Patents

Literature

403results about How to "Increase the amount of control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

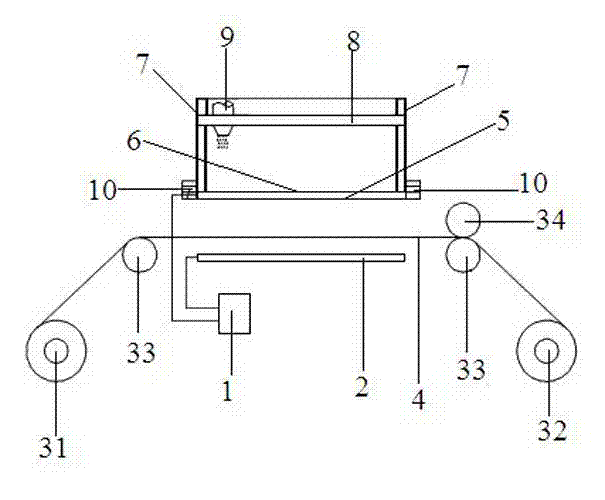

Method for supplementing lithium powder to lithium-ion battery negative plate

ActiveCN102779975AImprove first-time efficiencyIncrease battery capacityElectrode manufacturing processesElectric fieldLithium electrode

The invention belongs to the technical field of lithium-ion battery, and in particular relates to a method for supplementing lithium powder to a lithium-ion battery negative plate. The method comprises the following steps: a first step, putting the cold-pressed negative plate on an unwinding and rewinding mechanism, and putting lithium powder to a feeding mechanism above the negative plate; a second step, adding electric fields and opening the feeding mechanism, so that the lithium powder is adsorbed on the surface of the negative plate under the action of the electric fields; and a third step, rolling the negative plate adsorbed with the lithium powder. Compared with the prior art, the method can control the movement of the lithium powder to overcome the flotation of metal lithium powder in air through electrostatic effect provided by the electric fields, and can simultaneously control the addition of the lithium powder and the dispersion degree of the lithium powder on the negative plate, thereby uniformly, quantitatively and precisely dispersing the lithium powder on the surface of the negative plate. Besides, the whole process provided in the invention is only needed to be carried out in a drying environment without adding the lithium powder in a process of preparing slurry, has a simple manufacture process and low cost, and is suitable for large-scale production.

Owner:NINGDE AMPEREX TECH

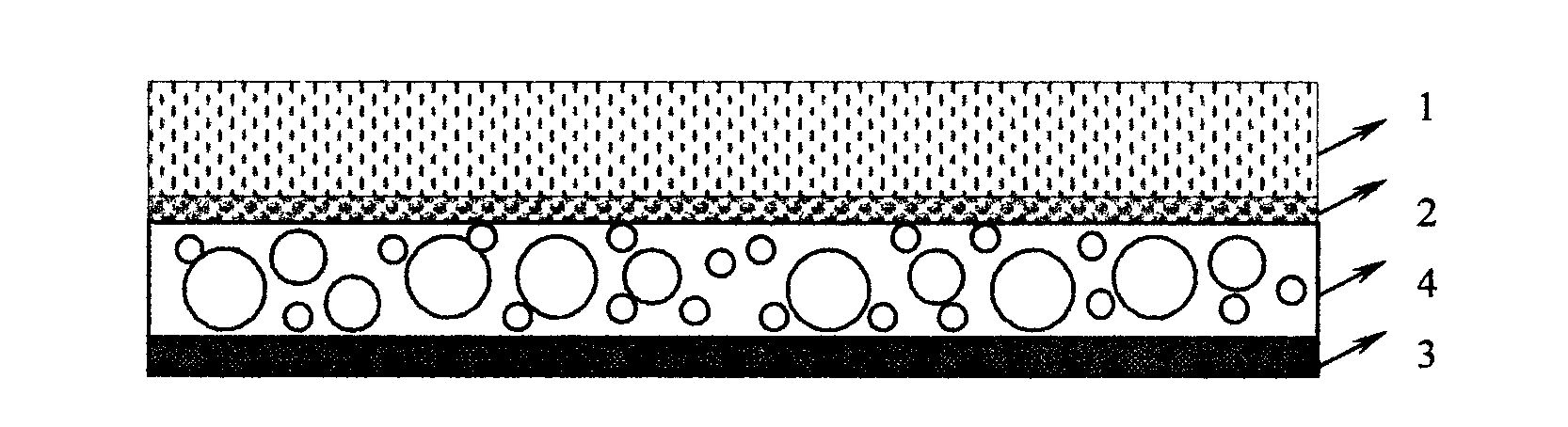

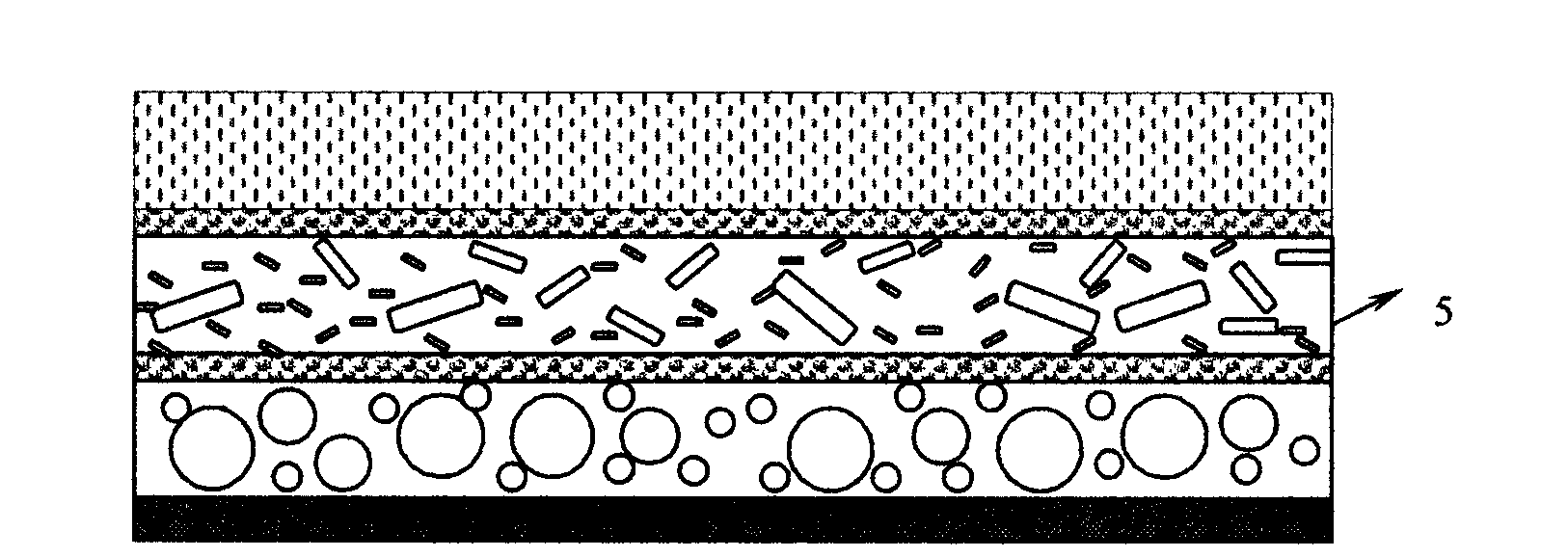

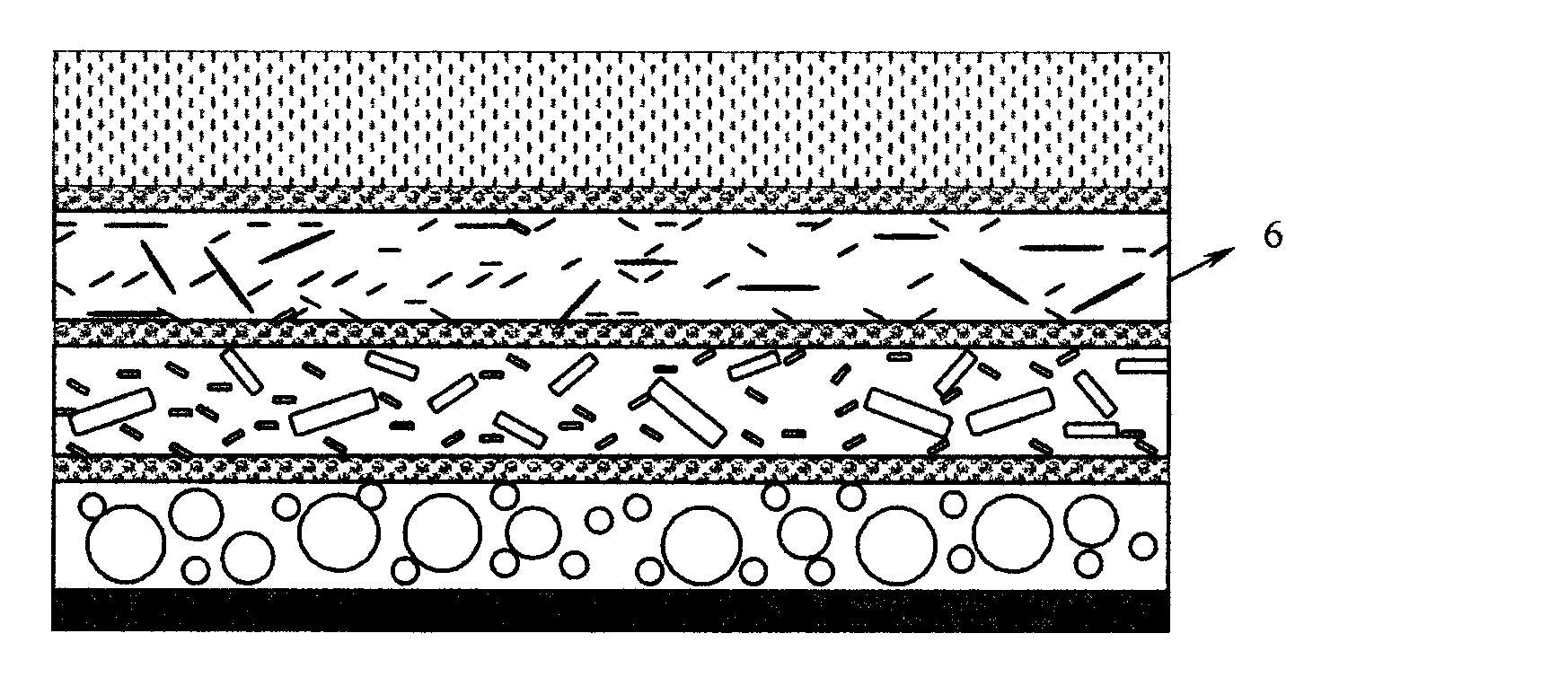

Efficient sound insulation material and manufacturing method thereof

InactiveCN103903608AImprove heat and aging resistanceExcellent ozone resistanceSynthetic resin layered productsSound producing devicesInsulation layerFoaming agent

The invention relates to the field of products of sound insulation material, solves the problems in the prior art that the sound insulation material is poor in sound insulation effect, is incomprehensive in high and low frequency sound insulation, causes pollution and is easy to age, and provides an efficient sound insulation material and a manufacturing method thereof. The efficient sound insulation material includes a sound insulation layer, a sound absorption layer, and a bubble layer, wherein the bubble layer is located between the sound insulation layer and the sound absorption layer. The sound absorption layer is made of a sound insulation compound, and the sound insulation compound is prepared by raw materials of the following substances: a thermoplastic resin, inorganic fillers, and a foaming agent, wherein the inorganic fillers account for 15-80wt%, the foaming agent accounts for 5-15wt%, and the rest is the thermoplastic resin. In the efficient sound insulation material, the fillers with different particle diameters correspond to sound waves of different wave bands or frequencies, and thus consumption of sound energy of different frequencies is relatively comprehensive, and the sound insulation effect is good, so the sound insulation material is suitable for popularization and application.

Owner:浙江艾迪雅汽车部件新材料有限公司

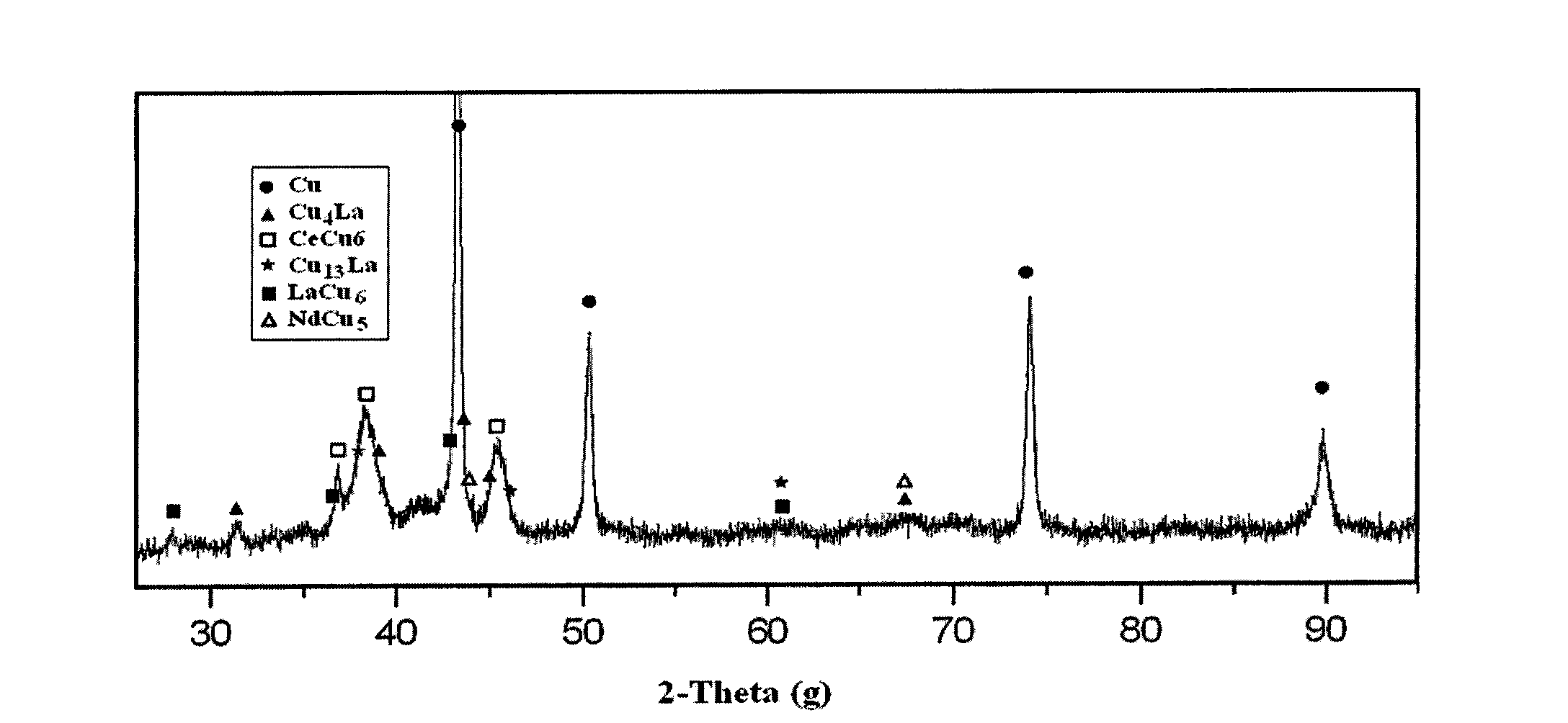

High Cu-RE interalloy refining agent for refining scrap copper and preparation and application thereof

The invention relates to a high Cu-RE refining agent which has high efficiency and low burning loss rate and can be used for copper and copper alloy, applied to mass refining of the copper and the copper alloy, especially applied to refining and modification of red impure copper and white impure copper. The Cu-RE interalloy refining agent is prepared by a vacuum melting method, wherein, rare earth content is up to 30-65%; and only 2-6g / kg refining agent is added while the Cu-RE interalloy refining agent is applied to remelting refining of scrap copper. The Cu-RE refining agent enhances slagging and deslagging of copper fused mass, reduces deleterious substances in the fused mass of the scrap copper, and improves texture and performance of the copper and the copper alloy, therefore, products prepared from the red impure copper as a raw material reach or exceed the quality of the products prepared from electrolytic copper as a raw material, and the white copper process waste can be used for directly producing high-quality products after remelting refined, thus promoting recycle and reutilization of the scrap copper, saving energy and resource, reducing environmental pollution and generating significant economic and social benefits.

Owner:CENT SOUTH UNIV

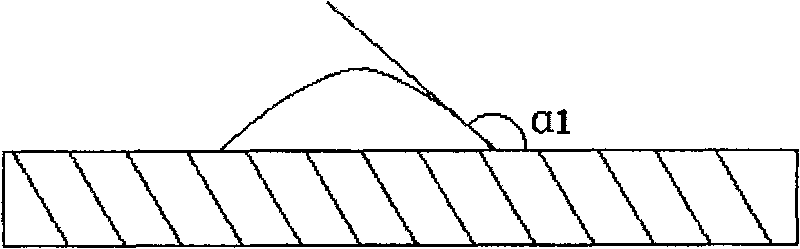

Nickel-base welding rod

InactiveCN101745759AGood production technologyImprove yieldWelding/cutting media/materialsSoldering mediaSlagManganese

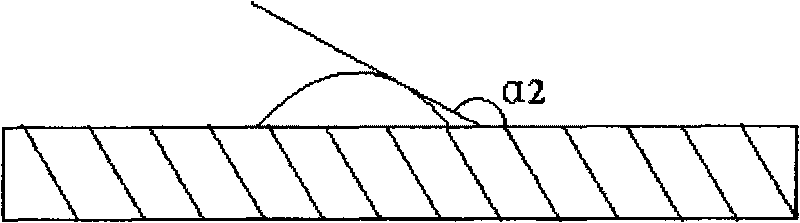

The invention relates to a welding material technology, in particular to a nickel-base welding rod. The welding rod uses a SNi6062 welding wire as a core wire. The electrode coating comprises the following solid ingredients in percentage by mass: 36-50% of rutile, 2-7% of titanium pigment, 20-30% of fluorite, 3-8% of cryolite, 2-4% of phlogopite, 2-4% of zircon sand, 0.5-1.5% of sodium carbonate, 5-10% of manganese metal, 2-4% of ferrotitanium containing 25-35% of Ti, and 2-4% of ferroniobium containing 50-60% of Nb. The nickel-base welding rod has the advantages of favorable performance of production technique, smooth welding rod surface, high yield, stable eccentricity; during welding, the nickel-base welding rod has the advantages of stable electric arc, basically no splash, favorable slag detachability and outstanding operating performance; and the appearance of the welding seam is beautiful, the height of a weld bead is moderate, the wetting angle of a welding seam is moderate, and the strength and plasticity of deposited metals are moderate.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

