Patents

Literature

38results about How to "Strong manufacturing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

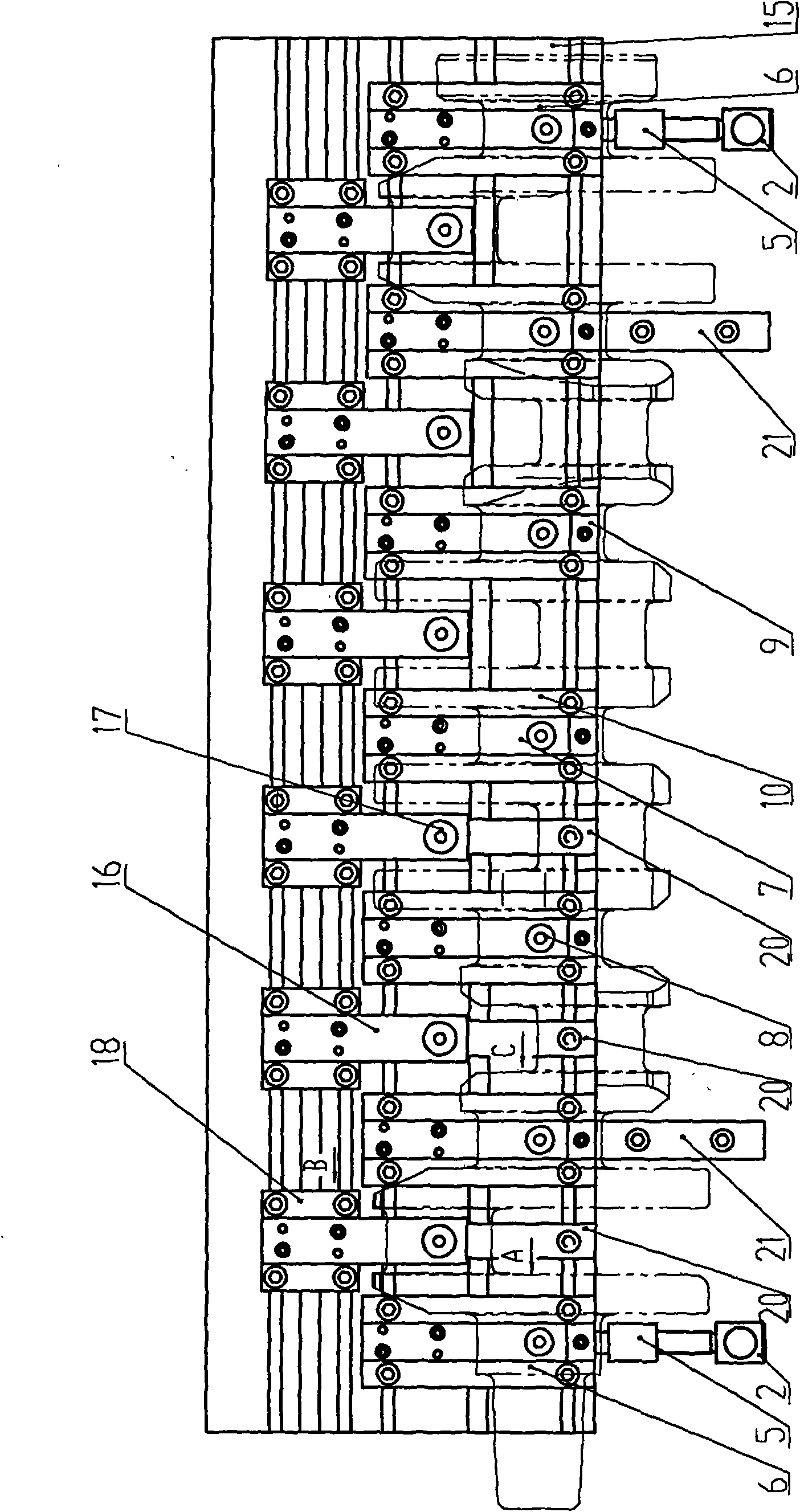

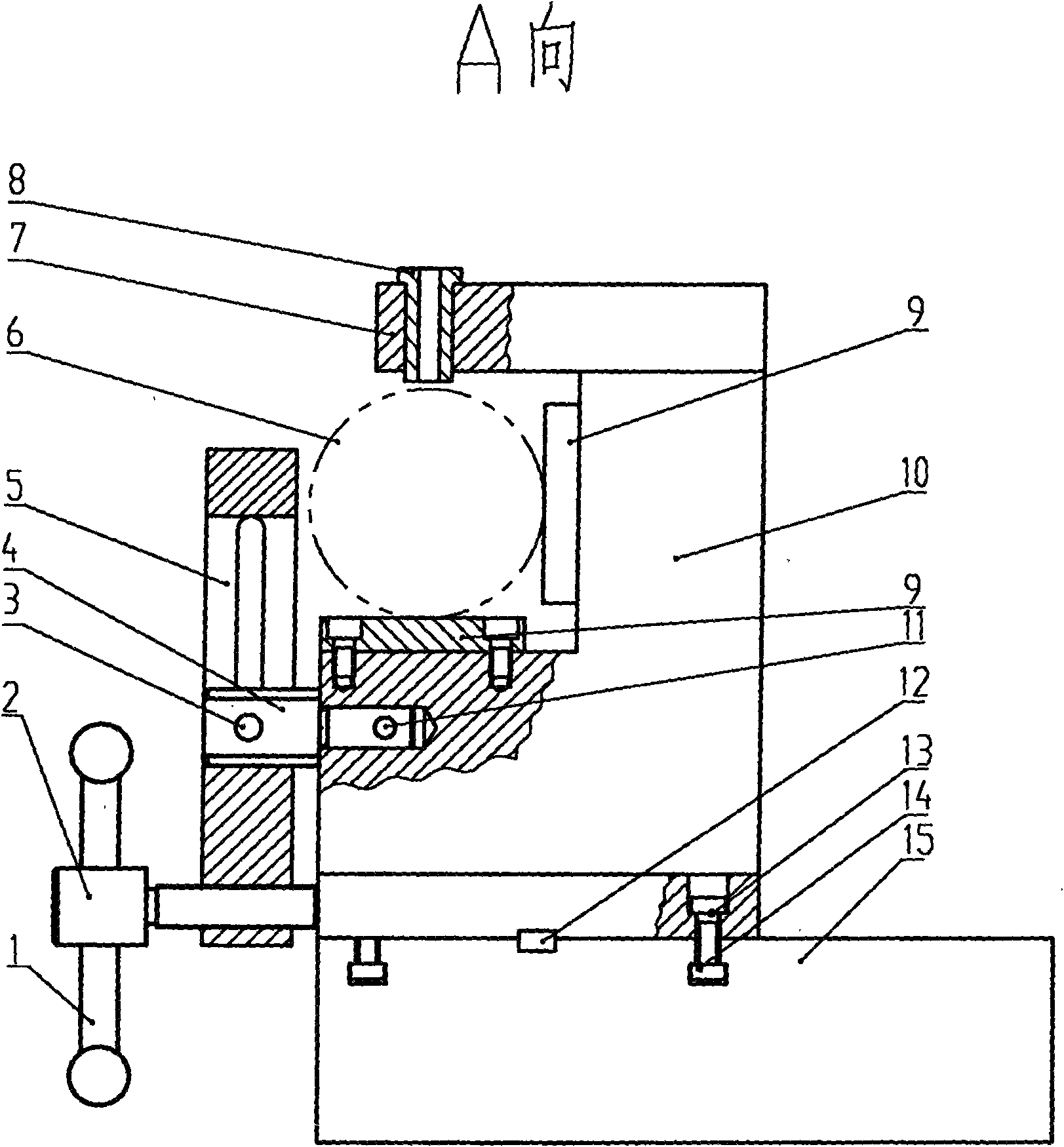

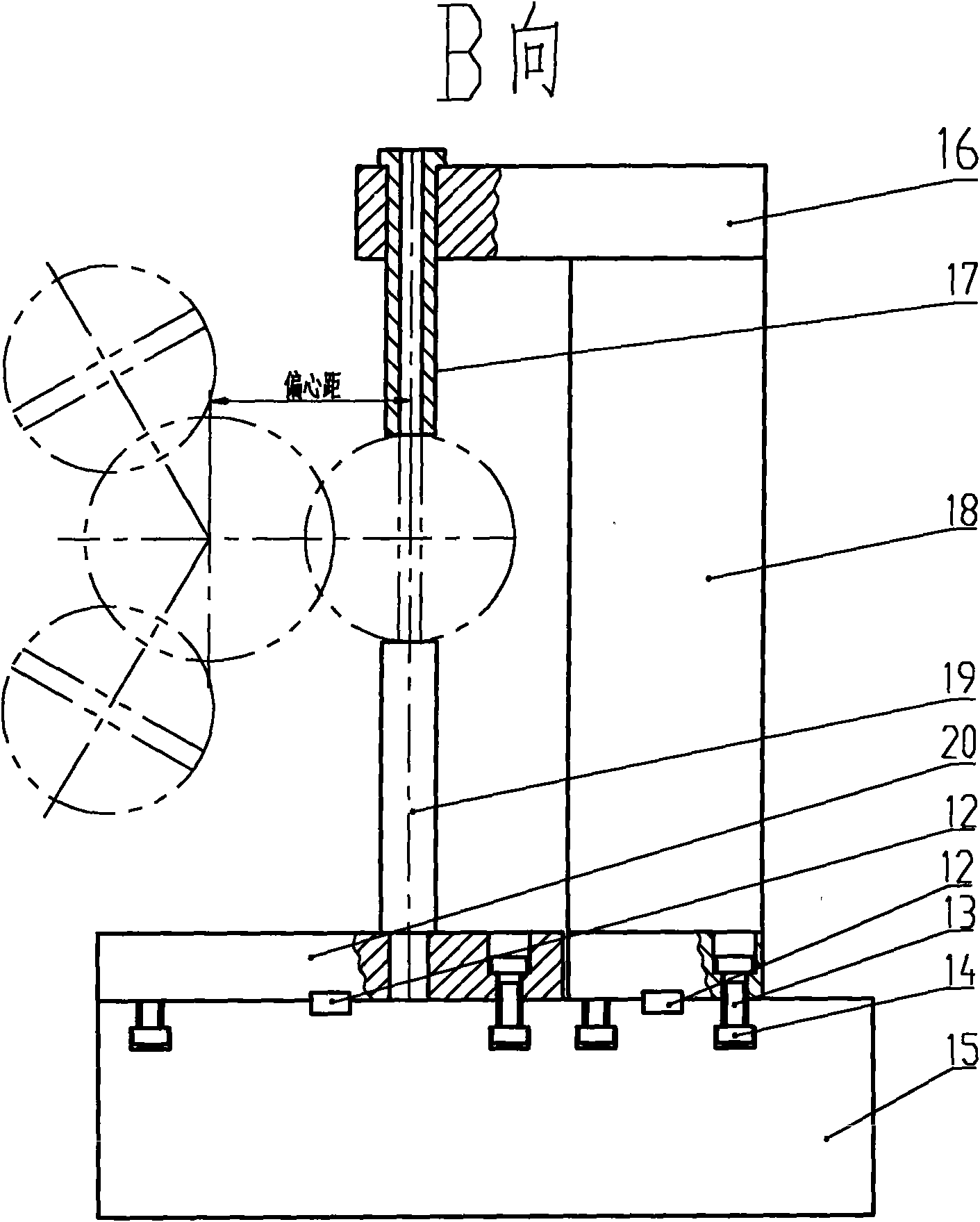

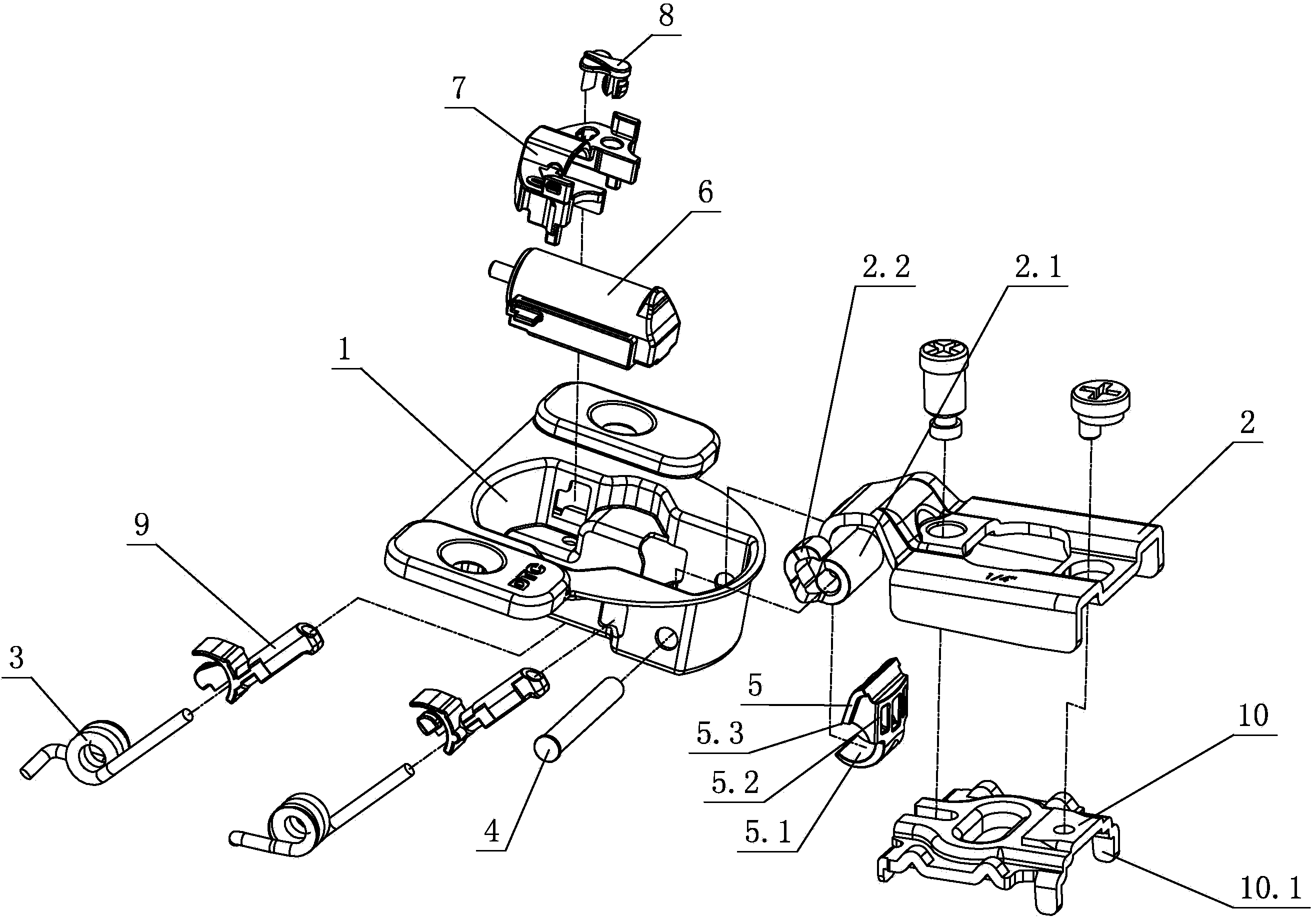

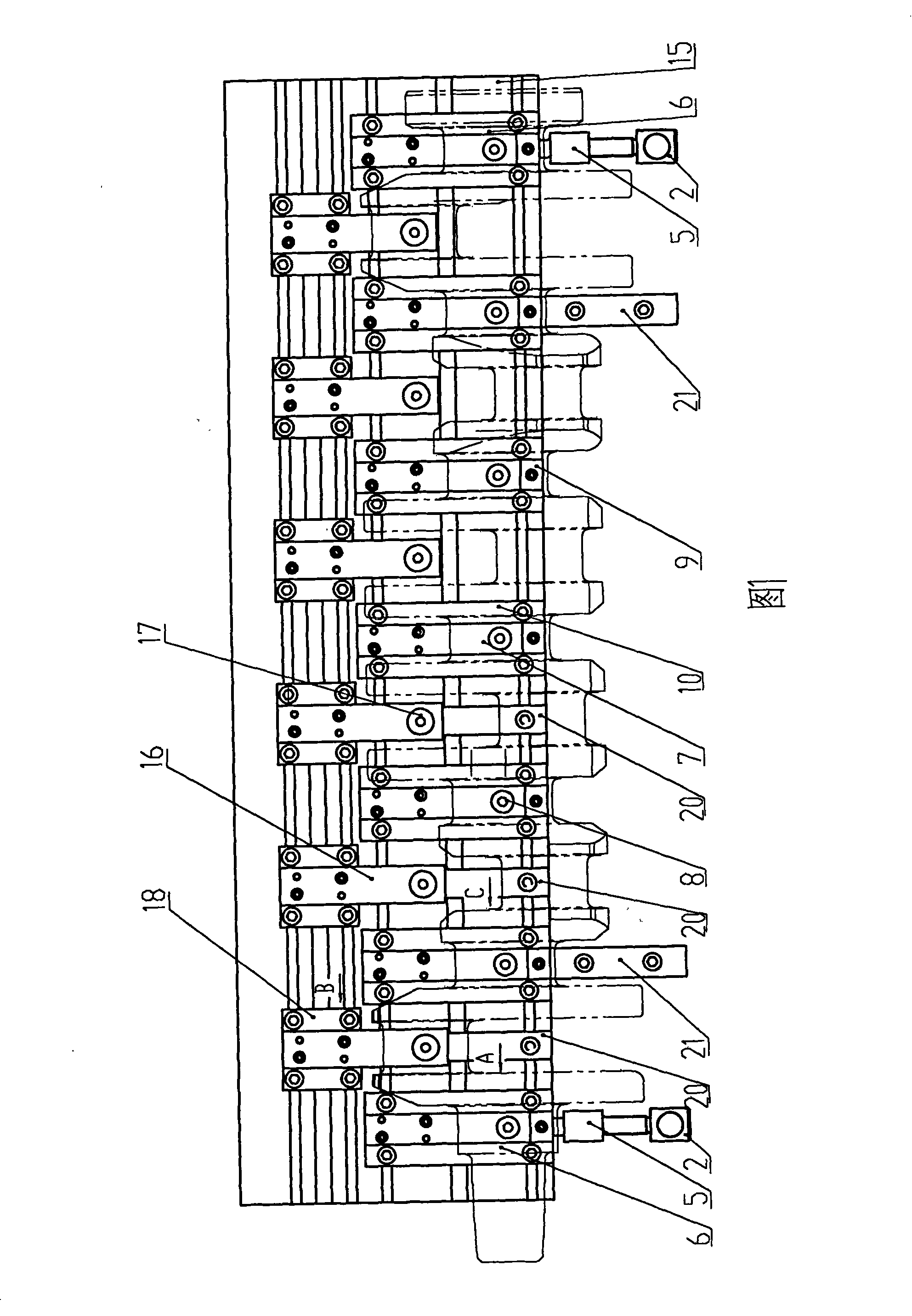

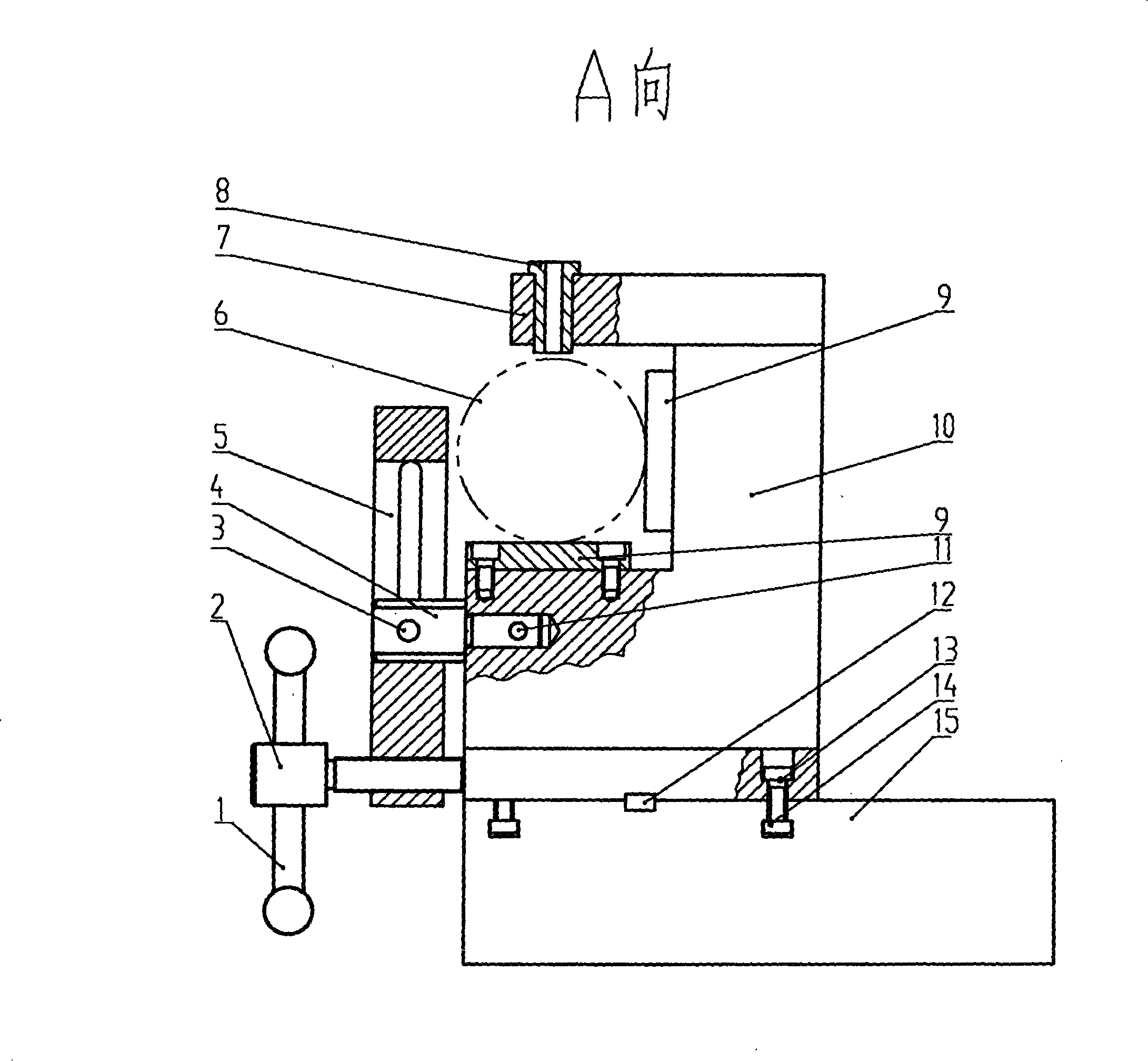

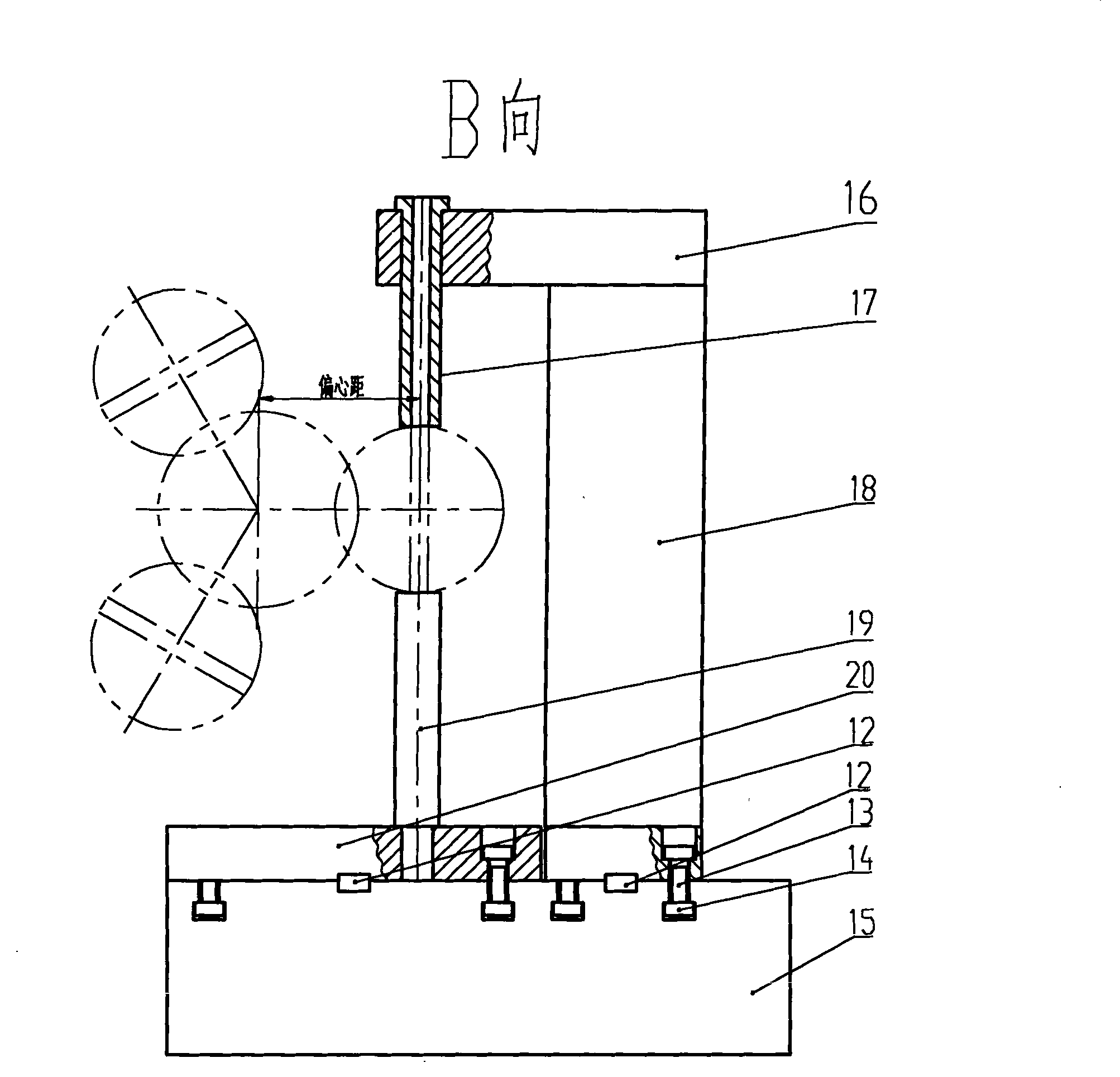

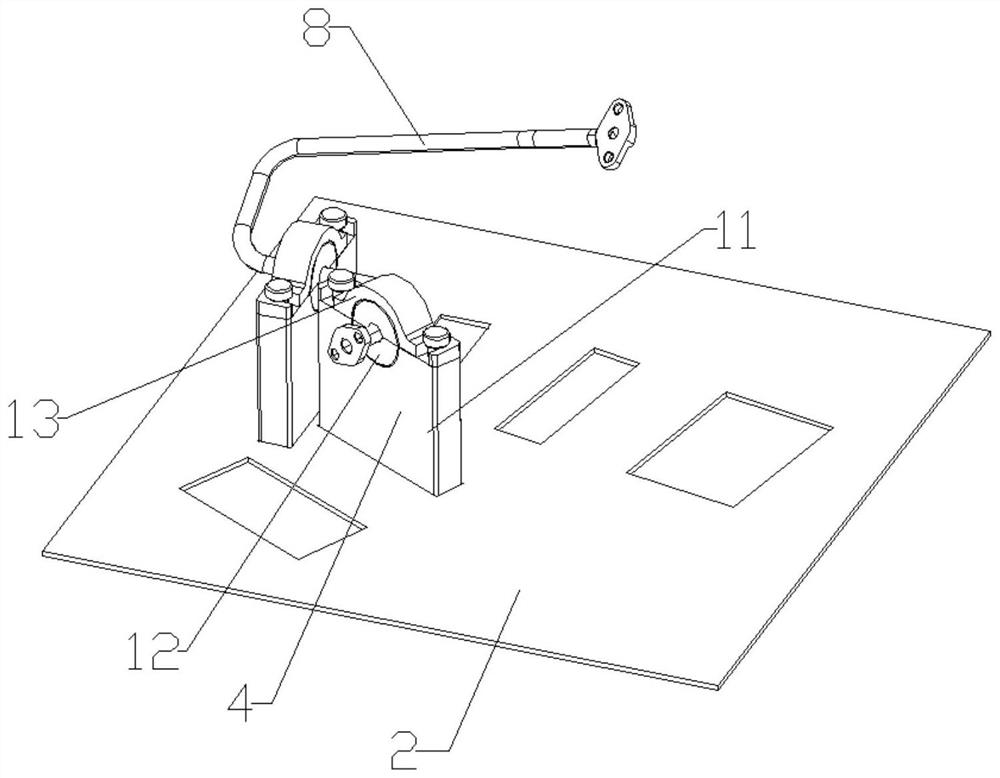

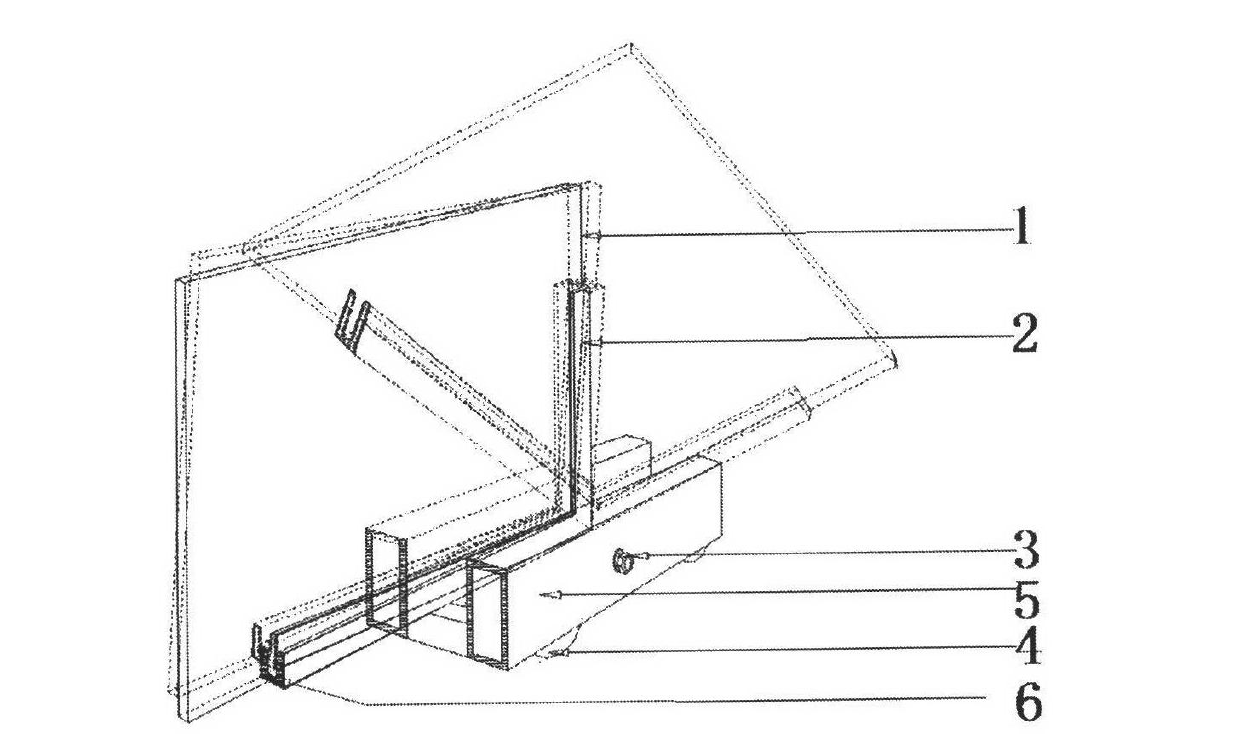

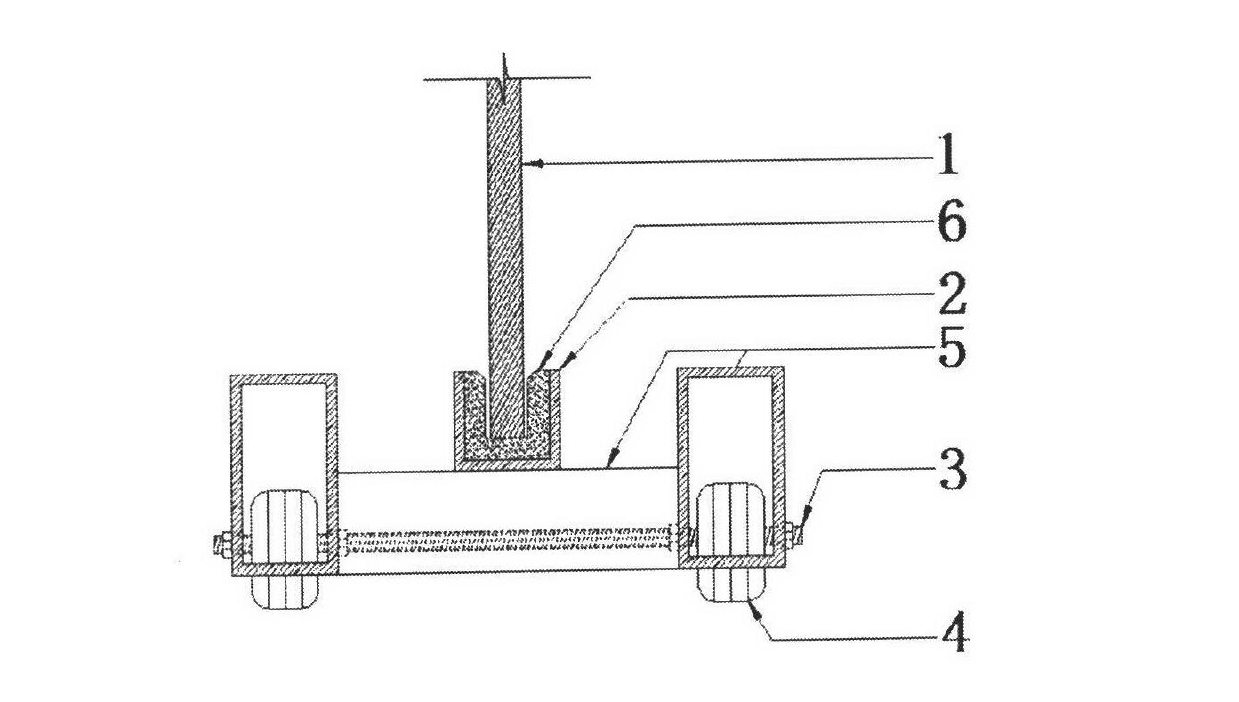

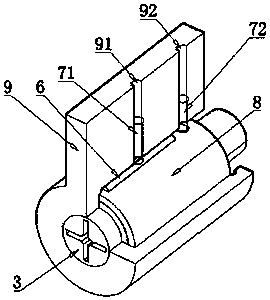

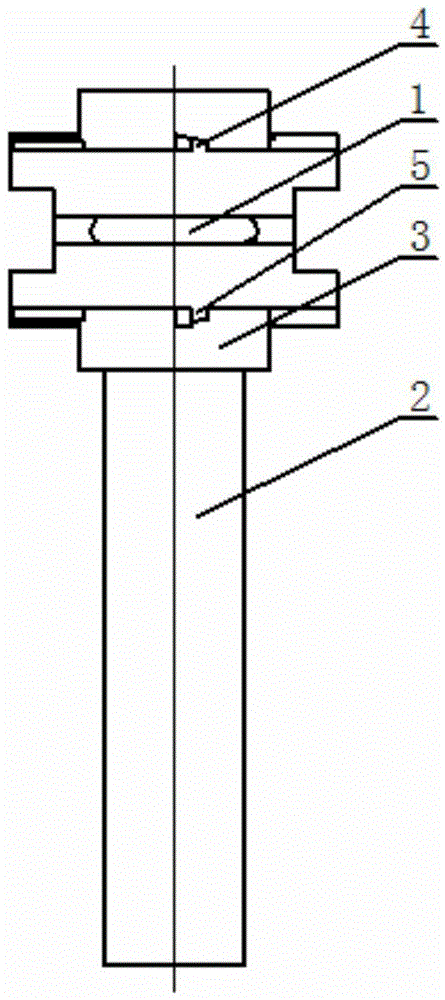

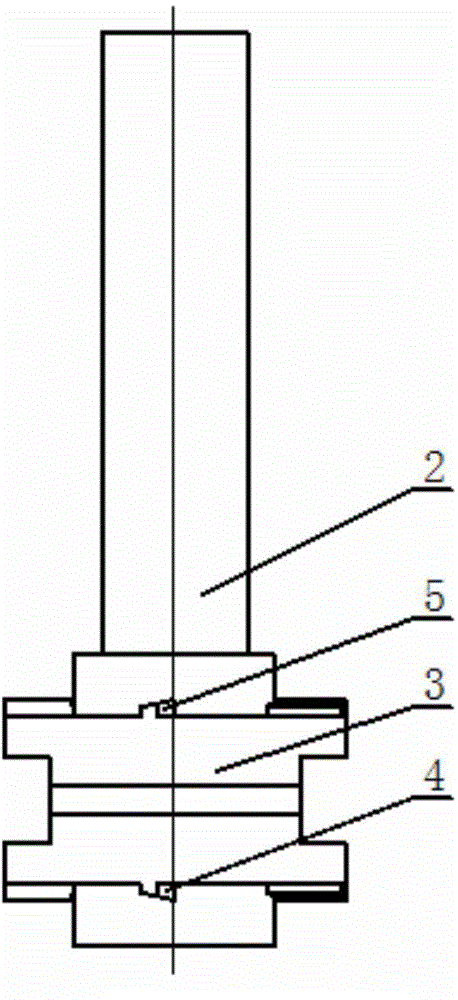

Clamp for drilling oil hole on crankshaft

InactiveCN101628384APrecise positioningImprove drilling efficiencyPositioning apparatusDrill jigsCrankshaftDrill bushing

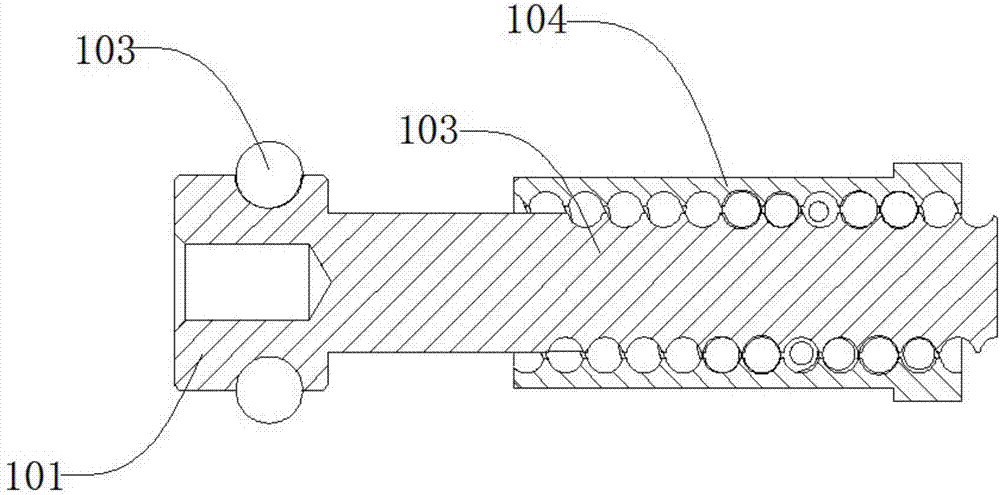

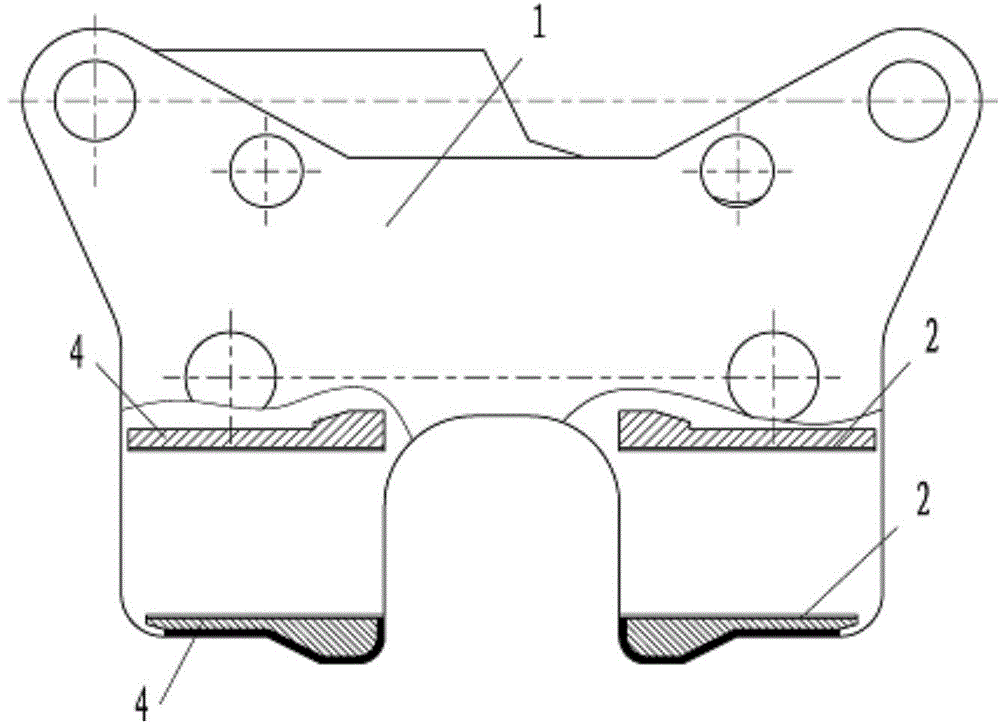

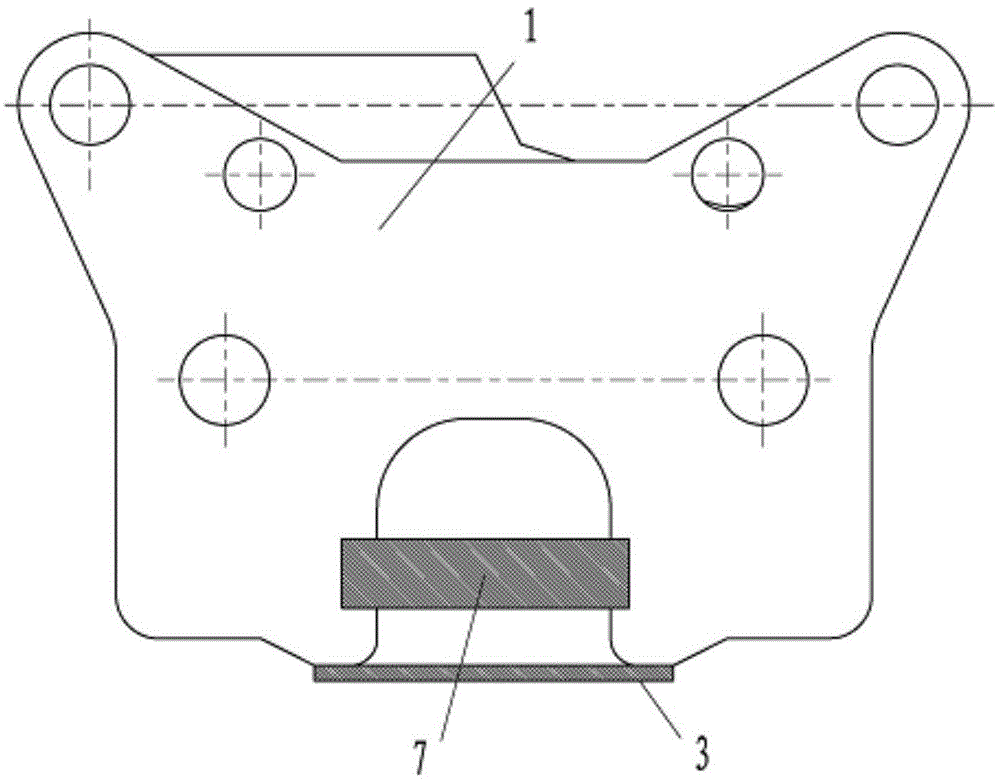

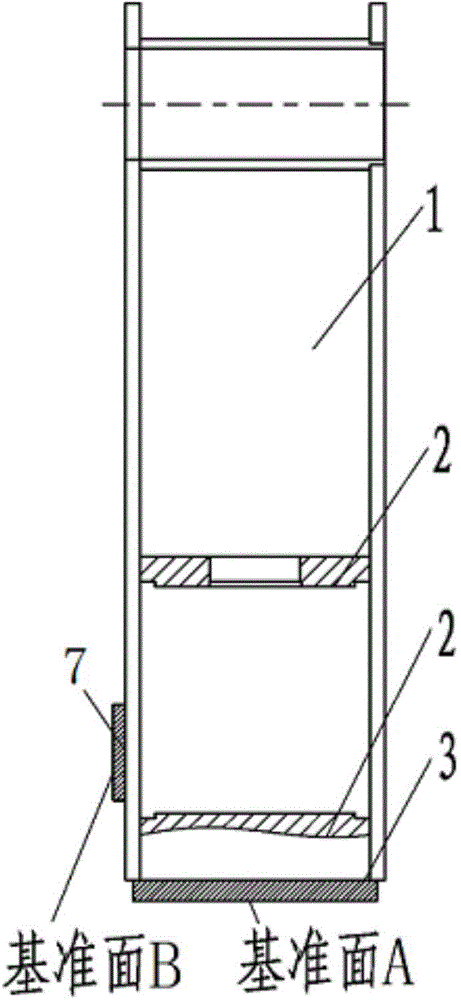

The invention relates to a clamp for drilling oil holes on a crankshaft, which comprises a clamp body, a clamping mechanism, a connecting rod positioning mechanism and a drilling jig frame mechanism, wherein the clamping mechanism is provided with a drilling jig supporting seat, a pressing plate and a replaceable cushion block; the drilling jig supporting seat is movably arranged on the clamp body; the pressing plate is arranged on a pressing plate strut on the drilling jig supporting seat through a hinge pin; the lower part of the pressing plate is provided with a hold-down bolt; the hold-down bolt is screwed in, passes through the pressing plate and presses against the drilling jig supporting seat; a turn-knob compresses the bolt; a spindle neck is compressed or loosened through the lever action of the hinge pin arranged on the pressing plate and the pressing plate strut; the connecting rod positioning mechanism comprises a positioning column and a liner plate; the positioning column is arranged in a replaceable liner plate positioning hole; the top of the positioning column supports a connecting rod neck; and the drilling jig frame mechanism comprises the drilling jig supporting seat, a drilling jig plate and a drill bush. The clamp has the advantages of reasonable structure, convenient assembly, low manufacturing cost, strong popularity, and high efficiency of drilling the oil holes, greatly shortens the manufacturing period, and is suitable for clamping various crankshafts for drilling straight oil holes.

