Patents

Literature

691 results about "Drill bushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A drill bushing, also known as a jig bushing, is a tool used in metalworking jigs to guide cutting tools, most commonly drill bits. Other tools that are commonly used in a drill bushing include counterbores, countersinks, and reamers. They are designed to guide, position, and support the cutting tool.

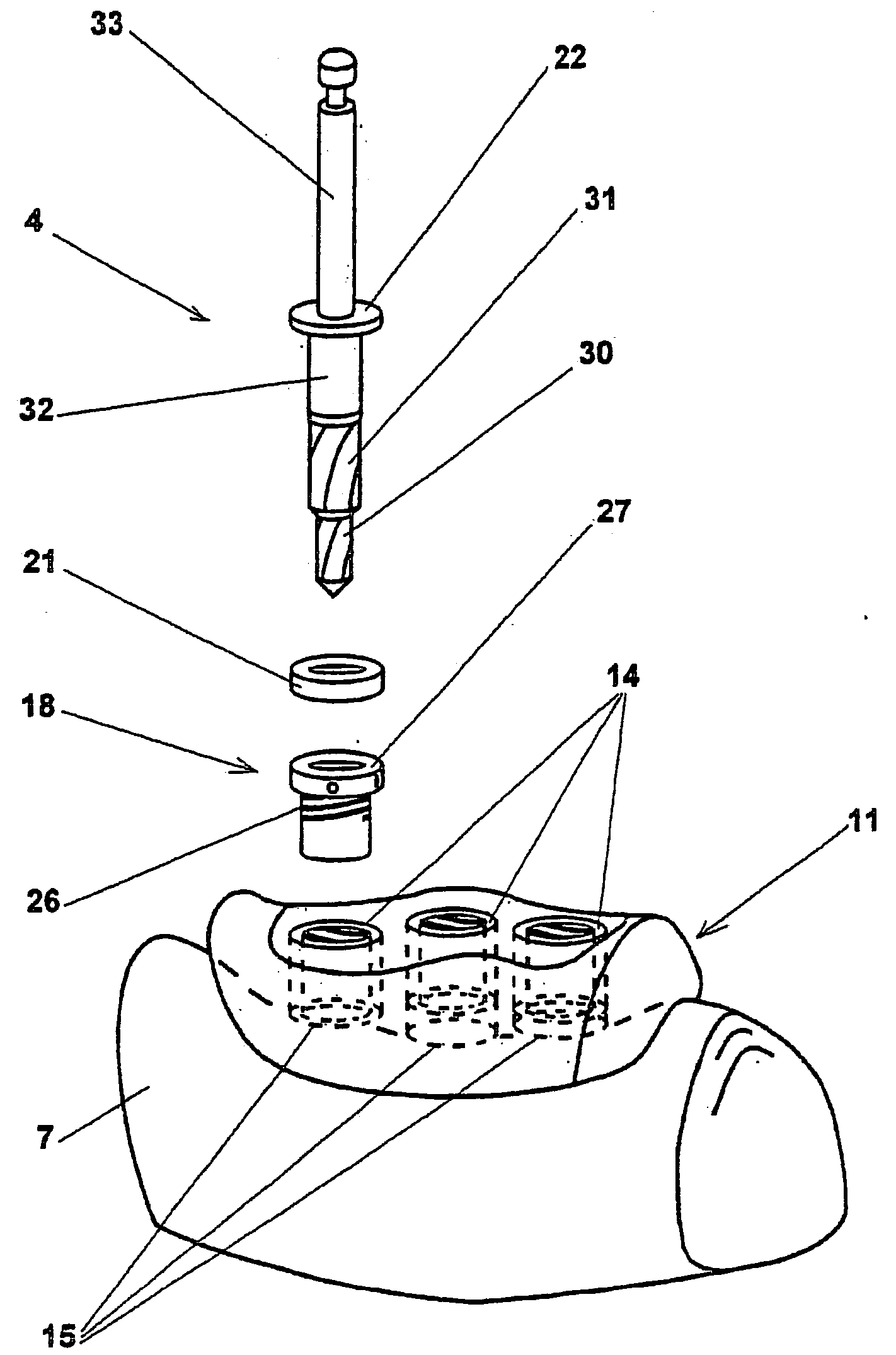

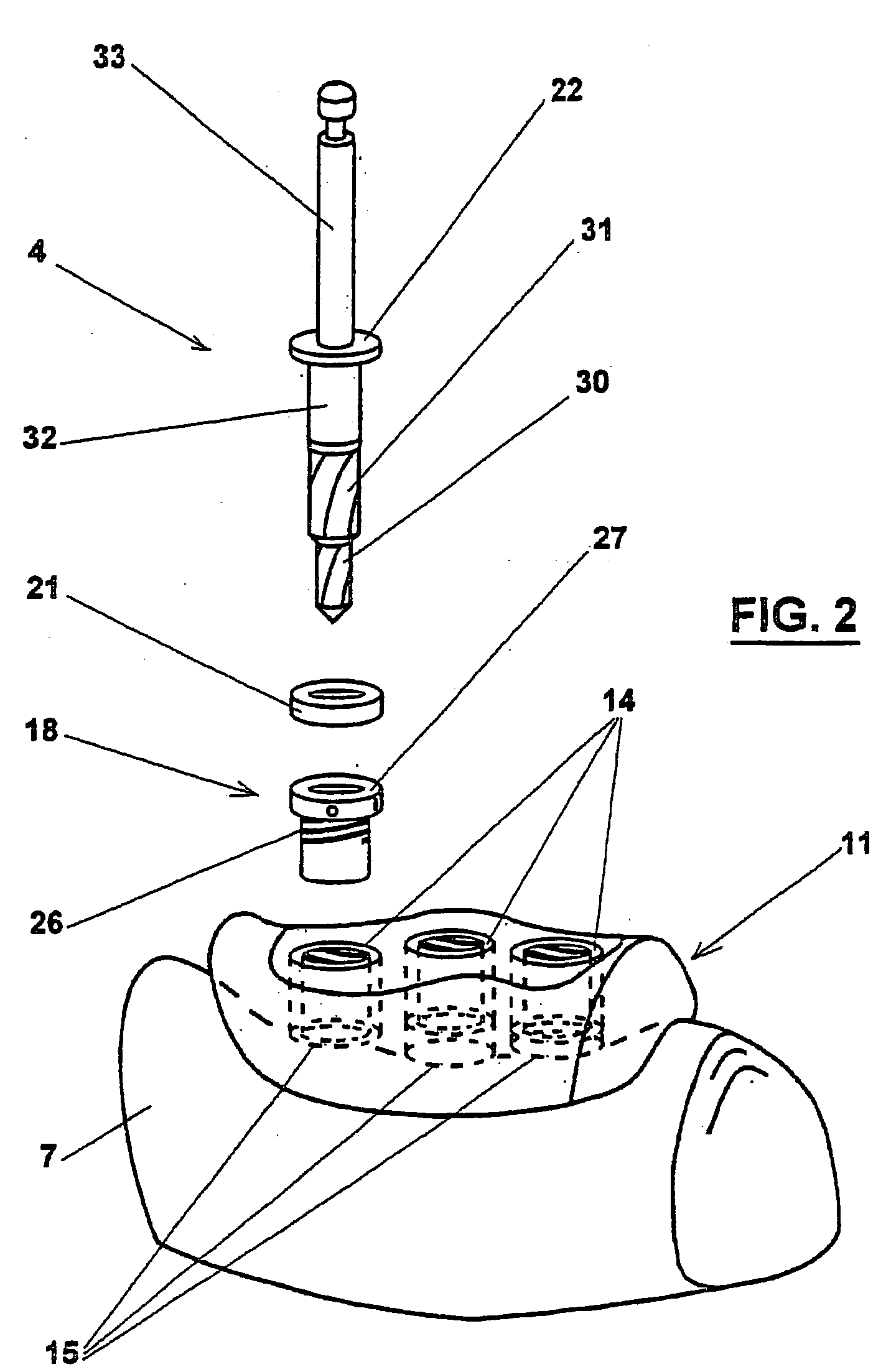

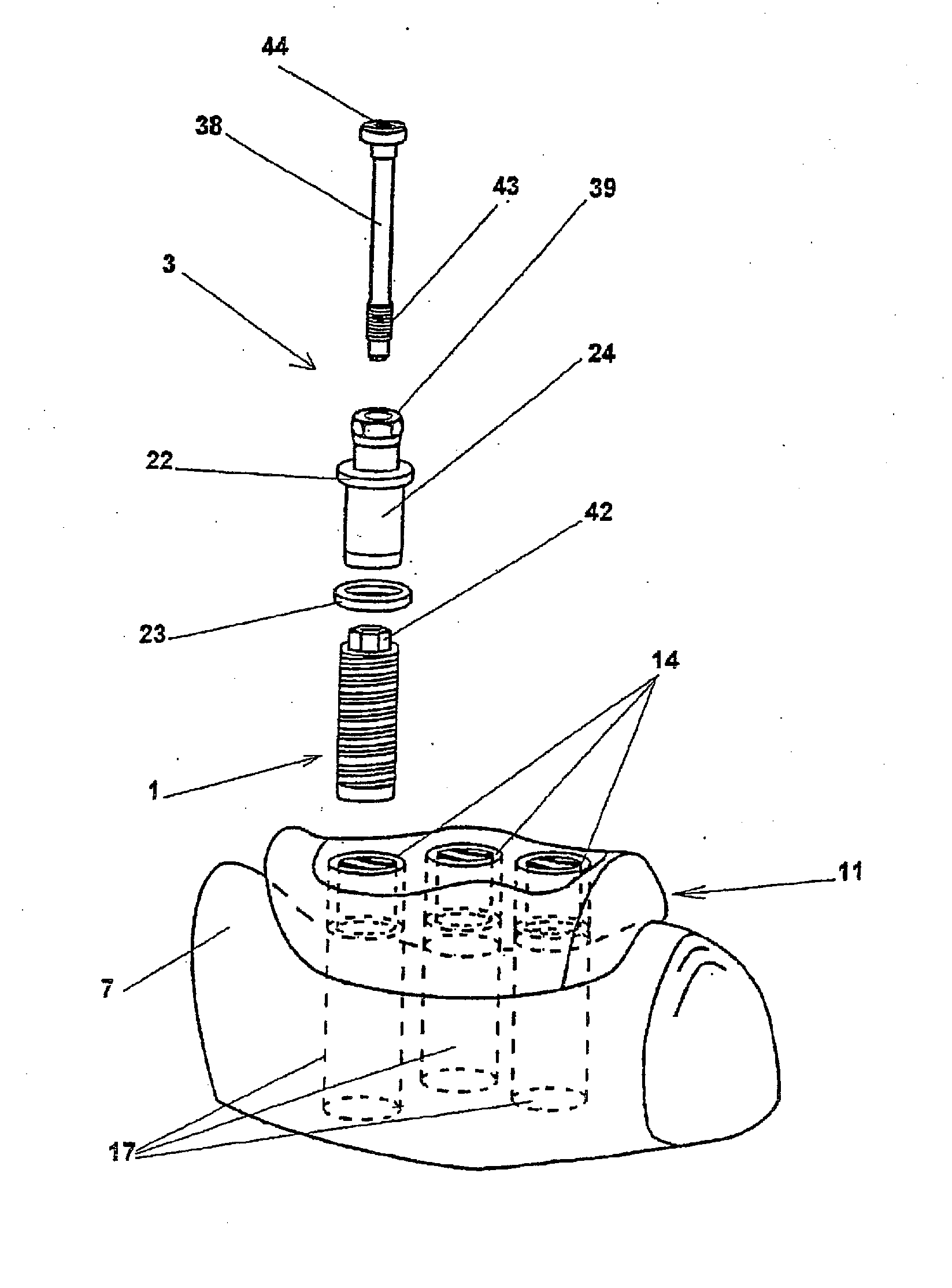

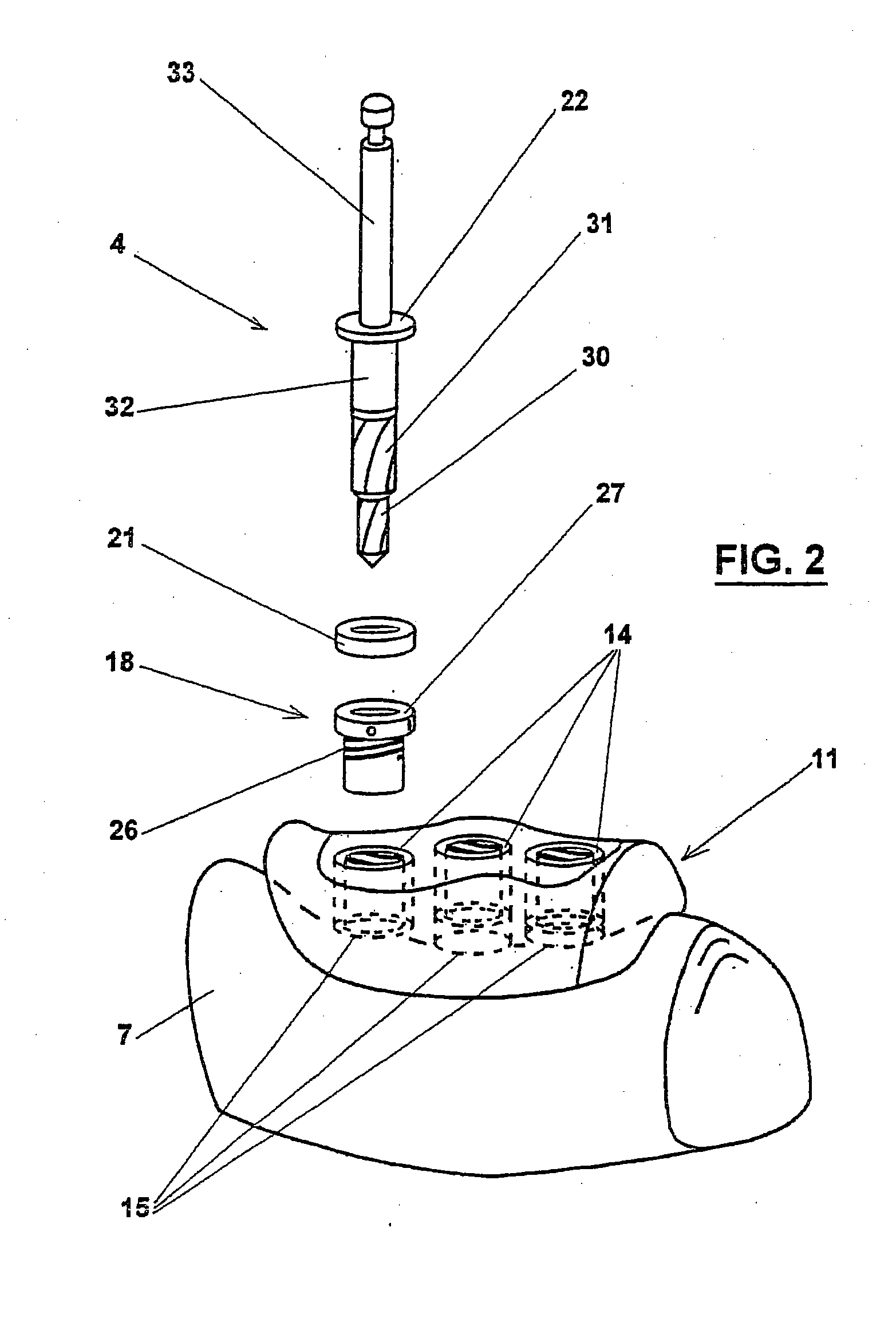

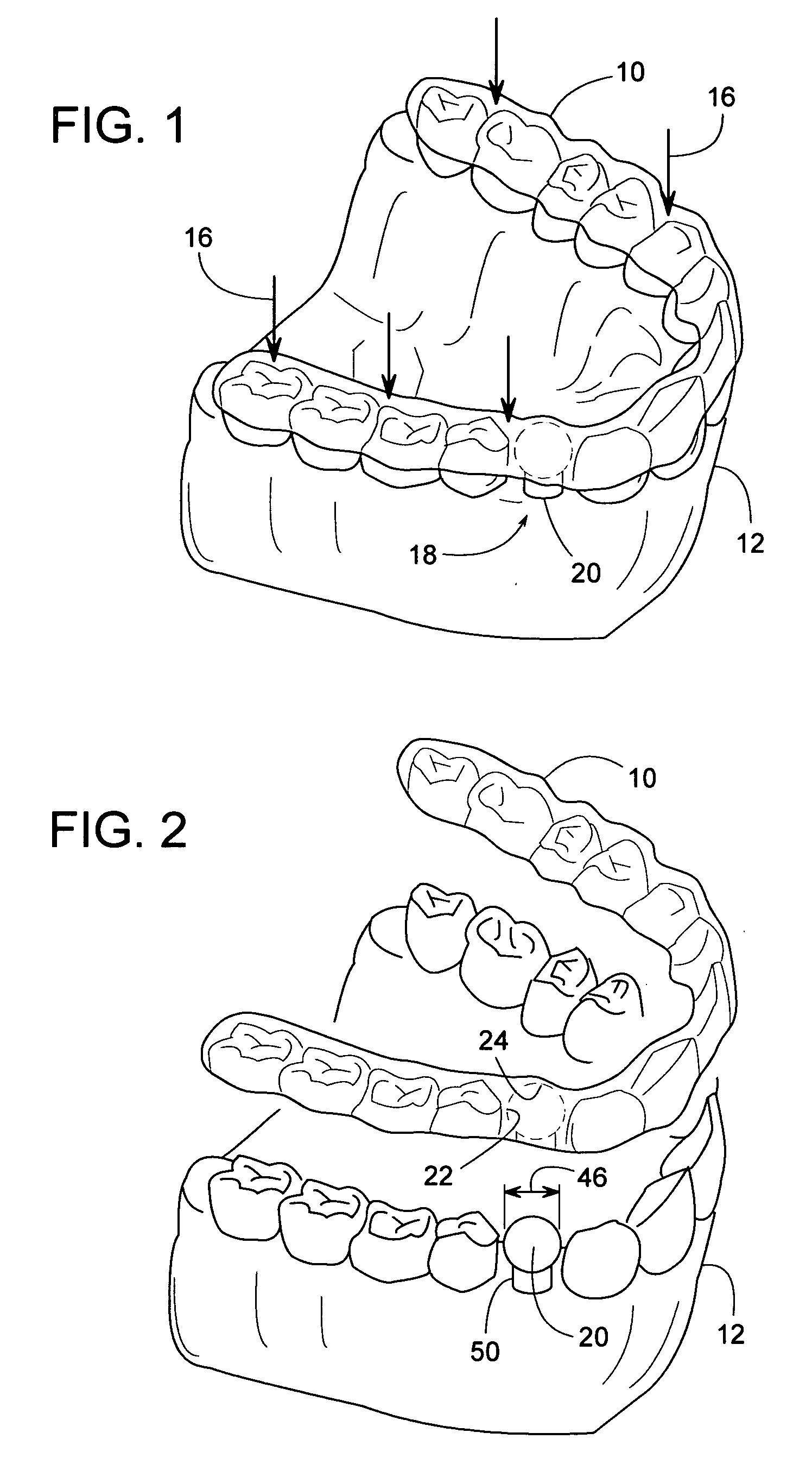

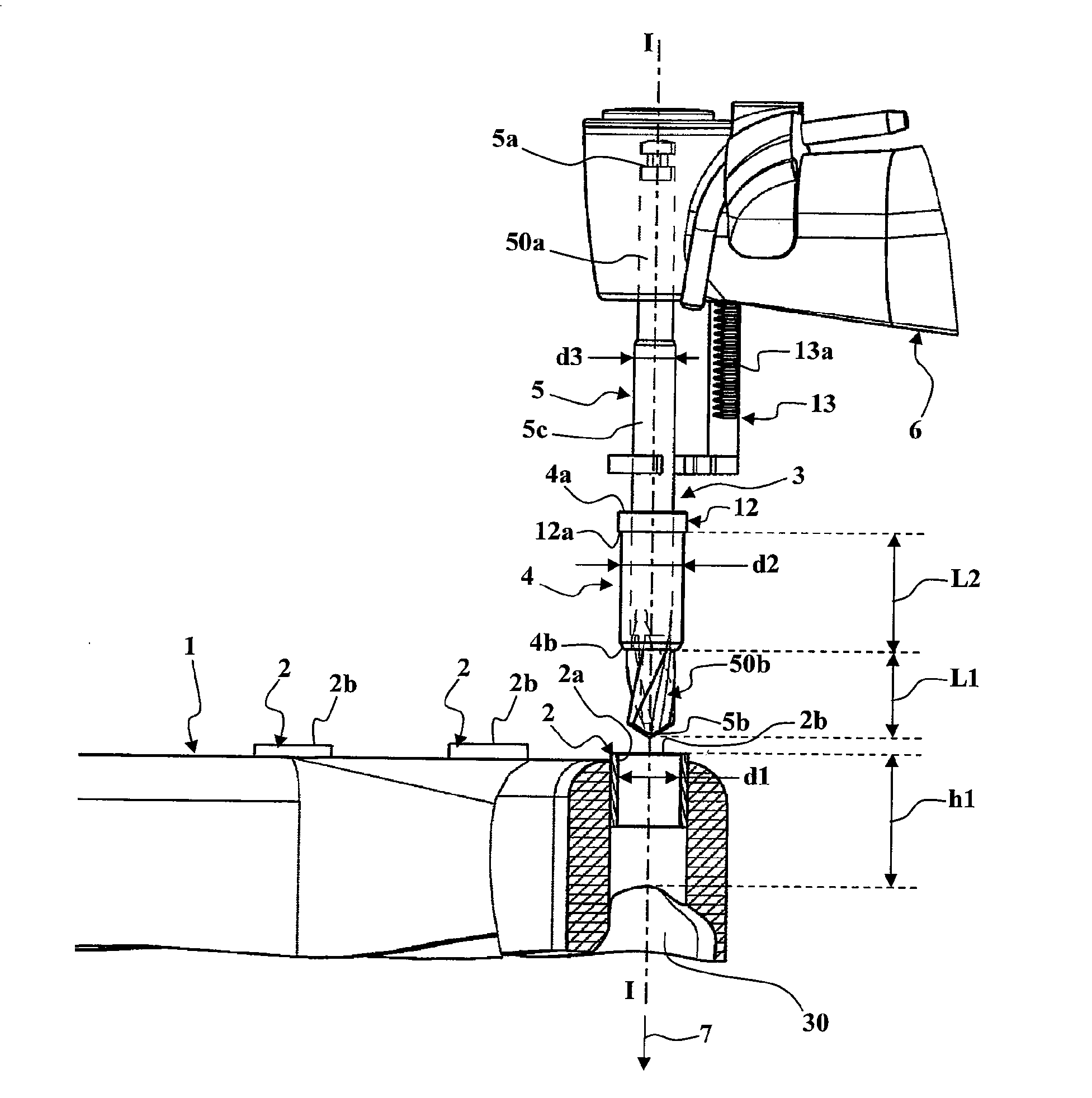

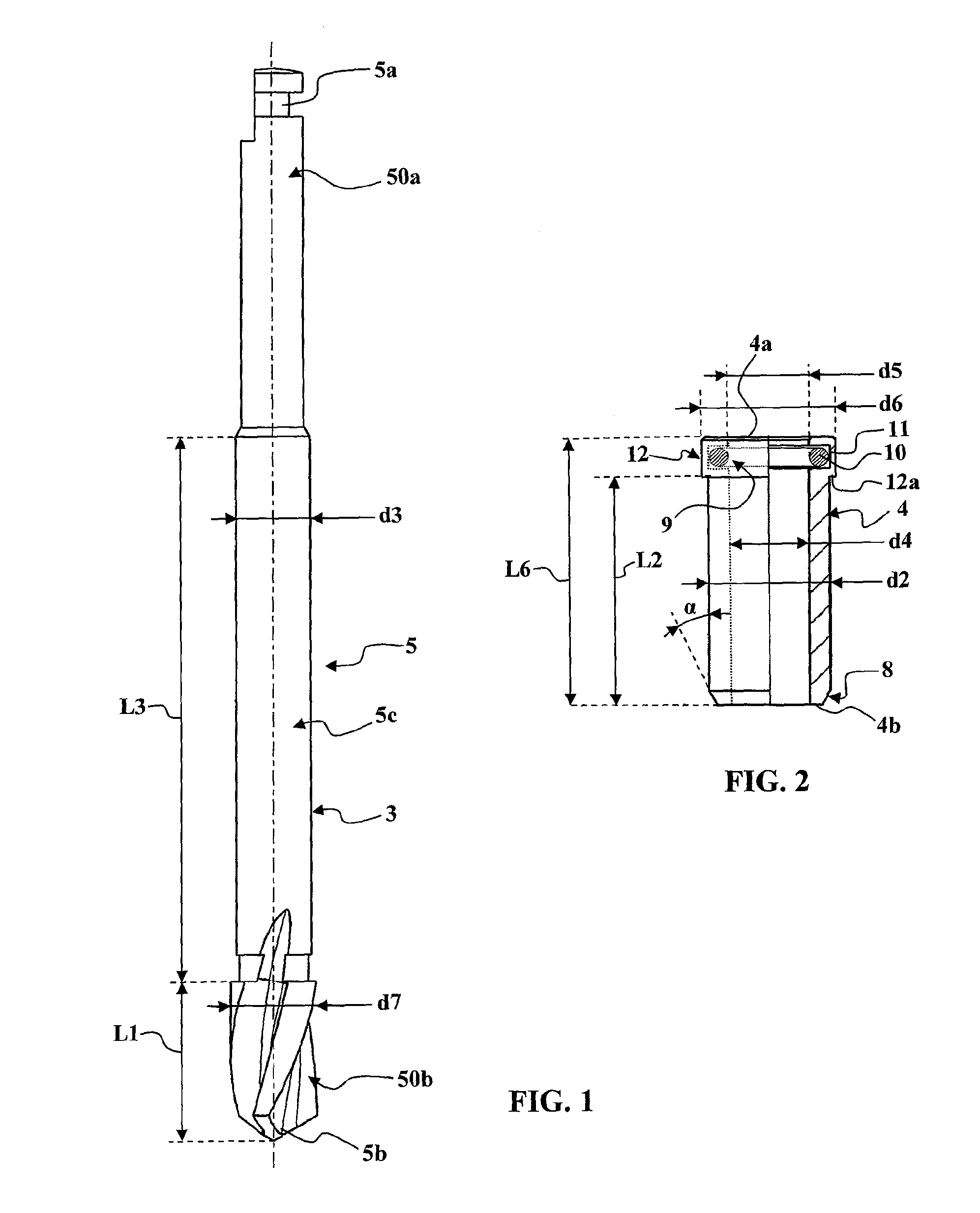

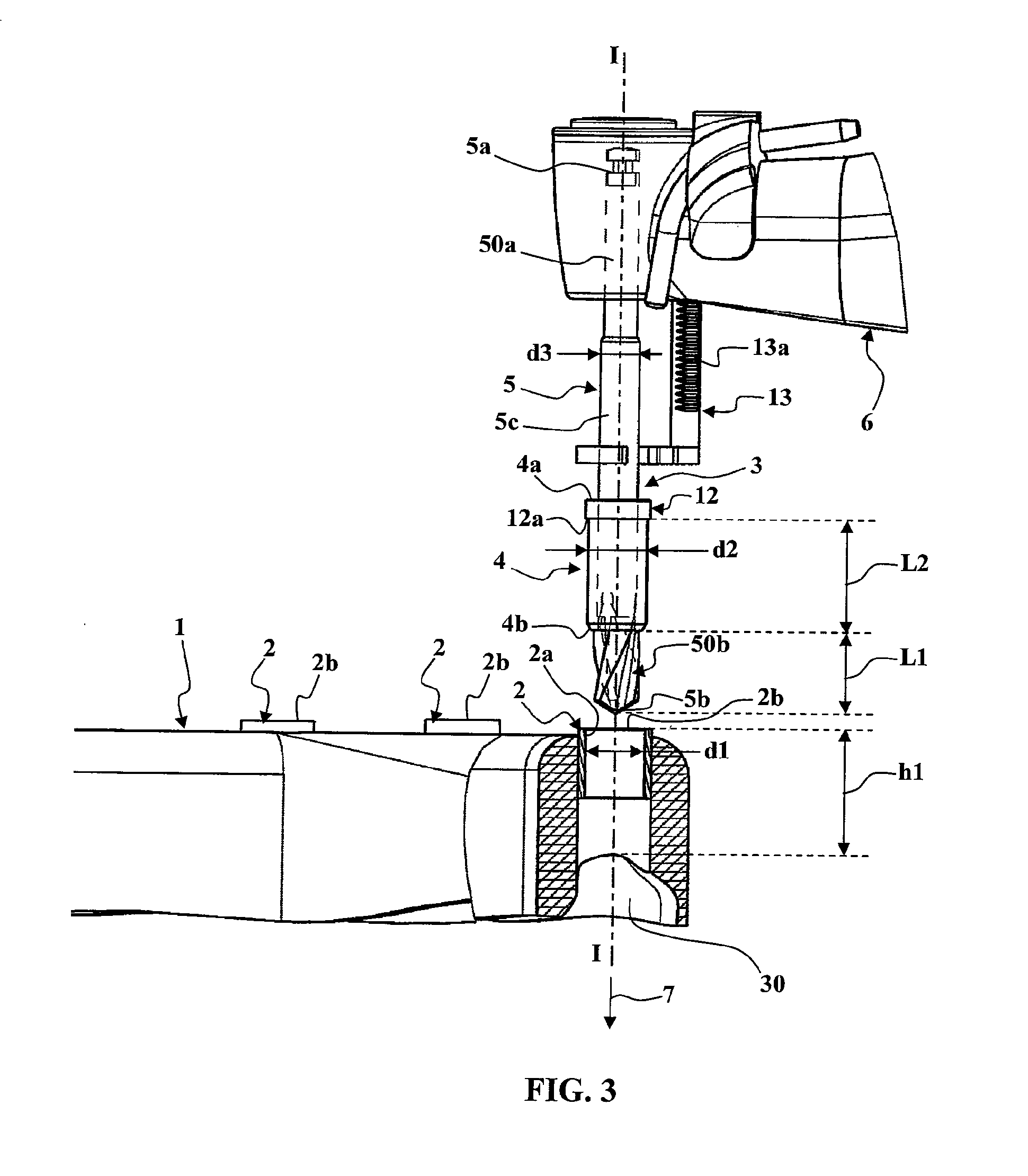

Method and device for placing dental implants

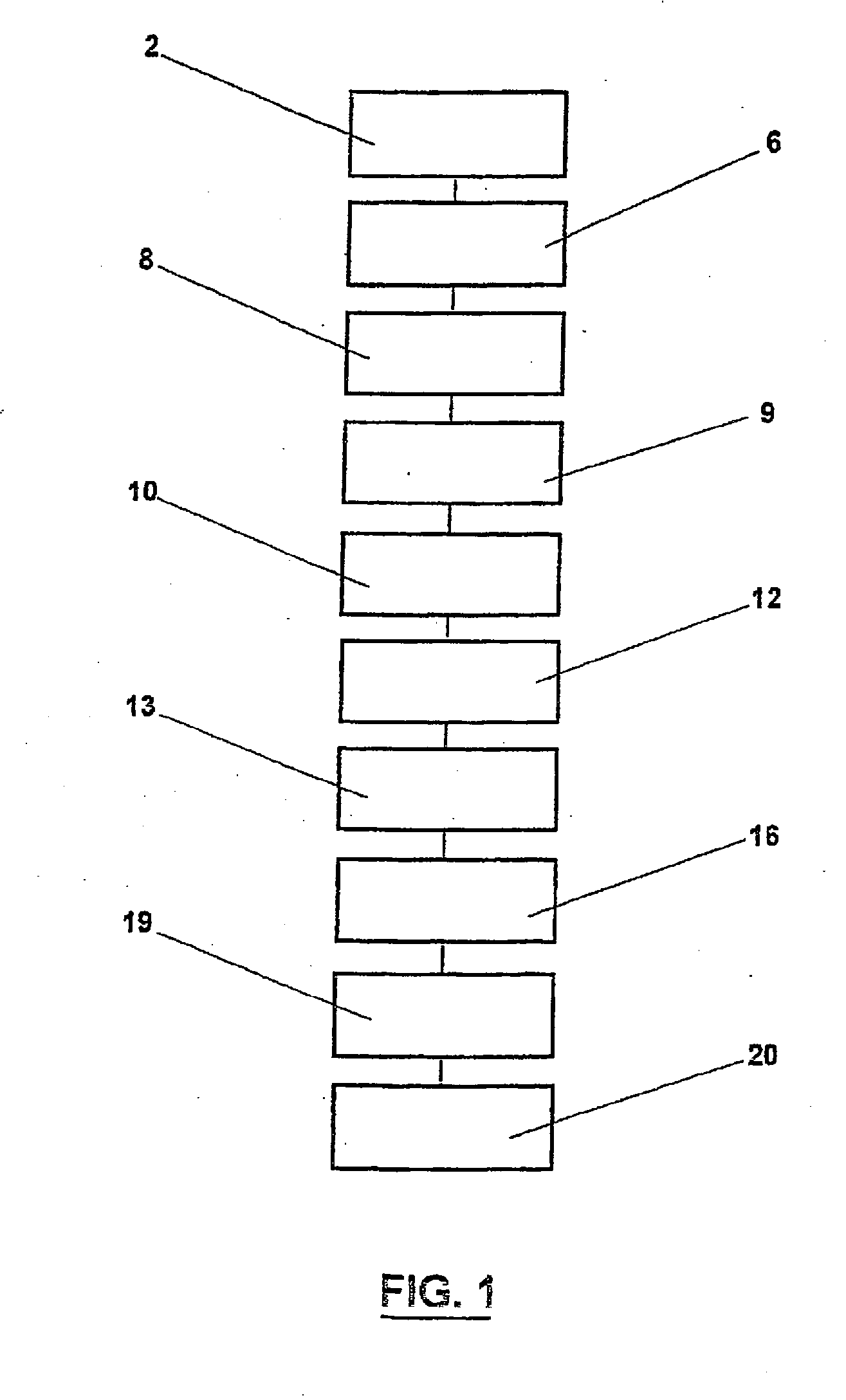

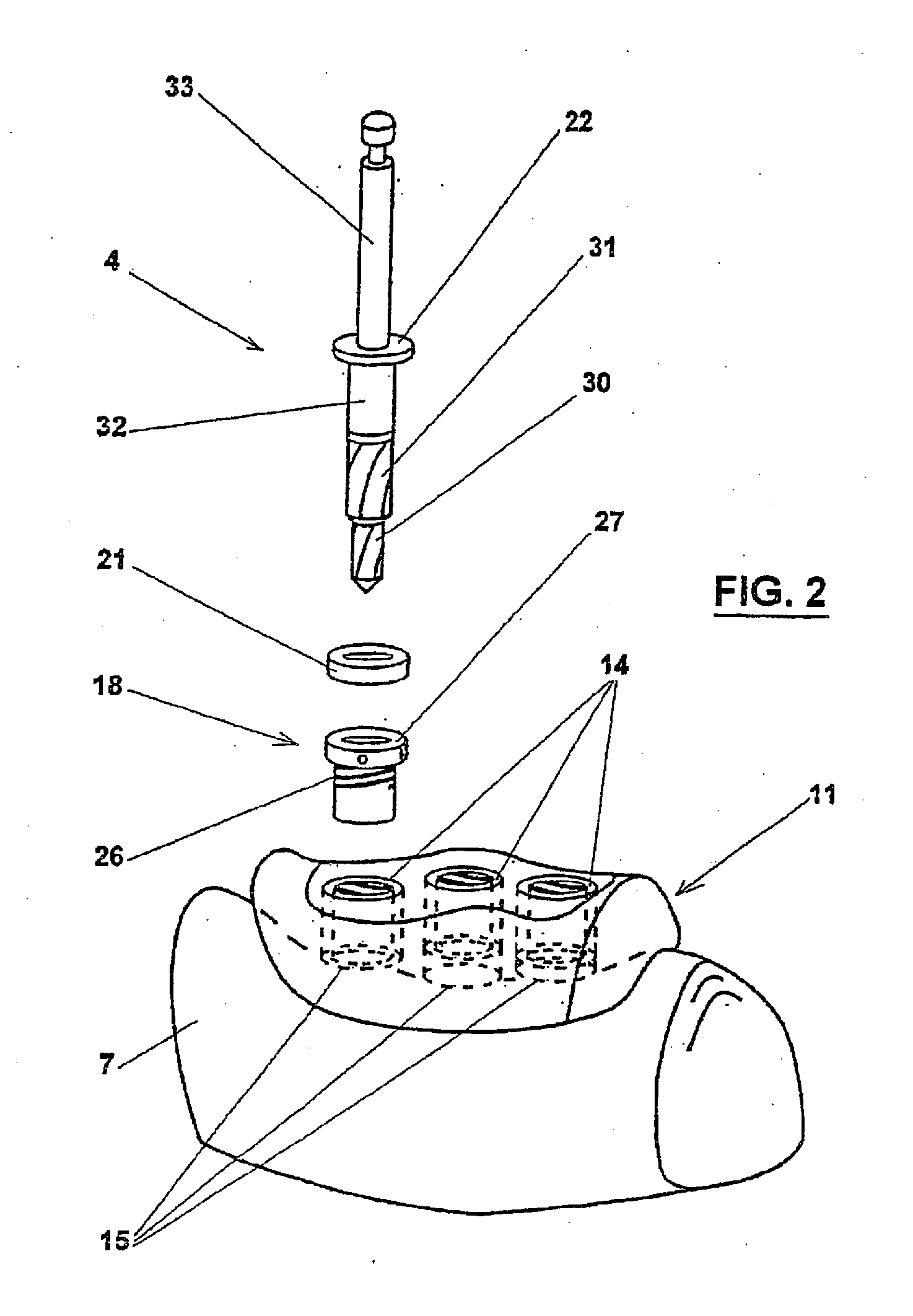

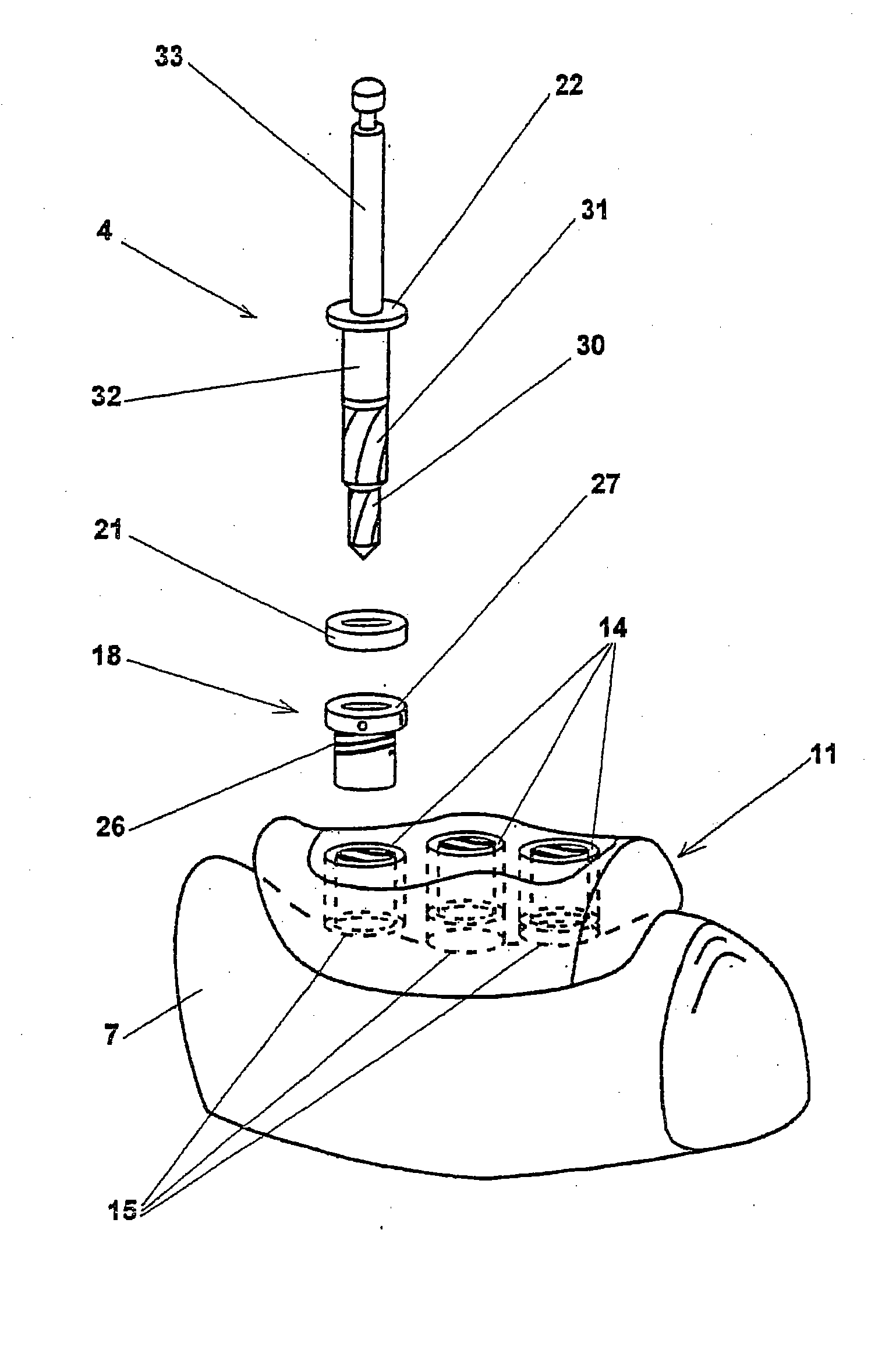

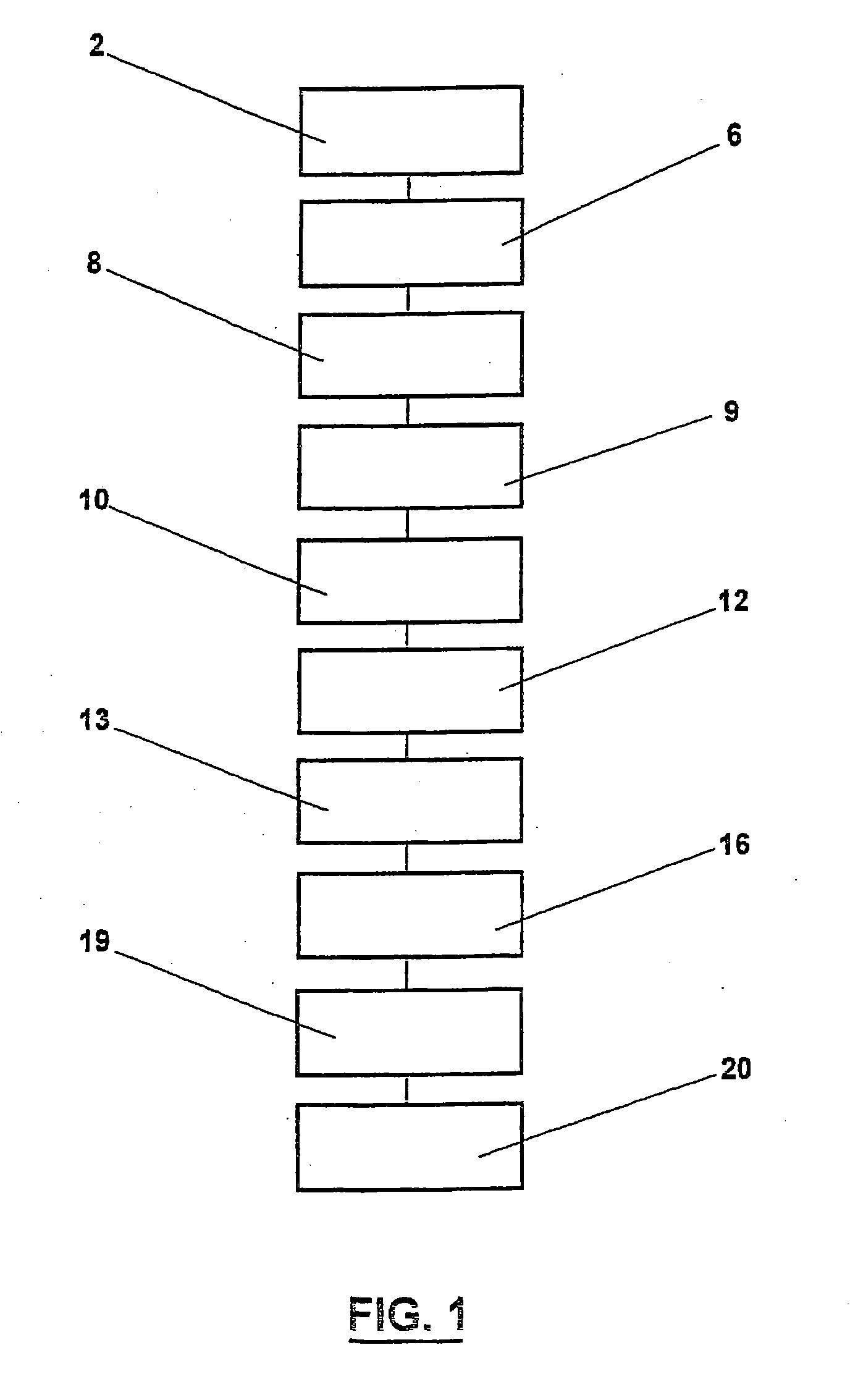

The invention relates to a method and device for placing implants (1) using a surgical template (11) which is made from tomographic cuts in the patient's jawbone (7). According to the invention, step drills (4) and calibrating drills (5), having a single standard diameter for each type of implant (1), are guided through drill bushings (18) which are inserted into bores (15) in the template (11) in order to produce any drilling sequence corresponding to an implant plan. The penetration depth of the drills (4, 5) is controlled by the height of the bores (15) or by the drill rings (21). The aforementioned template (11) bores (15) serve as a guide for the precise placement of the implants (1) owing to the adapted implant supports (3). Moreover, washers (23), which are mounted around the implant supports (3), limit compression in relation to the implants (1) while said implants are being placed (20). The above-mentioned characteristics serve to limit the required number of drills (4, 5) and implant supports (3) to the longest models only. The inventive method and device are particularly suitable for computer-assisted implantology systems.

Owner:MATERIALISE DENTAL NV

Method and device for placing dental implants

The invention relates to a method and device for placing implants using a surgical template which is made from tomographic cuts in the patient's jawbone. Step drills and calibrating drills, having a single standard diameter for each type of implant, are guided through drill bushings which are inserted into bores in the template in order to produce any drilling sequence corresponding to an implant plan. The penetration depth of the drills is controlled by the height of the bores or by the drill rings. The method limits the required number of drills and implant supports to the longest models only. The inventive method and device are particularly suitable for computer-assisted implantology systems.

Owner:DENTSPLY IMPLANTS NV

Method and device for placing dental implants

The invention relates to a method and device for placing implants (1) using a surgical template (11) which is made from tomographic cuts in the patient's jawbone (7). According to the invention, step drills (4) and calibrating drills (5), having a single standard diameter for each type of implant (1), are guided through drill bushings (18) which are inserted into bores (15) in the template (11) in order to produce any drilling sequence corresponding to an implant plan. The penetration depth of the drills (4, 5) is controlled by the height of the bores (15) or by the drill rings (21). The aforementioned template (11) bores (15) serve as a guide for the precise placement of the implants (1) owing to the adapted implant supports (3). Moreover, washers (23), which are mounted around the implant supports (3), limit compression in relation to the implants (1) while said implants are being placed (20). The above-mentioned characteristics serve to limit the required number of drills (4, 5) and implant supports (3) to the longest models only. The inventive method and device are particularly suitable for computer-assisted implantology systems.