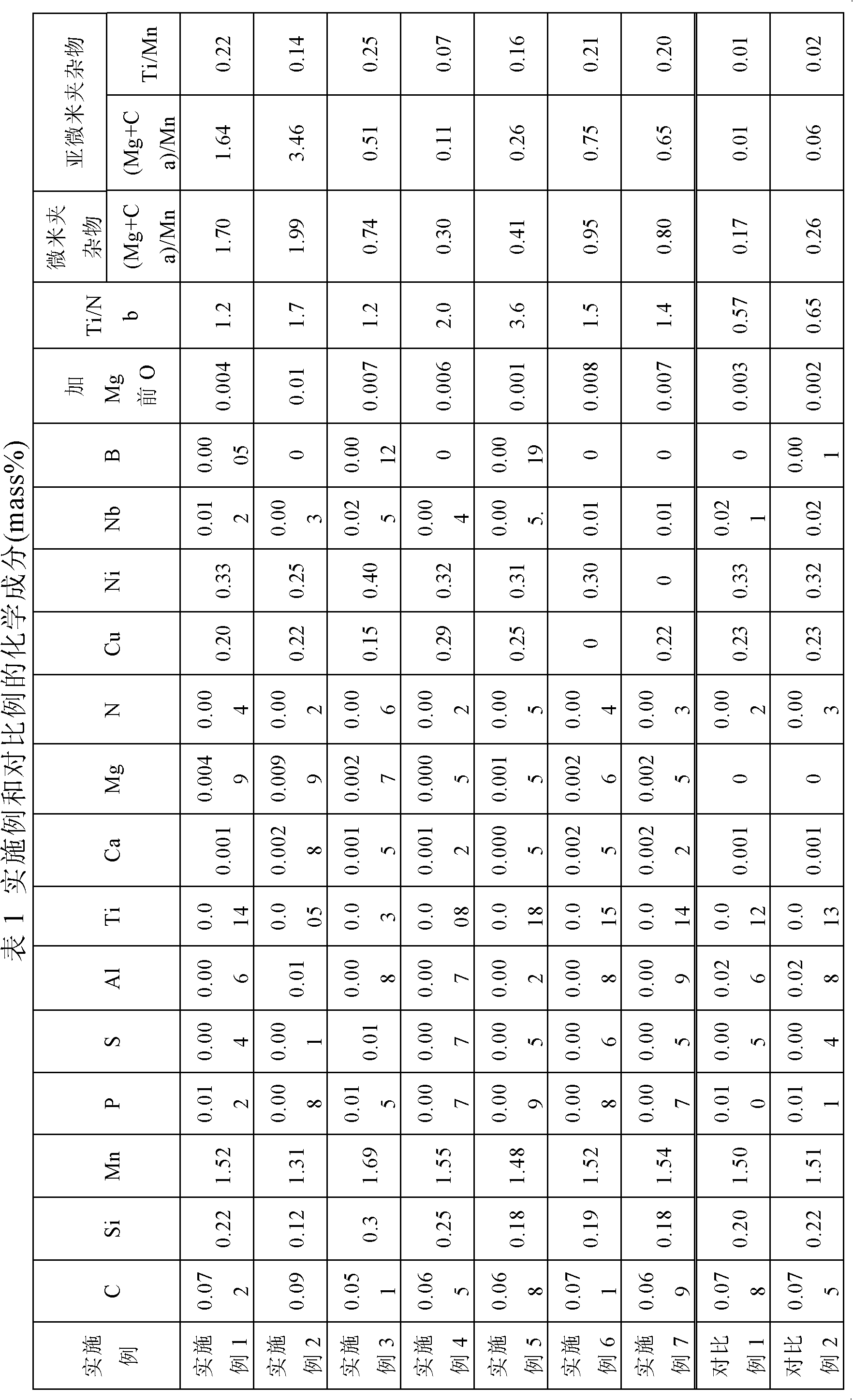

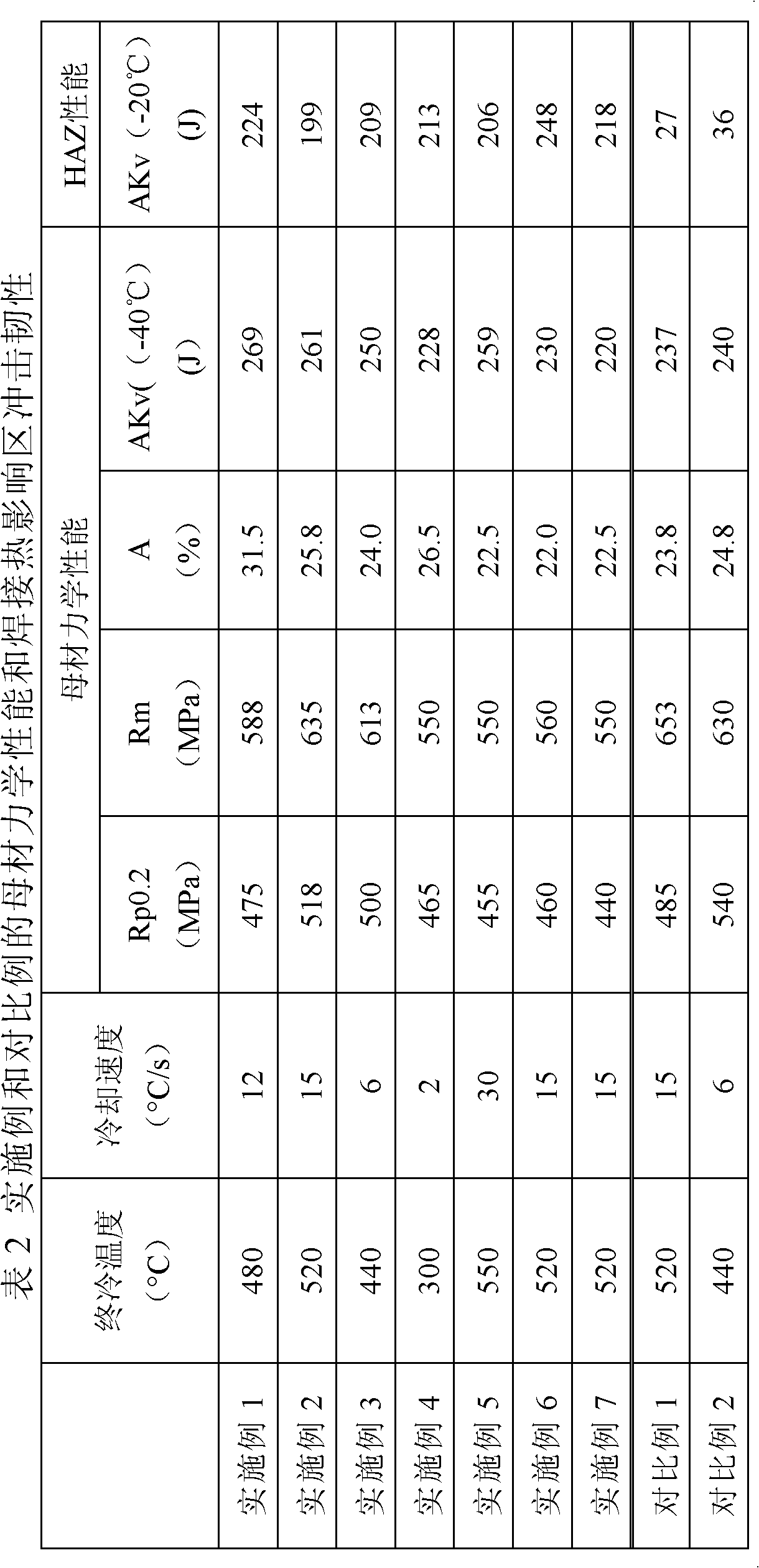

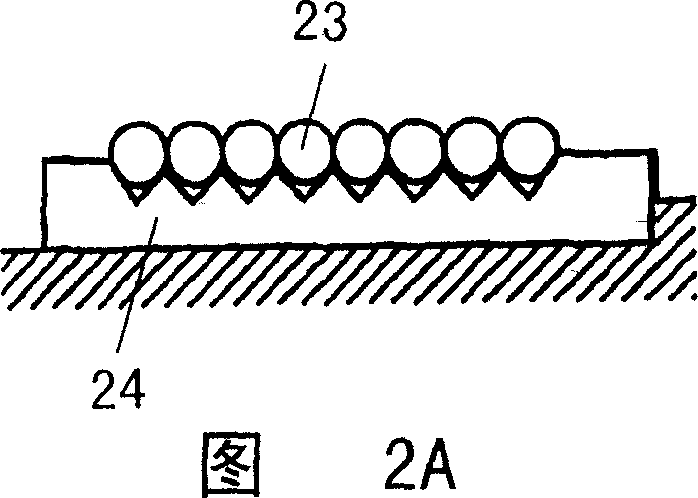

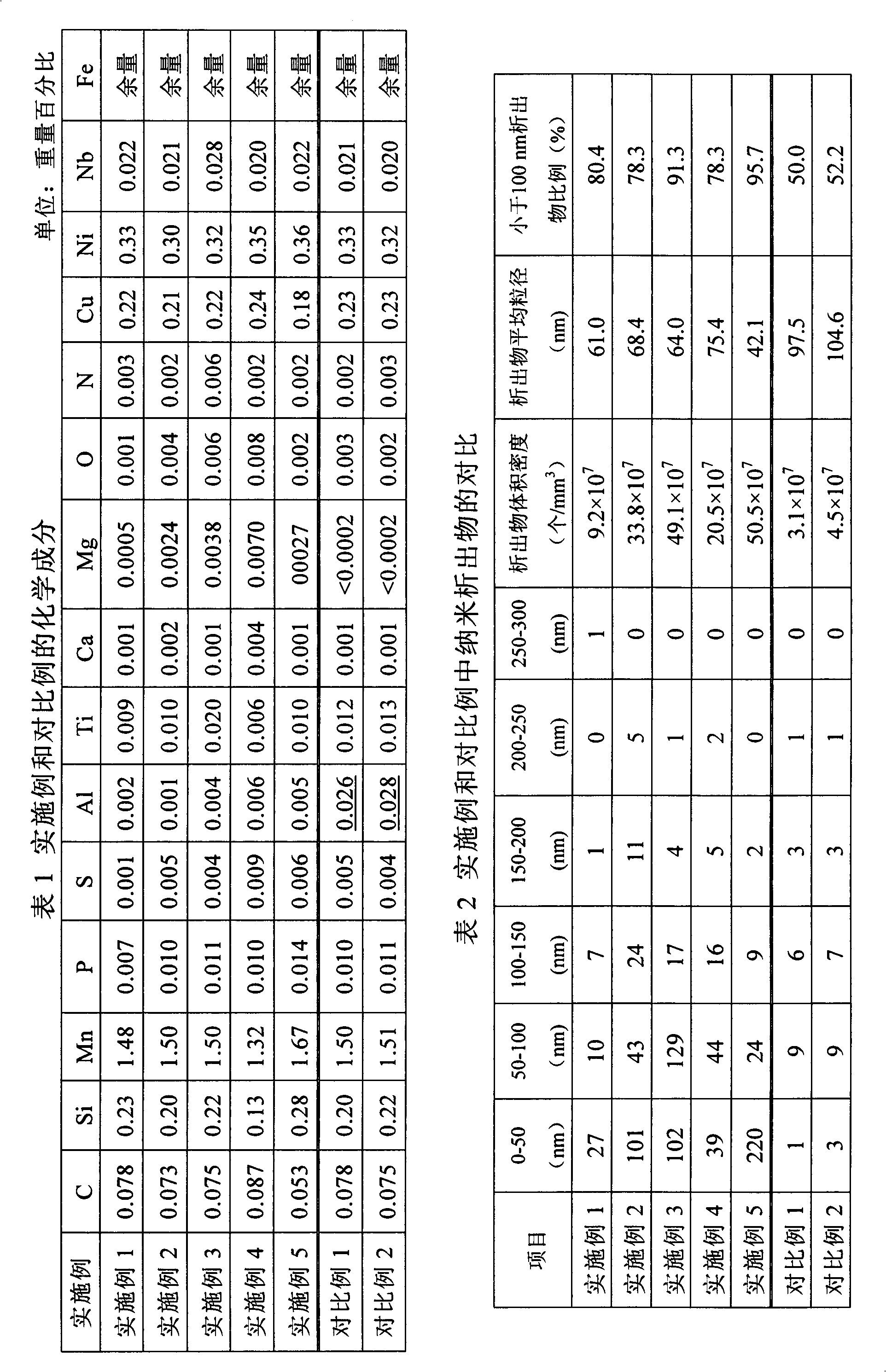

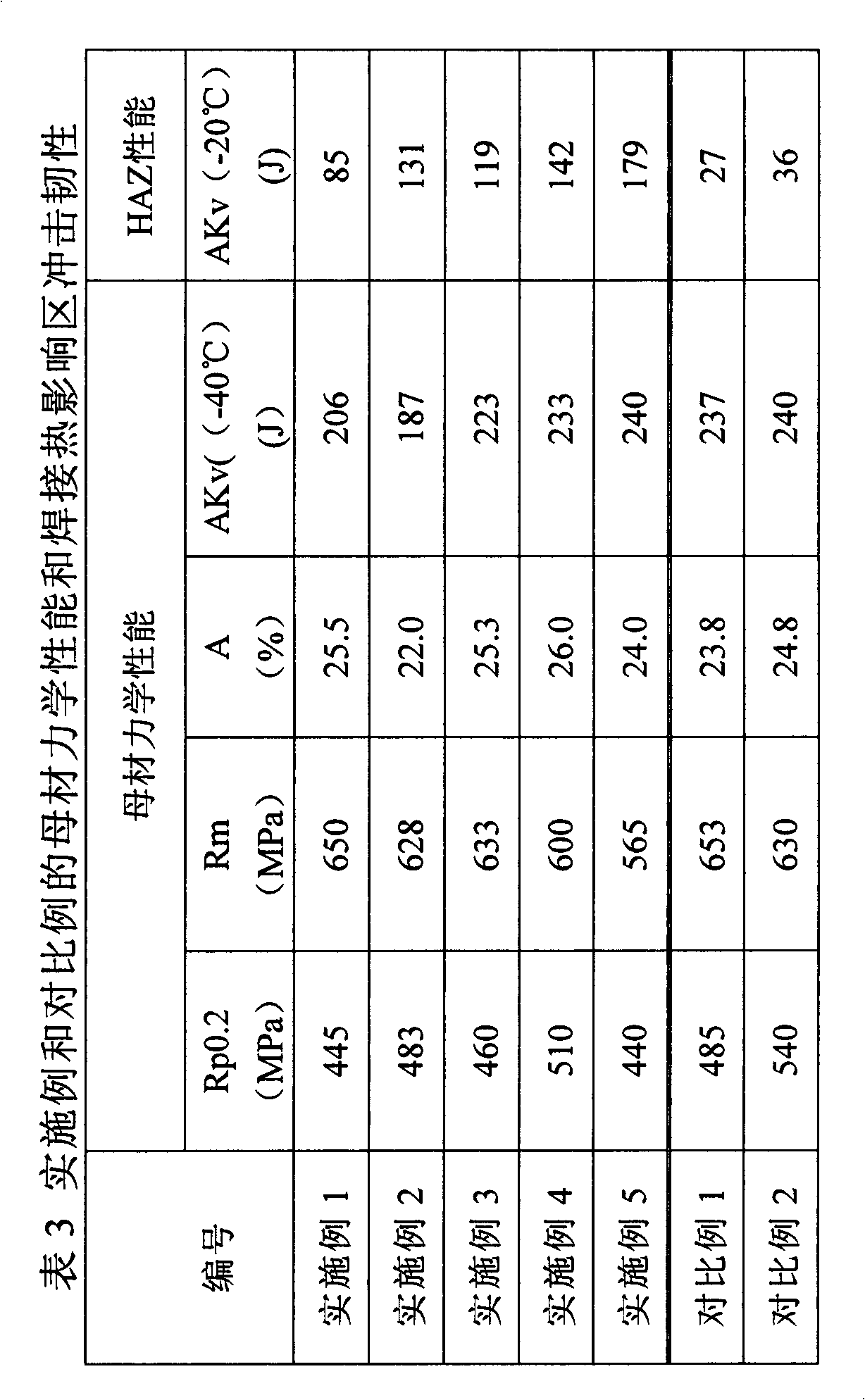

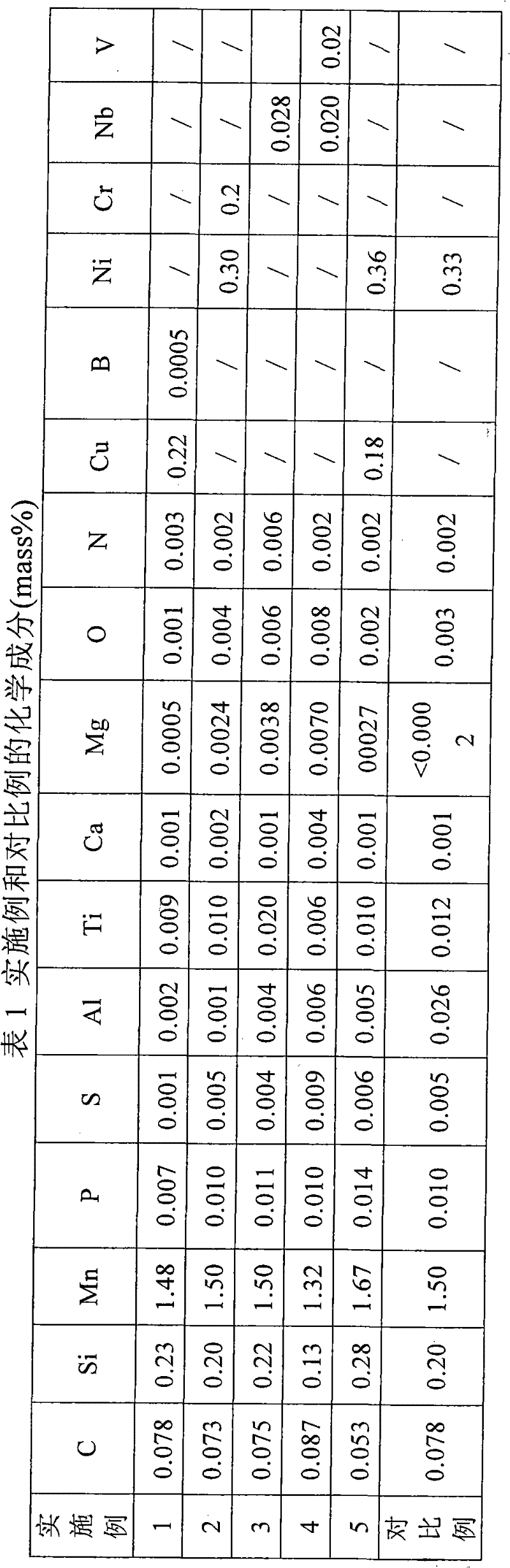

High-heat-input welding thick steel plate and manufacturing method thereof

Disclosed are a high-heat-input welding thick steel plate and a manufacturing method thereof. The manufacturing method includes following steps: a) smelting, refining and continuous casting; b) rolling; and c) cooling. Steel consists of components including, by weight percentage, from 0.05 to 0.09% of C, from 0.10 to 0.30% of Si, from 1.3 to 1.7% of Mn, from 0.005 to 0.03% of Ti, from 0.003 to 0.025% of Nb, from 0.001 to 0.01% of S, smaller than or equal to 0.015% of P, smaller than or equal to 0.006% of N, from 0.0005 to 0.01% of Mg, smaller than or equal to 0.01% of Al, smaller than or equal to 0.003% of Ca, more than one of smaller than or equal to 0.3% of Cu, smaller than or equal to 0.4% of Ni and smaller than or equal to 0.002% of B, and the balance Fe; and Ti / Nb is larger than or equal to 1.2, deoxidant Mn, Si, Al, Ti, Ca and Mg are successively added in a steel liquid deoxidizing process, wherein (Mg+Ca) / Mn is larger than or equal to 0.3 for micrometer impurities with the grain size larger than or equal to 1.0 micrometer in the steel, (Mg+Ca) / Mn is larger than or equal to 0.1 for sub-micron impurities with the grain size ranging from 0.1 micrometer to 1.0 micrometer in the steel, and Ti / Mn is larger than or equal to 0.07. A large quantity of impurities which are distributed in a dispersion manner are formed, growth of austenite grains in a welding heat affected zone can be restrained, growth of intra-granular ferrite is promoted, and the high-heat-input welding performance of the thick plate is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

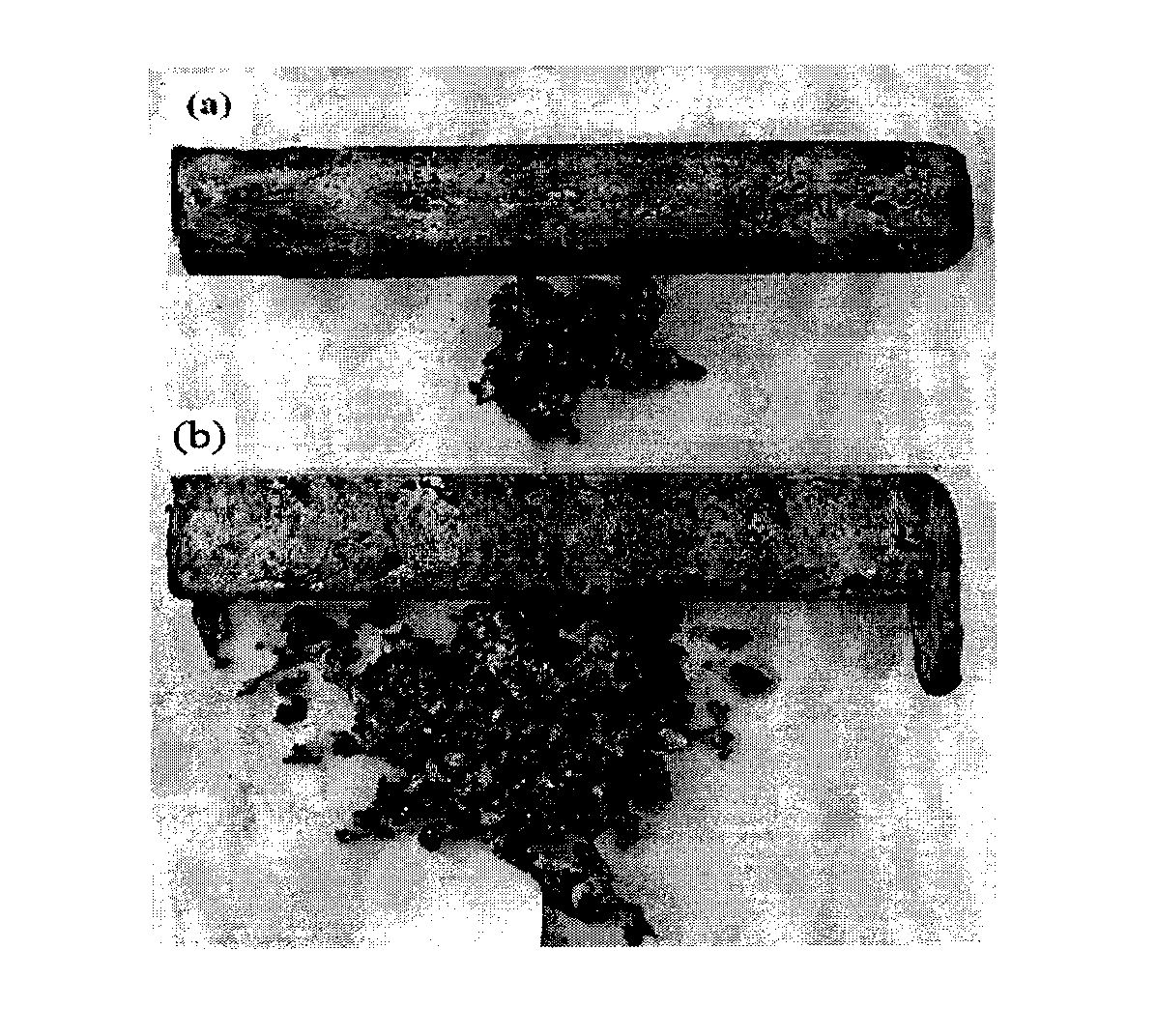

Method for producing oxygen-free copper rod from secondary copper

ActiveCN103114208ALow costReduce physical workloadProcess efficiency improvementMetal rolling arrangementsNatural gasMetal impurities

The invention discloses a method for producing an oxygen-free copper rod from secondary copper, which comprises the following steps of: (A) feeding the secondary copper into a furnace, and heating for melting; (B) refining to remove metal impurities; (C) reducing with natural gas to obtain pure copper; (D) adding rare earth and a complex deoxidizer and then outputting copper; and (E) casting, and performing continuous casting and rolling to obtain an oxygen-free copper rod. Compared with a traditional up-draw process, the method disclosed by the invention can adopt the easily available secondary copper as a raw material for production and can process a great quantity of secondary copper once, and overcomes the shortcomings of high production cost and low production efficiency of the up-draw process adopting secondary copper as raw material; natural gas reduction replaces poling, thereby being more environment-friendly and ensuring lower cost; and moreover, the labor capacity is small, and the defect of bad working condition in poling is overcome.