Owner:TIANRUN IND TECH CO LTD

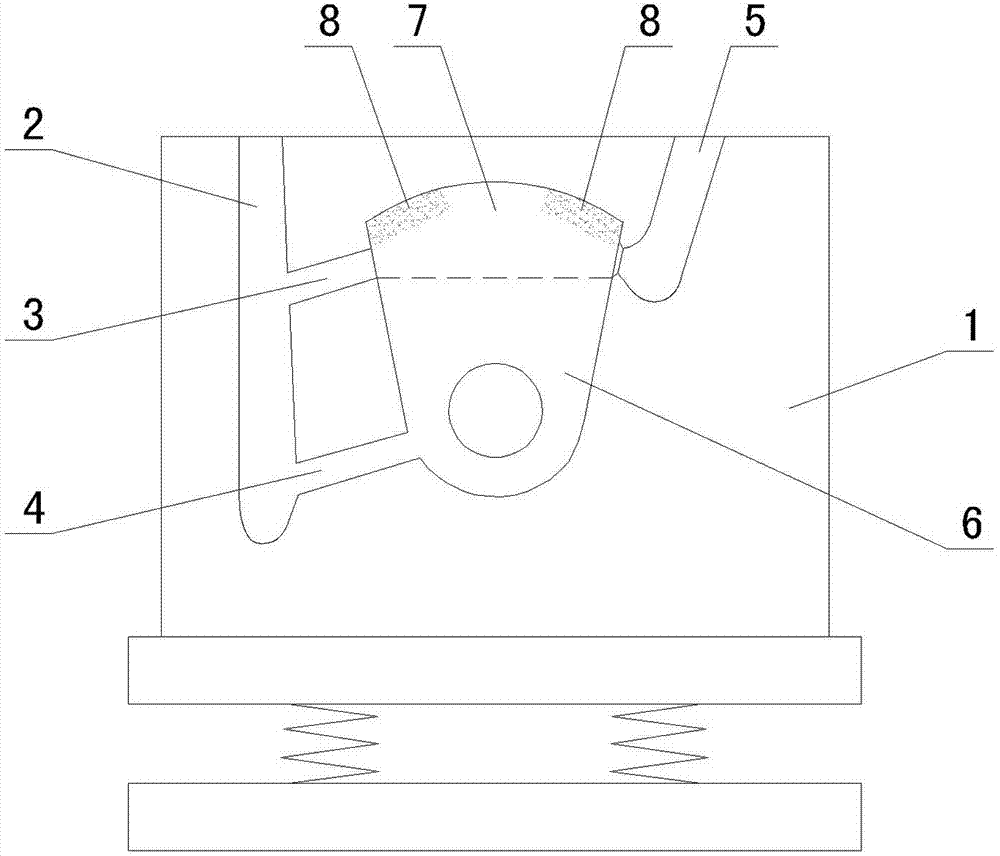

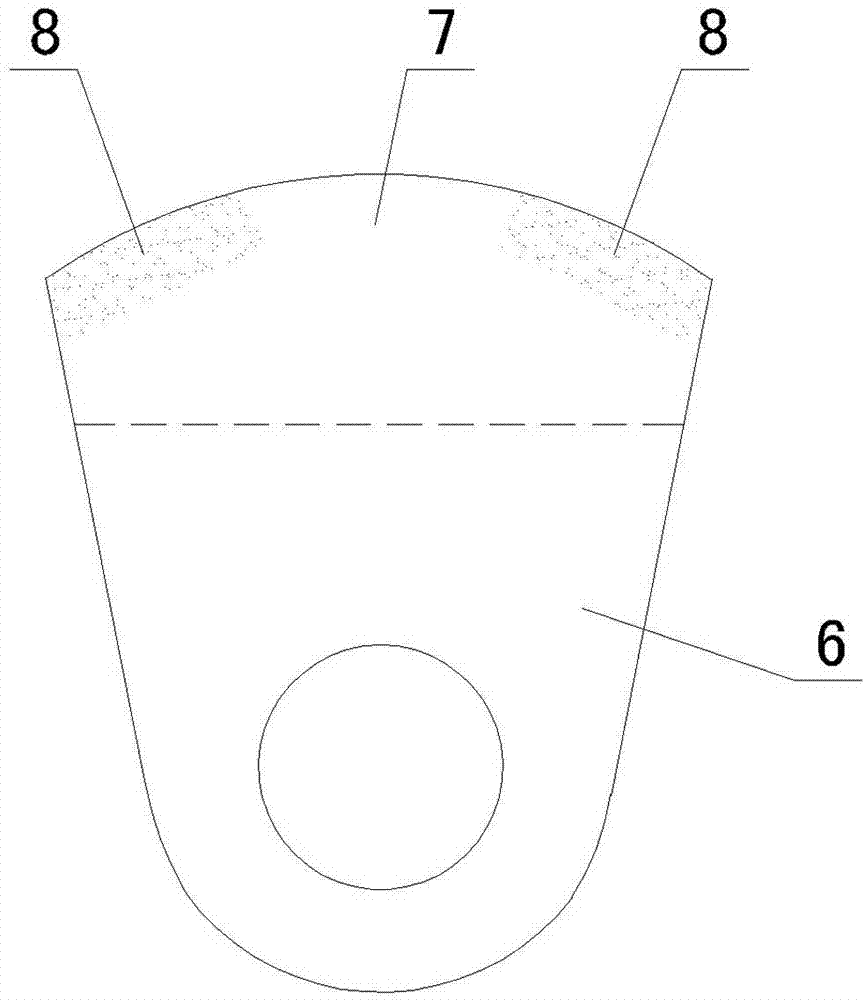

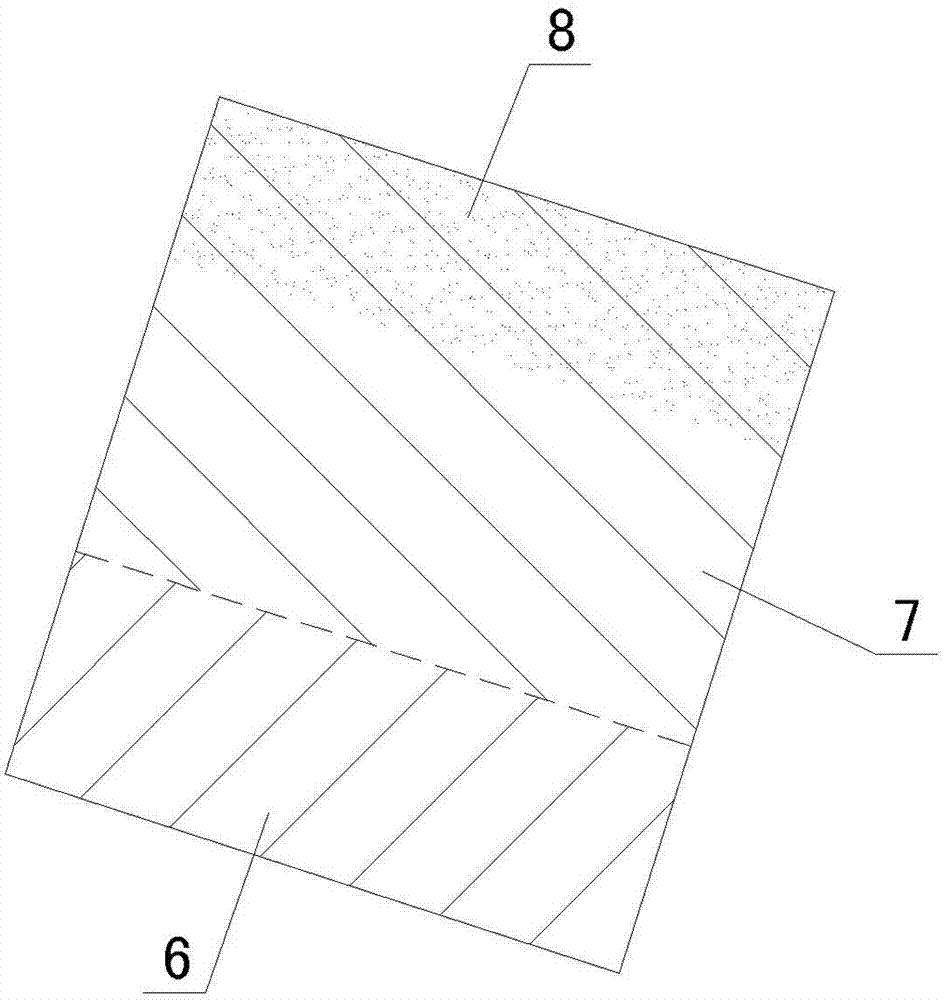

Manufacturing method for composite hammer head of hammer crusher

A manufacturing method for a composite hammer head of a hammer crusher includes the steps that firstly, a composite hammer head mould is manufactured; secondly, ceramic particles are fixed in the mould to manufacture a cavity of a use part of the hammer head; thirdly, mould assembling is conducted, wherein the mould is fixed to a mechanical vibration device, low-carbon and low-alloy steel is cast at first, then, high-chromium iron is cast, the mechanical vibration device is started while the high-chromium iron is cast, mechanical vibration enables the mould to be solidified, and the composite hammer head can be obtained through processing after the mould is cooled; fourthly, the composite hammer head is subjected to thermal treatment. According to the manufacturing method, the ceramic particles are adopted in the use part of the hammer head to reinforce the high-chromium iron composite materials, the low-carbon and low-alloy steel with good obdurability is adopted in an installation area, and the composite hammer head is manufactured in a bi-liquid compositing method; meanwhile, diffusion of elements in an interface of the liquid high-chromium iron and liquid low-carbon and low-alloy steel is accelerated through a mechanical vibration method, therefore, stable interface metallurgical bonding is achieved, high abrasive resistance and high obdurability of the composite hammer head are achieved, an abraded region is not prone to falling off, and the service life of the composite hammer head is long; in addition, by the adoption of the manufacturing method, the manufacturing process is simple, the manufacturing cost is low and the practicability is high.

Owner:GUANGDONG INST OF NEW MATERIALS

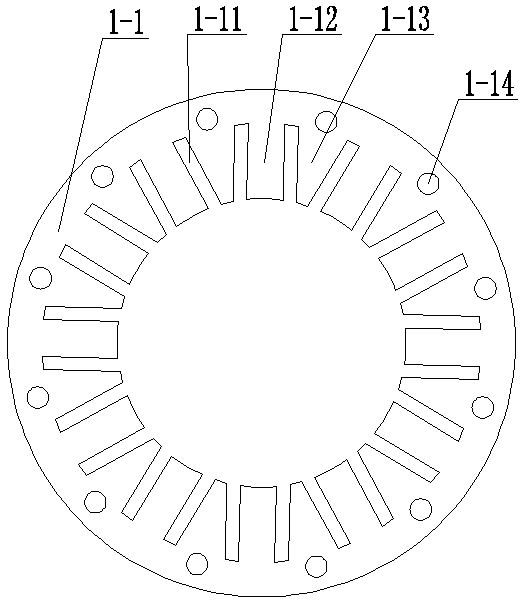

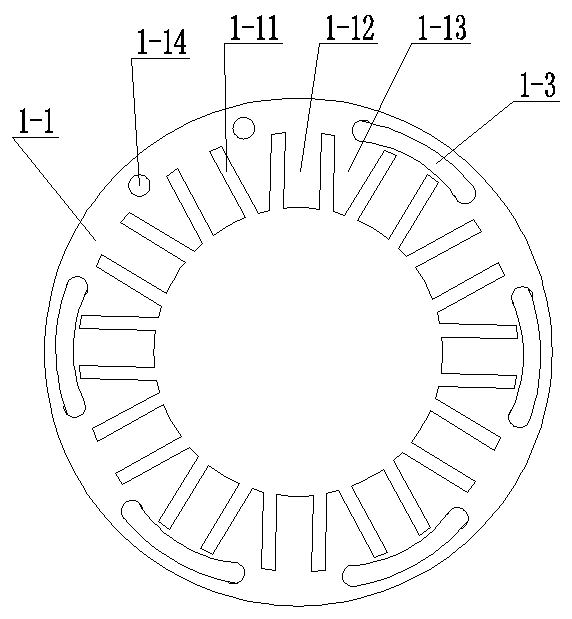

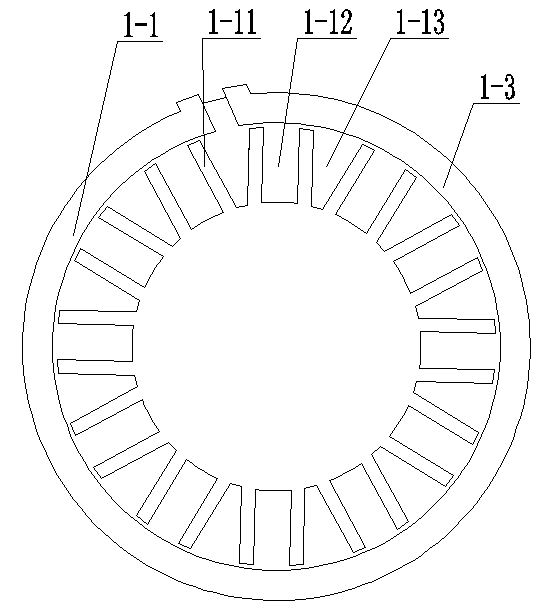

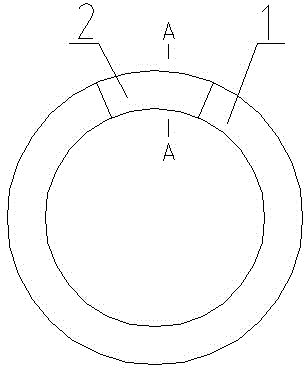

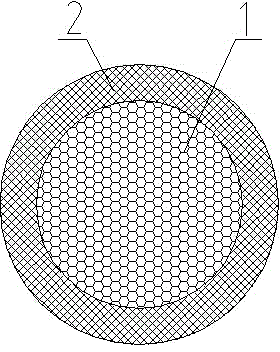

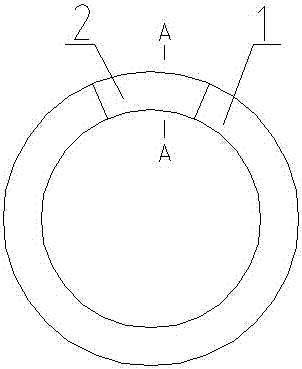

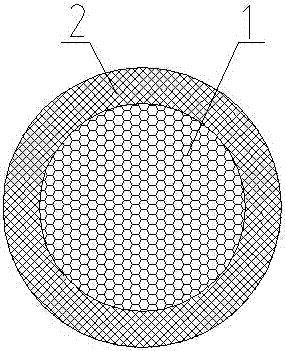

Permanent magnet synchronous motor with high-power density

InactiveCN101882850AIncrease in sizeImprove space utilizationSynchronous machine detailsMagnetic circuit stationary partsSynchronous motorPermanent magnet synchronous motor

The invention relates to a permanent magnet synchronous motor with high-power density, which belongs to the technical field of motors and solves the problem that the motor volume is large or the motor efficiency is decreased as pipelines are arranged in the motor to cool the motor with a liquid cooling method in the traditional multi-phase permanent magnet synchronous motor. The synchronous motor comprises a stator and a rotor. A gas gap is formed between the stator and the rotor, and the stator comprises an armature iron core and an armature winding. The gas gap side surface of the armature iron core is in a tooth groove structure. The interval arrangement of parallel teeth and trapezoidal teeth are formed on the gas gap side surface of the armature iron core by a plurality of parallel grooves. The gas gap side edges of the trapezoidal teeth are short edges, and the middle of the tooth root of each trapezoidal tooth is provided with an axial circular through hole. The armature winding is sheathed on the parallel teeth, and is formed by connecting single-layer coils in series or parallel, wherein the coil is square. The invention is suitable for permanent magnetic synchronous motors.

Owner:HARBIN INST OF TECH

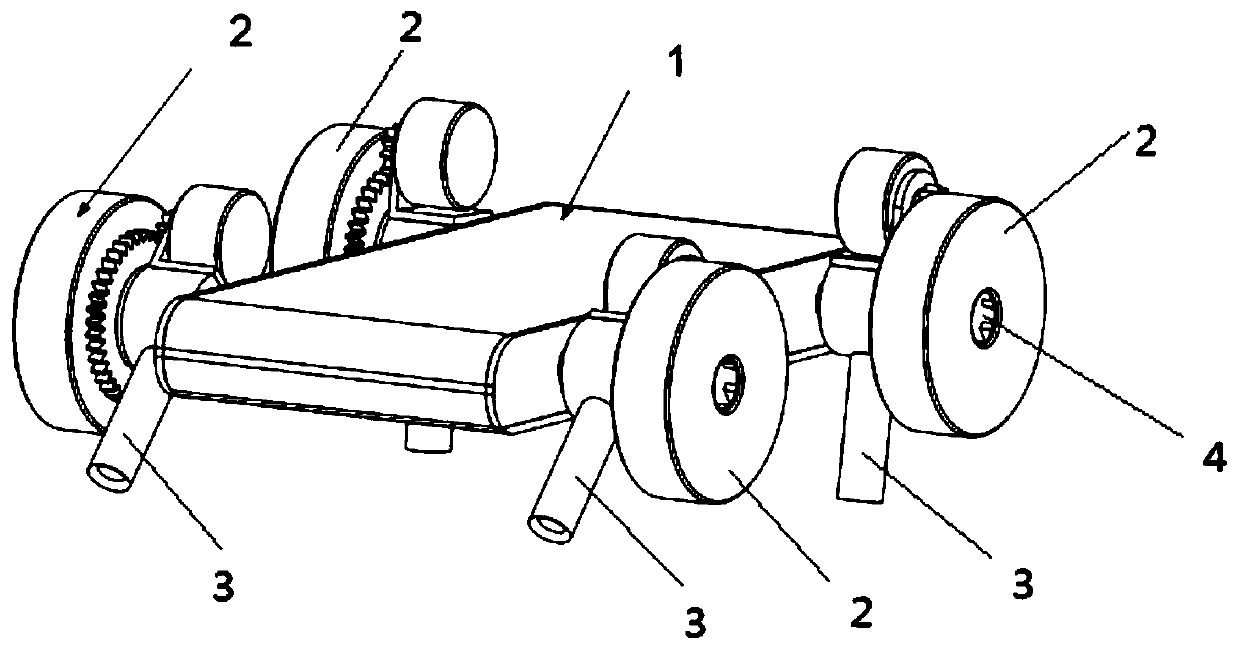

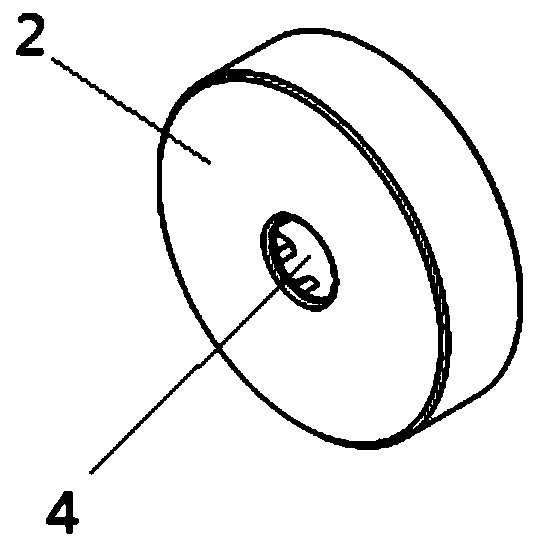

Amphibious robot

The invention relates to the technical field of robots, and aims to provide an amphibious robot with good mobility, low manufacturing cost, small size and wide application range. The amphibious robotcomprises a vehicle body and at least four wheel-leg composite mechanisms arranged on the two sides of the vehicle body, wherein the wheel-leg composite mechanisms comprise composite wheels with hollow inner parts and supporting legs, the axial direction of the supporting legs is perpendicular to the axial direction of the composite wheels, the upper parts of the supporting legs are rotatably connected with and communicate with the axial center of the composite wheels, the composite wheels are driven by wheel drive assemblies, the supporting legs are driven by leg drive parts, impellers are arranged in the composite wheels, water inlets are formed in the outer sides of the composite wheels, and water outlets are formed in the bottoms of the supporting legs. Through the amphibious robot, the problems that an existing amphibious robot is complex in structure, high in manufacturing cost and large in size, is not suitable for working in narrow space and is small in application range are solved.

Owner:SHANDONG UNIV

Nitrogen-self-generating storage system

PendingCN109018704AImplement a modular setupIncrease or decrease quantityPackaging under vacuum/special atmosphereShock-sensitive articlesNitrogenNitrogen gas

The invention relates to a nitrogen-self-generating storage system. The nitrogen-self-generating storage system comprises a storage space and is characterized in that the nitrogen-self-generating storage system further comprises an electronic sieve oxygen generation module; the electronic sieve oxygen generation module comprises an oxygen generation membrane and a gas outlet channel; the interiorof the storage space communicates with the oxygen generation membrane so as to adsorb oxygen in air in the storage space, and thus nitrogen in the air is left in the storage space; the electronic sieve oxygen generation module has the characteristics of adsorbing and collecting the oxygen in the air, and when being combined with any object with a storage space, the electronic sieve oxygen generation module can rapidly absorb and collect oxygen in the storage space and reserves nitrogen in the storage space for refreshment and preservation of food, valuables and the like; and the system can bewidely used for transportation and logistics, cultural relic storage, refrigerator preservation, food refreshment and quality preservation and the like.

