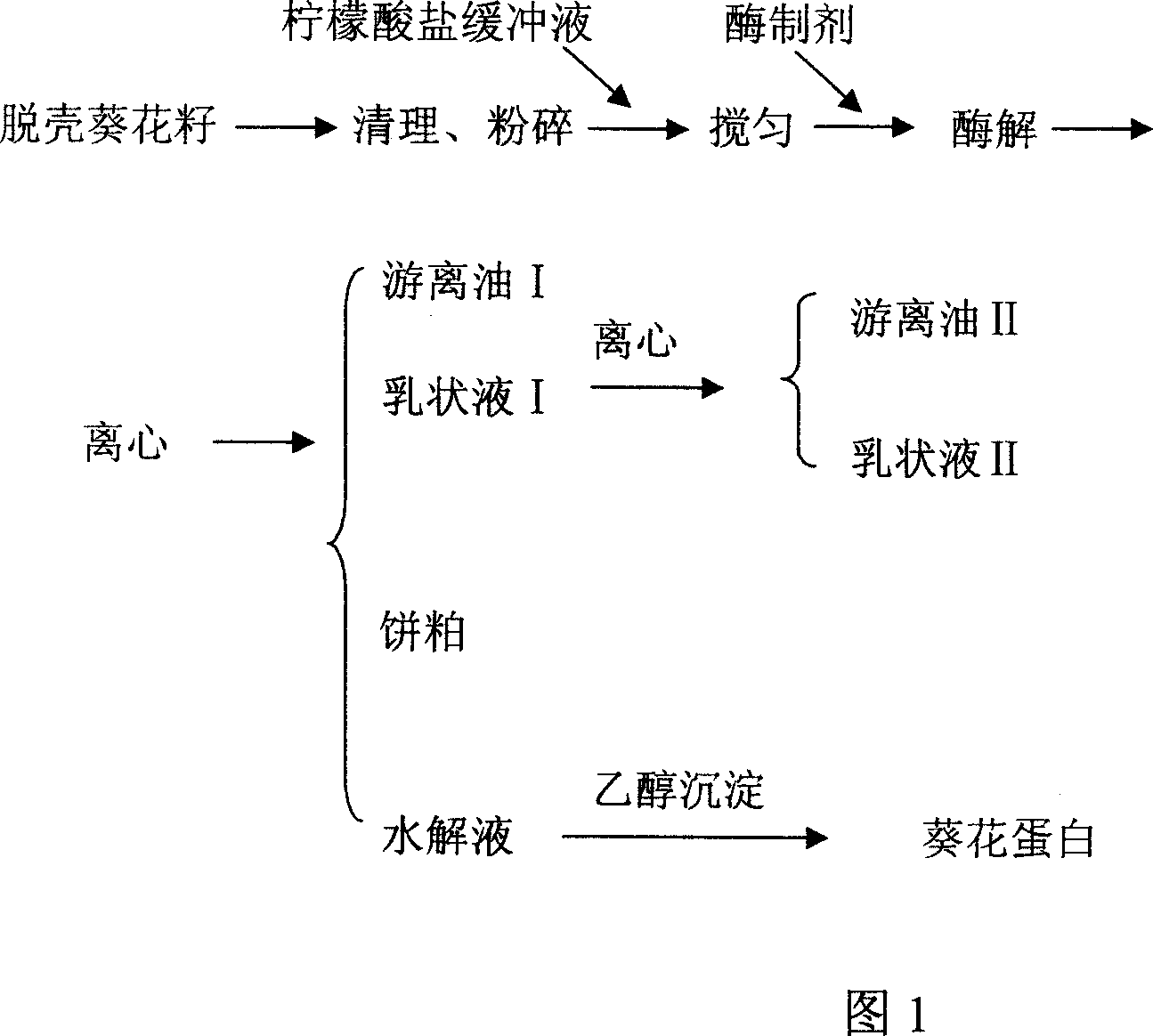

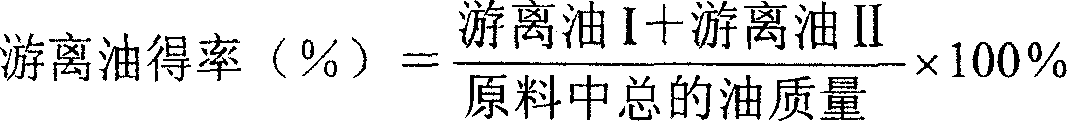

Process for extracting sunflower seed oil and recovering protein by aqueous enzymatic method

InactiveCN1952094AQuality improvementMild treatment conditionsEnzymesFatty-oils/fats productionCelluloseNutritive values

The method relates to the method to extract the sunflower oil and recover the protein by water-enzyme method. The producing procedure comprises the following steps: dry-pulverizing the uncoated sunflower seed, adding citrate buffer to the powder and decomposing the powder by compound cellulose; centrifugalizing to get free oil, emulsion, digest and tablet; high speed centrifugalizing to get some free oil; filtering, vacuum concentrating, alcohol precipitating, centrifugalizing and freeze-drying to recycle the protein. The special treatment in the invention has substantially increased the free oil yield and the quality of the free oil is better than the refined oil. The water-extracting and alcohol-precipitating method to get the protein is simple and efficient; besides, the method has maintained the sunflower protein's nutritive value and functional value very well. Compared with the traditional squeezing and water-extracting technologies, the invention has many advantages such as simple producing equipments, safe operation, less energy expenditure and less pollution.

Owner:JIANGNAN UNIV

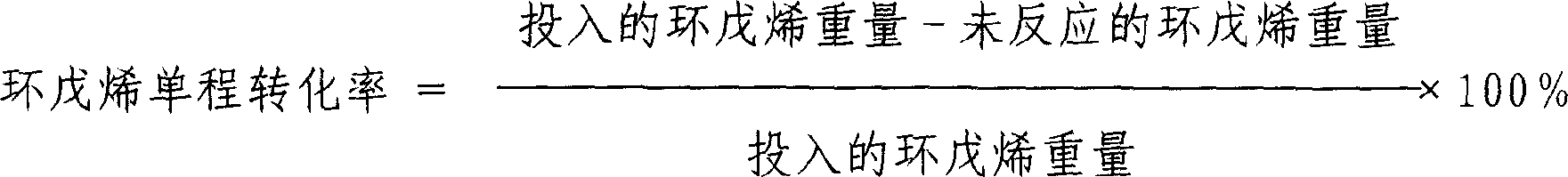

Cyclopentanol preparing and refining method

ActiveCN1676504AEasy to refineHigh selectivityOrganic compound preparationPreparation by hydroxy group additionHydration reactionCyclopentene

This invention is a making and refining method of cyclopentanol, which includes: 1) the materials comprises cyclopentene, phenylic acid solvent, water activator continuously pass through catalyst fixed bed to carry out hydration reaction, and the volume space velocity is 2-15hr to the power -1, the mole ratio of cyclopentene and water is 0.8-5.0, the weight ratio of phenylic acid and cycloamylene is 0.5-1.0. the intensity of activator is 0.01-0.2wt%, the reaction temperature is 130-180deg.C, the reaction pressure is 1.0-3.0MPa, the catalyst is strong acid cation exchange resin with sulfo group anchored on the surface, and the activating solvent is trialkylamine; 2)the reacted materials cool to house temperature and demix into oil phase and aqueous phase, the oil phase materials through continuous distilling separation procedure get non-reacting cycloamylene, refined cyclopentanol and phenylic acid full of solvent. The strong points of this invention are that the conversion of cyclopentene and selectivity of cyclopentanol are high, and the refining of cyclopentanol is simple and low energy consumption.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Method for aqueous enzymatic extraction of gardenia oil

InactiveCN103060078AHigh yieldHigh crude oil qualityFatty-oils/fats productionOrganic solventCentrifugation

The invention relates to a method for aqueous enzymatic extraction of gardenia oil. The method adopts gardenia fruits as raw materials, which are subjected to crushing, enzymolysis and centrifugation, thus obtaining the gardenia oil. The gardenia oil prepared by the invention has high yield and high quality, is easy to refine, and maintains the natural nutrients and function of gardenia oil. Compared with the traditional squeezing method and organic solvent extraction method, the method has the advantages of simple production equipment, safe operation, less pollution, and low energy consumption, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Extraction of hickory nut oil from water enzyme

The invention relates to the pecan oil which is a kind of natural health product, it is essentially an aqueous enzymatic extraction method of the pecan oil, the following is the process: (1) the peeled pecan kernel is milled according to the ratio of the weight of the material and the volume of the liquid is 1:3-5, the pecan kernel is milled approximately to 60-150 sieve number, and the juice is put out. (2) The pH of the juice will be adjusted: the pH of the juice from the milling process will be adjusted to 4.0-5.5 with chlorhydric acid and citric acid. (3) The process of thermolysis catalyzing: put the juice in the water bath, the temperature of which is 50-60DEG C,to thermolysis catalyze it for 1-5h,after the pH of it has been adjusted (4) Centrifuging to isolate it: the juice or above will be centrifuged at 4000-6000r / min for 15-3o minutes, the boiled oil which is at the super layer of the juice after the isolation will be exsucted out, and the boiled oil is just the the pecan oil that we need. The excellence of the method is: the oil yield and the oil quality are high, the technology is simple and secure, tand the cost is very lower.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

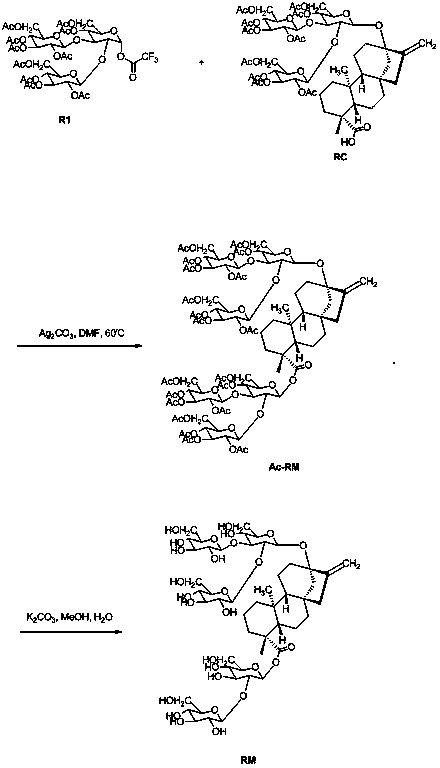

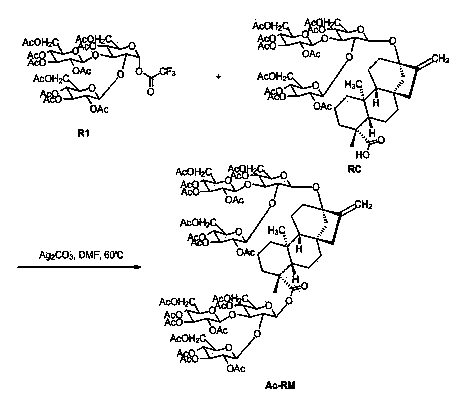

Process for preparing rebaudioside M

InactiveCN104163839ALow costMild reaction conditionsSugar derivativesSugar derivatives preparationChemical compoundHazardous substance

A process for preparing rebaudioside M is disclosed. The process includes: a step of subjecting rebaudioside C (RC) that is adopted as a substrate and a chemical compound R1 to a substitution reaction under the action of silver carbonate to obtain an intermediate Ac-RM; and a step of performing hydrolysis to obtain the product rebaudioside M (RM). By the manner, the process has characteristics of low raw material cost, mild reaction conditions, convenient purification, simple operation, good product quality, high yield, no generation of toxic harmful compounds in the whole process, and good environment protection effects, and is suitable for industrial production.