Owner:MATERIALISE DENTAL NV

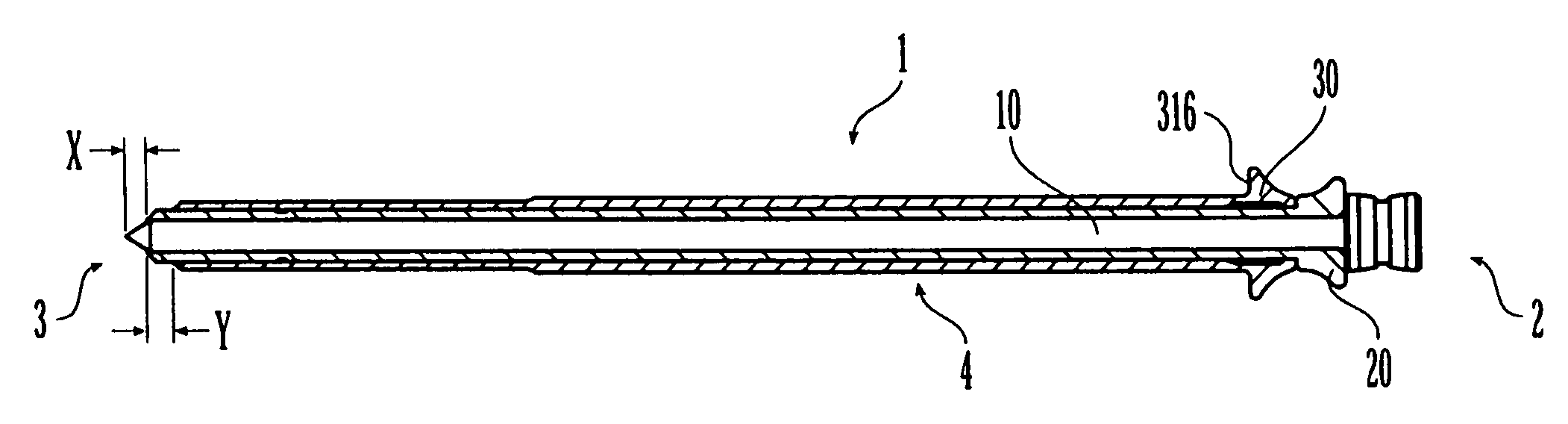

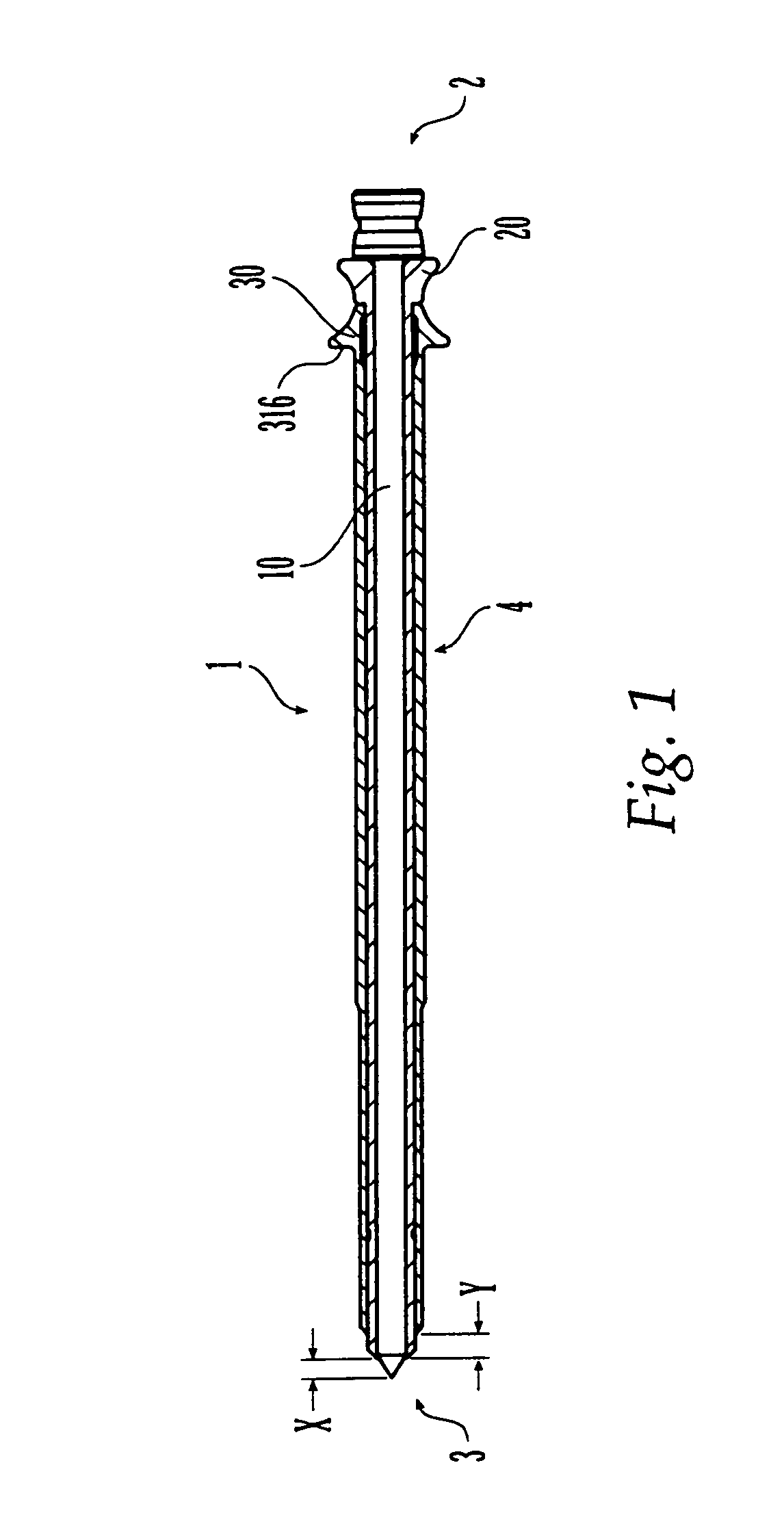

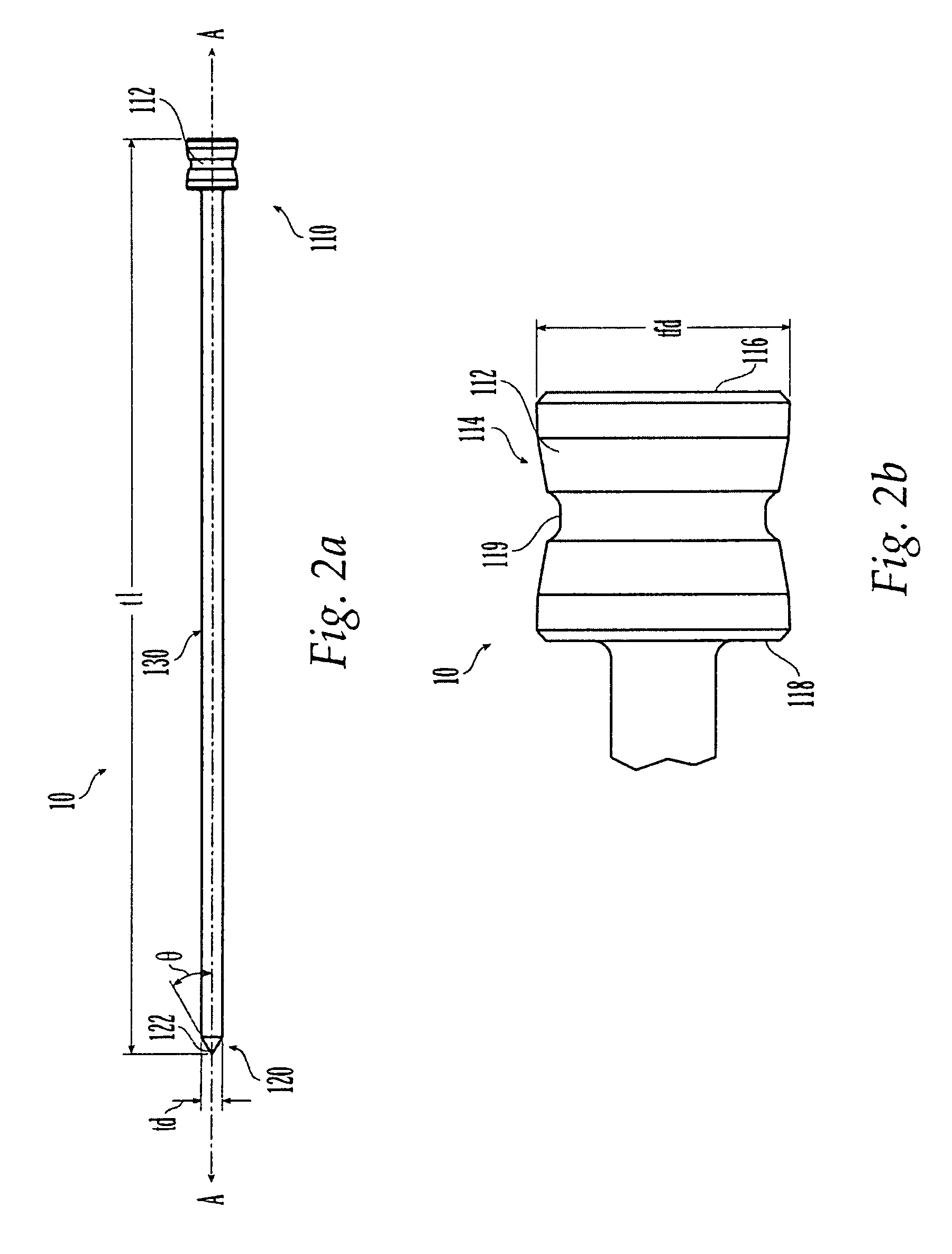

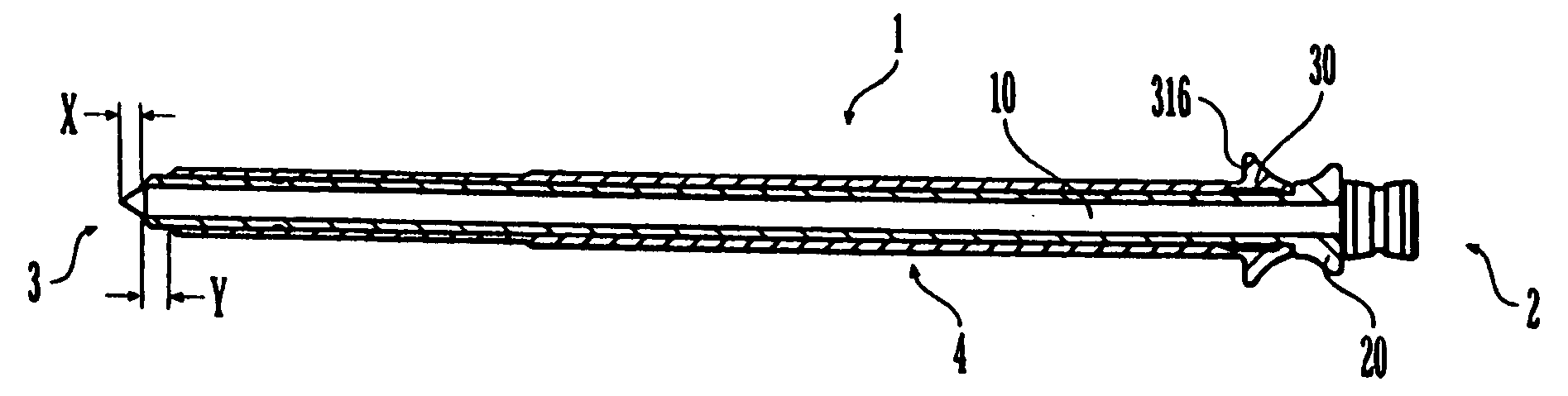

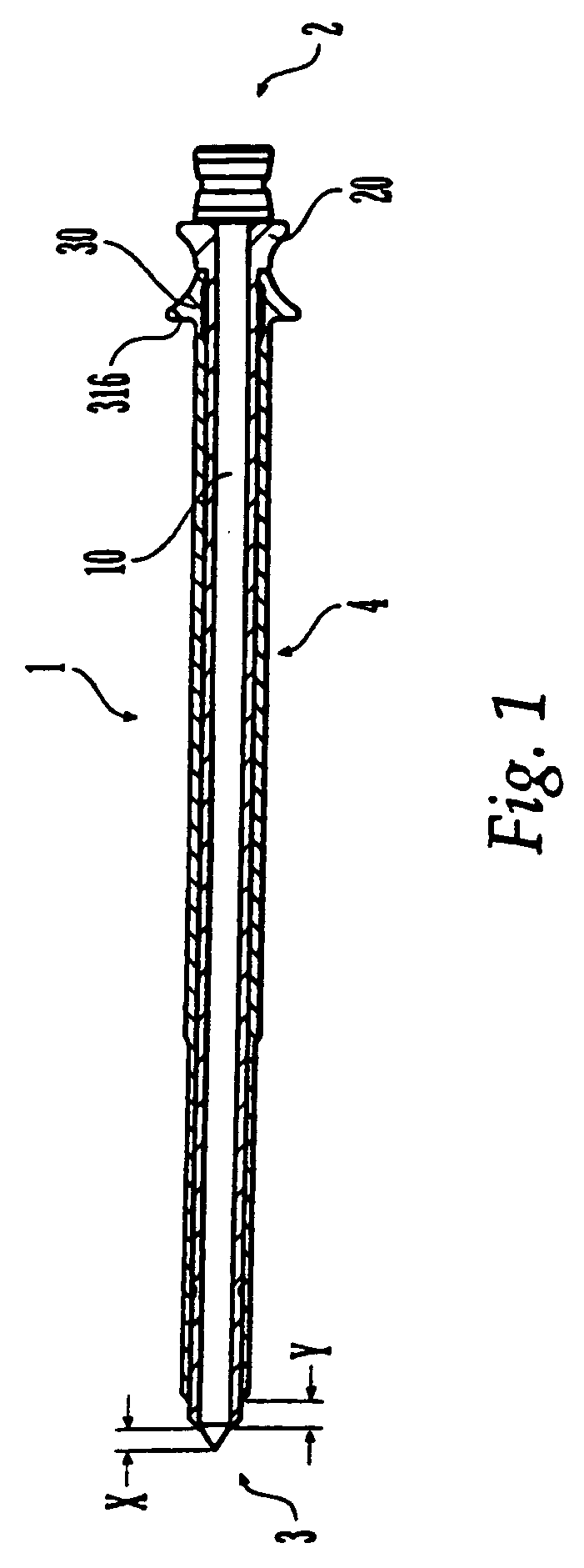

Snap-lock for drill sleeve

Owner:SYNTHES USA

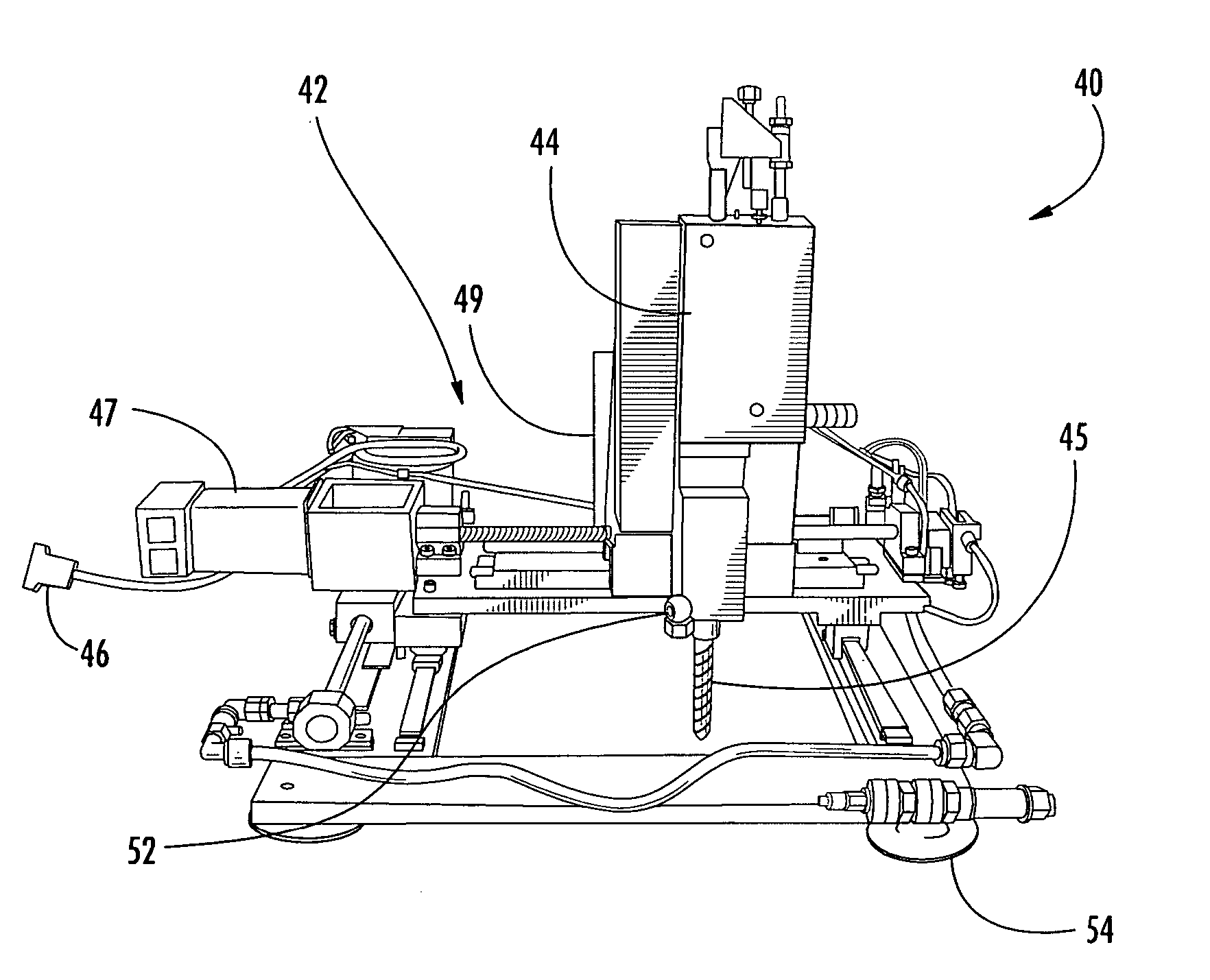

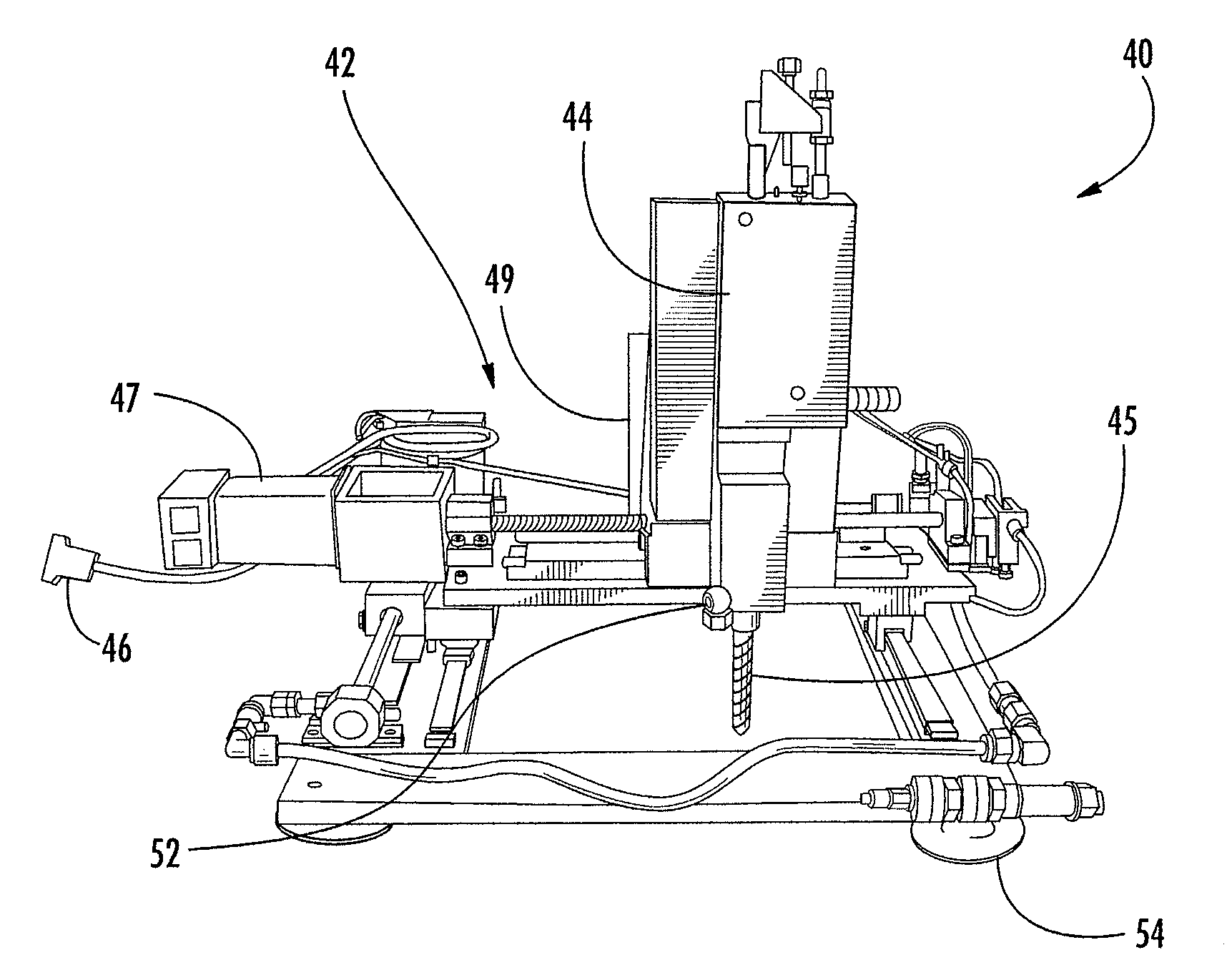

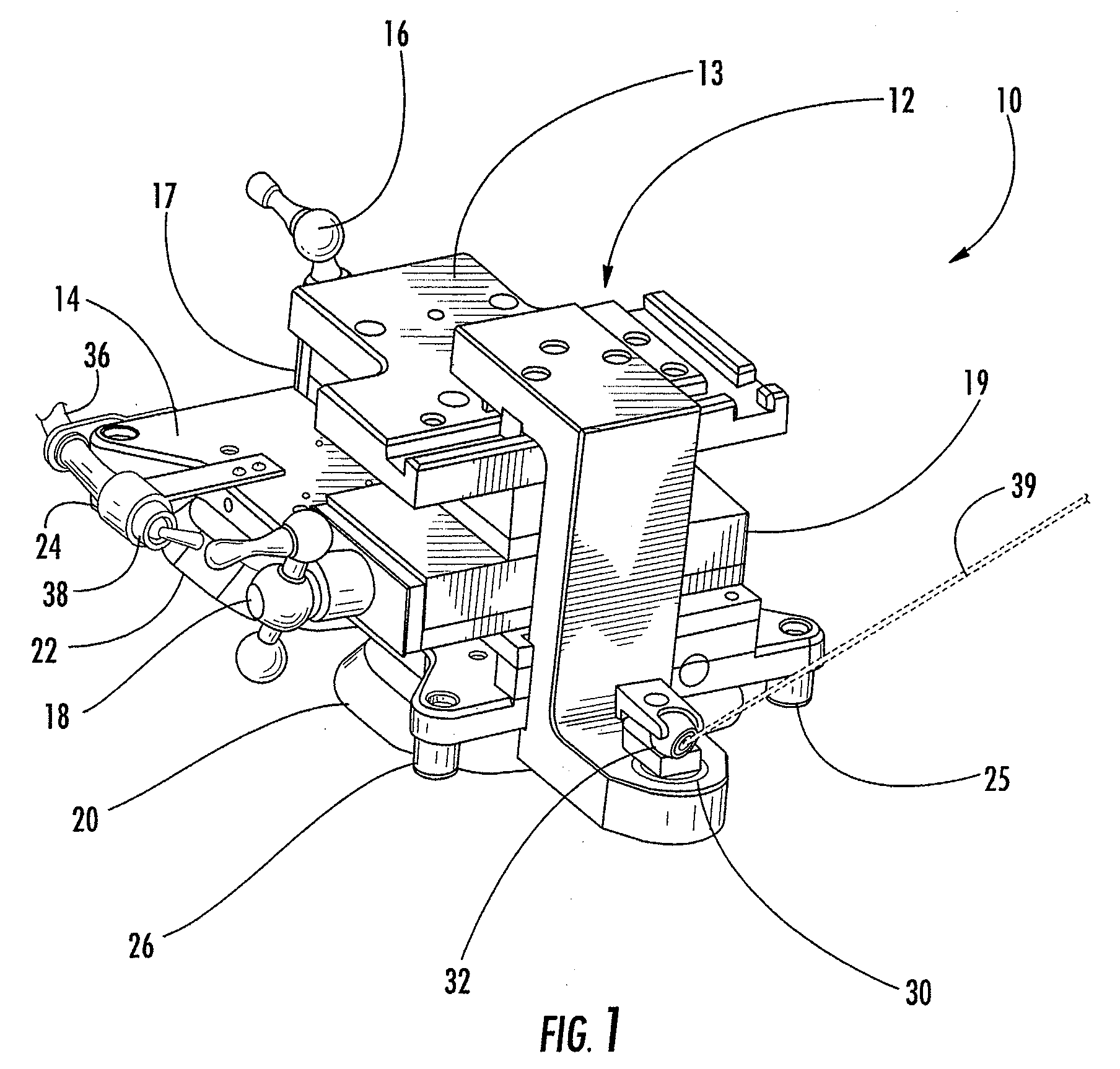

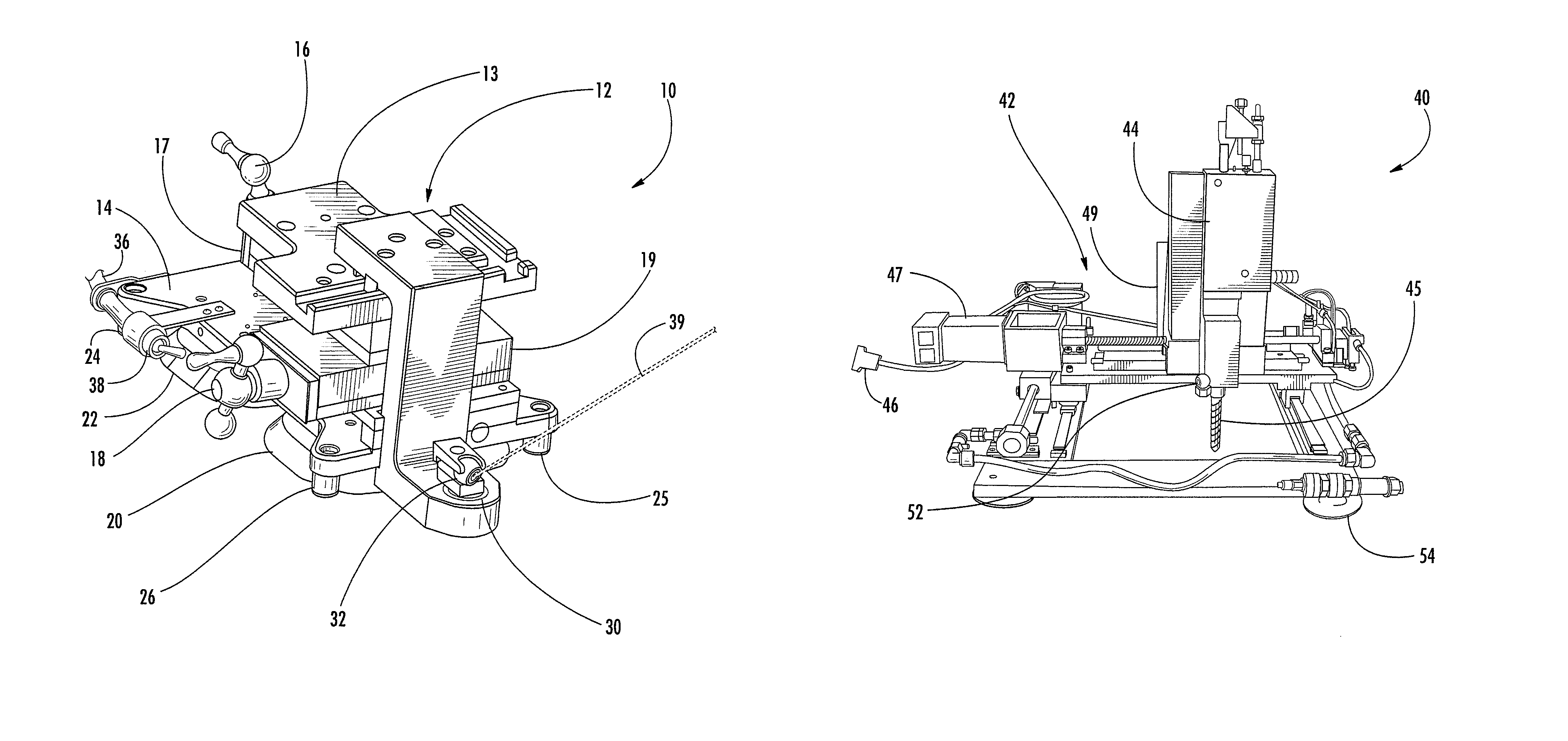

Laser-guided coordination hole drilling

ActiveUS20050147477A1Suitable for machiningEliminate needAircraft componentsDrilling/boring measurement devicesLaser targetLaser tracker

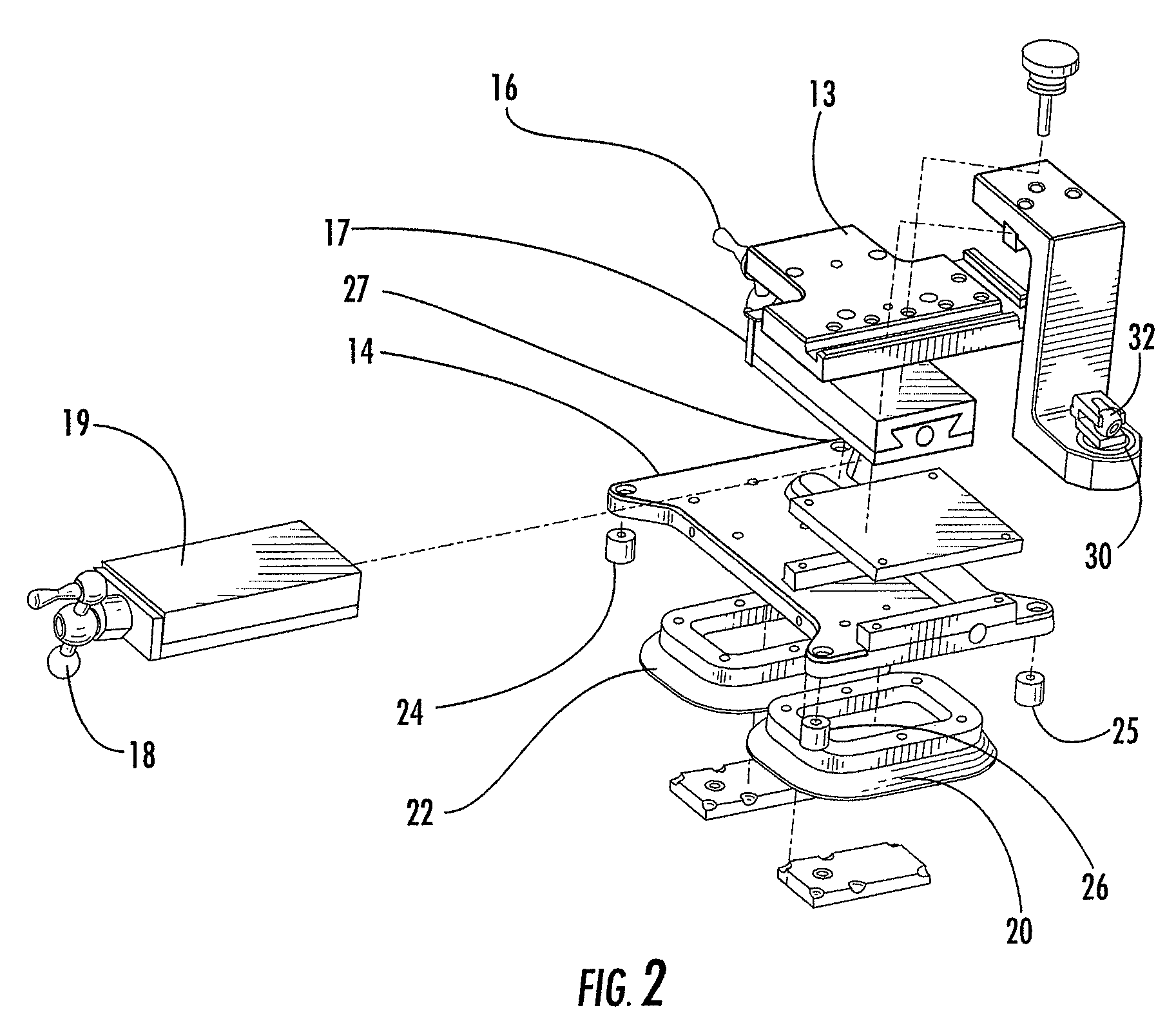

A laser-guided coordination hole tool for precisely drilling holes in large parts includes a positioning table, a bushing cavity for receiving drill bushings, a clamping device, and a laser target. A laser-guided coordination hole tool may include a software interlock to prevent drilling in an improper location on the part. A method of drilling coordination holes includes probing a part to determine its reference frame, rigidly affixing a