Owner:绵阳铜鑫铜业有限公司

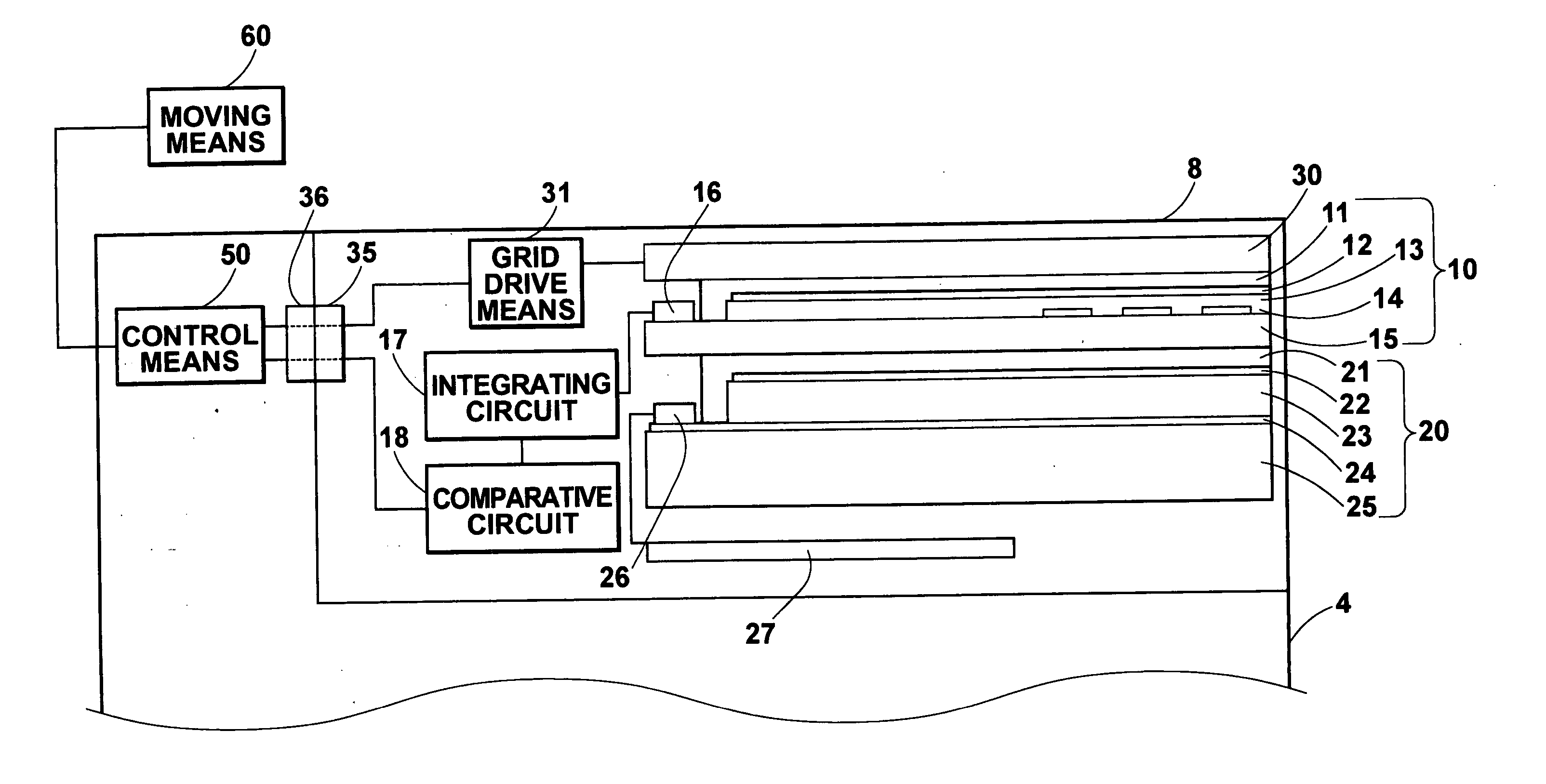

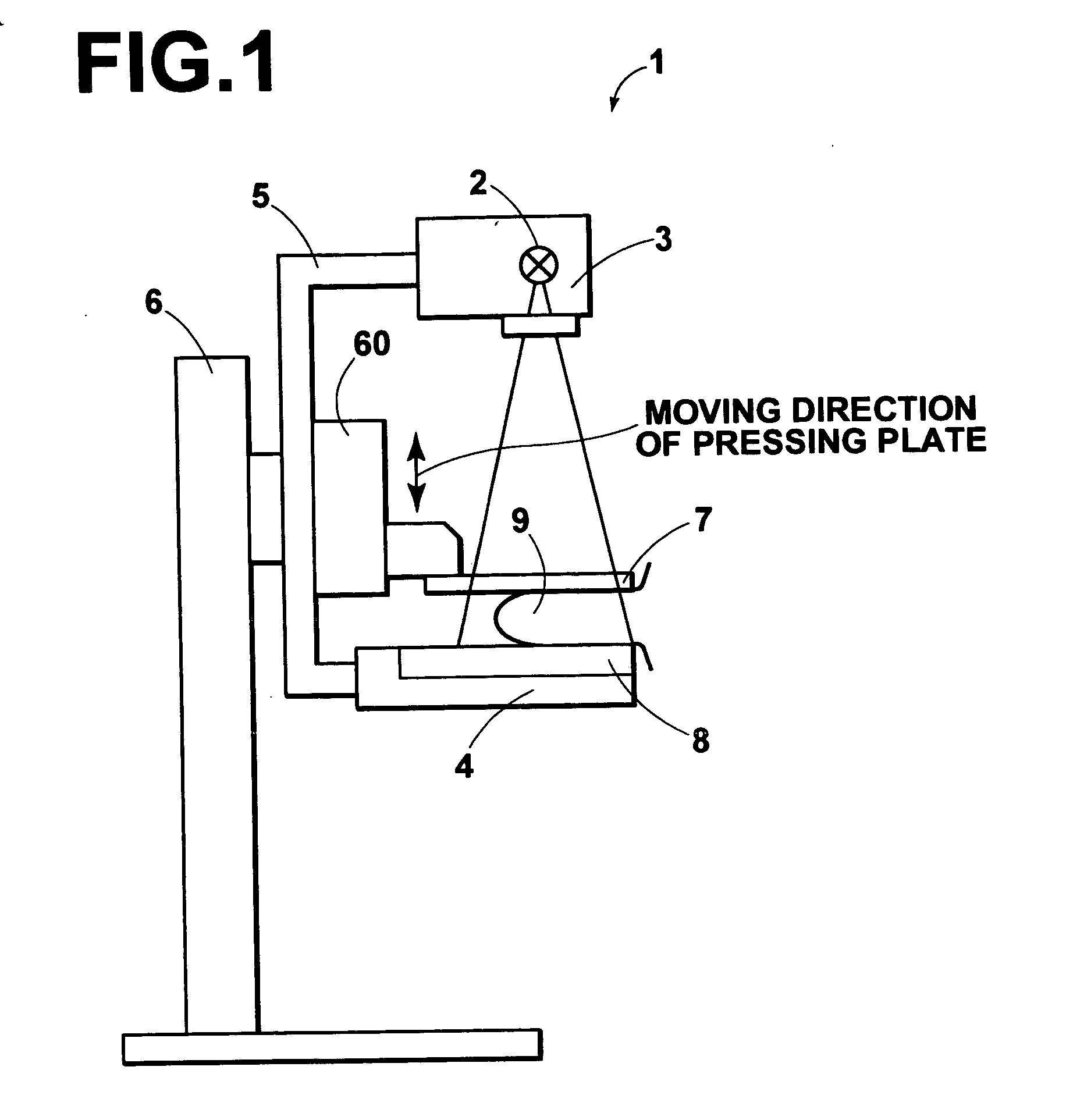

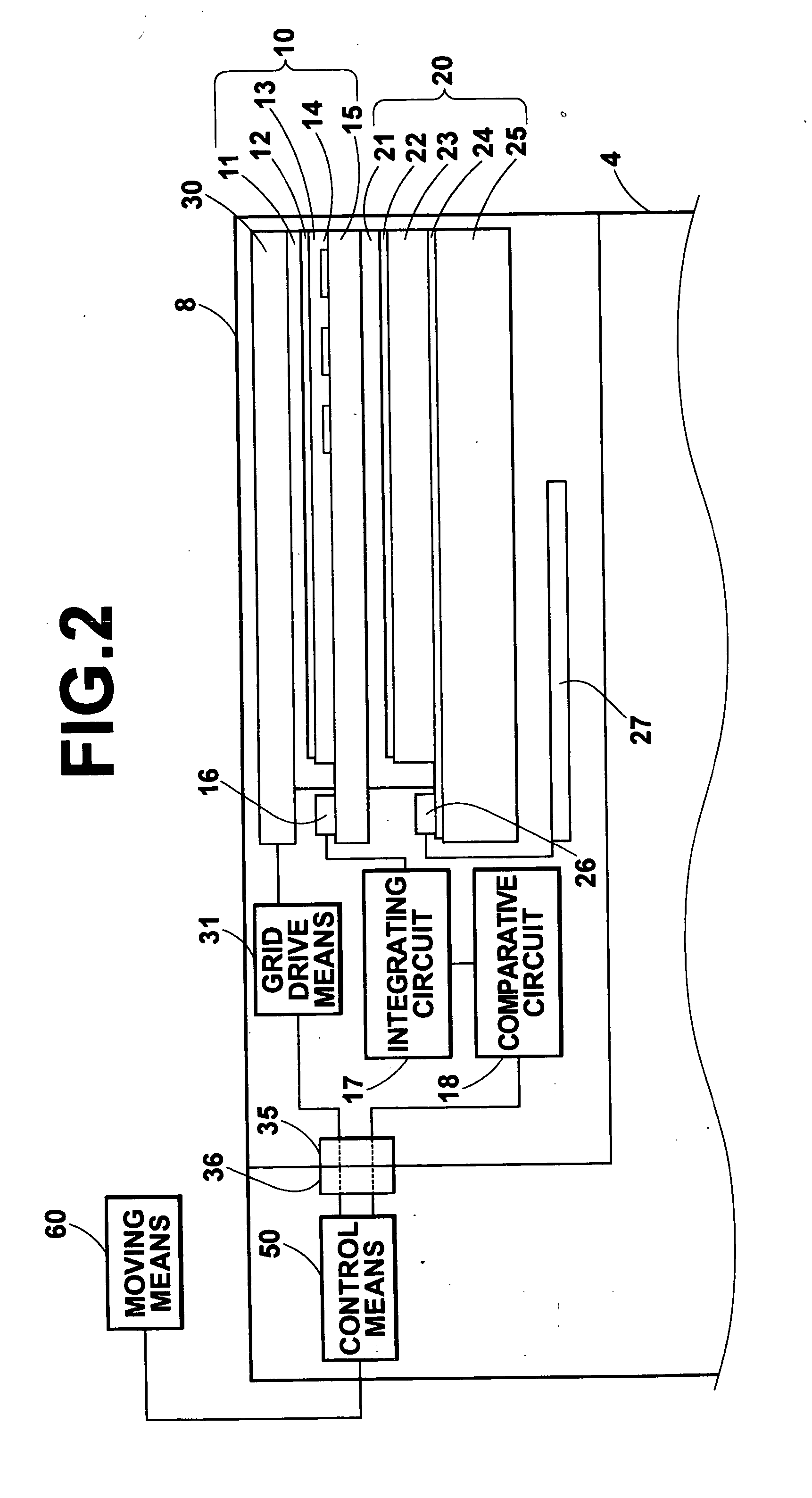

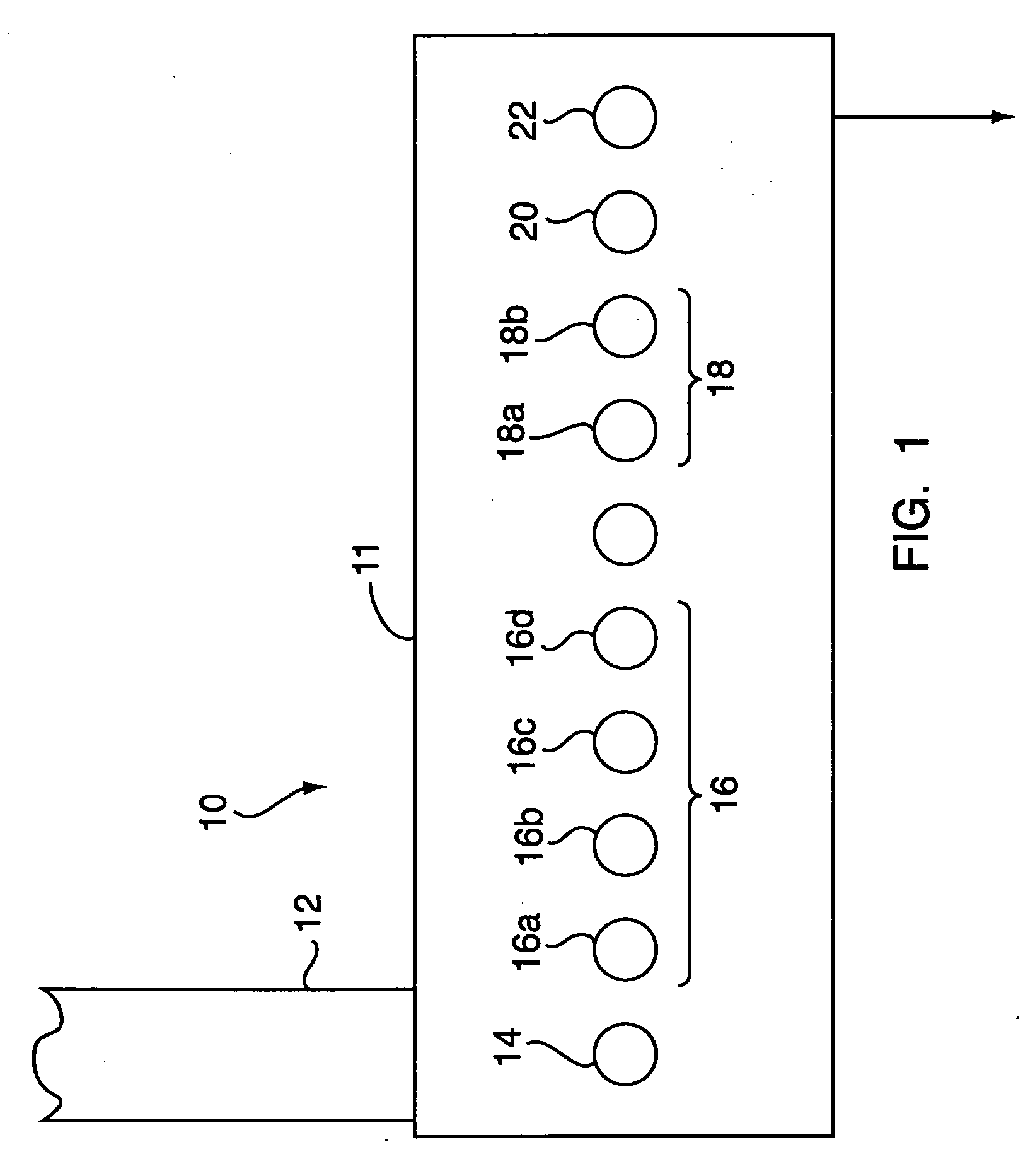

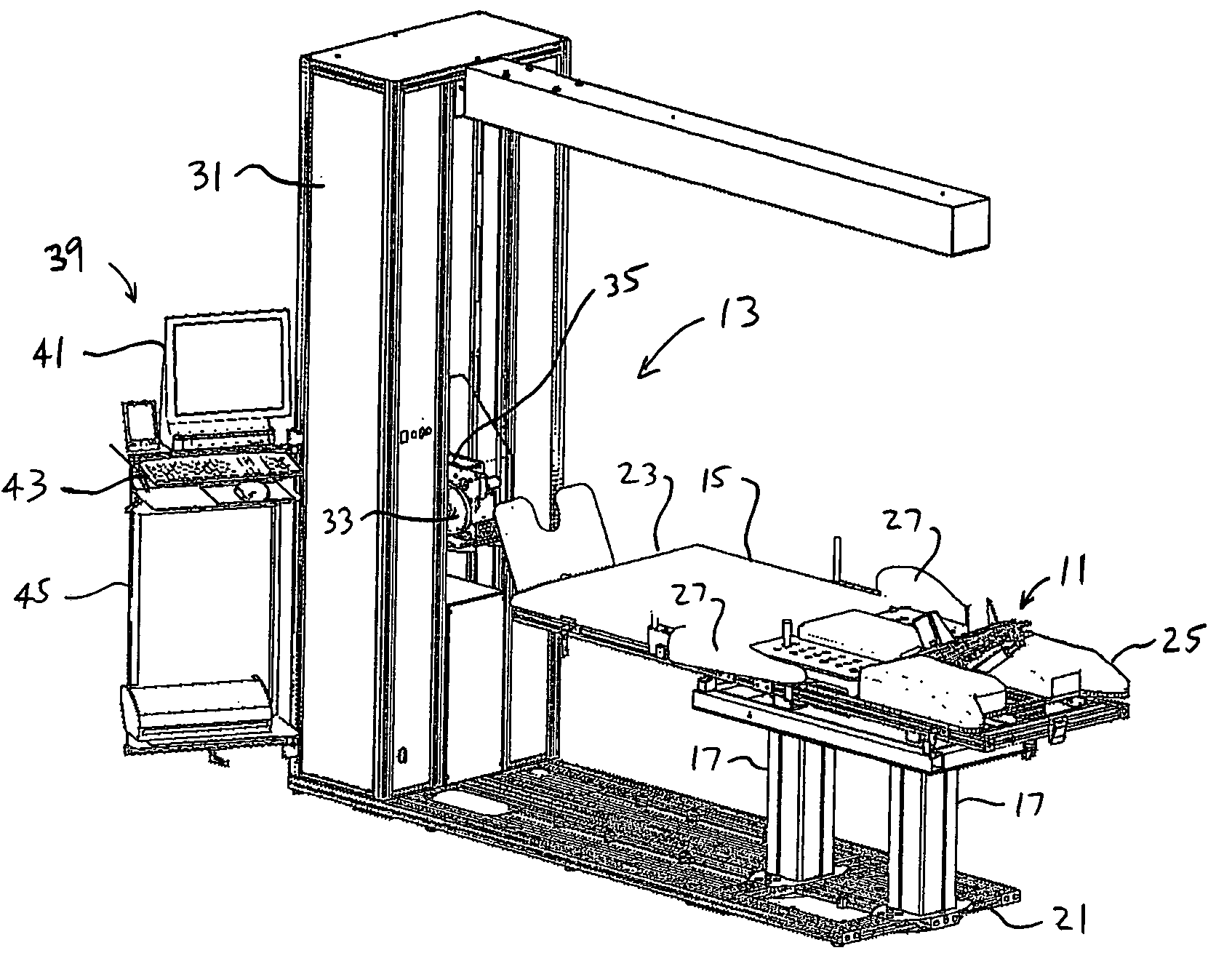

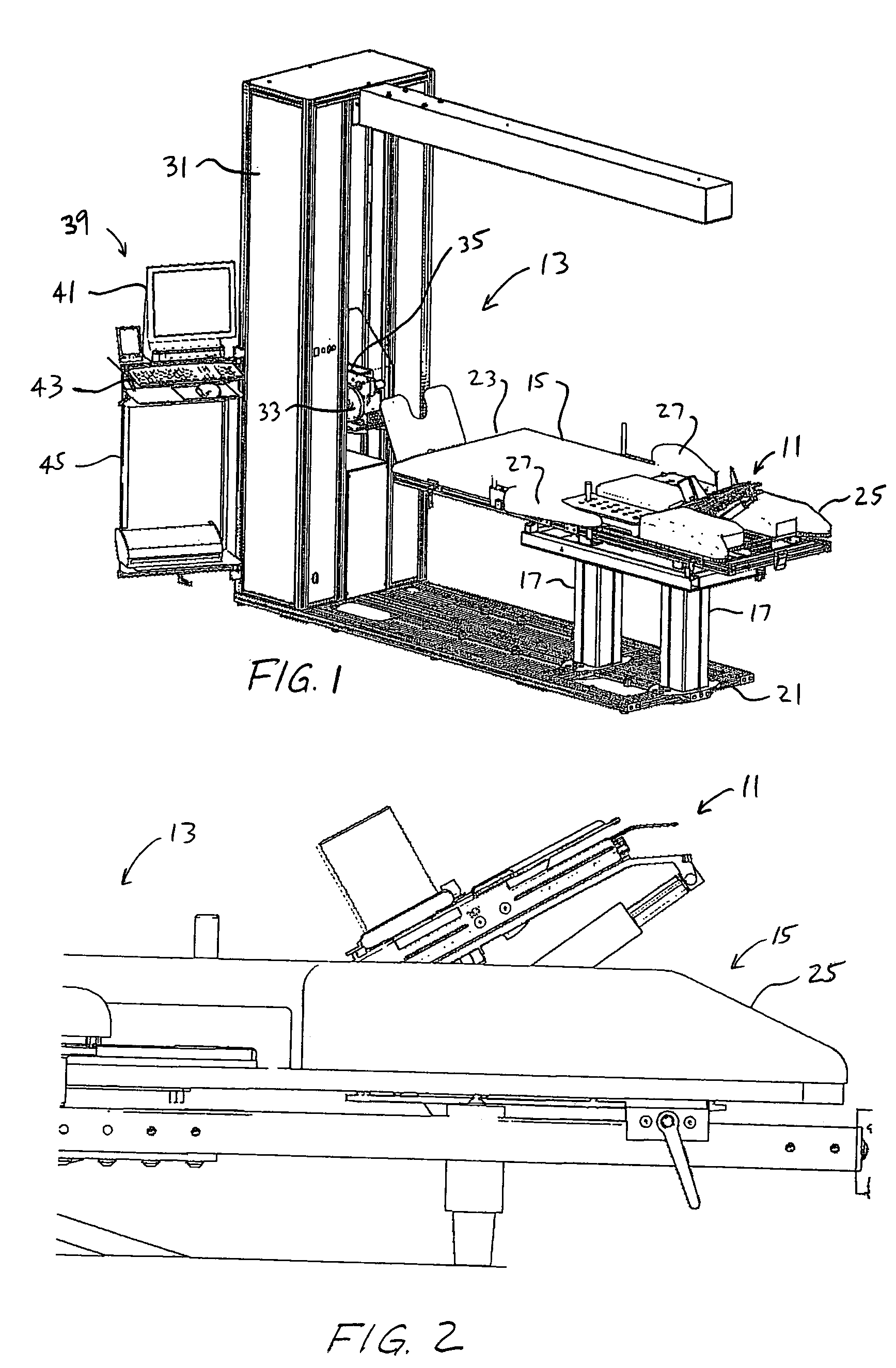

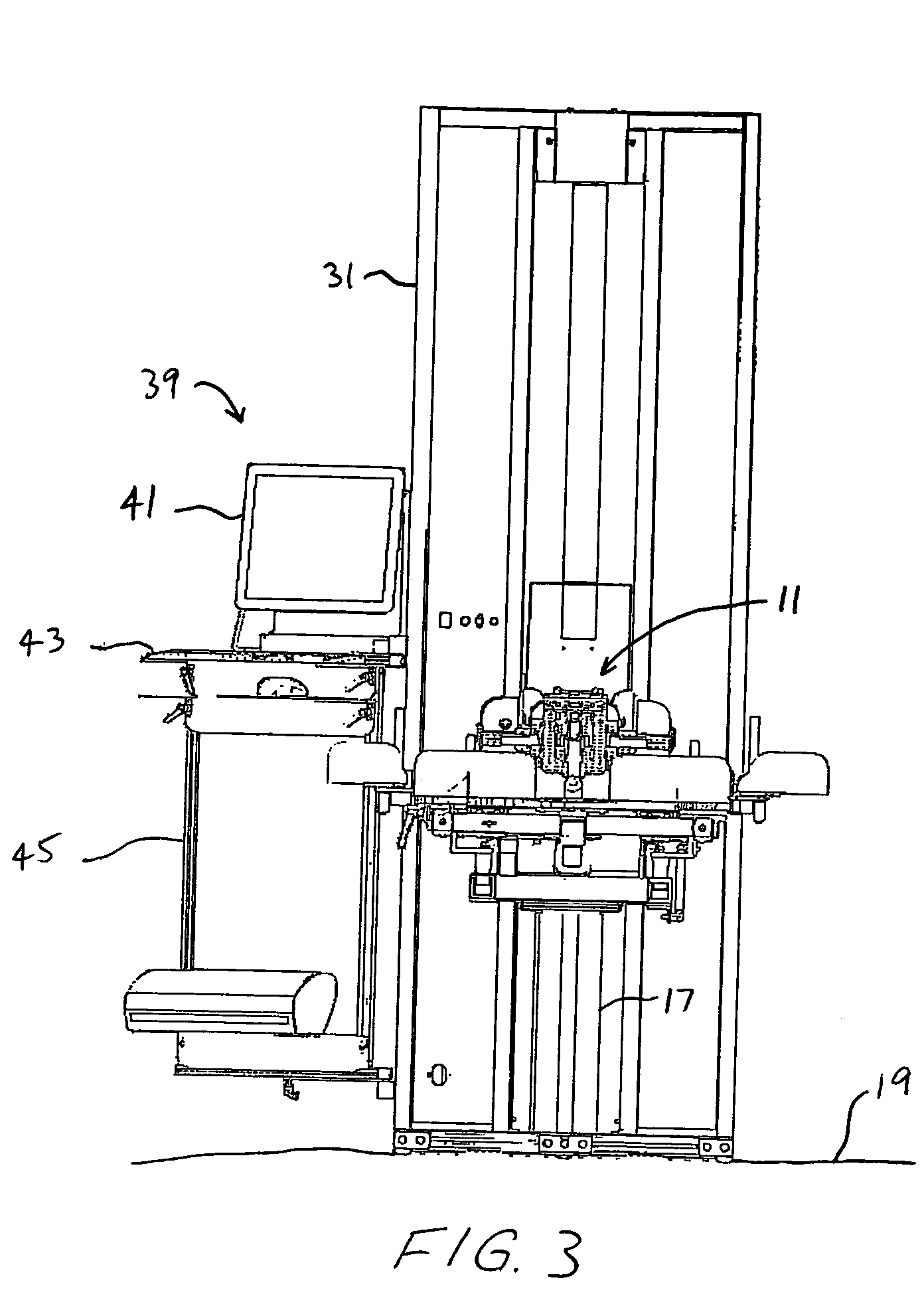

Mammography apparatus and detecting unit

InactiveUS20050111617A1Improve amount of controlDetection accuracyDosimetersPhotometrySolid state detectorX ray image

Detection accuracy of X-ray dosages, to be applied to control the amount of irradiated X-rays, is improved in a mammography apparatus that employs solid state detectors as X-ray image detecting means, and that is capable of interchangeably utilizing solid state detectors of various sizes, without adversely influencing detection of images by the solid state detector. A solid state detector, for recording image information by receiving irradiation of X-rays that bear the image information, and for outputting image signals that represent the recorded image information, an X-ray dosage detector, for detecting the amount of irradiated X-rays, and a moving grid, for removing scattered radiation, are housed within a detecting unit, stacked in this order. The detecting unit is configured to be removably attachable to an imaging table of a mammography apparatus. Thereby, interchangeable use of detecting units having solid state detectors of various sizes housed therein is enabled.

