Battery pack thermal management system based on a flat heat pipe and operation method thereof

A heat management system and flat heat pipe technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of increasing temperature difference, limited heat exchange area, uneven temperature distribution of batteries, etc., to reduce thermal resistance, Large heat transfer area, increased rigidity and critical heat flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

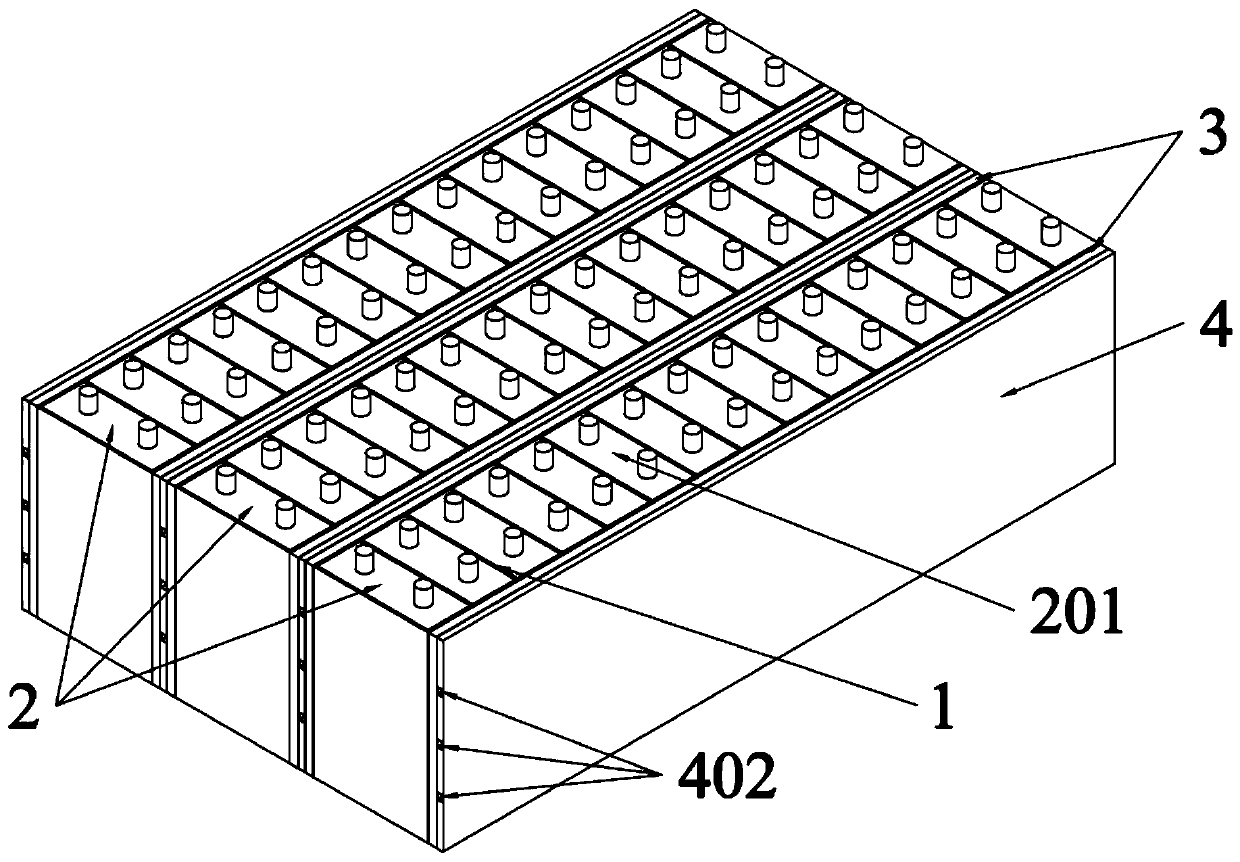

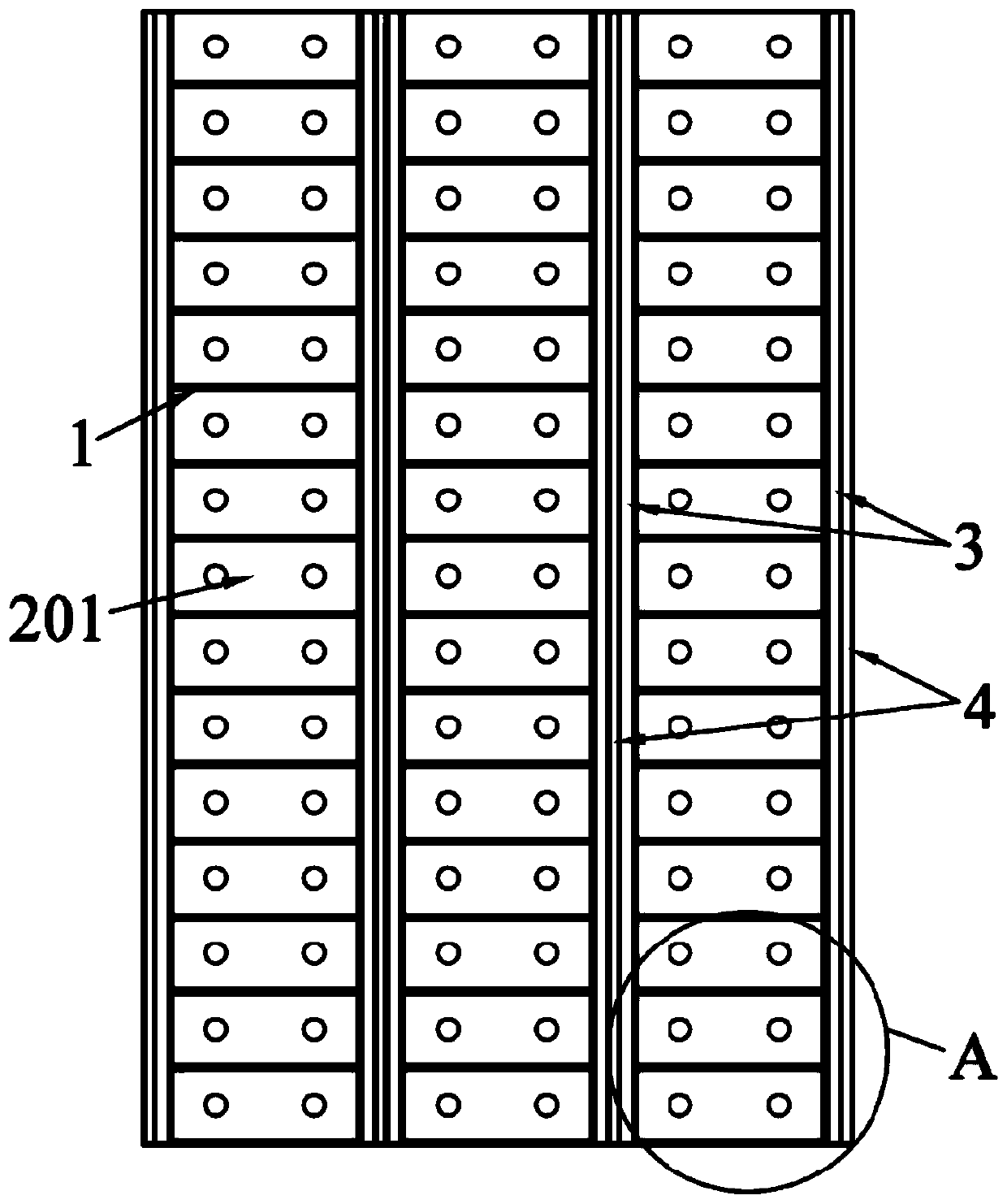