laser-guided coordination hole tool to the part, probing a target on the laser-guided coordination hole tool to determine the reference frame for the laser-guided coordination hole tool, accurately positioning a drill bushing over the hole location, and drilling a hole. A system for drilling coordination holes includes a laser-guided coordination hole tool, a bushing, a tooling, a drill motor, a laser tracker, and a computer running a coordination-hole drilling program.

Owner:THE BOEING CO

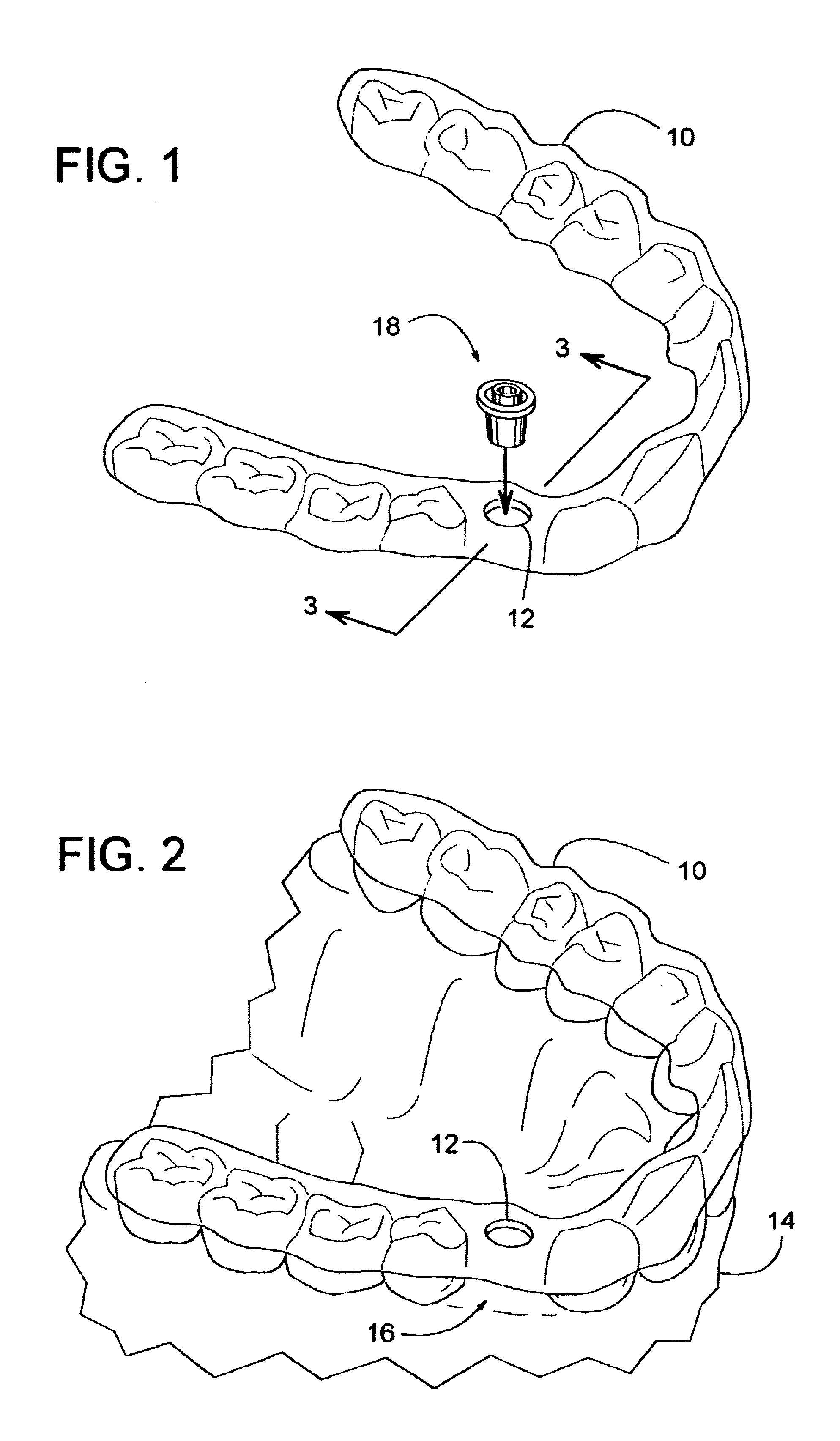

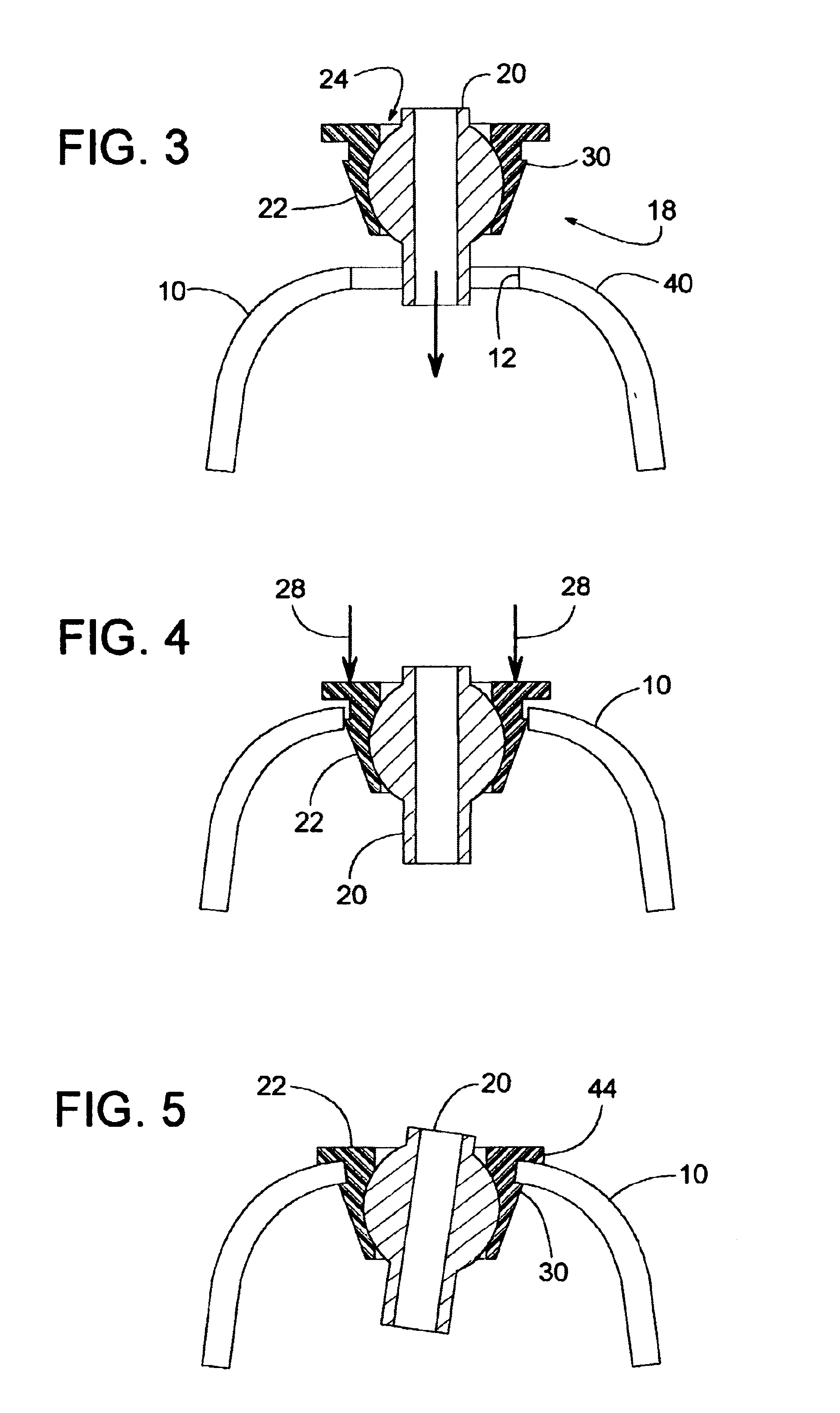

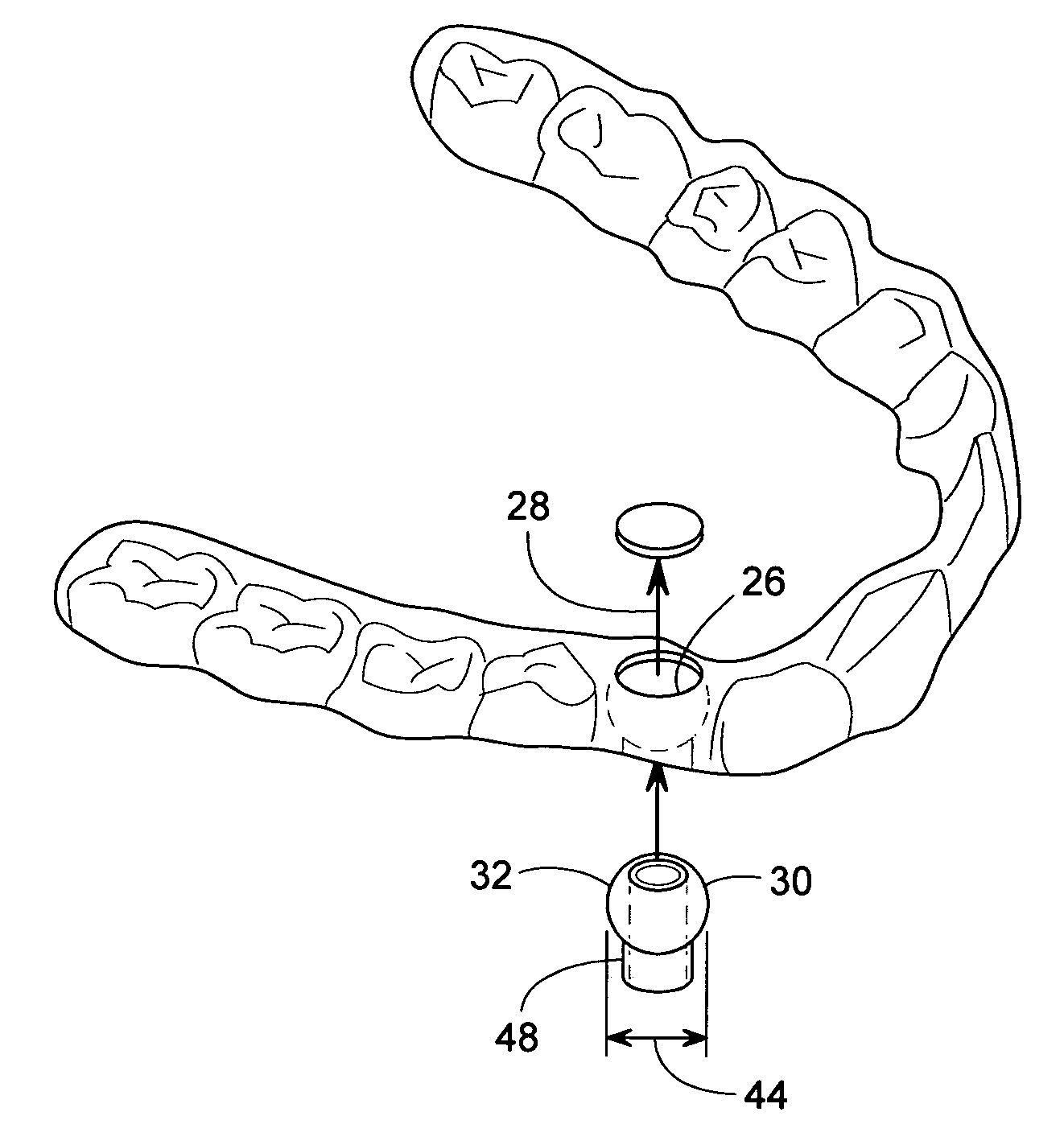

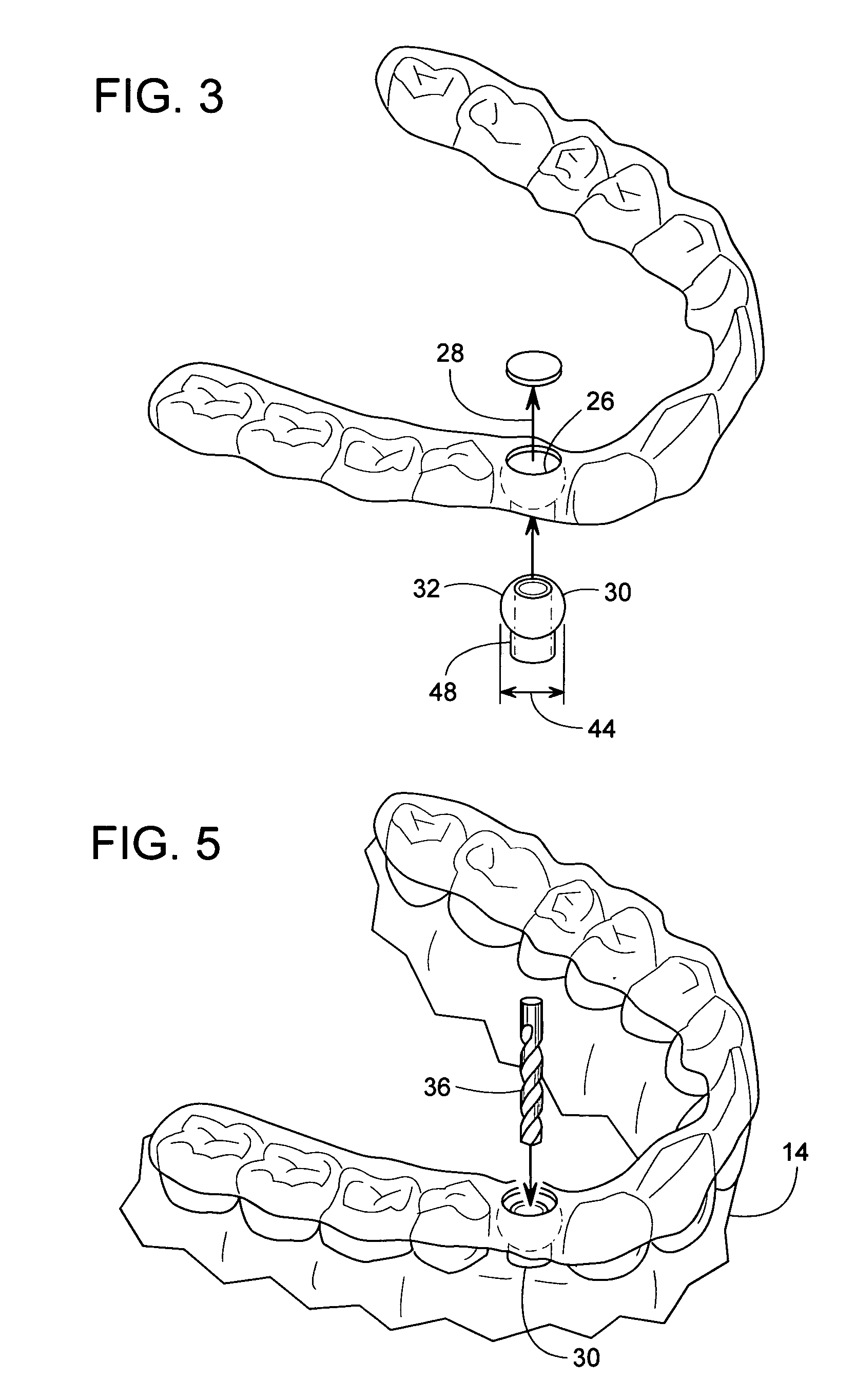

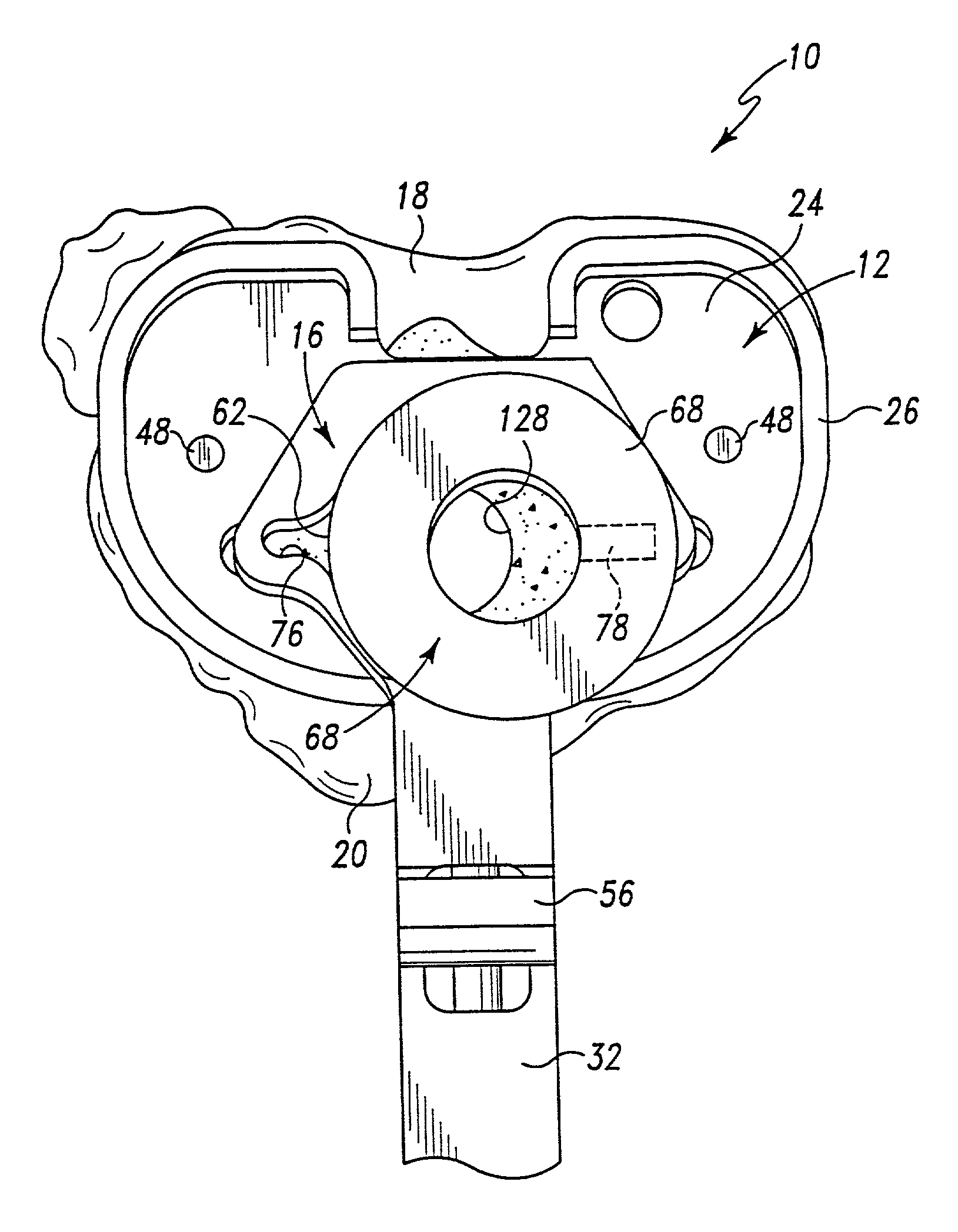

Dental implant tool with attachment feature

A dental tool for guiding a drill bit during a dental implant procedure includes a pivotal drill bushing attached to a bushing holder. The bushing holder, in turn, is attached to a surgical dental stent that fits a patient's jaw. The bushing holder attaches to the stent by extending into a hole or bore of the stent. In some cases, the bushing holder snaps into the hole.

