Loose filler structure body for package and connecting bar thereof

A structure and filler technology, which is applied in the field of loose filler structures for packaging and their connecting rows, can solve the problems of loss of impact, small change range of filling space, and reduction of the adaptation range of packaged objects, so as to avoid displacement changes, Guaranteed effective fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

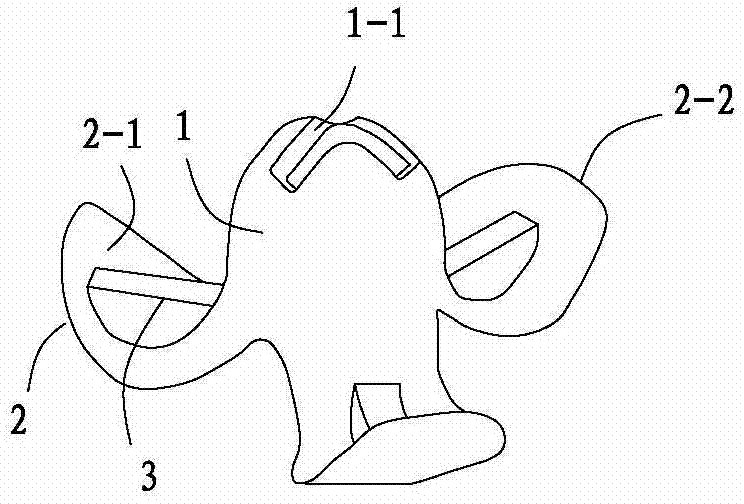

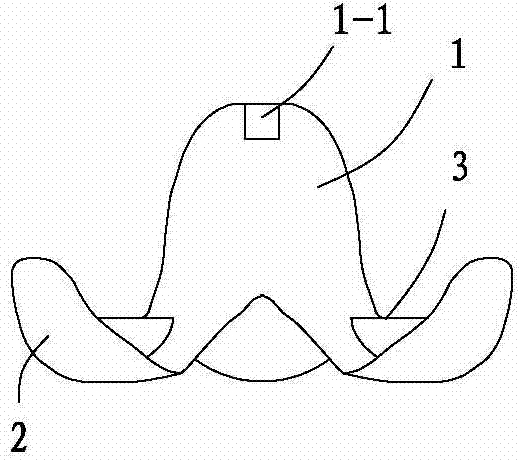

[0023] A kind of packaging loose-fill structure embodiment, see Figure 1 to Figure 3 , the filler structure includes a semi-arc-shaped shell 1, along the outside of the semi-arc-shaped shell, along the bottom, outward and upward, there are a plurality of curved wings 2 composed of space curved surfaces 2-1, so A rib-shaped protrusion 3 is provided on one side of the curved surface of the wing, and a groove 1-1 is provided on the top of the semi-arc-shaped shell.

[0024] The curled wing-like structure forms a "hook" shape, which makes the loose-fill structure generate hook chain nesting effect between materials during random filling, avoiding the migration of packaged products caused by the movement between loose-fill materials, and obtaining reliable The buffer protection function.

[0025] In order to obtain the best hook chain effect, the unfolded shape of the curved wings is a gourd shape with a narrow front and a wide rear, and the end surface 2-2 is a circular arc. The...

Embodiment 2

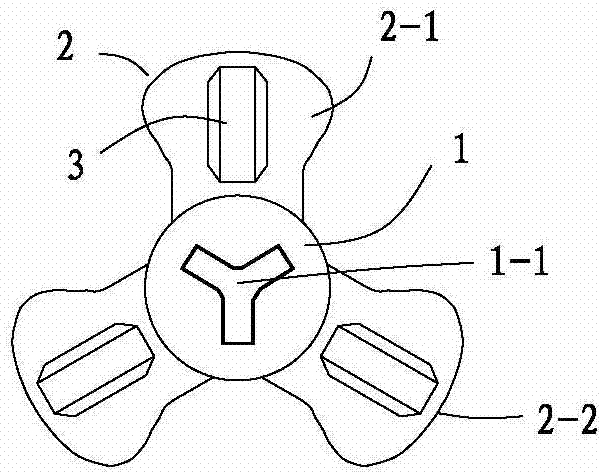

[0031] A kind of embodiment of connecting row of loose packing structure for packaging, see Figure 4 And embodiment 1, the connecting row is composed of a plurality of loose-fill structures for packaging according to embodiment 1 arranged along a plane, and the loose-fill structures for packaging include a semicircle-shaped shell, along a semicircle The arc-shaped shell is extended outward and upward along the bottom with a plurality of curved wings made of space curved surfaces 2-1. One side of the curved surface of the wings is provided with rib-shaped protrusions. The top of the arc-shaped shell is provided with a groove.

[0032]There are three curved wings extending upward along the bottom of the semi-circular arc-shaped shell, and the three curved wings are arranged at an angle of 120 degrees around the semi-circular arc-shaped shell; The unfolded shape is a gourd shape with a narrow front and a wide rear, and an arc-shaped end face. The upward bending radius of curvat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com