Owner:FOSHAN SHUNDE GELINMEI ELECTRONIC PROD CO LTD

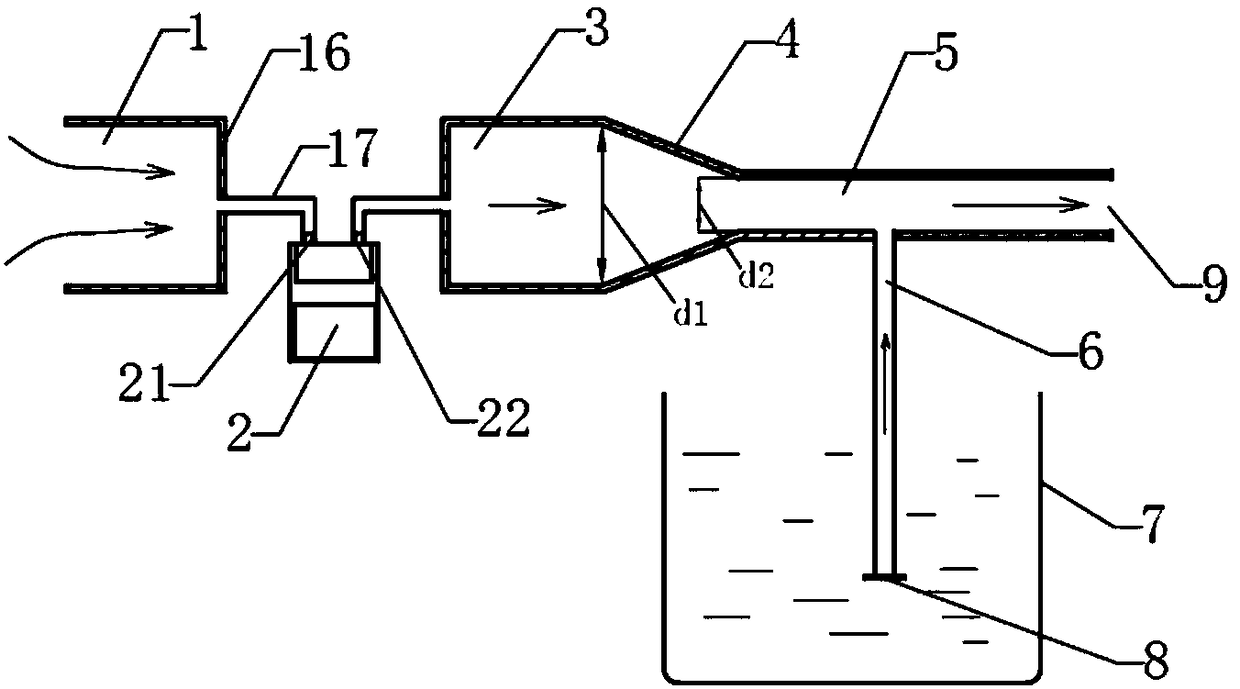

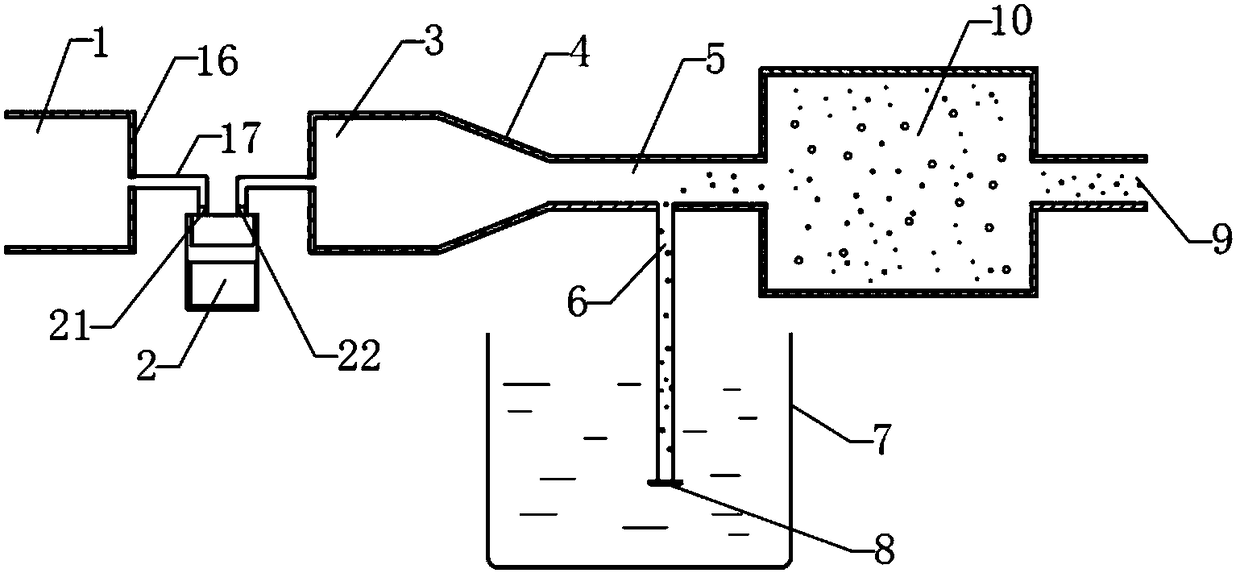

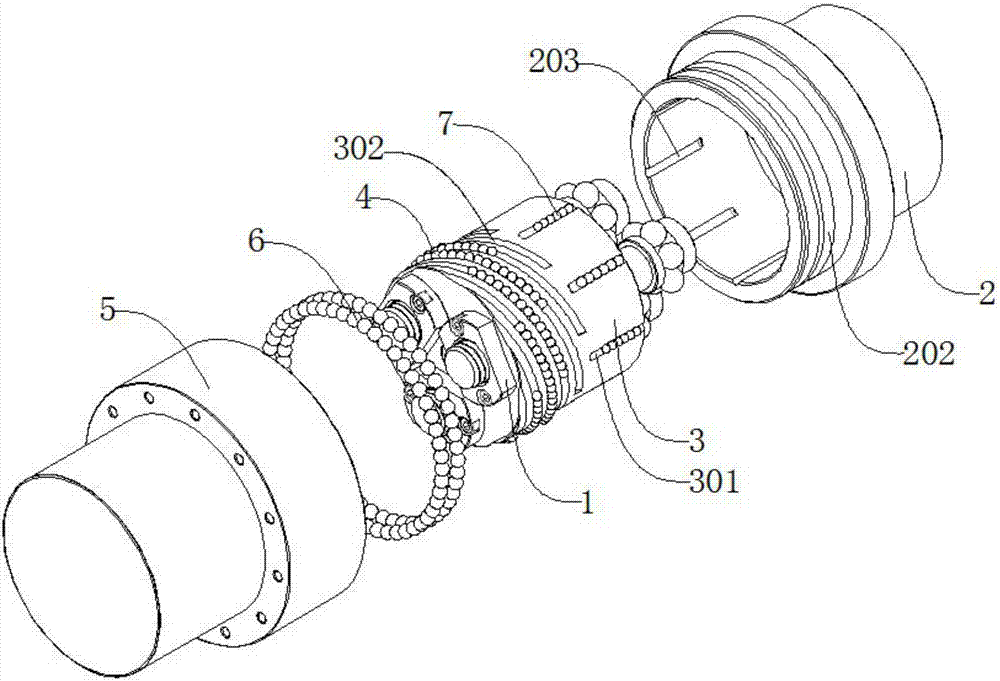

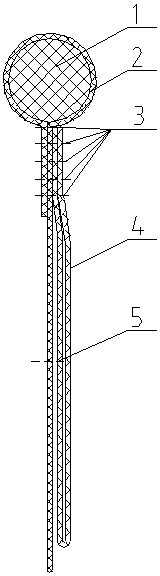

Nano vaporization fogging device

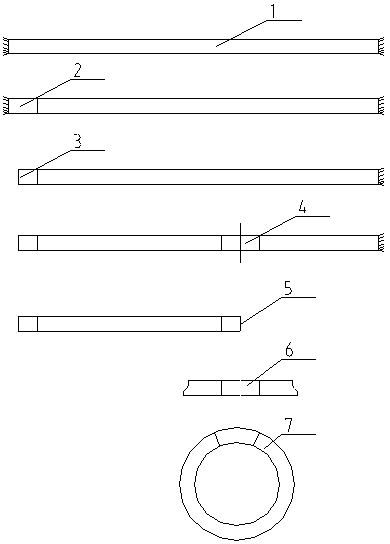

PendingCN108465389AStrong manufacturing costLow Fog EfficiencyFlow mixersTransportation and packagingVaporizationEngineering

The invention discloses a nano vaporization fogging device. A gas inlet tube (1) is connected with the sucking hole (21) of a gas pump (2); the discharge hole (22) of the gas pump (2) is connected with a gas outlet tube (3); the gas outlet tube (3) is connected with the large diameter end of a reducing pipe (4); the small diameter end of the reducing pipe (4) is connected with a venturi tube (5);the venturi tube (5) is arranged horizontally or in an inclined manner; a vaporization tube (6) is connected below the venturi tube (5); the lower end of the vaporization tube (6) is inserted below the liquid level inside a liquid tank (7); an ejection hole (9) is formed in the tail end of the venturi tube (5). By adopting the nano vaporization fogging device, an intense low-pressure environment is constructed by virtue of jet flow principles, so that a liquid can be vaporized to generate nano vapor and is mixed with high-speed air after air flow induction , then nano atomization can be achieved, and the device has multiple advantage of being high in vaporization efficiency, moderate and adjustable in liquid mist temperature, simple in process, low in manufacturing cost, and the like.

Owner:HANGZHOU QINGKE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Titanium boride-based coating composite material for aluminum electrolysis, preparation method and coating method thereof

ActiveCN103194101ALower sintering temperatureReduce manufacturing costCoatingsGraphite carbonAluminium electrolysis

The invention discloses a titanium boride-based coating composite material for aluminum electrolysis, a preparation method and a coating method thereof. The composite material consists of the following raw materials in percentage by weight: 55%-70% of titanium boride-oxide composite particles, 8%-15% of a carbon additive, 15%-30% of an organic resin adhesive and 0.5%-2% of a reinforcing agent. The coating method comprises the following steps: (1) putting a graphite base material into a coating mould, and then, pouring the obtained slurry into a mould; (2) curing the base material coated with the slurry at 15 DEG C-35 DEG C for 24h-48h, and then, curing the base material at 80 DEG C-150 DEG C for 12h-24h; and (3) putting the base material coated with the slurry into a graphite crucible, filling graphite carbon powder into the graphite crucible, and carbonizing and sintering the graphite crucible in an inert gas atmosphere or in vacuum, wherein the carbonizing and sintering temperature is 850-1050 DEG C, and the carbonizing and sintering time is 80-120 hours. The titanium boride-based coating composite material for aluminum electrolysis has high combination degree with a base and good tensile strength high up to 8-10MPa; and a coating structure is dense and has strong anti-scouring property.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

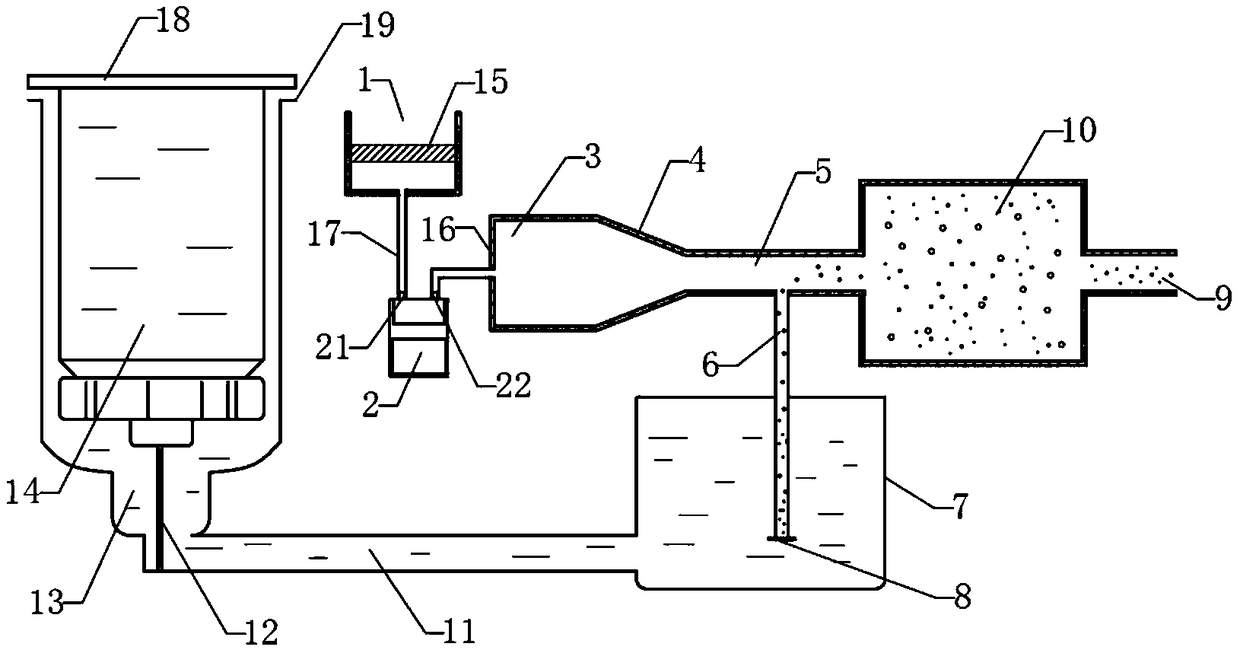

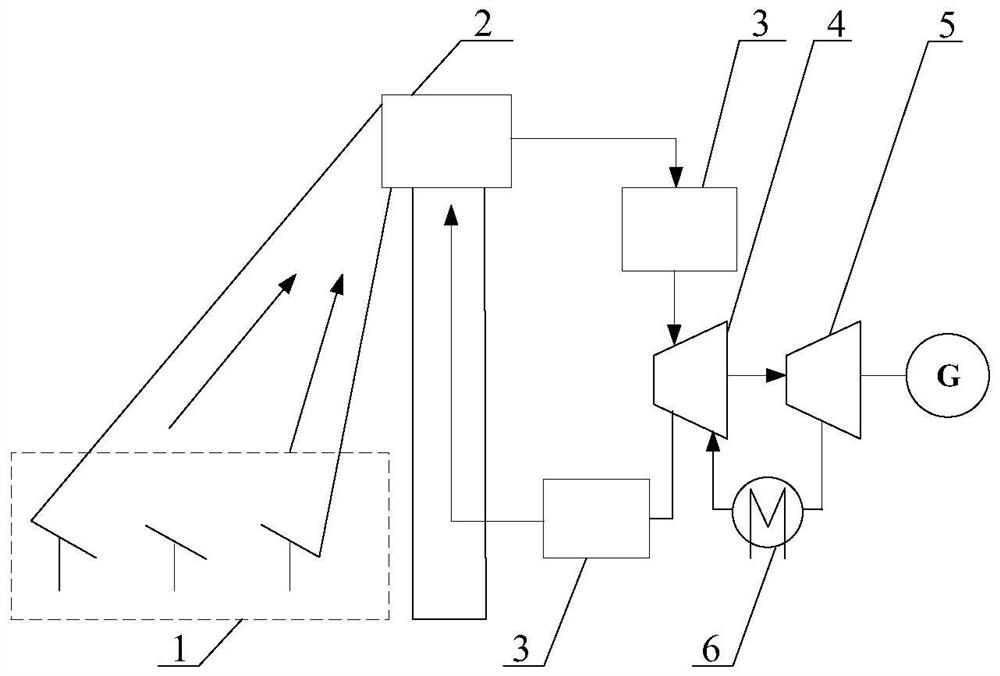

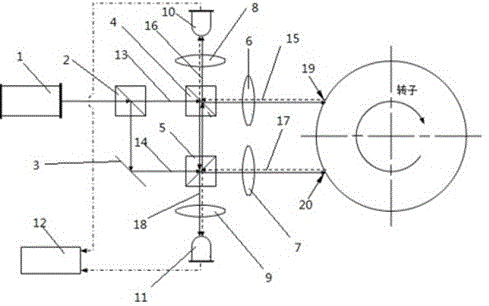

Vibration measurement device for laser interference rotor and measurement method thereof

InactiveCN103335704AReduce machining errorsImplementing FM MeasurementsSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansVibration measurementLaser interference

The invention provides a technical scheme of a vibration measurement device for a laser interference rotor and a measurement method thereof. The scheme can simultaneously detect bending vibration and torsional vibration of a high-speed rotor based on beat frequency generated by laser Doppler effect, realizes frequency modulation measurement of a vibration signal under the condition of not using an expensive frequency shift device, and precisely distinguishes the directions of bending vibration and torsional vibration, has very strong anti-environment disturbance capability, and is low in manufacturing cost. The scheme belongs to non-contact measurement, the motion state of the to-be-measured rotor is free from interference, the accuracy in measurement is high, the response speed is fast, the dynamic range is wide, and the measurement can be performed at a further distance. The processing error of the rotor and measurement interference of torsional vibration and bending vibration from other vibration states are small.

Owner:SOUTHWEAT UNIV OF SCI & TECH

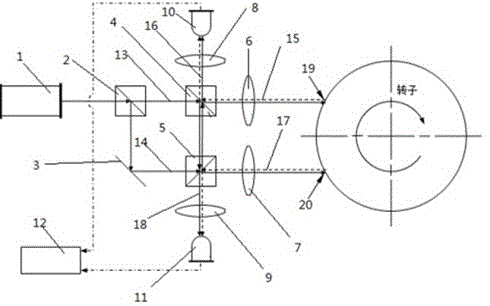

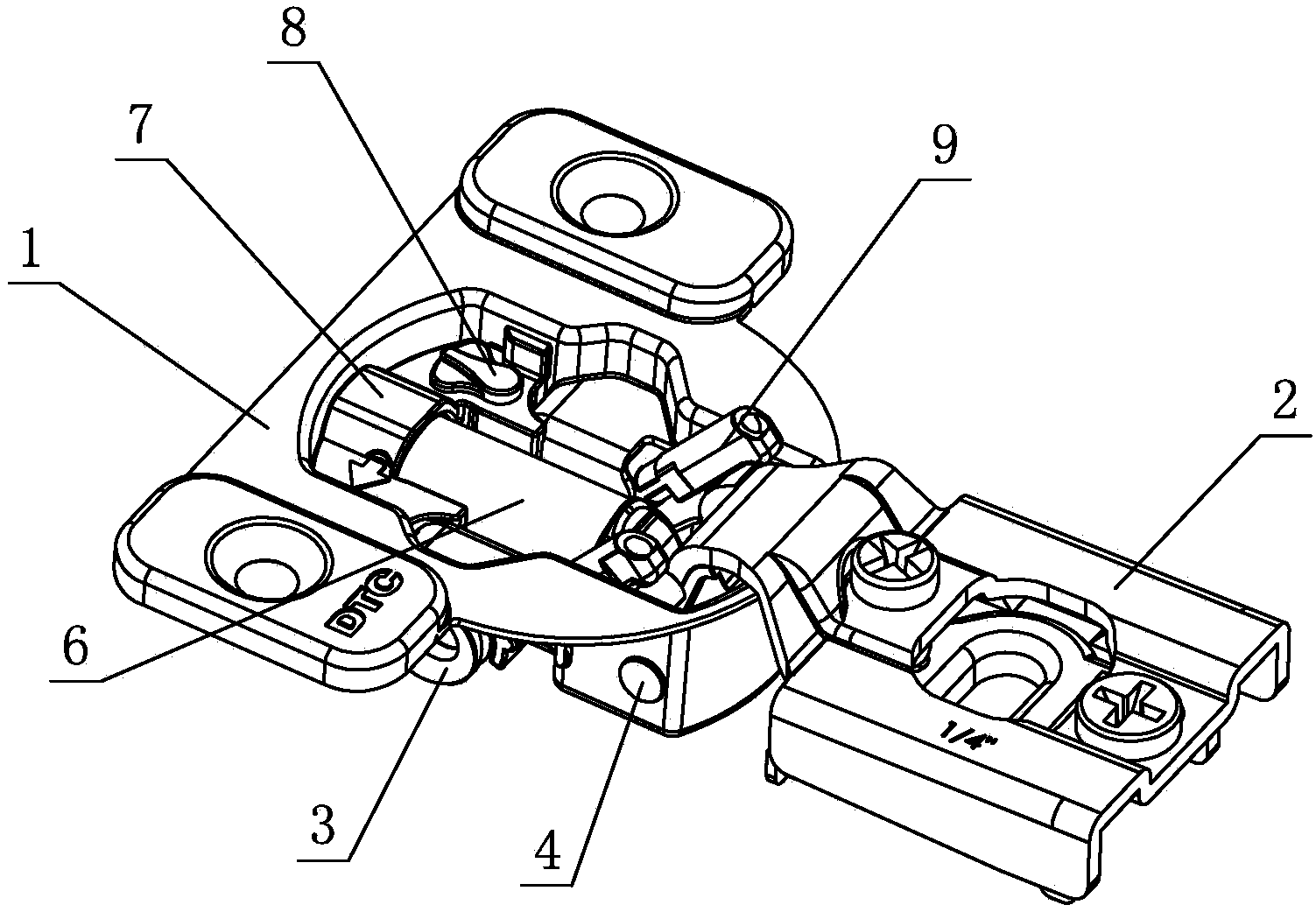

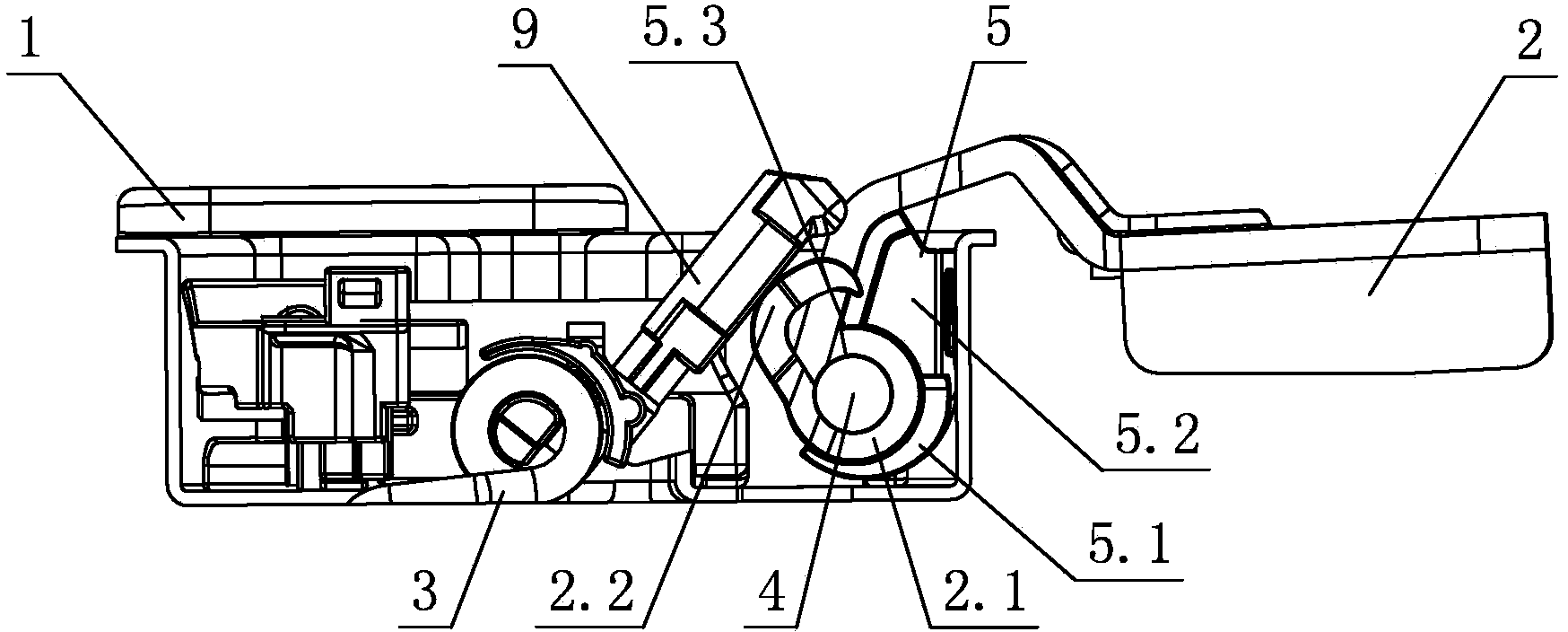

Hinge capable of limiting opening angle of furniture door

InactiveCN103835603AEasy to useReduce noiseBuilding braking devicesWing accessoriesEngineeringMechanical engineering

The invention discloses a hinge capable of limiting the opening angle of a furniture door. The hinge capable of limiting the opening angle of the furniture door comprises a movable hinge cup, a hinge arm and elastic pieces, wherein the elastic piece are arranged on the movable hinge cup and act on the hinge arm, and the hinge arm is arranged on the movable hinge cup in a rotary mode through a supporting piece. The hinge capable of limiting the opening angle of the furniture door is characterized in that the hinge arm is made of metal, a cylinder part is integrally formed in the middle of the hinge arm, the supporting piece is arranged on the movable hinge cup in a rotary mode through a through hole in the cylinder part, action parts provided with arc surfaces are integrally formed on the two sides of the cylinder part, one end of each elastic piece acts on the corresponding action part, and a plastic limiting piece with certain elasticity is arranged on the inner side of the hinge arm and is supported by the movable hinge cup in a rotary mode through the hinge arm to limit the opening angle of the hinge. According to the hinge capable of limiting the opening angle of the furniture door, the plastic limiting piece is arranged on the hinge arm and is supported by the movable hinge cup by rotating the hinge arm, so that the opening angle of the hinge is limited, the closing angle of the hinge is not limited, and the practicability is high.