Owner:FUJIFILM HLDG CORP +1

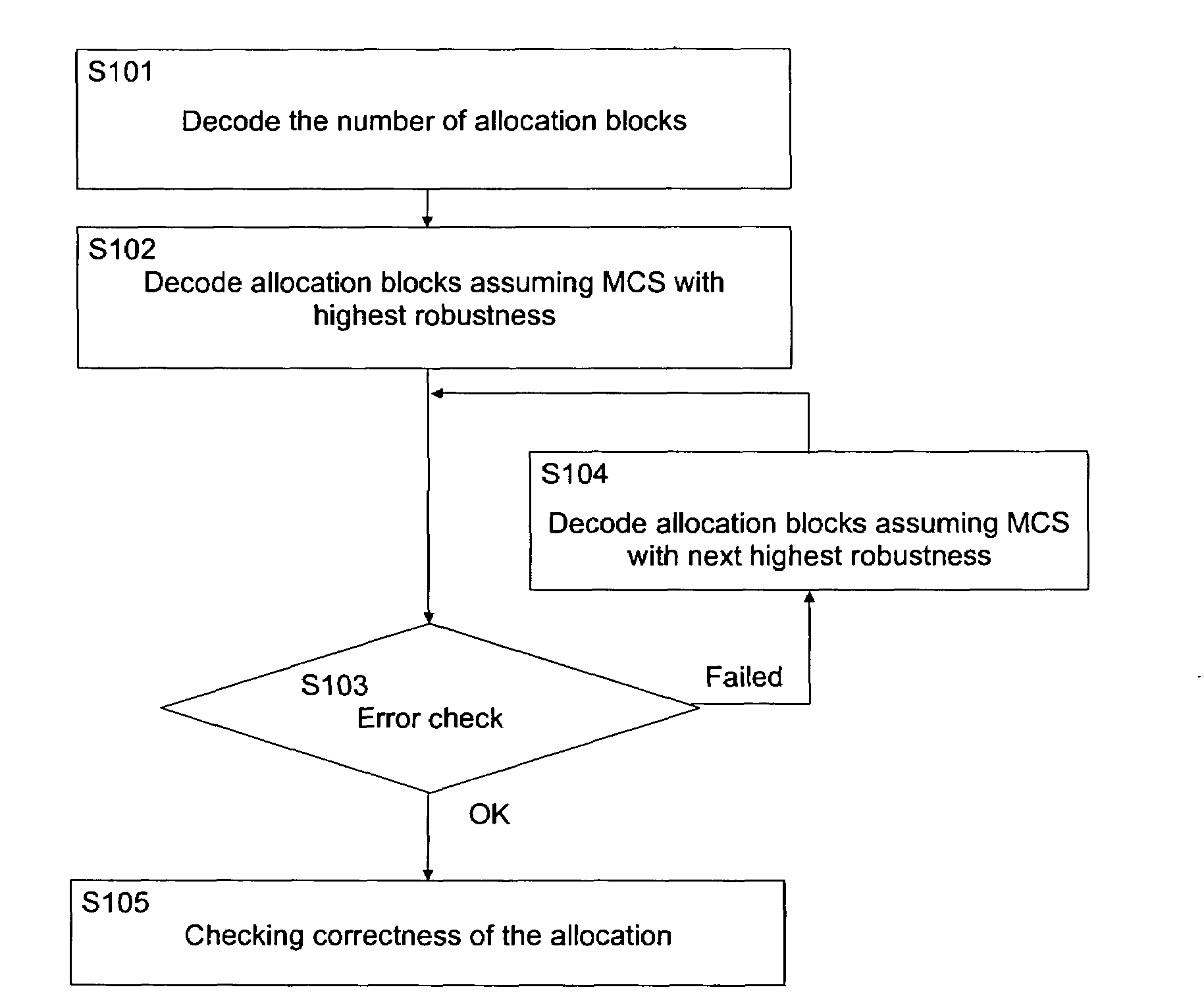

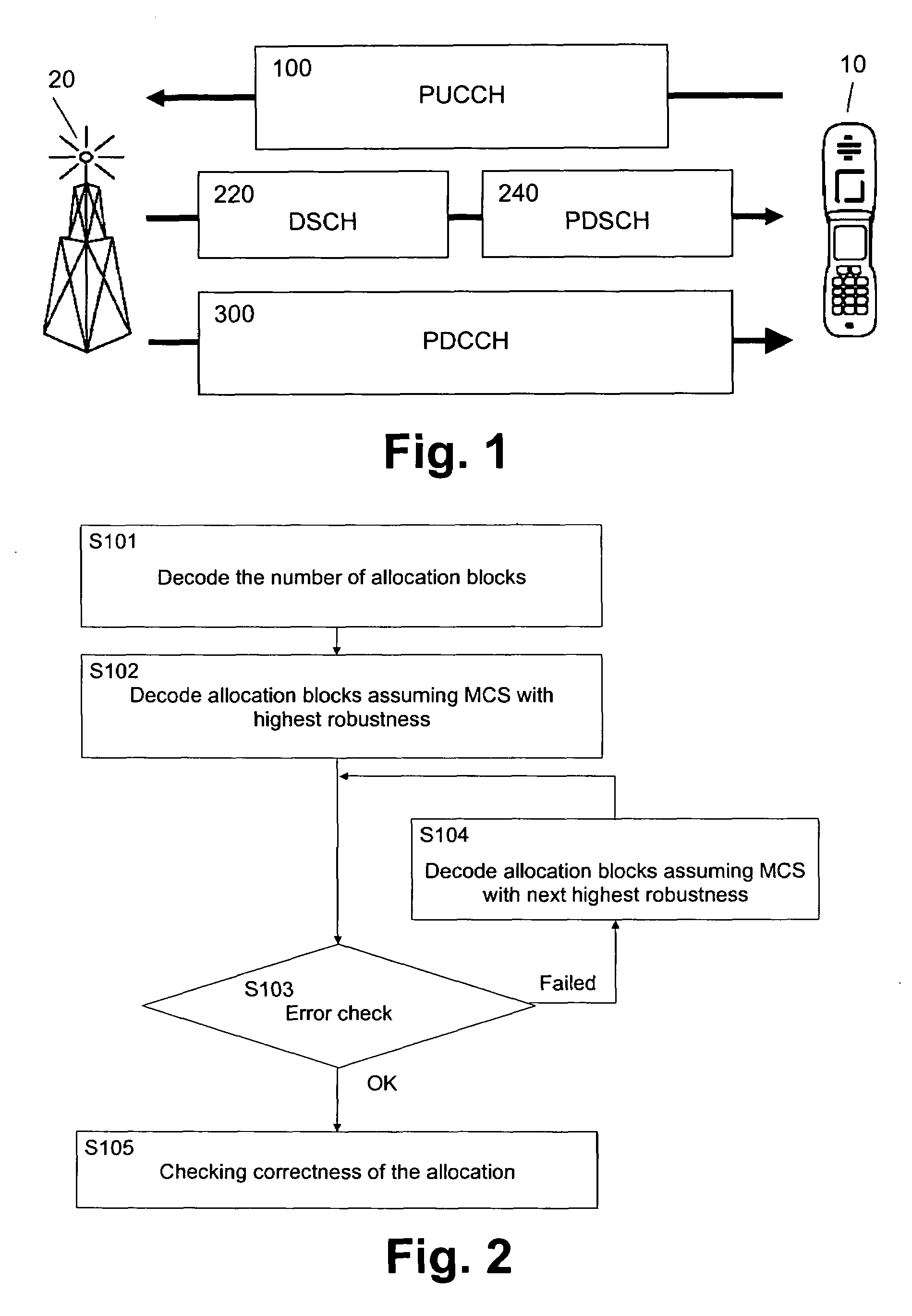

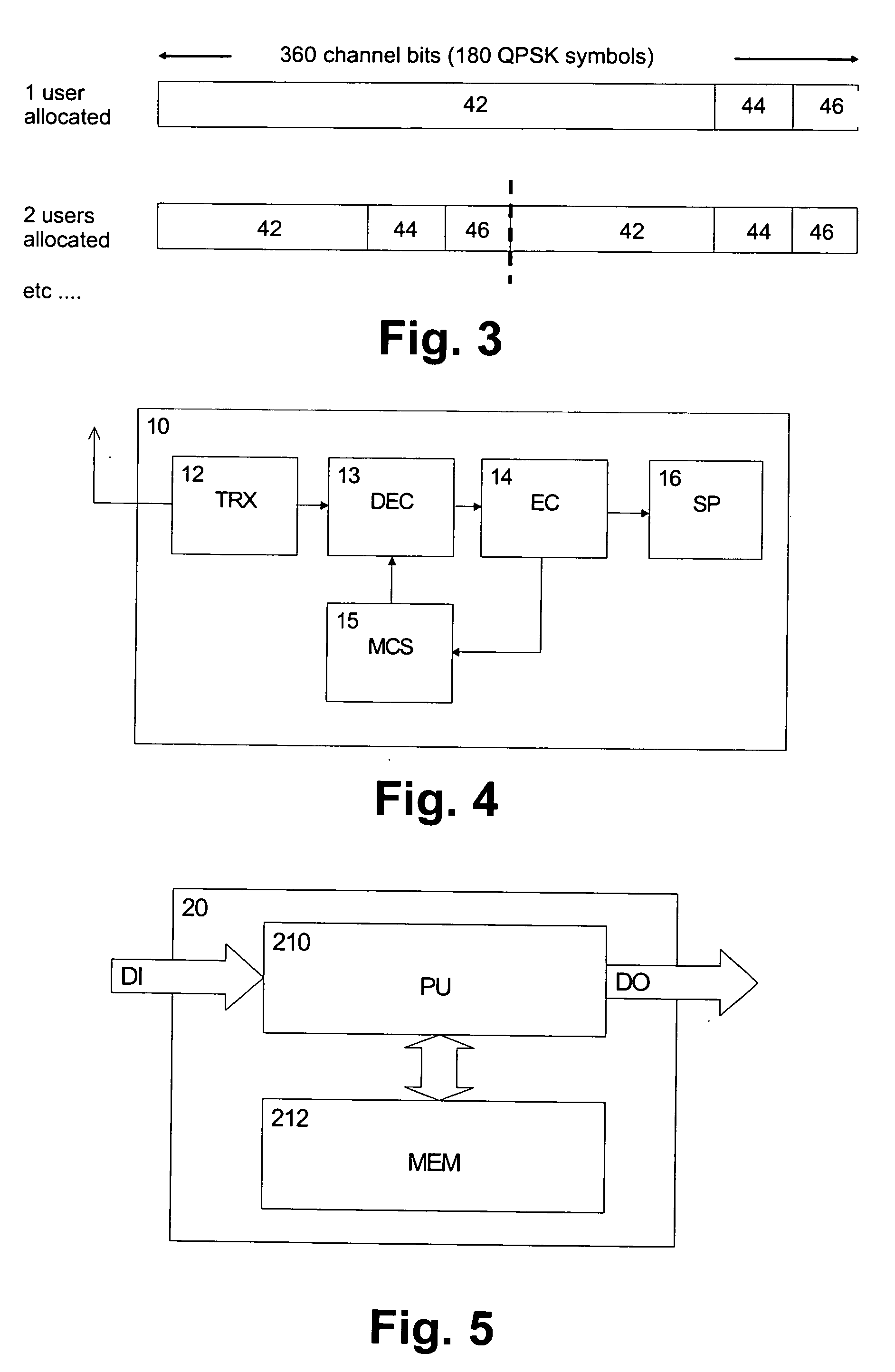

Blind estimation of control channel

ActiveUS20080163002A1Amount of control be reduceAmount of control is limitedHardware monitoringTransmission path multiple useControl channelComputer program

A method, system, apparatus, and computer program product for decoding control information, wherein a total number of allocation blocks defining control channels to be allocated to users for at least one of uplink and downlink directions is determined. Then, a format which determines resource allocation within allocation blocks is selected, allocation blocks are decoded using the selected format, and an error checking is performed for the decoded allocation blocks. This selecting, coding and error checking is repeated for different available formats until no error is revealed in said error checking. Thereby, a blind estimation of a format chosen for the control channel information can be achieved, so that additional amount of control signalling can be reduced.

Owner:NOKIA TECHNOLOGLES OY

Red soup hotpot base material and preparation method thereof

The invention provides a red soup hotpot base material, which comprises 20 to 30 parts of vegetable oil, 5 to 15 parts of salt, 30 to 45 parts of hot pepper, 15 to 30 parts of thick broad-bean sauce, 1 to 5 parts of spice and 3 to 10 parts of internal heat clearing material. Compared with the prior art, the formula of the red soup hotpot base material provided by the invention is reasonable, and the formula has no components which affect the nutritional components and the mouthfeel with one another. Therefore, the red soup hotpot base material is hot, spicy, fresh, delicious, unique in flavor and proper in mouthfeel. In addition, because the internal heat clearing material is added in the formula, a user does not suffer from internal heat after the red soup hotpot base material is used. The invention also provides a preparation method of the red soup hotpot base material.

Owner:甘丘平

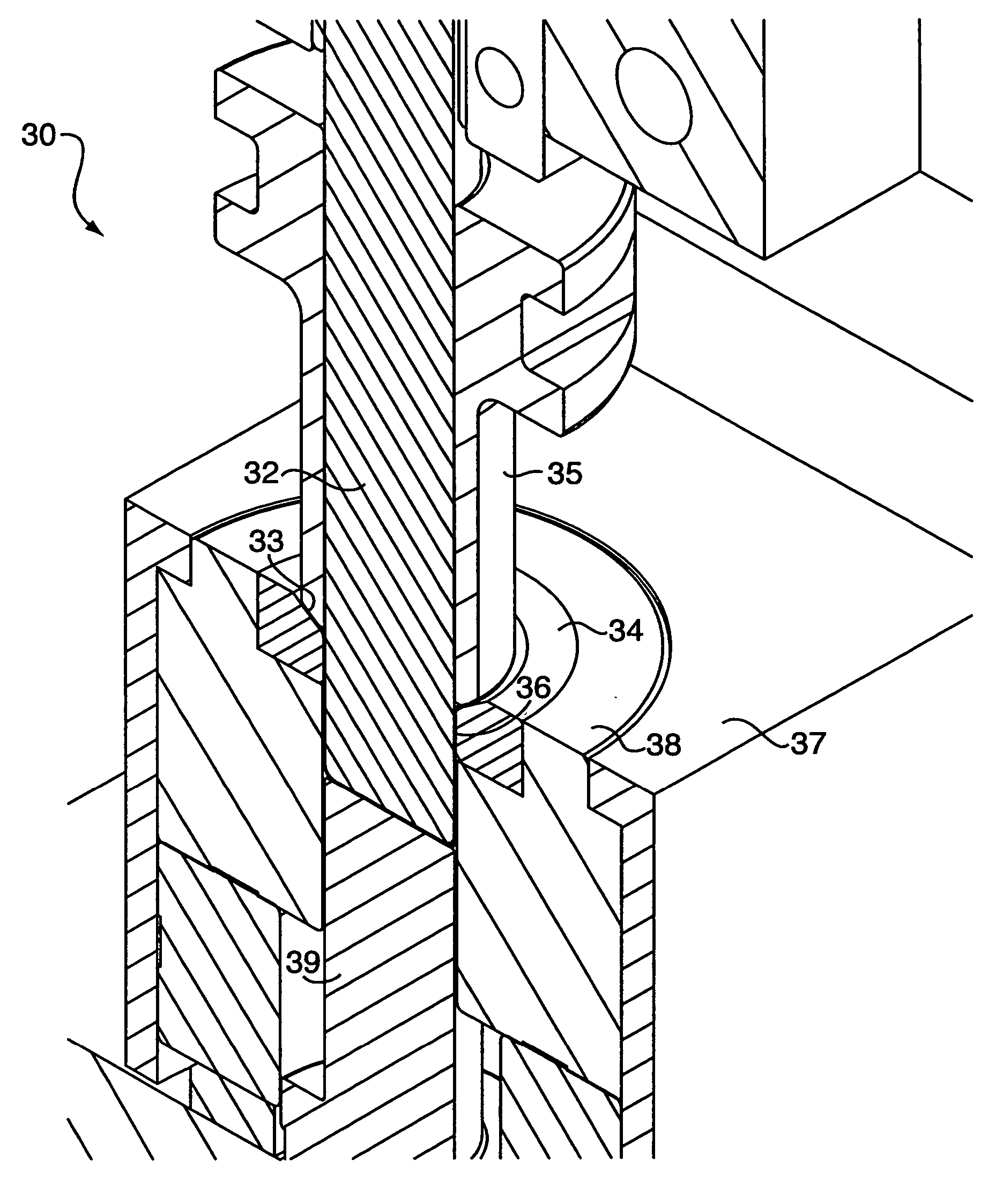

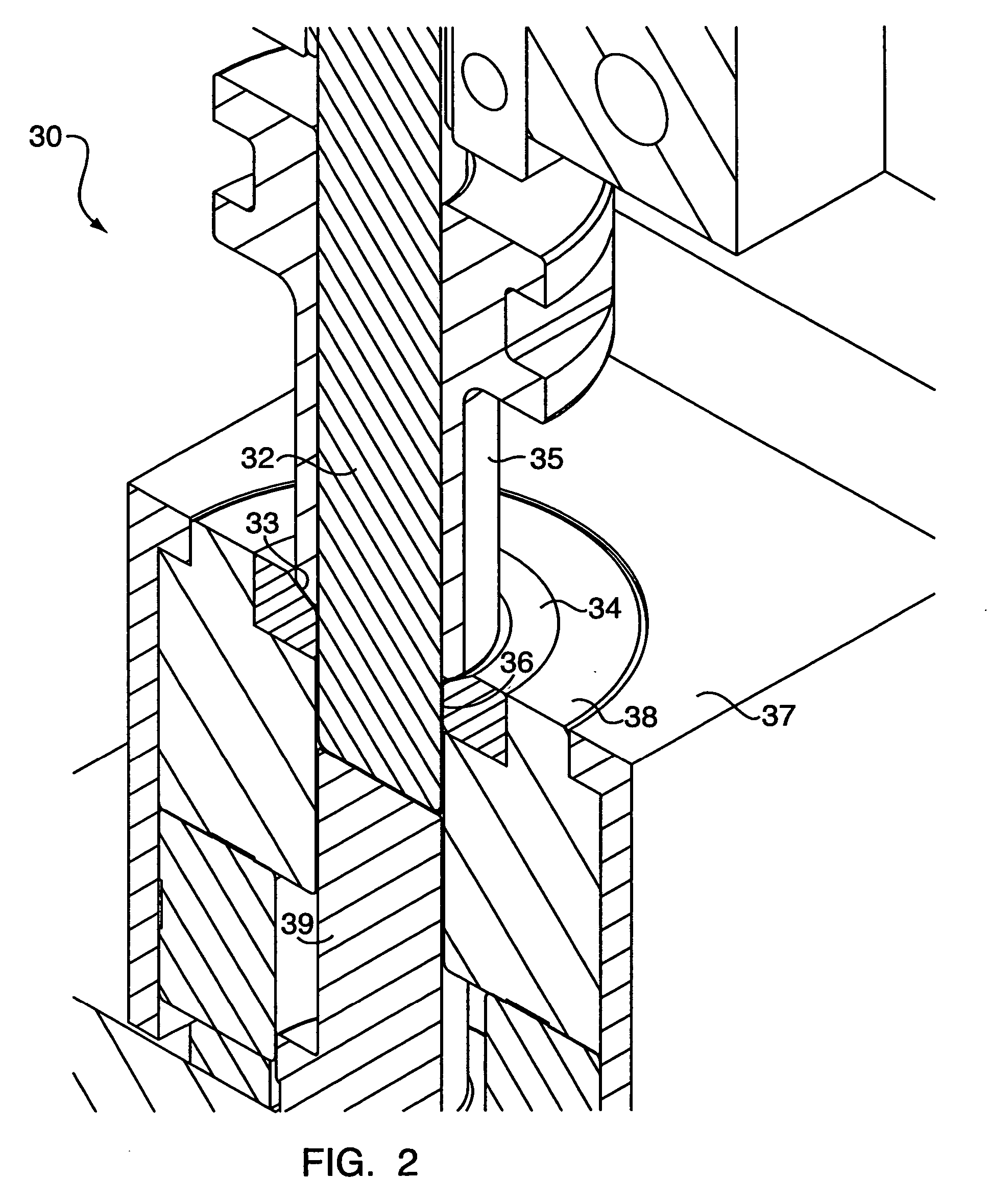

System and process for forming battery cans

InactiveUS20060159989A1Moderate roughnessMinimize internal resistanceSmall-sized cells cases/jacketsDry cellsElectricityEngineering

A process for producing a battery can in a transfer press comprises drawing a metal cup in a first station to form an elongated cylinder, ironing the elongated cylinder in a second station, and redrawing the elongated cylinder in a third station. In either or both the drawing and ironing steps, the cup or the elongated cylinder may be processed in more than one station. The process includes a final redraw station for redrawing the cylinder so as to roughen the inner surface of the battery can to improve its electrical properties.

Owner:H & T BATTERY COMPONENTS USA

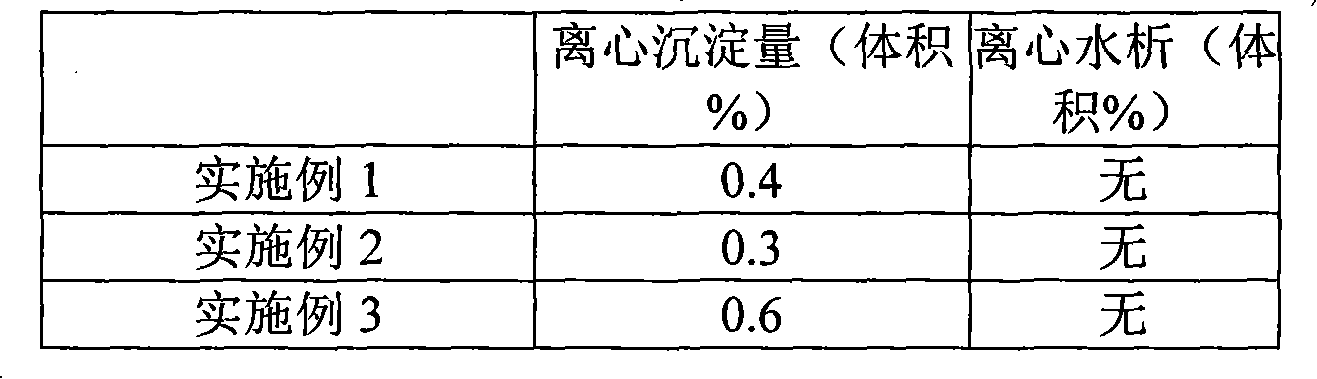

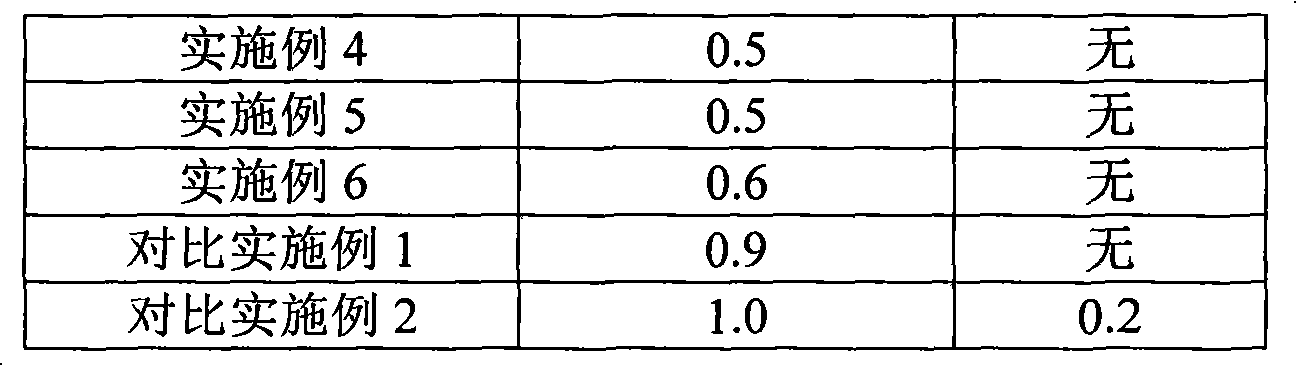

Fermented milk beverage containing red date particles and preparation method thereof

ActiveCN101874520AUniform suspension distributionSmooth online mixingMilk preparationGellan gumFlavor

The invention relates to the field of liquid milk, in particular to a fermented milk beverage containing red date particles and a preparation method thereof. The milk beverage comprises the following components in percentage by weight: 24 to 80 percent of milk, 0.0025 to 0.005 percent of lactic acid bacteria baking agent, 0.25 to 1 percent of stabilizer, 1 to 20 percent of red date particles, 0.1 to 0.4 percent of acidity regulator and the balance of water, wherein the stabilizer consists of a thickener and / or an emulsifier, and the thickener contains 0.1 to 0.15 weight percent of high acyl gellan gum. The milk beverage containing the red date particles ensures that the red date particles can more completely, uniformly and stably suspend in milk for long time while the nutrition of yogurt, the flavor of the red date and the chewing sense of the red date particles are effectively combined, and enables consumers to truly feel the real existence of the red date particles in taste and vision of the product.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

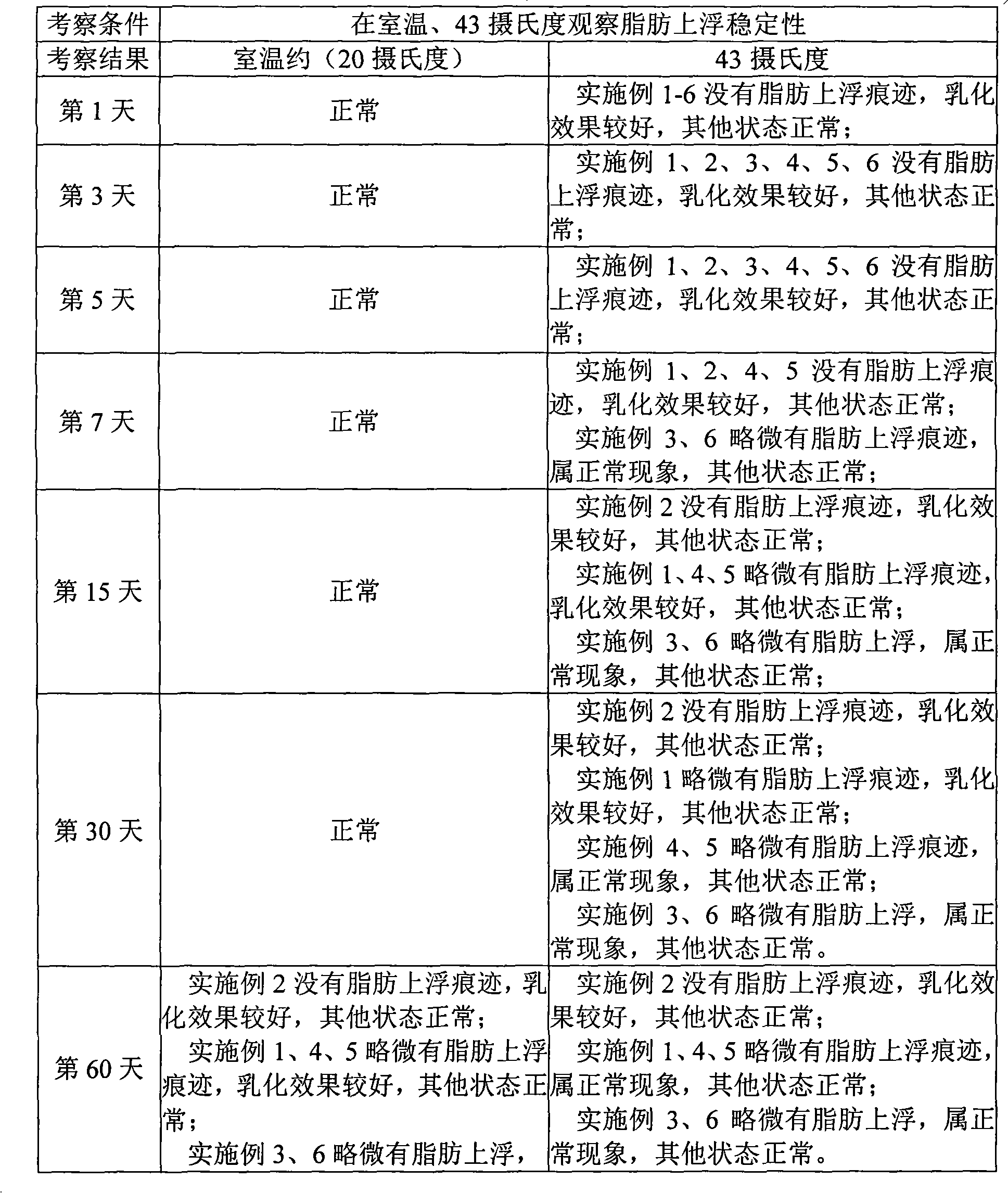

Coal-fired boiler SNCR and SCR combined denitration system and method thereof

ActiveCN105289233AImprove mixing uniformityImprove distribution uniformityLighting and heating apparatusDispersed particle separationBoiler furnaceProcess engineering

The invention relates to a coal-fired boiler SNCR and SCR combined denitration system. The denitration system comprises a boiler SNCR reaction system and a SCR reactor; the boiler SNCR reaction system comprises the boiler, an urea solution distribution module and a metering module, and an urea injection system and an urea supply system which are connected with the urea solution distribution module and the metering module; the urea injection system comprises multilayer-designed short spray guns with upper elevation in a 25m to 40m scope in a boiler furnace combustion zone, and multilayer-designed porous long spray guns having an furnace arch with the boiler, wherein, in each layer, at least one porous long spray gun vertically stretches into the boiler, and extends and passes through the cross section; the SCR reactor is connected with a boiler tail through a flue gas mixer; in the SCR reactor, the multilayer cellular catalyst can be arranged at a space between a coal economizer and an air preheater. According to the method, a mol ratio of ammonia nitrogen in an inlet cross section of the SCR catalyst is uniformly distributed, and denitration efficiency of the SCR reactor is enhanced.

