Laser-guided coordination hole drilling

a laser guide and coordination hole technology, applied in the direction of drilling/boring measurement devices, manufacturing tools, transportation and packaging, etc., can solve the problems of high cost of machines, difficult modification, difficult to set up, etc., to reduce drilling accuracy, large numerical control, and large work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

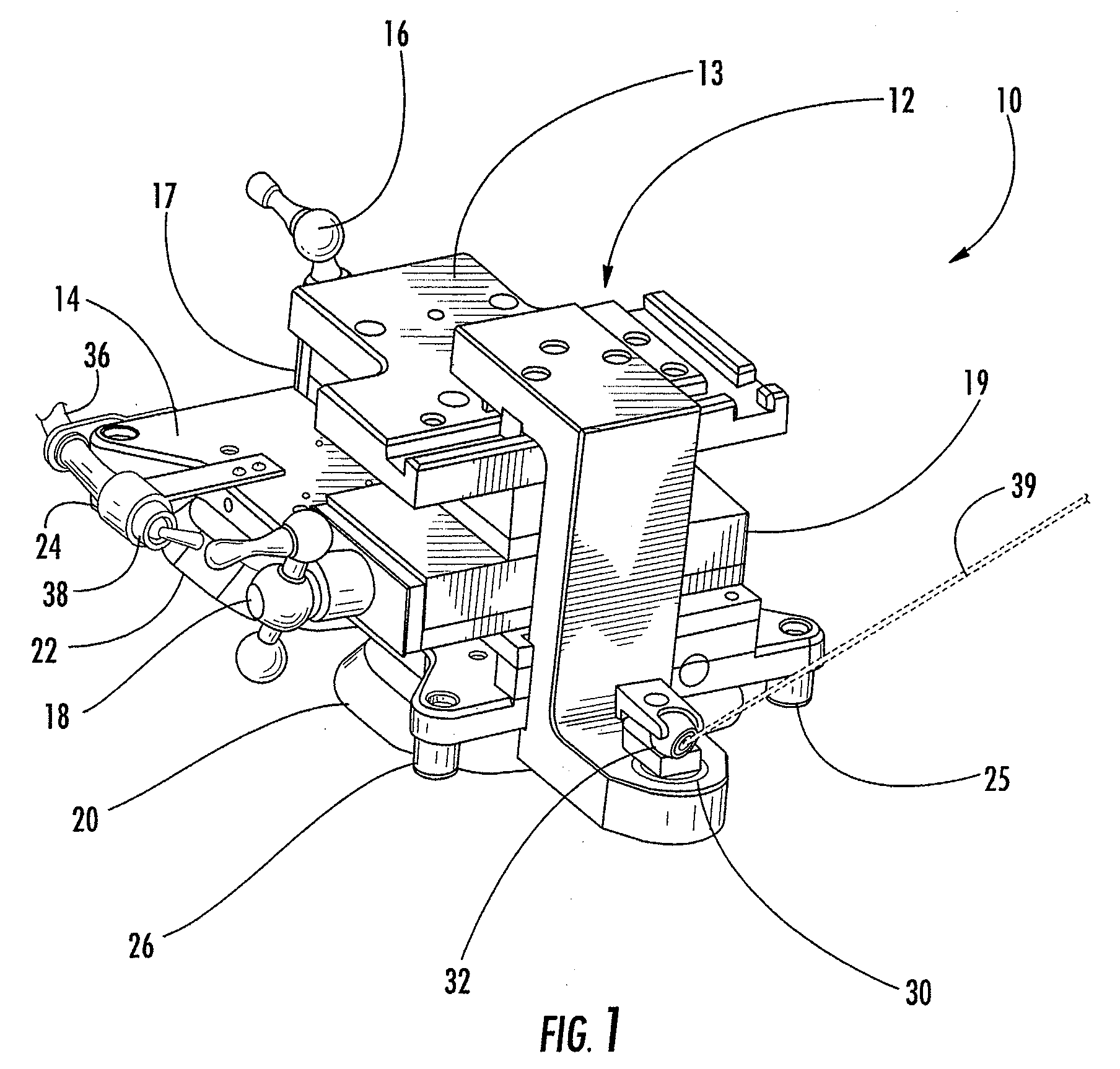

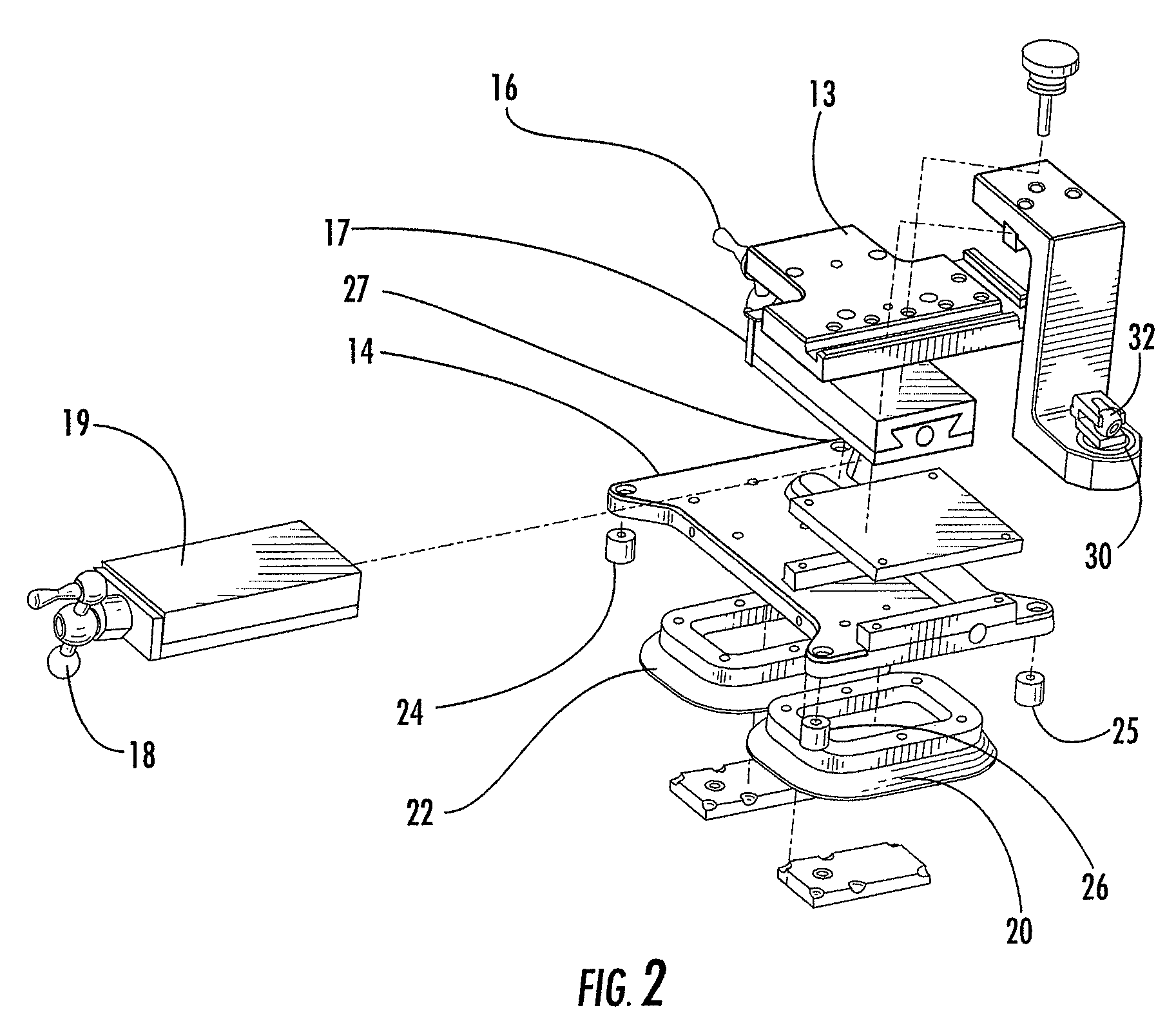

[0031]FIG. 1 is a perspective view of a coordination hole drilling apparatus of the present invention, which may also be referred to as a coordination hole tool or a laser drill jig. A drilling apparatus 10 of one embodiment of the present invention includes an x-y positioning platform or table 12. A positioning platform 12 allows for movement of a moveable portion 13 of the platform along one or more axes while a foundation portion 14 of the platform remains stable. An x-y positioning platform provides for movement along orthogonal axes, the x- and the y-axes. The movable portion 13 of a positioning platform for a drilling apparatus 10 of the present invention defines at least a bushing cavity 30 for accepting bushings to hold a laser target 32 or receive different sized tools.

[0032]A positioning platform 12 may be supported by legs or feet 24 upon which the drilling apparatus 10 may rest against a part. Typically, the positioning platform 12 is in an approximately parallel plane t...