Owner:伍志勇

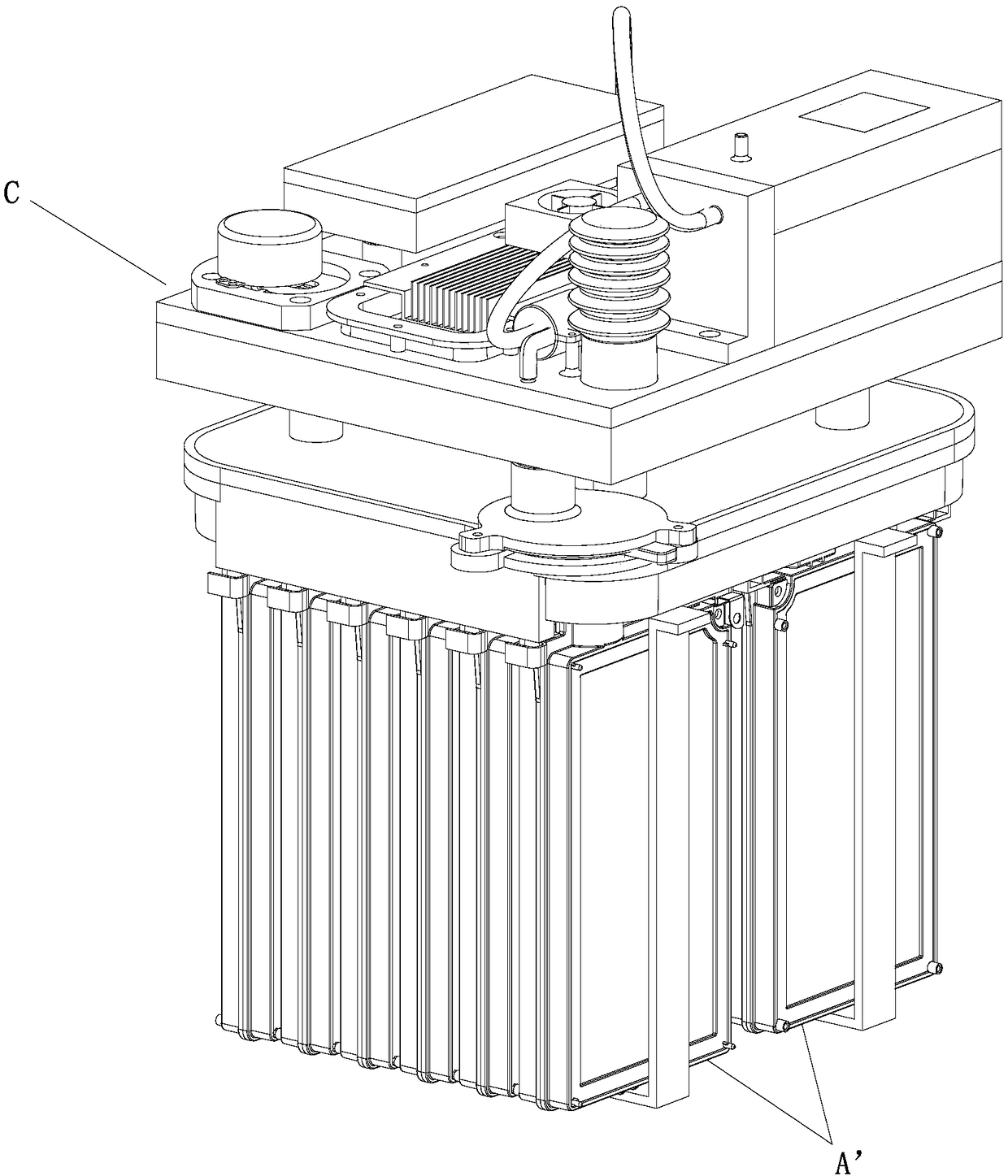

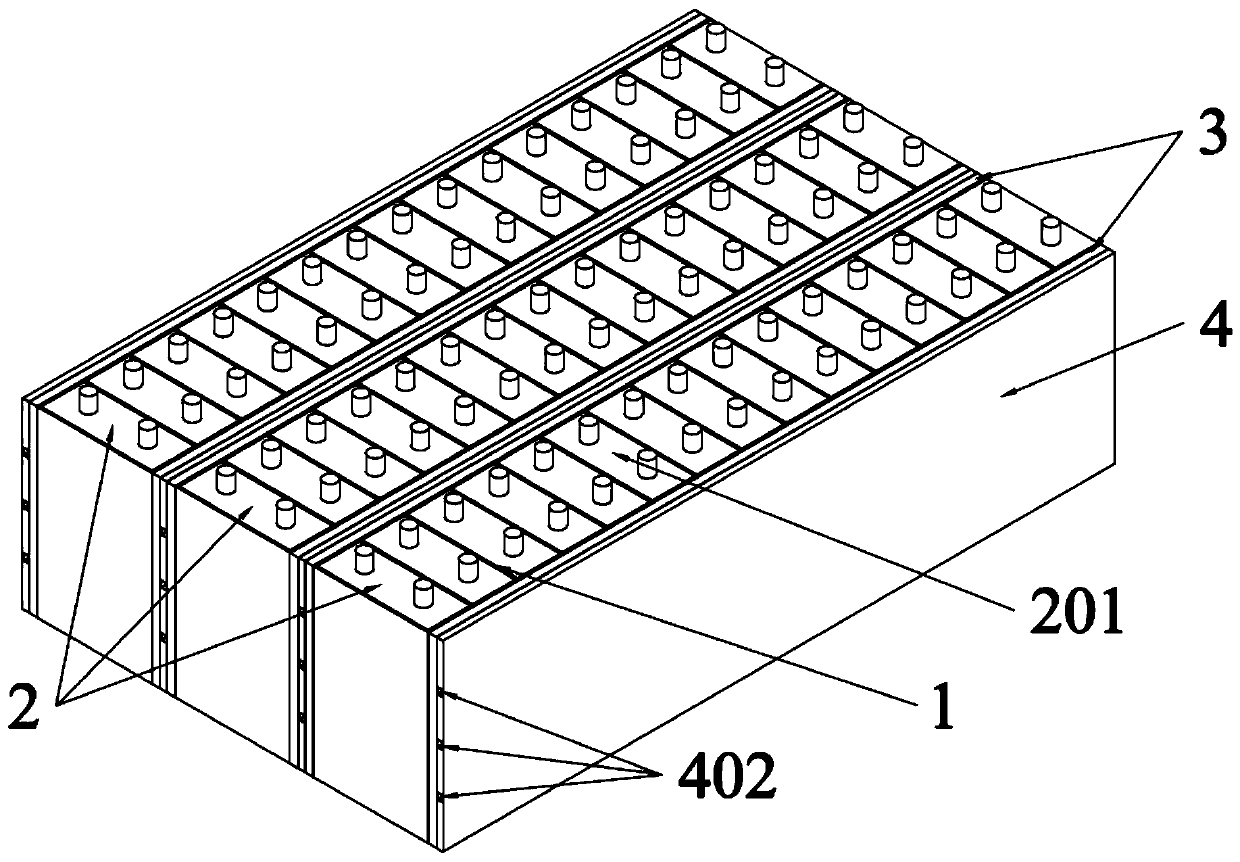

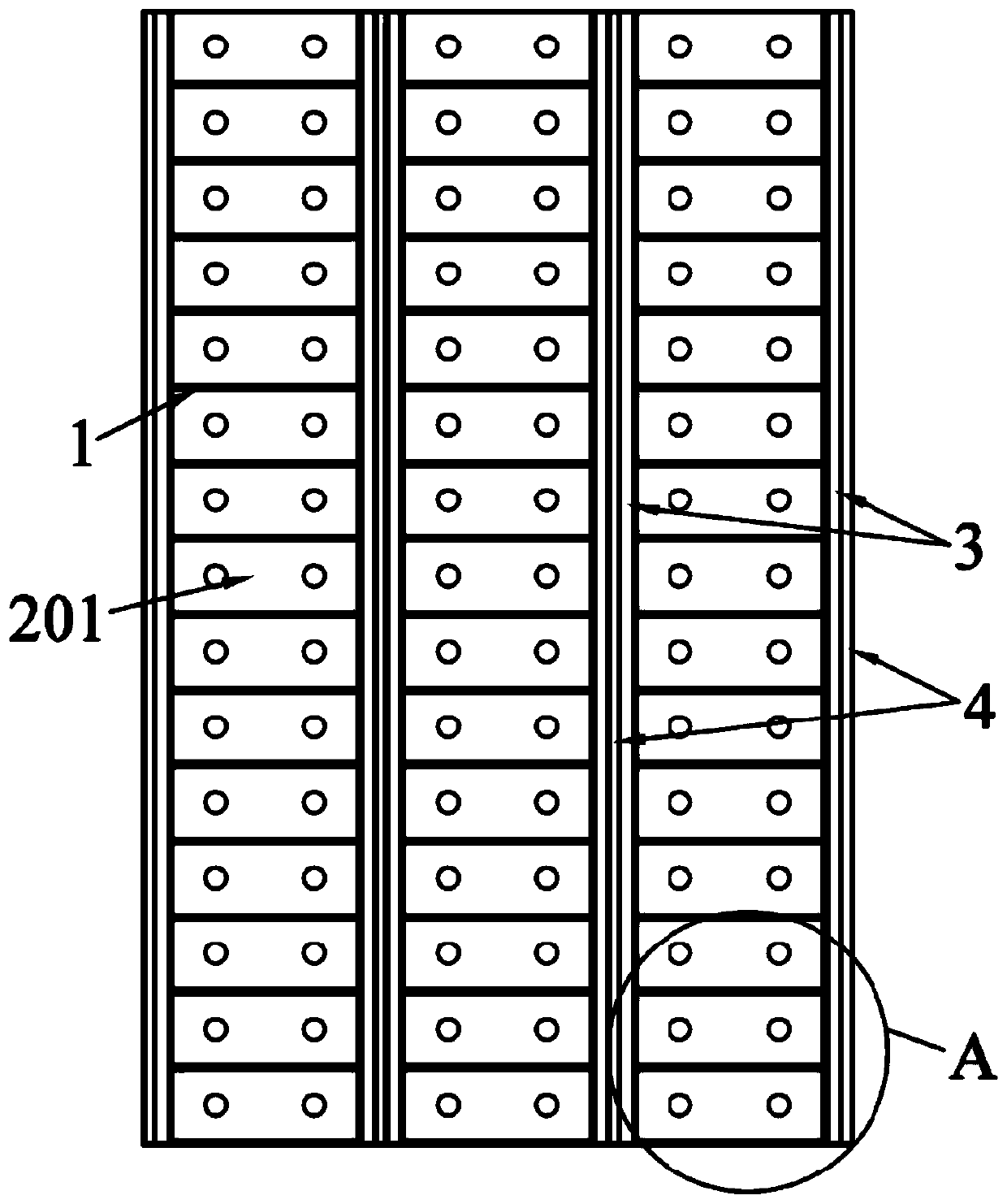

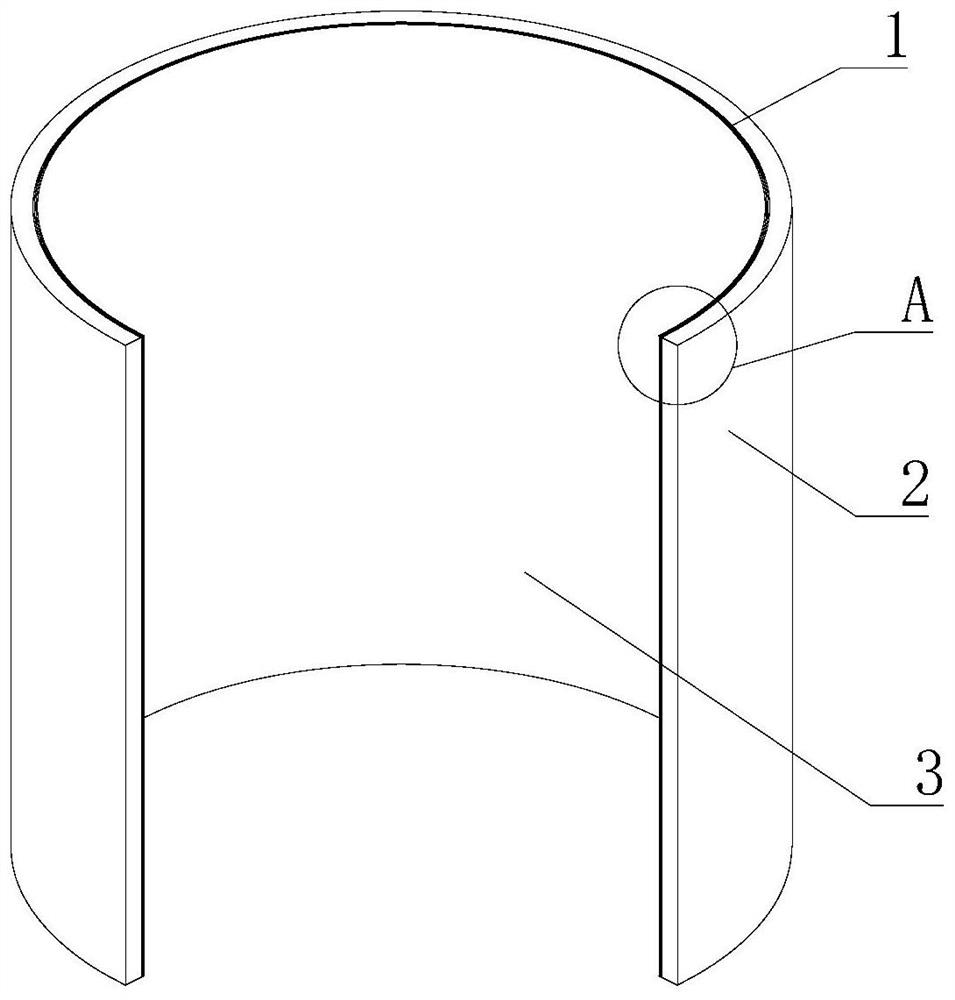

Battery pack thermal management system based on a flat heat pipe and operation method thereof

PendingCN110010995AUniform temperature distributionSimple structureSecondary cellsPower batteryElectrical battery

The invention relates to the field of thermal management of power batteries, and discloses a battery pack thermal management system based on a flat heat pipe. The system comprises a battery pack, a flat heat pipe, U-shaped graphite sheets and heat exchange plates; the battery pack comprises a plurality of square battery cells, and the U-shaped graphite sheets are in one-to-one correspondence withthe battery cells; the U-shaped graphite sheet at least coat the two opposite sides of the battery cells to form battery units which are attached to one another in order to form a battery module; theheat exchange plates are arranged in order at intervals, the battery module is arranged between the adjacent heat exchange plates in the length direction of the battery module, and the flat heat pipeis located between the battery module and the heat exchange plates. The present invention further discloses an operation method based on the battery pack thermal management system based on the flat heat pipe. The system is simple and compact in structure and small in occupied area, can effectively improve the uniformity of the temperature in the battery pack while perform efficient heat dissipation / heating of the battery pack.

Owner:SOUTH CHINA UNIV OF TECH

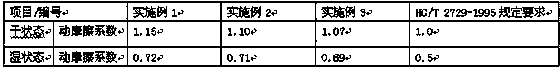

Anti-slip rubber composite for sole and preparation method of anti-slip rubber composite

InactiveCN108102153AImprove grip performanceImprove friction resistanceSolesRubber materialPolymer science

The invention belongs to the technical field of rubber materials and relates to an anti-slip rubber composite for a sole and a preparation method of the anti-slip rubber composite. The anti-slip rubber composite for the sole is prepared from raw materials in parts by weight as follows: 90-110 parts of natural rubber, 40-50 parts of carbon black, 4-6 parts of zinc oxide, 1-3 parts of stearic acid,0.8-1.2 parts of antioxidant 4010NA, 0.8-1.2 parts of antioxidant RD, 1-3 parts of accelerator CZ, 1-3 parts of accelerator D and 1-3 parts of sulfur. The anti-slip rubber composite for the sole has the advantages of large friction coefficient, good wear resistance, improved walk stability, improved comfort and the like; the preparation method adopts a simple process and is convenient to operate.

Iron tailing-fly ash-polystyrene blended concrete wall material and preparation method thereof

The invention relates to an iron tailing-fly ash-polystyrene blended concrete wall material and a preparation method thereof, and belongs to the technical field of building material engineering, the iron tailing-fly ash-polystyrene blended concrete wall material comprises the following raw materials by weight: 45 parts to 60 parts of iron tailings, 12.4 parts to 15 parts of cement clinker, 4.2 parts to 5 parts of micro silica fume, 7 parts to 11.4 parts of machine-made sand, 16 parts to 23 parts of fly ash, 0.4 part to 0.6 part of polystyrene foam particles, 0.2 part to 0.4 part of polypropylene fiber, 20 parts to 30 parts of water, 0.8 part to 1.5 parts of a high-efficiency water reducing agent, 0.05 part to 0.2 part of hydroxypropyl methyl cellulose HPMC and 0.05 part to 0.2 part of redispersible latex powder. The material has the advantages that the cost is reduced, the environmental pollution is reduced, and the resource waste is avoided; the process is simple, operation is convenient, and installation is convenient; and the material has the advantages of light weight, fire resistance, sound insulation, moisture resistance, shock resistance, good durability, strong adhesiveness and the like.

Owner:NORTHEASTERN UNIV +1

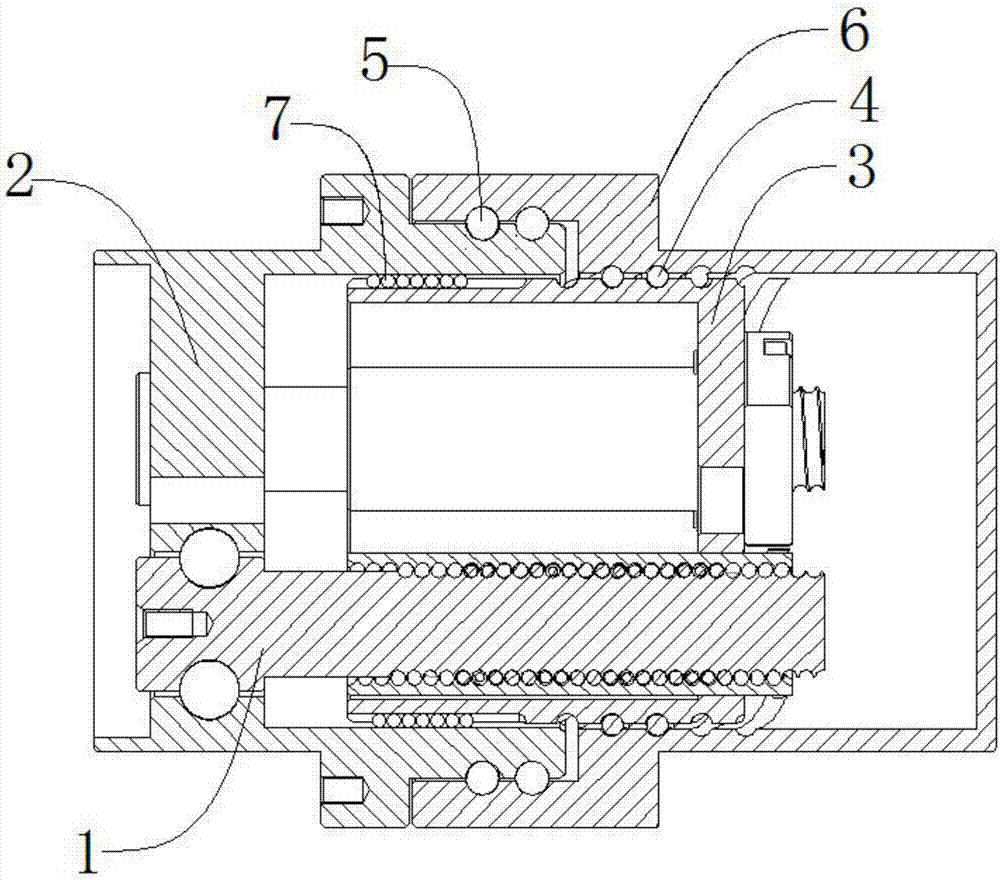

Serial connection type power dividing ball joint

ActiveCN106855105AReduce backlashHigh repeat positioning accuracyJointsGearingBall (bearing)Electrical and Electronics engineering

The invention discloses a serial connection type power dividing ball joint which comprises more than two high-speed screw mechanisms, a static ring, a low-speed nut sleeve, low-speed balls, a dynamic ring, first support balls and guide balls, multiple groups of high-speed screw mechanisms work, feed nuts and the low-speed nut sleeve can only move along high-speed screws due to fixed connection, at the same time, the low-speed nut sleeve, the low-speed balls and the dynamic ring form a screw transmission pair, and the guide balls limit the low-speed nut sleeve to rotate, so that the low-speed nut sleeve converts linear movement into rotation of the dynamic ring, and accordingly, gearing-down transmission is realized. The device structure is simple, power dividing is performed through the multiple groups of high-speed screw mechanisms, not only are the transmission accuracy and bearing capacity high, but also the manufacturing cost is low, and the transmission efficiency is high; at the same time, the structure is compact, the size is small, the movement is almost pure rolling movement, the friction coefficient is very low, the hysteresis phenomenon in the transmission is reduced, and the repeated positioning accuracy of the robot joint is improved from the source.

