Drilling fixture for cylinder cover

A drilling fixture and cover technology, which is applied in the direction of drilling dies, clamping, and manufacturing tools for workpieces, can solve the problems of workpiece positioning, unreliable clamping, low production efficiency, and low machining accuracy, and can reduce the The effect of labor intensity of workers, improving production efficiency, and convenient opening and closing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

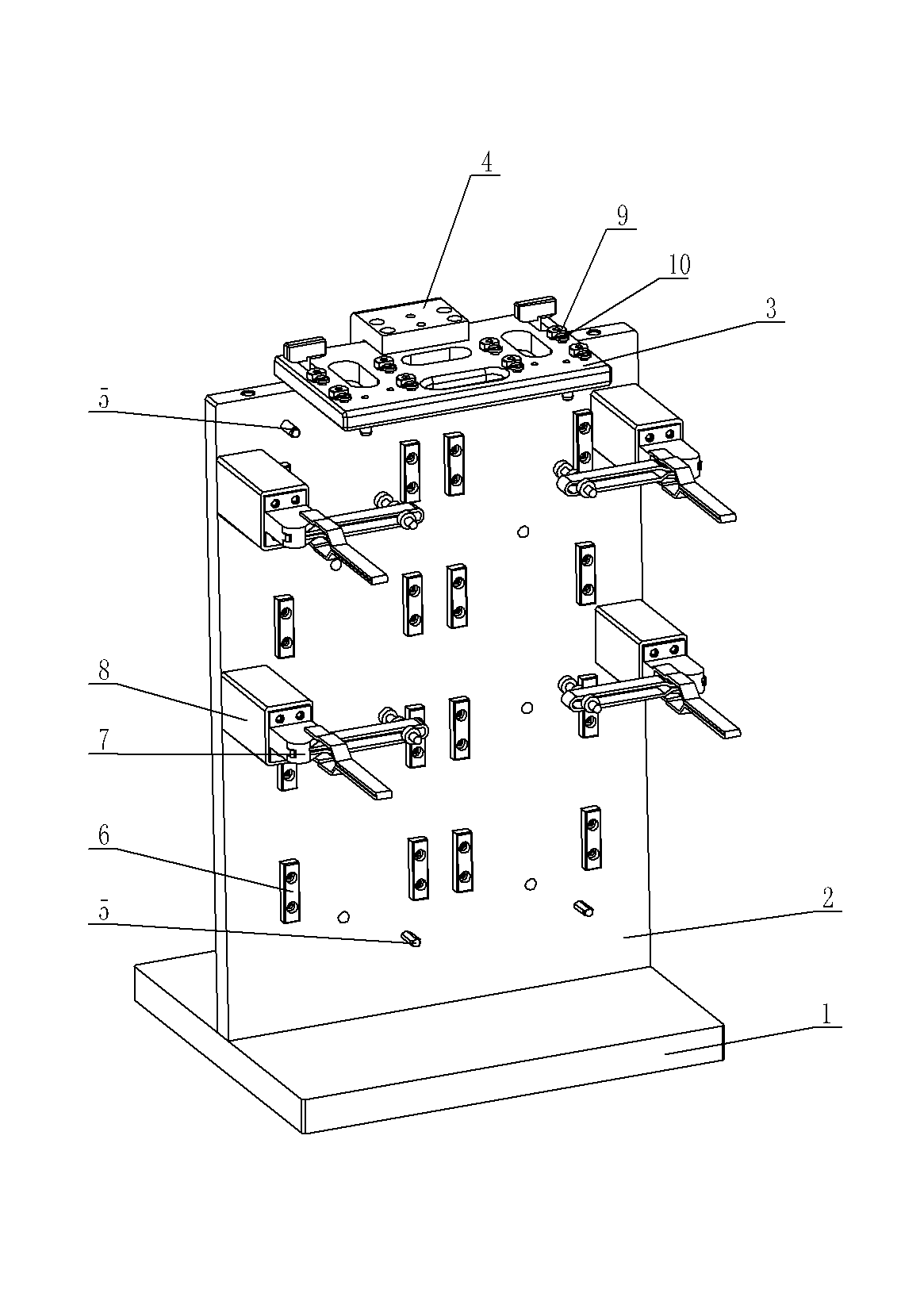

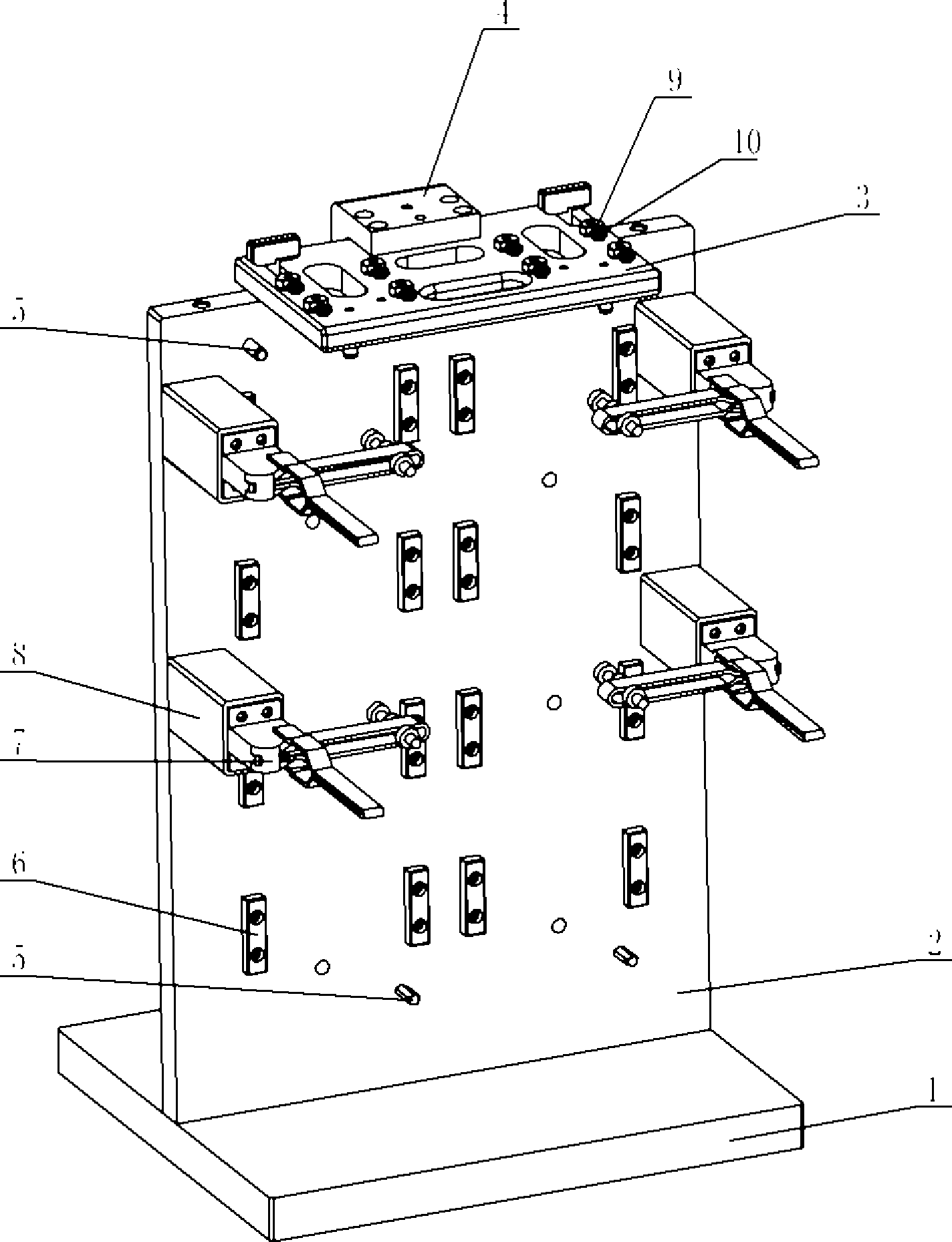

[0008] See figure 1 , the present invention comprises base plate 1, and fixed plate 2 is vertically installed on base plate 1, and it also comprises workpiece positioning clamping device and drilling plate mold 3, and workpiece positioning clamping device is fixed on the workpiece clamping surface of fixing plate 2, and drilling plate formwork 3 is connected to the upper end of the fixed plate 2 through the hinge device 4, and the drill sleeve 9 is correspondingly installed on the drilling template 3 according to the position to be drilled of the workpiece. The workpiece positioning and clamping device includes positioning pin 5, support plate 6 and pliers 7. The locating pin 5 and the support plate are fixed on the workpiece positioning surface of the fixed plate 2. The position of the positioning pin 5 is set according to the design reference position of the workpiece. The pliers 7 pass through Pad block 8 is fixed on the workpiece clamping surface of 2 fixed plates; Drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com