Special lathe for drilling and boring hole for motor shell-like part

A technology of motor housing and special lathe, applied in boring/drilling, drilling/drilling equipment, repairing and other directions, can solve the problems of low work efficiency, high labor intensity, and low specificity, etc. The effect of improving efficiency, saving resources and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

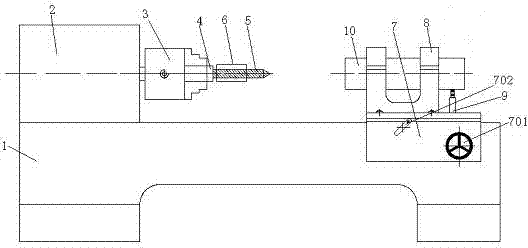

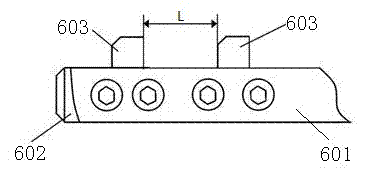

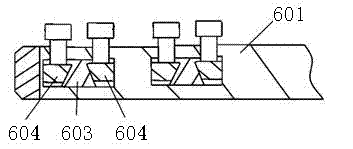

[0018] Referring to the accompanying drawings, a special lathe for drilling and boring motor shell parts, including a frame 1, a spindle box 2, a chuck 3, a drill bushing 4, a drill bit 5, a combined tool 6, an intermediate slide plate 7, and a pressing device 8 and a positioning device 9, one end of the vehicle frame 1 is provided with a spindle box 2 and the other end is provided with a middle slide plate 7, the chuck 3 is installed on the spindle box 2, the drill bit 5 is installed on the chuck 3 through the drill sleeve 4, and the combined tool 6 is installed on the In the drill bit 5, the workpiece 10 is installed on the pressing device 8, and the workpiece 10 is positioned by the positioning device 9. The pressing device 8 is installed on the middle sliding plate 7 through fastening screws, and the positioning device 9 is installed on the middle sliding plate 7. The positioning device 9 inside is provided with spring. The middle slide plate 7 has a lateral movement mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com