Owner:池州市弥优机床有限公司

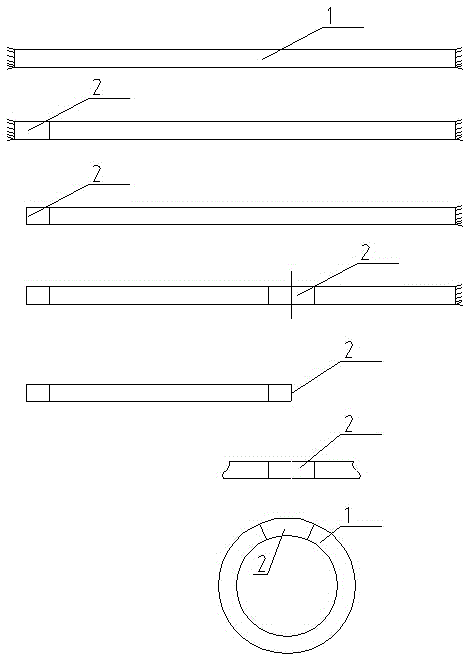

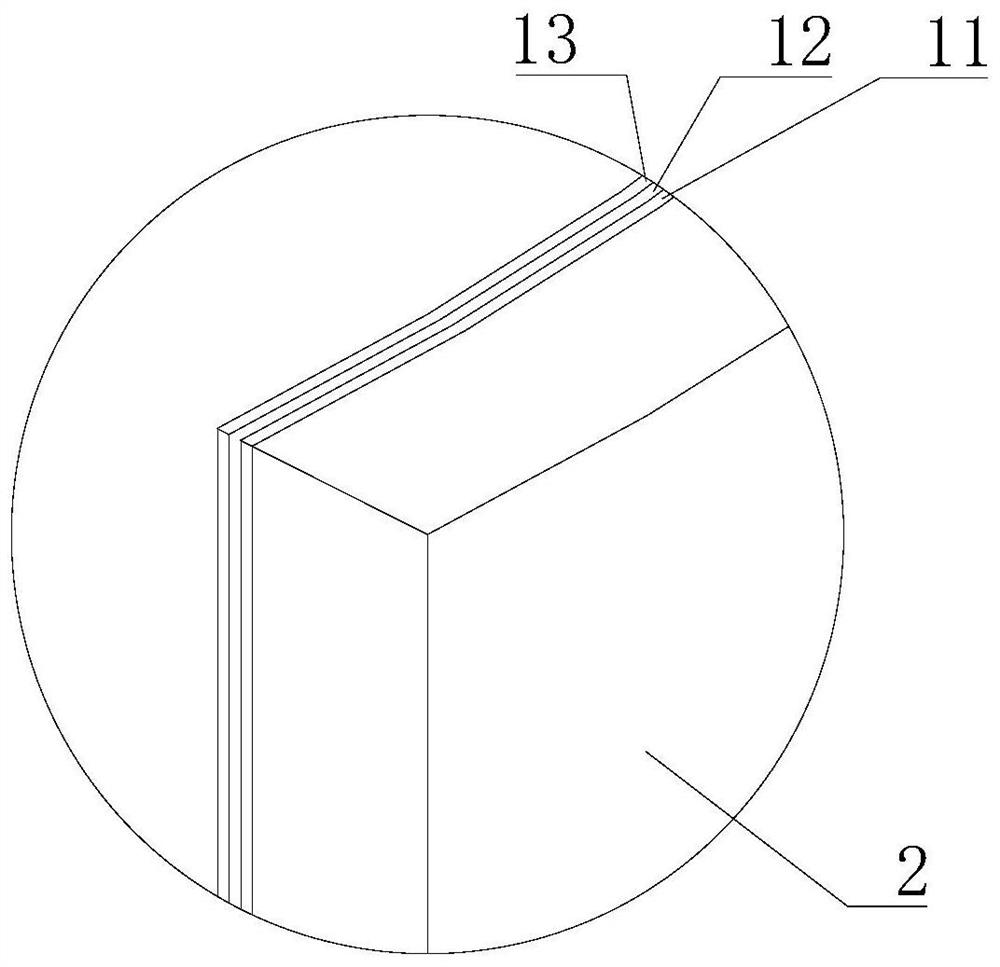

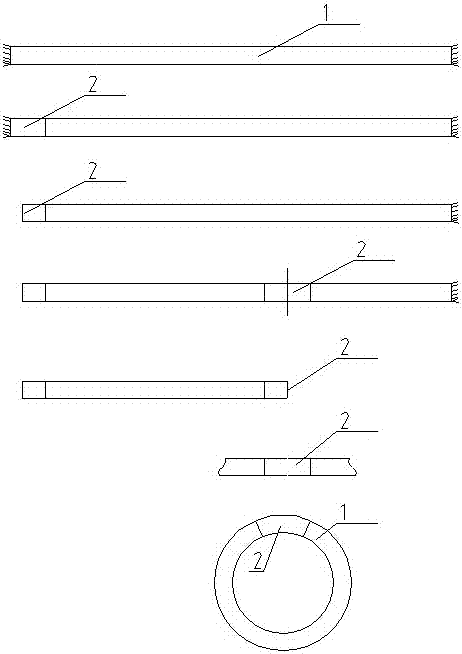

Special sealing ring for filter plates with embedded filter cloth and method for manufacturing special sealing ring

ActiveCN104565373AGood sealing performanceApplicable should be strongEngine sealsFilm materialEngineering

The invention relates to a special sealing ring for filter plates with embedded filter cloth and a method for manufacturing the special sealing ring. A cotton rope loop of the special sealing ring replaces a rubber O-shaped sealing ring to be used as a filter cloth fixing material, a sealing ring is made of the filter cotton rope loop, and film material sleeves are arranged at two ends of the cotton rope loop and are oppositely connected with each other, so that the sealing ring with a cotton rope can be formed. The special sealing ring and the method have the advantages that the special sealing ring is good in sealing fixing performance; the special sealing ring not only can be used under the conditions of most acid, alkali and organic solvents, but also can be used within wide temperature ranges and accordingly is extremely high in adaptability; the special sealing ring is low in manufacturing cost, convenient to quickly mount and detach and free of environmental pollution, and detached materials of the special sealing ring are easy to scatter.