Owner:CHINA HUANENG GRP CO LTD +1

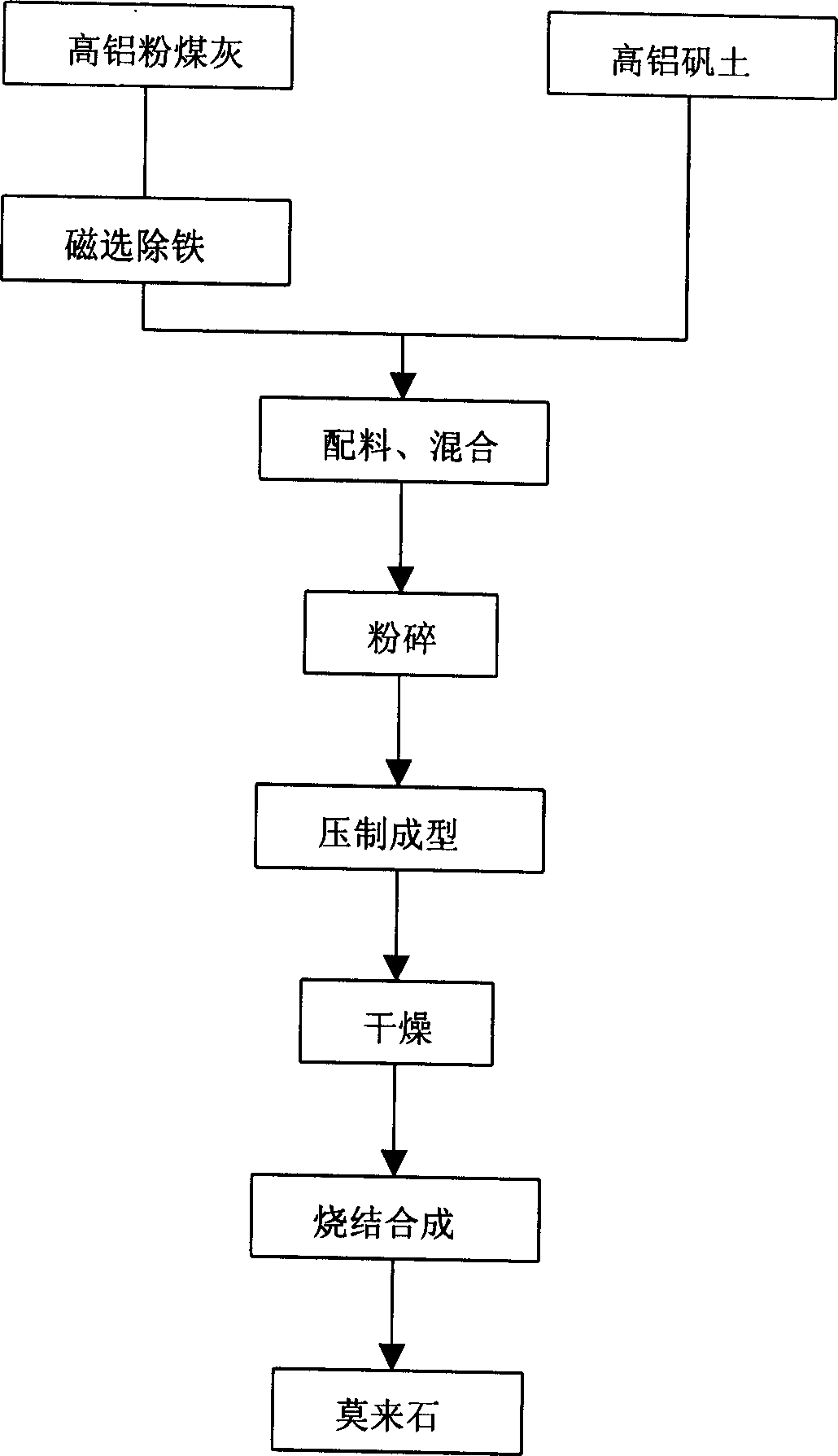

Agglomeration method for synthesizing mullite by using high aluminous fly ash

ActiveCN1696075ARealize comprehensive utilizationReduce manufacturing costTunnel kilnPolymer science

Owner:TSINGHUA UNIV +1

Anti-icing coating for ultra-high voltage power transmission line and preparation method thereof

The invention discloses an anti-icing coating for an ultra-high voltage power transmission line. The coating includes the following raw materials by weight: 50-60 parts of silicon fluorine resin, 6-10 parts of diamond like carbon, 2-3 parts of carbon nanotube, 5-8 parts of nano TiO2, 8-12 parts of nano SiO2, 0.3-1 part of a dispersant, 0.5-1 part of an antifoaming agent, 0.3-1 part of a leveling agent, 1-3 parts of an anticorrosive and bactericidal agent, and 20-30 parts of a solvent. The anti-icing coating for ultra-high voltage power transmission line has contact angle with water reaching 135-165 DEG C, also has good heating effect, the average temperature rise of 9.5-16 DEG C, very high hardness, excellent adhesion performance, acid and alkali resistance and wear resistance.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

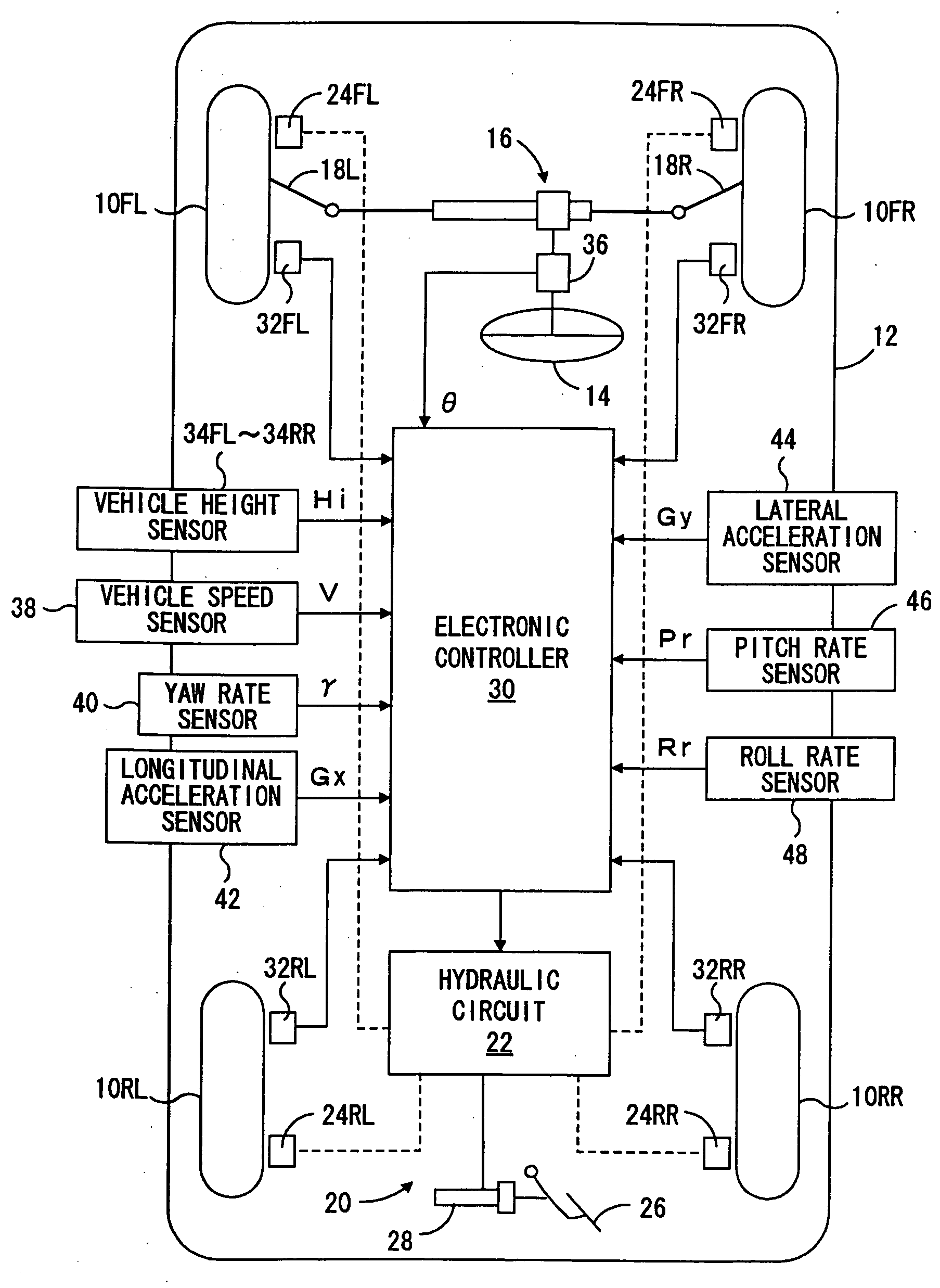

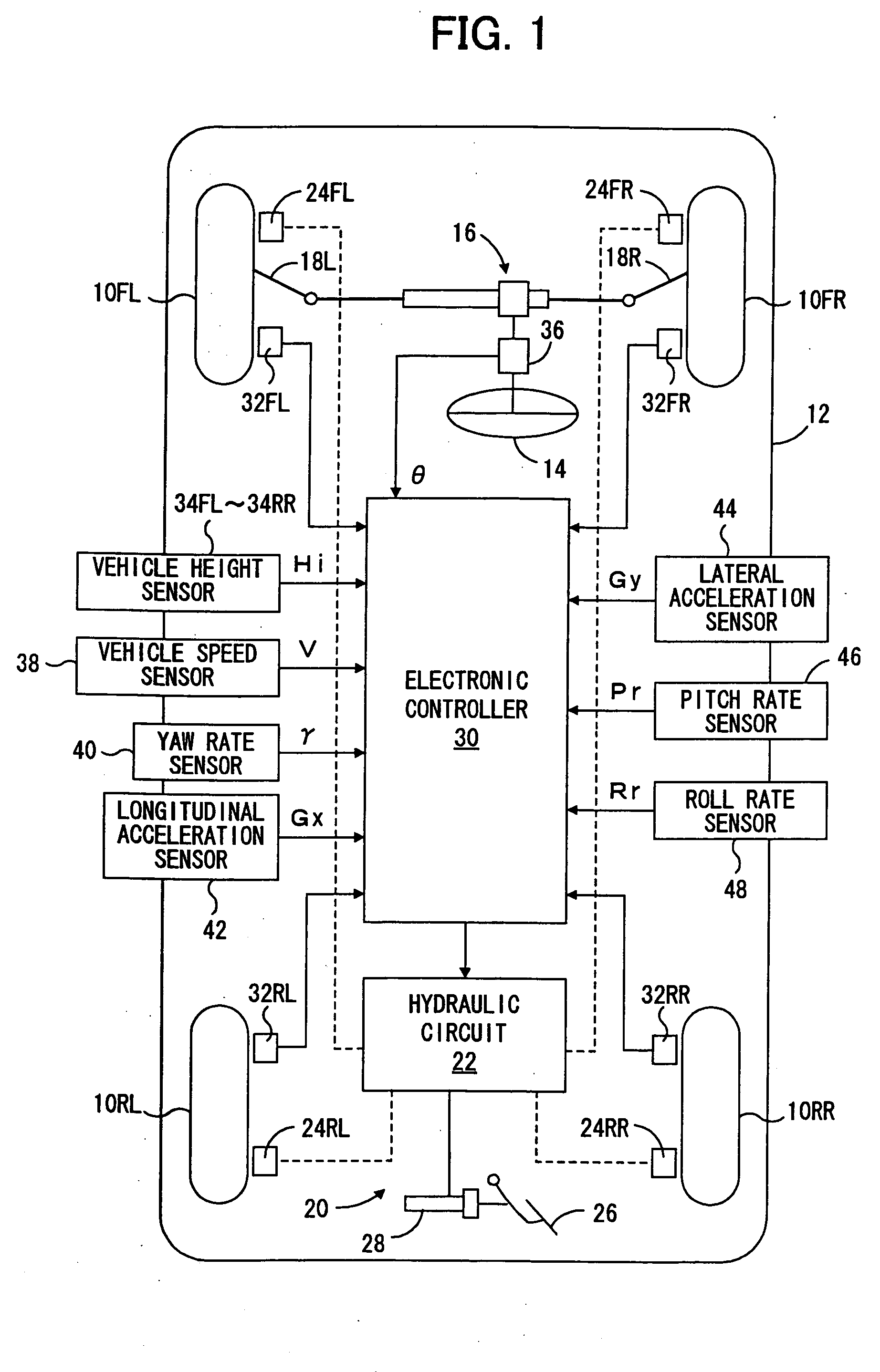

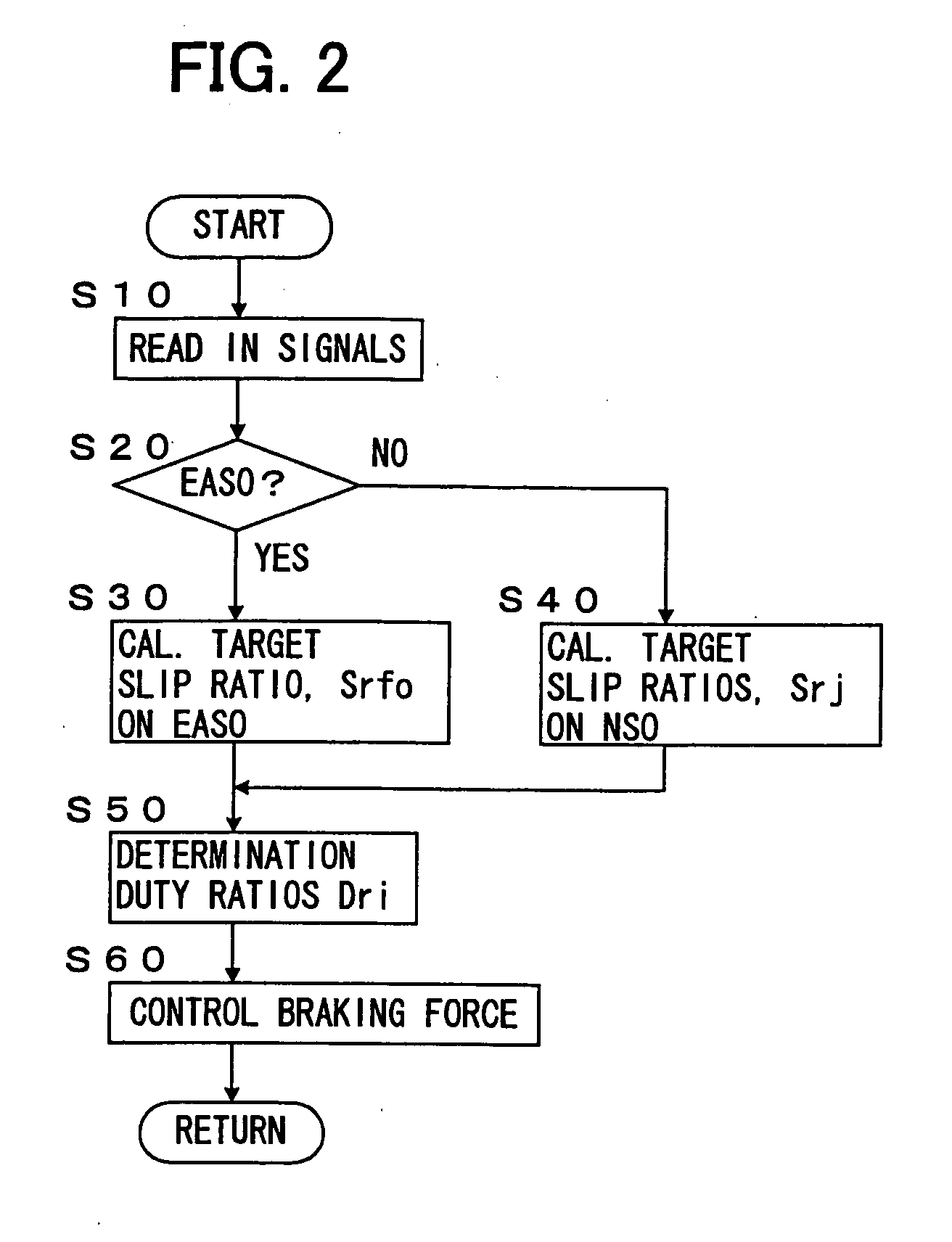

Vehicle behavior control device

ActiveUS20050029754A1Inhibit deteriorationCorrecting and inhibiting excessive deteriorationAnalogue computers for trafficPedestrian/occupant safety arrangementTarget controlBrake control

The inventive vehicle behavior control device employs a novel control strategy, suppressing deterioration of a vehicle behavior which would be induced during control processes, and being useful especially for correcting or inhibiting excessive deterioration of a vehicle behavior such as when a risk of rolling-over is detected. The device firstly judges if a possibility of rolling-over of the vehicle is high and calculates a target braking control amount for reducing the possibility of rolling-over in accordance with the result of the judgment of a possibility of rolling-over of the vehicle, where the target control amount when the possibility of rolling-over is high is set higher than when the possibility is low. Then, under control of the inventive control device, wheel braking force is controlled based upon the target braking control amount. After the starting of control of the wheel braking force, however, increasing and decreasing gradients of wheel braking force is restricted when a high possibility of rolling-over is judged.

Owner:TOYOTA JIDOSHA KK

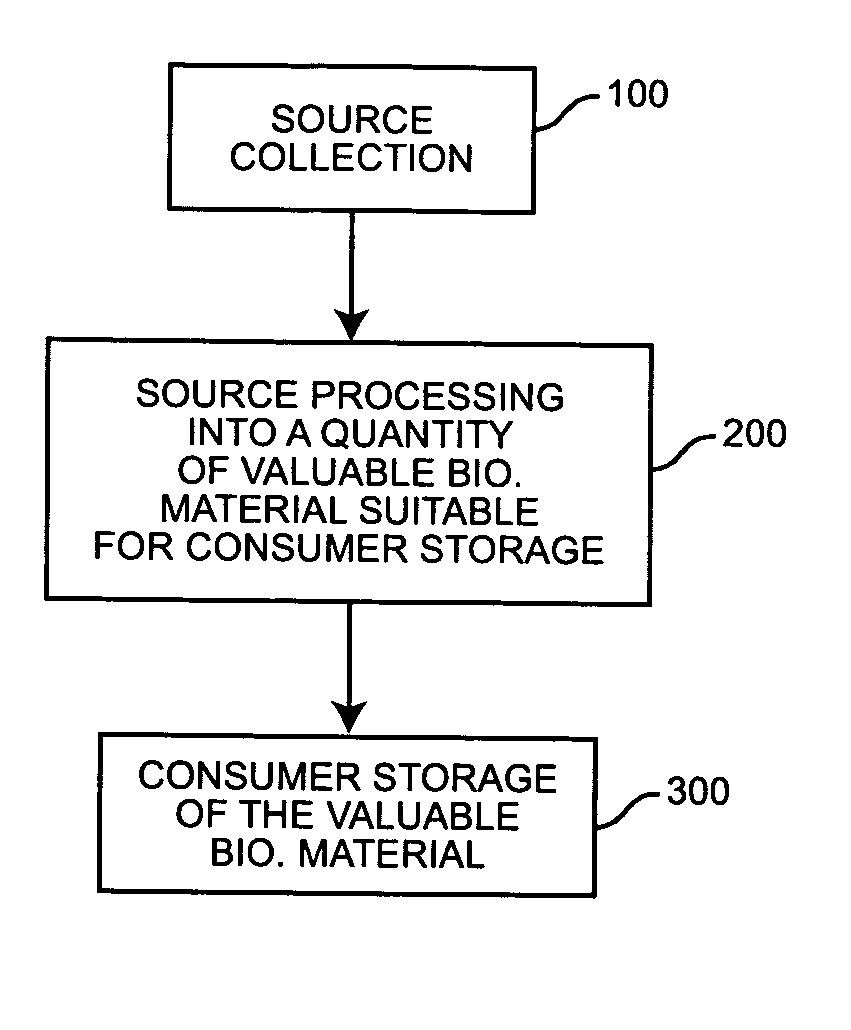

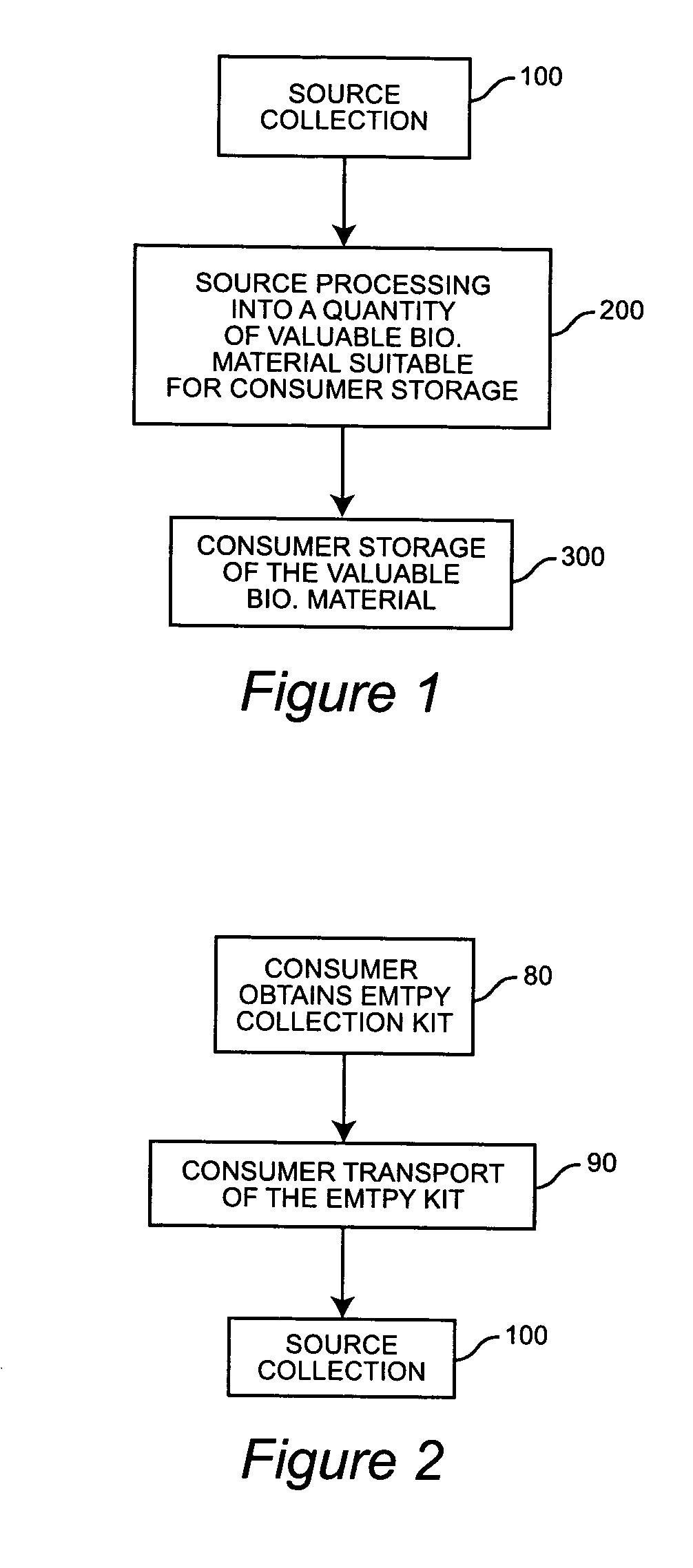

Portable and other consumer storage for biological material

InactiveUS20050233298A1Increase the amount of controlIncrease influenceBioreactor/fermenter combinationsBiological substance pretreatmentsBiological materialsBiological system

Owner:FARSEDAKIS LEWIS E

High-gloss real stone lacquer and marble simulation lacquer

The invention discloses a high-gloss stone lacquer and a marble simulation lacquer. The high-gloss stone lacquer is characterized by being prepared from the following raw materials in weight percentage: 20.7%-25.8% of silicone-acrylic emulsion, 4%-6% of HEC (Hydroxy Ethyl Cellulose) solution with the concentration being 2.5%, 0.5%-0.7% of coalescent alcohol ester-12, 0.35%-0.45% of ethylene glycol, 10.4%-15.5% of color sand in 40-80 meshes, 15.55-20.6% of color sand in 80-120 meshes, 36.1%-41.3% of color sand in 120-200 meshes, 0.008%-0.012% of mildew preventive, 0.008%-0.012% of corrosion preventive, 0.008%-0.012% of fungicide, 0.35%-0.45% of moisturizing and polishing agent and 0.5%-0.7% of dye leveler. The high-gloss stone lacquer can be changed into the marble simulation lacquer by adding rock sheets. According to the high-gloss stone lacquer and the marble simulation lacquer, the color is not dark any more, the flower-appearing cannot be caused in construction any more, fast-drying cannot be generated any more, and the high-gloss stone lacquer and the marble simulation lacquer can be subjected to spraying, roller painting and brush coating and are convenient to use.