Owner:LEO J MARLIN

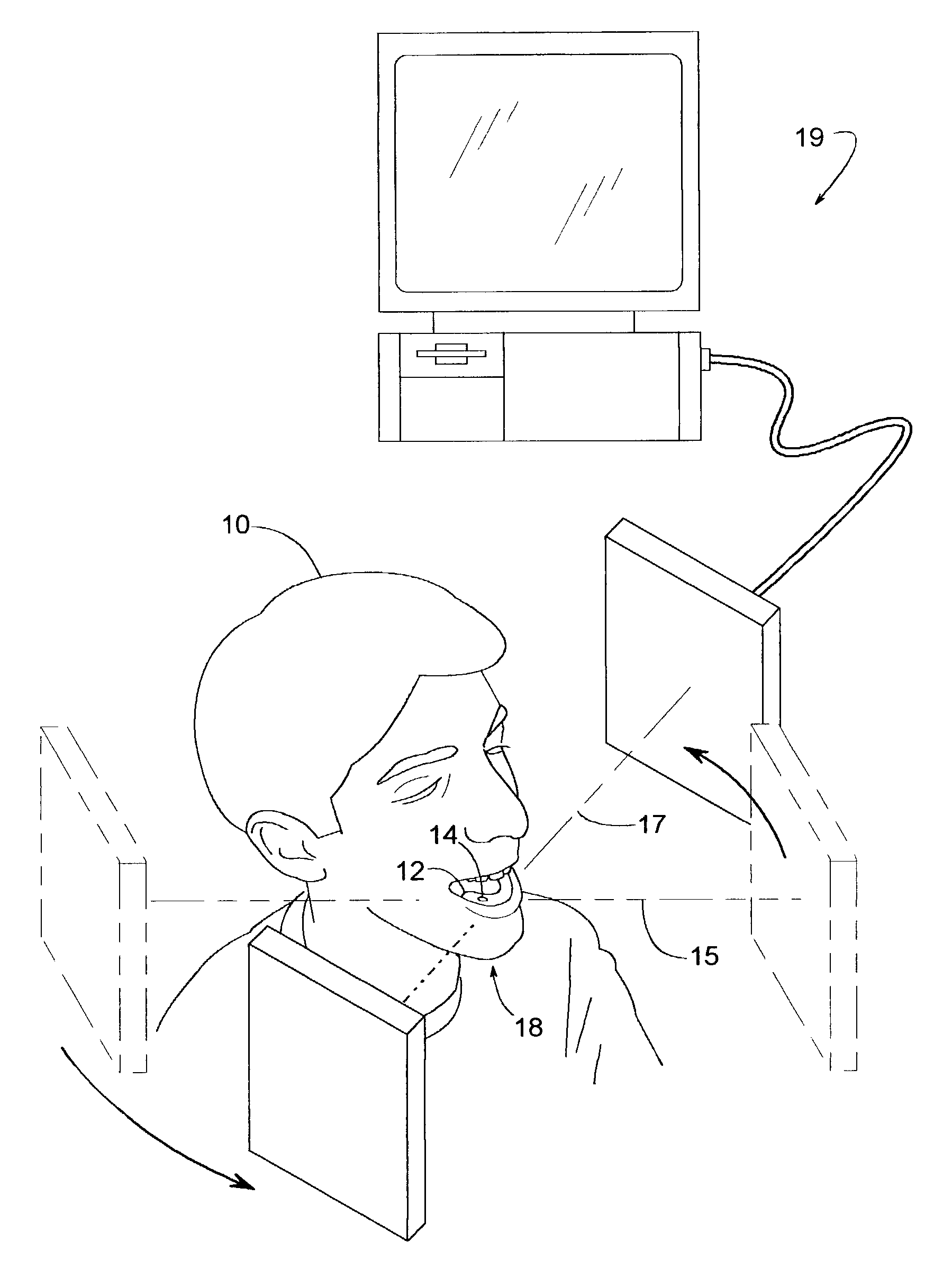

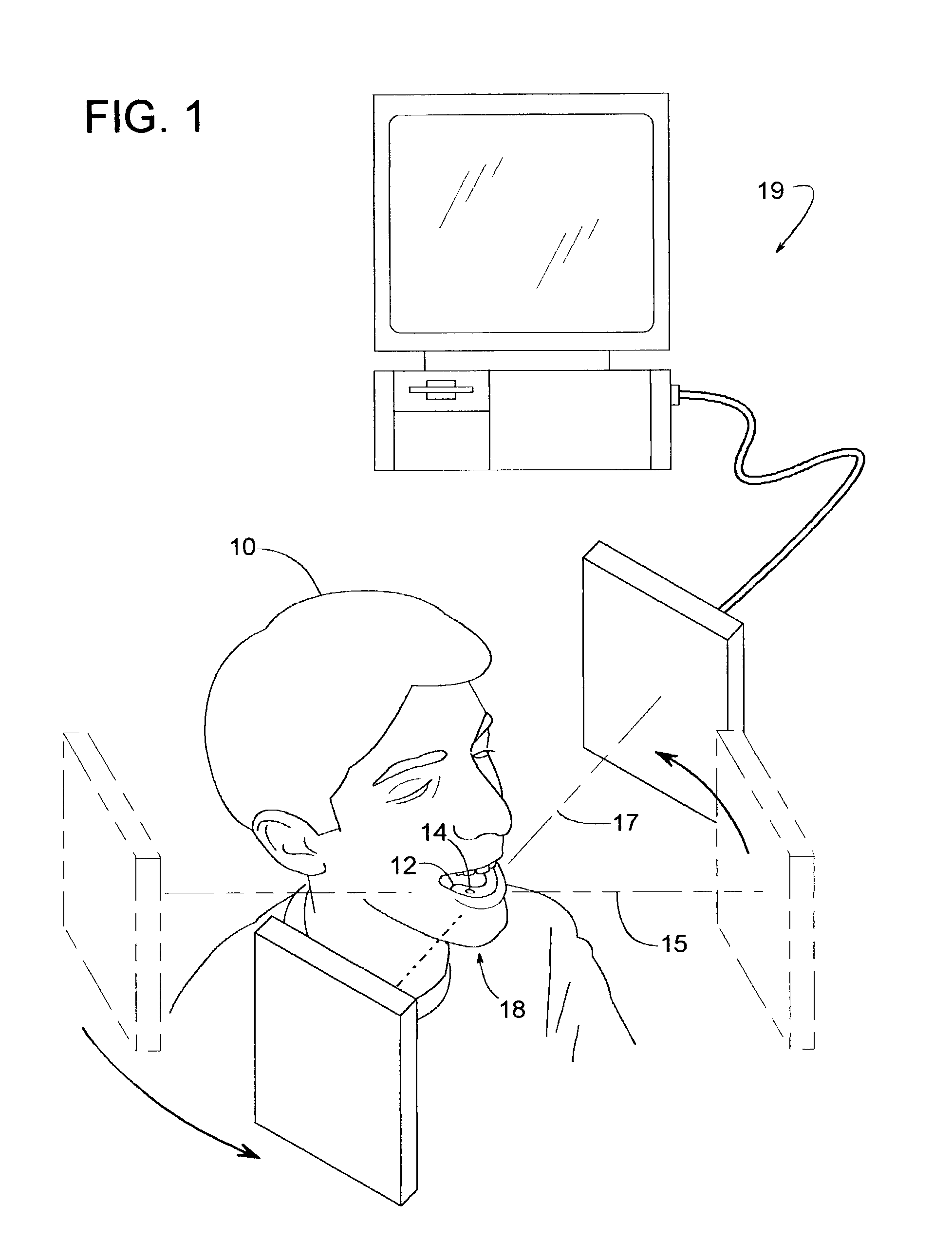

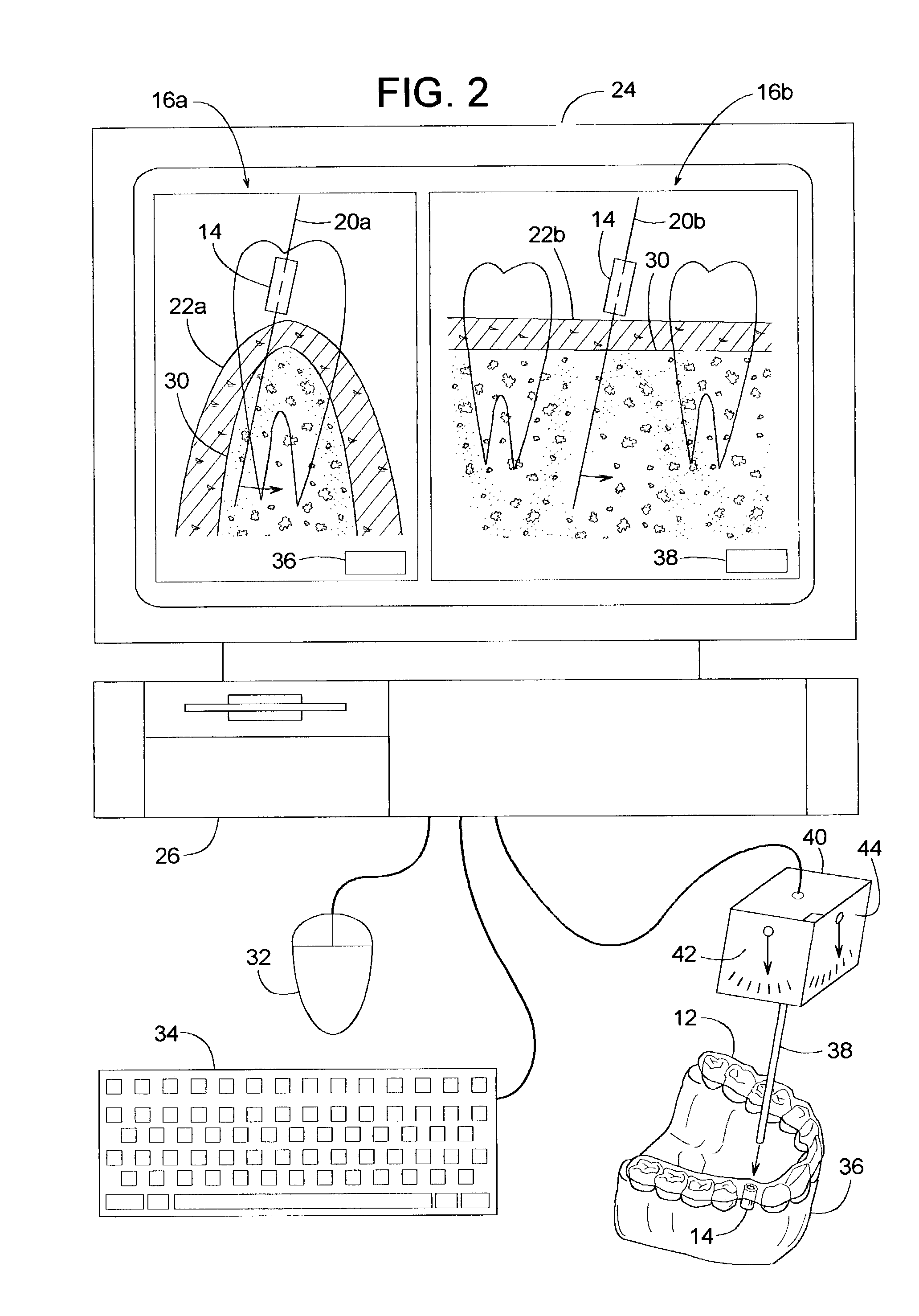

Method of adjusting a drill bushing for a dental implant

InactiveUS6966772B2Generally instantaneous feedbackDental implantsImpression capsComputer scienceDental implant

A method for a dental implant process involves creating an overall image that shows a trajectory of a drill bushing in relation to a patient's jaw. The overall image shows a trajectory image that represents the trajectory of the drill bushing and a jaw image that represents the jaw. The method allows a user to move the trajectory image relative to the jaw image, which can be useful when adjusting the angular position of the actual drill bushing.

Owner:LEO J MALIN

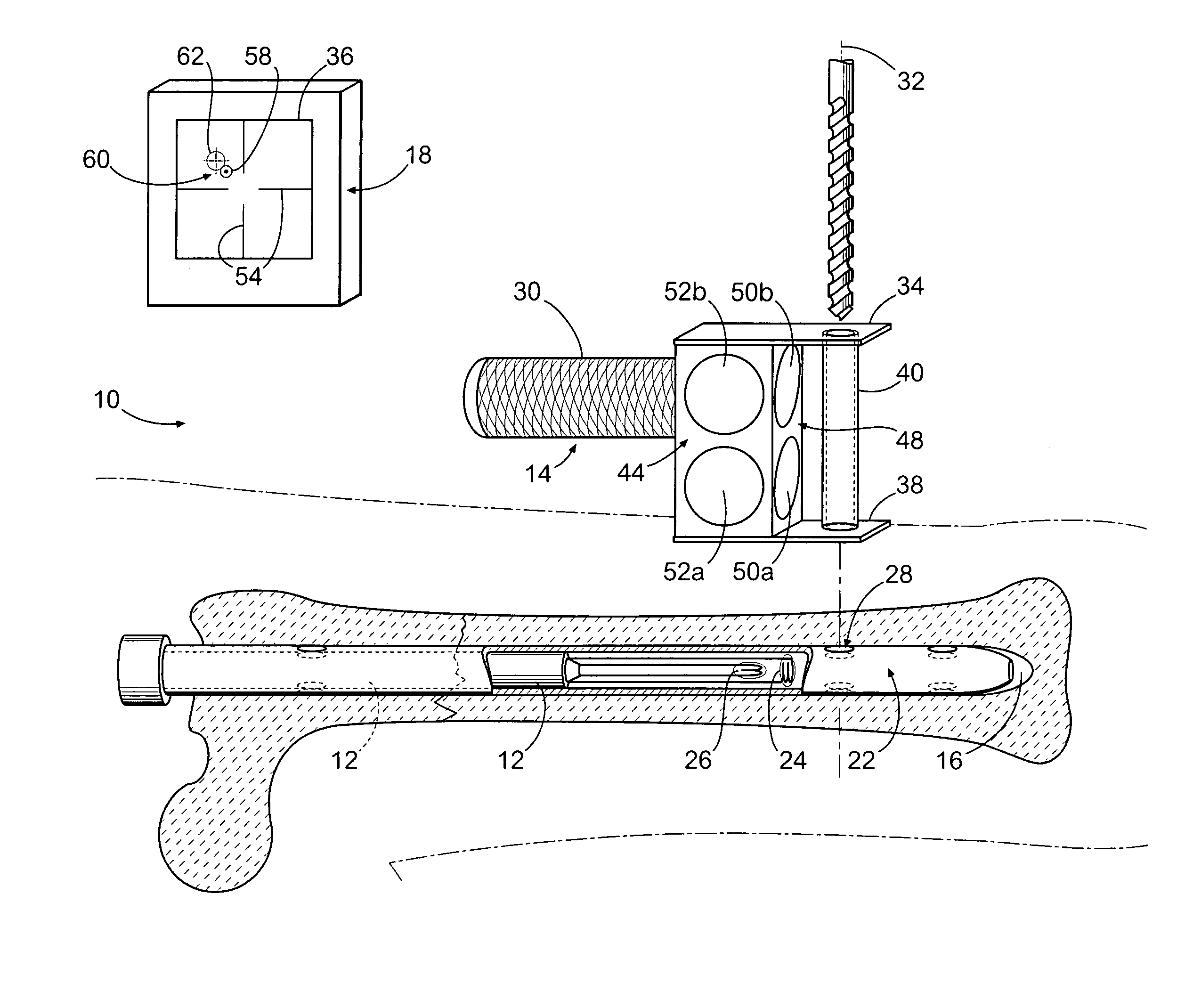

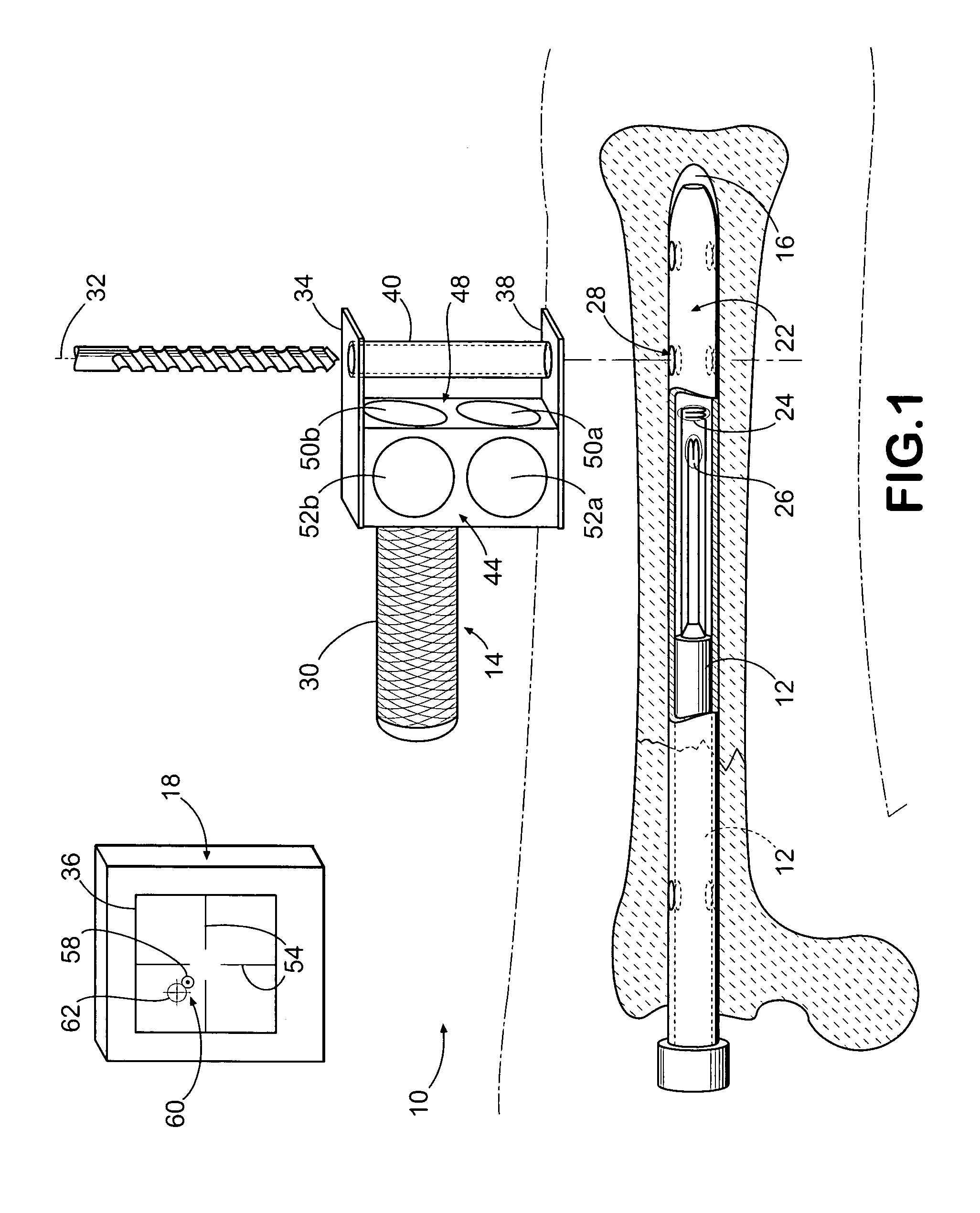

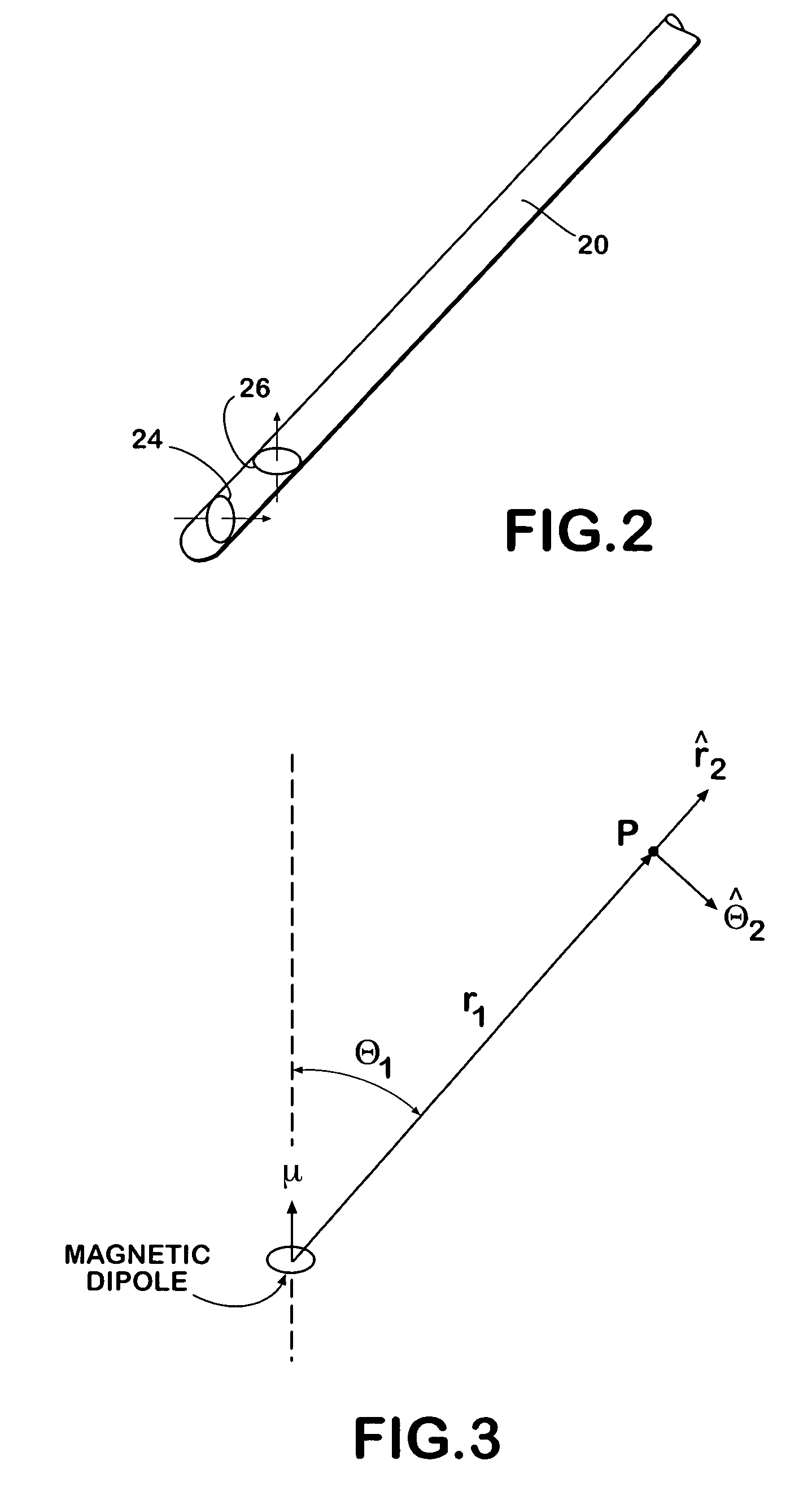

Method and apparatus for distal targeting of locking screws in intramedullary nails

InactiveUS7029478B2Simple formatHigh mechanical strengthProsthesisOsteosynthesis devicesIntramedullary rodDisplay device

