Processing method of blast furnace furnace jacket upper inclined hole

A processing method and blast furnace shell technology, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of unguaranteed opening quality, overall blast furnace strength damage, and slow speed, so as to save manpower, The effect of high accuracy and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

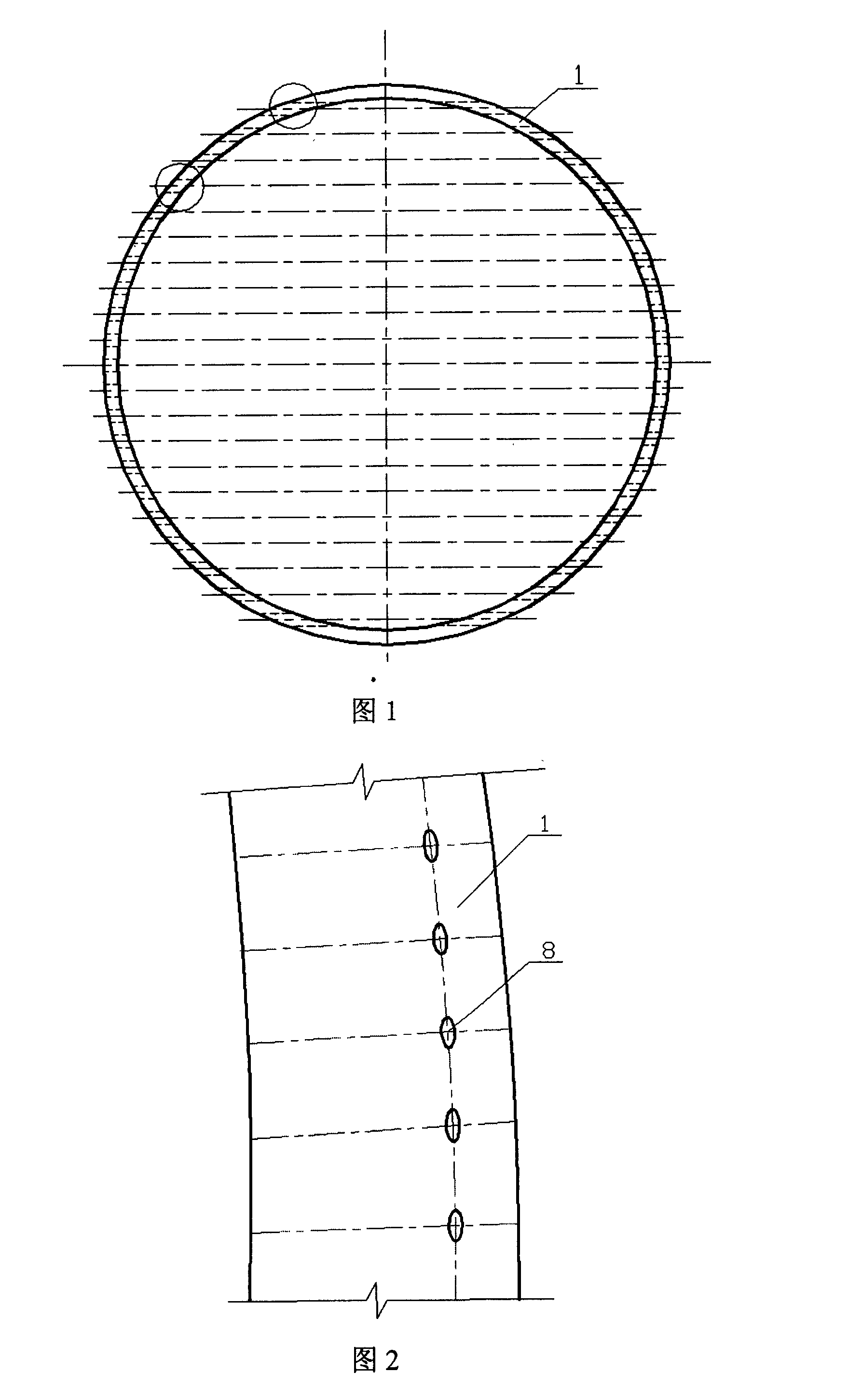

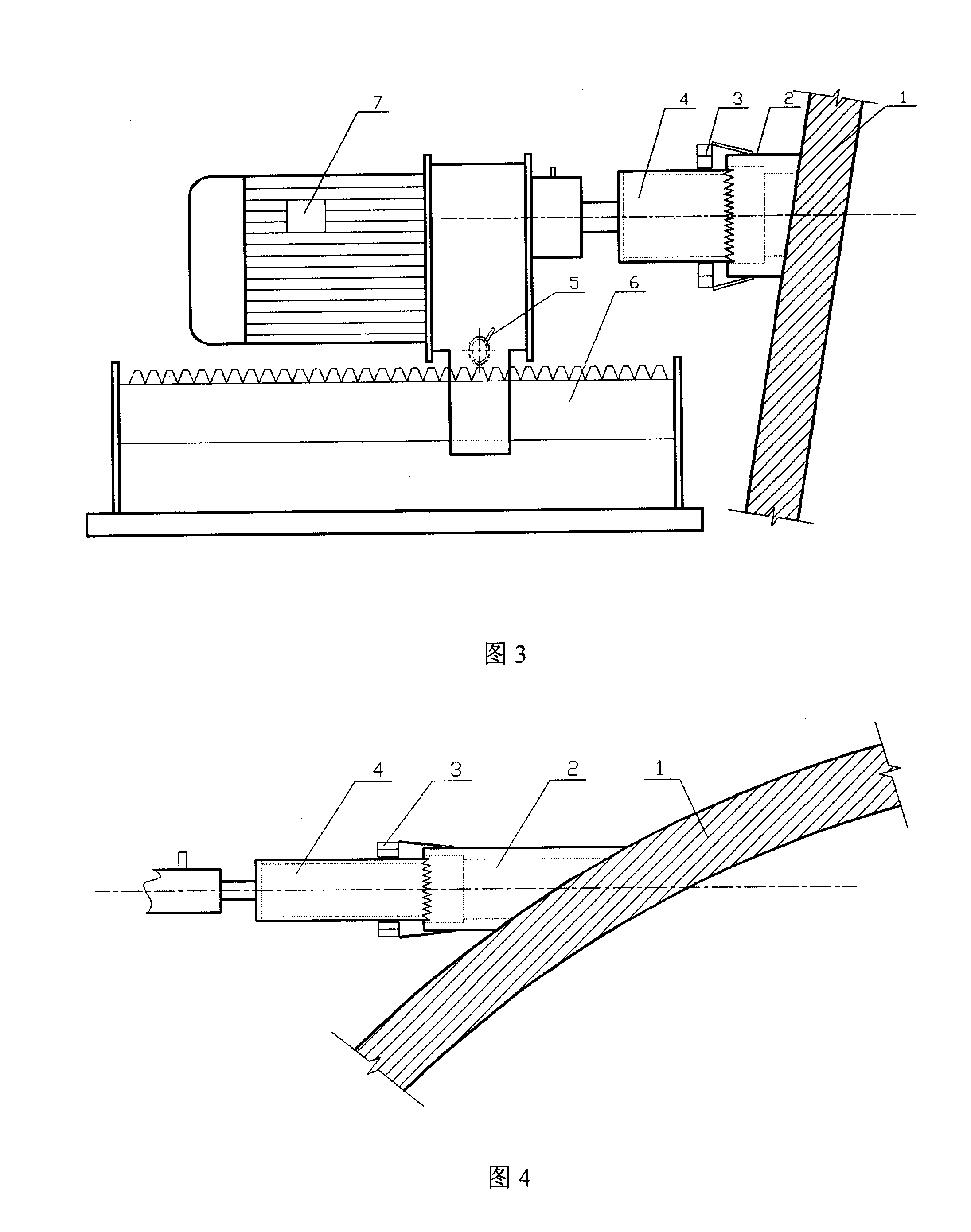

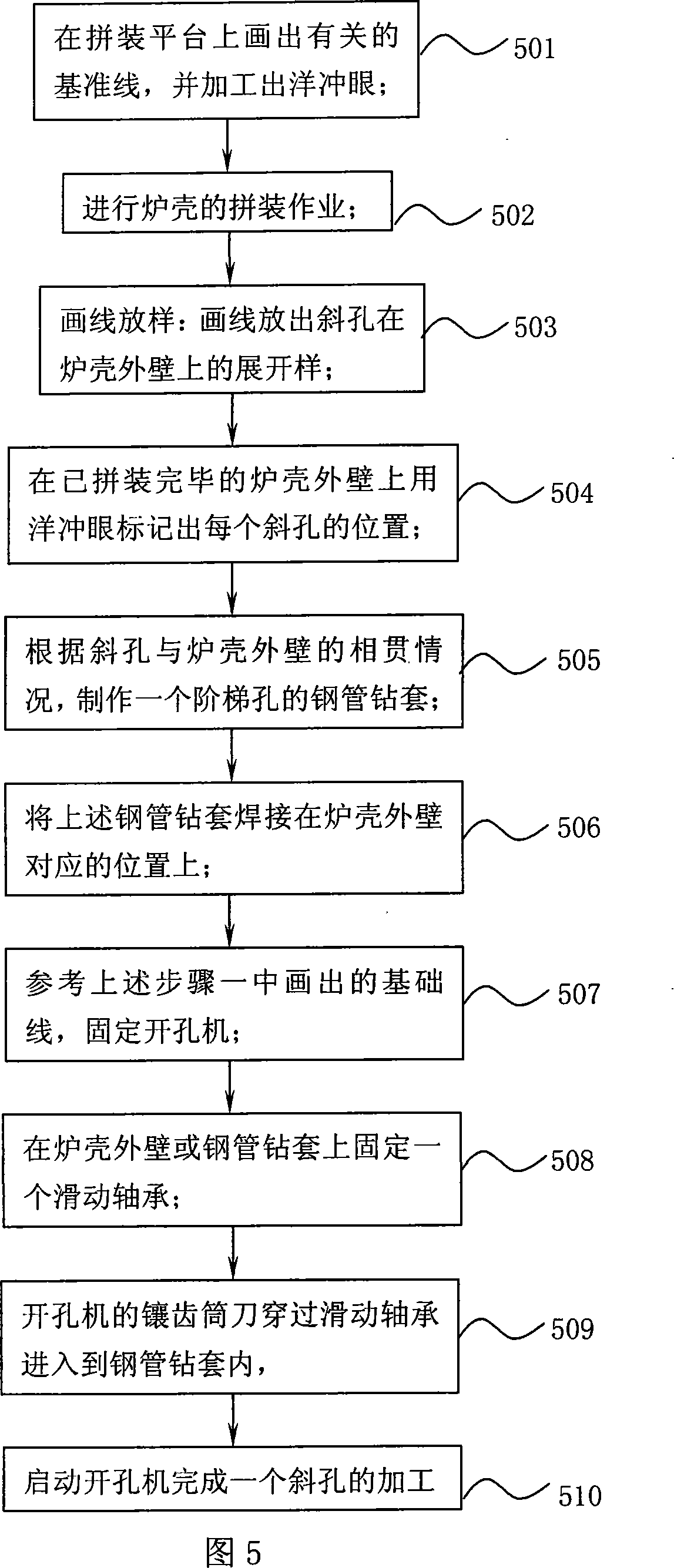

[0025] Generally, there are two main shapes of blast furnace shells, one is cylindrical, and the other is conical. The method for machining inclined holes in the present invention is suitable for machining inclined holes on blast furnace shells of the above two shapes. The present invention mainly utilizes the positioning and fixing of the steel pipe drill sleeve and unfolds the development diagram of each inclined hole according to the outer wall of the furnace shell to carry out the plane positioning of the drilling machine and carry out the drilling. Thereby overcoming the problems of uneven cutting and difficult positioning of inclined holes in the prior art; in addition, the effective fixation of sliding bearings and furnace shells or steel pipe drill sleeves is used to solve the problem of cutting the cutter head due to excessive vibration of the drilling machine during drilling. Falling off technical issues.

[0026] The present invention will be described in further de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com