Hydraulic synchronous lifting crane for low-altitude building

A hydraulic synchronization, crane technology, applied in the direction of lifting frame, lifting device, etc., to achieve high-precision adjustment, avoid displacement changes, and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

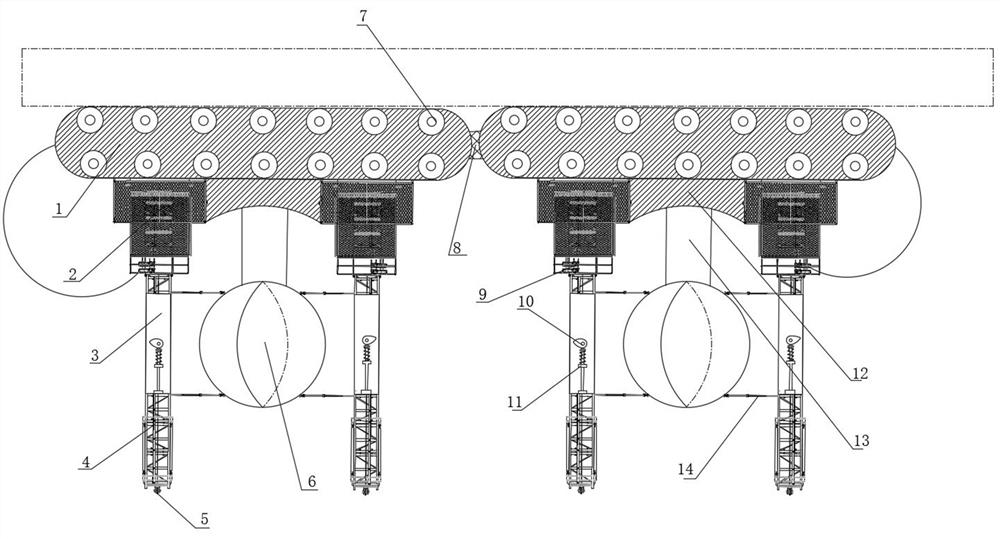

[0025] Please refer to the attached figure 1 , this embodiment provides a low-altitude building hydraulic synchronous lift crane, the low-altitude building hydraulic synchronous lift crane is mainly used to solve the need for multi-angle lifting when the cranes in the prior art cannot solve the lifting of building materials in a small space For the problem of transportation, the low-altitude building hydraulic synchronous lift crane is already in the actual use stage.

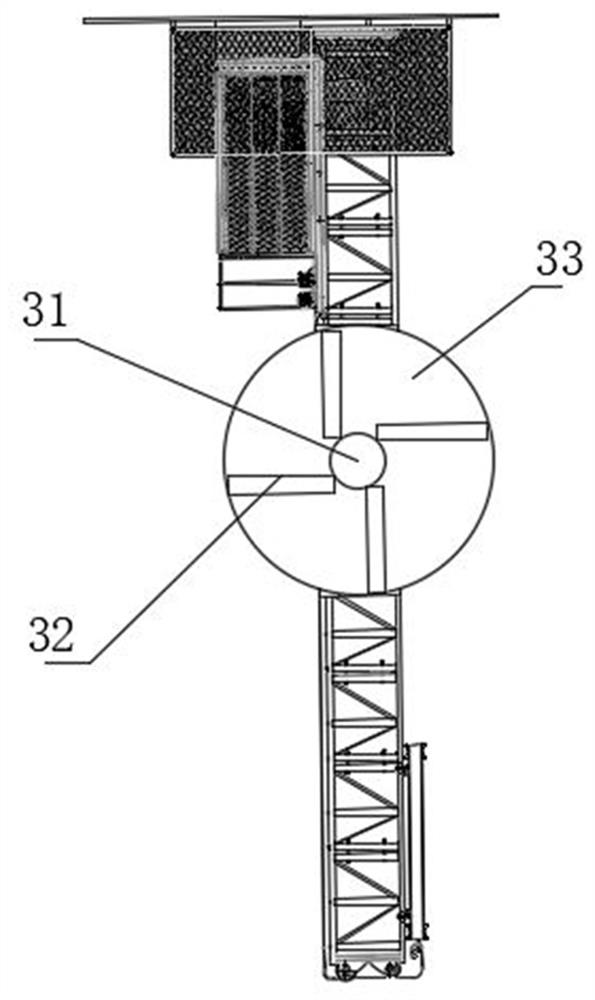

[0026] Such as figure 1 with figure 2 As shown, a low-altitude construction hydraulic synchronous lifting crane includes a device body, and a first lifting machine and a second lifting machine are detachably connected to the device body through a fixed block 8; the first lifting machine and the A flexible positioning plate 1 for carrying objects to be installed, a lifting component, and an adjustment component are fixedly arranged in the second lifting machine from top to bottom; a plurality of magnetic rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com