Owner:苏州景泓生物技术有限公司

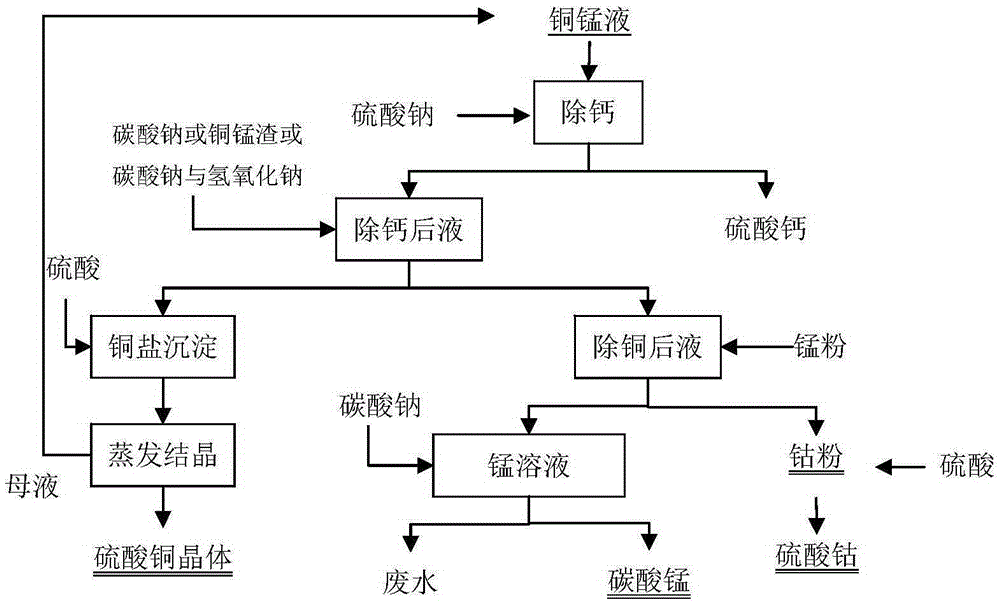

Method for separating copper, cobalt and manganese from cupric chloride manganese-cobalt-calcium-zinc impurity removal solution

ActiveCN105296754AShort processLow costRotary drum furnacesCrucible furnacesManganese(II) carbonateSulfate

The invention relates to a method for separating copper, cobalt and manganese from a cupric chloride manganese-cobalt-calcium-zinc impurity removal solution. The method comprises the steps that sodium sulfate is added to the cupric chloride manganese-cobalt-calcium-zinc solution, and calcium sulfate is removed by filtration; then sodium carbonate is added to a solution obtained in step one, a pH value is adjusted to 4.0-6.0 to allow copper ions in the solution to be precipitated, and copper precipitates are obtained by filtration separation; the copper precipitates are dissolved with sulfuric acid and are subjected to evaporation crystallization to form copper sulfate crystals; manganese powder is added to a solution after copper removal to allow cobalt ions to be reduced to cobalt powder to be precipitated, and cobalt powder is obtained after the filtration separation and is dissolved with acid to form a cobalt solution; and a solution after cobalt removal contains manganese and a little zinc and calcium, manganese is precipitated through the evaporation crystallization or by adding sodium carbonate, and manganese salts such as rough manganese carbonate are obtained. With the adoption of the method, three main valuable metals, namely copper, cobalt and manganese, can be separated and extracted economically and conveniently.