Owner:DEPUY PROD INC

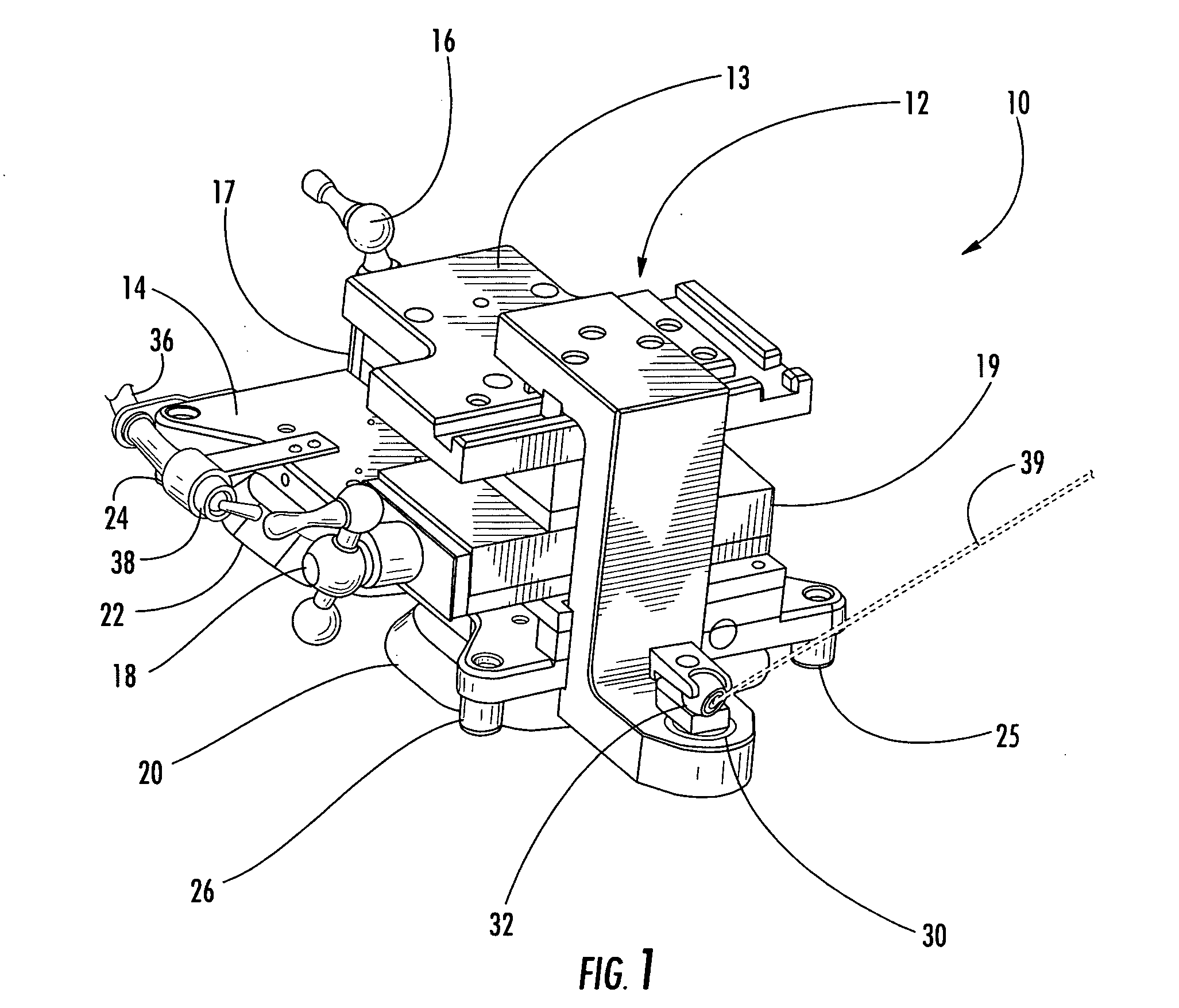

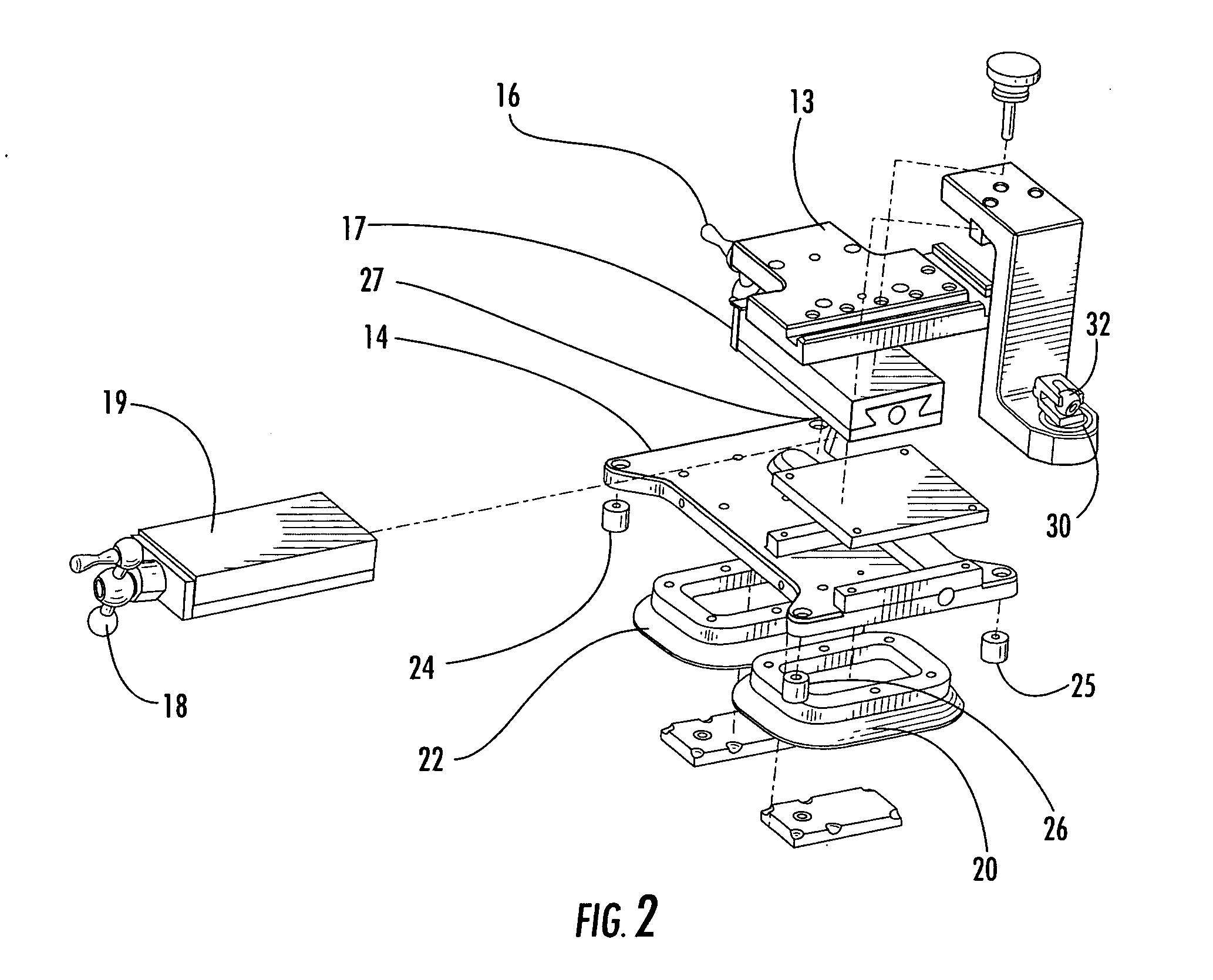

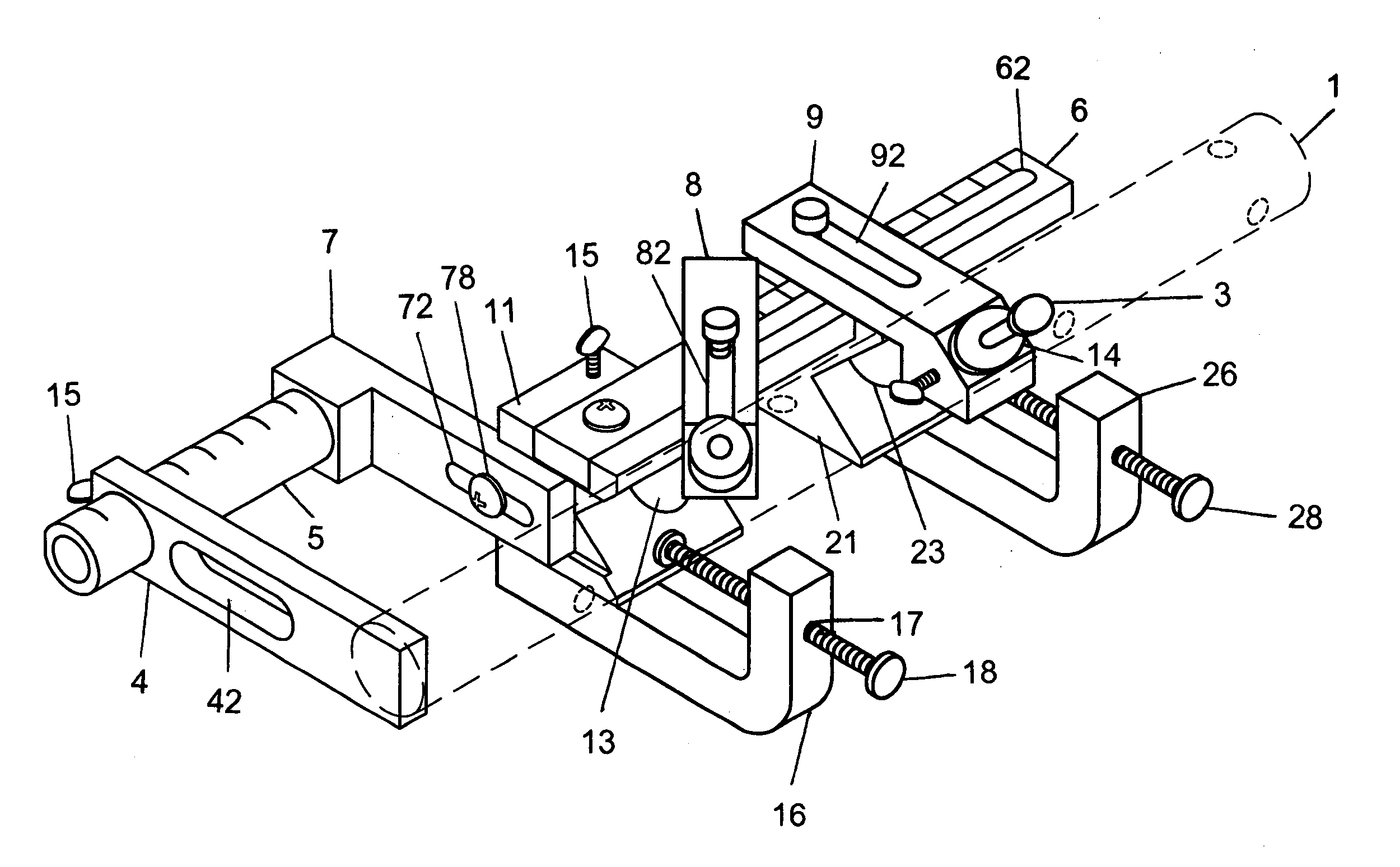

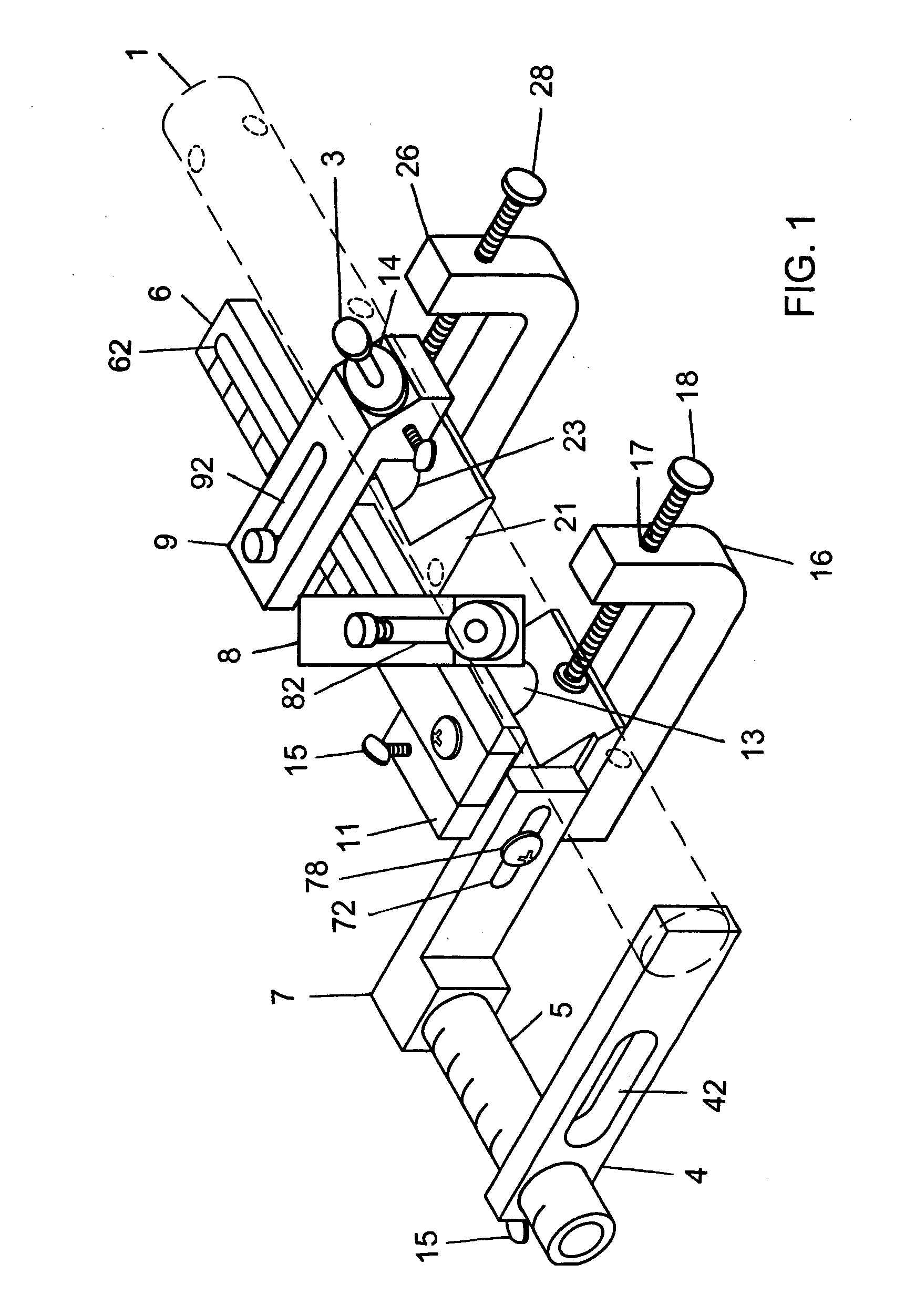

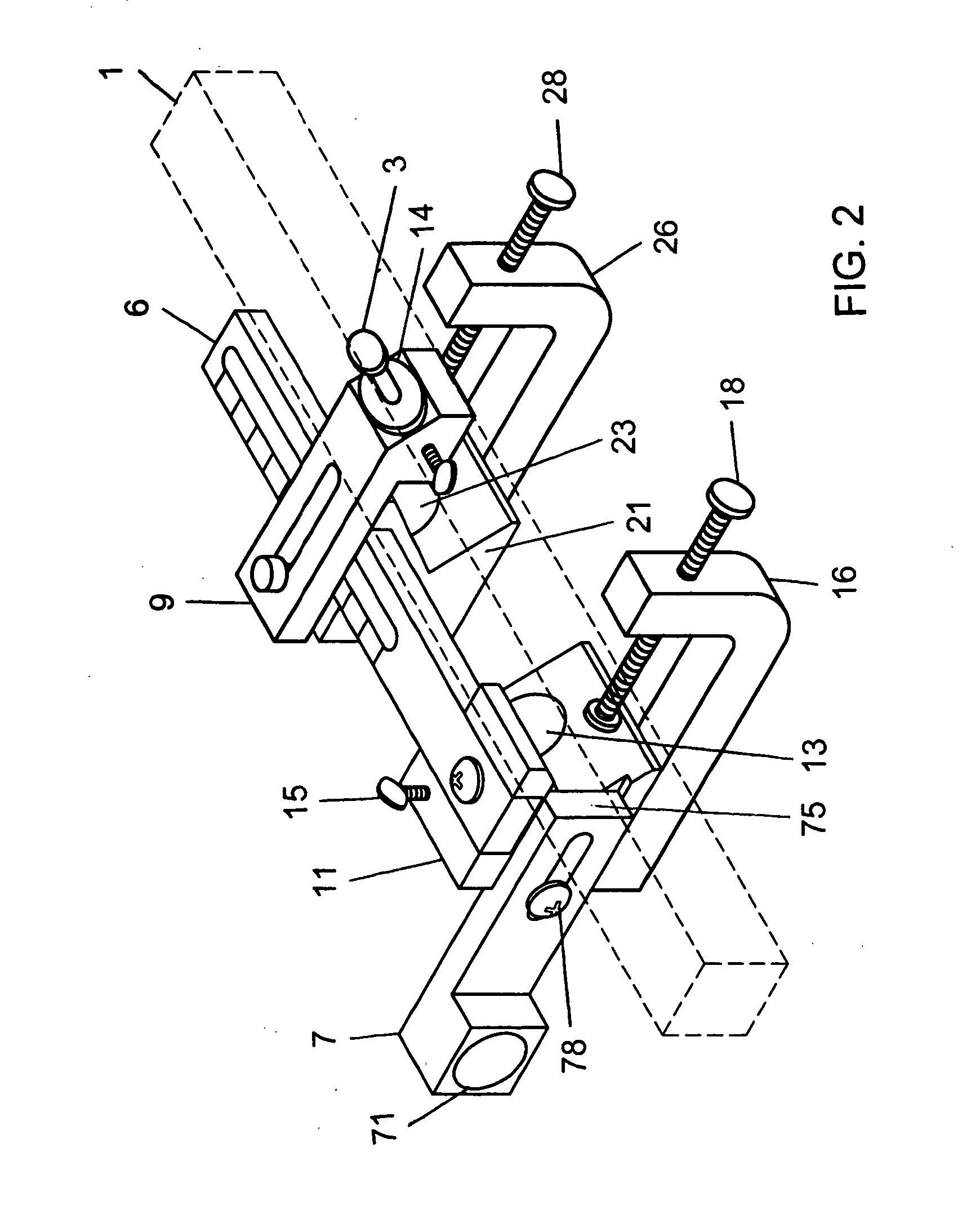

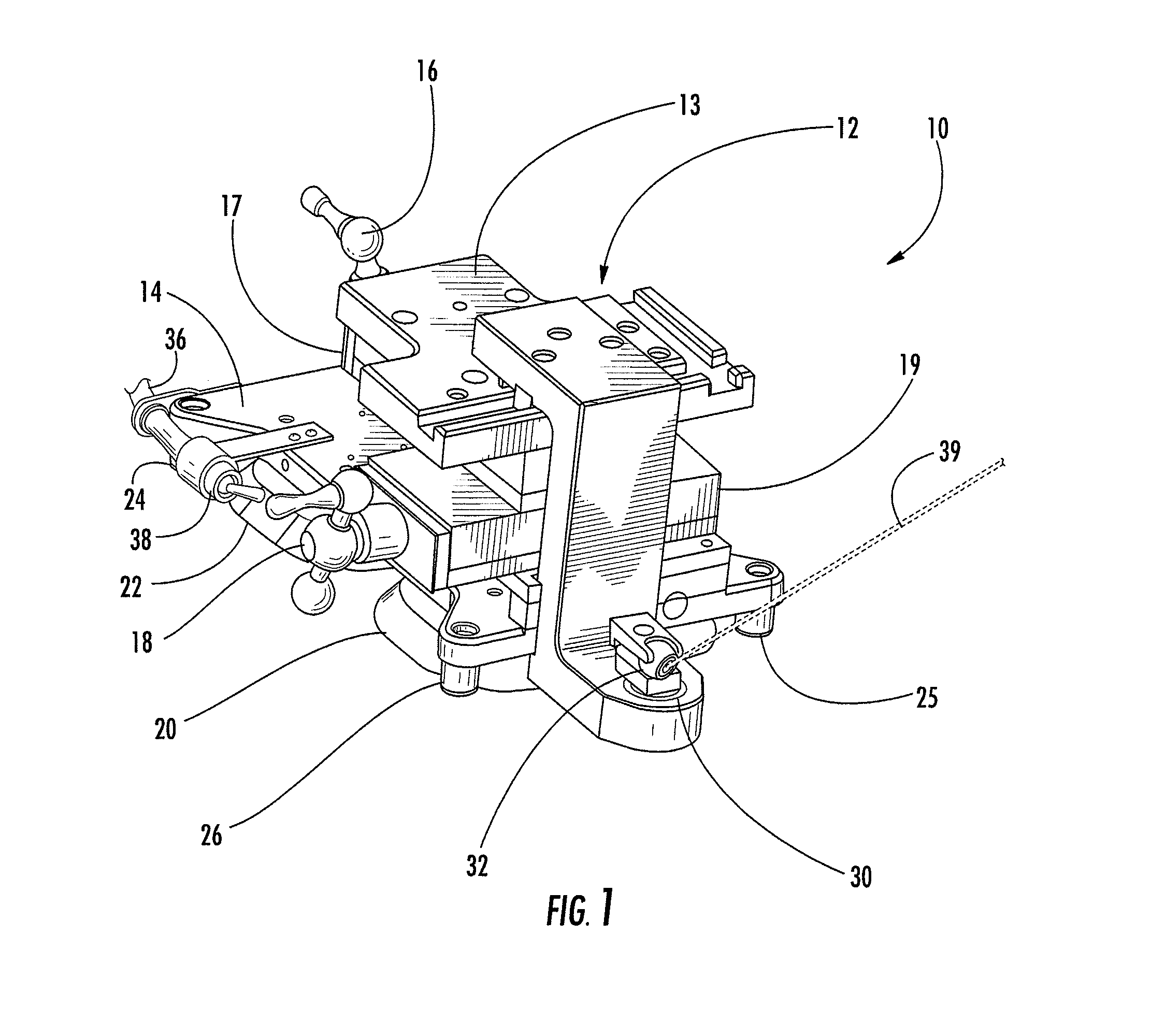

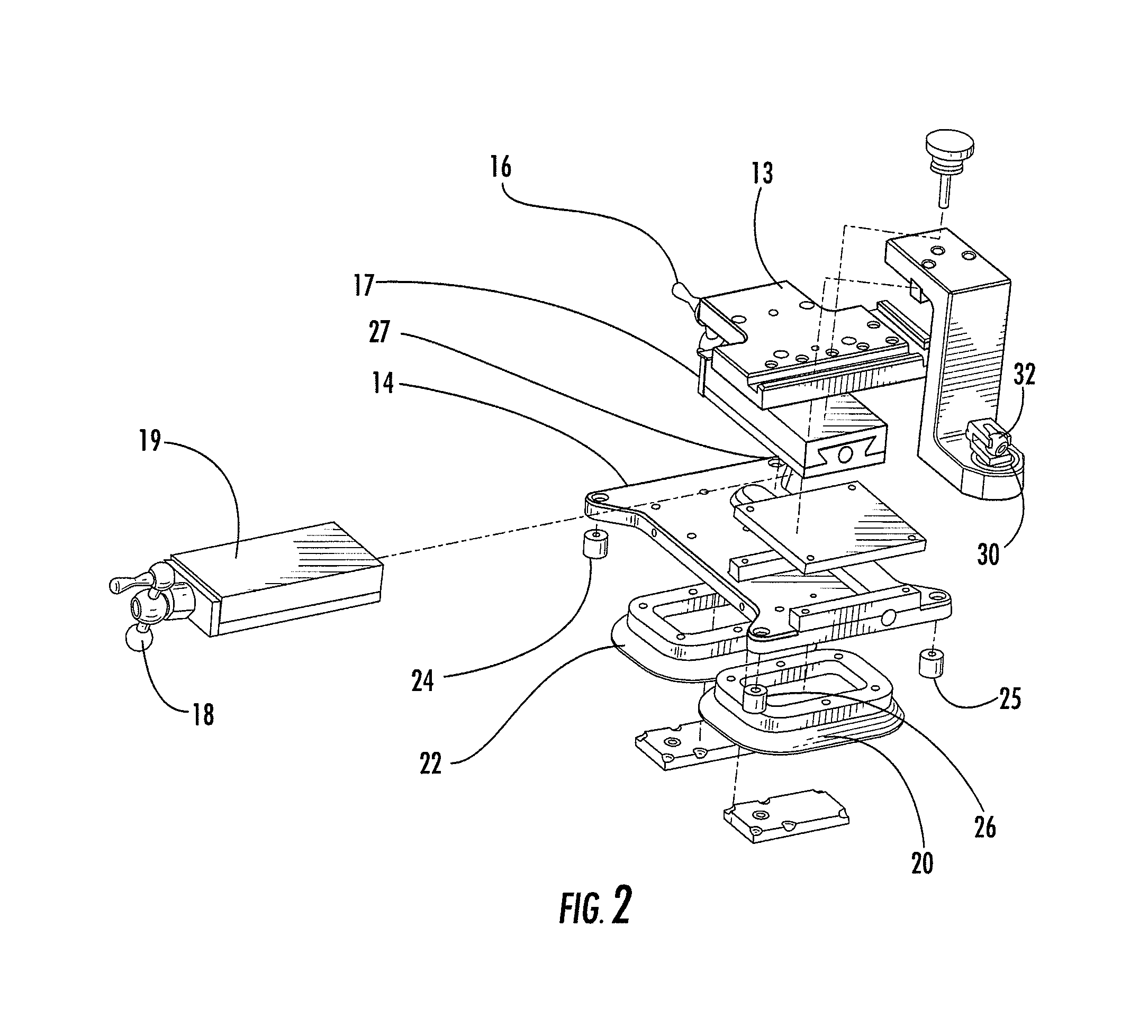

Fixturing device for drilling workpieces

InactiveUS20060233620A1Easy to manufactureEasy maintenanceThread cutting machinesDrill jigsEngineeringMechanical engineering

A fixturing device for holding a workpiece with a longitudinal axis is disclosed. The fixturing device includes a first v-block with holding surfaces that intersect each other at an intersection and form a v-shape. The first v-block has a hole formed therein with a center axis that is substantially perpendicular to the longitudinal axis of the workpiece and intersects the intersection of the holding surfaces. A clamping arm mounted to the first v-block for clamping the workpiece in the first v-block. A second v-block that is similar to the first v-block is also provided. A clamping arm is mounted to the second v-block for clamping the workpiece to the second v-block. A cross-member adjustably attaches the first v-block to the second v-block. At least one drill bushing is removably disposed in one of the hole in the first v-block and the hole in the second v-block.

Owner:HERRICK RICHARD

Device for centering and guiding a drill bit of a dental handpiece

ActiveUS20100311006A1Precise positioningControlling the riskDental implantsDiagnosticsDrill bushingPetroleum engineering

A device for centering and guiding at least one drill bit of a dental handpiece when drilling a hole in the jaw of a patient in cooperation with a surgical guide equipped with a tubular drill bushing. A support holds a tubular guide sleeve permanently in a coaxial and sliding position with respect to the drill bit. The tubular guide sleeve is able to engage with slight play in the tubular drill bushing. The support insures the engagement of the guide sleeve in the tubular drill bushing at the latest when the drill bit starts to drill in the patient's jaw, thus insuring the centering and guiding of the drill bit.

Owner:ANTHOGYR

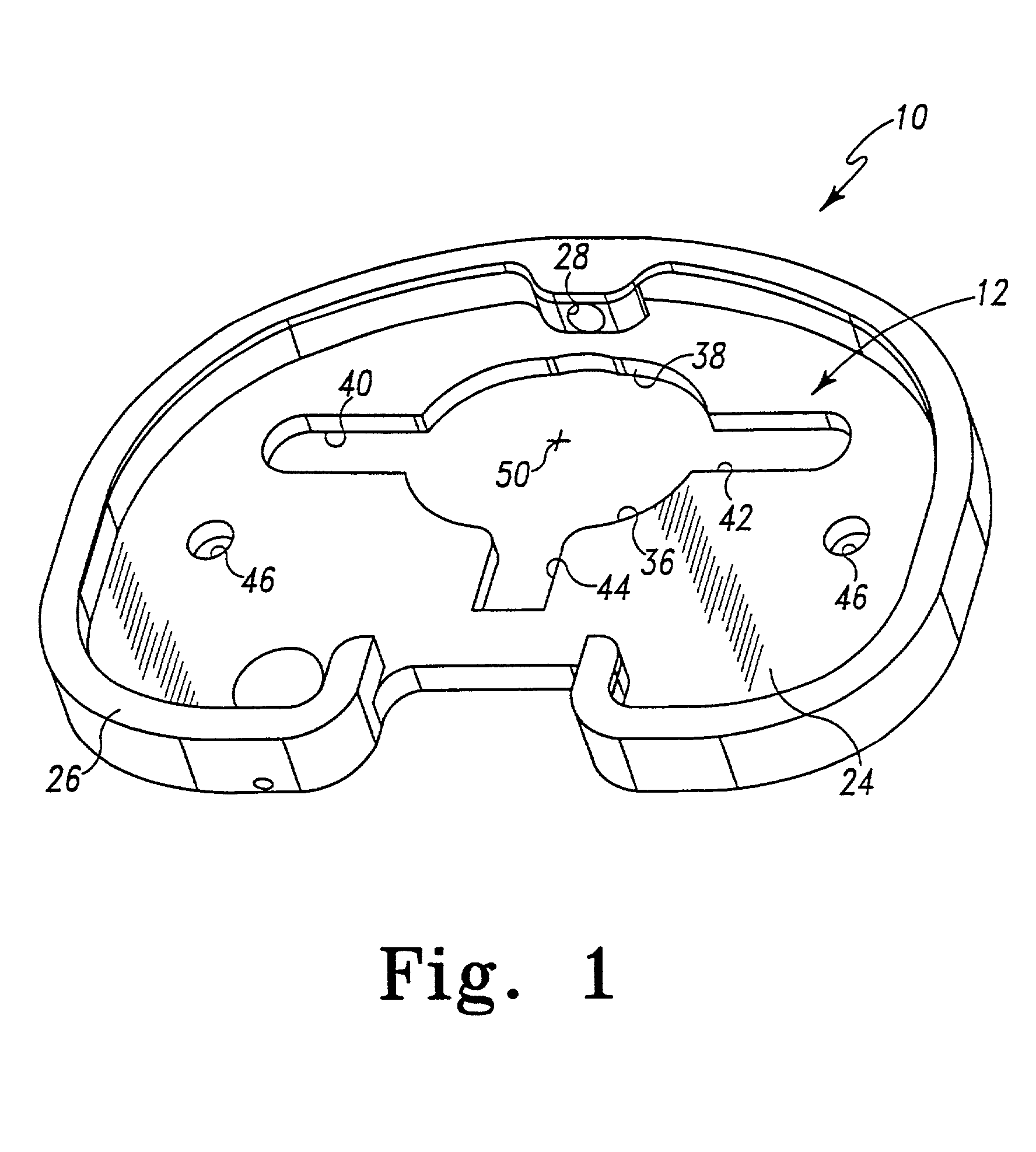

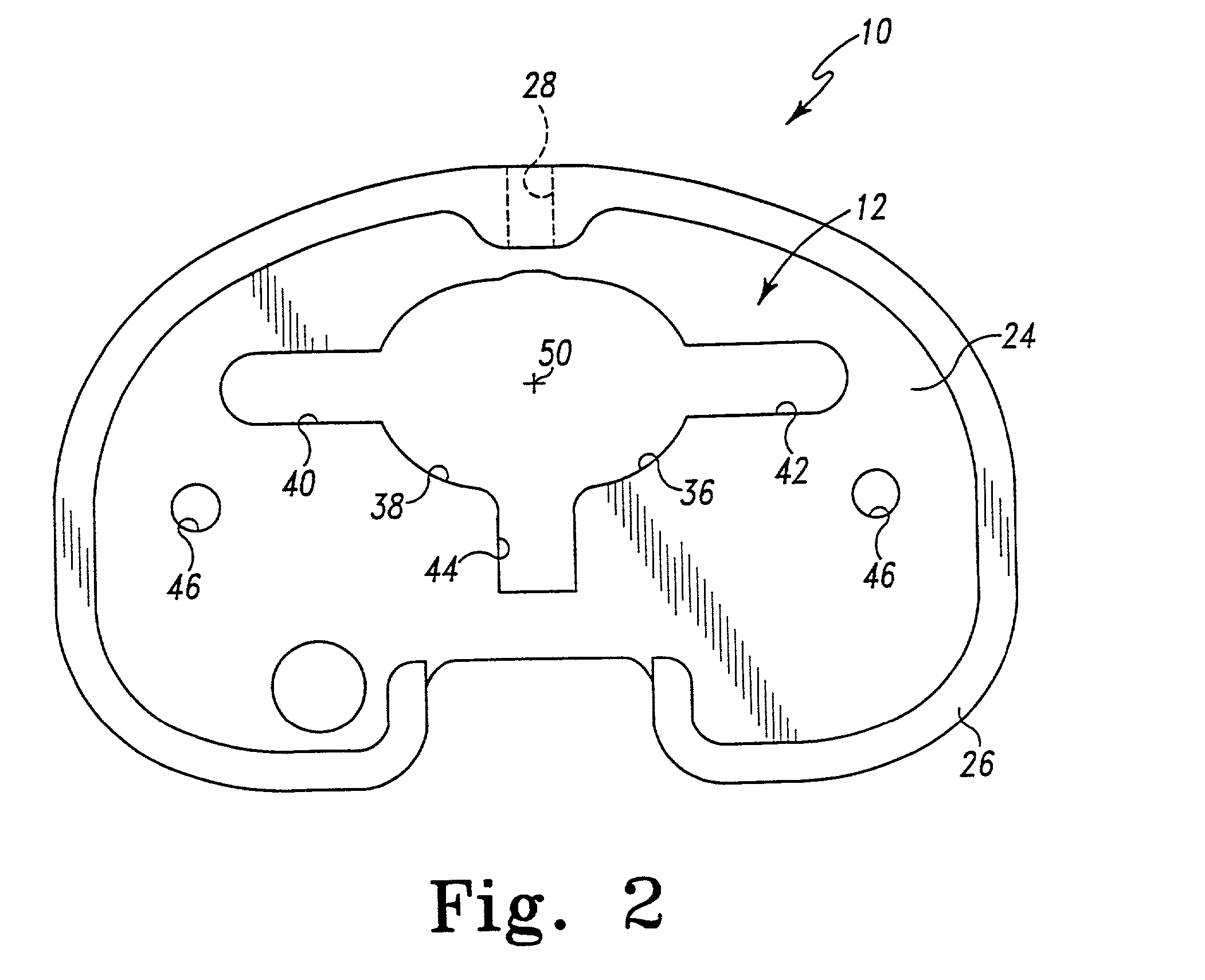

Method and apparatus for surgically preparing a tibia for implantation of a prosthetic implant component which has an offset stem

InactiveUS7001394B2Eliminate needSimple methodJoint implantsNon-surgical orthopedic devicesTibiaBiomedical engineering

A surgical assembly for preparing a tibia for implantation of a prosthetic implant includes a tray trial adapted to be secured to a proximal end of the tibia. The tray trial includes a plate having a plate opening defined therein. The plate opening has a center point. The surgical assembly also includes a first guide adapted to be secured to the tray trial. The first guide has a guide opening defined therein. The guide opening has a first bushing-receiving portion and a second bushing-receiving portion which is distinct from the first bushing-receiving portion. The surgical assembly also includes a drill bushing positionable in either the first bushing-receiving portion of the guide opening or the second bushing-receiving portion of the guide opening. The drill bushing has a bushing bore extending therethrough. The bushing bore has a center point. The center point of the bushing bore of the drill bushing is offset from the center point of the plate opening of the tray trial in a first direction when the drill bushing is positioned in the first bushing-receiving portion of the guide opening. The center point of the bushing bore of the drill bushing is offset from the center point of the plate opening of the tray trial in a second direction when the drill bushing is positioned in the second bushing-receiving portion of the guide opening. A method of surgically preparing a tibia for implantation of a prosthetic implant is also disclosed.

Owner:DEPUY PROD INC

Snap-lock for drill sleeve

Owner:DEPUY SYNTHES PROD INC

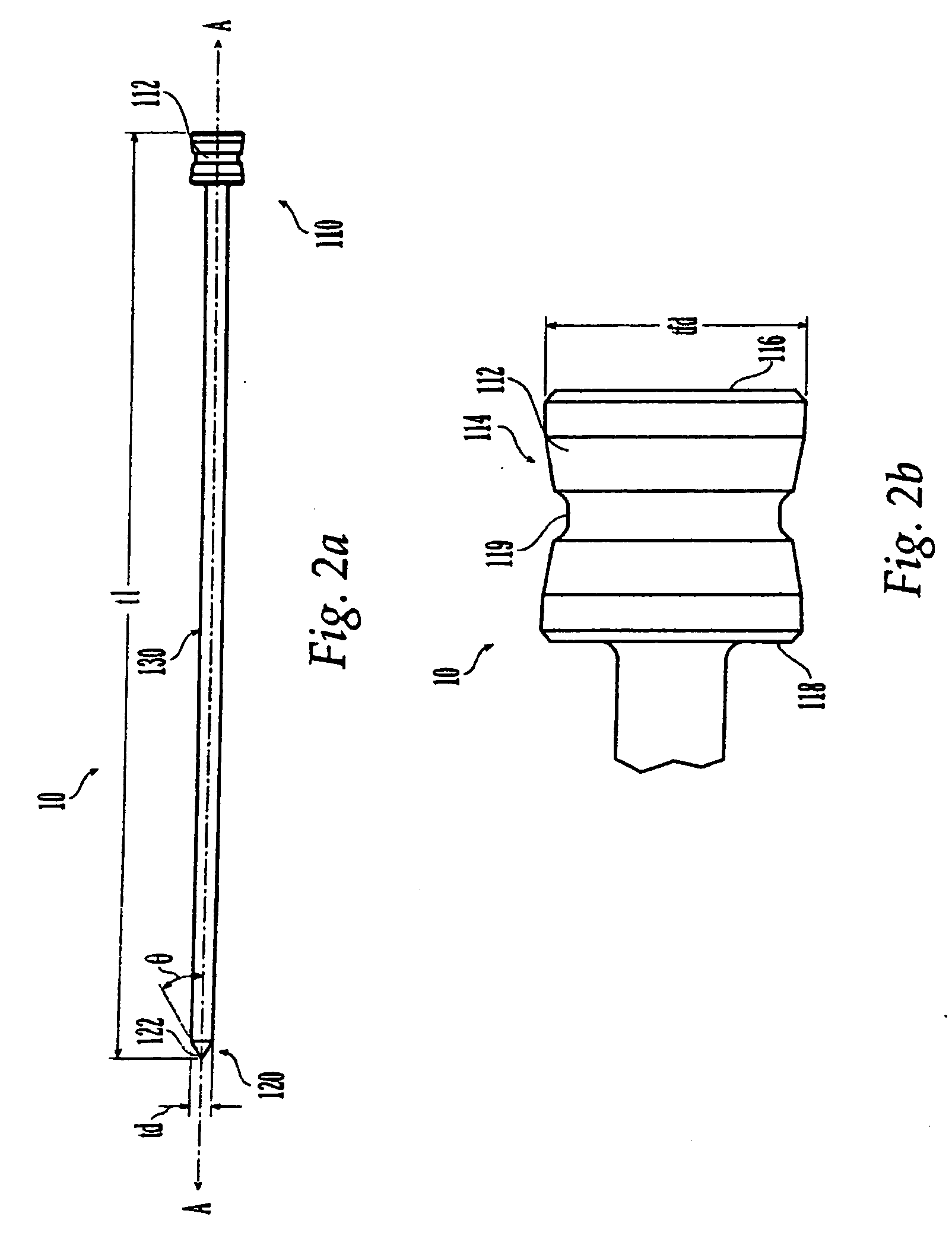

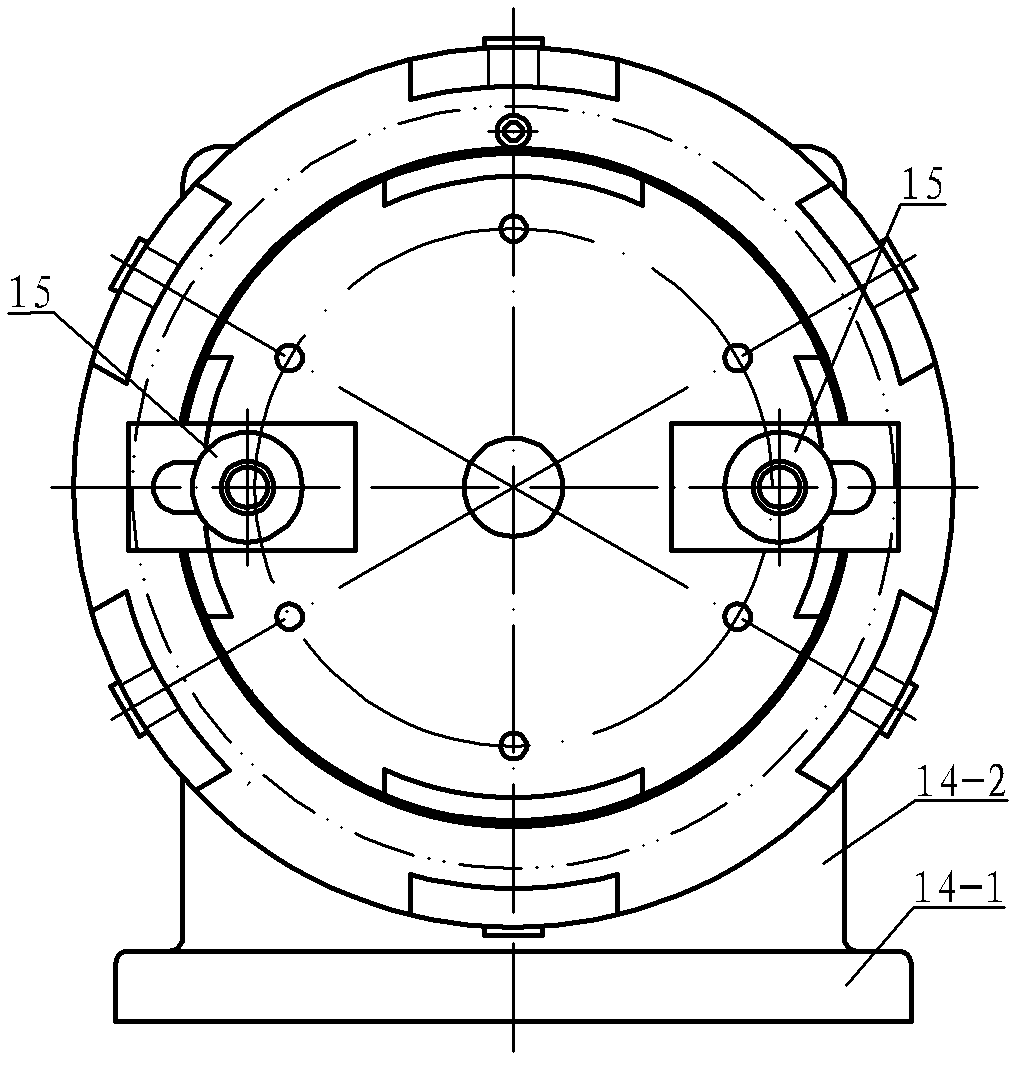

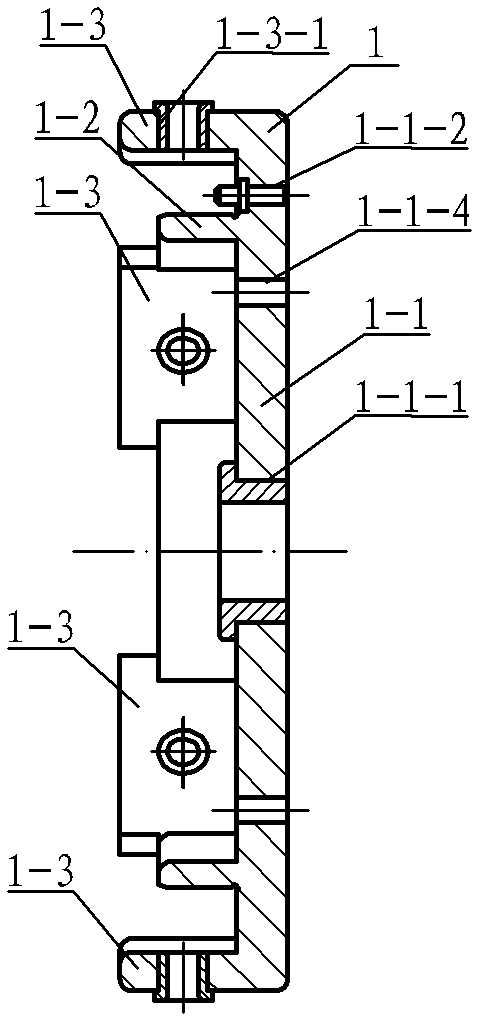

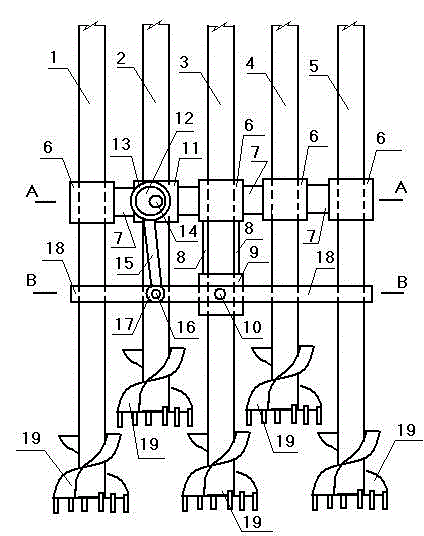

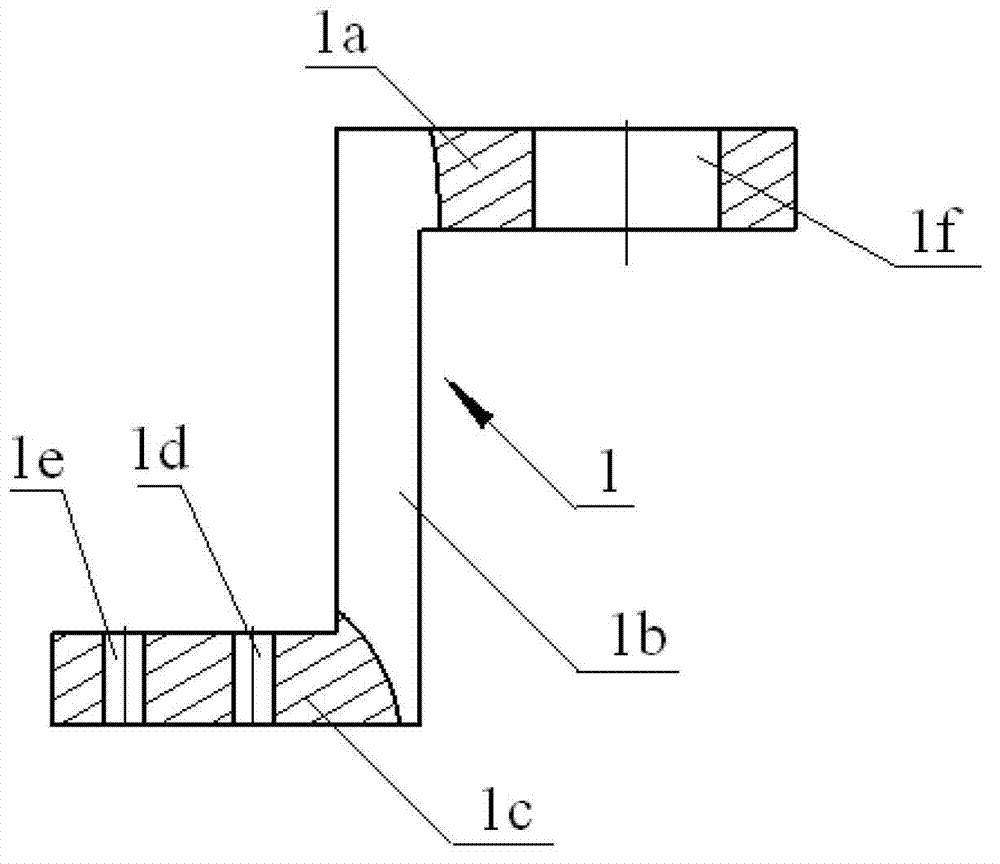

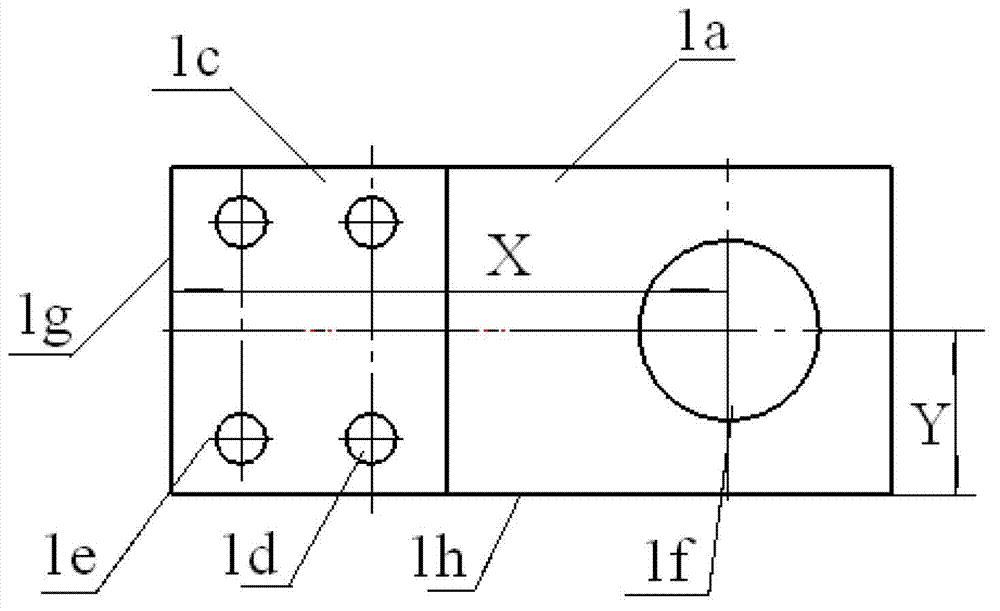

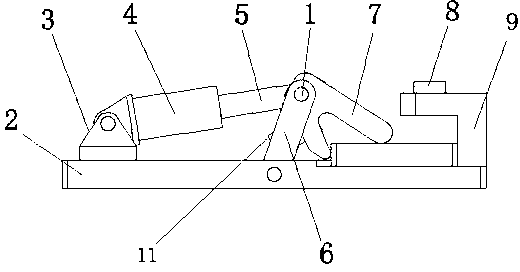

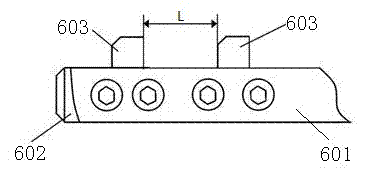

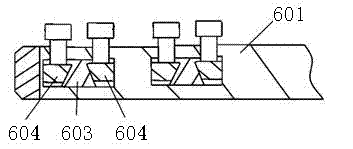

Pipe fitting radial indexing drilling clamp tooling

ActiveCN102962497AGuaranteed assembly qualitySave assembly timePrecision positioning equipmentPositioning apparatusNumerical controlPipe fitting

The invention relates to a pipe fitting radial indexing drilling clamp tooling, which relates to a clamp tooling of a pipe fitting excircle drilling work procedure and solves the problems that each connecting hole on the existing pipe fitting excircle is processed by boring and milling equipment and precise numerical control equipment, and the mass production requirements cannot be met. A drill bush is arranged in each drill bush hole arranged in an indexing disc, each screw rod hole arranged in the indexing disc is matched with one pressing screw rod, in addition, one end of the pressing screw rod is connected with the screw rod hole through screw threads, the other end of the pressing screw rod passes through a press plate to be connected with a pressing screw nut through screw threads, a positioning pin is arranged in a first positioning pin hole, a copper bush is arranged in a copper bush installing hole, a middle shaft is arranged in a middle shaft installing hole and an inner hole of the copper bush, a middle shaft at one end of the copper bush is connected with a screw nut through screw threads, a middle shaft of one end of a first flange is connected with a fastening handle through screw threads, a positioning screw and a positioning threaded hole are connected through screw threads, an indexing pin is embedded in a second positioning pin, and a position limiting pin is arranged in a first position limiting pin hole and a second position limiting pin hole. The clamp tooling is used for processing each hole on the excircle surface of pipe fittings.