Owner:尚怀兴

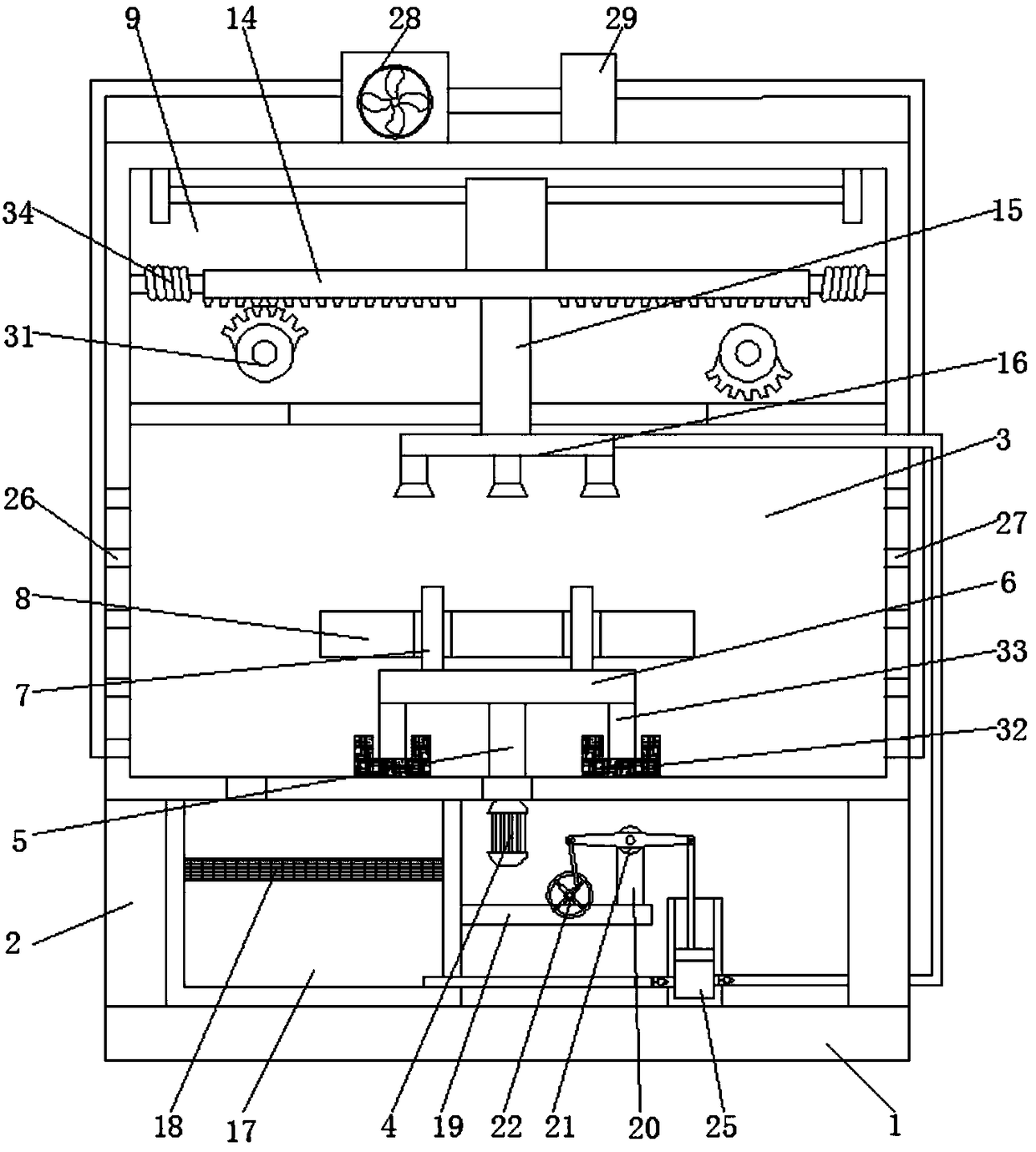

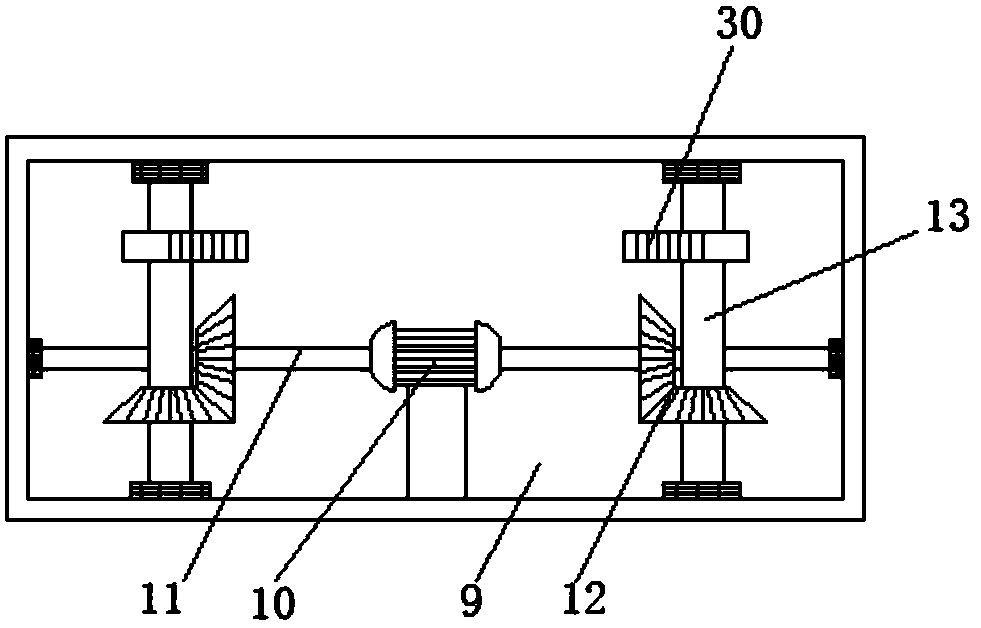

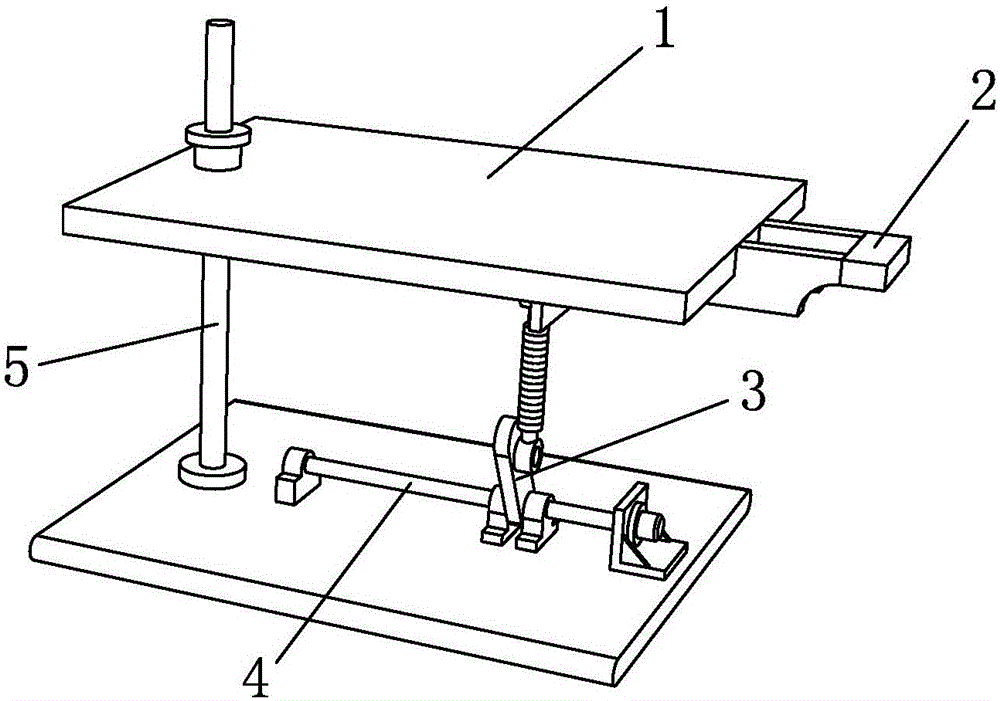

Hardware product paint spraying device

InactiveCN108525903AEvenly paintedImprove painting efficiencyLiquid spraying apparatusSpray nozzleMechanical engineering

The invention provides a hardware product paint spraying device. The hardware product paint spraying device comprises a base, supporting columns are fixedly mounted on the left and right sides of thetop of the base, and a spraying box is fixedly installed at the tops of the supporting columns. A rotating disc motor is fixedly installed at the middle of the bottom of the spraying box, and a rotating shaft is arranged at the top of the rotating disc motor. The rotating shaft penetrates through the spraying box and extends into the spraying box. A rotating disc is fixedly installed at the top ofthe rotating shaft, and plug pins are fixedly installed on both sides of the top of the rotating disc. According to the hardware product paint spraying device, a plate is firmly fixed to the turntable by arranging the plug pins; by arranging the turntable motor to be matched with the rotating shaft, the rotating disc can drive the plate to rotate, so that paint spraying is more uniform and the paint spraying efficiency is improved; by arranging a moving box, spray nozzles can move left and right to expand the range of rotation; and by arranging a rack to be matched with driving of two half gears, a connecting rod can move left and right to drive the spray nozzles to move left and right.

Owner:新昌县盛南建材有限公司

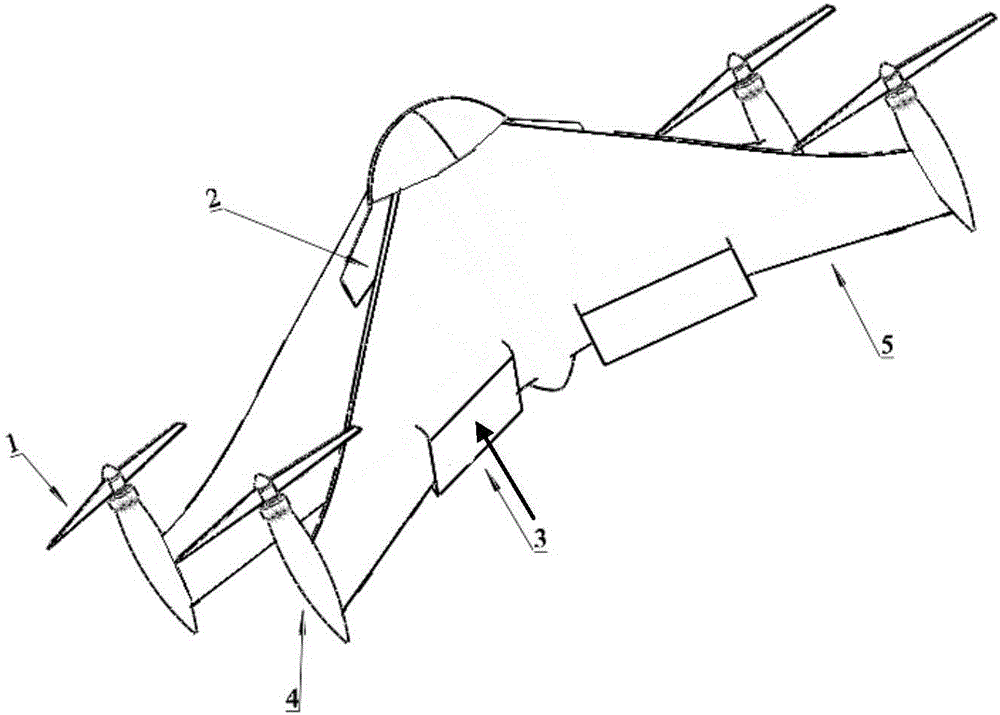

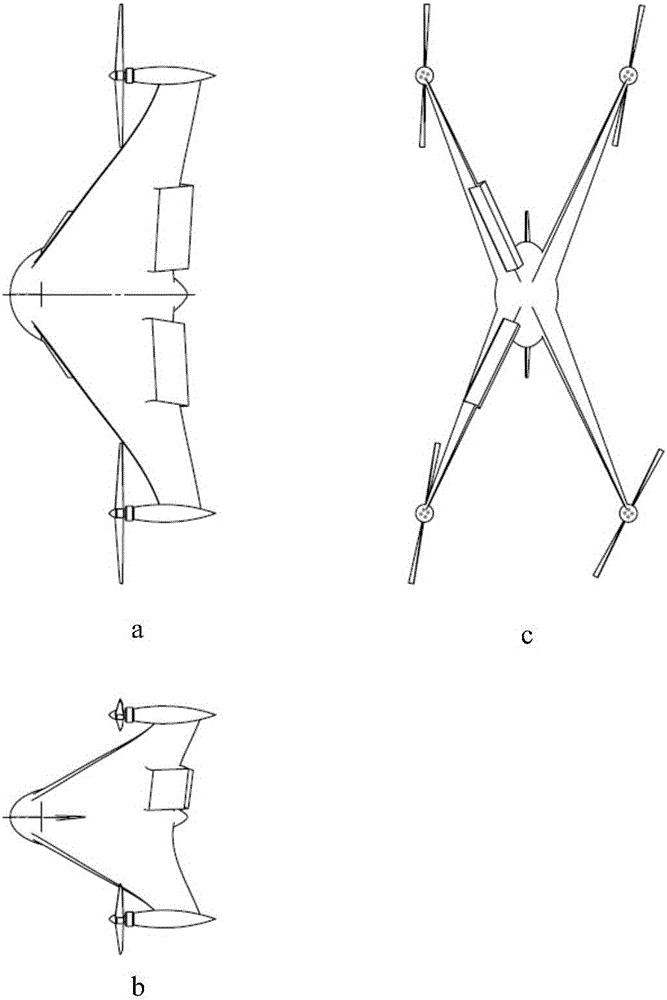

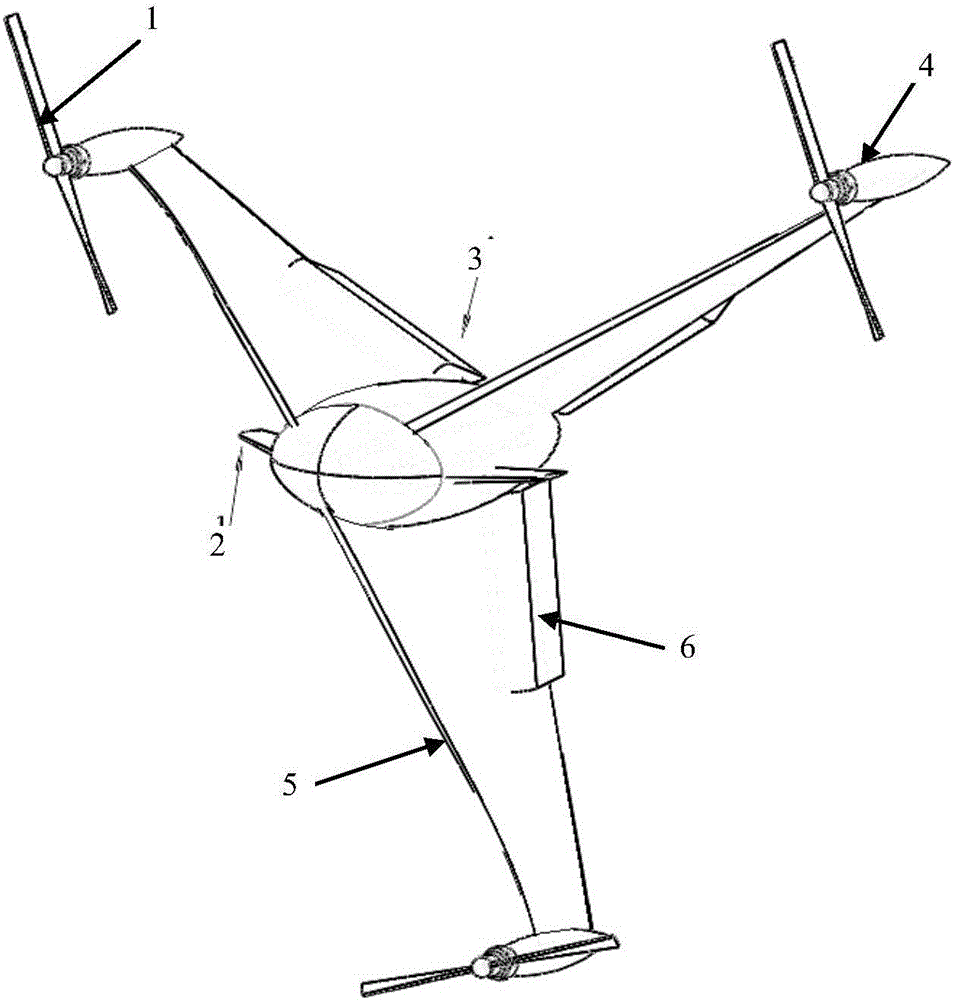

Detachable tailstock type vertical take-off and landing unmanned aerial vehicle

The invention provides a detachable tailstock type vertical take-off and landing unmanned aerial vehicle. Wings and a fuselage can be detachably assembled. The wings and the fuselage can form two overall arrangement forms. According to the X-shaped overall arrangement form, two pairs of wings are mounted on the fuselage and are bilaterally symmetrical, and each pair of wings is of a longitudinal symmetry structure; and the included angle between the wings in each pair is 120 degrees, and the four wings form an X shape. According to the Y-shaped overall arrangement form, three wings are mounted on the fuselage, the included angel between every two adjacent wings is 120 degrees, and the three wings form a Y shape. The unmanned aerial vehicle of the X-shaped overall arrangement form is suitable for long-distance flight under a wind-free condition. The vertical take-off and landing unmanned aerial vehicle of the Y-shaped overall arrangement form is suitable for short-distance flight under a lateral wind condition. According to the detachable tailstock type vertical take-off and landing unmanned aerial vehicle, the structure is simple, and control is easy; and since the wings and the fuselage are connected detachably, the unmanned aerial vehicle is suitable for different occasions, singular problems in a transition mode are avoided, and long endurance and long-distance flight can be achieved.

Owner:BEIHANG UNIV

Communication device, processing device and method for transmitting buffer status report

InactiveUS20190215717A1Increase the number ofEfficiently receive/transmitNetwork traffic/resource managementConnection managementRadio Link ControlComputer science

In the present invention, the method, communication device or processing device determines an amount of uplink (UL) data available for a logical channel group (LCG); and transmit the buffer status report including information on the amount of UL data available for the LCG. In the present invention, the amount of UL data available for the LCG is selected based on all logical channels of the LCG except for a logical channel related to a suspended radio link control (RLC) entity among RLC entities configured for the communication or processing device.

Owner:LG ELECTRONICS INC

Cervical distraction device

ActiveUS6984217B2Eliminates flexibilityIncrease the amount of controlChiropractic devicesFractureDistractionGynecology

Owner:NORTH AMERICAN MEDICAL CORPORTAION

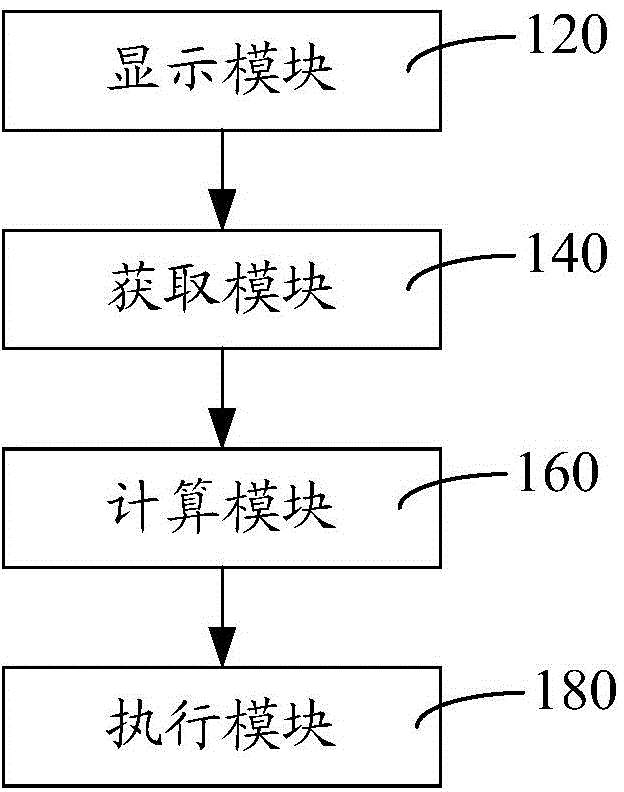

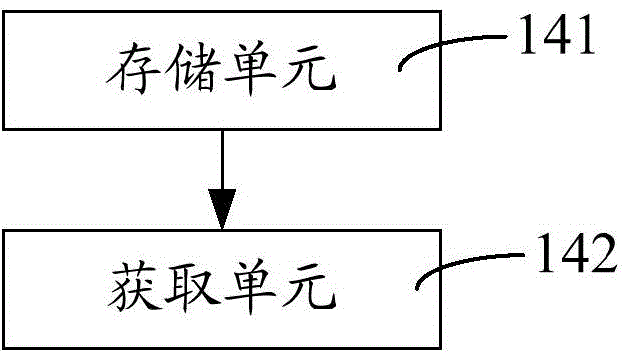

Intelligent kitchen seasoning machine

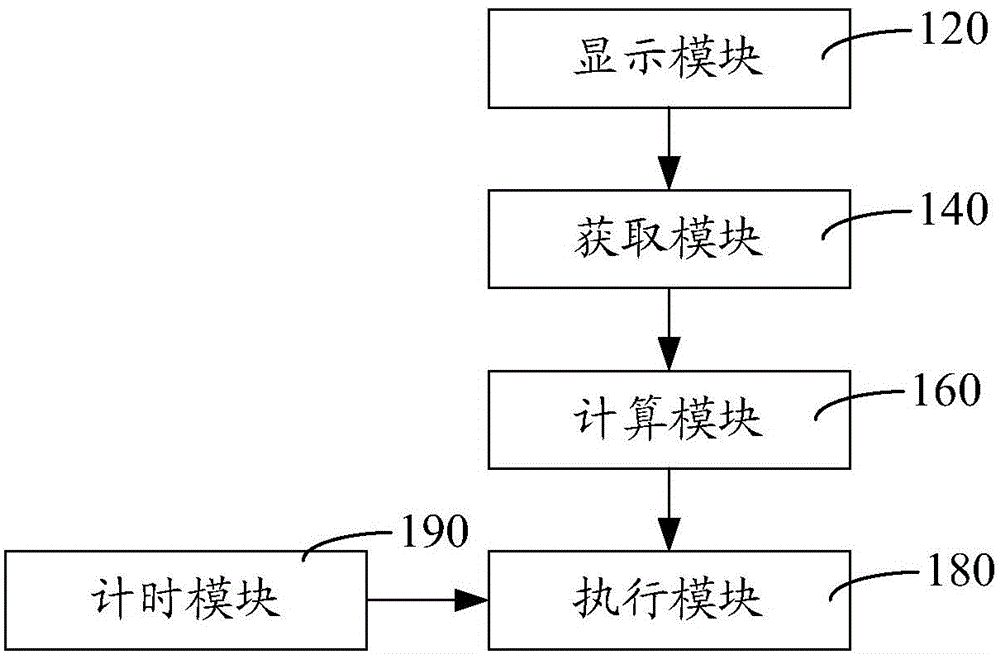

InactiveCN104921603AIncrease the amount of controlControl the time and amount of additionCooking vesselsAdditive ingredientFood material

The invention relates to an intelligent kitchen seasoning machine. The intelligent kitchen seasoning machine comprises a display module, an acquisition module, a calculation module and an execution module, wherein the display module is used for selecting the names of dishes, the acquisition module is used for acquiring the cooking steps of the dishes, the calculation module is used for calculating the proportional relation between ingredients in the cooking steps and the time intervals between the cooking steps according to the quantity value of food materials related to the dishes, and the execution module is used for executing the cooking steps according to the proportional relation between the ingredients in the cooking steps and the time intervals between the cooking steps. Or the intelligent kitchen seasoning machine comprises a controller and an execution mechanism, wherein the controller is used for acquiring the cooking steps of the dishes according to the names of the dishes and for calculating the proportional relation between the ingredients in the cooking steps and the time intervals between the cooking steps according to the quantity value of the food materials related to the dishes, and the execution mechanism is used for executing the cooking steps according to the instruction of the controller. By the aid of the intelligent kitchen seasoning machine, the adding time and the adding quantity of the ingredients can be controlled accurately, and each dish can be in the optimum taste for people.