Owner:长沙百汇新材料科技有限公司

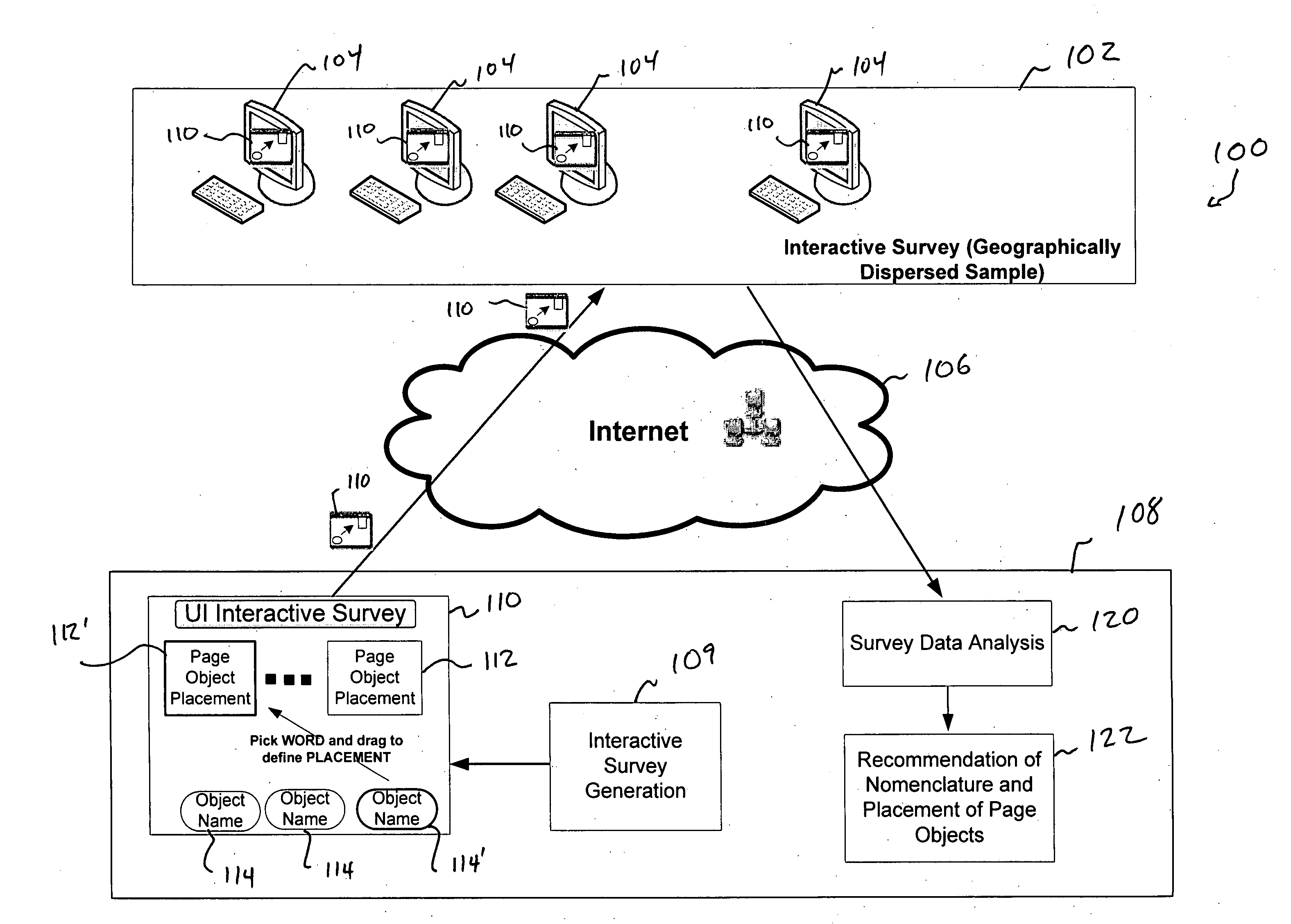

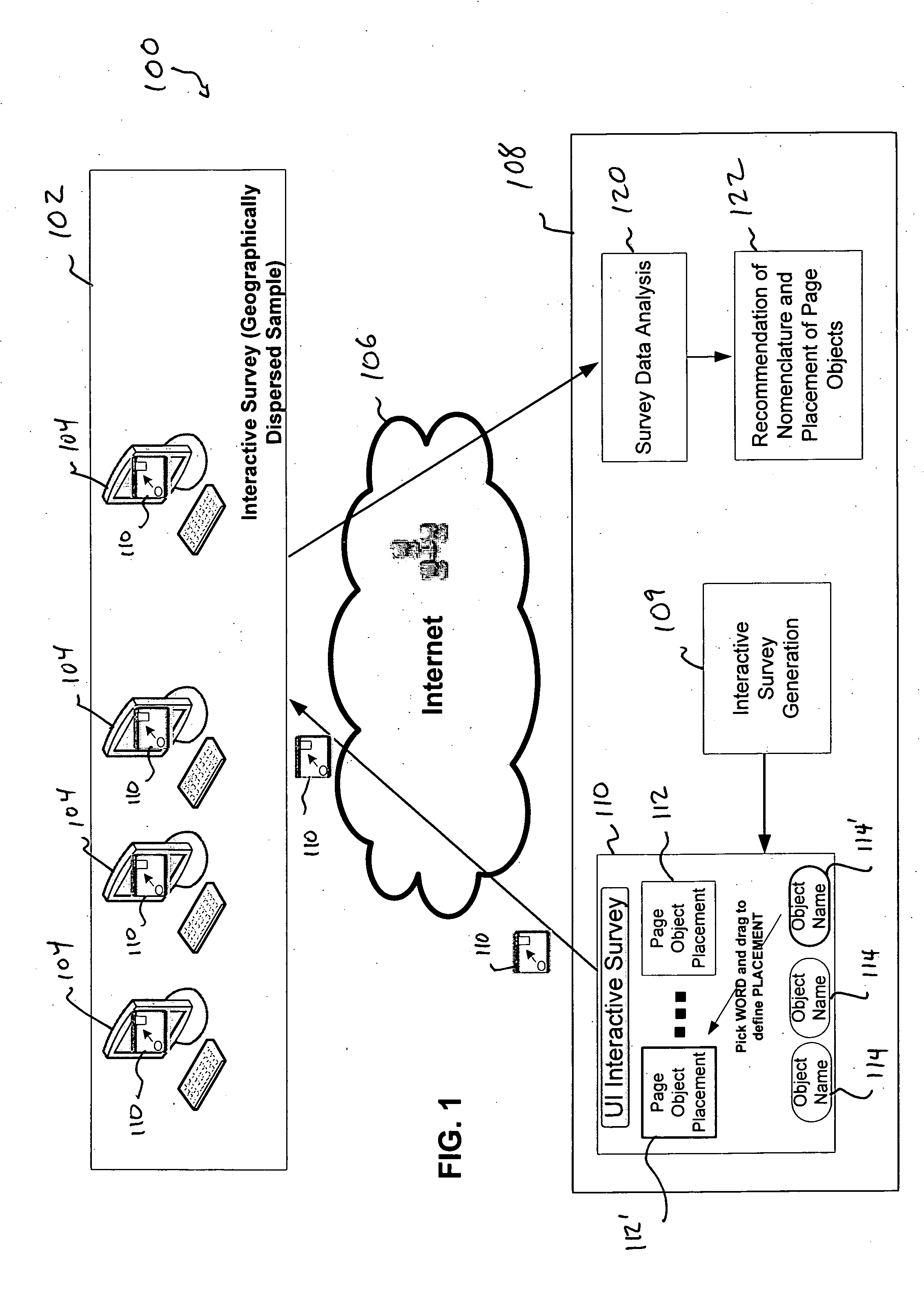

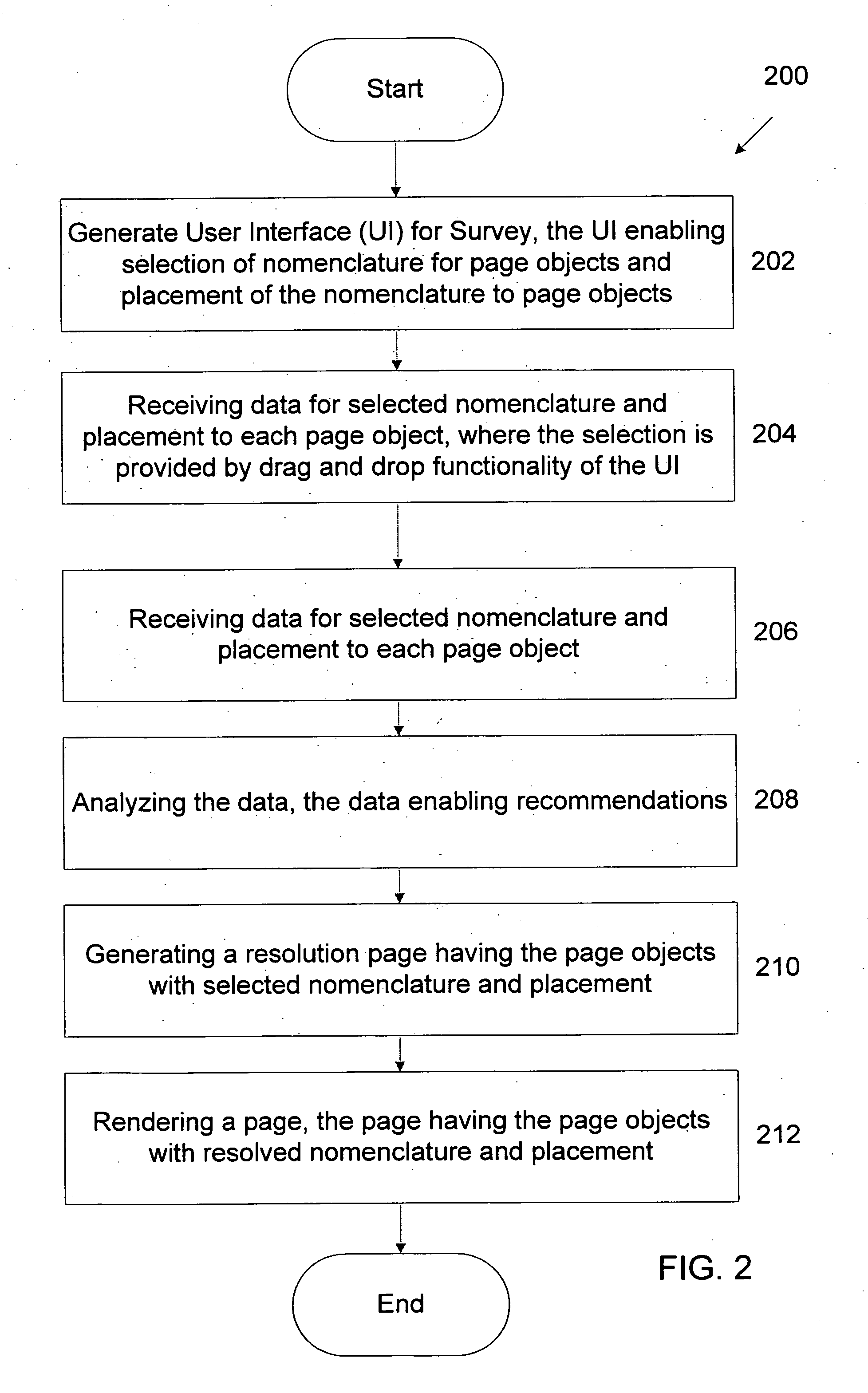

Interactive user interface for collecting and processing nomenclature and placement metrics for website design

ActiveUS20080126175A1Easy to refineEasy to processMarket predictionsNatural language data processingWeb siteDrag and drop

Computer implemented methods for conducting interactive surveys that define aspects of a web page, is disclosed. One method includes generating an interactive survey user interface (UI), where the interactive survey UI provides a plurality of selectable nomenclature items for a plurality of page objects of the web page. Then, enabling selection of one nomenclature item from the plurality of selectable nomenclature items. A drag and drop operation enables the selection of the one nomenclature item and dragging to the one of the plurality of page objects to define a placement for the one nomenclature item. The selection of the one nomenclature item and the defined placement is received to build metrics from multiple survey participants, where the metrics are used to define recommendation for rendering the plurality of page objects on the web page. The recommendations identify nomenclature and placement of page objects for the design of the web page.

