Bias correction method of drill bushing mounting hole of drill plate

A technology of deviation correction and mounting holes, which is applied in the direction of drilling/drilling equipment, drilling templates for workpieces, boring machines/drilling machine parts, etc., which can solve the problems of long construction period, low efficiency, and inability to meet urgent processing, etc., to achieve The effect of shortening the construction period and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

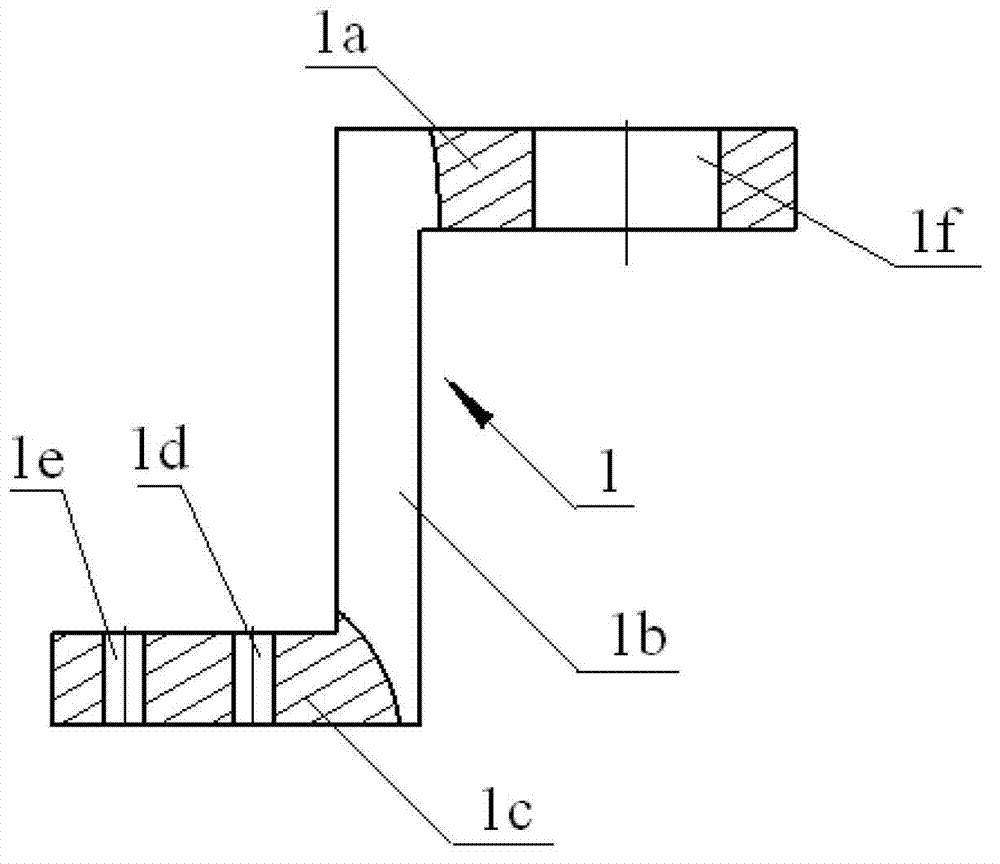

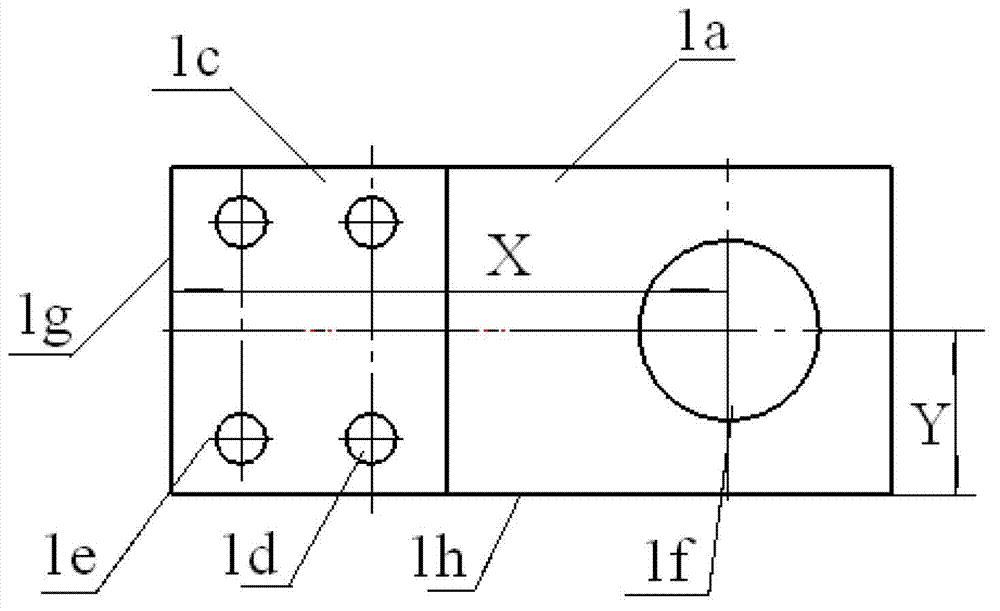

[0017] Example 1, there is a drill sleeve installation hole with a diameter of Φ12mm on a drilling template of a fixture, the distance from the axis of the drill sleeve installation hole to the first positioning surface is 150mm, and the existing deviation is 0.1mm. The distance from the axis to the second positioning surface is 50mm, and the existing deviation is 0.06mm. The steps to correct the deviation of the drill sleeve installation hole are:

[0018] 1.1. Measure the deviation value of the drill sleeve installation hole: use the three-coordinate measuring machine tool to measure the deviation value of the drill sleeve installation hole ΔX is 0.1mm, and ΔY is 0.06mm;

[0019] 1.2. Eccentric reaming: fix the drilling template on the boring machine, firstly align the mounting hole of the drill sleeve, make the distance from the axis of the boring machine to the first positioning surface 150mm, the alignment deviation ΔX1 is 0.01mm, and the axis of the boring machine to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com