Owner:HARBIN JIANCHENG GRP

Laser-guided coordination hole drilling

InactiveUS20090022556A1Eliminate needAircraft componentsDrilling/boring measurement devicesLaser targetLaser tracker

A laser-guided coordination hole tool for precisely drilling holes in large parts includes a positioning table, a bushing cavity for receiving drill bushings, a clamping device, and a laser target. A laser-guided coordination hole tool may include a software interlock to prevent drilling in an improper location on the part. A method of drilling coordination holes includes probing a part to determine its reference frame, rigidly affixing a laser-guided coordination hole tool to the part, probing a target on the laser-guided coordination hole tool to determine the reference frame for the laser-guided coordination hole tool, accurately positioning a drill bushing over the hole location, and drilling a hole. A system for drilling coordination holes includes a laser-guided coordination hole tool, a bushing, a tooling, a drill motor, a laser tracker, and a computer running a coordination-hole drilling program.

Owner:THE BOEING CO

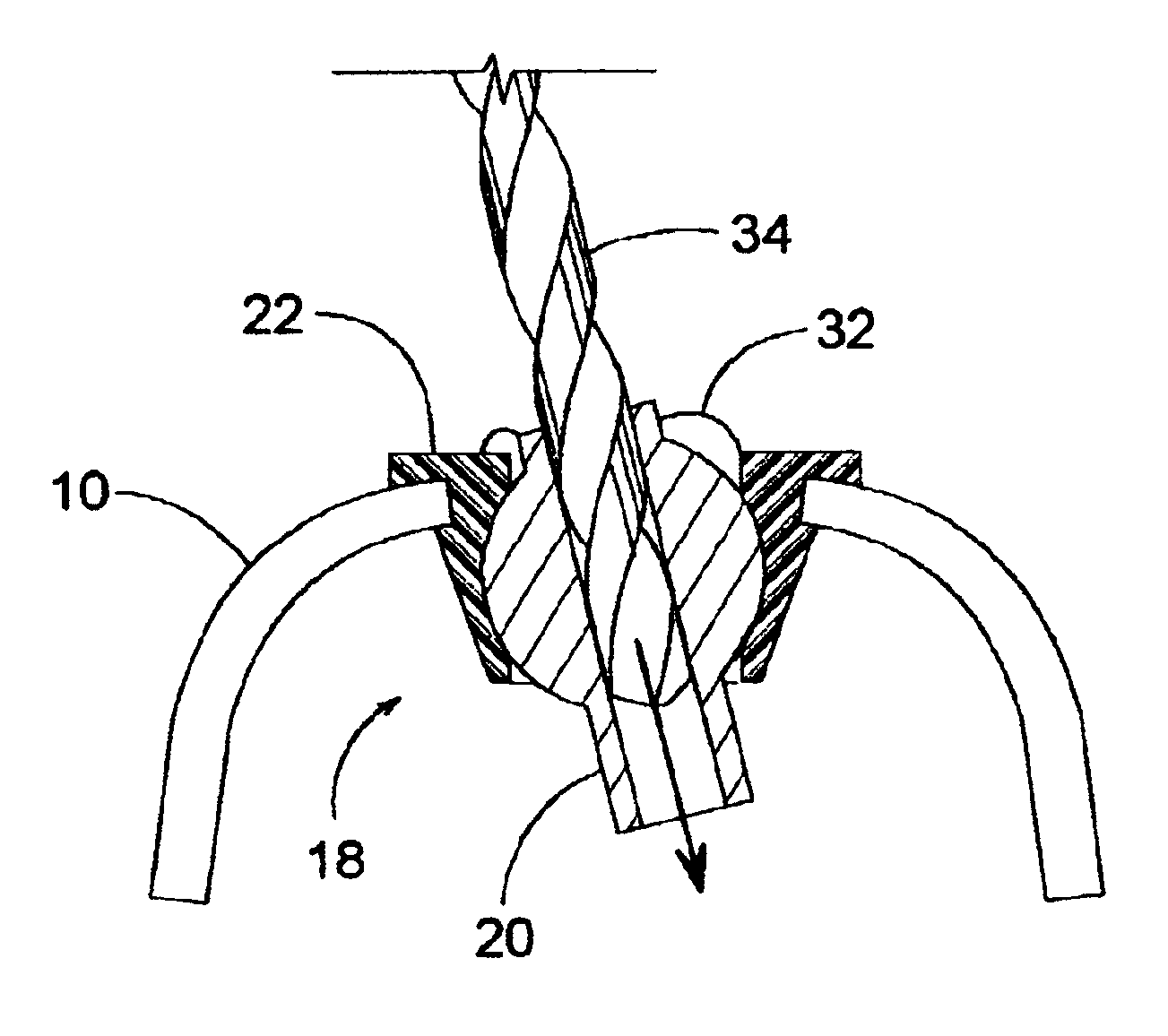

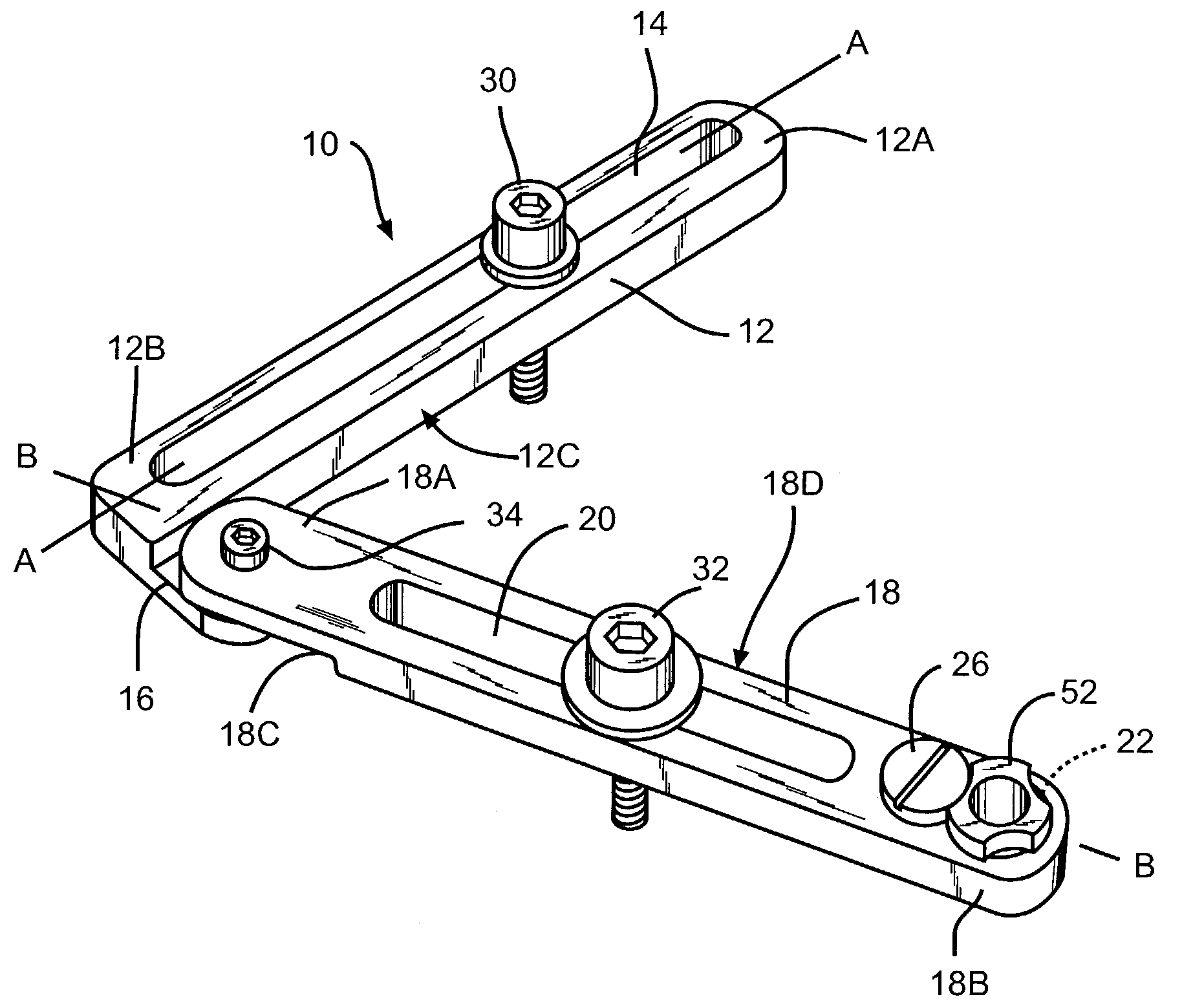

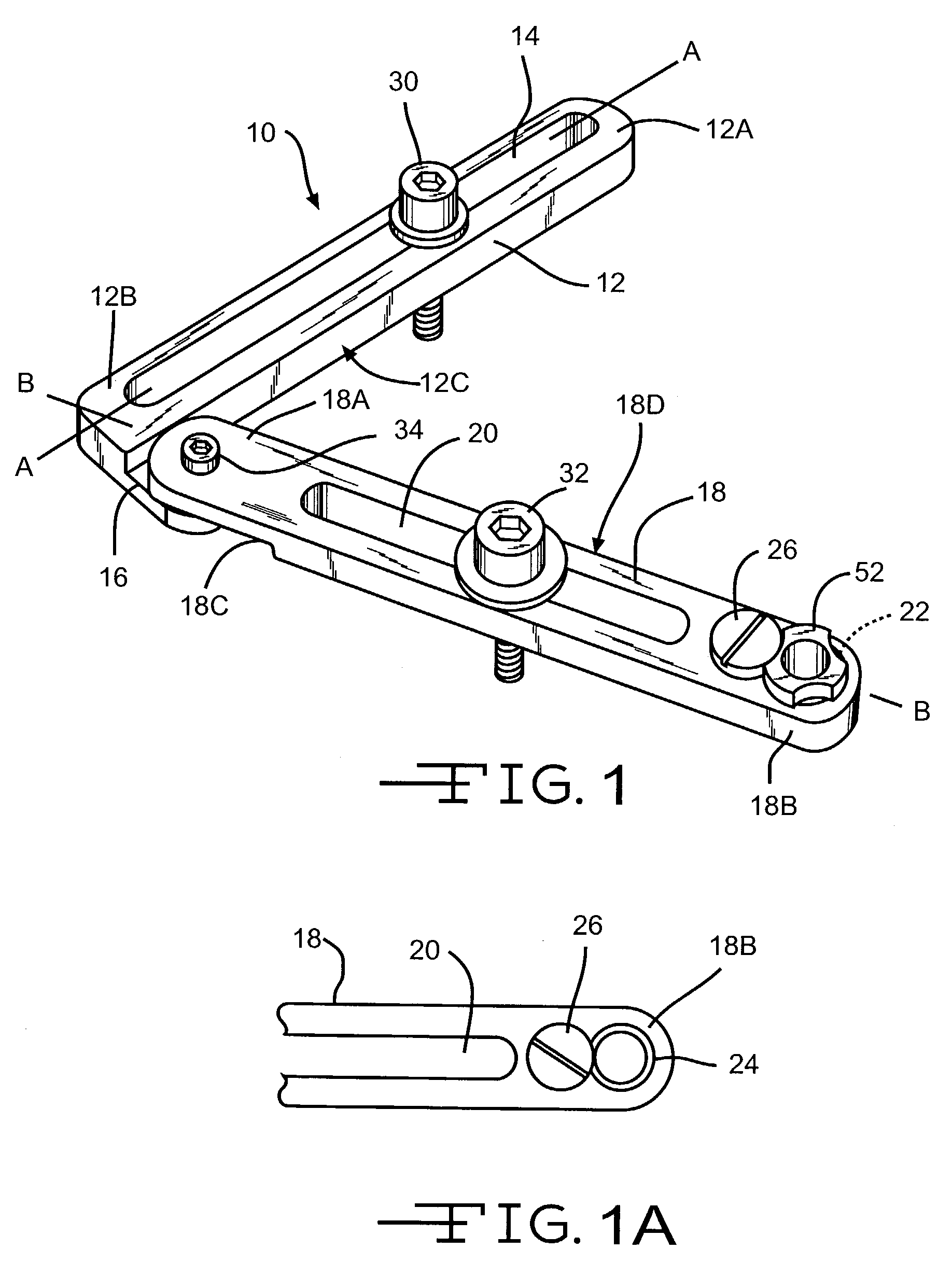

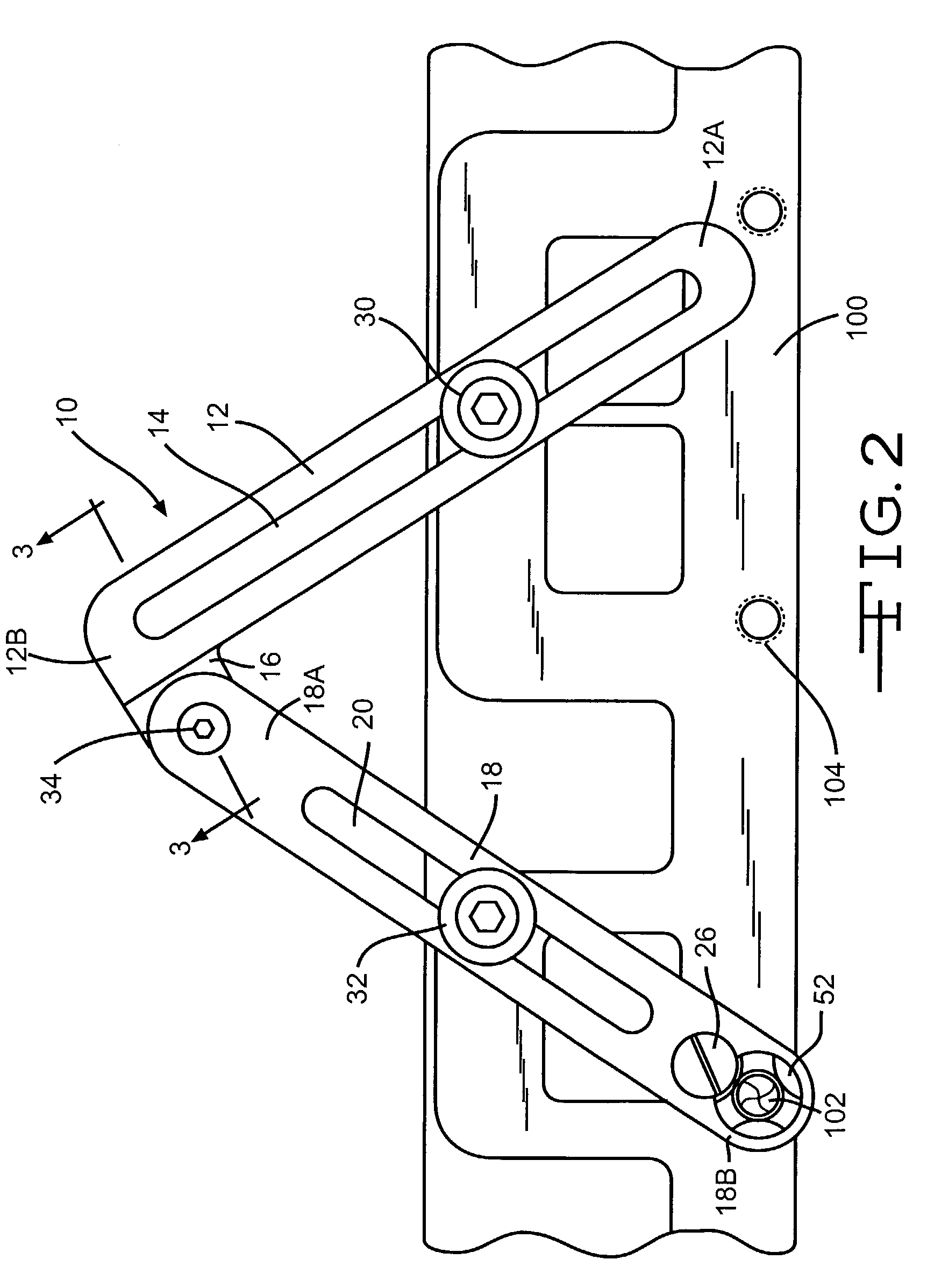

Tool for removing an object from a workpiece

ActiveUS7229237B1Fast and easy removalQuick alignmentDrilling/boring measurement devicesThread cutting machinesEngineeringMechanical engineering

A tool for removing an object from a hole in a workpiece which includes a first and second arm pivotably connected together. Each arm having an opening between the ends. The second arm also has a drill hole at the second end. A liner bushing and a drill bushing can be provided in the drill hole. To remove the object from the workpiece, the drill hole is positioned over the object and the arms are adjusted until at least one (1) of the openings of one of the arms is positioned over an existing hole in the workpiece. A securing bolt is then inserted through the opening in the arm into the hole in the workpiece and tightened to secure the tool to the workpiece. Next, a drill bit is positioned in the opening of the drill bushing adjacent the object and rotated until the drill bit is completely through the object.

Owner:FULGHAM CHARLES A

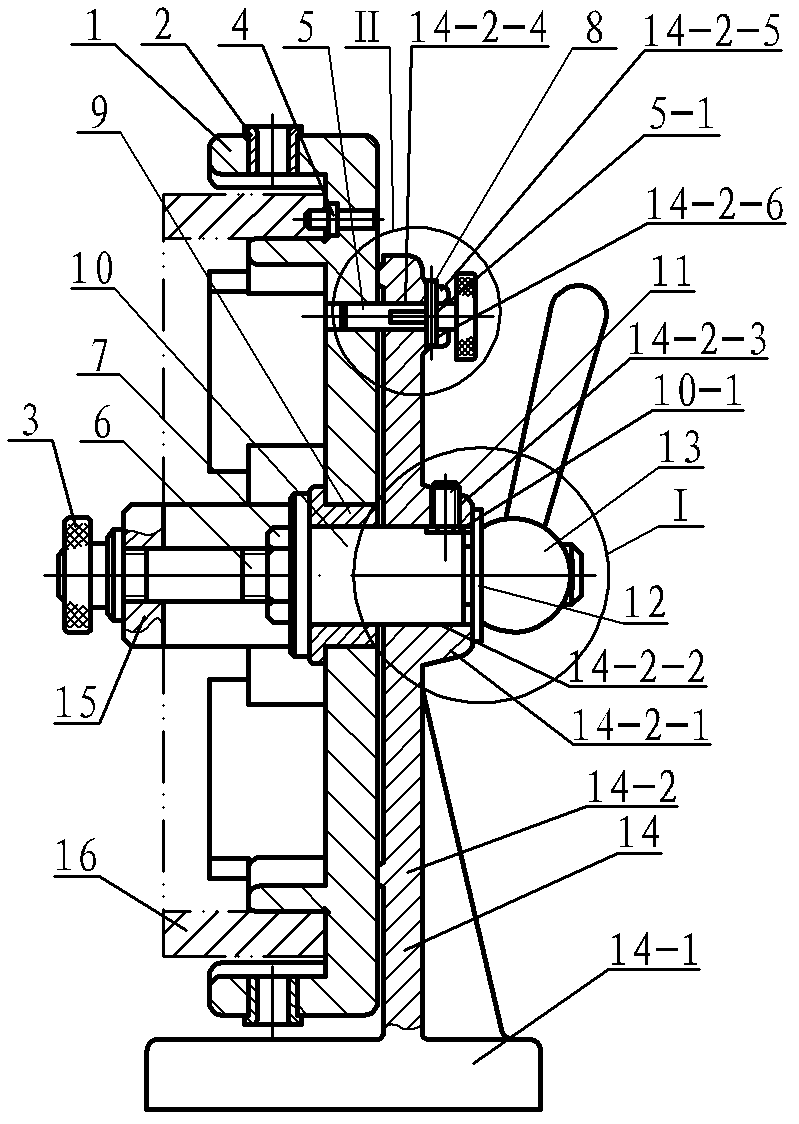

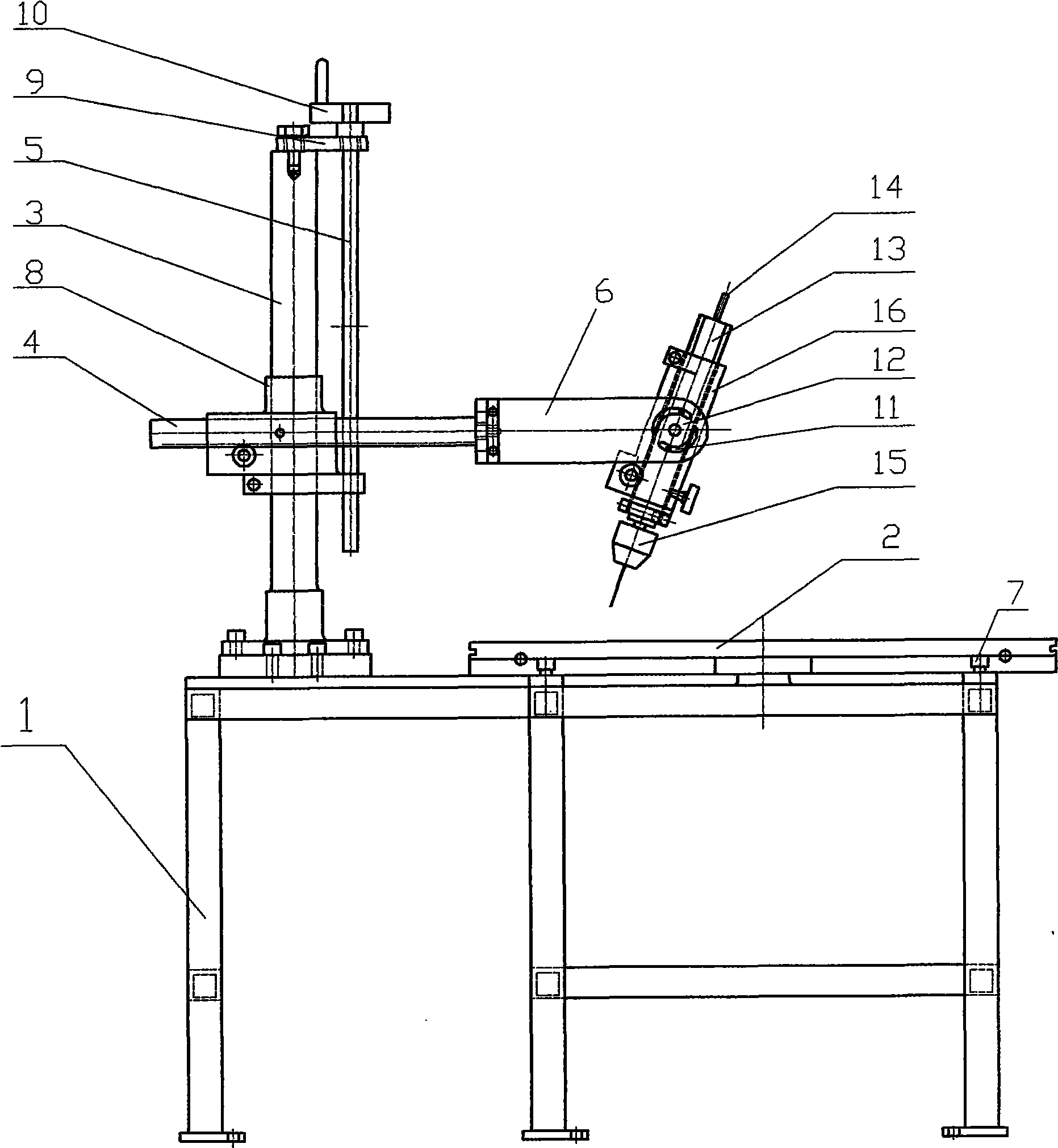

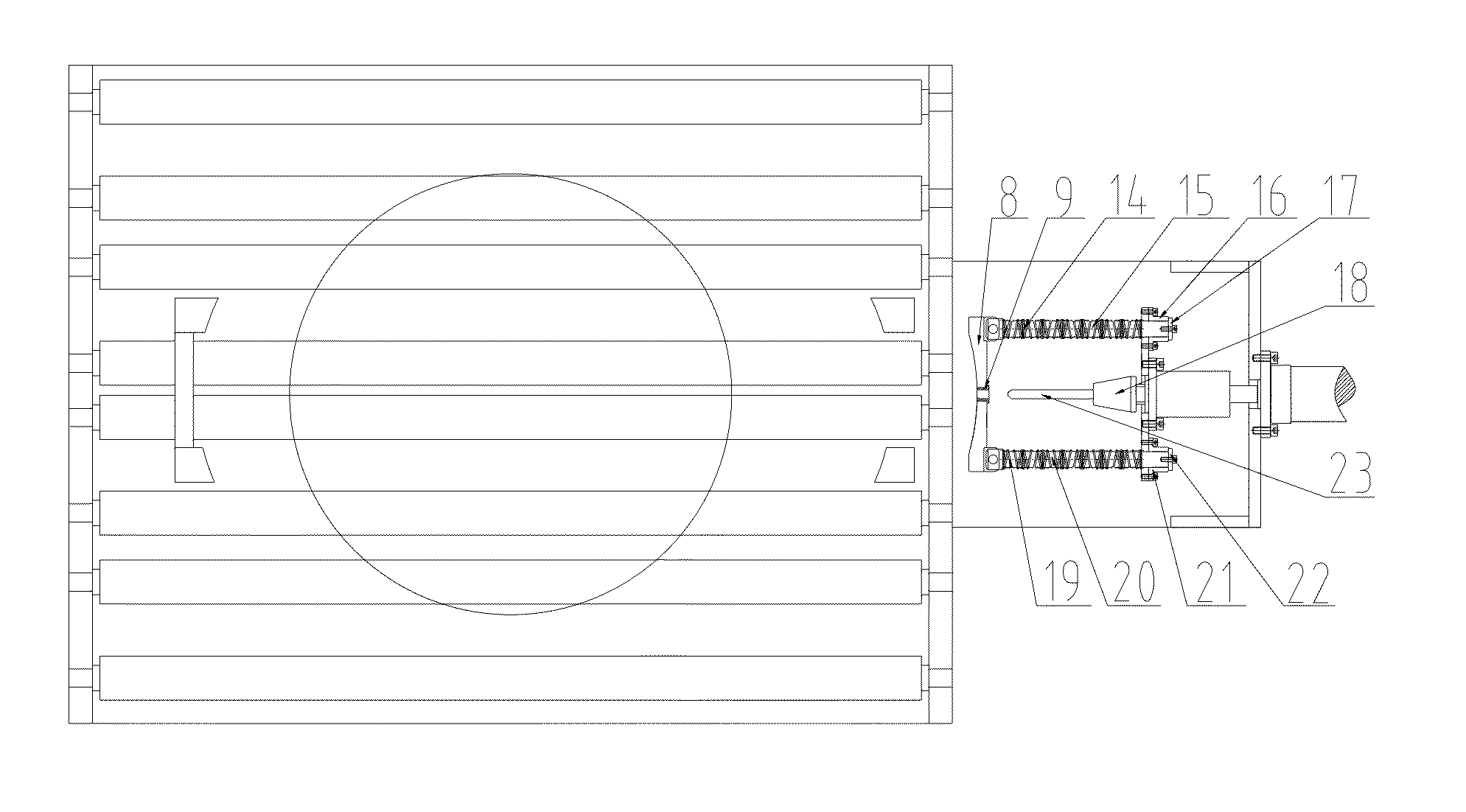

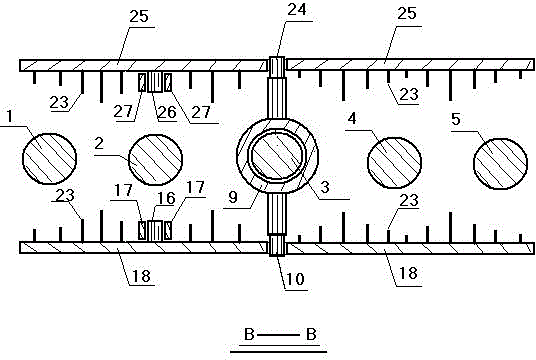

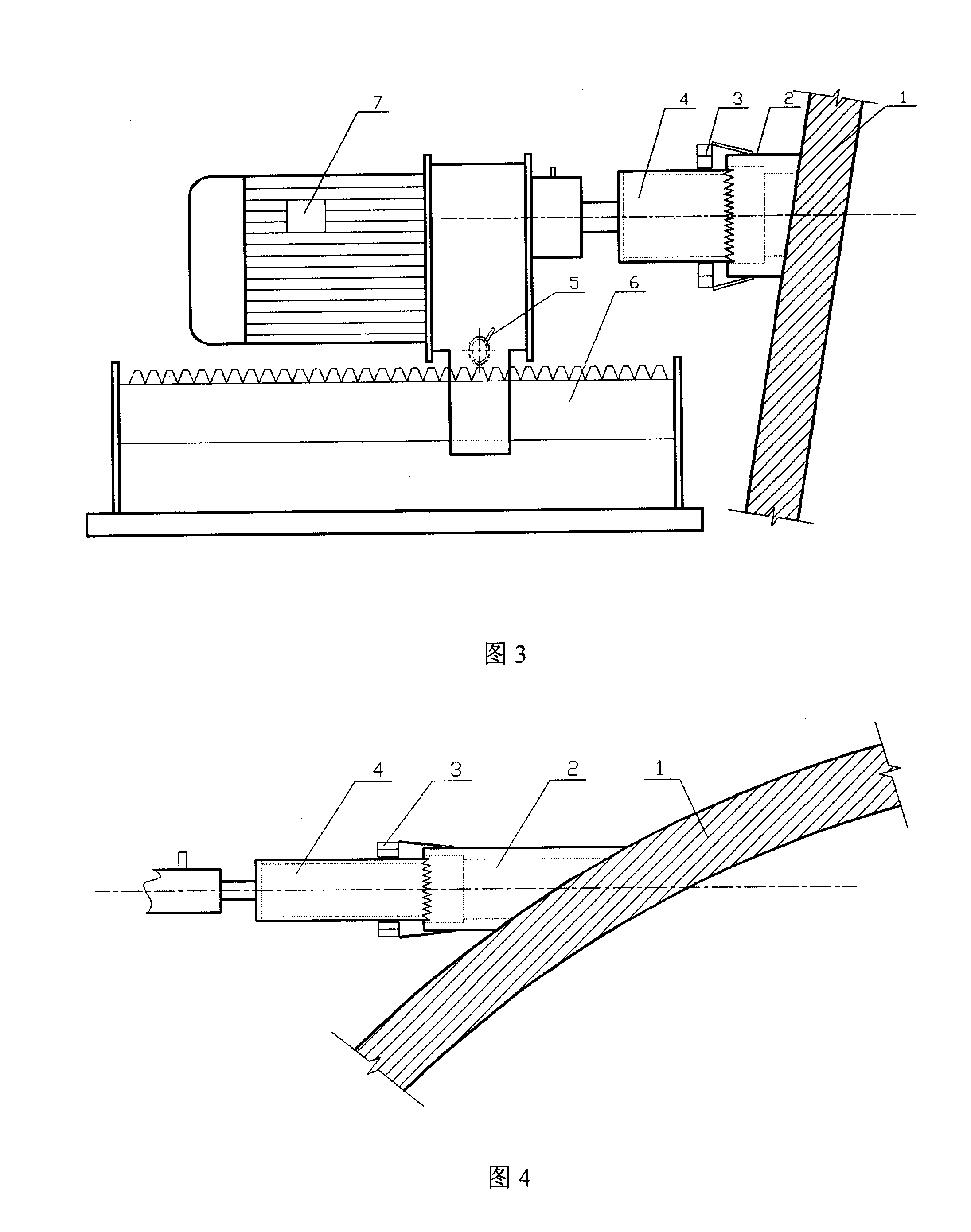

Multidirectional tire-mold drilling bench

InactiveCN101486108ASimple structureEasy to useLarge fixed membersBoring/drilling machinesSlope angleDrill bushing

The invention relates to a drill press, in particular to a drilling table of a multidirectional tyre mould. The invention provides the drill press which has a simple structure and convenient use and is convenient to solve the problem of processing a micropore on a curved surface. The drill press comprises a supporting platform (1), an upper bedplate (2) and a supporting rod (3); a transverse movable shaft (4) is arranged on the supporting rod (3); the supporting rod (3) is provided with a lifting screw rod (5) parallel to the supporting rod (3); the outer end of the transverse movable shaft (4) is provided with a slope angle connecting plate (6); and the top end of the slope angle connecting plate (6) is provided with a universal drilling mechanism (5). The universal drilling mechanism (5) comprises a drill bush seat (16), a pneumatic drill (15), a drill sleeve (13), and an air pipe (14). With the structure, as the transverse movable shaft can move up and down and right and left, the upper bedplate can rotate to certain degree and is fixed by a stable pin; through rotation of the universal drilling mechanism, holes are drilled arbitrarily according to the design so as to realize the aim of drilling holes on different curved surfaces.