Owner:R2 SOLUTIONS

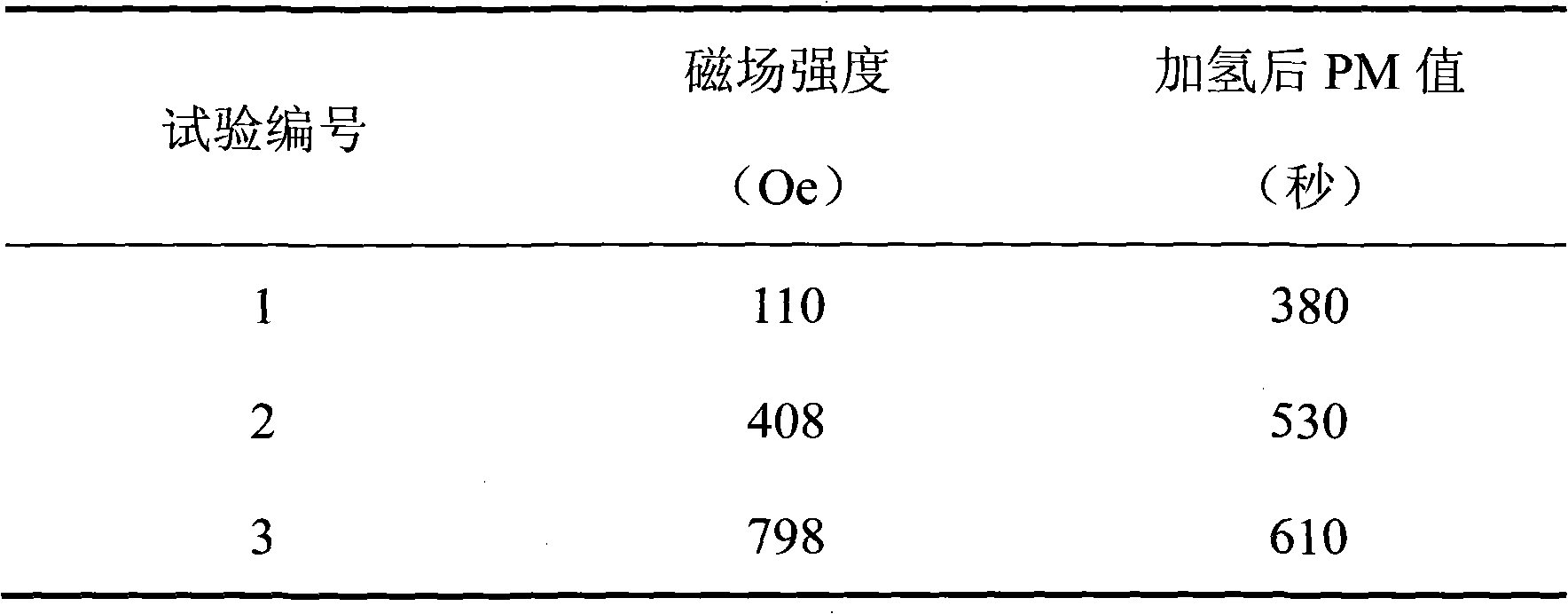

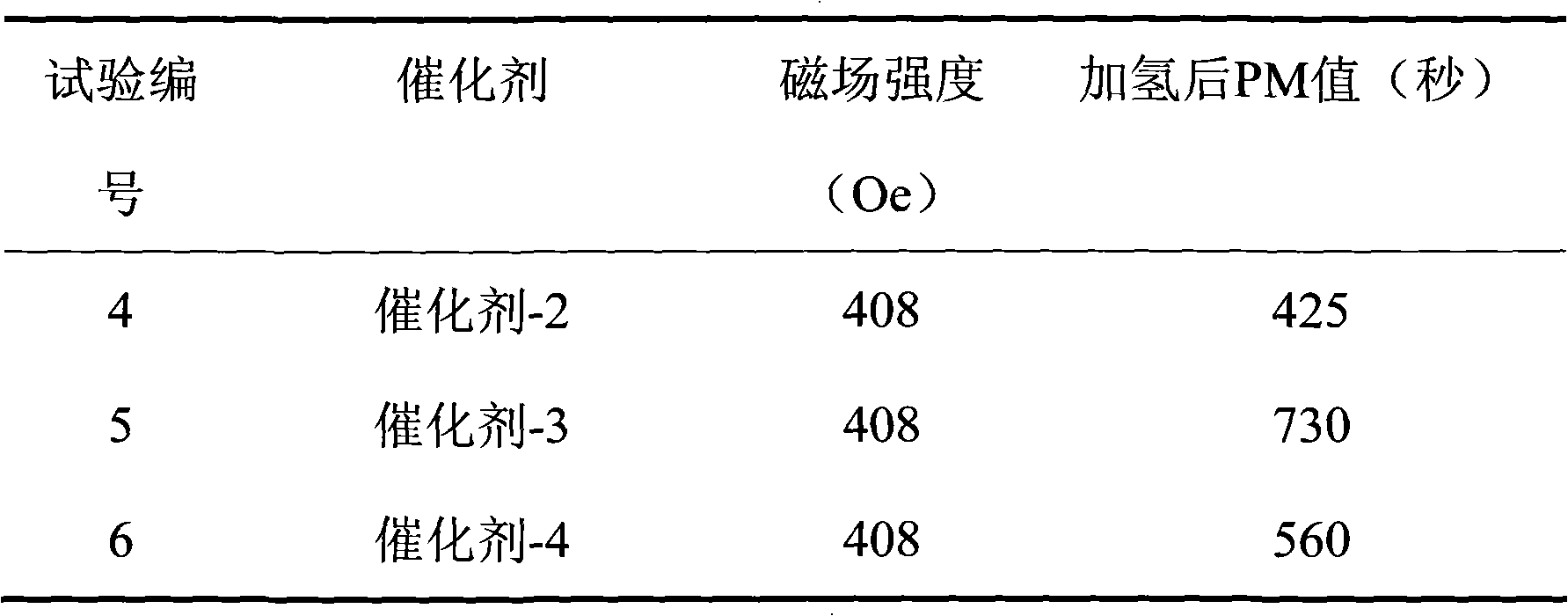

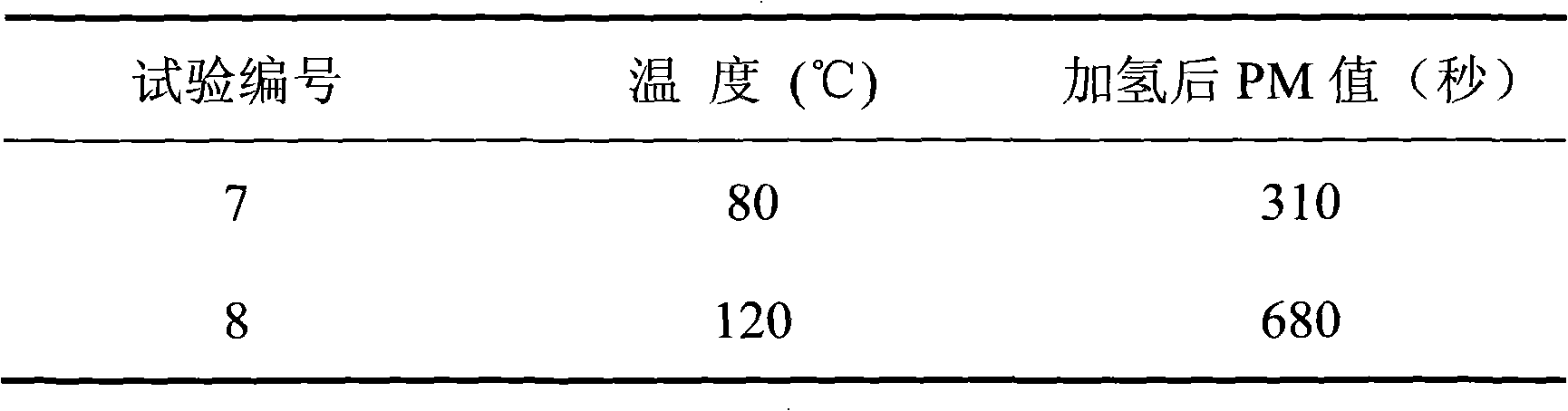

Method for hydrofining caprolactam in magnetically stabilized bed

ActiveCN102050783ARealize the operationReduce pollutionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsEvaporationCaprolactam

The invention relates to a method for hydrofining caprolactam in a magnetically stabilized bed. The method comprises the following steps: the acidamide oil is extracted and distilled with benzene / cyclohexane to obtain the caprolactam crude product; in a magnetically stabilized bed reactor, the hydrogenation reaction is carried out under the action of a catalyst formed by active components such as platinum or / and palladium and a magnetic spherical carrier, so that the unsaturated substance in the liquid caprolactam crude product reacts with hydrogen to generate a saturated substance; and then the saturated substance is rectified to obtain the caprolactam product. The active components in the catalyst occupy 0.01-5 percent (wt); and the hydrogenation reaction conditions are as follows: temperature: 80 DEG C to 140 DEG C, pressure: 0.5 to 3.0 MPa, air speed: 2 to 60h-1, and magnetic field intensity: 10 to 1500 oersteds. Compared with the prior art, the method has the advantages that the procedures of water re-extraction and dehydration by evaporation are reduced, the refining process is greatly simplified, and the refining operation process is optimized; and the method is favorable for reducing energy consumption and environmental pollution and enhancing the processing capacity of the device.

Owner:CHINA PETROLEUM & CHEM CORP +3

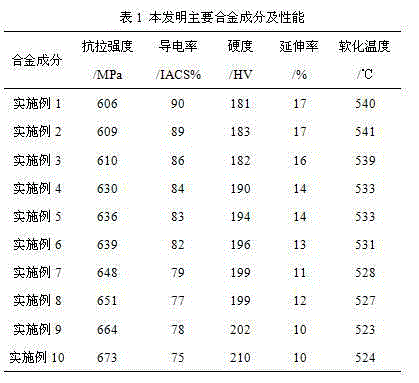

High-strength and high-conductivity rare earth copper alloy for contact lines and preparation method thereof

The invention relates to a high-strength and high-conductivity rare earth copper alloy for contact lines and a preparation method thereof. The rare earth copper alloy is composed of chromium, zirconium, zinc, titanium, silver, copper, rare earth elements and inevitable impurity elements, wherein during preparation, a Cu-Zr intermediate alloy and a Cu-rare earth intermediate alloy are prepared at first, and then the Cu-Zr intermediate alloy and the Cu-rare earth intermediate alloy are smelted and subjected to mould casting with copper, zinc, silver and titanium to form a cast ingot, the cast ingot is subjected to hot extrusion to obtain a bar billet, the bar billet is subjected to solution treatment, the treated alloy is subjected to drawing deformation, and then subjected to aging treatment to prepare the high-strength and high-conductivity rare earth copper alloy. The conductivity, elongation, strength and softening temperature of the alloy disclosed by the invention can be greatly improved; the machining performances of the alloy are remarkably improved; the manufacturability of the alloy can be changed, thus benefiting refining, degassing and microalloying; and the requirements of a material for the industrial field of contact lines on the performances of copper alloys can be met well. The alloy disclosed by the invention is simple in preparation process, short in process flow, high in strength, good in conductivity and excellent in hot-working property.

Owner:HENAN UNIV OF SCI & TECH

Production technique of xylose

The invention discloses a production technique of xylose. The production technique comprises the following steps: pulverizing, boiling with high-temperature water, hydrolyzing, decolorizing, refining, carrying out continuous film concentration, carrying out steam vaporization concentration, crystallizing, centrifuging and drying, thereby finally obtaining the crystalline xylose finished product. The xylose mother solution is sold as the byproduct and used as the raw material for preparing the caramel pigment product. The corn cobs are pulverized, thereby increasing the specific area, shortening the contact and soak time, enhancing the hydrolysis efficiency, and increasing the xylose yield. The hydrochloric acid is used for hydrolyzing the corn cobs to prepare the xylose, thereby saving the subsequent decolorant consumption, and reducing the environmental pollution. The continuous film concentration technique is adopted to partially substitute the steam vaporization technique, thereby having favorable energy-saving effect. The technique has the advantages of high waste acid / alkali recovery efficiency and favorable effect, and can save the acid / alkali consumption. The technique simplifies the technical process, shortens the production cycle, enhances the production efficiency, lowers the xylose production cost and reduces the wastewater emission.

