Push-pull pulley tool for transporting glass in hanging mode

A pulley and glass technology, applied in the direction of transportation and packaging, manual conveying devices, etc., can solve the problems of potential safety hazards, long installation time, and a large amount of manpower, so as to reduce safety hazards, reduce unloading time, and manufacturing costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

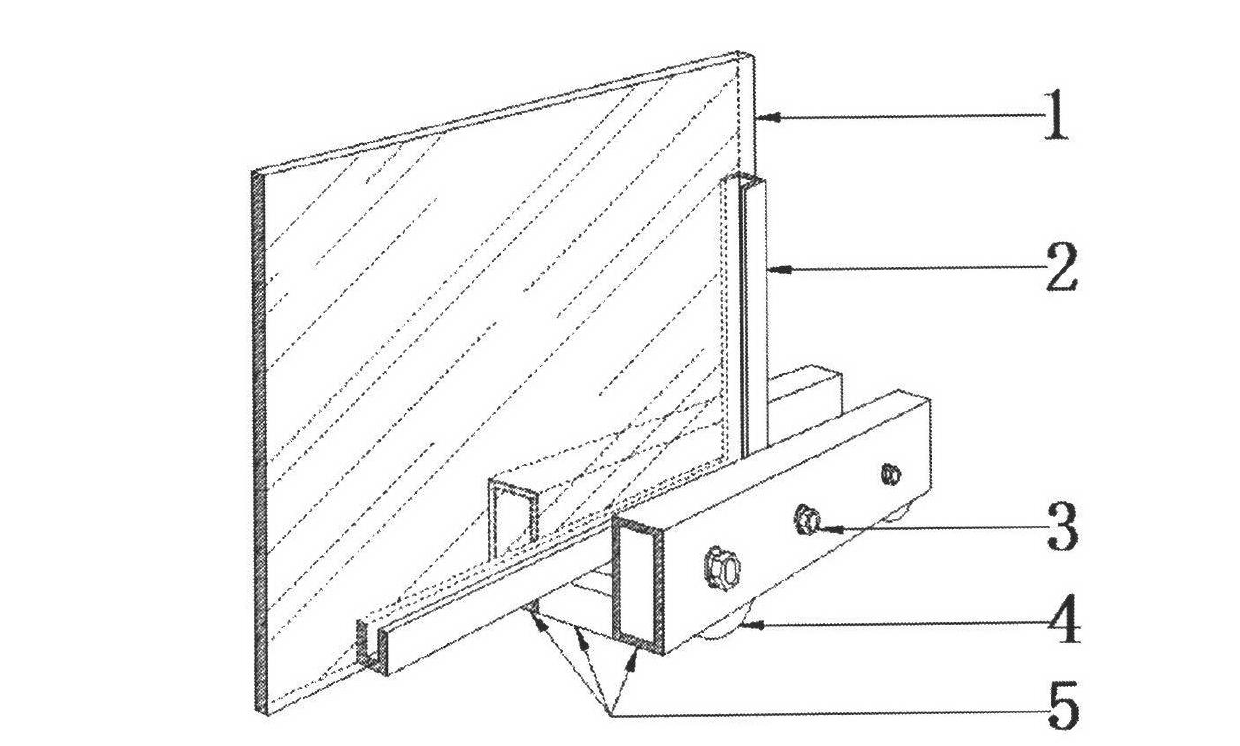

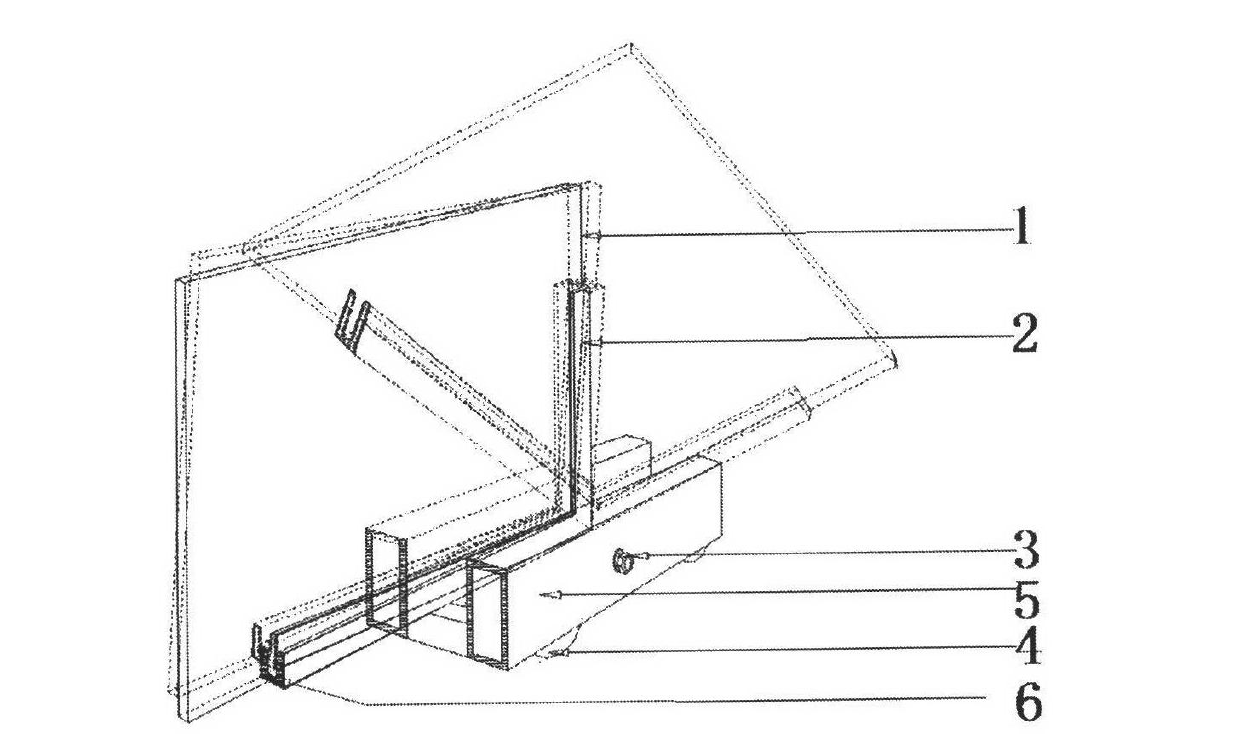

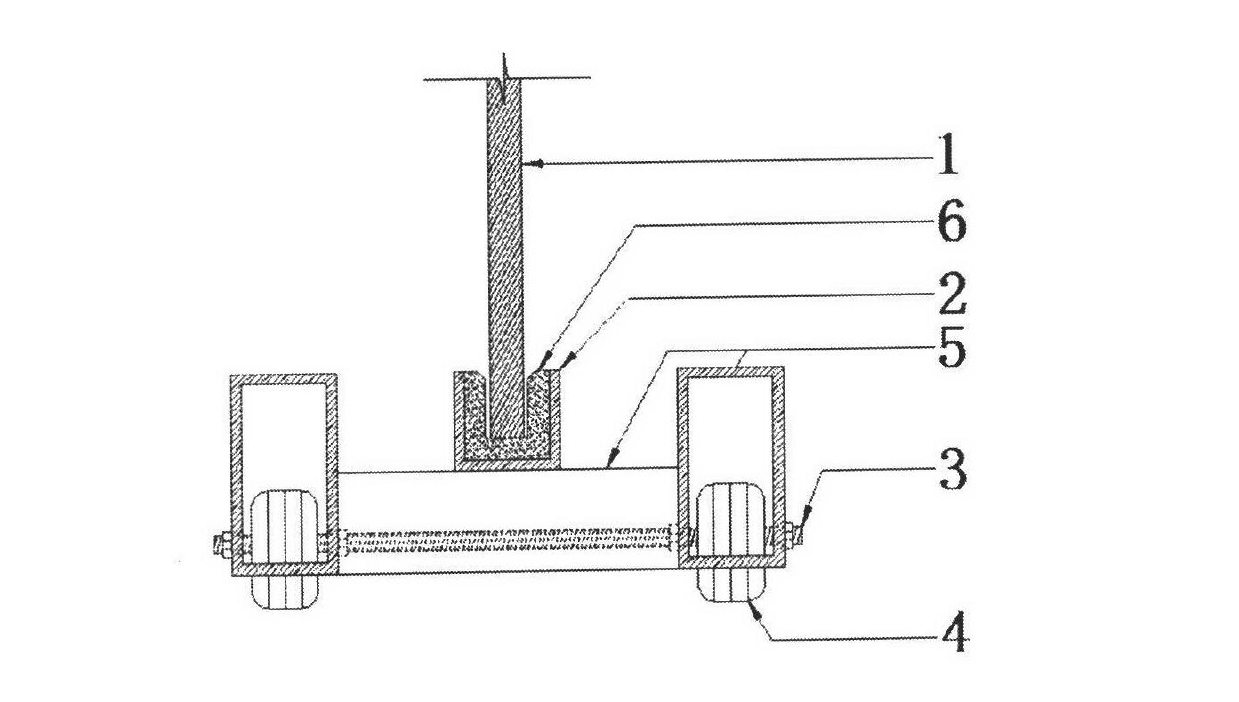

[0014] Example: such as figure 1 , figure 2 , image 3 As shown, a push-pull pulley tool for hoisting glass, which includes a 90-degree steel frame corner guard 2 for supporting the glass 1, a load-bearing pulley 4, and a load-bearing platform 5. The 90-degree steel frame corner guard 2 is passed through by lengthening The self-tightening screw 3 is rotatably installed on the bearing platform 5, and the load-bearing pulley 4 is rotatably installed on the bearing platform 5 by lengthening the self-tightening screw 3 through the lengthening.

[0015] The 90-degree steel frame corner protector 2 includes two U-shaped grooves set at 90 degrees, and a plastic flexible gasket 6 is arranged in the U-shaped groove, so that the glass 1 can obtain the plastic flexible gasket 6 under the action of external force. buffer protection. The carrying platform 5 is made by welding steel rectangular tubes, and the welding needs to be fully welded. The unilateral length of the 90-degree steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com