Owner:王建军

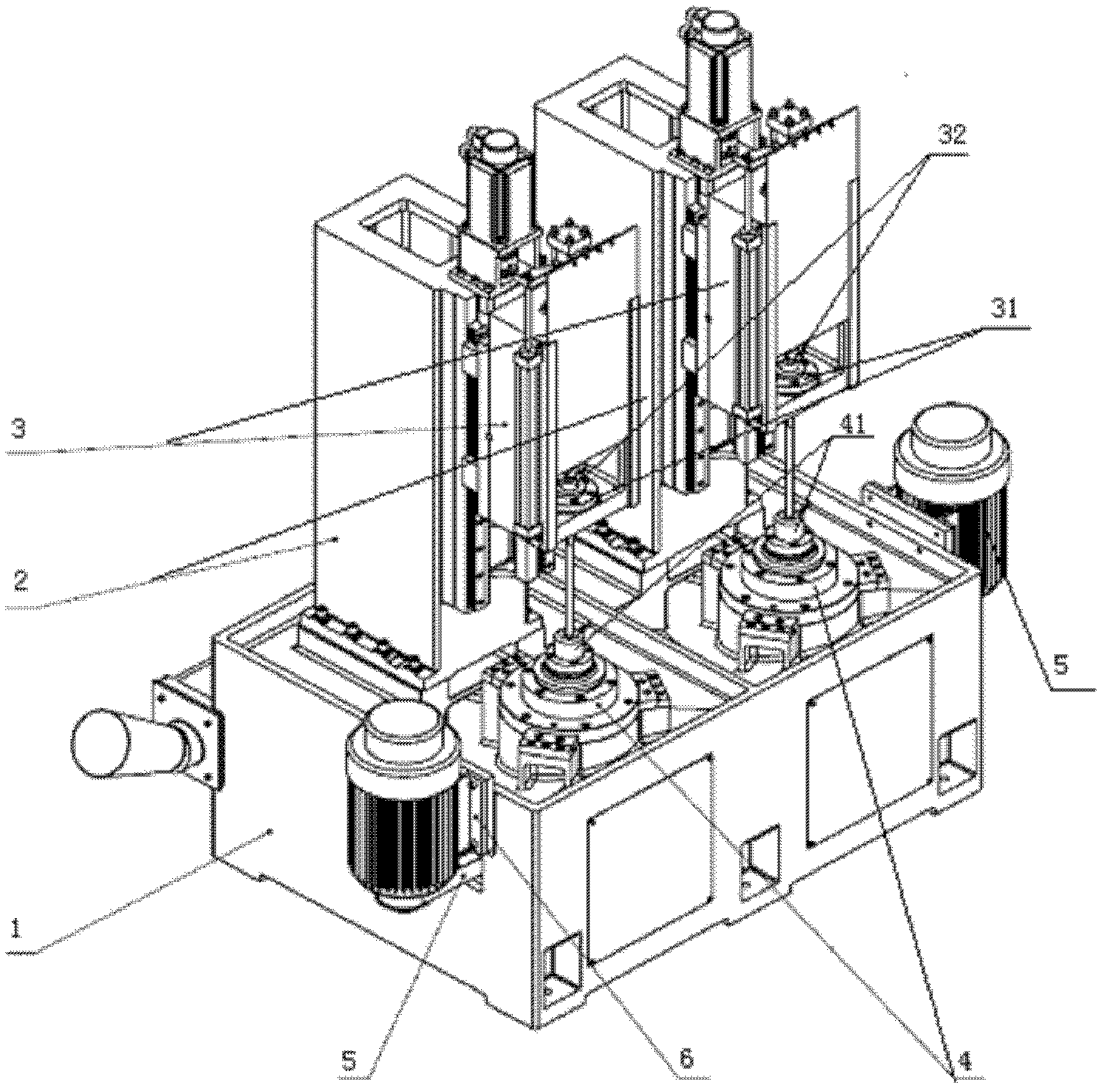

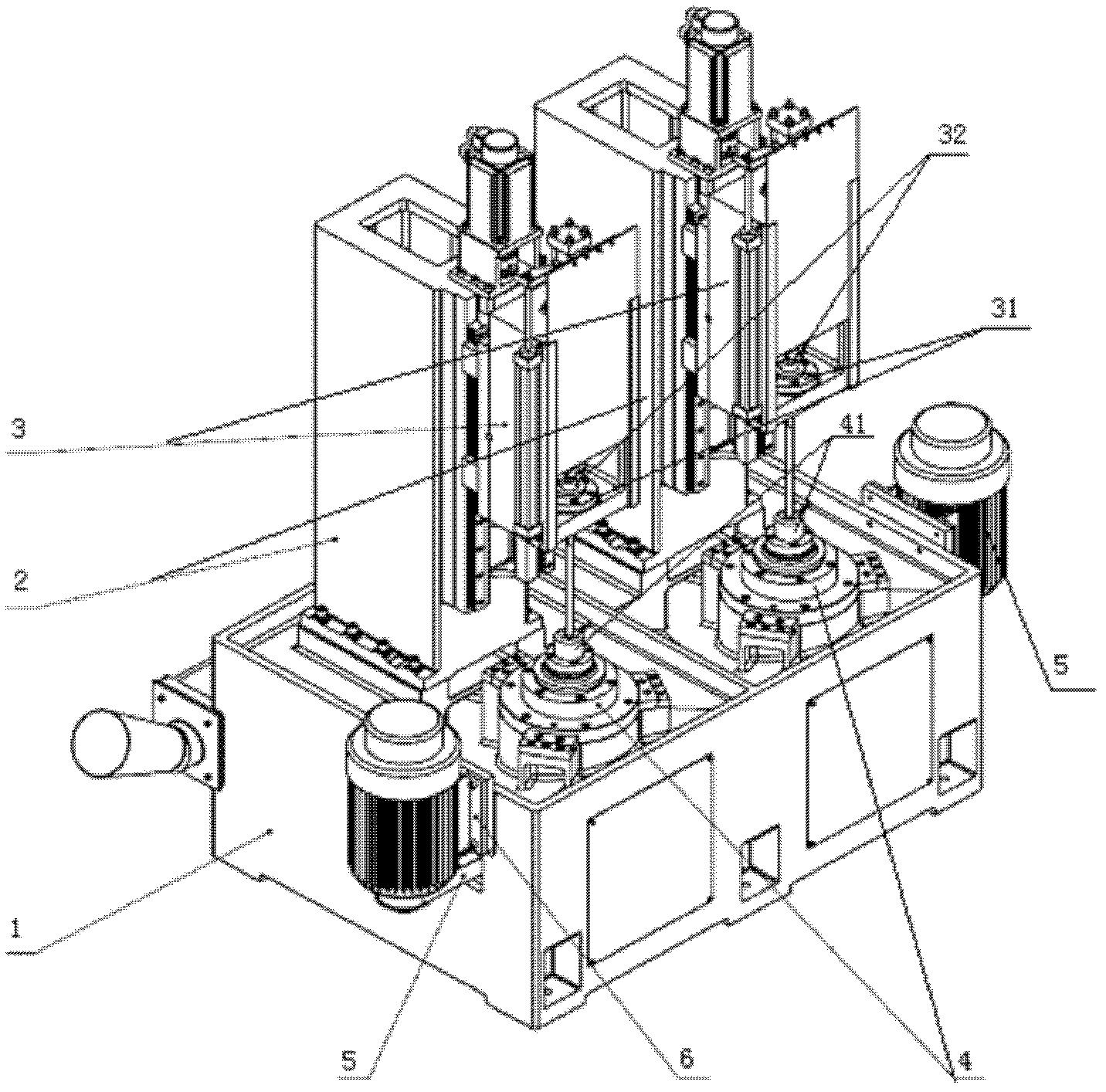

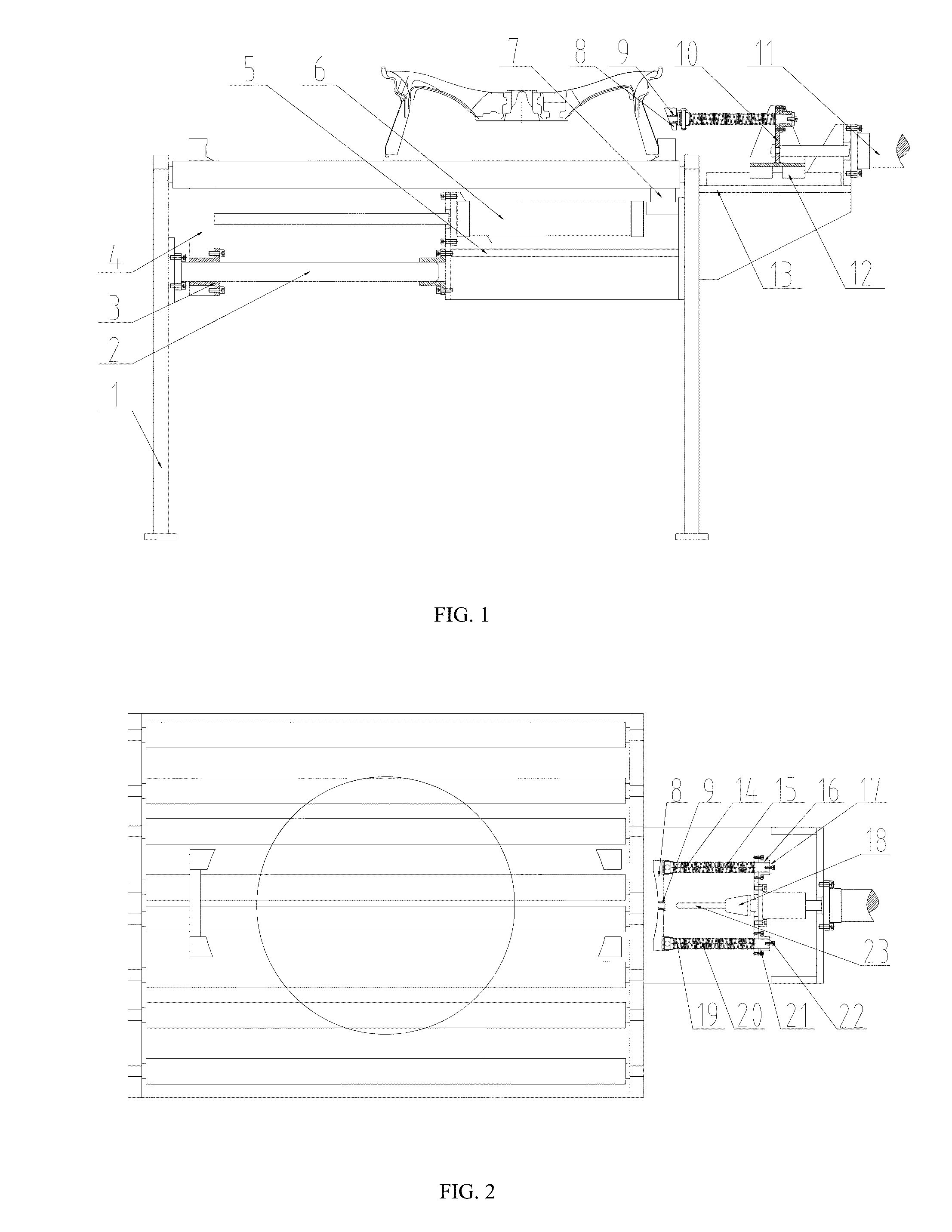

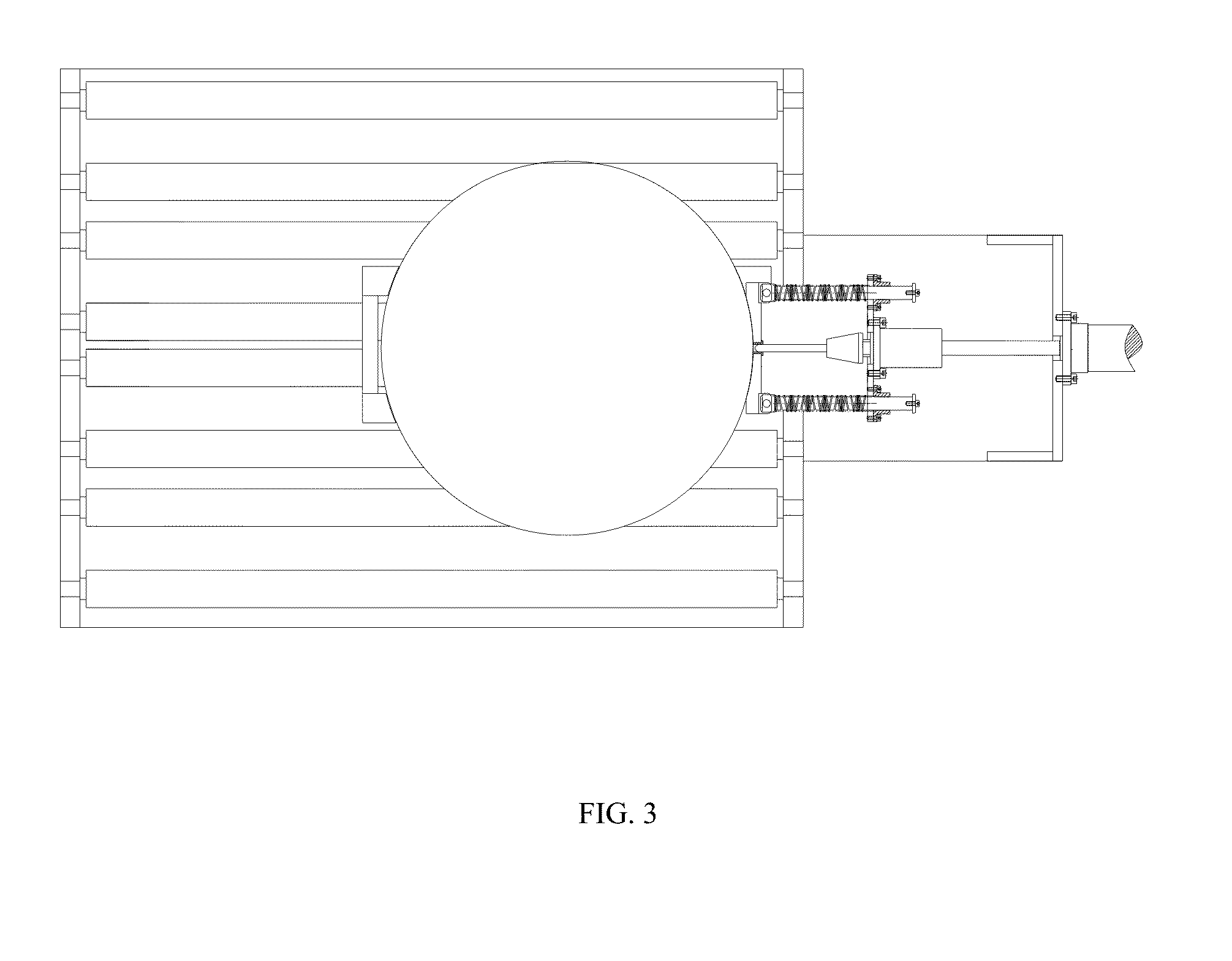

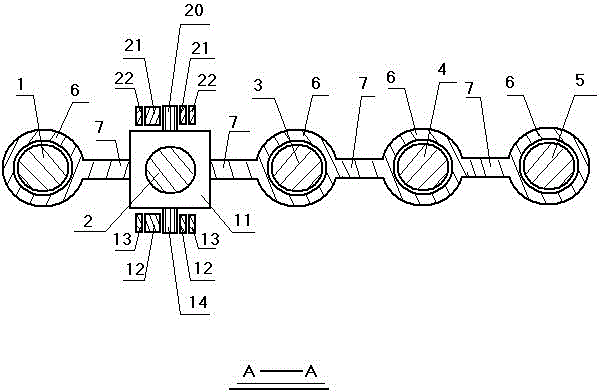

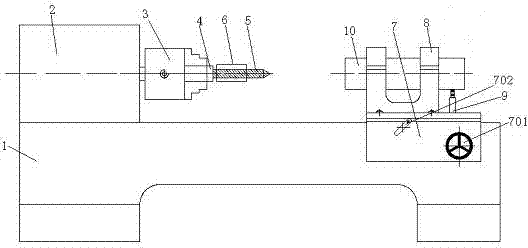

Numerical control inverted double-station deep hole drilling machine

InactiveCN102615305AEnsure dimensional accuracyEnsure internal surface finishBoring/drilling componentsMaintainance and safety accessoriesNumerical controlWork unit

The invention discloses a numerical control inverted double-station deep hole drilling machine. The numerical control inverted double-station deep hole drilling machine comprises a double-station machine body component, wherein the rear table surface of the machine body component is fixedly and vertically provided with a left frame type upright post component and a right frame type upright post component; two frame type compressing components are connected with the left upright post component and the right upright post component respectively along a sliding plate up and down by taking a slide rail as a guide; the compressing components are provided with drill bushing assembly seats, drill bushings and hydraulic oil cylinders, so that workpieces can be positioned and clamped; the front table surface of the machine body component is fixedly provided with a left main shaft component and a right main shaft component; the main shaft of the main shaft components is provided with a special deep hole gun drill; both sides of the machine body component are fixedly provided with variable frequency speed regulation motors; and the variable frequency speed regulation motors are in transmission connection with the main shaft components through synchronous belts. An inverted structure that a drill is arranged on the lower side effectively improves the chip removal and the heat dissipation during the deep hole machining and improves the surface accuracy of parts at the same time. A left working unit and a right working unit can be alternately used in waiting time during operation, so that the production efficiency is improved.

Owner:ANHUI LICHENG MACHINERY EQUIP

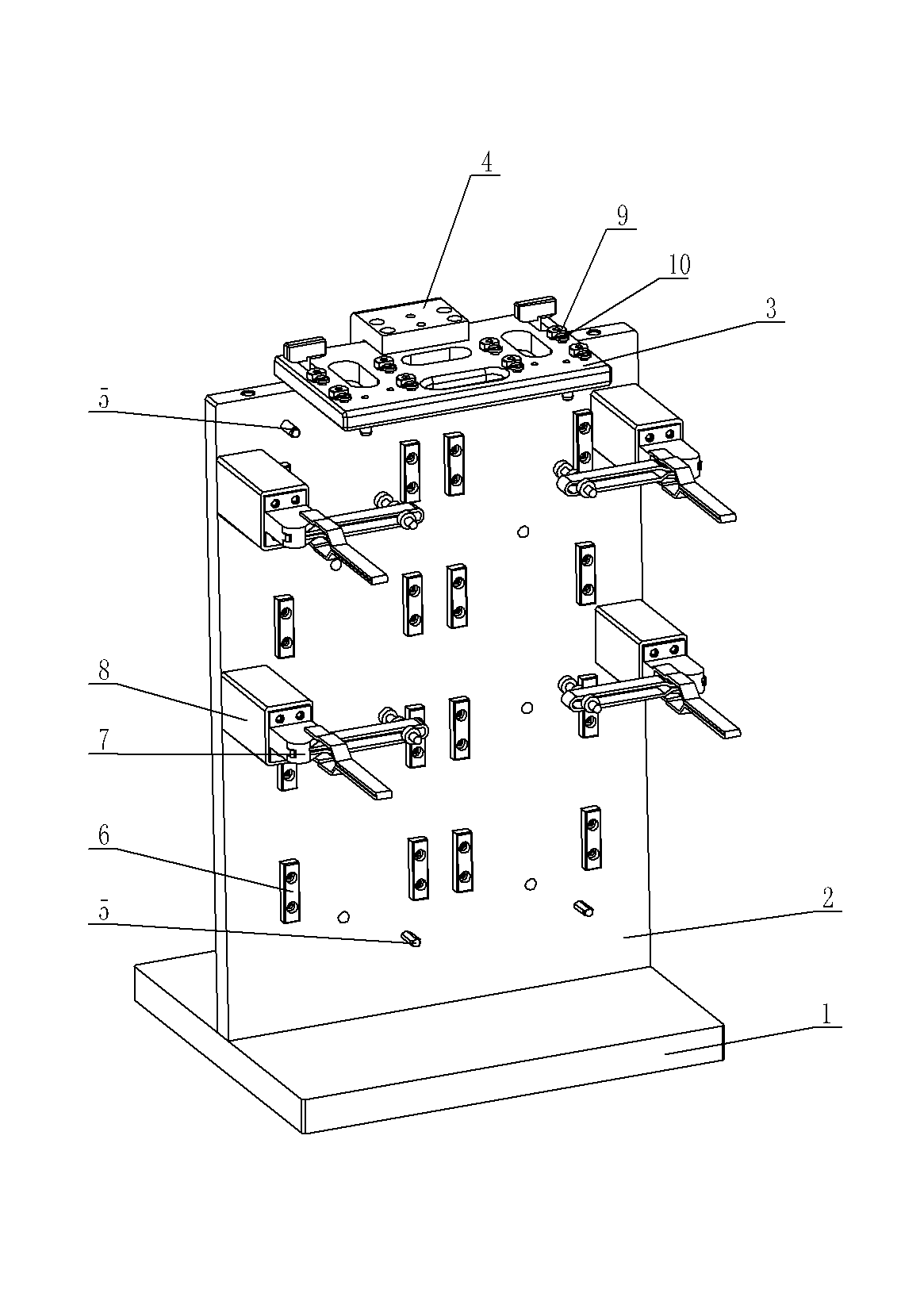

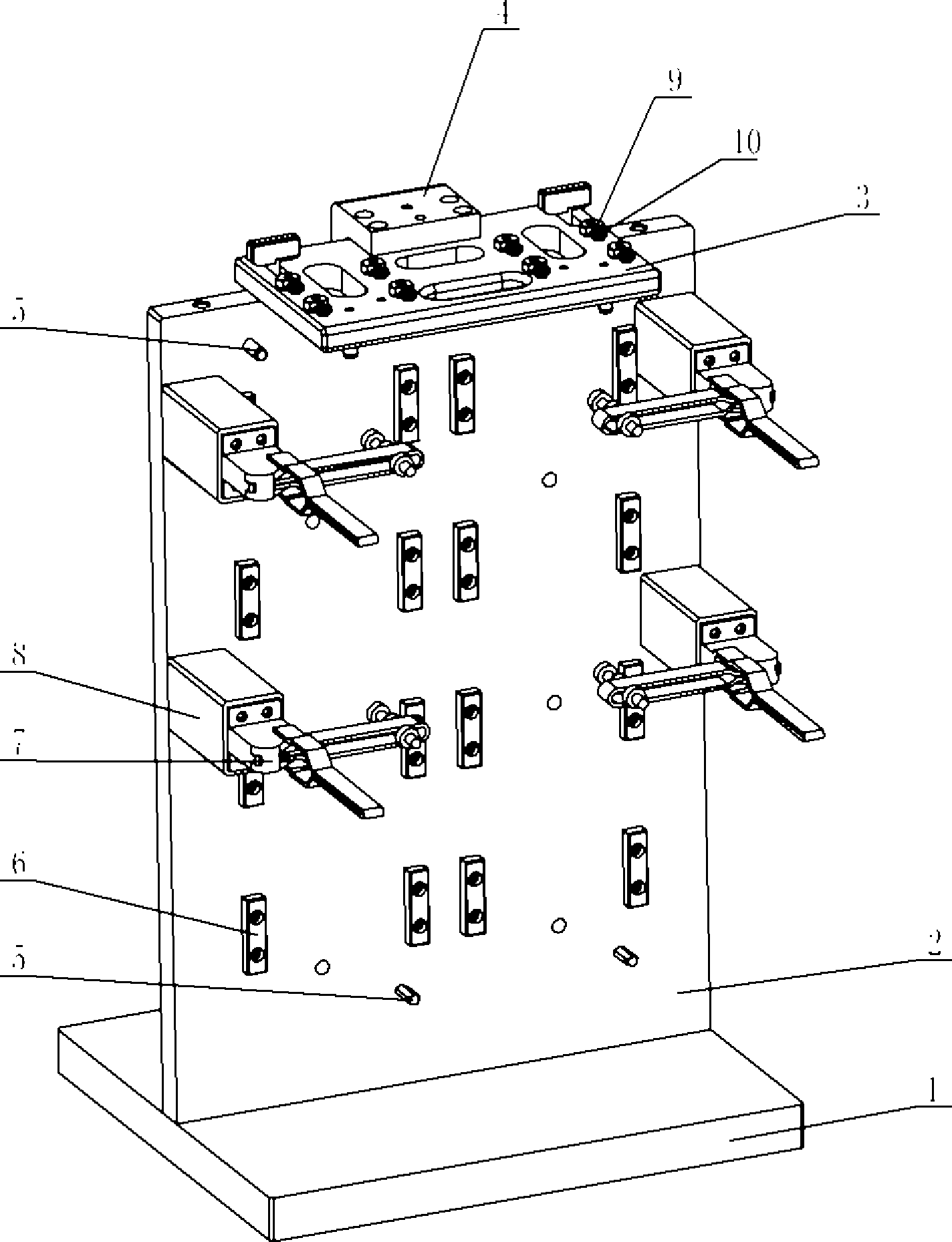

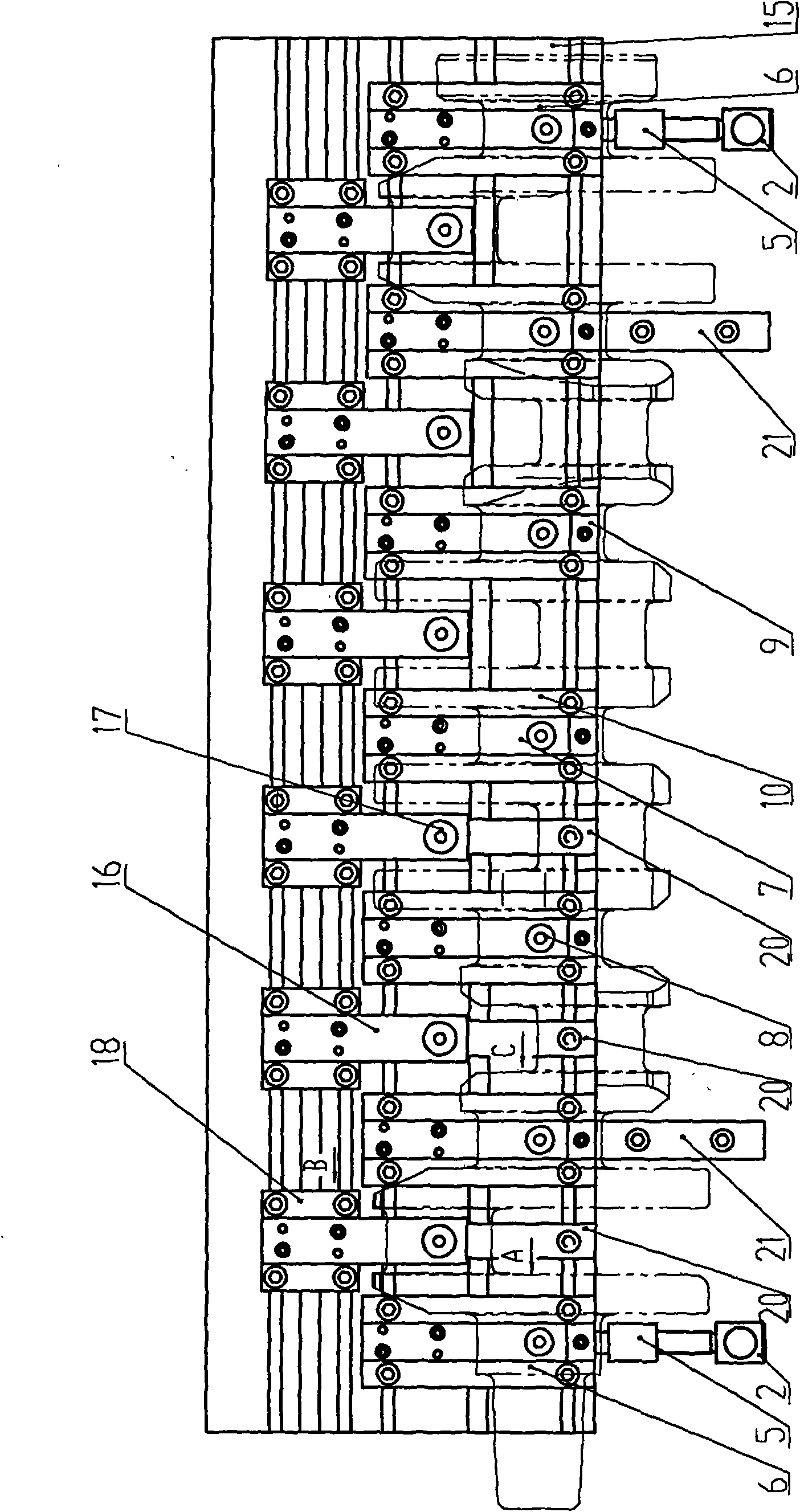

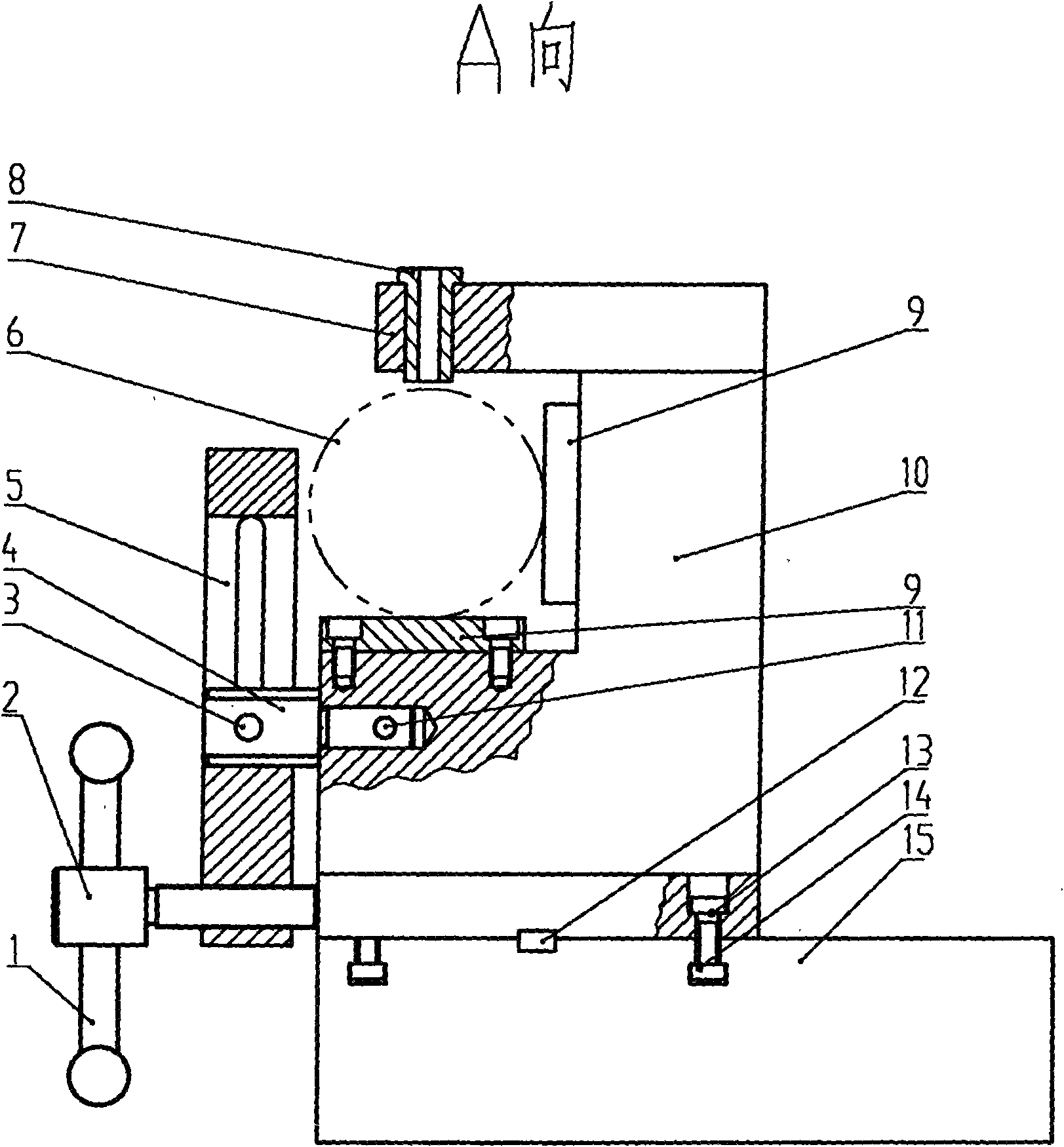

Drilling fixture for cylinder cover

InactiveCN102554659APrecise positioningClamp firmlyPositioning apparatusDrill jigsMechanical engineeringDrill bushing

The invention provides a drilling fixture for a cylinder cover, which can effectively improve positioning precision and clamping precision of a workpiece, accordingly guarantees machining precision of the workpiece, can greatly reduce labor intensity of workers, enhances production efficiency and lowers production cost. The drilling fixture comprises a bottom plate, and a fixing plate is vertically mounted on the bottom plate. The drilling fixture is characterized by further comprising a workpiece positioning and clamping device and a plate jig, the workpiece positioning and clamping device is fixed onto a workpiece clamping surface of the fixing plate, the plate jig is connected with the upper end of the fixing plate by a hinge device, and a drill bushing is correspondingly mounted on the plate jig according to a to-be-drilled position of the workpiece.