Owner:HARBIN YOULI XYLITOL TECH CO LTD

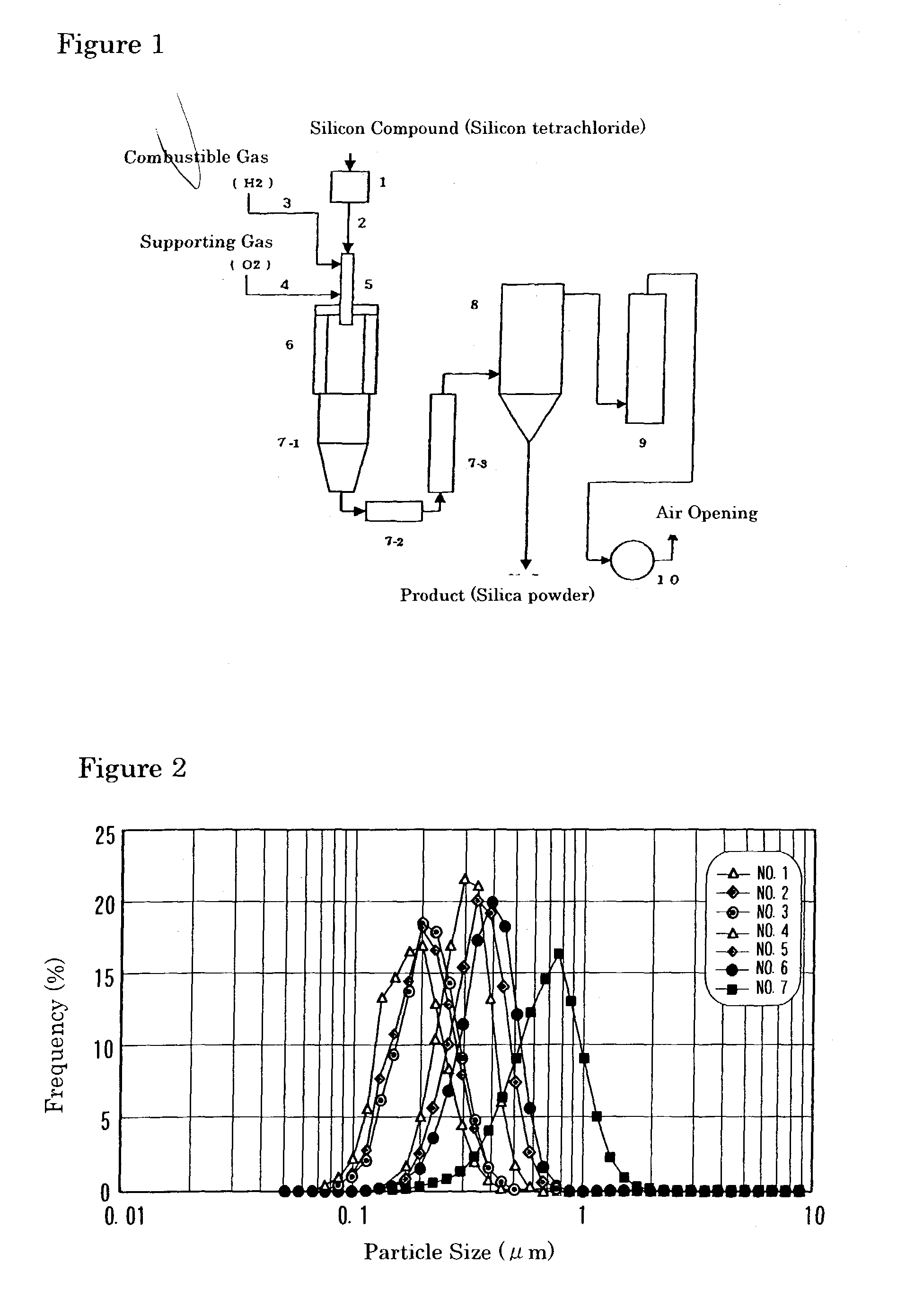

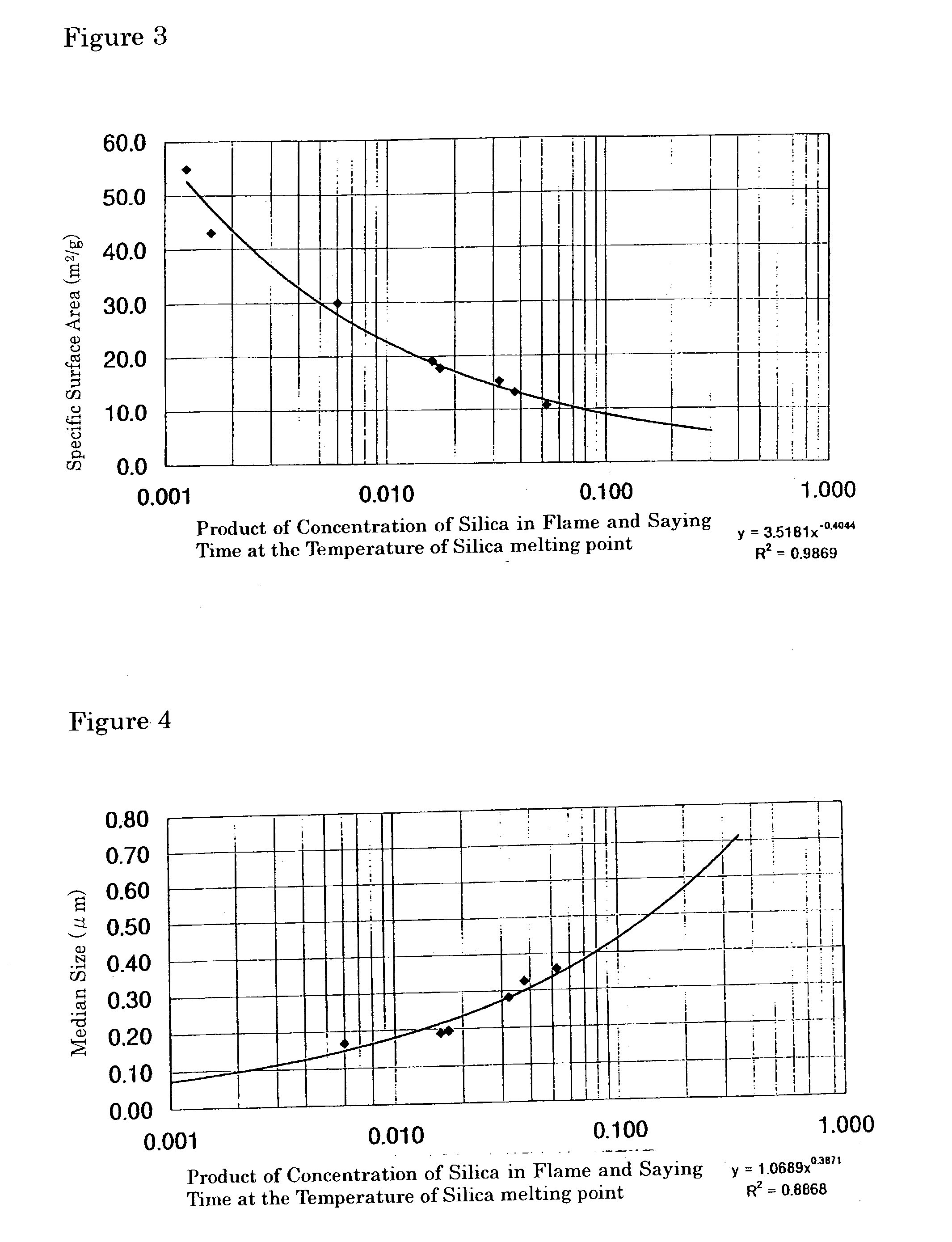

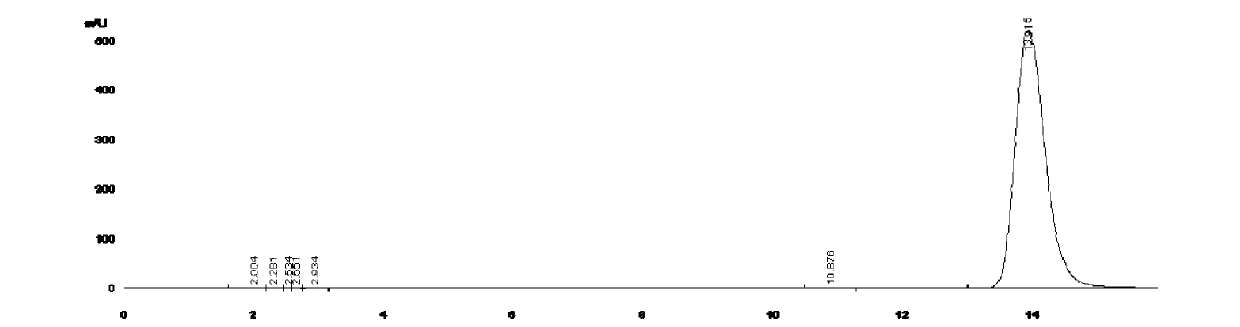

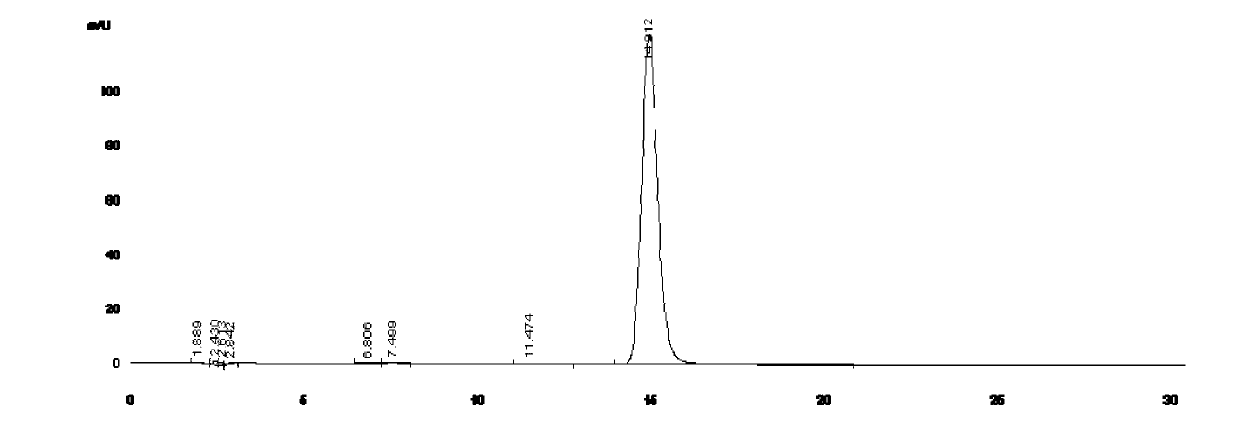

Amorphous, fine silica particles, and method for their production and their use

InactiveUS20030152506A1Easy to disassembleHigh purityMaterial nanotechnologyPigmenting treatmentSilica particleSilicon dioxide

The amorphous-silica particle having 0.1-0.7 mum of the average particle diameter, 5-30 m2 / g of the specific surface area, less than 40 of the dispersion coefficient, and 20 muC / m2 of the absolute value of the triboelectrostatic charge, can be obtained, by setting flame temperature to more than melting point of silica, raising the silica concentration in a flame, and staying the generated silica particle in the flame for a short time to be grew up. Since this silica particle has a particle shape being near a true sphere, and a particle size of said particle is remarkably uniform, so it is suitable for a filler of a semiconductor sealing agent or various materials, etc. In addition, since said particle has strong electrification, it is also suitable for an outer or an inner additional agent of a toner for an electronic photograph, a photo conductor material for a electronic photograph, and a material of an electric charge transportation layer, etc.

Owner:NIPPON AEROSIL

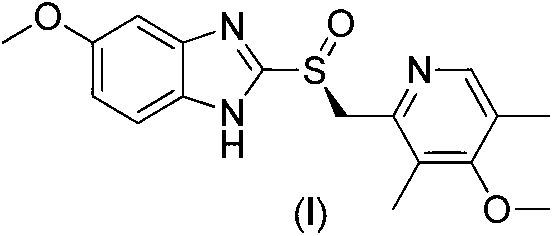

Esomeprazole and preparation method of magnesium trihydrate of esomeprazole

The invention provides esomeprazole and a preparation method of magnesium trihydrate of the esomeprazole. The preparation method includes the following steps of subjecting racemization omeprazole and inorganic base to acid-base neutralization reaction in an alcoholic solution to obtain racemization omeprazole sodium salt; dissolving omeprazole sodium salt, organic metal coordination agents, chelating agents and organic base in an organic solvent for complex reaction to obtain esomeprazole complex; subjecting S-mandelic acid and the esomeprazole complex to condensation reaction to obtain an esomeprazole mandelate compound; dissolving the esomeprazole mandelate compound in an acetone solution, and performing filtering to obtain S-omeprazole-S-mandelate compound; and suspending the S-omeprazole-S-mandelate compound in a first solvent to obtain a suspension solution, and adjusting potential of hydrogen (pH) of the suspension solution to be 8-10 to obtain the esomeprazole, wherein the first solvent includes 30-32v / v% of an alkaline aqueous solution and 68-70v / v% of an organic solvent. By means of the preparation method, the technical problem that the yield and the purity of the esomeprazole in prior art are low is solved.

Owner:HUNAN FANGSHENG PHARMACEUTICAL CO LTD

New energy automobile battery tray high-strength aluminum alloy sectional material and preparation method thereof

The invention relates to the technical field of aluminum alloy materials and provides a new energy automobile battery tray high-strength aluminum alloy sectional material and a preparation method thereof. The problems that an aluminum alloy sectional material in the prior art is poor in tensile strength, yield strength or corrosion resistance and cannot meet the requirement for high-quality battery trays are solved. The aluminum alloy sectional material comprises chemical components: by mass, 0.65-0.8% of Si, 0.48-0.6% of Mg, 0.3-0.4% of Zn, 0.06-0.10% of Fe, 0.15-0.25% of Cu, 0.02-0.04% of Zr, 0.05-0.07% of rare earth elements, 0.03-0.06% of Mo, 0.04-0.06% of Mn, 0.03-0.04% of Ti, 0.01-0.03% of Cr, and the balance Al. The preparation method comprises the following steps of (1) smelting; (2) refining; (3) casting; (4) homogenizing treatment; (5) extrusion; (6) solid solution quenching; and (7) aging treatment.

Owner:FUJIAN MINFA ALUMINUM

Search system with query refinement and search method

ActiveUS8694530B2Easy to refineImprove refinementWeb data indexingDigital data processing detailsElectronic documentDocumentation

A search system and method for searching for electronic documents, and providing a search result in response to a search query. In one embodiment, the search system includes a processor, a user interface module adapted to receive a search query from a user that includes a search query term, a search engine that electronically searches for electronic documents that satisfy the search query term, and a query processing module that identifies at least one alternative term for the search query term, and provides the alternative term to the user interface module for display to the user, and also provides the alternative term to the search engine to search for electronic documents that satisfy the alternative term.

Owner:TEXTDIGGER

Ultrasonic-assisted extraction process for pleurotus eryngii polysaccharides

The invention discloses an ultrasonic-assisted extraction process for pleurotus eryngii polysaccharides. The ultrasonic-assisted extraction process includes soaking dry pleurotus eryngii hyphae in a distilled water solvent container; placing the container in ultrasonic grinding equipment, and grinding cell wall structures of the pleurotus eryngii hyphae by the aid of ultrasonic waves to obtain pleurotus eryngii hypha mixed liquid; heating the pleurotus eryngii hypha mixed liquid by a hot water extraction method to enable polysaccharides in cells of the pleurotus eryngii hyphae to seep out so as to obtain extract liquid; performing centrifugation, concentration, ethanol precipitation and ion-exchange chromatography on the extract liquid to obtain the pleurotus eryngii polysaccharides. The ultrasonic-assisted extraction process for the pleurotus eryngii polysaccharides has the advantages that cell walls of the hyphae are broken due to extremely high pressure generated by the aid of ultrasonic cavitation, effective ingredients in the pleurotus eryngii hyphae are fed into solvents in an accelerated manner, repeated extraction is omitted, the polysaccharide yield is high, the extraction process is simplified, and the polysaccharide extraction efficiency is high.

