Method for producing novel high precision optical fiber array

An optical fiber array and manufacturing method technology, which is applied to the coupling of optical waveguides and other directions, can solve the problems of difficulty in grasping the amount of adhesive added to the upper cover plate 22, complex process, difficulty in mass production, etc., and is suitable for mass production. , the process is simple, the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

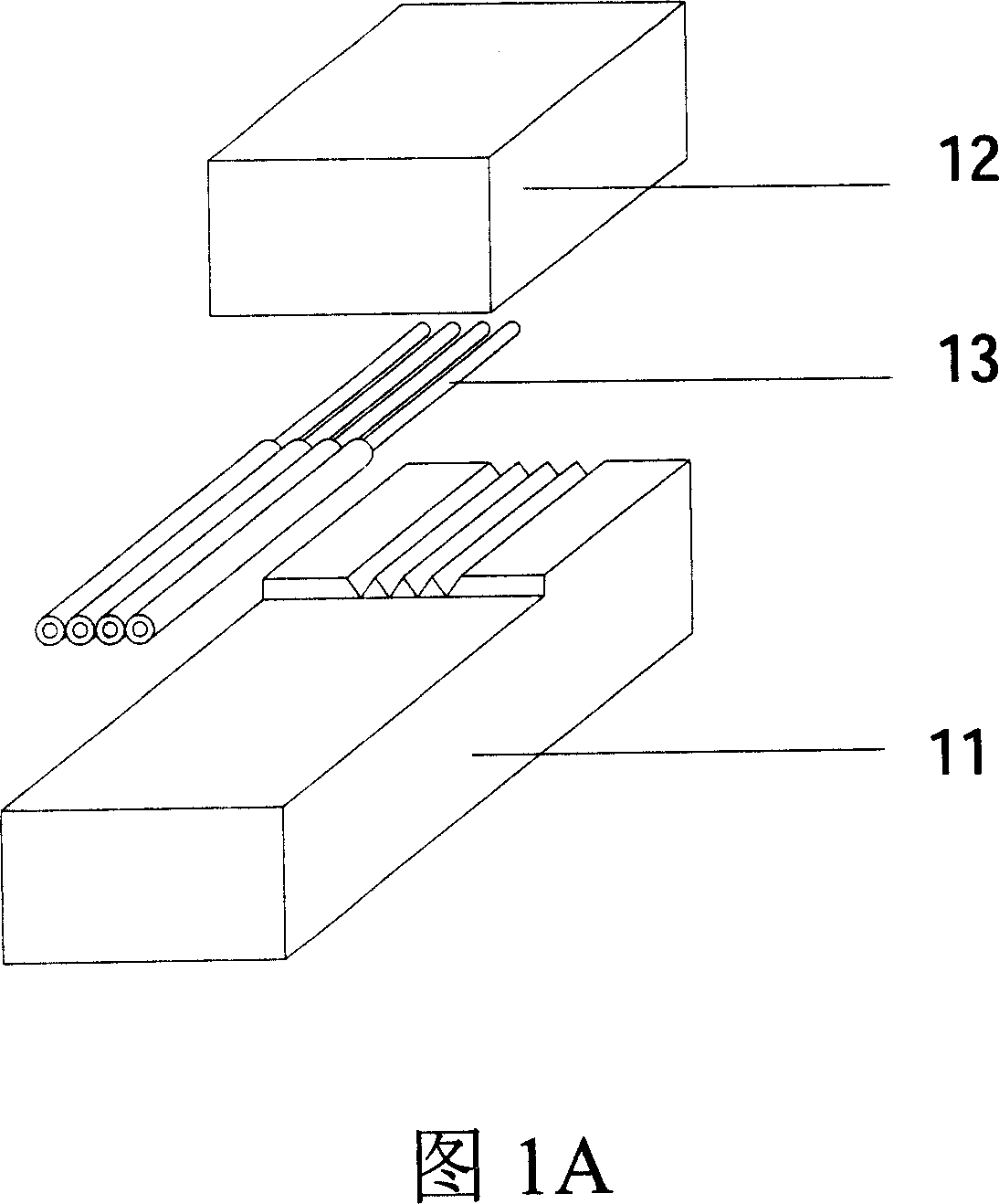

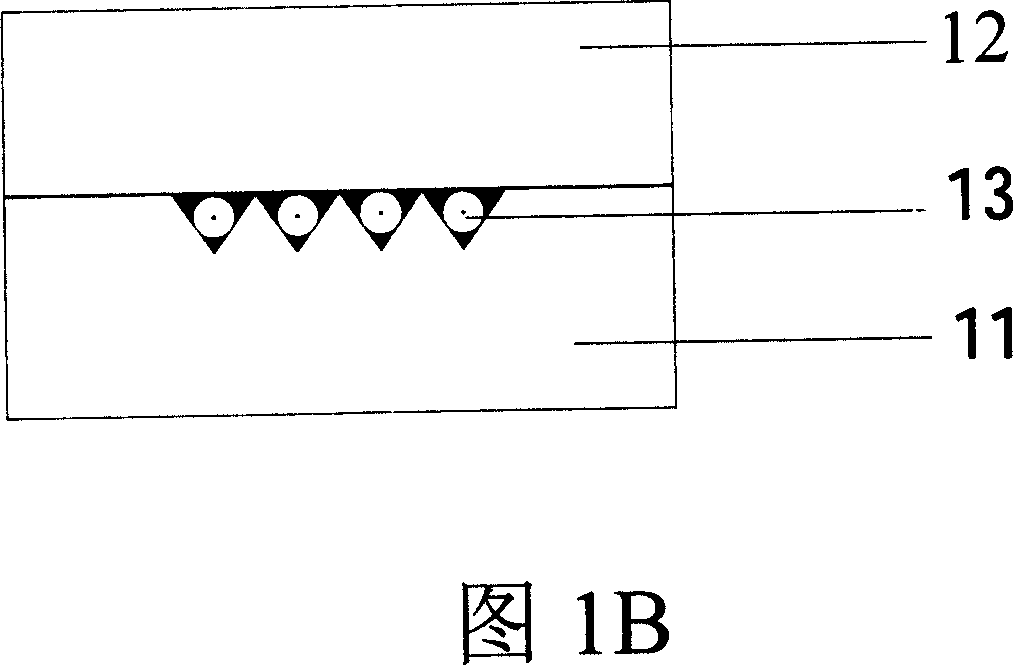

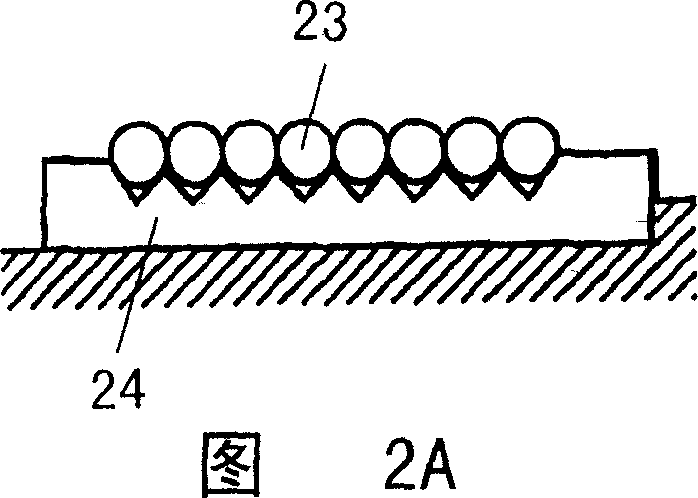

[0022] The current standard specifications for single-mode fiber are: coating diameter of 250 microns, cladding diameter of 125 microns and core diameter of 9 microns. According to the different requirements of the fiber core spacing, there are two standard specifications for the fiber array: 250 microns and 127 microns. Two arrangements are thus produced, please refer to Fig. 3, Fig. 3A shows the situation that the front and rear ends of a kind of optical fiber ribbon are all single layers (corresponding to the situation that the fiber core spacing is 250 microns), Fig. 3B shows a kind of optical fiber front end to go The case where the coating layer is a single layer and the rear end is a double layer (corresponding to the case where the fiber core spacing is 127 μm). Below we describe the method of the present invention based on a single-layer optical fiber ribbon arrangement, but it should be understood that the method of the present invention is also applicable to a doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com