Owner:苏州辰傲电子科技有限公司

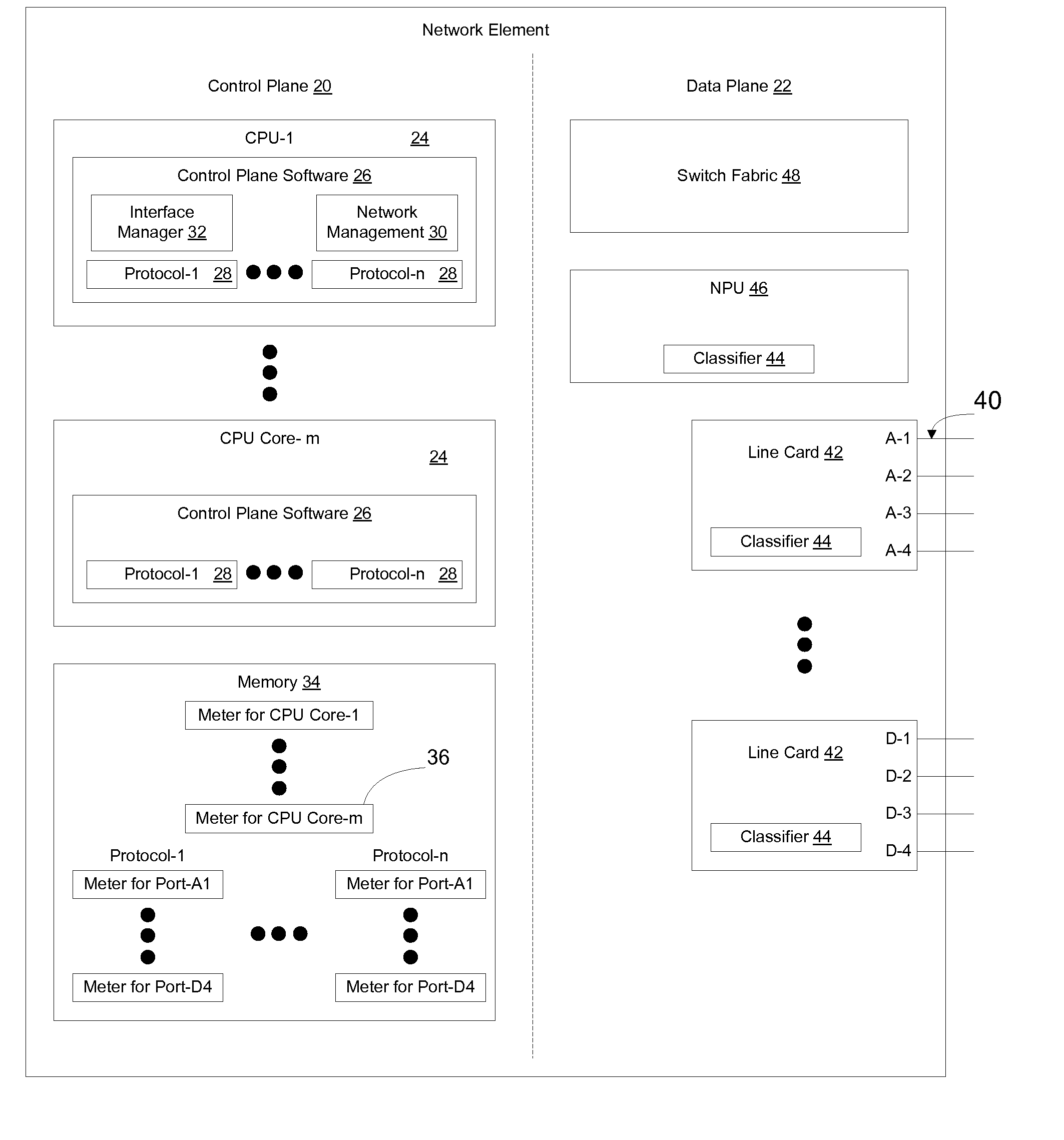

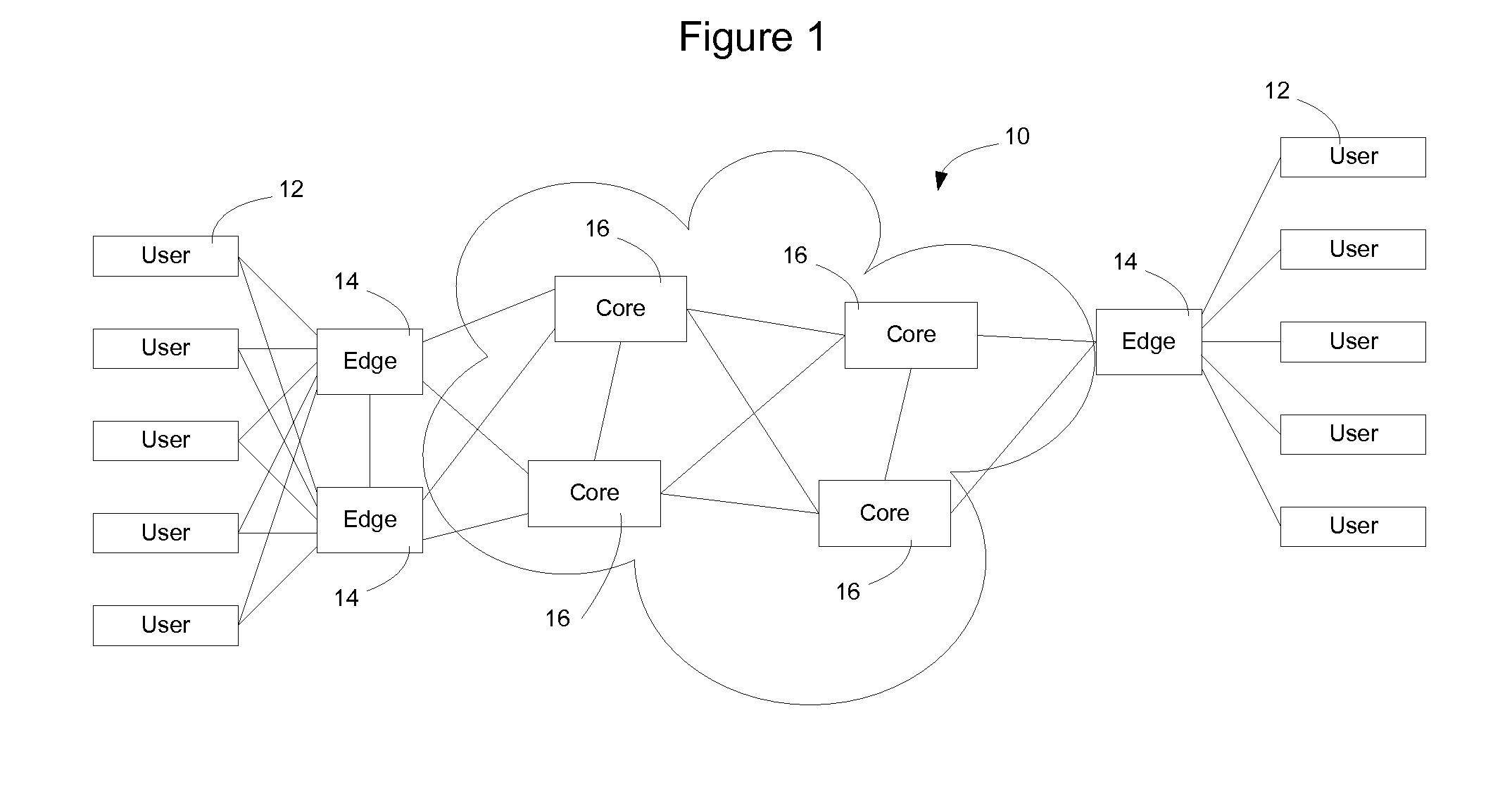

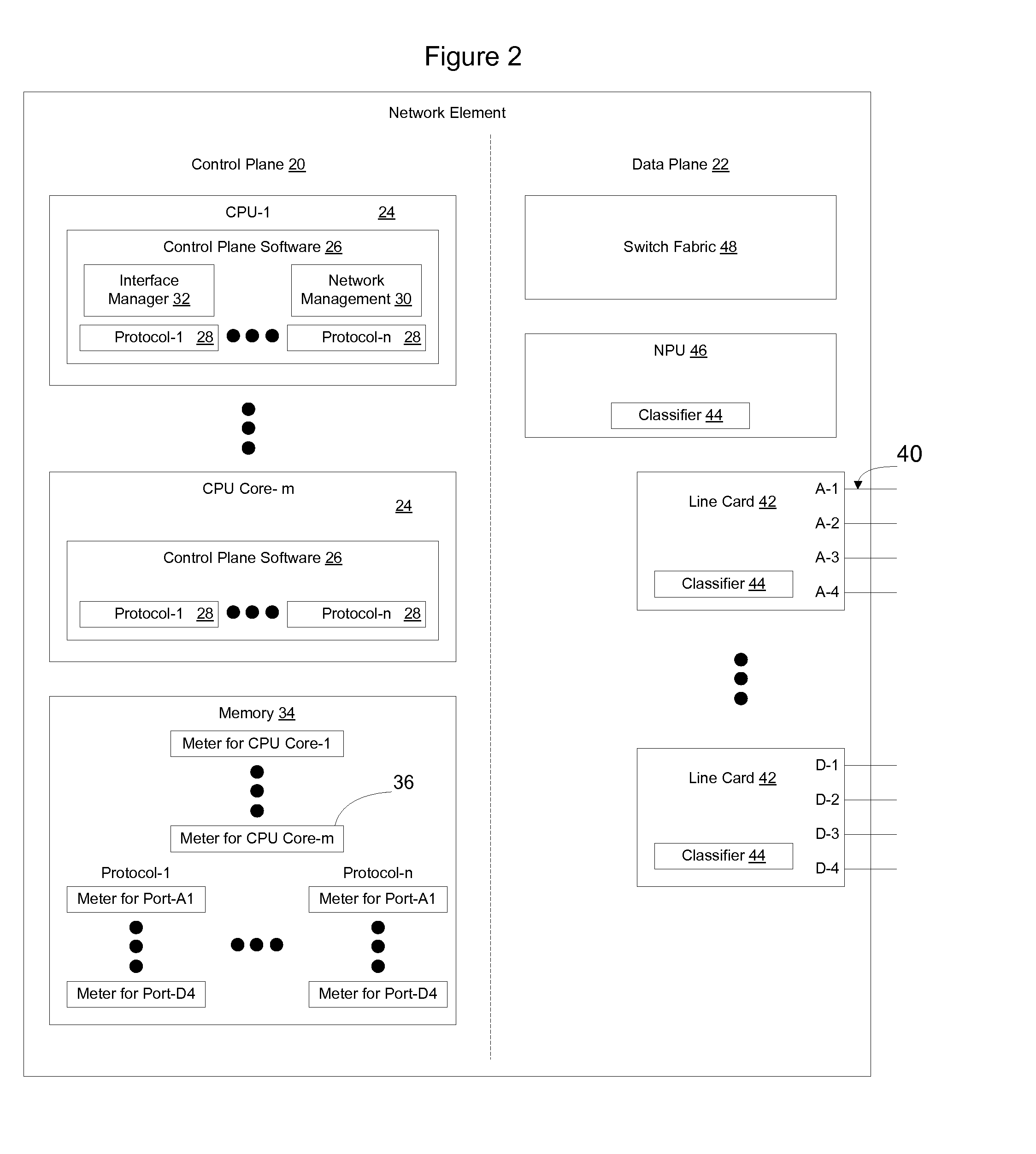

Method and Apparatus for Control Plane CPU Overload Protection

ActiveUS20130250763A1Increase the amount of controlIncrease volumeError preventionFrequency-division multiplex detailsTraffic capacityGranularity

Control packets received at a network element are pre-classified to enable out of profile traffic to be traced to an offending port. Pre-classified control packets are metered at a desired granularity using dynamically configured meters which adjust as ports are put into service or removed from service, and as services are applied to ports. CPU metering is implemented on a per-CPU core basis, but the per-CPU meters are used to perform flow control rather than as thresholds for ejecting errant control traffic. The combination of these three aspects provides robust CPU overload protection while allowing appropriate levels of control traffic to be provided to the control plane for processing, even in the event of a control traffic burst on one or more ports of the network element.

Owner:EXTREME NETWORKS INC

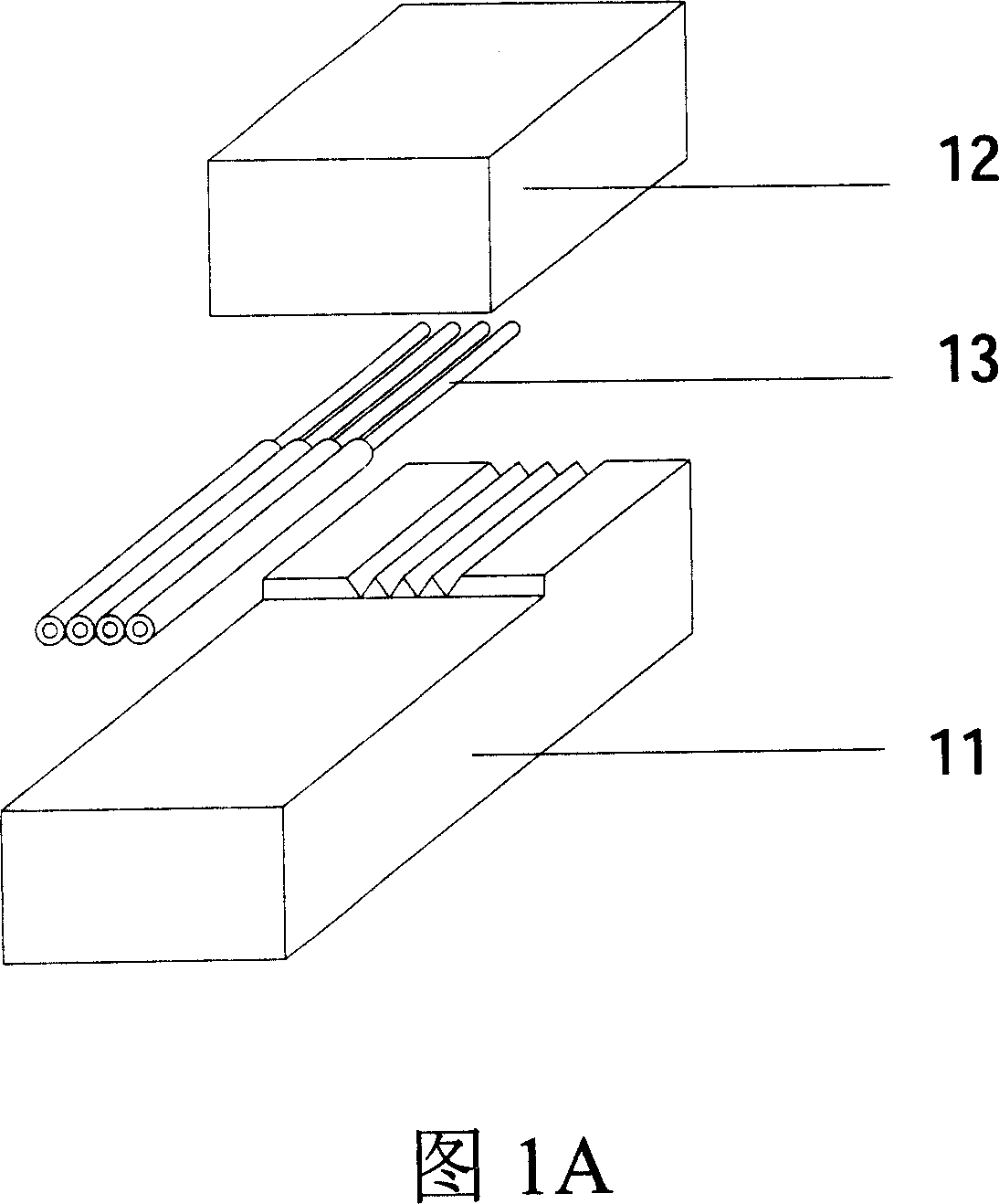

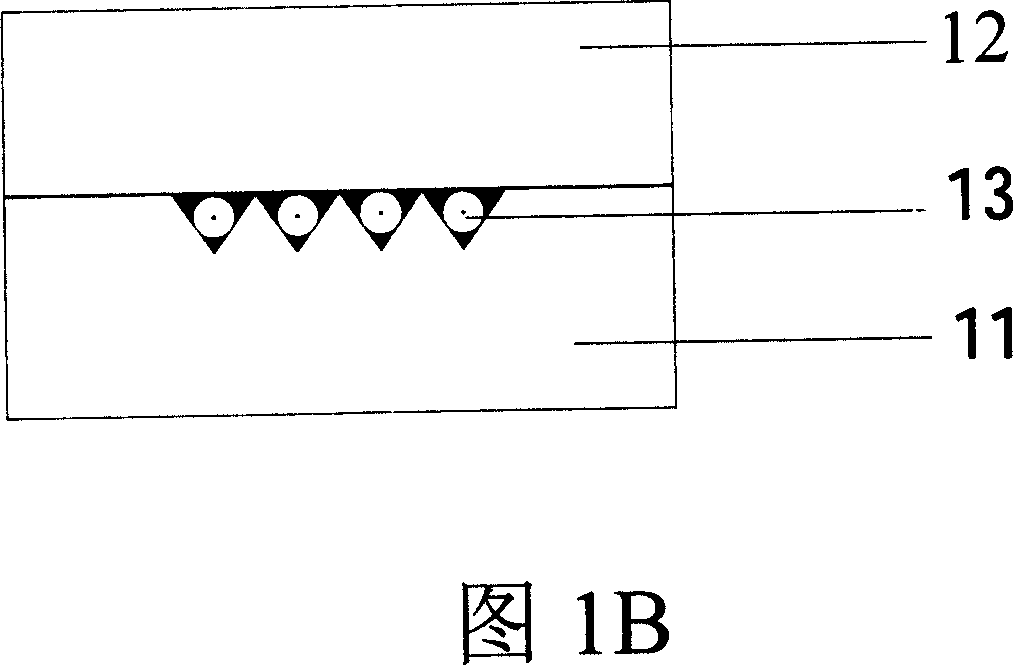

Method for producing novel high precision optical fiber array

InactiveCN101051105AAvoid displacement changesIncrease the amount of controlCoupling light guidesFiber arrayEngineering

A method for preparing optical fiber array with high accuracy includes arranging precise optical fiber fixing mould and optical fiber array bottom base plate as well as optical fiber belt fixing base in sequence, laying and fixing optical fiber belt with coated layer being removed at front end uniformly on said units, covering top cover plate of optical fiber array on bottom base plate, setting control unit on top cover plate to make fiber core of each optical fiber on bottom base plate be on the same plane, adding adhesive in from back end of top cover plate then curing it and adding adhesive on optical fiber belt uncovered by top cover plate and set on bottom base plate the curing it.

Owner:BROADEX TECH

Preparation method of biodegradable polyether urethane sponge

InactiveCN105001393AImprove mechanical propertiesIncrease the amount of controlSurgical adhesivesPharmaceutical delivery mechanismPrepolymerPolyester

The invention discloses a preparation method of biodegradable polyether urethane sponge. The preparation method comprises 1, double hydroxyl-terminated prepolymer synthesis, 2, double isocyanate group-terminated prepolymer synthesis, 3, polyurethane material preparation and 4, porous sponge preparation. The mechanical properties of the biodegradable polyether urethane sponge can be simply adjusted by adjustment of a ratio of a soft section (comprising polyester and polyether chain segments) to a hard section (comprising a carbamate chain segment), and the degradability of the biodegradable polyether urethane sponge can be simply adjusted by control of content of a hydrophilic component (comprising hydrophilic polyether diol). The biodegradable polyether urethane sponge can be used for organs such as ear, nose and other cavities needing compressing hemostasis.

Owner:SHANDONG NORMAL UNIV

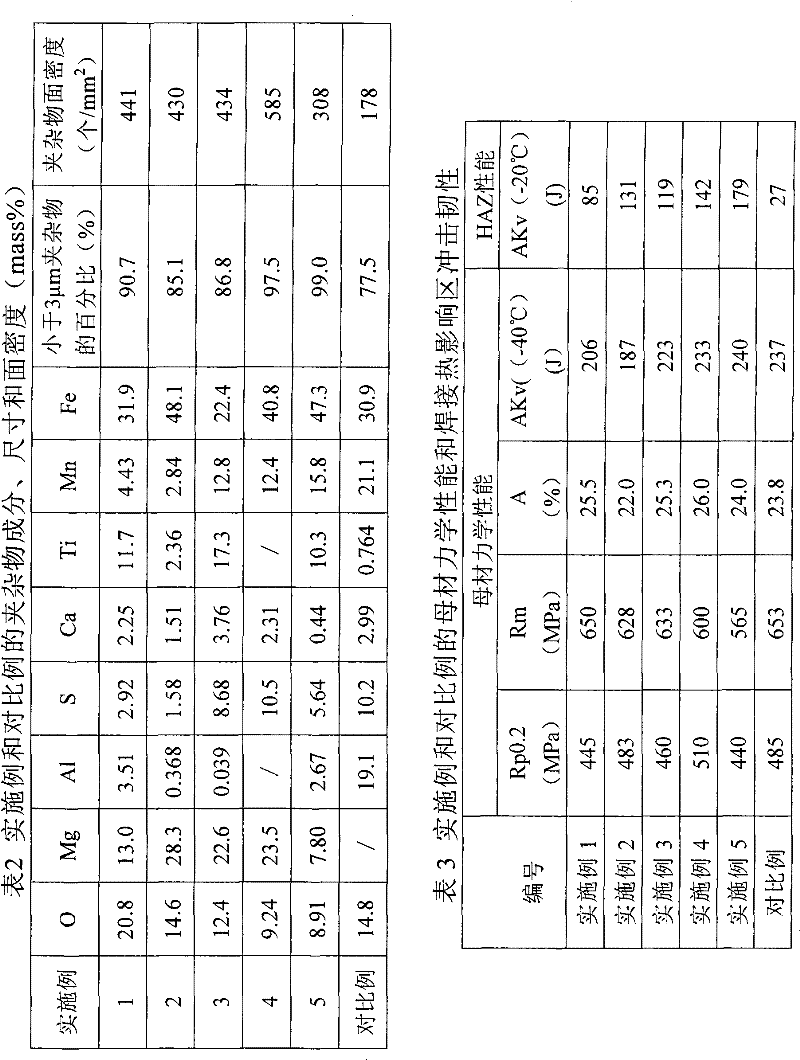

Method for raising large heat input weldability of thick steel plate

ActiveCN102373371AIncrease the amount of controlPrecise control of initial oxygen positionHeat-affected zoneAustenite

The invention discloses a method for raising large heat input weldability of a thick steel plate, comprising the following steps: 1) smelting and casting to form a steel plate: adding deoxidizers in the deoxidation process of the liquid steel according to the following types and order: Mn, Si, Al, Ti, and Ca and / or Mg, controlling the initial oxygen place in the liquid steel when Mn deoxidation is carried out in casting, adding Fe2O3 powder to let the oxygen content in the liquid steel be 0.001-0.008 wt%, wherein, the steel plate comprises 0.05-0.09 wt% of C, 0.10-0.30 wt% of Si, 1.3-1.7 wt% of Mn, 0.005-0.02 wt% of Ti, no larger than 0.015 wt% of P, no larger than 0.01 wt% of S, no larger than 0.006 wt% of N, no larger than 0.004 wt% of Ca, and the balance consisting of Fe; in the steel, the volumn density of TiN deposition with the particle size of less than 500 nm is larger than 9.0*107 PCs / mm<3>, the average particle size is less than 80 nm, and the proportion of the deposition with the particle size of less than 100 nm is larger than 75 %; 2) rolling and cooling. The large amount of nano TiN deposition with dispersive distribution formed by the invention can inhibit the growth of austenite crystals in the heat affected zone, and greatly raise the large heat input weldability of the thick steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for improving high heat input welding performance of thick steel plates

ActiveCN102191429AIncrease the amount of controlPrecise control of initial oxygen positionHeat-affected zoneSheet steel

The invention discloses a method for improving the high heat input welding performance of thick steel plates. The method comprises the following steps of: 1) smelting and casting to obtain an ingot, wherein deoxidants are added in the deoxidation process of molten steel, the adding sequence of the deoxidants is Mn and Si, Al, Ti, and Ca, a Mg deoxidant is added in the casting process of the molten steel, and the initial oxygen potential during the deoxidation of Mg is accurately controlled by adding Fe2O3 powder into a casting ingot mould; and 2) rolling and cooling. In the method, microfine dispersive distribution and Mg-containing inclusions, which are formed by adding the deoxidants in the deoxidation process of the molten steel and adding the Fe2O3 powder into the casting ingot mould to accurately control the oxygen potential during the deoxidation of the Mg, can inhibit the growth of austenite grains in a welding heat affected zone, and promotes the growth of ferrite in the grains, so that the high heat input welding performance of the thick steel plates is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