Owner:四川省砚山中药饮片有限公司

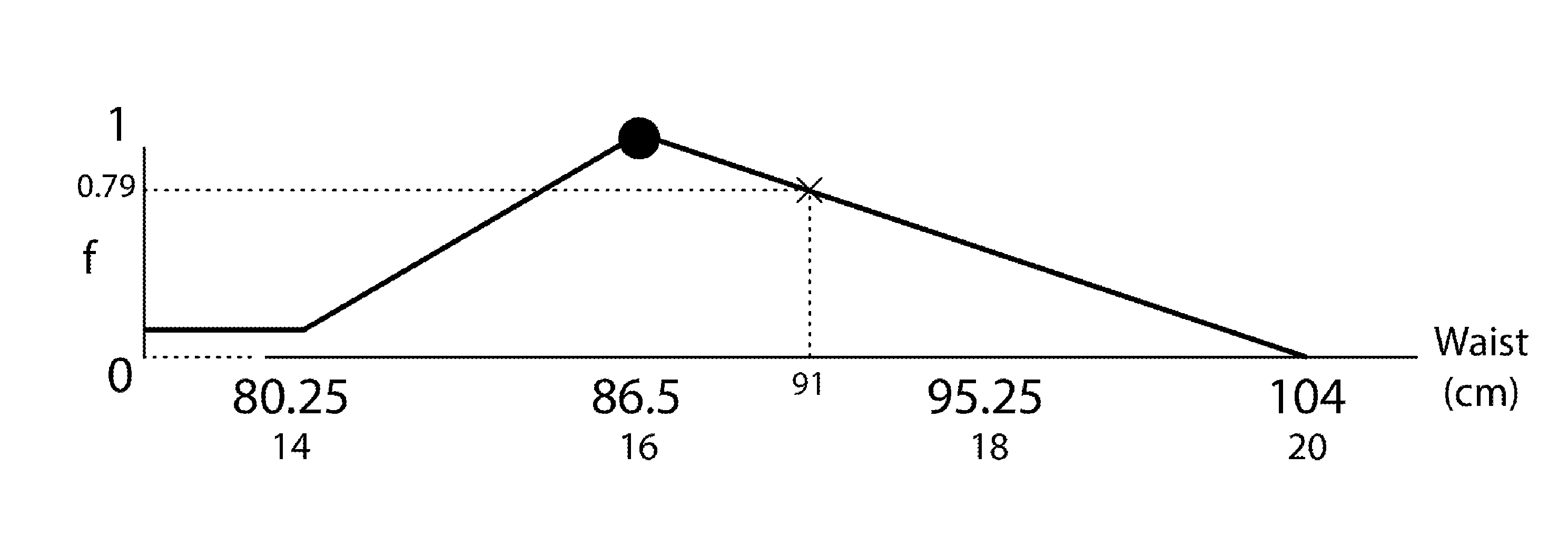

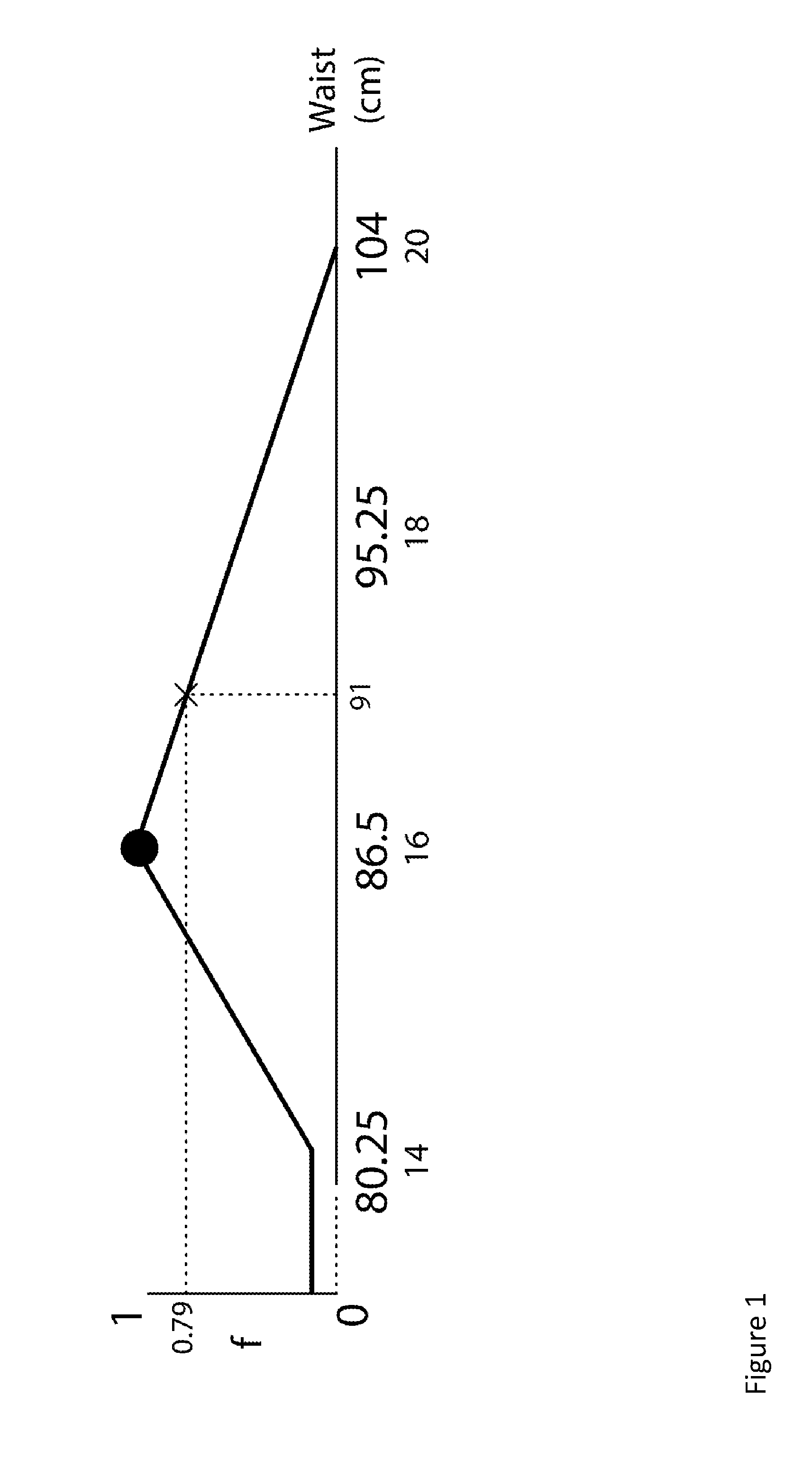

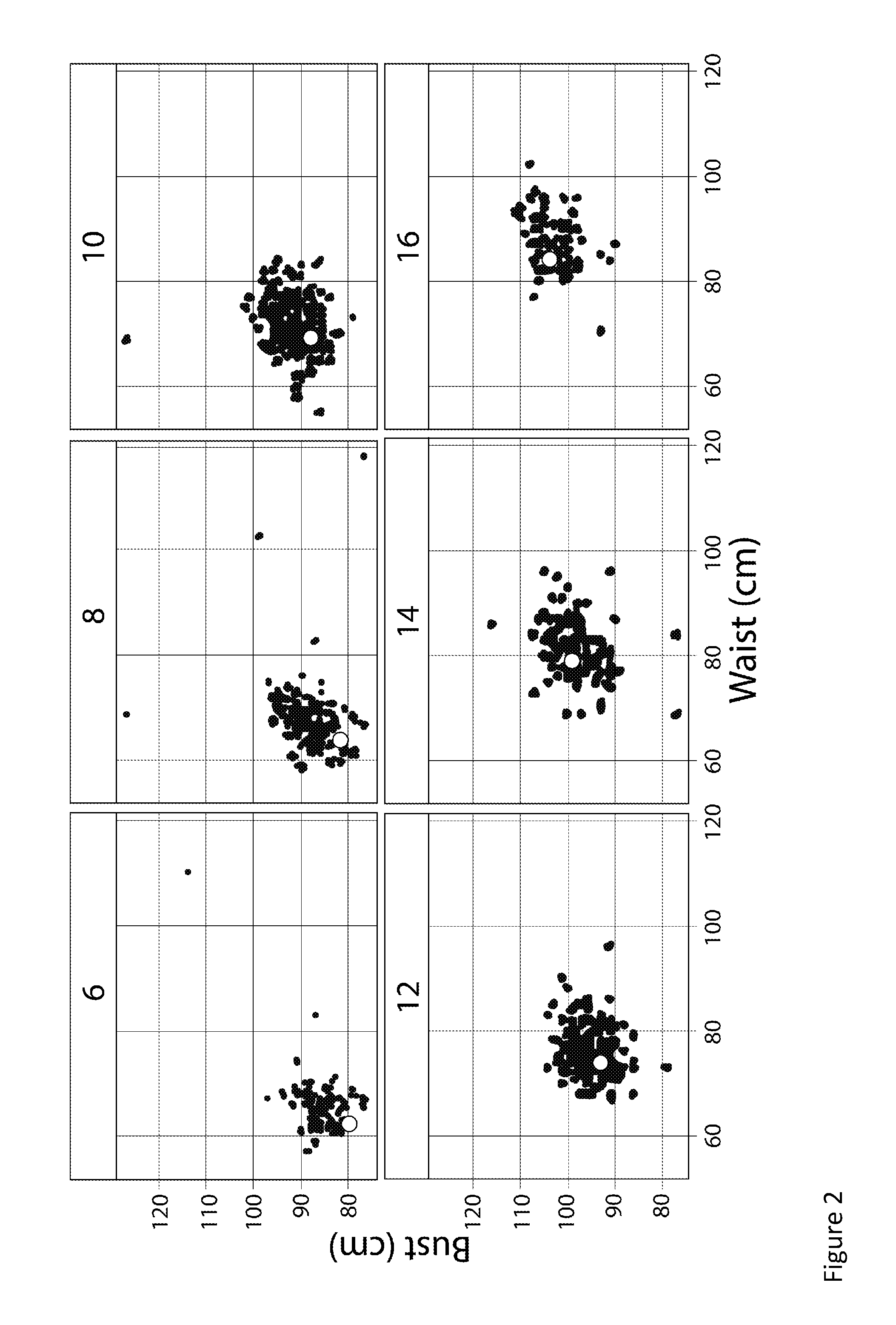

Garment size recommendation and fit analysis system and method

InactiveUS20170039622A1Easy to refineEasy to updateDrawing from basic elementsGarmentsAlgorithmEngineering

A computer-implemented garment size recommendation and fit analysis system in which a memory stores a virtual profile or model of an end-user and a processor is programmed to receive an end-user's selection of a garment and to then determine, using a garment fit algorithm, how well that garment will fit the end-user's profile or model, and in which the algorithm is trained on actual sales data.

