Clamp for drilling oil hole on crankshaft

A crankshaft oil hole and fixture technology, which is applied in boring/drilling, drilling/drilling equipment, clamping and other directions, can solve the problems of high fixture manufacturing cost, long production cycle, and many clamping times, etc. The effect of good quality, low manufacturing cost and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

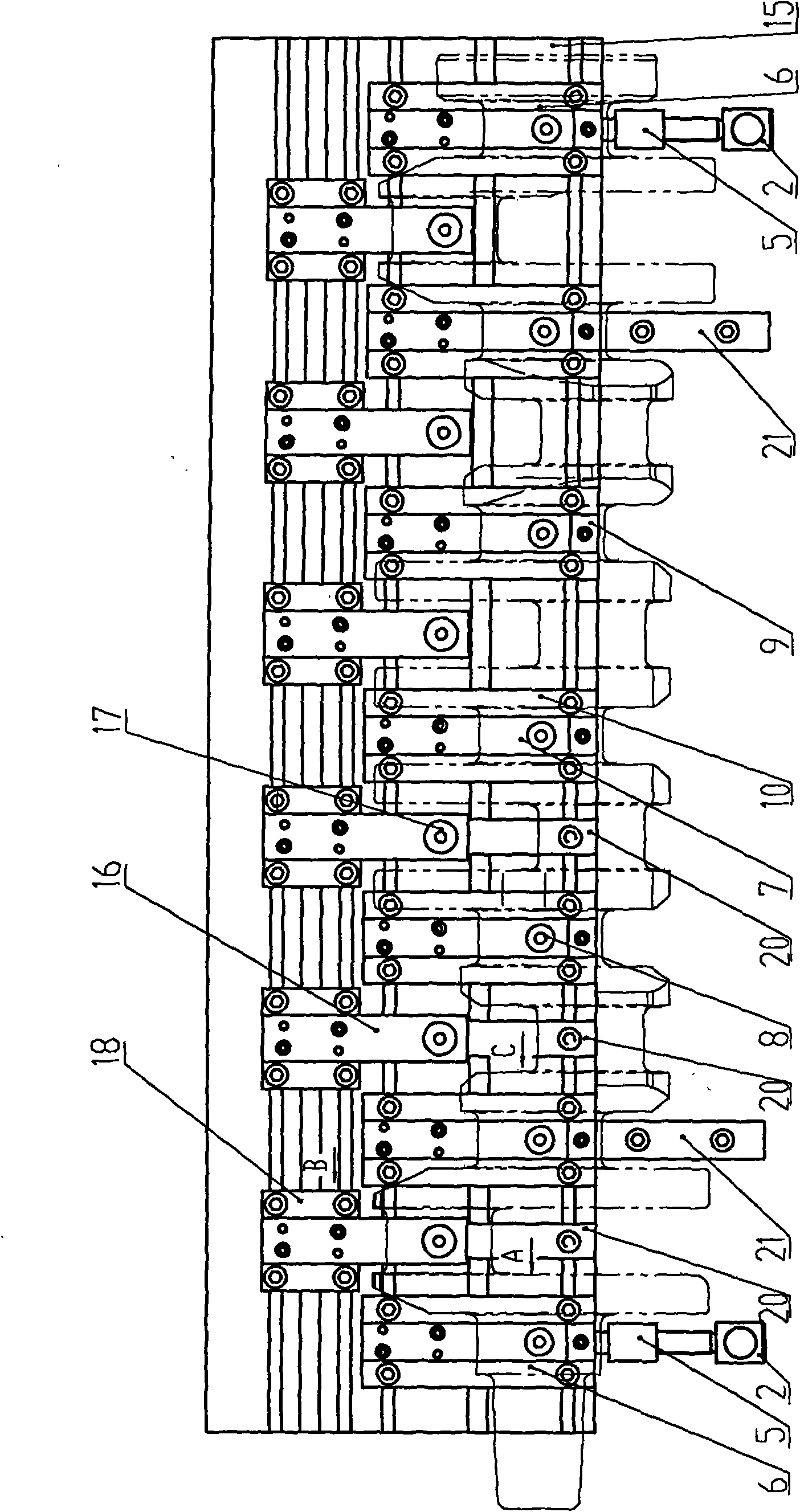

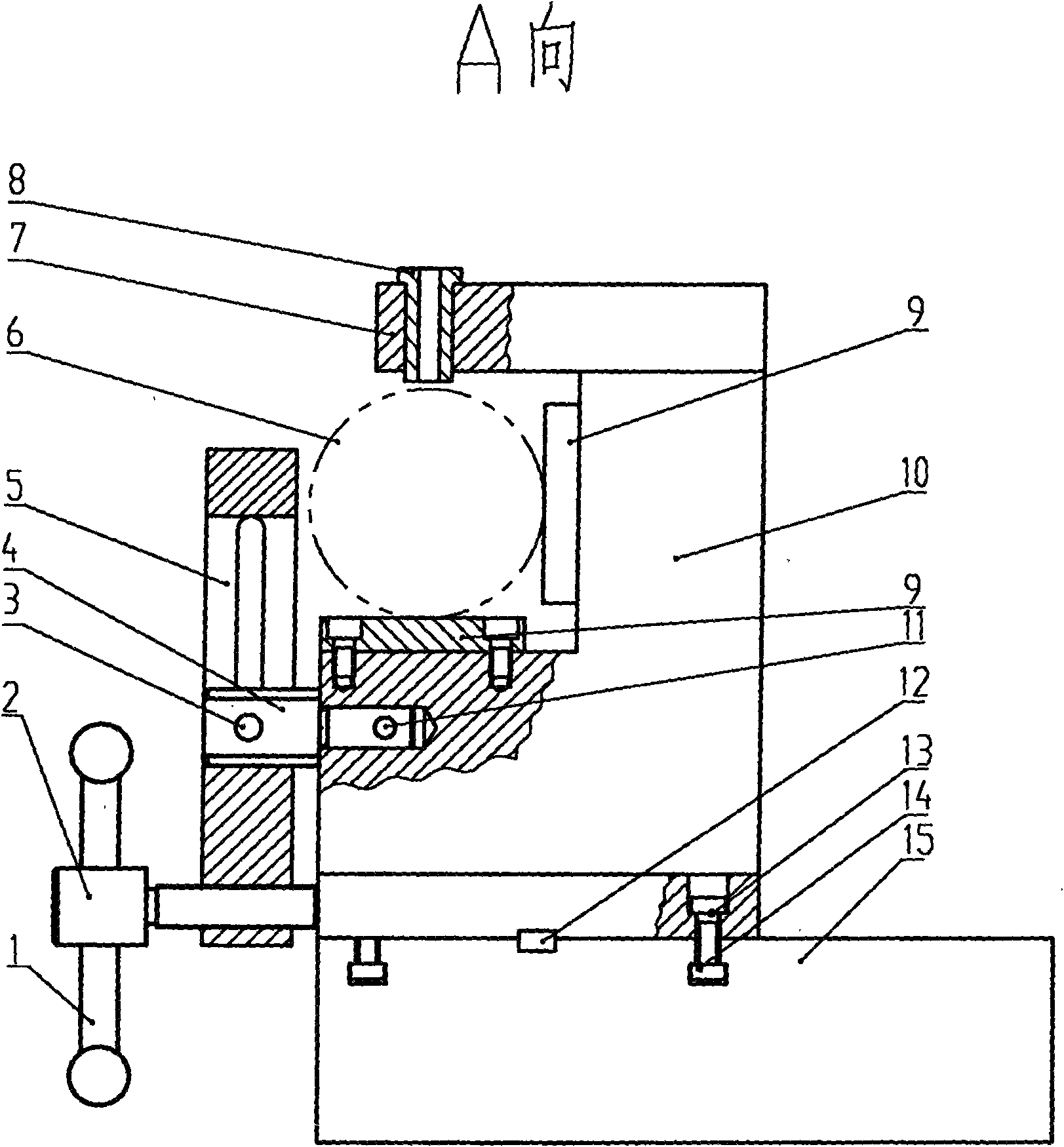

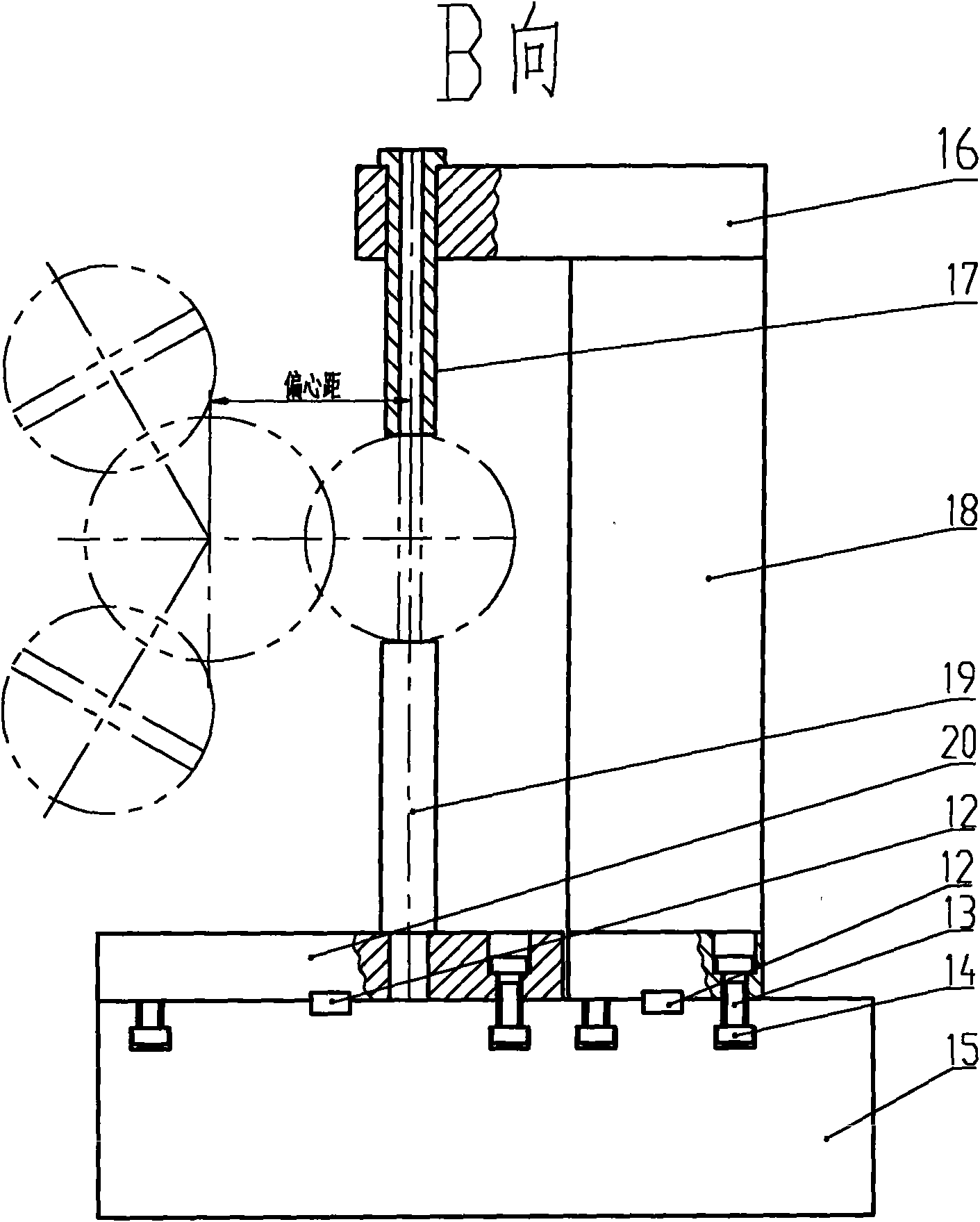

[0017] figure 1 It is a schematic diagram of the assembly structure of the present invention and the crankshaft. from figure 1 It can be seen that a crankshaft oil hole drilling jig includes a clamp body 15, a clamping mechanism, a connecting rod positioning mechanism, a drilling formwork frame mechanism, and the like. All kinds of crankshafts are clamped and fixed in the fixture according to drilling needs, so as to carry out the operation of drilling crankshaft oil holes. The jigsaw mechanism is generally a main shaft jigsaw mechanism, and it can also be two kinds of spindle jigsaw mechanism and connecting rod jigsaw mechanism. The connecting rod jig frame mechanism can be selectively used as required. In this way, it can not only be used to drill the straight oil hole of the main journal of the crankshaft, but also can drill the straight oil hole of the connecting rod neck according to the needs.

[0018] from figure 1 , figure 2 It can be seen that the clamping mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com