Non-interception type direct current beam position and beam spot shape measurement method and system

A beam position, non-intercepting technology, applied in measurement devices, radiation measurement, X/γ/cosmic radiation measurement, etc., can solve the problems of easily damaged and ablated measurement objects, high use cost, and easy interference. To achieve the effect of simple structure, low manufacturing cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

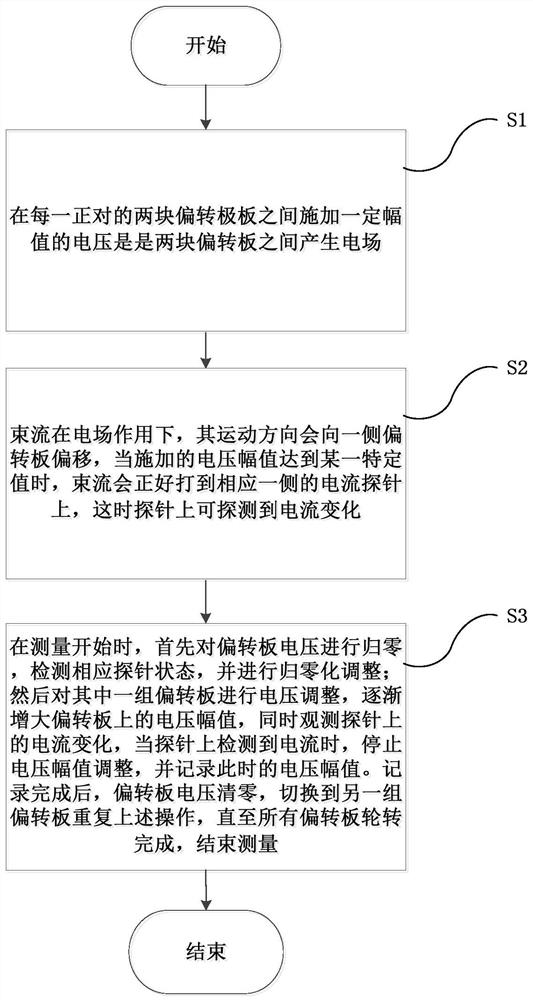

[0058] Beam position and beam spot shape measuring method of the present invention, carry out as follows:

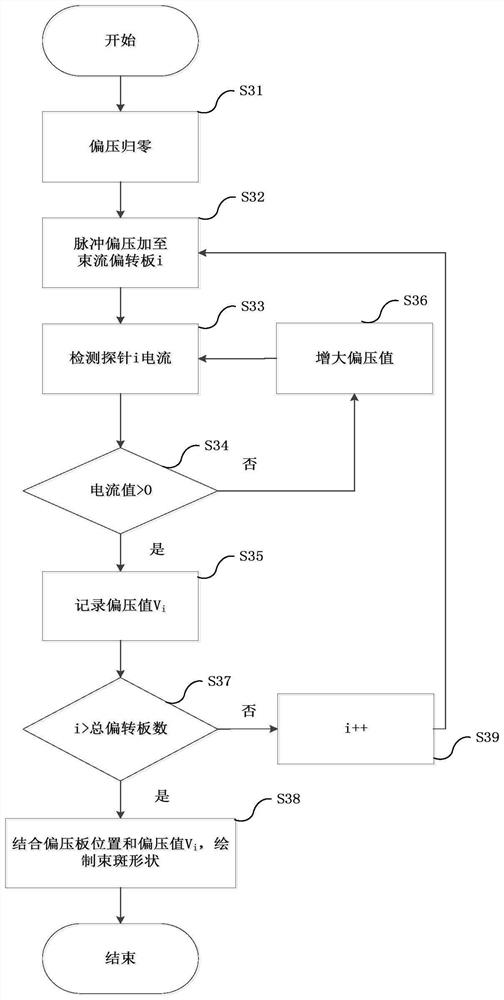

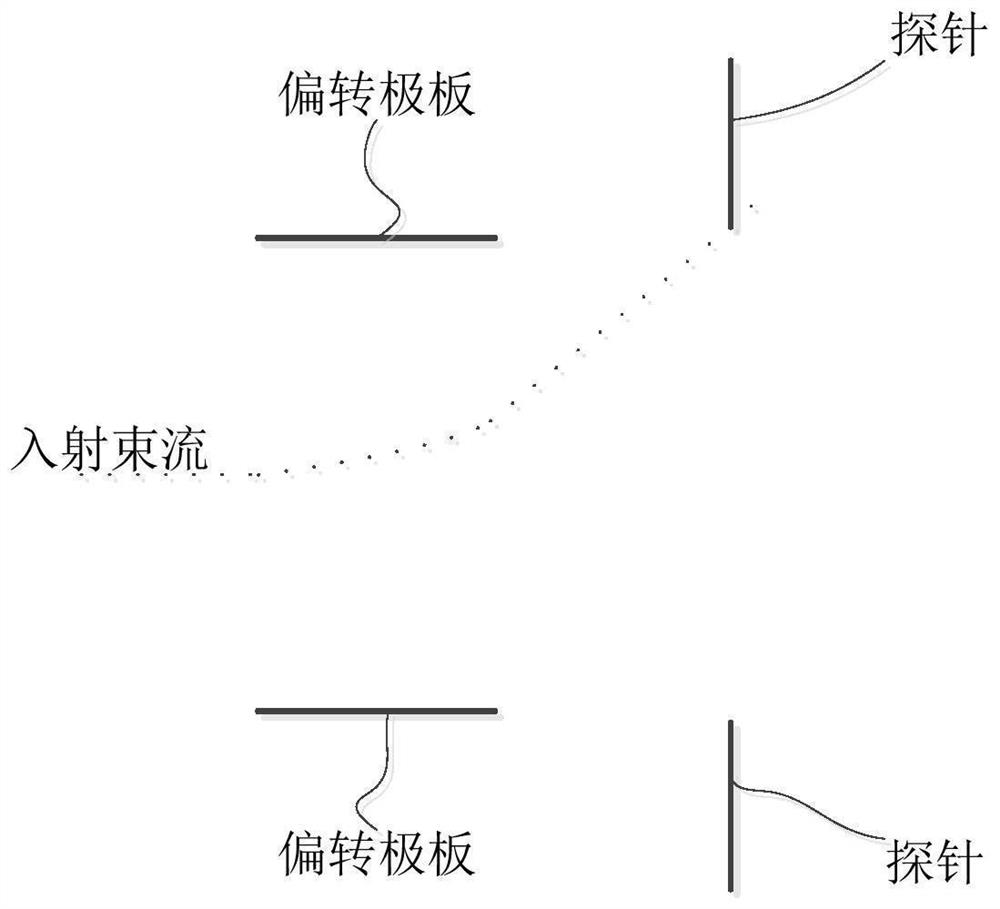

[0059] like image 3 As shown, a pulse voltage with variable amplitude can be applied between each pair of two deflecting plates to deflect the beam; the current probe can detect the deflected beam hitting the probe. The whole detection system is composed of n pairs of deflection plates and n pairs of probes. The deflection plates are arranged in a circle with the center of symmetry as the axis, and the corresponding probes are placed at a certain distance behind the deflection plates.

[0060] Define the amplitude of the pulse voltage applied across the deflection plate as V i , i represents the serial number of each deflection plate.

[0061] Acquisition of pulse voltage value of deflection plate

[0062] like figure 1 and Figure 4 As shown, S1, applying a voltage of a certain magnitude between each pair of two deflection plates is to generate an electric field b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com