Owner:METAIL

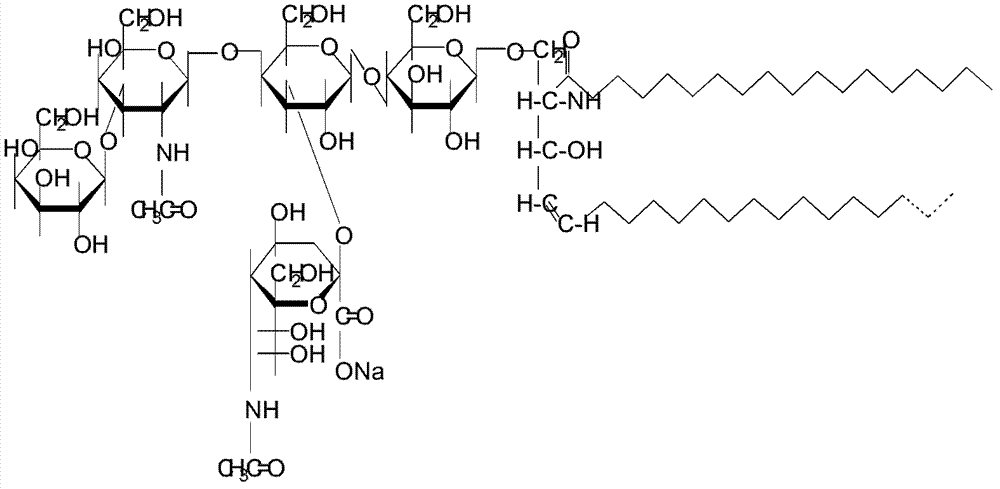

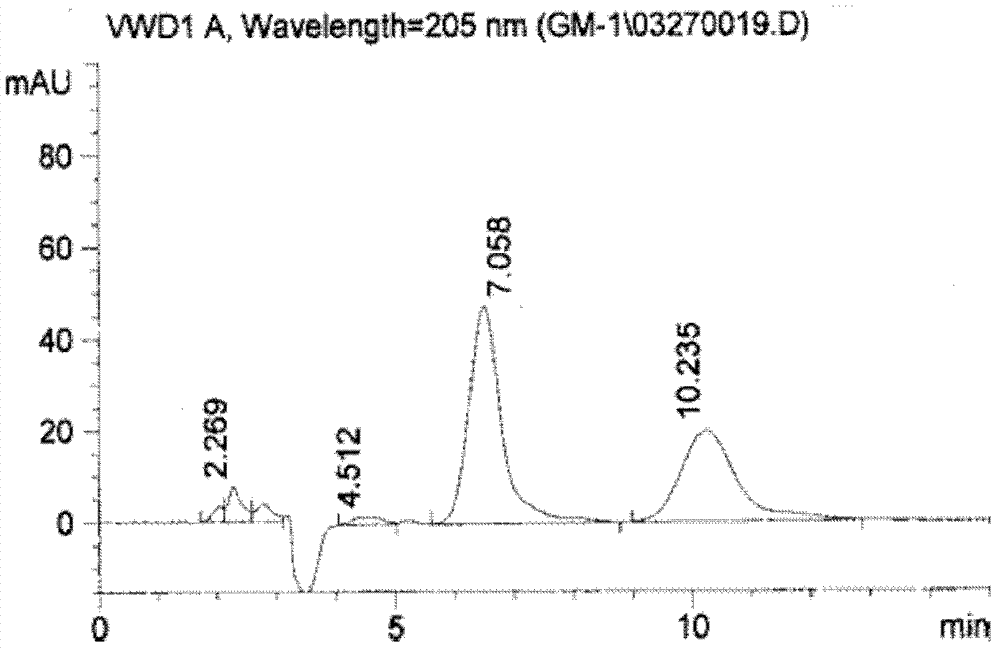

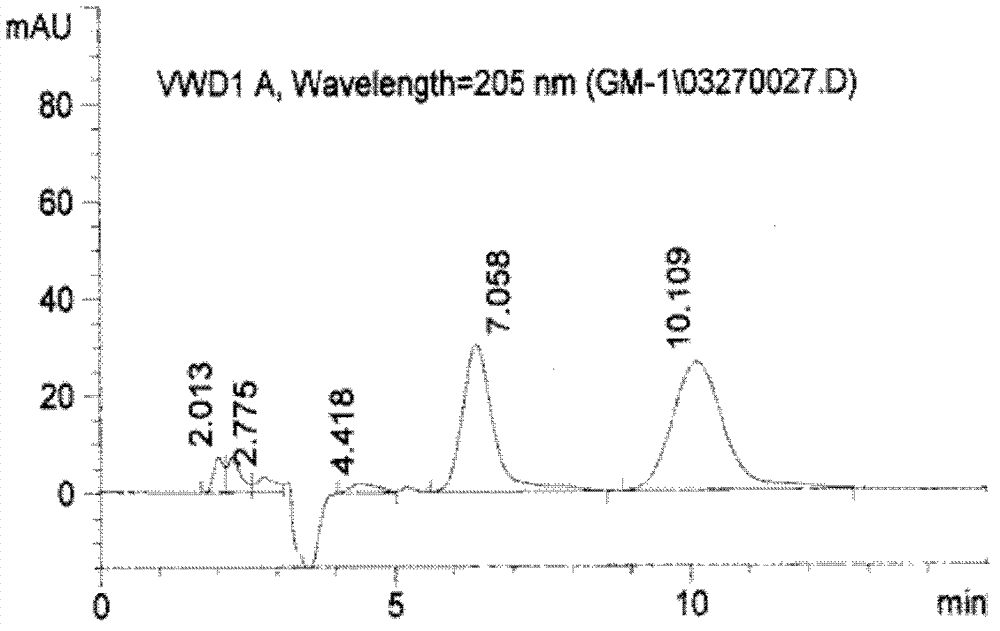

Preparation method of monosialoteterahexosylganglioside

ActiveCN102731584AReduce water soluble impuritiesInhibit degradationSugar derivativesSugar derivatives preparationAcid hydrolysisStereochemistry

The invention discloses a method for preparing high-purity monosialoteterahexosylganglioside (GM1), comprising the steps of preparing acetone powder of pig brains, preparing total ganglioside and conducting acid hydrolysis. According to the invention, the yield and purity of the obtained monosialoteterahexosylganglioside are raised, the application amount of organic solvent is saved, the extraction time is saved, the efficiency is raised, and convenience is brought to the subsequent process.

Owner:四川奇格曼药业有限公司

Art oil paint containing nano-pigment and method for manufacturing same

InactiveCN101225253ABright and brightSaturated and IntenseWax coatingsArtist's paintsALUMINUM STEARATESCobalt

The invention relates to art oil paint with nano-pigment and the preparation method, which is characterized in that the beeswax is added into refined linseed oil and polly seed salad oil and blended evenly to make bond after heating and melting. The nano-pigment is added into the bond to blend evenly and then the pigment is added in and blended evenly. Then aluminum stearate, 2-ethyl hexanol cobalt (CAS No.13586-82-8), silicon dioxide hydrate, hydrafil, phenoxetol, butyl-p-cresol and lithopone are added in and then blended evenly. The product can be obtained after grinding. The preparation method first disperses the nano-pigment into the bond and drains most air on the surface of the common pigment grain, and then disaggregates the large grain and small gobbet of the sizing agent by the large shearing force, extrusion force and grinding force between the two rollers generated by the turn of the three-roller muller. During the grinding process, the bond with nano-pigment or latex covers the surface of the pigment grain and then permeates through the gaps of the grains. The product made has the advantages of rich color, bright colour and luster, fresh tint, strong tinctorial strength and good chromaticity.

Owner:宋健

Method for synchronously preparing walnut oil and walnut protein peptide by microwave-assisted protease hydrolysis

The invention provides a method for synchronously preparing walnut oil and walnut protein peptide by microwave-assisted protease hydrolysis, comprising the following steps of: grinding walnut raw materials into walnut powder, adding 100,000 to 1000,000 units of protease or composite protease to 1kg of walnut powder, adding water in the mass ratio of the walnut powder to the water is 1: (0.5-20), and then performing microwave processing for 1-10 minutes under the stirring condition of 60 to 300rpm when the microwave power is 10 to 1000 W / L and the temperature is 35 to 65 DEG C, and performing centrifugal separation of oil phase, aqueous phase and solid phase after the reaction ends, wherein the oil phase is walnut oil, the aqueous phase is walnut protein peptide, and the solid phase is residues. The method provided by the invention has mild extraction condition and excellent product performance, and can improve the efficiency of ingress of oil. Furthermore, the obtained walnut oil is higher in quality and is easy to refine; the processing time is greatly shortened by microwave-assisted extraction; the oil phase, the aqueous phase and the solid phase residues can be separated at the same time, therefore, the production efficiency is efficiently improved; and no waste water, waste air or waste residues exists in the producing process, therefore, the invention is environmentally-friendly.

Owner:KUNMING UNIV OF SCI & TECH

1960 MPa grade galvanized steel wire rope for ocean engineering, and production method of 1960 MPa grade galvanized steel wire rope

ActiveCN108486478AHigh tensile strengthEasy to refineHot-dipping/immersion processesMetallurgyMartensite

The invention provides a 1960 MPa grade galvanized steel wire rope for ocean engineering, and a production method of the 1960 MPa grade galvanized steel wire rope. The 1960 MPa grade galvanized steelwire rope for the ocean engineering comprises the following components of, 0.87-0.91% of C, 0.15-0.30% of Si, 0.65-0.85% of Mn, 0.15-0.25% of Cr, 0.020-0.060% of V, less than or equal to 0.015% of P,less than or equal to 0.010% of S, less than or equal to 0.05% of Ni, less than or equal to 0.10% of Cu, less than or equal to 0.010% of Alt, less than or equal to 1.0 PPm of H, and the balance Fe andunavoidable impurity elements. Compared with the prior art, refining and continuous casting technologies are optimized, so that composition segregation is avoided; with the adoption of an optimized rolling-control and cold-control rolling technology, network cementite and martensite are avoided, so that a metallographic structure with the sorbitizing rate of 90% or above can be obtained; and a galvanized steel wire made of a hot rolling wire fully meets the use requirement of the 1960 MPa grade galvanized steel wire rope for the ocean engineering.

Owner:MAANSHAN IRON & STEEL CO LTD

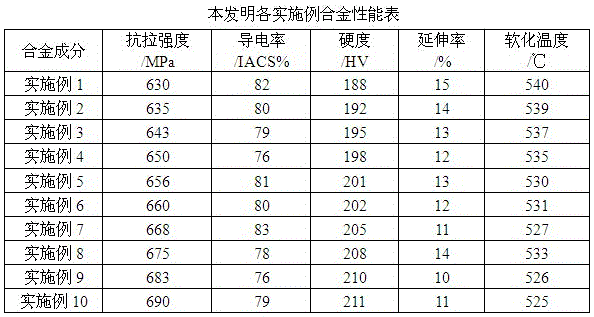

High-strength and high-conductivity rare earth copper and zirconium alloy and preparation method thereof

High-strength and high-conductivity rare earth copper and zirconium alloy is composed of zirconium, nickel, silicon, copper and rare earth elements and comprises, by weight, 0.1-0.5% of zirconium, 0.1-0.5% of nickel, 0.1-0.15% of silicon, 0.2-0.4% of silver, 0.02-0.1% of a rare earth element and the balance copper. The high-strength and high-conductivity rare earth copper and zirconium alloy has the beneficial effects that the reparation process is simple, the technological process is short, the strength, the conductivity and elasticity are high, the hot-working character is good, and the tensile strength of the high-strength and high-conductivity rare earth copper and zirconium alloy can reach 690 MPa.

