Drilling fixture

A drilling jig and drill sleeve technology, applied in the field of machining, can solve the problems of easy shaking, unfavorable staff safety, affecting processing accuracy, etc., and achieves the effects of strong flexibility, stable drilling quality, and reliable workpiece fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

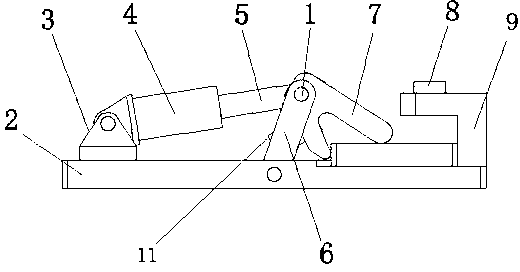

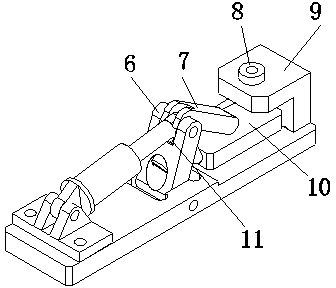

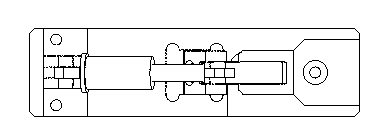

[0015] Such as Figure 1-3 The shown drilling jig includes a base 2, a positioning plate 9 and a drill sleeve 8. The positioning plate 9 includes a top plate and a support plate connected to one end of the top plate. The top plate and the support plate are perpendicular to each other, and the support plate is movably connected to the base 2. A vertical groove structure is formed between the positioning plate 9 and the base 2; the drill sleeve 8 passes through the top plate of the positioning plate 9 and is arranged on the top plate.

[0016] Before the workpiece is installed, the spring 11 can balance the gravitational effect of the pressing block 7, so as to prevent the excessive drooping angle of the pressing block 7 from affecting the installation of the workpiece; the processed part 10 is placed in the groove of the base 2, and the cylinder piston 5 is stretched out to drive the connecting rod 6 and the briquetting block 7 rotate, and the two legs of the briquetting block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com