Owner:HANGZHOU XINGYUAN FILTER TECH

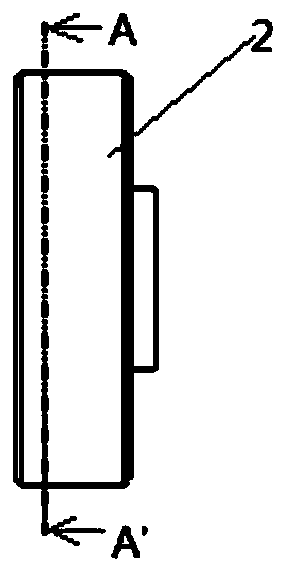

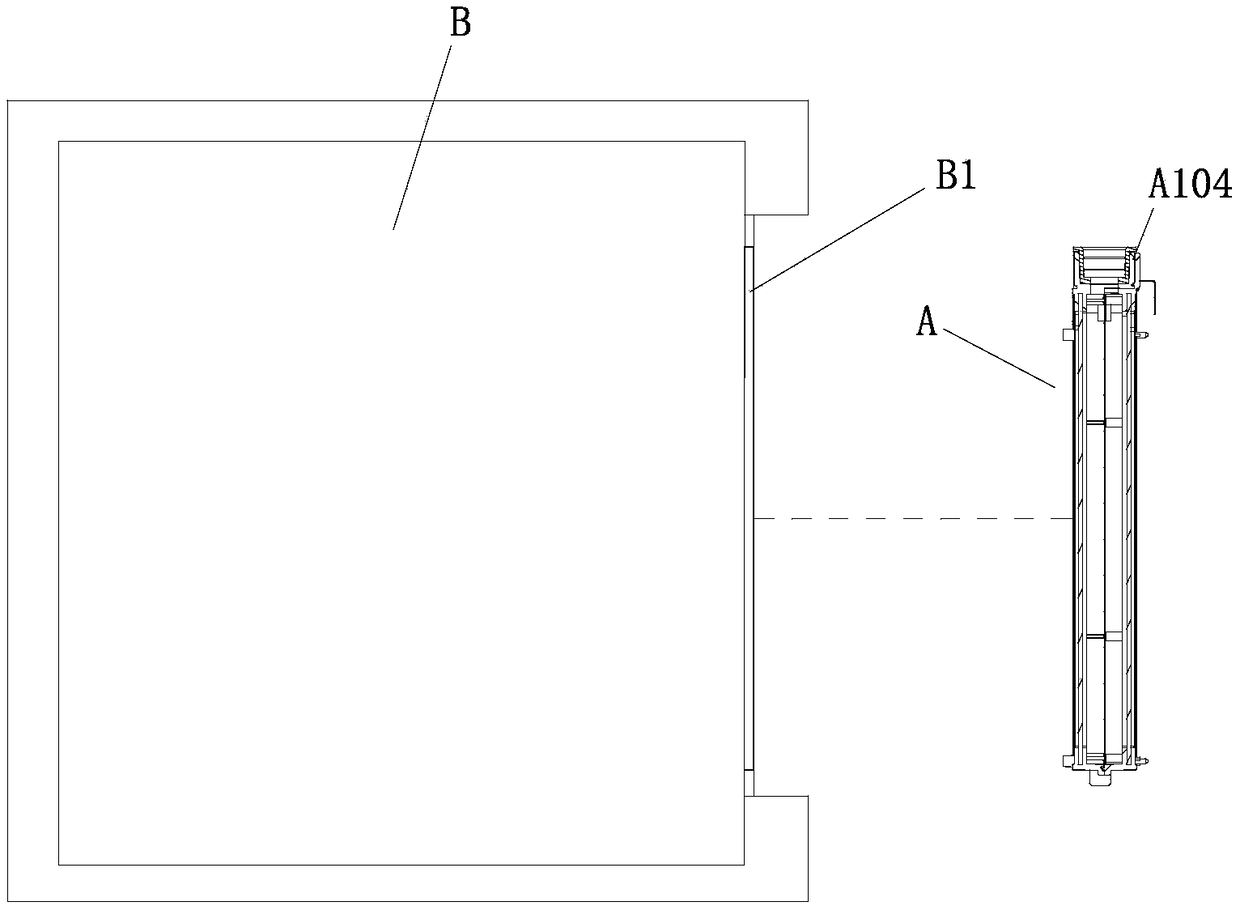

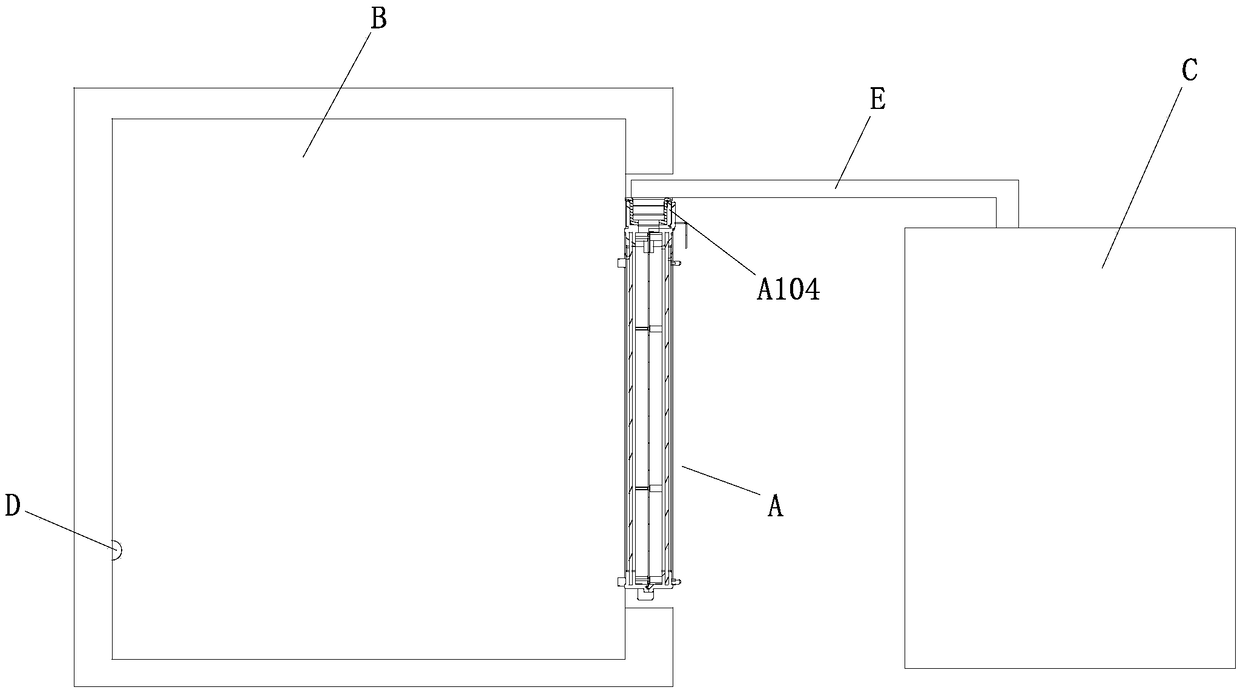

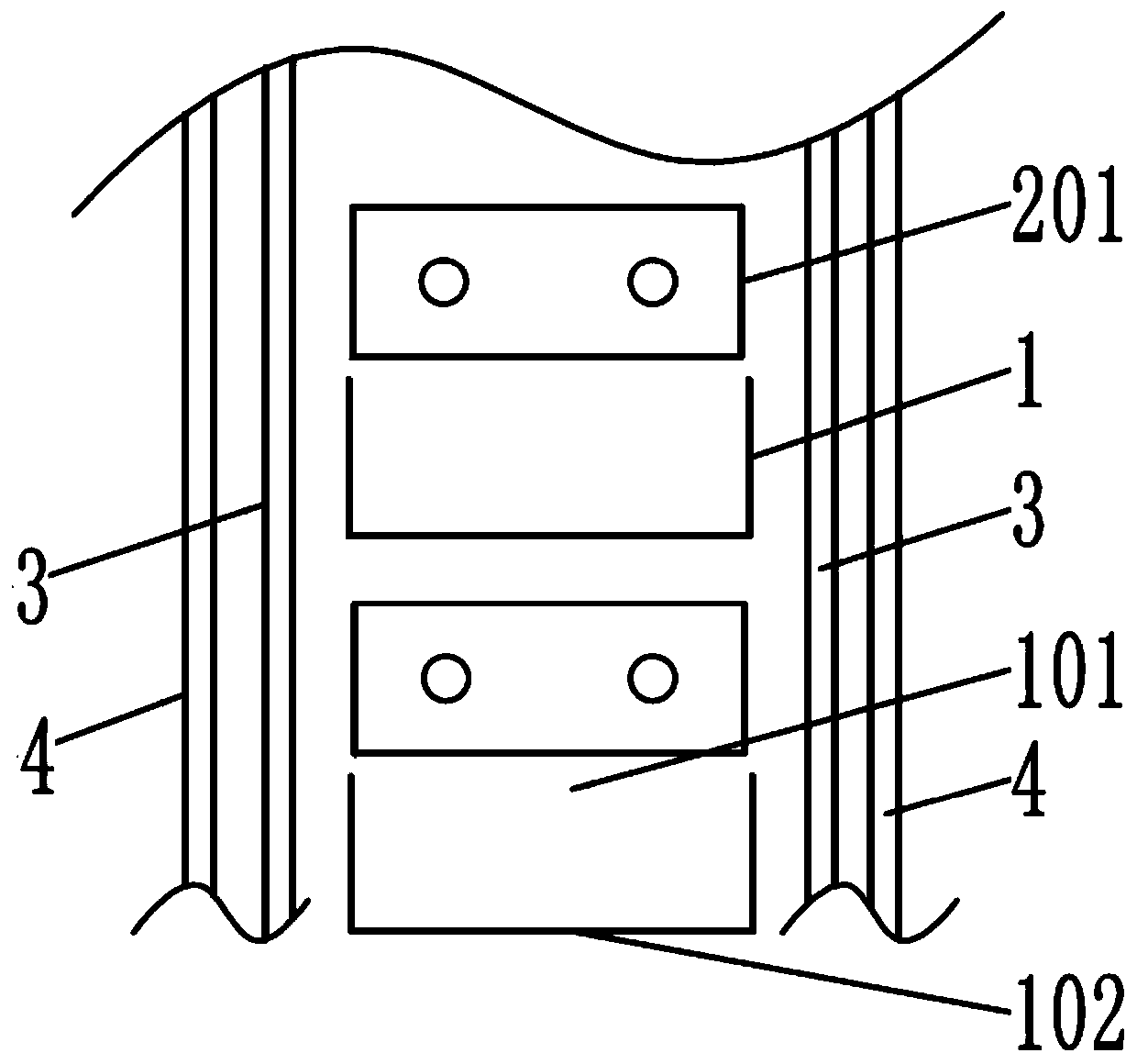

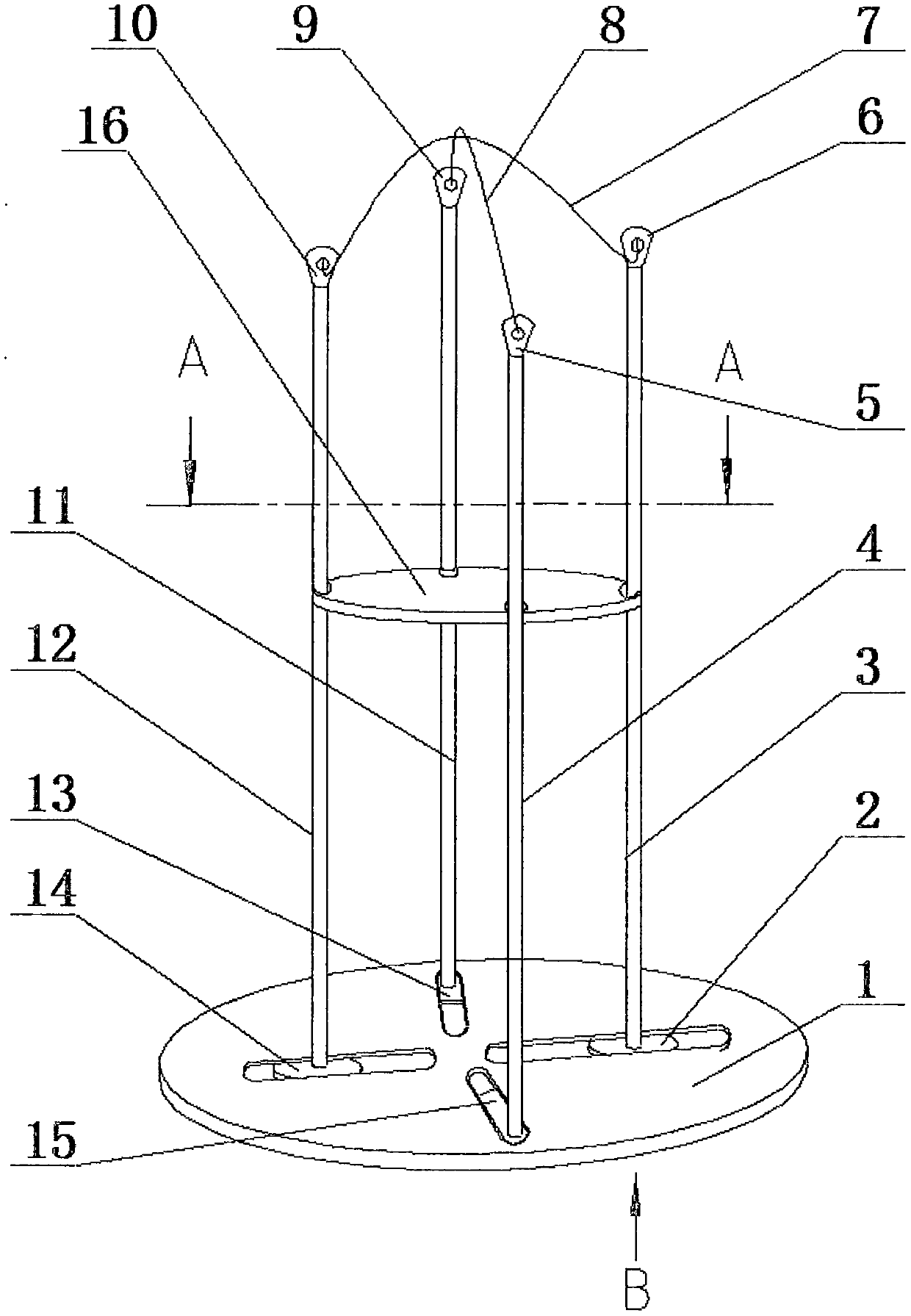

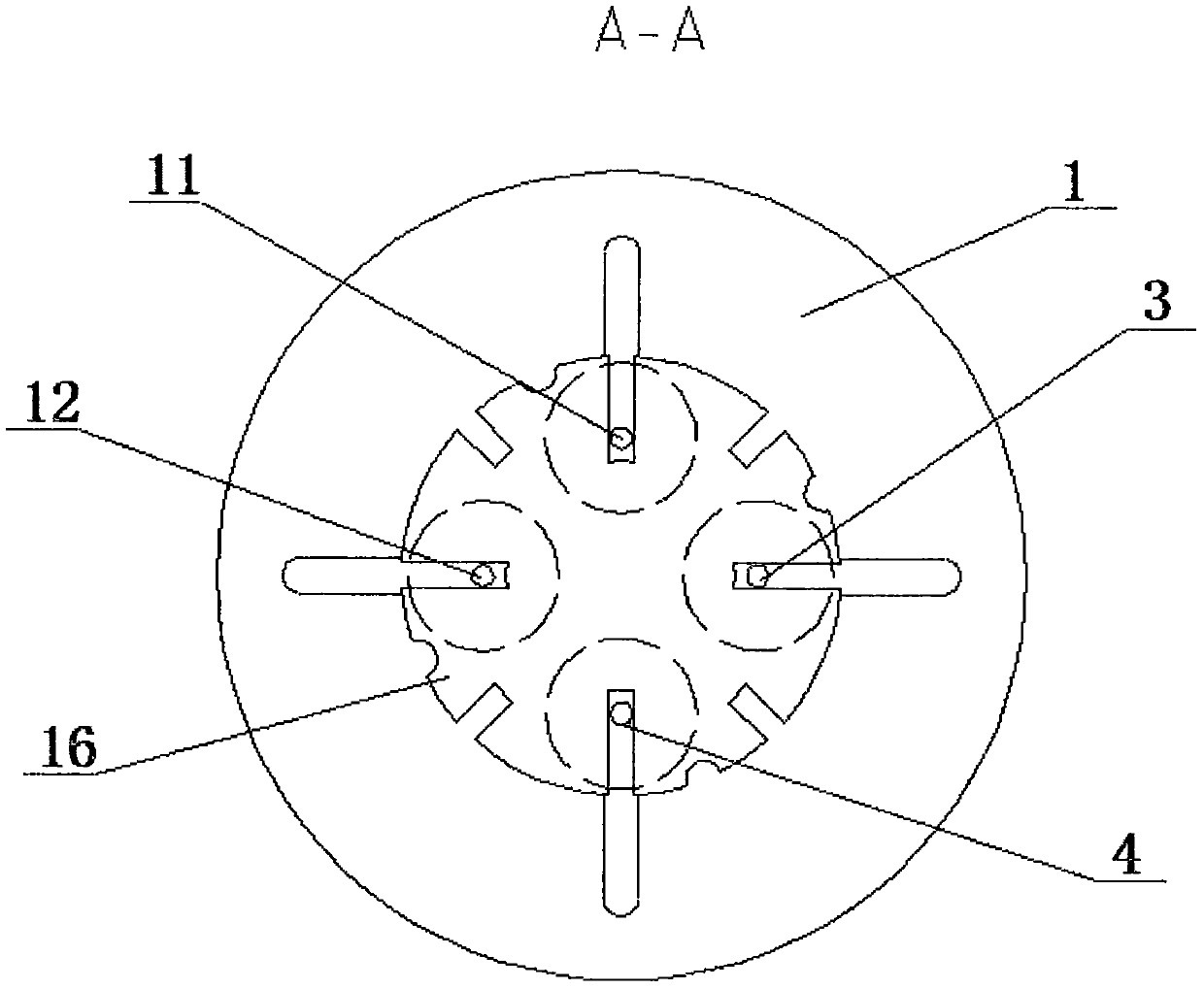

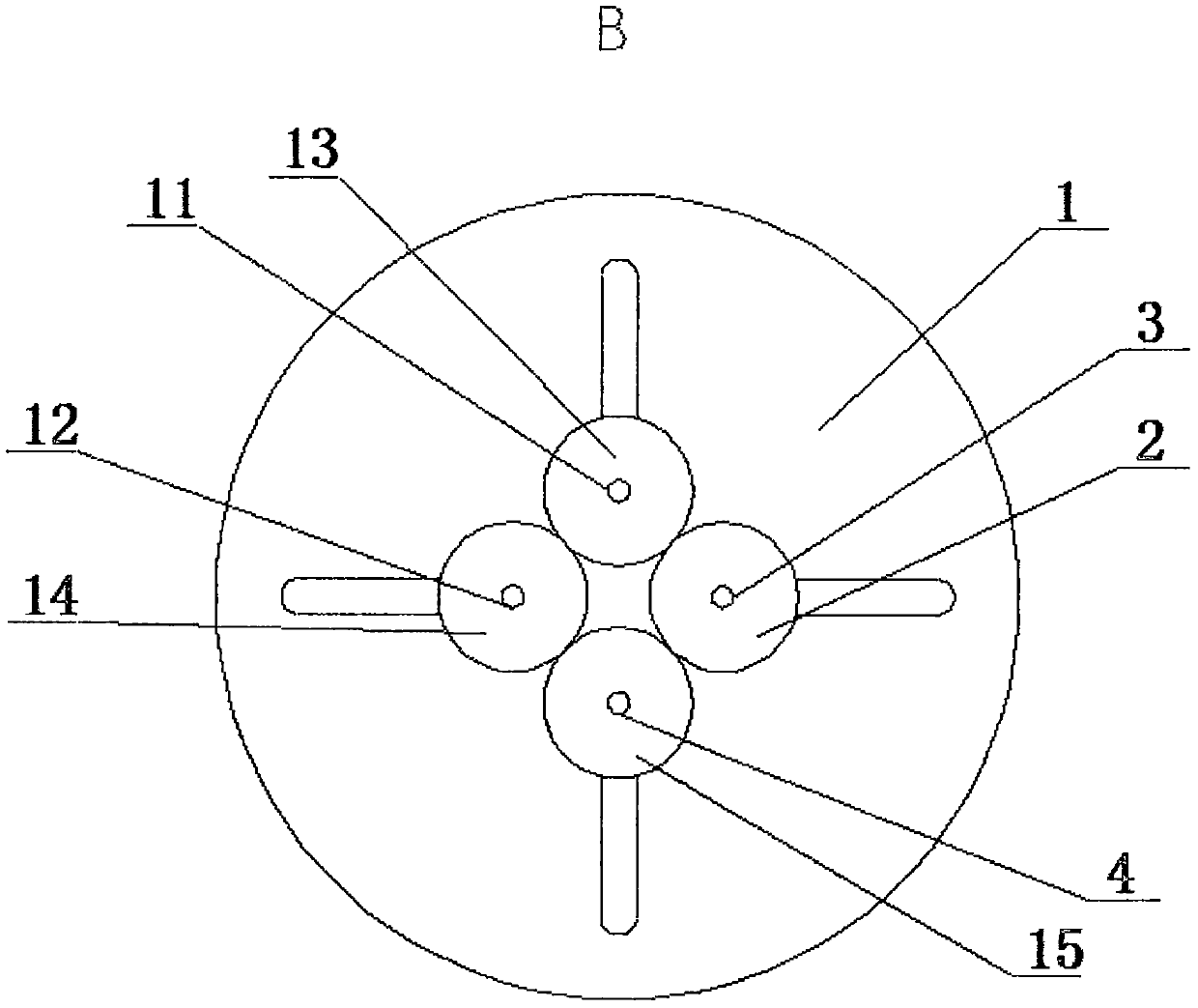

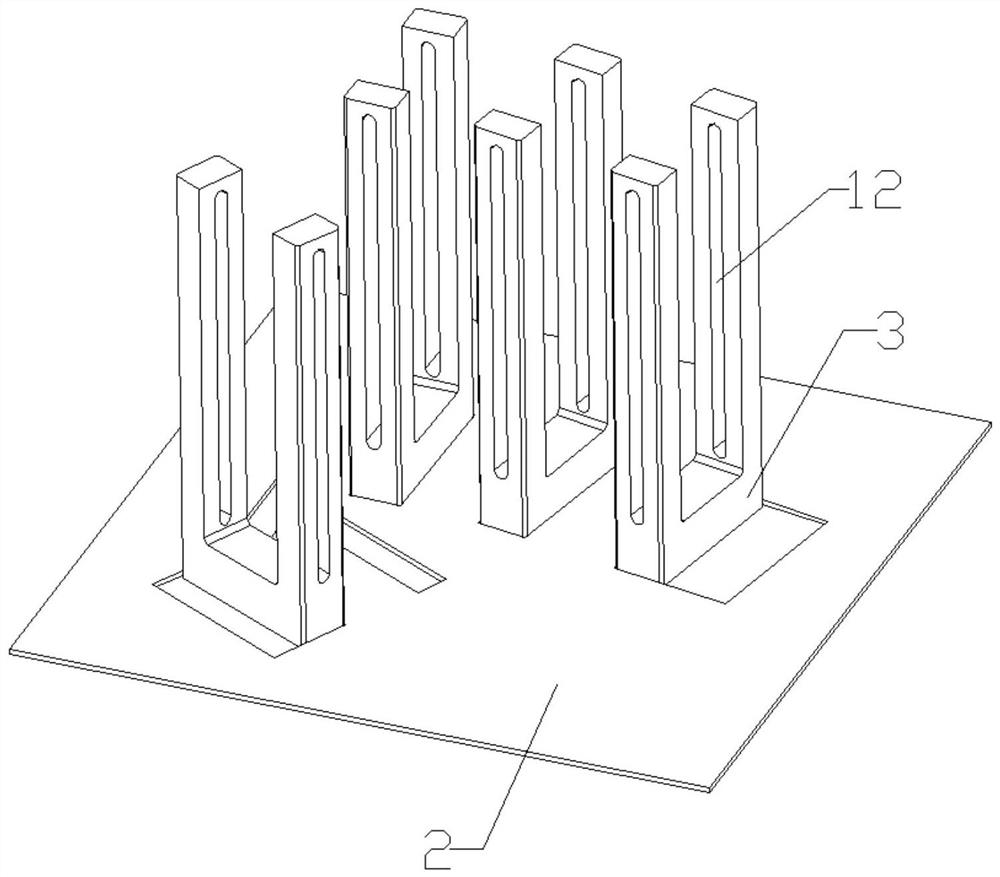

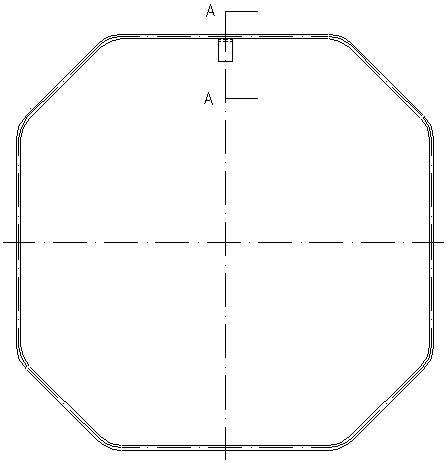

Stator punching sheet storage and transportation device

The invention relates to a storage and transportation device for stator punching, which includes a chassis and a chuck. The chassis is provided with 4 oblong holes, which are arranged in a cross shape. Column A, column B, and column C pass through the four oblong holes. and column D, the bottom surfaces of column A, column B, column C and column D are respectively provided with the heads of disc A, disc B, disc C and disc D, column A, column B, column C and column D Hook A, hook B, hook C and hook D are set respectively, hook A and hook D are connected by sling A, hook B and hook C are connected by sling B, and the diameter of the disc is larger than the width of the oblong hole , the diameter of column A, column B, column C and column D is smaller than the width of the oblong hole, and the edge of the chuck is evenly provided with 4 bar-shaped grooves A, 4 bar-shaped grooves B and gaps; the present invention has the advantages of convenient access, storage The utility model has the advantages of various types, convenient adjustment, simple structure and low cost.

Owner:刘晓东

Clamp for drilling oil hole on crankshaft

InactiveCN101628384BPrecise positioningImprove drilling efficiencyPositioning apparatusDrill jigsEngineeringCrankshaft

The invention relates to a clamp for drilling oil holes on a crankshaft, which comprises a clamp body, a clamping mechanism, a connecting rod positioning mechanism and a drilling jig frame mechanism, wherein the clamping mechanism is provided with a drilling jig supporting seat, a pressing plate and a replaceable cushion block; the drilling jig supporting seat is movably arranged on the clamp body; the pressing plate is arranged on a pressing plate strut on the drilling jig supporting seat through a hinge pin; the lower part of the pressing plate is provided with a hold-down bolt; the hold-down bolt is screwed in, passes through the pressing plate and presses against the drilling jig supporting seat; a turn-knob compresses the bolt; a spindle neck is compressed or loosened through the lever action of the hinge pin arranged on the pressing plate and the pressing plate strut; the connecting rod positioning mechanism comprises a positioning column and a liner plate; the positioning column is arranged in a replaceable liner plate positioning hole; the top of the positioning column supports a connecting rod neck; and the drilling jig frame mechanism comprises the drilling jig supporting seat, a drilling jig plate and a drill bush. The clamp has the advantages of reasonable structure, convenient assembly, low manufacturing cost, strong popularity, and high efficiency of drilling theoil holes, greatly shortens the manufacturing period, and is suitable for clamping various crankshafts for drilling straight oil holes.

Owner:TIANRUN IND TECH CO LTD

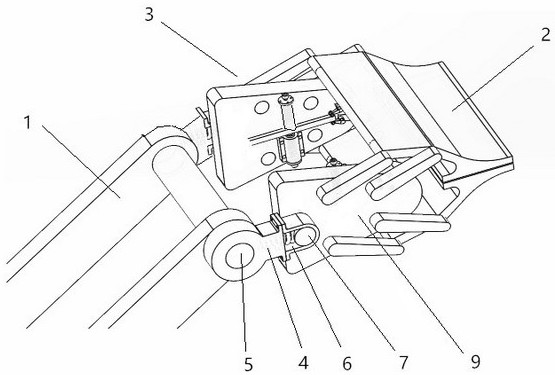

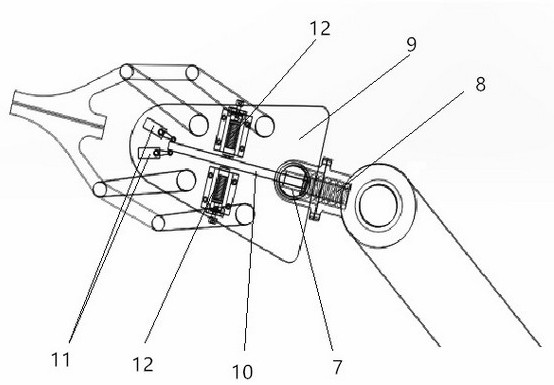

Follow-up bending machine clamp

PendingCN112007972ASimple structureIngenious designMetal-working feeding devicesMetal working apparatusRobotic armEngineering

The invention discloses a follow-up type bending machine clamp. The follow-up type bending machine clamp is characterized in that the clamp is composed of mechanical arms, a clamp body and a connecting mechanism between the mechanical arms and the clamp body; the connecting mechanism comprises two first connecting pieces which are symmetrically distributed; the first connecting pieces are hinged with the end parts of the mechanical arms through first rotating shafts; elongated slots are formed in the first connecting pieces; second rotating shafts are slidably connected into the elongated slots; meanwhile, springs abutting between the inner walls of the second rotating shafts are further arranged in the elongated slots; distance sensors are further arranged in the elongated slots; the second rotating shafts are movably connected to second connecting pieces in a penetrating mode; angle swing rods are connected to the free ends of the second rotating shafts, and angle sensors matched with the free ends of the angle swing rods are arranged on the second connecting pieces; and meanwhile, two buffer springs which are distributed with the angle swing rods as the center in an axial symmetry mode are further arranged on the second connecting pieces, and the tail ends of the second connecting pieces are connected with the clamp body.

Owner:CHINA HUALU PANASONIC AVC NETWORKS

Method for slotting and cutting inner wall of noncontinuous box

ActiveCN104668884AImprove rigidityReduce distortionPlaning/slotting machinesProcess supportEngineering

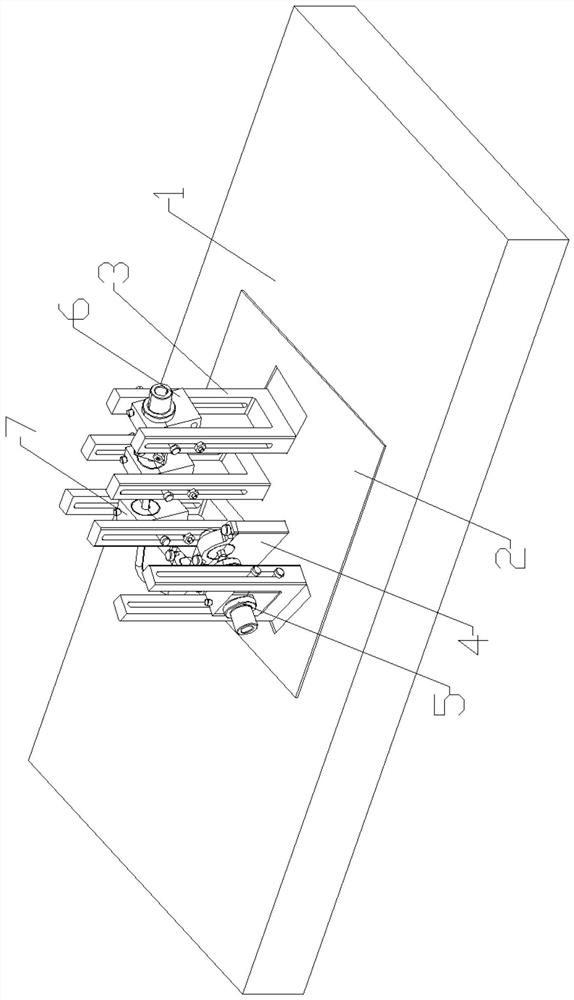

The invention discloses a method for slotting and cutting the inner wall of a noncontinuous box. The method includes: step 1, making two process supports, and machining a reference face; step 2, machining six connecting holes; step 3, machining a right inner wall face; step 4, machining a left inner wall face. By the method, machining of the noncontinuous box on a slotting machine is realized, and shape and position accuracy of each machined face is guaranteed effectively; the problem of machining rebound deformation caused by rigidity difference of the noncontinuous box is solved; the problem of deformation of a toolbar due to the fact that the toolbar extends out excessively is solved; the problems of positioning and centering when the noncontinuous box is machined on the slotting machine are solved; requirements on position degree between holes in the box and the left inner wall face as well as the right inner wall face of the box are met, the method is high in universality, and production efficiency is improved effectively.

Owner:BAOJI PETROLEUM MASCH CO LTD

General aero-engine external pipeline space size detection and setting device

ActiveCN113701585AImprove the defect of poor bending compatibilitySimple designMechanical measuring arrangementsStructural engineeringMachining

The invention discloses a general aero-engine external pipeline space size detection and setting device, which comprises a magnetic platform, a positioning bottom plate, a sliding frame, a pipe body positioning assembly, a joint positioning assembly A, a joint positioning assembly B, an angle adjusting assembly and a workpiece; the positioning bottom plate is adsorbed on the magnetic platform through magnetic force, and the lower part of the sliding frame is connected with the positioning bottom plate; a sliding groove is formed in the sliding frame, the connector positioning assembly A and the connector positioning assembly B are connected with the two ends of a workpiece respectively, and the angle adjusting assembly is arranged on the outer side of the middle of the workpiece in a sleeving mode. The general aero-engine external pipeline space size detection and setting device has the design advantages that the device is high in bending compatibility for workpieces with different diameter specifications and different bending angles, simple in device mechanism, convenient and accurate in measurement method, high in universality, simple in design structure, stable, safe, reliable, low in manufacturing cost, easy to manufacture and reusable; and in the using process, convenience and rapidness are achieved, and operability is high. The device can be popularized and applied to various machining fields.

Owner:GUIZHOU HANGFEI PRECISION MFG CO LTD

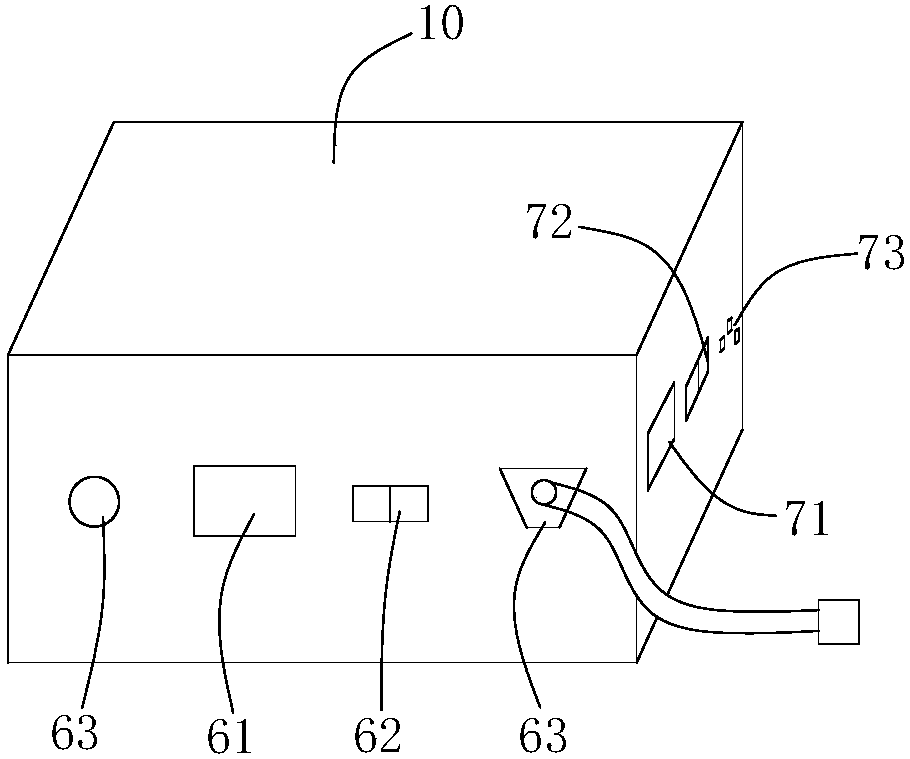

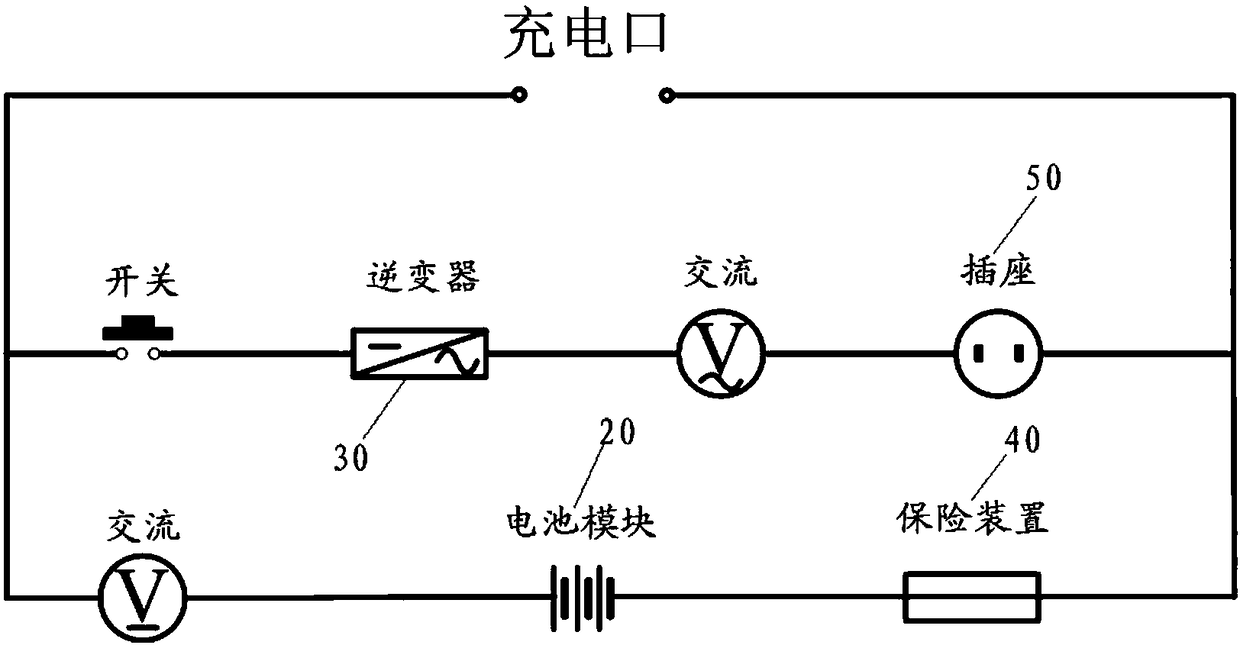

Multifunctional portable charging device

PendingCN108075546AVersatileSimple structureCircuit monitoring/indicationDifferent batteries chargingPower flowElectrical battery

The invention discloses a multifunctional portable charging device which comprises a power box, a battery module, an inverter, an alternating and direct voltage table and a safety device. The inverteris installed in a power box and used for converting stable direct voltages generated by the battery module into controllable alternating voltages. The alternating and direct voltage table is used fordisplaying the real-time current and voltage value of the charging device. The safety device is arranged on an input panel of the power box through a fastening rotary knob, connected to the battery module in series through a wire and used for preventing the short-circuit of an electrical circuit and the power burning-out caused by too large currents. By means of the multifunctional portable charging device, the problems that a cannon-carried storage battery is not stable in performance, charging and maintenance are difficult, the function is simplex and elements are not complete are effectively solved; according to the charging device, a maintenance-free storage battery pack is adopted as the power supply, the high-power high-conversion-rate inverter serves as the core, alternating voltages meeting different load requirements of cannons can be output, cannon shooting training can be continuously conducted, and electric appliances for external maintenance guarantee are powered under the night battle illumination and field battle conditions.