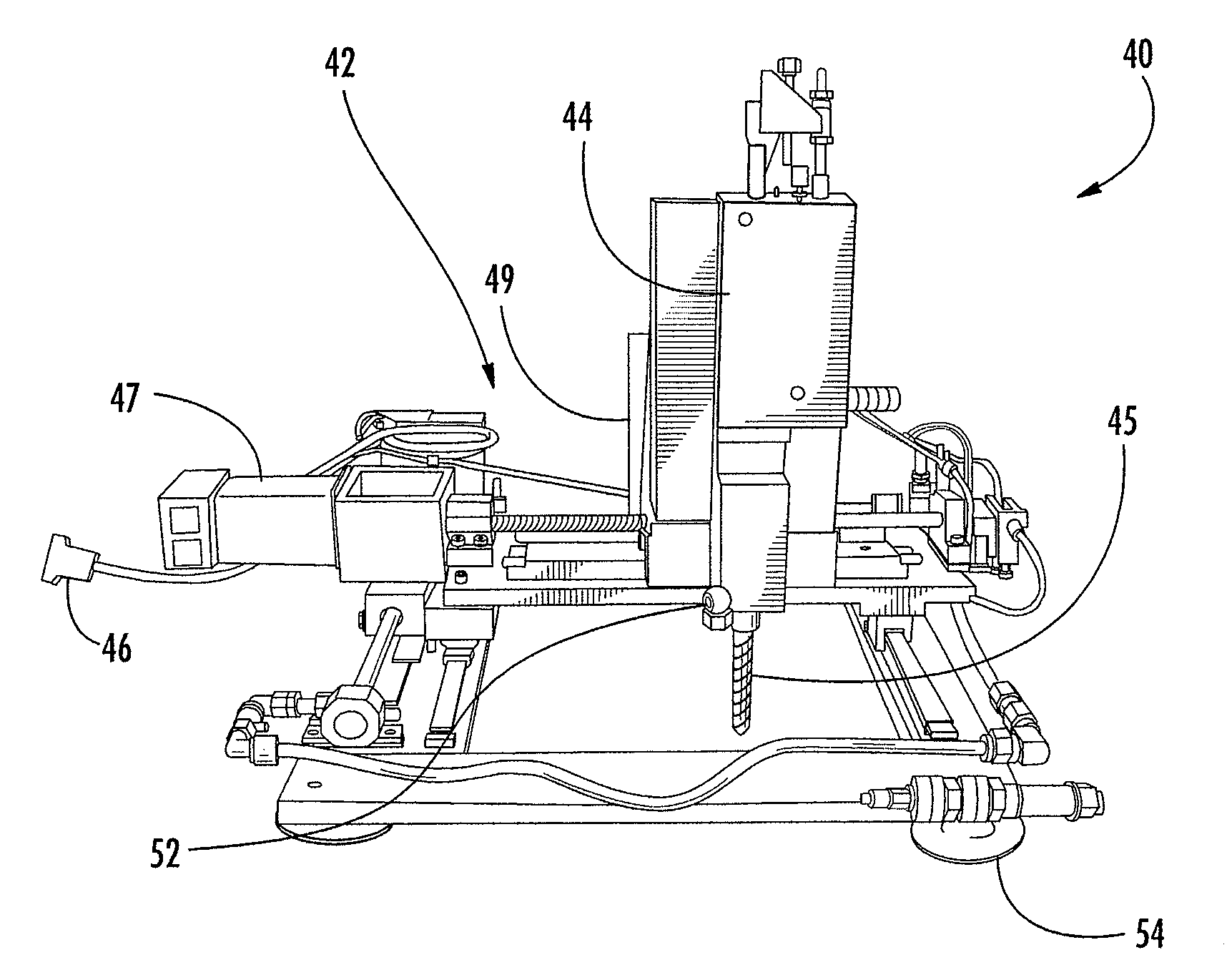

third embodiment

[0036]FIG. 4 is a perspective view of a coordination hole drilling apparatus 60 of the present invention. The embodiment shown in FIG. 4 is an example of a coordination hole drilling apparatus of the present invention that includes screw clamps 66, 68 to rigidly affix the drilling apparatus 60 to a part.

[0037]FIG. 5 is a schematic diagram showing vacuum cups 20, 22 of the coordination hole drilling apparatus 10 of FIGS. 1 and 2. Vacuum cups allow a drilling platform of the present invention to easily be positioned on a part, even against the pull of gravity, such as drilling upside down. The vacuum cups 20, 22 of this embodiment are two-staged, concentric vacuum cups for rigidly affixing the positioning table to a surface on the part. A two-stage vacuum cup provides a low vacuum for positioning and a high vacuum for providing additional stability during drilling. However, as exemplified by the screw clamps 66, 68 in the third embodiment shown in FIG. 4, any type of clamping device t...

fourth embodiment

[0038]FIG. 6 is a perspective view of a coordination hole drilling apparatus 70 of the present invention. The embodiment shown in FIG. 6 is a more compact version of a drilling apparatus of the present invention. This embodiment is just one more example of the variety of design possibilities for creating a drilling apparatus of the present invention. The drilling apparatus is typically designed based upon the intended use and application. For example, a smaller device may be more practical for delicately drilling smaller holes or repeatedly moving the drilling apparatus to drill a large plurality of holes. Conversely, a larger drilling platform may be beneficial for drilling applications that require more force or drilling a smaller number of holes. Regardless of the application, a drilling apparatus of the present invention may be designed and made from appropriate materials to provide appropriate hardness, stiffness, and accuracy for precision hole drilling, such as granite, tungs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com