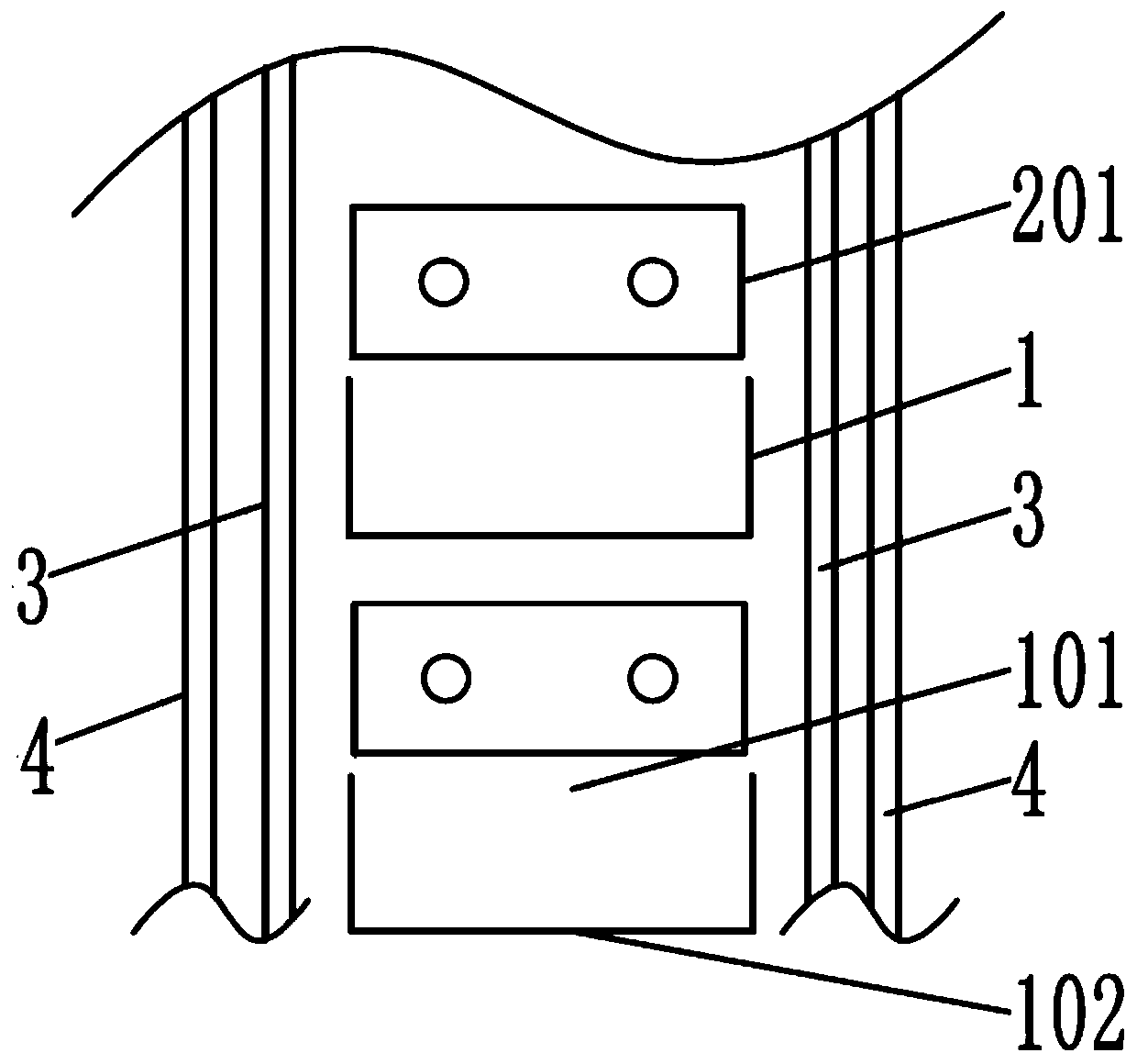

[0031] like Figure 1-Figure 3 A battery pack thermal management system based on a flat heat pipe is shown, including a battery pack 2, a flat heat pipe 3, a U-shaped graphite sheet 1, and a heat exchange plate 4 with a circulating fluid inside; the battery pack 2 includes a plurality of A square unit battery 201, the U-shaped graphite sheet 1 corresponds to the unit battery 201 one by one, and the U-shaped graphite sheet 1 covers at least two opposite sides of the unit battery 201 to form a battery unit, A plurality of battery cells are laminated in sequence to form a battery module, wherein the two side plates of the U-shaped graphite sheet 1 are parallel to the length direction of the battery module, (that is, the two side plates of the plurality of U-shaped graphite sheets 1 are along the length direction of the battery module. The length direction is arranged sequentially) a plurality of heat exchange plates 4 are sequentially arranged at intervals, the battery module is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com