Owner:WUXI DAWN DIE & STAMPING

Device for Automatically Drilling Wheel Rim Online

InactiveUS20150273595A1Extended service lifeAvoid breakingDrilling/boring measurement devicesThread cutting machinesX-rayEngineering

The present invention provides an automatic wheel rim online drilling device, comprising a frame, an air cylinder, a profiling drill jig, a drill bush, a servo electric cylinder, a drilling power head, etc. Firstly, a sensor enables a wheel to be positioned, and the air cylinder causes left clamping blocks to move rightward by two guide rods and guide sleeves so as to clamp the wheel jointly with a right clamping block; the servo electric cylinder causes a drilling system to move toward the wheel and the profiling drill jig can first come into good contact with the wheel rim and then the servo electric cylinder moves continuously to compress upper and lower springs so that the drill bit enters the drill bush, and at this time the drilling power head drives the drill bit to rotate, thus starting drilling on the wheel rim. By using the device of the present invention, X-ray rejects of wheels can be automatically marked by drilling, and the device can adapt to flow casting spun blanks with thick rims; and through orientation of the drill bush, the situation that the drill bit is frequently broken when drilling on the arc surface of the outer side of the wheel rim can be effectively avoided.

Owner:CITIC DICASTAL

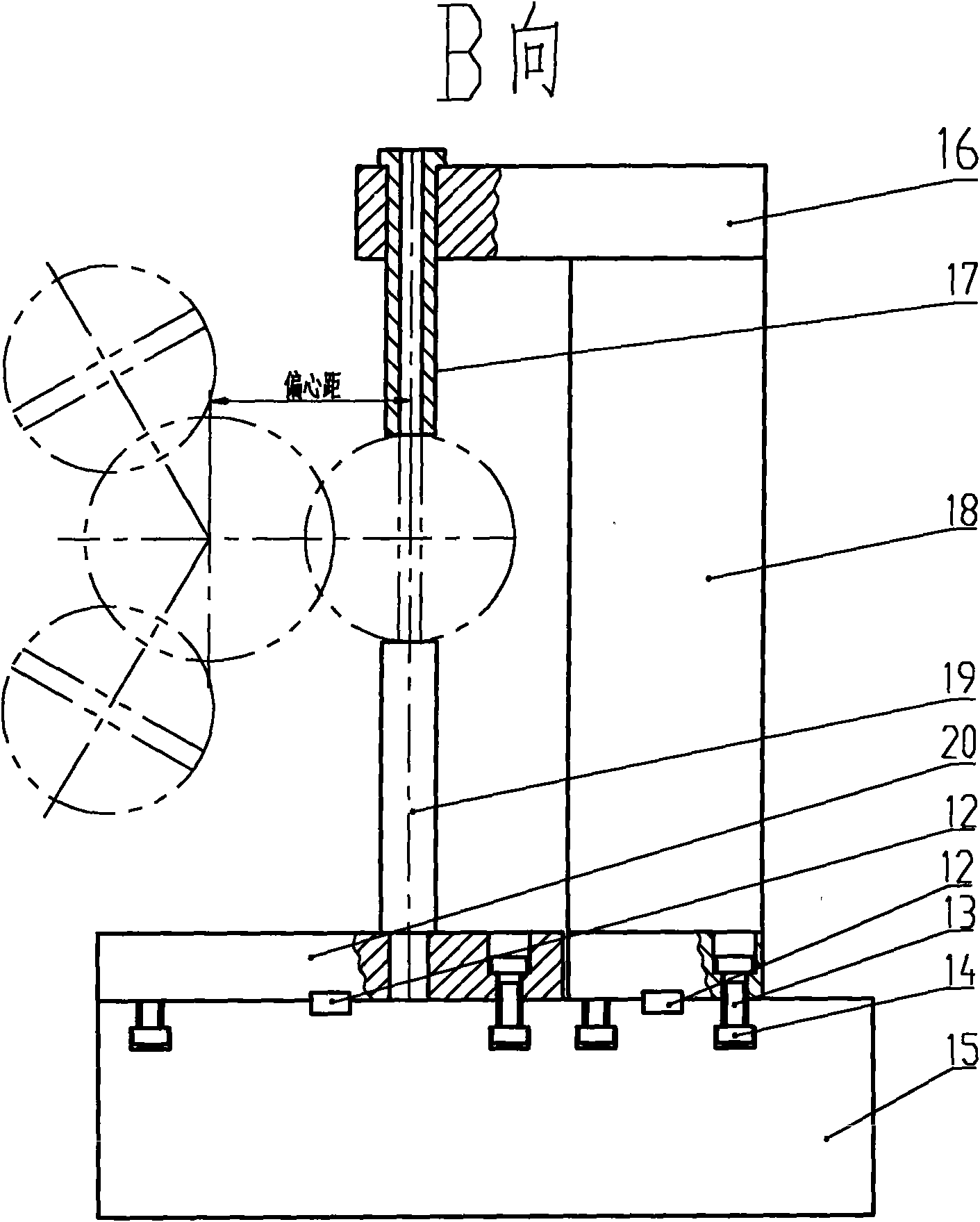

Five-axis SMW pile machine

Disclosed is a five-axis SMW pile machine. A second drill spindle is arranged on the front portion of a transfer case, a first eccentric shaft is fixed to the second drill spindle, a first wheel sleeve is arranged on the periphery of the first eccentric shaft, the lower portion of the first wheel sleeve is connected to a second wheel sleeve through a connecting plate, a third drill spindle is arranged in the second wheel sleeve and fixed to the left potion of a first stirring arm, a first drill spindle is hinged to the middle of the first stirring arm and fixed to the front portion of a second drill bushing, and the second drill bushing is fixed to a first drill bushing on a third drill rod through a second clamping plate; a fourth drill spindle is arranged on the rear portion of the transfer case, a second eccentric shaft is fixed to the fourth drill spindle, a third wheel sleeve is arranged on the periphery of the second eccentric shaft, the lower portion of the third wheel sleeve is connected to a fourth wheel sleeve through a connecting plate, a sixth drill spindle is arranged in the fourth wheel sleeve and fixed to the left portion of a second stirring arm, a fifth drill spindle is hinged to the middle of the second stirring arm and fixed to the rear portion of the second drill bushing, multiple stirring bars are fixed to the inner side of the first stirring arm, and multiple stirring bars are fixed to the inner side of the second stirring arm.

Owner:胡仔娟

Laser-guided coordination hole drilling

ActiveUS7384220B2Eliminate needAircraft componentsDrilling/boring measurement devicesLaser targetLaser tracker

A laser-guided coordination hole tool for precisely drilling holes in large parts includes a positioning table, a bushing cavity for receiving drill bushings, a clamping device, and a laser target. A laser-guided coordination hole tool may include a software interlock to prevent drilling in an improper location on the part. A method of drilling coordination holes includes probing a part to determine its reference frame, rigidly affixing a laser-guided coordination hole tool to the part, probing a target on the laser-guided coordination hole tool to determine the reference frame for the laser-guided coordination hole tool, accurately positioning a drill bushing over the hole location, and drilling a hole. A system for drilling coordination holes includes a laser-guided coordination hole tool, a bushing, a tooling, a drill motor, a laser tracker, and a computer running a coordination-hole drilling program.

Owner:THE BOEING CO

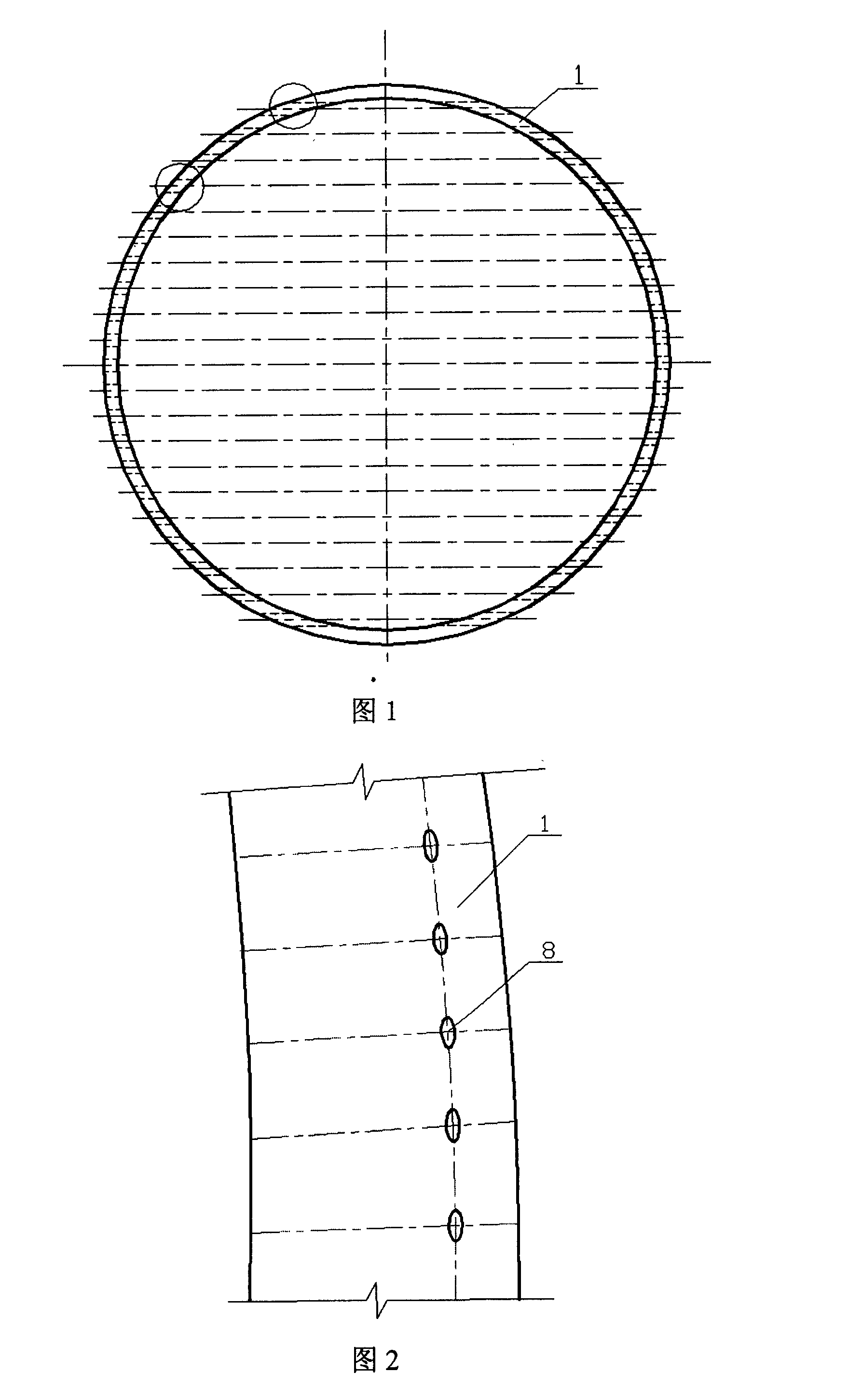

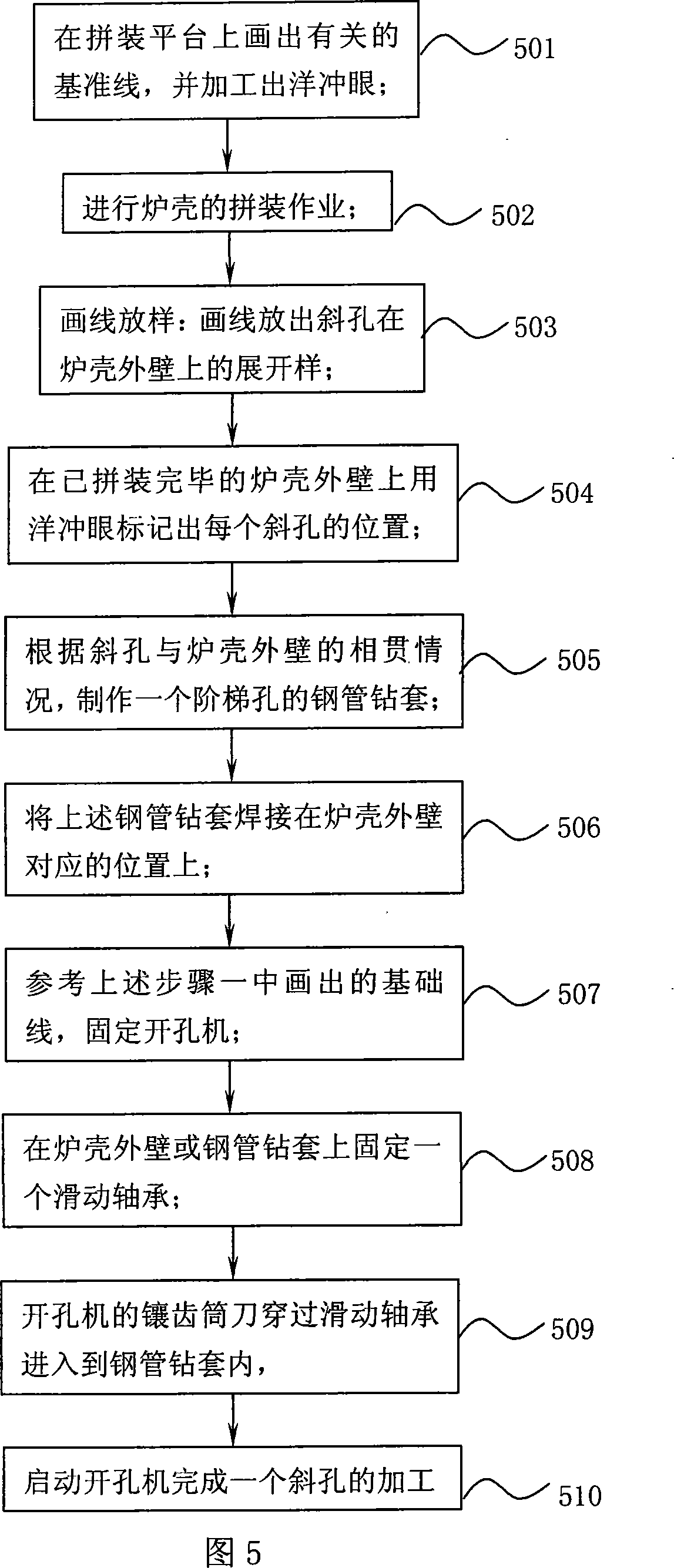

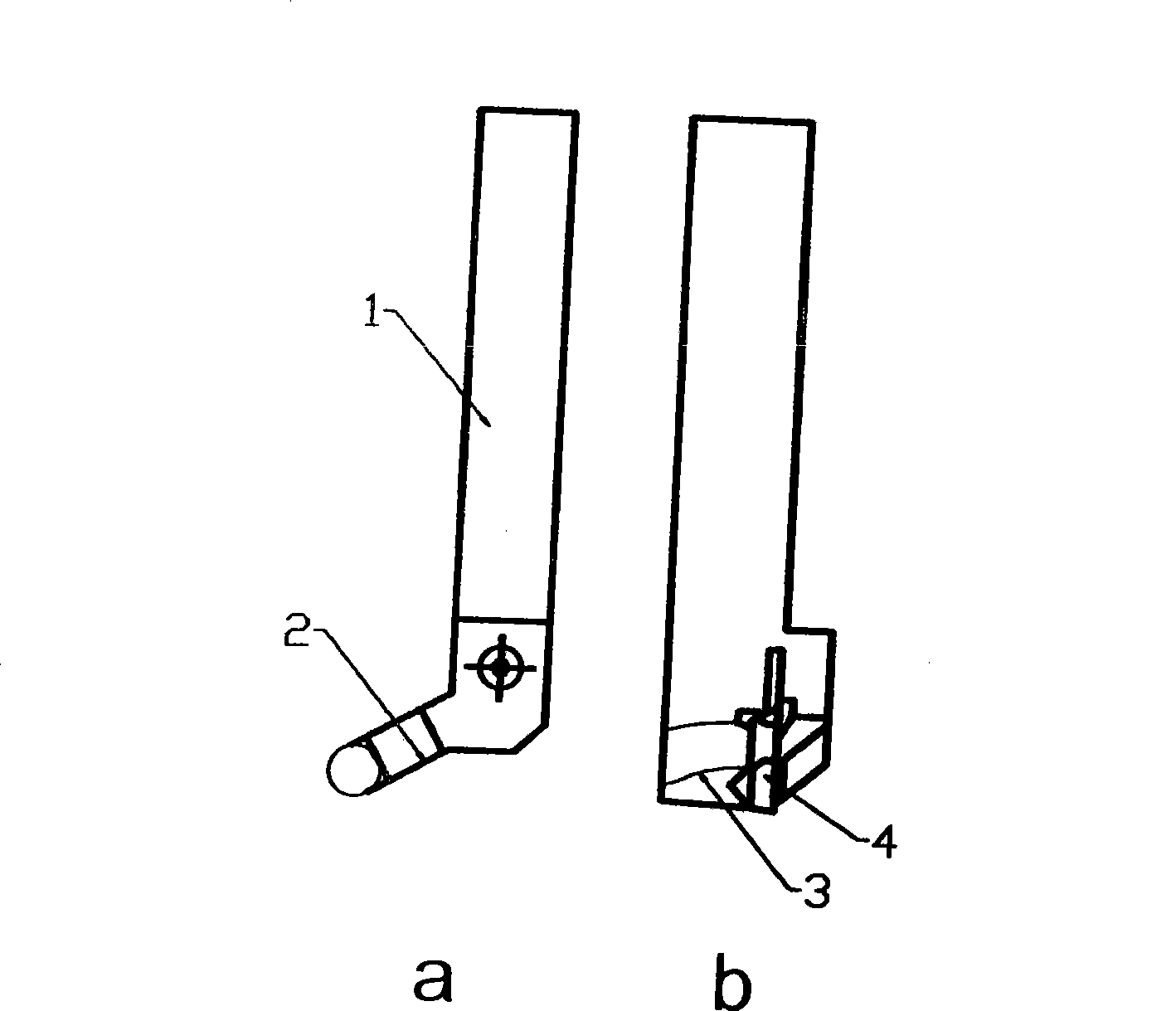

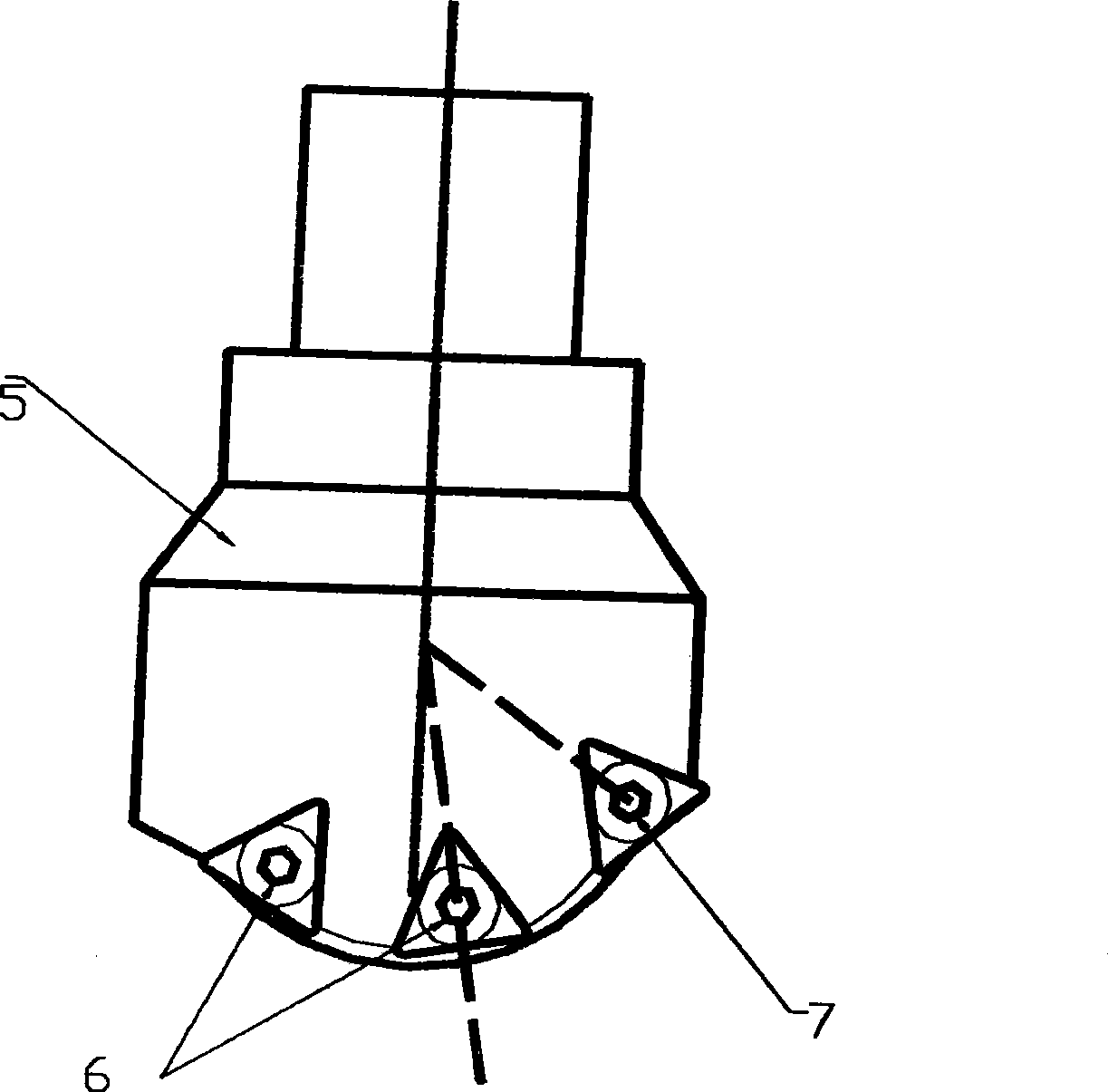

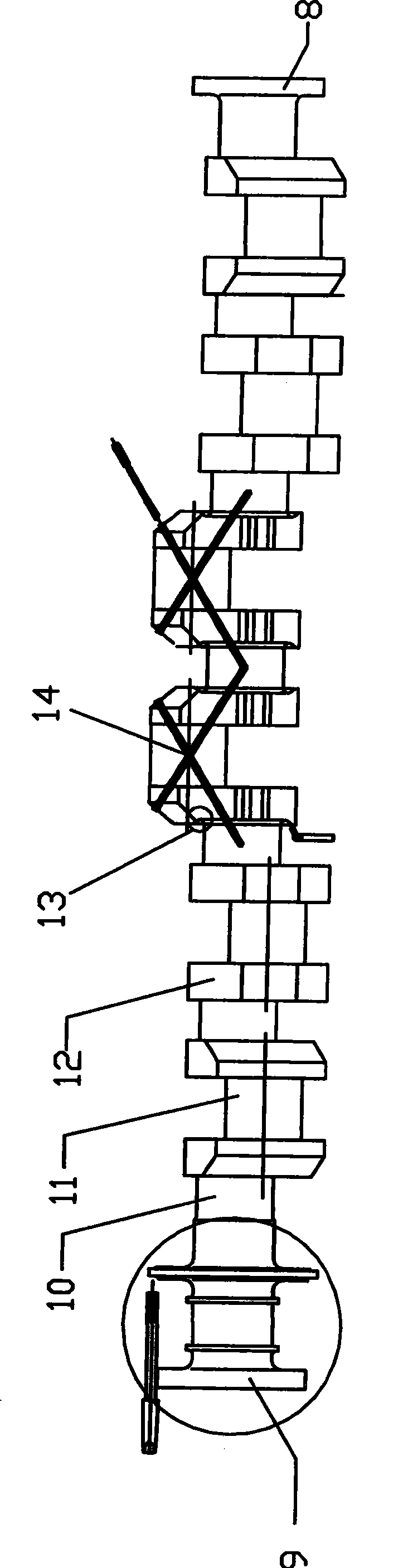

Processing method of blast furnace furnace jacket upper inclined hole

InactiveCN101157146AImprove accuracyAvoid damageDrilling/boring measurement devicesOther workshop equipmentEngineeringProjection line

The invention discloses a processing method of an inclined hole on a blast furnace casing, and the processing method comprises the following steps that: a datum line for assembling the furnace casing and a projection line for a water tube on an assembling platform are drawn, and a straight drift eye is processed on a suitable position; a splicing operation of the furnace casing is performed; lines are drawn to show out the expanding shape of the inclined hole on the outer wall of the furnace casing; each inclined hole is marked on the outer wall of the furnace casing through the straight drift eye; a steel tube drill bush for a shoulder hole is made; the steel tube drill bush produced which keeps consistent with the inclined hole sample of the outer wall of the furnace casing according to the intersecting die then is welded on the corresponding position of the outer wall of the furnace casing; according to the projection line and the datum line for the cooling water tube drawn in step 1, the horizontal location of a tapping machine is fixed; a sliding bearing is made according to the size of the steel tube drill bush and the cog cutter of the tapping machine; the cog cutter of the tapping machine is threaded into the sliding bearing and then arranged into the steel tube drill bush, and then the sliding bearing is fixed with the steel tube drill bush or the furnace casing; the tapping machine is connected, started, and operated to finish the processing of an inclined hole.

Owner:TIANJIN 20 CONSTR

Tool and method for processing half-speed machine crankshaft

ActiveCN101462178AGuarantee product qualityIncrease productivityMilling cuttersTurning toolsEngineeringMachine tool

The invention relates to a tool and a method for machining a crankshaft of a medium speed machine. The machining tool is provided with a cutter for machining a load release groove, a R40 special molding cutter for machining the surface of a balance block and a plug of a crossed hole of a drill gun. The machining method comprises: firstly, according to the prior method, a crankshaft billet of the medium speed machine is subjected to primary TR forging and molding; a main journal, a turning journal, the load release groove, the output end of the load release groove and a free end flange are subjected to machining; the milling balance block ,the shape of a turning arm, and end flange drilling are evenly distributed with holes and screw holes are subjected to machining; the main journal and the turning journal are ground and are subjected to final finishing; subsequently, the load release groove is processed through the cutter for machining the load release groove from outside to inside for a few times by delamination. The R40 special molding cutter is used to machine the surface of the balance block in a vertical cutting mode. The gun drill drills and cuts a guide hole and an oil hole to a crossed hole, and a plug is adopted in the crossed hole. A phi 700 flange hole is drilled through an aiguille and is machined through a Mohs lengthening drill bush. The tool and the method for machining can ensure the quality of a product and greatly improve production efficiency.

Owner:武汉重工铸锻有限责任公司

Bias correction method of drill bushing mounting hole of drill plate

InactiveCN103203581AShorten the construction periodImprove efficiencyDrilling/boring measurement devicesDrill jigsDrill bushingPetroleum engineering

The invention belongs to the mechanical processing technology, and relates to a bias correction method of a drill bushing mounting hole of a drill plate. The method for correcting the drill bushing mounting hole comprises the following steps of: measuring a bias value of the drill bushing mounting hole; eccentrically chambering; installing a correction bushing; and installing a drill bushing provided with a correction bushing in the chambered drill bushing mounting hole. According to the bias correction method of the drill bushing mounting hole of the drill plate, a drill bushing does not need to be newly manufactured, thereby shortening the working period, improving the efficiency and meeting the requirement of nasty piece processing.

Owner:HARBIN

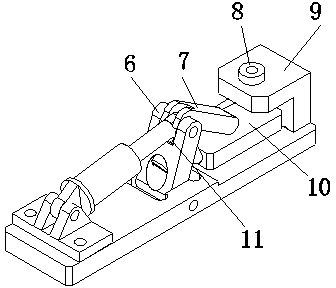

Clamp for drilling oil hole on crankshaft

InactiveCN101628384APrecise positioningImprove drilling efficiencyPositioning apparatusDrill jigsCrankshaftDrill bushing

The invention relates to a clamp for drilling oil holes on a crankshaft, which comprises a clamp body, a clamping mechanism, a connecting rod positioning mechanism and a drilling jig frame mechanism, wherein the clamping mechanism is provided with a drilling jig supporting seat, a pressing plate and a replaceable cushion block; the drilling jig supporting seat is movably arranged on the clamp body; the pressing plate is arranged on a pressing plate strut on the drilling jig supporting seat through a hinge pin; the lower part of the pressing plate is provided with a hold-down bolt; the hold-down bolt is screwed in, passes through the pressing plate and presses against the drilling jig supporting seat; a turn-knob compresses the bolt; a spindle neck is compressed or loosened through the lever action of the hinge pin arranged on the pressing plate and the pressing plate strut; the connecting rod positioning mechanism comprises a positioning column and a liner plate; the positioning column is arranged in a replaceable liner plate positioning hole; the top of the positioning column supports a connecting rod neck; and the drilling jig frame mechanism comprises the drilling jig supporting seat, a drilling jig plate and a drill bush. The clamp has the advantages of reasonable structure, convenient assembly, low manufacturing cost, strong popularity, and high efficiency of drilling the oil holes, greatly shortens the manufacturing period, and is suitable for clamping various crankshafts for drilling straight oil holes.

Owner:TIANRUN IND TECH CO LTD

Special fixture of drill blade top centre hole for blade

ActiveCN101372046AReduce overall man-hoursReduce turnoverDrilling/boring measurement devicesPositioning apparatusEngineeringDrill bushing

The invention relates to a special clamp for drilling a blade tip centre hole and used for a blade. The special clamp is suitable for drilling blade tip centre hole of the blade with a plurality of sizes and has wide range of application. The special clamp comprises a jig body, an upper drill plate, a drill bush. The jig body is internally provided with a locating base; the two sides of the locating base and the side wall of the jig body are provided with a side locator key; the special clamp is characterized in that: the two side of the upper drill plate is embedded on the side locator key; the bit bush is inverted on the upper drill plate; the exit and the opening of the bit bush are arranged on the bottom of the upper bit panel; the jig body, the locating base and the upper drill plate have the same centre.

Owner:WUXI TURBINE BLADE

Method for pulling out deep pile foundation by utilizing full slewing drilling machine

InactiveCN101629421AReduce frictional resistanceReduce the impactBorehole drivesRotary drillingHigh pressureDrill bushing

The invention provides a method for pulling a deep pile foundation by utilizing a full slewing drilling machine, comprising the following steps: a position for positioning the pile foundation is measured, and the full slewing drilling machine is fixed on the center of a drilled pile; after being well positioned, the full slewing drilling machine is utilized for drilling holes, and a first section of steel sleeve is drilled into the hole; in the process of utilizing the full slewing drilling machine for drilling the steel sleeve into the hole, a high pressure water gun is used for brushing a gap between the pipe wall of the steel sleeve and the pile foundation; after the drill bushing of the first section of steel sleeve is accomplished, the operation of drilling is stopped, a second section of steel sleeve is used for lengthening the first section of steel sleeve by connection, and the drilling of the entire steel sleeve is sequentially accomplished; and the operation of pile extraction is carried out when drilling is carried out to pile bottom. The technical scheme can reduce the frictional resistance in the process of drilling the steel sleeve into the hole, prevents soil bodies and water around pile bodies from flowing into pile bottom gaps after pile extraction, and reduces the influence on the ambient environment.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

Drilling fixture

ActiveCN103286598AEasy to fixDrilling quality is stablePositioning apparatusMetal-working holdersPositioning systemDrill bushing

The invention discloses a drilling fixture which comprises a base, a positioning plate and a drill bushing. The positioning plate comprises a top plate and a supporting plate connected with one end of the top plate, the top plate is perpendicular to the supporting plate which is movably connected to the base, a vertical groove structure is formed between the positioning plate and the base, and the drill bushing penetrates the top plate and is arranged on the same. The drilling fixture has high flexibility, and processing of different parts can be realized by the same fixture. Since workpieces can be clamped by force from both the top surface and the side surface, the workpieces can be fixed firmly, and drilling quality is stable. Besides, the drilling fixture has a pneumatic locking effect, and accordingly is convenient and reliable.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

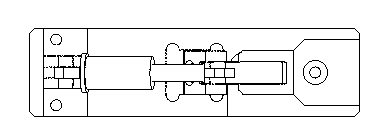

Special lathe for drilling and boring hole for motor shell-like part

InactiveCN102962491AGuaranteed accuracyImprove efficiencyTransportation and packagingBoring/drilling machinesSlide plateDrill bushing

The invention discloses a special lathe for drilling and boring a hole for a motor shell-like part. The special lathe comprises a frame, a spindle box, a chuck, a drill bushing, a drill bit, a combined tool, a middle sliding plate, a compressionng device and a positioning device, wherein one end of the frame is provided with the spindle box, and the other end of the frame is provided with the middle sliding plate; the chuck is arranged on the spindle box; the drill bit is arranged on the chuck through the drill housbushing; the combined tool is arranged in the drill bit; a workpiece is arranged on the compressionng device; the workpiece is positioned through the positioning device; the compressionng device is arranged on the middle sliding plate through a fastening screw; the positioning device is arranged on the middle sliding plate; and a spring is arranged in the positioning device. The defects of the prior art are overcome by the special lathe disclosed by the invention; the design transformation layout is reasonable. Through the combined tool, when the hole is processed, a process of drilling and boring the hole and a process of deburring end faces are completed simultaneously, and therefore, the efficiency and the processing precision are improved.

Owner:ANHUI PROVINCE JINGDE COUNTY STAR ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com