Follow-up bending machine clamp

A bending machine and follow-up technology, which is applied in mechanical equipment, manufacturing tools, vibration suppression adjustment, etc., can solve the problems of bending machine position and angle error, inability to realize automation, and lack of real-time motion parameter manipulator linkage function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

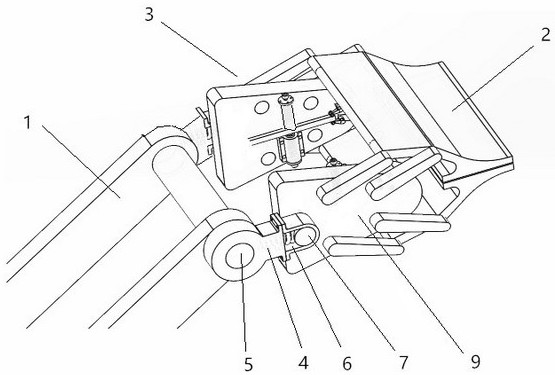

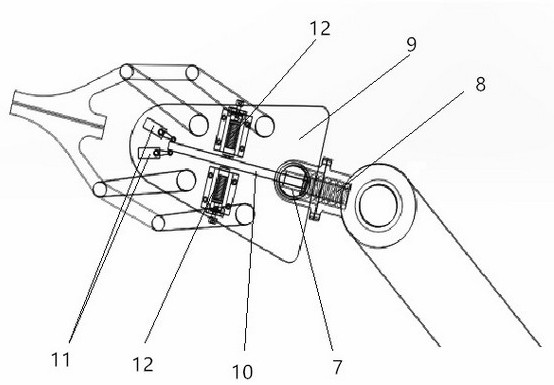

[0013] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 Shown: a follow-up bending machine clamp, which is composed of a mechanical arm 1, a clamp body 2 and a connecting mechanism 3 between them,

[0014] The connecting mechanism 3 includes two symmetrically distributed first connecting parts 4, the first connecting parts 4 are hinged to the end of the mechanical arm 1 through the first rotating shaft 5, and there are long lengths on the first connecting parts 4. Slot 6, the second rotating shaft 7 is slidably connected in the long slot 6, and a spring 8 is also provided in the long slot 6 between its inner wall and the second rotating shaft 7, and a distance is also provided in the long slot 6 sensor, the first connecting piece 4 is also slidably connected with the second connecting piece 9 through a chute slider mechanism, and the first connecting piece 4 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com