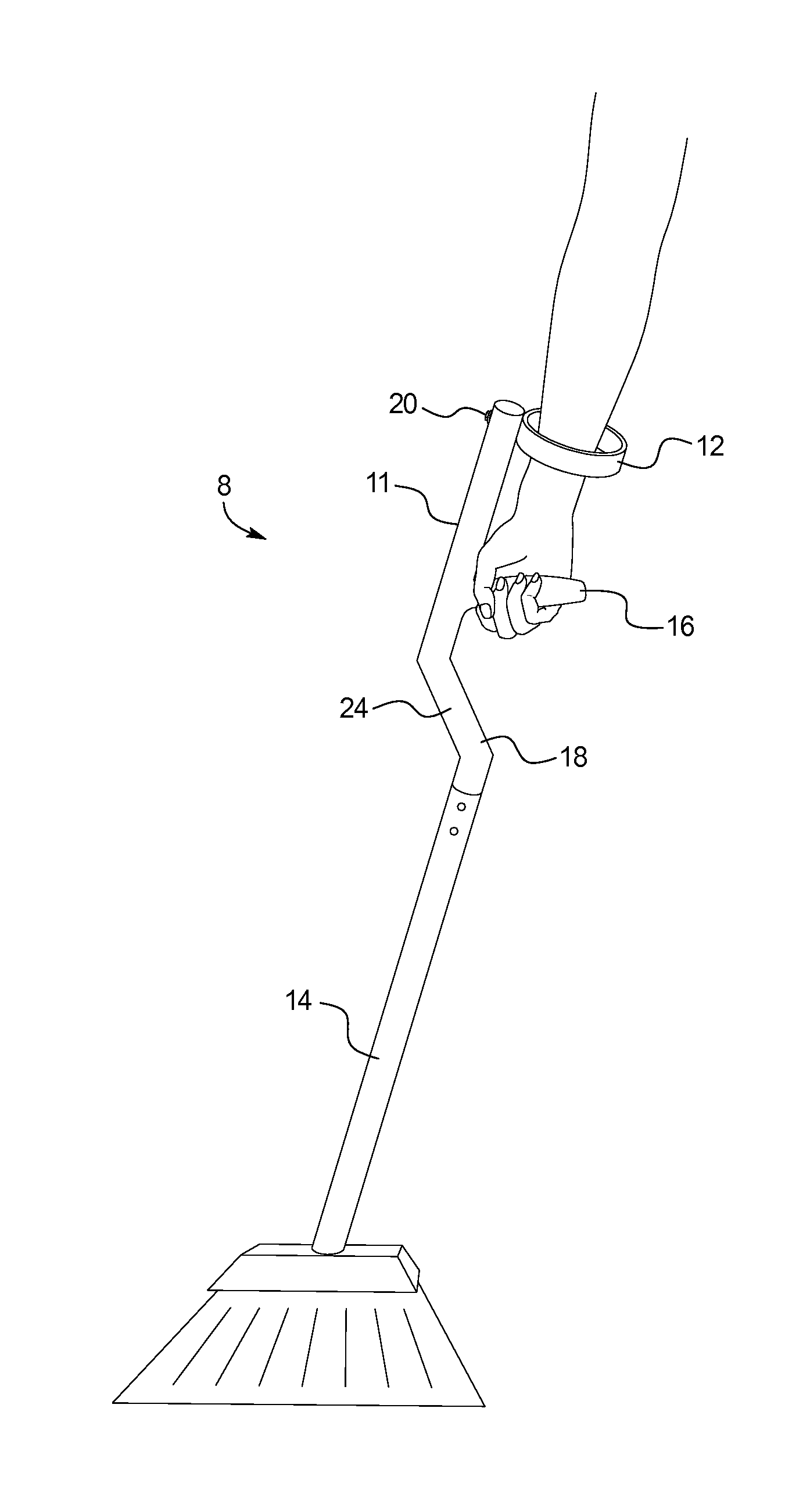

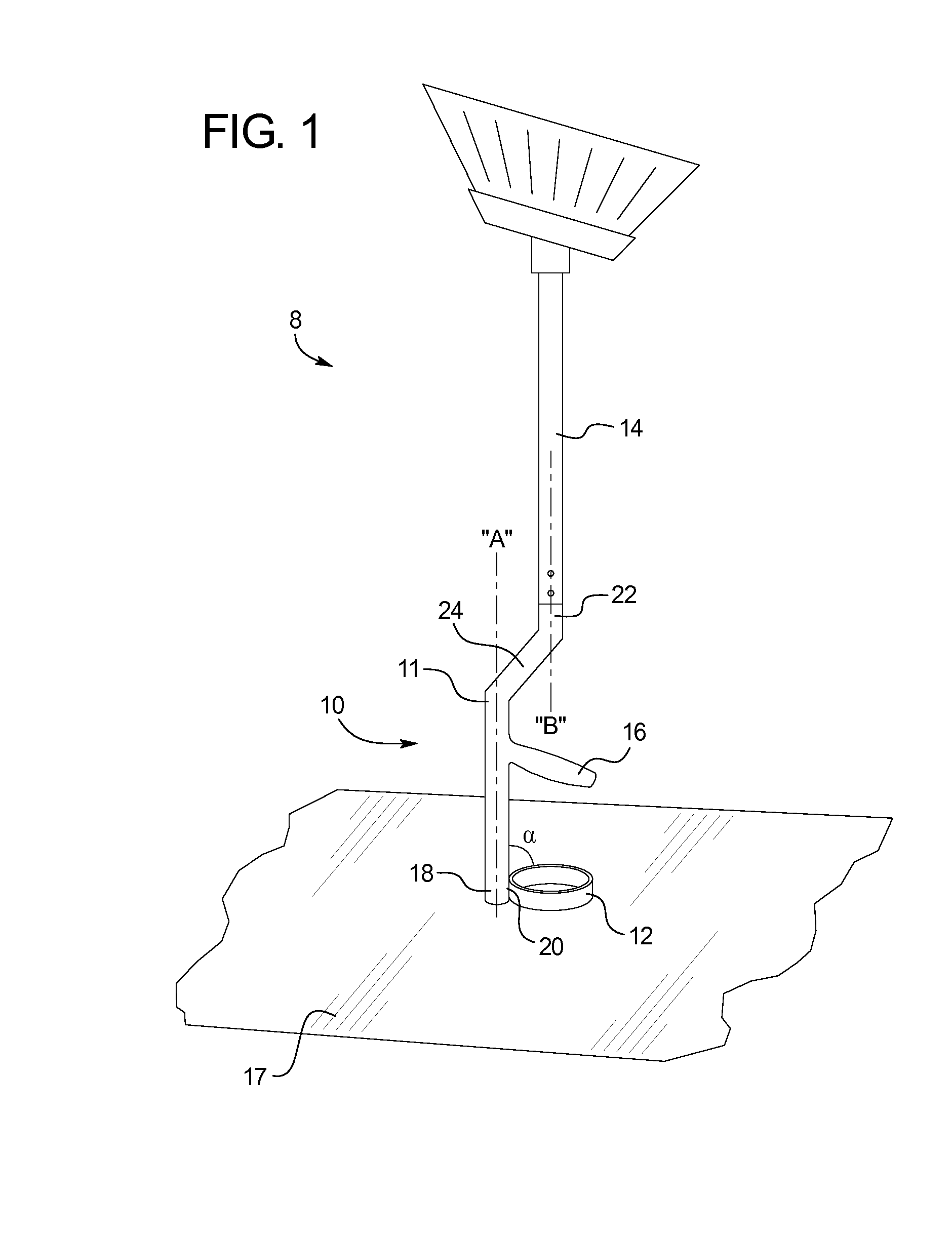

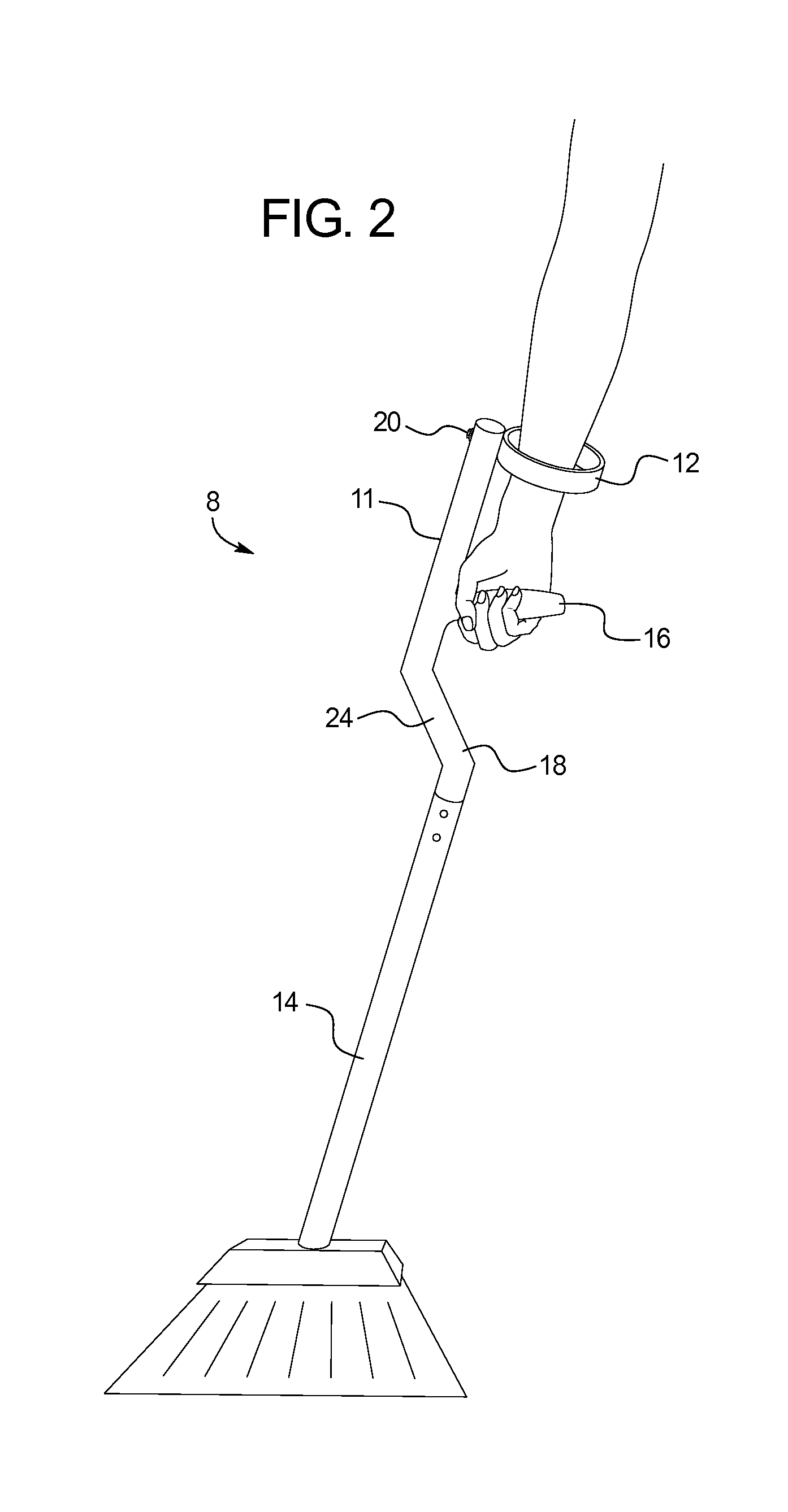

Ergonomic tool handle enhancement

InactiveUS20120144964A1Increase the amount of controlEasy to operateCarpet cleanersFloor cleanersSoftware engineeringHand arm

A tool handle including: a body configured to receive a handle of a tool; a hand grip extending approximately perpendicular from the body; and an arm ring rotatably disposed on the body, wherein the arm ring is adapted to be placed in at least two positions, a first position in which the arm ring is generally perpendicular to the hand grip such that a user may place the user's forearm through the arm ring to grasp the hand grip and a second position in which the arm ring is generally parallel to the hand grip so as to minimize the width of the tool handle.

Owner:LEE SUNG K

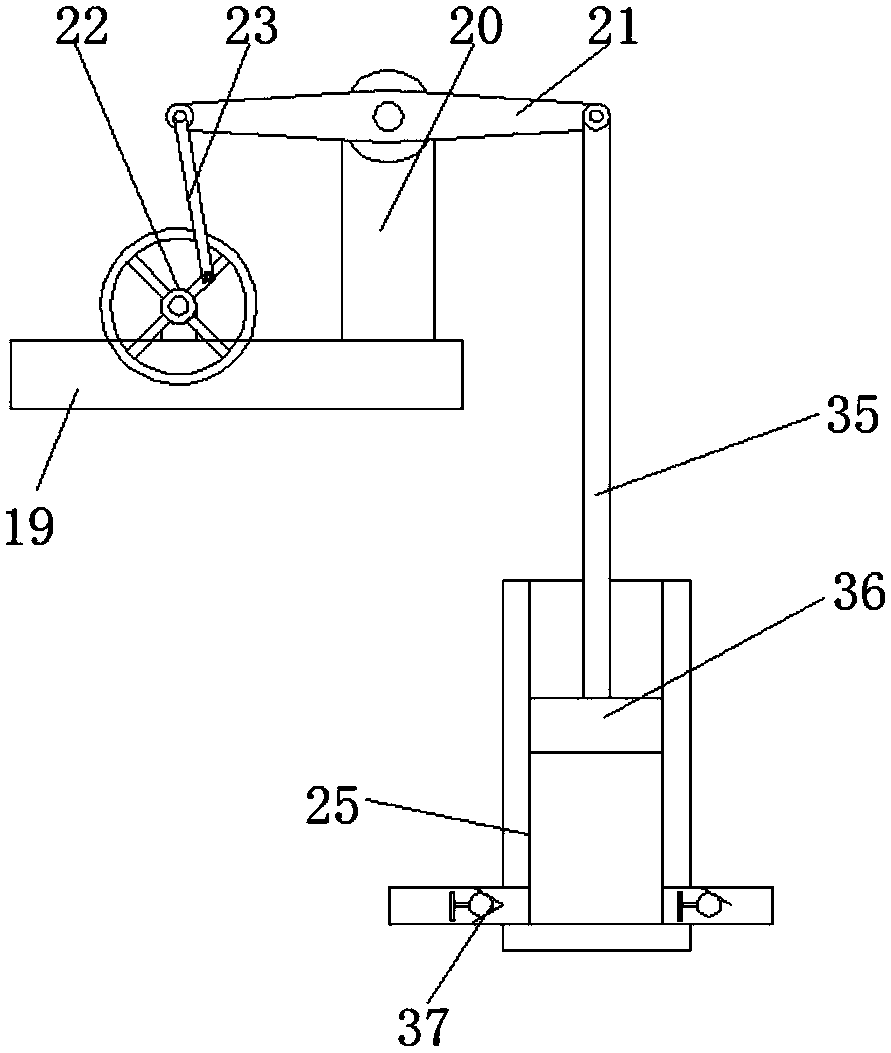

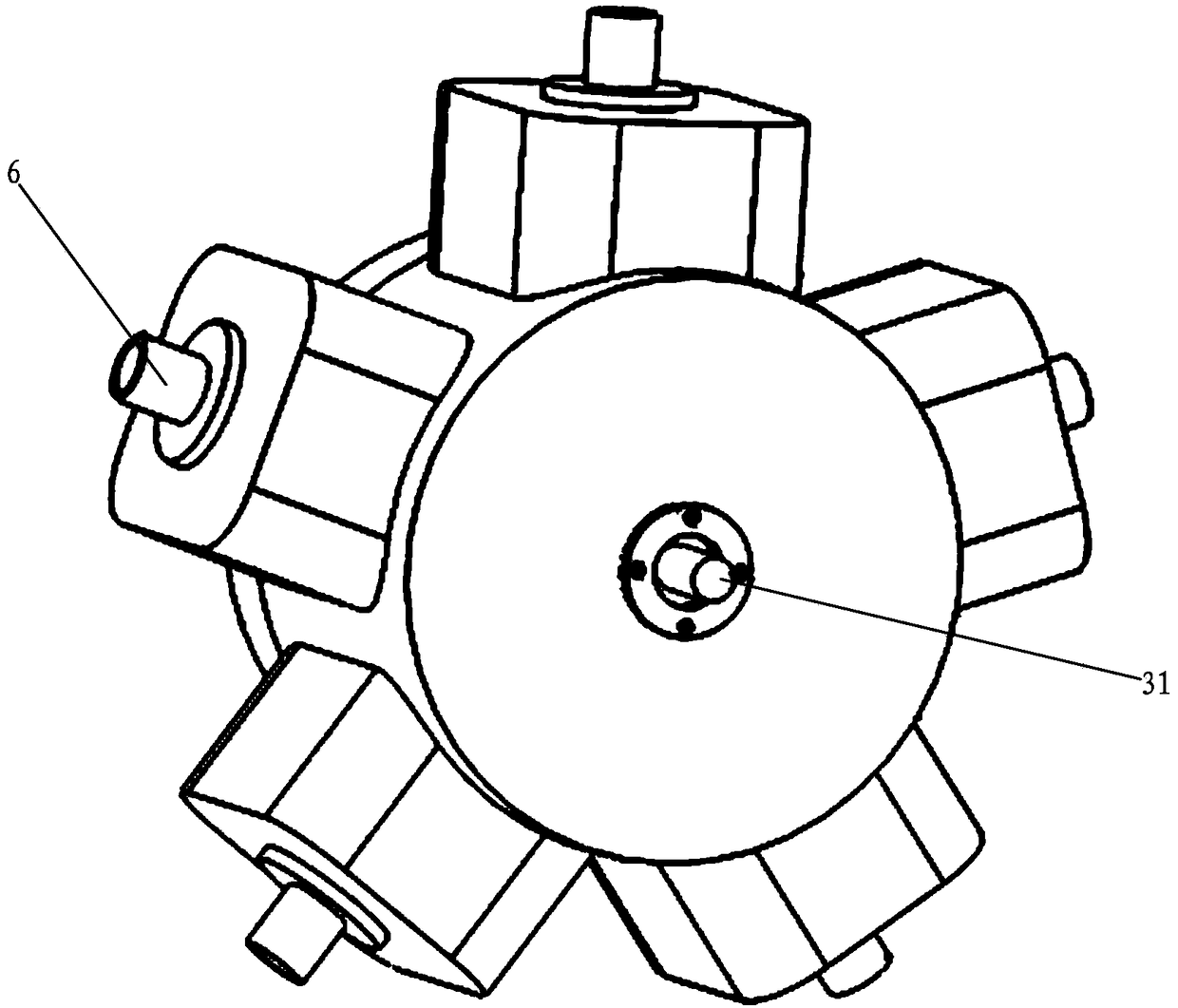

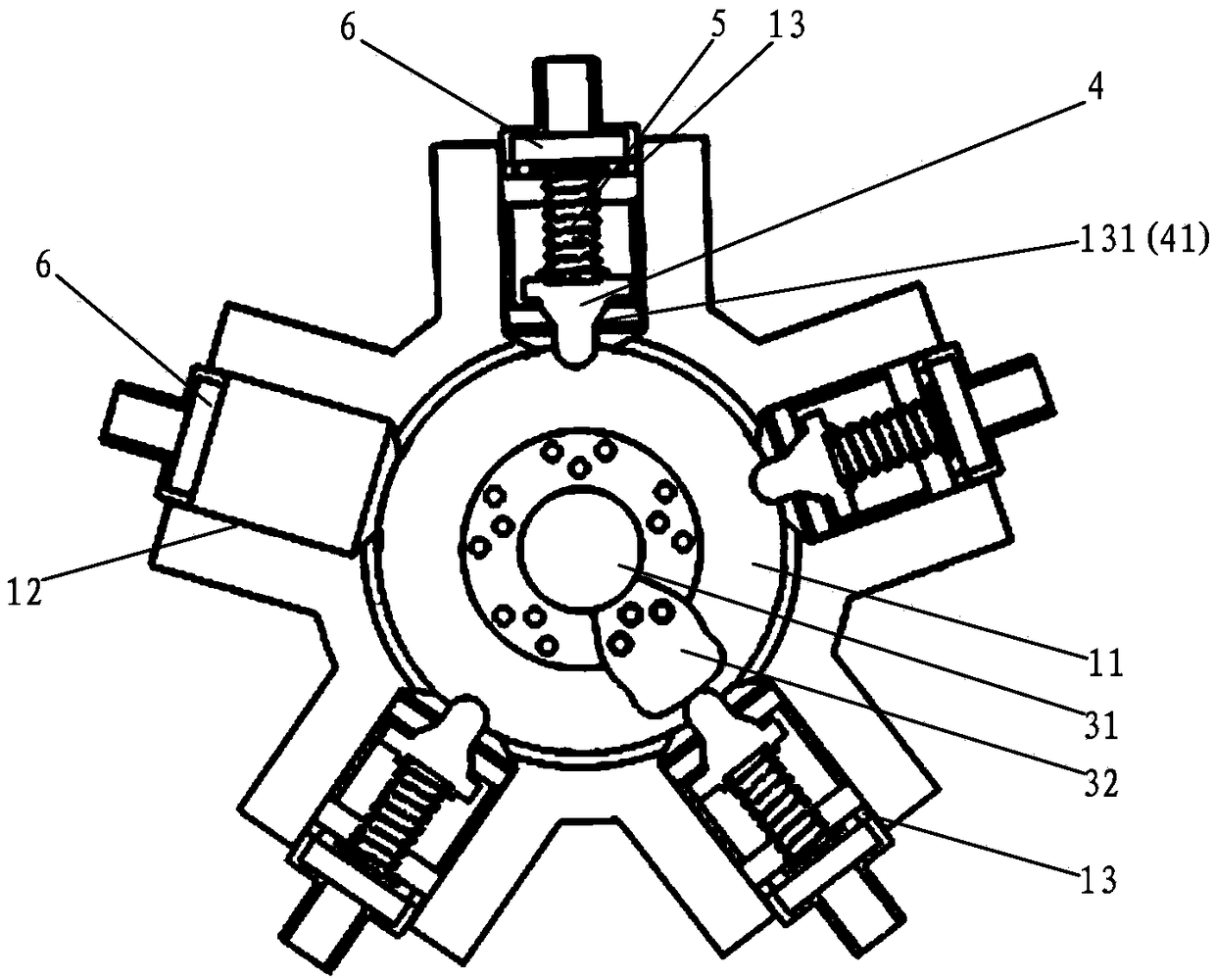

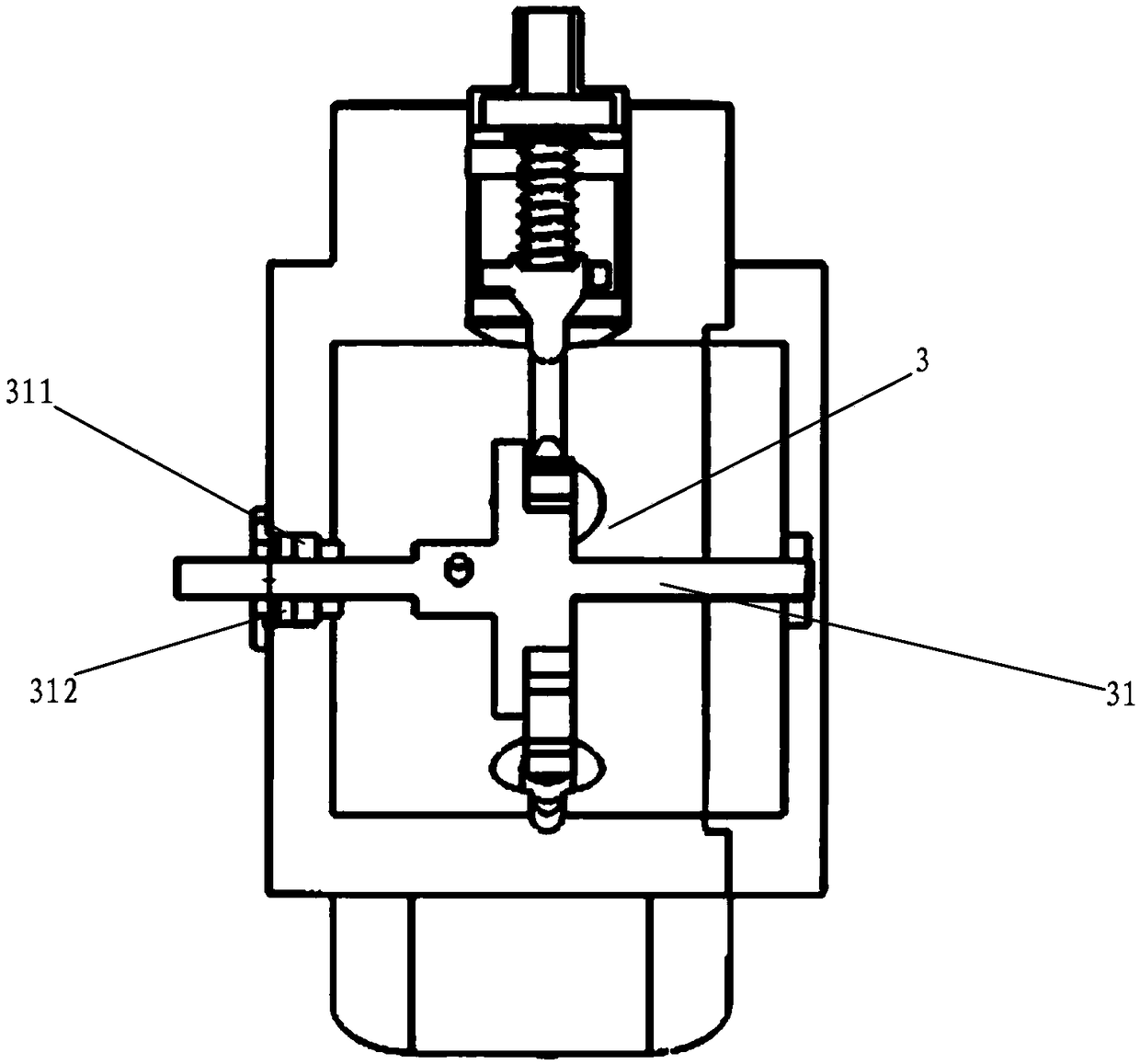

Multi-way rotor control valve

InactiveCN109084050ALow input costSimple control structureOperating means/releasing devices for valvesMultiple way valvesEngineeringCam

The invention discloses a multi-way rotor control valve which comprises a valve body, a valve cover, a rotating mechanism, a valve core, an elastic member and a connecting seat. The valve body is provided with a built-in cavity, and a first through hole and a plurality of second through holes, communicating with the built-in cavity, are formed in the valve body in a circumferential direction; thevalve core is slidably mounted in the second through hole, and the connecting seat is installed at the opening end of the second through hole in a threaded connecting mode; the rotating mechanism includes or rotates a rotating shaft mounted on the valve body, one end of the rotating shaft is fixedly mounted on a rotating shaft cam, when the rotating shaft rotates, the other end of the rotating shaft cam periodically opens the valve core to connect the built-in cavity with the second through hole; the first through hole is a water inlet or a water outlet, and the water outlet or the water inletis formed in the connecting seat to form a one inlet and multiple outlets control valve structure, or a one outlet and multiple inlets control valve structure. According to the multi-way rotor control valve, a function of supplying the multi-channel fluid circuit in turn through a control valve is realized, a control structure is greatly simplified, structure is simple, control is convenient, andthe input cost of hardware is reduced.

Owner:GUANGDONG MECHANICAL & ELECTRICAL COLLEGE

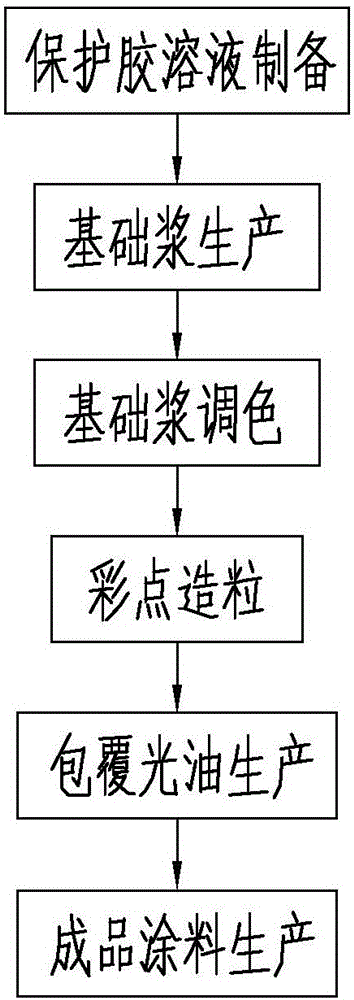

Production method of water-in-water colorful paint containing color sand

ActiveCN105925096ACost-effectiveFast manufacturingAntifouling/underwater paintsPaints with biocidesWeather resistanceSlurry

The invention discloses a production method of water-in-water colorful paint containing color sand. The production method comprises the following steps: (a), preparing a protection glue solution; (b), producing basic slurry; (c), matching the color of the basic slurry; (d), performing color point granulation; (e), producing coating gloss oil; (f), producing finished paint. Granite-shaped particle containing particles are formed on the surface of the paint produced by the method, imitated-marble granite paint can be prepared from the paint, formed patterns are simple, artistic and elegant, and the paint prepared by the method is level in surface and not easy to form ash deposition, can keep the overall appearance longer, and has stain resistance; the special coating gloss oil can keep the color on the surface of the paint to be permanent and fresh, and has weather resistance; the paint is high in water resistance and rot resistance, is neither absorbed by a wall surface nor damaged in rainy days, and can protect the overall shapes of buildings.

Owner:ZHEJIANG KEDA NEW BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com