Owner:ARMY ENG UNIV OF PLA

Thermal electron enhanced heat exchange device, heat exchange system and heat exchange method

ActiveCN111457770BSimple structureImprove securityIndirect heat exchangersHeat exchange apparatusHot TemperatureMaterials science

The invention relates to the technical field of heat collection and heat exchange, and discloses a thermal electron enhanced heat exchange device, a heat exchange system and a heat exchange method. The thermal electron enhanced heat exchange device includes a thermal electron heat transfer layer and a high-temperature heat source layer, wherein the thermal electron heat transfer layer includes a high-temperature cathode layer, a vacuum spacer layer, and a low-temperature anode layer in sequence from outside to inside, and the inner space of the low-temperature anode layer forms It is a low-temperature medium channel. The high-temperature cathode layer overflows hot electrons at high temperature, and the hot electrons take away part of the heat from the high-temperature cathode layer and transfer it to the low-temperature anode layer. The heated low-temperature anode layer exchanges heat with the low-temperature medium circulating in the low-temperature medium channel. The thermal electron enhanced heat exchange device provided by the present invention has a simple and compact structure, does not need to be additionally provided with a low-temperature medium circulation system, and has high safety and good reliability. In addition, the dual superposition of thermal electron heat transfer and radiation heat transfer is used to effectively improve the heat transfer efficiency and meet the heat transfer requirements in high temperature environments.

Owner:ZHEJIANG UNIV

Titanium boride-based coating composite material for aluminum electrolysis and its preparation method and coating method

ActiveCN103194101BLower sintering temperatureReduce manufacturing costCoatingsGraphite carbonAluminium electrolysis

The invention discloses a titanium boride-based coating composite material for aluminum electrolysis and its preparation method and coating method. The composite material is composed of the following raw materials by weight percentage: titanium boride-oxide composite particles: 55%~ 70%; carbonaceous additives: 8%~15%; organic resin glue: 15%~30%; reinforcing agent: 0.5%~2%. The coating method includes the following steps: (1) putting the graphite base material into a coating mold, and then pouring the obtained slurry into the mold; (2) heating the base material coated with the slurry at 15°C~ Curing treatment at 35°C for 24h~48h, and then curing treatment at 80°C~150°C for 12h~24h; (3) Put the base material coated with slurry in step (2) in a graphite crucible, and bury graphite carbon powder, Then carry out carbonization and sintering in an inert gas atmosphere or in a vacuum; the carbonization and sintering temperature is 850-1050° C., and the carbonization and sintering time is 80h-120h. The titanium boride-based coating composite material for aluminum electrolysis of the invention has a high degree of bonding with a matrix, and the tensile strength can reach 8-10 MPa; the coating structure is compact and has strong erosion resistance.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

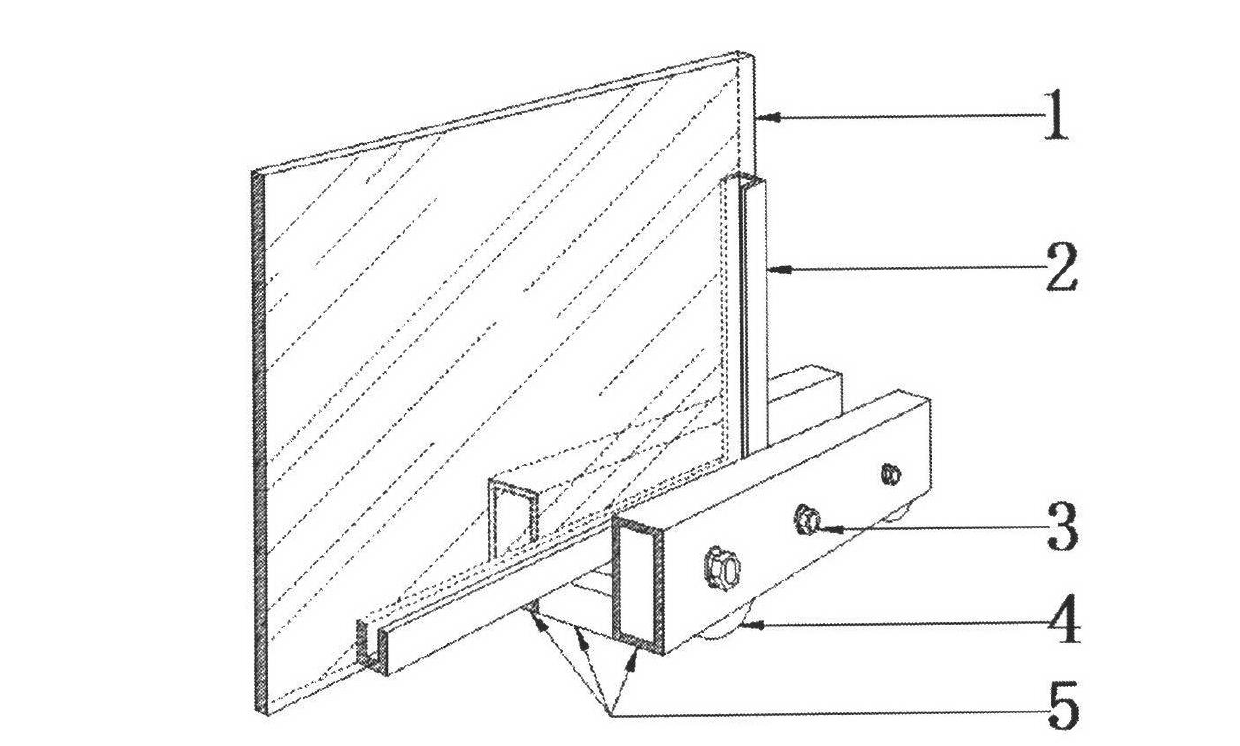

Push-pull pulley tool for transporting glass in hanging mode

InactiveCN102556567ASolve the problem of difficult horizontal shiftShorten the timeManual conveyance devicesClassical mechanicsSteel frame

The invention discloses a push-pull pulley tool for transporting glass in hanging mode, which comprises a 90-degree steel frame protection corner (2) used for supporting and bearing glass (1), a bearing pulley (4) and a load bearing platform (5). The 90-degree steel frame protection corner (2) is rotatably installed on the load bearing platform (5) through lengthening pair-penetrating self-tightening screws (3), and the bearing pulley (4) is rotatably installed on the load bearing platform (5) through the lengthening pair-penetrating self-tightening screws (3). The 90-degree steel frame protection corner (2) comprises two U-shaped grooves which are arranged in 90 degrees, and plastic flexible gaskets (6) are arranged in the U-shaped grooves. The push-pull pulley tool is capable of reducing safety hazards, reducing glass discharging time and improving working efficiency, convenient and flexible in use, strong in operation performance, low in manufacture cost and simple in manufacture.

Owner:GOLD MANTIS CONSTR DECORATION

A laser interference rotor vibration measuring device and its measuring method

InactiveCN103335704BReduce machining errorsImplementing FM MeasurementsSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansVibratory signalTorsional vibration

The invention provides a technical scheme of a vibration measurement device for a laser interference rotor and a measurement method thereof. The scheme can simultaneously detect bending vibration and torsional vibration of a high-speed rotor based on beat frequency generated by laser Doppler effect, realizes frequency modulation measurement of a vibration signal under the condition of not using an expensive frequency shift device, and precisely distinguishes the directions of bending vibration and torsional vibration, has very strong anti-environment disturbance capability, and is low in manufacturing cost. The scheme belongs to non-contact measurement, the motion state of the to-be-measured rotor is free from interference, the accuracy in measurement is high, the response speed is fast, the dynamic range is wide, and the measurement can be performed at a further distance. The processing error of the rotor and measurement interference of torsional vibration and bending vibration from other vibration states are small.

Owner:SOUTHWEAT UNIV OF SCI & TECH

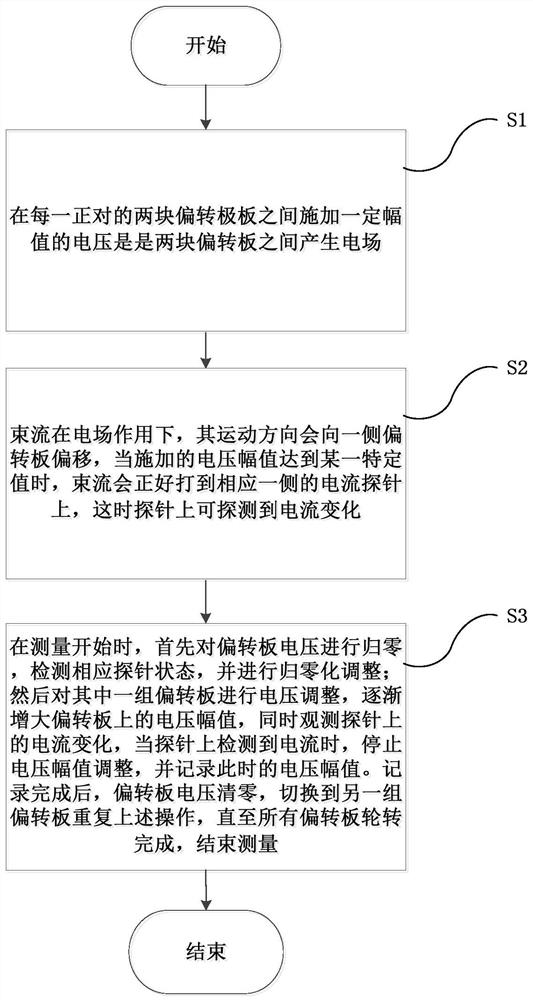

Non-interception type direct current beam position and beam spot shape measurement method and system

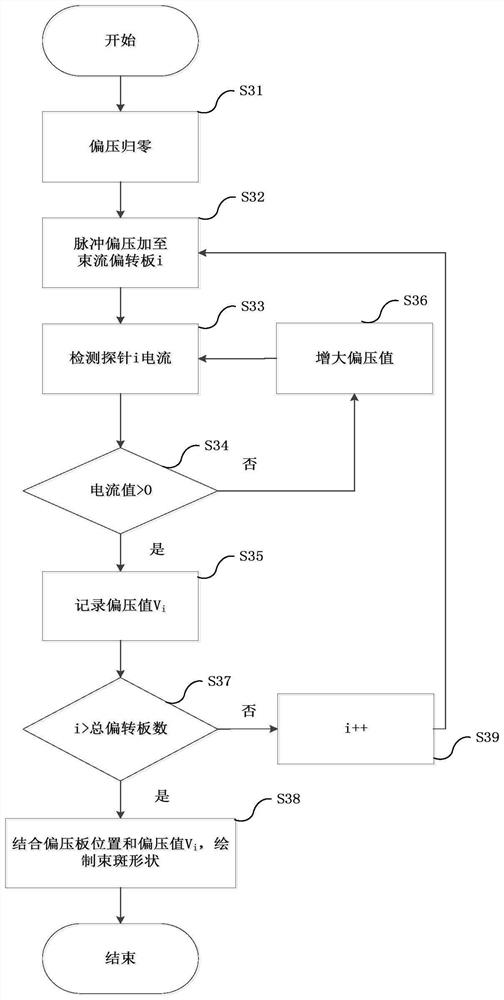

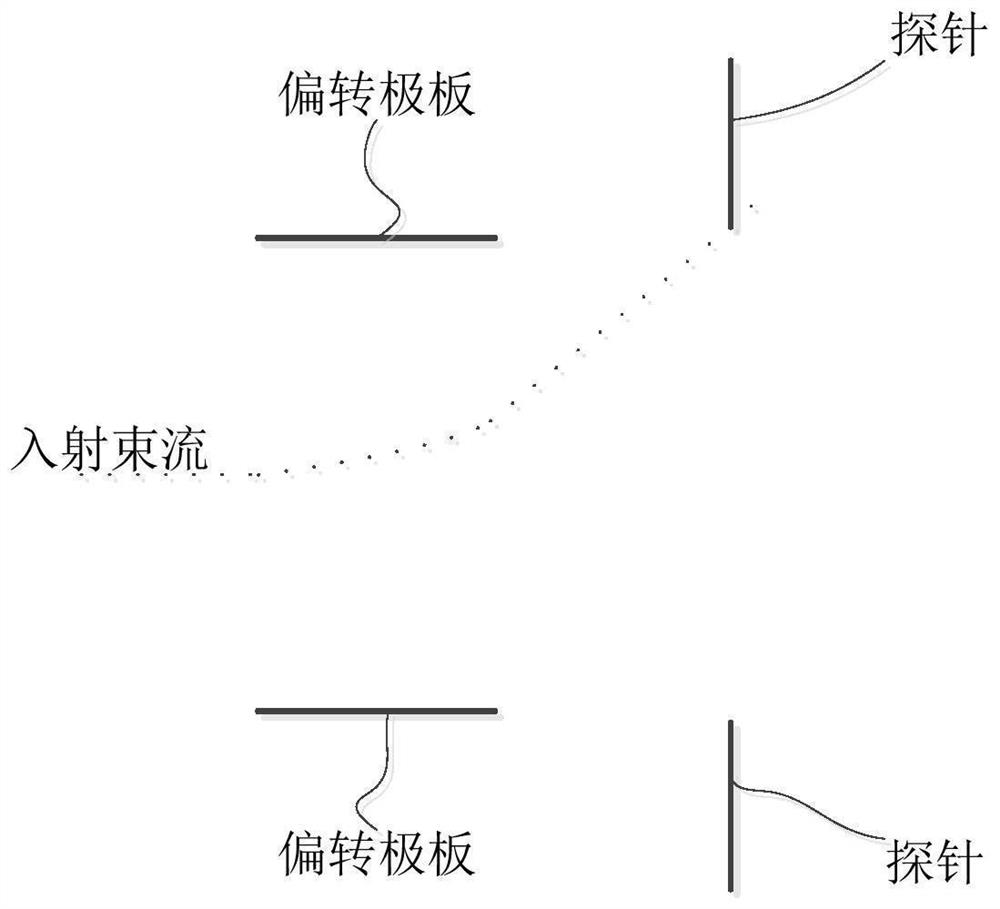

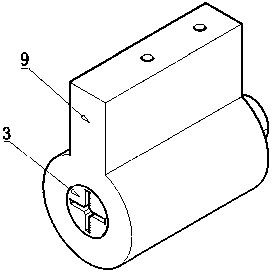

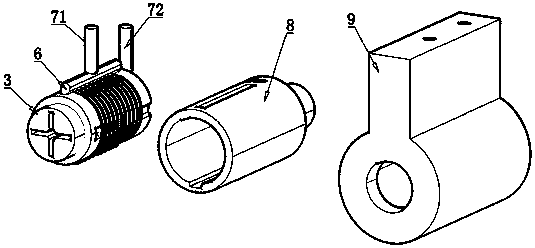

PendingCN114460621AReduce the impactAvoid ablationX/gamma/cosmic radiation measurmentVoltage amplitudeMechanical engineering

The invention provides a non-interception type direct current beam position and beam spot shape measurement method and system. The method comprises the following steps: applying a voltage with a preset amplitude between each two opposite deflection polar plates in a measurement probe so as to generate an electric field between the two deflection polar plates; enabling the beam current to hit on a current probe through the electric field so as to detect the current change; returning the voltage of the deflection pole plates to zero, adjusting the voltage of the deflection pole plates until the current probe detects the current, recording the voltage amplitude at the moment, and circulating the operation on each group of deflection pole plates until the measurement is finished; and processing the voltage amplitude by a preset logic to obtain an offset displacement so as to obtain the beam position and the beam spot shape. The technical problems that the structure is complex, interference is likely to happen, the use cost is high, damage and ablation are likely to happen, and the measured object is single are solved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

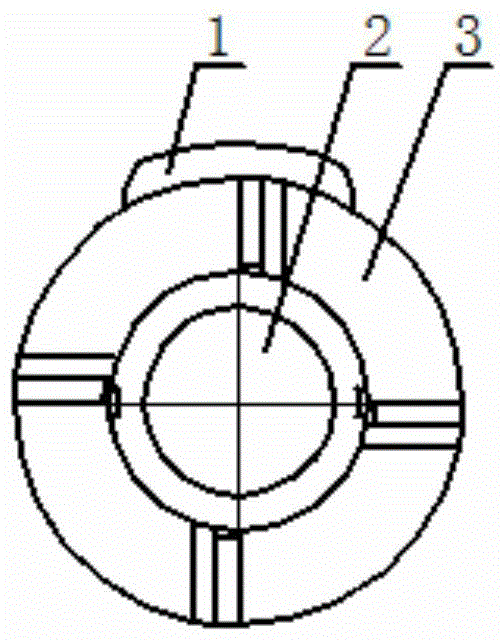

Clutch lock and key

ActiveCN104912386BImprove rotational stabilityStrong manufacturing costKeysPuzzle locksEngineeringClutch

Owner:徐明达

A special sealing ring for an embedded filter cloth filter plate and its manufacturing method

The invention relates to a special sealing ring for filter plates with embedded filter cloth and a method for manufacturing the special sealing ring. A cotton rope loop of the special sealing ring replaces a rubber O-shaped sealing ring to be used as a filter cloth fixing material, a sealing ring is made of the filter cotton rope loop, and film material sleeves are arranged at two ends of the cotton rope loop and are oppositely connected with each other, so that the sealing ring with a cotton rope can be formed. The special sealing ring and the method have the advantages that the special sealing ring is good in sealing fixing performance; the special sealing ring not only can be used under the conditions of most acid, alkali and organic solvents, but also can be used within wide temperature ranges and accordingly is extremely high in adaptability; the special sealing ring is low in manufacturing cost, convenient to quickly mount and detach and free of environmental pollution, and detached materials of the special sealing ring are easy to scatter.

Owner:HANGZHOU XINGYUAN FILTER TECH

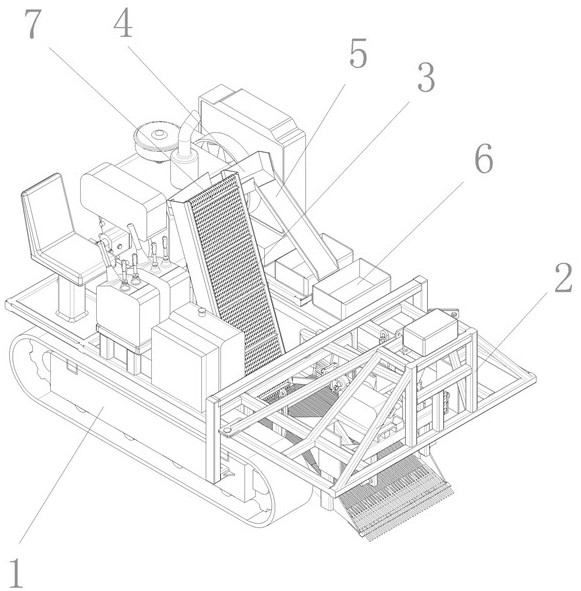

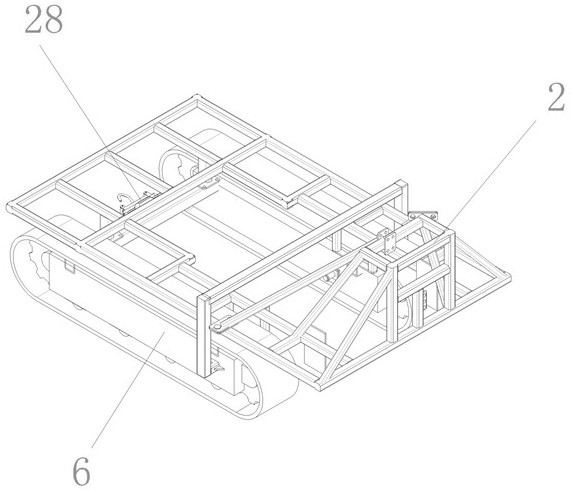

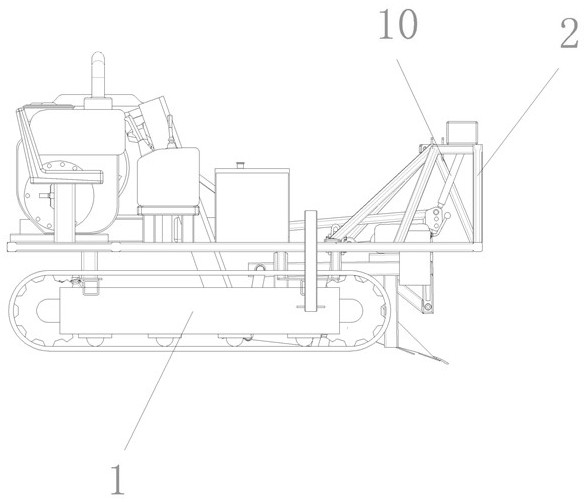

In-situ harvesting device suitable for various clams

PendingCN114557326ASimple structureIngenious designSievingScreeningStructural engineeringEngineering physics

Owner:DALIAN OCEAN UNIV +1

Boring tool for differential mechanism

InactiveCN105798337AEasy to processSimplify processing difficultyTurning toolsMechanical engineeringEngineering

The invention relates to a boring tool for a differential mechanism. The boring tool for the differential mechanism comprises a tool handle, a tool rest, a plug pin, tool edges and a positioning screw. The lower end of the tool handle is coaxially inserted in the tool rest. The tool handle and the tool rest are connected through the plug pin inserted in the tool rest. The upper tool edge is arranged at the upper end of the tool rest and the lower tool edge is arranged at the lower end of the tool rest. The boring tool for the differential mechanism is ingenious in design, reasonable in structure, convenient to use, high in practicality, low in overall manufacturing cost and convenient to retrofit (the tool edges can be replaced). After the boring tool for the differential mechanism is used, the production efficiency can be improved, automatic production can be achieved, manpower can be reduced, and the production cost is reduced for enterprises.

Owner:TIANJIN SHENGJIN METAL PROD CO LTD

Filter press filter plate embedded filter cloth filter plate sealing rope ring and manufacturing method

ActiveCN104595489BGood dispersionNo pollution in the processEngine sealsOrganic solventPulp and paper industry

The invention relates to an embedded filter cloth filter plate sealed rope loop for a filter press filter plate adopting a cotton rope loop to replace an O-shaped rubber seal ring as a filter cloth fixation material, and a manufacturing method. Filter cloth is embedded in a sealed groove in the filter plate through the sealed cotton rope loop, and the filter cloth is fixed and sealed. The rope loop and the manufacturing method have the following advantages: first, the sealing and fixing performance is good; second, the sealed rope loop can be used in the most of acid, alkali and organic solvent, and can be used in the larger temperature range, so the application is very strong; third, the manufacturing cost is low; the fast installation and dismantlement are very convenient; dismantling objects are easy to disperse; pollution to the environment is avoided.

Owner:HANGZHOU XINGYUAN FILTER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com