Owner:HENAN UNIV OF SCI & TECH

Process for preparing biodiesel by one-step method using biomass based sulfonation charcoal as fatty acid esterification and triglyceride transform esterification catalysts

InactiveCN101289629AReduce manufacturing costImprove catalytic performancePhysical/chemical process catalystsFatty acid chemical modificationPtru catalystCarbonization

The invention relates to a method for making biodiesel oil through adopting biomass-based sulfonated carbon as fatty acid esterifying and triglyceride transesterification catalyst one-step method. The method is as follows: biomass raw material containing abundant lignin is crushed and dipped in dilute sulfuric acid, and then is dried and carbonized at the low temperature to obtain biomass-based sulfonated carbon with a porous structure; and the biomass-based sulfonated carbon is taken as catalyst to make fatty acid mono-alkyl ester (biodiesel oil) through base oil fatty acid esterifying and triglyceride transesterification one-step method. The method solves the problems that: the manufacturing process of biodiesel oil through the prior acid-base catalysis method is limited by the acid value of base oil; and waste water discharge is great. The catalyst, which is insensitive to the by-product moisture generated during biodiesel oil production and is easy to separate, is propitious to the purification of crude glycerol; moreover, the catalyst, with low production cost, not only can be reused, but also can be abandoned to be used as a soil improvement material.

Owner:NANCHANG UNIV

Process method for microwave assistant supercritical extraction of active ingredients of curcuma

InactiveCN102100875AIncrease polarityAvoid multi-stage extractionMetabolism disorderAntinoxious agentsFiltrationBULK ACTIVE INGREDIENT

The invention discloses a process method for microwave assistant supercritical extraction of active ingredients of curcuma. In the method, the active ingredients, namely curcumin and fat soluble curcuma oil, of curcuma are extracted by the synergistic action of the microwave technology and the supercritical technology. The process method mainly comprises the following steps of: performing microwave intermittent sudden heating and then carbon dioxide (CO2) supercritical extraction; separating CO2 and curcuma oil in an analyzing kettle; and adding water or ethanol into curcuma residue in a solid-to-liquid weight ratio of 1:7-14, and performing microwave action, twice soaking, filtration, condensation and spray drying to obtain the curcumin. The process method solves the problem that in the prior art, only single active ingredient can be extracted or the compositions of the extract are not balanced, and realizes the extraction of two main active ingredients, namely curcuma oil and curcumin, of the curcuma at the same time, and the yield is over 8 percent and 13 percent respectively. The process method is the physical method and has the advantages of no product pollution, high purity, low cost, simple process and easy mass production.

Owner:GUANGZHOU RZN BIOTECH CO LTD

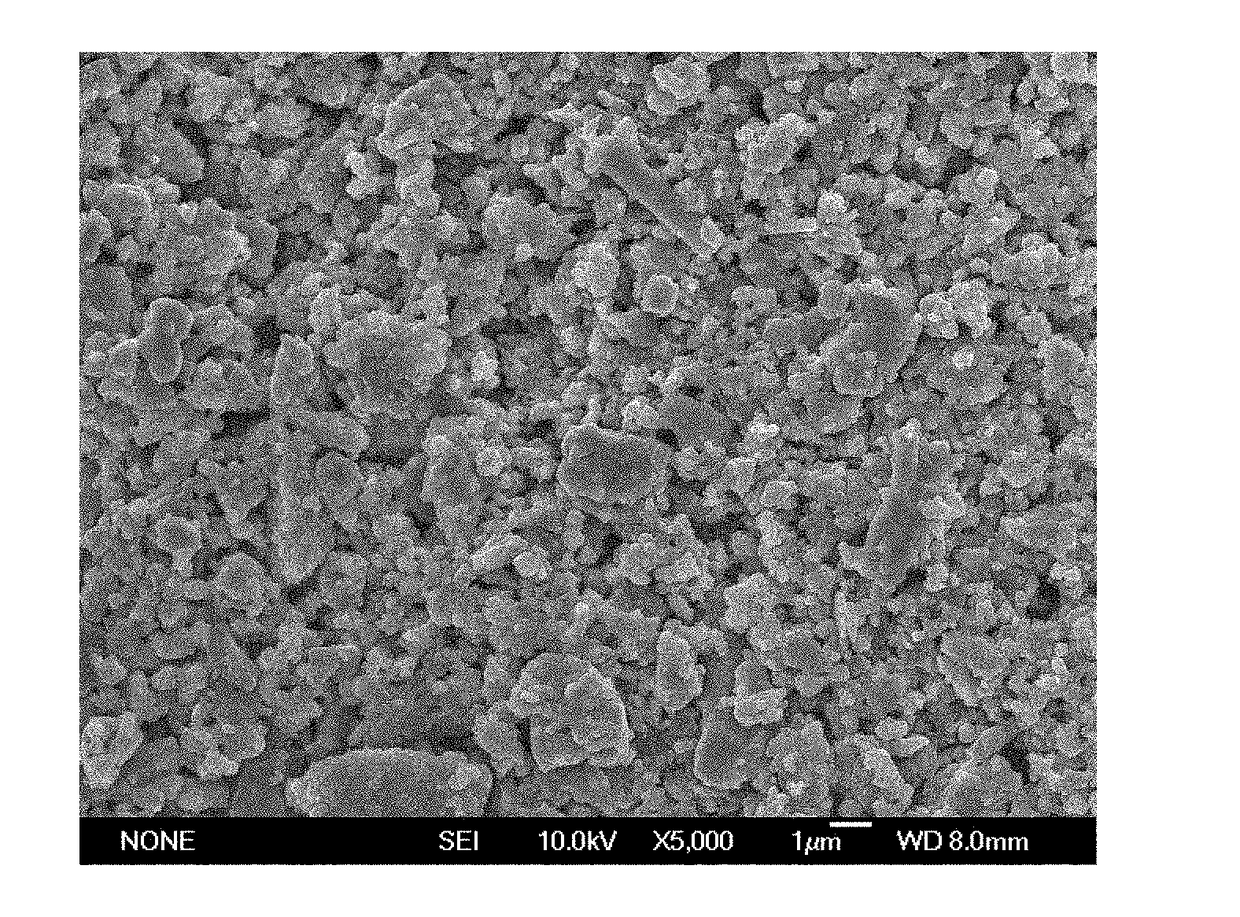

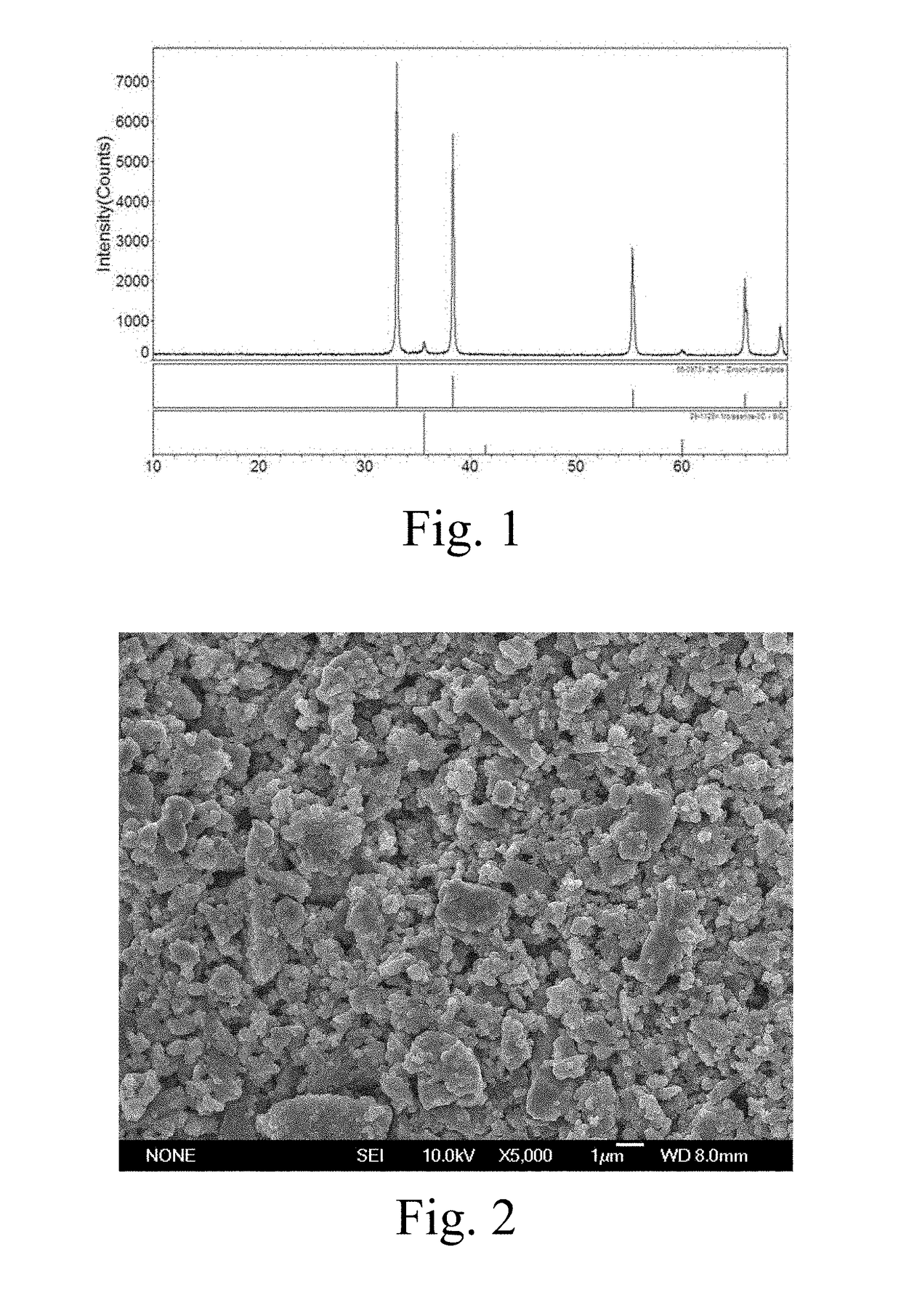

Method for synthesizing high-purity ultrafine ZrC-SiC composite powder

ActiveUS20180186700A1High water solubilityCost reductionOxy/sulfo carbidesSource materialCarbon source

A method for synthesizing high-purity ultrafine ZrC—SiC composite powder is provided. The high-purity ultrafine ZrC—SiC composite powder is prepared by utilizing zirconium silicate only or zirconium silicate with one or both of zirconium oxide or silica sol as a zirconium source and a silicon source material, utilizing sucrose or glucose as a carbon source material, and utilizing acrylamide monomer and N,N′-methylene diacrylamide cross-linking agent as a gel material.

Owner:SHANDONG ULSTREETCARING FINE CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com